Page 1

Cat.No. M066–E1–1

H8GN

Preset Counter/Timer

USER’S MANUAL

Page 2

Preface

The H8GN supports serial communications specifications, CompoWay/F and Sysway.

This User's Manual describes the communications functions of the H8GN.

Before using your H8GN thoroughly read and understand this manual in order to

ensure correct use.

Also, store this manual in a safe place so that it can be retrieved whenever necessary.

E OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein.

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Moreover, because

I

Page 3

PRECAUTIONS

When the product is used under the circumstances or environments described in this

manual always adhere to the limitations of the rating and functions. Also, for safety,

take countermeasures such as fitting failĆsafe installations.

DO NOT USE:

• In circumstances or environments that have not been described in this manual.

• For control in nuclear power, railway, aircraft, vehicle, incinerator, medical, enterĆ

tainment, or safety applications

• Where death or serious property damage may occur, or where extensive safety preĆ

cautions are required.

II

Page 4

SAFETY PRECAUTIONS

JSafety Signal Words

This manual uses the following signal words to mark safety precautions for the H8GN.

These precautions provide important information for the safe application of the product. You

must be sure to follow the instructions provided in all safety precautions.

Indicates information that, if not heeded, could result in relatively serious or

CAUTION

minor injury, damage to the product, or faulty operation.

JSafety Precautions

CAUTION

F Electric Shock Warning

Tighten the terminal screws properly. Loose screws may cause ignition and malfunction.

Tightening torque :0.5 Nm max.

Do not operate this product in flammable and explosive gas atmospheres.

The life expectancy of the output relays varies greatly with the switching capacity and other switching

conditions. Always use the output relays within their rated load and electrical life expectancy. If an outĆ

put relay is used beyond its life expectancy, its contacts may become fused or burned.

Never disassemble, repair or modify the product.

Doing so may cause electric shock, fire or malfunction.

Do not allow metal fragments or lead wire scraps to fall inside this products.

These may cause leak of electricity, fire or malfunction.

III

Page 5

NOTICE

Be sure to observe these precautions to ensure safe use.

(1) When storing the H8GN, make sure that the ambient temperature and humidity are within the

rated values. Leave the H8GN at room temperature for at least three hours before using the H8GN

if it has been stored at an ambient temperature of Ć10_C or below.

(2) Do not use the H8GN in the following locations.

Ă• Locations with excessive vibration or shock.

Ă• Locations where the H8GN is exposed to sprayed water or oil.

(3) Do not use the H8GN in dusty environments or expose it to corrosive gases or direct sunlight.

(4) Be sure to use the H8GN according to its rated ambient operating temperature and humidity

ranges.

(5) Make sure that the voltage is applied within the specified range. Otherwise the internal elements

of the H8GN may be damaged.

(6) When using the H8GN in an area with excess electronic noise, separate the H8GN, wiring, and the

equipment which generates the input signals as far as possible from the noise sources. It is also

recommended to shield the input signal wiring to prevent electronic interference.

(7) If the H8GN is used in locations with high static electricity, such as sites with pipes transporting

molding materials, powders, or liquids, be sure to separate the H8GN from all sources generating

static electricity.

(8) Organic solvents (such as paint thinner), as well as very acidic or basic solutions can damage the

outer casing of the H8GN.

IV

Page 6

NOTICE

(1) Do not use the H8GN in the following locations:

Ă• Locations with high humidity that may result in condensation

Ă• Locations with radical temperature changes

(2) Pay the utmost attention not to make mistakes in polarity when wiring the Timer.

(3) Always maintain the power supply voltage within the specifications.

(4) Connect the power supply voltage through a relay or switch in such a way that the voltage reaches

a fixed value at once. Otherwise, the H8GN may not be reset or outputs may turn ON.

(5) Be sure that the capacity of the power supply is large enough, otherwise the H8GN may not start

due to inrush current (Approx. 15A) that may flow for an instant when the H8GN is turned on.

(6) For the power supply of an input device for the H8GN, use an isolating transformer with the primaĆ

ry and secondary windings mutually isolated and the secondary winding not grounded.

(7) Leaving the H8GN with outputs ON at a high temperature for a long time may hasten the degradaĆ

tion of internal parts (such as electrolytic capacitors). For this reason, by using in combination

with relays, avoid situations where outputs are left ON for a long time (e.g. one month or more).

(8) If the watertight rubber packing is not compressed sufficiently, water may penetrate the panel. For

this reason, be sure to tighten the reinforcement screws of the Mounting Adapter (Y92FĆ34).

(9) The output contacts are SPSTĆNO and SPSTĆNC. For this reason, be sure not to use these contacts

in circuits that will result in 3Ćpoint shortĆcircuits (power supply shortĆcircuiting due to arcing).

(10) In counter operation:

Ă• Changing the set value

When changing the set value during operation, the output will turn ON if the set value equals

the present value.

Ă• Operation with set value and present value of 0

The output will turn ON if the set value of 0 equals the present value. The output will be OFF

while the Reset Key is pressed or the reset input is ON.

(11) In timer operation:

Ă• Changing the set value

When changing the set value during operation, the H8GN operates in the same way as when the

present value reached the set value because a constant readĆin system is in use. And output may

turn ON depending on the output mode if the set value is changed as follows:

Input mode UP: Present value y Set value

Input mode DOWN: Elapsed time y Set value (Present value=0)

Note: When in DOWN mode, the amount set value is changed is added to or subtracted from

the present value.

Ă• Operation with set value of 0

a) When the output mode is set to A, B (oneĆshot output), D, or F, output will turn ON when

the start signal is input.

b) When the output mode is set to B (hold output), E, or Z, output will remain OFF even when

the start signal is input.

V

Page 7

(12) To allow for the startup time of peripheral devices (sensors, etc.), the H8GN starts timing operaĆ

tion between 210 to 260 ms after power is turned ON. For this reason, in operations where timing

starts from power ON, the time display will actually start from 258 ms. If the set value is 258 ms

or less, the time until output turns ON will be a fixed value between 210 and 260. (Normal operaĆ

tion is possible for set value of 259 ms or more.) In applications where a set value of 258 ms or less

is required, use start timing with signal input.

VI

Page 8

Table of Contents

Preface I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions III. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice IV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 1 ABOUT COMMUNICATIONS METHODS 1-1. . . . . .

This chapter briefly describes the supported communications methods and how

to wire equipment. First-time users should read this chapter without fail to ensure

proper installation of the equipment.

1.1 Outline 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission procedure 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications parameters 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 2 COMPOWAY/F COMMUNICATIONS

PROCEDURES 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read this chapter if you are to communicate using the CompoWay/F format.

2.1 Data Format 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command frame 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Response frame 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications data 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example of end code 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Structure of Command Text 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PDU structure 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area definitions 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type code (variable type) 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addresses 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of elements 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of services 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Details of Services 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read from variable area 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write to variable area 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read controller attributes 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read controller status 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Echoback test 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation instructions 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Response Code List 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

CHAPTER 3 COMMUNICATIONS DATA 3-1. . . . . . . . . . . . . . . . . .

This chapter lists the details of each of the communications data in the CompoWay/F communications procedures.

3.1 Variable Area (setup range) List 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Status 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Sample Program 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII List A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INDEX

Page 10

CHAPTER1

CHAPTER 1

ABOUT

COMMUNICATIONS

METHODS

This chapter briefly describes the supported communications methods

and how to wire equipment. FirstĆtime users should read this chapter

without fail to ensure proper installation of the equipment.

CHAPTER 1 ABOUT COMMUNICATIONS METHODS

1.1 Outline 1Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications specifications 1Ć2. . . . . . . . . .

Transmission procedure 1Ć3. . . . . . . . . . . . . . . .

Interface 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications parameters 1Ć4. . . . . . . . . . . .

1–1

Page 11

CHAPTER 1 30P aaaaaaa

1.1 Outline

JIntroduction

The program for the communications functions are created on the host

computer, and the H8GN's parameters are monitored or set from the host

computer. Therefore, the description provided here is from the viewpoint

of the host computer.

CompoWay/F is OMRON's standard communications format for general

serial communications. This format uses a standard frame format as well

as the FINS* commands which have proven successful in OMRON's PLCs.

Therefore, it can simplify communications between components and the

host computer.

* FINS (Factory Interface Network Service)

The FINS protocol provides message communications between controlĆ

lers in OMRON FA networks.

The H8GN have the following communications functions:

Ă• Reading/writing of parameters

Ă• Operation instructions

Ă• Selection of setup levels

Communications are subject to the following condition:

Ă• Parameters can be written only when the communications writing"

parameter is set to ON (enabled).

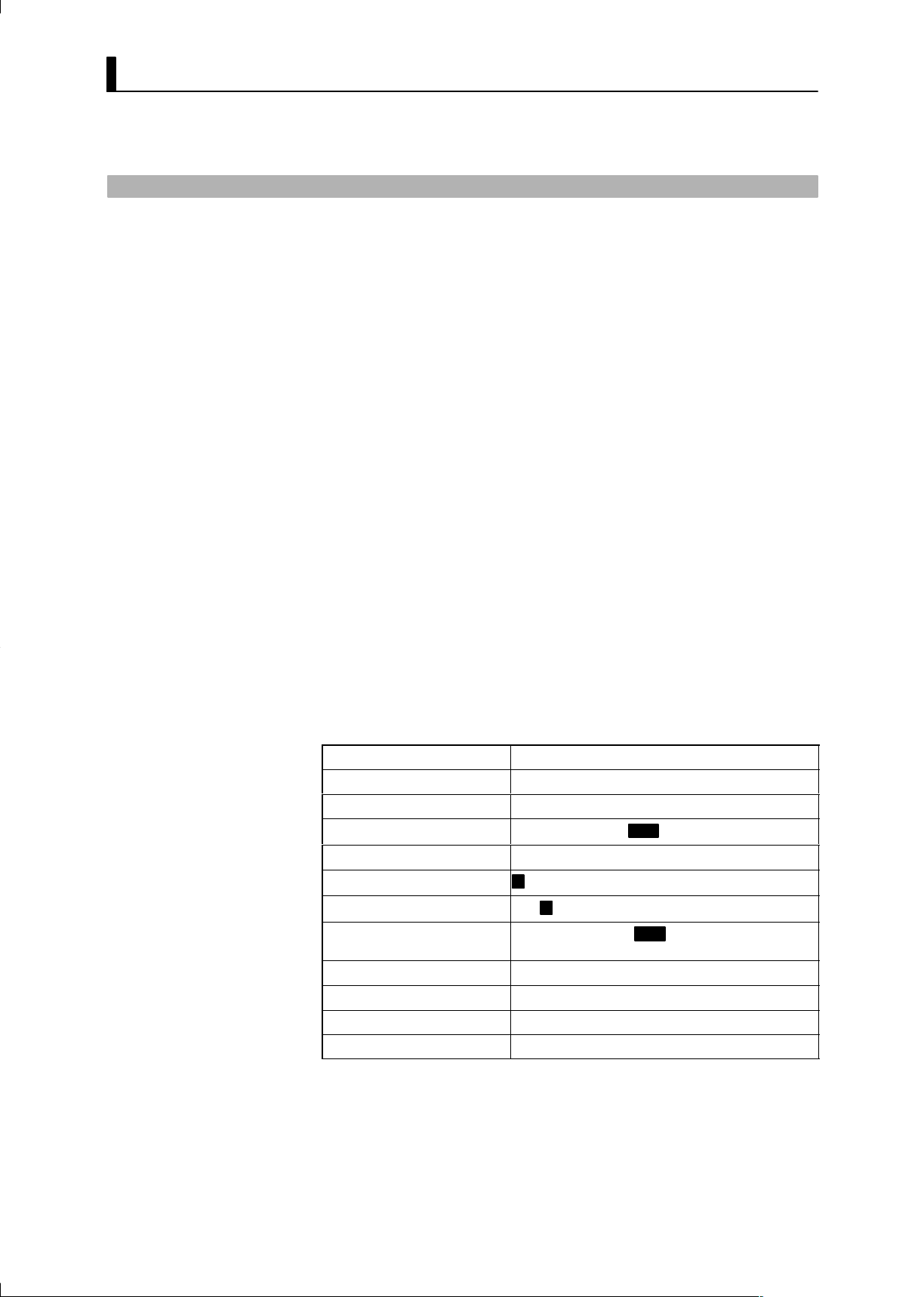

JCommunications specifications

Transmission line connection Multiple point

Communications method RS-485 (2-wire, half-duplex)

Synchronization method Start-stop synchronization

Baud rate

Communication code ASCII

Data bits

Stop bits

Error detection Vertical parity (non, even, or odd)

Flow control None

Interface RS-485

Retry function None

Communications buffer 40 byte

*1 Baud rate, data bits, stop bits and vertical parity can each be set indeĆ

pendently in the communications setting level. Highlighted characters

in the table above indicate defaults.

*1

*1

*1

1200, 2400, 4800, 9600 (bit /s)

7 or 8 bits

1 or 2 bits

BCC (block check character)

1–2

Page 12

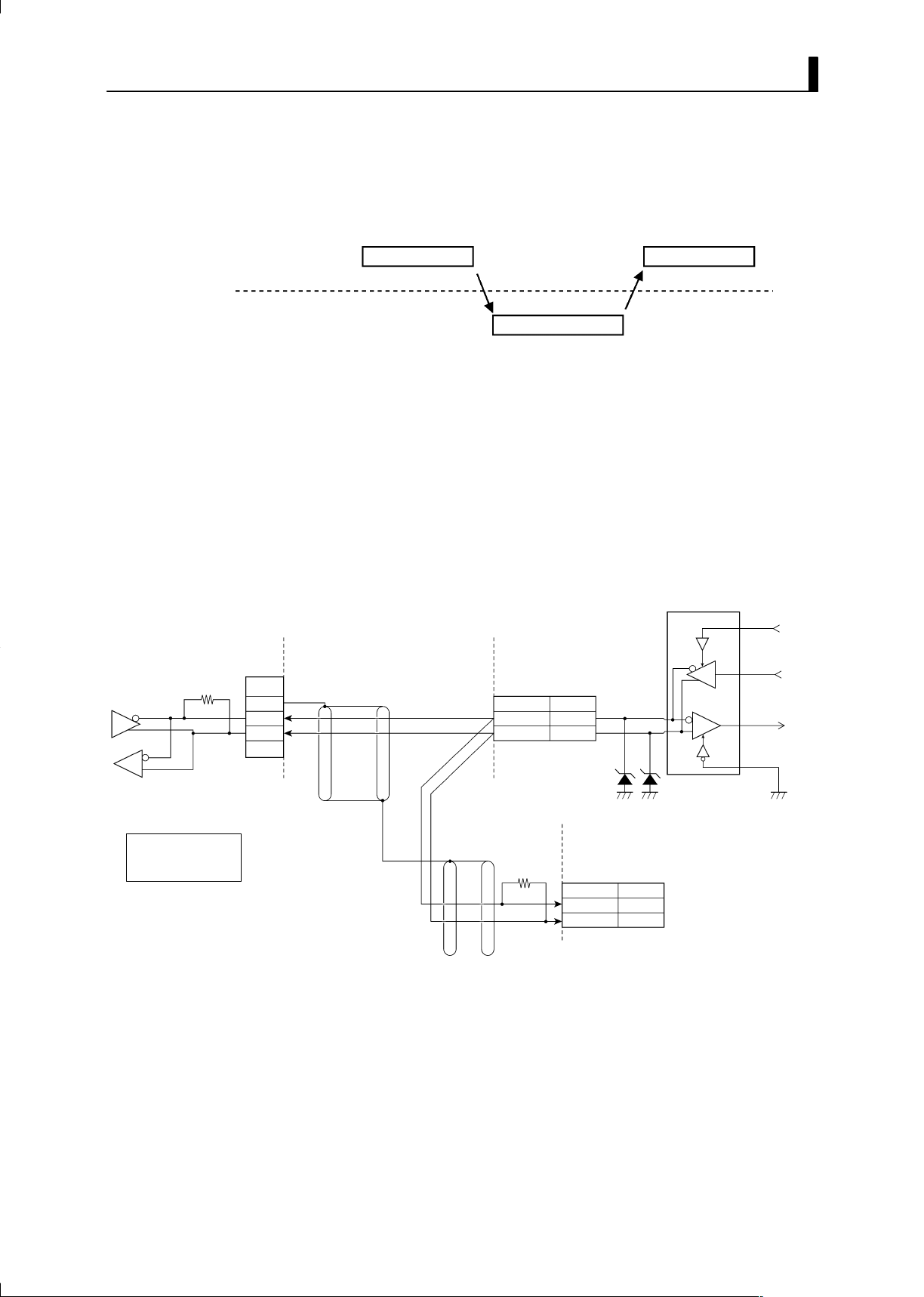

JTransmission

procedure

When the host computer transmits a command frame, the H8GN transĆ

mits a response frame that corresponds to the command frame. A single

response frame is returned for each command frame. The following diaĆ

gram shows the operation of the command and response frames.

JInterface

JWiring

Host computer

Host computer

H8GN

RS-485

Abbr

FG

–

+

SG

Command frame

Response frame

Command frame

Allow a wait time of at least 2 ms until the next command is sent after the

host computer receives a response from the H8GN.

Communications with the host computer are carried out through a stanĆ

dard RSĆ485 interface.

Ă• RSĆ485 connections can be 1 : 1 or 1 : N. A maximum of 32 Units (including

the host computer) can be connected in oneĆtoĆN systems.

Ă• The total cable length is 500 m max.

Ă• Use a shielded, twistedĆpair cable AWG28 or larger for wiring the H8GN.

Communications transceiver

H8GN

RS-485

Pin No. Abbr

8

A(–)

7

B(+)

TX

RX

Shielded cable

A<B: [1] mark

A>B: [0] space

Both ends of the transmission line

(including the host computer) must be

specified (by setting terminator ON) as

the end node. The total resistance of

the terminators must be at least 54Ω.

Match the communications specifications of the H8GN and the host comĆ

puter. If a oneĆtoĆN system is being used, be sure that the communications

specifications of all devices in the system (except individual unit numbers)

are the same.

Terminator

Shielded cable

6.8V

120Ω

(1/2W)

H8GN

end node

RS-485

Pin No. Abbr

8

A(–)

7

B(+)

Use a terminator of resistance

120Ω = (1/2W).

1–3

Page 13

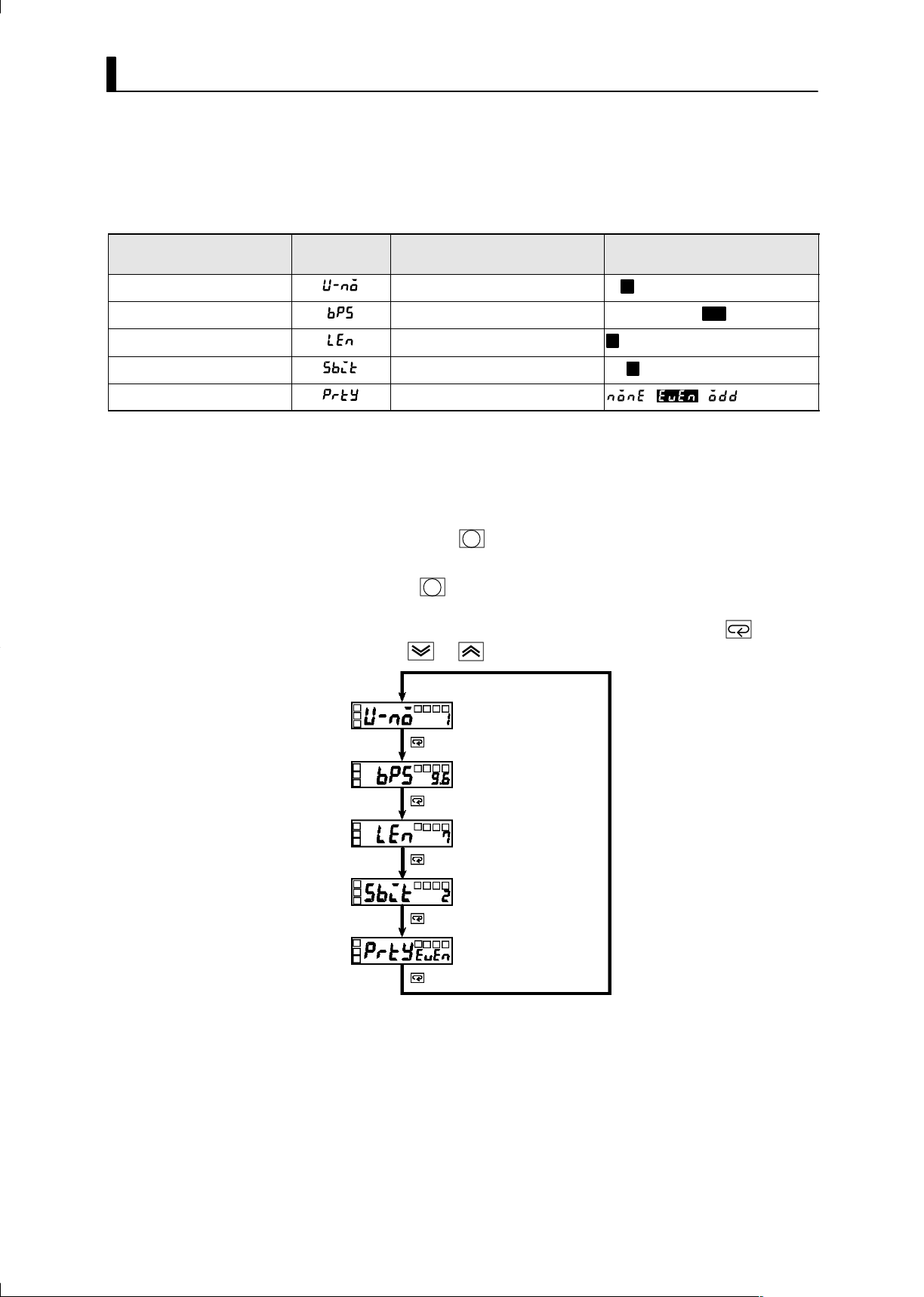

JCommunications

parameters

The H8GNs communications specifications are set in the communications

setting level. These parameters are set on the H8GNs front panel.

The following table shows the communications parameters and their setĆ

ting ranges.

Parameter

Communications unit No. 0 to 99

Baud rate 1.2 / 2.4 / 4.8 / 9.6 (k bit/s)

Communications data length 7 / 8 (bit)

Communications stop bit 1/2

Communications parity None / even / odd

Displayed

Characters

Setting Range Set Value

Highlighted characters indicate defaults.

F Communications

parameter setup

Before you carry out communications with the H8GN, set up communicaĆ

tions unit No., Communication rate and other parameters by carrying out

the following procedure.

(1) Hold down the key for at least three seconds to move from the

operation level" to the initial setting level."

(2) Press the key for less than one second to move from the initial

setting level" to the communications setting level."

(3) Select the parameters as shown below by pressing the key.

(4) Use the or keys to change the parameter set values.

0, 1 to 99

1.2 / 2.4 / 4.8 / 9.6 (k bit/s)

7 / 8 (bit)

1/2

//

Communications unit No.

Baud rate

Communications data length

Communications stop bit

Communications parity

H8GN

1–4

Page 14

F Communications

parameter setup

Note that communications parameters are enabled after they have been

changed by resetting the controller.

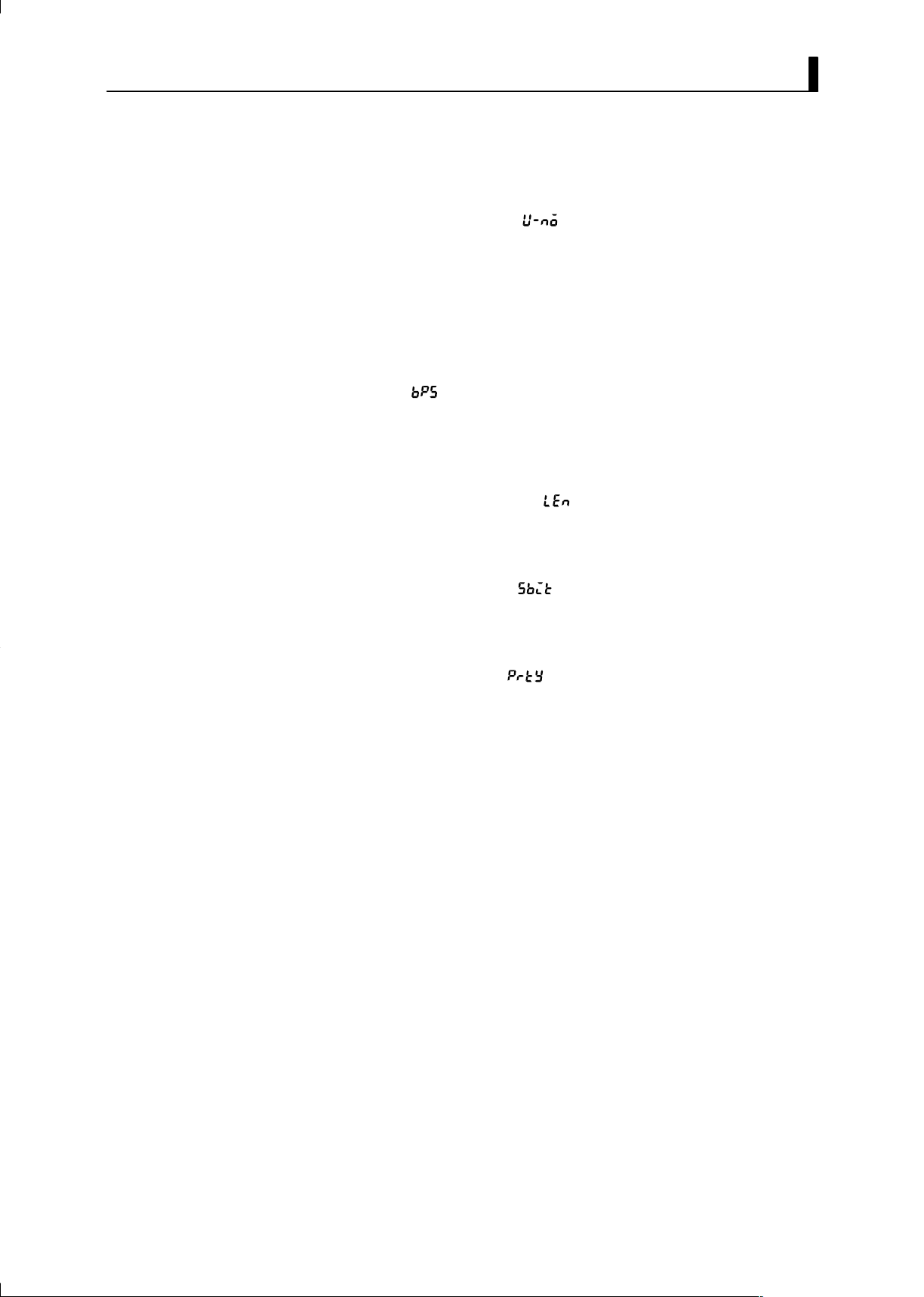

Ă• Communications unit No. ( )

This parameter is for setting the unit No. to each of the H8GN. This unit

No. is set so that the host computer can identify the H8GN when commuĆ

nications are carried out with the host computer. Set a unit No. within

the range 0 to 99 for each H8GN connected to the host computer on the

network. Default is 1". When two or more H8GN are used, do not set

the same unit No. Doing so will prevent normal operation.

Ă• Baud rate ( )

This parameter is for setting the baud rate when communicating with

the host computer. Set one of 1.2 (1200 bit/s)", 2.4 (2400 bit/s)", 4.8

(4800 bit/s)" and 9.6 (9600 bit/s)".

Ă• Communications data length ( )

This parameter is for setting the communications data length. Set either

of 7 bits" or 8 bits".

Ă• Communications stop bit ( )

This parameter is for setting the communications stop bit. Set either of

1" or 2".

Ă• Communications parity ( )

This parameter is for setting the communications parity. Set one of

none", even" or odd".

1–5

Page 15

1–6

Page 16

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

CHAPTER2

CHAPTER 2

CompoWay/F

COMMUNICATIONS

PROCEDURES

Read this chapter if you are to communicate using the CompoWay/F

format.

2.1 Data Format 2Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Command frame 2Ć2. . . . . . . . . . . . . . . . . . . . . . .

Response frame 2Ć3. . . . . . . . . . . . . . . . . . . . . . . .

Communications data 2Ć4. . . . . . . . . . . . . . . . . .

Example of end code 2Ć4. . . . . . . . . . . . . . . . . . . .

2.2 Structure of Command Text 2Ć5. . . . . . . . . . . . .

PDU structure 2Ć5. . . . . . . . . . . . . . . . . . . . . . . . .

Area definitions 2Ć5. . . . . . . . . . . . . . . . . . . . . . . .

Type code (variable type) 2Ć5. . . . . . . . . . . . . . .

Addresses 2Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of elements 2Ć5. . . . . . . . . . . . . . . . . . . .

List of services 2Ć6. . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Details of Services 2Ć7. . . . . . . . . . . . . . . . . . . . . .

Read from variable area 2Ć7. . . . . . . . . . . . . . . .

Write to variable area 2Ć8. . . . . . . . . . . . . . . . . . .

Read controller attributes 2Ć10. . . . . . . . . . . . . . .

Read controller status 2Ć11. . . . . . . . . . . . . . . . . .

Echoback test 2Ć12. . . . . . . . . . . . . . . . . . . . . . . . . .

Operation instructions 2Ć13. . . . . . . . . . . . . . . . . .

2.4 Response Code List 2Ć15. . . . . . . . . . . . . . . . . . . .

2–1

Page 17

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

2.1 Data Format

Unless otherwise indicated, numbers in this manual are expressed in hexĆ

adecimal. Values in double quotation marks, such as 00", are ASCII.

The number underneath each delimiter in a frame indicates the number

of bytes.

JCommand frame

Text

Node No. Sub-address Command text

STX 0 0 ETX

12 21 11

0

BCC calculation range

BCCSID

STX

Node number • This number specifies the transmission’s destination.

Sub-address This is not used on the H8GN. Be sure to set the sub-address to “00”.

SID (service ID) This is not used on the H8GN. Be sure to set the sub-address to “00”.

Command text Command text area. For details, see “2.2 Structure of Command Text.”

ETX This code (03) indicates the end of the text.

BCC Block Check Character

This code (02) indicates the beginning of the communications frame (text).

Always set this character in the first byte.

When STX is received again during reception, reception is carried out again from

the point where STX was received.

• Specify the H8GN’s “Communications unit No.”.

• BCD range “00” to “99” and “XX” can be set.

• Specify “XX” for a broadcast transmission. No response will be returned for broad-

cast transmissions.

• No responses will be returned from node Nos. set otherwise from the above.

The BCC result is found by calculating the exclusive OR of the bytes from the node

No. up to ETX.

2–2

Page 18

2.1Data Format

F BCC calculation

example

The BCC is formed by converting the 8Ćbit value obtained by converting

the exclusive OR of the node No. up to ETX into two ASCII characters, and

setting this to the BCC area.

STX SID ETX BCC

Node No. Sub-address Command text

BCC=30H30H30H30H30H30H35H30H33H03H=35H

Calculation result 35H is set to the BCC area.

The symbol indicates exclusive OR operation and the H indicates hexadecimal code.

JResponse frame

STX ETX

12 2 2 11

End

code

00 Normal completion The command ended normally without error. None

0F FINS command error The specified FINS command could not be executed.

10 Parity error The sum total of bits whose received data is “1” does not

11 Framing error Stop bit is “0”. 1

12 Overrun error An attempt was made to transfer new data when the recep-

13 BCC error The calculated BCC value is different from the received BCC

14 Format error • The command text contains characters other than 0 to 9,

16 Sub-address error • Illegal (unsupported) sub-address

18 Frame length error The received frame exceeds the fixed (supported) number of

Name Description

The FINS response code should indicate why the command

could not be executed.

match the set value of “communications parity.”

tion data was already full.

value.

and A to F. This error is not applicable to the echoback test.

(For details, see chapters 2.3 “Echoback test.”)

• No SID and command text. Or, no command text

• “MRC/SRC” not included in command text

• No sub-address, SID and command text

• Sub-address less than two characters, and no SID and

command text

bytes.

03H 35H02H 0(30H) 0(30H) 0(30H) 0(30H) 0(30H) 0(30H) 5(35H) 0(30H) 3(33H)

BCCNode No. Sub-address Command textEnd code

Error

Detection

Priority

8

2

3

5

7

6

4

Ă• The end code is returned to received command frames addresses to the

self node.

Ă• No response will be returned if all the items in the response frame are

incomplete up to the ETX and BCC.

Ă• Error Detection Priority" indicates the priority when two or more

errors occur simultaneously.

2–3

Page 19

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

JCommunications data

Set (monitor) Value Minus Value Decimal point

8 digits (Hex) 2’s complement Decimal point is removed and the result is converted to hexadecimal.

Example) 105.0 ! 1050 ! 000041A

JExample of end

code

The following examples show an end code when a command did not end

normally.

Example 1) Illegal subĆaddress, and no SID and command text

Command Format

Node No. Sub-address

STX 0 ETX

A

BCC

Response Format

Node No. Sub-address End code

STX 0 ETX

A16

BCC

End code is 16" (subĆaddress error).

This is because a subĆaddress was received and the subĆaddress

error has a higher error detection priority than the format error.

Example 2) No command text

Command Format

Node No. Sub-address

STX 0 ETX

SID

0

0

BCC

Response Format

Node No. Sub-address End code

STX 0 ETX

014

BCC

End code is 14" (format error).

Example 3) All node Nos. not provided

Command Format

BCC

STX ETX

The node No. is lacking one character.

Response Format

No response

Example 4) No subĆaddress, and illegal BCC

Command Format

Node No.

STX ETX

BCC

Err

Response Format

Node No. Sub-address End code

STX 0 ETX

013

SubĆaddress is 00" and end code is 13" (BCC error).

BCC

2–4

Page 20

2.2 Structure of Command Text

2.2Structure of Command Text

JPDU structure

An MRC (Main Request Code) and SRC (SubĆRequest Code) followed by

the various required data is transferred to the command text.

Service request PDU

MRC SRC

MRES (Main Response Code) and SRES (SubĆResponse Code) are

transferred following the above MRC/SRC. Data is then transferred

following these MRES and SRES.

Service response PDU (during normal operation)

MRC SRC MRES SRES

If the specified command text could not be executed, only the MRC/

SRC and MRES/SRES become the target response PDUs.

Service respons e PDU (at non-ex ec ut ion of specified command text )

MRC SRC MRES SRES

MRES/SRES becomes the response code except when processing

ends in normal completion."

Data

Data

JArea definitions

JType code

(variable type)

JAddresses

JNumber of

elements

Areas comprise only variable area.

The following defines variable area type codes.

Variable

type

C0 R/O (read only) parameter.

C1 Protect level parameter.

C2 Operation and adjustment level parameter.

C3 Initial setting, communications setting and advanced function set-

ting level parameter.

Each of the variable types is appended with an address. Express addresses

in 2Ćbyte hexadecimal code.

The number of elements is expressed in 2Ćbyte hexadecimal code. Specify

the number of elements within the range 0 to 2".

For example, when the number of elements is 0002", specify data for two

items from the address.

Description

2–5

Page 21

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

JList of services

MRC SRC Name of service Process

01 01 Read from variable

area

01 02 Write to variable area This service writes to variable areas.

05 03 Read controller

attributes

06 01 Read controller

status

08 01 Echoback test This service carries out the echoback test.

30 05 Operation

instructions

* In a memory error (RAM error) or initial state (until the control starts normaly after the

power is turned ON), all commands will not be accepted, and no response will be returned.

This service reads from variable areas.

This service reads the model No. and communications buffer size.

This service reads the run status of the

controller.

This service carries out reset, communications writing, multi-SP, move to protect

level, move to setup area 1 and software

reset.

The following table summarizes setup areas 0 and 1.

Area Description

Setup area 0 This area groups together the protect, operation and adjustment

levels.

Setup area 1 This area groups together the initial setting, communications set-

ting and advanced function setting levels.

2–6

Page 22

2.3 Details of Services

2.3Details of Services

JRead from

variable area

This service reads from variable areas.

Service request PDU

MRC SRC

0101 00

222 4 2 4

Variable

type

Read start

address

Bit

position

Number of

elements

Service response PDU

MRC SRC Response

code

0101

2 2 4 0 or 8 or 16

Read data

(for number of elements)

(1) Variable type and read start address

For details on variable types and read start addresses, see Chapter 3

Communications Data."

(2) Bit position

Bit accessing is not supported on the H8GN. Fixed to 00".

(3) Number of elements

Number of

elements

0000 Read is not carried out (the service response PDU is not

appended with read data), and processing ends in “normal

completion.”

0001 to 0002 Read is carried out, and processing ends in “normal completion.”

Process

(4) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Error name Cause

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1101 Area type error The variable type is wrong.

1103 Start address out-of-

range error

110B Response too long The number of elements is

1100 Parameter error The bit position is other than

2203 Operation error CPU or EEPROM error

The read start address is

out of range.

larger than “0002”.

“00”.

2–7

Page 23

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

JWrite to variable

area

This service writes to variable areas.

Service request PDU

MRC SRC

0102 00

222 4 2 4

Vari-

able

type

Read start

address

Bit

posi-

tion

Number of

elements

Write data

(for number of elements)

0 or 8 or 16

Service response PDU

MRC SRC Response

code

0102

22 4

(1) Variable type and write start address

For details on variable types and write start addresses, see Chapter

3ăCommunications Data."

(2) Bit position

Bit accessing is not supported on the H8GN. Fixed to 00".

(3) Number of elements

Number of

elements

0000 Write is not carried out (the service response PDU is not

appended with write data), and processing ends in “normal

completion.”

0001 to 0002 W rite is carried out, and processing ends in “normal completion.”

Process

2–8

Page 24

2.3Details of Services

(4) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Error name Cause

1002 Command too short The command is too short.

1101 Area type error Wrong variable type

1103 Start address out-of-

range error

1104 End address out-of-

range error

1003 Number of elements/

data mismatch

1100 Parameter error • Bit position is other than “00”.

3003 Read-only data Variable type “C0” was written to.

2203 Operation error • The “communications writing”

Write start address is out of range.

The write end address (write start

address + number of elements)

exceeds the final address of the variable area.

The number of data does not match

the number of elements.

• Write data is out of setting range.

parameter is set to “OFF” (disabled).

• Writing was carried out on the

parameters from setup areas 0 to 1.

• Writing was carried out on a protected parameter other than in the

protect level.

• CPU or EEPROM error

2–9

Page 25

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

JRead controller

attributes

This service reads the model No. and communications buffer size.

Service request PDU

MRC SRC

0503

22

Service response PDU

MRC SRC Response

code

0503

22 4 4

Model No.

10

Communica-

tions buffer size

0028

(1) Model No.

The model No. is expressed in 10Ćbyte ASCII code. Empty bytes are

space codes.

Example:

The model number for the H8GN is expressed as follows:

H 8GN– AD

(2) Communications buffer size

The communications buffer size is expressed in 2Ćbyte hexadecimal

code, and read after being converted to 4Ćbyte ASCII code.

Buffer size: 40 bytes (= H'0028)

(3) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

2–10

Page 26

2.3Details of Services

JRead controller

status

This service reads the run status of the controller.

Service request PDU

MRC SRC

0601

22

Service response PDU

Related

MRC SRC Response

code

0601

22 4

Run

informa-

status

tion

22

(1) Run status

Run status Description

00 Status in which the count (timer) input can be accepted (error not

generated when setup area is 0)

01 Status in which the count (timer) input cannot be accepted (other

than above)

(2) Related information

706543 12 Bit position

000 00

00

PV underflow

(3) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

2–11

Page 27

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

JEchoback test

This service carries out the echoback test.

Service request PDU

MRC SRC

0801

22

Test data

0 to 23

Service response PDU

MRC SRC Response

code

0801

22

Test data

0 to 23

(1) Test data

Set any test data within the range 0" to 23".

Set a value for the test data within the ranges shown below according

to the communications data length.

Communications

data length

8 bits 20 to 7E, A1 to FE converted to ASCII code

7 bits 20 to 7E converted to ASCII code

T est data

(2) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Name Description

1001 Command too long The command is too long.

2203 Operation error CPU or EEPROM error

2–12

Page 28

2.3Details of Services

JOperation

instructions

This service carries out reset, communications writing, multiĆSP, move to

protect level, move to setup area 1 and software reset.

Service request PDU

Related

MRC SRC

3005

22

Instruc-

code

in-

tion

forma-

tion

22

Service response PDU

MRC SRC Response

code

3005

22 4

(1) Instruction code and related information

Instruction

code

00 Communications writing 00: OFF (disabled)

01 Reset 00: Reset PV

02 SV-bank 00: Set value 0

06 Software reset * 00

07 Move to setup area 1 00

08 Move to protect level 00

* No response will be returned when a software reset is carried out.

Description Related information

01: ON (enabled)

01: Reset totalizing count value

02: Reset PV/totalizing count value

01: Set value 1

02: Set value 2

03: Set value 3

(2) Response code

At normal completion

Response code Name Description

0000 Normal completion No errors were found.

At occurrence of error

Response code Error name Cause

1001 Command too long The command is too long.

1002 Command too short The command is too short.

1100 Parameter error Instruction code and related informa-

tion are wrong.

2203 Operation error • The “communications writing”

parameter is set to “OFF” (disabled). However , note that the error

is accepted regardless of the “com-

munications writing” parameter setting (ON/OFF).

• The command cannot be processed. For details, see “(3)

Description of operating instructions and precautions” below.

• CPU or EEPROM error

2–13

Page 29

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

(3) Description of operation instructions and precautions

FĂCommunications writing

Set the communications writing" parameter to ON: enabled" or

OFF: disabled" according to related information. This instruction can

be accepted at both setup areas 0 and 1.

FĂReset

The PV and/or total count value is reset according to the related value.

[Reset PV]

Resets the PV." This can be accepted only in setup area 0. The operaĆ

tion error" occurs in the following instance:

Ă• When the reset is issued in setup area 1"

[Reset totalizing count value]

Resets the totalizing count value." This can be accepted only in setup

area 0. The operation error" occurs in the following instances:

Ă• When the reset is issued in setup area 1"

Ă• When select function" is set to timer"

Ă• When use total counter" is set to OFF"

[Reset PV/totalizing count value]

Resets the PV" and the totalizing count value." This can be accepted

only in setup area 0. The operation error" occurs in the following

instances:

Ă• When the reset is issued in setup area 1"

Ă• When select function" is set to timer"

Ă• When use total counter" is set to OFF"

FĂSVĆbank

Set four set value beforehand in the adjustment level so that you switch to

a desired set value. SVĆbank can be accepted at both setup areas 0 and 1.

The operation error" occurs in the following instance:

Ă• When use SVĆbank " is set to OFF"

FĂSoftware reset

This instruction resumes processing after the power is turned OFF.

This instruction can be accepted at both setup areas 0 and 1. No

response will be returned for this operation instruction.

FĂMove to setup area 1

This instruction moves to setup area 1" and can be accepted at both

setup areas 0 and 1. However, note that when initial setup/communicaĆ

tions protection" is set to 2", an operation error" is generated, and

move to setup area 1 is forbidden.

When this move is carried out from setup area 0, the display indicates

the select function" in the initial setting level." When this operation

instruction is issued in setup area 1, the display will not change.

FĂMove to protect level

This instruction moves to the protect level" and can be accepted only

in setup area 0. When this instruction command is issued in setup area

1, an operation error" is generated, and move to setup area 1 is forbidĆ

den.

2–14

Page 30

2.4 Response Code List

At normal completion

2.4Response Code List

Response

code

0000 Normal

Name Description

No errors were found. None

completion

At occurrence of error

Response

code

0401 Unsupported

1001 Command too

1002 Command too

1101 Area type error The variable type is wrong. 4

1103 Start address

1104 End address

1003 Number of ele-

110B Response too

1100 Parameter error • The bit position is other than “00”.

3003 Read-only error Variable type “C0” was written to. 10

2203 Operation error • The “communications writing”

Name Description

The service function for the relevant

command

long

short

out-of-range

error

out-of-range

error

ments/data mismatch

long

command is not supported.

The command is too long. 2

The command is too short. 3

The read/write start address is out of

range.

The write end address (write start

address + number of elements)

exceeds the final address of the variable area.

The number of data does not match

the number of elements.

The response exceeds the communications buffer size (when larger than

number of elements 0002).

• The write data is out of the setting

range.

• The instruction code and related

information in the operating instruction is wrong.

parameter is set to “OFF” (disabled).

• Writing was carried out on the

parameters from setup areas 0 to 1.

• Writing was carried out on a protected parameter other than in the

protect level.

• Processing is not possible by operating instruction.

• CPU or EEPROM error

Error

detection

priority

Error

detection

priority

1

5

6

7

8

9

11

2–15

Page 31

CHAPTER 2 CompoWay/F COMMUNICATIONS PROCEDURES

2–16

Page 32

CHAPTER3

CHAPTER 3

COMMUNICATIONS

DATA

This chapter lists the details of each of the communications data in the

CompoWay/F communications procedures.

CHAPTER 3 COMMUNICATIONS DATA

3.1 Variable Area (setup range) List 3Ć2. . . . . . . . .

3.2 Status 3Ć8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Sample Program 3Ć9. . . . . . . . . . . . . . . . . . . . . . .

N88Basic 3Ć9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protocol macro 3Ć11. . . . . . . . . . . . . . . . . . . . . . . .

3–1

Page 33

3.1 Variable Area (setup range) List

The following table lists the variable areas. Items expressed in hexadeciĆ

mal in the Set (monitor) Value" column are the setting range. Values in

parentheses ()" are the actual setting range.

For details of variable areas that are described not in numerical values but

by text, refer to the relevant parameter descriptions.

Variable

type

C0 0000 Version * Note 1 H’00000100

C0 0001 PV H’FFFFFC19 to H’0000270F (–999 to 9999)

C0 0002 Status * Note 1 See “3.2. Status.”

C0 0003 Totalizing count value H’00000000 to H’05F5E0FF (0 to 99999999) Operation

C1 0000 Operation/adjustment

C1 0001 Initial setting/commu-

C1 0002 Setting change protec-

C1 0003 Reset key protection H’00000000 (0): OFF (reset key enabled)

Address Item Set (monitor) V alue Level

Operation

* Counter

* At PV underflow,

lower limit value=H’FFFFFC19 (–999)

H’00000000 to H’0000270F (0 to 9999)

* Time range at timer=other than - -m- -s, - -h- -m

H’00000000 to H’000026E7 (0:00 to 99:59)

* Time range at timer=- -m- -s, - -h- -m

protection

nications protection

tion

H’00000000 (0): No restrictions in operation and ad -

justment levels

H’00000001 (1): Move to adjustment level restricted

H’00000002 (2): Display and change of only PV/SV

parameters enabled

H’00000003 (3): Display of only PV/SV parameters

enabled

H’00000000 (0): Move to initial setting/communica-

tions setting level enabled (move t o

advanced function setting level dis-

played)

H’00000001 (1): Move to initial setting/communica-

tions setting level enabled (move t o

advanced function setting level not

displayed)

H’00000002 (2): Move to initial setting/communica-

tions setting level restricted

H’00000000 (0): OFF (changing of setup on control-

ler display enabled)

H’00000001 (1): ON (changing of setup on controller

display disabled)

H’00000001 (1): ON (reset key disabled)

Protect

3–2

Page 34

Variable

type

Address Item Set (monitor) Value Level

C2 0000 Set value H’00000000 to H’0000270F (0 to 9999)

* Input mode at counter=incremental or decre-

mental

H’FFFFFC19 to H’0000270F (–999 to 9999)

* Input mode at counter=individual or phase dif-

ferent input

H’00000000 to H’0000270F (0 to 9999)

* Time range at timer=other than - -m- -s,

- -h- -m and output mode=A,B,D,E,F

H’00000000 to H’000026E7 (0:00 to 99:59)

* Time range at timer=- -m- -s, - -h- -m and

output mode=A,B,D,E,F * Note 2

H’00000000 to H’00000064 (0 to 100)

* Output mode at timer=Z

C2 0001 Set value 0 H’00000000 to H’0000270F (0 to 9999)

* Input mode at counter=incremental or decre-

mental

H’FFFFFC19 to H’0000270F (–999 to 9999)

* Input mode at counter=individual or phase dif-

ferent input

H’00000000 to H’0000270F (0 to 9999)

* Time range at timer=other than - -m- -s,

- -h- -m and output mode=A,B,D,E,F

H’00000000 to H’000026E7 (0:00 to 99:59)

* Time range at timer=- -m- -s, - -h- -m and

output mode=A,B,D,E,F * Note 2

H’00000000 to H’00000064 (0 to 100)

* Output mode at timer=Z

C2 0002 Set value 1 Same as set value 0

C2 0003 Set value 2 Same as set value 0

C2 0004 Set value 3 Same as set value 0

C2 0005 Cycle time H’00000000 to H’0000270F (0 to 9999)

* Time range at timer=other than - -m- -s,

- -h- -m

H’00000000 to H’000026E7 (0:00 to 99:59)

* Time range at timer=- -m- -s, - -h- -m * Note 2

Operation

Adjustment

Operation

* Note 1: This item is not displayed on the controller display.

* Note 2: Even if the set value is within the setting range, the outĆofĆrange error occurs when the 2nd digit (sextal number) is six

or above such as 5:60 (H*00000230).

3–3

Page 35

CHAPTER 3 COMMUNICATIONS DATA

Variable

type

C3 0000 Select function H’00000000(0): Counter

C3 0001 Input mode H’00000000(0): Incremental

C3 0002 Time range H’00000000(0): 0.000s to 9.999s

C3 0003 Timer mode H’00000000(0): Elapsed time

C3 0004 Output mode (counter) H’00000000(0): N

C3 0005 Output mode (timer) H’00000000(0): A

C3 0006 Output time H’00000001 to H’0000270F (0.01 to 99.99) * counter

C3 0007 Counting speed H’00000000(0): 30Hz

C3 0008 Input signal width H’00000000(0): 20ms

Address Item Set (monitor) V alue Level

H’00000001(1): Timer

H’00000001(1): Decremental

H’00000002(2): Individual

H’00000003(3): Phase difference

H’00000001(1): 0.00s to 99.99s

H’00000002(2): 0.0s to 999.9s

H’00000003(3): 0s to 9999s

H’00000004(4): 0m0s to 99m59s

H’00000005(5): 0.0m to 999.9m

H’00000006(6): 0h0m to 99h59m

H’00000007(7): 0.0h to 999.9h

H’00000008(8): 0h to 9999h

H’00000001(1): Remainning time

H’00000001(1): F

H’00000002(2): C

H’00000003(3): K

H’00000001(1): B

H’00000002(2): D

H’00000003(3): E

H’00000004(4): F

H’00000005(5): Z

H’00000000 to H’0000270F (0.00 to 99.99) * timer

H’00000001(1): 5kHz

H’00000001(1): 1ms

Initial setting

3–4

Page 36

3.1Variable Area (setup range) List

Variable

type

C3 0009 Decimal point H’00000000(0): - - - -

C3 000A Pre-scale value H’00000001 to H’0000270F (0.001 to 9.999)

C3 000B Input signal edge H’00000000(0): Rise edge

C3 000C Communications unit

C3 000D Baud rate *1 H’00000000(0): 1.2

C3 000E Communications data

C3 000F Communications stop

C3 0010 Communications parity H’00000000(0): None

C3 0011 Use SV-bank H’00000000(0): OFF

C3 0012 Use totalizing counter H’00000000(0): OFF

C3 0013 Display auto-return

C3 0014 Move-to-protect-level

* 1: Communications parameters are enabled after they have been changed by turning the power OFF then back ON again.

Address Item Set (monitor) V alue Level

Initial setting

H’00000001(1): - - -.H’00000002(2): - -.- H’00000003(3): -.- - -

H’00000001(1): Fall edge

No. *1

length *1

bit *1

time

time

H’00000000 to H’00000063 (0 to 99) Communica-

H’00000001(1): 2.4

H’00000002(2): 4.8

H’00000003(3): 9.6

H’00000007(7): 7

H’00000008(8): 8

H’00000001(1): 1

H’00000002(2): 2

H’00000001(1): Even

H’00000002(2): Odd

H’00000001(1): ON

H’00000001(1): ON

H’00000000(0): OFF

H’00000001 to H’00000063 (1 to 99)

H’00000003 to H’0000001E (3 to 30)

tions setting

Advanced

function setting

3–5

Page 37

CHAPTER 3 COMMUNICATIONS DATA

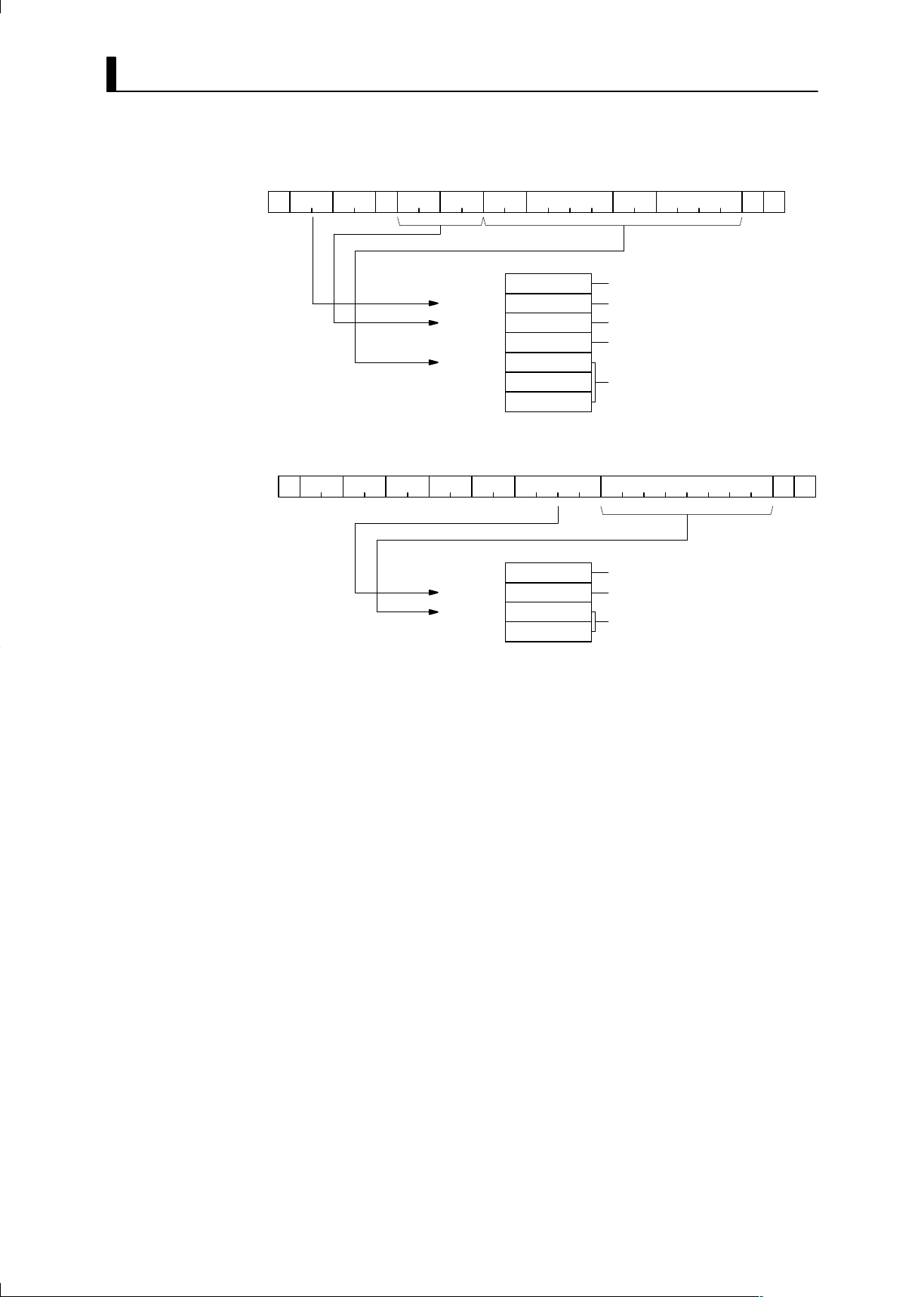

3.2 Status

The figure below shows the structure of the status data:

12131415

0

0

000 000 00

4567891011

0

0123

Bit position

PV underflow

Spare

Spare

Spare

CP1 (signal) input

CP2 (gate) input

Reset input

Spare

Spare

Spare

Spare

Spare

Output

Spare

Spare

Spare

Input status Output statusError info

3–6

Page 38

3.2Status

28293031

0000

0000000

0

21222324252627

0200

16171819

Bit position

Operating status

Setup area

Communications writing

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

Spare

3–7

Page 39

CHAPTER 3 COMMUNICATIONS DATA

The following shows the status contents.

Bit position Status

0 1

0 PV underflow *1 Not generated Generated

1 Spare

2 Spare

3 Spare

4 CP1 (signal) input *1 OFF ON

5 CP2 (gate) input *1 OFF ON

6 Reset input *1 OFF ON

7 Spare

8 Spare

9 Spare

10 Spare

11 Spare

12 Output *1 OFF ON

13 Spare

14 Spare

15 Spare

16 Setup area Setup area 0 Setup area 1

17 Communications writing OFF (disabled) ON (enabled)

18 Spare

19 Spare

20 Spare

21 Spare

22 Spare

23 Spare

24 Spare

25 Spare

26 Spare

27 Spare

28 Spare

29 Spare

30 Spare

31 Spare

Bit Description

3–8

* Spare" bits are OFF at all times.

*1: The status is as follows when reading is carried out in setup area 1:

@ PV underflow: Previous value is held until reset is generated.

@ CP1 (signal) input, CP2 (gate) input, reset input: OFF (0)

@ Output: OFF (0)

Page 40

3.3 Sample Program

3.3Sample Program

JN88Basic

The following sample program displays responses returned from the

H8GN on screen when command data is entered from the keyboard.

Enter starting with the unit up to the number of elements as the command

data.

This sample program was created using N88BASIC

1000 ’------------------------------------------------------1010 ’PROGRAM: H8GN Communication Sample Program (Compo Way/F)

1020 ’VERSION: 1.00

1030 ’(c) Copyright OMRON Corporation 2000

1040 ’All Right Reserved

1050 ’------------------------------------------------------1060 ’

1070 ’= Communications port setting (PARITY=EVEN, DATA=7, STOP=2)=”

1080 ’

1090 OPEN ”COM: E73” AS #1

1100 ’

1110 *REPEAT

1120 ’

1130 ’=====Transmission processing==========

1140 ’

1150 ’---------- Entry of send data ---------1160 INPUT ”SEND DATA:”, SEND$

1170 ’

1180 ’---------- To exit processing if there is no entry ----------

1190 IF SEND$=”” THEN * EXIT

1200 ’

1210 ’---------- Calculation of BCC ---------1220 BCC=0

1230 SEND$=SEND$+CHR$ (3)

1240 FOR I=1 TO LEN (SEND$)

1250 BCC=BCC XOR ASC (MID$ (SEND$, I, 1))

1260 NEXT I

1270 BCC$=CHR$ (BCC)

1280 ’

1290 ’---------- Transmission ---------1300 SDATA$=CHR$ (2)+SEND$+BCC$

1310 PRINT #1, SDATA$;

1320 ’

1330 ’=====Reception processing==========

1340 ’

1350 *LOOP0

1360 RDATA$=””

1370 TIMEOUT=0

1380 *LOOP

1390 ’---------- Detection of time–out ---------1400 TIMEOUT=TIMEOUT+1

1410 IF TIMEOUT>2000 THEN RESP$=”No Response”: GOTO * REND

1420 IF LOC (1)=0 THEN * LOOP

1430 ’

3–9

Page 41

CHAPTER 3 COMMUNICATIONS DATA

1440 ’----- Identification of end character

1450 RDATA$=RDATA$+INPUT$ (LOC (1), #1)

1460 IF LEN (RDATA$)<2 THEN * LOOP

1470 IF MID$ (RDATA$, LEN (RDATA$) –1, 1)<>CHR$ (3) THEN * LOOP

1480 RESP$=MID$ (RDATA$, 2, LEN (RDATA$) –2)

1490 IF RDATA$=SDATA$ THEN * LOOP0

1500 * REND

1510 ’

1520 ’---------- Display receive data ---------1530 PRINT ”RESPONSE:”; RESP$

1540 GOTO * REPEAT

1550 ’

1560 * EXIT

1570 ’=====End processing==========

1580 CLOSE #1

1590 END

FĂSample operation

Read the PV of unit No.00. (In this example, PV=335.)

(reading is continued if character is not end character)

RUN

SEND DATA: 000000101C00001000001

RESPONSE: 000000010100000000014F

SEND DATA : [STX] 00

RESPONSE : [STX] 00 00 00 0101 0000 000014F [ETX] [BBC]

00 0 0101 C0 0001 00 0001 [ETX] [BBC]

Number of elements

Bit position

Read start address

Variable type

MRC/SRC

SID

Sub–address

Node No.

Read data

Response code

MRC/SRC

Final code

Sub–address

Node No.

3–10

Page 42

JProtocol macro

3.3Sample Program

F What is a “proto-

col macro?”

Connection

The protocol macro function uses the PMCR command in a ladder proĆ

gram to execute a data send/receive sequence (protocol) with various comĆ

munications devices such as generalĆpurpose components connected to

the RSĆ232C or RSĆ422A/RS Ć485 interface to control the device.

Standard system protocol is preĆinstalled on Serial Communications

Board/Unit for enabling control of OMRON components (e.g. controllers

and temperature control units).

For details on protocol macros, refer to the CS1WĆSCB21/41/ĆSCU21

User's Manual" (Cat. No. W336).

Use port 2 on the Serial Communications Board (CS1WĆSCB41) for direct

connection to the RSĆ485.

CPU unit

CS1H

Serial Communications Board

CS1W-SCB41

Port 2

RS-485

Sample ladder

program

Set the TERM switch on the Serial Communications Board to ON and the

WIRE switch to “2". Attach a terminator to H8GN.

Read the PV of H8GN using sequence No. 600 send/receive with ASCII

conversion (response ON)" of the standard system protocol CompoWay

/F Host" built into the Serial Communications Board.

“Network

Input

condition

000000

“Network

communication

error” flag

A21900

communication

command

executable” flag

A20200

“Protocol macro

in progress” flag

191915

PMCR

#02E1

#0258

D01000

D01500

FAL(06) 01

Communication port 0

Serial port 2

Destination address E1

(serial communication board)

Sequence No. 0258H (=600)

First word address for transmission data

First word address for reception data

The PV is stored to D01502 and D01503 if the read PV command is set to

D01000 onwards.

If a communications error occurs, execute the FAL command (continue

operation and analyze trouble command).

3–11

Page 43

CHAPTER 3 COMMUNICATIONS DATA

FĂData transmission word assignment

Node

STX

02H ”01” ”00””0” ”01” ”01” ”C0” ”0001” ”00””0001” 03H

Sub-

No.

address SID MRC SRC

Variable

type Address

Bit

position Number of elements EXT BCC

D01000

D01001

D01002

D01003

D01004

D01005

D01006

0007

0001

0101

000C

C000

0100

0001

No. of transmission words (D01000 to D01006)

Node No. of H8GN: 1

CompoWay/F command: Variable area read

No. of bytes transmitted: 12

Variable type, read start address, bit position,

Number of elements

FĂData reception word assignment

Node

Sub-

STX

No.

address MRC SRC EXT BCC

02H ”01” ”00” ”01” ”01” 03H

End

code Response code Data

Process value

0004D01500

D01501

D01502

D01503

Number of reception words (D01500 to D01503)

Response code

Current process value

3–12

Page 44

APPENDIX

APPENDIX

ASCII List AĆ2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1

Page 45

APPENDIX

ASCII LIST (ANSI X 3.4-1986)

b

8

7

6

5

0b

0b

0b

00 10 11 1

10 01 10 1

01 01 01 1

8

#

Even parity

b

b

3

4

b

b

1

2

00 00 NUL0 SPAC

00 10 SOH1 !DC1 A1 aQ q

C

R

0

21 43 65 7b5b6b7b

DEL @0 P p

E

00 01 STX2 ”DC2 B2 bR r

00 11 ETX3 #DC3 C3 cS s

10 00 EOT4 $DC4 D4 dT t

10 10 ENQ5 %NAK E5 eU u

10 01 ACK6 &SYN F6 fV v

10 11 BEL7 ’ETB G7 gW w

01 00 BS8 (CAN H8 hX x

01 10 HT9 )EN I9 iY y

01 01 LFA *SUB J: jZ z

01 11 VTB +ESC K; k[ {

11 00 FFC ,FS L< l\ |

11 10 CRD -GS M= m] }

11 01 SOE .RS N> n^

X

11 11 SIF /US O? o_ DEL

A–2

Page 46

INDEX

A

Addresses 2Ć5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area definitions 2Ć5. . . . . . . . . . . . . . . . . . . . . . .

ASCII list AĆ2. . . . . . . . . . . . . . . . . . . . . . . . . . .

B

BCC 1Ć2, 2Ć2, 2Ć3, 2Ć4. . . . . . . . . . . . . . . . . . . . .

C

Command frame 1Ć3, 2Ć2. . . . . . . . . . . . . . . . . .

Command text 2Ć2, 2Ć5. . . . . . . . . . . . . . . . . . . .

Communications data 2Ć4, 3Ć1. . . . . . . . . . . . .

Communications data length 1Ć4, 1Ć5. . . . . . .

Communications methods 1Ć1, 1Ć2. . . . . . . . . .

Communications parameters 1Ć4. . . . . . . . . . .

Communications parity 1Ć4, 1Ć5. . . . . . . . . . . .

Communications specifications 1Ć2. . . . . . . . .

Communications stop bit 1Ć4, 1Ć5. . . . . . . . . .

Communications unit No. 1Ć4, 1Ć5. . . . . . . . . .

CompoWay/F 1Ć2, 2Ć1, 3Ć1. . . . . . . . . . . . . . . . .

D

Data format 2Ć2. . . . . . . . . . . . . . . . . . . . . . . . . .

Details of services 2Ć7. . . . . . . . . . . . . . . . . . . . .

E

Echoback test 2Ć6, 2Ć12. . . . . . . . . . . . . . . . . . . .

End code 2Ć3, 2Ć4. . . . . . . . . . . . . . . . . . . . . . . . .

ETX 2Ć2, 2Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F

FINS 1Ć2, 2Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Interface 1Ć2, 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . .

L

List of services 2Ć6. . . . . . . . . . . . . . . . . . . . . . . .

N

Number of elements 2Ć5. . . . . . . . . . . . . . . . . . .

O

Operation instructions 2Ć6, 2Ć14. . . . . . . . . . .

P

PDU 2Ć5, 2Ć10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

R

Read controller attributes 2Ć6, 2Ć10. . . . . . . . .

Read controller status 2Ć6, 2Ć11. . . . . . . . . . . .

Read from variable area 2Ć6, 2Ć7. . . . . . . . . . .

Response code list 2Ć15. . . . . . . . . . . . . . . . . . . .

Response frame 2Ć3. . . . . . . . . . . . . . . . . . . . . . .

S

Sample program 3Ć9. . . . . . . . . . . . . . . . . . . . . .

SID 2Ć2, 2Ć4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status 3Ć6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STX 2Ć2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

Transmission procedure 1Ć3. . . . . . . . . . . . . . .

Type code (variable type) 2Ć5. . . . . . . . . . . . . .

V

Variable area (setup range) list 3Ć2. . . . . . . . .

W

Wiring 1Ć3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write to variable area 2Ć6, 2Ć8. . . . . . . . . . . . .

Page 47

Revision History

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

Cat. No. M066ĆE1Ć1

Revision code

The following table outlines the change made to the manual during each revision. Page numbers refer

to previous version

Revision code

1 June 2000 Original production

Data Revised content

Loading...

Loading...