Page 1

Multi-maintenance Counter H8BM

3 s age se g

s age se g

Nine Built-in Counters/Timers to

Measure Equipment Utilization

Up to nine Counters can be used as counters or

accumulative timers.

Can be used as a multi-stage preset counter.

Individual outputs to indicate maintenance timing.

Pre-forecast/Forecast and machine stoppage

output provided.

IP54F enclosure rating for resistance to oil and

water.

Compact, short-body: 72 x 72 x 79 mm (DIN).

Directly connectable to 2-wire DC sensors.

Ordering Information

RC

Number

3-stage setting

1-stage setting

of stages

NPN H8BM-B

PNP H8BM-BP

NPN H8BM-BD

PNP H8BD-BDP

Accessories (Order Separately)

Replacement Parts

Name Model

Hard Protective Cover Y92A-72C

Rubber Packing

A

Hard Protective Cover and Rubber Packing are

Counter.

Y92S-25

supplied with the

Output Model

Short

Bar

Short

Bar

When the Counter is used as a multi-stage preset counter, wiring

will be facilitated if Counter inputs 1 through 9 are short-circuited

with

the following Short Bar

5-pole

4-pole

Both

the 5-pole and 4-pole Short Bars are used to short-circuit the 9

Counter

inputs.

Y92S-26

.

1

Page 2

H8BM

Specifications

Item H8BM-B, H8BM-BP H8BM-BD, H8BM-BDP

Classification

Mounting method

External connections

Enclosure ratings

Display mode

Output mode

Reset system

T

iming function

Input signal method

Control output No-contact outputs: NPN outputs (RUN, forecast,

Display

LCD with backlight Yes

Built-in counter number

Number of stages

Digits

Max. time settings

Memory backup

Approved standards

3-stage setting 1-stage setting

Flush mounting

Screw terminals

IP54F (panel surface)

Up display

F mode

External, manual resets

Yes

V

oltage inputs: High and low signal voltages (count, reset, re-monitor

machine stoppage) (PNP outputs for -BP)

Count, preset value, counter number

reset, I/O inhibit, and re-monitor modes displayed on LCD characters

Output indication on LCD characters and LEDs

9 (counters 1 to 9) (see Note 1)

3 stages (see Note 2)

Forecast value:

Pre-forecast value:

Machine stoppage:

Forecast value:

Pre-forecast value:

Machine stoppage:

Backup time for power interruption: Approx. 10 years at 25

UL508, CSA C22.2 No.14

6 digits (999999)

–5 digits (see Note 3)

+5 digits (see Note 4)

99999.9 hr (0.1 hr or more)

–9999.9 hr (see Note 3)

+9999.9 hr (see Note 4)

, and error codes displayed on 7-segment LCD Power-ON, mode,

H8BM

, counter select, I/O inhibit)

No-contact outputs: NPN outputs (RUN, forecast)

(PNP outputs for -BDP)

1 stage (see Note 5)

6 digits (999999)

99999.9 hr (0.1 hr or more)

°C

Note: 1.

Each channel operates on an separate I/O.

2. Pre-forecast:

Forecast:

Machine stoppage:

3.

The pre-forecast value is set as a negative offset in respect to the forecast value.

4.

The machine stoppage value is set as a positive of

5.

This model operates on the forecast value only

Ratings

Rated

voltage

Operating voltage range

Power consumption

Max. counting speed

Min. input signal width

One-shot output time

Count, reset, re-monitor

output number request, and

I/O inhibit input

Control output

Case color

Note: 1.

Ripple content: 20% max.

2.

On power application, an inrush current of approx. 1.2 A flows into the Counter

3.

This signal is output as a carry signal when the Counter is used as a totalizing counter

This signal can also be used as a no-voltage input signal depending on the wiring (refer to Input Connections).

4.

,

Displayed only on LCD (No external output is provided.)

Displayed on LCD and LED and output (Output for each Counter)

Displayed on LCD and LED and output

(Output when the count value of one or more of Counters 1 to 9 has reached its machine stoppage value.)

fset in respect to the forecast value.

.

24 VDC

85% to 1

Approx. 1.8 W (at 24 VDC) (see Note 2)

30 cps (ON:OFF = 1:1)

Counter No. selection input:

Reset input:

Re-monitor input:

Output number request input:

I/O inhibit input:

20 ms (see Note 3)

V

High level:

Low level:

Open-collector output: 100 mA max. at 30 VDC max.

Light gray (Munsell 5Y3/1)

10% of rated voltage (see Note 1)

16.7 ms max.

100 ms max.

30 ms max.

30 ms max.

16.7 ms max.

oltage input (see Note 4) (input resistance: approx. 2.2 k

16 to 30 VDC

0 to 3 VDC

.

Ω)

.

2

Page 3

H8BM

Characteristics

Insulation

Dielectric strength

Impulse withstand voltage

Noise immunity

Static immunity

V

ibration resistance

Shock resistance

Ambient temperature

Ambient humidity

Weight

resistance

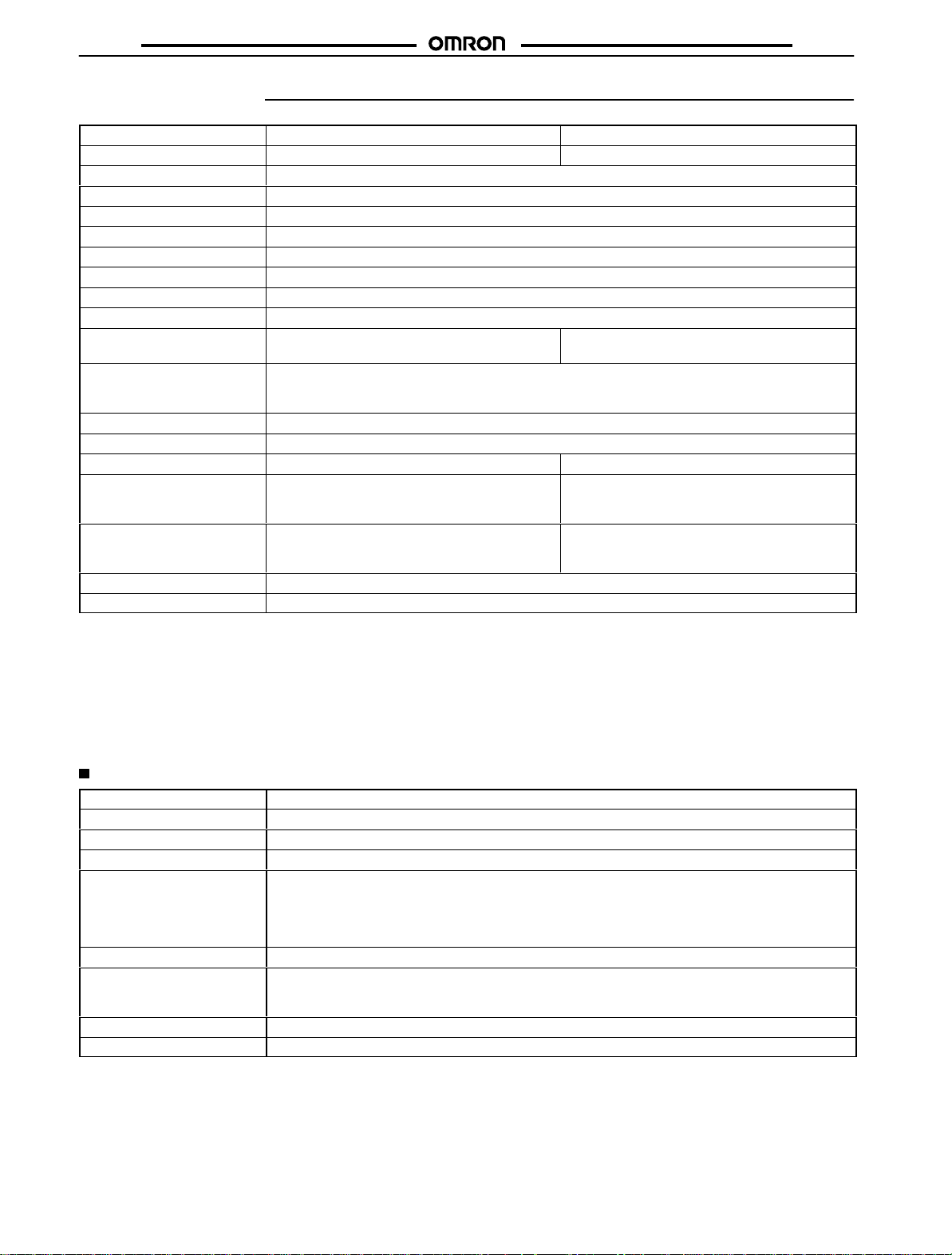

Block Diagram

H8BM

100 MΩ min. (at 250 VDC) (between current-carrying terminals and exposed non-current-carrying

metal parts)

1,000 V

AC, 50/60 Hz for 1 min (between current-carrying terminals and exposed non-current-carrying

metal parts)

1 kV (between power terminals)

1.5 kV (between current-carrying terminals and exposed non-current-carrying metal parts)

±

1 kV (between power terminals) and ±600 V (between input terminals), square-wave noise via noise

simulator (pulse width: 100 ns/1

Malfunction: 8 kV

Destruction:

Malfunction:

Destruction:

Malfunction:

Operating: –10°

Storage: –25°

; destruction: 15 kV

10 to 55 Hz with 0.75 mm single amplitude in three directions

10 to 55 Hz with 0.5 mm single amplitude in three directions

2

294 m/s

2

196 m/s

C to 55°C (with no icing)

C to 65°C (with no icing)

Operating: 35% to 85%

Approx. 290 g

µs, 1-ns rise)

Although

the input terminals are electrically insulated from the internal circuit, do not conduct

I/O Functions

Inputs

Count

(1 to 9)

Reset

Re-monitor

Counter No. select

I/O inhibit

Function

setting circuit

Key switch

circuits

Input circuits

(count 1 to 9,

reset, re-monitor,

output number

request, I/O inhibit)

(DC) input

Counter clock

generator

ROM RAM LCD driver

Count

circuits

Power circuits*

System clock

generator

Count

circuits

Battery

LCD reference

voltage generator

One-chip

microcomputer

Power failure

detector

LCD

Output circuits

(Output 1 to 9,

RUN, machine

stoppage)

LED

an insulation resistance test on these terminals.

Input count values.

Used as time count input signals when Counter is used as timer

.

Maximum counting speed: 30 Hz (minimum signal width: 16.7 ms)

Resets displayed count (timing) value of a specified Counter

Counter under reset does not operate ad its output is turned OFF

.

.

Reset signal input during re-monitor input restores reset count (timing) value of the specified Counter

While reset signal is ON, RST indicator lights.

Reset count (timing) value of specified Counter can be re-monitored, and restored by reset input.

While re-monitor signal is ON, RCV indicator lights.

Specifies Counter whose count (timing) value is to be displayed.

Inhibits count inputs of all Counters.

T

urns OFF all forecast outputs, RUN outputs, and machine stoppage outputs.

While I/O inhibit signal is ON, INHB indicator lights.

.

3

Page 4

H8BM

Outputs

Forecast (1 to 9)

RUN T

Machine stoppage

Each of these outputs turns ON when its forecast value has been reached.

When Counter is used as totalizing counter

, output one-shot signals as carry signals.

Retain outputs until count values are reset.

urns ON when Counter is operating normally

T

urns ON when count value of one Counter has reached set machine set machine stoppage value.

.

Retains output until count value is reset.

H8BM

Note: The

input and output signals are enabled when power is applied to the Counter

and

the output signals are turned OFF

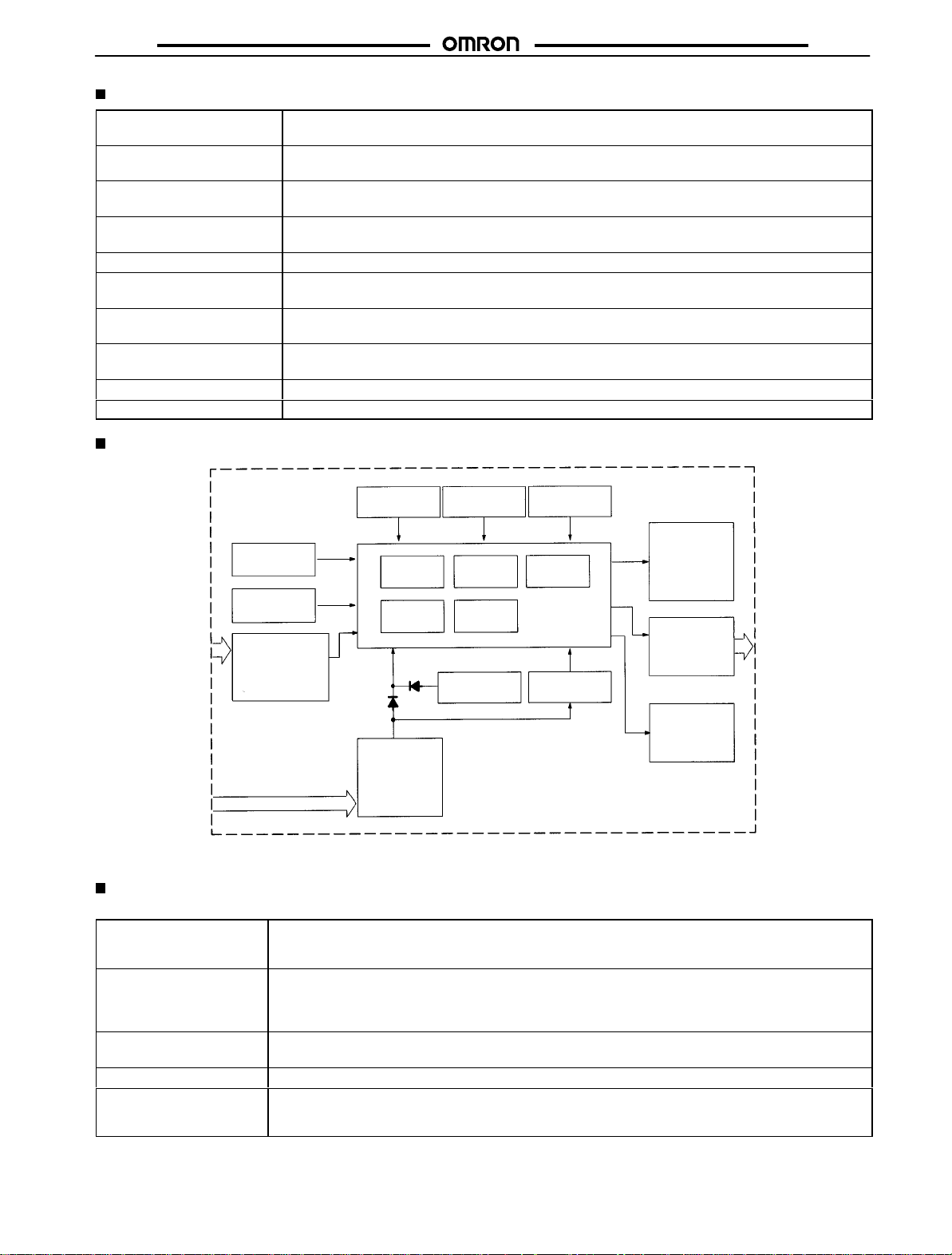

Nomenclature

I/O Inhibit Indicator

Indicates that the input/output

inhibit input signal is ON.

Re-monitor Input Indicator

Indicates that the re-monitor

input signal is ON.

Reset Input Indicator

Indicates that the reset input

signal is ON.

Counter No. Indicator

Indicates the number of the

Counter whose data (count

value, preset value, etc.) is

currently displayed.

RESET Key

Resets the count value

and output signals.

COUNTER No. Key

Selects the Counter in

sequence each time this

Selector is pressed: (Any

Counter whose forecast value

is set to 0 is skipped in the

RUN mode.)

RUN

.

The following indicators light to show that the count value has reached

the preset value and that the output has turned OFF.

Control Output Indicator (Red LED):

Pre-forecast value: LCD lights

Forecast value: RED LED lights

Control Output Indicator (LCD):

Machine stoppage value: Indicator flashes between red and green

CNT

MODE

No.

MODE Key

Selects the mode in sequence each time

this key is pressed:

Forecast

value

Pre-forecast

value

Machine

stoppage

value

. During a power failure, the input signals are disabled,

and LCD output indicator flashes.

Count Value

Indicates the current count (current time in

timer mode)

Set Mode Indication

Preset Value

Always indicates the forecast value during

the RUN operation. Indicates the set

value in each setting mode.

Up Keys 1 to 6

Each of these keys increments the preset

value of the corresponding digit, each

time it is pressed.

SET Key

Inputs the set or changed data.

: RUN mode

: Forecast value

: Pre-forecast value

: Machine stoppage value

Note: Models with only 1-stage setting (H8BM-jDj) are not provided with pre-forecast

forecast output function is provided.

4

and machine stoppage output function; only the

Page 5

H8BM

Operation

H8BM

Operation

1. Selecting Counter/Timer Operation

Whether

each Counter operates as a counter or a timer can be spe

cified on a DIP switch provided on the side panel of the Counter.

Open

the lid of the switch compartment on the side of the Counter

Set

each DIP

figure:

The setting of the DIP switch is read on power application.

Note: The setting of the DIP switch that is used to select the

2. Changing Mode

Each

switch pin as necessary by referring to the following

Timer

Counter

or timer operation of each Counter is read on power

counter

application. Setting change of this DIP switch while the

Counter

is operating will be ignored. Power must be turned

off

then back on again after changing settings.

DIP switch compartment

time the MODE Key is pressed, the mode changes as follows:

Note: 1. The modes marked * are not provided on the 1-stage

Counter

-

type

.

2. I/O operations are always performed regardless of the

.

mode.

3. If

no key is pressed for 1 minute in each mode, the RUN

mode

is automatically restored.

3. Setting/Changing Data (3-stage Type)

Setting/Changing

1. Press the MODE Key to enter the forecast value setting

mode. The same Counter number as in the RUN mode is

displayed.

2. Press the COUNTER No. Key to select the Counter whose

data is to be set or changed. The Counters are selected in

sequence each time the COUNTER No. Key is pressed. A

Counter can also be selected by inputting the Counter No.

selection.

Forecast V

alue

RUN mode

Forecast value mode

Mode

Key

Pre-forecast value mode*

Mode

Key

Mode

Key

Mode

Key

RUN

Mode Indication

Forecast Value Setting

Mode Indication

Flashing

Pre-forecast V

Setting Mode Indication

Flashing

Machine Stoppage V

Setting Mode Indication

alue

alue

Flashing

3. Use the Up Keys (1 to 6) to change the values of the digits.

When an Up Key is pressed, the corresponding digit starts

flashing.

The preset value is zero-suppressed. Each time the

Up

Key is pressed, the specified value increment as:

Flashing

In

the following example, the forecast value

to

35000.

of Counter 2 is set

Machine stoppage mode*

Flashing

Flashing

5

Page 6

H8BM

H8BM

4. Press the SET Key to determine the set value. If o Key is

pressed within 5 seconds after the SET Key has been

pressed,

the RUN mode is automatically restored. Key inputs

made

during the 5 seconds are valid.

After the set forecast value has flashed, the display is

changed

automatically as below

RUN Mode Indication

.

4. Resetting Count Value

Resetting Value for Each Counter

1. Select

the Counter whose count value is to be reset by either

pressing the COUNTER No Key or inputting the Counter No.

select.

The count value can be reset in any mode.

5. Re-monitoring Count Value

A

count value that has been reset by mistake can e recovered. (ex.

Recover

previously reset count value “23456” of Counter No. 3)

1. Turn ON the re-monitor input. The count value which was

reset will be displayed. At this time, the count value is only

displayed and not recovered internally. The Counter whose

count

value is displayed remains in the RUN mode.

2. Press the COUNTER No. Key (or apply the Counter No.

3. Press the RESET Key (or apply the reset input). The

input) to access the Counter whose count value

select

recovered.

the

recovered value will flash 3 times, and the count value that

was

While

remain displayed. However, the internal mechanism of the

Counter will continue operating from the count value before

resetting.

If the count value does

following operations are not necessary

reset will be recovered

the

recovery input is ON, the recovered count value will

not need to be recovered,

.

for the designated Counter only

is to be

.

2. Either press the RESET Key or input the reset signal. The

value of the selected Counter will be reset to 0.

count

6

4. Turn

OFF the re-monitor input to restore normal operation.

6. Checking Count Values (RUN Mode)

Select

the Counter whose count value is to be checked by pressing

the COUNTER No. Key in the RUN mode, or by inputting the

Counter No. select. The Counter number changes in sequence

each time the COUNTER No. Key is pressed. However, any

Counter

not

used (whose forecast value is set to 0) will be skipped.

Page 7

H8BM

H8BM

7. Count Value Display

While the count input is ON, the period on the count value display

flashes.

The timer operation

of

the count input.

measures time by totaling the ON time

8. Output Indicator

The

status of the pre-forecast,

puts

is displayed as follows:

1. Pre-forecast:

has

reached the pre-forecast value is displayed on the LCD.

The

pre-forecast is only displayed on LCD as

no

actual output is issued.

2. Forecast

the

Counter whose count value is displayed on the LCD.

The number of the Counter whose count value

Output:

forecast, and machine stoppage out

a message and

A red indicator lights above the number of

9. Clearing Settings

• The count values of all the Counters can be cleared by

simultaneously holding down the RESET Key and COUNTER

No. Key for 3 seconds.

The

same

and

function is ef

reset input are simultaneously applied for 3 seconds.

fected if the Counter number select input

• The count value, pre-forecast value, forecast value, and

machine stoppage value of all the Counters can be cleared by

simultaneously holding down the RESET and SET Keys for 3

seconds.

10. When Used as Totalizing Counter/Timer

Counter

By

setting the forecast value of a Counter to 999999 (99999.9 hr),

the

Counter can be used as a totalizing

stoppage

izing

output for 20 ms as a carry signal when the count value changes

from

output

counter

999999 to 0.

of this Counter is not issued. When used as a total

, the forecast output of this Counter issues a one-shot

counter/timer

11. Self-diagnostic Function

The

following displays will appear if an error occurs.

Display Meaning Output

E1 CPU

Error

E2 Memory

Error

status

OFF Press

Recov-

ery

RESET

Key

Normal counter

operation is

recovered using

count and set

values from

before the error

Factory setting

. The machine

-

Setting after

recovery

.

3. Machine Stoppage Output: The background alternately

lights

in red and green, and the number of the Counter whose

machine

Flashing

Note: When

stoppage output is issued is flashed on the LCD.

any of the pre-forecast, forecast,

page outputs of a Counter has turned ON, the Counter

number of that Counter is automatically displayed. When

an

attempt to reset the count value is made at this time, the

count

value of only

rently displayed is reset (in RUN mode only).

the Counter whose count value is cur

and machine stop

-

-

7

Page 8

H8BM

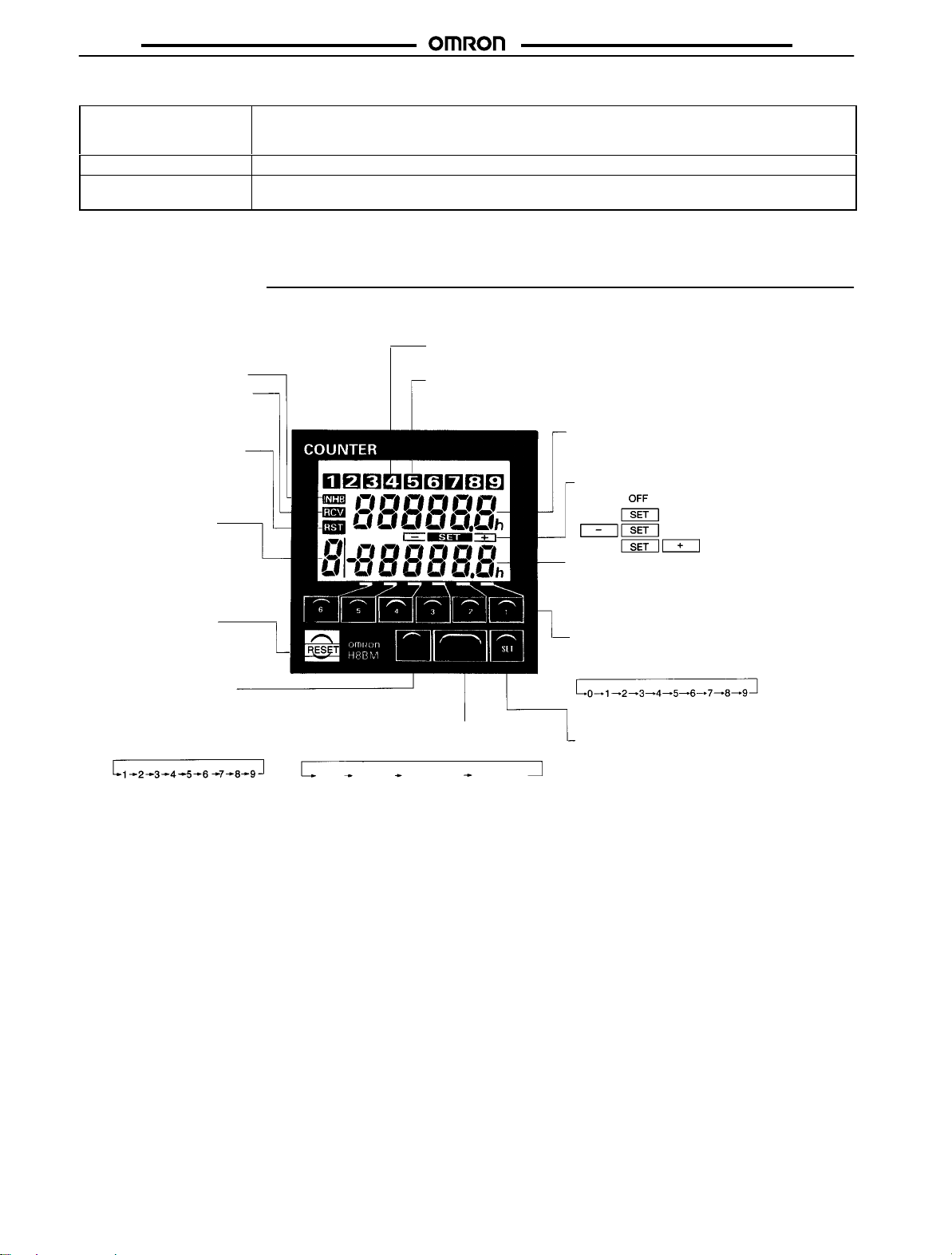

Timing Charts

H8BM

Counter (3-stage Preset Operation)

Reset input

Count input

Machine stoppage value

Count value

Pre-forecast indicator

output and indicator

999999

Forecast value

Pre-forecast value

Forecast output

and indicator

Machine stoppage

0

Totalizing Counter Operation

Reset input

Count input

999999

Count value

Forecast output

(indicator)

0

One-shot output time: 20 ms

Timer (3-stage Preset Operation)

Reset input

Count input

Machine stoppage value

Time value

99999.9 hr

Forecast value

Pre-forecast value

Pre-forecast indicator

Machine stoppage

output and indicator

0.0 hr

Forecast output

and indicator

Totalizing Timer Operation

Reset input

Count input

99999.9 hr

Time value

0.0 hr

Forecast output

(indicator)

One-shot output time: 20 ms

Dimensions

Note: All

Panel Cutouts

Panel cutout is as shown below (according to DIN43700). The

mounting

units are in millimeters unless otherwise indicated.

panel thickness should be 1 to 5 mm.

Hard Protective

Cover (transparent)

8

Page 9

H8BM

Installation

Mounting

To

mount the Counter

to the left and right sides of the

ries

knurled

screws on the brackets. If any other screws are used to at

tach

the brackets, or if the knurled screws are excessively tightened

with

a tool, damage may result.

Hard Protective

Cover (transparent)

, attach the two fixtures supplied as accesso

Rubber packing

Counter

Mounting bracket

Mounting

panel

, and securely tighten the

(2 sets)

Knurled screw

H8BM

-

Provide

enough space around the Counter when mounting it to en

a proper working space.

sure

-

Other components

-

Terminal Arrangement

22 23 24 25 26 27 28

15 16 17 18 19 20 21

8 9 10 11 12 13 14

12 3 4 5 6 7

22 23 24 25 26 27 28

Reset

input

Count No.

selection

15 16 17 18 19 20 21

Re-monitor

input

8 9 10 11 12 13 14

RUN

output

1 2 3 4 5 6 7

Power

supply: 0 V

I/O inhibit

input

Machine

stoppage

output

Power

supply:

24 V

Count

input 1

Count

input 6

Forecast

output 1

Forecast

output 6

Count

input 2

Count

input 7

Forecast

output 2

Forecast

output 7

Count

input 3

Count

input 8

Forecast

output 3

Forecast

output 8

Count

input 4

Count

input 9

Forecast

output 4

Forecast

output 9

Count

input 5

Input COM

Forecast

output 5

Output

COM

9

Page 10

H8BM

Connections

NPN Output

H8BM

Count input 1

Note: Short-circuit

Count input 2

Count input 3

Count input 4

Count input 5

Count input 6

Count input 7

Count input 8

Count input 9

Count No.

selection

Reset input

I/O inhibit input

Re-monitor input

INPUT COM

16 to 30 VDC

terminals 1 and 7 when the power source of the Counter is shared.

DISPLAY

Count value

Setting value

Count up

6 digit, 3-stage

preset Counter

x 9

5 V

H8BM-BD/-BDP outputs the forecast and machine stoppage values simultaneously

RUN, machine stoppage,

forecast outputs 1 to 9

Load

Power

circuit

.

Forecast output 1

Forecast output 2

Forecast output 3

Forecast output 4

Forecast output 5

Forecast output 6

Forecast output 7

Forecast output 8

Forecast output 9

Machine

stoppage output

RUN output

OUTPUT COM

+24 V

0 V

+10%

24 VDC

–15%

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

* Connect

a diode to suppress Counter surge when an inductive

load is connected.

Note: When

damaged.

30 VDC

Max.

the load is short-circuited, the internal circuits may be

10

Page 11

H8BM

PNP Output

H8BM

16 to 30 VDC

Note: H8BM-BD/-BDP

Count input 1

Count input 2

Count input 3

Count input 4

Count input 5

Count input 6

Count input 7

Count input 8

Count input 9

Count No.

selection

Reset input

I/O inhibit input

Re-monitor input

INPUT COM

DISPLAY

Count value

Setting value

Count up

6 digit, 3-stage

preset Counter

x 9

5 V

Power

circuit

outputs the forecast and machine stoppage values simultaneously

OUTCOM

All outputs

Load

30 VDC

Max.

OUTPUT COM

Forecast output 1

Forecast output 2

Forecast output 3

Forecast output 4

Forecast output 5

Forecast output 6

Forecast output 7

Forecast output 8

Forecast output 9

Machine

stoppage output

RUN output

24 VDC

.

+24 V

0 V

+10%

–15%

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

* Connect

a diode to suppress Counter surge when an inductive

load is connected.

Note: When

the load is short-circuited, the internal circuits may be

damaged.

Output

Output method

Applicable voltage

Rated current

Residual voltage

Leakage current

I/O Connections

Input Circuits

INCOM

Input

The

1.2 kΩ

430 Ω

1.2 kΩ

input terminals are electrically

insulated from the internal circuits.

Photocoupler

RUN,

Open collector

30 V max.

100 mA

2 V max.

100 µA max.

5 V

machine stoppage, forecast 1 to 9

Output Circuits

NPN Type

10 Ω

39 V

OUTCOM*

The

OUT COM and 0 V terminals

are internally connected.

Output

PNP Type

39 V

10

OUTCOM

Output

Ω

11

Page 12

H8BM

Example of Input Connections (Solid-state Switches)

Two-wire

The

put, and re-monitor input signals are enabled when voltage is applied.

Sensors

count input, counter No. select input,

Two-wire sensor

reset input, I/O inhibit in

H8BM

All inputs

-

H8BM

Note: Use

1. High-level; transistor ON

2.

3.

Use

the following two-wire sensors:

Min. switching capacity: 5 mA max.

Residual voltage: 4 V max.

Low-level: transistor OFF

Leakage current: 1.5 mA max.

Power voltage range: 20.4 to 30 VDC

of the OMRON TL-XD or E2E-XD-N Sensors is recommended.

Three-wire

24 VDC

Two-wire sensor

24 VDC

IN COM

H8BM

IN COM

All inputs

Sensors

NPN Type PNP Type

H8BM

COM

Main

sensor

circuit

All inputs

H8BM

COM

Main

sensor

circuit

All inputs

Main

sensor

circuit

Main

sensor

circuit

H8BM

All inputs

COM

H8BM

All inputs

COM

Contact

Switch Connection

H8BM

All inputs

COM

H8BM

COM

All inputs

*H: Contact ON.

*Use contact that can break 13 mA, 30 V

12

Page 13

H8BM

Precautions

Power Supply

• The power supply and input circuits are electrically insulated

inside

the Counter

• When turning the power on and off, input signal reception is

sometimes not possible as shown in the diagram below. The

unstable

period

conditions

ON

Power supply

OFF

Input signal

reception

.

will vary with power supply voltage and the load

on external power supplies.

24 V

0 V

250

ms

Impossible

14 V

0 to 50 ms

Count

Unstable

12 V

10 ms to 0.9 s

Impossible

Unstable

H8BM

• Turn on or off the operating power source all at once by using

or relay contact.

switch

Operating Environment

• The front panel of the Counter is dust-proof and oil-proof.

However,

oil

• When

generated

far

of

• Organic

or

if the Counter is exposed to a large quantity of water or

for a long time, the internal components may be af

using

the Counter in a location where excessive noise is

keep the

away as possible from the noise source and power lines.

shielded cable as input signal lines is recommended.

solvents (such as paint thinner), as well as strong acids

strong alkalies can damage the housing of the Counter

Counter

, input devices, and input wiring as

fected.

Use

.

Others

• To

conduct a dielectric strength test between the electric circuits

and

non-current-carrying metal parts with the Counter installed

in the control panel, either disconnect the Counter from the

or short-circuit all the terminals of the Counter (this is to

circuit,

prevent the test voltage from sneaking into the Counter and

the internal circuitry of the Counter from being damaged

prevent

in case the insulation of some device in the control panel

ruptures.

• The terminal screw is M3 x 5. Use the solderless terminal as

shown

in the following illustration.

Caution

!

This product contains a lithium battery. Lithium batteries explode

if incinerated. Dispose of the Counter as a

item.

tible

non-combus

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

Cat. No. M042-E1-1D

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial

Measuring and Supervisory Controls Department

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7108/Fax: (81)75-344-7189

Automation Company

-

o convert grams into ounces, multiply by 0.03527.

Printed

in Japan

0101-0.5C (0499)

13

Loading...

Loading...