Omron H5S DATASHEET

Digital Time Switch

y

H5S

Easier, More Convenient Time Switches, with

New 4-circuit Output and Yearly Models in

Addition to 2-circuit Weekly Models

• Independent Day Keys provide easier operation.

• Temporary holiday setting function makes it easy to turn OFF output

for holidays and non-operating days.

• Settings can be made even with the Time Switch turned OFF.

• Test mode enables easy program checking.

• Complies with EMC Directives, UL/CSA, and other safety standards.

• Includes summer time (DST) adjustment.

Yearly models also offer automatic switching to DST.

• Set value can be changed both upward and downward for speedier

setting.

• Integrated temperature compensation circuit helps keep accurate

time over a wide temperature range. (See note 1.)

• Includes time counter and total counter functions with alarm indicator.

(See note 2.)

• Bank function allows program switching by an external input. (See

note 3.)

• New 4-circuit output models with a compact, 72 × 72-mm DIN size

added to the series.

Note: 1. Available only on yearly models.

2. Available only on 2-circuit models.

3. Available only on weekly models.

Features

Easier and More Convenient to Use

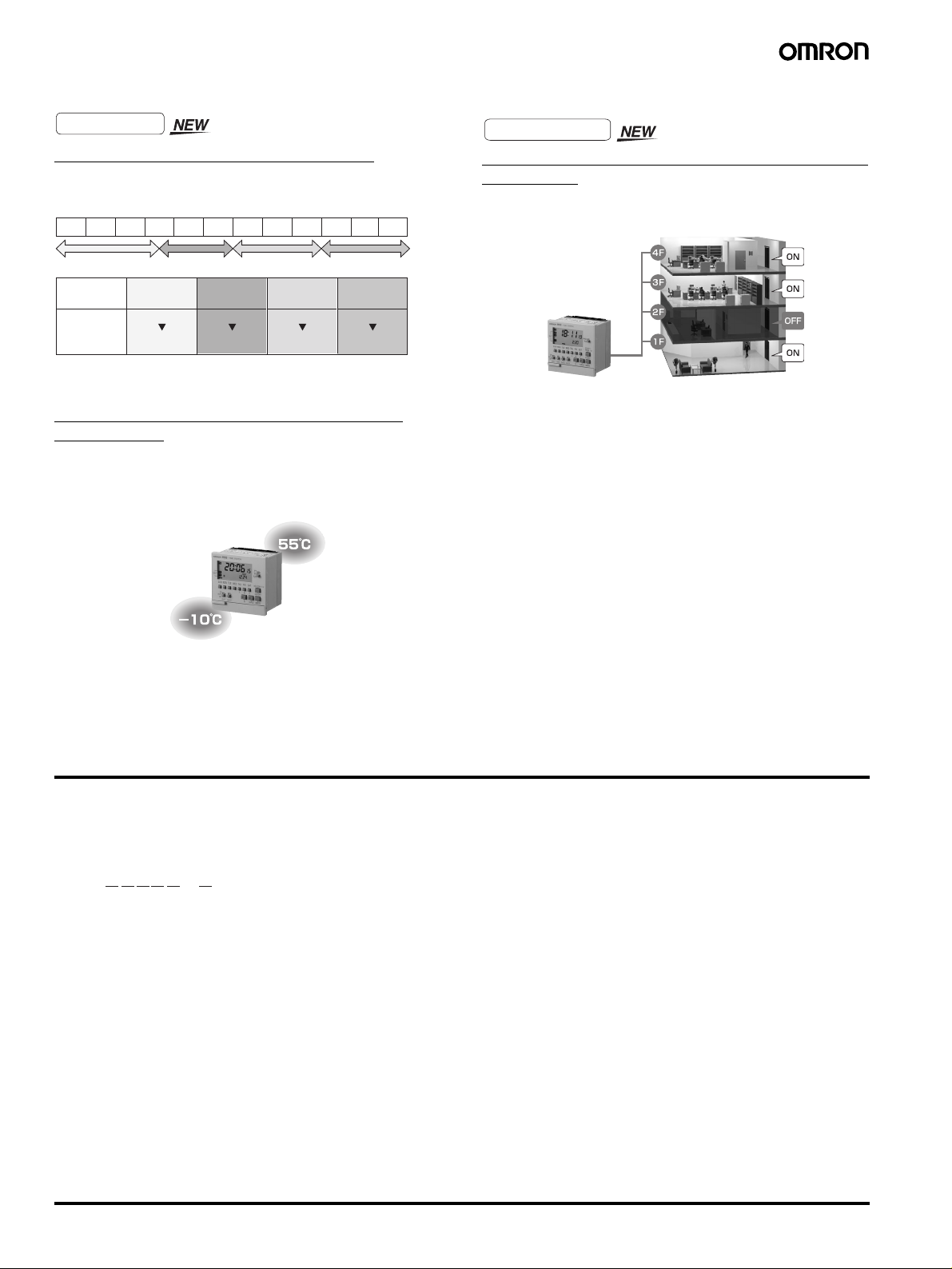

■ Simple Setting

Independent Day Keys make setting easy.

■ Convenient Functions

Time Counter/Total Counter Functions (See note.)

This function makes it possible to monitor the total time that a load

has been applied, or the total number of operating cycles. It allows

the Time Switch to be used for managing maintenance.

With alarm indicator

Up/down set value changing

for speedy setting.

Temporary holidays

(non-operating days)

are also easy to set.

Weekly models: Specify the day.

Ye a r l

models: Specify the date.

Shows total lamp ON time

Time Adjustment Function (See note.)

The time can be set to 00 min 00 s by using an external input. The

times on multiple Time Switches can also be easily synchronized.

Synchronized!

Master

Note: Equipped on 2-circuit models.

Slave

Slave

Digital Time Switch H5S 1

More Applications on New Series Models

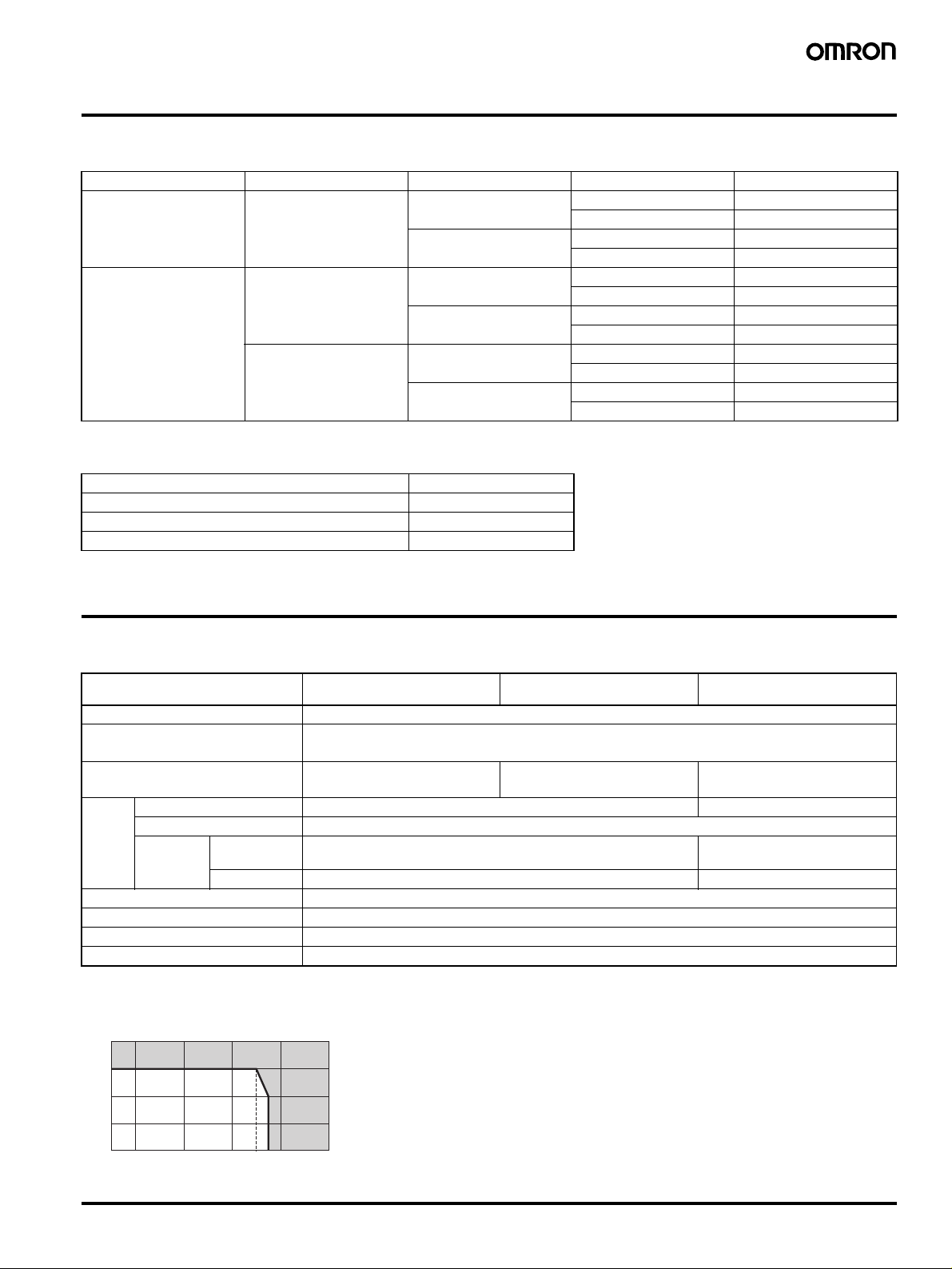

Yearly Models

Automatic Program Switching by Seasons

The yearly operation can be set to automatically change the weekly

program depending on the season. (See note.)

Mar Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb

Spring Summer Autumn Winter

Season

(See note 2.)

Program

example

Note: Up to four seasons can be set for 4-circuit models, and up to

two seasons for 2-circuit models.

Spring

17:30 ON

21:00 OFF

Summer

19:00 ON

22:00 OFF

Autumn

18:00 ON

21:00 OFF

Winter

17:00 ON

21:00 OFF

Temperature Compensation Circuit Maintains

Accurate Time

A temperature compensation circuit is provided in the yearly models

to maintain accurate time keeping even when the ambient

temperature varies greatly. This ensures precise operation with

minimal time lags all year round, regardless of temperature changes.

4-circuit Models

Space-saving, Economical 4-circuit Models Added

to the Series

The new 4-circuit models are 72 × 72-mm DIN size. Their spacesaving size allows use in more applications.

Control all four

floors with a

single unit.

Model Number Structure

■ Model Number Legend

Note: This model number legend includes combinations that are not available. Please check the “List of Models” for availability.

H5S- @@@@@ - @

1 2 3 4 5

1. Control cycle

W: Weekly

Y: Yearly

2. Mounting method

None: Flush mounting

F: Surface mounting/track mounting

3. Panel language

B: English

A: Japanese

6

4. Number of outputs

2: 2 circuits

4: 4 circuits

5. Supply voltage

None: 100 to 240 VAC

D: 24 VDC

6. Time accuracy

None: Standard

X: With temperature compensation

2 Digital Time Switch H5S

Ordering Information

■ List of Models

Control cycle Number of outputs Mounting method Supply voltage Models

Weekly 2 circuits Flush mounting 100 to 240 VAC H5S-WB2

24 VDC H5S-WB2D

Surface mounting/

track mounting

Yearly 2 circuits Flush mounting 100 to 240 VAC H5S-YB2-X

Surface mounting/

track mounting

4 circuits Flush mounting 100 to 240 VAC H5S-YB4-X

Surface mounting/

track mounting

■ Accessories (Order Separately)

Name Model

Large Terminal Cover (in pairs) Y92A-72H

Protective Cover Y92A-72C

Track Mounting Base Y92F-90

100 to 240 VAC H5S-WFB2

24 VDC H5S-WFB2D

24 VDC H5S-YB2D-X

100 to 240 VAC H5S-YFB2-X

24 VDC H5S-YFB2D-X

24 VDC H5S-YB4D-X

100 to 240 VAC H5S-YFB4-X

24 VDC H5S-YFB4D-X

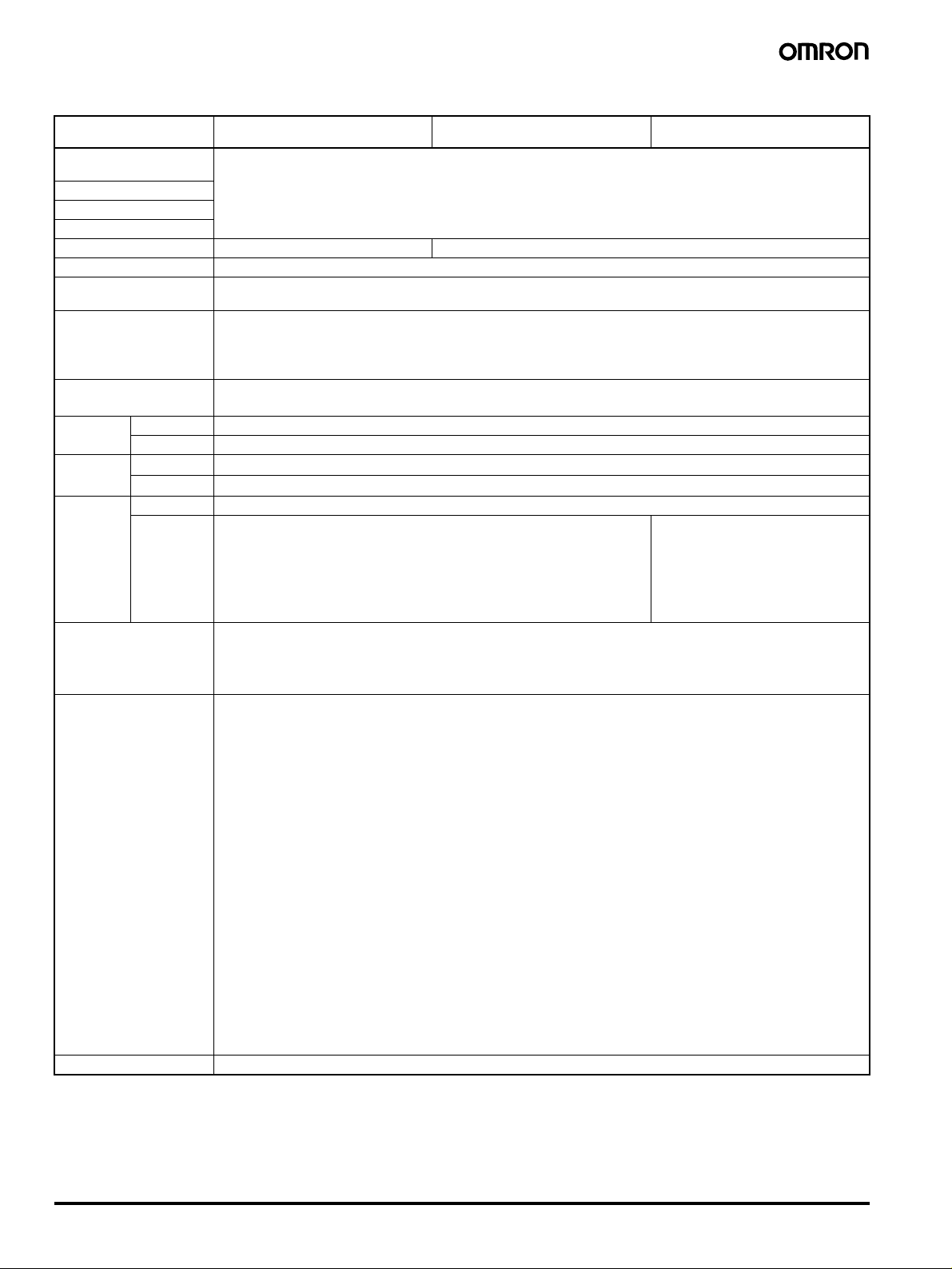

Specifications

■ Ratings

Item Weekly 2-circuit Models

Rated supply voltage 100 to 240 VAC (50/60 Hz), 24 VDC (See note 1.)

Operating voltage range AC: 85% to 110% rated supply voltage

DC: 85% to 120% rated supply voltage

Power consumption Approx. 2.9 VA at 264 VAC 60 Hz

Approx. 0.8 W at 28.8 VDC

Control

outputs

Ambient operating temperature

Ambient operating humidity 25 to 85%

Storage temperature

Case color Light gray (Munsell 5Y7/1)

Note: 1. Do not use inverter output as a power supply. For details, refer to Precautions for Safe Use, item 24, on page 12.

Number of circuits SPST-NO

Circuits Power supply circuit and other (no-voltage) circuit

Capacity Resistive load

2. The capacity is 15 A per circuit, but derating of the total current for two circuits is required as shown below depending on the ambient

temperature.

40

30

(cos

φ = 1)

Inductive load 10 A at 250 VAC (cos

15 A at 250 VAC (See note 2.) 3 A at 250 VAC

−10 to 55°C (with no icing or condensation)

−25 to 65°C (with no icing or condensation)

(H5S-W@2)

× 2 circuits SPST-NO × 4 circuits

φ = 0.7) 2 A at 250 VAC (cosφ = 0.4)

Yearly 2-circuit Models

(H5S-Y@2)

Approx. 3.2 VA at 264 VAC 60 Hz

Approx. 0.9 W at 28.8 VDC

Yearly 4-circuit Models

(H5S-Y@4)

Approx. 3.5 VA at 264 VAC 60 Hz

Approx. 1.0 W at 28.8 VDC

20

Total current (A)

10

0

10 0 20 40 50 55 60 80

Ambient temperature (˚C)

Digital Time Switch H5S 3

■ Characteristics

Item Weekly 2-circuit Models

Accuracy of operating

time

Setting error

Influence of voltage

Influence of temperature

Cyclic error

Memory protection Continuous use: 5 years min. (at 25

Insulation resistance 100 M

Dielectric strength 2,950 VAC, 50/60 Hz for 1 min (between current-carrying terminals and exposed non-current carrying metal parts)

Noise immunity

Vibration

resistance

Shock

resistance

Life

expectancy

Approved standards cURus: UL 508/CSA C22.2 No.14,

EMC (EMI) EN 60730-2-7

Weight Approx. 200 g

Destruction 10 to 55 Hz with 0.375-mm single amplitude in 3 directions for 2 hours each

Malfunction 10 to 55 Hz with 0.25-mm single amplitude in 3 directions for 10 minutes each

Destruction

Malfunction

Mechanical 100,000 operations min.

Electrical 50,000 operations min. (15 A at 250 VAC, resistive load)

±0.01%±0.05 s max. (See note 1.)

The

±15 s per month (at 25°C) ±15 s per month (at −10 to 45°C), ±20 s per month (at 45 to 55°C)

circuit and control output circuit, between control output circuits, and between non-continuous contacts.)

2,000 VAC, 50/60 Hz for 1 min (between operation circuit and control output circuit, and between control output

circuits)

1,000 VAC, 50/60 Hz for 1 min (between non-continuous contacts)

±1,500 V (between power terminals, for AC power models), ±500 V (between power terminals, for DC power models)

Square-wave noise by noise simulator (pulse width: 100 ns, for 1

300 m/s

100 m/s

50,000 operations min. (10 A at 30 VDC, resistive load)

50,000 operations min. (10 A at 250 VAC, inductive load (cos

50,000 operations min. (1 HP at 250 VAC, motor load)

50,000 operations min. (100 W at 100 VAC, lamp load)

10,000 operations min. (300 W at 100 VAC, lamp load)

Conforms to EN 60730-2-7(Pollution degree 2/overvoltage category II),

Conforms to VDE 0106/part100.

Conforms to Electrical Appliance and Material Safety Law (for Japan)

EMI Radiated: EN 60730-2-7 (CISPR 22 Class B)

EMI Conducted (Continuous): EN 60730-2-7 (CISPR 22 Class B)

EMI Conducted (Non-continuous): EN 60730-2-7 (CISPR 14-1)

Harmonic Current: EN 60730-2-7 (IEC 61000-3-2 Class A)

Voltage fluctuation/flicker: EN 60730-2-7 (IEC 61000-3-3)

(EMS) EN 60730-2-7

ESD Immunity: EN 60730-2-7 (IEC 61000-4-2): 6 kV contact discharge

Radiated Electromagnetic Field Immunity: EN 60730-2-7 (IEC 61000-4-3): 10-V/m AM modulation

Conducted Disturbance Immunity: EN 60730-2-7 (IEC 61000-4-6): 10 V (0.15 to 80 MHz)

Burst Immunity: EN 60730-2-7 (IEC 61000-4-4): 2 kV power line

Surge Immunity: EN 60730-2-7 (IEC 61000-4-5): 1 kV line to line (power line, output line)

line)

Voltage Dip/Interrupting Immunity: EN 60730-2-7 (IEC 61000-4-11): 0.5-s cycle, 100% (rated voltage)

(H5S-W@2)

±0.01% value applies to the set time interval.

°C) (See note 2.)

Ω min. (between current-carrying terminals and exposed non-current carrying metal parts, between operation

2

3 times each in x, y, and z axes, 6 directions

2

3 times each in x, y, and z axes, 6 directions

Yearly 2-circuit Models

(H5S-Y@2)

µs, 1-ns rise time)

φ = 0.7))

Yearly 4-circuit Models

(H5S-Y@4)

50,000 operations min. (3 A at 250

VAC, resistive load)

50,000 operations min. (3 A at 30

VDC, resistive load)

8 kV air discharge

(80 MHz to 1 GHz, 1.4 GHz to 2 GHz)

10-V/m pulse modulation (900 MHz)

1 kV control line

2 kV line to ground (power line, output

0.5 kV line to line (input line)

1 kV line to ground (input line)

Note: 1. The total error including the repeat accuracy, setting error, variation due to voltage change, and variation due to temperature change is

±0.01% ±0.05 s max.

2. The total time when power is not being supplied.

4 Digital Time Switch H5S

■ Operation

Item Weekly 2-circuit Models

(H5S-W@2)

Yearly 2-circuit Models

(H5S-Y@2)

Yearly 4-circuit Models

(H5S-Y@4)

Operation method Digital quartz

Operation period 1 week (7 days) 1 year (with integrated calendar to 2099)

Display • Day, hrs (switchable between 24-hr indication and a.m./p.m. 12-hr indication), minutes, seconds

(0.00 to 23:59, 0.00 to 11:59 a.m., 0.00 to 11:59 p.m.)

• Digital indication by LCD (character height: 10 mm)

• Digital display of operation schedule during operation

• Timing chart display of operation schedule during operation

Min. setting unit 1 min

Number of

steps that

can be set

Weekly program

(See note 1.)

Yearly program --- 4 yearly programs/circuit

Number of

40 steps/circuit 48 steps/circuit (See note 2.)

24 steps/circuit (See note 3.)

--- 16

48 steps/circuit (See note 2.)

12 steps/circuit (See note 3.)

settable yearly

temporary

holiday settings

Note: 1. Depending the operation, the following steps can be used for weekly programs.

Timer operation: 2 steps

Pulse-output operation: 1 step

Cyclic operation: 4 steps

2. When the season switching setting is not being used.

3. When the season switching setting is being used.

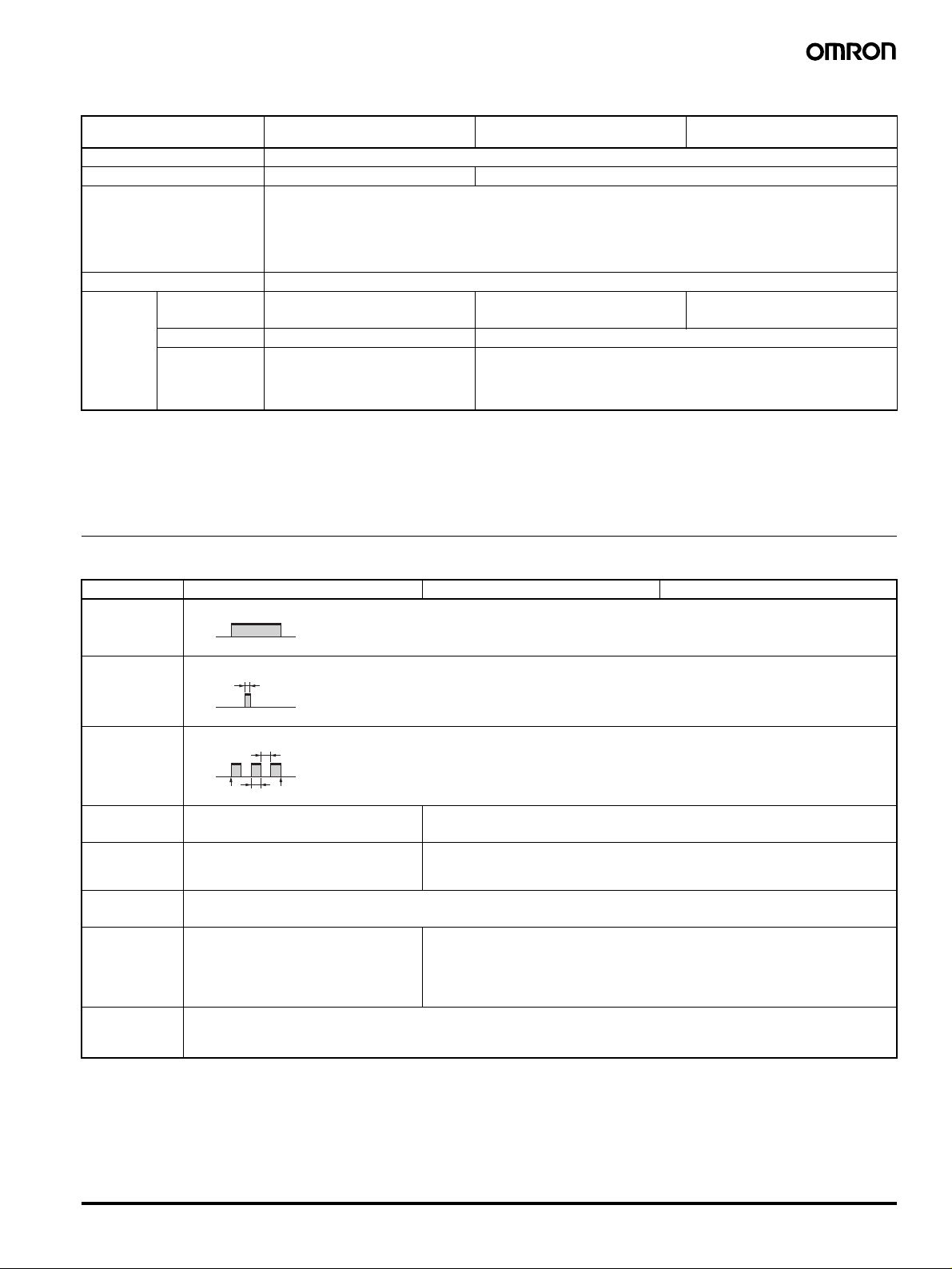

■ Operation Functions

Item Weekly 2-circuit Models (H5S-W@2) Yearly 2-circuit Models (H5S-Y@2) Yearly 4-circuit Models (H5S-Y@4)

Weekly timer

operation

Weekly pulseoutput

operation

Weekly cyclic

operation

Yearly timer

Timer operation

ON OFF

Pulse output operation

Cyclic operation

Pulse width

ON

OFF

StopStart

ON

--- Adds a yearly timer operation to the weekly timer program.

operation

Yearly pulse-

--- Adds a yearly pulse-output operation to the weekly pulse-output program.

output

operation

Temporary

holiday setting

Day override

operation

Sets temporary holidays (non-operating days) without having to revise the existing program.

For details, refer to Setting Temporary Holidays (Weekly) and Setting Temporary Holidays (Yearly) on page 20.

Executes the operation for one day

temporarily on another day in the 7-day

period starting from the current day.

For details, refer to Day Override

Operation on page 21.

Program check Consecutively displays the days and times when the output is set to turn ON and OFF over the course of one week in the

sequence in which the Time Switch is to operate.

For details, refer to Program Check Function on page 21.

Controls the output according to the set time of ON and OFF.

• Min. setting unit: 1 min

• Multiple-day operation also possible.

Output turns ON for a fixed period (pulse width) at the set ON time.

• Pulse width: 1 to 59 s (in 1-s increments), or 1 to 60 min (in 1-min increments)

• The pulse width can be set for each step.

Repeatedly turns ON and OFF during the period from the cyclic start time to the stop time.

Independent ON- and OFF-time settings are possible.

• Min. setting unit: 1 min

For details, refer to About Yearly Programs on page 18.

For details, refer to About Yearly Programs on page 18.

---

Digital Time Switch H5S 5

Item Weekly 2-circuit Models (H5S-W@2) Yearly 2-circuit Models (H5S-Y@2) Yearly 4-circuit Models (H5S-Y@4)

Checking the

settings

Forced ON/OFF

operation

Override and

automatic

return

operation

Summertime

(DST)

adjustment

Time counter/

total counter

display

Time

adjustment

input

Manual

operation on

recovery from

power failure

Bank switching Allows two groups (banks) of programs to

Season

switching

Power OFF

settings

Consecutively displays the times when the output is set to turn ON and OFF for one day in the sequence in which the Time

Switch is to operate.

For details, refer to Checking the Settings on page 21.

Allows the output to be forcibly turned ON/OFF by the Output ON/OFF Switch regardless of the control output setting.

Allows the control output to be maintained in the ON (or OFF) state until the next OFF (or ON) time. This operation is controlled

by using the Output ON/OFF Switch and Write Key. When completed, the Time Switch automatically resumes the previously

set operation.

For details, refer to Override and Automatic Return Operation on page 22.

Switches the current time from “current time” to “current time + 1 h” for daylight savings time. Yearly models also offer automatic

switching to daylight savings time.

For details, refer to Manual Summertime (DST) Adjustment on page 21.

Displays the total elapsed time and total count of external input. It also displays a

warning when a set value is entered.

For details, refer to Total Time/Count Display on page 23.

Allows the time to be set to 00 min 00 s at the same time as an external input is

applied.

For details, refer to Time Adjustment Input Function on page 24.

Allows the output state to be specified following recovery from a power failure.

For details, refer to Manual Operation on Recovery from Power Failure on page 24.

--be registered and switched by external

input.

For details, refer to Bank Switching on

page 24.

--- Allows weekly programs to be automatically switched in response to seasons

throughout the year.

For details, refer to Season Switching on page 24.

Allows the display to remain lit even when the power is turned OFF, and settings to be made for all functions except Override

and Automatic Return Operation.

• The display illumination will turn OFF when there has been no operation for 2 min. The display will light again when any key

other than a slide switch is pressed for at least 1 s.

• No output will be generated.

---

---

---

6 Digital Time Switch H5S

Connections

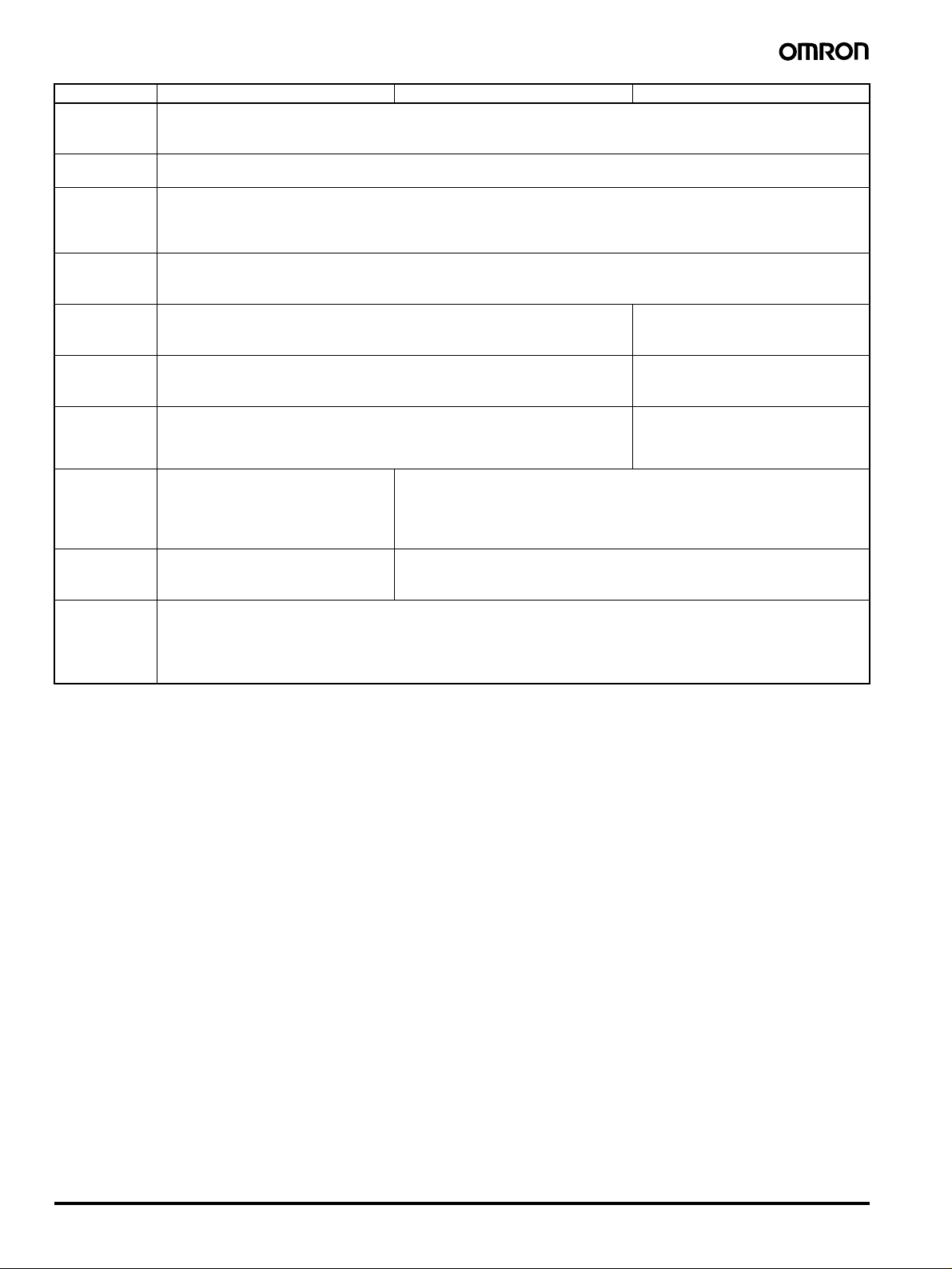

■ Terminal Arrangement

H5S-@A@/-@B@ Flush Mounting Models

(2-circuit models) (4-circuit models)

Output 2

(Rear View)

GAH

Input

JI

(Rear View)

DCB

Output 2 Output 3

H

F

G

I

D

C

A

B

Output 4

J

E

+ ∼−

source

∼

Output 1Power

+ ∼−

source

∼

Output 1Power

H5S-@FA@/-@FB@ Surface Mounting Models

(2-circuit models) (4-circuit models)

Output 2Output 3

H

G

I

J

B

C

D

E

− ∼+

Output 1 Power

source

∼

(Front View)

Output 2Input

FGH

CB

Output 1

I

E

D

− ∼+

Power

source

(Front View)

∼

Output 4

F

A

Note: 1. The Time Switch output uses a no-voltage contact. An external power supply is required for applications in which a load is driven.

2. The output contact ratings are different for 2-circuit and 4-circuit models.

■ Input Connection (2-circuit Models Only)

Use a switch or relay as the input contact.

Use a contact that is capable of operating with 5 V, 0.1 A (with a minimum signal input width of 100 ms).

Flush mounting models

(H5S-@A2@/-@B2@)

Surface mounting models

(H5S-@FA2 @/-@FB2@)

J

I

G

F

Note: Input must be selected using the “F2: Input selection” step of initial setting mode. For details, refer to Using Advanced Functions on page 23.

Digital Time Switch H5S 7

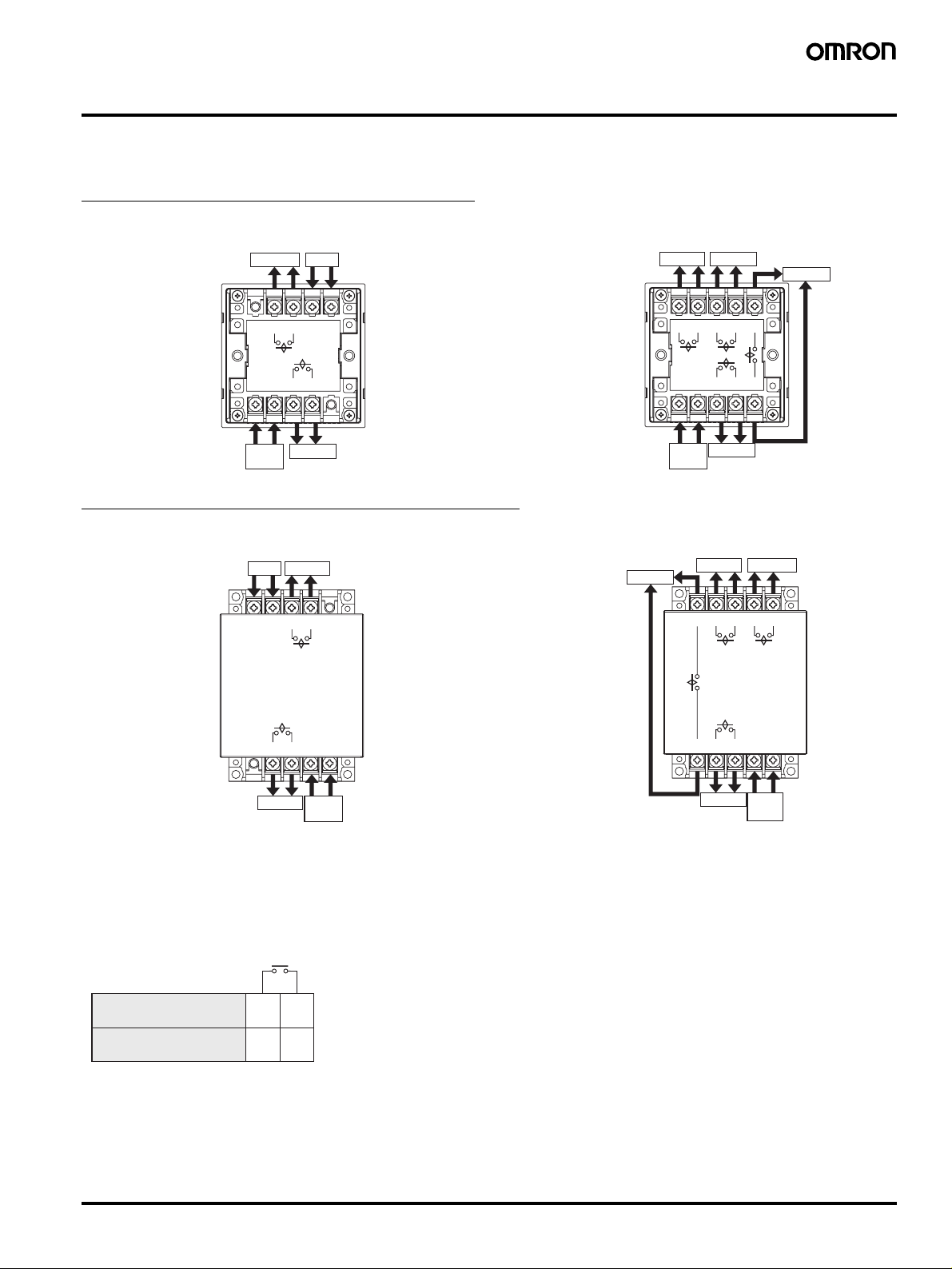

Nomenclature

py/Cy

y

y

/

Front Panel (with Cover Open)

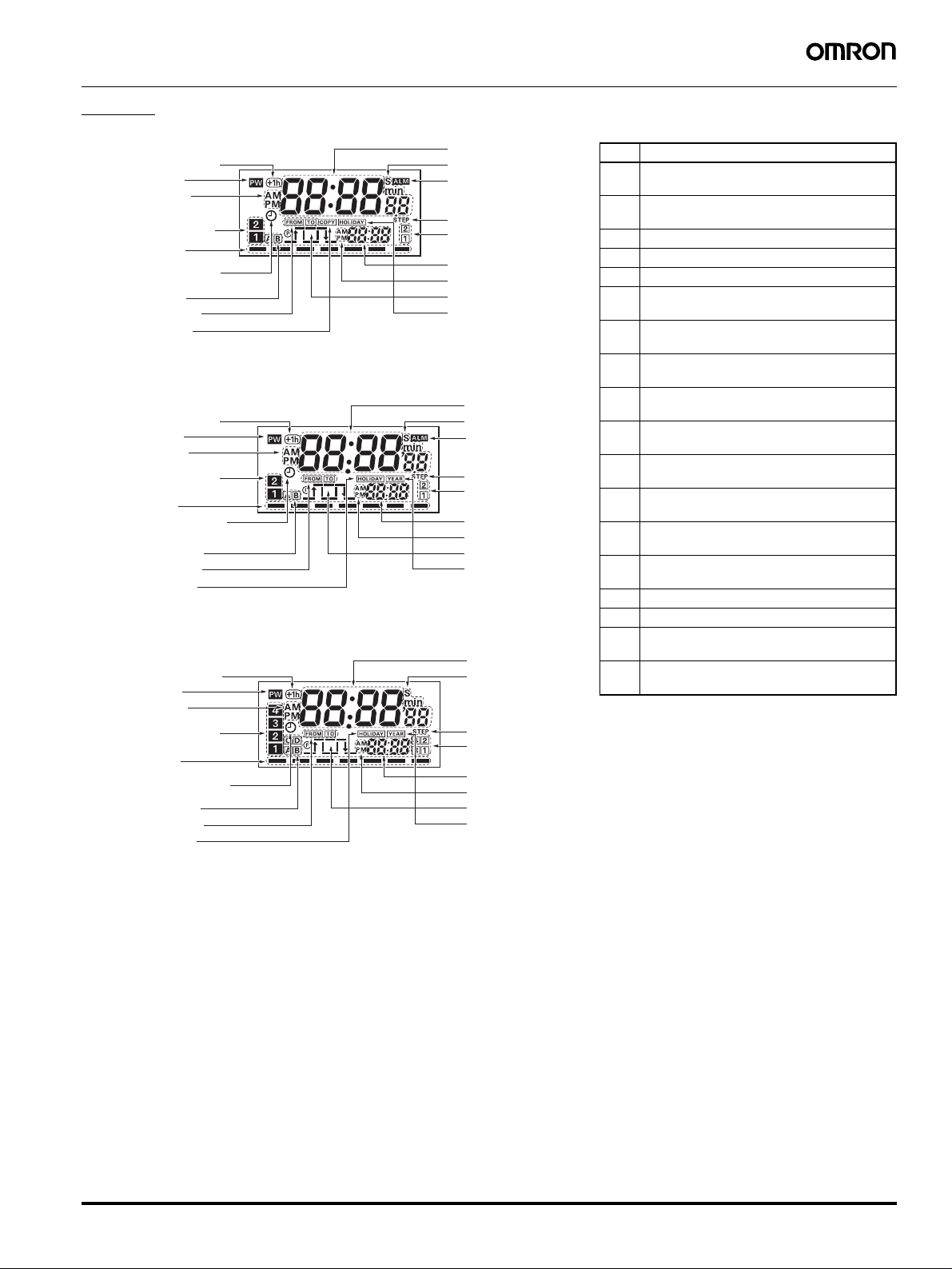

(Weekly 2-circuit models)

13. Day Keys

12. Output

ON/OFF

Switches

11. Output

Setting

Switches

10. Time Adjustment

Key

(Yearly 2-circuit models)

13. Day Keys

12. Output

ON/OFF

Switches

11. Output

Setting

Switches

10. Time Adjustment

Key

(Yearly 4-circuit models)

13. Day Keys

12. Output

ON/OFF

Switches

11. Output

Setting

Switches

10. Time Adjustment

Key

9. Test

Ke

9. Test/

Year

Key

9. Test/

Year

Key

8. Co

8. Cycle Key

8. Cycle Key

cle Ke

1. Mode

Switch

2. Holiday/

Down Key

3. Write Key

4. m/Pulse Key

5. h Key

6. Reset Key

7. +1h/Clear

Key

1. Mode

Switch

2. Holiday/

Down Key

3. Write Key

4. m/Pulse Key

5. h Key

6. Reset Key

7. +1h/Clear

Key

1. Mode

Switch

2. Holiday/

Select Program

Down Key

3. Write Key

4. m/Pulse Key

5. h Key

6. Reset Key

7. +1h/Clear

Key

Key Operations

No. Functions

1 (2-circuit models)

P1: Circuit (output) 1 Setting mode

P2: Circuit (output) 2 Setting mode

RUN: RUN mode

(4-circuit models)

PRGM: Setting mode (allows use of the Select Program Key

to set the circuit (output) number)

RUN: RUN mode

2 (2-circuit models)

In RUN mode, this key shifts the Time Switch to the Holiday

Setting mode

In Setting mode or Time Adjustment mode, this key

decrements the value for the operation just completed.

(4-circuit models)

In RUN mode, this key shifts the Time Switch to the Holiday

Setting mode.

When selecting the output, this key is used to set the circuit

(output) number.

In Setting mode or Time Adjustment mode, this key

decrements the value for the operation just completed.

3 Sets parameters.

4 Used to set the current time, ON/OFF time, or pulse width.

5

6 Used to reset all parameters, including the current time.

7 In RUN mode, this key sets or cancels summer time (+1 h)

In Setting mode, this key clears the parameter.

8 In RUN mode (weekly models only), this key shifts the Time

Switch to the Day Override operation setting mode.

In Setting mode, this key shifts the Time Switch to cyclic

operation setting.

9 In RUN mode, this key shifts the Time Switch to the Program

Check mode.

In Setting mode (yearly models only), this key is used to set

the yearly program.

10 This key shifts the Time Switch to the time adjustment mode.

11 TIMER: Executes a timer or cyclic operation.

PULSE: Executes a pulse-output operation.

12 ON: Turns ON the output regardless of the setting.

AUTO: Executes automatic operation as specified by these

settings.

OFF: Turns OFF the output regardless of the setting.

13 • Used to set the current day, operating day, etc.

• Used to specify the date (yearly models only)

• In RUN mode, these keys are used to shift the Time Switch

to the Checking the Settings mode.

8 Digital Time Switch H5S

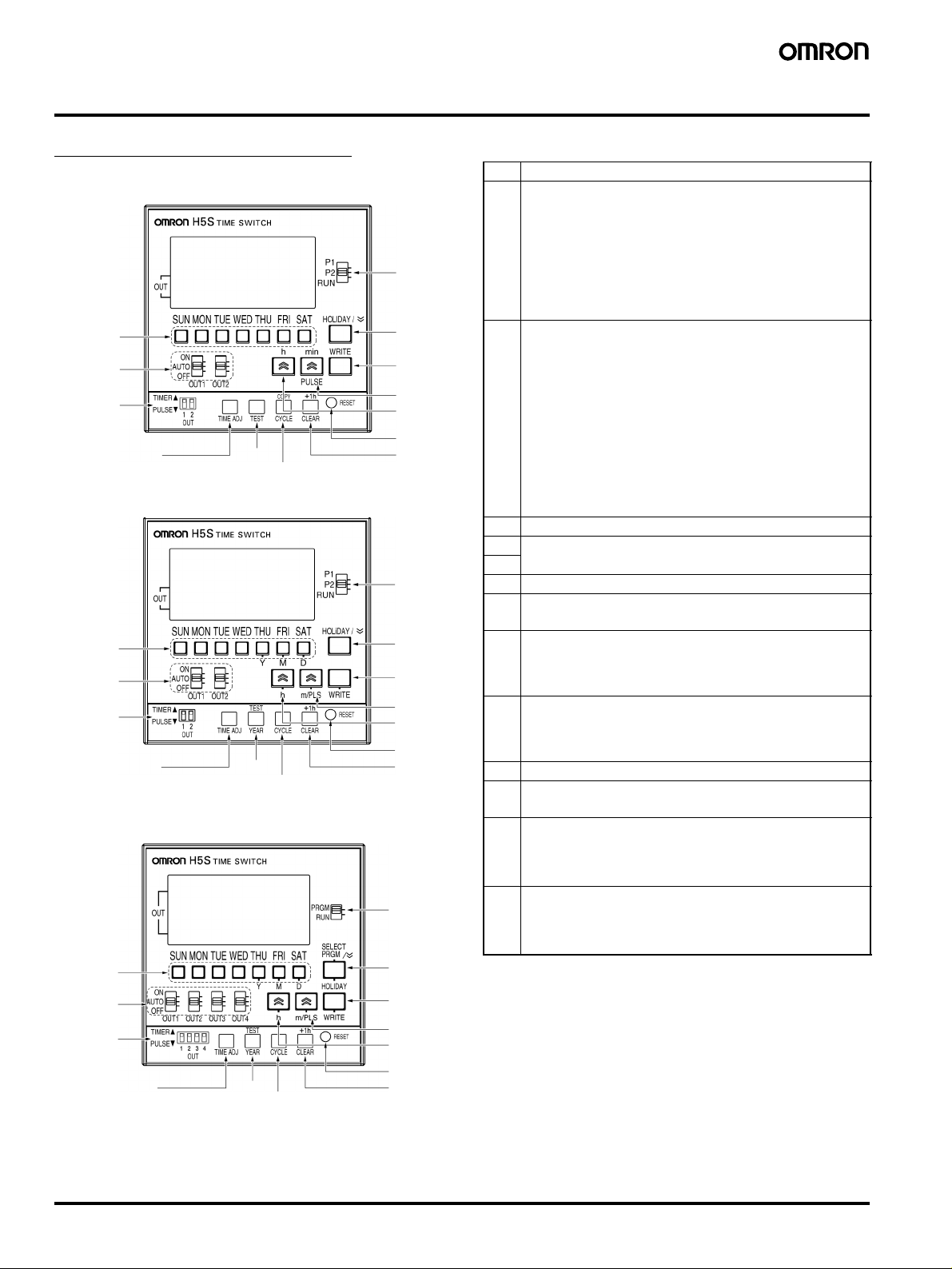

Display

r

y

y

y

(Weekly 2-circuit models)

3. Summer time indicator

1. Power indicator

2. AM/PM indicator

18. Output circuit number

indicator

17. Day indicator

16. Time adjustment mode

indicator

11. Bank indicator

12. From/To indicator

14. Copy indicator

(Yearly 2-circuit models)

3. Summer time indicator

1. Power indicator

2. AM/PM indicator

18. Output circuit number

indicator

17. Day indicator

16. Time adjustment mode

indicator

11. Season indicators

12. From/To indicator

13. Holida

(Yearly 4-circuit models)

3. Summer time indicator

1. Power indicator

2. AM/PM indicator

18. Output circuit number

17. Day indicators

16. Time adjustment mode

11. Season indicator

12. From/To indicator

13. Holida

N

indicator

indicator

indicator

indicator

4. Main display

5. Pulse width unit indicato

6. Total value alarm

indicator

7. Display of number

of remaining steps

8. Set circuit number

indicator

9. Sub-display

2. AM/PM indicator

10. Timing chart display

13. Holiday indicator

4. Main display

5. Pulse width unit

indicator

6. Total value alarm

indicator

7. Display of number

of remaining steps

8. Set circuit number

indicator

9. Sub-display

2. AM/PM indicator

10. Timing chart display

15. Year indicator

4. Main display

5. Pulse width unit

indicator

7. Display of number

of remaining steps

8. Set circuit number

indicator

9. Sub-display

2. AM/PM indicator

10. Timing chart displa

15. Year indicator

Display Description

No. Function

1 Lights when power is supplied to the Time

Switch.

2 When 12-hour display is selected, either AM

or PM lights. (24-hour display is the default.)

3 Lights when summer time (+1 h) is activated.

4 Displays the current time and other values.

5 Displays the unit for the pulse width.

6 Lights when the total time or count value

exceeds the alarm setting.

7 Displays the number of remaining steps for

programming in setting mode.

8 Displays the number of the circuit (output)

that has been set.

9 Displays the time for the next operation, the

date (yearly models only), and other values.

10 Displays the next operation and other

information in chart form.

11 Displays the bank name (weekly models) or

season name (yearly models).

12 Lights when setting the ON/OFF time or

when setting a day override operation.

13 Lit during the temporary holiday operation or

when setting a temporary holiday.

14 Lit during the day override operation or when

setting a day override operation.

15 Lit during setting a yearly program.

16 Flashes during the Time Adjustment mode.

17 Displays the current day or the day set for an

operation.

18 Displays the number of the circuit (output) for

which output is ON.

Digital Time Switch H5S 9

Loading...

Loading...