Page 1

1

Solid-state Timer H3Y

Miniature Timer Compatible with the MY

Relay

Large

transparent time-setting knob facilitates time

setting. Flat-blade and Phillips screwdrivers can

also be used for time setting.

Approved by UL and CSA.

Pin

configuration compatible with

MY Power Relay

.

LED indication for power and output statuses.

Conforms to EMC standards.

High repeat accuracy.

RC

Ordering Information

Operation/resetting

Time-limit

contact

T

ime ranges

Supply voltage

Model

Ope a o / ese g

system

ecoac

e a ges

Supp y o age

Surface /DIN-track

mounting (with socket)

T

ime-limit operation/

DPDT

0.1 s to 30 min

1

10 V

AC

H3Y-2

eoeao/

self-resetting

0so30

220 V

AC

3

24 VDC

4PDT

1

10 V

AC

H3Y-4

220 V

AC

3

24 VDC

Note:

Specify the model number

, supply voltage, and rated time when ordering.

Ex. H3Y-2 1

10 V

AC 1 s

Rated time

Supply voltage

Accessories

Track

mounted socket (see note )

Back connecting socket

ac ou ed soc e (see o e )

Solder terminal

W

ire-wrap terminal PC terminal

PYF08A, PYF08A-N, PYF08A-E

PY08 PY08QN(2) PY08-02

PYF14A, PYF14A-N, PYF14A-E

PY14 PY14QN(2) PY14-02

Note: T

rack mounted socket can be used as a front connecting socket.

Specifications

Time Ranges

Rated

time

1 s 5 s

10 s 30 s 60 s

3 min 30 min

T

ime setting

range

0.1 to 1 s 0.2 to 5 s

0.5 to 10 s 1.0 to 30 s 2.0 to 60 s

0.1 to 3 min 1.0 to 30 min

Page 2

H3Y

H3Y

2

Ratings

Item H3Y-2/H3Y-4

Rated

supply voltage

1

10, 220 V

AC (50/60 Hz), 24 VDC (see note)

Operating voltage range

85% to 1

10% of rated supply voltage

Power consumption

100 V

AC: Relay ON:

1.5 V

A (1.3 W)

Relay OFF:

0.8 V

A (0.5 W)

200 V

AC: Relay ON:

1.8 V

A (1.5 W)

Relay OFF:

1.2 V

A (0.9 W)

24 VDC: Relay ON:

0.9 W

Relay OFF:

0.07 W

Control outputs H3Y

-2: 5 A at 250 V

AC, resistive load (cosφ

= 1)

H3Y

-4: 3 A at 250 V

AC, resistive load (cosφ

= 1)

Note:

With DC ratings, single-phase full-wave rectified power sources may be used.

Characteristics

Accuracy

of operating time

±

2% max.

Setting error ±

10% (max. time division at rated voltage and room temperature)

Reset time

0.1 s max.

Influence of voltage

±

2% max.

Influence of temperature

±

5% max.

Insulation resistance

100 MΩ min. (at 500 VDC)

Dielectric strength

2,000 V

AC, 50/60 Hz for 1 min (between current-carrying terminals and exposed

non-current-carrying metal parts) (see note)

2,000 V

AC, 50/60 Hz for 1 min (between operating power circuit and control output) (see note)

2,000 V

AC, 50/60 Hz for 1 min (between different pole contacts; 2-pole model) (see note)

1,500 V

AC, 50/60 Hz for 1 min (between dif

ferent pole contacts; 4-pole model)

1,000 V

AC, 50/60 Hz for 1 min (between non-continuous contacts)

V

ibration resistance

Destruction:

10 to 55 Hz with 1.0-mm double amplitude

Malfunction:

10 to 55 Hz with 1.0-mm double amplitude

Shock resistance

Destruction:

1,000 m/s2 (approx. 100G)

Malfunction:

100 m/s2 (approx. 10G)

Ambient temperature

Operating: –10°C to 50°C (with no icing)

Ambient humidity

Operating: 35% to 85%

Life expectancy

Mechanical:

10,000,000 operations min. (under no load at 1,800 operations/h)

Electrical:

H3Y

-2: 500,000 operations min. (5 A at 250 V

AC, resistive load at 1800 operations/h)

H3Y

-4: 200,000 operations min. (3 A at 250 V

AC, resistive load at 1800 operations/h)

EMC Emission Enclosure: EN55011 Group 1 class A

Emission AC Mains:

EN55011 Group 1 class A

Immunity ESD:

IEC801-2:

4 kV contact discharge (level 2)

4 kV air discharge (level 2)

Immunity RF-interference:

ENV50140:

10 V/m (80 MHz to 1 GHz) (level 3)

Immunity Conducted Disturbance:

ENV50141:

10 V (0.15 to 80 MHz) (level 3)

Immunity Burst:

IEC801-4:

2 kV power-line (level 3)

2 kV I/O signal-line (level 4)

Approved standards

UL (File No. E41515), CSA (File No. LR22310)

Conforms to EN50081-2, EN50082-2

Weight

Approx. 50 g

Note: T

erminal screw sections are excluded.

Page 3

H3Y

H3Y

3

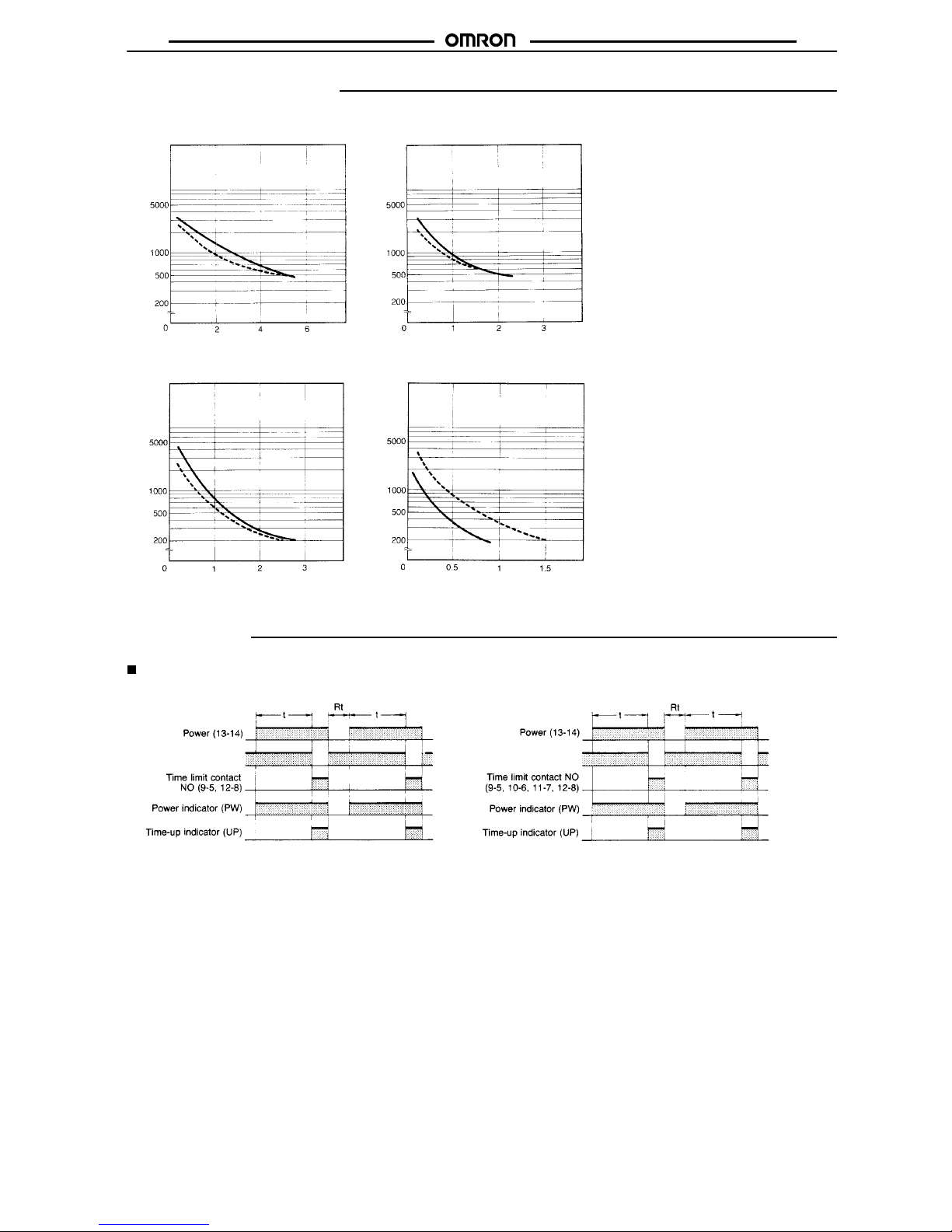

Engineering Data

H3Y-2

Switching operations (x 10 )

3

Load current (A)

H3Y-2

H3Y-4

Switching operations (x 10 )

3

Load current (A)

Switching operations (x 10 )

3

Load current (A)

H3Y-4

Switching operations (x 10 )

3

Load current (A)

250 VAC, cosφ

= 1

24 VDC, cosφ

= 1

250 VAC, cosφ

= 0.4

24 VDC, L/R = 7 ms

250 VAC, cosφ

= 1

24 VDC, cosφ

= 1

250 VAC, cosφ

= 0.4

24 VDC, L/R = 7 ms

Reference: A

maximum current of 0.6 A can be

switched at 125 VDC (cosφ

= 1).

Maximum current of 0.2 A can be

switched if L/R is 7 ms. In both

cases, a life of 100,000 operations

can be expected.

The minimum applicable load is

1 mA at 5 VDC (P reference value).

Reference:

A maximum current of 0.5 A can be

switched at 125 VDC (cosφ

= 1).

Maximum current of 0.2 A can be

switched if L/R is 7 ms. In both

cases, a life of 100,000 operations

can be expected.

The minimum applicable load is

1 mA at 1 VDC (P reference value).

Operation

Timing Chart

H3Y-2 H3Y-4

Time limit contact

NC (9-1, 12-4)

Time limit contact NC

(9-1, 10-2, 1

1-3, 12-4)

Page 4

H3Y

H3Y

4

Dimensions

Note: All

units are in millimeters unless otherwise indicated.

Timers

H3Y-2 H3Y-4

(63.0)

6.4

6.3

(63.0)

6.4

6.3

28

max.

21.5

max.

28 max.

21.5

max.

Accessories (Order Separately)

Use

the PYF

jA, PYj

, PYj-02, or PYjQN(2) to mount the H3Y. When ordering any one of these sockets, replace “j” with “08” or “14.”

T

erminal Arrangement

(T

op V

iew)

Track Mounting/Front Connecting Sockets

PYF08A

Eight,

M3

×

8 sems

Two, 4.2 ×

5

mounting holes

Two, 4.5 dia.

M4 or M3

Mounting

Holes

6

72

max.

23 max.

30 max.

16.5

35.4

3.4

4

6

59±0.3

15±0.2

PYFjA

90.5

86.6

H3Y

Series

Terminal

Arrangement

(T

op V

iew)

PYF14A

Mounting Holes

Fourteen,

M3

×

8 sems

Two, 4.2 ×

5

mounting holes

Two, 4.5 dia.

M4 or M3

6

72 max.

29.5 max.

30 max.

16.5

35.4

3.4

4

6

59±0.3

22±0.2

Page 5

H3Y

H3Y

5

PYF08A-N

Terminal

Arrangement

Mounting Holes

(for Surface Mounting)

4 1

8 5

12 9

14 14

13

424412

14

41 11

A2 A2 A1

19.8

3.2 dia.

3.6 dia.

4

42

8

44

1

12

5

14

41

12

A2

14

11

9

A113A2

14

22 max.

66.5 max.

PYF-08A-N

30 max.

4 3 2 1

8 7 6 5

12 11 10 9

14 14

13

20.8

Two, 3.5 dia.

30 max.

4

42332222112

8447

34

6245

14

411231

11

211011

9

A1

13

A214A2

14

66.5 max.

PYF-14A-N

29.5

max.

42 32 22 12

44 34 24 14

41 31 21 11

A2 A2 A1

PYF14A-N

Terminal

Arrangement

Mounting Holes

(for Surface Mounting)

PYF08A-E

31

max.

72 max.

23 max.

(Top View)

PYF14A-E

31

max.

72 max.

29.5 max.

(Top View)

Eight,

M3

×

8 sems

Two, 4.2 ×

5

mounting holes

Two, 4.5 dia.

M4 or M3

Two, 4.5 dia.

M4 or M3

Two, 4.2 ×

5

mounting holes

Eight, M3 ×

8 sems

Page 6

H3Y

H3Y

6

Panel Cutout

Back Connecting Sockets

PY08, PY14

Terminal

Arrangement

(Bottom View)

PY08QN, PY14QN

PY08QN(2), PY14QN(2)

PY08-02, PY14-02

Eight, 3× 1.2 dia. holes

only for PY08 (Fourteen, 3

× 1.2 dia. holes)

(See

note)

Note: With PYjQN(2), dimension * should

read

20 max. and dimension ** 36.5 max.

29.5

max.

25.5

max.

24 max.

0.3

2.7 7.7

20 max.

2.6

2.7

29.5 max.

41.5 max.

(see note)

25 max. *

24 max.

22 max.

**

H3Y

Series

PYj, PYj-02,

PYjQN(2)

29.5

max.

25.5

max.

22

max.

0.3

2.7

4.3

16.5 max.

2

PY08-02 PY14-02

59.3

21.4

+0.2

0

Terminal

Arrangement

(Bottom View)

T

erminal Arrangement

(Bottom View)

PY08QN

PY08QN(2)

PY14QN

PY14QN(2)

PY08 PY14

25.8

+0.2

0

1

x 1

Page 7

H3Y

H3Y

7

Socket Mounting Plates (t = 1.6)

Applicable

socket

For mounting 1 socket

For mounting 18 sockets

PY08, PY14, PY08QN(2), PY14QN(2)

PYP-1 PYP-18

Note:

PYP-18 may be cut to any desired length.

PYP-1

Two, 3.4-dia. holes

PYP-18

Relay Hold-down Clips Y92H-3 for

PYFjA Socket

Y92H-4 for

PYj Socket

Mounting Track

PFP-100N/PFP-50N

(see note 1)

End Plate

PFP-M

1000 (500) (See note 2)

Note: 1. Meets

DIN EN50022

2.

This dimension applies to PFP-50N.

Spacer

PFP-S

Page 8

H3Y

H3Y

8

Installation

Connection

H3Y-2 H3Y-4

Connect

the DC power supply to

terminals 13 and 14 according

to the polarity marks.

Connect the DC power supply to

terminals 13 and 14 according to

the polarity marks.

Precautions

When selecting a control output, use the H3Y-2 for switching ON

and OFF the power and the H3Y-4 for switching ON and OFF the

minute

load.

The

operating voltage will increase when using the H3Y in any place

where

the ambient temperature

is more than 50°C. Supply 90% to

110%

of the rated voltages (at 12 VDC: 95% to 1

10%) when operat

-

ing

at 50°C or higher

.

Do

not leave the H3Y in time-up condition for

a long period of time

(for

example, more than one month in any place where the

ambient

temperature is high), otherwise the internal parts (aluminum electrolytic

capacitor) may become damaged. Therefore, the use of the

H3Y

with a relay as shown in the following circuit diagram is recom

-

mended

to extend the service life of the H3Y

.

MY Relay

H3Y

Do

not connect the H3Y as shown in the following circuit diagram on

the

right hand side, otherwise the H3Y’s internal contacts dif

ferent

from

each other in polarity may become short-circuited.

Correct Incorrect

Use

the following safety circuit when building a self-holding or self-

resetting circuit with the H3Y and an auxiliary relay

, such as an MY

Relay,

in combination.

: H3Y

Auxiliary relay:

MY Relay

Do

not use the

H3Y in places where there is excessive dust, corro

-

sive

gas, or direct sunlight.

Do not mount more than one H3Y closely together, otherwise the

internal parts may become damaged. Make sure that there is a

space

of 5 mm or

more between any H3Y Models next to each other

to

allow heat radiation.

The

internal parts may become damaged if a supply voltage other

than

the rated ones is imposed on the H3Y

. When more than 100 V is

applied

to 12 or 24 VDC, the internal element (varistor) may break.

OMRON Corporation

Supervisory Control Devices Division

28th Fl., Crystal T

ower Bldg.,

1-2-27, Shiromi, Chuo-ku,

Osaka 540-6028 Japan

Phone: (81)6-949-6035 Fax: (81)6-949-6069

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

o convert grams into ounces, multiply by 0.03527.

Cat. No. L097-E1-1 In the interest of product improvement, specifications are subject to change without notice.

Printed

in Japan

0597-2M (0597)

a

Limited issue for Southeast Asian countries

Loading...

Loading...