Machine Automation Controller NJ-series

General-purpose Seriarl

Connection Guide (RS-232C)

OMRON Corporation

G9SP Safety Controller

P545-E1-01

About Intellectual Property Rights and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

EtherCAT

is registered trademark and patented technology, licensed by Beckhoff Automation

®

GmbH, Germany.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

Company names and product names in this document are the trademarks or registered

trademarks of their respective companies.

Table of Contents

1. Related Manuals........................................................................................ 1

2. Terms and Definitions

3. Remarks..................................................................................................... 2

4. Overview

5. Applicable Products

5.1. Applicable Products ........................................................................... 4

5.2. Devi

6. Serial Comm

6.1. Serial Communications Se

6.2. Cable Wiring Diagram........................................................................ 7

6.3. Example of Checking Connection...................................................... 8

7. Connection Procedure.............................................................................. 9

7.1. Work Flow.......................................................................................... 9

7.2. Setting Up the Safety Controller

7.3. Setting Up the Controller ...................................................................11

7.4. Connection St

8. Initialization

8.1. Initializing the Controller................................................................... 24

9. Project File............................................................................................... 26

9.1. Overview.......................................................................................... 26

9.2. Destination Devi

9.3. Error Detection Processing.............................................................. 33

9.4. Variables.......................................................................................... 34

9.5. Ladder Program............................................................................... 37

9.6. Timing Chart

9.7. Error St

10. Revision Hi story

.................................................................................................... 3

ce Configuration .......................................................................... 5

unications Settings ............................................................. 6

Method................................................................................ 24

atus List ...............................................................................51

............................................................................... 1

and Support Software............................................ 4

ttings........................................................ 6

....................................................... 10

atus Check.................................................................22

ce Command.......................................................... 29

s...................................................................................49

...................................................................................... 54

1. Related Manuals

1. Related Manuals

The table below lists the manuals related to this document.

To ensure system safety, make sure to always read and heed the information provided in all

Safety Precautions, Precautions for Safe Use, and Precaution for Correct Use of manuals for

each device which is used in the system.

Cat. No. Model Manual name

W500 NJ501-[][][][] NJ-series CPU Unit Hardware User's Manual

W501 NJ501-[][][][] NJ-series CPU Unit Software User's Manual

W494 CJ1W-SCU[]2 CJ-series Serial Communications Units Operation Manual for

NJ-series CPU Unit

W502 NJ501-[][][][] NJ-series Instructions Reference Manual

W504 SYSMAC-SE2[][][] Sysmac Studio Version 1 Operation Manual

Z922 G9SP-[][][][] G9SP Series Safety Controller Operation Manual

Z923 G9SP-[][][][] G9SP Series Safety Controller Instructions Reference Manual

2. Terms and Definitions

Terms Explanation and Definition

No-protocol No-protocol Mode enables you to receive or send data by using SCU

Send Serial (SerialSend) or SCU Receive Serial (SerialRcv)

instructions. In this mode, messages are sent/received to/from a

destination device.

Send message A send message is a communications frame (command) sent from the

Serial Communications Unit to the destination device. This is executed

by the SerialSend instruction and sent to the destination device.

Receive message A receive message is a communications frame (response) sent from the

destination device to the Serial Communications Unit. The SerialRcv

instruction is used to read data received from the destination device.

1

3. Remarks

(1) Understand the specifications of devices which are used in the system. Allow some

margin for ratings and performance. Provide safety measures, such as installing safety

circuit in order to ensure safety and minimize risks of abnormal occurrence.

(2) To ensure system safety, always read and heed the information provided in all Safety

Precautions, Precautions for Safe Use, and Precaution for Correct Use of manuals for

each device used in the system.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part of or whole part of this

document without the permission of OMRON Corporation.

(5) The information contained in this document is current as of August 2013. It is subject to

change without notice for improvement.

The following notation is used in this document.

Indicates a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, or may result in serious

injury or death. Additionally there may be significant property

damage.

3. Remarks

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

2

4. Overview

This document describes the procedure for connecting a Safety Controller (G9SP series) of

OMRON Corporation (hereinafter referred to as OMRON) with an NJ-series Machine

Automation Controller (hereinafter referred to as the Controller) via serial communications,

and the procedure for checking their connection.

Refer to the serial communications settings of the project file you prepared to understand the

setting method and key points to connect the devices via serial communications.

This project file is used to check a serial connection by sending the monitor I/O command to

the destination device.

Obtain the latest "Sysmac Studio project file" from OMRON beforehand.

Name

Sysmac Studio project file

(extension: SMC)

File name

OMRON_G9SP_SERI232_LD_E

V100.SMC

Version

Ver.1.00

4. Overview

This document aims to explain the wiring method and communications settings

necessary to connect the corresponding devices and provide the setting

procedure. The program used in this document is designed to check if the

connection was properly established, and is not designed to be constantly used

at a site. Therefore, functionality and performances are not sufficiently taken into

consideration. When you construct an actual system, please use the wiring

method, communications settings and setting procedure described in this

document as a reference and design a new program according to your

application needs.

3

5. Applicable Products and Support Software

5. Applicable Products and Support Software

5.1. Applicable Products

The applicable devices are as follows:

Manufacturer Name Model

OMRON NJ series CPU Unit NJ501-[][][][]

NJ301-[][][][]

OMRON Serial Communications Unit CJ1W-SCU[]2

OMRON Safety Controller G9SP-[][][][]

OMRON Expansion I/O Unit CP1W-20EDT[]

CP1W-32ET[]

OMRON RS-232C Option Board CP1W-CIF01

OMRON G9SP Configurator Support Software WS02-G9SP[][]-V1

Precautions for Correct Use

As applicable devices above, the devices with the models and versions listed in Section 5.2.

are actually used in this document to describe the procedure for connecting devices and

checking the connection.

You cannot use devices with versions lower than the versions listed in Section 5.2.

To use the above devices with versions not listed in Section 5.2 or versions higher than those

listed in Section 5.2, check the differences in the specifications by referring to the manuals

before operating the devices.

Additional Information

This document describes the procedure to establish the network connection. Except for the

connection procedure, it does not provide information on operation, installation or wiring

method. It also does not describe the function or operation of the devices. Refer to the

manuals or contact your OMRON representative.

4

5. Applicable Products and Support Software

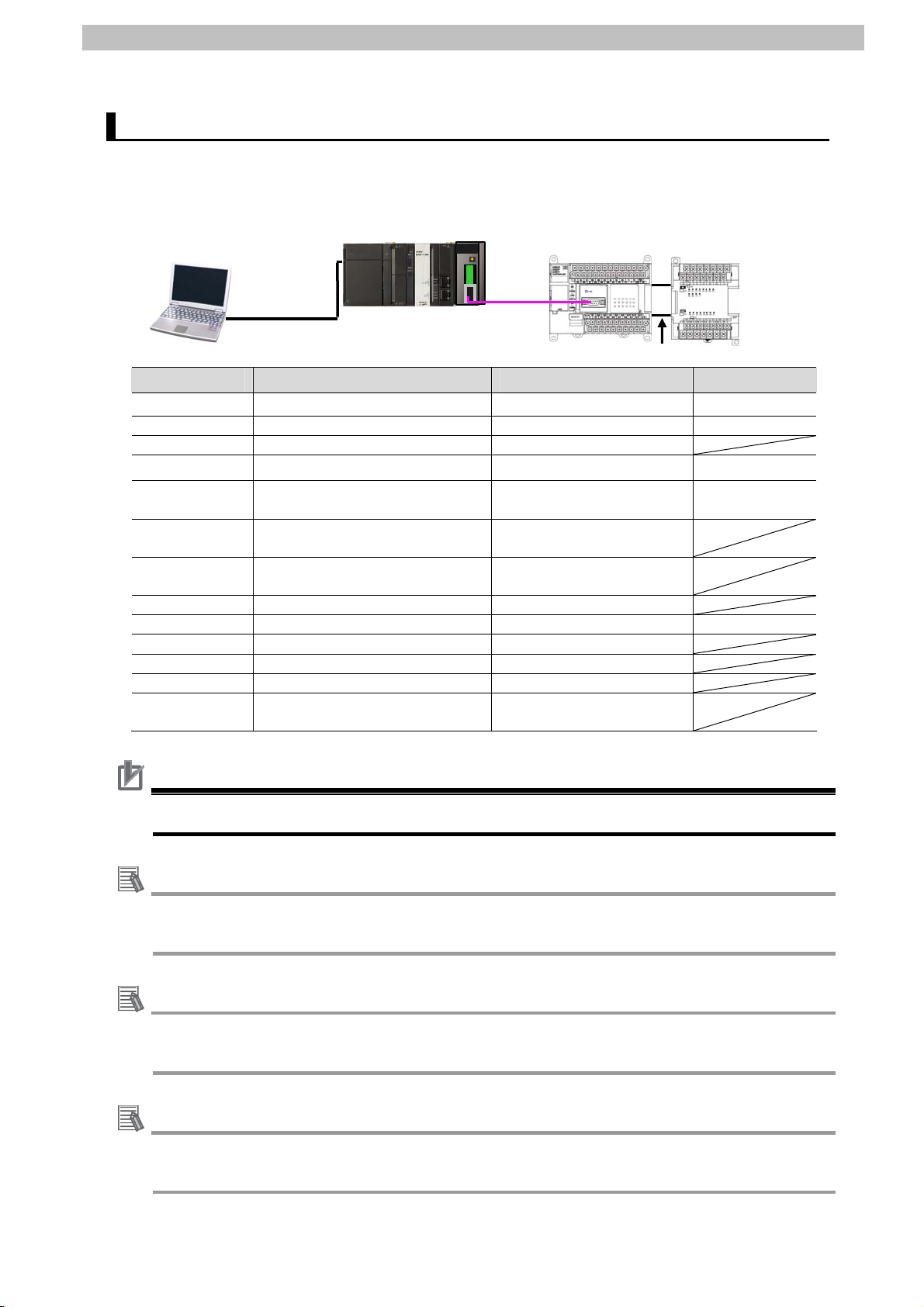

5.2. Device Configuration

The hardware components to reproduce the connection procedure of this document are as

follows:

Personal computer

(Sysmac Studio installed,

OS:Windows7)

4

USB cable

NJ501-1500+

CJ1W-SCU42

Serial Communications

Cable (RS-232C)

G9SP-N20S

CP1W-CIF01

CP1W-ME05M

Expansion I/O Connecting Cable

Manufacturer Name Model Version

OMRON Serial Communications Unit CJ1W-SCU42 Ver.2.0

OMRON NJ-series CPU Unit NJ501-1500 Ver.1.01

OMRON Power Supply Unit NJ-PA3001

OMRON Sysmac Studio

SYSMAC-SE2[][][]

OMRON Sysmac Studio project file OMRON_G9SP_SERI23

2_LD_EV100.SMC

- Personal computer

-

(OS: Windows 7)

- USB cable

-

(USB 2.0 type B connector)

- Serial Communications Cable -

OMRON Safety Controller G9SP-N20S Ver.1.00

OMRON RS-232C Option Board CP1W-CIF01

OMRON Memory Cassette CP1W-ME05M

OMRON Expansion I/O Unit CP1W-20EDT

OMRON Expansion I/O Connecting

CP1W-CN811

Cable

CP1W-20EDT

(Up to 2 Expansion I/O

Units can be connected.)

Ver.1.02

Ver.1.00

Precautions for Correct Use

Obtain the latest Sysmac Studio project file from OMRON in advance.

(To obtain the files, contact your OMRON representative.)

Additional Information

It may not be possible to reproduce the same operation with different devices or versions.

Check the configuration, model and version. If they are different from your configuration.

Contact your OMRON representative.

Additional Information

For information on the serial cable (RS-232C), refer to 3-3 RS-232C and RS-422A/485

Wiring in the CJ-series Serial Communications Units Operation Manual for NJ-series CPU

Unit (Cat.No. W494).

Additional Information

In this document, a USB is used to connect with the Controller. For information on how to

install a USB driver, refer to A-1 Driver Installation for Direct USB Cable Connection of the

Sysmac Studio Version 1 Operation Manual (Cat.No. W504).

5

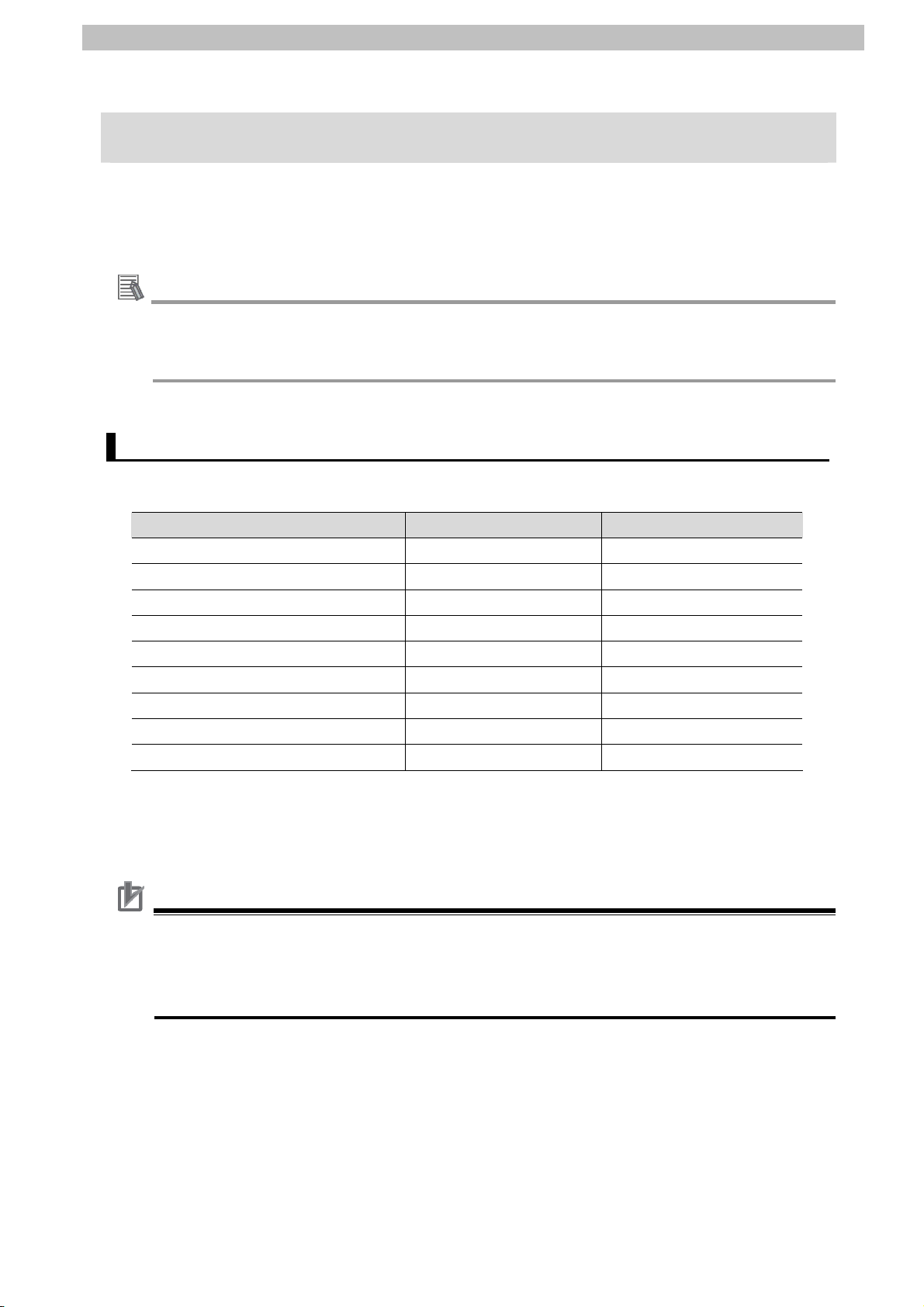

6. Serial Communications Settings

6. Serial Communications Settings

This section describes the specifications such as cable wiring and communication parameters

that are set in this document.

Additional Information

This document and project file can be used to perform operations using the settings and

command described in this section. Modifications are necessary to perform communications

using different settings.

6.1. Serial Communications Settings

The table below lists the settings for serial communications.

CJ1W-SCU42 G9SP-N20S

Unit number 0 Communications (connection) port Port 2 (RS-232C) Serial communications mode No-protocol Data length 8 bits 8 bits (fixed)

Stop bit 1 bit 1 bit (fixed)

Parity Even (default value) Even (fixed)

Baud rate 9,600 bps (default value) 9,600 bps (fixed)

No-protocol Start Code Yes (#40) #40 (fixed)

No-protocol End Code No (#2A0D (fixed))

*One byte data can only be set as the no-protocol End Code. Thus, in this document, #2A0D

is treated as data.

Precautions for Correct Use

This document explains the setting procedure with Serial Communication Unit CJ1W-SCU42

whose Unit No. is 0, communication port is port 2 and device name is SCU. To connect

devices under different conditions, refer to 9. Project File and create a ladder program by

changing the variable names and setting values.

6

6. Serial Communications Settings

6.2. Cable Wiring Diagram

For details on the cable wiring, refer to Section 3 Installation and Wiring in the CJ-series Serial

Communications Units Operation Manual for NJ-series CPU Unit (Cat.No. W494).

Check the connector configuration and pin assignment before wiring.

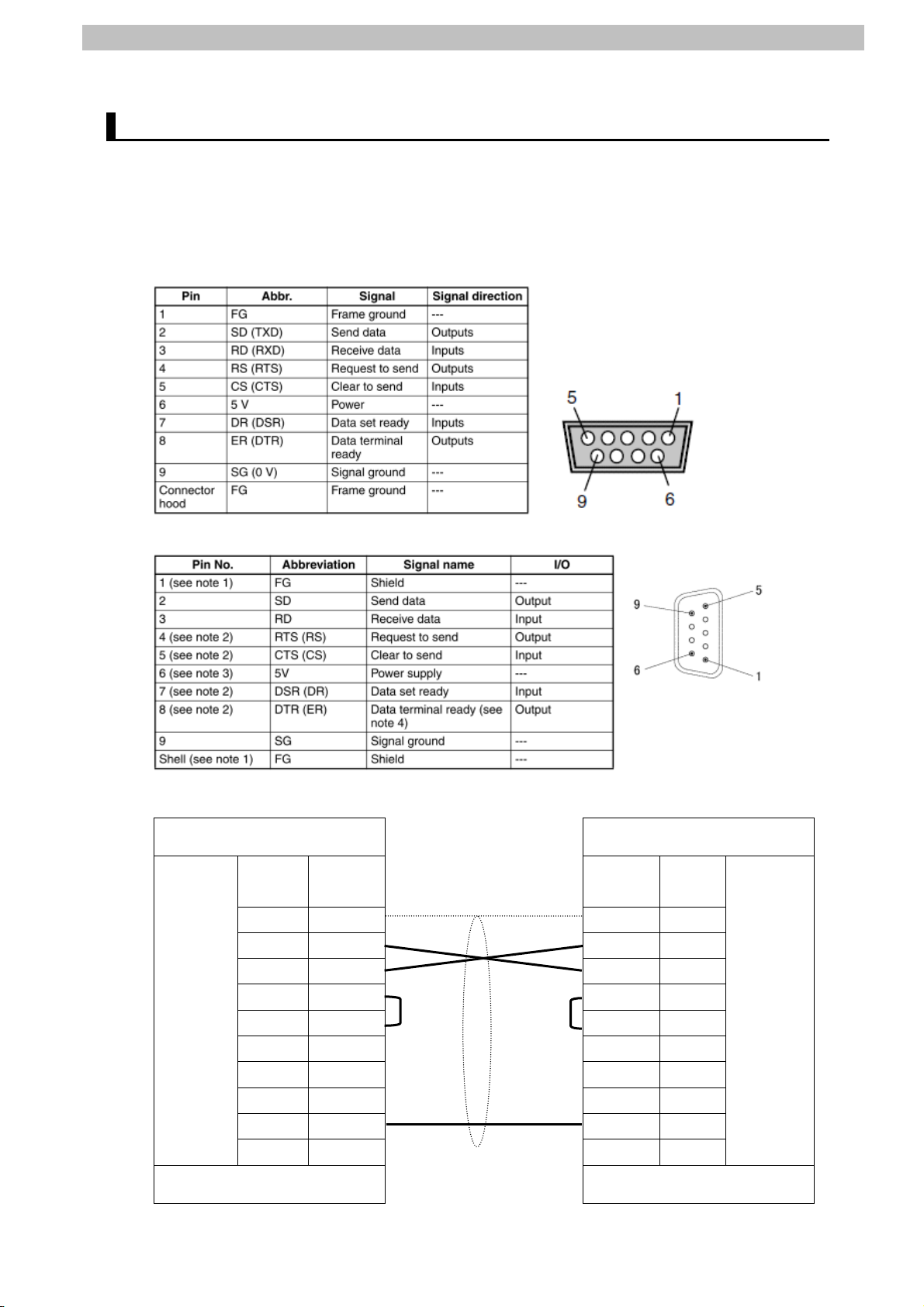

■Connector configuration and pin assignment

< OMRON G9SP-N20S + CP1W-CIF01 > Applicable Connectors: D-sub 9 pin

<OMRON CJ1W-SCU42> Applicable connector: D-sub 9 pin

■Cable/pin assignment

CJ1W-SCU42 Serial

Communications Unit

RS-232C

Interface

D-sub 9-pin

Cable connector type: Male

Signal

name

FG 1 1 FG

SD 2 2 SD

RD 3 3 RD

RS 4 4 RS

CS 5 5 CS

5V 6 6 5V

DR 7 7 DR

ER 8 8 ER

SG 9 9 SG

FG Shell Shell FG

Pin No. Pin No. Signal

Safety Controller

D-sub 9-pin

(G9SP-N20S)

RS-232C

name

Cable connector type: Male

Interface

7

6. Serial Communications Settings

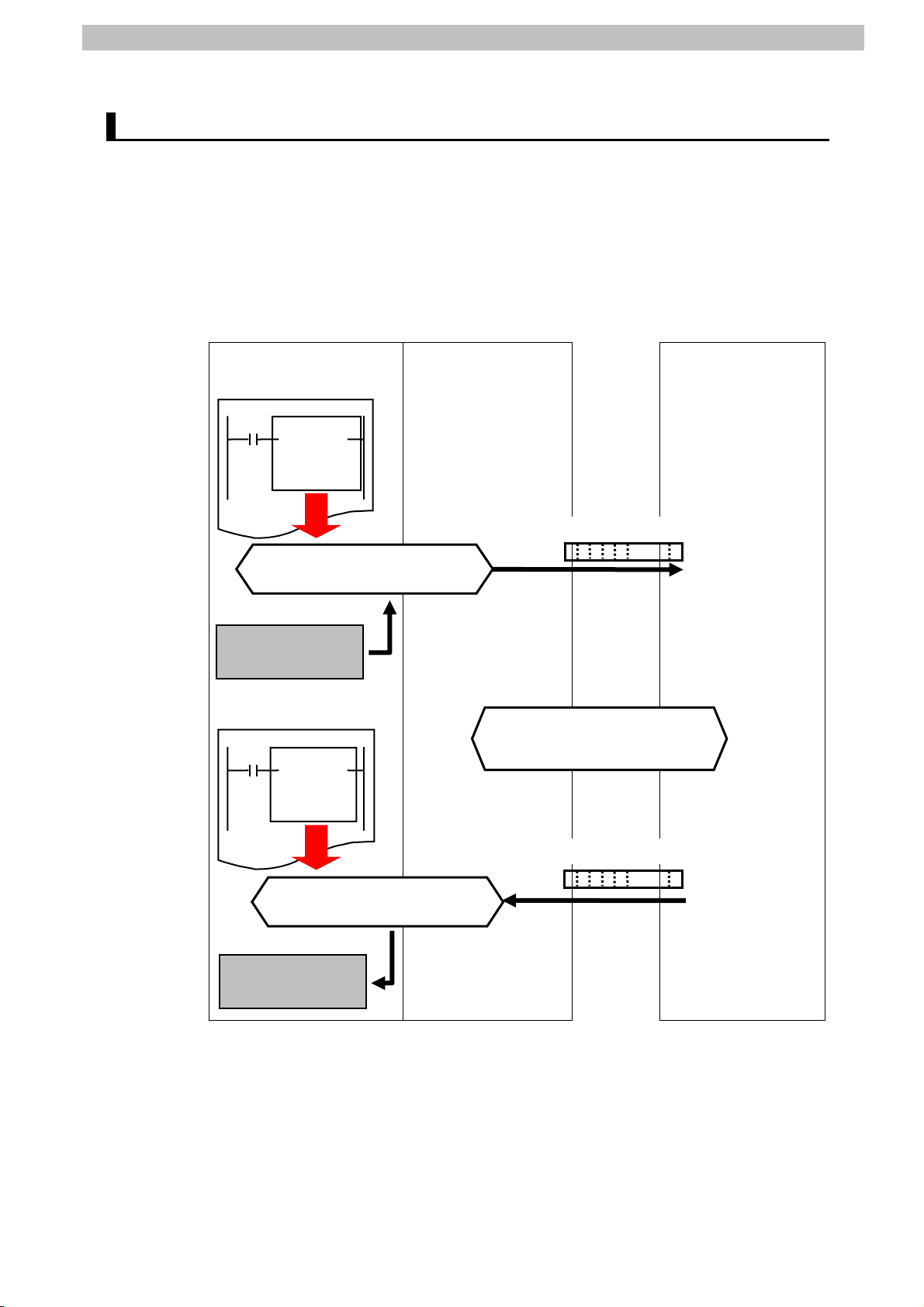

6.3. Example of Checking Connection

This connection example uses the ladder program for network connection. For details on the

ladder program, refer to 9. Project File.

The Controller and Safety Controller send and receive a message of Monitor I/O. The

following figure shows the outline of the operation.

CPU Serial

Communications

Unit

User memory

Ladder program

SerialSend

instruction

RS-232C Safety Controller

G9SP_

Comma

ndData

G9SP_

Respon

seData

Executing SerialSend instruction

Monitoring I/O

Send data

Send data

Setting area

Sending/receiving serial

communication command

Monitoring I/O

SerialRcv

instruction

Receive data

Executing SerialRcv instruction

Monitoring I/O

Receive data

Storage area

8

7. Connection Procedure

7. Connection Procedure

This section describes the procedure for connecting the Controller via serial communications.

This document explains the procedures for setting up the Controller from the factory default

setting. For the initialization, refer to Section 8 Initialization Method.

7.1. Work Flow

Take the following steps to connect the Controller via serial communications.

7.2 Setting Up the Safety Controller Set up the Safety Controller.

↓

7.2.1 Installing the Option Board

↓

7.3 Setting Up the Controller Set up the Controller.

↓

7.3.1 Hardware Settings of the Serial

Communications Unit

↓

7.3.2 Starting the Sysmac Studio and

Importing the Project File

↓

7.3.3 Going Online and Transferring

the Project Data

↓

7.4 Connection Status Check Check the serial network connection status.

↓

7.4.1 Checking the Connection Status Confirm that serial communications are performed

↓

7.4.2 Checking Data that are Sent and

Received

Install the Option Board of the Safety Controller.

Set the hardware switches on the Serial

Communications Unit and connect to the Controller.

Start the Sysmac Studio, and import the Sysmac

Studio project file.

Connect online with the Sysmac Studio and transfer

the project data to the Controller.

normally.

Confirm that the correct data are sent and received.

Precautions for Correct Use

Obtain the latest Sysmac Studio project file from OMRON in advance.

(To obtain the files, contact your OMRON representative.)

9

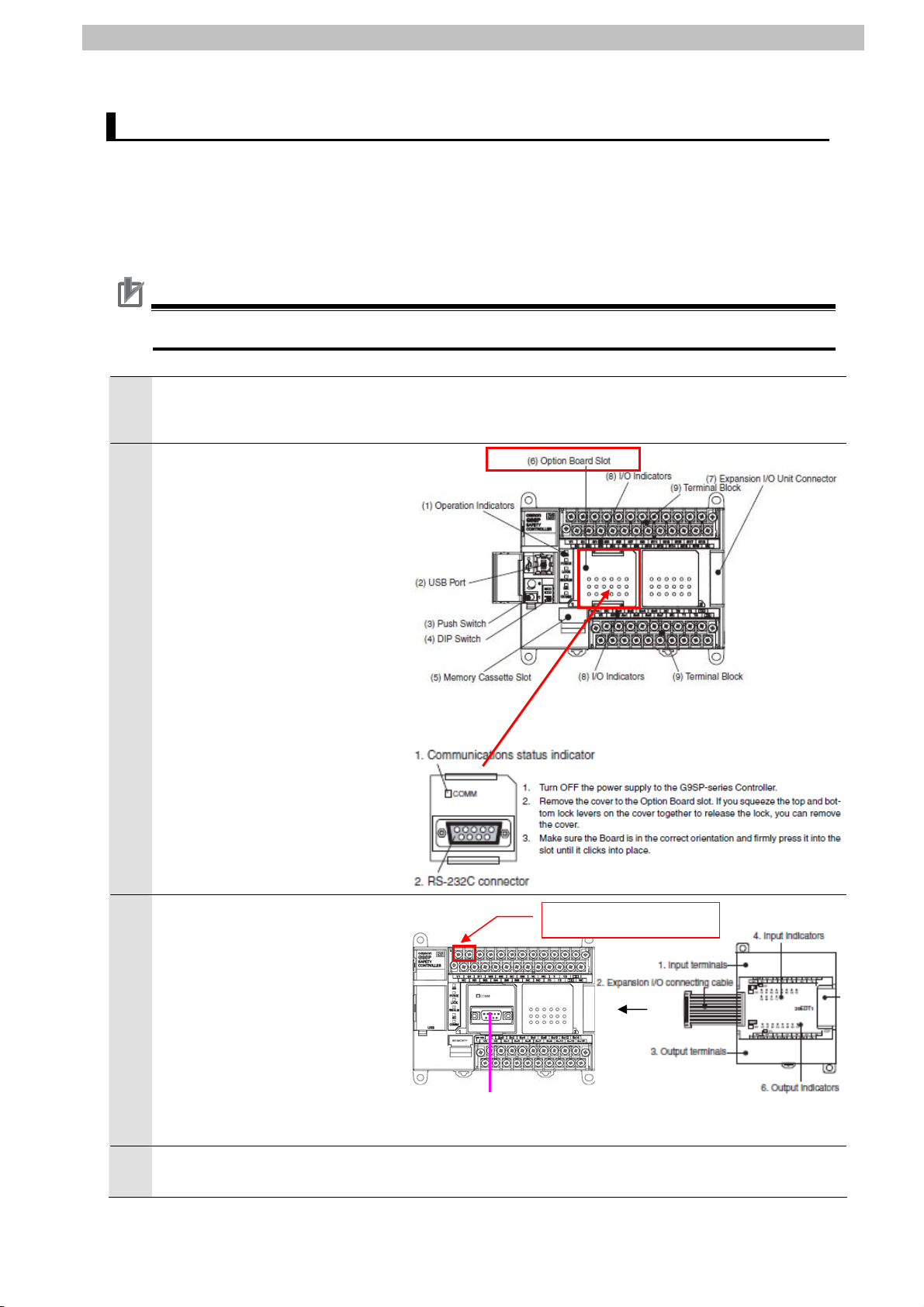

7.2. Setting Up the Safety Controller

Set up the Safety Controller.

7.2.1. Installing the Option Board

Install the Option Board.

Precautions for Correct Use

Make sure that the power supply is OFF when you install.

Confirm that the power supply to

1

the Safety Controller is OFF.

Remove the cover of the option

2

board slot, and install the

RS-232C option board

(CP1W-CIF01).

RS-232C communications

settings of the Safety Controller

are as follows and cannot be

changed.

•RS-232C communications

setting (fixed)

Baud rate: 9,600 bps

Data length: 8 bits

Stop bits: 1 bit

Parity: E (Even parity)

7. Connection Procedure

(Front of Safety Controller)

Connect the serial cable

3

(RS-232C) to the Safety

Controller as shown on the right.

Connect the expansion I/O

connecting cable to the Safety

Controller.

Connect the 24VDC(+) line to

terminal V1 of the Safety

Controller, and the GND line to

terminal G1.

Turn ON the power supply to the

4

Safety Controller.

(RS-232C Option Board)

24VDC power supply

Serial Cable

10

7. Connection Procedure

7.3. Setting Up the Controller

Set up the Controller.

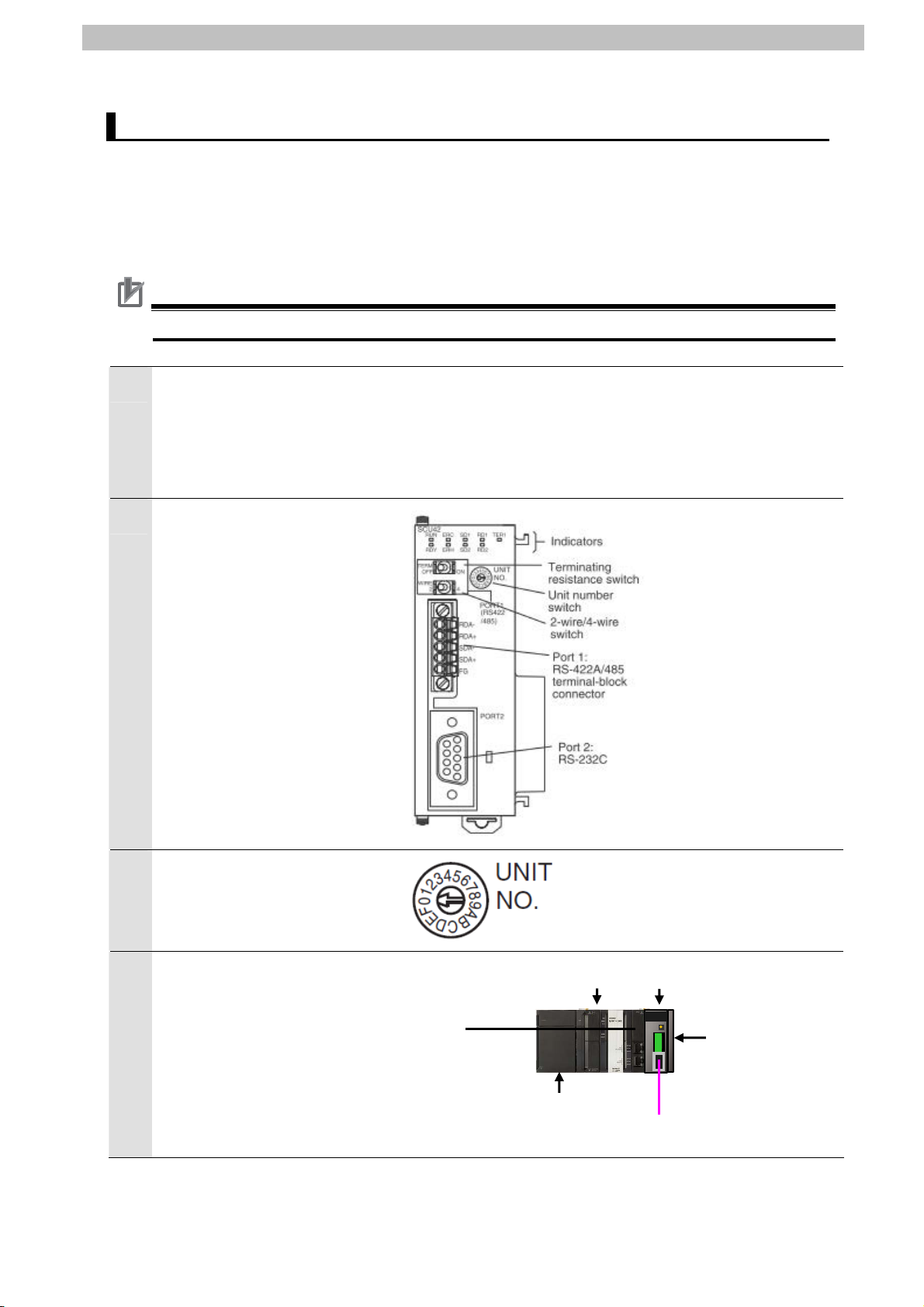

7.3.1. Hardware Settings of the Serial Communications Unit

Set the hardware switches on the Serial Communications Unit.

Precautions for Correct Use

Make sure that the power supply is OFF when you perform the setting up.

Confirm that the power supply to

1

the Controller is OFF.

*If the power supply is turned

ON, settings may not be

applicable as described in the

following procedure.

Connect the serial cable

2

(RS-232C) to Port 2 connector.

*This setting is required to use

Port 2 of Serial

Communications Unit.

Set the Unit No. Switch to 0.

3

(The unit number is factory-set

to 0.)

Connect the Serial

4

Communications Unit to the

Controller.

Connect the personal computer,

Safety Controller and Controller

using the Serial cable and USB

cable as shown in 5.2 Device

Configuration.

Turn ON the power supply to the

Controller.

USB cable

NJ501-1500

Power Supply Unit

CJ1W-SCU42

End cover

Serial Cable

11

7. Connection Procedure

7.3.2. Starting the Sysmac Studio and Importing the Project File

Start the Sysmac Studio, and import the Sysmac Studio project file.

Install the programming software and USB driver in the personal computer beforehand.

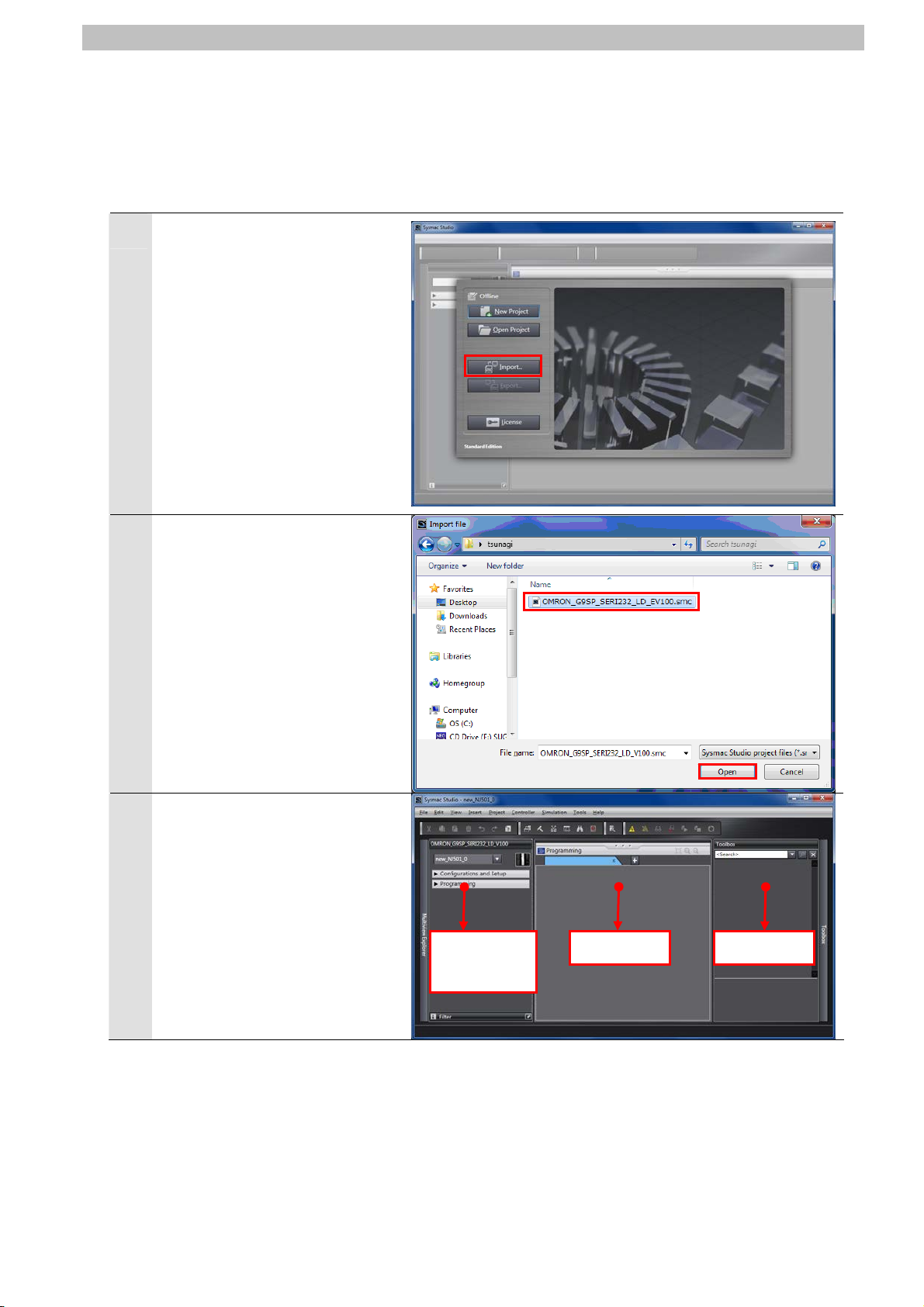

Start the Sysmac Studio.

1

Click the Import Button.

*If a confirmation dialog for an

access right is displayed at

start, select to start.

The Import File Dialog Box is

2

displayed. Select

OMRON_G9SP_SERI232_LD_

EV100.smc (Sysmac Studio

project file) and click the Open

Button.

*Obtain the Sysmac Studio

project file from OMRON.

OMRON_G9SP_SERI232_LD_

3

EV100 project is displayed.

The left pane is called Multiview

Explorer, the right pane is called

Toolbox and the middle pane is

called Edit Pane.

Multiview

Explorer

Edit Pane Toolbox

12

7. Connection Procedure

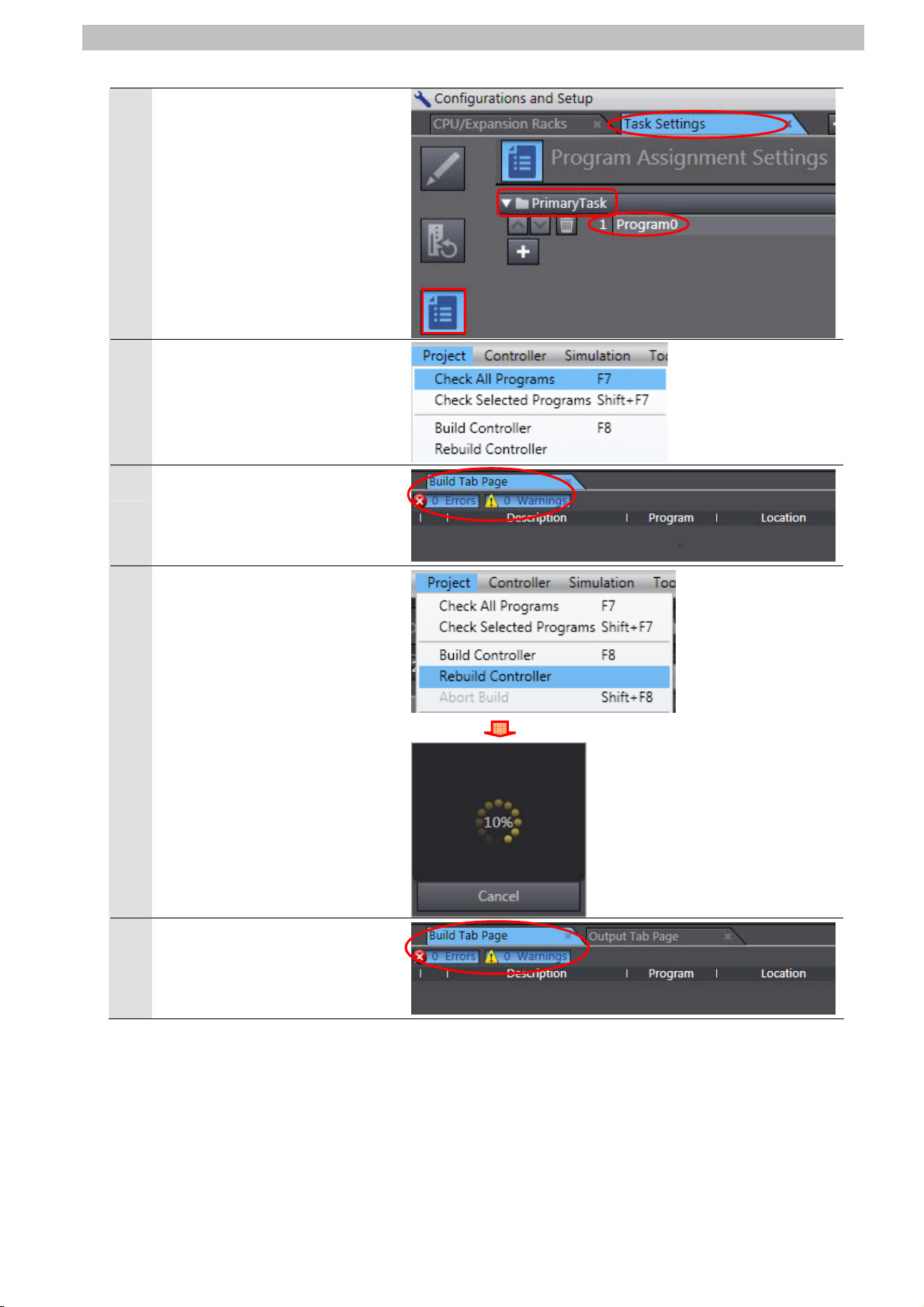

7.3.3. Checking the Parameters and Building

Check the set parameters, execute the program check on the project data and build the

Controller.

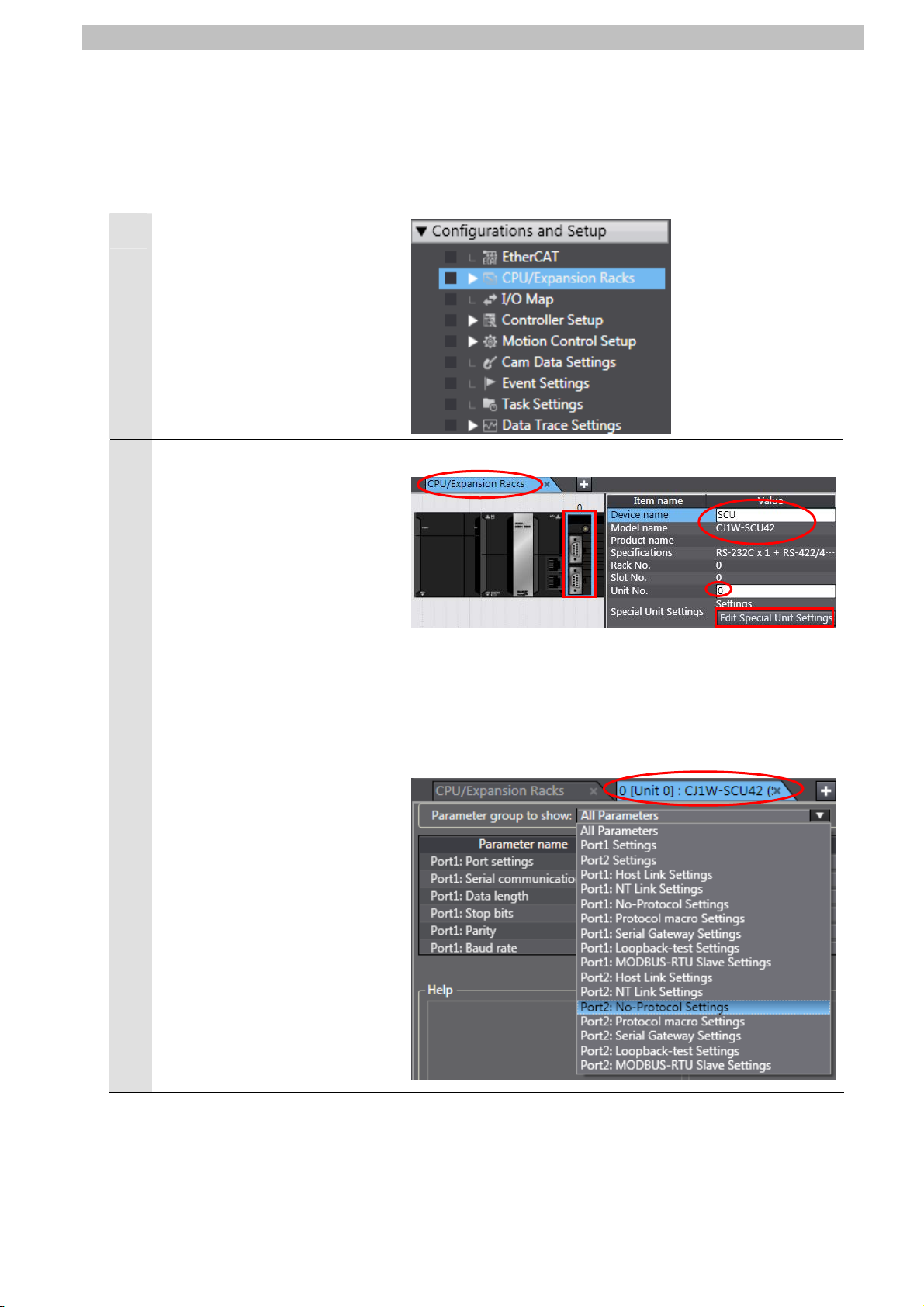

Double-click CPU/Expansion

1

Racks under Configurations

and Setup in the Multiview

Explorer.

The CPU/Expansion Racks Tab

2

is displayed on the Edit Pane.

Select the Serial

Communications Unit icon as

shown on the right.

Confirm that CJ1W-SCU42 is

displayed, the device name is

SCU, and the unit number is 0.

*If the settings are different,

change the values.

Click Edit Special Unit

Settings.

The 0 [Unit 0]: Tab is displayed.

3

Open the pull-down menu of

Parameter group to show and

select Port2: No-Protocol

Settings.

13

7. Connection Procedure

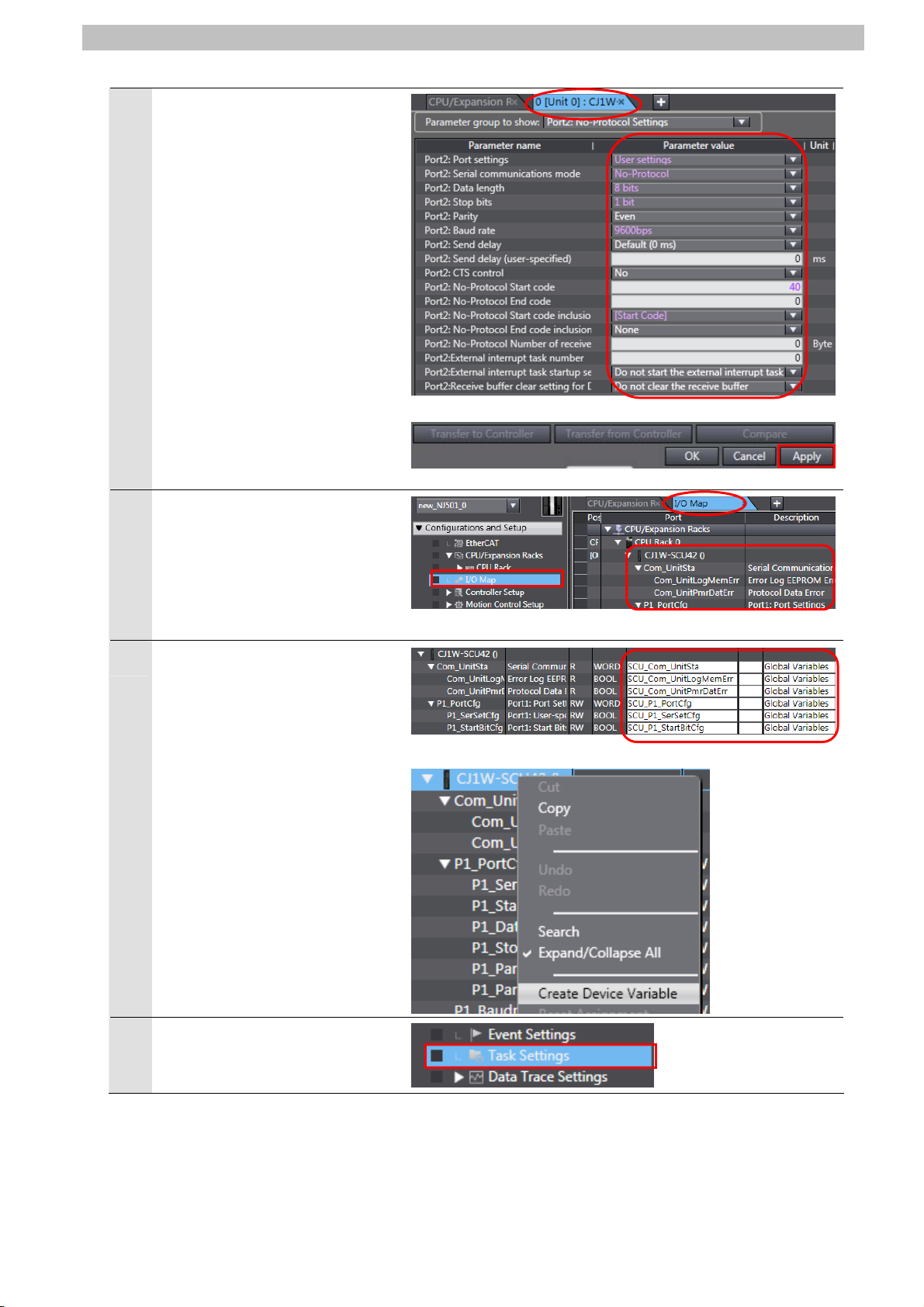

Parameter group to show is set

4

to Port 2: No-Protocol Settings.

The items of the Port 2:

No-Protocol Settings are

displayed.

Confirm that the Port2: Port

settings is set to User settings

and other items are the same as

Section 6.1.

*If the settings are different from

the above, change the values

from the pull-down menu. Click

the Apply Button after

changing values.

Double-click I/O Map under

5

Configurations and Setup on

the Multiview Explorer.

The I/O Map Tab Page is

displayed and the parameters of

the Unit are displayed.

Confirm that the data in the

6

Variable Columns on the I/O

Map Tab Page start with SCU

and that the Global Variables

are set in the Variable Type

Columns.

*If the settings are different from

the above, right-click on

CJ1W-SCU42 and select

Create Device Variable.

Double-click the Task Settings

7

under Configurations and

Setup in the Multiview Explorer.

14

The Task Settings Tab Page is

8

displayed in the Edit Pane.

Click the Program Assignment

Settings Button and confirm

that Program0 is set under

PrimaryTask.

Select Check All Programs

9

from the Project Menu.

The Build Tab Page is displayed

10

in the Edit Pane.

Confirm that "0 Errors" and "0

Warnings" are displayed.

Select Rebuild Controller from

11

the Project Menu.

A screen is displayed indicating

the conversion is being

performed.

7. Connection Procedure

12

Confirm that "0 Errors" and "0

Warnings" are displayed in the

Build Tab Page.

15

7. Connection Procedure

7.3.4. Going Online and Transferring the Project Data

Connect online with the Sysmac Studio and transfer the project data to the Controller.

Always confirm safety at the destination node before you transfer a user

program, configuration data, setup data, device variables, or values in memory

used for CJ-series Units from the Sysmac Studio.

The devices or machines may perform unexpected operation regardless of the

operating mode of the CPU Unit.

Always confirm safety before you reset the Controller or any components.

Select Change Device from the

1

Controller Menu.

The Change Device Dialog Box

2

is displayed.

Confirm that the Device and

Version are set as shown on the

right.

*If the settings are different,

change the value from the

pull-down list.

Click the OK Button.

If the settings were changed in

3

Step 2, the Build Dialog Box is

displayed. Click the Yes Button.

16

Select the Communications

4

Setup from the Controller Menu.

The Communications Setup

5

Dialog Box is displayed.

Select the Direct Connection via

USB Option in the Connection

Type Field.

Click the OK Button.

7. Connection Procedure

Select Online from the

6

Controller Menu.

A confirmation dialog box is

displayed. Click the Yes Button.

*The displayed dialog depends

on the status of the Controller

used. Select the Yes Button to

proceed with the processing.

Additional Information

For details on online connections to a Controller, refer to Section 5 Going Online with a

Controller in the Sysmac Studio Version 1.0 Operation Manual (Cat. No. W504).

When an online connection is

7

established, a yellow bar is

displayed on the top of the Edit

Pane.

Select Synchronization from

8

the Controller Menu.

17

The Synchronization Dialog Box

9

is displayed.

Confirm that the data to transfer

(NJ501 in the right figure) is

selected. Then, click the

Transfer to Controller Button.

A confirmation dialog is

10

displayed. Click the Yes Button.

A screen stating "Synchronizing"

is displayed.

A confirmation dialog box is

displayed. Click the No Button.

7. Connection Procedure

Confirm that the synchronized

11

data is displayed with the color

specified by “Synchronized” and

that a message is displayed

stating "The synchronization

process successfully finished".

If there is no problem, click the

Close Button.

*If the synchronization fails,

check the wiring and repeat the

procedure described in this

section.

18

Select Reset Controller from

12

the Controller Menu.

*When Mode is set to RUN

Mode, Reset Controller cannot

be selected. In this case, select

Mode - PROGRAM Mode from

the Controller Menu to change

to PROGRAM mode and

perform the procedure in this

step.

7. Connection Procedure

13

14

A confirmation dialog box is

displayed several times. Click

the Yes Button.

The Controller is reset, and

Sysmac Studio goes offline.

The yellow bar on the top of the

Edit Pane disappears.

Use steps 6 and 7 to go online.

19

7.3.5. Transferring the Unit Settings

Transfer the setting data of the Serial Communication Unit.

Select Mode - PROGRAM

1

Mode from the Controller Menu.

A confirmation dialog box is

2

displayed. Click the Yes Button.

7. Connection Procedure

PROGRAM mode is displayed

3

on the Controller Status Pane.

Double-click CPU/Expansion

4

Racks under Configurations

and Setup in the Multiview

Explorer.

Select the Serial

Communications Unit figure.

Click Edit Special Unit

Settings.

The 0 [Unit 0]: Tab is displayed.

5

Click the Transfer to Controller

Button.

20

A confirmation dialog box is

6

displayed.

Click the Yes Button.

A dialog box is displayed

indicating transferring is being

performed.

A confirmation dialog box is

displayed.

Click the Yes Button.

The Port Selection Dialog Box is

7

displayed.

Select All ports and click the

OK Button.

*You can select HostLink2

instead of All ports.

7. Connection Procedure

A confirmation dialog box is

8

displayed.

Click the OK Button.

Select Port2: No-Protocol

9

Settings from the pull-down list

of Parameter group to show.

Click the Compare Button.

Confirm that “≠” (mismatch) is

10

not shown in the red frame on

the right.

21

7. Connection Procedure

7.4. Connection Status Check

Execute the project file that was transferred and confirm that serial communications are

performed normally.

Sufficiently confirm safety before you change the values of variables on a Watch

Tab Page when the Sysmac Studio is online with the CPU Unit. Incorrect

operation may cause the devices that are connected to Output Units to operate

regardless of the operating mode of the Controller.

Precautions for Correct Use

Please confirm that the serial cable is connected before proceeding to the following steps.

If it is not connected, turn OFF the power of the devices, and then connect the serial cable.

7.4.1. Executing the Ladder Program and Checking the Receive Data

Execute the ladder program and confirm that the correct data are written to the variables of

the Controller.

Select Mode - RUN Mode from the

1

Controller Menu.

A confirmation dialog box is

displayed. Click the Yes Button.

RUN mode is displayed on the

2

Controller Status Pane.

Select Watch Tab Page from the

3

View Menu.

22

7. Connection Procedure

The Watch Tab Page is displayed in

4

the lower section of the Edit Pane.

Confirm that the following values

5

are displayed in the Name Columns.

Input_Start

Output_Status

Output_ErrorCode1

Output_ErrorCode2

G9SP_ResponseData[0-198]

G9SP_CommandData

*If the necessary variables are not

displayed, click Input Name to

add.

Click TRUE on the Modify Column

6

of Input_Start.

The Online value of Input_Start

changes to True.

The Online Values of Output Status

and etc. are initialized to FFFF.

When serial communications are

completed normally, the Online

Values of Output Status and etc.

change to 0000.

The response data that was

7

received are stored in

G9SP_ResponseData[0] to [198].

Specify variables you want to see in

the Watch Tab Page as shown in the

right figure and check them.

If values are stored in

G9SP_ResponseData[2] to [5] as

shown on the right, the operation is

completed normally.

G9SP_ResponseData[2]:C3

G9SP_ResponseData[3]:00

G9SP_ResponseData[4]:00

G9SP_ResponseData[5]:CB

←Response length

←End code (H)

←End code (L)

←Service code

←Communications

←Same as above

←Same as above

←Same as above

send data

23

8. Initialization Method

8. Initialization Method

This document explains the setting procedure from the factory default setting.

Some settings may not be applicable as described in this document unless you use the

devices with the factory default setting.

8.1. Initializing the Controller

To initialize the Controller, it is necessary to initialize the CPU Unit and Serial Communications

Unit.

8.1.1. CPU Unit

To initialize the settings of the Controller, select Clear All Memory from the Controller

Menu of the Sysmac Studio.

24

8. Initialization Method

8.1.2. Serial Communications Unit

To initialize the settings of the Serial Communications Unit, select Edit Special Unit Settings

of CJ1W-SCU42 in CPU/Expansion Racks from the Sysmac Studio.

Click the Return to default Button and click the Apply Button. Then, click the Transfer to

Controller Button.

25

9. Project File

9. Project File

This section describes the details on the project file used in this document.

9.1. Overview

This section explains the specifications and functions of the project file used to connect the

Safety Controller (hereinafter referred to as the destination device or G9SP) to the Controller

(Serial Communications Unit) (hereinafter referred to as an SCU Unit).

The project file means a Sysmac Studio project file.

The following data has already been set in this project file.

·SCU Unit communications settings and program task settings

·Ladder program for serial communications

·Variable tables and data type definitions of the variables used in ladder programs

This project file uses the serial communications of the SCU Unit to execute “read the I/O

monitor results” on the destination device and to detect whether the operation ends normally

or abnormally.

A normal end of this project file means a normal end of that the serial communications.

An error end means an error end of the serial communications and a destination device error

(Detected with the response data from the destination device).

Additional Information

OMRON has confirmed that normal communications can be performed using this project file

under the OMRON evaluation conditions including the test system configuration, version of

each product, and product Lot, No. of each device which was used for evaluation.

OMRON does not guarantee the normal operation under the disturbance such as electrical

noise or the performance variation of the device.

Additional Information

With Sysmac Studio, the “data type + #” prefix is added to decimal data and “data type + # +

16 + #" prefix is added to hexadecimal data when it is necessary to distinguish between

decimal and hexadecimal data. (e.g., INT#1000 decimal -> INT#16#03E8 hexadecimal. For

DINT, a data type + "#" are unnecessary.)

26

9. Project File

9.1.1. Communications Data Flow

The following figure shows the data flow from when the Controller (SCU Unit) issues a

communications command (hereinafter referred to as command) to the destination device

until when the SCU receives the response data from the destination device.

1. Sending a command The SCU Unit sends the send message set with the

ladder program to the destination device.

↓

2. Receiving a response The response data, which was received by the SCU

Unit from the destination device, is stored in the

specified internal variable of the CPU Unit.

9.1.2. Serial Communications Instruction and Send/Receive Message

This section outlines the function blocks for Serial Communications Unit (hereinafter

referred to as serial communications instructions) and the general operation of the

send/receive messages.

Additional Information

For details, refer to Communications Instructions under Section 2 Instruction Descriptions of

NJ-series Instructions Reference Manual (Cat. No. W502).

●Serial communications instructions

In this project file, serial communications are performed by using the following 2 types of

standard instructions.

Name Function blocks Description

SCU Send Serial SerialSend Sends data in No-protocol Mode from a

serial port. (Send instruction)

SCU Receive Serial SerialRcv Reads the receive data from the serial port in

No-protocol Mode. (Receive instruction)

●Serial communications instructions argument data

·SCU Send Serial

27

·SCU Receive Serial

9. Project File

·The data type (_sPORT) of destination port (Port)

●Send/receive messages

[Overview of send/receive message]

256 bytes or less

Send message

Controller

:SerialSend instruction SrcDat[]

Data

Destination

device

Data

Receive message

256 bytes or less

:SerialRcv instruction DstDat[]

*The set values shown below for the SCU Unit are stored in ST (Start Code) and ED (End

Code).

28

9.2. Destination Device Command

This section explains the destination device command used in this project file.

9.2.1. Command Format

The command format of the destination device is as follows:

Variable Type Data Code Remarks

ST Start code #16#40 Fixed

G9SP_Send

Command_

BYTE[0] #16#00 Fixed

BYTE[1] #16#00 Fixed

BYTE[2] #16#0F Fixed

BYTE[3] #16#4B Fixed

BYTE[4] #16#03 Fixed

BYTE[5] #16#4D Fixed

BYTE[6] #16#00 Fixed

BYTE[7]

BYTE[8] #16#aa Bits 00 to 07

BYTE[9] #16#bb Bits 08 to 15

BYTE[10] #16#cc Bits 16 to 23

BYTE[11]

BYTE[12] #16#e0 Bit 7: Echo back

BYTE[13]

BYTE[14] #16#ff Checksum (Leftmost)

BYTE[15]

BYTE[16] #16#2A Fixed

BYTE[17]

Data

Fixed data

Communications

receive data

Echo back

Checksum

End code

*The checksum is calculated based on ST and G9SP_SendCommand_BYTE[0] to [13].

#16#01 Fixed

#16#dd Bits 24 to 31

#16#00 Fixed

#16#gg Checksum (Rightmost)

#16#0D Fixed

9. Project File

29

9.2.2. Response Format

The response format of the destination device is as follows:

<Normal response>

Variable Type Data Value Remarks

ST Start code #16#40 Fixed

G9SP_Response

Data[0] #16#00 Fixed (Response length (HL))

Data[1] #16#00 Fixed (Response length (LH))

Data[2]

Data[3] #16#00 Fixed (End code (H))

Data[4]

Data[5] Service code #16#CB Fixed

Data[6] #16#aa Bits 00 to 07

Data[7] #16#bb Bits 08 to 15

Data[8] #16#cc Bits 16 to 23

Data[9]

Data[10] #16#ee Bits 00 to 07

Data[11] #16#ff Bits 08 to 15

Data[12] #16#0g Bits 16 to 19

Data[13] to [15]

Data[16] #16#hh Bits 00 to 07

Data[17] #16#ii Bits 08 to 15

Data[18] to [19]

Data[20] #16#jj Bits 00 to 07

Data[21] #16#kk Bits 08 to 15

Data[22] #16#0l Bits 16 to 19

Data[23] to [25]

Data[26] #16#mm Bits 00 to 07

Data[27] #16#nn Bits 08 to 15

Data[28] to [29]

Data[30] to [39]

Data[40] to [53]

Data[54] to [63]

Data[64] to [69]

Data[70] to [71] Reserved #16#00 Not used

Data[72] #16#ww

Data[73]

Data

Response length

End code

Communications

send data

Safety input

terminal data

Safety input

terminal data

Safety input

terminal status

Safety output

terminal status

Safety input

terminal error

cause

Safety output

terminal error

cause

Unit Status and

echo-back

#16#C3 Fixed (Response length (LL))

#16#00 Fixed (End code (L))

#16#dd Bits 24 to 31

#16#00 Not used

#16#00 Not used

#16#00 Not used

#16#00 Not used

#16#oo

#16#pp

Safety input

terminal 01

Safety input

terminal 03

:

#16#qq

#16#rr

Safety input

terminal 17

Safety input

terminal 19

#16#00 Not used

#16#ss

#16#tt

Safety input

terminal 01

Safety input

terminal 03

:

#16#uu

#16#vv

Safety input

terminal 17

Safety input

terminal 19

#16#00 Not used

Bit 7: Echo-back

Bit 0: Unit Normal Operating Flag

#16#xx

Bit 5: Function Block Execution

Error Flag

Bit 2: Safety I/O Terminal Error

Flag

Bit 1: Output Power Supply Error

Flag

9. Project File

Safety input

terminal 00

Safety input

terminal 02

Safety input

terminal 16

Safety input

terminal 18

Safety input

terminal 00

Safety input

terminal 02

Safety input

terminal 16

Safety input

terminal 18

30

Variable Type Data Value Remarks

Data[74] #16#yy Rightmost byte

Data[75]

Configuration ID

#16#zz Leftmost byte

Data[76] #16#aa First byte

Data[77] #16#bb Second byte

Data[78] #16#cc Third byte

Data[79]

Unit Conduction

Time

#16#00 Not used

Data[80] to [99] Reserved #16#00 Not used

Data[100] to [111]

Data[112] #16#hh Error Log Count

Data[113]

Present Error

Information

Error Log Count

(Operation Log

#16#dd

#16#ee

:

#16#ff

#16#gg

#16#ii Operation Log Count

Error Information Map 0

Error Information Map 1

Error Information Map 10

Error Information Map 11

Count)

Data[114] to [153]

#16#jj Error code 1

#16#kk Conduction Time first byte at

error

#16#ll Conduction T ime second byte at

error

#16#mm Conduction Time third byte at

Error Log (Error

Code: Conduction

Time)

: :

#16#nn Error code 10

error

#16#oo Conduction Time first byte at

error

#16#pp Conduction Time second byte at

error

#16#qq Conduction Time third byte at

error

Data[154] to [193]

#16#rr Operation code 1

#16#ss Conduction Time first byte at

error

#16#tt Conduction Time second byte at

error

Operation Log

(Operation

Code:

Conduction

Time)

#16#uu Conduction Time third byte at

error

: :

#16#vv Operation code 10

#16#ww Conduction Time first byte at

error

#16#xx Conduction Time second by te at

error

#16#yy Conduction Time third byte at

error

Data[194] #16#zz Checksum (Leftmost)

Data[195]

Data[196] #16#2A Fixed

Data[197]

Checksum

#16#aa Checksum (Rightmost)

End code

#16#0D Fixed

*The checksum is calculated based on ST and G9SP_ResponseData[0] to [193].

*The response length is calculated based on G9SP_ResponseData[3] to [197].

9. Project File

31

<Error response>

Variable Type Data Code Remarks

ST Start code #16#40 Fixed

G9SP_Response

Data[0] #16#00 Fixed (Response length (HL))

Data[1] #16#00 Fixed (Response length (LH))

Data[2]

Data[3] #16#00 Fixed (End code (H))

Data[4]

Data[5] Service code #16#CB Fixed

Data[6] to [7] Data #16#aa Reserved (Specified by user)

Data[8] #16#bb Checksum (Leftmost)

Data[9]

Data[10] #16#2A Fixed

Data[11]

Data

Response

length

End code

Checksum

End code

#16#09 Fixed (Response length (LL))

#16#00 Fixed (End code (L))

#16#cc Checksum (Rightmost)

#16#0D Fixed

*The checksum is calculated based on ST and G9SP_ResponseData[0] to [7].

*The response length is calculated based on G9SP_ResponseData[3] to [11].

9. Project File

Additional Information

For details, refer to Section 7 Communications with a Standard PLC Using an Option Board

in the G9SP-series Safety Controller Operation Manual (Z922).

9.2.3. Send/Receive Messages

Data are sent in sequence from ST of the command format.

Data are received in sequence from ST of the response format.

*Send message

40 00 00 0F 4B 03 4D 00 01 ..(Total of 19 bytes)

*Receive message 1 (at normal processing)

40 00 00 C3 00 00 CB aa ..(Total of 199 bytes)

*Receive message 2 (at error processing)

40 00 00 09 00 00 CB aa ..(Total of 13 bytes)

32

9. Project File

9.3. Error Detection Processing

This project file detects and handles errors (1) to (3). For information on error codes, refer to

9.7 Error Status List.

NJ501-1500+

Destination device

CJ1W-SCU42

Serial cable

(1) (2) (3)

(1) Errors during execution of SerialSend/SerialRcv instructions (communications instruction

errors)

An error end of SerialSend/SerialRcv instruction due to an incorrect SCU Unit setting or

incorrect variable setting, etc is detected as a communications instruction error. The error is

detected with the error flag (Error) at the execution of an instruction.

(2) SCU Unit errors (Unit errors)

An error that prevents the SCU Unit from being ready for communications is detected as a

Unit error. This error is detected when a timeout occurs.

(3) Errors in the destination device (Destination device errors)

An error that occurs during communications with a destination device is detected as a

destination device error. Destination device errors include a transmission error caused by a

destination device's command error, parameter error, data error and an error that preven ts

execution, character corruption or unmatched baud rate setting. The error is detected with

the response data which is sent from the destination device.

With this project file, the destination device error is detected when there is a difference

between a normal receive message (hereinafter referred to as a normal message) and an

error receive message (hereinafter referred to as an error message). (Refer to 9.2.3.

Send/Receive Message for details.)

#40 #0000C3 #0000 #CB 188Byte #**** #2A0D Normal

message

(Normal

response)

Start code Response

length

End code Service

code

Data Checksum Delimiter

#40 #000009 #0000 #CB #**** #**** #2A0D Error

message

(Error

response)

Start code Response

length

End code Service

code

Reserve

data

Checksum Delimiter

33

9. Project File

9.4. Variables

The table below lists the variables used in this project file.

9.4.1. External variables

These external variables are necessary to execute this program.

To use global variables, they must be declared in each program.

Additional Information

With the Sysmac Studio, the data type is expressed as ARRAY[0..2] OF WORD when an

array is specified for a data type. However, a data type of an array is simplified in this

document (e.g. WORD[3]).

It is possible to set either of the following to specify an array for a data type with the Sysmac

Studio.

·ARRAY[0..2] OF WORD

·WORD [3]

In the example above, 3 WORD array elements are secured.

●Variables that are used

(1)These variables are used to operate and check this program.

Name Data type Description

Input_Start BOOL

Output_Status WORD

Output_ErrorCode1 WORD

Output_ErrorCode2 DWORD

SCU_Inport _sPORT

G9SP_CommandData

G9SP_SendCommand

_BYTE

G9SP_SendCommand

_Checksum_WORD

G9SP_SendCommand

_Checksum_HighByte

G9SP_SendCommand

_Checksum_LowByte

G9SP_ResponseData BYTE[199] BYTE array data received by the SerialRcv instruction

G9SP_Com

mandFormat

BYTE[18]

WORD

BYTE

BYTE

This project file is started by changing from FALSE

(OFF) to TRUE (ON).

Stores the execution results of this project file.

#16#FFFF: Default

#16#0000: Normal end

#16#FF01: SerialSend instruction error

#16#FF02: SerialRcv instruction error

#16#FF03: Destination device error (receive data

value error)

#16#FF04: Communications error (timeout

detection)

Stores the value of ErrorID and destination device

error code for each instruction when an instruction

error occurs.

(Default: #16#FFFF)

Stores the value of ErrorIDEx and destination device

error code for each instruction when an instruction

error occurs.

(Default: #16#FFFF FFFF)

Sets the unit number and port number of the SCU

Unit.

Sets the command sent to G9SP.

Data obtained by converting G9SP_CommandData

into a BYTE array to be used in the SerialSend

instruction.

Checksum value (WORD) of the send data

The leftmost byte data of the checksum value

(WORD)

The rightmost byte data of the checksum value

(WORD)

34

9. Project File

(2)These variables of the SCU Unit are used in this program.

Name Data type Description

SCU_P2_NopSerialS

endExecSta

SCU_P2_NopRcvCo

mpleteSta

SCU_P2_NopRcvCn

tSta

BOOL

BOOL

UINT Receive counter: Stores the size of the received data.

Additional Information

For information on variables of the Serial Communications Unit, refer to 5-2 Device Variables

for CJ-series Unit and System-defined Variables (During Serial Gateway Mode) in the

CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit (Cat.No.

W494).

(3)This system variable is used in this program.

Name Data type Description

_Port_isAvailable BOOL Communications Port Enabled Flag

SerialSend instruction executing flag:

ON during data send operation and OFF when the send

operation is completed.

Receive completion flag:

ON when reception of data is completed and OFF when

storing the receive data in a variable specified with the

SerialRcv is completed.

Additional Information

For information on system variables when using the serial communications instructions, refer

to SerialSend and SerialRecv in Section 2 Instruction Descriptions of the NJ-series

Instructions Reference Manual (Cat. No. W502).

●Structure

The structures used in the external variables are shown below.

(1)_sPORT

Variable Meaning Description Data type Valid range Default

SCU_Inport Destination

port

UnitNo Unit number Unit number of SCU

PhysicP

ortNo

Serial port

number

Destination port _sPORT

_eUnitNo _CBU_No00 to

Unit

Serial port number of

SCU Unit

USINT 1 or 2 1

-

_CBU_No15

_CBU_No00

(2)G9SP_CommandFormat

Variable Meaning Description Data type Valid range Default

G9SP_Comman

dFormat

FixationArea1 Fixed area 1 Sets the fixed data that

SendData User

CheckSum Checksum

FixationArea2 End code

G9SP

command

setting

specification

area

area

area

Specifies command

data sent to G9SP.

cannot be changed by

the user.

Sets communications

receive data and echo

back data that can be

changed by the user.

Sets a checksum value. UINT #16#00 to

Sets the end code

(#16#2A0D).

G9SP_Comm

andFormat

USINT[8] Fixed -

USINT[6] #16#00 to

USINT[2] Fixed -

-

16#FF

#16#FF

-

-

35

9. Project File

9.4.2. Internal Variables

These internal variables are necessary to execute this project file.

They can be used only in this program.

●Variables for internal processing

These function blocks are used in this program.

Name Data type Description

G9SP_SerialSend_Instance SerialSend The instance of the SerialSend instruction

G9SP_SerialRcv_Instance SerialRcv The instance of the SerialRcv instruction

Data receive waiting timer. Normally, the SerialRcv

instruction is executed after the reception of data is

completed (after SCU_P2_NopRcvCompleteSta is

G9SP_RcvWait_Timer TON

G9SP_Check_Timer TON

●Variables that are used

These variables are used in this program.

Name Data type Description

G9SP_ResponseData_OK BOOL

G9SP_Error_End BOOL Turns ON an error occurs after executing this program.

G9SP_Excuting BOOL

G9SP_SerialSend_Excute BOOL

G9SP_SerialSend_Wait BOOL

G9SP_SerialSend_End BOOL

G9SP_SerialSend_Error BOOL

G9SP_SerialRcv_Excute BOOL

G9SP_SerialRcv_End BOOL

G9SP_SerialRcv_Error BOOL

G9SP_TimeOUT BOOL

turned ON). This timer is used to execute the

SerialRcv instruction after a certain pe riod of time

after completion of the send processing even if

completion of the receive operation cannot be

detected. (Setting value: 200 ms)

G9SP send/receive completion check timer. This

timer operates after Input_Start is turned ON until

send/receive operations are completed. A timeout

error occurs when this timer is turned ON. (Setting

value 20 seconds)

Turns ON when this program receives a normal

response.

Serial communications executing flag.

Turns ON from when Input_Start is turned ON until

when the normal end (G9SP_ResponseData_OK) or

the error end (G9SP_Error_End) is turned ON.

SerialSend instruction execution flag.

Turns ON during execution of the SerialSend

instruction (until Done is turned ON).

Data sending flag.

Turns ON after the SerialSend instruction is completed

until the data send processing is completed (until

SCU_P2_NopSerialSendExecSta is turned OFF).

Data send completion flag.

Turns ON when the data send processi ng is completed.

SerialSend instruction error flag.

Turns ON when the SerialSend instru ction ends in an

error.

SerialRcv instruction execution flag.

Turns ON during execution of the SerialRcv instruction

(until Done is turned ON).

Data receive completion flag.

Turns ON when the data receive processing is

completed.

SerialRcv instruction error flag.

Turns ON when the SerialRcv instruction ends in an

error.

G9SP send/receive timeout flag.

Turns ON when the G9SP_Check_Timer times out.

36

Name Data type Description

G9SP_ReceiveData_error BOOL

Receive data error flag.

Turns ON when the receive data is not normal.

9.5. Ladder Program

9.5.1. Ladder Program Function Configuration

The functional configuration of this program is as follows

Major

classification

1. Initialization

processing

2. Managing

the

SerialSend

instruction

executing

status

3. Managing

the SerialRcv

instruction

executing

status

4.End

processing

1.1. SCU Unit setting

1.2. Setting the G9SP command

1.3. Generating a checksum

1.4. Converting the send data

1.5. Initializing the response data

1.6. Turning ON the serial

2.1. Generating a SerialSend

2.2. Executing the SerialSend

2.3. Checking for the SerialSend

2.4. Waiting for data send

2.5. Checking for data send

2.6. Saving the error status

3.1. Generating a SerialRcv

3.2. Executing the SerialRcv

3.3. Checking for SerialRcv

3.4. Checking for data receive

3.5. Saving the error status

4.1. Checking the response data

4.2. Generating an error flag

Minor classification Description

data

(USINT→BYTE)

area and status

communications executing

flag and enabling the monitor

timer (20 seconds)

instruction execution flag

instruction

instruction error

completion

completion

instruction execution flag

instruction

instruction error

completion

9. Project File

Preparation for communications.

Variables to be used are cleared

and initialization settings are

performed.

The SerialSend instruction is

executed and the program waits

for the completion of data send

operation.

The error status is stored in the

status area when the operation

ends in an error.

The SerialRcv instruction is

executed and the program waits

for the completion of data receive

operation.

The error status is stored in the

status area when the operation

ends in an error.

The receive data is checked.

The error flag is turned ON when

an error occurs.

37

9. Project File

9.5.2. Explanation on Each Functional Component

This section shows the details on the functions of this program.

1. Initialization processing

No. Overview Description

1.1. SCU Unit setting Sets the Unit number and serial port number of the SCU Unit

in the SCU_Inport structure.

38

9. Project File

No. Overview Description

1.2. Setting the G9SP

command data

1.3. Generating a

checksum

Sets a command sent to G9SP.

Data in the red frame are communication receive data and

echo back data that can be changed by the user. Any value

can be set.

Calculates the checksum value of the set command data.

39

9. Project File

No. Overview Meaning

1.4. Converting the send

data

(USINT→BYTE)

Converts the set command data and calculated checksum

value into a BYTE array to set them for the SerialSend

instruction.

40

9. Project File

No. Overview Meaning

1.5. Initializing the

response data area

and status

1.6. Turning ON the

serial

communications

executing flag and

executing the

monitor timer (20

seconds)

Initializes the response area and status area. The status area

is initialized to #16#FFFF.

Tur ns ON G9SP_Excuting that indicates the serial

communications are in progress.

G9SP send/receive completion check timer

(G9SP_Check_Timer) is operated to detect a timeout.

When the G9SP send/receive completion check timer times

out, G9SP_TimeOUT is turned ON and the error status is

stored.

41

2. Managing the SerialSend instruction executing status

9. Project File

No. Overview Meaning

2.1. Generating a

SerialSend instruction

execution flag

2.2. Executing the

SerialSend instruction

2.3. Checking for a

SerialSend instruction

error

2.4. Waiting for data send

completion

2.5. Checking data send

completion

Tur ns ON G9SP_SerialSend_Excute and starts the

SerialSend instruction execution processing if the

SerialSend instruction executing flag is not turned ON.

Turns OFF this flag when Done flag of the SerialSend

instruction is turned ON.

Executes the SerialSend instruction.

Turns ON the G9SP_SerialSend_Error flag when Error flag

of the SerialSend instruction is turned ON.

Tur ns ON G9SP_SerialSend_Wait when

G9SP_SerialSend_Excute is turned OFF. When the

SerialSend instruction executing flag is turned ON, the send

processing is completed, G9SP_SerialSend_Wait is turned

OFF and G9SP_SerialSend_End is turned ON.

42

No. Overview Meaning

2.6. Saving error status Sets the following status when the SerialSend instruction

ends in an error.

·Output_Status: #16#FF01

·Output_ErrorCode1: ErrorID of SerialSend instruction

·Output_ErrorCode2: ErrorIDEx of SerialSend instruction

9. Project File

Additional Information

For information on the error status, refer to 9.7 Error Status List.

43

3. SerialRcv instruction execution management

9. Project File

No. Overview Description

3.1. Generating a

SerialRcv instruction

execution flag

3.2. Executing the

SerialRcv instruction

3.3. Checking for

SerialRcv instruction

error

3.4. Checking for data

receive completion

If G9SP_SerialSend_End is turned ON and the receive

completion flag is turned ON, Turns ON

G9SP_SerialRcv_Excute and starts the SerialRcv instruction

execution processing.

This flag is turned OFF when Done flag of the SerialRcv

instruction is turned ON.

If the receive completion flag is not turned ON for a certain

period of time (200 ms), G9SP_SerialRcv_Excute is turned

ON and the SerialRcv instruction is executed.

Executes the SerialRcv instruction

Tur ns ON the G9SP_SerialRcv_Error flag when the Error flag

of the SerialRcv instruction is turned ON.

Tur ns ON G9SP_SerialSend_End when

G9SP_SerialRcv_Excute is turned OFF.

44

No. Overview Meaning

3.4. Checking for data

receive completion

3.5. Saving the error

status

Tur ns ON G9SP_SerialSend_End when

G9SP_SerialRcv_Excute is turned OFF.

Sets the next status when the SerialRcv instruction ends in an

error.

·Output_Status: #16#FF02

·Output_ErrorCode1: ErrorID of SerialRcv instruction

·Output_ErrorCode2: ErrorIDEx of SerialRcv instruction

9. Project File

Additional Information

For derails on the error status, refer to 9.7 Error Status List.

45

4. End processing

9. Project File

No. Overview Meaning

4.1. Checking if the

response data is

normal

Checks if the receive response data

(G9SP_ResponseData[2] to [5]) is the same as the fixed

data. If they are the same, the following data are set.

Output_Status: #16#0000

Output_ErrorCode1: #16#0000

Output_ErrorCode2: #16#00000000

G9SP_ResponseData_OK: ON

46

9. Project File

47

No. Overview Meaning

4.2. Saving the response

data error code

4.3. Generating an error

flag

If the comparison results are different in No. 4.1, the following

data are set.

Output_Status: #16#FF03

G9SP_ResponseData_error: ON

Output_ErrorCode: G9SP_ResponseData[5]+[2] (Service

code+Response length)

Output_ErrorCode: G9SP_ResponseData[7]+[6]+[4]+[3]

(Reserve data at error response+End code)

Tur ns ON G9SP_Error_End when an error occurs.

9. Project File

48

9. Project File

9.6. Timing Charts

This section explains the timing charts of the ladder program.

The definitions of the timing chart patterns are as follows:

Pattern Normal

end

Command Normal Error Normal or error Normal

Destination

Normal Normal or error Normal or error Error

device

Response Yes No No Yes

(1) Normal end

Error end (1)

Communications

instruction error

Error end (2)

Unit error

Error end (3)

Destination Device

error

Serial communications being performed.

Execute SerialSend instruction.

Wait for send data completion.

Wait for the receive data.

Execute SerialRcv instruction.

Completed data receive operation.

Check if data is normal.

49

(2) Error end 1 (Communications instruction error)

SerialSend instruction error SerialRcv instruction error

SerialSend instruction error end

SerialSend instruction error end

9. Project File

(3) Error end 2 (Unit error) (4) Error end 3 (Destination device error)

SerialSend not executed.

Response data error occurs

Timeout error

50

9.7. Error Status List

9.7.1. SerialSend/SerialRcv instruction errors

This error occurs when the SerialSend/SerialRcv instruction ends in an error.

The status code (Output_Status) for each instruction error is shown below.

SerialSend instruction error: #16#FF01

SerialRcv instruction error: #16#FF02

Each error status is stored in the following.

ErrorID: Output_ErrorCode1, ErrorIDEx: Output_ErrorCode2

[Error status (error code) list]

*Output_ErrorCode1

9. Project File

*Output_ErrorCode2

51

Additional Information

For details on the errors, refer to A-3 Error Code Details in the NJ-series Instructions

Reference Manual (Cat. No. W502).

For troubleshooting the errors, refer to 9-3 Troubleshooting in the CJ-series Serial

Communications Units Operation Manual for NJ-series CPU Unit (Cat.No. W494).

9.7.2. Destination Device Error

The error codes for destination device errors are shown below.

The status code (Output_Status) of the destination device error is #16#FF03.

[Destination device error code list]

Meaning Destination device

error code

ErrorCode1

rightmost

ErrorCode1

leftmost

ErrorCode2

rightmost

ErrorCOde2

leftmost

·Destination device error record function

The response data from the Safety Controller include Present Error Information, Error

Log Count (Operation Log Count), Error Log (Error Code: Conduction Time), Operation

Log (Operation Code: Conduction Time), which are stored in

G9SP_ResponseData[100] and the subsequent variables.

Note that this project does not detect these errors.

Response

length

Service code #16#CB

End code #16#0000

Reserve data

at error

response

#16#C3

#16#09

#16#00

#16#xx

#16#xx

#16#xxxx

#16#0000

#16#xxxx

Description

Normal

Error response

No response data

Other errors

Both normal/error response

(#CB is received)

Other errors

Normal

Incorrect command

Normal

Error state

9. Project File

Additional Information

For details and troubleshooting the destination device errors, refer to Section 13

Troubleshooting in the G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

52

9. Project File

53

10. Revision History

Revision

code

01 Aug. 1, 2013 First edition

Date of revision Revision reason and revision page

10. Revision History

54

2013

P545-E1-01

1308**(-)

Loading...

Loading...