Page 1

HOST CONNECTION

M ANUAL

Cat. No. Z924-E1-01

G9SP Series

Safety Controller

Page 2

OMRON, 2010

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 3

1

Introduction

Thank you for purchasing a G9SP-series Safety Controller. This manual contains information

required to use the G9SP-series Controller. Please thoroughly read and understand this manual

before you use the G9SP-series Controller.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical

systems (an electrical engineer or the equivalent).

- Personnel in charge of installing FA systems.

- Personnel in charge of designing FA systems.

- Personnel in charge of managing FA systems and facilities.

- Personnel in charge of qualifications and authority in all phases, including system design,

installation, operation, maintenance, and disposal.

Page 4

2

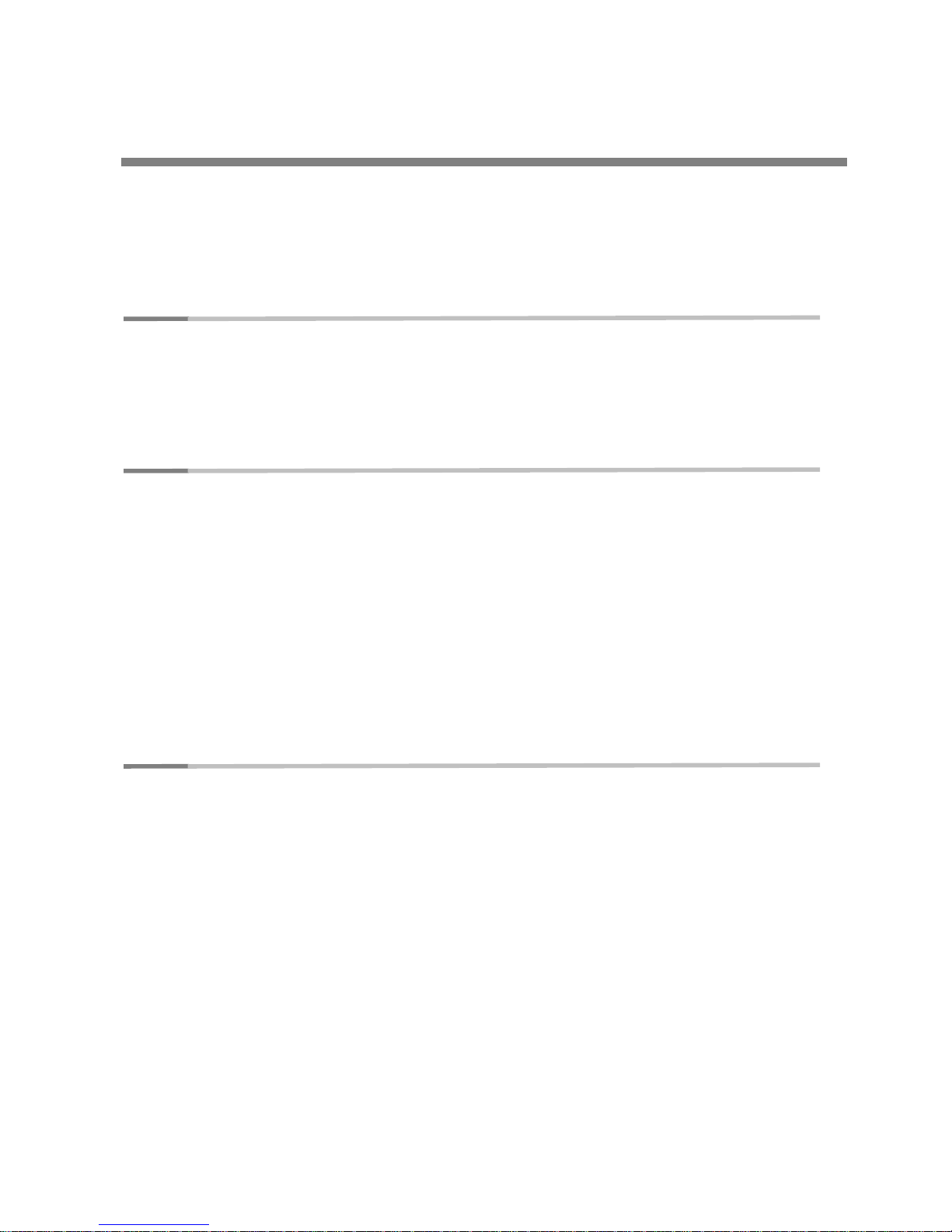

Manual Configuration

Information on the operation of G9SP-series Safety Controllers is provided in the following

manuals. Refer to the specific manual depending on the information that is required.

Manula name Contents Cat. No.

G9SP-series Safety Controller

Host Connection Manual (this

manual)

This manual provides sample ladder

programming and describes how to

connect to a Standard PLC from another

manufacturer using the communications

functionality of the G9SP-series Controller's

Option Board. The procedure for connecting to a

Standard PLC from another manufacturer is

described in the G9SP Operation Manual.

Z924

G9SP-series Safety Controller

Operation Manual

This manual provides detailed specifications and

describes functions and application methods for

the G9SP-series Controller in detail.

Z922

G9SP-series Safety Controller

Instructions Reference Manual

This manual describes the safety programming

methods, provides the specifications, and

describes the functions and operating methods

of the G9SP-series Controllers.

Z923

Page 5

3

Table of Contents

Introduction ....................................................................................................................1

Manual Configuration.....................................................................................................2

Table of Contents

...........................................................................................................3

Section 1Connecting to OMRON PLCs

1 - 1 Functionality ..................................................................................................1-2

1 - 2 RS-232C Serial Communications..................................................................1-3

1 - 3 Ethernet Communications .............................................................................1-4

Section 2Connecting to Mitsubishi Electric PLCs

2 - 1 Functionality ..................................................................................................2-2

2 - 2 RS-232C Serial Communications..................................................................2-3

2 - 2 - 1 Communication Format..............................................................2-3

2 - 2 - 2 Application Example 1(Connecting to the Mitsubishi Standard PLC

Q Series)....................................................................................2-3

2 - 2 - 3 Application Example 2(Connecting to the Mitsubishi Standard PLC

FX Series)................................................................................2-10

2 - 3 Ethernet Communications ...........................................................................2-16

2 - 3 - 1 Communication Format............................................................2-16

2 - 3 - 2 Application Example ..............................................................2-16

Section 3Connecting to Siemens PLCs

3 - 1 Functionality ..................................................................................................3-2

3 - 2 RS-232C Serial Communications..................................................................3-3

3 - 2 - 1 Communication Format..............................................................3-3

3 - 2 - 2 Application Example ................................................................3-3

3 - 3 Ethernet Communications ...........................................................................3-11

3 - 3 - 1 Communication Format............................................................3-11

3 - 3 - 2 Application Example ..............................................................3-11

Page 6

Page 7

This section describes how to perform communications with OMRON standard

PLC through an RS-232C Option Board or Ethernet Option Board.

1 - 1 Functionality.................................................................................................. 1-2

1 - 2 RS-232C Serial Communications................................................................. 1-3

1 - 3 Ethernet Communications

............................................................................. 1-4

Connecting to OMRON PLCs

Page 8

1-2

1 - 1 Functionality

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

Page 9

1 - 2 RS-232C Serial Communications

1-3

1

Connecting to OMRON PLCs

1 - 2 RS-232C Serial Communications

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

Page 10

1-4

1 - 3 Ethernet Communications

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

Page 11

This section describes how to perform communications with Mitsubishi Electric

Standard PLC through an RS-232C Option Board or Ethernet Option Board.

2 - 1 Functionality.................................................................................................. 2-2

2 - 2 RS-232C Serial Communications................................................................. 2-3

2 - 2 - 1 Communications Format ..................................................................2-3

2 - 2 - 2

Application Example 1(Connecting to the Mitsubishi Standard PLC Q

Series.) .............................................................................................2-3

2 - 2 - 3

Application Example 2(Connecting to the Mitsubishi Standard PLC FX

Series.) ...........................................................................................2-10

2 - 3 Ethernet Communications............................................................................2-16

2 - 3 - 1 Communications Format ................................................................2-16

2 - 3 - 2

Application Example.......................................................................2-16

Connecting to Mitsubishi Electric PLCs

Page 12

2-2

2 - 1 Functionality

Refer to Section 7 Communications with a Standard PLC Using an Option Board of

the G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

Page 13

2 - 2 RS-232C Serial Communications

2-3

2

Connecting to Mitsubishi Electric PLCs

2 - 2 RS-232C Serial Communications

This section provides a description and example of connection to a Mitsubishi

Electric Standard PLC. The No-protocol communications are available for

connection with a Mitsubishi Electric Standard PLC.

2 - 2 - 1 Communications Format

Refer to Section 7 Communications with a Standard PLC Using an Option Board of

the G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

2 - 2 - 2 Application Example 1(Connecting to the Mitsubishi Standard

PLC Q Series.)

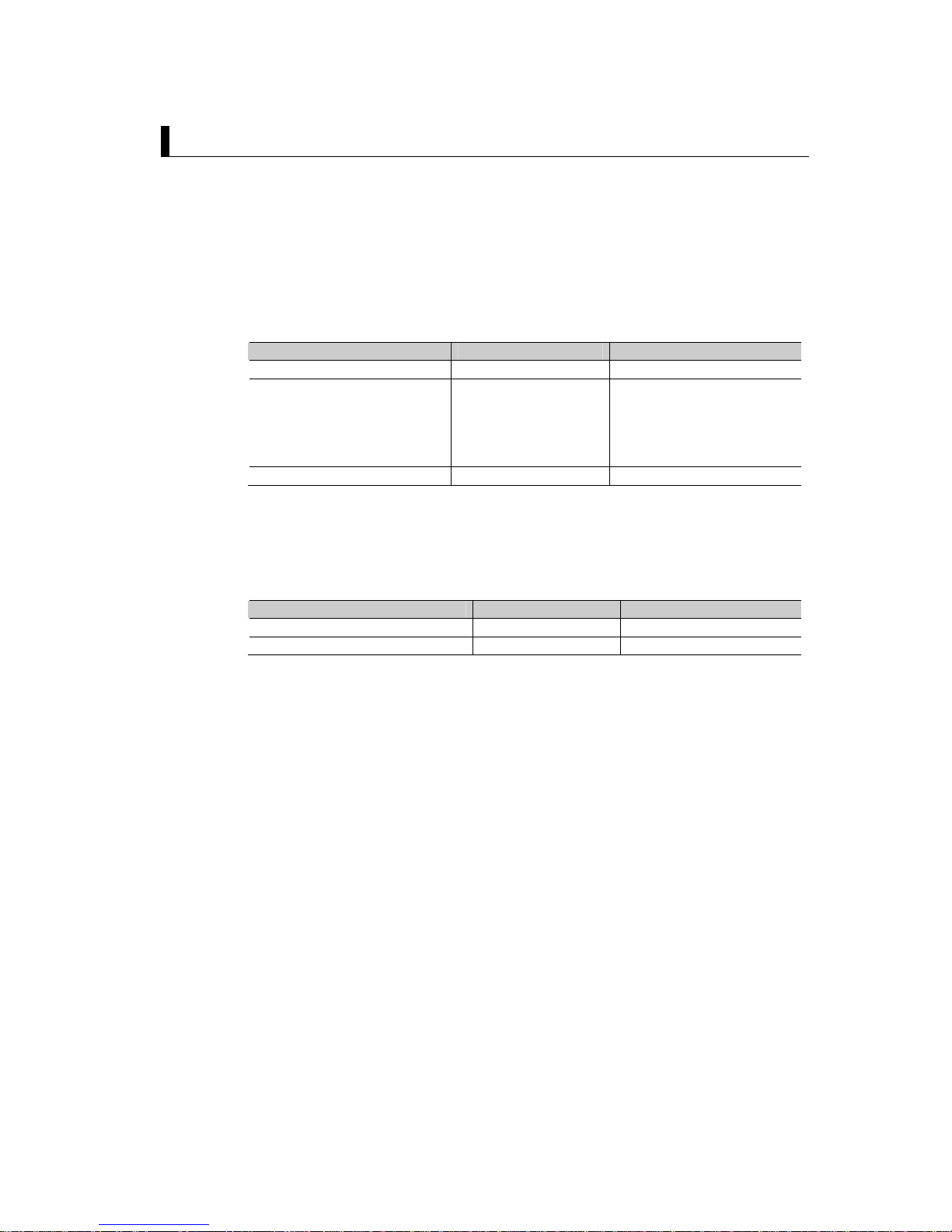

System Configuration

This section uses the following example to describe how to access the

G9SP-series Controller by performing serial communications through a

RS-232C Serial Comm- unications Board (CP1W-CIF01) from a Mitsubishi

Electric Standard PLC Q series.

MELSEC-Q

series

Serial

Communication

Module

G9SP-series

No-protocol

Mitsubishi Standard PLC(See Note.)

CP1W

-

CIF01

Option Board

Note:

This example uses the following Mitsubishi Electric Standard PLC.

Product Model/version

CPU Unit (Standard PLC) Q02HCPU

Serial Communication Module

QJ71C24N-R2

Support Software (for setup and creating ladder

programs)

GX Developer Version 8.90U

GX Configurator-SC Version2.21X

G9SP-series Controller Settings

Settings are not required. Make the communications settings in the Mitsubishi

Electric Standard PLC to match the serial communications specifications of the

G9SP-series Controller.

Page 14

2-4

Mitsubishi Electric PLC Q series Settings

Set serial communication module CH2 as given below in the PLC parameter using

the GX Developer and CH2 No-protocol system setting using the intelligent

function utility.

z PLC parameter settings

Set serial communication module CH2 as given below in the PLC parameter by

selecting[Project data list]-[Parameter]-[PLC parameter]-[I/O assignment].

Parameter Description Set value for this example

Communication protocol setting Communication protocol Non-procedure

Transmission setting Transmission setting Data bit :8bits

Parity bit :Yes

Odd/even parity:Even

Stop bit :1bit

Sum check code :No

Communication rate setting Baud rate 9600bps

z Intelligent function utility settings

Set serial communication module CH2 as given below in the CH2 Non procedure

system setting by selecting [Tools]-[Intelligent function utility]-[Start].

Parameter Description Set value for this example

Received data count designation Received data count 00C7(199bytes)

Receive complete code designation Receive complete code FFFF(Not desig nated)

Page 15

2 - 2 RS-232C Serial Communications

2-5

2

Connecting to Mitsubishi Electric PLCs

Communications cable

The suited cable is different according to the combination of component. Please

produce the cable of the following connecting wires when connecting with a

Mitsubishi Electric Standard PLC Q series (QJ71C24N-R2).

G9SP-series

RS-232C Serial Communications

Board

Mitsubishi Electric Q series

serial communication module

Connector Signal Pin No.

Pin No. Signal Connector

FG 1 1 CD

SD 2 2 RD

RD 3 3 SD

RS 4 4 ER

CS 5 5 SG

5V 6 6 DR

DR 7 7 RS

ER 8 8 CS

D-Sub

male

9-pin

SG 9 9 RI

D-Sub

male

9-pin

Sample Ladder Programming for Mitsubishi Electric PLC Q series

This section provides an example of programming to monitor Safety Input terminal

data of a G9SP-series Controller from a Mitsubishi Electric Standard PLC Q

series.

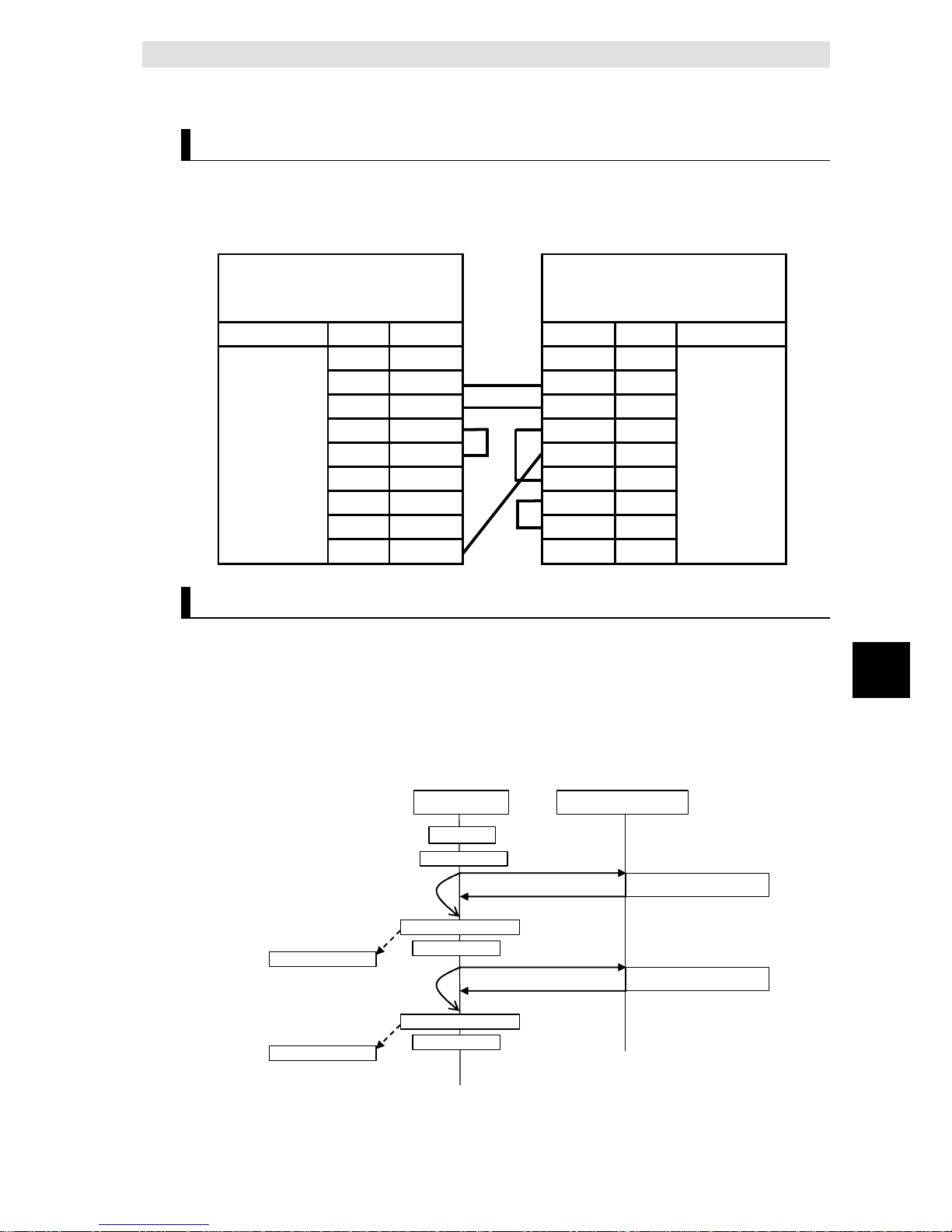

z RS-232C Serial Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

Standard PLC.

Standard PLC G9SP-series Controller

Send processing

Initialization

Send/receive processing

Send/receive processing

Sent command

Reception response

Sent command

Reception response

Receive processing

Send processing

Receive processing

Send processing

Receive processing

after 300 ms

Receive processing

after 300 ms

Receive End

Receive End

Page 16

2-6

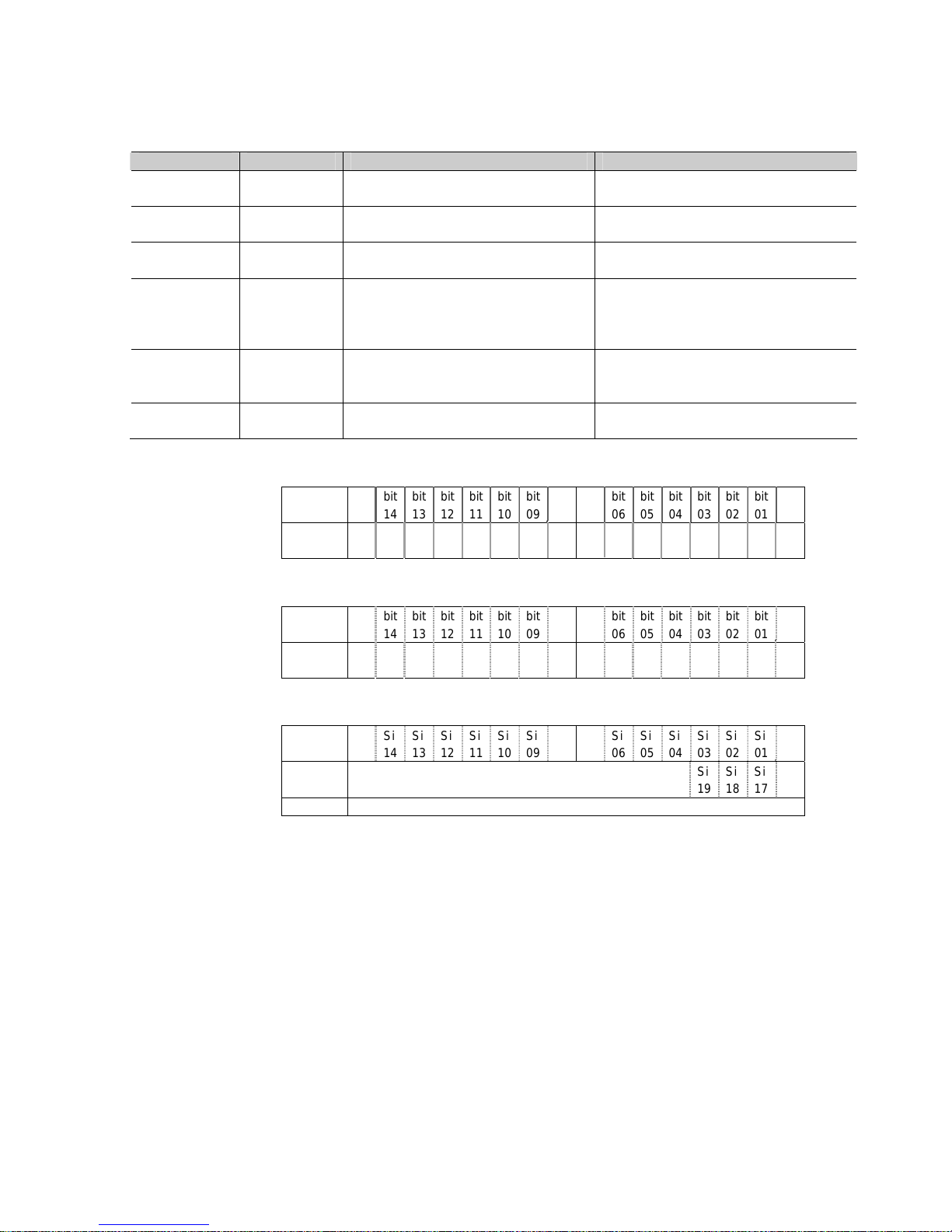

z Mitsubishi Electric Standard PLC Q series Memory Allocations

Start address End address Contents Description

D11 D20 RS-232C send command Data sent by the Standard PLC to the

G9SP-series Controller

D110 D209 RS-232C reception response Data received by the Standard PLC from

the G9SP-series Controller

D330 D351 Checksum calculation work area Work area for RS-232 C communications.

Used to calculate the check-sum

X100 X11F G9SP communications reception data

(written to G9SP-series Controller)

Data written to G9SP-series Controller from

Standard PLC. Stored in the communications reception data of the G9SP-series

Controller.

Y200 Y21F G9SP communications transmission data

(read from the G9SP-series Controller)

Communications data sent from the G9SPseries Controller is read.

Y220 Y24F G9SP Safety Input terminal data (read

from the G9SP-series Controller)

Safety Input terminal data of the G9SPseries Controller is read.

- G9SP Communications Reception Data

15 8 7 0

X100 bit

15

bit

14

bit13bit12bit11bit10bit09bit08bit07bit06bit05bit

04

bit

03

bit

02

bit01bit

00

X110 bit

31

bit

30

bit29bit28bit27bit26bit25bit24bit23bit22bit21bit

20

bit

19

bit

18

bit17bit

16

- G9SP Communications Transmission Data

15 8 7 0

Y200 bit

15

bit

14

bit13bit12bit11bit10bit09bit08bit07bit06bit05bit

04

bit

03

bit

02

bit01bit

00

Y210 bit

31

bit

30

bit29bit28bit27bit26bit25bit24bit23bit22bit21bit

20

bit

19

bit

18

bit17bit

16

- G9SP Safety Input Terminal Data

15 8 7 0

Y220 Si

15

Si

14 Si13Si12Si11Si10Si09Si08Si07Si06Si05

Si

04

Si

03

Si

02 Si01Si00

Y230 Reserved Si

19

Si

18 Si17Si16

Y240 Reserved

Page 17

2 - 2 RS-232C Serial Communications

2-7

2

Connecting to Mitsubishi Electric PLCs

z Sample Ladder Programming

- From Initial Settings to Cyclic Send/Receive

Initial Settings

Reception processing

Send processing

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Page 18

2-8

- Reception completion processing

Reception complet io n pro ce ss i n g

(9)

(10)

Page 19

2 - 2 RS-232C Serial Communications

2-9

2

Connecting to Mitsubishi Electric PLCs

- Checksum Calculation Subroutine

Step Description

(1) The fixed portion of the send command is set. This processing is performed once at

startup.

(2) A communications refresh timer of 300 ms is started. This performs the first sending after

300 ms.

(3) Once 300 ms has elapsed, the RS-232C reception end bit (X0A) is checked, and receive

processing is performed if data has been received. A send command from the Standard

PLC is initially required, and so reception processing is performed after completing the

first send.

(4) To store the reception response in D100, the INPUT instruction is executed.

(5) G9SP communications reception data is set to the send command from X 100 and echo

back bit.

(6) The send command is transferred to the RS-232C send port, which enables sending to

the G9SP-series Controller.

(7) The checksum and the end code are set to the transmission command.The send

command is transferred to the RS-232C send port, which enables sending to the

G9SP-series Controller.

(8) The timer is restarted and the next receive processing is performed after 300 ms.

(9) The checksum calculation subroutine given above is called, and the checksum of the

reception response is calculated.

(10) The checksum of the reception response and the end code are checked, and the G9SP

Communications Transmission Data is copied to Y 200 and G9SP Safety Input Terminal

Data is copied to Y 220.

Page 20

2-10

2 - 2 - 3 Application Example 2(Connecting to the Mitsubishi Standard

PLC FX Series.)

System Configuration

This section uses the following example to describe how to access a G9SP-series

Controller by performing serial communications through a RS-232C Serial

Communications Board (CP1W-CIF01) from a Siemens Standard PLC FX series.

MELSEC-FX

series

Communi

cation

Adapter

G9SP-series

Non procedure

Mitsubishi Standard PLC(See Note.)

CP1W

-

CIF01

Option Board

Note:

This example uses the following Mitsubishi Electric Standard PLC.

Product Model/Version

CPU Unit (Standard PLC) FX3UC-32MT-LT

RS-232C Communication Adapter FX3U-232AP

Support Software (for setup and creating ladder

programs)

GX Developer Version 8.90U

G9SP-series Controller Settings

Settings are not required. Make the communications settings in the Mitsubishi

Electric Standard PLC to match the serial communications specifications of the

G9SP-series Controller.

Mitsubishi Electric PLC FX series Settings

Set RS-232C communication adapter CH1 as given below in the PLC parameter

using the GX Developer.

z PLC parameter settings

Set RS-232C communication adapter CH2 as given below in the PLC parameter

by selecting[Project data list]-[Parameter]-[PLC parameter]-[PLC System(2)].

Parameter Description Set value for this

example

Protocol Communication protocol Non-procedural

Data length 8bit

Parity Even

Stop bit

Transmission setting

1bit

Transmission Speed Baud rate 9600

Header Set the header. Yes

H/W Type Normally choose RS-232 or

RS-485.

Regular/RS232C

Transmission control

procedure

Choose format 1/format 4. Form1(without

CR,LF)

Time out judge time Set the time-out period. 30(300msec)

Page 21

2 - 2 RS-232C Serial Communications

2-11

2

Connecting to Mitsubishi Electric PLCs

Communications cable

The suited cable is different according to the combination of component. Please

produce the cable of the following connecting wires when connecting with a

Mitsubishi Electric Standard PLC FX series.

G9SP-series

RS-232C Serial Communications

Board

Mitsubishi Electric FX series

RS-232 communication adapter

Connector Signal Pin No.

Pin No. Signal Connector

FG 1 1 CD

SD 2 2 RD

RD 3 3 SD

RS 4 4 ER

CS 5 5 SG

5V 6 6 DR

DR 7 7

ER 8 8

D-Sub

male

9-pin

SG 9 9

D-Sub

male

9-pin

Page 22

2-12

Sample Ladder Programming for Mitsubishi Electric PLC FX series

This section provides an example of programming to monitor Safety Input terminal

data of a G9SP-series Controller from a Mitsubishi Electric Standard PLC FX

series.

z RS-232C Serial Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

tandard PLC.

Standard PLC

G9SP-series Controller

Sent command

Reception response

Receive processing

after 300 ms

Send/Receive processing

Initialization

Send processing

Receive processing

Send processing

Sent command

Reception response

Send/Receive processing

Receive processing

Send processing

Receive processing

after 300 ms

z Mitsubishi Electric Standard PLC FX series Memory Allocations

Start address End address Contents Description

D100 D108 RS-232C send command Data sent by the Standard PLC to the

G9SP-series Controller

D200 D298 RS-232C reception response Data received by the Standard PLC from

the G9SP-series Controller

D330 D336 Checksum calculation work area Work area for RS-232C communications.

Used to calculate the check-sum

X100 X11F G9SP communications reception data

(written to G9SP-series Controller)

Data written to G9SP-series Controller from

Standard PLC. Stored in the communications reception data of the G9SP-series

Controller.

Y200 Y21F G9SP communications transmission

data (read from the G9SP-series Controller)

Communications data sent from the G9SPseries Controller is read.

Y220 Y24F G9SP Safety Input terminal data (read

from the G9SP-series Controller)

Safety Input terminal data of the G9SPseries Controller is read.

Page 23

2 - 2 RS-232C Serial Communications

2-13

2

Connecting to Mitsubishi Electric PLCs

- G9SP Communications Reception Data

15 8 7 0

X100 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

X110 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Communications Transmission Data

15 8 7 0

Y200 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

Y210 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Safety Input Terminal Data

15 8 7 0

Y220 Si

15 Si14Si13Si12Si11Si10Si09Si08Si07Si06

Si

05

Si

04

Si

03

Si 02Si01Si

00

Y230 Reserved Si

19

Si 18Si17Si

16

Y240 Reserved

z Sample Ladder Programming

- From Initial Settings to Cyclic Send/Receive

Initial Settings

(1)

Page 24

2-14

(6)

(2)

(3)

(4)

(5)

(7)

(8)

(9)

(10)

(11)

Reception processing

Send processing

Page 25

2 - 2 RS-232C Serial Communications

2-15

2

Connecting to Mitsubishi Electric PLCs

- Checksum Calculation Subroutine

Step Description

(1) The fixed portion of the send command is set. This processing is performed once at startup.

(2) A communications refresh timer of 300 ms is started. This performs the first sending after

300 ms.

(3) To execute the sending and receiving of the RS232C port, the RS instruction is executed.

(4) Once 300 ms has elapsed, to execute the transmission processing, the pulse is set to M0.

(5) Once 300 ms has elapsed, the RS-232C reception end bit (M8123) is checked, and receive

processing is performed if data has been received. A send command from the Standard

PLC is initially required, and so reception processing is performed after completing the first

send.

(6) The checksum calculation subroutine given above is called, and the checksum of the

reception response is calculated.

(7) The checksum of the reception response and the end code are checked, and the G9SP

Communications Transmission Data is copied to Y200 and G9SP Safety Input Terminal

Data is copied to Y220.

(8) G9SP communications reception data is set to the send command from X 100.

(9) The checksum calculation subroutine given above is called, and the checksum of the

transmission command is calculated.

(10) The checksum are set to the transmission command.The send command is transferred to

the RS-232C send port, which enables sending to the G9SP-series Controller.

(11) The timer is restarted and the next receive processing is performed after 300 ms.

Page 26

2-16

2 - 3 Ethernet Communications

This section provides a description and example of connection to a Mitsubishi

Electric Standard PLC. The FINS/UDP Protocol are available for connection with a

Mitsubishi Electric Standard PLC.

2 - 3 - 1 Communications Format

Refer to Section 7 Communications with a Standard PLC Using an Option Board of

the G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

2 - 3 - 2 Application Example

System Configuration

This section uses the following example to describe how to access the

G9SP-series Controller by performing Ethernet communications through a

Ethernet Communica- tions Board (CP1W-CIF41) from a Mitsubishi Electric

Standard PLC Q series.

Q002

Ethernet

Interface

Unit

G9SP Series

FINS/UDP

Mitsubishi Standard PLC(See Note.)

Option Board

CP1W-CIF41

192.168.250.18

192.168.250.11

Switching HUB

Note:

This example uses the following Mitsubishi Electric Standard PLC.

Product Model/Version

CPU Unit (Standard PLC) Q02HCPU

Ethernet Interface Unit QJ71E71-100

Support Software (for setup and creating ladder

programs)

GX Developer Version 8.90U

Page 27

2 - 3 Ethernet Communications

2-17

2

Connecting to Mitsubishi Electric PLCs

G9SP-series Controller Settings

Make the settings for TCP/IP in the system settings of the G9SP Configurator.

These settings are set in the G9SP-series Controller and Ethernet Option Board when the

configuration data is downloaded.

Parameter Description Set value for this

example

IP address

IP address of Ethernet Option Board.

Default value: 192.168.250.1

192.168.250.11

Subnet mask

Subnet mask of Ethernet Option Board.

Default value: 255.255.255.0

No change is

required.

Default gateway

Set the IP address of the default gateway.

Default value: 0.0.0.0 (IP routing not supported)

No change is

required.

FINS node address

Set the FINS node address of the Ethernet Option Board. If

automatic setting is specified, a value that matches the

rightmost byte of the IP address is stored.

Default value: Automatic (matching the rightmost byte of the

IP address)

Setting range: 1 to 254

No change is

required.

FINS/UDP port

Specify the UDP port number that is specified in the FINS

communications service. The UDP port number is a number

used by UDP to identify the application layer (here, the FINS

communications service).

Default value: 0 (9600)

Setting range: 0 to 65535. When set to 0, the FINS/UDP port

number is 9600.

No change is

required.

IP address table

Set the table that defines correspondence between the FINS

node address and IP address at the Standard PLC.

Set the IP address table when IP routing is used.

No change is

required.

Page 28

2-18

Mitsubishi Electric PLC Q series Settings

Set the Ethernet Intarface Unit as given below in the network parameter of the

Ethernet port using the GX Developer.

z Network parameters : Setting the number of Ethernet/CC IE/MELSECNET cards

Set the setting the number of Ethernet/CC IE/MELSECNET cards by selecting

[Project data list]-[Parameter] – [Network param] – [Ehternet/CC IE/MELSECNET].

Parameter Description Set value for this example

Network type Select installed unit Ethernet

Starting I/O No. Set a top address of unit 0000

Network No. Set a network number of unit 1

Group No. Set a group number of unit 1

Station No. Select a station number of unit 1

Mode Select a operation mode of unit On line

z Operation Settings

Set the setting the Ethernet operations by selecting [Project data list]-[Parameter]

– [Network param] – [Ehternet/CC IE/MELSECNET] – [Operation Settings].

Parameter Description Set value for this example

IP Address IP address of QJ71E7 1-100. 192.168.250.18

Page 29

2 - 3 Ethernet Communications

2-19

2

Connecting to Mitsubishi Electric PLCs

z Open Settings

Set the setting the Ethernet operations by selecting [Project data list]-[Parameter]

– [Network param] – [Ehternet/CC IE/MELSECNET] – [Open Settings].

Parameter Description Set value for this example

Protocol Set a communication protocol UDP

Fixed buffer

communication

procedure

Select a communicatin procedure using

fixed buffer

No procedure

Paring open Select a paring open Enable

Existence

confirmation

Select an existence confirmation Confirm

Host station Port No. Set a port number of the host station 2580

Transmission target

device IP address

Set an IP address of the transmission

target device

192.168.250.11

Transmission target

device Port No.

Set a por number of the transmission

target device

2580

Communication cable

The Ethernet Option Board is connected with a switching HUBs by using the

twisted-pair cable that applies the modular connector of the RJ45 form to both

ends. Either of category 3, 4, 5 or 5e UTP cable (Unshield twist pair cable), or STP

cable (Shield twist pair cable) is available.

Page 30

2-20

Sample Ladder Programming for Mitsubishi Electric PLC Q series

This section provides an example of programming to monitor Safety Input terminal

data of a G9SP-series Controller from a Mitsubishi Electric Standard PLC Q

series.

z Ethernet Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

Standard PLC.

Standard PLC G9SP-series Controller

Send processing

Initialization

Send/receive processing

Send/receive processing

Sent command

Reception response

Sent command

Reception response

Receive processing

Send processing

Receive processing

Send processing

Receive processing

after 300 ms

Receive processing

after 300 ms

Receive End

Receive End

z Mitsubishi Electric Standard PLC Q series Memory Allocations

Start address End address Contents Description

D300 D312 Ethernet send command Data sent by the Standard PLC to the G9SP-series

Controller.

D500 D603 Ethernet reception response Data received by the Standard PLC from the G9SP-

series Controller.

D3000 - BUFSND instruction control

data

Control data for the BUFSND instruction is stored.

D5000 - BUFRCV instruction control

data

Control data for the BUFRCVinstruction is stored.

X100 X11F G9SP communications rece-

ption data (written to G9SPseries Controller)

Data written to G9SP-series Controller from Standard

PLC. Stored in the communications reception data of the

G9SP-series Controller.

Y200 Y21F G9SP communications

transmission data (read from

the G9SP-series Controller)

Communications data sent from the G9SP-series

Controller is read.

Y220 Y24F G9SP Safety Input terminal

data (read from the G9SPseries Controller)

Safety Input terminal data of the G9SPseries

Controller is read.

Page 31

2 - 3 Ethernet Communications

2-21

2

Connecting to Mitsubishi Electric PLCs

-

- G9SP Communications Reception Data

15 8 7 0

X100 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

X110 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Communications Transmission Data

15 8 7 0

Y200 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

Y210 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Safety Input Terminal Data

15 8 7 0

Y220 Si

15 Si14Si13Si12Si11Si10Si09Si08Si07Si06

Si

05

Si

04

Si

03

Si 02Si01Si

00

Y230 Reserved Si

19

Si 18Si17Si

16

Y240 Reserved

z Sample Ladder Programming

- From Initial Settings to Cyclic Send/Receive

Initialization

(1)

(2)

(3)

Page 32

2-22

Send processing

Reception processing

(5)

(6)

(7)

(8)

(9)

(4)

Reception completion processing

Step Description

(1) The fixed portion of the connection process is set. This processing is performed once at startup.

(2) The connection is open after the initialization process is completed.

(3) A communications refresh timer of 300 ms is started. This performs the first sending after 300 ms.

(4)

Once 300 ms has elapsed, the reception completion bit (M40) is checked, and receive

processing is performed if data has been received. A send command from the Standard PLC is

initially required, and so reception processing is performed after completing the first send.

(5) Set the FINS data to the sending command.

(6) Set the “G9SP communication reception data” to X100 of sending command and set the “Echo back

bit” and transfer to Ethernet port. By this flow, the sending command is transfered to the G9SP series.

(7) The timer is restarted and the next receive processing is performed after 300 ms.

(8) The ZB.BUFRCV instruction is executed because the reception response is stored to D500.

(9) The checksum of the reception response and the end code are checked, and the G9SP Comm-

unications Transmission Data is copied to Y200 and G9SP Safety Input Terminal Data is copied to

Y220.

Page 33

This section describes how to perform communications with a Siemens Standard

PLC through an RS-232C Option Board or Ethernet Option Board.

3 - 1 Functionality................................................................................................... 3-2

3 - 2 RS-232C Serial Communications..................................................................... 3-3

3 - 2 - 1 Communications Format ..................................................................3-3

3 - 2 - 2

Application Example.........................................................................3-3

3 - 3 Ethernet Communications............................................................................3-11

3 - 3 - 1 Communications Format ................................................................3-11

3 - 3 - 2

Application Example.......................................................................3-11

Connecting to Siemens PLCs

Page 34

3-2

3 - 1 Functionality

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

Page 35

3 - 2 RS-232C Serial Communications

3-3

3

Connecting to Siemens PLCs

3 - 2 RS-232C Serial Communications

This section provides a description and example of connection to a Siemens Standard PLC.

Freeport protocol communications are used for connection with a Siemens Standard PLC.

3 - 2 - 1 Communications Format

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

3 - 2 - 2 Application Example

System Configuration

This section uses the following example to describe how to access a G9SP-series Controller

by performing serial communications through a RS-232C Serial Communications

Board (CP1W-CIF01) from a Siemens Standard PLC.

S7-200 series PLC

RS-232

p

ort

G9SP-series

Controller

Freeport protocol

Siemens Standard PLC(See Note.)

CP1W

-

CIF01

Option Board

Note: This example uses the following Siemens Standard PLC.

Product Model/version

CPU Unit (Standard PLC) S7-200 CPU 224XP

Support Software (for setup and

creating ladder programs)

STEP 7-Micro/WIN V4.0.5.08

G9SP-series Controller Settings

Settings are not required. Make the communications settings in the Siemens Standard PLC

to match the serial communications specifications of the G9SP-series Controller.

Page 36

3-4

Siemens PLC Settings

Set serial port 1 as given below in the Ladder using the STEP 7-Micro/WIN.

Parameter Description Set value for this

example

Freeport

Control

Registers

Control Freeport

communication for

serial port

Please set SMB130 to $49.

SMB130 Bit Format

MSB LSB

7 6 5 4 3 2 1 0

P D B M

P:Parity(0 1=Even parity)

D:Data bits(0=8 data bits per character)

B:Baud rate(0 1 0=9600bps)

M:Protocol(0 1=Freeport protocol)

Communications cable

The suited cable is different according to the combination of component. Please use the

RS-232/PPI Multi-Master cable when connecting with RS-232C port of a Siemens Standard

PLC.

G9SP-series

RS-232C Serial Communications

Board

Siemens S7-200-series

RS-232 port

Connector Signal Pin No. Pin No. Signal Connector

FG 1 1 CD

SD 2 2 RD

RD 3 3 SD

RS 4 4 ER

CS 5 5 SG

5V 6 6 DR

DR 7 7 RS

ER 8 8 CS

D-Sub

male

9-pin

SG 9 9 RI

D-Sub

male

9-pin

Page 37

3 - 2 RS-232C Serial Communications

3-5

3

Connecting to Siemens PLCs

Sample Ladder Programming for Siemens PLC

This section provides an example of programming to monitor Safety Input terminal data of a

G9SP-series Controller from a Siemens Standard PLC.

z RS-232C Serial Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

Standard PLC.

Standard PLC G9SP-series Controller

Sent command

Reception response

Send processing

after 300 ms

Send processing

Send/receive processing

Initialization

Receive processing

Sent command

Reception response

Send/receive processing

Send processing

Send processing

Send processing

after 300 ms

Receive processing

Page 38

3-6

z Siemens PLC Memory Allocations

Start address End address Contents Description

V0 V19 RS-232C send command Data sent by the Standard PLC to the

G9SP-series Controller

V100 D299 RS-232C reception response Data received by the Standard PLC from

the G9SP-series Controller

M0 M7 Checksum calculation work area Work area for RS-232C communications.

Used to calculate the check-sum

I0 I3 G9SP communications reception data

(written to G9SP-series Controller)

Data written to G9SP-series Controller from

Standard PLC. Stored in the communications reception data of the G9SP-series

Controller.

Q0 Q3 G9SP communications transmission

data (read from the G9SP-series Controller)

Communications data sent from the G9SPseries Controller is read.

Q4 Q9 G9SP Safety Input terminal data (read

from the G9SP-series Controller)

Safety Input terminal data of the G9SPseries Controller is read.

- G9SP Communications Reception Data

15 8 7 0

I0-I1 bit

15

bit

14

bit13bit12bit11bit10bit09bit08bit07bit06bit05bit

04

bit

03

bit

02

bit01bit

00

I2-I3 bit

31

bit

30

bit29bit28bit27bit26bit25bit24bit23bit22bit21bit

20

bit

19

bit

18

bit17bit

16

- G9SP Communications Transmission Data

15 8 7 0

Q0-Q1 bit

15

bit

14

bit13bit12bit11bit10bit09bit08bit07bit06bit05bit

04

bit

03

bit

02

bit01bit

00

Q2-Q3 bit

31

bit

30

bit29bit28bit27bit26bit25bit24bit23bit22bit21bit

20

bit

19

bit

18

bit17bit

16

- G9SP Safety Input Terminal Data

15 8 7 0

Q4-Q5 Si

15

Si

14 Si13Si12Si11Si10Si09Si08Si07Si06Si05

Si

04

Si

03

Si

02 Si01Si00

Q6-Q7 Reserved Si

19

Si

18 Si17Si16

Q8-Q9 Reserved

Page 39

3 - 2 RS-232C Serial Communications

3-7

3

Connecting to Siemens PLCs

z Sample Ladder Programming

- Initial Settings(MAIN)

Initial Settings

(1)

(2)

Page 40

3-8

- Send processing(INT_1)

1

1

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Page 41

3 - 2 RS-232C Serial Communications

3-9

3

Connecting to Siemens PLCs

- Reception processing(INT_1)

(10)

(11)

- Send end processing(INT_2)

(12)

Page 42

3-10

- Checksum Calculation Subroutine

Step Description

(1) Control Freeport communication for port1 This processing is performed once at startup.

(2) Enables the 150ms-timer event, receive complete event and send complete even. This processing is performed

once at startup.

(3) Once 100 ms has elapsed,to process each 300ms the counter is added

(4) Once 300 ms has elapsed, enables receive complete event.

(5) Once 300 ms has elapsed, the fixed portion of the send command is set.

(6) G9SP communications reception data is set to the send command from I 0.

(7) The checksum calculation subroutine given above is called, and the checksum of the send command is calculated.

(8) The checksum and the end code are set to the transmission command.The send command is transferred to the

RS-232C send port, which enables sending to the G9SP-series Controller.

(9) The timer is restarted and the next send processing is performed after 300 ms.

(10) The checksum calculation subroutine given above is called, and the checksum of the reception response is

calculated.

(11) The checksum of the reception response and the end code are checked, and the G9SP Communications

Transmission Data is copied to Q 0 and Q 3 and G9SP Safety Input Terminal Data is copied to Q 4 to Q 9.

(12) After the transmission is completed, the reception interruption is enabled.

Page 43

3 - 3 Ethernet Communications

3-11

3

Connecting to Siemens PLCs

3 - 3 Ethernet Communications

This section provides a description and example of connection to a Siemens

Standard PLC. Connection can be performed to an Siemens Standard PLC

using the FINS/UDP protocol.

Note: Only CP1W-CIF41 Ethernet Option Boards with unit version 2.0 or later can be used.

If another Option Board is used, the G9SP-series Controller will detect an Unsupported Option Board Error (the MS indicator will flash red).

3 - 3 - 1 Communications Format

Refer to Section 7 Communications with a Standard PLC Using an Option Board of the

G9SP Series Safety Controller Operation Manual (Cat. No. Z922).

3 - 3 - 2 Application Example

System Configuration

This section uses the following example to describe how to access the G9SP-series

Controller from a Standard PLC by performing Ethernet communications through an

Ethernet Communications Board (CP1W-CIF41).

S7-300

Ethernet

Interface

Unit

G9SP-series Controller

FINS/UDP

Siemens Standard PLC(See Note)

CP1W-CIF41

Option Board

192.168.250.1

192.168.250.2

Switching HUB

Note: This example uses the following Siemens Standard PLC.

Product Model/version

CPU Unit (Standard PLC) S7-300 CPU315-2 DP

Ethernet Interface Unit CP343-1

Support Software (for setup and creating

ladder/Function Block programs)

STEP 7 V5.3+SP3

Page 44

3-12

G9SP-series Controller Settings

Make the settings for TCP/IP in the system settings of the G9SP Configurator.These

settings are set in the G9SP-series Controller and Ethernet Option Board

when the configuration data is downloaded.

Parameter Description Set value for this

example

IP address IP address of Ethernet Option Board.

Default value: 192.168.250.1

192.168.250.2

Subnet mask Subnet mask of Ethernet Option Board.

Default value: 255.255.255.0

No change is

required.

Default gateway Set the IP address of the default gate-

way. Default value: 0.0.0.0 (IP routing not supported)

No change is

required.

FINS node address Set the FINS node address of the Ethernet Option Board. If

automatic setting is specified, a value that matches the rightmost

byte of the IP address is stored.

Default value: Automatic (matching the

rightmost byte of the IP address)

Setting range: 1 to 254

No change is

required.

FINS/UDP port Specify the UDP port number that is specified in the FINS

communications service. The UDP port number is a number

used by UDP to identify the application layer (here, the FINS

communications service).

Default value: 0 (9600)

Setting range: 0 to 65535. When set to

0, the FINS/UDP port number is 9600.

No change is

required.

IP address table Set the table that defines correspondence between the FINS

node address and IP address at the Standard PLC.Set the IP

address table when IP routing is used.

No change is

required.

Page 45

3 - 3 Ethernet Communications

3-13

3

Connecting to Siemens PLCs

Siemens PLC Settings

Set the Ethernet port as shown below in the Hardware Configuration using the STEP7.

z Ethernet Interface unit settings

Set Ethernet interface unit as given below in the H/W Config by selecting [General] [Properties...].

Parameter Description Set value for this example

IP address IP address of the CP343-1 192.168.250.1

Subnet mask Subnet mask of the CP343-1 255.255.255.0

Communications cable

This is the connector used to connect the twisted-pair cable to the Ethernet.

• Electrical characteristics: Conforms to IEEE802.3 standards.

• Connector structure: RJ45 8-pin modular connector (conforms to ISO8877).

Page 46

3-14

Sample Ladder Programming for Siemens PLC

This section provides an example of programming to monitor Safety Input terminal data of a

G9SP-series Controller from a Siemens Standard PLC.

z Ethernet Communications Sequence

The G9SP-series Controller returns a response to the command sent from the

Standard PLC.

Standard PLC

G9SP-series Controller

Sent command

Reception response

Receive processing

after 300 ms

Send/Receive processing

Initialization

Send processing

Receive processing

Send processing

Sent command

Reception response

Send/Receive processing

Receive processing

Send processing

Receive processing

after 300 ms

z Siemens PLC Memory Allocations

Start address End address Contents Description

DB201.0 DB201.23 Ethernet send command Data sent by the Standard PLC to the

G9SP-series Controller

DB201.50 DB201.261 Ethernet reception response Data received by the Standard PLC from

the G9SP-series Controller

DB200.4.0 DB200.6.0 FC6 instruction control data Control data for the FC6 instruction is

stored.

DB200.4.0 DB200.6.0 FC5 instruction control data Control data for the FC5 instruction is

stored.

IW100 IW101 G9SP communications reception data

(written to G9SP-series Controller)

Data written to G9SP-series Controller from

Standard PLC. Stored in the communications reception data of the G9SP-series

Controller. (Refer to Operation Manual

7-1-3 Transmission/Reception Data.)

QW100 QW101 G9SP communications transmission

data (read from the G9SP-series Controller)

Communications data sent from the G9SPseries Controller is read. (Refer to Operation

Manual 7-1-3 Transmission/Reception Data.)

QW102 QW104 G9SP Safety Input terminal data (read

from the G9SP-series Controller)

Safety Input terminal data of the G9SPseries Controller is read. (Refer to Operation

Manual 7-1-3 Transmission/Reception Data.)

-

Page 47

3 - 3 Ethernet Communications

3-15

3

Connecting to Siemens PLCs

- G9SP Communications Reception Data

15 8 7 0

IW100 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

IW101 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Communications Transmission Data

15 8 7 0

QW100 bit

15

bit14bit13bit12bit11bit10bit09bit08bit07bit06bit

05

bit

04

bit

03

bit02bit01bit

00

QW101 bit

31

bit30bit29bit28bit27bit26bit25bit24bit23bit22bit

21

bit

20

bit

19

bit18bit17bit

16

- G9SP Safety Input Terminal Data

15 8 7 0

QW102 Si

15 Si14Si13Si12Si11Si10Si09Si08Si07Si06

Si

05

Si

04

Si

03

Si 02Si01Si

00

QW103 Reserved Si

19

Si 18Si17Si

16

QW104 Reserved

z Sample Ladder Programming

- DB200 Settings

Page 48

3-16

- Initial Settings

(1)

(2)

Page 49

3 - 3 Ethernet Communications

3-17

3

Connecting to Siemens PLCs

- Reception processing

1

1

(3)

(4)

Page 50

3-18

(5)

Page 51

3 - 3 Ethernet Communications

3-19

3

Connecting to Siemens PLCs

(5)

1

1

Page 52

3-20

- Send processing

(6)

(6)

1

1

1

1

1

1

Page 53

3 - 3 Ethernet Communications

3-21

3

Connecting to Siemens PLCs

(6)

(7)

1

1

Step Description

(1) A communications refresh timer of 300 ms is started. This performs the first sending after 300 ms.

(2) Once 300 ms has elapsed,send and receive processing is performed and the timer is restarted and

the next send and receive processing is performed after 300 ms

(3) Clear the receive area in preparation for the FC6 instruction. The reception size (#STAT15) is

checked, and receive processing is performed if data has been received. A send command from the

Standard PLC is initially required, and so reception processing is performed after completing the first

send.

(4) Once the data has been stored in the cleared receive area, check the size, and then start receive

processing.

(5) Copy G9SP Communications Transmission Data to QW 100 and QW 101 and G9SP Safety Input

Terminal Data to QW 102 to QW 104.

(6) The fixed portion of the send command is set.

(7) Once receive processing has been completed, set G9SP Communications Reception Data to the

send command from IW 100. The send command is sent to the Ethernet send port, which enables

sending to the G9SP-series Controller.

Loading...

Loading...