Power Relay

G2A

Highly Reliable, 4-pole Miniature Relay Ideal

for Sequence Control

• Card lift-off employed for greater life and stable quality.

• Long endurance and stable quality are assured by card lift-off

system.

• Mounting interchangeability with MY-series Relays.

• Operation indicator mechanism incorporated for at-a-glance

monitoring of ON/OFF operation. In addition, a built-in operation

indicator model is also included in this Relay Series.

Ordering Information

Classification Plug-in terminals/Solder terminals PCB terminals

Standard model G2A-432A G2A-4321P

Arc barrier equipped model G2A-432AY ---

Built-in diode model G2A-432A-D G2A-4321P-D

Built-in operation indicator model G2A-432A-N ---

Built-in operation indicator and diode model G2A-432A-N1 ---

UL-

approved

model

Standard model G2A-432A-US G2A-4321P-US

Arc barrier equipped model G2A-432AY-US ---

Note: 1. When placing your order, add the coil voltage rating listed in the specifications to the model number as shown below.

2. Built-in diode model and the operating coil of the G2A-432A-N1 are available only with DC ratings.

3. The Latching Relay (G2AK) and Fully sealed Relay (G2A-434A) developed based on the G2A are also available in this se ries.

Example: G2A-432A 100/110 VAC

Rated coil voltage

Model Number Legend

G2A-@@@@@-@

1. Number of Poles and Contact Form

2. Contact Type

3. Enclosure Construction

4. Terminal Shape

Note: 1. The coil of the G2A-432A-N1 or a built-in diode model operates with DC only.

1 2 3 4 5 6

5. Safety Breaking Mechanism

4: 4PDT

3: Crossbar bifurcated

2: Casing

A: Plug-in

1P: PCB

2. The G2A Series include the G2A-434A Power Relay and G2AK Latching Relay. Refer to page 133 for details.

3. Built-in indicator models satisfying international standards are available. Contact your OMRON representative for details.

None: No

Y: Arc barrier

6. Special Element

None: Standard

D: Built-in diode

N: Built-in operation indicator

N1: Built-in operation indicator and diode

US: UL-approved

Power Relay G2A 119

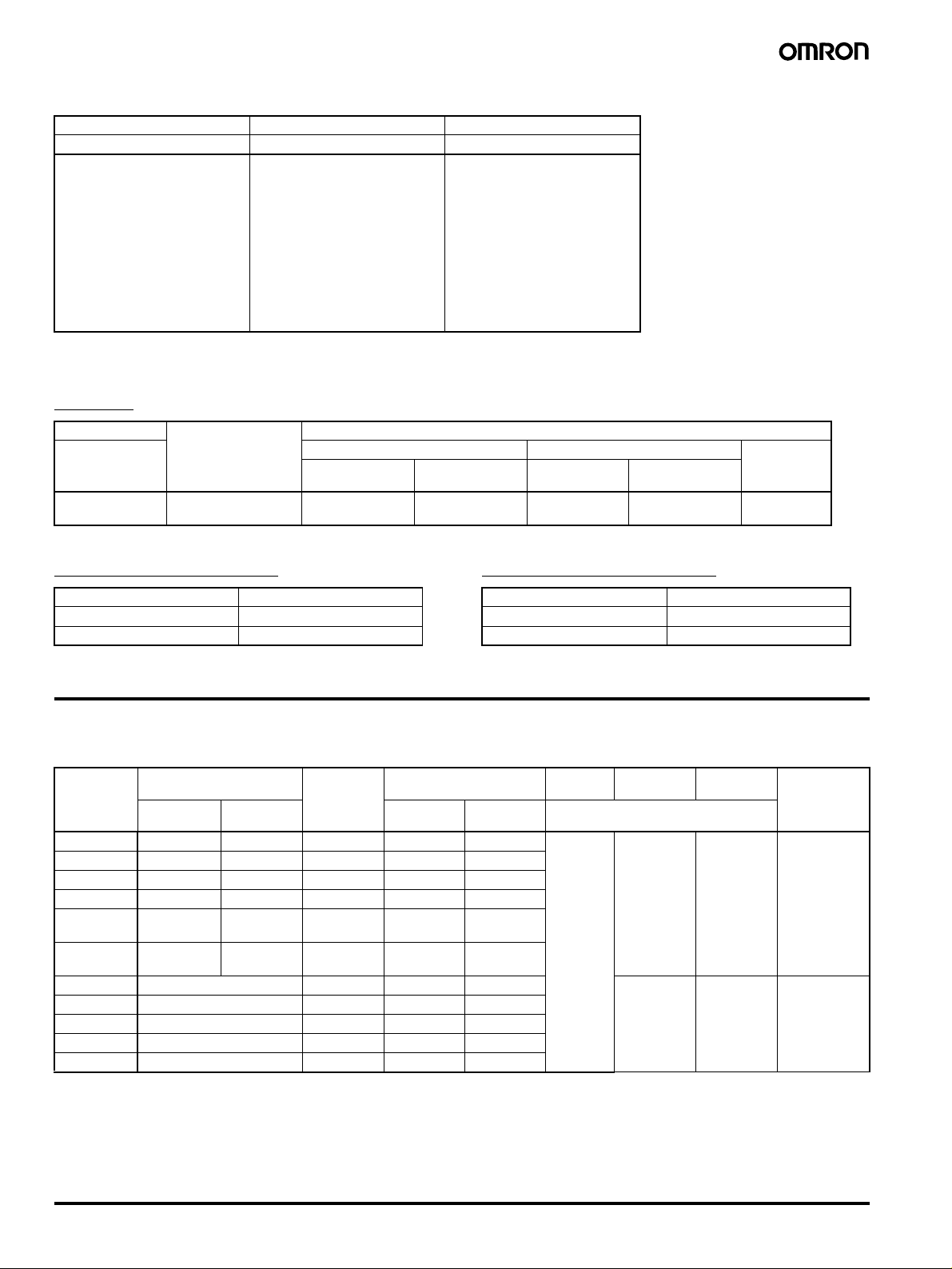

■ Relays Other than Standard Models

Arc barrier equipped Built-in diode Built-in operation indicator

G2A-432AY G2A-432A-D G2A-432A-N

The arc barrier equipped model is

a relay designed to prevent arc

short-circuiting between phases

and can be used in a circuit which

has potential difference between

phases. The switching power of

such a circuit with potential difference must be limited to less than

1/2 the rated load when using this

Relay.

The built-in diode model is a relay

which incorporates a diode for absorption of the reverse voltage

that may be generated when the

coil is de-energized. Because the

release time of this model is longer than the standard model, pay

adequate attention to this point in

designing a circuit. Also, pay attention to the + polarity of the coil.

The reverse-breakdown voltage

of the diode is 1,000 V.

The built-in operation indicator

model has a newly added operation indicator to the conventional

operation indication mechanism

and facilitates operation monitoring without being affected by ambient illumination.

With the -N model (rated at 16,

12, 24, and 48 VDC) and -N1

model rated at 6, 12, 24, 48, and

100 VDC), pay attention to the +

polarity of the coil.

■ Accessories

Sockets

Track mounting Front-connecting

Screw terminals Solder terminals Wire-wrap terminals PCB

PYF14A PYF14(-E), PYF14A-

Note: With monitor terminal.

Socket

TU, PYF14T

Without Hold-

down Clip

PY14, PY14-3

(see note)

With Hold-down

Clip

PY14-Y2 PY14QN(2) PY14QN(2)-Y2 PY14-0,

Without Hold-

down Clip

With Hold-down

Clip

terminals

PY14-02

Relay Hold-down Clips Socket Mounting Plates

For Front-connecting Socket PYC-A2

For Back-connecting Socket PYC-3/PYC-5

For Socket Mounting Plate PYC-2

For one Socket PYP-1

For 18 Sockets PYP-18

For 36 Sockets PYP-38

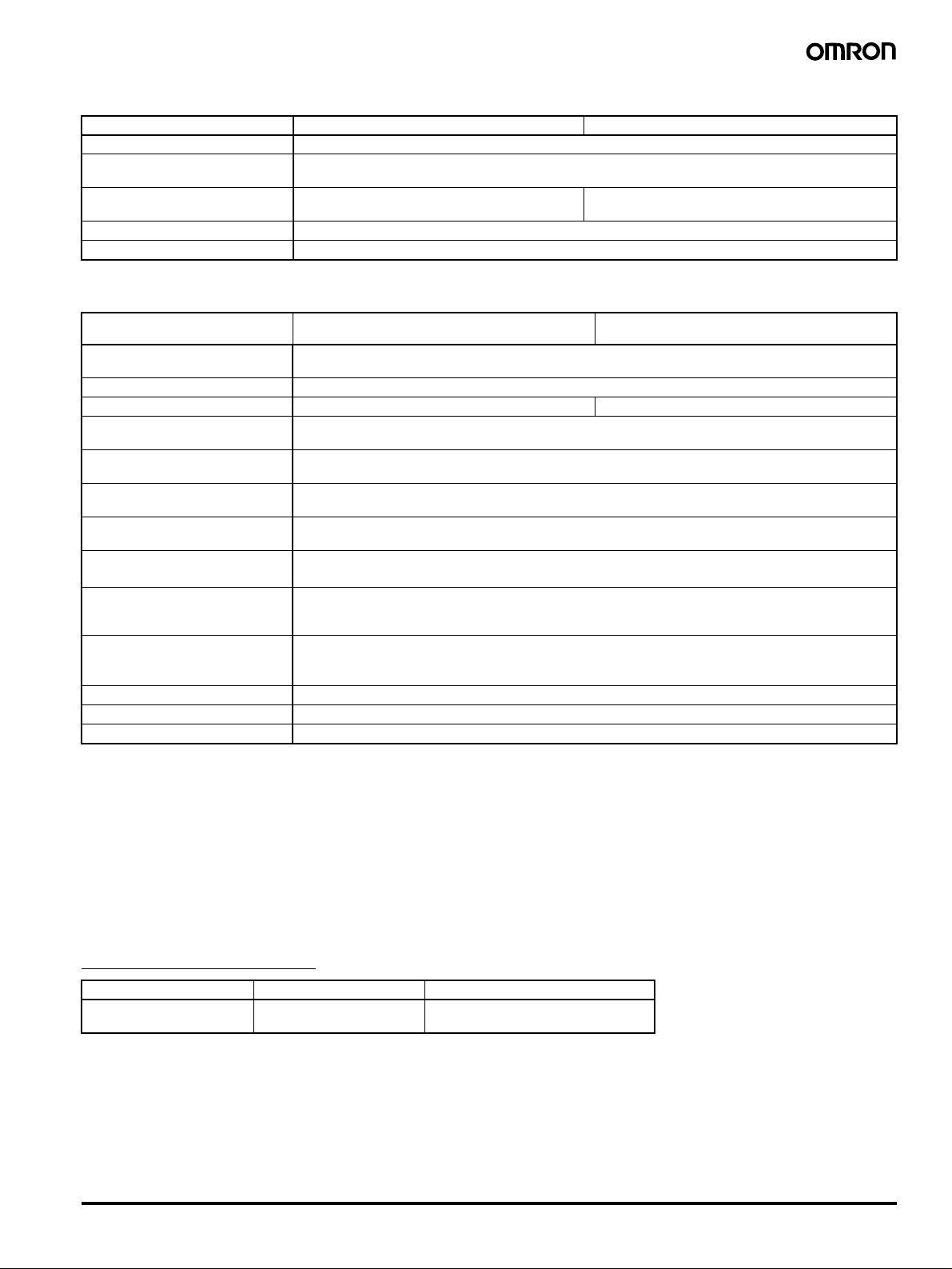

Specifications

■ Coil Ratings

The rated currents for some of the built-in operation indicator models differ from the values given in this table. Refer to note 5 below.

Rated

voltage

6 VAC 295 mA 233 mA 8.9

12 VAC 148 mA 117 mA 34

24 VAC 73 mA 58 mA 136

50 VAC 35 mA 28 mA 530

100/

110 VAC

200/

220 VAC

6 VDC 176 mA 34

12 VDC 88 mA 136

24 VDC 45 mA 530

48 VDC 22 mA 2,200

100 VDC 11.4 mA 8,800

Rated current Coil

50 Hz 60 Hz Armature

17.7/

21.4 mA

8.9/

10.8 mA

14/

16.8 mA

7/8.4 mA 8,800

resistance

Ω 0.048 H 0.065 H 80 % max. 30 % min. 110 % Approx. 1.4 VA

Ω 0.166 H 0.257 H

Ω 0.691 H 1.04 H

Ω 3.08 H 4.53 H

2,200

Ω 12.42/

12.38 H

Ω 42.2/

41.8 H

Ω 0.14 H 0.26 H 10 % min. 110 % Approx. 1.1 W

Ω 0.6 H 1.0 H

Ω 2.7 H 4.6 H

Ω 11 H 19 H

Ω 43 H 73 H

Coil inductance (ref.

value)

OFF

Armature

ON

18/16.4 H

72/65.5 H

Must

operate

Must

release

% of rated voltage

Max.

voltage

Power

consumption

Note: 1. The rated current and coil resistance are measured at a coil temperature of 23

±15% for DC coil resistance.

2. The AC coil resistance and coil inductance values are for reference only.

3. Performance characteristic data is measured at a coil temperature of 23

4. The maximum voltage is one that is applicable instantaneously to the Relay coil at an ambient temperature of 23

5. For built-in operation indicator models rated at 6, 12, and 24 VDC, add an LED current of approx. 5 mA to the rated currents.

°C with tolerances of +15%/–20% for AC rated current and

°C.

120 Power Relay G2A

°C and not continuously.

■ Contact Ratings

Load Resistive load (cosφ = 1) Inductive load (cosφ = 0.4) (L/R = 7 ms)

Contact type Crossbar bifurcated

Contact material Movable: AgAu-clad AgPd

Rated load 0.3 A at 110 VAC

Rated carry current 3 A

Max. switching power 250 VAC, 125 VDC

Fixed: AgPd

0.5 A at 24 VDC

0.2 A at 110 VAC

0.3 A at 24 VDC

■ Characteristics

Classification Standard/Acr barrier equipped/Built-in operation

Contact resistance

(see note 2)

Operate time (see note 3) 15 ms max.

Release time (see note 3) 15 ms max. 30 ms max.

Max. operating frequency Mechanical: 18,000 operations/hour

Insulation resistance

(see note 4)

Dielectric strength 1,500 VAC, 50/60 Hz for 1 min between coil and contacts and contacts of different polarities (700 VAC be-

Vibration resistance Destruction: 10 to 55 to 10 Hz, 0.75 mm single amplitude (1.5 mm double amplitude)

Shock resistance

Error rate (level P)

(Reference value)

(see note 6)

Endurance Mechanical: 100,000,000 operations min. (at operating frequency of 18,000 operations/hour)

Ambient temperature Operating:–10

Ambient humidity Operating:5% to 85%

Weight Approx. 38 g

Note: 1. The data shown above are initial values.

2. The contact resistance was measured with 0.1 A at 5 VDC using the voltage drop method.

3. The operate or release time was measured with the rated voltage imposed with any contact bounce ignored at an ambient temperature

of 23

°C.

4. The insulation resistance was measured with a 500-VDC megger applied to the same places as those used for checking the dielectric

strength.

5. The electrical endurance was measured at an ambient temperature of 23

6. This value was measured at a switching frequency of 60 operations per minute.

100 m

Electrical: 1,800 operations/hour (under rated load)

100 M

tween contacts of same polarity)

Malfunction: 10 to 55 to 10 Hz, 0.5 mm single amplitude (1.0 mm double amplitude)

Destruction: 1,000 m/s

Malfunction: 100 m/s

1 mA at 100 mVDC

Electrical: 5,000,000 operations min. (under rated load and at operating frequency of

indicator models (G2A-@-N)

Ω max.

Ω min. (at 500 VDC)

2

2

1,800 operations/hour) (see note 5)

°C to 40°C (with no icing or condensation)

°C.

Built-in diode/Built-in operation indicator models

(G2A-@-N1)

■ Approved by Standards

UL508 (File No. E41515)

Model Coil ratings Contact ratings

G2A-@-US 6 to 120 VAC

6 to 120 VDC

1 A 120 VAC (resistive load)

1 A 30 VDC (inductive load)

Power Relay G2A 121

Engineering Data

Maximum Switching Power Endurance

10,000

DC resistive load

5,000

24-VDC resistive load

AC resistive load

AC inductive load

(cosφ = 0.4)

Switching current (A)

DC inductive load

L/R = 7 ms

Switching voltage (V)

Ambient Temperature vs.

Must-operate and Must-release

Voltage

G2A AC (60 Hz)

Must-operate

Number of Relays: 5

Must-operate and reset voltage (%)

voltage

Must-release

voltage

3

1,000

500

100

50

Endurance (x10 operations)

10

Ambient Temperature vs.

Coil Temperature Rise

G2A 110 VAC (50 Hz)

Contact

Number of Relays: 5

°

Coil temperature rise ( C)

carry current

24-VDC

inductive load

L/R = 7 ms

110-VAC

resistive load

110-VAC

inductive load

cosφ = 0.4

Switching current (A)

Malfunctioning Shock

G2A-432A 100/110 VAC

Not energized

Energized

G2A DC

Number of Relays: 5

Must-operate and reset voltage (%)

Ambient temperature (°C)

Must-operate

voltage

Must-release

voltage

Ambient temperature (°C)

G2A DC

°

Coil temperature rise ( C)

Ambient temperature (°C)

Number of Relays: 5

Ambient temperature (°C)

Contact

carry current

Shock direction

Number of samples = 5

Measurement conditions: Impose a shock of

2

100 m/s

in the ±X, ±Y, and ±Z directions three

times each with the Relay energized and not

energized to check the shock values that cause

the Relay to malfunction.

Unit: m/s

2

122 Power Relay G2A

Contact Reliability

(JIS C 4530 Allen-Bradley Test Circuit)

100 VAC

λ60

= 0.00153 × 10

Ω

−

6

Carry contact

Break contact

Make contact

Self-holding

contact

24 VDC

λ60

Ω

= 0.00153 × 10

Contact Reliability

(Improved Allen-Bradley Test Circuit)

Contact load: 1 mA at 5 VDC (resistive load)

Failure criterion contact resistance: 100 Ω

−

−

6

Carry contact

Break contact

Make contact

Self-holding

contact

Ω

λ60

= 0.00153 × 10

6

Carry contact

Break contact

Make contact

Self-holding

contact

Contact resistance (m )

Operations (x 10

4

)

Contact resistance (m )

Operations (x 10

Coil Self-load Life Curve

(Unit: mA)

Model Specifications No. of Relays

123510

G2A-432A 100 VAC, 60 Hz 14 28 42 70 140

24 VDC 45 90 135 225 450

Relay Mounting Adjacent Distance vs. Coil Temperature Rise

G2A-432A 24 VDC

Condition: The

°

saturated coil

temperature is

measured with rated

coil voltage

(24 VDC) imposed.

Coil temperature rise ( C)

Relay

mounting

position

Average of No. 1 and No. 3

Average of No. 4. and No. 6

Upper

Lower

110 VAC

Condition: The saturated

°

coil temperature is

measured with rated

voltage (110 VAC) at 60 Hz

imposed.

Coil temperature rise ( C)

4

)

4

Life (x10 )

Relay

mounting

position

Contact resistance (m )

Number of Relays

Upper

Lower

Operations (x 10

100 VAC

24 VDC

4

)

Average of No. 7 and No. 9

Mounting adjacent distance l (mm)

Average of No. 1 and No. 3

Average of No. 4. and No. 6

Average of No. 7 and No. 9

Mounting adjacent distance l (mm)

Power Relay G2A 123

Accessories (Order Separately)

Connecting Sockets

Front-connecting

Back-connecting Socket

Socket

DIN track/screw

Solder terminals Wire-wrap terminals PCB terminals

mounting

PYF14A(-E)

PYF14A-TU

PYF14T

PY14

PY14-Y3

PY14-Y2

(with Relay

Hold-down Clip)

PY14QN(2)

PY14QN(2)-Y2

(with Relay

Hold-down Clip)

PY14-0

PY14-02

Note: 1. The PYF@A-TU is a high-humidity relay with nickel-plated rustproof terminal screws that are the same as the PYF@A in size.

2. The PYF14T is slightly different from the PYF14A(-TU) in shape and size.

3. The PYF@A-E is a finger-protection model, for which round terminals are not available. Use fork-shaped terminals or equivalent ones

instead.

PY14-3 Back-connecting Socket

(with check terminals for operation monitoring)

81

56

28

Check terminal for operation monitoring

Built-in operation monitoring lamp possible

38.5

9 (7.7)

2

0.3

34.5±0.4

36

+0.3

−0

Panel Cutout

+0.3

78

−0

+0

77.5

−0.4

2-dia. hole

Three, 1.2-dia. holes

Shorting lead

Relay Mounting Height with Socket

With Front-connecting Socket

G2A

76.5

Note: PYF14A can be used for both DIN

PYF14A

track mounting and screw mounting.

73

With Back-connecting Socket

G2A

45.5

PY14 Socket

Relay Hold-down Clips

For Front-connecting Socket For Back-connecting Socket For Socket mounting plate

PYC-A2

PYC-3

Note: When using a Relay Hold-down Clip for the built-in operation indicator model, use of the PYC-A2 or PYC-5, which allows easy viewing of

the indicator, is recommended.

PYC-5

PYC-2

124 Power Relay G2A

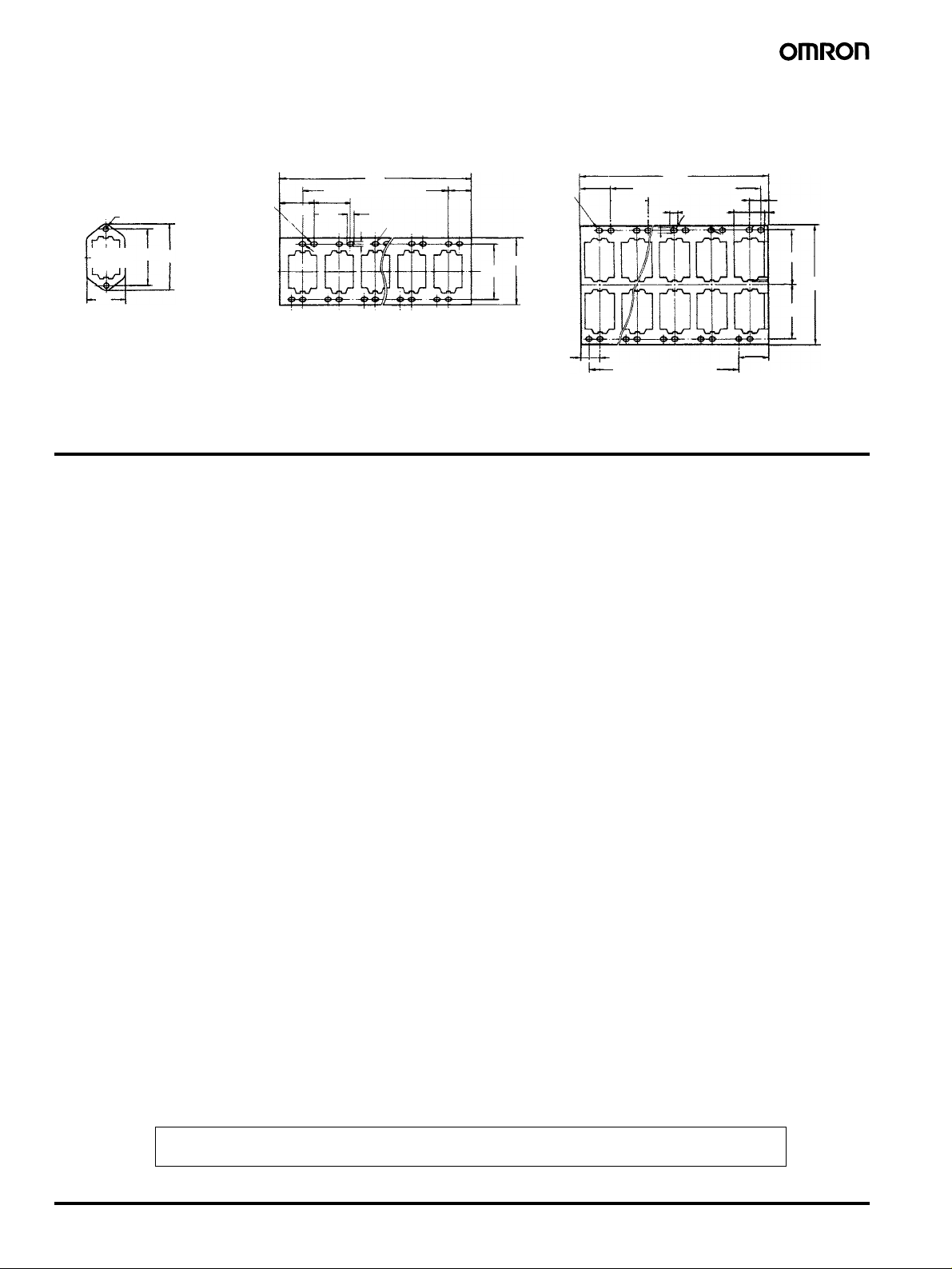

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Dimensional tolerances are

±0.1 mm.

Solder Terminal Models PCB Terminal Models

2.6

21.5 max.

Fourteen, 1.2-dia. 1.2 holes x 3 elliptic holes

0.5

28.5 max.

1.8

42.5 max.

5.4

42.5 max.

Terminal Arrangement/Internal Connections

(Bottom View)

Standard Models Make-before-break

Contact Models

Arc Barrier Equipped Models Built-in Diode Models

Built-in Operation Indicator Models

Color of operation indicator

AC model: Red

DC model: Green

G2A-432A-N

100/110, 200/220 VAC

6, 12, 24, 50 VDC

6, 12, 24 VDC

48, 100 VDC

1.8

0.5

1

21.5 max.

2.6

0.5

28.5 max.

4

Mounting Holes on PCB

(Bottom View)

5

Fourteen, 1.5-dia. holes

4.1

12.65

6.35

7.3

4.4

4.4

13.2

G2A-432A-N1

6, 12, 24 VDC

48, 100 VDC

Note: Do not reverse the polarity of the coil of DC Relays that have a built-in indicator or diode.

Power Relay G2A 125

Socket Mounting Plates (t = 1.6 mm)

Use any of these plates when mounting two or more Sockets side-by-side

PYP-1 (for Single Socket Mounting) PYP-18 (for Mounting 18 Sockets) PYP-36 (for Mounting 36 Sockets)

492

27.4 x 17 = 465.8±0.6

4.5

3.4

R1.7

13.1

21.6

Two, 3.4-dia. holes

Square

42±0.1

hole

28

49

72 elliptic holes

492

27.4 x 17 = 465.8±0.6

21.6

27.4

±0.15

Note: PYP-18 and PYP-36 can be cut to a desired length for

mounting less than 18 or 36 Sockets, respectively.

3.4

4.5

R1.7

13.1

72 elliptic holes

49

42±0.1

21.6

27.4

±0.15

13.1

27.4 x 17 = 465.8±0.6

Precautions

Refer to page 11 for general precautions.

A DC coil model with a built-in indicator or built-in diode has coil

polarity. Be sure to wire the terminals correctly, otherwise the diode

may be broken or the operating indicator may not be lit. Furthermore,

as a result of the short-circuiting of the built-in diode, the devices in

the circuit may be damaged.

21.4

39.7±0.2

39.7±0.2

+0.2

−0

86.4

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. J014-E1-02

In the interest of product improvement, specifications are subject to change without notice.

126 Power Relay G2A

Loading...

Loading...