Page 1

Vision Sensor

FH/FZ5 Series

Vision System

User’s Manual for Communications Settings

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ5-6

FZ5-6-

FZ5-11

FZ5-11-

FZ5-L35

FZ5-L35-

Z342-E1-08

Page 2

Introduction

Thank you for purchasing the FH/FZ5.

This manual provides information regarding functions, performance and operating methods that

are required for using the FH/FZ5.

When using the FH/FZ5, be sure to observe the following:

• The FH/FZ5 must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

NOTE

• All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein.

Moreover, because OMRON is constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without notice. Every precaution

has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation

in Japan and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

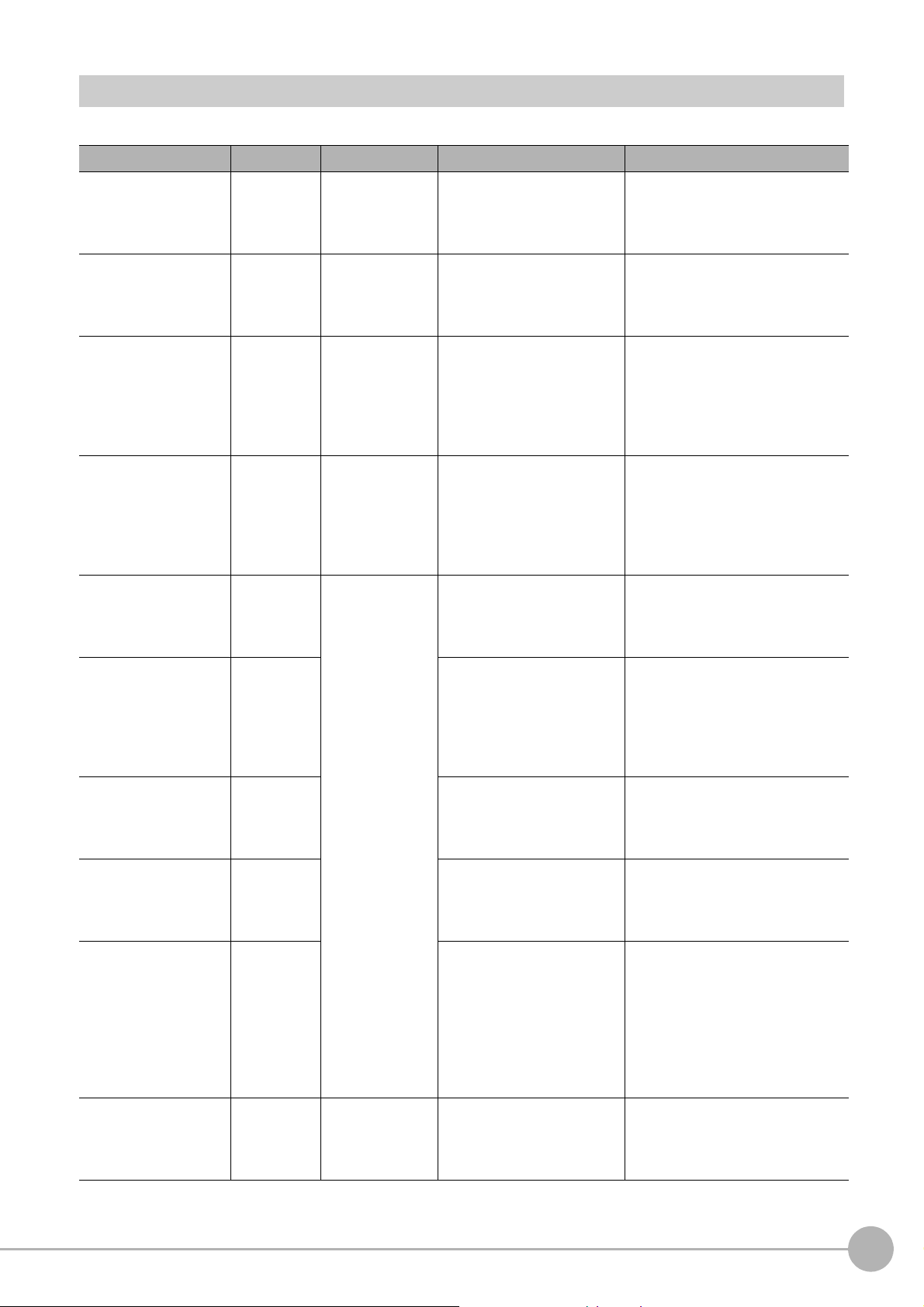

FH/FZ5 Manual Configuration

The following table gives the manual configuration of the FH/FZ5.

Name of Manual Cat. No. Model Proposes Contents

Vision System FH

Instruction Sheet

Vision System FH-L

Instruction Sheet

Vision System FZ5

Instruction Sheet

Vision System FZ5-L

Instruction Sheet

Vision System FH/FZ5

Se

ries User’

Vision System FH/FZ5

s

eries Hardware

Manual

Vision System FH/FZ5

series Macro Customize

Functions Programming

Manual

Vision System FH/FZ5

se

ries Proc

Function Reference

Manual

Vision System FH/FZ5

Series User’

for Communications

Settings

Vision System FH

Series Operation

Ma

nual for Sysmac

Studio

s Manual

Setup

essing Item

s Manual

9607479-9

9606631-1

9524422-4

9910002-2

Z365

Z366

Z367

Z341

Z342

Z343

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ5-6

FZ5-6-

FZ5-11

FZ5-11-

FZ5-L35

FZ5-L35-

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ

FZ5-L35-

FZ5-6

FZ5-6-

FZ5-11

FZ5-11-

FH-1

FH-1-

FH-3

FH-3-

5-L3

5

T

o

confirm the safety and

usage precautions of the

Vision System FH series

Sensor Controller.

To

confirm the safety and

usage precautio

Vision System FH-Lite series

Sensor Controller.

To confirm the setup

proce

dures, safe

usage precautions of the

Vision System FZ5 series

Sensor Controller, including

I/O setup and wiring

To confirm the setup

proce

dures, safe

usage precautions of the

Vision System FZ5-L Series

Sensor Controller, including

I/O setup and wiring.

When User want to know how

to setup the Sensor Controller

of the Vision System FH/FZ5

series.

When User want to know

about the Hard-ware

specifications or to setup the

Sensor Controller of the

Vision System FH/FZ5

series.

When User operate or

programming using Macro

Customize functions.

When User confirm the details

of each processing items at

the create the measurement

flow or operate it.

When User confirm the

setti

ng of co

functions.

Wh

en User connect to NJ

series via EtherCA

communication.

ns of the

ty and

ty and

mmunication

T

Describes the definitions of basic

t

erms, meaning of signal words,

and precautions for correct use of

FH series in the manual.

Describes the definitions of basic

t

erms, meaning of signal words,

and precautions for correct use of

FH-L series in the manual.

Describes the definitions of basic

t

erms, me

and precautions for correct use of

FZ5 series in the manual.

Describes the definitions of basic

t

erms, me

and precautions for correct use of

FZ5-L series in the manual.

Describes the soft functions, setup,

and operations to use Sensor

Controller of the Vision System FH/

FZ5 series.

Describes FH/FZ5 series

sp

ecifications

names, I/O information, installation

information, and wiring information.

Describes the functions, settings,

and operations for using Macro

Customize function of the FH/FH5series.

Describes the software functions,

settings, and operations for using

FH/FH5-series.

Describes the functions, settings,

and communications methods for

communicating between FH/FH5

series.

The following communication

protocol are described.

Parallel, PLC Link, EtherNet/IP,

Ethe

Describes the operating

procedures for setti

operating FH series Vision Sensors

from the Sysmac Studio FH Tools.

aning of signal words,

aning of signal words,

, dimensions, part

, and Non-procedure

rCAT

ng up and

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

1

Page 4

Conventions Used in This Manual

Symbols

The symbols used in this manual have the following meanings.

IMPORTANT

Note

Indicates relevant operational precautions tha

Indicates operation-related suggestions from OMRON.

t must be followed.

Use of Quotation Marks and Brackets

In this manual, menus and other items are indicated as follows.

[ ] Menu Indicates the menu names or processing items shown in the menu bar.

“ ” Item name Indicates the item names displayed on the screen.

2

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 5

Terms and Conditions Agreement

Warranty, Limitations of Liability

z Warranties

Exclusive Warranty

Omron's exclusive warranty is that the Products will be free from defects in materials and workmanship for a

period of twelve months from the date of sale by Omron (or such other period expressed in writing by

Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION,

INFRINGEMENT,

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties

infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) repl

with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii)

repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price of the

non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity

or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or

inappropriate modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of

Products in combination with any electrical or electronic components, circuits, system assemblies or any

other materials or substances or environments. Any advice, recommendations or information given orally or

in writing, are not to be construed as an amendment or addition to the above warranty.

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

and resp

onsibility of any type for claims or expenses based on

EXPRESS OR IMPLIED, ABOUT NON-

ace (in the form originally shipped

See http://www.omron.com/global/ o

r contact your

Omron representative for published information.

z Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron C

liability is asserted.

ompanies

exceed the individual price of the Product on which

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

3

Page 6

Application Considerations Warranties

Suitability of Use

Omron Companies shall not be responsible for conformity with any st

apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying ratings and limitations of use

which apply to the Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to

Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

andards, codes or regulations which

NEVER USE THE PRODUCT FOR AN APPLICATION INVOL

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’

consequence thereof.

VING SERIOUS R

s

programming of a programmable Product, or any

ISK TO LIFE OR

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and oth

in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test

conditions, and the user must correlate it to actual application requirements. Actual performance is subject to

the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed

reasons. It is our practice to change part numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the Product may be changed

without any notice. When in doubt, special part numbers may be assigned to fix or establish key

specifications for your application. Please consult with your Omron’s representative at any time to confirm

actual specifications of purchased Product.

er materials is provided as a guide for the user

at

any time based on improvements and other

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no

sponsibili

re

4

ty is assumed for clerical, typographical or proofreading errors or omissions.

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 7

Safety Precautions

For details on Safety Precautions, refer to Safety Precautions in the Vision System FH/FZ5 Series User's

Manual (Cat. No. Z365).

Precautions for Safe Use

For details on Precautions for Safe Use, refer to Precautions for Safe Use in the Vision System FH/FZ5

Series User's Manual (Cat. No. Z365).

Precautions for Correct Use

For details on Precautions for Correct Use, refer to Precautions for Correct Use in the Vision System FH/FZ5

Series User's Manual (Cat. No. Z365).

Regulations and Standards

For details on Regulations and Standards, refer to Regulations and Standards in the Vision System FH/FZ5

Series User's Manual (Cat. No. Z365).

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

5

Page 8

MEMO

6

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 9

Contents

FH/FZ5 Manual Configuration .............................................................................................................. 1

Conventions Used in This Manual ........................................................................................................

Terms and Conditions Agreement ........................................................................................................

Safety Precautions ...................................................................................................................

Precautions for Safe Use ................................................................................................................

Precautions for Correct Use ...........................................................................................................

Regulations and Standards ...............................................................................................................

1. Overview .......................................................................................................................................11

Introduction .............................................................................................................................................. 12

Confirming the System Configuration .....................................................................................................

System Configuration ..................................................................................................................

Communicating with an External Device ................................................................................................

Basic Control Operations of the Sensor Controller ........

Communication between the Sensor Controller and an External De

Control Methods for the Sensor Controller ....

Communication Protocols for Communication with the Sensor Controller

Saving Sensor Controller Data to an External Device ...

Control Methods Using an External Device ..................

Control with Control Signals and Status Signals ................................................................................22

Command/Res

Data Output after Measurements .......................................................................................................

Setting Procedures for Communications ................................................................................................

Communications Setup Procedures ..............................

Communications Protocols and Communications Modules ................................................................ 36

Differences in Specifications Based on th

List of Supported Signals by Communications Protocol ..................................................................... 37

Restrictions when Using Different Communic

Models That Are Compatible with the C

ponse Method .............................................................................................................

e Communications Protocol .................................................... 37

..................................................................................... 17

ation

ommunications Protocols ..................................................... 40

..................................................................... 14

vice ........................................... 16

......................................... 19

..................................................................... 20

........................................................................... 22

..................................................................... 35

Protocols Simultaneously ................................... 39

............. 5

...... 5

...... 5

... 5

. 13

....... 13

. 14

25

26

. 35

2

3

2. Methods for Connecting and Communicating with External Devices ....................................43

EtherCAT Connections (FH-1000 series/FH-3000 series only) ............................................................... 44

Introduction to EtherCAT ................................................................................................................

Structure of CAN Application Protocol over EtherCAT (CoE) ............................................................. 47

EtherCAT Slave Information Files (ESI Files) ....................................................................................

Transitions of Communications States ...............................................................................................

Process Data Objects (PDOs) ...........................................................................................................

Service Data Objects (SDOs) .....................................

Communications between an EtherCAT Master and Slaves

FH-series Vision Sensor Communications Method When Connected

Communications Settings ...............................................................................................................

Communications Module Settings (Startup Settings) .

Communications Specifications Settings ............................................................................................ 6

Output Data Settings (Processing Item Registration) ........

EtherCAT Network Configuration Settings ......................................................................................... 69

Communicat

I/O Ports by Area (PDO Mapping) and Memory Assignments ............................................................ 71

I/O Signals ......................................................................................................................

Measurement Results That You Can Output with Fieldbus Data Ou

ions Test .....................................................................................................................

........................................................................ 53

.............................................................. 54

to EtherCAT ........................... 55

........................................................................ 62

................................................................. 66

......

tput ........................................... 80

.... 44

. 4

49

. 50

.... 60

.... 70

.............. 76

8

3

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

7

Page 10

Command List ..................................................................................................................................... 81

Measurement Trigger Input ...............................................................................................................

Command Response Processing ....................................................................................................... 8

Data Output ..........................................................................................................................

Time Charts ..........................................................................................................................

.............. 88

.............. 90

EtherCAT Troubleshooting ................................................................................................................

Sysmac Error Status ....................................................................................................................

....... 96

Sysmac Device Features ................................................................................................................

Object Dictionary .....................................................................................................................

......... 112

Communicating with PLC Link .............................................................................................................

Communications Processing Flow .................................................................................................... 162

Communicat

ions Setup Procedures ..............................

Communications Module Settings (Startup Settings) .

................................................................... 164

...................................................................... 164

Communications Specifications Settings .......................................................................................... 166

Output Da

ta Settings (Processing Item Registration) ........

............................................................... 184

Testing Communications ................................................................................................................

Memory Allocation .......................................................................................................................

I/O Signals ............................................................................................................................

Output Items .........................................................................................................................

Command List ..........................................................................................................................

..... 192

............ 195

............ 198

......... 199

Command Response Processing ..................................................................................................... 202

Data Ou

tput ..........................................................................................................................

Time Charts ..........................................................................................................................

............ 205

............ 207

PLC Link Troubleshooting ..............................................................................................................

Communicating with EtherNet/IP .........................................................................................................

Introduction to EtherNet/IP ...................................

............................................................................ 213

Data Exchange with EtherNet/IP ......................................................................................................

EtherNet/IP Communications ...........................................................................................................

Communications Processing Flow .................................................................................................... 218

Communicat

ions Setup Procedures ..............................

Communications Module Settings (Startup Settings) .

................................................................... 220

...................................................................... 221

Communications Specifications Settings .......................................................................................... 222

Tag Data Link Setting Meth

Output Data Settings (Processing Item Registration) ........

ods ........................................................................................................

............................................................... 232

Testing Communications ................................................................................................................

Memory Allocation .......................................................................................................................

I/O Signals ............................................................................................................................

Output Items .........................................................................................................................

Command List ..........................................................................................................................

..... 238

............ 247

............ 250

......... 251

Command Response Processing ..................................................................................................... 255

Data Ou

tput ..........................................................................................................................

Time Charts ..........................................................................................................................

Communicating with the Sensor Controller with EtherNet

/IP Message Communications ................ 264

............ 258

............ 260

Command Setting Example ..............................................................................................................

EtherNet/IP Troubleshooting ............................................................................................................

Non-procedure Communications ........

................................................................................................... 269

Communications Processing Flow .................................................................................................... 269

Communicat

ions Setup Procedures ..............................

Communications Module Settings (Startup Settings) .

................................................................... 270

...................................................................... 271

Communications Specifications Settings .......................................................................................... 272

Output Da

ta Settings (Processing Item Registration) ........

............................................................... 279

Testing Communications ................................................................................................................

. 84

5

. 94

.. 110

.. 162

.. 189

.. 210

.. 213

214

217

228

.. 236

267

267

.. 285

8

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 11

Output Items ..................................................................................................................................... 288

Command Formats ........................................................................................................................... 289

Command List ................................................................................................................................... 292

Output Format ................................................................................................................................... 296

Non-procedure Communications Troubleshooting ........................................................................... 298

Parallel Communications ....................................................................................................................... 299

Communications Processing Flow .................................................................................................... 299

Communications Setup Procedures ................................................................................................. 301

Communications Module Settings (Startup Settings) ....................................................................... 302

Communications Specifications Settings .......................................................................................... 303

Output Data Settings (Processing Item Registration) ....................................................................... 310

Testing Communications .................................................................................................................. 318

I/O Signals ........................................................................................................................................ 320

Output Items ..................................................................................................................................... 330

Command Formats ........................................................................................................................... 332

Time Charts ...................................................................................................................................... 336

Parallel Troubleshooting ................................................................................................................... 347

3. Appendices .................................................................................................................................349

Command Control .................................................................................................................................. 350

Parameter Notation Examples for Command Control ...................................................................... 350

Details of Commands Used in EtherCAT Communication ............................................................... 354

Command List ................................................................................................................................... 355

Command Details for PLC Link, EtherNet/IP, and EtherCAT ........................................................... 361

Non-procedure Command Details .................................................................................................... 426

Manual Revision History ........................................................................................................................ 520

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

9

Page 12

10

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 13

Overview

This section provides a basic overview of the communications specifications and Sensor

Controller control methods. This information is required before performing

communications between the FH/FZ5 and an external device.

Introduction........................................................................ 12

Confirming the System Configuration............................. 13

.................. 14

Communicating with an External Device

Control Methods Using an External Device ..

......

.................. 22

1

Overview

Setting Procedures for Communications......

Differences in Specifications Based on the

Communications Protocol................................................ 37

.................. 35

Page 14

Introduction

This section provides a basic overview of the communications specifications and Sensor Controller control

methods. This information is required before performing communications between the FH/FZ5 and an external

device.

Confirming the System Configuration (Refer to Confirming the System Configuration (p.13))

This section describes the external device configuration that is required to perform measurement processing with the FH/FZ5.

↓

Communicating with an External Device

This section describes the basic operations of the Sensor Controller, how the Sensor Controller works, and the

specifications for communications between the Sensor Controller and an external device. The following information is

provided.

Basic Flow of Communications and Signals (Refer to

• Process from Starting Measurements at the Sensor Controll

Sensor Controller and an External Device (p.16))

• Sensor Controller Control Meth

Controller (p.17))

• Types of Communications Protocols for Communica

Protocols for Communication with the Sensor Cont

• Moving Data between the Sensor Controller and an External

External Device (p.20))

↓

Control Methods Using an External Device

ods (Control

Signals, Commands, etc.) (Refer to Control Methods for the Sensor

Basic Control Operations of the Sensor Controller (p.14))

er to Data Output (Reference: Communication between the

ting with th

roller (p.19))

e Sensor Controller (Refer to Communication

Device (Refer to Saving Sensor Controller Data to an

This section describes the methods that you can use to control the Sensor Controller from an external device.

Control with Control Signals and Status Signa

Command/Response Method (Refer to

Data Output after Measurements (Refer to

↓

Setting Procedures for Communications (Refer to Setting Procedures for Communications (p.35))

This section describes the procedures that are required to set up

between the Sensor Controller and an external device.

↓

Differences in Specifications Based on the

Commu

This section explains the types and differences of communication pr

Sensor Controller.

nications Protocol

ls (Refer to Control with Control Signals and Status Signals (p.22))

Command/Response Method (p.25))

Data Output after Measurements (p.26))

communications before starting communications

(Refer to

Communications Protocols and Communications Modules (p.36))

otocols that are used for communication with the

12

Introduction

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 15

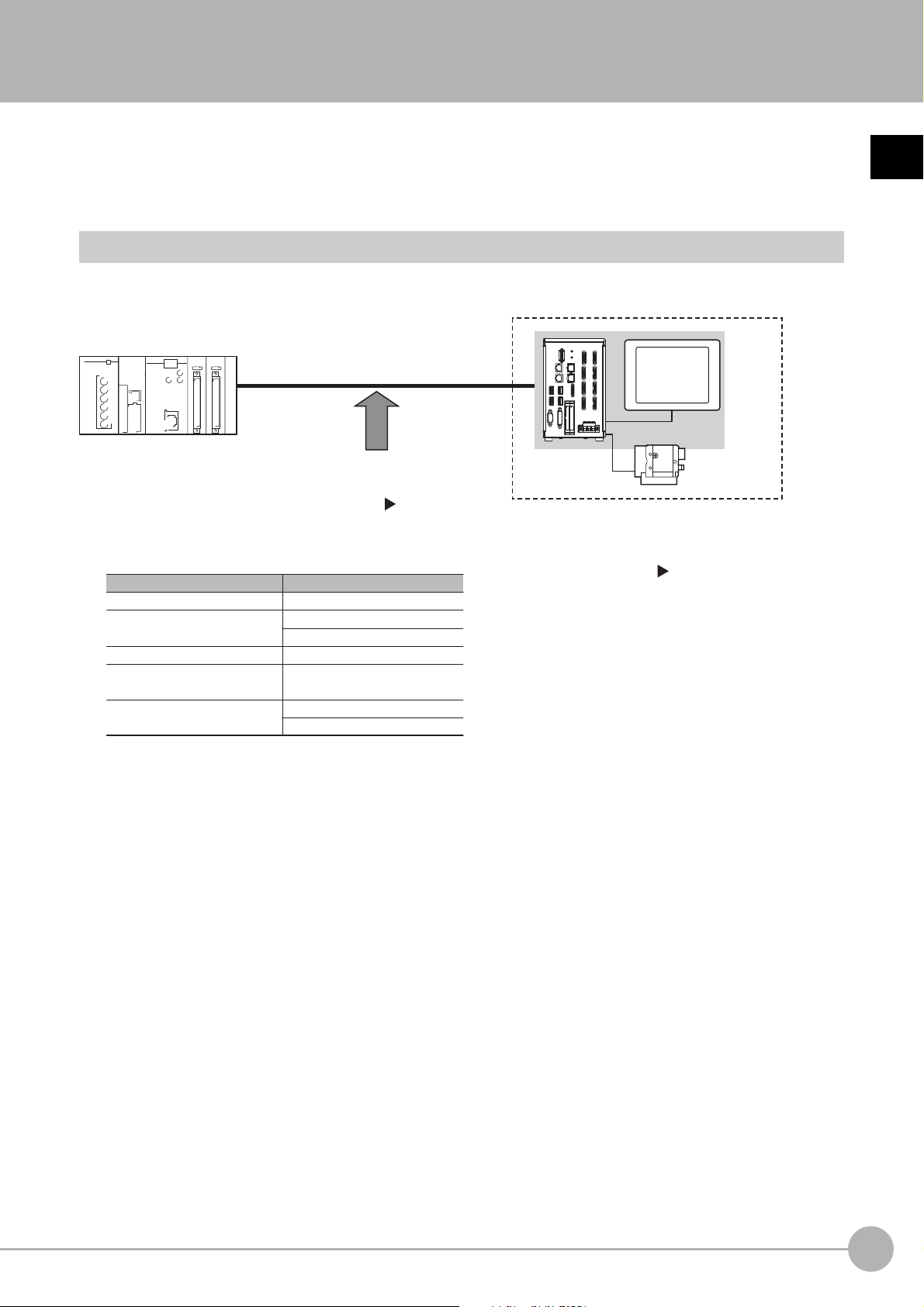

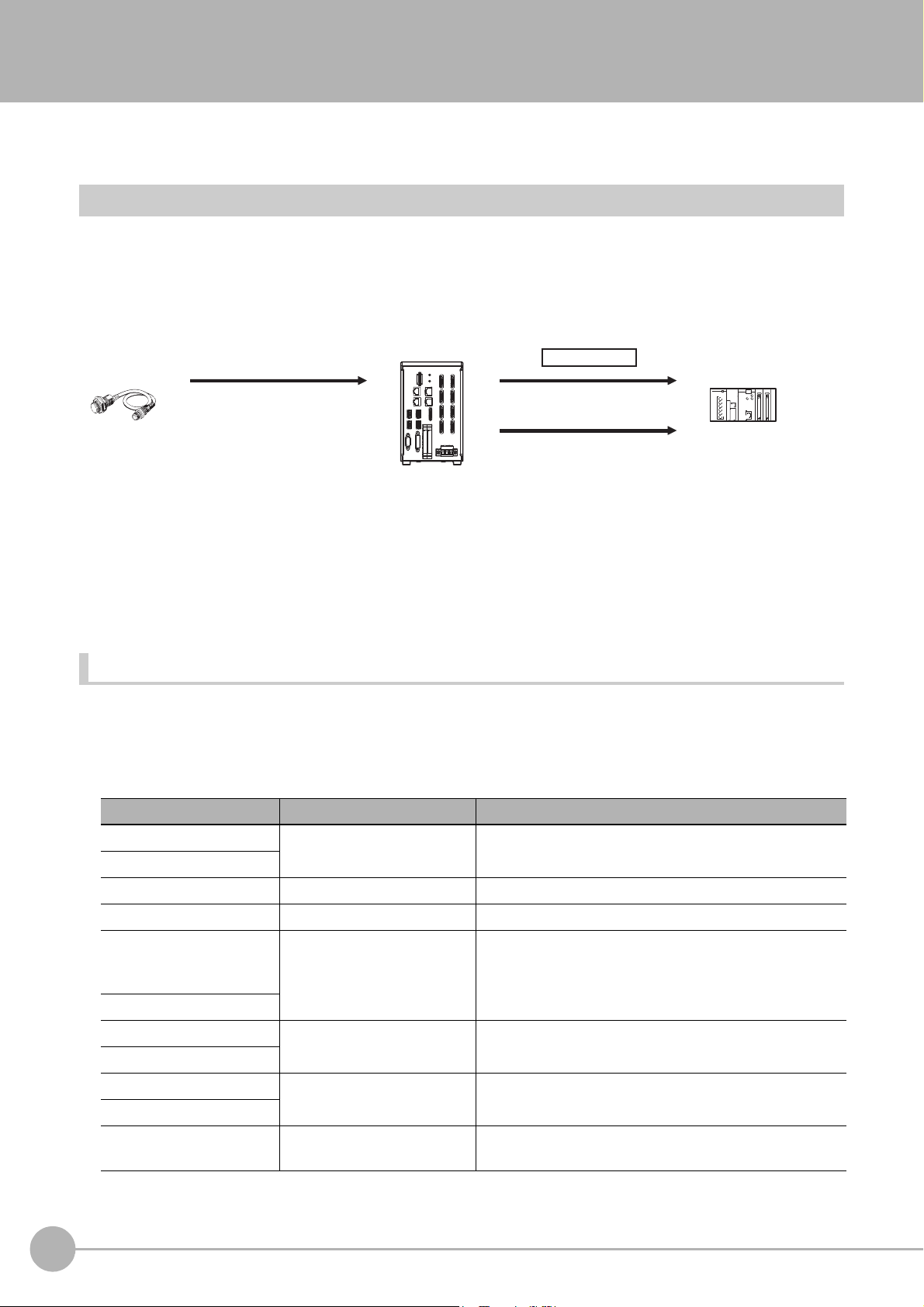

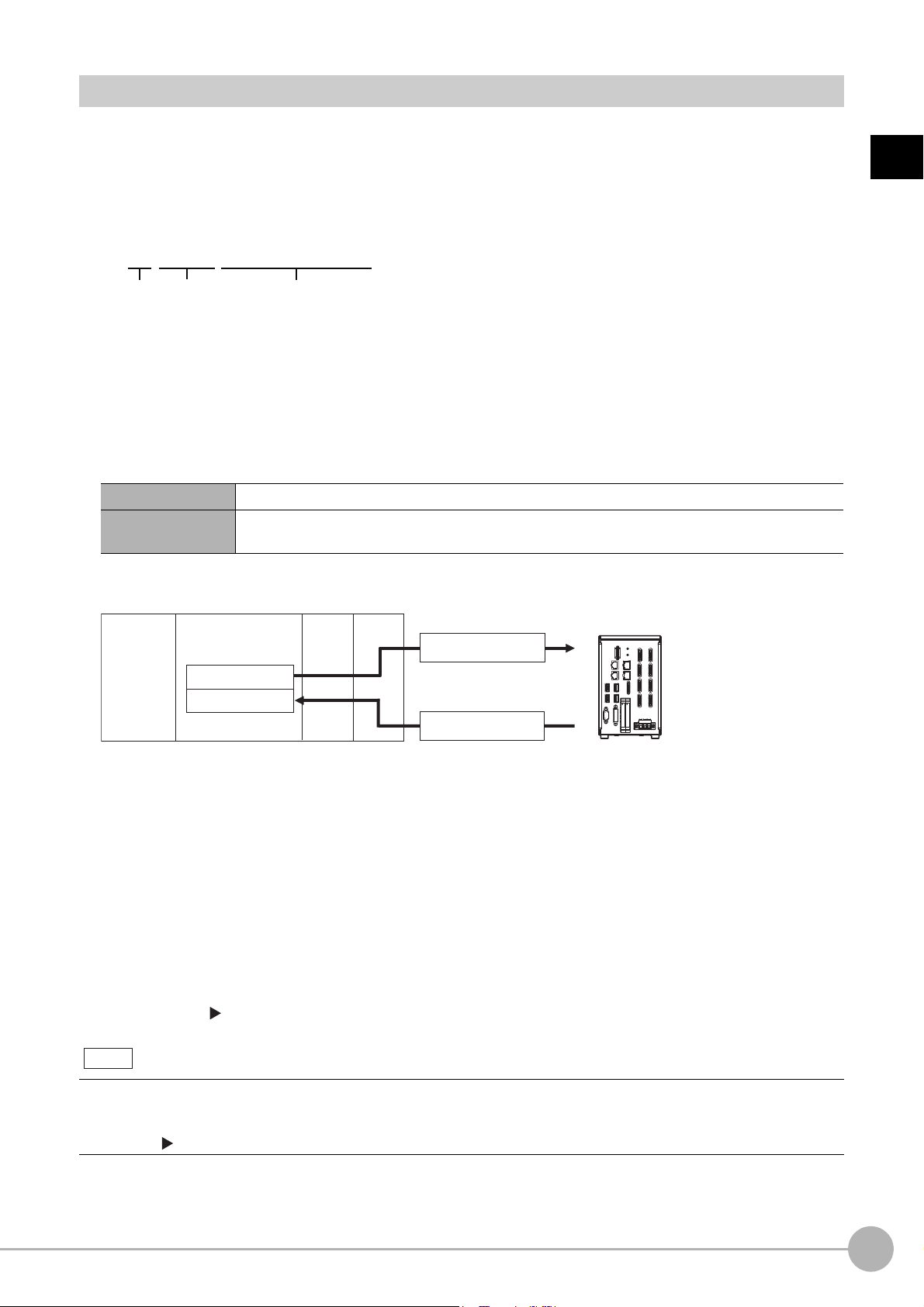

Confirming the System Configuration

Sensor Controller

External device (e.g, PLC)

Parallel Parallel I/O cable

Ethernet cablePLC Link

RS-232C cable

EtherNet/IP Ethernet cable

Ethernet cable

Ethernet cableNon-procedure

RS-232C cable

Camera

Communications protocol

Communications cable

EtherCAT (FH-1000 series/

FH-3000 series only)

An LCD monitor (BOX type only) for operation

and monitoring and a camera are connected to

the Sensor Controller unit.

For details, refer to the

Vision System FH/FZ5

Series User's Manual (Cat. No. Z365) and the

Instruction Manual that is provided with each

individual device.

The Sensor Controller is connected to an external device (PLC, etc.)

by a communication cable, and communication can be performed

using various communication protocols. Refer to Methods for

Connecting and Communicating with External Devices (p.43) for

information on the different communications protocols.

The FH/FZ5 are Vision Systems that perform measurement processing through a Sensor Controller on

measurement objects that are imaged by a Camera.

puter,

In a system configuration that is connected to a PLC, com

commands can be received from and measurement results can be output to the external device.

System Configuration

An overview of the FH/FZ5 series system configuration is given below.

or other external device, measurement

1

Overview

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Confirming the System Configuration

13

Page 16

Communicating with an External Device

Trigger sensor

PLC

External device

External device

PLC

The measurement

results are output.

• Status signals

• Overall judgement

• Measured values

• Character output

Sensor Controller

Measurement triggers

and other control

commands are input.

This section gives the communications specifications, describes the control methods that you can use for

communications, and describes the settings that are required before starting communications with an external

device.

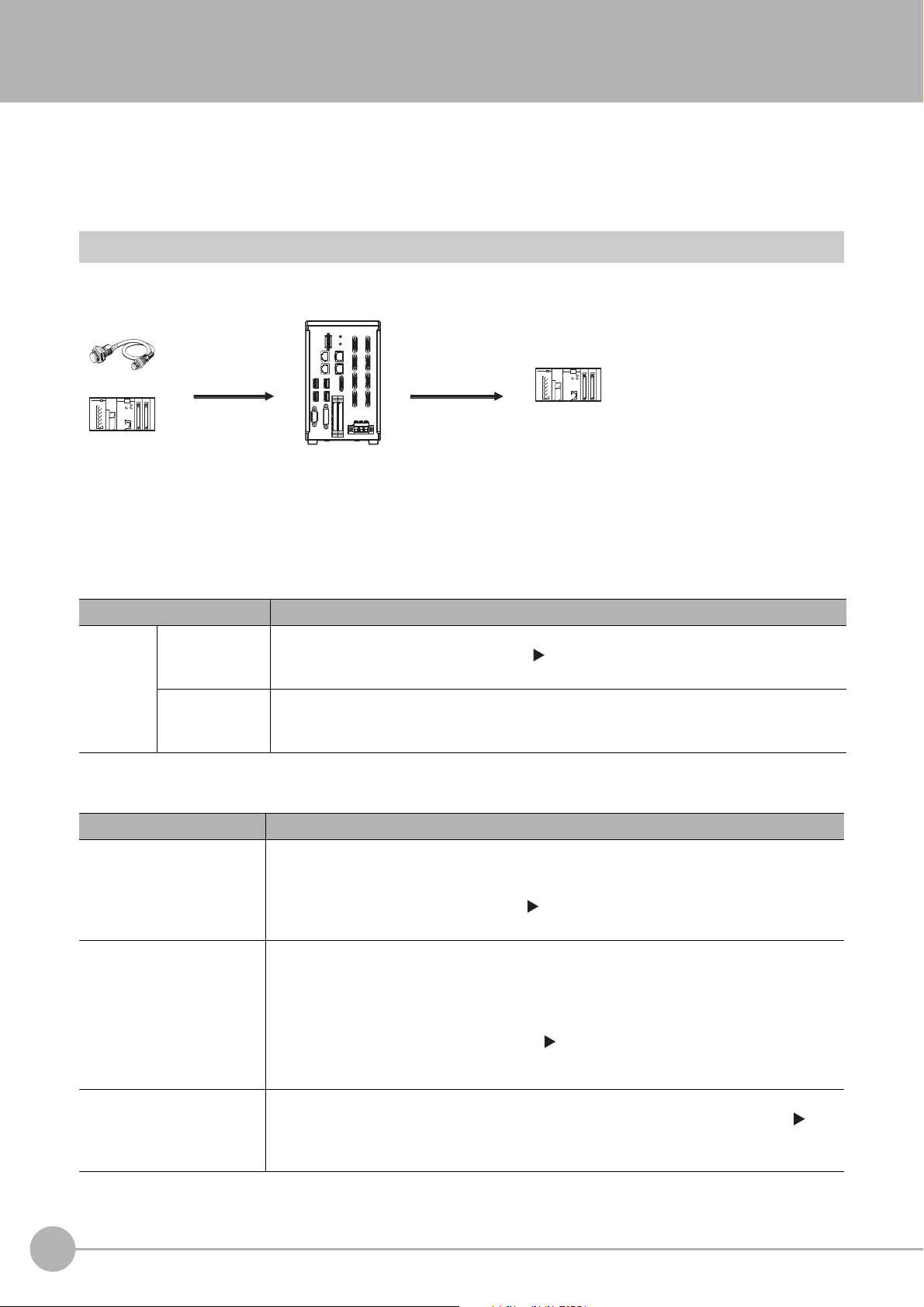

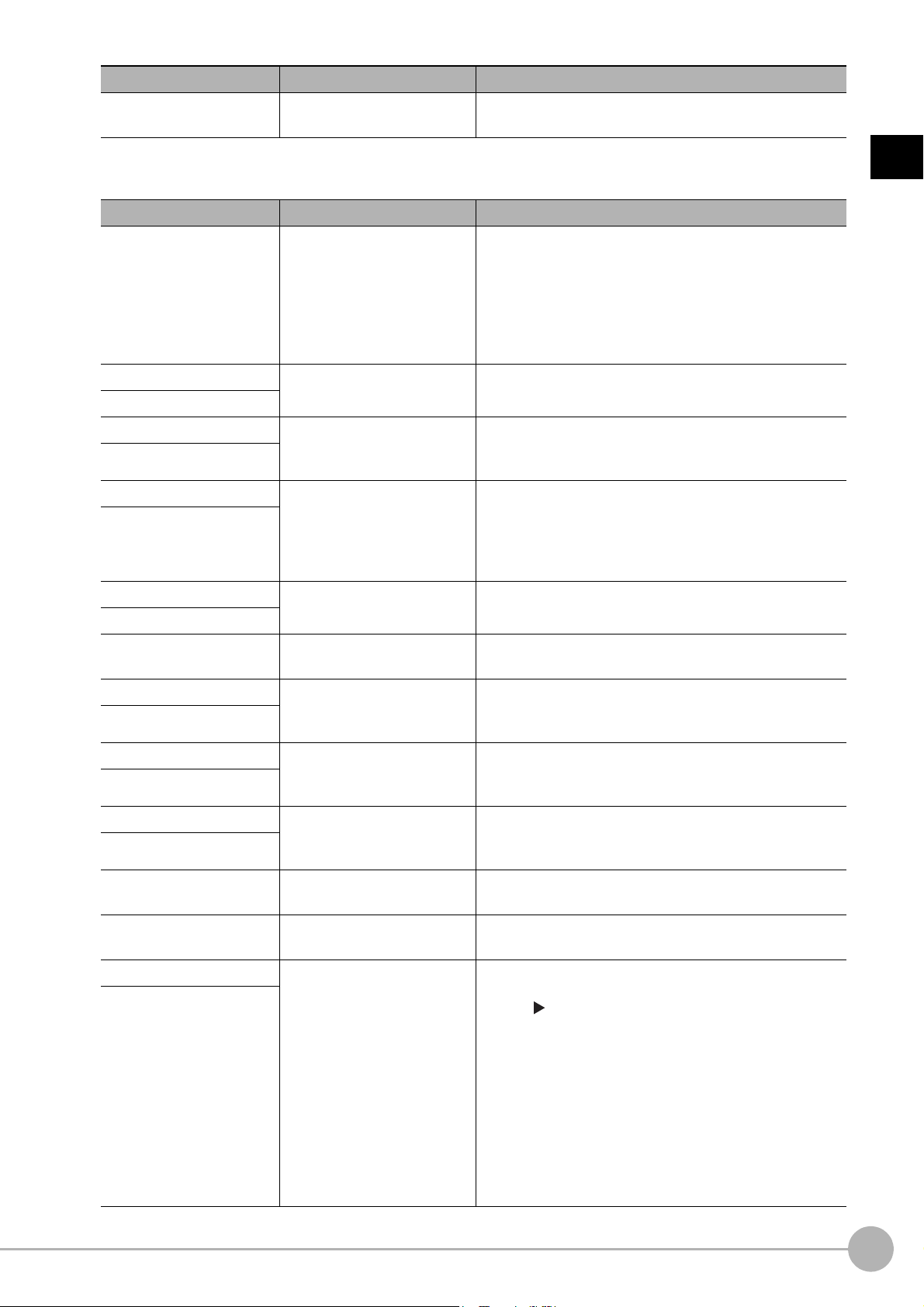

Basic Control Operations of the Sensor Controller

The following figure shows basic communications between an external device and the Sensor Controller and the

flow of signals and data.

The following methods can be used to exchange data between

Commands That Can Be Input to the Sensor Contro

Typ e Description

Control sig

(input signals)

Control

commands

Communications

comma

nals

nd input

Data Output to an External Device from th

Typ e Description

Status signals

Overall judgement

Measured values

A measurement is executed when a measurement trigger (i.e., an ON ST

For information on control signals, refer to Control with Control Signals and Status Signals

(p.22).

ou can send commands to perform measurements

Y

tasks. The communications commands depend on the communications protocol that you

use. Refer to the section for each communications protocol for details.

e Sensor Controller

When the Sensor Controller confirms a control

begins measurement processing, the status of the Sensor is reported to the external device

through status signals (e.g., a BUSY signal).

For information on status signals, refer to Control with Control Signals and Status Signals

(p.22).

NG is output whenever there is one or more NGs i

processing items.

The overall judgement can be output through the OR signal or through the TJG output

parameter.

*1: This behavior can be changed in the settings.

For information on the OR signal, refer to Control with Control Signals and Status Signals

(p.22).

For information on the TJG output parameter.

The measured values from processing items can be output. The output items must be

processing items for output and registered as output data (data 0 to data 7). Refer to

Settings Required for Data Output (p.29) for details. You can also use commands to obtain

results after a measurement is performed.

*1

ller from an External Device

an external device and the Sensor Controller.

EP signal) is input.

, change scene groups, or perform other

nal or communications command input and

sig

the judgement results for multiple

n

14

Communicating with an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 17

Typ e Description

Note

Character output (PLC Link

or non-procedure

communications only)

You can also use the FTP server to obtain logged image files and logged data files saved in the FH/FZ5 (or in external

memory) from a web

browser or FTP client.

You can output character strings and numbers that are read by proce

Character Inspection, Barcode, or 2DCode. Refer to Items that Can Be Output as Output

Data (p.28) for details.

You can also use commands to obtain results after a measurement is performed.

ssing items such as

1

Overview

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Communicating with an External Device

15

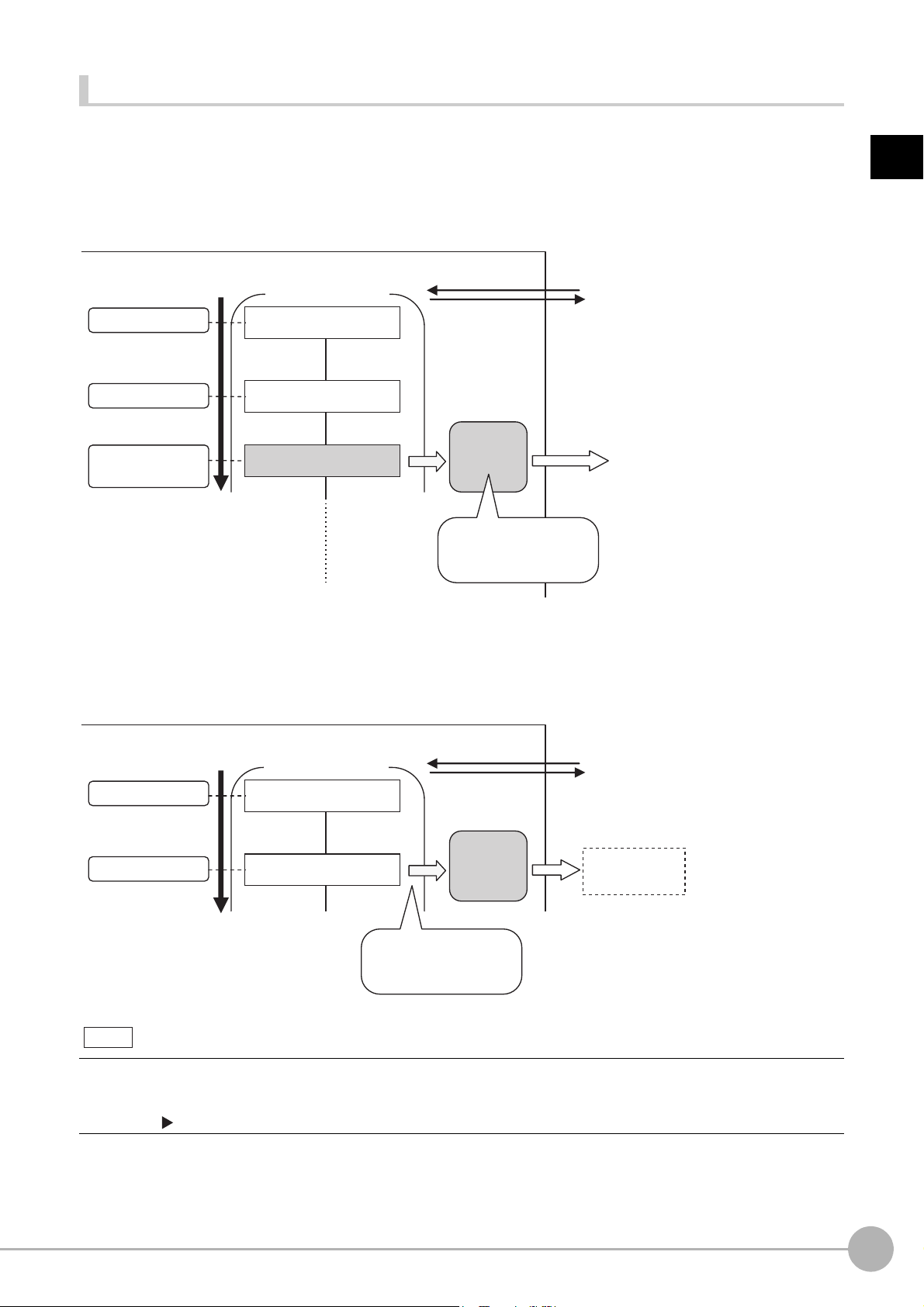

Page 18

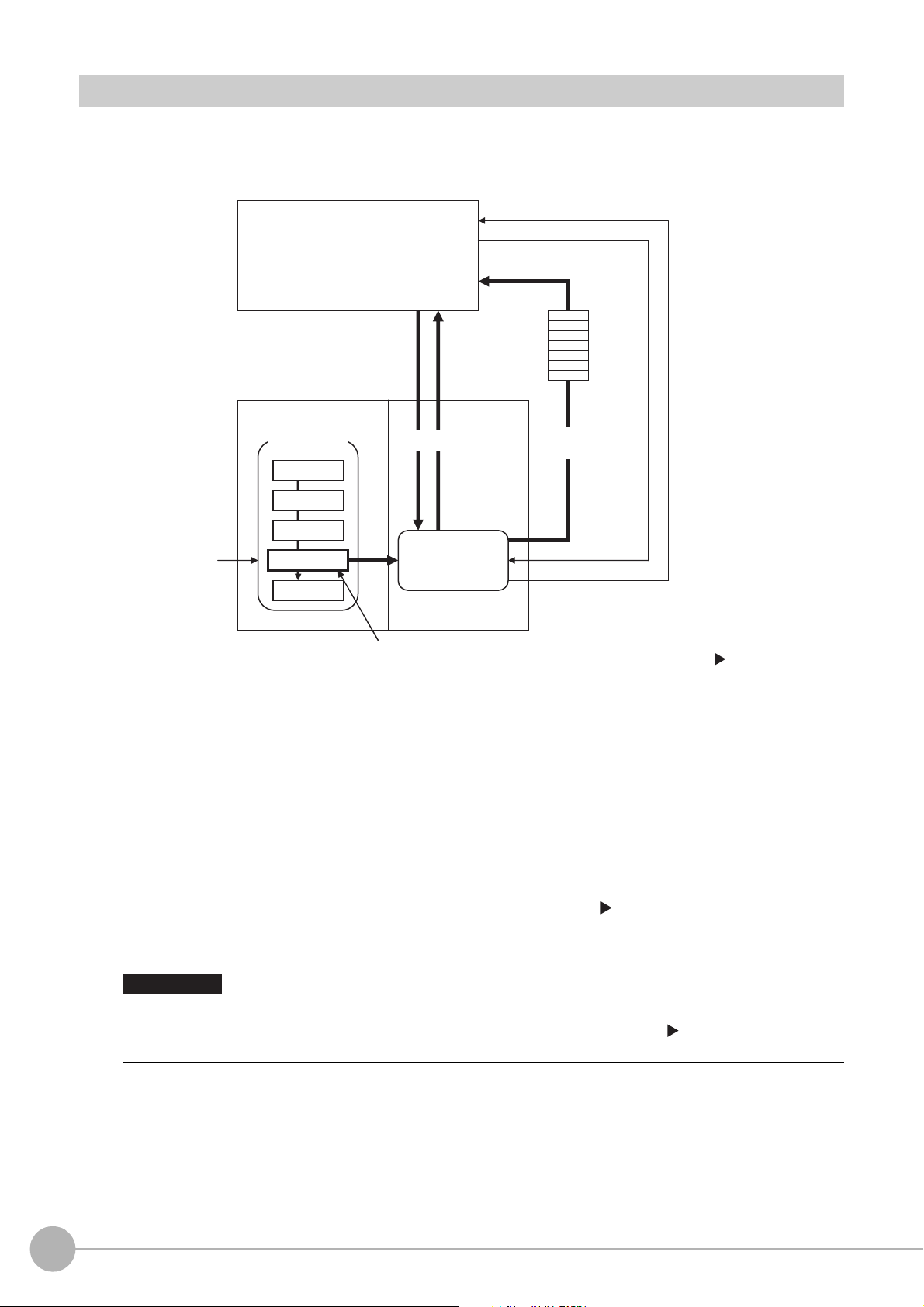

Communication between the Sensor Controller and an External Device

PLC or other external device

Camera Input

Search

Output Unit

Measurement

flow

Sensor Controller

Communications

Module

Communications processing

Example: Starting a

measurement, etc.

Response

Data output request

(DSA signal)*1

Result Completion signal (GATE signal)*1

(1) Command

Communications

processing

(2) The data at this

point is output to the

Communications

Module.

An Output Unit processing item is required to

perform data output. (Multiple Output Unit items

can be used.)

(3) Data

output

*1: When output control is set to [Handshaking]

(data output is controlled by the DSA and

GATE signals). Refer to Control with

Control Signals and Status Signals (p.22).

IMPORTANT

Communication between the Sensor Controller and external device takes place as shown below.

The following figure shows the flow when a communications command is used to start a measurement and then

output d

ata.

*2: If handshaking is used for output control, the measurement data will remain in the Communications Module in a standby state

16

Communicating with an External Device

(1) When the Sensor Controller receives a command from a PLC or

other external device, it executes the

command and returns a response.

(2) The data obtained after the measurement is performed is

output via the Communications Module by

the Output Unit (an abbreviation for Results Output Unit) processing item in the measurement flow.

(3) The measurement data is output when the Output Unit is executed, n

actually finished.(*2)

until a data output request (DSA signal) is received from an external device. Refer to Data Output Control with Handshaking

(p.32).

To output data, you must place an Output Unit processing item in the measurement flow.

You can place multiple Output Unit processing ite

Data Output (p.29).

ms in the measurement flow. Refer to Settings Required for

Vision System FH/FZ5 Series User’s Manual

ot when the measurement is

for Communications Settings (Z342)

Page 19

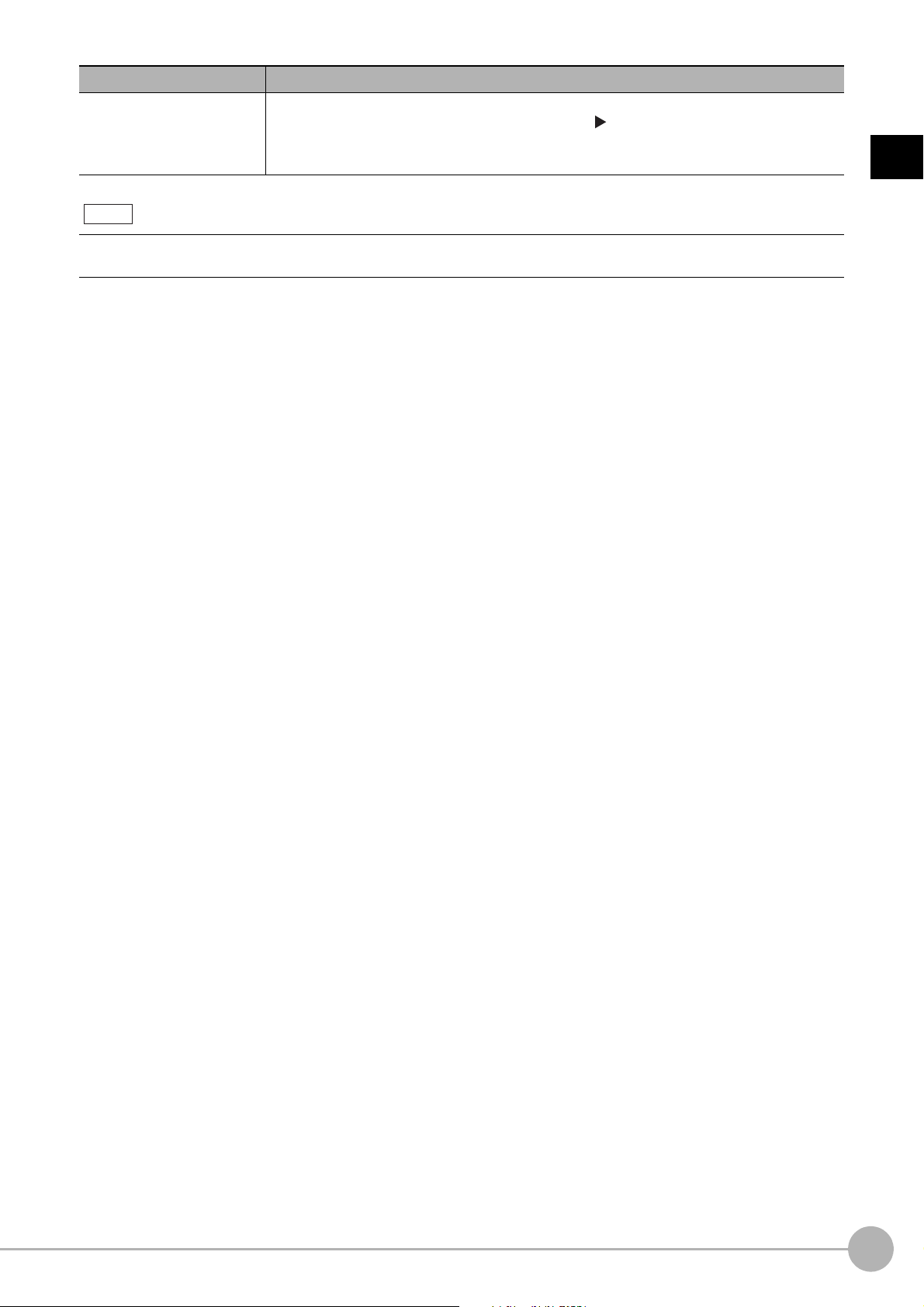

Control Methods for the Sensor Controller

There are three methods that you can use to control the Sensor Controller from a PLC or other external device.

They are described in this section.

For details on each control method, refer to their corresponding section.

Control Methods

Method Overview Trigger type or area Signals or area used

n is controlled by the

trol commands. The

ON/OFF status of the control

sig

nals and status signals

The control command code is

stored in the I/

PLC and then the Request Bit is

turned ON.

O m

emory of the

Control signals and status

signals

PLC I/O memory (Com

Area

and Response Area)

mand

Control signals and

status signals

Control with

commands and

responses

Operatio

ON/OFF status of the

Measurement Trigger Signal

(STEP) and Command Request

Bit (EXE).

Control is performed by sending

con

execution results of the

command can be confirmed in

the response from the Sensor

Controller.

1

Overview

Data output after

me

asurement

s

After a measurement is

pe

med, the previously

rfor

specified measurement data is

output automatically.

Not required. (Output is

p

rmed automatically after

erfo

measurement.)

PLC I/O memory (Data Output

Area)

1 Control with Control Signals and Status Signals (Refer to Control with Control Signals and

Status Signals (p.22))

Control and status confirmation for the Sensor Controller is performed with the ON/OFF status of the

control and status signals.

s m

This method is best suited for basic operations such a

status of the Sensor Controller.

Trigger sensor

External device

Control signal

Status signal

Sensor Controller

easurement triggers or to check the operating

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Communicating with an External Device

17

Page 20

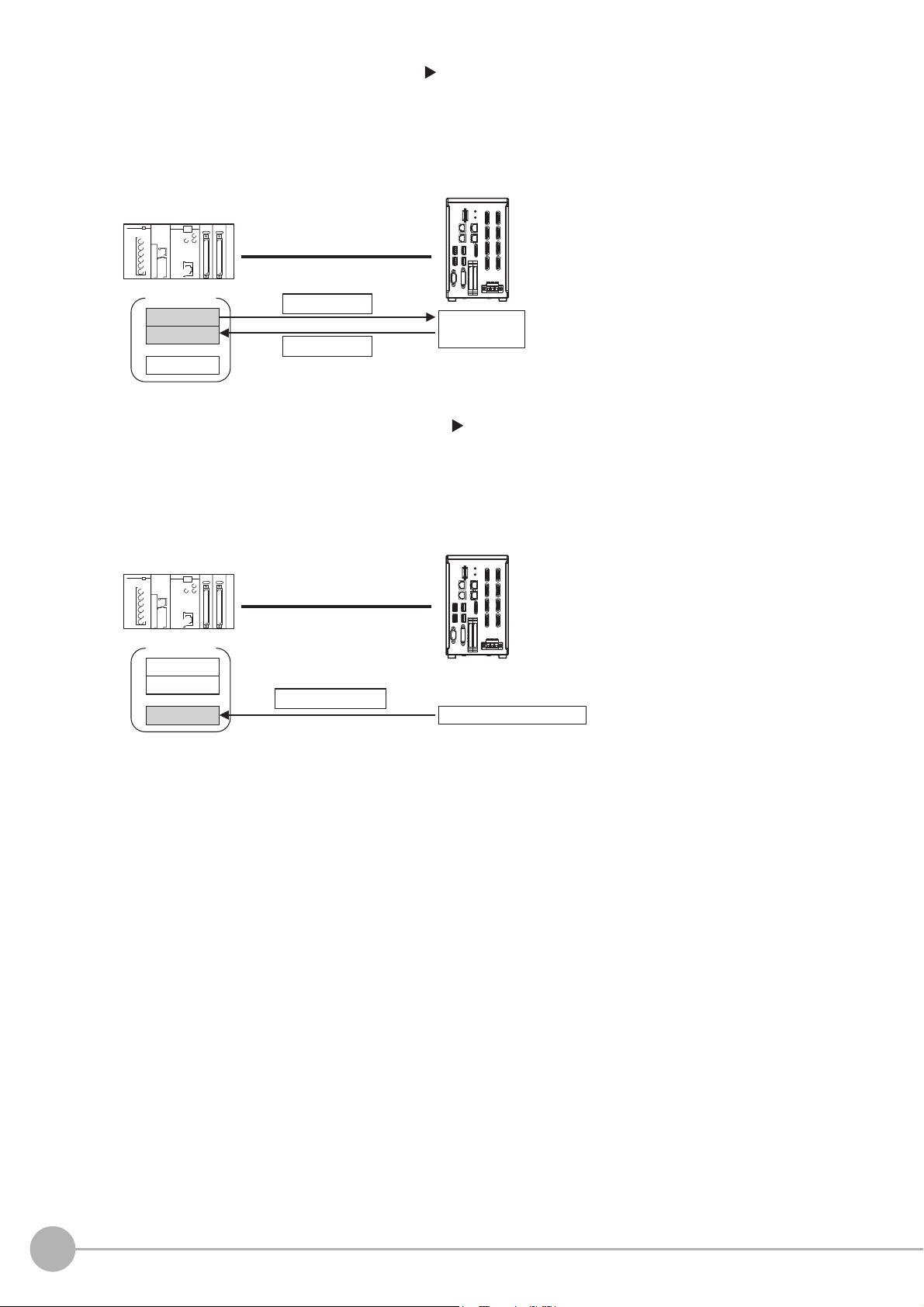

2 Command/Response Method (Refer to Command/Response Method (p.25))

External device

I/O memory

Sensor Controller

Command Area

Response Area

(1) Command

(3) Response

Output Area

(2) Command

execution

Control is performed by storing the control command and the response to that command in the I/O

memory of a PLC.

ands

This method is best suited to send multiple comm

to the Sensor Controller without using PLC

communications instructions.

3 Data Output after Measurements (Refer to Data Output after Measurements (p.26))

After a measurement is executed, the measurement data specified for output is automatically output to the

specified words in the I/O memory of the PLC.

This allows you to output measurement results from the Sensor Controller to the PLC automatically

ut h

witho

External device

aving to send data requests from the PLC.

Sensor Controller

I/O memory

Command Area

Response Area

Output Area

(2) Measurement data

(1) Measurement processing

18

Communicating with an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 21

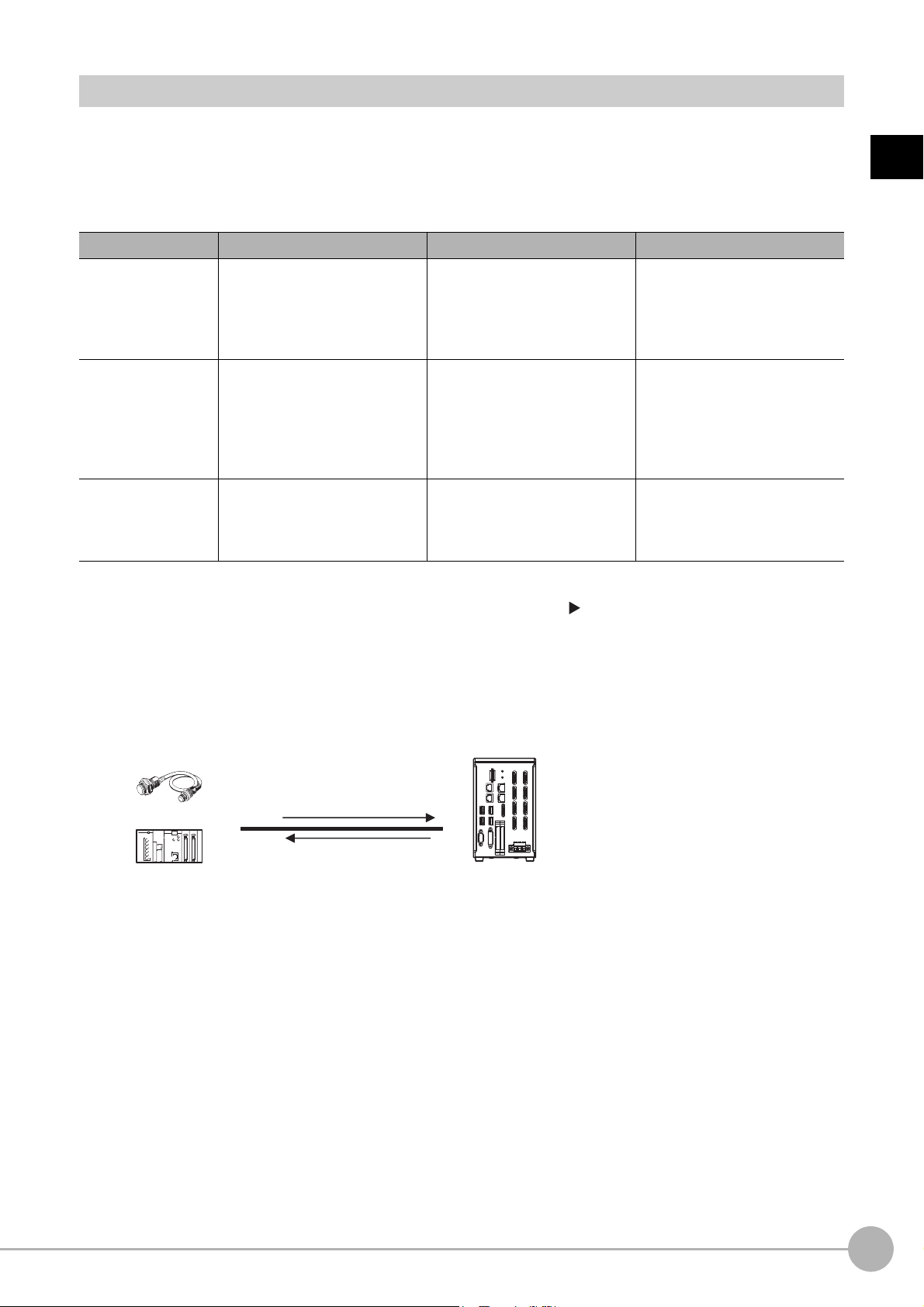

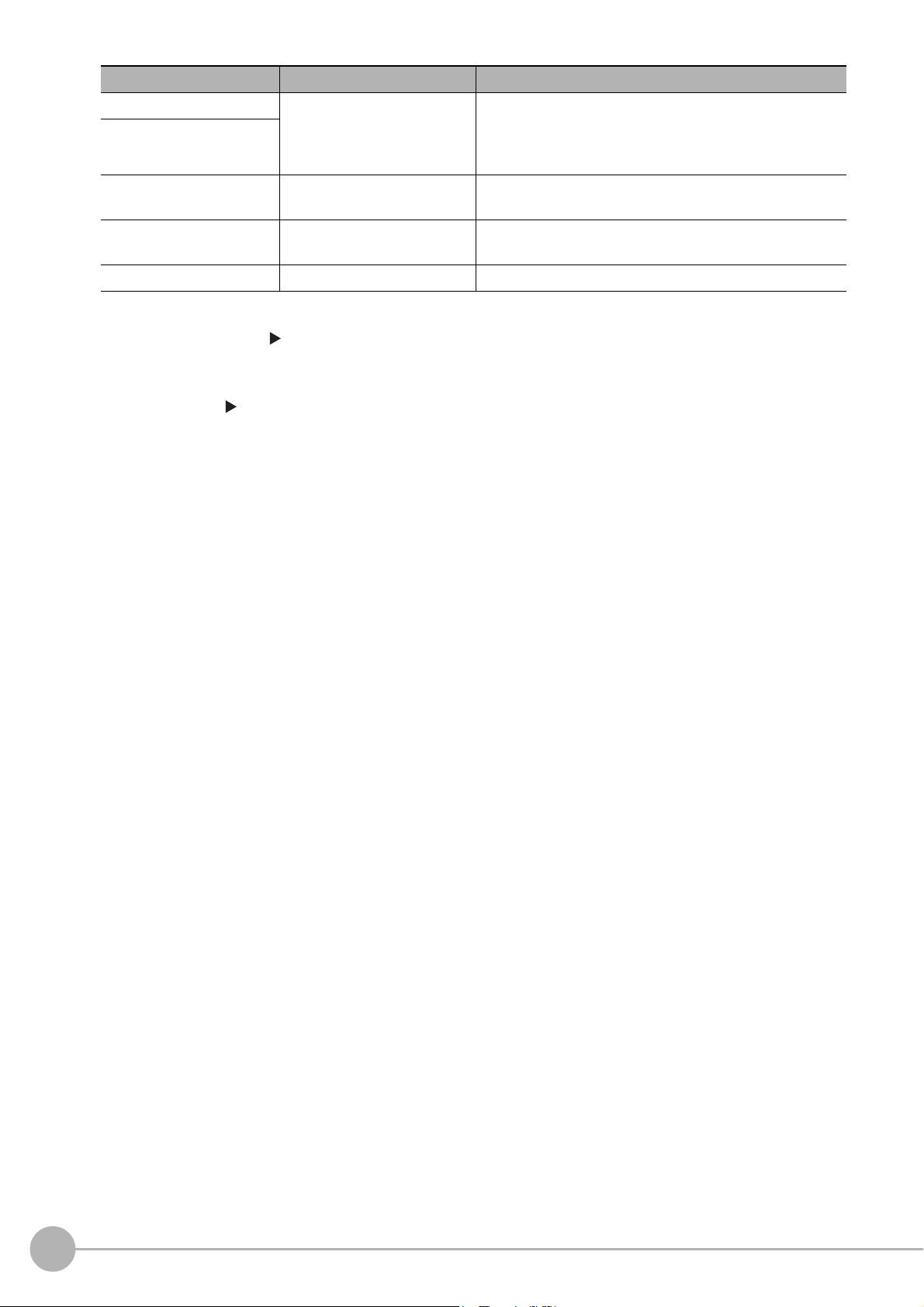

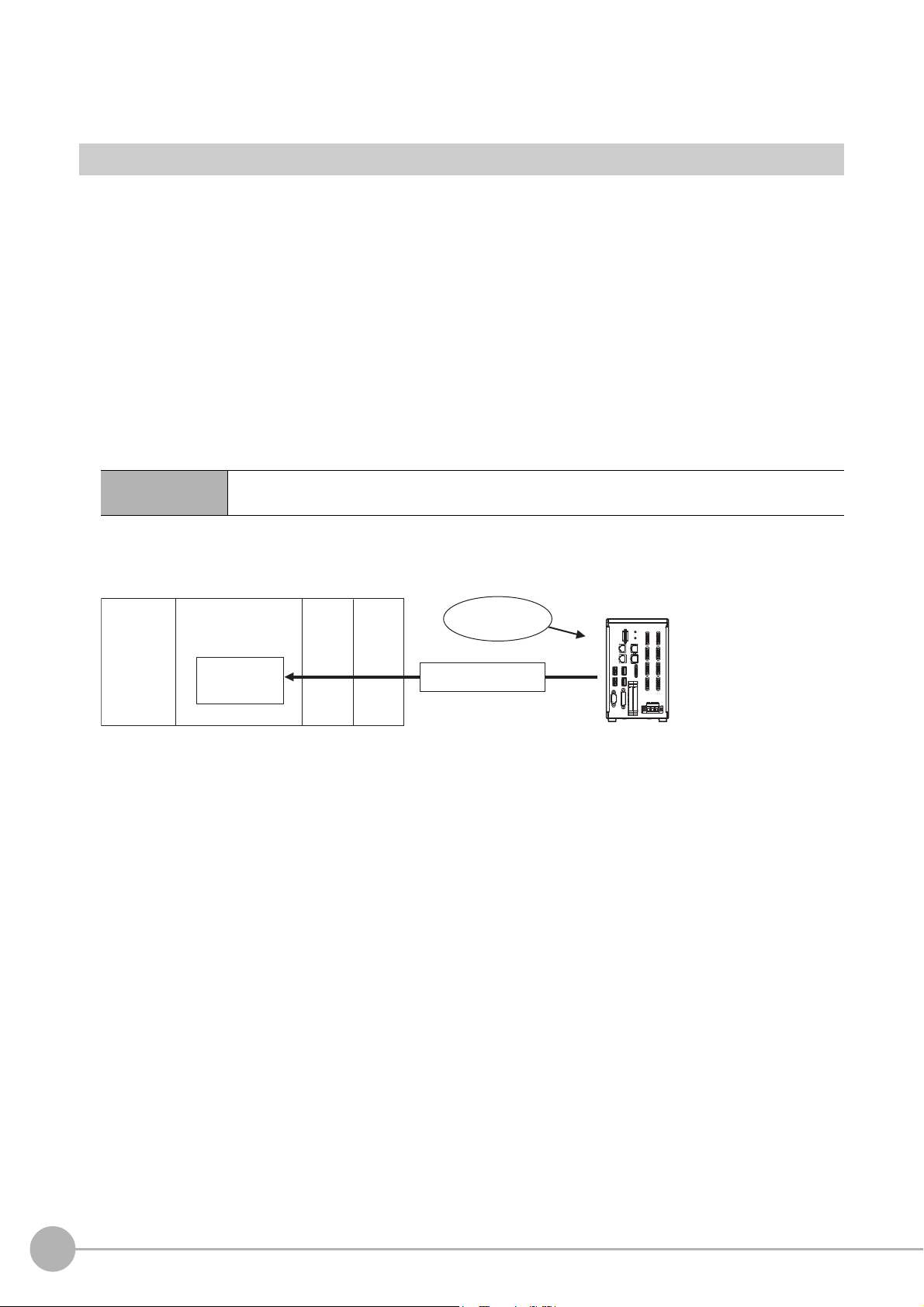

Communication Protocols for Communication with the Sensor Controller

PLC

Computer

EtherNet/IP

EtherCAT

Non-procedure

Parallel

PLC Link

Sensor Controller

Control can be performed through different communications protocols.

The Sensor Controller can be controlled from a PLC, computer, or other external device using a variety of

communication protocols.

us

The communication protocols that can be

described below.

Applicable Communications Protocols

The communication protocols of each communication method that can be used with the Sensor Controller

are as follows:

OK: Supported, ---: Not supported.

Communi-

cations

method

Communi-

cations

protocol

ed to control the Sensor Controller from an external device are

Communications cable type

Overview

Parallel

I/O

Ethernet

RS-232C/

422

1

Overview

*2

Contact

inputs

Data

sharing

Parallel

PLC Link

EtherNet/IP

EtherCAT

(FH-1

000

series/FH3000 series

only)

Data is exchanged between an external device and the

Sensor Control

signals from multiple physical contacts.

Thi

s is OMRON’s communications protocol for Vision

System.

The control sig

area to store measurement data are assigned in the I/O

memory of the PLC, and data is exchanged cyclically to

share data between the PLC and the Vision System.

This is an open communications protocol.

Tag data links are used for communication with the

Sensor Con

On the PLC, structure varia

correspond to the control signals, command/response

data, and measurement data. These variables are then

used as tags to input and output data through tag data

links to exchange data between the PLC and the Sensor

Controller.

This is an open communications protocol.

PDO (process data object) communications are used to

co

mmun

I/O ports that correspond to the control signals,

co

mmand/respon

prepared in advance, and the variables assigned to those

I/O ports are used to input and output data via PDO

communications to exchange data between the PLC and

the Sensor Controller.

ler through combinations of ON/OFF

nals, Command Are

ler.

trol

*1

icate with the Sensor Controller.

se data, and measurement data are

a/Respo

bles are created

nse Area, and

that

OK --- ---

--- OK OK

--- OK ---

--- OK ---

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Communicating with an External Device

19

Page 22

OK: Supported, ---: Not supported.

Communi-

cations

method

Frame

transmission

Communi-

cations

protocol

Nonproce

dure

Overview

Command frames are sent to the Sensor Con

response

frames are received from the Sensor Controller

troller and

without the use of any specific protocol.

Data can be exchanged between the PLC, computer, or

other exte

rnal device and the Sensor Controller by

Communications cable type

Parallel

I/O

Ethernet

RS-232C/

422

--- OK OK

sending and receiving ASCII or binary format data.

*1: When connected to a CJ-series PLC, specify the areas in the I/O memory.

*2: FH-1000, FH-3000, and FH-L series are able to connect via only RS-232C.

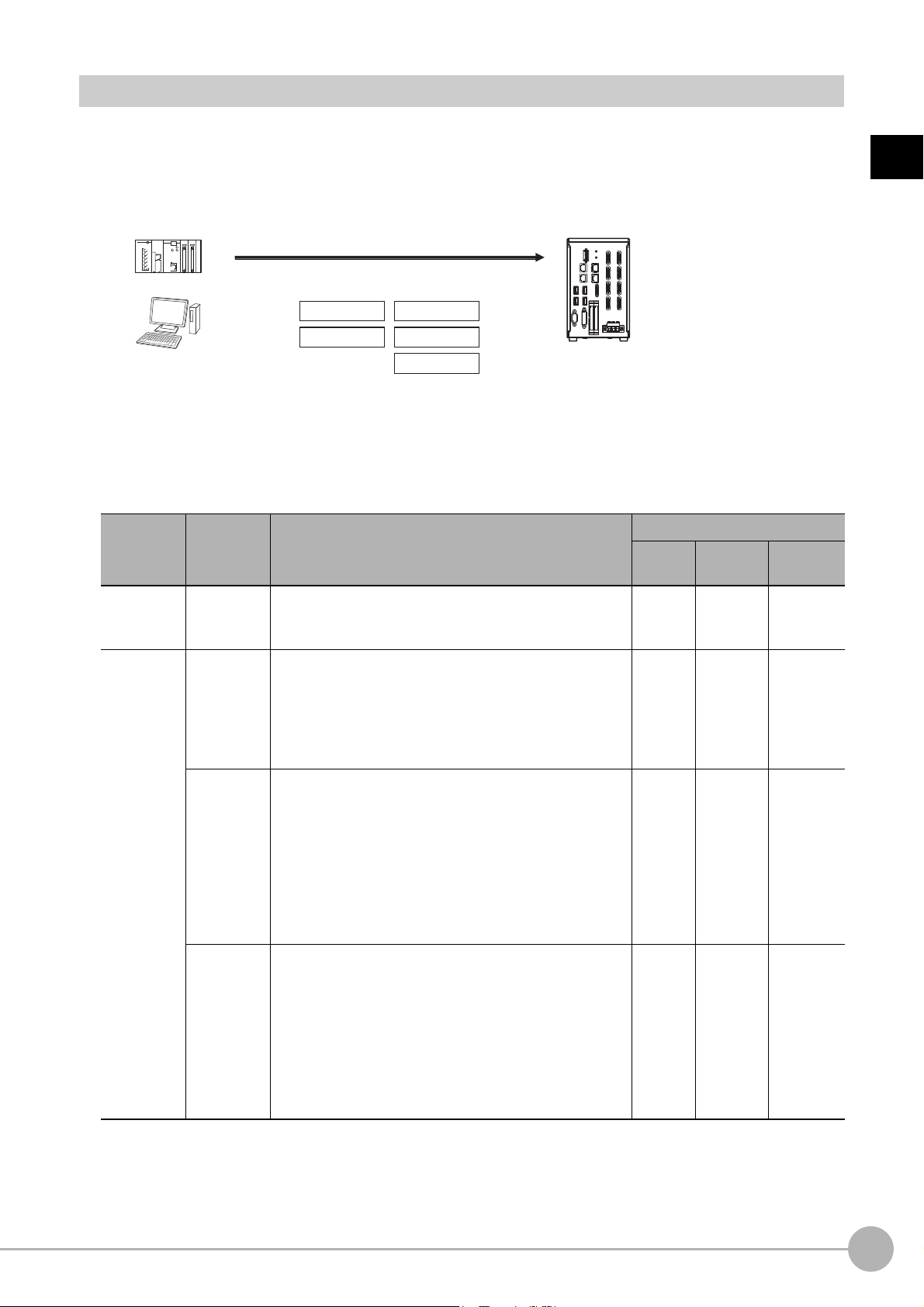

Saving Sensor Controller Data to an External Device

In addition to sending and receiving data via a communication protocol, you can also save Sensor Controller

data to an external device using the methods described below.

For details, refer to the V

ision System FH/FZ5 Series User's Manual (Cat. No. Z365).

Connecting the FH/FZ5 as an External Drive

In addition to the Sensor Controller's built-in RAM disk, you can directly save various types of data such as

scene data, scene group data, logged data, and logged images to the external media below.

• External Memory (Refer to Using External Memory Devices in the Vision System FH/FZ5 Series User's Manual

(Cat. No. Z365).)

Data can be saved directly to a

• Network Drive (Refer to Shared folder on a computer connected

User's Manual (Cat.

No. Z365).)

You can save data directly to a shared folder on

B memory stick or SD Memory Card inserted into the slot on the Sensor Controller.

US

to the network in the Vision System FH/FZ5 Series

a computer connected via Ethernet.

*2

Computer Sensor Controller

Ethernet

Saved directly.

Shared computer folder (the

shared folder settings must

be set on the computer)

• Logged images

• Logged data

The Sensor Controller is set

up to save to the shared

folder on the computer.

• Data Transfer (FTP Server) (Refer to Saving Data to an External Device in the Vision System FH/FZ5 Series User's

Manual (Cat. No. Z365).

You can move logged image files and other data saved in the Sensor Controller's RAM

)

disk or a USB memory stick to

a computer via Ethernet.

The computer must provide FTP client

to access the

FH/FZ5.

The computer cannot be accessed directly from the Sensor Controller.

Browser

(FTP client)

Computer

Ethernet

Access via FTP

Images files moved to the computer.

Sensor Controller (FTP server)

RAM disk

Image files

This enables you to move logged images off of the Sensor Controller’s RAM disk before it becomes full.

20

Communicating with an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 23

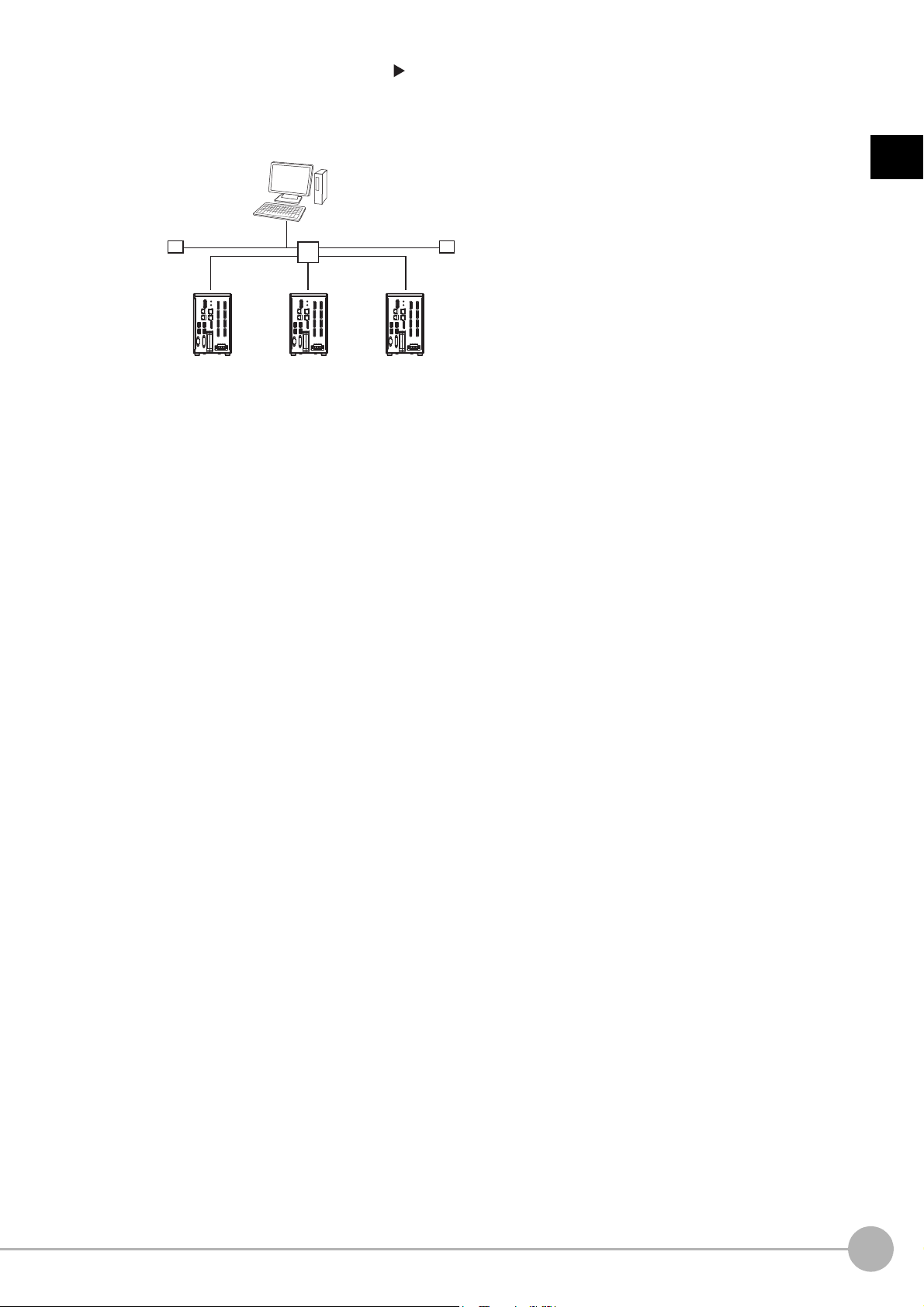

• Remote Operation over a Network (Refer to Remotely Operating the Controller (Remote Operation) in the Vision

Sensor

Controller

Ethernet

Computer (FH/FZ5 software)

Hub

Sensor

Controller

Sensor

Controller

Operate/monitor

System FH/FZ5 Series User's Manual (Cat. No

If more than one Sensor Controller is connected via Ethernet, a compute

Ethernet network can be used to operate and monitor all the Sensor Controllers at once.

. Z365).)

r (the FH/FZ5 Tool) connected to the same

1

Overview

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Communicating with an External Device

21

Page 24

Control Methods Using an External Device

Trigger sensor Sensor Controller

(1) Measurement trigger input

(STEP signal: ON).

Control signal

(2) Command received.

(BUSY signal turned ON.)

(3) Judgement results are output.

(OR signal turned ON.)

Status signals

External device

This section describes the methods that you can use to control the Sensor Controller from a PLC or other external device.

Control with Control Signals and Status Signals

Control and status confirmation for the Sensor Controller is performed with the ON/OFF status of the control and

status signals.

Measurement triggers and other commands are input as control signals from the PLC.

The operating status of the Sensor, judgement results, an

d other st

status signals sent from the Sensor Controller.

(1) The external device turns ON the STEP signal to input a measurement trigger.

atus information can be confirmed through

(2) When the Sensor Controller confirms that the STEP signal is ON, it outputs the BUSY signal to the

external de

(3) When the Sensor Controller finishes the measurement, it

vice and begins a measurement.

outputs the judgement results on the OR

signal.

Control Signals and Status Signals

The signals that the Sensor Controller can input and output as control signals and status signals are described in

the following tables.

Input Signals (PLC to Sensor Controller)

Signal Signal name Function

EXE

Command Request

Trigger Measure Bit Turn ON this signal to execute measurements.

STEP Measure Bit Turn ON this signal to execute measurements.

DSA

(Used only for handshaking

output control.)

Result Set Request

Control Command Execution

Si

gnal

Da

ta Output Request Signal

rn ON this signal (from the PLC) to send a command to

Tu

the FH/FZ5.

Use this signal (from the PLC) during handshaking to

request from the F

output results from the execution of the measurement flow.

H/FZ5 the external output of the data

ERCLR

Error Clear

XEXE

Flow Command Request

DI (DI0 to DI7) Command Input Signals

22

Control Methods Using an External Device

Error Clear Bit

Flow Command Request Bit

Turn ON this signal to clear the ERR signal from the Sensor

Con

trol

ler.

Turn ON this signal to execute a command during

execution of PLC Link, fieldbus, or parallel flow control.

These signals are used to input commands from a parallel

in

terface.

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 25

Signal Signal name Function

ENCTRIG

Encoder Trigger Input (Phase

A, Phase B, or Phase

Output Signals (Sensor Controller to PLC)

Signal Signal name Function

BUSY Busy Signal

FLG

Command Completion

Control Command Completion

Si

gnal

Z)

This is the encoder input signal. This signal is only used

when you use an encoder trigger.

This signal tells when new commands and other external

inputs

cannot be acknowledged during processing of other

external inputs.

Just because this signal is ON does not necessarily mean

that a

command is being executed. To check whether a

command is being executed, access the Command

Completion (FLG) signal.

The FH/F

command execution has been completed.

Z5 uses this signal to tell the user (PLC) that

1

Overview

GATE

Result Notification

READY

Trigger Ready

OR

Overall Judgment

DO (DO0 to DO15) Data Output Signals

XFLG

Flow Command Completion

XBUSY

Flow Command Busy

XWAIT

Flow Command Wait

Data Output Completion

Si

gnal

Camera Image Input Enabled

Signal

Overall Judgement Output

Signal

Flow Command Completion

Bit

Measurement Command Busy

Bit

Measurement Command Wait

Bit

gnal tells the timing to load the output data to the

This si

User (PLC).

Data output is enabled when this signal is ON.

This signal indicates when the STEP (Measurement

Trigger) signal or the Trigger signal can be input.

When using the multi-input function, the succeeding STEP

or Trigger signals are accepted only after this signal turns

ON.

This si

gnal gives the results of the overall judgement.

These signals are used to output parallel data and parallel

ju

dgement

This signal tells when execution of a command that was

executed during execution of PLC Link or fieldbus flow

control has been completed.

This signal tells when a command that was input during

execu

executed.

This signal tells when input of a command can be

acknowledged du

flow control.

s through a parallel interface.

tion of PLC Link or fieldbus flow control is being

ring execution of PLC Link or fieldbus

*1

*2

*3

Trigger ACK

Command Ready

ERR

Error Status

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Trigger Signal Acknowledged

Bit

Command Execution Ready

Bit

Error Signal

The FH/FZ5 uses this signal to acknowledge reception of a

T

rigger signal.

This signal tells when control command can be executed.

The FH/FZ5 provides notification with this signal when it

de

tects the following errors.

Refer to Erro

ision System FH/FZ5 Series User's Manual (Cat.

V

Z365).

• Camera connection error

• Battery error

• Fan error

Th

e ERR signal does not turn OFF even after the error is

eliminated. The signal turns OFF only when the error status

is cleared by a control command.

r Messages and Troubleshooting in the

No.

• System error

• Communications timeout

• STEP input during

measureme

Control Methods Using an External Device

nt

23

Page 26

RUN

Run Mode

Signal Signal name Function

This is a notification signal indicating the FH/FZ5 Sensor

Measurement Mode Signal

Controller is in Run mode (In a measurement capable state

with [RUN signal output] checked in the Layout settings for

the currently displayed line).

ACK Command Completion Flag

SHTOUT Exposure Completion Signal

STGOUT Strobe Trigger Output

*1: This signal is linked to the Output Unit processing items in the measurement flow.

It is not associated with the BUSY signal. It is not related to the parallel interface OR signal. Note that the operation is different

when using PLC Link. See Communicating with PLC Link (p.162).

*2: This signal is always OFF during display of a through image.

If you use a Camera with Lighting Controller, the time required

increase in comparison with not using a Camera with a Lighting Controller.

For details, refer to Camera Image Input

Items Reference Manual (C

*3: The OR signal is output only when the [Output] option is selected in the Adjustment Window.

at. No. Z341).

FH or Camera Image Input HDR in the Vision System FH/FZ5 Series Processing

This signal tells when execution of the DI command has

be

en completed

.

This signal tells when Camera exposure has been

completed.

This is the trigger signal for the strobe.

or the READY or Trigger Ready signal to turn OFF may

f

24

Control Methods Using an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 27

Command/Response Method

DI7 DI6 DI4 DI3 DI2 DI1 DI0

Execution

Command

Command information

DI5

(1) Command Area

(5) Response Area

(2) Command

(4) Response

PLC

CPU Unit

I/O memory

(communications areas)

• Switch Scene Number

• Single Measurement, etc.

OK, etc.

(3) Command is processed.

Sensor Controller

Note

Parallel

Commands are input to the Sensor Controller by turning the DI signals (DI0 through DI7) ON and OFF. There

is no direct response to these commands. Confirm whether a command was received by checking the ACK

signal. With an FZ5-series Controller, you can check the BUSY status signal instead of the ACK signal.

The command code is input with signals DI0 through DI6, and the command is executed by turning ON DI7.

PLC Link, EtherNet/IP, or EtherCAT

Command/response control signals can be exchanged by storing control commands from the PLC to the

Sensor Controller and responses from the Sensor Controller to the PLC in the I/O memory of the PLC. This

enables you to send single measurement and scene switch requests to the Sensor Controller without any

sequence control with communications commands from the PLC.

Memory Areas Used by the Command/Response Control Method

Command Area You write the control commands to execute for the Sensor Controller to this area.

Response Area

You read the results of executing the control commands that

from this area.

were written to the Command Area

1

Overview

Flow of Communications between the PLC and the Sensor Controller

(1) The PLC (the user) writes a control command to a specified PLC I/O memory area (the Command

Area).

(2) The PLC (the user) then turns ON the EXE bit to send the control command to the Sensor Controller.

(3) The Sensor Controller executes the received control command.

(4) The Sensor Controller returns a response to the PLC after the control command is executed.

(5) The PLC (the user) stores the response in a specified PLC I/O

The available control commands depend on the communication

Refer to the Command List (p.355).

Command-driven character string output is

EtherCAT.

To output character strings, send the commands using EtherNet/IP me

Refer to the Communicating with the Sensor Controller with EtherNet/IP

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

mory area (the Response Area).

me

s protocol that is used.

not supported when using EtherNet/IP tag data link communication or

ssage communication.

Message Communications (p.264)

Control Methods Using an External Device

25

Page 28

Non-procedure Communications

Data

Output Area

• Specified data is automatically output.

• Output characters

(2) Data

CPU Unit

PLC

I/O memory

(communications areas)

Sensor Controller

Measurement

execution

(1)

Communications commands are sent to the Sensor Controller through sequence control in the PLC. An

external device and the Sensor Controller communicate through non-procedure (normal) communications.

Data Output after Measurements

After a Single Measurement or Start Continuous Measurements command is executed, the Sensor Controller

automatically outputs the data that corresponds to the measurements that have been specified as output items

to the PLC. This allows you to easily pass measurement results data from the processing items to the PLC. You

can also choose to output only when the PLC meets the conditions that are required to receive the data (i.e.,

when handshaking is turned ON).

The output destination for data depends on the protocol th

at is used to

device and the Sensor Controller, as described below.

PLC Link, EtherNet/IP, or EtherCAT

The output data is automatically output to the following area that is specified PLC I/O memory.

Area of Memory Used for Data Output after Measurement

communicate between the external

Data Output Area

The output data for the measurement is written to this are

of the measurement.

a by the Sensor Controller after execution

Flow of Communications between the PLC and the Sensor Controller

The data to output after measurement and the PLC I/O memory area (Data Output Area) to store that data

are specified in advance. (Reference: Settings Required for Data Output (p.29).)

(1) Measurement is executed.

emen

(2) After a measurement is executed, the specified measur

t data is stored in the Data Output Area

in the PLC.

Parallel

The output data is output to the PLC signal wires via the DO signals (DO0 to DO15).

Non-procedure Communications

The output data is output to the PLC reception buffer through non-procedure (normal) communications.

26

Control Methods Using an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 29

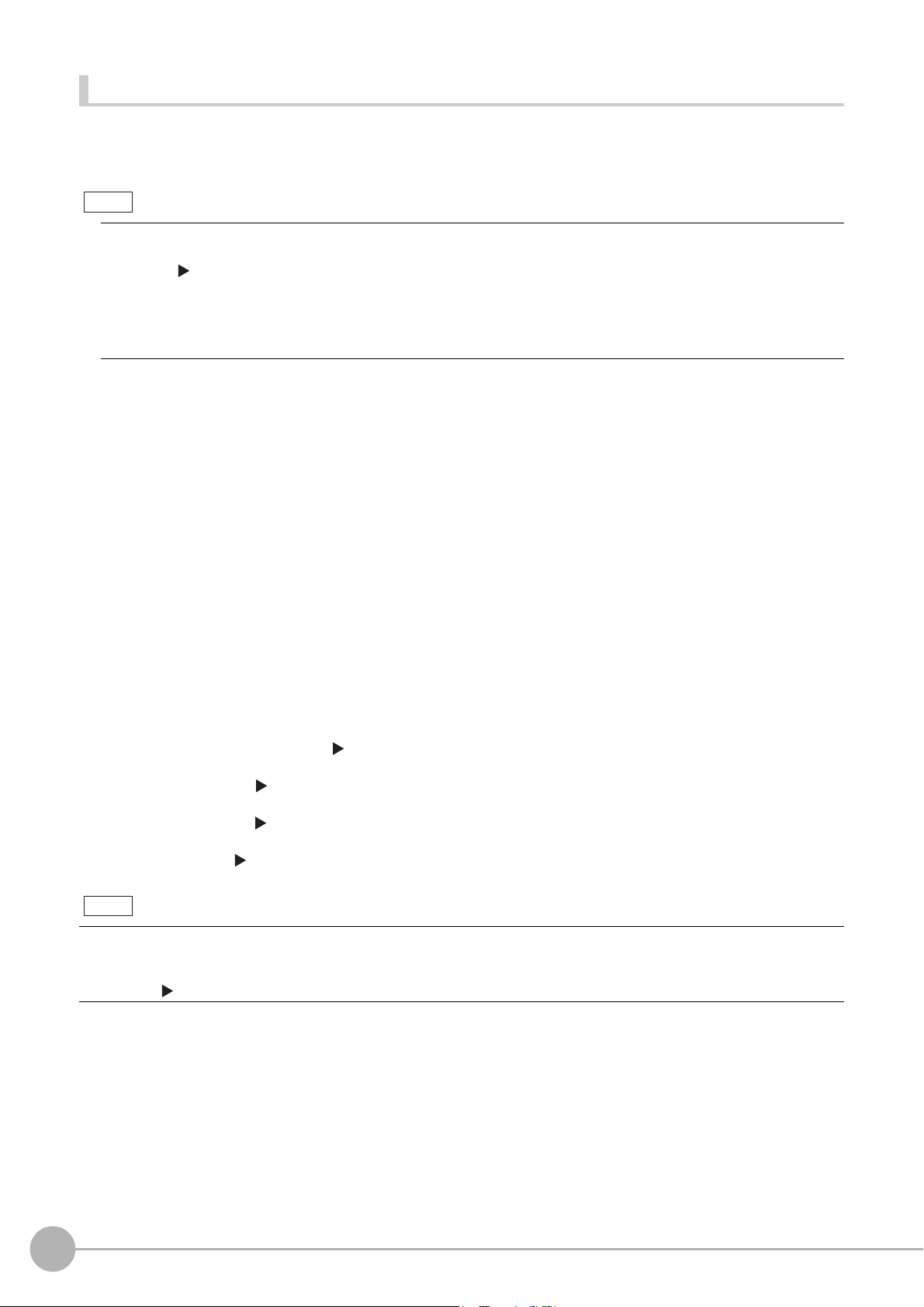

Outputting the Output Data

Search measurement

results output.

Processing

order

Measurement started.

0.Camera Image Input

1.Search

2.Data Output

Communications

Module

Measurement flow

Sensor Controller

Measurement executed.

Processing started

(BUSY).

Single Measurement

command

The results for

measurements for

1. Search are output.

Processing

order

Measurement started.

0.Camera Image Input

1.Character Inspection

Communications

Module

Measurement flow

Sensor Controller

Measurement processed.

Processing started

(BUSY).

Single Measurement

command

Characters are output

at the same time that

the characters are read.

Read charac-

ters are output.

Note

The measurement data is output to the external device via the Communications Module by the Data Output

processing unit located in the measurement flow.

t Un

Therefore, to output measurement data, you must place an Outpu

The measurement data is output when the Output Unit is execute

finished.

it processing unit in the measurement flow.

d, not when the measurement is actually

1

Overview

You can output character strings that were read by processing items that read characters, such as Character

Inspection, Barc

Character strings are output simultaneously

Command-driven character string output is not supported when using EtherNet/IP tag data link communication or

EtherCAT.

To output character strings, send the commands using EtherNet/IP me

Refer to the Communicating with the Sensor Controller with EtherNet/IP Message Communications (p.264)

ode, or 2DCode. (You must use PLC Link communications to do this.)

when

the processing item is executed.

ssage communication.

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Control Methods Using an External Device

27

Page 30

Items that Can Be Output as Output Data

Note

Note

Measurement Data

You can output up to eight items (32 bytes) with one Output Unit processing unit.

• If you need to output nine or more data items, set more than one Output

flow.

Refer to Outputting Multiple Measurement Data Items (p.30).

• The number of data items that can be output by

setting when using PLC Link or EtherCAT communications, as described below.

• PLC Link: 256 max. (1,024 bytes max.)

• EtherCAT: 64 max. (256 bytes max.)

one Output Unit processing unit can be increased by changing a

Unit processing unit in the measurement

The following items can be output:

• Judgement result

• Measured parameters (correlation values, reference coordinates, etc.)

• Results calculated based on the values of the measured parameters

• Judgement results from expression results (Parallel Judgement Output)

Character Output (PLC Link Communications or Non-procedure Communications Only)

You can output the characters that were read by processing items such as Character Inspection.

• Character output is supported only for PLC Link communications or non-procedure communications.

• Maximum number of output chara

• Character Inspection: 32 characters

• Barcode:1024 characters

• 2DCode: 652 characters

• OCR: 128 characters (32 characters × 4 lin

• T

he Read string is output as NULL(/0).

cters are as follows.

es)

The processing items that support character output are listed below.

Refer to the descriptions for each processing item for d

• Character Inspection (Refer to Character Inspection in the Vision System FH/FZ5 Series Processing Items

Reference Manual (Cat. No

• Barcode (Refer to Barcode in the V

Z341).)

• 2DCode (Refer to 2

Z341).)

• OCR (Refer to OCR in the Vision System FH/FZ5 Series Processin

Command-driven character string output

EtherCAT.

To output character strings, send the commands using EtherNet/IP me

Refer to the Communicating with the Sensor Controller with EtherNet/IP

. Z341).)

DCode in the V

is not supported when using EtherNet/IP tag data link communication or

ision System FH/FZ5 Series Processing Items Reference Manual (Cat. No.

ision System FH/FZ5 Series Processing Items Reference Manual (Cat. No.

etails on the character output format.

g Items Referen

ssage communication.

Message Communications (p.264)

ce Manual (Cat. No. Z341).)

28

Control Methods Using an External Device

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 31

Settings Required for Data Output

Use the following procedure to set up Output Unit processing units for data output.

Measurement Data

1 Place the output data in the processing flow.

Place the processing unit for data output in the measurement flow.

Processing Units That Serve as Output Units

The processing items under [Output result] in the processing item tree in the Flow Editor serve as Output

Units.

Output Unit Selection

Select the Output Units according to the communications protocol based on the combinations that are

shown in the following table.

For information on communications protocols, refer to Communication Protocols for Communication

with the Sensor Controller (p.19).

OK: Data can be output, ---: Data cannot be output.

1

Overview

Communications protocol

Output unit

Parallel Data Output OK --- --- --- ---

Parallel Judgement Output OK --- --- --- ---

Data Output --- OK --- --- OK

Fieldbus Data Output --- --- OK OK ---

Parallel PLC Link EtherNet/IP EtherCAT

2 Set the items to output.

Set the items to output as output data in the Output Units that you have placed in the measurement flow.

Refer to the descriptions for the communications protocol for

items in the Output Units.

Character Output (PLC Link Non-procedure Communications Only)

Set the character output settings for processing items that read output characters, such as Character

Inspection.

The character output operation is

set an Output Unit in the measurement flow.

Refer to the descriptions for individua

output.

• Character Inspection (Refer to Character Inspection in the Vision System FH/FZ5 Series Processing Items

Reference Manual (Cat. No

• Barcode (Refer to Barcode in the V

Z341).)

• 2DCode (Refer to 2

Z341).)

DCode in the V

executed by th

l proc

. Z341).)

ision System FH/FZ5 Series Processing Items Reference Manual (Cat. No.

ision System FH/FZ5 Series Processing Items Reference Manual (Cat. No.

e above processing items. In this case, it is not necessary to

essing items for details on the settings required for character

the specific procedures to set the output

Non-

procedure

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Control Methods Using an External Device

29

Page 32

• OCR (Refer to OCR in the Vision System FH/FZ5 Series Processing Items Reference Manual (Cat.

Note

Processing

order

Measurement started.

Search measurement

results output.

0.Camera Image Input

1.Search

4.Data Output

Communications

Module

Measurement flow

Sensor Controller PLC

Command

Area

I/O memory

Response

Area

Output Area

2.Data Output

3.Position Compensation

The data that is output

first is overwritten by the

second data output

Position compensa-

tion values output.

No. Z341).)

Command-driven character string output is not supported when using EtherNet/IP tag data link communication or

EtherCAT.

To output character strings, send the commands using EtherNet/IP message communication.

Refer to the Communicating with the Sensor Controller with EtherNet/IP

Message Communications (p.264)

Outputting Multiple Measurement Data Items

Using Multiple Output Units for Data Output

You can register more than one Output Unit in the measurement flow.

If you want to output different types of data during measure

more than nine different data items, you must register multiple Output Units in the measurement flow.

ment flow processing, or if you want to output

Data output is executed for each Output Unit set in the measureme

data is the same PLC I/O memory area (the Data Output Area).

In this case, the output data that is

output first will be overwritten by

one of the following methods if you want to save all the output data.

nt flow, but the output destination for that

any output data written afterwards. Use

Offsets (PLC Link Communications Only)

When you use multiple Output Units to output data, you can offset the write destination of the output data

for each Output Unit.

Set the [Offset] for the Data Outpu

Registration) (p.232).

30

Control Methods Using an External Device

t pr

ocessing item. Refer to Output Data Settings (Processing Item

Vision System FH/FZ5 Series User’s Manual

for Communications Settings (Z342)

Page 33

Controlling Data Output with Handshaking

Note

16 bits

Parallel data output

PLC

0. Measurement data 0

7. Measurement data 7

Reception

buffer

Data output order

Measurement

data 7

Measurement

data 0

GATE

signal

DO0 to DO15

signals

ON

OFF

If handshaking is used to control data output, the timing of outputting the data is controlled by I/O signals.

Each time that data is output, read the output data and move it to a dif

ferent part of I/O memory in the

PLC.