Page 1

Cat. No. Z290-E1-0

FZ3

Xpectia Series

Vision Sensor

USERS MANUAL

Page 2

Introduction

Thank you for purchasing the FZ3 Series.

This manual provides information regarding functions, performance and operating methods that

are required for using the FZ3 Series.

When using the FZ3 Series, be sure to observe the following:

• The FZ3 Series must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

Contents

1. Before Operation

Operation Flow………………………………………………………………………………………………10

Layouts of Screens/Windows………………………………………………………………………………11

Layout of Main Screen (ADJUST Window) ……………………………………………………………11

Layout of Main Screen (RUN Window)…………………………………………………………………14

Layout of Edit Flow Window ……………………………………………………………………………17

Layout of Property Setting Window ……………………………………………………………………19

Checking System Configuration …………………………………………………………………………20

Basic Configuration of FZ3 Series………………………………………………………………………20

Description of Model-specific Functions ………………………………………………………………21

Preparing Controllers and Cameras ………………………………………………………………………23

Preparing Controllers ……………………………………………………………………………………23

Adjusting Cameras ………………………………………………………………………………………23

Intelligent Camera (with Lighting Function) ……………………………………………………………24

Input Operations ……………………………………………………………………………………………25

Operation of Touch Pen …………………………………………………………………………………25

Basic Operation of Mouse and Trackball ………………………………………………………………25

Returning Controller to Factory Settings …………………………………………………………………27

Initializing Controller [System Initialization] ……………………………………………………………27

Restarting Controller [System Restart]…………………………………………………………………27

Saving Settings and Turning Power Off …………………………………………………………………28

Turning Off LCD …………………………………………………………………………………………28

Setting Operation Mode ……………………………………………………………………………………30

Operation Mode Selection Guidelines …………………………………………………………………32

High-speed Logging Mode ………………………………………………………………………………32

Parallel-operation High-speed Mode …………………………………………………………………33

Single-line High-speed Mode……………………………………………………………………………35

Multi-line Random-trigger Mode ………………………………………………………………………37

Non-stop Adjustment Mode ……………………………………………………………………………38

…………………………………………………………………………………………9

2. Setting Scenes (Measurement Flow)

What Is a Scene?……………………………………………………………………………………………42

Scene Examples …………………………………………………………………………………………42

What Is a Scene Group?……………………………………………………………………………………46

Creating a Scene ……………………………………………………………………………………………47

Processing Item Selection Guidelines ……………………………………………………………………49

Selecting Measurement Processing Items Using a Chart ……………………………………………49

Selecting Measurement Processing Items According to the Measurement Method and Purpose

……………………………………………………………………………………………………………………56

Editing Processing Units in Scenes ………………………………………………………………………63

Switching Scenes and Scene Groups ……………………………………………………………………65

Switching Scenes ………………………………………………………………………………………65

Switching Scene Groups ………………………………………………………………………………65

Editing Scenes ………………………………………………………………………………………………67

Copying a Scene …………………………………………………………………………………………67

Clearing a Scene …………………………………………………………………………………………67

FZ3 User's Manual 1

…………………………………………………………41

Page 4

Renaming a Scene and Adding a Description…………………………………………………………68

Editing Scene Groups ………………………………………………………………………………………70

Copying a Scene Group …………………………………………………………………………………70

Deleting a Scene Group …………………………………………………………………………………71

Renaming a Scene Group ………………………………………………………………………………71

3. Performing Test Measurement/Starting Operation

ADJUST Window and RUN Window………………………………………………………………………74

ADJUST Window …………………………………………………………………………………………74

RUN Window ……………………………………………………………………………………………74

Switching to the RUN Window …………………………………………………………………………76

Switching to the ADJUST Window ……………………………………………………………………76

Performing Test Measurement ……………………………………………………………………………77

Key Points for Adjustment …………………………………………………………………………………79

Stabilizing Measurement ………………………………………………………………………………79

Shortening Processing Time ……………………………………………………………………………81

Arranging the RUN Window ………………………………………………………………………………82

Displaying Multiple Windows Together ………………………………………………………………82

Changing Display Contents ……………………………………………………………………………83

Enlarging Measurement Images [Zoom Images] ……………………………………………………87

Displaying Flow and Detailed Results …………………………………………………………………87

Switching the RUN Window to Fast View Mode [Select RUN Mode] ………………………………88

Changing Display Contents on the RUN WindowMeasurement Information Display Area ………89

Changing Functions That Can Be Operatedfrom the RUN Window Tool Box ……………………89

Useful Functions for Operation ……………………………………………………………………………90

Remeasuring Saved Images ……………………………………………………………………………90

Improving Adjustment Efficiency ………………………………………………………………………91

Changing Judgement Conditions without Stopping Measurement …………………………………93

Changing Regions as a Batch [Shift area] ……………………………………………………………94

Monitoring Measurement Value Trends ………………………………………………………………95

Logging Measurement Values and Measurement Images …………………………………………96

Analyzing Logging Data ………………………………………………………………………………102

Clearing Measurement Results ………………………………………………………………………104

Clearing Saved Images ………………………………………………………………………………104

Capturing Screens………………………………………………………………………………………105

………………………………………73

4. Using Tool

Using NG Analyser ………………………………………………………………………………………108

Layouts of NG Analyser Screens ……………………………………………………………………109

Using Method of NG Analyser …………………………………………………………………………111

5. Saving/Loading Data

Basic Knowledge about Data Saving ……………………………………………………………………116

About Saving Areas ……………………………………………………………………………………116

About USB Drive Names ………………………………………………………………………………116

Saving Settings Data to Controller Memory ……………………………………………………………118

When Using Scene Group 0 …………………………………………………………………………118

When Using Scene Groups 1 to 31 …………………………………………………………………118

Saving Settings Data to RAMDisk/USB Device ………………………………………………………120

2 FZ3 User's Manual

………………………………………………………………………………………………107

………………………………………………………………………………115

Page 5

Saving Logging Images to RAMDisk/USB Device ……………………………………………………122

How to Use USB Memory (FZ3-9/H9only)………………………………………………………………123

Copying/Moving Files ……………………………………………………………………………………124

Loading Settings Data to Controller ……………………………………………………………………126

6. Changing the System Environment

Setting Conditions for Camera Use ……………………………………………………………………128

Checking Camera Connections [Camera Connection] ……………………………………………128

Setting Trigger Delay [Inter-camera Setting]…………………………………………………………128

Setting Conditions Related to Operation during Measurement ………………………………………130

Setting the System Operation Environment ……………………………………………………………131

Setting the Date and Time [Date-time Setting] ………………………………………………………131

Selecting the Language [Language Setting] …………………………………………………………131

Setting the Fan Rotation Speed [Fan Control Setting]………………………………………………132

Setting the Start-up Status [Startup Setting] …………………………………………………………133

Setting the RUN Window Display [RUN mode View Setting] ………………………………………140

Setting the RUN Window Shortcut [Create Shortcut] ………………………………………………140

Setting the Encoder Trigger [Encoder Trigger Setting] ……………………………………………141

Setting the STEP Input Detection Pulse Width [STEP Setting] ……………………………………142

Setting the RUN Window Password [Password Setting]……………………………………………143

Checking System Information [System Information] ………………………………………………145

7. Methods for Connecting and Communicating with External Devices

About Connecting with External Devices ………………………………………………………………148

Communicating through Serial Communication (PLC Link) …………………………………………151

Communication Processing Flow (PLC Link) ………………………………………………………151

Setting Communication Specifications (Ethernet - PLC Link) ……………………………………151

Setting Communication Specifications (RS-232C/422-PLC Link) …………………………………156

Memory Allocation (PLC Link)…………………………………………………………………………160

Command Control (PLC Link) …………………………………………………………………………162

Data Output (PLC Link) ………………………………………………………………………………171

Timing Chart (PLC Link) ………………………………………………………………………………171

Ladder Program Example (PLC Link)…………………………………………………………………175

Controlling/Outputting through Serial Communication (Non-procedure) ……………………………176

Communication Processing Flow (Non-procedure) …………………………………………………176

Setting Communication Specifications (Ethernet - Non-procedure) ………………………………176

Setting Communication Specifications (RS-232C/422 - Non-procedure)…………………………180

Checking Communication Status (Non-procedure) …………………………………………………181

Command Format (Non-procedure) …………………………………………………………………182

Command List (Non-procedure) ………………………………………………………………………183

Output Format (Non-procedure) ………………………………………………………………………208

Controlling/Outputting through Parallel Communication ………………………………………………211

Setting Communication Specifications (Parallel Interface)…………………………………………211

Checking Communication Status (Parallel Interface) ………………………………………………213

I/O Format (Parallel Interface)…………………………………………………………………………214

Timing Chart ……………………………………………………………………………………………218

Externally Outputting Data through FTP ………………………………………………………………226

Setting Communication Specifications ………………………………………………………………226

Communication Example ………………………………………………………………………………228

…………………………………………………………127

…………147

FZ3 User's Manual 3

Page 6

8. External Reference Tables

Input image…………………………………………………………………………………………………232

Measurement Image Switching ………………………………………………………………………232

Measurement ………………………………………………………………………………………………233

Search ……………………………………………………………………………………………………233

Flexible Search …………………………………………………………………………………………234

Sensitive Search ………………………………………………………………………………………235

ECM Search ……………………………………………………………………………………………237

EC Circle Search ………………………………………………………………………………………238

Shape Search+ …………………………………………………………………………………………240

Classification ……………………………………………………………………………………………242

Edge Position ……………………………………………………………………………………………243

Edge Pitch ………………………………………………………………………………………………244

Scan Edge Position ……………………………………………………………………………………245

Scan Edge Width ………………………………………………………………………………………246

Color Data ………………………………………………………………………………………………247

Gravity and Area ………………………………………………………………………………………248

Labeling …………………………………………………………………………………………………250

Label Data ………………………………………………………………………………………………252

Labeling+ ………………………………………………………………………………………………253

Defect ……………………………………………………………………………………………………257

Precise Defect …………………………………………………………………………………………258

Fine Matching……………………………………………………………………………………………259

Character Inspection……………………………………………………………………………………260

Date Verification ………………………………………………………………………………………261

Model Dictionary ………………………………………………………………………………………262

Barcode+…………………………………………………………………………………………………262

2D Code+ ………………………………………………………………………………………………264

Circle Angle ……………………………………………………………………………………………265

Compensate image ………………………………………………………………………………………267

Position Compensation…………………………………………………………………………………267

Trapezoidal Correction+ ………………………………………………………………………………267

Filtering …………………………………………………………………………………………………268

Background Suppression ………………………………………………………………………………268

Color Gray Filter…………………………………………………………………………………………269

Extract Color Filter………………………………………………………………………………………270

Anti Color Shading………………………………………………………………………………………271

Stripes Removal Filter+ ………………………………………………………………………………271

Halation Cut+ ……………………………………………………………………………………………272

Panorama+ ………………………………………………………………………………………………272

Polar Transformation …………………………………………………………………………………273

Support measurement ……………………………………………………………………………………274

Calculation ………………………………………………………………………………………………274

Line Regression…………………………………………………………………………………………274

Circle Regression ………………………………………………………………………………………275

Calibration+ ……………………………………………………………………………………………275

Set Unit Data ……………………………………………………………………………………………276

Get Unit Data ……………………………………………………………………………………………276

Set Unit Figure …………………………………………………………………………………………276

………………………………………………………………………229

4 FZ3 User's Manual

Page 7

Get Unit Figure …………………………………………………………………………………………276

Trend Monitor……………………………………………………………………………………………277

Image Logging …………………………………………………………………………………………278

Data Logging ……………………………………………………………………………………………278

Elapsed Time ……………………………………………………………………………………………279

Wait ………………………………………………………………………………………………………279

Focus ……………………………………………………………………………………………………279

Iris ………………………………………………………………………………………………………279

Branch ………………………………………………………………………………………………………281

Conditional Branch ……………………………………………………………………………………281

DI Branch ………………………………………………………………………………………………281

Output result ………………………………………………………………………………………………282

Data Output ……………………………………………………………………………………………282

Parallel Data Output ……………………………………………………………………………………282

Parallel Judgement Output ……………………………………………………………………………283

Display result ………………………………………………………………………………………………284

Result Display …………………………………………………………………………………………284

Display Image File………………………………………………………………………………………284

Display Last NG Image …………………………………………………………………………………284

9. Appendixes

About Lenses ………………………………………………………………………………………………288

Error Messages and Troubleshooting …………………………………………………………………294

FAQ …………………………………………………………………………………………………………297

During Start-up …………………………………………………………………………………………297

During Operation ………………………………………………………………………………………297

For Measurement ………………………………………………………………………………………298

About Parallel Interface ………………………………………………………………………………299

About Serial Interface (RS-232C/422 Connection) …………………………………………………299

Measurement Mechanism ………………………………………………………………………………300

Color Processing Mechanism …………………………………………………………………………300

Search Processing Mechanism ………………………………………………………………………300

Edge Detection Measurement…………………………………………………………………………304

Defect Detection Measurement ………………………………………………………………………306

Handling Coordinates …………………………………………………………………………………307

Terminology Explanations ………………………………………………………………………………309

Basic Knowledge about Operations ……………………………………………………………………313

Inputting Values …………………………………………………………………………………………313

Inputting Text ……………………………………………………………………………………………313

Selecting Files and Folders ……………………………………………………………………………314

Available Operations in Select File Window …………………………………………………………316

Using the Zoom Function ………………………………………………………………………………317

Setting Figures ……………………………………………………………………………………………319

Layout of Figure Setting Area …………………………………………………………………………319

Setting Methods…………………………………………………………………………………………320

About OR Setting/NOT Setting ………………………………………………………………………328

About Number of Logging Images ………………………………………………………………………330

About Limits on the Number of Image Input Processing Items Used ………………………………331

About Max. Number of Loading Images during Multiple Image Input ………………………………333

………………………………………………………………………………………………287

FZ3 User's Manual 5

Page 8

Character Code Table ……………………………………………………………………………………334

Upper Limits of Processing Item Parameters …………………………………………………………335

About Memories Usable with FZ Series…………………………………………………………………336

Index

……………………………………………………………………………………………………………337

6 FZ3 User's Manual

Page 9

How This Manual Is Organized

This manual includes two manuals: the "User's Manual", which describes basic operations and settings

for vision sensors, and the "Processing Item List Manual", which describes the setting options for each

processing item.

Conventions Used in This Manual

Symbols

The symbols used in this manual have the following meanings.

Indicates relevant operational precautions that must be followed.

Indicates operation-related suggestions from OMRON.

Use of Quotation Marks and Brackets

In this manual, menus and other items are indicated as follows.

[ ] Menu Indicates the menu names or processing items shown in the menu bar.

" " Item name Indicates the item names displayed on the screen.

Version Upgrade Information (at Oct.1 2009)

The newly added functions are described here.

Revision history : FZ3-9 /H9 series (V3.0)

Newly added

function

Special function

corresponding to

FZ3-9 /H9

series

Operation modes, NG analyser, focus, iris and other functions

have been added.

※ The correspondence software is different in FZ3-3 /H3

/7 /H7 series.

The latest software is Ver2.1.

Description of newly added functions Reference in manual

Reference: "User's Manual",

"De scription of M odel-specific

Functions" (p.21)

FZ3 User's Manual 7

Page 10

8 FZ3 User's Manual

Page 11

Before Operation

This chapter describes the basic flow and preparations

before beginning operation.

Reference: Operation Flow (p.10)

Reference: Layouts of Screens/Windows (p.11)

Reference: Checking System Configuration (p.20)

Reference: Preparing Controllers and Cameras (p.23)

Reference: Input Operations (p.25)

Reference: Returning Controller to Factory Settings (p.27)

Reference: Saving Settings and Turning Power Off (p.28)

1

Before Operation

FZ3 User's Manual 9

Page 12

1

Before Operation

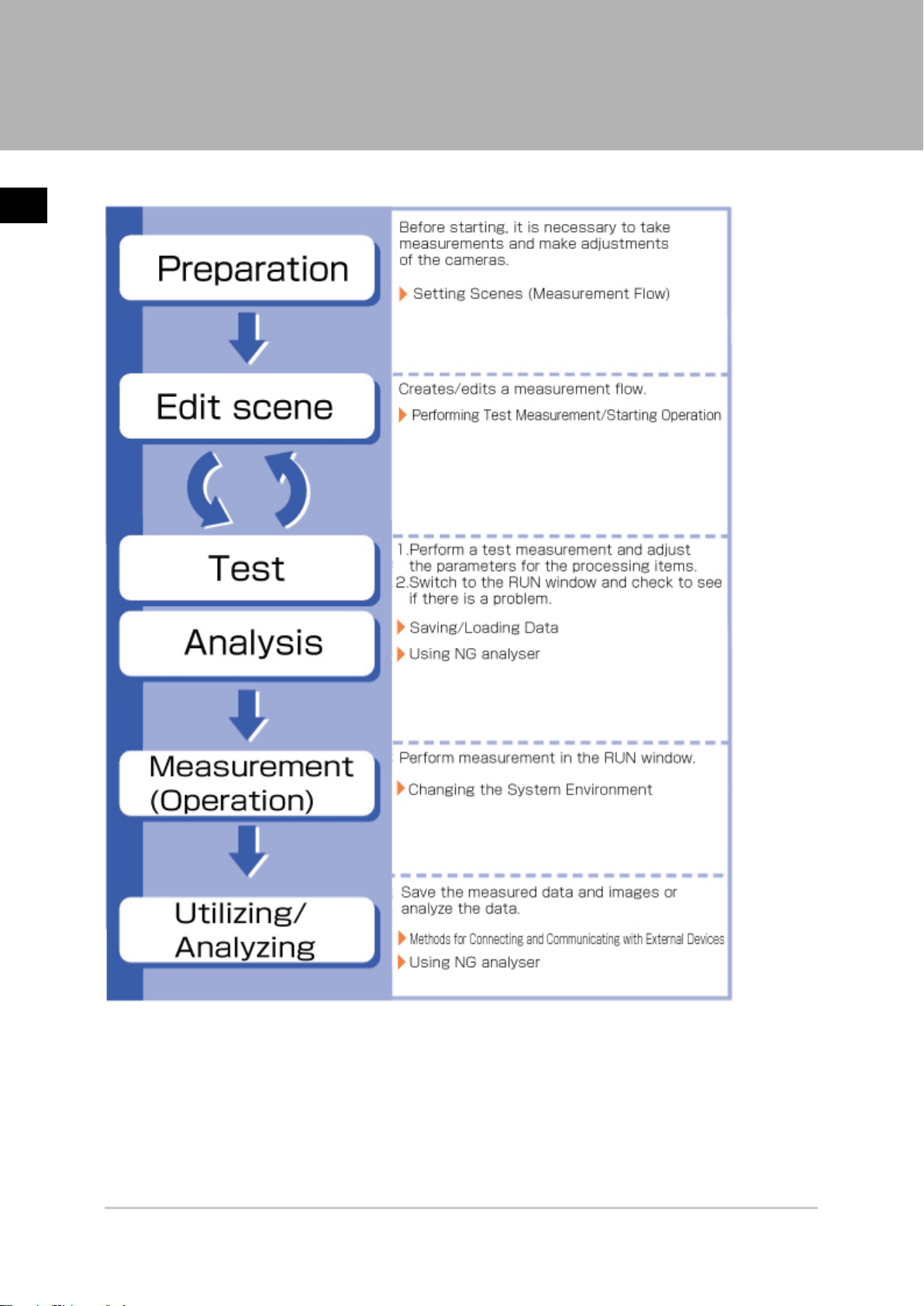

Operation Flow

Here describes the operation flow.

10 Operation Flow FZ3 User's Manual

Page 13

Layouts of Screens/Windows

Screens vary with the status of the operation being performed. The structure of some typical screens

and the functions for the various buttons are described here.

1

Before Operation

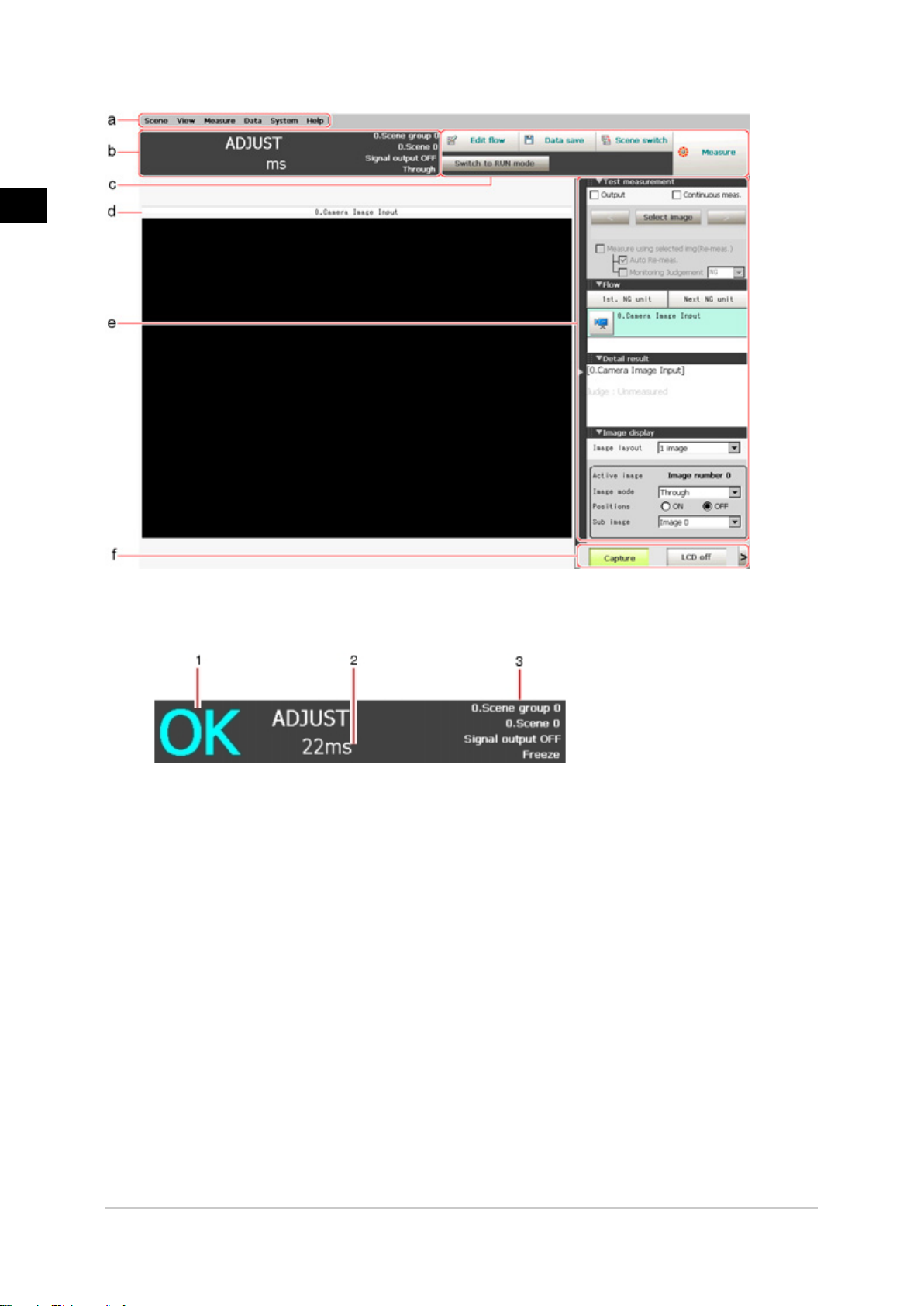

Layout of Main Screen (ADJUST Window)

This screen is used to check whether measurement is being performed correctly according to the set

conditions.

FZ3 User's Manual Layouts of Screens/Windows 11

Page 14

1

Before Operation

Menu Bar

a.

Select operations and settings menus related to measurement.

Measurement Information Display Area

b.

Overall judgement

1.

Displays a scene's overall judgement result ( [OK]/ [NG]).

Processing time

2.

Displays the time required for the measurement process.

Status display

3.

Displays the scene group number, scene number, external output status, and image mode

for the currently displayed scene.

Toolbar

c.

Commonly-used functions appear in the toolbar.

●

Edit flow

The Edit Flow window is displayed. Addition and deletion of processing units and switching

of the processing sequence is performed in the Edit Flow window.

●

Data save

Setting data is saved into the internal flash memory in the controller. Make sure to save

when settings have been modified.

●

Scene switch

To switch a scene group or scene.

●

Measure/Stop meas.

12 Layouts of Screens/Windows FZ3 User's Manual

Page 15

Starts/stops measurement.

●

Switch to RUN mode

Switches to the RUN window.

Image Display Area

d.

Displays the measured image.

Property setting buttons

1.

Displays the name of the currently selected processing item.Moving to the property setting

window can be done by tapping here.

Control Area

e.

Displays "Test measurement", "Flow", "Detail result", and "Image display".

●

Test measurement

Use when test measurement conditions and images that have been acquired are used for

remeasurement.

1

Before Operation

●

Flow

Displays the judgement results for the flow and each unit.

1. Moves to the top processing unit with an NG error.

2. Moves to the next processing unit with an NG error.

●

Detail result

The detailed measurement results of the processing units selected in the measurement

flow are displayed as text.

FZ3 User's Manual Layouts of Screens/Windows 13

Page 16

1

Before Operation

●

Image display

Sets the display method for the Image Display area.

Measurement Manager Bar

f.

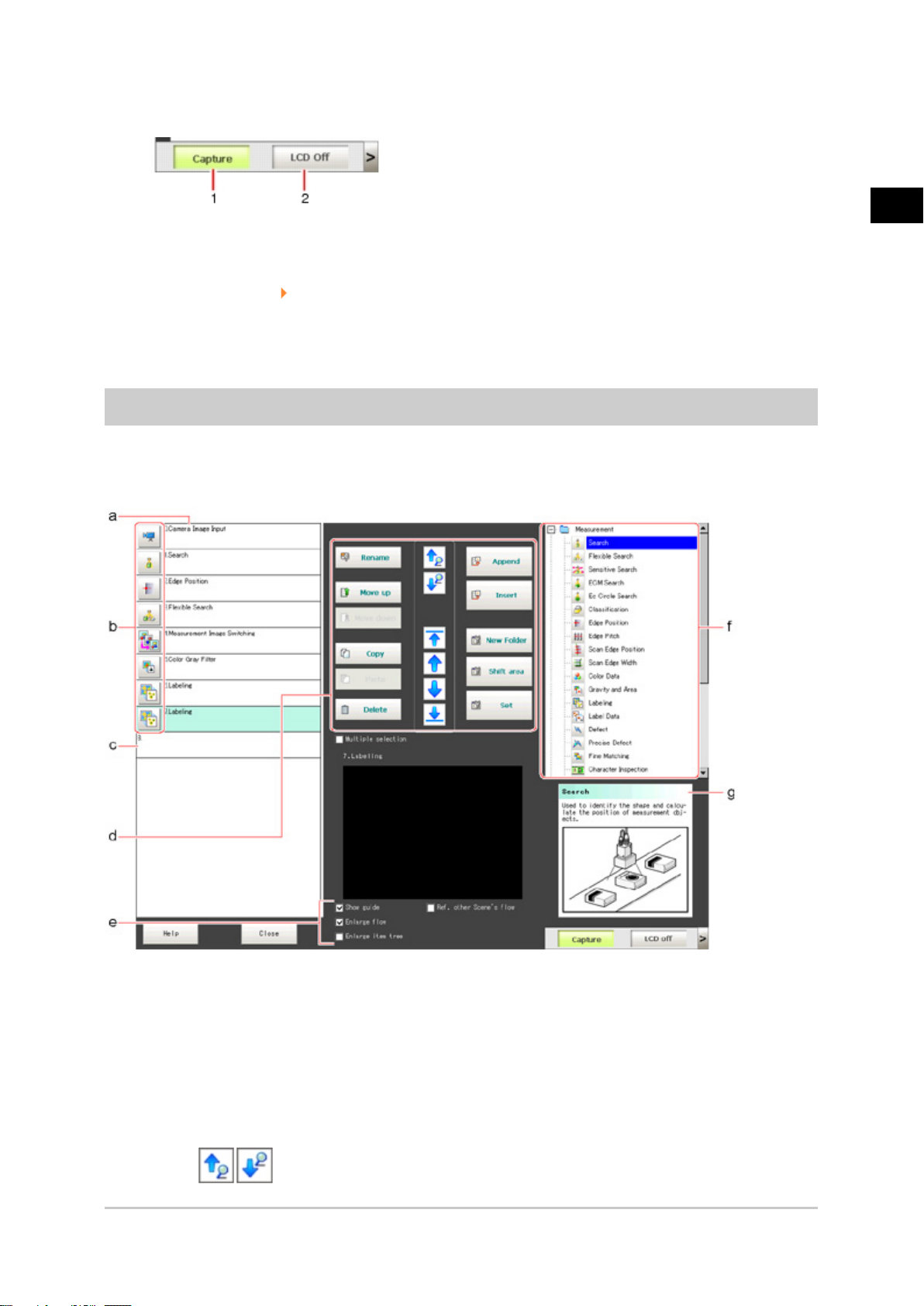

[Capture]

1.

Saves the content displayed on the monitor as an image.

Reference: Set the save destination for captured images. (p.106)

[LCD Off] (Displayed only with LCD-integrated controllers.)

2.

Turns off power to the LCD monitor. Tap the bottom of the monitor screen to turn on power

to the LCD monitor again.

Layout of Main Screen (RUN Window)

This window is used during operation.

14 Layouts of Screens/Windows FZ3 User's Manual

Page 17

Measurement Information Display Area

a.

1

Before Operation

Overall judgement

1.

Displays a scene's overall judgement result ( [OK]/ [NG]).

The judgement results for each processing unit are displayed in the Control area.

Processing time

2.

Displays the time required for the measurement process.

Scene Group Name, Scene Name

3.

Displays the scene group number and the scene number of the currently displayed scene.

Image Display Area

b.

Displays the measured image.

Property setting buttons

1.

Displays the name of the currently selected processing item.

FZ3 User's Manual Layouts of Screens/Windows 15

Page 18

1

Before Operation

Control Area

c.

Displays [Flow], [Detail result], [Image display], and [Tool box].

●

Flow

Displays the judgement results for the flow and each unit.

1. Moves to the top processing unit with an NG error.

2. Moves to the next processing unit with an NG error.

Note

●

The size of the processing unit buttons can be changed through [View] menu - [Display the enlarged flow] in the

ADJUST Window.

●

Detail result

The detailed measurement results of the processing units selected in the measurement

flow are displayed as text.

●

Image display

Sets the display method for the Image Display area.

●

Tool box

Starts and stops simplified non-stop adjustment, and switches to the ADJUST window.

Items for which operation is performed in the ADJUST window can be allocated to buttons,

and they can then be executed in the RUN window.

16 Layouts of Screens/Windows FZ3 User's Manual

Page 19

Measurement Manager Bar

d.

[Capture]

1.

Saves the content displayed on the monitor as an image.

Reference: Set the save destination for captured images. (p.106)

[LCD Off] (Displayed only with LCD-integrated controllers.)

2.

Turns off power to the LCD monitor. Tap the bottom of the monitor screen to turn on power

to the LCD monitor again.

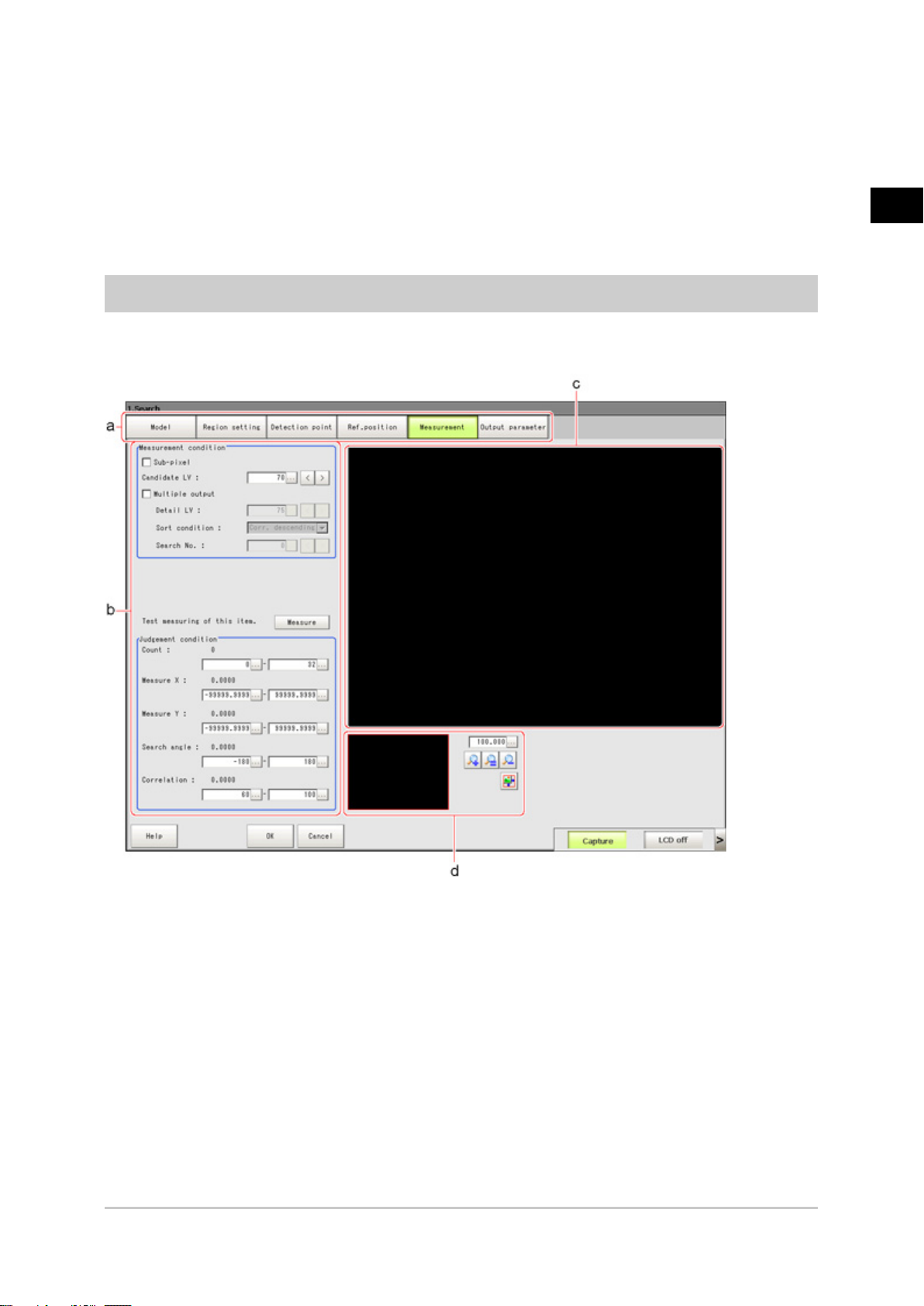

Layout of Edit Flow Window

This window is for compiling the measurement flow.Flow parts are displayed on the right side and the

measurement flow is displayed on the left. If the measurement trigger is activated, processing is

executed in sequence starting from the top of the flow.

1

Before Operation

Unit List

a.

Lists the processing units included in the flow.

You can create a flow for a scene by adding processing items to the unit list.

Property Setting Buttons

b.

Displays the property setting window where detailed settings can be performed.

End Marker

c.

Indicates the end of the flow.

Edit Flow Buttons

d.

●

FZ3 User's Manual Layouts of Screens/Windows 17

Search up/Search down

Page 20

1

Before Operation

Searching can be performed to find out what position a processing item occupies in the

unit list.

The icon for the processing item to be searched for is selected in the processing item tree

and clicked.

This function is convenient when setting long flows.

●

Select top/Select bottom

Selects the processing unit at the top or bottom of the flow.

●

Select above/Select below

Selects the processing unit located one above or one below the currently selected

processing unit.

●

Rename

Displays a window for renaming the selected processing unit.

●

Move up/Move down

Moves the selected processing unit upward or downward.

●

Copy

Copies the selected processing unit.

●

Paste

Pastes the copied processing unit immediately before the selected processing unit.Pasting

cannot be performed if any operations other than paste are performed after copying.

●

Delete

Deletes the selected processing unit.

●

Append (Bottom)

Adds a processing unit to the bottom of the flow.

●

Insert

Inserts a new processing unit immediately before the selected processing unit.

●

New folder

Used when multiple processing units are managed as one group.

●

Shift area

Changes related figure data in one batch.

●

Multiple selection

Used when processing units are copied or deleted together.

●

Set

Displays the processing item setting window for the selected processing unit.

Display Options

e.

●

Show guide

When checked, explanations for processing items are displayed.

●

Enlarge flow

When checked, the "a Unit list" flow is displayed with large icons.

●

Enlarge item tree

When checked, the "f Processing item tree" is displayed with large icons.

●

Ref. other Scene's flow

When checked, other scene flows within the same scene group can be referred to.

Processing Item Tree

f.

This area is for selecting processing items to add to the flow.Processing items are classified by

type and displayed as a tree. Tapping the plus sign "+" of any item displays expanded contents

18 Layouts of Screens/Windows FZ3 User's Manual

Page 21

below that item. Tapping the minus sign "-" of any item collapses the expanded contents.

When "Ref. other Scene's flow" is checked, the scene select box and other scene flows are

displayed.

Guide

g.

Shows an explanation for the processing item selected in the processing item tree.These are

used as reference when selecting processing items. To display guides, check "Show guide" in "e

Display options".

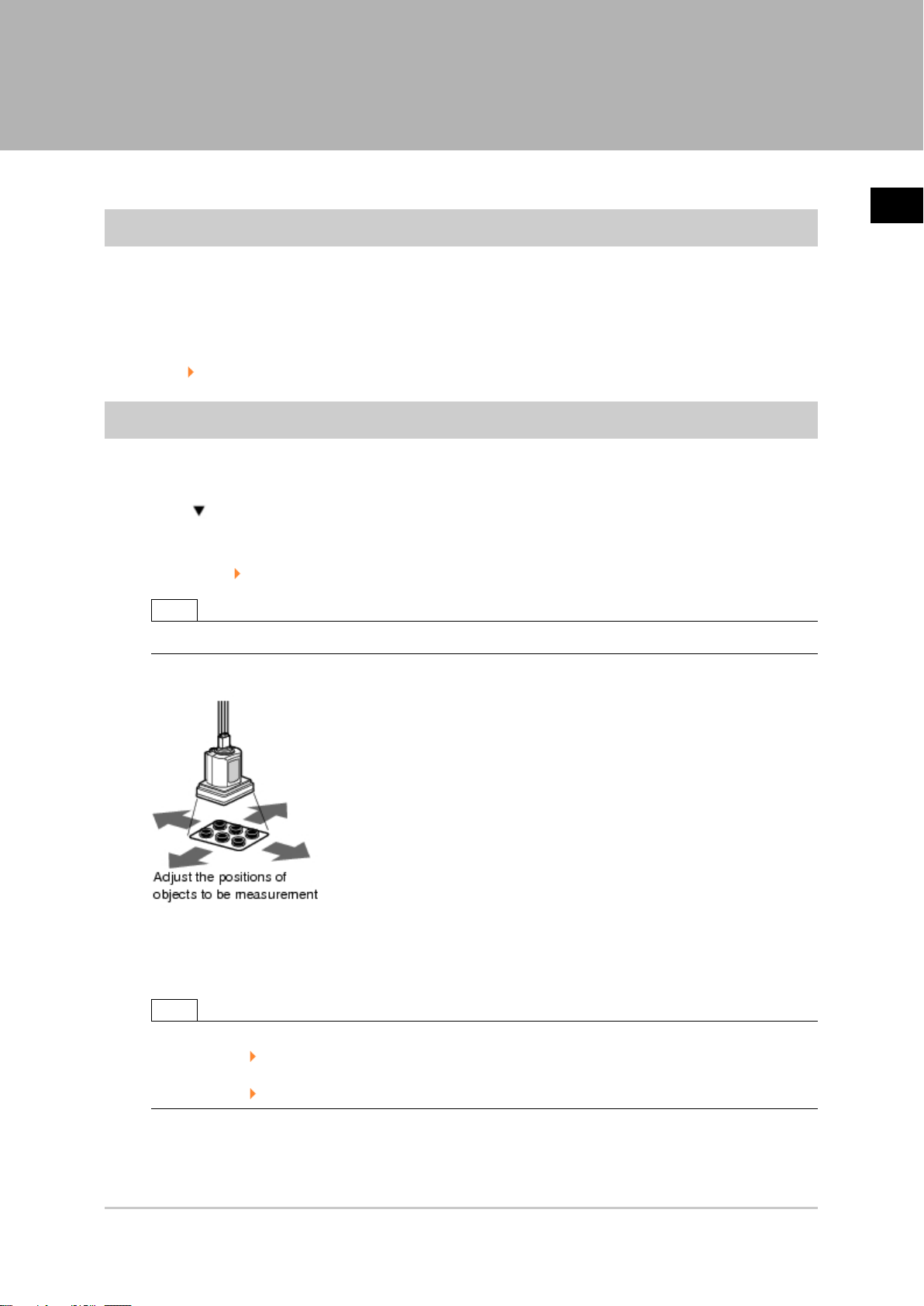

Layout of Property Setting Window

This window is used for detailed setting of measurement parameters and judgement conditions for

processing items.

1

Before Operation

Item Tab Area

a.

Displays the settings items for the processing unit currently being set.Perform settings starting

with the item on the left.

Detail Area

b.

Set detailed items.

Image Display Area

c.

Displays camera images, figures, and coordinates.

Zoom Browser Area

d.

Zooms in and out from the displayed image.

FZ3 User's Manual Layouts of Screens/Windows 19

Page 22

1

Before Operation

Checking System Configuration

This product is a vision sensor for performing image processing measurement through a controller of

objects photographed using a camera. By connecting an external device such as a PC, measurement

commands can be input and measurement results can be output from the external device.

Basic Configuration of FZ3 Series

*1: The touch pen is a controller accessory.

*2: FZ-SC2M and FZ-S2M cannot be connected with the FZ3-3 /FZ3-H3 series.

*3: Lenses for small-size cameras are required for small-size 0.3 megapixel cameras.

*4: FZ-SC5M/FZ-S5M cannot be connected with the FZ3-3 /FZ3-H3 series.

Note

●

For details on connector specifications, etc., see the "Operator's Manual (Setup)" of each model.

20 Checking System Configuration FZ3 User's Manual

Page 23

Description of Model-specific Functions

FZ3-9 /H9 Series Added Functions

Operation mode

Thanks to the dual core CPU, different operation modes can be set to meet different purposes of use.

A desired operation mode can be selected from [Parallel-operation high-speed mode], [Single-line

high-speed mode], [High-speed logging mode], [Non-stop adjustment mode] and [Multi-line

random-trigger mode].

Reference: Setting Operation Mode (p.30)

Useful processing items when setting up camera

[Focus] (focus adjustment) and [Iris] (iris adjustment) have been added to support camera adjustment

during startup.

Reference: "Processing Item List Manual", "Focus" (p.389)

Reference: "Processing Item List Manual", "Iris" (p.392)

NG analyser

This tool supports various analysis tasks at startup and during operation, such as identifying optimal

thresholds using sample images and finding the causes of problems occurring on the line by analyzing

logging images.

Reference: Using NG Analyser (p.108)

1

Before Operation

PLC link Support of Mitsubishi Electric Corporation PLC

The MELSEC Q series (by Mitsubishi Electric Corporation) has been added to the list of devices this

sensor can communicate with via PLC link.

Reference: Setting Communication Specifications (Ethernet - PLC Link) (p.151)

Reference: Setting Communication Specifications (RS-232C/422 - PLC Link) (p.156)

List of model-specific new functions

Type of controller

New function

Function

Operation mode

Reference: Setting Operation Mode (p.30)

Analyser

Reference: Using NG Analyser (p.108)

Support of PLC link (MELSEC Q series)

Reference: Setting Communication

Specifications (Ethernet - PLC Link) (p.151)

Reference: Setting Communication

Specifications (RS-232C/422 - PLC Link) (p.156)

Processing item

Standard processing item ○ ○ ○ ○ ○ ○

Sophisticated processing item (processing

item having + at the end of the item name)

FZ3

-3

- - - - ○ ○

- - - - ○ ○

- - - - ○ ○

- ○ - ○ - ○

-H3

FZ3

-7

FZ3

-H7

FZ3

FZ3

-9

FZ3

-H9

FZ3 User's Manual Checking System Configuration 21

Page 24

1

Before Operation

U s e f u l p ro c e s s ing item s w h en s e t tin g u p c a m era

R e f e re n c e : "P ro ce ss in g It e m L i s t M a n u a l", "F o c u s "

(p.3 8 9 )

R e f e re n c e : "P ro ce ss in g It e m L i s t M a n u a l", "I ri s " ( p .3 9 2 )

- - - - ○ ○

22 Checking System Configuration FZ3 User's Manual

Page 25

Preparing Controllers and Cameras

Preparing Controllers

No special preparation is required with this product as processing items are pre-installed.Please check

that the controller is switched on and that the Main screen is displayed.

For details, see the User's Manual.

The first time the program is started up, the Language Setting window is displayed, so select the

language.

Reference: Selecting the Language [Language Setting] (p.131)

Adjusting Cameras

Confirm what kind of images are being taken.

Adjust the position of measurement objects and the focus of the lens.

Tap [ ] of "Image mode" in [Image display] of the Main screen Control area, and select

1.

"Through".

The through images captured from the camera are viewed in the Image Display area.

Reference: Changing Display Contents (p.83)

1

Before Operation

Note

●

The same operation is available by tapping [View] - [Image mode] - [Through].

Adjust the position of measurement objects so that they display at the center of the monitor.

2.

Adjust the focal distance of the lens.

3.

When using an auto-focus camera or an intelligent camera, focus and the iris can be

automatically adjusted.

Note

●

If a camera is used together with a lens, turn the focus ring of the lens to adjust the focus.

Reference: "Processing Item List Manual", "Lens Setting" (p.21)

●

The light intensity of an intelligent camera can be adjusted from the controller.

Reference: "Processing Item List Manual", "Lighting Control" (p.19)

FZ3 User's Manual Preparing Controllers and Cameras 23

Page 26

1

Before Operation

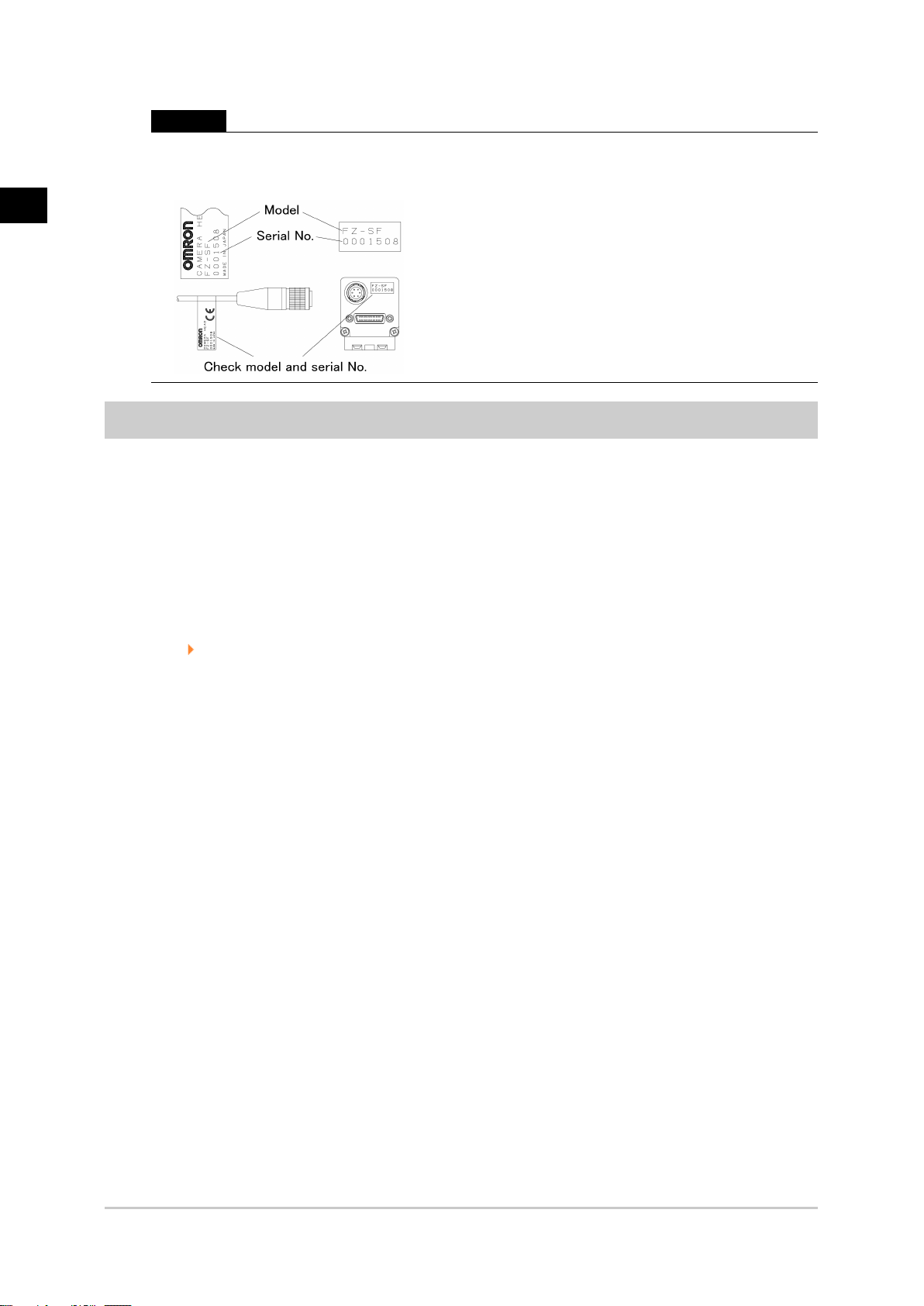

Important

●

When using a small-size digital camera, check that the model and serial number of the camera head

and camera amplifier match.When a camera head and camera amplifier of different models and serial

numbers are connected, they may not operate correctly.

Intelligent Camera (with Lighting Function)

Proper lighting is of crucial importance to vision sensors.

If an intelligent camera is connected, lighting can be controlled from the controller.

Features of intelligent cameras are as follows:

●

A single camera enables testing of illumination from various angles, so it is possible to shorten

the lighting setting time and test measurement time.

●

The controller controls lighting, so lighting can be adjusted depending upon the product type.

●

Reproducibility of lighting settings is improved.

●

Settings can be modified without changing lighting.

Reference: "Processing Items List Manual", "Screen Adjust Settings (Camera Image Input)" (p.18)

24 Preparing Controllers and Cameras FZ3 User's Manual

Page 27

Input Operations

Input operations differ depending on the type of controller.

●

Controller integrated with LCD: Operation with touch pen

●

BOX-type controller: Operation with mouse and trackball

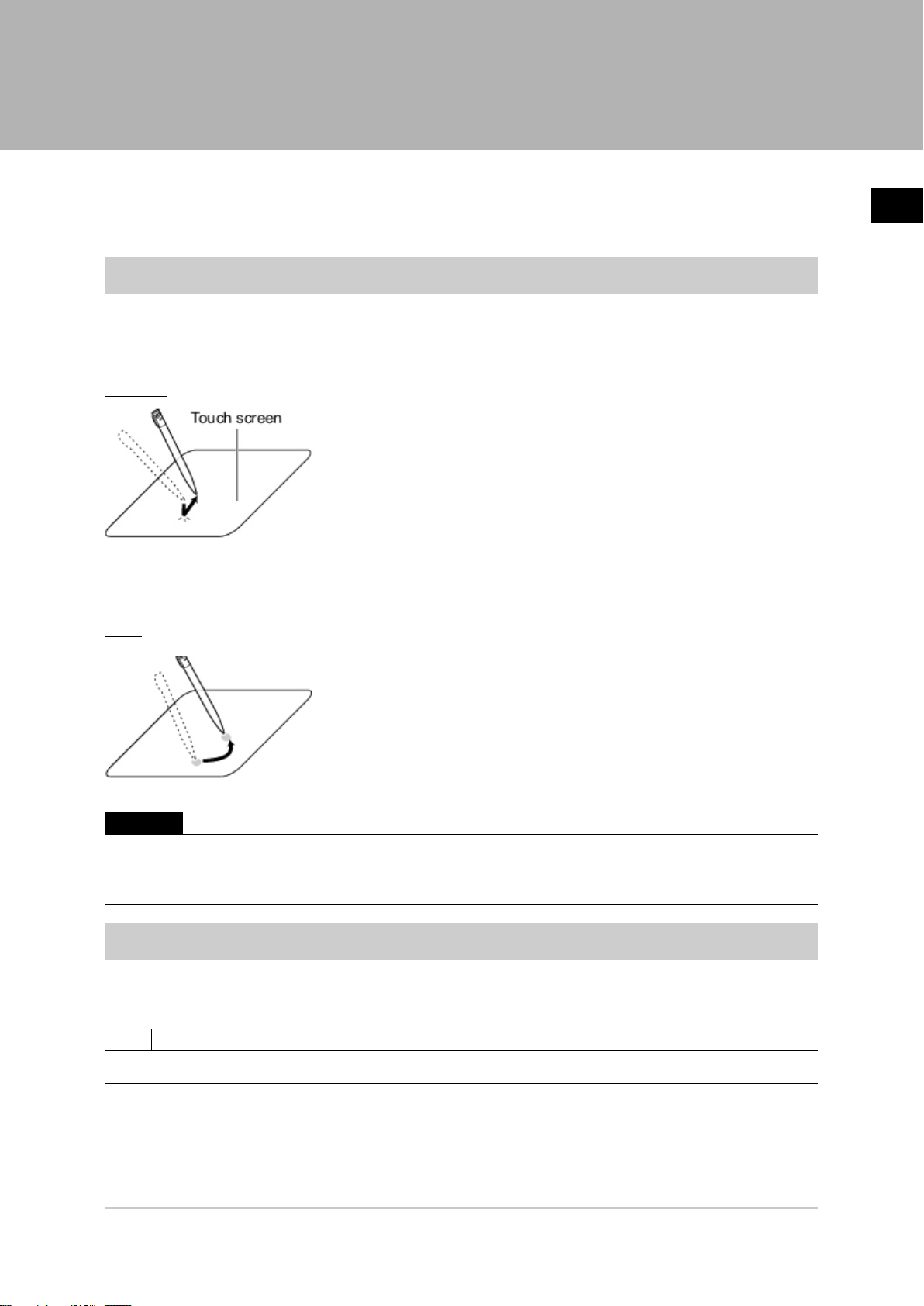

Operation of Touch Pen

With a Controller integrated with LCD, perform the following operations when operating the touch screen

with the touch pen.

Tapping

Lightly touch the screen once with the touch pen and immediately take it off. Perform when selecting

items, etc.

1

Before Operation

Drag

Draw while pressing on the screen lightly with the touch pen.

Important

●

Be sure to use the supplied touch pen for touch screen operations.Using a pencil or ballpoint pen may damage

the touch screen.

●

In addition, response to operations may be delayed if the screen is tapped continuously and rapidly.

Basic Operation of Mouse and Trackball

With a BOX-type controller, use a mouse with a USB interface or commercially-available trackball.

(See the list for recommended products. Please refer to the product catalog.)

Note

●

Do not use the right mouse button, scroll wheel, or other buttons.

FZ3 User's Manual Input Operations 25

Page 28

1

Before Operation

Click

Press the left mouse button once. Perform when selecting items, etc.

Note

●

This document primarily describes operations using the term "tapping". When using a mouse or trackball, read

"Tapping" to mean "Clicking".

Drag

Move the mouse with the left mouse button held down.

26 Input Operations FZ3 User's Manual

Page 29

Returning Controller to Factory Settings

All controller settings can be restored to factory default status (initialization).

In addition, the controller can be restarted.

●

Reference: Initializing Controller [System Initialization] (p.27)

●

Reference: Restarting Controller [System Restart] (p.27)

Initializing Controller [System Initialization]

Restores the controller to factory default status. Before initialization, back up required data such as

scene data and system data.

Reference: Saving Settings Data to RAMDisk/USB Device (p.120)

On the Main screen, tap [System] - [Controller] - [System initialization].

1.

The System Initialization window is displayed.

Tap [Execute].

2.

1

Before Operation

A confirmation window is displayed.

Tap [Yes].

3.

The controller is initialized and restarts.

Restarting Controller [System Restart]

Restart the controller. Before restarting, back up required data such as scene data and system data.

Reference: Saving Settings Data to Controller Memory (p.118)

On the Main screen, tap [System] - [Controller] - [System restart].

1.

The System Restart window is displayed.

Tap [OK].

2.

The controller restarts.

FZ3 User's Manual Returning Controller to Factory Settings 27

Page 30

1

Before Operation

Saving Settings and Turning Power Off

Before turning off power to the controller, perform the following operations to save the data that you

have set.

The controller loads scene data from the flash memory each time during start-up. Therefore, if the power

is turned off without saving data to the flash memory, any changes made will not be saved.

On the Main screen (ADJUST window), tap [Data save] in the toolbar to save the setting data.

1.

Exit after powering off the controller.

2.

Note

●

Data to be saved

Scene data and system data are saved in the controller. Logging images and data saved in the RAMDisk

are not saved. Perform any of the following procedures to keep this data.

- Copy data saved in the RAMDisk to the USB memory.

Reference: Copying/Moving Files (p.124)

- Change the save destination of logging data to USB memory.

Reference: Saving Logging Images to RAMDisk/USB Device (p.122)

●

When using the scene group function

The scene data set in Scene group 0 is saved in the controller. The scene data from scene groups 1 to

31 is saved to the USB memory and overwrites previous saved data. (For FZ3-9 /H9 , all data

are saved in the controller.)

Turning Off LCD

This function is specific to FZ3-300/700/900 series LCD-integrated controllers.

Turn off the LCD only without turning off the controller.

Open the measurement manager bar at the bottom right of the Main screen and tap [LCD Off].

1.

A confirmation message is displayed.

Tap [OK].

2.

28 Saving Settings and Turning Power Off FZ3 User's Manual

Page 31

Power to the LCD is turned off.

Turning LCD On Again

This function is specific to FZ3-300/700/900 series LCD-integrated controllers.

Tap the lower part of the monitor screen.

Then, the LCD will be switched on.

1

Before Operation

FZ3 User's Manual Saving Settings and Turning Power Off 29

Page 32

1

Before Operation

Setting Operation Mode

This section describes the operation mode (FZ3-9 /H9 only). Utilize the dual core CPU to set

an operation mode appropriate for the condition of use. This function is effective in improving the takt

time and reducing the downtime. For setting, use Startup setting.

Reference: Setting the Start-up Status "Startup Setting" (p.133)

On the Main screen, tap the [System] menu - [Controller] - [Startup setting].

1.

Tap [Operation mode].

2.

30 Setting Operation Mode FZ3 User's Manual

Page 33

Tap [ ] and select a desired operation mode.

3.

1

Before Operation

Tap [OK].

4.

On the Main screen (ADJUST window), tap [Data save] in the toolbar to save the setting data.

5.

On the Main screen, tap [System] menu - [Controller] - [System restart].

6.

The System Restart window is displayed.

Tap [OK].

7.

FZ3 User's Manual Setting Operation Mode 31

Page 34

Operation Mode Selection Guidelines

1

Before Operation

This section describes how to set an operation mode suitable for your specific purpose.

[Note 1]: Reference: About Multiple Image Input Function (p.218)

High-speed Logging Mode

Normally one CPU is used to perform measurement, image logging and image display. The FZ3-9 /

H9 series performs processing using two CPUs, with one CPU used exclusively for measurement

and the other performing non-measurement processing. This ensures maximum measurement

performance at all times.

32 Setting Operation Mode FZ3 User's Manual

Page 35

Parallel-operation High-speed Mode

Two CPUs are used to share and process measurement tasks internally. Processing is executed in

parallel to shorten the measurement time to maximal 50%.

Parallel processing is performed for each processing unit to shorten the total processing time.

1

Before Operation

Processing items supporting the aforementioned parallel processing are specified below.

You can improve the takt time effectively by combining the applicable units using an ingenious

processing flow.

-: Not supported ○ : Supported

Processing item

Camera image input - Fine matching ○ Set unit data -

FZ3 User's Manual Setting Operation Mode 33

Parallel

processing

Processing item

Parallel

processing

Processing item

Parallel

processing

Page 36

1

Before Operation

Camera image input

HDR+

Camera switching - Date verification - Set unit figure -

Measurement image

switching

Search ○ Barcodes+ ○ Trend monitor -

Flexible search ○ 2D codes+ ○ Image logging -

Sensitive search ○ Circle angle ○ Data logging -

ECM search ○ Position compensation - Elapsed time -

EC circle search ○ Trapezoidal correction+ - Wait -

Shape search+ ○ Filtering -

Classification ○ Background suppression - End -

Edge position ○ Color gray filter - DI branch -

Edge pitch ○ Color extraction filter - Data output -

Scan edge position ○ Anti color shading -

Scan edge width ○ Stripes removal filter+ -

Color data ○ Halation cut+ - Result display -

Gravity and area ○ Panorama+ - Display image file -

Labeling ○ Polar transformation -

Label data - Calculation - Focus ○

Labeling+ ○ Line regression - Iris ○

Defects ○ Circle regression -

Precise defect ○ Calibration+ -

- Character inspection ○ Get unit data -

- Model dictionary - Get unit figure -

Conditional

branch

Parallel data

output

Parallel

judgement output

Display last NG

image

-

-

-

-

Note

●

Depending on the processing unit, the processing speed of the unit itself can be raised.

34 Setting Operation Mode FZ3 User's Manual

Page 37

Single-line High-speed Mode

Measurement is performed using 2 CPUs, which means that compared to conventional models twice the

number of measurement targets can be inspected in the same time. In this Single-line High-speed

Mode, CPU0 and CPU1 execute the same inspection flow alternately for each STEP input, to improve

the multiple image input performance and reduce the takt time to as much as one half.

Reference: About Multiple Image Input Function (p.224)

1

Before Operation

Important

●

The time needed to measure one work is shorter when [Parallel-operation High-speed mode] is selected.

●

[Single-line High-speed mode] is only effective when the multiple image input function is used. If the multiple

image input function cannot be used, consider using [Parallel-operation High-speed mode].

Reference: About Multiple Image Input Function (p.224)

●

Presence of certain processing items such as [Data Output], [Parallel Data Output] and [Parallel Judgement

Output] in the first half of the flow may cause the performance to drop when [Single-line High-speed mode] is

selected. If the performance drops markedly, consider using [Parallel-operation High-speed mode].

●

In the Single-line High-speed Mode, certain processing items such as [Trend Monitor] and [Display Last NG

Image] may not function properly. Do not use these items. Also with the processing item [Calculation],

calculations that use values in previous steps do not function properly.

●

When [Single-line High-speed mode] is selected, [Enter simplified non-stop adj.] cannot be used.

●

The functions to set/get measured values using external commands do not operate correctly. Do not use these

items.

FZ3 User's Manual Setting Operation Mode 35

Page 38

1

Before Operation

1 CPU

2 CPUs (FZ3-9 /H9 only)

36 Setting Operation Mode FZ3 User's Manual

Page 39

Multi-line Random-trigger Mode

Use this mode if you want to measure 2 lines using 1 controller. Measurement can be performed

independently on line 0 and line 1 in response to inputs from different cameras.

You can switch the monitoring target between line 0 and line 1 using the Line button in the Image display

setting area.

1

Before Operation

Camera No. Recognition in software

Camera 0 Camera 0 on line 0

Camera 1 Camera 0 on line 1

Camera 2 Camera 1 on line 0

Camera 3 Camera 1 on line 1

FZ3 User's Manual Setting Operation Mode 37

Page 40

1

Before Operation

Important

●

If Ethernet is used, set a different port number for each line.

●

RS-232C/422 can be set at line 0 only.

●

If parallel communication is used, the I/O format changes.

Reference: I/O Format (Parallel Interface) (p.214)

●

Parallel communication can only be set at line 0. Line 1 uses the settings of line 0.

●

Date-time setting, language setting and operation mode setting can be set at line 0 only.

●

If STEP is input to line 0 and line 1 at exactly the same time, measurement on one side may be delayed

(approximately by a time corresponding to the camera image input unit).

●

Error messages are the same. If an error occurs on either line, an error message is displayed.

●

If logging is performed for line 0 and line 1 at the same time, measurement may take a longer time.

●

User data of line 1 is saved in the controller.

Non-stop Adjustment Mode

The measurement flow can be changed and adjusted during operation without stopping the

measurement process.

Set images using saved image files. The modified measurement flow can be reflected during operation.

Utilization example of non-stop adjustment

In the "Control" area of the Main screen (RUN window), tap [Tool box].

1.

Tap [Enter non-stop adj.].

2.

Transfers to non-stop adjustment mode. Measurement will continue without stopping.

38 Setting Operation Mode FZ3 User's Manual

Page 41

Tap the icon of the processing unit to be adjusted.

3.

To change the flow, do so by selecting [Edit flow] in the toolbar.

The setting window for the selected unit appears.

Change each processing unit.

4.

1

Before Operation

Tap [OK].

5.

The setting window closes, and the screen returns to the Main screen.

When changing judgement conditions for multiple processing units, repeat steps

Reference: 3 (p.39) to Reference: 5 (p.39) .

The changes are not yet reflected at this point.

Tap [Transfer data] in the toolbar on the Main screen.

6.

The changes are reflected.

Tap [Return to RUN mode] in the toolbar on the Main screen.

7.

FZ3 User's Manual Setting Operation Mode 39

Page 42

1

Before Operation

The screen returns to the RUN window.

Important

●

When [Transfer data] is executed, the results of [Trend Monitor] and [Expression], etc. are cleared.

●

If the scene or scene group was switched or any setting of a processing unit was changed during operation

using an external command, the result is not yet reflected when you switch to the non-stop adjustment window.

●

If non-stop adjustment is performed after changing the scene group during operation, scene group data may be

overwritten against your wish.

●

Measurement commands (parallel, non-procedure, PLC link) and continuous measurement commands (parallel

only) are the only communication commands that are accepted during data transfer.

●

Data transfer takes a longer time when the scene group file size is larger.

●

If the RUN window is displayed in the fast view mode, non-stop adjustment cannot be performed.

●

Communication settings cannot be changed on the non-stop adjustment window.

●

Do not register any new camera image input unit on the non-stop adjustment window.

●

If RAMDisk does not have enough free disk capacity, data may not be transferred. Specify an image logging

destination other than RAMDisk or otherwise set applicable items to minimize the usage of RAMDisk.

●

Performing non-stop adjustment changes the display mode to freeze.

●

If image logging is performed in the non-stop adjustment mode, data transfer may be disabled. To prevent this

from happening, set the trigger interval longer than the logging time.

40 Setting Operation Mode FZ3 User's Manual

Page 43

Setting Scenes (Measurement Flow)

A measurement flow consisting of a series of combined

processing items is called a scene.This chapter explains

how to create and edit scenes.

Reference: What Is a Scene? (p.42)

Reference: What Is a Scene Group? (p.46)

Reference: Creating a Scene (p.47)

Reference: Processing Item Selection Guidelines (p.49)

Reference: Editing Processing Units in Scenes (p.63)

Reference: Switching Scenes and Scene Groups (p.65)

Reference: Editing Scenes (p.67)

Reference: Editing Scene Groups (p.70)

2

Setting Scenes (Measurement Flow)

FZ3 User's Manual 41

Page 44

2

Setting Scenes (Measurement Flow)

What Is a Scene?

Processing items for use with various measurement objects and measurement objectives are provided

in this product. By combining and executing these processing items, measurement adapted to the

purpose can be implemented. A combination of processing items is called a "scene" and scenes can be

easily created by combining processing items that are suited to the measurement purpose from the list

of processing items provided.

Changing the set-up using the scene function

Multiple scenes can be created.For example, by creating scenes for each measurement object such as

using "Scene 0" to inspect an "ABC" label and "Scene 1" to inspect an "XYZ" label, changing the set-up

can be performed smoothly just by changing the scene even when the measurement object and

measurement objective have changed.

Reference: Switching Scenes and Scene Groups (p.65)

Up to 32 scenes can be set. In case where over 32 scenes are required, these can be divided into scene

groups for easier management.

Reference: What Is a Scene Group? (p.46)

Scene Examples

The processing items registered to the scene are called processing units. In the Edit Flow window where

scenes are created, select processing items required for measurement and add them to the flow. The

number at the top of the processing unit is called the "Unit No.". If the measurement trigger is activated,

processing is executed in the numerical sequence of the processing unit numbers.

42 What Is a Scene? FZ3 User's Manual

Page 45

Example) Normal measurement

2

Setting Scenes (Measurement Flow)

Note

●

The processing item "Camera Image Input" is set in processing unit 0 beforehand.

FZ3 User's Manual What Is a Scene? 43

Page 46

2

Setting Scenes (Measurement Flow)

Example) When adding Position Compensation for two measurement objects in the same field of view

44 What Is a Scene? FZ3 User's Manual

Page 47

Example) When judging type from the image and dividing later inspection conditions according to type

(branch processing)

2

Setting Scenes (Measurement Flow)

FZ3 User's Manual What Is a Scene? 45

Page 48

2

Setting Scenes (Measurement Flow)

What Is a Scene Group?

A "scene group" refers to a grouping of 32 individual scenes. Creating a scene group is convenient when

increasing the number of scenes and when managing a number of scenes according to category.

USB memory is required for creating a scene group. Scene group 0 is saved in the controller while

scene groups 1 to 31 are saved in USB memory. (For FZ3-9 /H9 , all data are saved in the

controller.)

Note

●

The maximum number of scenes that can be used is 1024. 32 scenes are handled as 1 scene group, and up to

32 scene groups can be set. In other words, 32 scenes x 32 scene groups = 1,024 scenes, which is the

maximum number that can be used.

●

There are multiple USB ports on the controller, but it is necessary to assign the drive name "USBDisk" to the

USB memory in which the scene group data being used is stored. When other USB memory devices are already

inserted, perform this operation after removing all USB memory devices other than the one in which the scene

group data is stored.

●

If the USB memory capacity is insufficient for the data size, it is possible that the number of scenes can be set is

lower than 1,024. The scene data size varies depending on the contents of settings.

●

The data size that can be set (available data memory) can be checked in the system menu.

Reference: Checking System Information [System Information] (p.145)

46 What Is a Scene Group? FZ3 User's Manual

Page 49

Creating a Scene

This section explains methods for adding a new processing unit to a scene.

Display the scene to edit on the Main screen.

1.

Reference: Switching Scenes and Scene Groups (p.65)

Tap [Edit flow] in Toolbar.

2.

The Edit Flow window is displayed.

Select a processing item to be added from the processing item tree.

3.

2

Setting Scenes (Measurement Flow)

Tap [Append].

4.

The selected processing item is appended at the bottom of the unit list (flow).

FZ3 User's Manual Creating a Scene 47

Page 50

Continue to add processing units.Repeat the steps after Reference: 3 (p.47) .

5.

Note

●

Limitations on settings

The number of image input processing items that can be used is limited.

Reference: About Limits on the Number of Image Input Processing Items Used (p.331)

2

Setting Scenes (Measurement Flow)

Either tap the icon of the processing unit to be set or tap the Set button.

6.

The property setting window is displayed.Set detailed conditions. The displayed contents vary

depending on the processing item.

Set conditions.

7.

The displayed contents vary depending on the processing item.

48 Creating a Scene FZ3 User's Manual

Page 51

Processing Item Selection Guidelines

Processing items for performing measurement are provided with this product. Application-oriented

measurement can be configured by combining processing items or changing the settings of processing

items.

The method for searching for processing items appropriate to the target measurement is shown here.

●

Reference: Selecting Measurement Processing Items Using a Chart (p.49)

●

Reference: Selecting Measurement Processing Items According to the Measurement Method

and Purpose (p.56)

Selecting Measurement Processing Items Using a Chart

Select processing items appropriate to the target using the chart.

Item References

Performing position

compensation for objects

Measuring the position of objects

Inspecting the status of objects

Inspecting for defective products

Reference: Position Compensation (p.50)

Reference: Locating (Measurement Objects Not Inclined) (p.51)

Reference: Locating (Measurement Objects Inclined) (p.52)

Reference: Internal and External Inspection (p.52)

Reference: Presence Inspection (p.53)

Reference: Dimension Inspection/Measurement (p.53)

Reference: Text Comparison/Inspection (p.54)

Reference: Quantity Inspection/Measurement (p.55)

Reference: Defect/Contamination Inspection (p.55)

Reference: Burr Inspection (p.54)

Reference: Inspection for Presence of Different Objects (p.56)

2

Setting Scenes (Measurement Flow)

FZ3 User's Manual Processing Item Selection Guidelines 49

Page 52

2

Setting Scenes (Measurement Flow)

Position Compensation

50 Processing Item Selection Guidelines FZ3 User's Manual

Page 53

Locating (Measurement Objects Not Inclined)

2

Setting Scenes (Measurement Flow)

FZ3 User's Manual Processing Item Selection Guidelines 51

Page 54

2

Setting Scenes (Measurement Flow)

Locating (Measurement Objects Inclined)

Internal and External Inspection

52 Processing Item Selection Guidelines FZ3 User's Manual

Page 55

Presence Inspection

2

Setting Scenes (Measurement Flow)

Dimension Inspection/Measurement

FZ3 User's Manual Processing Item Selection Guidelines 53

Page 56

2

Setting Scenes (Measurement Flow)

Burr Inspection

Text Comparison/Inspection

54 Processing Item Selection Guidelines FZ3 User's Manual

Page 57

Defect/Contamination Inspection

2

Setting Scenes (Measurement Flow)

Quantity Inspection/Measurement

FZ3 User's Manual Processing Item Selection Guidelines 55

Page 58

2

Setting Scenes (Measurement Flow)

Inspection for Presence of Different Objects

Hole Position Measurement

Selecting Measurement Processing Items According to the Measurement Method and Purpose

This section describes methods for selecting processing items appropriate to different measurement

objectives such as counting quantities, checking for deformation, and checking for contamination.

●

Reference: Measuring positions (p.57)

●

Reference: Detecting defects and foreign materials (p.58)

●

Reference: Count (p.59)

●

Reference: Measuring dimensions (p.59)

56 Processing Item Selection Guidelines FZ3 User's Manual

Page 59

●

Reference: Measuring folding of papers and sheets (p.60)

●

Reference: Checking the interior/exterior and direction (p.60)

●

Reference: Checking for mixing of different objects (p.61)

●

Reference: Checking for deformation (p.61)

●

Reference: Inspecting characters (p.62)

●

Reference: Reading barcodes (p.62)

●

Reference: Reading 2D codes (p.62)

●

Reference: Increasing camera installation efficiency (p.62)

Measuring positions

2

Setting Scenes (Measurement Flow)

Method,

objective

Positioning of

the

measurement

objects with low

contrast

Label position

detection

Robot arm

positioning

Position

measurement

for

measurement

objects with

variations

References

[ECM Search], [Shape Search+ (FZ3-Hxxx series)]

Effective for positioning measurement objects, such as LCD substrates, glass substrates, and

sheets, which have low contrast and in which color differences at measurement locations are

not obvious.

Reference: "Processing Item List Manual", "ECM Search" (p.73)

Reference: Processing Item List Manual, "Shape Search+" (p.94)

[Edge Position]

Effective for detecting whether the label position is off-center, raised or lowered, and whether

the label is affixed on bottles and cans.

Reference: "Processing Item List Manual", "Edge Position" (p.114)

[Search]

Effective for position measurement that includes tilting of the measurement object due to

handling with robot arms.

Reference: "Processing Item List Manual", "Search" (p.42)

[Flexible Search]

Effective for position measurement of measurement objects in which there are variations in

markings or shape such as with inspection of packaging, etc.

Reference: "Processing Item List Manual", "Flexible Search" (p.53)

Measurement of

the inclination of

a circular

measurement

[Circle angle]

Effective when measuring bottle caps, etc., after correcting the rotation angle.

Reference: "Processing Item List Manual", "Circle Angle" (p.275)

object

FZ3 User's Manual Processing Item Selection Guidelines 57

Page 60

[Search]

If the shape and background of the measurement object are constant, a processing item such

as one that registers an image as a model and searches for this image is effective.

Reference: "Processing Item List Manual", "Search" (p.42)

2

Setting Scenes (Measurement Flow)

Other

positioning

Detecting defects and foreign materials

Method, objective References

Detection of the defect,

stain and spot of plain

measurement objects

[Defect] [Precise Defect (FZ3-Hxxx series)]

Effective for inspection for contamination or spots on plain backgrounds.

Reference: "Processing Item List Manual", "Defect" (p.209)

Reference: "Processing Item List Manual", "Precise Defect" (p.217)

[Defect] [Precise Defect (FZ3-Hxxx series)]

Effective for exterior inspection of scratches and burrs on parts.

Reference: "Processing Item List Manual", "Defect" (p.209)

Scratches, burrs

Inspection for minor

defects, contamination

and objects with

backgrounds other than

plain

Reference: "Processing Item List Manual", "Precise Defect" (p.217)

[Fine Matching]

Effective for detection of minor defects and contamination on labels, etc.

Reference: "Processing Item List Manual", "Fine Matching" (p.225)

58 Processing Item Selection Guidelines FZ3 User's Manual

Page 61

Count

Method, objective References

[Edge Pitch]

Effective when calculating the number of IC or connector pins.

Reference: "Processing Item List Manual", "Edge Pitch" (p.124)

Inspection for

number of pins

2

Setting Scenes (Measurement Flow)

Inspection of the

number of screws

Inspection of the

number of labels

[EC Circle Search]

Effective when inspecting by focusing on circular outline information.

Reference: "Processing Item List Manual", "EC Circle Search" (p.84)

[Labeling] [Labeling+ (FZ3-Hxxx series)]

Effective when counting the labels and measuring their positions.

Reference: "Processing Item List Manual, "Labeling" (p.172)

Reference: "Processing Item List Manual", "Labeling+" (p.190)

Measuring dimensions

Method,

objective

Measurement

of width of

measurement

objects

Dimension

inspection of

finished

products

Dimension

inspection for

circular shapes

and tilted parts

[Edge Position]

Effective when measuring the width of measurement objects.

Reference: "Processing Item List Manual", "Edge Position" (p.114)

[Edge Position] [Calculation]

To measure the dimensions of finished products, combine [Edge Position] and [Calculation]. Use

[Edge Position] to measure position, and [Calculation] to calculate dimensions by calculating the

distance between positions.

Reference: "Processing Item List Manual", "Edge Position" (p.114)

Reference: "Processing Item List Manual", "Calculation" (p.330)

[Edge Position] [Calculation]

[Edge Position] is effective when measuring the dimensions of circular works and tilted

measurement objects. Use this processing item to measure position, [Calculation] to calculate

the spacing of positions and then the dimensions.

Reference: "Processing Item List Manual", "Edge Position" (p.114)

Reference: "Processing Item List Manual", "Calculation" (p.330)

References

FZ3 User's Manual Processing Item Selection Guidelines 59

Page 62

2

Setting Scenes (Measurement Flow)

Measuring folding of papers and sheets

Method, objective References

Check for folding on plain

measurement objects

[Defect] [Precise Defect (FZ3-Hxxx series)]

Effective when checking for folding on plain works.

Reference: "Processing Item List Manual", "Defect" (p.209)

Checking the interior/exterior and direction

Method, objective References

[Flexible Search]

Effective when there is variation in the size and position of the markings to be

checked.

Reference: "Processing Item List Manual", "Flexible Search" (p.53)

Interior/exterior and

orientation inspection

through presence of

markings

When precision is required

for measurement of

markings

[Fine Matching]

Effective when there are patterns on the background of markings, markings have a

complex shape, or precision is required for measurement of markings.

Reference: "Processing Item List Manual", "Fine Matching" (p.225)

60 Processing Item Selection Guidelines FZ3 User's Manual

Page 63

Checking for mixing of different objects

Method, objective References

[Flexible Search]

Effective for inspection of mixing of different objects in which there are variations with

markings and the shape of measurement objects.

Reference: "Processing Item List Manual", "Flexible Search" (p.53)

Inspection for mixing of

different measurement

objects with variations

2

Setting Scenes (Measurement Flow)

Inspection for mixing of

different objects for

objects with plain

background

When accuracy is required

for inspection of mixing of

different objects

When not all characters

and markings are the

same

When performing different

inspections according to

the type

[Search]

Effective for inspection of mixing of different objects for packaging that has plain

background.

Reference: "Processing Item List Manual", "Search" (p.42)

[Fine Matching]

Effective when precision is required for inspection of mixing of different objects such

as inspection of nameplates and objects other than those with plain backgrounds.

Reference: "Processing Item List Manual", "Fine Matching" (p.225)

[Sensitive Search]

Effective when the difference between the model image and measurement image is

small. The models are automatically finely divided and matched in detail.

Reference: "Processing Item List Manual", "Sensitive Search" (p.62)

[Classification]

Effective for inspections performed on lines where different types of products are

manufactured.

Reference: "Processing Item List Manual", "Classification" (p.104)

Checking for deformation

Method, objective References

Deformation check when

there are multiple

acceptable shapes

When measuring the

shape more strictly

[Flexible Search]

Effective when performing inspection for deformation of measurement objects based

on multiple acceptable shapes.

Reference: "Processing Item List Manual", "Flexible Search" (p.53)

[Fine Matching]

Effective when inspecting the shape of workpieces to a high degree of precision.

Reference: "Processing Item List Manual", "Fine Matching" (p.225)

FZ3 User's Manual Processing Item Selection Guidelines 61

Page 64

Inspecting characters

2

Setting Scenes (Measurement Flow)

Method,

objective

Inspection of the

date

Inspection of

arbitrary

character strings

Registration of

character strings

[Date Verification]

Effective when inspecting date character strings that show the production date, etc. The

verification date can be set automatically.

Reference: "Processing Item List Manual", "Date Verification" (p.244)

[Character Inspection]

Effective when inspecting arbitrary character strings.

Reference: "Processing Item List Manual", "Character Inspection" (p.236)

[Model Dictionary]

To inspect character strings with [Date Verification] or [Character Inspection], register the target

character strings with [Model Dictionary].

Reference: "Processing Item List Manual", "Model Dictionary" (p.253)

References

Reading barcodes

Method, objective References

When reading

barcodes

[Barcode+ (FZ3-Hxxx series)]

Effective when reading barcodes and outputting the information to an external device.

Reference: "Processing Item List Manual", "Barcodes+" (p.261)

Reading 2D codes

Method, objective References

When reading 2D

codes

[2D Code+ (FZ3-Hxxx series)

Effective when reading 2D codes for classification, etc.

Reference: "Processing Items List Manual", "2D Codes+" (p.268)

Increasing camera installation efficiency

Method,

objective

When adjusting

the focus

When adjusting

the lighting

[Focus (FZ3-9 /H9 only)

Effective when the measurement position changes and the camera becomes out of focus.

Reference: "Processing Item List Manual", "Focus" (p.389)

[Iris (FZ3-9 /H9 only)]

Effective when performing lighting adjustment according to the changing brightness at the

measurement site.

Reference: "Processing Item List Manual", "Iris" (p.392)

References

62 Processing Item Selection Guidelines FZ3 User's Manual

Page 65

Editing Processing Units in Scenes

In the Edit Flow window, editing buttons in the window can be used to change the order of processing

units within the scene or to delete processing units.

2

Setting Scenes (Measurement Flow)

●

Searching a processing unit ( ) ( )

Convenient when the processing unit you want to select is not displayed on the screen.

●

Selecting a processing unit ( ) ( ) ( ) ( )

In addition to tapping the property setting button icons, the editing buttons can be used to

automatically select the processing unit at the top or bottom, or above or below an arbitrarily

selected processing unit in the unit list.

●

Specifying the position for a processing unit and adding it ( ) ( )

Adds and inserts a processing unit at the bottom position of the scene or another specified

position.

●

Moving a processing unit ( ) ( )

Moves a processing unit within a scene and changes the processing order.

●

Copying and pasting a processing unit ( ) ( )

Copies and pastes a processing unit while maintaining settings data.

●

Deleting a processing unit ( )

Deletes processing units within a scene.

●

Changing the name of a processing unit ( )

Changes processing unit names within a scene. Unit names must begin with a character other

than ゜ (semi-voiced sound symbol) and ゛ (voiced sound symbol). Also, unit names cannot

FZ3 User's Manual Editing Processing Units in Scenes 63

Page 66

consist of only a single-byte number, only a "+", or only a ".".

●

Setting details of a processing unit ( )

Sets the properties of any processing unit within a scene.

●

Shift area ( )

2

Setting Scenes (Measurement Flow)

Changes related figure data in one batch.

●

New Folder ( )

Used when multiple processing units are managed as one group.

●

Operating processing units as a group ( )

Used when processing units are copied or deleted together. A checkbox is displayed in the

processing unit if [Multiple selection] is tapped. Checked processing items can be operated as a

group.

●

Ref. other Scene's flow ( )

Units of other scenes can be referred to and added to the current scene flow.

Selecting a scene to refer to displays the flow for that scene.

Note

●

If a processing unit is inserted, the numbers for the subsequent processing units increase by one. With

processing items related to results output or branch control, the numbers for processing units set as references

also automatically increase by one.

●

If a button other than [Paste] is tapped after pasting a processing unit, continued pasting of the processing

cannot be performed.

●

If a processing unit is deleted, the numbers for the subsequent processing units decrease by one. With

processing items related to results output or branch control, the numbers for processing units set as references

also automatically decrease by one.

●

To make a specific processing unit not display in a flow on the ADJUST window or RUN window, insert a "*"

(single byte) at the beginning of the processing unit name.

64 Editing Processing Units in Scenes FZ3 User's Manual

Page 67

Switching Scenes and Scene Groups

Set-up can be changed by changing the scene. With factory settings, the default display is scene 0 when

the power is switched on. In addition, multiple scenes can be created (Scene 1 to 31).

Also, when combined with the scene group function, up to 1024 scenes can be set.

Instructions for switching scene groups and scenes can also be performed from external devices.

Reference: Methods for Connecting and Communicating with External Devices (p.147)

Switching Scenes

Tap "Scene switch" in the toolbar on the Main screen.

1.

The Switch Scene window is displayed.

Note

●

The same operation is available by tapping [Scene] menu - [Scene switch].

2

Setting Scenes (Measurement Flow)

Tap [ ] to select the scene to switch.

2.

To switch a scene group, tap [Switch], then tap [ ] in the displayed window to select the scene

group to switch.

Tap [OK].

3.

The scene switches.

Switching Scene Groups

Switches to the scene group in which the scene to be edited is stored.

On the Main screen, tap [Scene] - [Scene maintenance].

1.

The Scene Maintenance window is displayed.

FZ3 User's Manual Switching Scenes and Scene Groups 65

Page 68

2

Setting Scenes (Measurement Flow)

Tap [Switch] for the scene group.

2.

The Switch Scene Group window is displayed.

Switch to the scene group to edit.

3.

Tap [ ] and select the scene group to edit.

1.

Select whether a scene group should be saved when switching to another scene group.

2.

Setting

Setting item

Save scene

group on

switch scene

value

[Factory

default]

[Checked]

Unchecked

Description

When the scene group is switched, the data of the

scene group before switching is saved.

The scene group data is not saved when switching to

another scene group. Therefore, the switching period

can be shortened.

Note

●

The setting for whether to save a scene group during switching is linked to the settings of the

Measurement Setting window.

Reference: Setting Conditions Related to Operation during Measurement (p.130)

Tap [OK].

3.

The scene group is switched and the screen returns to the Scene Maintenance window.

Important

●

When a check is inserted in "Save scene group on switch scene", data may be lost if the power is cut off

during scene group switching.During scene group switching, make sure that the power is not cut off.

66 Switching Scenes and Scene Groups FZ3 User's Manual

Page 69

Editing Scenes

Copying a Scene

Copies and pastes scenes within a scene group.

This is a convenient function for reusing a created scene with only one portion being changed.

On the Main screen, tap [Scene] - [Scene maintenance].

1.

The Scene Maintenance window is displayed.