Page 1

Smart Camera

FQ2-S/CH Series

User's Manual

for Communications Settings

Cat. No. Z338-E1-02

Page 2

Introduction

Thank you for purchasing the FQ2-S/CH.

This manual provides information regarding functions, performance and operating methods that

are required for using the FQ2-S/CH.

When using the FQ2-S/CH, be sure to observe the following:

• The FQ2-S/CH must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

APPLICATION CONSIDERATIONS

(Please Read)

User's Manual for

Communications Settings

Overview of Communication Specifications

Controlling Operation and Outputting

Data with a Parallel Connection

Controlling Operation and Outputting

Data with an Ethernet Connection

Controlling Operation and Outputting

Data with an RS-232C Connection

Appendices

1

2

3

4

5

Smart Camera

FQ2-S/CH

Page 4

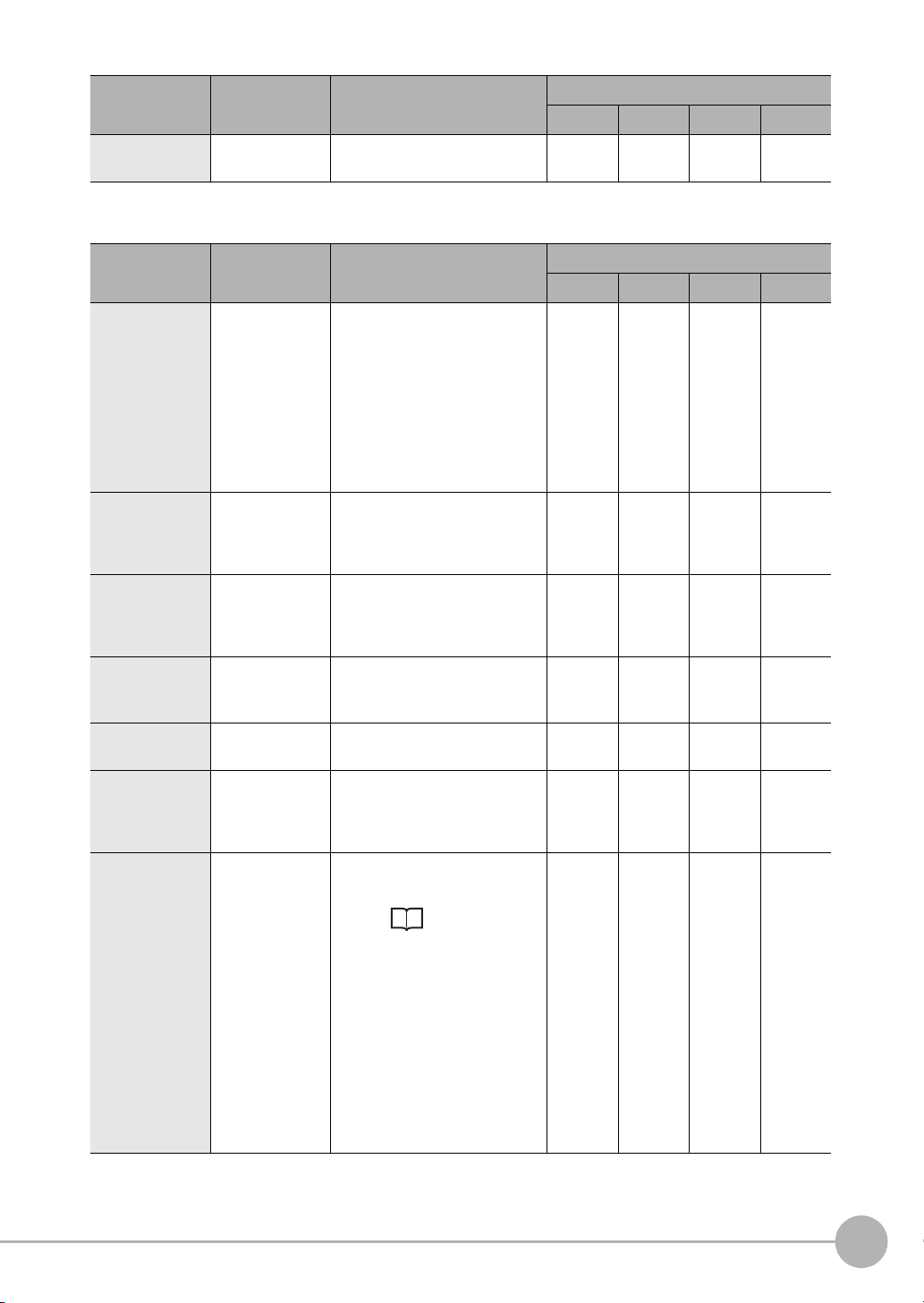

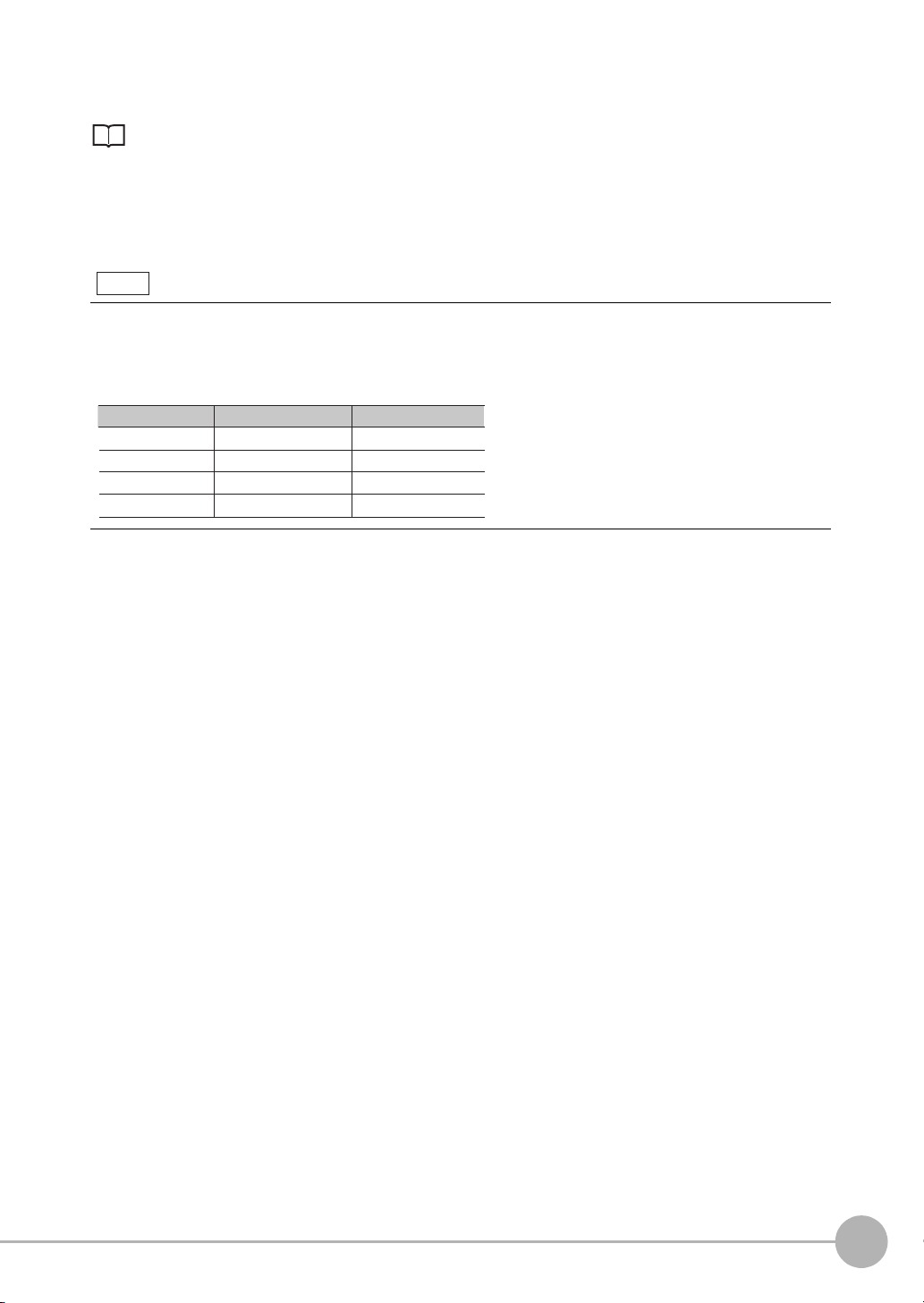

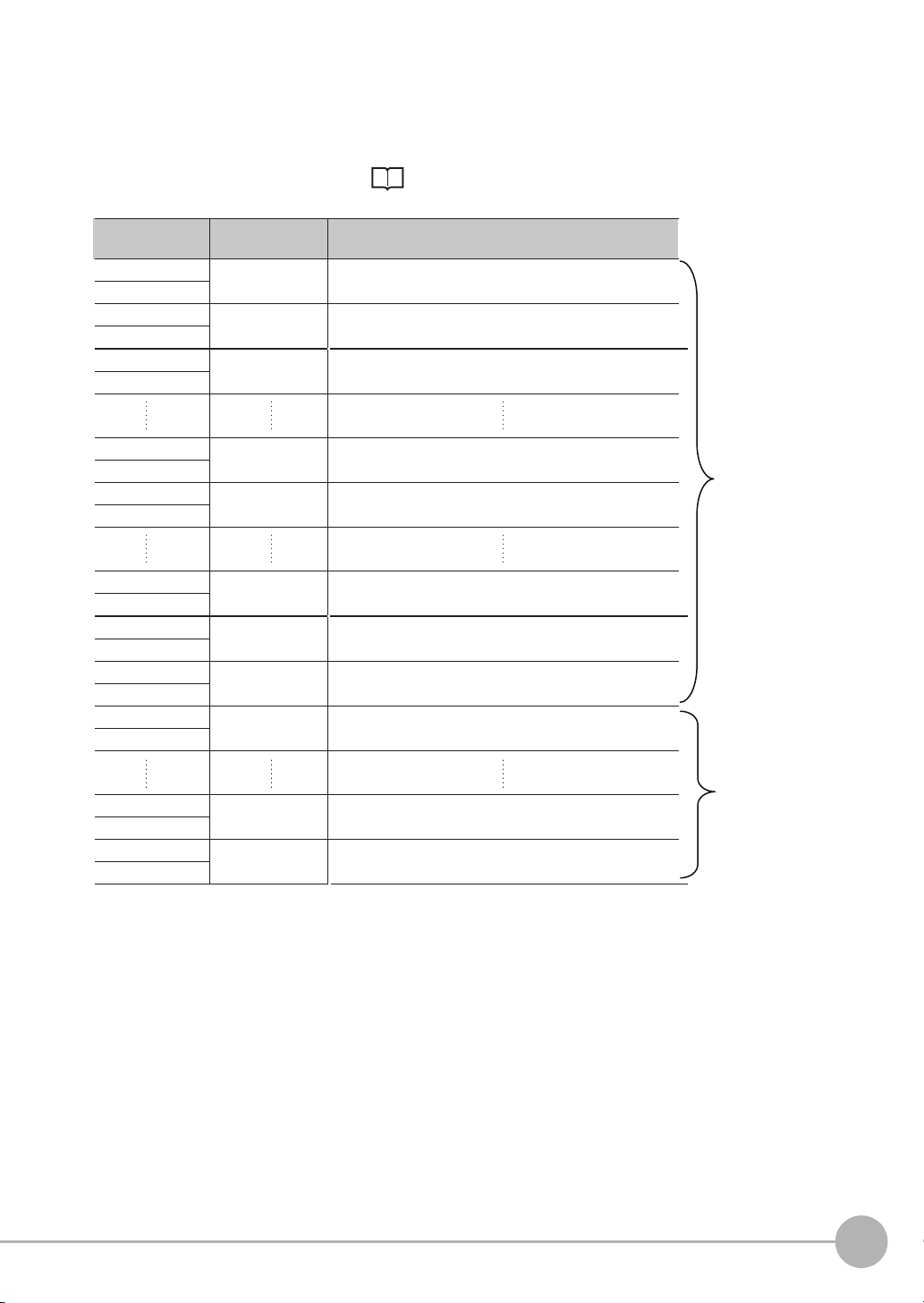

Product manuals

Important

Note

2-2 Par

FQ2-CH1

FQ2-S1 FQ2-S2 FQ2-S3

Shows the models that support the function being described.

Shows that the FQ2-S1 supports the function.

Shows that the FQ2-S2 supports the function.

Shows that the FQ2-S3 supports the function.

Shows that the FQ2-S4 supports the function.

Shows that the FQ2-CH supports the function.

FQ2-CH

FQ2-S4

FQ2-S3

FQ2-S2

FQ2-S1

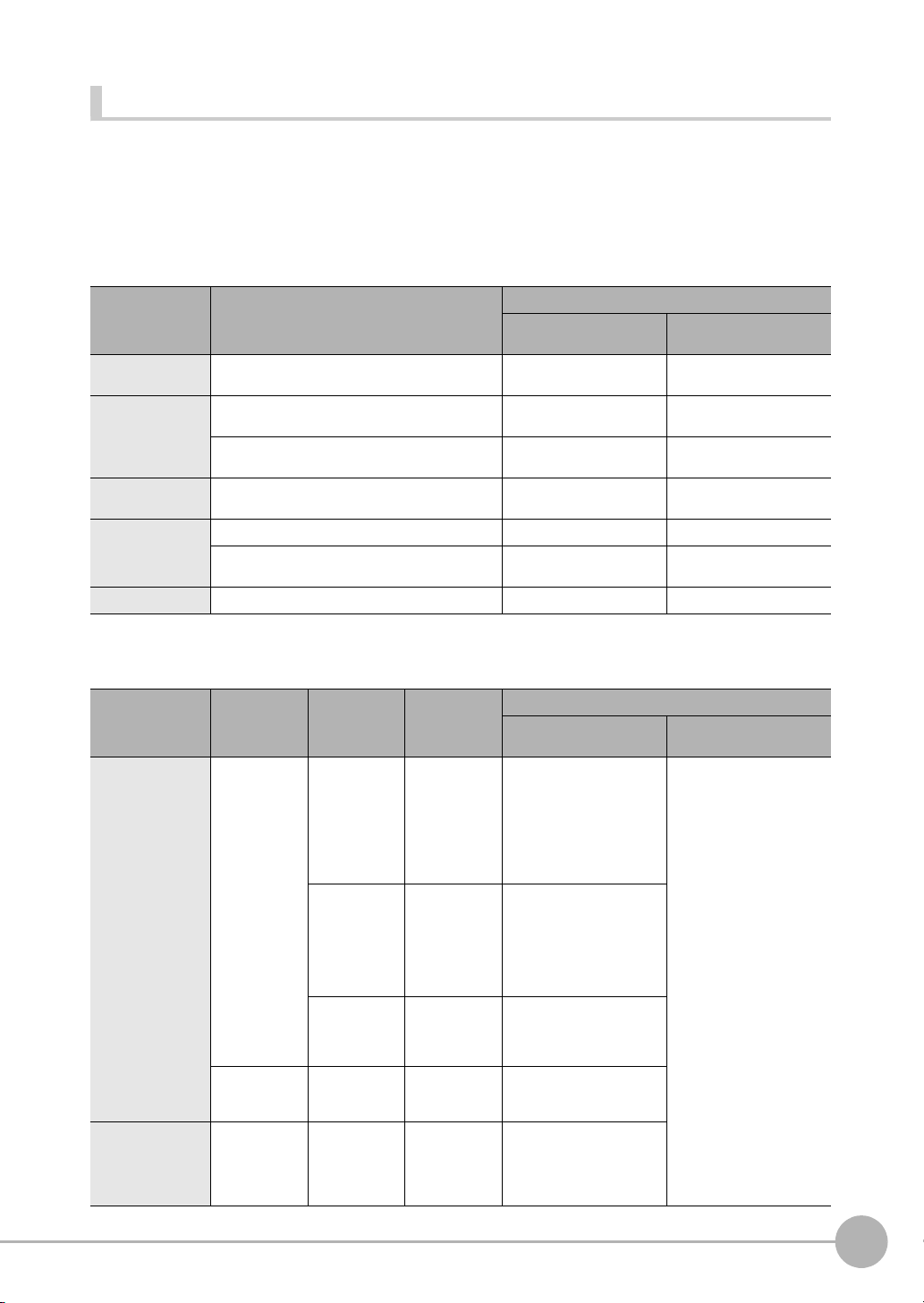

The information required to use the FQ2-S/CH Series is divided into two manuals by objective: “FQ2-S/CH

Series User’s Manual” and “FQ2-S/CH Series User's Manual for Communications Settings”. Read each

manual as appropriate for your objective.

Manual Description Contents

FQ2-S/CH Series User's Manual

(Cat. No. Z337)

(This manual) FQ2-S/CH Series

User's Manual for Communications

Settings (Cat. No. Z338)

Describes the product specifications,

basic settings, and other information

required to use the FQ2-S/CH Series.

Provides information required to operate the sensor by remote control.

Product specifications

Connections, wiring

Camera, image adjustment

Inspection item settings

Test measurement, operation

Troubleshooting

System configuration

Sensor control method

Data input/output specifications

Connectable network types

Communication settings

Output data settings

Editor's Note

■ Meaning of Symbols

Menu items that are displayed on the Touch Finder LCD screen, and windows, dialog boxes and other GUI

elements displayed on the PC are indicated enclosed by brackets "[ ]".

■ Visual Aids

Indicates points that are important to achieve the full product performance,

such as operational precautions.

2

Indicates application procedures.

Indicates pages where related information can be found.

FQ2-S/CH User’s Manual

for Communications Settings

Page 5

Table of Contents

1. Overview of Communication Specifications

1-1 Confirming the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FQ2-S/CH Series System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-2 Communicating with an External Device . . . . . . . . . . . . . . . . . . . . . . . . . 10

Basic Control Operations of the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Methods for the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Communication Protocols for Communication with the Sensor . . . . . . . . . . . .12

1-3 Control Methods Using an External Device . . . . . . . . . . . . . . . . . . . . . . . 18

Control with Control Signals and Status Signals . . . . . . . . . . . . . . . . . . . . . . . . 18

Command/Response Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Data Output after Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. Controlling Operation and Outputting Data with a Parallel Connection

2-1 Controlling Operation and Outputting Data

with the Sensor's Standard Parallel Connection . . . . . . . . . . . . . . . . . . . 34

Basic Operation with a Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting the Measurement Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting the Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Controlling the Sensor from an External Device . . . . . . . . . . . . . . . . . . . . . . . . 46

2-2 Controlling Operation and Outputting Data

with a Parallel Interface Sensor Data Unit . . . . . . . . . . . . . . . . . . . . . . . . 60

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting the Measurement Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Aligning the Data Output Timing with the External Device . . . . . . . . . . . . . . . . 66

Changing the Settings of the I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Controlling Operation from an External Device . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table of Contents

FQ2-S/CH User’s Manual

for Communications Settings

3

Page 6

3. Controlling Operation and Outputting Data with an Ethernet Connection

3-1 Controlling Operation and Outputting Data

with EtherNet/IP Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Introduction to EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

FQ2 Communications for EtherNet/IP Connections . . . . . . . . . . . . . . . . . . . . . 90

Setting Up EtherNet/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Tag Data Link Setting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Setting the Data to Output Automatically after Measurements . . . . . . . . . . . . . 97

Memory Assignments and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Timing Chart for EtherNet/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . 114

Sample Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Communicating with the Sensor Controller

with EtherNet/IP Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Command Setting Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3-2 Controlling Operation and Outputting Data

with PLC Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Communications Processing Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Setting Up PLC Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Setting the Data to Output Automatically after Measurements . . . . . . . . . . . . 124

Memory Assignments for PLC Link Communications . . . . . . . . . . . . . . . . . . . 129

Timing Chart for PLC Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Sample Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

3-3 Outputting Data and Controlling Operation through PROFINET . . . . . 140

Overview of PROFINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

FQ2 Communications for PROFINET Connections . . . . . . . . . . . . . . . . . . . . 144

Setting Up EtherNet/IP Communications (PROFINET) . . . . . . . . . . . . . . . . . . 145

Communication Settings Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Setting the Data to Output Automatically after Measurements . . . . . . . . . . . . 148

Memory Assignments and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Timing Chart for EtherNet/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . 161

Sample Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

3-4 Control and Output in No-Protocol (TCP) / No-Protocol (UDP) . . . . . . 167

Communications Processing Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Setting Up No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Setting the Data to Output Automatically after Measurements . . . . . . . . . . . . 169

Controlling the Sensor from an External Device

(Procedure for No-protocol Command/Response Communications) . . . . . . .176

Binary Data File Load and Save Commands . . . . . . . . . . . . . . . . . . . . . . . . . 183

4

FQ2-S/CH User’s Manual

for Communications Settings

Page 7

3-5 Controlling Operation and Outputting Data

with FINS/TCP No-protocol Commands . . . . . . . . . . . . . . . . . . . . . . . . . 188

Introduction to FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Setting Up FINS/TCP No-protocol Communications . . . . . . . . . . . . . . . . . . . . 189

List of FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4. Controlling Operation and Outputting Data with an RS-232C Connection

4-1 Introduction to RS-232C Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4-2 Controlling Operation and Outputting Data

with RS-232C No-protocol Communications . . . . . . . . . . . . . . . . . . . . . 197

Communications Processing Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Setting Up No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Setting the Data to Output Automatically after Measurements . . . . . . . . . . . . 198

Controlling the Sensor from an External Device

(Procedure for No-protocol Command/Response Communications) . . . . . . .198

5. Appendices

5-1 Command Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Parameter Notation Examples for Command Control . . . . . . . . . . . . . . . . . . . 200

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

5-2 Detailed EtherNet/IP Communications Specifications . . . . . . . . . . . . . 433

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

FQ2-S/CH User’s Manual

for Communications Settings

5

Page 8

6

FQ2-S/CH User’s Manual

for Communications Settings

Page 9

1

Overview of Communication Specifications

Overview of Communication Specifications

1-1 Confirming the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .8

1-2 Communicating with an External Device . . . . . . . . . . . . . . . . . . . . . . . 10

1-3 Control Methods Using an External Device . . . . . . . . . . . . . . . . . . . . . 18

Page 10

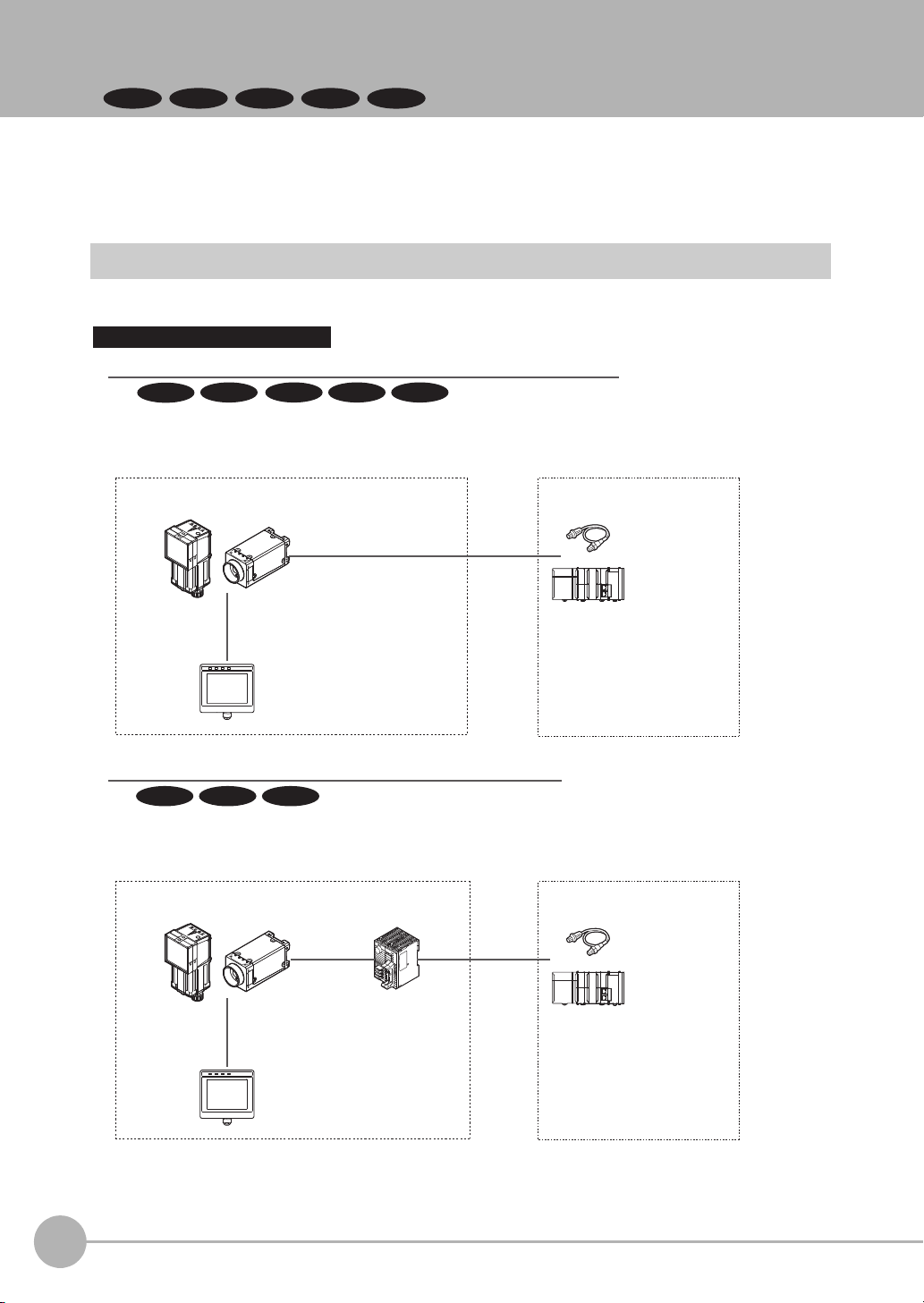

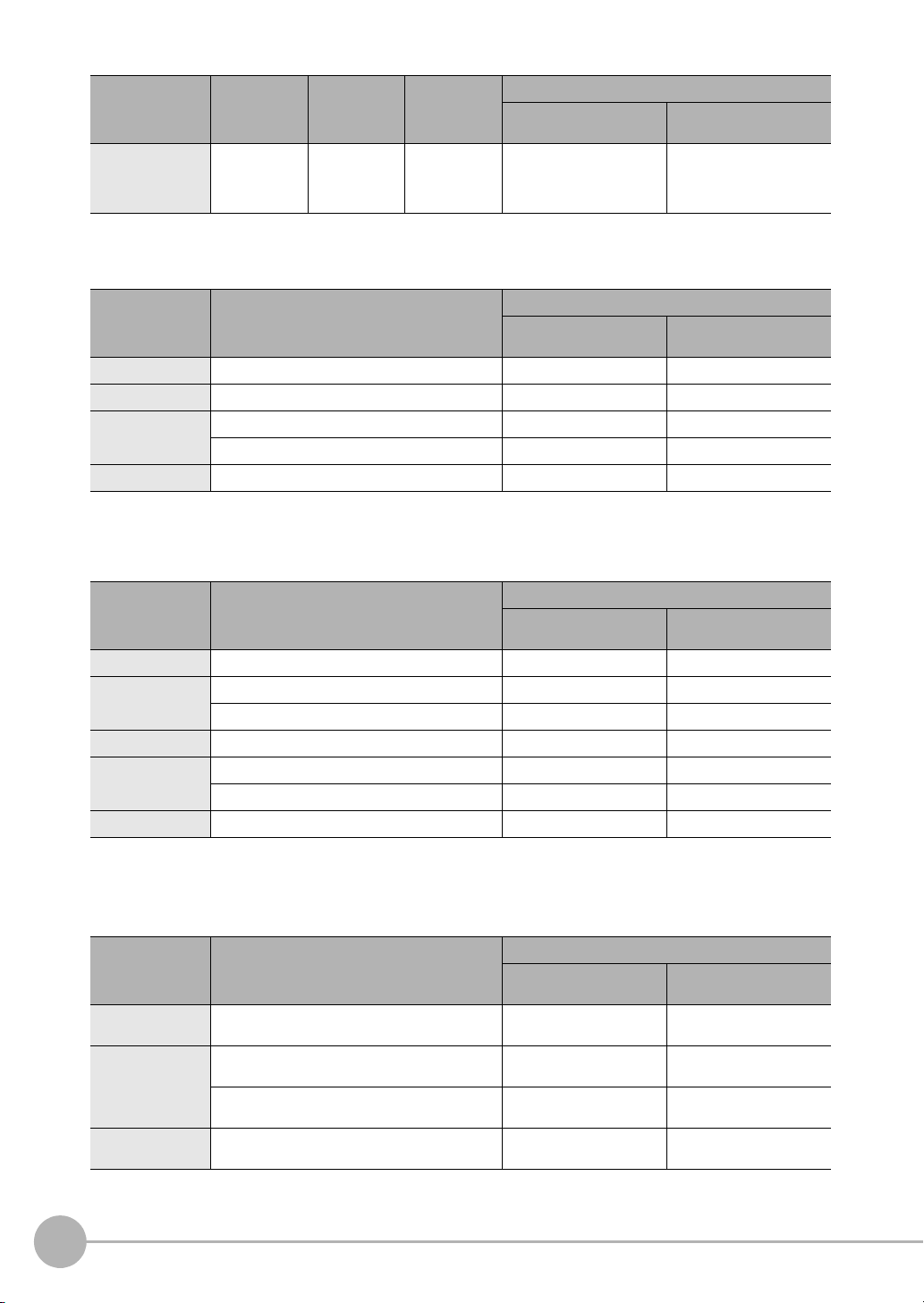

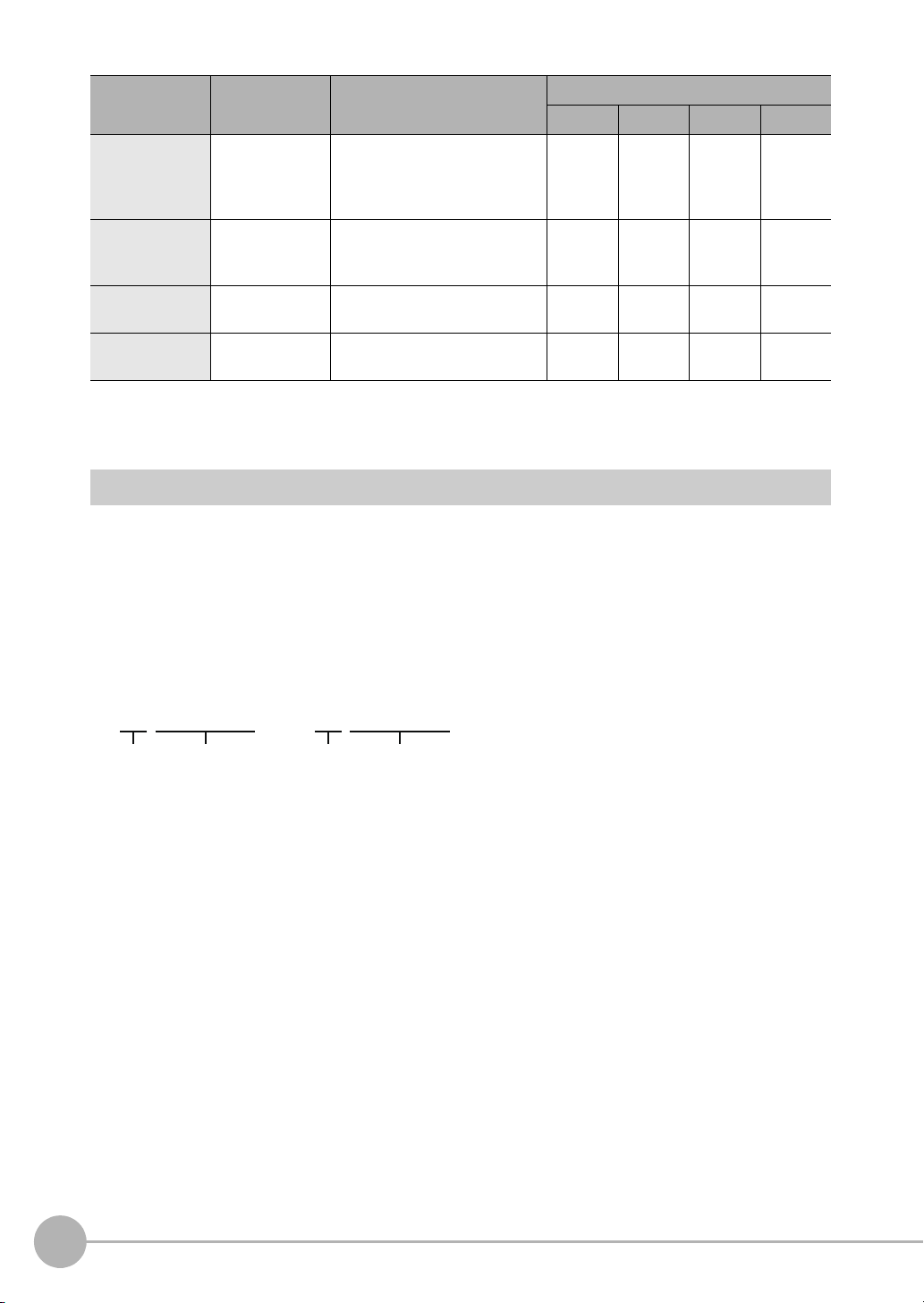

1-1 Confirming the System Configuration

FQ2-S1

FQ2-S2

FQ2-CH

Parallel Interface Connection

Sensor Data

Unit cable

Parallel Interface

Sensor Data Unit

I/O cable

Basic configuration External devices

Setup Tool

(Touch Finder or PC Tool)

Special Ethernet Cable

(RJ45/M12)

Connection with Standard Parallel Interface of the Vision Sensor

I/O control PLC

I/O cable

Basic configuration

FQ2-S/CH Series

FQ2-S/CH Series

External devices

Trigger sensor

I/O control PLC

Trigger sensor

Setup Tool

(Touch Finder or PC Tool)

Special Ethernet Cable

(RJ45/M12)

A Parallel Interface Sensor Data Unit can be installed to enable output of measured values,

parameters, calculation results, and other information.

Use an I/O cable for input of measurement triggers and communication commands,

and for output of OK/NG judgement results.

Connection through a Parallel Interface Sensor Data Unit

FQ2-S1

FQ2-S3 FQ2-S4 FQ2-CH

FQ2-S3 FQ2-S4 FQ2-CH

FQ2-S2

FQ2-S3 FQ2-S4

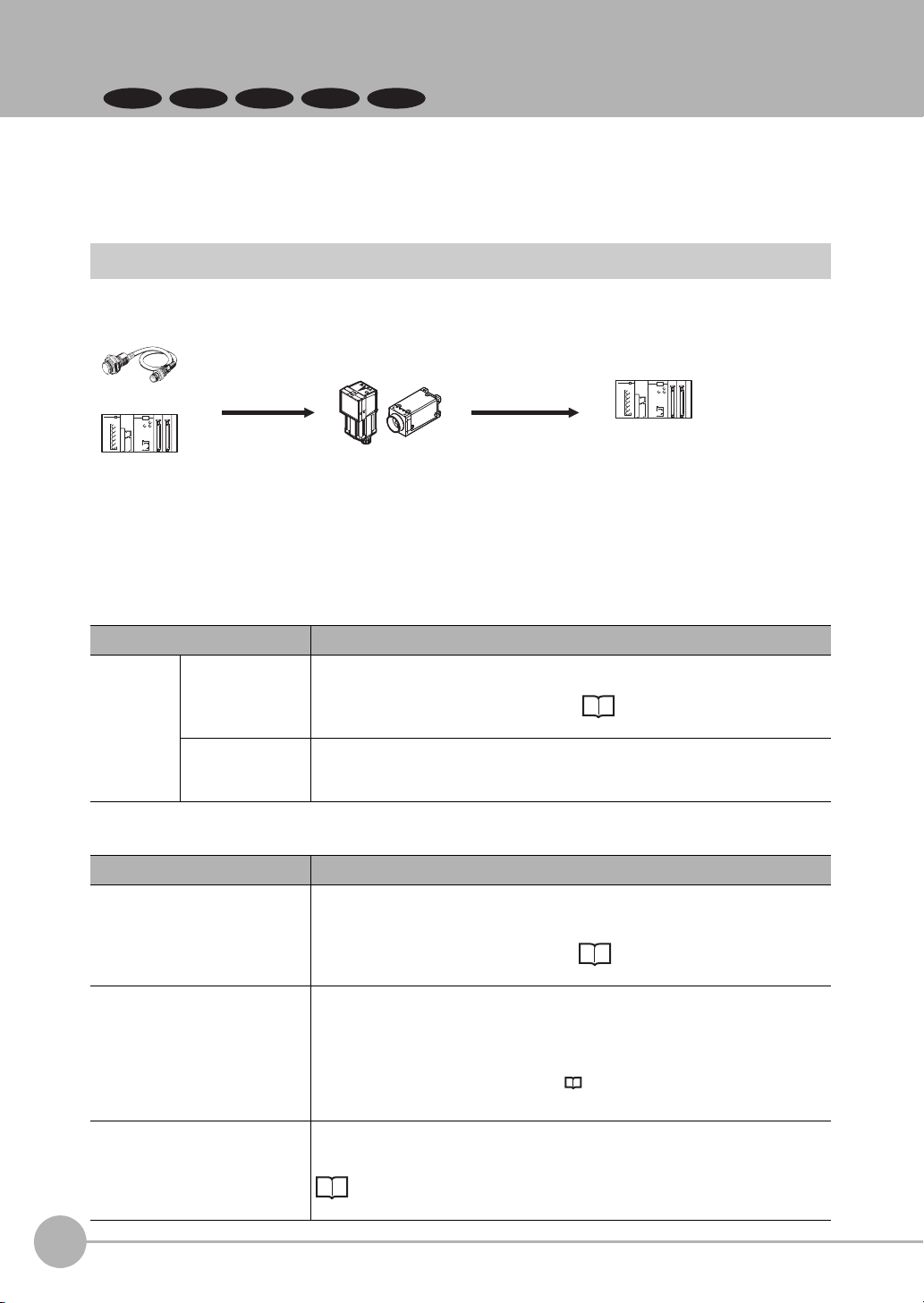

The FQ2-S/CH series is Vision System that perform measurement processing through measurement objects

that are imaged by a Camera.

In a system configuration that is connected to a PLC, computer, or other external device, measurement

commands can be received from and measurement results can be output to the external device.

FQ2-S/CH Series System Configuration

The following types of system configurations can be used with the FQ2.

8

Confirming the System Configuration

FQ2-S/CH User’s Manual

for Communications Settings

Page 11

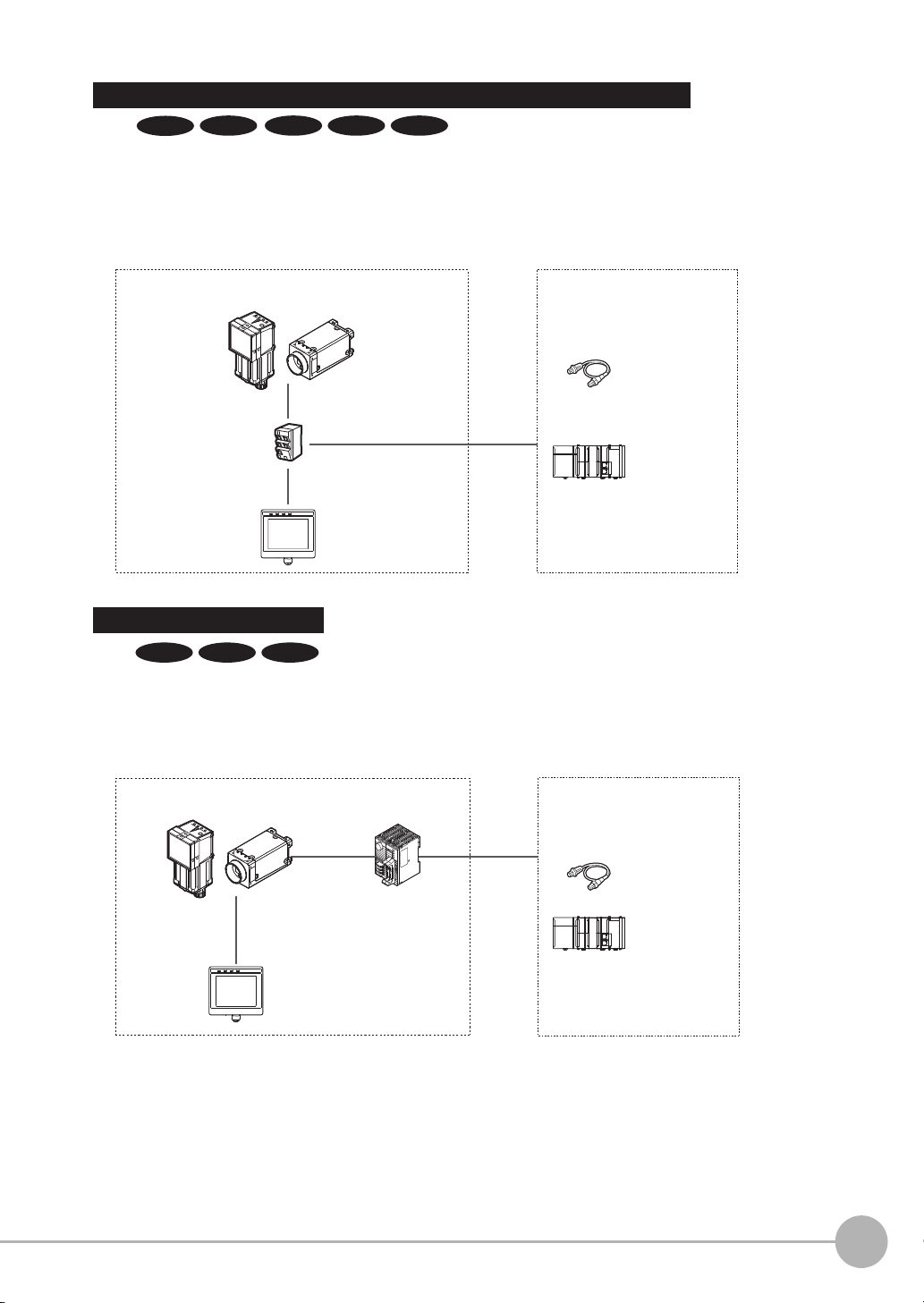

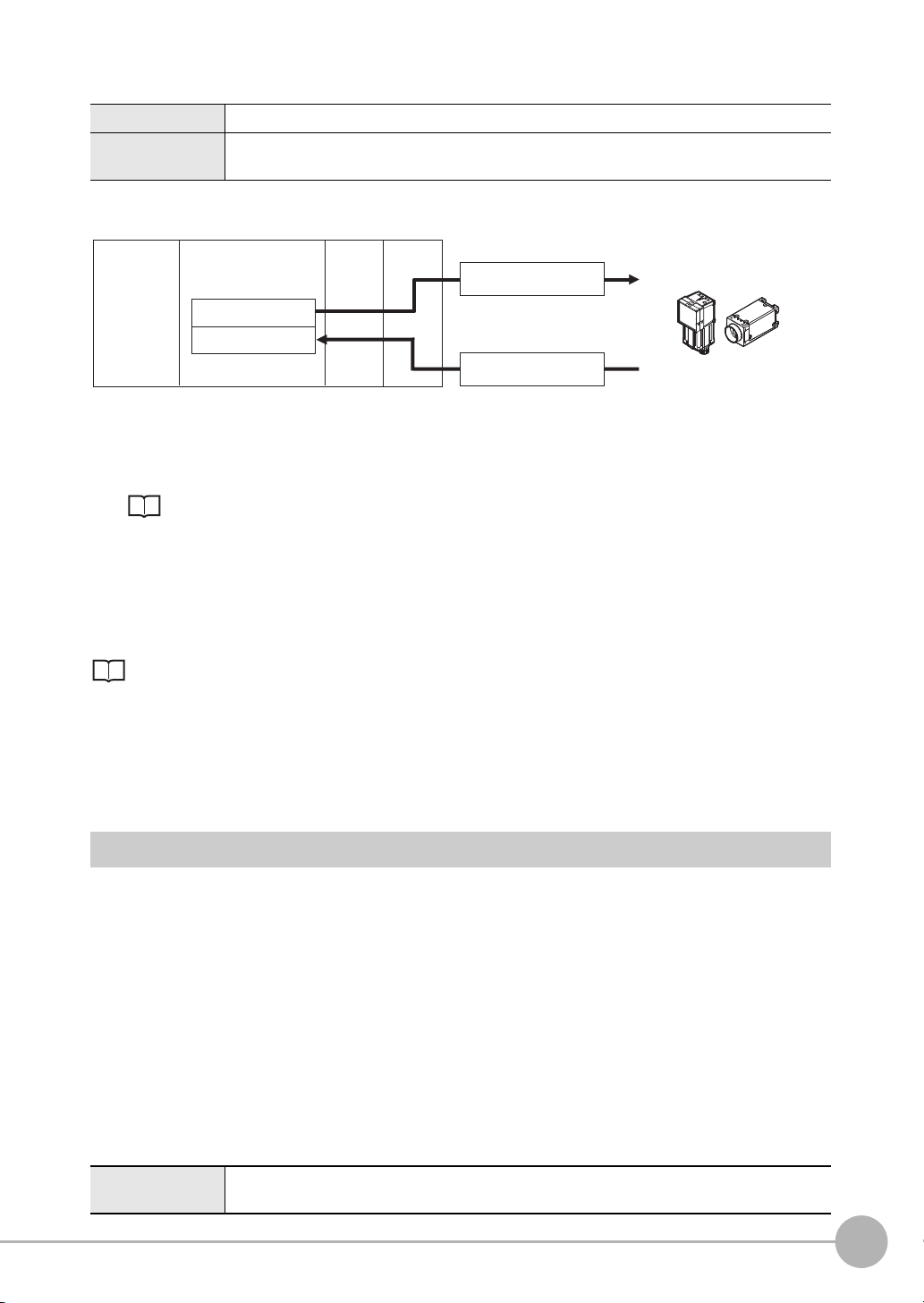

Ethernet (EtherNet/IP, PLC Link, No-protocol, or PROFINET) Connection

Basic configuration External devices

I/O control PLC

Trigger sensor

Setup Tool

(Touch Finder

or PC Tool)

General-purpose Ethernet cable

Switching hub for

EtherNet/IP

(industrial Ethernet)

FQ2-S/CH Series

FQ2-S/CH Series

RS-232C Serial Connection

RS-232C

cable

RS-232C Interface

Sensor Data Unit

*2

Sensor Data

Unit cable

Basic configuration External devices

Sensor control PLC

I/O control PLC

Trigger sensor

Setup Tool

(Touch Finder or PC Tool)

An RS-232C Interface Sensor Data Unit can be connected to the Sensor by RS-232C cable to

enable input of measurement triggers and communication commands, and output of measurement

results (judgement results, measured values). Measurement triggers can also be input from a parallel

connection.

Ethernet cable can be used to connect to a variety of networks in order to input measurement

triggers and communication commands, and to output measurement results (judgement results,

measured values). Measurement triggers can also be input from a parallel connection. The data

link function for each network (excluding no-protocol networks) can be used to periodically

transfer data between the sensor and external devices.

Special Ethernet Cable

(RJ45/M12)

*1

General-purpose Ethernet cable

*1: A special Ethernet cable is used to connect to the sensor.

*2: A parallel cable (FQ-SDU2 special-purpose cable) can be used to connect to external devices from the Sensor Data Unit.

In this case, an ACK signal can be used as an additional output signal.

Special Ethernet Cable

(RJ45/M12)

FQ2-S1

FQ2-S3 FQ2-S4 FQ2-CHFQ2-S2

FQ2-S3 FQ2-S4 FQ2-CH

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Confirming the System Configuration

9

Page 12

1-2 Communicating with an External Device

FQ2-S1

FQ2-S2

FQ2-CH

Trigger sensor

PLC

PLC

The measurement

results are output.

• Status signals

• Overall judgement

• Measured values

• Character strings

Measurement

triggers and other

control commands

are input.

Sensor

FQ2-S3 FQ2-S4

This section gives the communications specifications, describes the control methods that you can use for

communications, and describes the settings that are required before starting communications with an external

device.

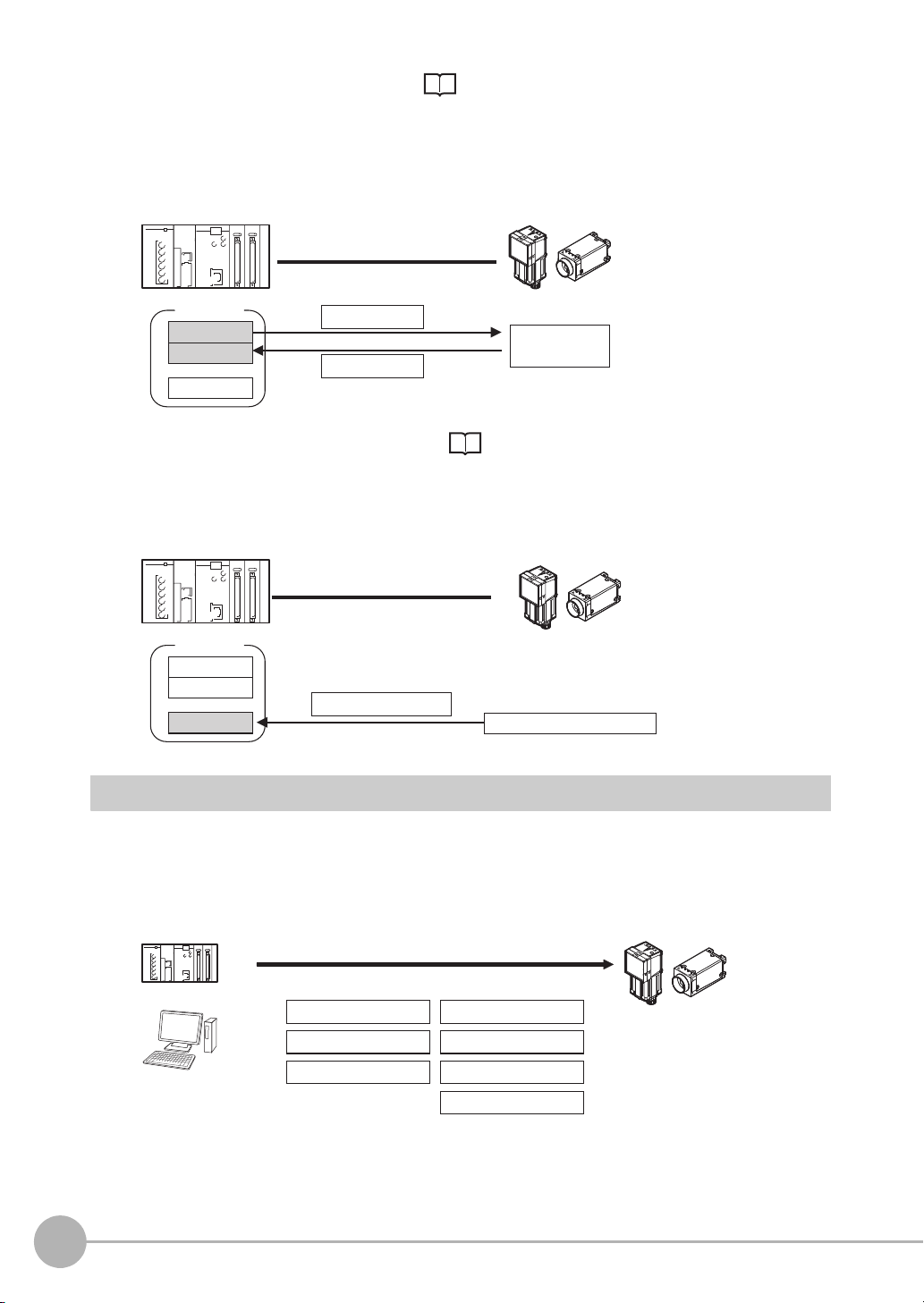

Basic Control Operations of the Sensor

The following figure shows basic communications between an external device and the Sensor and the flow of

signals and data.

The following methods can be used to exchange data between an external device and the Sensor.

10

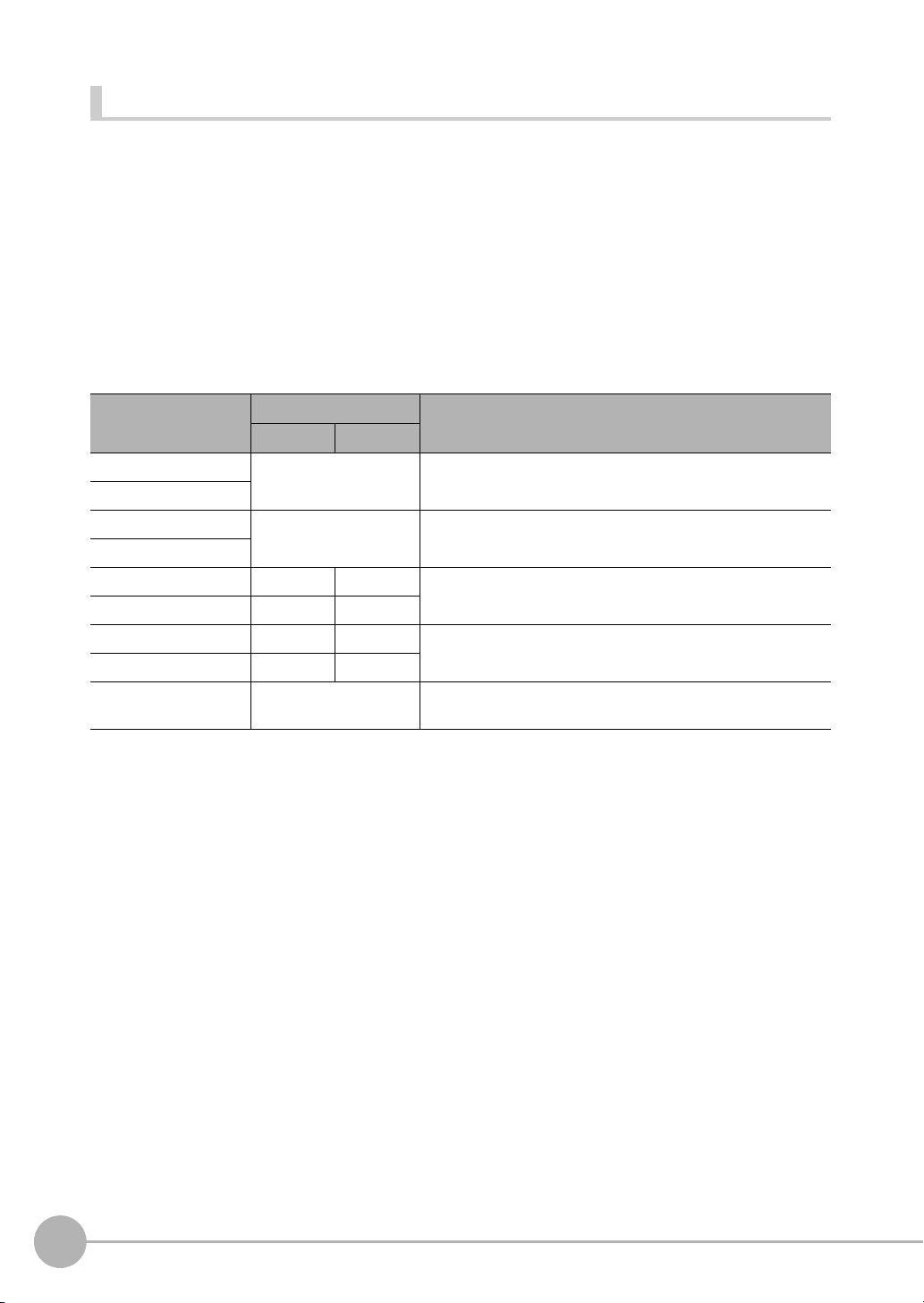

Commands That Can Be Input to the Sensor from an External Device

Ty p e Description

Control commands

Control signals

(input signals)

Communications

command input

A measurement is executed when a measurement trigger (i.e., an ON TRIG signal) is input.

For information on control signals, refer to Control with Control Signals and

Status Signals: p.18.

Various commands can be executed, such as measuring commands and scene

change. The communications commands depend on the communications protocol that you use. Refer to the section for each communications protocol for details.

Data Output to an External Device from the Sensor

Ty p e Description

Status signals When the Sensor confirms a control signal or communications command input

and begins measurement processing, the status of the Sensor is reported to the

external device through status signals (e.g., a BUSY signal).

For information on status signals, refer to Control with Control Signals and

Status Signals: p.18.

Overall judgement NG is output whenever there is one or more NGs in the judgement results for mul-

Measured values The measured values from inspection items can be output. The output items must

Communicating with an External Device

tiple inspection items.

The overall judgement can be output through the OR signal or through the JG output parameter.

*1: This behavior can be changed in the settings.

For information on the OR signal, refer to Control with Control Signals and Status Signals: p.18.

For information on the JG output parameter.

be inspection items for output and registered as output data (data 0 to data 31).

Refer to the following for details.

Settings Required for Data Output: p.61, 97, 124, 148, 169, 198.

You can also use commands to obtain results after a measurement is performed.

*1

FQ2-S/CH User’s Manual

for Communications Settings

Page 13

Ty p e Description

Trigger sensor

External device

Status signal

Control signal

Sensor

Character output (FQ2-S4/CH

series only)

You can output character strings and numbers that are read by inspection items

such as OCR, Barcode, 2D-code, or 2D-code (DPM). Refer to Items That

Can Be Output as Output Data: p.22 for details.

You can also use commands to obtain results after a measurement is performed.

1

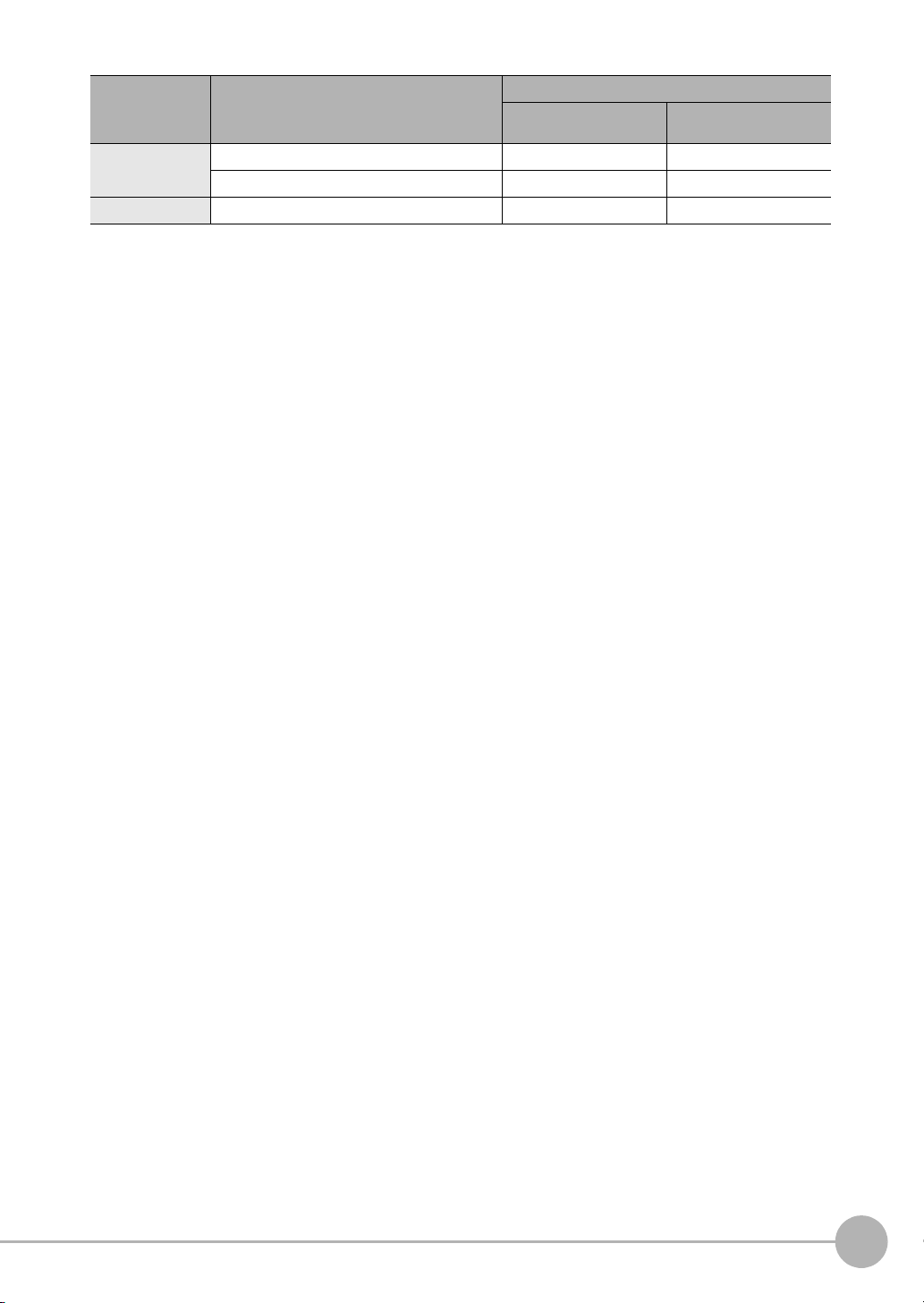

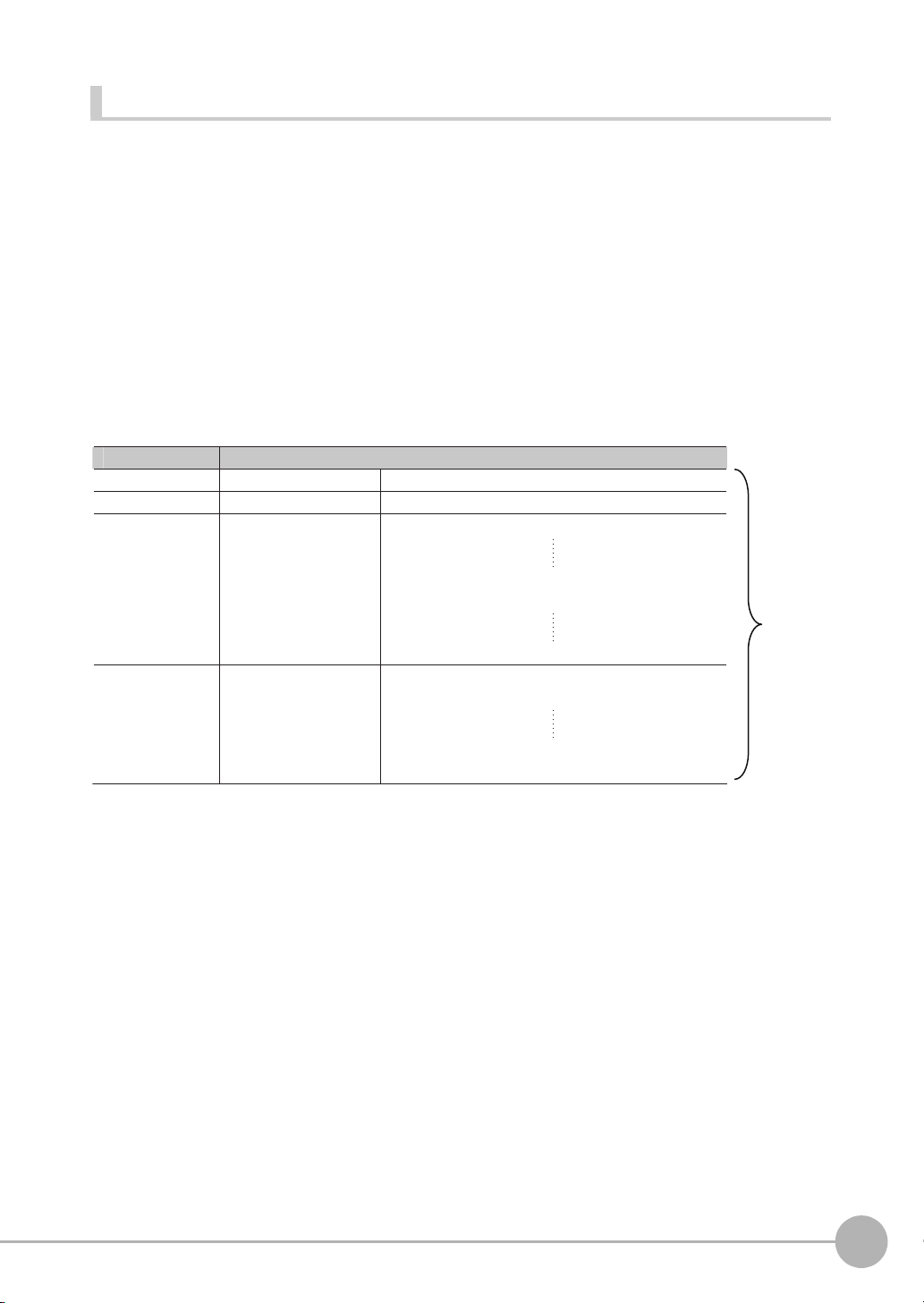

Control Methods for the Sensor

There are three methods that you can use to control the Sensor from a PLC or other external device. They are

described in this section.

For details on each control method, refer to their corresponding section.

Control Methods

Method Overview Trigger type or area Signals or area used

Control signals and

status signals

Control with commands and

responses

Data output after

measurements

Operation is controlled by the

ON/OFF status of the Measurement Trigger Signal

(TRIG) and Command

Request Bit (EXE).

Control is performed by sending control commands. The

execution results of the command can be confirmed in the

response from the Sensor.

After a measurement is performed, the previously specified measurement data is

output automatically.

ON/OFF status of the control

signals and status signals

The control command code is

stored in the I/O memory of

the PLC and then the Request

Bit is turned ON.

Not required. (Output is performed automatically after

measurement.)

Control signals and status signals

PLC I/O memory (Command

Area and Response Area)

PLC I/O memory (Data Output Area)

1 Control with Control Signals and Status Signals (Refer to Control with Control Signals and

Status Signals: p.18)

Control and status confirmation for the Sensor is performed with the ON/OFF status of the control and

status signals.

This method is best suited for basic operations such as measurement triggers or to check the operating

status of the Sensor.

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Communicating with an External Device

11

Page 14

2 Command/Response Method (Refer to Command/Response Method: p.20)

External device

I/O memory

Sensor

Command Area

Response Area

(1) Command

(3) Response

Output Area

(2) Command

execution

External device

I/O memory

Sensor

Command Area

Response Area

(2) Measurement data

Output Area

(1) Measurement processing

Control is performed by storing the control command and the response to that command in the I/O memory of a PLC.

This method is best suited to send multiple commands to the Sensor without using PLC communications

instructions.

3 Data Output after Measurements (Refer to Data Output after Measurements: p.21)

After a measurement is executed, the measurement data specified for output is automatically output to

the specified words in the I/O memory of the PLC.

This is suited to reception of the measurement result data of each inspection item.

The Sensor can be controlled from a PLC, computer, or other external device using a variety of communication

protocols.

The communication protocols that can be used to control the Sensor from an external device are described

below.

12

Communicating with an External Device

Communication Protocols for Communication with the Sensor

PLC

Computer

Control can be performed through different communications protocols.

Parallel

PLC Link

No-protocol (TCP)

EtherNet/IP

PROFINET

No-protocol (UDP)

No-protocol (FINS/TCP)

Sensor

FQ2-S/CH User’s Manual

for Communications Settings

Page 15

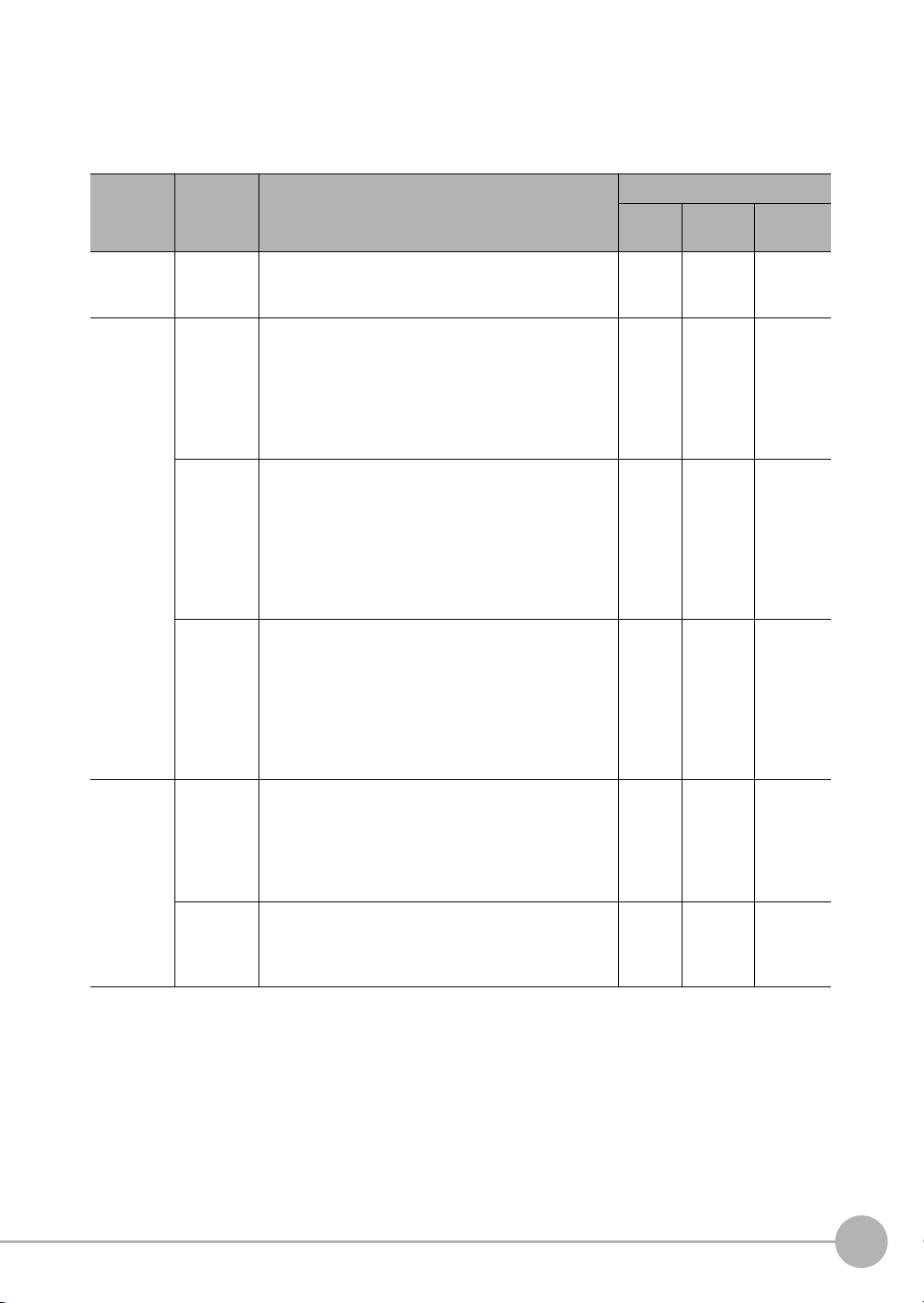

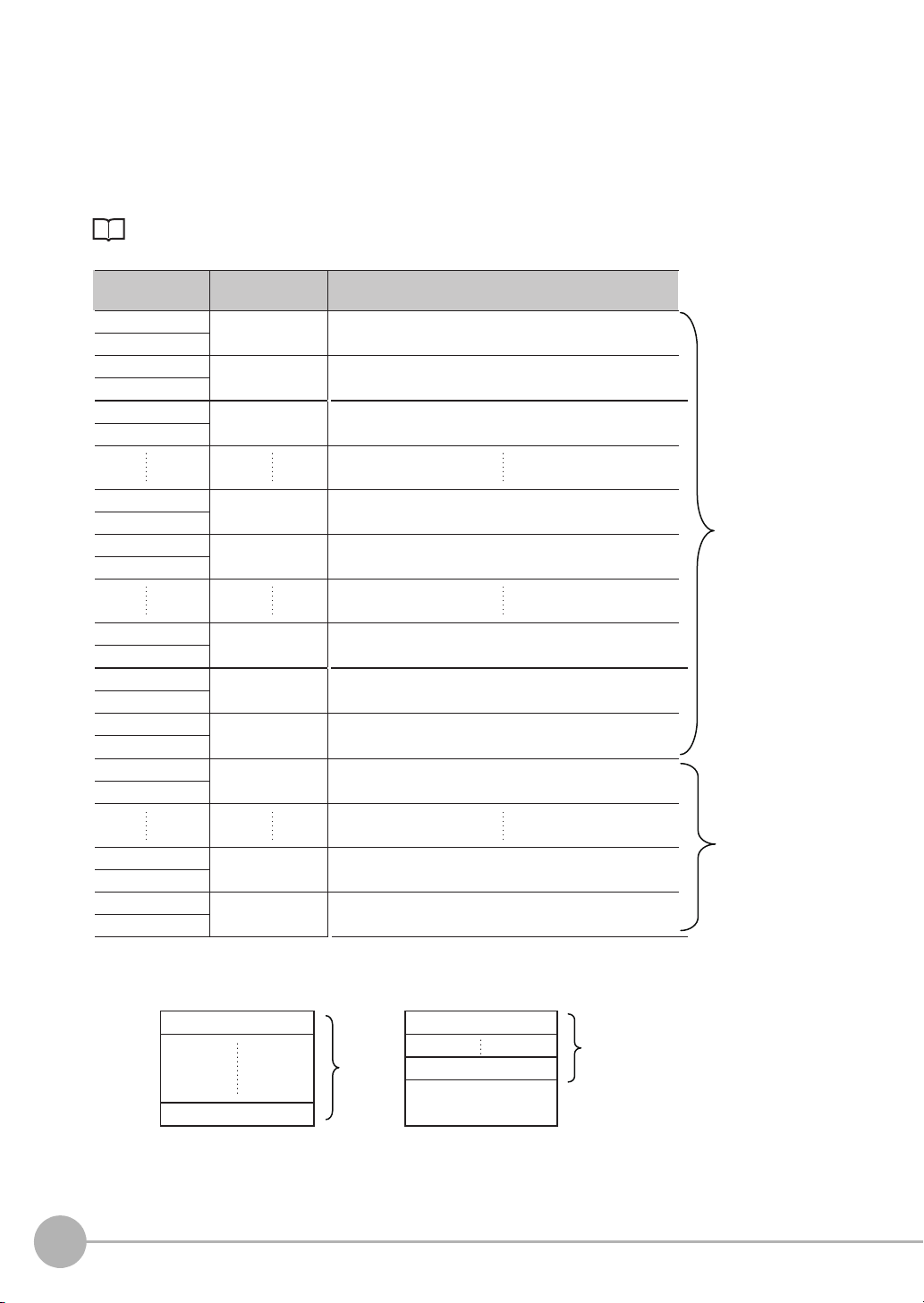

Applicable Communications Protocols

The communication protocols of each communication method that can be used with the Sensor are as follows:

OK: Supported, ---: Not supported.

Communications

method

Contact

inputs

Data sharing

Frame

transmission

*1: When connected to a CJ-series PLC, specify the areas in the I/O memory.

*2: This connection is via the RS-232C Interface Sensor Data Unit. Only supported on the FQ2-S3/S4/CH series.

Communi-

Overview Communications cable type

cations

protocol

Parallel Data is exchanged between an external device and the

Sensor through combinations of ON/OFF signals from

multiple physical contacts.

PLC Link This is OMRON’s communications protocol for Vision

System.

The control signals, Command Area/Response Area,

and area to store measurement data are assigned in

the I/O memory of the PLC, and data is exchanged

cyclically to share data between the PLC and the Vision

System.

EtherNet/IP This is an open communications protocol.

Tag data links are used for communication with the Sen-

sor.

On the PLC, structure variables are created that corre-

spond to the control signals, command/response data,

and measurement data. These variables are then used

as tags to input and output data through tag data links

to exchange data between the PLC and the Sensor.

PROFINET This is an open communications protocol.

RT (Real-time) of soft real-time communication (SRT) is

used for communication with the Sensor.

The control signals, Command Area/Response Area,

and area to store measurement data are assigned in

the I/O memory of the PLC, and data is exchanged

cyclically to share data between the PLC and the Vision

System.

No-protocol (TCP)

No-protocol (UDP)

No-protocol (FINS/

TCP)

Command frames are sent to the Sensor and response

frames are received from the Sensor without the use of

any specific protocol.

Data can be exchanged between the PLC, computer, or

other external device and the Sensor by sending and

receiving ASCII or binary format data.

This is a command system (FINS) for message services

that can be used in common on OMRON networks.

Data can be exchanged between an OMRON PLC and

the Sensor by a command/response method.

*1

Parallel

I/O

OK --- OK

--- OK ---

--- OK ---

--- OK ---

--- OK ---

--- OK ---

Ethernet RS-232C

*2

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Communicating with an External Device

13

Page 16

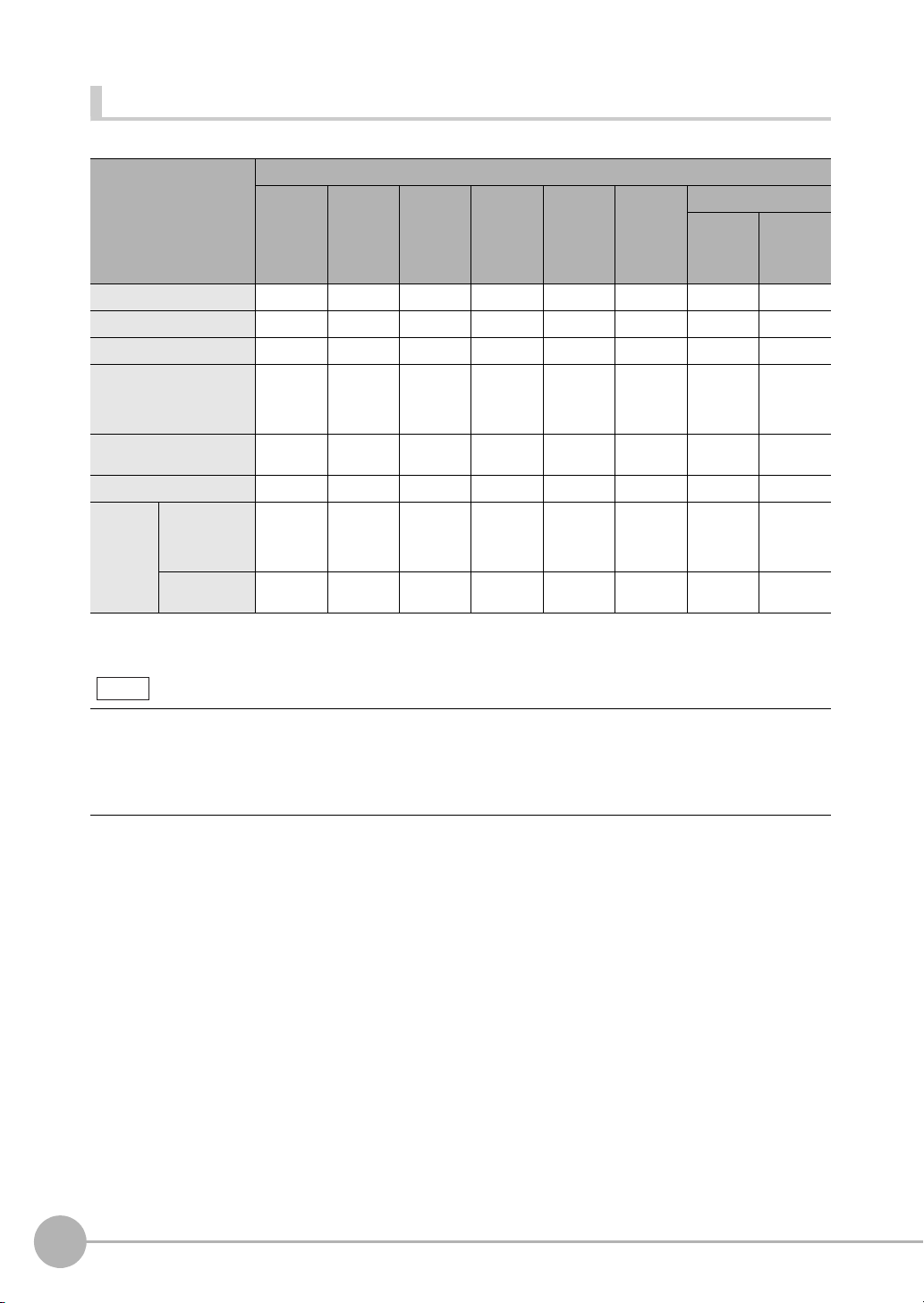

Connection Compatibility

Note

Yes: Supported, No: Not supported

Type of connection to

FQ2-S/CH

EtherNet/IP --- No No Yes Yes Yes Yes Yes

PLC Link on Ethernet No --- No Yes Yes Yes Yes Yes

PROFINET No No --- Yes Yes Yes Yes Yes

TCP no-protocol communications on Ethernet,

UDP no-protocol communications on Ethernet

FINS/TCP no-protocol communications on Ethernet

RS-232C

Parallel

communications

*1: This applies when an RS-232C Interface Sensor Data Unit is connected.

*2: This applies when a Parallel Interface Sensor Data Unit is connected.

*1

Sensor’s standard parallel

communications

Parallel Inter-

*2

face

Other connection

EtherNet/IP PLC Link

Yes Yes Yes --- No No Yes Yes

YesYesYesNo --- No YesYes

YesYesYesNo No --- YesNo

YesYesYesYesYesYes--- No

YesYesYesYesYesNo No ---

on Ethernet

PROFINET

TCP no-protocol

communications on

Ethernet,

UDP no-protocol

communications

on Ethernet

FINS/TCP

no-protocol communications

on Ethernet

RS-232C *1Parallel communications

Sensor’s

standard

parallel communications

Parallel

Interface

*2

Connections Across Network Routers

You can connect to a Sensor on a different network than the Touch Finder or PC Tool through a router.

• To connect to a Sensor, directly specify the IP address of the Sensor. Automatic connection to a Sensor is not

possible.

• Use a fixed IP address for the Sensor to connect to.

14

Communicating with an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 17

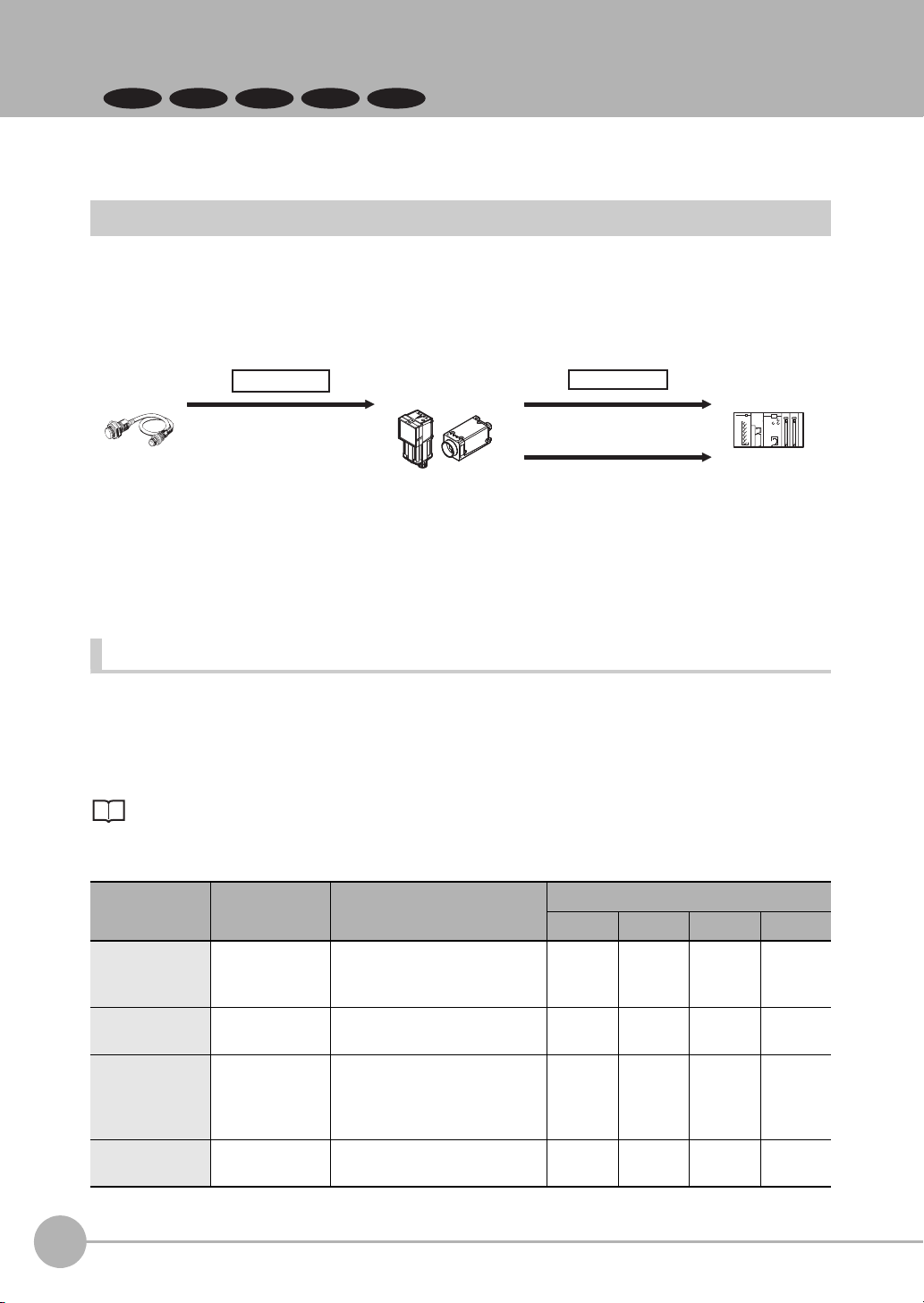

Models That Are Compatible with the Communications Protocols

This section lists the external devices that can communicate with the FQ2-S/CH series for each

communications protocol.

PLC Link

OMRON

❍: Can connect U: Only some models can connect ✕: Cannot connect

Series CPU Unit Interface

Direct connection with CPU

unit (built-in port)

SYSMAC_CJ2 CJ2H or CJ2M U (Built-in port only.) CJ1W-EIP21 (PLC Link

SYSMAC_CJ1 CJ1H or CJ1G ✕ CJ1W-EIP21 (PLC Link

CJ1M U (Built-in port only.) CJ1W-EIP21 (PLC Link

SYSMAC_CS CS1H, CS1D, or CS1G ✕ CS1W-EIP21 (PLC Link

SYSMAC_CP1 CP1L U (Built-in port only.) ---

CP1H ✕ CJ1W-EIP21 (PLC Link

SYSMAC_One NSJ ✕ NSJW-ETN21

Connection via Ethernet unit

only) or CJ1W-ETN21

only) or CJ1W-ETN21

only) or CJ1W-ETN21

only) or CS1W-ETN21

only) or CJ1W-ETN21

Mitsubishi Electric

❍: Can connect U:Only some models can connect ✕: Cannot connect

Series Model name CPU Unit CPU name Interface

MELSEC-QnU Universal mod-

MELSEC-Q Series High-

els

Basic models QnCPU Q00JCPU,

performance

models

QnUDECPU

QnUDCPU

QnUCPU Q00UJCPU,

QCPU Q02CPU,

Q03UDECPU,

Q04UDEHCPU,

Q06UDEHCPU,

Q10UDEHCPU,

Q13UDEHCPU,

Q20UDEHCPU,

or

Q26UDEHCPU

Q03UDCPU,

Q04UDHCPU,

Q06UDHCPU,

Q10UDHCPU,

Q13UDHCPU,

Q20UDHCPU, or

Q26UDHCPU

Q00UCPU,

Q01UCPU, or

Q02UCPU,

Q00CPU, or

Q01CPU

Q02HCPU,

Q06HCPU,

Q12HCPU, or

Q25HCPU

Direct connection with CPU

unit (built-in port)

❍ QJ71E71-100, Q71E71-B2,

✕

✕

✕

✕

Connection via Ethernet unit

or QJ71E71-B5

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Communicating with an External Device

15

Page 18

Series Model name CPU Unit CPU name Interface

MELSEC-QnAS

Series

--- --- Q2ASCPU,

Q2ASCPU-S1,

Q2ASHCPU, or

Q2ASHCPU-S1

Direct connection with CPU

unit (built-in port)

✕ A1SJ71QE71N3-T

Connection via Ethernet unit

EtherNet/IP

❍: Can connect U:Only some models can connect ✕: Cannot connect

Series CPU Unit Interface

Direct connection with CPU

unit (built-in port)

SYSMAC NJ NJ501 or NJ301 ❍ CJ1W-EIP21

SYSMAC_CJ2 CJ2M or CJ2H U (Built-in port only.) CJ1W-EIP21

SYSMAC_CJ1 CJ1H or CJ1G ✕ CJ1W-EIP21

CJ1M U (Built-in port only.) CJ1W-EIP21

SYSMAC_CS CS1H, CS1D, or CS1G ✕ CS1W-EIP21

Connection via EtherNet/IP

unit

No-protocol (TCP), No-protocol (UDP)

OMRON

Series CPU Unit Interface

Direct connection with CPU

unit (built-in port)

SYSMAC CJ2 CJ2H or CJ2M --- CJ1W-ETN21

SYSMAC CJ1 CJ1H or CJ1G --- CJ1W-ETN21

CJ1M --- CJ1W-ETN21

SYSMAC CS CS1H, CS1D, or CS1G --- CS1W-ETN21

SYSMAC CP1 CP1L U (Built-in port only.) ---

CP1H --- CJ1W-ETN21

SYSMAC One NSJ --- NSJW-ETN21

Connection via Ethernet unit

No-protocol (FINS/TCP)

OMRON

Series CPU Unit Interface

Direct connection with CPU

unit (built-in port)

SYSMAC CJ2 CJ2H or CJ2M U (Built-in port only.) CJ1W-EIP21 or CJ1W-

SYSMAC CJ1 CJ1H or CJ1G --- CJ1W-EIP21 or CJ1W-

CJ1M U (Built-in port only.) CJ1W-EIP21 or CJ1W-

SYSMAC CS CS1H, CS1D, or CS1G --- CS1W-EIP21 or CS1W-

16

Communicating with an External Device

Connection via Ethernet unit

ETN21

ETN21

ETN21

ETN21

FQ2-S/CH User’s Manual

for Communications Settings

Page 19

Series CPU Unit Interface

Direct connection with CPU

unit (built-in port)

SYSMAC CP1 CP1L U (Built-in port only.) ---

CP1H --- CJ1W-ETN21

SYSMAC One NSJ --- NSJW-ETN21

Connection via Ethernet unit

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Communicating with an External Device

17

Page 20

1-3

FQ2-S1

FQ2-S2

FQ2-CH

Trigger sensor Sensor

(1) Measurement trigger input

(TRIG signal: ON).

Control signal

(2) Command received.

(BUSY signal turned ON.)

(3) Judgement results are output.

(OR signal turned ON.)

Status signals

External device

Control Methods Using an External Device

FQ2-S3 FQ2-S4

This section describes the methods that you can use to control the Sensor from a PLC or other external device.

Control with Control Signals and Status Signals

Control and status confirmation for the Sensor is performed with the ON/OFF status of the control and status

signals.

Measurement triggers and other signals are input as control signals from the PLC.

The operating status of the Sensor, judgement results, and other status information can be confirmed through

status signals sent from the Sensor.

(1) The external device turns ON the TRIG signal to input a measurement trigger.

(2) When the Sensor confirms that the TRIG signal is ON, it outputs the BUSY signal to the external device

and begins a measurement.

(3) When the Sensor finishes the measurement, it outputs the judgement results on the OR signal.

Control Signals and Status Signals

The types of signals that are input to and output from the sensor as control signals and status signals are

shown below. “Use of signal in each protocol” in the table below lets you check whether or not a signal is used

in each protocol.

Note that this table does not show whether simultaneous use of signals in differing communication protocols is

possible. For restrictions on communication protocols that can be used simultaneously, refer to

Connection Compatibility on page 14.

Input Signals (PLC to Sensor)

Signal Signal name Function

EXE Control Com-

mand Execution

Signal

TRIG Measure Bit Turn ON this signal to execute

DSA

(Used only for

handshaking output control.)

ERCLR Error Clear Bit

18

Control Methods Using an External Device

Data Output

Request Signal

Turn ON this signal (from the

PLC) to send a command to the

FQ-S/CH series.

measurement.

Use this signal (from the PLC) during handshaking to request from

the FQ-S/CH series the external

output of the data output results.

Turn ON this signal to clear the ERR

signal from the Sensor Controller.

Signals for each communications protocol

Parallel PLC Link

--- OK OK OK

OK --- OK OK

OK OK OK OK

--- --- OK OK

EtherNet/IP

FQ2-S/CH User’s Manual

for Communications Settings

PROFINET

Page 21

Signal Signal name Function

IN (IN0 to IN7) Command Input

Signals

These signals are used to input

commands from a parallel interface.

Signals for each communications protocol

Parallel PLC Link

OK --- --- ---

EtherNet/IP

PROFINET

Output Signals (Sensor to PLC)

Signal Signal name Function

BUSY Busy Signal

FLG Control Com-

mand Completion Signal

GATE Data Output

Completion Signal

READY Camera Image

Input Enabled

Signal

OR

DO (DO0 to

DO15)

ERR Error Signal The FQ2-S/CH series provides

Overall Judgement

Output Signal

Data Output Signals

This signal tells when new commands and other external inputs

cannot be acknowledged during processing of other external inputs.

Just because this signal is ON

does not necessarily mean that a

command is being executed. To

check whether a command is

being executed, access the Command Completion (FLG) signal.

The FQ2-S/CH series uses this

signal to tell the user (PLC) that

command execution has been

completed.

This signal tells the user (PLC) when

to read the measurement results.

Data output is enabled when this

signal is ON.

This signal tells when the TRIG

(Measurement Trigger) signal

can be input.

This signal gives the results of

the overall judgement.

These signals are used to output

parallel data and parallel judgements through a parallel interface sensor data unit.

notification with this signal when

it detects the following errors.

Refer to Section 8 Trouble-

shooting in Vision Sensor FQ2S/CH User's Manual (Cat. No.

Z337).

• Communication timeout

• TRIG Input while measurement

The ERR signal does not turn

OFF even after the error is eliminated. The signal turns OFF only

when the error status is cleared

by a control command.

*2

*5

Signals for each communications protocol

Parallel PLC Link

OK OK OK OK

*1

--- OK OK OK

OK OK OK OK

--- --- OK OK

OK --- OK OK

OK --- --- ---

OK OK OK OK

EtherNet/IP

1

Overview of Communication Specifications

PROFINET

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

19

Page 22

Signal Signal name Function

IN5IN4 through IN0

Execution

Command

Execution

Command

IN7IN6 through IN0

Standard Parallel Parallel Interface Sensor Data Unit

RUN Measurement

Mode Signal

ACK Command Com-

pletion Flag

SHTOUT Exposure Com-

pletion Signal

STGOUT Strobe Trigger

Output

*1: The execution of commands or other processing received through any other protocol cannot be detected.

The parallel BUSY signal can be used in all protocols.

If you use more than one protocol and need to detect command execution, use the parallel communications BUSY signal.

*2: This signal is linked to the measurement processing.

It is not associated with the BUSY signal. It is not related to the parallel interface OR signal.

The FQ2-S/CH series turns ON

this signal when measurements

can be performed and it is in Run

Mode.

This signal tells when execution

of the DI command has been

completed.

This signal tells when Camera

exposure has been completed.

This is the trigger signal for the

strobe.

Signals for each communications protocol

Parallel PLC Link

OK --- OK OK

OK --- --- ---

OK --- --- ---

OK --- --- ---

EtherNet/IP

PROFINET

Command/Response Method

Parallel

Commands are input to the Sensor by turning the IN signals (Standard Parallel: IN0 to IN5, Parallel Interface

Sensor Data Unit: IN0 to IN7) ON and OFF. There is no direct response to these commands. Confirm whether

a command was received by checking the BUSY signal.

The command code is input with part of the IN signals (Standard Parallel: IN0 to IN4, Parallel Interface Sensor

Data Unit: IN0 to IN6), and the command is executed by turning ON the execution bit (Standard Parallel: IN5,

Parallel Interface Sensor Data Unit: IN7).

PLC Link, EtherNet/IP, or PROFINET

Command/response control signals can be exchanged by storing control commands from the PLC to the

Sensor and responses from the Sensor to the PLC in the I/O memory of the PLC. This enables you to send

single measurement and scene switch requests to the Sensor without any sequence control with

communications commands from the PLC.

20

Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 23

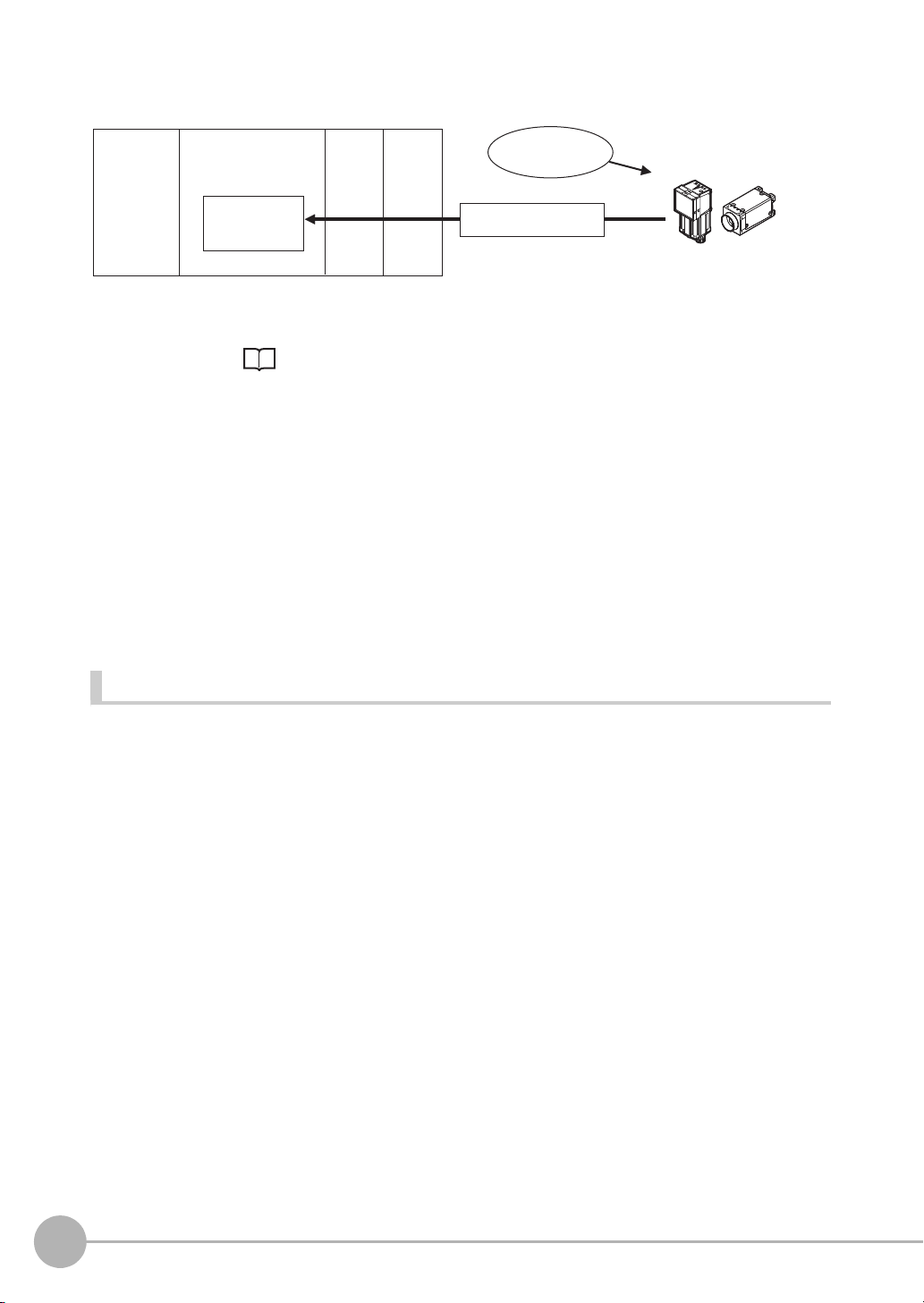

Memory Areas Used by the Command/Response Control Method

(1) Command Area

(5) Response Area

(2) Command

(4) Response

PLC

CPU Unit

I/O memory

(communications areas)

• Switch Scene Number

• Single Measurement, etc.

OK, etc.

(3) Command is processed.

Sensor

Command Area You write the control commands to execute for the Sensor to this area.

Response Area You read the results of executing the control commands that were written to the Command Area

from this area.

Flow of Communications between the PLC and the Sensor

(1) The PLC (the user) writes a control command to a specified PLC I/O memory area (the Command Area).

Parameter Notation Examples for Command Control: p.200

(2) The PLC (the user) then turns ON the EXE bit to send the control command to the Sensor.

(3) The Sensor executes the received control command.

(4) The Sensor returns a response to the PLC after the control command is executed.

(5) The PLC (the user) stores the response in a specified PLC I/O memory area (the Response Area).

The available control commands depend on the communications protocol that is used.

Command List: p.202.

1

Overview of Communication Specifications

No-protocol (TCP) Communications, No-protocol (UDP) Communications, No-protocol (FINS/

TCP) Communications

Communications commands are sent to the Sensor through sequence control in the PLC. An external device

and the Sensor communicate through no-protocol communications.

Data Output after Measurements

After a Single Measurement or Start Continuous Measurements command is executed, the Sensor

automatically outputs the data that corresponds to the measurements that have been specified as output items

to the PLC. This allows you to easily pass measurement results data from the inspection items to the PLC. You

can also choose to output only when the PLC meets the conditions that are required to receive the data (i.e.,

when handshaking is turned ON).

The output destination for data depends on the protocol that is used to communicate between the external

device and the Sensor, as described below.

PLC Link, EtherNet/IP, or PROFINET

The output data is automatically output to the following area that is specified PLC I/O memory.

Area of Memory Used for Data Output after Measurement

Data Output Area The output data for the measurement is written to this area by the Sensor after execution of the

measurement.

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

21

Page 24

Flow of Communications between the PLC and the Sensor

Data

Output Area

• Specified data is automatically output.

• Output characters

(2) Data

CPU Unit

PLC

I/O memory

(communications areas)

Sensor

Measurement

execution

(1)

The data to output after measurement and the PLC I/O memory area (Data Output Area) to store that data are

specified in advance. ( Setting Required for Data Output: p.61, 97, 124, 148, 169, 198.)

(1) Measurement is executed.

(2) After a measurement is executed, the specified measurement data is stored in the Data Output Area in

the PLC.

Parallel

A Parallel Interface Sensor Data Unit can be installed to enable data output.

The output data is output to the PLC signal wires via the D signals (D0 to D15).

This is only supported on the FQ2-S4/CH series.

No-protocol (TCP) Communications, No-protocol (UDP) Communications

The output data is output to the PLC reception buffer through non-procedure (normal) communications.

Items That Can Be Output as Output Data

Measurement Data

The following data items can be output by allocating measurement results and judgement results to output data

0 to output data 31.

• Judgement result

• Measured parameters (correlation values, reference coordinates, etc.)

• Results calculated based on the values of the measured parameters

• Judgement results from expression results (Parallel Judgement Output)

Character Output (This is Only Supported on the FQ2-S4/CH Series.)

After measurement, you can automatically output character strings that are read by OCR and other inspection

items to the PLC. Character strings can be output for the following inspection items.

•OCR

• Bar code

•2D-code

•2D-code (DPM)

Number of Characters That Can Be Output

The number of characters that can be output are shown below for each inspection item.

22

• OCR: Max. 128 characters

• Bar code, 2D-code, 2D-code (DPM): Max. 1024 characters

Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 25

For the character output setting procedures and output specifications for each communication type, refer to the

Note

CR

Before conversion After conversion

LF

&h0D

&h7F

&h8541

DEL

&h8543

Character code

&h0A

&hFF

&h8542

&h8544

FF

following:

Outputting Character Strings

• EtherNet/IP: p.101

• PLC link: p.128

• PROFINET: p.151

• No-protocol (TCP), No-protocol (UDP): p.175

• Endian

Little endian data is output.

• Code Conversion

The converted codes are outputted for the following character codes.

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

23

Page 26

Order of Output of Measurement Data and Characters (Only Supported on the FQ2-S4/CH Series)

When measurement data the data (output data settings 0 to 31) and characters are output together, the

characters are output after the data such as inspection item parameters and calculation results are output.

Example:

Read result 1: ABC

Read result 2: 0123

[Data output] − [Data 0]: 3 (Number of characters: 1)

[Data output] − [Data 1]: 4 (Number of characters: 2)

The following information will be output for the above.

EtherNet/IP, PLC Link, PROFINET

Increment from first

address in output area

+0 Data 0 (4 bytes) Inspection item 0: Number of characters

+1

+2 Data 1 (4 bytes) Inspection item 1: Number of characters

+3

+4 ‘B’ ‘A’ Inspection item 0: Characters “ABC”

+5 00 ‘C’

+6 ‘1’ ‘0’ Inspection item 1: Characters “0123”

+7 ‘3’ ‘2’

+8 00 Filled with zeros. (Only when the character string length is not a

Output data Assigned output data

Upper byte Lower byte

multiple of 4.)

No-protocol (TCP)

3 (Field delimiter) 4 (Record delimiter) ABC (Field delimiter) 0123 (Record delimiter) CR

CR is Delimiter, CR is not output by No-protocol (UDP) Communications.

24

Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 27

Output Data Size and Number of Output Data Upper Value Setting (EtherNet/IP, PLC Link, PROFINET)

Data 0

Output data Setting

Data 1

Data 2

I0.X[0] Inspection item 0: Position X for Search

I0.Y[0] Inspection item 0: Position Y for Search

LPC

(0,30,I1.X,I1.Y)

Inspection item 1: Position X 1st point for Shape Search II

Inspection item 1: Position X 30th point for Shape Search II

Inspection item 1: Position Y 1st point for Shape Search II

Inspection item 1: Position Y 30th point for Shape Search II

Data 3 LPR

(0,10,I2.X,I2.Y)

Inspection item 2: Position X 1st point for Shape Search II

Inspection item 2: Position Y 1st point for Shape Search II

Inspection item 2: Position X 10th point for Shape Search II

Inspection item 2: Position Y 10th point for Shape Search II

328

bytes

When more than one inspection result is output, the size of the data that is output for the data output settings

could exceed the limit that is set in the [Max output data] (number of output data upper value) parameter

setting.

If that occurs, increase the set value of the number of output data upper value setting or adjust the output data

settings so that data output size is not exceeded.

If the size of the data that is output exceeds the data size that can actually be output (output data limit), the

remaining data is handled as follows in each communication protocol.

• EtherNet/IP, PROFINET: The remaining data is divided and output over several cycles.

• PLC Link: The remaining data is discarded.

Example

Output data size: 328 bytes

Number of output data upper value setting: 256 bytes

Data Output Settings

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

25

Page 28

EtherNet/IP, PROFINET

+0

Output data Assigned output data

+1

Output data 0

(4 bytes)

Output data 1

(4 bytes)

Output data 2

(4 bytes)

Output data 31

(4 bytes)

Output data 32

(4 bytes)

Output data 61

(4 bytes)

Output data 62

(4 bytes)

Output data 63

(4 bytes)

Output data 0

(4 bytes)

Output data 6

(4 bytes)

Output data 7

(4 bytes)

Inspection item 0: Position X for Search

+2

+3

Inspection item 0: Position Y for Search

+4

+5

Inspection item 1: Position X 1st point for Shape Search II

+62

+63

Inspection item 1: Position X 30th point for Shape Search II

+64

+65

Inspection item 1: Position Y 1st point for Shape Search II

+122

+123

Inspection item 1: Position Y 30th point for Shape Search II

+124

+125

Inspection item 2: Position X 1st point for Shape Search II

+126

+127

Inspection item 2: Position Y 1st point for Shape Search II

+0

+1

Inspection item 2: Position X 2nd point for Shape Search II

+12

+13

Inspection item 2: Position X 10th point for Shape Search II

+14

+15

Inspection item 2: Position Y 10th point for Shape Search II

Offset from first

address in output area

256 bytes

(Data that is

output the

first cycle.

*1

)

72 bytes

(Data that

is output

the second

cycle.

*2

)

The output data that is assigned is output to the output area as shown below.

Output data that exceeds the size (e.g., 256 bytes) that is set for the output data size parameter is separated

over more than one cycle.

To ensure that no data is lost when receiving data that is divided and output over several cycles, use the

handshake function.

Data Output Control with Handshaking: p.30

*1: At the first data output, a GATE (Data Output Completion) signal is output.

*2: If the size of the specified output data exceeds the set value of the output data size setting, the data is output separately as shown below.

26

Control Methods Using an External Device

Output data size setting: 256 bytes

First Data Output

Output data 0 Output data 0

Output data 63

256

bytes

Second Data Output

Output data 7

Zeros are written to

unused bytes.

72 bytes

The previous data will be

overwritten. Adjust the

timing with handshaking to

get the data.

FQ2-S/CH User’s Manual

for Communications Settings

Page 29

PLC Link

+0

Output data Assigned output data

+1

Output data 0

(4 bytes)

Output data 1

(4 bytes)

Output data 2

(4 bytes)

Output data 31

(4 bytes)

Output data 32

(4 bytes)

Output data 61

(4 bytes)

Output data 62

(4 bytes)

Output data 63

(4 bytes)

Output data 64

(4 bytes)

Output data 65

(4 bytes)

Output data 66

(4 bytes)

Inspection item 0: Position X for Search

+2

+3

Inspection item 0: Position Y for Search

+4

+5

Inspection item 1: Position X 1st point for Shape Search II

+62

+63

Inspection item 1: Position X 30th point for Shape Search II

+64

+65

Inspection item 1: Position Y 1st point for Shape Search II

+122

+123

Inspection item 1: Position Y 30th point for Shape Search II

+124

+125

Inspection item 2: Position X 1st point for Shape Search II

+126

+127

Inspection item 2: Position Y 1st point for Shape Search II

+128

+129

Inspection item 2: Position X 2nd point for Shape Search II

+160

+161

Inspection item 2: Position X 10th point for Shape Search II

+162

+163

Inspection item 2: Position Y 10th point for Shape Search II

Offset from first

address in output area

256 bytes

(Data that is

output the

first cycle.)

72 bytes

(The data that

exceeds the

set upper limit

is discarded.)

The output data that is assigned is output to the output area as shown below.

Any output data that exceeds the set value of the [Max output data] (number of output data upper value)

parameter setting (e.g., 256 bytes) is discarded.

For the [Max output data] setting, refer to Initial Settings for PLC Link Communications on page 122.

1

Overview of Communication Specifications

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

27

Page 30

Parallel Output of Measurement Data (Only Supported on the FQ2-S3/S4/CH Series)

4 bytes

Parallel data output

PLC

0. Measurement data 0

31. Measurement data 31

Reception

buffer

Data output order

Measurement

data 31

Measurement

data 0

GATE

signal

D0 to D31

signals

ON

OFF

Parallel judgement

output D0

Parallel data output

(data 0)

Parallel judgement

output D1

Parallel data output

(data 0)

Parallel judgement

output D15

Parallel data output

(data 0)

D0

D1

D15

When a Parallel Interface Sensor Data Unit is connected to the Sensor, the two types of data output below can

be performed, in addition to output of measurement judgement results.

Output data type Output data

Parallel Data Output The measurement data is output. A maximum of 32 items can be output.

Parallel Judgement Output The judgement results are output. A maximum of 16 judgement result items can be

output. The following two types of judgement results can be output:

• Judgement results for specified inspection items

• Judgement results of set judgement conditions for the specified item values

Order of Parallel Data Output

Parallel Output of Multiple Items

Items set to output numbers 0 to 31 of parallel data output are output by item (4 bytes) in ascending order to the

reception buffer of the PLC. The GATE signal turns OFF > ON

When this occurs, the first data item that was output to the PLC reception buffer (data 0) is overwritten by the

next output data item (data 1).

Therefore, the data output to the PLC reception buffer must be saved to PLC memory each time the GATE

signal turns ON for each data item.

*1

at each output.

*1: The operation of the DSA signal depends on whether handshaking for output control is enabled. Data Output Control with Handshak-

Data Output Timing

Output Sequence

If both parallel judgement output and parallel data output are performed at the same time, parallel judgement

output will be performed first followed by parallel data output.

Example: Parallel Judgement Output of D0 to D15 and Parallel Data Output of Data 0

28

Control Methods Using an External Device

ing: p.30.

FQ2-S/CH User’s Manual

for Communications Settings

Page 31

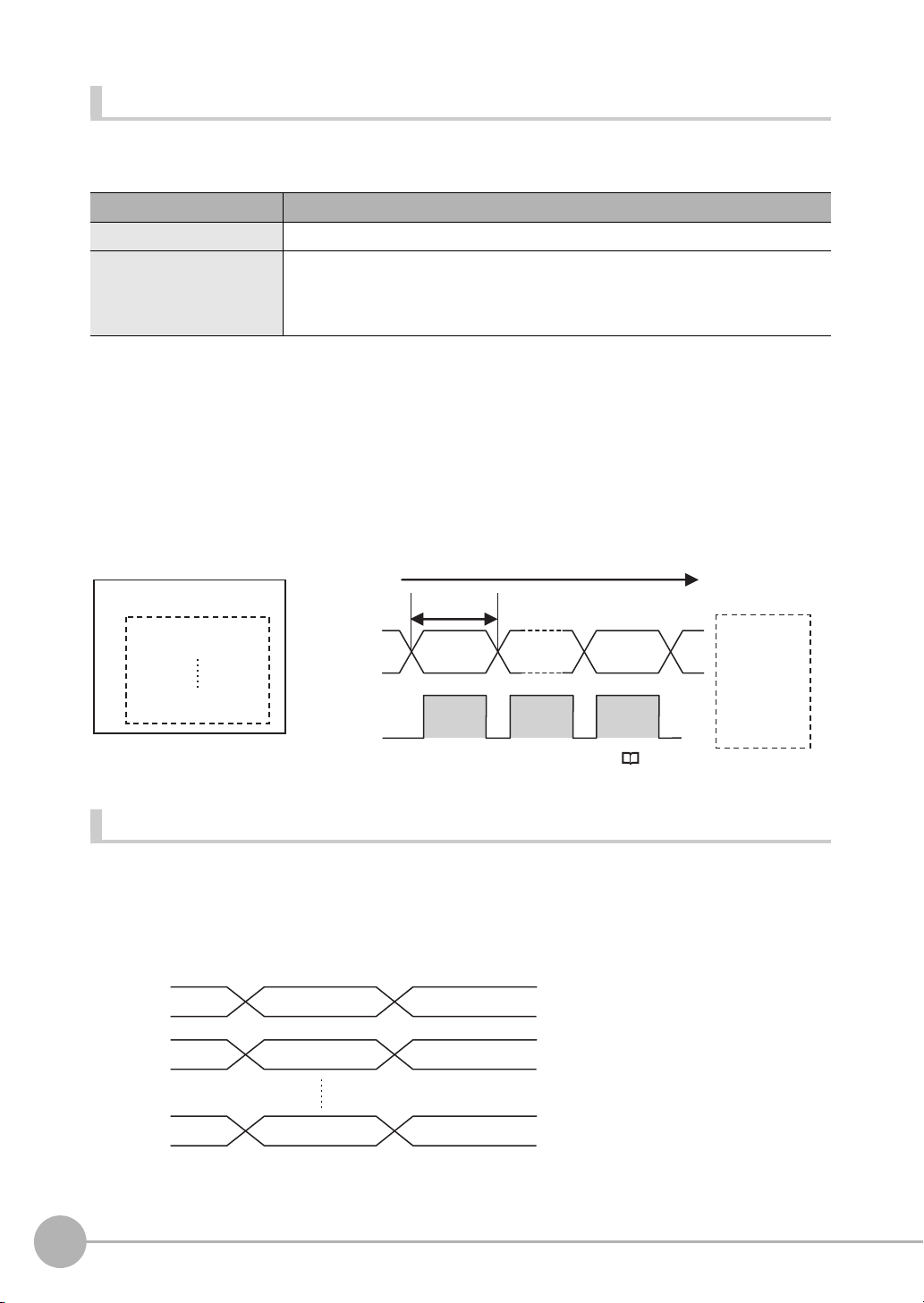

Timing Chart

Overall judgement

Parallel

judgement output

(D0 to D15)

BUSY signal

OFF

ON

OR signal

D signals

OFF

ON

RUN signal

OFF

ON

TRIG signal

OFF

ON

GATE signal

OFF

ON

Measurements executed.

GATE

ON delay

Output time

Output period

Run Mode entered.

ON for 1 ms min.

Setup Mode entered.

The FQ2 starts measurements when it detects the rising edge

(OFF to ON transition) of the TRIG signal.

The following timing chart shows the data output timing for parallel judgement outputs.

1

Overview of Communication Specifications

Output Signals

Signal Function

RUN This signal is ON while the Sensor is ready to take measurement and it is in Run Mode.

The RUN signal is OFF in Setup Mode. Change to Run Mode for operation.

BUSY This signal is ON when the Sensor is performing measurements, changing scenes, or performing other

tasks. Do not input the next command while the BUSY signal is ON.

The process that is currently being executed and the command that is input will not be executed correctly.

OR This signal outputs the overall judgement. The signal is valid when the measurements are completed (i.e.,

when the BUSY signal changes from ON to OFF).

D These signals output the parallel judgement output data and the calculation results of the expressions that

are set for parallel data output.

GATE This signal is used to control the timing of reading the D signals at an external device.

You can set whether the signal turns ON for an OK or for an NG judgement in the [Judgment output condition] output setting.

Changing the Judgement Output ON Conditions: p.44

It is turned ON for the period of time that is required to reliably read the D signals at the external device.

Set the output period so that the total output time is shorter than the measurement interval (i.e., the TRIG

signal input interval).

The GATE signal is output only if parallel judgement output and parallel data output are set. The OR signal

will be ON while the TRIG signal can be input.

Input Signals

Signal Function

TRIG This signal is used to input a measurement trigger from an external device, such as a photoelectric switch.

One measurement is performed on the rising edge (OFF to ON transition) of the TRIG signal. Keep the

TRIG signal ON for at least 1 ms.

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

29

Page 32

Data Output Control with Handshaking

External device

(1) DSA signal

(3) Measurement results output

(2) GATE signal

Sensor

The timing for data output can be controlled through the DSA and GATE signals.

The handshake function can only be used with EtherNet/IP, PLC Link, PROFINET, and parallel communication

(when a Sensor Data Unit is used).

Requirements for Using Data Output Control with Handshaking

To use data output control, set the output control method to [Handshaking] in the communications protocol

settings. For details, refer to Communications Specifications Settings for each communications protocol.

• Parallel Communications: Refer to Setting Data Communications Specifications: p.66.

• PLC Link Communications: Refer to Setting Up PLC Link Communications: p.122.

• EtherNet/IP and PROFINET Communications: Refer to Communications Specifications Settings (p.92 or

p.145).

Handshaking

If the external device does not turn ON the DSA signal, the measurement data will not be output to the external

device from the Sensor.

While the DSA signal is ON, the GATE signal turns ON when the measurement data is output from the Sensor.

The external device receives the measurement data when the GATE signal turns ON.

Signals Used for Handshaking

Signal Name Description

DSA Data Output Request Sig-

nal

GATE Data Output Completion

Signal

*1: If handshaking is not enabled for output control, the GATE signal will also be turned ON when data is output from the Sensor.

This signal is sent from the external device (PLC) to the Sensor to

request data output.

This signal is sent by the Sensor to the external device (PLC) to tell the

PLC when to receive the output data. This signal is sent only while the

DSA signal is ON.

*1

30

(1) The PLC turns ON the DSA signal and waits for the output data.

(2) The Sensor turns ON the GATE signal when the DSA signal is ON and it is ready to output the

measurement results.

(3) The Sensor turns ON the GATE signal and outputs the output data.

Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 33

Receiving Divided Output Data (Using EtherNet/IP)

Wait for the first cycle

of output data.

Measurement trigger

(e.g., TRIG signal) ON

Data Output Request

(DSA) signal

Result Completion

(GATE) signal

Output data

(DATA 0 to 7)

Wait for the second

cycle of output data.

ON

OFF

ON

OFF

ON

OFF

(2) (3) (4)(1)

First cycle of

output data

(256 bytes)

Second cycle of

output data

In EtherNet/IP, if the data size of the set output data exceeds the data size that the Sensor can actually output

in one cycle (256 bytes), the data is divided and output over multiple cycles.

In this case, use handshaking as shown below to receive the multiple cycles of output data.

Example: EtherNet/IP Communications with Handshaking

1 When the first data is received, the user (PLC) turns ON the measurement trigger and the DSA

signal.

2 The Sensor turns ON the GATE signal when the DSA signal is turned ON and outputs the first

data.

3 The user (PLC) turns OFF the DSA signal again when the GATE signal turns ON. Then, the user

(PLC) confirms the output data received in the PLC Data Output Area and moves the received

data to another area in PLC I/O memory.

4 The Sensor confirms that the DSA signal is OFF and automatically turns OFF the GATE signal.

5 When reception of the output data is completed and the GATE signal turns OFF, the user (PLC)

turns on the DSA signal again and waits for the second cycle of data which could not be sent in

the first cycle and was divided.

6 When the second data is output, the second data output is received when the GATE signal is

turned ON and steps 3 and 5 above are repeated.

1

Overview of Communication Specifications

Steps 3 through 5 above are repeated for all subsequent data output items.

FQ2-S/CH User’s Manual

for Communications Settings

Control Methods Using an External Device

31

Page 34

MEMO

32

Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

Page 35

Controlling Operation and Outputting Data with a Parallel Connection

2-1 Controlling Operation and Outputting Data with the Sensor's

Standard Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2-2 Controlling Operation and Outputting Data with a Parallel

Interface Sensor Data Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

allel Connection

2

Controlling Operation and Outputting Data with a Par-

Page 36

2-1

(2) Measurements

performed

(1) Measurement

trigger input

(3) Judgement

results output

Trigger Sensor

FQ2 Vision Sensor

External device

(3) Judgement results

output (overall

judgement: OR

signal)

Retained until the next

judgement results are

output.

Turned ON when overall judgement is NG.

(2) Executing

measurement

processing

(BUSY signal)

This signal stays ON until the next

measurement trigger can be input.

*1

You can confirm if measurements are in progress.

The trigger to perform measurements once is turned ON.

(1) Measurement

trigger input

(TRIG signal)

ON

OFF

ON

OFF

ON while measurements are in progress

Measurement

trigger input

(TRIG signal)

OFF

ON

BUSY signal

OFF

ON

OFF

ON

READY signal

ON while measurements are in progress

OFF while measurements are in progress

When the measurement

trigger is received, the BUSY

signal turns ON and the

READY signal turns OFF.

Important

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

This section explains how to directly connect the Sensor to external devices with the I/O cable, and control the

Sensor and execute output.

Basic Operation with a Parallel Connection

This section describes the basic connections and signal flow with external devices.

With the default settings, the Sensor operates in the following manner.

*1: You can also use the READY signal, which will turn ON when a measurement trigger can be input.

You can assign the READY signal to any output from OUT0 to OUT2.

( Getting Individual Judgements and Expression Judgements: p. 41)

• Create the ladder program to control the TRIG and IN5 input signals so that they do not turn ON while the BUSY

signal is ON. If not, a TRIG input error will occur and the ERROR signal will turn ON.

• Operation When the Sensor Power Supply Is Turned ON

The BUSY signal will operate as shown below when the Sensor’s power supply is turned ON.

Create the ladder program in the PLC or other external device so that the BUSY signal is ignored while it turns OFF,

ON, and OFF again for up to 5 s after the power supply is turned ON.

34

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

FQ2-S/CH User’s Manual

for Communications Settings

Page 37

24 V

BUSY

ON

OFF

0 V

Max 5 sec

Sensor system is initializing.

The time of initializing

depends on the scene data.

Turns OFF when the

Sensor is ready for

operation.

Power supply

Note

You can mount a Parallel Interface Sensor Data Unit to enable using other signals and increase the number of signals that you can use with parallel communications.

And in addition to outputting OR judgement results, you can also use a Parallel Interface Sensor Data Unit to output

the judgement results of judgement conditions that you set for parallel output (called parallel judgement output) and

the results of measurement values and expressions for inspection items (called parallel data output).

Controlling Operation and Outputting Data with a Parallel Interface Sensor Data Unit: p. 60

Configuring the Operation

The following settings can be selected depending on the system configuration and application.

Type of change Change Reference

Changing the type of measurement trigger Performing continuous measurements p. 37

Changing the output method of the judgement

results

Changing the polarity of the BUSY output Reversing the polarity of the BUSY signal p. 44

Changing the BUSY output condition Adjusting the end timing of the BUSY signal p. 45

Changing the polarity of the output signals

(OUT1 to OUT2)

Selecting the types of commands that can be

used

Obtaining individual judgement results p. 41

Adjust the judgement output timing p. 42

Changing the judgement output ON conditions p. 44

Reversing the output polarity of OUT1 to OUT2 p. 45

Changing the commands used in IN0 to IN5 p. 45

allel Connection

2

Controlling Operation and Outputting Data with a Par-

FQ2-S/CH User’s Manual

for Communications Settings

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

35

Page 38

Setting the Measurement Trigger

(2) Performs

measurements once

Trigger input Sensor

Or other

device

(1) TRIG signal ON

OFF

ON

OFF

ON

Turned ON when overall judgement is NG.

(OR output: ON for NG)

OR signal

ON while measurements are

being processed (depends

on BUSY output conditions)

BUSY signal

TRIG signal

ON for 1 ms min.

Important

The measurement trigger can be chosen from the following two types:

• One-shot measurement: One measurement is performed for each external trigger.

• Continuous measurement: Measurements are performed continuously.

Performing One Measurement for Each External Trigger

A measurement trigger is input as the TRIG signal from a proximity sensor, PLC, or other external device.

One measurement is performed when the TRIG signal turns ON.

Wiring

36

Color Signal Description

Pink TRIG Trigger signal

Black OUT0 (OR) Overall judgement (default

Orange OUT1 (BUSY) Processing in progress (default

assignment)

assignment)

The signals shown at the left are used.

Refer to the following information for signal wiring.

Section 2 Installation and Connections

in Vision Sensor FQ2-S/CH Series

User's Manual (Cat. No. Z337)

Timing Chart

1. Turn ON the TRIG signal while the BUSY signal is OFF.

2. Measurement begins and the BUSY signal is turned ON during the measurement process.

3. When the measurement has been finished, the measurement result is output using an OR signal, and the

BUSY signal is turned OFF.

*1: You can also set the signal to be turned OFF after data logging, image logging, or displaying results in the [BUSY output].

When the Brightness Correction Mode is ON, the timing when images are taken is delayed.

Section 3 Taking Images

in Vision Sensor FQ2-S/CH Series User's Manual (Cat. No. Z337)

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

*1

FQ2-S/CH User’s Manual

for Communications Settings

Page 39

Sample Ladder Program

SET

TRIG

W0.00 OUT1

0000

#2

TRIG

TMHH

RSET

TRIG

T0000

RSET

W0.00

++L

1000

++L

1002

OUT0

OUT0

OUT1

Single

measurement

command bit

BUSY signal

When the single measurement

command bit (W0.00) turns

ON, the TRIG signal is turned

ON if the BUSY signal is OFF.

TRIG signal

BUSY signal OR signal

OR signal

The TRIG signal is kept ON for

2 ms and then turned OFF.

When the BUSY signal turns OFF to

indicate that the measurement has been

finished, the judgement result is added

to the total count.

OK measurements: CIO 1000

NG measurements: CIO 1002

Important

PLC

(2) Performs continuous

Or other

device

(1) IN5 signal ON (IN0 to IN4 are OFF)

The following sample program is used to input a TRIG signal to perform a single measurement. A single

measurement will be performed when W0.00 turns ON.

• I/O Signal Allocations

allel Connection

2

Controlling Operation and Outputting Data with a Par-

Signal Address

Output signals OUT0 (OR signal) CIO 0.00

Input signals TRIG CIO 1.00

The BUSY signal will remain ON while the measurement is being executed.

Performing Continuous Measurements

Continuous measurements are performed while the continuous measurement command is input from an

external device.

Immediately after a measurement is performed, the next measurement is performed.

This is repeated while a continuous measurement command is input with the IN0 to IN5 signals.

FQ2-S/CH User’s Manual

for Communications Settings

OUT1 (BUSY signal) CIO 0.01

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

37

Page 40

Note

OFF

ON

OFF

ON

OFF

ON

OR signal

Turned ON when overall judgement is NG

(OR output: ON for NG)

ON while measurements are

being processed (depends on

BUSY output conditions)

BUSY signal

Start continuous measurements

End continuous measurements

IN5 signal

IN0 to IN4 signals

are OFF

Allow 5 ms min. and then turn ON IN5.

This function can be used only when the input mode is set to Expanded Mode.

Changing the Types of Commands That Can Be Used: p. 45

Wiring

Color Signal State Description

Gray IN0 OFF Command parameters for continu-

Green IN1 OFF

Red IN2 OFF

White IN3 OFF

Purple IN4 OFF

Ye l l o w I N 5 ON Command input for continuous

Black OUT0 (OR) -- Overall judgement (default assign-

Orange OUT1 (BUSY) -- Processing in progress (default

ous measurements

measurements

ment)

assignment)

Timing Chart

The signals shown at the left

are used.

Refer to the following information for signal wiring.

Section 2 Installation

and Connections

in Vision Sensor

FQ2-S/CH Series

User's Manual

(Cat. No. Z337)

1. Turn ON IN5 while IN0 to IN4 are OFF. If status is held while the BUSY signal is OFF, continuous

2. Continuous measurements end when IN5 is turned OFF.

38

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

measurements will begin and the BUSY signal will remain ON while continuous measurements are being

performed.

FQ2-S/CH User’s Manual

for Communications Settings

Page 41

Sample Ladder Program

MOV

#0000

Q:1

W0.00

0000

#5

TMHH

SET

IN5

T0000

OUT1

W0.00

RSET

W0.00

RSET

IN5

W0.01

RSET

W0.00

Continuous

measurement

command bit

Continuous

measurement

command bit

BUSY signal

Continuous

measurement

stop bit

When the continuous measurement command

bit (W0.00) turns ON, the command

parameter for continuous measurements

(00000) is output to Q:1 (IN0 to IN4).

If the BUSY signal is OFF 5 ms after the

command parameter is output, the command

input for continuous measurements (IN5) is

turned ON and continuous measurements start.

When the continuous measurement stop bit

(W0.01) turns ON, the command input for

continuous measurements (IN5) is turned

OFF and continuous measurements stop.

The following sample program is used to input a IN5 signal to perform continuous measurements. Continuous

measurements will be started when W0.00 turns ON and stopped when W0.01 turns ON.

allel Connection

2

Controlling Operation and Outputting Data with a Par-

• I/O Signal Allocations

Signal Address

Output signals OUT1 (BUSY signal) CIO 0.01

Input signals IN0 CIO 1.08

IN1 CIO 1.09

IN2 CIO 1.10

IN3 CIO 1.11

IN4 CIO 1.12

IN5 CIO 1.15

FQ2-S/CH User’s Manual

for Communications Settings

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

39

Page 42

Setting the Outputs

OK

NG

OK

Inspection

item 31

If there is even one NG judgement,

the overall judgement will be NG

and the output will be turned ON.

NG (OR signal ON)

Inspection

item 1

Overall judgement

Inspection

item 0

Individual judgement results

OK

Expression

OFF

ON

OFF

ON

Overall judgement

Turned ON when overall

judgement is NG.

(OR output: ON for NG)

OR signal

ON while measurements are

being processed (depends

on BUSY output conditions)

BUSY signal

TRIG signal

ON for 1 ms min.

Using the Overall Judgement Result

When the results of the inspection items are judged, if even one individual judgement result is NG, the OR

output signal is turned ON.

Note

• The overall judgement result output signal can also be turned ON when all individual judgement results are OK.

Changing the judgement output ON condition: p. 44

• You can select whether to include the judgement result of one of the expressions (0 through 31) in the overall judgement.

Section 4 Setting Up Inspections

in Vision Sensor FQ2-S/CH Series User's Manual (Cat. No. Z337)

• You can adjust the timing for outputting the OR signal and the ON time after judgement processing.

40

Adjust the Judgement Output Timing: p. 42

Wiring

Color Signal Description

Black OUT0 (OR) Overall judgement (default

assignment)

The signals shown at the left are used.

Refer to the following information for signal wiring.

Section 2 Installation and Connections

in Vision Sensor FQ2-S/CH Series User's Manual

(Cat. No. Z337)

Timing Chart

The OR signal that is output is held until the next overall judgement is output.

Controlling Operation and Outputting Data with the Sensor's Standard Parallel Connection

FQ2-S/CH User’s Manual

for Communications Settings

Page 43

Note

Note

Important