Page 1

Smart Camera

FQ2

User's Manual

Cat. No. Z326-E1-01A

Page 2

Introduction

Thank you for purchasing the FQ2.

This manual provides information regarding functions, perfor mance and operating methods that

are required for using the FQ2.

When using the FQ2, be sure to observe the following:

• The FQ2 must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

Page 3

APPLICATION CONSIDERA TIONS

(Please Read)

User's Manual

Introduction

Installation and Connections

Taking Images

Setting Up Inspections

Testing and Saving Settings

Operation

Convenient Functions

1

2

3

4

5

6

7

Smart Camera

FQ2

Controlling Operation and Outputting

Data with a Parallel Connection

Connecting through Ethernet

Connecting with RS-232C

Troubleshooting

Appendices

8

9

10

11

12

Page 4

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDIN G NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES TH AT THE BUYER OR USER ALONE HAS DET ER MI NE D THAT

THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON

DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE

PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT DESIGNED OR

RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES.

Please refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer’s application or use of the pr oduct.

At the customer’s request, OMRON will provide applicable third party cert ification document s identif ying ratings

and limitations of use that apply to the products. This information by itself is not sufficient for a complete

determination of the suitability of the products in combination with the end product, machine, system, or other

application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

2

FQ2 User’s Manual

Page 5

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safet y equipment, and in sta llat ions subject to sep arat e industr y

or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLE D FOR

THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DA TA

Performance data given in this document is provi ded as a guide f or the us er in determi nin g suitability and does

not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate

it to actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of

Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ra tings or features are changed, or when signifi cant

construction changes are made. However, some specifications of the product may be changed without any

notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your

application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequen ce

thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product. Please

notify us before copying or reproducing this document in any manner, for any other purpose. If copying or

transmitting this document to another, please copy or transmit it in its entirety.

FQ2 User’s Manual

3

Page 6

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally there may be

significant property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual

Indicates general prohibitions for which there is no specific symbol.

Indicates the possibility of laser radiation.

Indicates the possibility of explosion under speci fic conditions.

Indicates prohibition when there is a risk of minor injury from electrical shock or other

source if the product is disassembled.

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

The Sensor emits visible light, which may adversely affect the eyes in rare instances.

Do not look directly into the light emitted from the Sensor. When the subject is a specular

reflective object, protect your eyes from reflected light.

A lithium ion battery is built into the Touch Finder and may occasionally combust, explode, or

burn if not treated properly.

Dispose of the Touch Finder as industrial waste, and never disassemble, apply pressure that

would deform, heat to 100 °C or higher, or incinerate the Touch Finder.

High-voltage parts insid e; danger of electrical shock. Do not open the product cover.

4

FQ2 User’s Manual

Page 7

Precautions for Safe Use

The following points are important to ensure safety, so make sure that they are strictly observed.

1. Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/explosive gas.

• To secure the safety of operation and maintenance, do not install the product close to high-voltage devices

and power devices.

• Install the product in such a way that its ventila tion holes are not blocked.

• Tighten mounting screws at the torque specified in this manual.

2. Power Supply and Wiring

• The power supply voltage must be within the rated range (24 VDC ±10%), and an AC voltage must not be

used.

• Reverse connection of the power supply is not allowed. Do not short the load of the open collector output.

• The load must be within the rated range.

• High-voltage lines and power lines must be wired separately from this product. Wiring them together or

placing them in the same duct may cause induction, resulting i n malfunction or damage.

• Use the products within the power supply voltages specified in this manual.

• Use the specified size of crimp terminals to wire connections. Do not connect wires that have been simply

twisted together directly to the power supply or terminal block.

• Use a DC power supply with safety measures against high voltag es (safety extra low-voltage circuit).

• Use independent power sources for the products. Do not use a shared power source.

• Tighten mounting screws at the torque specified in this manual.

• Always turn OFF the power supply before connecting or disconnecting cables or the power supply wiring.

3. Battery

• Do not short the positive and negative terminals of the Battery.

• Do not use the Touch Finder in an environment that exceeds the operating temperature range o f the Batt ery.

If the Touch Finder is used at temperatures that exceed the operating temperature range, the protective

device may activate and prevent charging.

• Do not connect the Battery directly to a power supply or car cigarette lighter socket.

• Do not use the Touch Finder with any other type of battery.

• Turn OFF the power supply immed iately if t he Batter y leaks or pro duces an od or. Electrolyte leaked from the

Battery may ignite, possibly causing smoke, rupture, or fire.

• If during usage, charging, or storage, the Battery produces an odor, heats, becomes discolored, becomes

misshapen, or exhibits any other unusual conditions, remove it and do not use it. Continuing to use such a

Battery may result in the Battery heating, smoking, rupturing, or igniting.

• If the Touch Finder (FQ2-D31) will be installed permanently or semi-permanently, remove the Battery (FQBAT1). If the rated temp eratur e is exceed ed with the Bat tery in serted, t he prote ctive circuit may activat e and

stop the Touch Finder.

4. AC Adapter

• Use an AC cable that is suitable for the power supply and power voltage you are using.

• Do not touch the power plug with a wet hand. Doing so may result in electrical shock.

• If you notice an abnormal condition, such as smoke, abnormal heating of the outer surface, or a strange

odor, immediately stop using the AC Adapter, turn OFF the power, and remove the power plug from the

outlet.

Consult your dealer, as it is dangerous to attempt to repair the AC Adapter yourself.

• If the AC Adapter is dropped or damaged, turn OFF the power, remove the power plug from the outlet, and

contact your dealer. There is a risk of fire if you continue using the AC Adapter.

FQ2 User’s Manual

5

Page 8

5. Handling

• Connector Cover

Always attach the connector cover when you disconnect the cab le. If you d o not attach the connector cover,

foreign matter may enter the connection, causing malfunctions or damage.

• Lens Cap

Always attach a C-mount lens cap to the lens mount when you remove the lens. If dust or dirt adhere to the

imaging elements, false detection or failure may occur.

• Sensor Waterproof Sheets

Do not remove or damage the waterproof sheets on the sides of the Sensor. Doing so may allow dust, dirt,

or water drops to enter the Sensor and damage it.

6. Other

• Do not use this product in safety circuits associated with nuclear power and human life.

• Do not disassemble, repair, modify, deform by pressure, or incinerate this product.

• Dispose of this product as industrial waste.

• Connect the special products (Sensor, T o uch Fin der, Cables). The product might break down or malfunction

if you use a part not included in the special products.

• If you notice an abnormal condition, such as a strange odor, extreme heating of any product, or smoke,

immediately stop using the product, turn OFF the power, and consult your dealer.

• The Sensor surfaces become hot during use. Do not touch them.

• Do not drop or subject the products to shock.

• Use the special Sensor (FQ2-S), Touch Finder (FQ2-D), Sensor Data Unit (FQ-SDU), Cables (FQ-WN, FQWD, FQ-WU, and FQ-VP), Battery (FQ-BAT1), and AC Adapter (FQ-AC). Using other than the specified

products may cause fire, burning, malfunction or failure.

• If the product has a lock mechanism, always make sure it is locked before using the product.

7. Laws and Regulations, Standards

• This product complies with the following EC Directives and EN Standards:

EC Directive No.2004/104/EC

EN Standard s EN61326

6

FQ2 User’s Manual

Page 9

Precautions for Correct Use

25 mm25 mm

25 mm25 mm25 mm

25 mm 25 mm

Water-proof Sheet

Waterproof sheet

Observe the following precautions to prevent failure to operat e, malfun cti ons, or un desi r able effects on product

performance.

1. Installation Site

Do not install this product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Direct vibration or shock

• Strong ambient light (suc h as other laser beams, light from arc-welding machines, or ultraviolet light)

• Direct sunlight or near heaters

• Strong magnetic or electric field

Also, do not install this product in locations subjected to the following conditions to ensure its protective

performance as described in the specifications:

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Water, oil, or chemical fumes or spray, or mist atmospheres

Installing and Using a Sensor with Bui lt-in Lighting

• The front-panel plate may occasionally become fogged from the inside if the Sensor is used in location with

high humidity and the temperature changes drastically.

• Do not install any objects except for the special mounting brackets within the dotted lines in the following

figure. The front-panel plate may become fogged from the inside.

2. Power Supply, Connection, and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the operating

environment.

• Before turning ON the power after the product is connected, make sure that the power supply voltage is

correct, there are no incorrect connections (e.g. load short-circuit) and the load current is appropriate.

Incorrect wiring may result in breakdown of the product.

• Do not subject the Cables to twisting stress. Doing so may damage the Cables.

• Always turn OFF the power supply before connecting or disconnecting Cables. The Sensor may fail if a

Cable is connected or disconnected while power is being supplied.

• For cables, use only the special products specified in this manual.

p.487, p.488, p.489, p.490

• Use only combinations of the Sensor and Touch Finder specified in this manual. Using other combinations

may cause malfunction or damage.

FQ2 User’s Manual

7

Page 10

• Do not turn the power OFF in the following instances. Doing so will damage data that is in the process of

Important

Note

being saved.

- While data is being saved in internal memory

- While data is being saved on the SD card

• The LCD panel has been made using precision technology, and sometimes a few pixels are missing in the

panel. This is due to the structure of the LCD panel, and is not a malfunction.

• Influence of Temperature Changes on Optical Axis

Due to the characteristics of the materials that are used in the Sensor, changes in the ambient temperature

may cause the center of the optical axis to change by several pixels.

• Imaging Elements

Due to the specifications of the CMOS image sensors that are used in the Vision Sensor, lines may appear

in images for some measurement conditions or gain settings. These do not indicate defects or faults in the

Vision Sensor. Also, there may be some pixel defects, but these do not indicate defects or faults in the

Vision Sensor.

3. Battery

• Do not use or charge the Battery with other than the specified products.

• Do not charge the Battery with other than the specified AC adapter.

• When using the Touch Finder, the battery cover screw must be tightened.

4. AC Adapter

• During maintenance and when not using the Touch Finder for an extended time, remove the power plug

from the outlet.

• Do not bend the power cable past its natural bending radius.

• Do not use the AC Adapter with other than the specified products.

• If a voltage higher than 380 V is applied, there is a risk that the capacitor will be damaged, the pressure

valve will open, and vaporized gas will be emitted. If there is a possibility that a voltage higher than 380 V

will be applied, use a protective device.

5. Maintenance and Inspection

Do not use thinner, benze ne, aceto ne or kerosene to cl ean the Sensor and Touch Finder. If large dust particles

adhere to the Camera, use a blower brush (used to clean camera lenses) to blow them off. Do not use breath

from your mouth to blow the dust off. To remove dust particles from the Camera, wipe gently with a soft cloth

(for cleaning lenses) moistened with a small amount of alcohol. Do not use excessive force to wipe off dust

particles. Scratches to the Camera might cause erro r.

Editor's Note

■ Meaning of Symbols

Menu items that are displayed on the Touch Finder LCD screen, and windows, dialog boxes and other GUI

elements displayed on the PC are indicated enclosed by brackets "[ ]".

■ Visual Aids

Indicates points that are important to achieve the f ull product p erformance,

such as operational precautions.

Indicates application procedures.

Indicates pages where related information can be foun d.

8

FQ2 User’s Manual

Page 11

Table of Contents

1. Introduction

1-1 FQ2-series Vision Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-2 Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-3 Startup Display and Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Startup Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-4 Basic Operational Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2. Installation and Connections

2-1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-2 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FQ2-S@@@@@@ (Sensors with Built-in Lighting) . . . . . . . . . . . . . . . . . . . . . . .33

FQ2-S3@-@@@ (Sensors with C-mounts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Mounting to DIN Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mounting to a Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Using the Touch Finder as a Portable Device (with Battery) . . . . . . . . . . . . . . .40

Mounting to DIN Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

I/O Signal Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Power Supply Specifications When a Switching Regulator Is Connected . . . .43

Attaching the LED Warning Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2-5 Setting Up Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Connecting to Sensors from the Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . .53

Connecting to Sensors from External Devices Such as PLCs . . . . . . . . . . . . .54

Connecting to Sensors from a Computer Using the PC Tool . . . . . . . . . . . . . .54

Table of Contents

3. Taking Images

3-1 Selecting a Sensor for Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-2 Setting Conditions for Taking Images. . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

FQ2 User’s Manual

9

Page 12

3-3 Adjusting Image Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Adjusting the Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Adjusting Image Brightness with External Lighting . . . . . . . . . . . . . . . . . . . . . .61

Adjusting the Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Taking Clear Images of Moving Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Improving the Image Quality of Metallic and other Shiny Surfaces . . . . . . . . . .64

Adjusting the Colors of the Image (White Balance)

(Only for Sensors with Color Cameras) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

3-4 Adjusting the Timing of Taking Images . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Delaying the Image Capture Timing from the Trigger Input . . . . . . . . . . . . . . .66

Adjusting External Lighting Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Preventing Mutual Interference of Multiple Sensors . . . . . . . . . . . . . . . . . . . . .67

3-5 Adjusting the Images That Were Taken . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Image Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Filtering the Images (Filter Items) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Compensating for Position Offset (Position Compensation Items) . . . . . . . . . .74

Edge Rotation Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4. Setting Up Inspections

4-1 Inspection Item Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4-2 Setup Procedure for Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4-3 Configuring Inspection Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Adding New Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Modifying Existing Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Deleting Inspection Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

4-4 Inspecting with the Search Inspection Item . . . . . . . . . . . . . . . . . . . . . . . 95

Search Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Setup Procedure for the Search Inspection Item . . . . . . . . . . . . . . . . . . . . . . .95

Increasing Measurement Position Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Obtaining Multiple Results Simultaneously . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Select the Results to Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Unstable Search Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Increasing Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Editing the Model and Measurement Regions . . . . . . . . . . . . . . . . . . . . . . . .100

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10

FQ2 User’s Manual

Page 13

4-5 Inspecting with the Shape Search II Inspection Item. . . . . . . . . . . . . . . 105

Shape Search II Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Setup Procedure for the Shape Search II Inspection Item . . . . . . . . . . . . . . .105

Obtaining Multiple Results Simultaneously . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Select the Results to Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Unstable Shape Search II Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Increasing Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Editing the Model Regions and Measurement Region . . . . . . . . . . . . . . . . . .110

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

4-6 Inspecting with the Sensitive Search Inspection Item. . . . . . . . . . . . . . 113

Sensitive Search Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Setup Procedure for the Sensitive Search Inspection Item . . . . . . . . . . . . . . .113

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Increasing Measurement Position Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . .115

Select the Results to Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Changing the Number Region Divisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Inspecting Plain Regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Unstable Search Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Increasing Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Editing the Model Regions and Measurement Region . . . . . . . . . . . . . . . . . .117

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4-7 Inspecting with the Edge Position Inspection Item. . . . . . . . . . . . . . . . 120

Edge Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Setup Procedure for Edge Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Changing Edge Detection Conditions

(Sensors with Monochrome Cameras Only) . . . . . . . . . . . . . . . . . . . . . . . . . .122

Unstable Edge Position Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Increasing Processing Speed for Edge Position . . . . . . . . . . . . . . . . . . . . . . .125

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged for Edge Position . . . . . . . . . . . . . .125

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

. . . . . .125

4-8 Inspecting with the Edge Width Inspection Item . . . . . . . . . . . . . . . . . . 127

Edge Width Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Setup Procedure for Edge Width Inspection Item . . . . . . . . . . . . . . . . . . . . . .127

Changing Edge Detection Conditions

(Sensors with Monochrome Cameras Only) . . . . . . . . . . . . . . . . . . . . . . . . . .129

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Unstable Edge Width Results (Sensors with Color Cameras) . . . . . . . . . . . .129

Increasing Edge Width Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged for Edge Width . . . . . . . . . . . . . . . .130

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

. . . . . .129

FQ2 User’s Manual

11

Page 14

4-9 Inspecting with the Edge Pitch Inspection Item. . . . . . . . . . . . . . . . . . . 131

Edge Pitch Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Setup Procedure for Edge Width Inspection Item . . . . . . . . . . . . . . . . . . . . . .131

Changing Edge Detection Conditions

(Sensors with Monochrome Cameras Only) . . . . . . . . . . . . . . . . . . . . . . . . . .133

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Unstable Edge Pitch Results (Sensors with Color Cameras Only) . . . . . . . . .133

Increasing Edge Pitch Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged for Edge Pitch . . . . . . . . . . . . . . . .134

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . .134

4-10 Inspecting with Color Data Inspection Item . . . . . . . . . . . . . . . . . . . . . . 136

Color Data Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Setup Procedure for Color Data Inspection Item . . . . . . . . . . . . . . . . . . . . . . .136

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged (Color Data) . . . . . . . . . . . . . . . . . .139

Increasing Processing Speed for Color Data . . . . . . . . . . . . . . . . . . . . . . . . .139

. . . . . .138

4-11 Inspecting with the Area Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . 140

Area Inspection Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Setup Procedure for Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Unstable Area Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Changing the Area Detection Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Increasing Processing Speed for Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged for Area . . . . . . . . . . . . . . . . . . . . .145

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

. . . . . .145

4-12 Inspecting with the Labeling Inspection Item. . . . . . . . . . . . . . . . . . . . . 146

Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Setup Procedure for Labeling Inspection Item . . . . . . . . . . . . . . . . . . . . . . . .146

Unstable Labeling Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Changing the Label Detection Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Changing the Label Extraction Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Sorting Extracted Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Reflect in Total Judgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Editing the Measurement Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Increasing the Processing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Measurement Data That Can Be Used for External Outputs and Calculations

Measurement Data That Can Be Logged for Labeling . . . . . . . . . . . . . . . . . .154

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

. . . . . .153

12

FQ2 User’s Manual

Page 15

4-13 Calculations and Judgements Using Inspection Item Data . . . . . . . . . 155

Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Examples for Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Procedure (Calculation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

5. Testing and Saving Settings

5-1 Performing Test Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Performing Test Measurements with Samples . . . . . . . . . . . . . . . . . . . . . . . .170

Performing Test Measurements with Saved Images (Re-measuring) . . . . . . .170

5-2 Shortening the Measurement Takt Time . . . . . . . . . . . . . . . . . . . . . . . . . 172

Checking the Measurement Takt Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Increasing Image Input Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Changing the Image Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

5-3 Adjusting the Judgement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Adjusting Judgement Parameters While Looking at Measurement Results

Setting Up the Best Judgement Parameters Automatically . . . . . . . . . . . . . . .175

5-4 Checking a List of All Inspection Item Results . . . . . . . . . . . . . . . . . . . 177

5-5 Saving Data to the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

. . . . . . . .175

6. Operation

6-1 Starting Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Run Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Moving to Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

6-2 Configuring the Run Mode Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

6-3 Checking the Trend of Measurement Results with Graphs . . . . . . . . . 184

Trend Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Histograms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6-4 Adjusting Judgement Parameters during Operation. . . . . . . . . . . . . . . 187

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Changing the Judgement Parameters in Run Mode . . . . . . . . . . . . . . . . . . . .187

7. Convenient Functions

7-1 Changing the Scene to Change the Line Process . . . . . . . . . . . . . . . . . 190

What Are Scenes? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Creating New Scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Changing Scene Names, Copying Scenes, and Deleting Scenes . . . . . . . . .191

Switching Scenes from an External Device . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Setting the Startup Scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

FQ2 User’s Manual

13

Page 16

7-2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Setting the Calibration Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Selecting the Calibration Pattern to Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

7-3 Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Image Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Displaying a Live Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Displaying a Frozen Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Displaying a Saved Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Updating the Display and Measurement Results Only

for NG Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Automatically Changing to the Display for Any Sensor with an NG Result . . .202

Hiding the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Turning ON/OFF the Touch Finder Backlight . . . . . . . . . . . . . . . . . . . . . . . . . 202

Changing the Brightness of the Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . .202

7-4 Monitoring the Signal I/O Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

7-5 Connecting to More Than One Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Setting the Sensors to Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Selecting the Display When More Than One Sensor Is Connected . . . . . . . .206

7-6 Logging Measurement Data and Image Data . . . . . . . . . . . . . . . . . . . . . 208

Logging Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Logging All Data (File Logging) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Checking Recent Measurement Trends (Recent Results Logging) . . . . . . . .214

7-7 Saving Sensor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Backing Up Settings in External Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Restoring Data to the Sensor from External Memory . . . . . . . . . . . . . . . . . . .219

7-8 SD Card Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Inserting and Removing SD Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Checking the Available Space on the SD Card . . . . . . . . . . . . . . . . . . . . . . . .222

Formatting an SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

7-9 Convenient Functions for Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Setting a Password to Prevent Unwanted Changes . . . . . . . . . . . . . . . . . . . .223

Capturing the Displayed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Saving the Currently Displayed Camera Image . . . . . . . . . . . . . . . . . . . . . . .224

Setting the Startup Run Display Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Specifying the Sensors to Connect Continuously . . . . . . . . . . . . . . . . . . . . . .225

Monitoring and Setting Up a Sensor from Two Touch Finders . . . . . . . . . . . . 225

7-10 Convenient Functions for Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Making Settings with Stored Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

14

FQ2 User’s Manual

Page 17

7-11 Functions Related to the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Turning OFF the Integrated Sensor Lighting

(Only Sensors with Built-in Lighting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Switching the Display Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Setting the Time on the Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Initializing the Sensor and Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Restarting the Sensor and Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Checking Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Checking the Touch Finder Battery Level . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Changing the Sensor Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Checking Available Memory in the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Correcting the Touch Screen Positions of the Touch Finder . . . . . . . . . . . . . .230

Setting the Resolution of Measurement Objects Displayed on the PC Tool

Rotating the Touch Finder Image by 180° . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Changing the Sensor’s BUSY Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

. . . . . . . .230

8. Controlling Operation and Outputting Data

with a Parallel Connection

8-1 Controlling Operation and Outputting Data

with the Sensor's Standard Parallel Connection . . . . . . . . . . . . . . . . . . 234

Basic Operation with a Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . .234

Setting the Measurement Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

Setting the Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Controlling the Sensor from an External Device . . . . . . . . . . . . . . . . . . . . . . .246

8-2 Controlling Operation and Outputting Data

with a Parallel Interface Sensor Data Unit . . . . . . . . . . . . . . . . . . . . . . . 256

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Setting the Measurement Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Setting Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

Aligning the Data Output Timing with the External Device . . . . . . . . . . . . . . . 262

Changing the Settings of the I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Controlling Operation from an External Device . . . . . . . . . . . . . . . . . . . . . . . .271

9. Connecting through Ethernet

9-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

FQ2 User’s Manual

15

Page 18

9-2 Outputting Data and Controlling Operation through EtherNet/IP. . . . . 283

Introduction to EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

FQ2 Communications for EtherNet/IP Connections . . . . . . . . . . . . . . . . . . . .285

Setting Up EtherNet/IP Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . .289

Tag Data Link Setting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .292

Setting the Data To Output Automaticall y a fte r M ea su re m en t s . . . . . . . . . . .295

Memory Assignments and Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

Timing Chart for EtherNet/IP Communications . . . . . . . . . . . . . . . . . . . . . . . .318

Sample Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .323

9-3 PLC Link Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

Setting Up PLC Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .327

Setting the Data To Output Automaticall y a fte r M ea su re m en t s . . . . . . . . . . .329

Memory Assignments for PLC Link Communications . . . . . . . . . . . . . . . . . . . 334

Timing Chart For PLC Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . 347

Sample Ladder Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .349

9-4 Controlling Operation and Outputting Data

with TCP No-protocol Communications. . . . . . . . . . . . . . . . . . . . . . . . . 350

Setting Up No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . .351

Setting the Data To Output Automaticall y a fte r M ea su re m en t s . . . . . . . . . . .352

Controlling the Sensor from an External Device

(Procedure for No-protocol Command/Response Communications) . . . . . . .357

9-5 Controlling Operation and Outputting Data

with FINS/TCP No-protocol Commands . . . . . . . . . . . . . . . . . . . . . . . . . 376

Introduction to FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .376

Setting Up Communications (FINS/TCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . .377

List of FINS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .378

FINS Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 379

10. Connecting with RS-232C

10-1 Introduction to RS-232C Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 392

10-2 Controlling Operation and Outputting Data

with RS-232C No-protocol Communications . . . . . . . . . . . . . . . . . . . . . 393

Setting Up No-protocol Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . .394

Setting the Data To Output Automaticall y a fte r M ea su re m en t s . . . . . . . . . . .395

Controlling the Sensor from an External Device

(Procedure for No-protocol Command/Response Communications) . . . . . . .395

11. Troubleshooting

11-1 Error Histories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

11-2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

11-3 Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

16

FQ2 User’s Manual

Page 19

12. Appendices

12-1 Menu Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Image Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .404

Inspect Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .407

In/Out Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .414

Test Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .419

Run Tab Page (from Setup Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .420

Common Menu Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .429

12-2 External Reference Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Color Gray Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .430

Weak Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .431

Strong Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .431

Dilate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .431

Erosion, Median, Extract Edges, Extract Horizontal Edges, Extract . . . . . . . .432

Background Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .432

Shape Search II Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .434

Search Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 436

Edge Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Two-edge Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .441

Two-edge Midpoint Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .444

Edge Rotation Position Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .448

Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .451

Sensitive Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .454

Shape Search II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

Edge Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .460

Edge Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

Edge Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .462

Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

Color Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 466

Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

12-3 Specifications and Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .472

Touch Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .479

Sensor Data Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

System Requirements for PC Tool for FQ . . . . . . . . . . . . . . . . . . . . . . . . . . . .486

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .486

12-4 Updating the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

12-5 Connecting a Previous Touch Finder (FQ-D30/D31)

to the FQ2-S Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 492

12-6 LED Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Warning Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .497

FQ2 User’s Manual

17

Page 20

12-7 Requirements from Regulations and Standards . . . . . . . . . . . . . . . . . . 498

Summary of Requirements to Manufactures. . . . . . . . . . . . . . . . . . . . . . . . . . . 498

Summary of Requirements to User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500

Definitions of Laser Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

12-8 Detailed EtherNet/IP Communications Specifications . . . . . . . . . . . . . 502

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 512

18

FQ2 User’s Manual

Page 21

Introduction

1-1 FQ2-series Vision Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

1-2 Measurement Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1-3 Startup Display and Display Elements. . . . . . . . . . . . . . . . . . . . . . . . .22

1-4 Basic Operational Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1

Introduction

Page 22

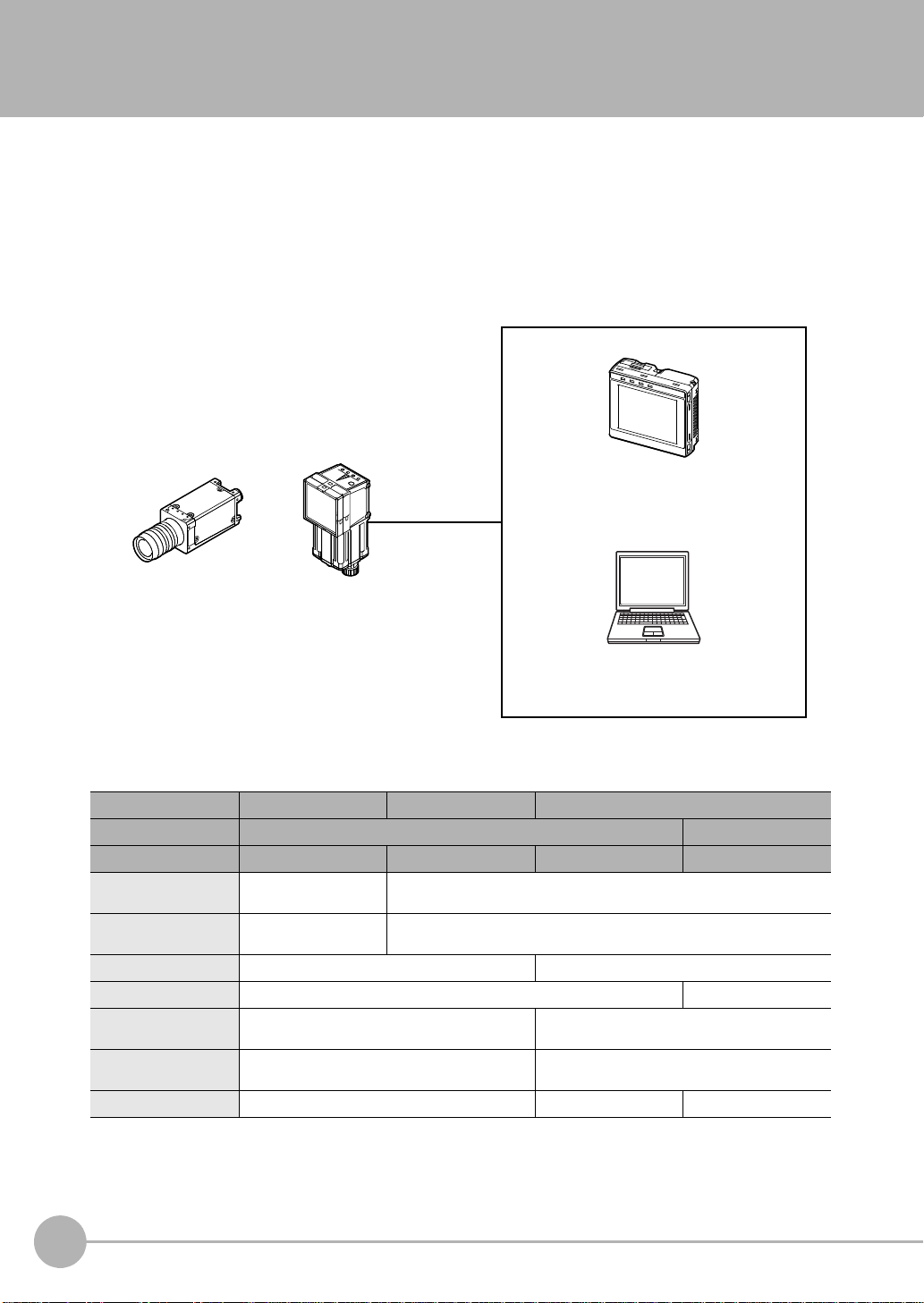

1-1 FQ2-series Vision Sensors

The same functions as those that are

provided by the Touch Finder can be

performed from a computer. The PC Tool

is available free of charge.

After the Sensor has been set up, it can be

operated alone to perform measurements

without the Touch Finder or PC Tool.

PC Tool

Used to check images and set the

judgement parameters. It can also be

used to save measurement results and

check status during operation.

FQ2 Vision Sensor

Touch Finder

Setup, Image Confirmation, and Logging Tools

Sensor with C-mount

Sensor with

Built-in Lighting

The FQ2 Series features Vision Sensors with integrated cameras and controllers. They can be used to easily

achieve simple inspections and measurements.

You can use parallel controls, no-protocol commun ications on Ethernet, PLC Link comm unications on Ethernet,

and EtherNet/IP communications on Ethernet as standard features. You can also use a Data Unit to enable

control with full-scale parallel communicati ons or RS-232C communications.

To set up and monitor the Vision Sensor, you can use either the Touch Finder or the PC Tool running on a

computer. For actual operation, you can use the Vision Sensor on a stand-alone basis.

FQ2-series Vision Sensors are available in two different models. There are also Sensors with C-mounts that

allow you to change the lens, and Sensors with Built-in Lighting. The differences are given in the following

table.

Models Single-function models Standard models High-resolution models

Type Sensors with Built-in Lighting Sensors with C-mounts

Model number FQ2-S1@@@@@ FQ2-S2@@@@@ FQ2-S3@@@@@-08@ FQ2-S3@-13@

Number of simultaneous

measurements

Number of registered

scenes

Partial input Horizontally only Horizontally and vertically

Lens mount --- C-mount

Image processing

method

Connection to Sensor

Data Unit

Processing resolution 752×480 928×828 1280×1024

132

832

Real color Real color or monochrome (Model numbers for

Not possible. Possible.

20

FQ2-series Vision Sensors

Monochrome Sensors end in “M.”)

FQ2 User’s Manual

Page 23

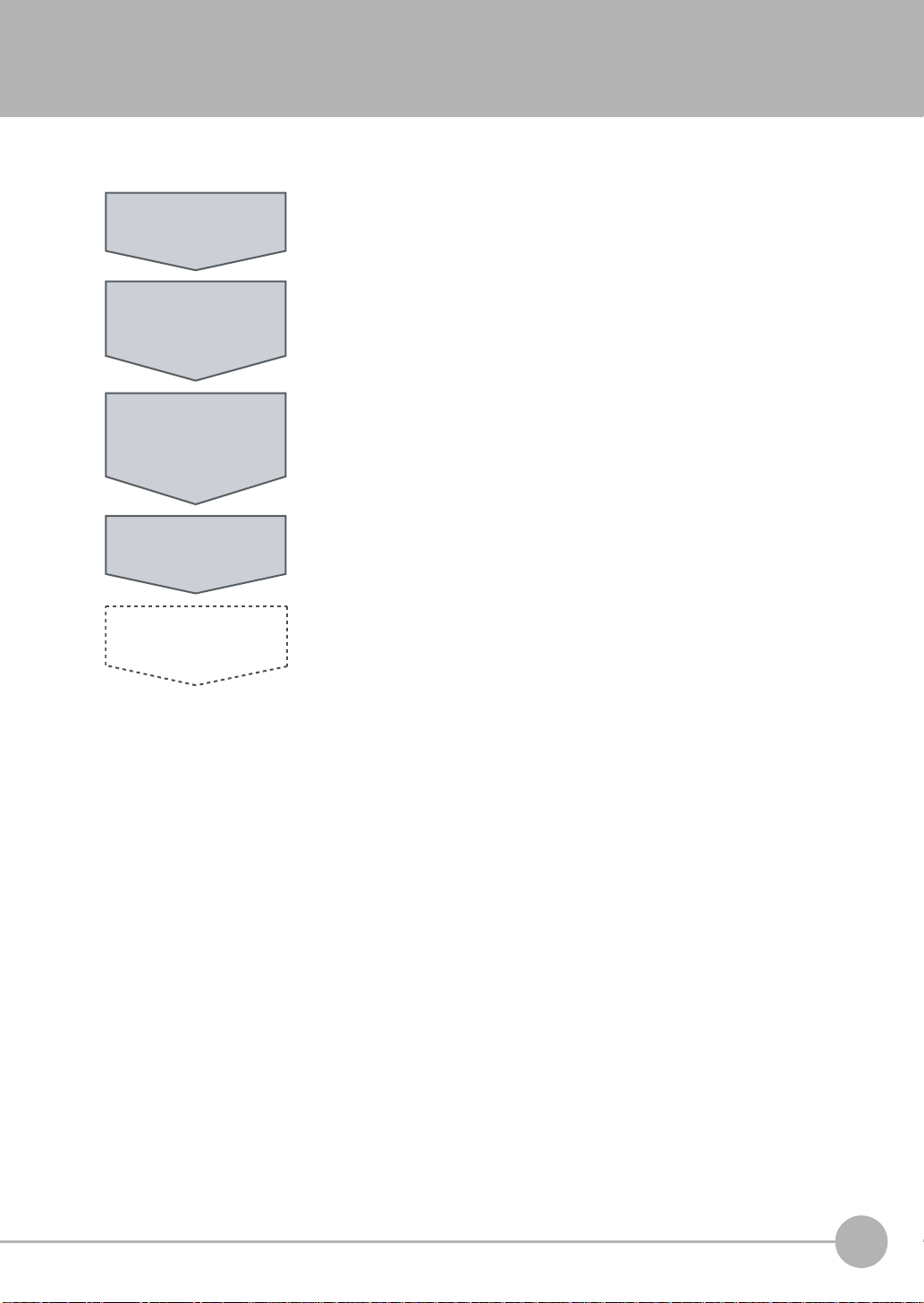

1-2 Measurement Process

Measurement

This section describes the basic flow of the measurement pr ocess.

Trigger input

Take image

Output

Logging

• The measurement is started by inputting a trigger signal from an external

device.

• Images are taken according to the trigger.

• The image is measured to see if it matches the configured settings.

• You can also perform calculations based on the measurement results from

inspection items.

• The overall judgement of all inspection items are output using OR logic.

• You can output detailed measurement result from the inspection items.

• Measurement data and image d ata can be logged in memory in the Sensor or

in an SD card.

1

Introduction

FQ2 User’s Manual

Measurement Process

21

Page 24

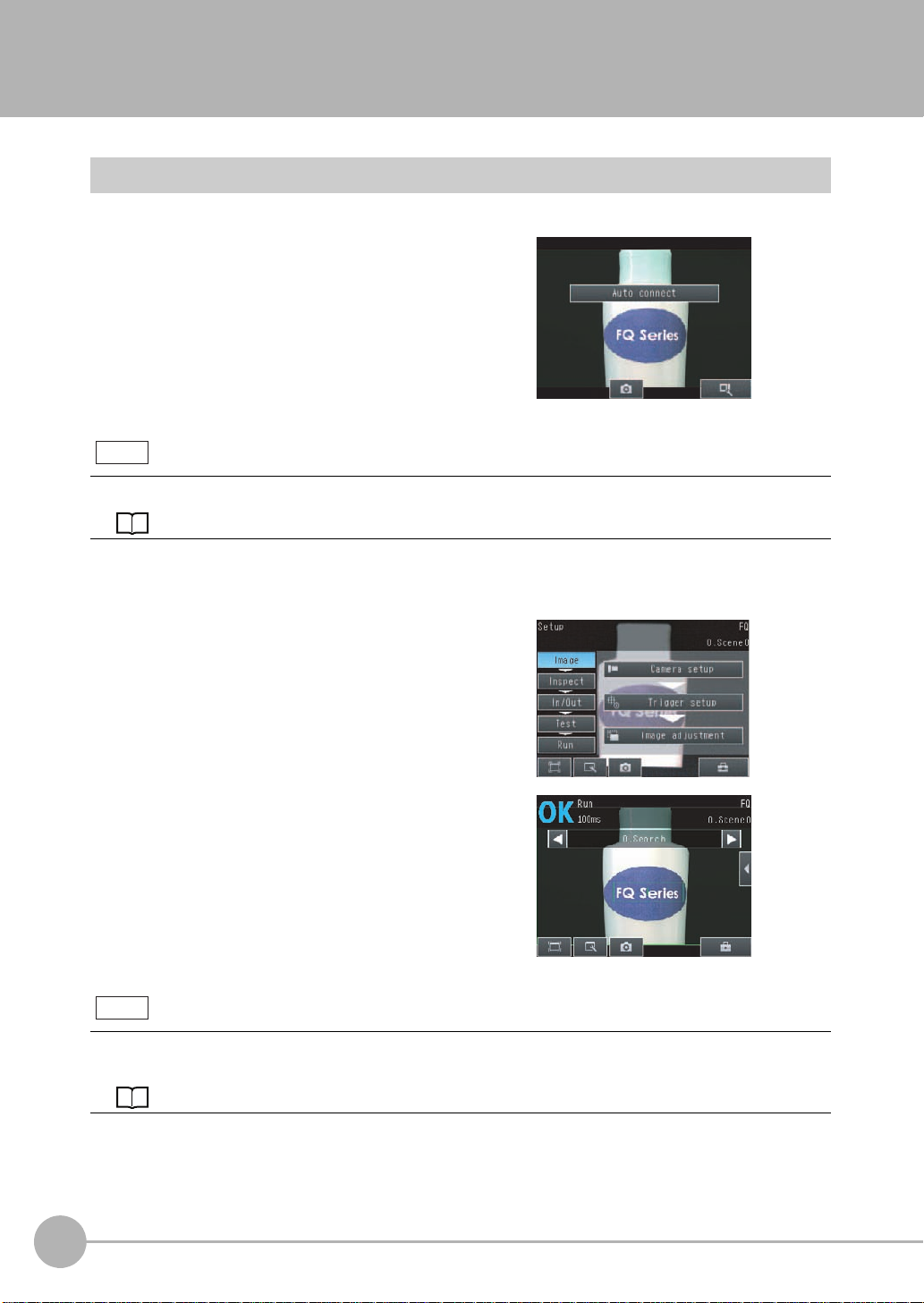

1-3 Startup Display and Display Elements

Note

Startup Display

1 The Se nsor is automatically detected by the T ouch

Finder when power supply to the Se nsor and Tou ch

Finder is turned ON.

The Auto Connect Display will appear if the Sensor cannot be detected. Check that cables are connected correctly to the Sensor and Touch Finder, and then press

[Auto connect].

Note

If the Sensor is still not detected after pressing [Auto Connect], refer to the following information.

The Sensor cannot be detected: p. 401

2 When the Sensor is detected, the following display will appear.

• The Setup Mode will appear if a Sensor that has not been

set up is connected.

• The Run Mode will appear if a Sensor that has been set

up is connected.

When the Touch Finder is started, IP addresses are automatically set for each Sensor.

To allocate specific IP addresses, set the IP address of each Sensor and the Touch Finder.

Setting Up Ethernet: p. 53

22

Startup Display and Display Elements

FQ2 User’s Manual

Page 25

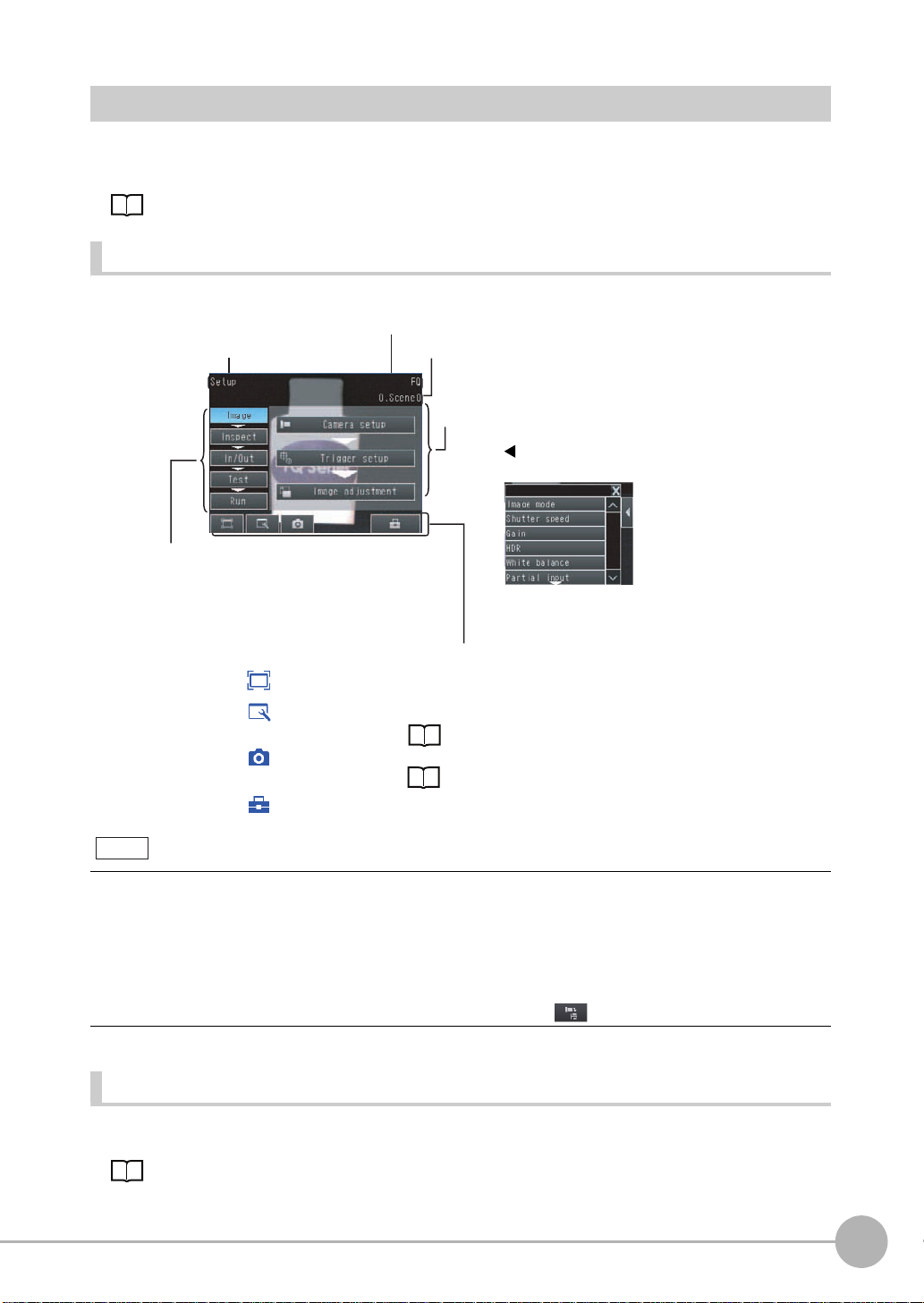

Display Elements

Tool Button: Used to call functions, such as saving data or select scenes.

Capture Button: Used to capture the current screen to the SD card.

This button menu is always displayed.

[Image]: Used to adjust the image.

[In/Out]: Used to set the I/O.

[Run]: Used to switch to Run Mode.

[Test]: Used to test and adjust the set measurements.

[Inspect]: Used to set the inspection items.

The setup flow is shown by these five tabs.

• If the [ ] Button appears, pressing it will display the

sub-menu or commands.

• Buttons will appear on the right according to the mode.

The menu changes according to the selected tab page.

The selected scene number is displayed.

The name of the Sensor being set up is displayed.

Only-image Button: Used to select either displaying the camera image and messages, or

only the camera image.

Display Button: Used to select the source of the image or to zoom the image.

The name of the mode or the

menu hierarchy is displayed.

p. 224

Display Functions: p. 200

This Sensor has a Setup Mode and a Run Mode.

Refer to the following information for menu items.

p. 404

Setup Mode

In Setup Mode, you can set the image conditions, judgement parameters, and I/O settings for the Sensor.

1

Introduction

Note

The Display Button can be used to switch between the following images.

• Camera: The image taken by the camera is displayed.

Live: The live image is displayed.

Freeze: The image that was taken last is displayed.

• Log: A log image saved in internal memory is displayed.

• Logging image file: A log image saved in external memory is displayed.

• Camera image file: An image that was saved in external memory with (Log Image Button) is displayed.

Run Mode

In Run Mode, measurements are performed, and measurement results are output.

p. 179

FQ2 User’s Manual

Startup Display and Display Elements

23

Page 26

1-4 Basic Operational Flow

Calibration Settings

Image Adjustment

Filtering the images

(filter items)

Compensating for position offset

(position compensation items)

Calculation Settings

([Inspect] Tab Page)

Connections and Wiring

Operation

*2

Starting Operation (Run Mode)

Saving the Settings

Adjusting Judgement

Parameters

Test Measurement and

Results Verification

Testing ([Test] Tab Page)

Output Settings

([In/Out] Tab Page)

Setup

Evaluation

*1

Setting Judgement

Parameters

Inspection Setup

([Inspect] Tab Page)

Teaching

Registering

Inspection Items

Image Setup

([Image] Tab Page)

Starting the Sensor

Inspection

Section 2 Installation and

Connections

Section 1

1-3 Startup Display and Display

Elements

Section 3 Taking Images

Section 4 Setting Up Inspections

Section 8 Controlling Operation and

Outputting Data with a Parallel

Connection

Section 9 Connecting through Ethernet

Section 10 Connecting with RS-232C

Section 5 Testing and Saving

Settings

Section 6 Operation

Section 7 Convenient Functions

Section 3

3-5 Adjusting the Images That We re

Taken

Section 4 Setting Up Inspections

The following flow shows the basic operation of FQ2-series Vision Sensors.

24

*1: In Setup Mode, the Sensor can be set up and adjusted, but it does not output signals on the I/O lines.

*2: In Run Mode, the Sensor performs measurements and outputs signals on the I/O lines.

Basic Operational Flow

FQ2 User’s Manual

Page 27

Installation and Connections

2-1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2-2 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 3

2-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2-5 Setting Up Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 3

2

Installation and Connections

Page 28

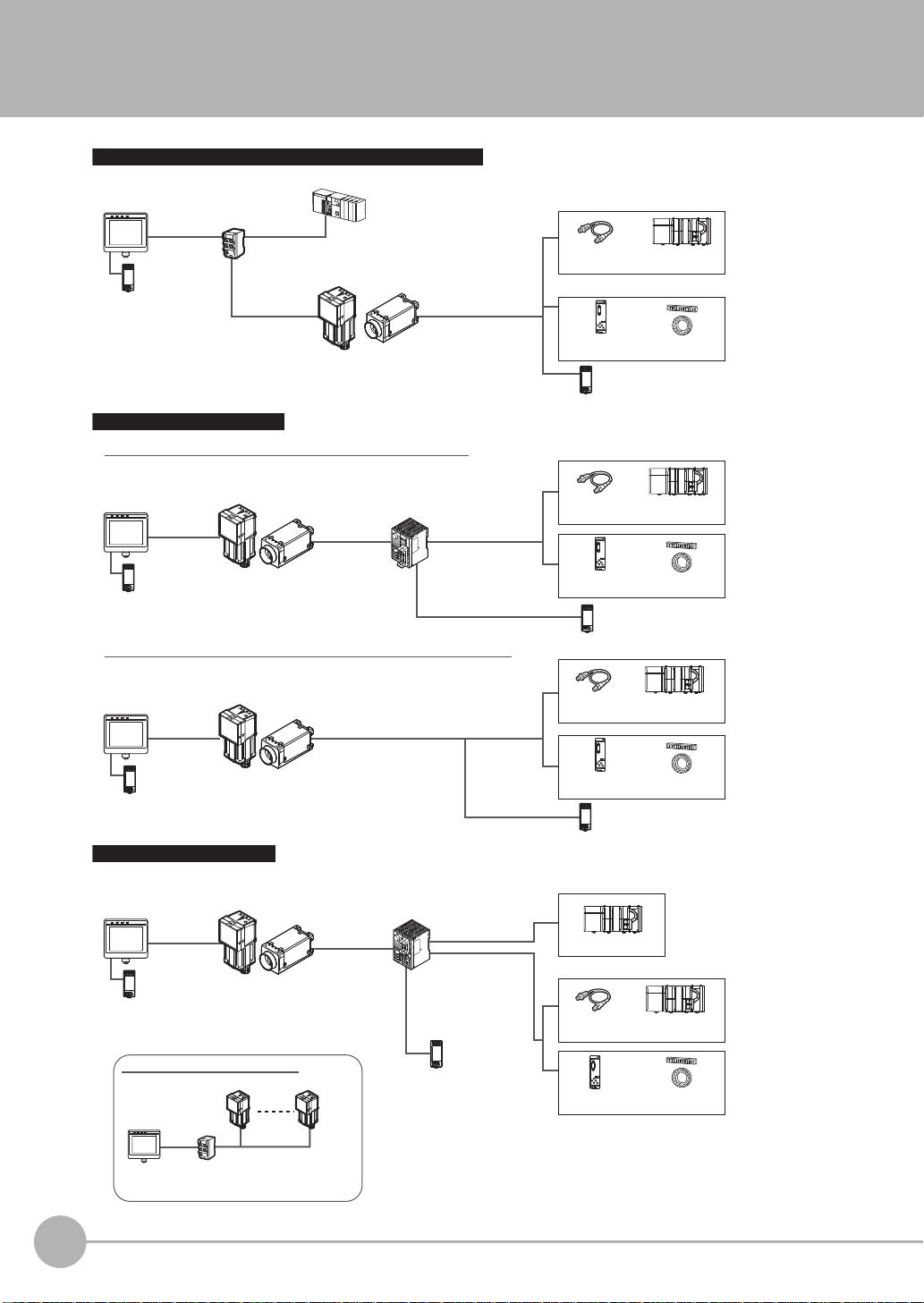

2-1 System Configuration

Ethernet (EtherNet/IP, No-protocol, or PLC Link) Connection

Parallel Interface Connection

I/O cable

Sensor Data

Unit cable

Parallel cable

for FQ-SDU1

Setup Tool

Touch Finder

or PC Tool

Connection through a Parallel Interface Sensor Data Unit

Connection with Standard Parallel Interface of the Vision Sensor

FQ2-S3

@@@@@-@@@

FQ2-S3@-

@@@

Sensor control PLC

I/O control PLC

Trigger sensor

24-V power supply

24-V power supply

FL-STC

Lighting Controller

Parallel Interface Sensor Data Unit

FL-series

External Lighting

FL-STC

Lighting Controller

FL-series

External Lighting

FL-series

External Lighting

24-V power supply

Special Ethernet Cable

(RJ45/M12)

Parallel cable

for FQ-SDU2

RS-232C cable

Setup Tool

Touch Finder

or PC Tool

Setup Tool

Touch Finder

or PC Tool

FQ2-S3

@@@@@-@@@

FQ2-S3@-

@@@

Sensor control PLC

I/O control PLC

Trigger sensor

Sensor control PLC

24-V power supply

24-V power supply

FL-STC

Lighting Controller

RS-232C Interface Sensor Data Unit

FQ2-S

@@@@@@-@@@

FQ2-S3@-

@@@

I/O control PLCTrigger sensor

24-V power supply

FL-STC

Lighting Controller

FL-series

External Lighting

RS-232C Serial Connection

Setup Tool

Touch Finder

or PC Tool

24-V power supply

Standard

Ethernet cable

Special Ethernet Cable

(RJ45/M12)

Standard Ethernet cable

Control PLC

I/O cable

Setup Tool

Touch Finder

or PC Tool

24-V power supply

Sensor control PLC

I/O control PLC

Trigger sensor

FQ2-S

@@@@@@-@@@

FQ2-S3@-

@@@

Switching Hub

FQ2 Vision Sensors (8 max.)

Connecting More Than One Sensors

The Setup Tool can detect up to 32 Sensors and

it can connect to up to eight Sensors at the same time.

Sensor Data

Unit cable

Industrial EtherNet/IP or

Ethernet Switching Hub

Special

Ethernet Cable

(RJ45/M12)

Special Ethernet

Cable

(RJ45/M12)

Special Ethernet

Cable (RJ45/M12)

26

System Configuration

FQ2 User’s Manual

Page 29

Product Model number Remarks

Important

FQ Vision Sensor FQ2-S@@@@@@-@@@

Touch Finder FQ2-D@@ This is a setup console.

PC Tool --- The PC Tool can be used instead of the Touch Finder. If you register as a member,

Parallel Interface

Sensor Data Unit

RS-232C Interface

Sensor Data Unit

FQ Ethernet Cable FQ-WN0@@ Connects the Sensors to external devices such as the Touch Finder, computers, and

Standard RJ45

Ethernet Cable

I/O Cable FQ-WD0@@ Connects the Sensor to the power supply and external devices.

Switching Hub W4S1-0@@ Used to connect multiple Sensors to one Touch Finder or PC Tool.

Sensor Data Unit

cable

Parallel cable for

FQ-SDU1

Parallel cable for

FQ-SDU2

RS-232C cable

(to connect to a

PLC)

FQ2-S3@-@@@

FQ-SDU1@ You can connect a Sensor Data Unit to the I/O cable connector on the Vision Sensor

FQ-SDU2@ You can connect a Sensor Data Unit to the I/O cable connector on the Vision Sensor

--- Connects the Switching Hub to the Touch Finder, computers, and PLCs. Use a con-

*1

FQ-WU0@@ This cable connects the FQ2-S3 Sensor to the Sensor Data Unit.

FQ-VP1@@@ This cable connects the Parallel Interface Sensor Data Unit to an external device.

FQ-VP2@@@ This cable connects the RS-232C Interface Sen so r Data Unit to an external device.

Recommended:

XW2Z-200S-V (2 m) or

XW2Z-500S-V (5 m)

This is the Vision Sensor.

you can download the free PC Tool as a special service to purchasers.

Refer to the Member Registration Sheet that is enclosed with the Sensor for the

member registration procedure and the down load proced ure for special member software.

and connect the Parallel Interf ace Sensor Data Unit to an e xternal device . This allows

you to output the results of judgement conditions, measurements from inspection

items, and the results of expressions with parallel communicat ions.

and connect the RS-232C Interface Sensor Data Unit to an external device. This

allows you to use no-protocol communications to send and receive commands,

inspection item parameters, and other data between the Sensor and the external

control device that is connected with the RS-232C cable. You can also use the ACK

signal (parallel command normal completion signal) for a parallel output from the

Sensor Data Unit.

PLCs.

nector that complies with the FCC RJ45 standard. (STP (shielded twisted-pair) cab le,

category 5e or 6, impedance: 100 Ω)

This cable connects the RS-232C Interface Sen so r Data Unit to an external device.

2

Installation and Connections

*1: The shape and dimensions of the Ethernet connector plug and jack are specified in ISO/IEC8877:1992 (JIS X 5110:1996) and RJ-45 of the

FCC regulations. T o pre v ent connector connection failures , the structure of the jack of this product does not allow insertion of plugs that do not

comply with the standard. If a commercially available plug cannot be inserted, it is likely that the plug is non-compliant.

Do not connect network devices other than PLCs on the same network as the Touch Finder or computer. If

another device is connected, the responsiveness of displays and settings of the Touch Finder or computer may

become slow.

FQ2 User’s Manual

System Configuration

27

Page 30

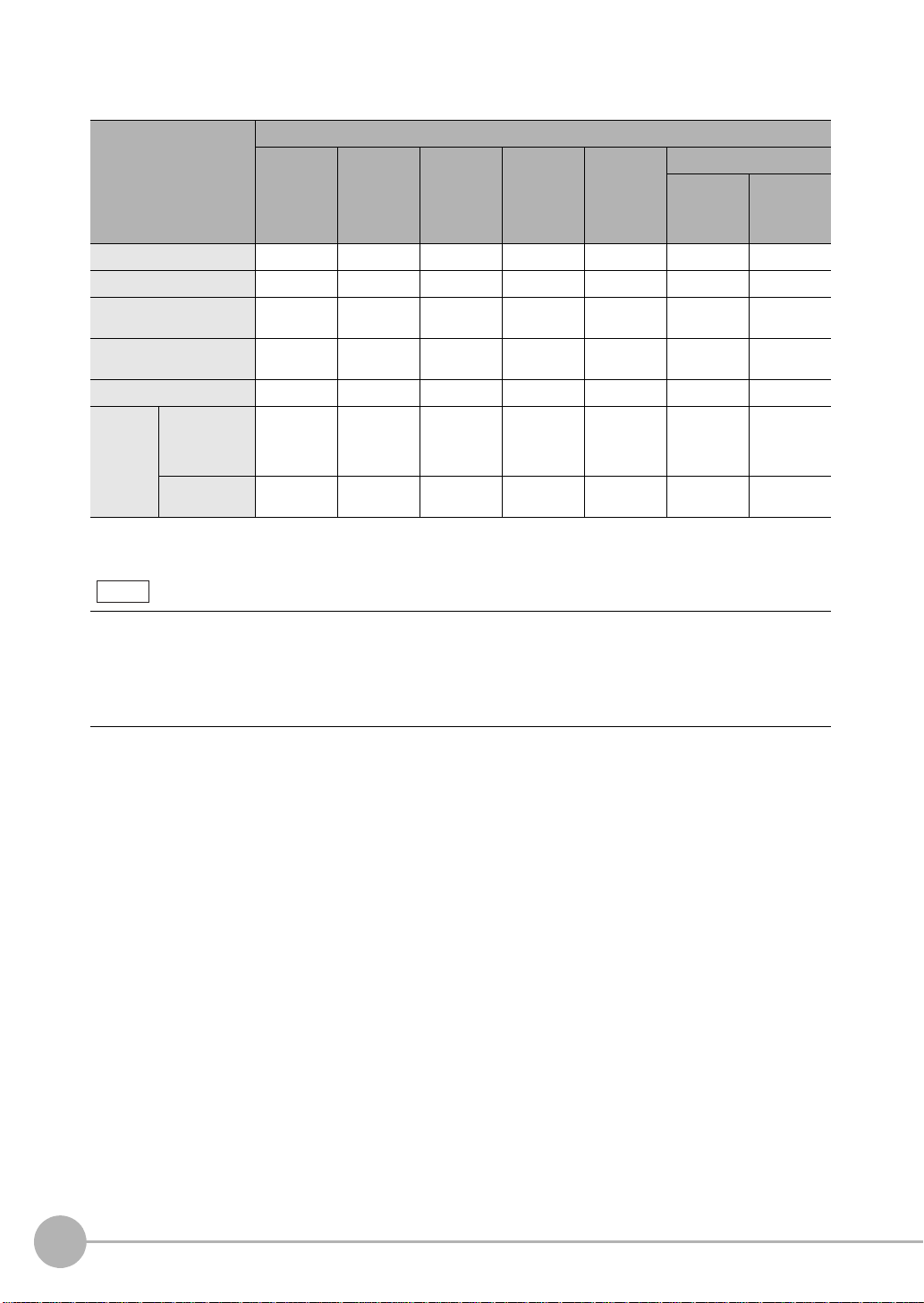

Connection Compatibility

Note

Yes: Supported, No: Not supported

Type of connection to FQ2-S Other connection

EtherNet/IP PLC Link on

EtherNet/IP --- No Yes Yes Yes Yes Yes

PLC Link on Ethernet No --- Yes Yes Yes Yes Yes

TCP no-protocol communi-

cations on Ethernet

FINS/TCP no-protocol com-

munications on Ethernet

RS-232C

Parallel

communications

*1: This applies when an RS-232C Interface Sensor Data Unit is connected.

*2: This applies when a Parallel Interface Sensor Data Unit is connected.

*1

Sensor’s standard parallel

communications

Parallel Inter-

*2

face

Yes Yes --- No No Yes Yes

Yes Yes No --- No Yes Yes

Yes Yes No No --- Yes No

Yes Yes Yes Yes No --- No

Yes Yes Yes Yes No No -- -

Ethernet

TCP no-protocol communications on

Ethernet

FINS/TCP

no-protocol

communications on

Ethernet

RS-232C *1Parallel communications

Sensor’s

standard parallel communications

Parallel Inter-

*2

face

Connections Across Network Routers

You can connect to a Sensor on a different network than the Touch Finder or PC Tool through a router.

• To connect to a Sensor, directly specify th e IP address of the Sensor. Automatic connection to a Sensor is not

possible.

• Use a fixed IP address for the Sensor to connect to.

28

System Configuration

FQ2 User’s Manual

Page 31

2-2 Part Names and Functions

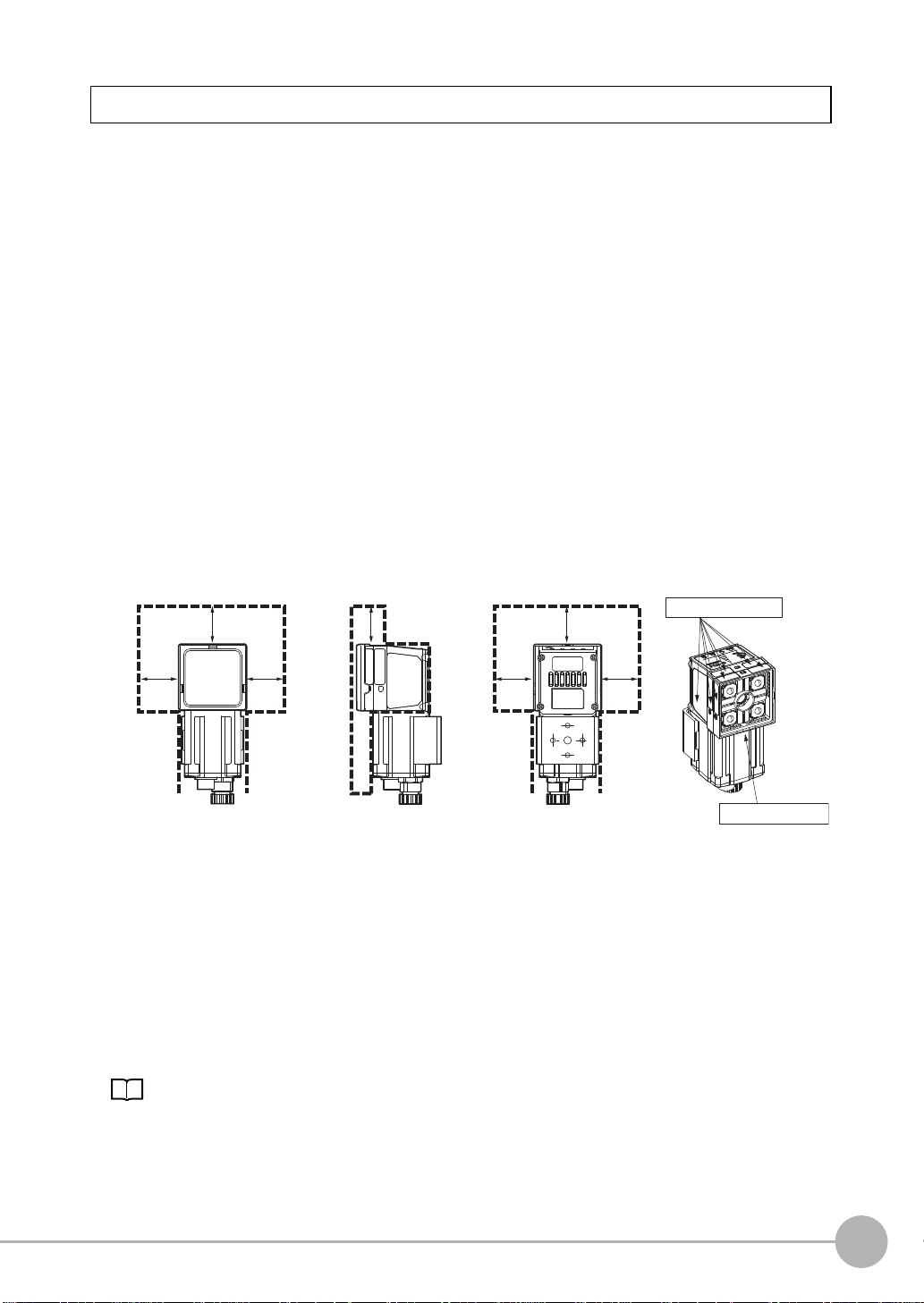

FQ2-S@@@@@@-@@@ (Sensors with Built-in Lighting)

(6)

(7)

No. Name Description

(1) Lighting LEDs for illumination

(2) Camera lens This lens can be focused.

(3) I/O Cable connector An FQ-WD or FQ-WU I/O Cable is used to connect the Sensor to the power

supply and external I/O.

(4) Ethernet cable connector An FQ-WN Ethernet Cable is used to connect the Sensor to external

devices such as PLCs, the Touch Finder, or computers.

(5) Focus adjustment screw Used to adjust the focus of the image.

(6) Operation

indicators

(7) Mounting Bracket Used to mount the Sensor.

OR Lights orange when the overall judgement output (OR) signal turns ON.

ETN Lights orange during Ethernet communications.

ERROR Lights red when an error occurs.

11-1 Error Histories p. 398

BUSY Lights green when the Sensor is executing a process.

* You can change the BUSY indicator to a RUN indicator.

This indicator is set by default to a BUSY indicator , b ut if y ou change it to a

RUN indicator, it will light green during operation.

Changing the Sensor’s BUSY Indicator: p. 231

The Mounting Bracket can be attached to the front, left side, right side, or

back of the Sensor.

(5)

(1)

(2)

(4)

(3)

2

Installation and Connections

FQ2 User’s Manual

Part Names and Functions

29

Page 32

(1)

(4)

(7)

(8)

(3)

(2)

(6)

(5)

(5)

(5)

(5)

Bottom

Sensor Mounted to Base

FQ2-S3@-@@@ (Sensors with C-mounts)

No. Name Description

(1) C-mount lens mounting surface The C-mount lens and macro ring are attached here. Determine the appro-

priate CCTV lens (C-mount lens) to use based on the field of view required

for the size of the measurement object.

Optical Diagrams: p. 35

(2) I/O Cable connector An FQ-WD or FQ-WU I/O Cable is used to connect the Sensor to the power

supply, external I/O, and Data Unit.

(3) Ethernet Cable connector An FQ-WN Ethernet Cable is used to connect the Sensor to external

devices such as the Touch Finder or computers.

(4) Operation

indicators

(5) Mounting holes These mounting holes for M3 screws are used to mount the Camera and to

(6) Mounting base (enclosed) The mounting base has 1/4-20UNC threads and is used to mount the Sen-

(7) C-mount cover This cover is attached to the C-mount lens fitting when a lens is not

(8) Connector cover This cover is attached to the connection when an Ethernet Cable is not con-

OR Lights orange when the overall judgement output (OR) signal turns ON.

ETN Lights orange during Ethernet communications.

ERROR

BUSY Lights green when the Sensor is executing a process.

Lights red when an error occurs.

11-1 Error Histories p. 398

* You can change the BUSY indicator to a RUN indicator.

This indicator is set by default to a BUSY indicator , b ut if y ou change it to a

RUN indicator, it will light green during operation.

Changing the Sensor’s BUSY Indicator: p. 231

mount to the base. There are mounting holes on the top, bottom, left, and

right surfaces.

Dimensions: p. 477

sor. The base can be attached to the bottom, top, left, or right side of the

Sensor.

* We recommend mounting the Sensor with the mounting screw holes. The

mounting base does not necessarily need to be used.

attached.

nected.

30

Part Names and Functions

FQ2 User’s Manual

Page 33

Touch Finder

(1)

(6) (7)

(3)

(4)

(5)

(2)

(12)

(10)

(11)

(8)

(9)

No. Name Description

(1) Operation

indicators

(2) LCD/touch panel Displays the setting menu, measurement results, and images input by the

(3) SD card slot An SD card can be inserted.

(4) Battery cover

(5) Power supply switch Used to turn the Touch Finder ON and OFF.

(6) Touch pen holder The touch pen can be stored here when it is not being used.

(7) Touch pen Used to operate the touch panel.

(8) DC power supply connector Used to connect a DC power supply.

(9) Slider Used to mount the Touch Finder to a DIN Track.

(10) Ethernet port Used when connecting the Touch Finder to the Sensor with an Ethernet

(11) Strap holder This is a holder for attaching the strap.

(12) AC power supply connector

*1: Applicable to the FQ2-D31 only .

POWER Lights green when the Touch Finder is turned ON.

ERROR Lights red when an error occurs.

11-1 Error Histories p. 398

SD ACCESS Lights yellow when an SD card is inserted.

Flashes yellow when the SD card is being accessed.

CHARGE

*1

*1

Lights orange when the Battery is charging.

camera.

The Battery is inserted behind this cover.

Remove the cover when mounting or removing the Battery.

p. 50

cable. Insert the connector until it locks in place.

*1

Used to connect the AC adapter.

2

Installation and Connections

FQ2 User’s Manual

Part Names and Functions

31

Page 34

Sensor Data Units

Front Surface of Parallel Interface

Sensor Data Unit

Back Surface of Parallel Interface

Sensor Data Unit

RS-232C Interface

Sensor Data Unit

(1)

(4)

(4)

(8)

(7)

(5)

(3) (6)

(2)

No. Name Description

(1) Sensor connector Connects to the FQ2-S3.

(2) Power supply and ground termi-

nal block

(3) Parallel I/O connector Connects to the I/O connector.

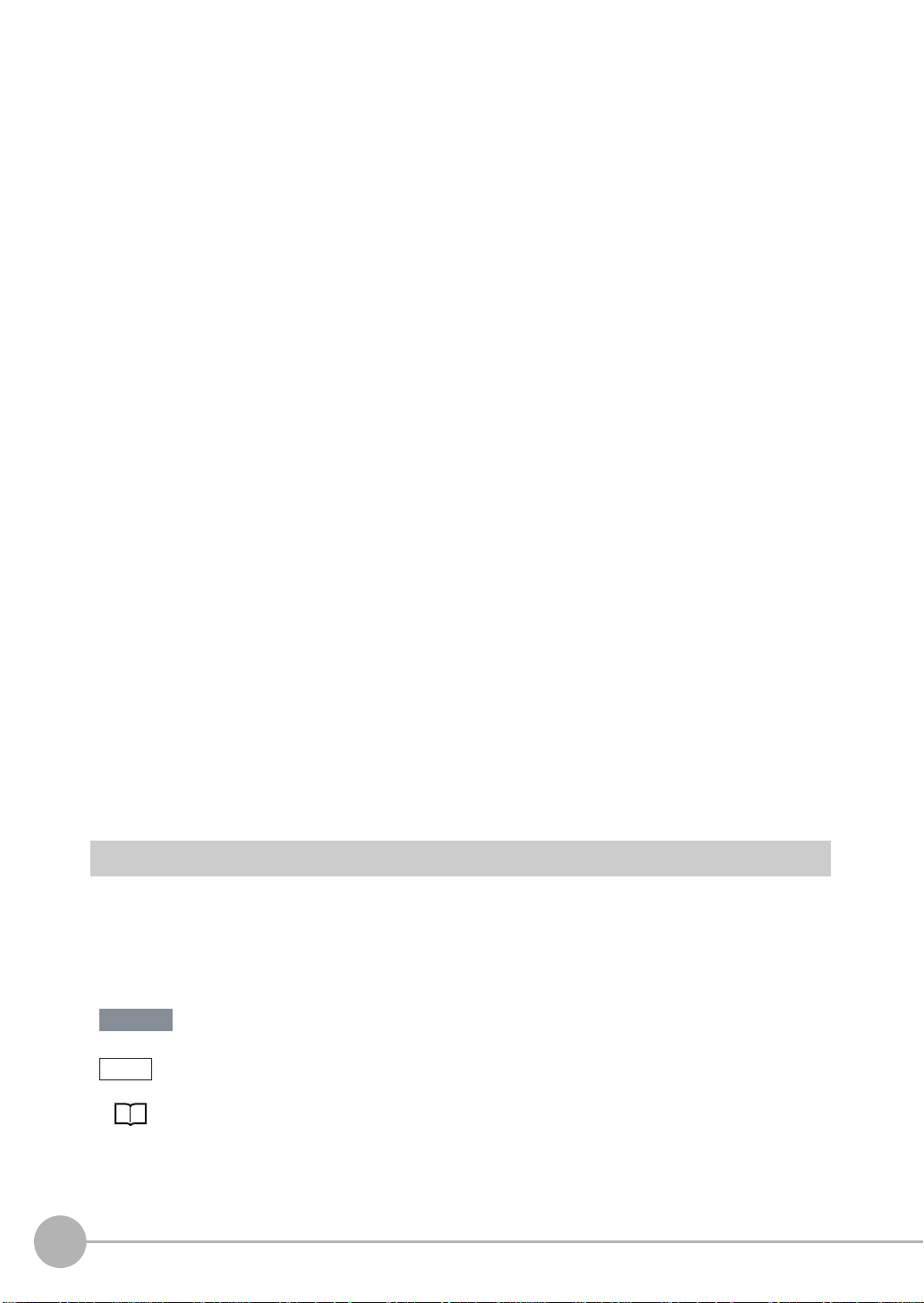

(4) I/O indicators POWER/

ERROR

RUN Lights green during operation.

BUSY Lights yellow when the Sensor is executing a process.

SENSOR Lights yellow when the Sensor is connected.

OR-OK Lights green when the overall judgement result is OK.

OR-NG Lights red when the overall judgement result is OFF or an error occurs.

232C_COM Lights yellow during RS-232C communications. (Provided only on the FQ-

(5) DIN Track mounting section Mounts the Data Unit to a DIN Track.

(6) Slider Used to secure the Data Unit to a DIN Track.

(7) RS-232C connector Connects to the RS-232C connector.

(8) Parallel I/O connector Connects to the I/O connector.

Connects to the 24-V power source and the ground line.