Page 1

Vision Sensor

FH/FHV Series

Vision System

User’s Manual

FH-1£££/FH-1£££-££

FH-2£££-££/FH-2£££-££

FH-3£££/FH-3£££-££

FH-5£££-££/FH-5£££-££

FH-L£££/FH-L£££-££

FHV7£-£££££-C/FHV7£-£££££-S££/FHV7£-£££££-S££-£

£/FHV7£-£££££-H££/FHV7£-£££££-H££-££

Z365-E1-06

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

• QR Code is a registered trademark of DENSO WAVE INCORPORATED.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the FH/FHV Series.

This manual contains information that is necessary to use the FH/FHV Series.

Please read this manual and make sure you understand the functionality and performance of the

FH/FHV Series before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• FH-1£££

• FH-1£££-££

• FH-2£££

• FH-2£££-££

• FH-3£££

• FH-3£££-££

• FH-5£££

• FH-5£££-££

• FH-L£££

• FH-L£££-££

• FHV7£-££££

Part of the specifications and restrictions are given in other manuals. Refer to Relevant Manuals on

Relevant Manuals on page 2 and Related Manuals on page 34.

FH/FHV Series Vision System User’s Manual (Z365-E1)

1

Page 4

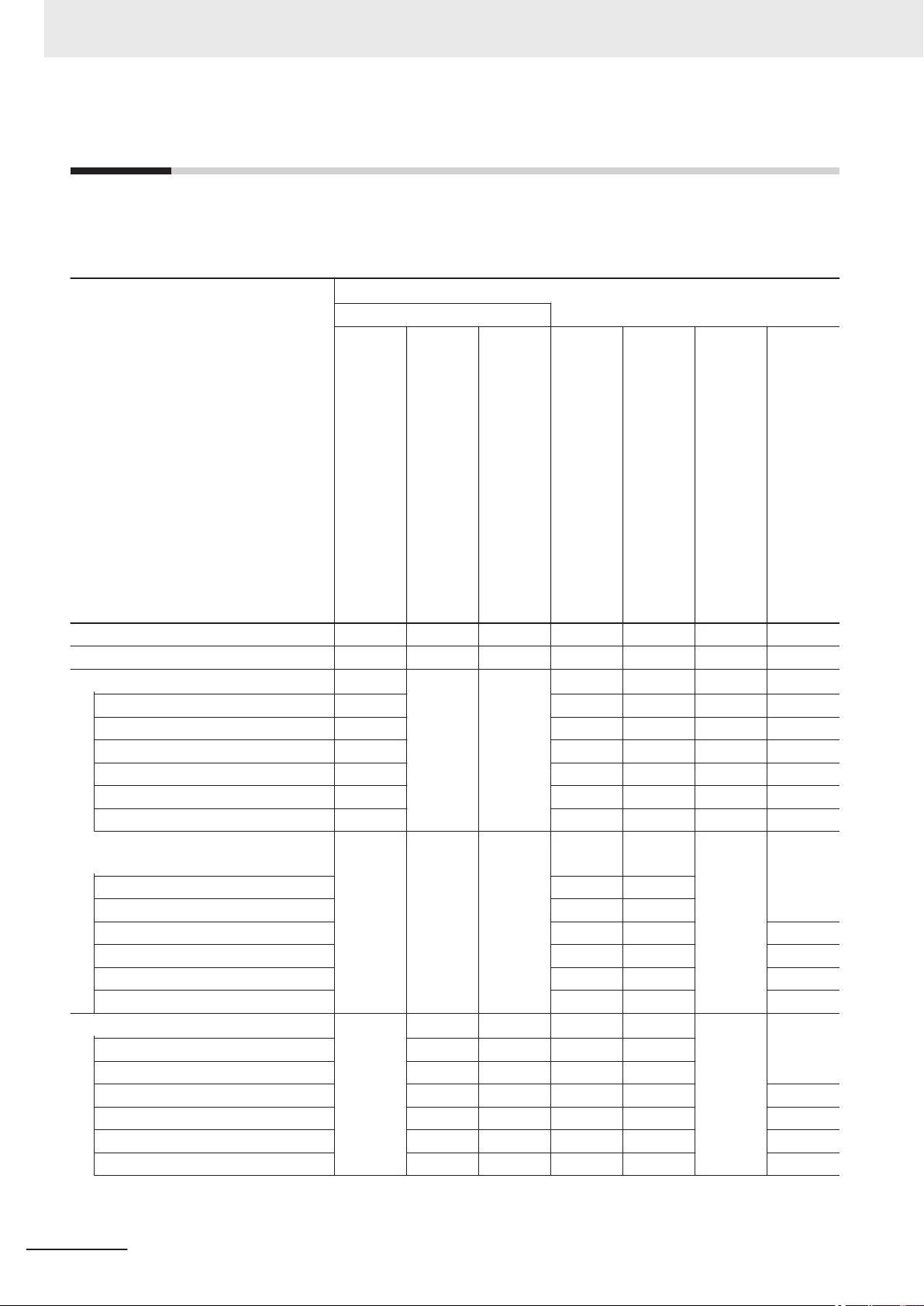

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for the FH/FHV Series.

Read all of the manuals that are relevant to your system configuration and application before you use

the FH/FHV Series.

User's Manual

Purpose of use

Basic information

FH/FHV Series Vision System

FH Series Vision System

Hardware Setup Manual

Manual

FHV Series Smart Camera

Setup Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

Programming Manual

FH Series Vision System

Macro Customize Functions

FH/FHV Series Vision System

User’s Manual for Communications Settings

FH/FHV Series Vision System

Operation Manual for Sysmac Studio

Overview of FH series

Overview of FHV7 series

Setup and Wiring

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the communication setting of Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

l l

l l

l l

l

l l l l

l

l l

2

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 5

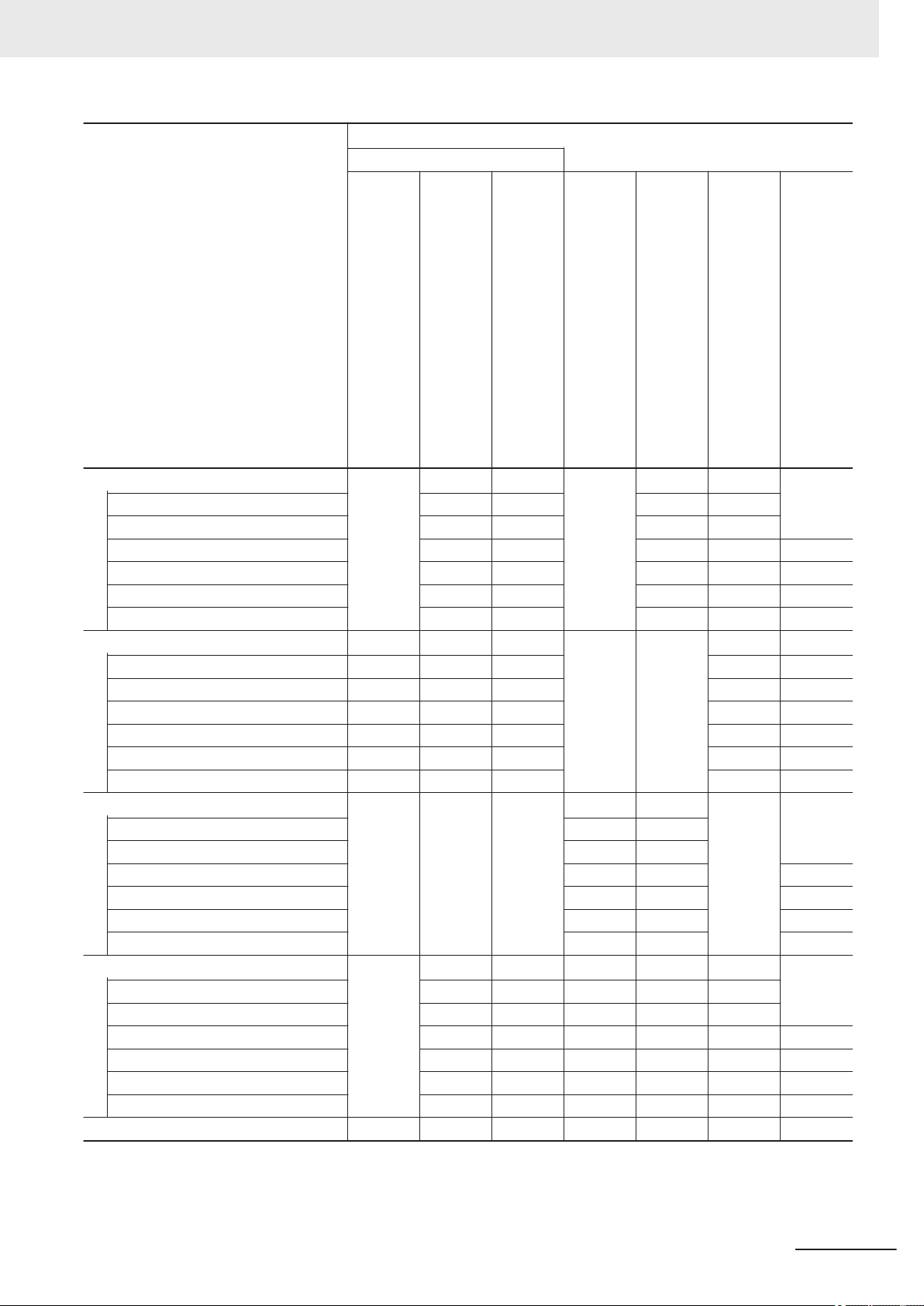

Purpose of use

Basic information

FH/FHV Series Vision System

User's Manual

Hardware Setup Manual

FH Series Vision System

FHV Series Smart Camera

Setup Manual

Relevant Manuals

Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

FH Series Vision System

Macro Customize Functions

Programming Manual

FH/FHV Series Vision System

User’s Manual for Communications Settings

FH/FHV Series Vision System

Operation Manual for Sysmac Studio

Create and Set the Scene

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Optimizing the Scene Flow

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Connecting the Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Using Helpful Functions

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Troubleshooting and Problem Solving

l

l l

l l

l

l l l l

l

l

l

FH/FHV Series Vision System User’s Manual (Z365-E1)

3

Page 6

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

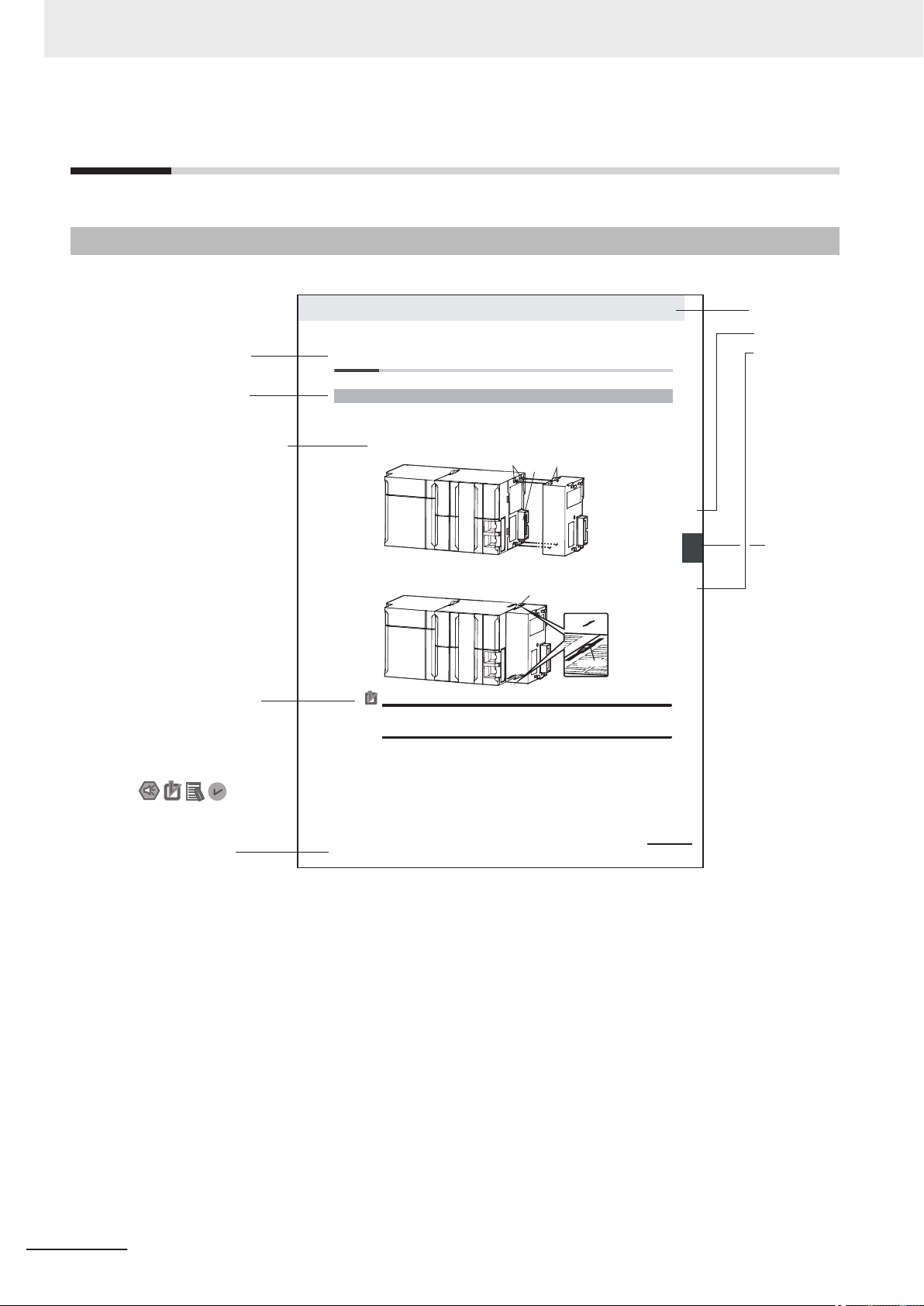

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

FH/FHV Series Vision System User’s Manual (Z365-E1)

5

Page 8

Manual Structure

6

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 9

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products .........................................................................................................................................1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information ..........................................................................................................................................5

Terms and Conditions Agreement........................................................................ 15

Warranty, Limitations of Liability ....................................................................................................................15

Application Considerations ............................................................................................................................16

Disclaimers ....................................................................................................................................................16

Safety Precautions................................................................................................. 18

Symbols and the Meanings for Safety Precautions Described in This Manual .............................................18

Meanings of Alert Symbols ............................................................................................................................18

Warning..........................................................................................................................................................19

CONTENTS

Precautions for Safe Use ...................................................................................... 20

Condition of the Fitness of OMRON Products ............................................................................................... 20

Installation Environment (FH series).............................................................................................................. 20

Installation Environment (FHV series) ...........................................................................................................21

Power Supply and Wiring (FH series)............................................................................................................ 21

Power Supply and Wiring (FHV series) .........................................................................................................21

Grounding (FH series) ...................................................................................................................................22

Mounting (FHV series)...................................................................................................................................23

Others (FH series) .........................................................................................................................................23

Others (FHV series).......................................................................................................................................24

Precautions for Correct Use ................................................................................. 25

Installation and Storage Sites (FH-1000/2000/3000/5000 series) ................................................................. 25

Installation and Storage Sites (FH-L series) ..................................................................................................25

Installation and Storage Sites (FHV series)...................................................................................................25

Orientation of Product....................................................................................................................................26

Ambient Temperature ....................................................................................................................................26

Noise Resistance...........................................................................................................................................26

Component Installation and Handling (FH series) ......................................................................................... 26

Component Installation and Handling (FHV series)....................................................................................... 27

Maintenance (FH series) ...............................................................................................................................27

Maintenance (FHV series) .............................................................................................................................27

Communications with Upper Device..............................................................................................................28

Failsafe Measures .........................................................................................................................................28

Connecting the Sensor Controller and Monitor with a Switcher and Splitter (FH series) ..............................28

Warm-up (FHV series)...................................................................................................................................28

Camera Installation (FHV series)................................................................................................................... 28

Beam (FHV series) ........................................................................................................................................29

Others (FHV series).......................................................................................................................................29

LED Safety (FHV series) ...............................................................................................................................29

Regulations and Standards .................................................................................. 31

All Series........................................................................................................................................................ 31

FH-1000/2000/3000/5000 series ...................................................................................................................31

FH-L series ....................................................................................................................................................32

FHV series .....................................................................................................................................................33

FH/FHV Series Vision System User’s Manual (Z365-E1)

7

Page 10

CONTENTS

Related Manuals..................................................................................................... 34

Terminology............................................................................................................ 37

Revision History..................................................................................................... 42

Sections in This Manual ........................................................................................ 43

Section 1 Overview

1-1 Checking the System Configuration .................................................................................. 1 - 2

1-1-1 System Configuration................................................................................................................1 - 2

1-1-2 Functional Comparison between the FH-series and FHV-series Controllers............................1 - 3

1-2 Flow of Application..............................................................................................................1 - 6

Section 2 Features

2-1 Basic Mechanism for Measurements.................................................................................2 - 2

2-2 Support for a Variety of Scenes and Measurement Lines................................................2 - 4

Section 3 Basic Operations

3-1 Preparing the Controller and Cameras .............................................................................. 3 - 2

3-1-1 Camera Setup ...........................................................................................................................3 - 2

3-1-2 Preparing the Controller ............................................................................................................3 - 4

3-1-3 Adjusting the Camera................................................................................................................3 - 4

3-2 Basic Knowledge about Operations ..................................................................................3 - 6

3-2-1 Inputting Values.........................................................................................................................3 - 6

3-2-2 Inputting Text.............................................................................................................................3 - 6

3-2-3 Selecting Files and Folders.......................................................................................................3 - 9

3-2-4 Available Operations in Select File Window............................................................................ 3 - 11

3-2-5 Using the Zoom Function ........................................................................................................3 - 13

3-2-6 Setting Figures ........................................................................................................................3 - 13

3-2-7 Changing the Image Mode and Other Display Contents.........................................................3 - 21

3-2-8 Changing the Display Ratio.....................................................................................................3 - 22

3-3 Checking System Information [System Information] .....................................................3 - 24

3-4 Checking the Memory Consumption and Percentage of Memory Used.......................3 - 28

3-5 Capturing Screen Images..................................................................................................3 - 29

3-5-1 Setting the Destination for Captured Images ..........................................................................3 - 29

3-5-2 Saving Captured Images.........................................................................................................3 - 29

3-6 Saving Settings before Turning OFF the Power and Restarting ...................................3 - 31

3-6-1 Saving the Setting to the Controller [Data Save].....................................................................3 - 31

3-6-2 Device Information Storage Tool .............................................................................................3 - 31

3-6-3 Restarting the Controller [System Restart]..............................................................................3 - 33

3-7 Initializing the Controller [System initialization].............................................................3 - 36

3-7-1 Initializing with Sensor Controller ............................................................................................3 - 36

3-7-2 Initializing with Remote Operation...........................................................................................3 - 36

3-8 Updating Measurement Application [Version-up]...........................................................3 - 38

3-8-1 By the Sensor Controller (FH Series)......................................................................................3 - 38

3-8-2 By the Sensor Controller (FHV Series) ...................................................................................3 - 43

3-8-3 By the Remote Operation........................................................................................................3 - 45

8

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 11

Section 4 Setting the Controller

4-1 Selecting Language [Startup Settings]..............................................................................4 - 2

4-2 Setting the Status at Startup [Startup Settings] ...............................................................4 - 3

4-3 Setting Communication [Startup Settings] .......................................................................4 - 6

4-4 Setting Operation Mode [Startup Settings] ..................................................................... 4 - 11

4-4-1 Setting the Operation Mode ....................................................................................................4 - 11

4-4-2 Parallel Processing .................................................................................................................4 - 27

4-5 Checking the Camera Connections [Camera Connection] ............................................ 4 - 38

4-6 Setting the Trigger Delay [Inter-camera Setting] ............................................................4 - 39

4-6-1 Trigger Delay Setting...............................................................................................................4 - 39

4-7 Setting the SHTOUT Signal [Output Signal Settings].....................................................4 - 42

4-8 Setting the Conditions Related to Communications ...................................................... 4 - 45

4-9 Setting Date/Time [Date/Time Settings]...........................................................................4 - 46

4-10 Setting Fan Control [Fan Control Setting].......................................................................4 - 48

4-11 Setting the Pulse Width for the STEP Input Detection [STEP Signal Filter Setting] ...4 - 49

4-12 Setting Encoder Trigger [Encoder Trigger Setting]........................................................4 - 50

4-13 Setting Network Drive [Network Drive Setting]...............................................................4 - 52

4-14 Setting Screen Capture [Screen Capture Setting] .......................................................... 4 - 55

4-15 Setting the Conditions that are Related to Operation during Measurement

[Measurement Conditions]................................................................................................4 - 56

4-16 Setting Logging Conditions [Logging Setting] ............................................................... 4 - 58

4-17 Setting Operation Log [Operation Log Setting] .............................................................. 4 - 59

4-18 Setting the Operation at Error [Error Setting] ................................................................. 4 - 60

4-19 Setting Character Code using Macro/Variable Function [Macro/Variable Func-

tion Setting] ........................................................................................................................ 4 - 62

4-20 Changing Display Settings for Screen Keyboard [Screen Keyboard Settings]...........4 - 63

CONTENTS

Section 5 Creating Measurement Scenes

5-1 What Is a Scene? .................................................................................................................5 - 2

5-1-1 Example of a Scene ..................................................................................................................5 - 3

5-2 Creating a Scene..................................................................................................................5 - 5

5-3 Editing Processing Units in Scenes...................................................................................5 - 7

5-4 Displaying and Checking Processing Branches in a Scene..........................................5 - 10

5-4-1 Overview [Flow Viewer]...........................................................................................................5 - 10

5-4-2 Window Configuration [Flow Viewer].......................................................................................5 - 10

5-4-3 Flow Editing Functions [Flow Viewer]......................................................................................5 - 11

5-4-4 Examples of Branch and Folder Views [Flow Viewer].............................................................5 - 13

5-5 Using Variables to Edit the Flow [TDM Editor]................................................................5 - 14

5-5-1 Edit Flow Screen .....................................................................................................................5 - 14

5-5-2 Editing Processing Units in a Scene [TDM Editor] ..................................................................5 - 24

5-5-3 Editing Scenes [TDM Editor] ...................................................................................................5 - 33

5-5-4 Using Variables .......................................................................................................................5 - 43

FH/FHV Series Vision System User’s Manual (Z365-E1)

9

Page 12

CONTENTS

Section 6 Performing Measurement and Adjustment

6-1 Executing Test Measurements ...........................................................................................6 - 2

6-2 Key Points for Adjustment..................................................................................................6 - 4

6-2-1 Stabilizing Measurements .........................................................................................................6 - 4

6-2-2 Shortening Processing Time .....................................................................................................6 - 5

6-3 Useful Functions for Operation .......................................................................................... 6 - 7

6-3-1 Logging Measurement Values and Measurement Images [Data Logging/Image Logging].......6 - 7

6-3-2 Saving Data to an External Device [FTP/Network Drive] ........................................................6 - 20

6-3-3 Remeasuring Saved Images [Remeasurement] .....................................................................6 - 23

6-3-4 Improving Adjustment Efficiency [Judgement result monitor]..................................................6 - 24

6-4 Analyzing Inspection and Measurement Results [NG Analyzer]...................................6 - 26

6-4-1 Layout of NG Analyzer Window ..............................................................................................6 - 26

6-4-2 Using Method of NG Analyzer.................................................................................................6 - 28

6-4-3 Saving Measurement Values...................................................................................................6 - 30

6-4-4 Changing Judgement Conditions without Stopping Measurement [Simplified Non-stop

Adjustment] .............................................................................................................................6 - 31

6-4-5 Changing Regions as a Batch [Shift area] ..............................................................................6 - 32

6-5 Updating the Reference Position Data for a Unit in the Measurement Flow [Up-

date Standard Position Tool] ............................................................................................6 - 34

6-5-1 Monitoring Measurement Value Trends [Trend Monitor] .........................................................6 - 35

6-5-2 Clearing Measurement Results [Clear measurement] ............................................................6 - 36

6-5-3 Clearing Saved Images [Clear logging image]........................................................................6 - 36

6-6 Managing Images used for Model Registration and Reference [Registered Im-

age Manager]......................................................................................................................6 - 38

6-6-1 Specifying the Destination to Save .........................................................................................6 - 38

6-6-2 Registering Images .................................................................................................................6 - 40

6-6-3 Renaming Image Names ........................................................................................................6 - 41

6-6-4 Deleting Images ......................................................................................................................6 - 41

6-6-5 Loading Images.......................................................................................................................6 - 42

6-7 Verifying Calibration Results [Calibration Support Tool]...............................................6 - 43

6-7-1 Checking the Calibration Results ............................................................................................6 - 43

6-7-2 Data Setting ............................................................................................................................6 - 43

Section 7 Increasing/Switching Measurement Scenes

7-1 What Is a Scene Group?......................................................................................................7 - 2

7-2 Switching the Scene or Scene Group ................................................................................ 7 - 3

7-2-1 Switching the Scene..................................................................................................................7 - 3

7-2-2 Switching Scene Groups...........................................................................................................7 - 3

7-3 Editing Scenes [Scene maintenance] ................................................................................7 - 6

7-3-1 Copying Scenes ........................................................................................................................7 - 6

7-3-2 Deleting Scenes ........................................................................................................................7 - 6

7-3-3 Renaming a Scene and Adding a Description ..........................................................................7 - 7

7-4 Editing Scene Groups [Scene Maintenance].....................................................................7 - 8

7-4-1 Copying Scene Groups .............................................................................................................7 - 8

7-4-2 Deleting Scene Groups .............................................................................................................7 - 8

7-4-3 Renaming the Scene Group Name ...........................................................................................7 - 9

7-5 Saving Scene Groups in External Storage [Scene Group Saving Destination

Settings].............................................................................................................................. 7 - 11

7-6 Increasing the Number of Scenes in a Group to more than 128 Scenes [Con-

version scene group data tool].........................................................................................7 - 14

7-6-1 Overview .................................................................................................................................7 - 14

7-6-2 Operating Procedure for the Conversion Scene Group Data Tool..........................................7 - 14

10

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 13

Section 8 Setting Windows

8-1 Windows ...............................................................................................................................8 - 3

8-1-1 Types of Windows.....................................................................................................................8 - 3

8-1-2 Overview of Window Navigation ...............................................................................................8 - 3

8-1-3 Main Window (Layout 0): Adjustment Window (Default)...........................................................8 - 4

8-1-4 Main Window (Layout 1): Run Window (Default) ......................................................................8 - 8

8-2 Adjustment Windows and Run Windows ..........................................................................8 - 9

8-2-1 Main Window (Layout 0): Adjustment Window (Default)...........................................................8 - 9

8-2-2 Main Window (Layout 1): Run Window (Default) ....................................................................8 - 10

8-2-3 Main Window (Layout 1): Switching to the Run Window.........................................................8 - 10

8-2-4 Main Window (Layout 1): Switching to the Adjustment Window .............................................8 - 10

8-3 Arranging Windows [Layout Functions]..........................................................................8 - 12

8-3-1 Arranging Window Elements [Layout Modification].................................................................8 - 12

8-3-2 Setting the Behavior of Output Signals for Each Layout [Layout setup] .................................8 - 22

8-3-3 Switching Layout Numbers in the Main Window [Switch layout].............................................8 - 24

8-3-4 Judgement Pane .....................................................................................................................8 - 24

8-3-5 Information Pane.....................................................................................................................8 - 24

8-3-6 Toolbox Pane ..........................................................................................................................8 - 25

8-3-7 Measurement Pane.................................................................................................................8 - 27

8-3-8 Flow Display Pane ..................................................................................................................8 - 27

8-3-9 Detail Result Pane ..................................................................................................................8 - 28

8-3-10 Image Container Pane ............................................................................................................8 - 29

8-3-11 Error Pane...............................................................................................................................8 - 33

8-3-12 Image File Display Pane .........................................................................................................8 - 34

8-3-13 Label Pane ..............................................................................................................................8 - 36

8-3-14 Extended Window Parts..........................................................................................................8 - 37

8-3-15 Data Grid Window (MDI_DataGrid.dll) ....................................................................................8 - 38

8-3-16 Login Account Display Window (MDI_DispLoginUser.dll).......................................................8 - 44

8-3-17 Setting Dialog Box Display Button Window (MDI_DispSetupBtn.dll) ......................................8 - 45

8-3-18 Text Display Window (MDI_DispText.dll).................................................................................8 - 47

8-3-19 Custom Dialog Display Button Window (MDI_ExecuteBtn.dll)................................................8 - 49

8-3-20 Macro Trigger Window (MDI_McrTrigger.dll)...........................................................................8 - 52

8-3-21 Message Box Display Window (MDI_MsgBox. dll) .................................................................8 - 53

8-3-22 Value Input Window (MDI_NumBox.dll) ..................................................................................8 - 54

8-3-23 Data Settings Button Window (MDI_SetDataBtn.dll) ..............................................................8 - 55

8-3-24 Simple Data Grid Window (MDI_SimpleDataGrid.dll) .............................................................8 - 58

8-3-25 Troubleshooting.......................................................................................................................8 - 63

8-4 Editing contents are not reflected when you confirm the Sensor Controller af-

ter edit a layout by remote control [Custom Dialog Tool]..............................................8 - 64

8-4-1 Flow of Use .............................................................................................................................8 - 64

8-4-2 Custom Dialog Tool .................................................................................................................8 - 64

8-4-3 Launching Your Custom Dialog Box........................................................................................8 - 83

CONTENTS

Section 9 Saving/Loading Data

9-1 Saving Data to the FH series/FHV series...........................................................................9 - 3

9-1-1 About Saving Areas ..................................................................................................................9 - 3

9-1-2 External Drive Names ...............................................................................................................9 - 5

9-1-3 Using External Storage Devices ...............................................................................................9 - 5

9-1-4 Shared Folder on a Computer Connected to the Network ........................................................9 - 6

9-2 Saving Settings Data to the Flash Memory .......................................................................9 - 7

9-3 Saving Setting Data to the Controller RAMDisk or an External Storage Device ...........9 - 8

9-4 Saving Logged Images in the Controller Memory (RAM) to a RAMDisk or an Ex-

ternal Storage Device ........................................................................................................9 - 10

9-5 Copying or Moving Files between the Controller RAMDisk and an External

Storage Device ................................................................................................................... 9 - 12

FH/FHV Series Vision System User’s Manual (Z365-E1)

11

Page 14

CONTENTS

9-6 Loading Settings Data from the Controller RAMDisk or an External Storage De-

9-7 Backing up Sensor Controller Setting Data [Configuration Copy] ...............................9 - 15

9-8 Copying Settings for Each Line in Multi-line Random-trigger Mode [Line Main-

9-9 Saving Image Files to a RAMDisk or an External Storage Device [Image File Save] .. 9 - 46

9-10 Outputting a list of Scene Data Setting Values [Setting Values Download/

9-11 Saving/Loading Layout Settings [Layout Upload, Download Tool] ..............................9 - 53

vice to the Sensor Controller............................................................................................9 - 13

9-7-1 Before Backing up...................................................................................................................9 - 15

9-7-2 Backing up Sensor Controller Settings ...................................................................................9 - 17

9-7-3 Restoring Saved Settings........................................................................................................9 - 27

9-7-4 Troubleshooting.......................................................................................................................9 - 30

tenance] ..............................................................................................................................9 - 32

9-8-1 Before use of Line Maintenance .............................................................................................9 - 32

9-8-2 Line Maintenance tool operations ...........................................................................................9 - 36

9-8-3 Operating with Functional Limitations .....................................................................................9 - 41

9-8-4 Troubleshooting.......................................................................................................................9 - 45

9-9-1 Saving Logging Images...........................................................................................................9 - 46

9-9-2 Saving Image Files..................................................................................................................9 - 47

Upload Tools] .....................................................................................................................9 - 49

9-10-1 Downloading Setting Values....................................................................................................9 - 49

9-10-2 About Downloaded CSV Files.................................................................................................9 - 50

9-10-3 Uploading Setting Values........................................................................................................9 - 51

Section 10 Advanced Usage

10-1 Remotely Operating the Controller [Remote Operation]................................................10 - 3

10-1-1 Environment Settings ..............................................................................................................10 - 4

10-1-2 Connection Method for Remote Operation .............................................................................10 - 9

10-1-3 Terminating Remote Operation .............................................................................................10 - 12

10-1-4 Differences from Local Operation and Limitations ................................................................10 - 13

10-2 Multi-trigger Imaging Processing with Any Timing [Multi-trigger Imaging]...............10 - 15

10-2-1 Settings for Multi-trigger Imaging ..........................................................................................10 - 15

10-2-2 Restrictions ...........................................................................................................................10 - 17

10-2-3 Setting Methods ....................................................................................................................10 - 18

10-2-4 About Multi-input Function (Multi-trigger Imaging) ................................................................10 - 22

10-2-5 Troubleshooting.....................................................................................................................10 - 28

10-3 Limiting User Operations [Security Settings] ...............................................................10 - 29

10-3-1 Setting Accounts (Account List) ............................................................................................10 - 29

10-3-2 Setting Layout Restrictions ...................................................................................................10 - 33

10-3-3 Setting User Group Operation Restrictions...........................................................................10 - 34

10-3-4 Saving/Loading/Deleting the Security Settings .....................................................................10 - 36

10-4 Recording the Operation History [Operation Log] .......................................................10 - 42

10-4-1 Using the Operation Log .......................................................................................................10 - 42

10-4-2 Operation Log Format ...........................................................................................................10 - 45

10-5 Setting the Keyboard Layout for the Controller [Keyboard Layout Selection Tool] .10 - 46

10-6 Switching User Accounts................................................................................................10 - 48

10-6-1 Logging in..............................................................................................................................10 - 48

10-6-2 Logging out ...........................................................................................................................10 - 49

10-7 Customizing Communication Commands [Communication Command Macro]........10 - 50

10-8 Extending the Functions in a Measurement Flow or Scene [Scene Control Mac-

ro Tool]..............................................................................................................................10 - 51

10-9 Positioning workpieces for stage and robot applications [Alignment Function]......10 - 52

10-9-1 Overview ...............................................................................................................................10 - 52

10-9-2 Execution of Calibration ........................................................................................................10 - 54

10-9-3 Troubleshooting.....................................................................................................................10 - 60

12

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 15

10-9-4 Alignment ..............................................................................................................................10 - 61

10-9-5 Alignment Processing Items..................................................................................................10 - 67

Section 11 What to Do!

11-1 Error Messages and Troubleshooting ............................................................................. 11 - 2

11-2 FAQ......................................................................................................................................11 - 9

11-2-1 During Start-up........................................................................................................................ 11 - 9

11-2-2 During Operation................................................................................................................... 11 - 10

11-2-3 For Measurement.................................................................................................................. 11 - 11

11-2-4 About Parallel Interface......................................................................................................... 11 - 12

11-2-5 Serial Interface (RS-232C/422 Connection).......................................................................... 11 - 13

11-2-6 Camera with Lighting Controller............................................................................................ 11 - 14

Appendices

A-1 Menu List ............................................................................................................................. A - 3

A-2 External Tool List ................................................................................................................ A - 6

A-3 FHV series tools.................................................................................................................. A - 7

A-4 FHV series Processing items............................................................................................. A - 8

A-4-1 Measurement ........................................................................................................................... A - 8

A-4-2 Input image .............................................................................................................................. A - 8

A-4-3 Compensate image .................................................................................................................. A - 9

A-4-4 Support measurement.............................................................................................................. A - 9

A-4-5 Branch...................................................................................................................................... A - 9

A-4-6 Output result........................................................................................................................... A - 10

A-4-7 Display result.......................................................................................................................... A - 10

A-5 Measurement Mechanism ................................................................................................ A - 11

A-5-1 Color Processing Mechanism .................................................................................................A - 11

A-5-2 Search Processing Mechanism.............................................................................................. A - 12

A-5-3 Edge Detection Measurement................................................................................................ A - 15

A-5-4 Defect Detection Measurement.............................................................................................. A - 18

A-5-5 Handling Coordinates............................................................................................................. A - 19

A-6 Image file ........................................................................................................................... A - 21

A-6-1 IFZ file type ............................................................................................................................ A - 21

A-6-2 BMP(BFZ) file type................................................................................................................. A - 21

A-6-3 JPG(JFZ) file type .................................................................................................................. A - 21

A-6-4 Differences among IFZ/BMP(BFZ)/JFZ(JFZ) file types.......................................................... A - 22

A-7 About Number of Logging Images .................................................................................. A - 24

A-7-1 Calculation method ................................................................................................................ A - 24

A-7-2 Color camera.......................................................................................................................... A - 25

A-7-3 Monochrome camera ............................................................................................................. A - 25

A-7-4 FHV series ............................................................................................................................. A - 26

A-8 About Max. Number of Loading Images during Multi-input.......................................... A - 27

A-8-1 FH series................................................................................................................................ A - 27

A-8-2 FHV series ............................................................................................................................. A - 27

A-9 About Memories Usable with FH series/FHV series ...................................................... A - 29

A-10 Memory Usage Guidance For Processing Items ........................................................... A - 30

A-11 Memory Display Image on PLC I/O.................................................................................. A - 36

A-12 Sharing Data Within the Controller [User Data Tool]..................................................... A - 37

A-12-1 Setting Procedure for User Data ............................................................................................ A - 37

A-13 Operation log input information list................................................................................ A - 39

A-14 Character Code Table....................................................................................................... A - 50

CONTENTS

FH/FHV Series Vision System User’s Manual (Z365-E1)

13

Page 16

CONTENTS

A-15 List for Processing Item Identifier................................................................................... A - 51

Index

14

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 17

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

l

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

l

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

l

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

FH/FHV Series Vision System User’s Manual (Z365-E1)

15

Page 18

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

16

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 19

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

FH/FHV Series Vision System User’s Manual (Z365-E1)

17

Page 20

Safety Precautions

Safety Precautions

Symbols and the Meanings for Safety Precautions Described in This

Manual

The following notation is used in this manual to provide precautions required to ensure safe usage of a

Sensor Controller. The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoid-

WARNING

ed, will result in minor or moderate injury, or may result in serious injury or death.

Additionally there may be significant property damage.

Caution

Meanings of Alert Symbols

General Prohibition

Indicates general prohibitions, including warnings, for which there is no specific

symbol

General Caution

Indicates general cautions, including warnings, for which there is no specific symbol.

Electrical Hazard

Indicates the possible danger of electric shock under specific conditions.

Explosion Hazard

Indicates the possible danger of explosion under specific conditions.

LED light Hazard

Indicates the possible danger of LED radiation or light.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury or in property damage.

18

High Temperature Caution

Indicates the possible danger of injury by high temperature under specific conditions.

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 21

Warning

This product must be used according to this manual and Instruction Sheet.

Failure to observe this may result in the impairment of functions and performance of the

product.

This product is not designed or rated for ensuring the safety of persons.

Do not use it for such purposes.

Never connect the AC power supply with this product. When the AC power supply is connected, it causes the electric shock and a fire.

A lithium battery is built into the Controller and may occasionally combust, explode, or burn if

not treated properly. Dispose of the Controller as industrial waste, and never disassemble,

apply pressure that would deform, heat to 100°C or higher, or incinerate the Controller.

Safety Precautions

WARNING

If you keep watching the LED light, it may have an adverse effect on the eyes, do not stare

directly into the light emitted from the LED. If a specular object is used, take care not to allow

reflected light to enter your eyes.

Do not touch the terminals while the power supply is ON.

Doing so may result in electrical shock.

Please take external safety measures so that the system as a whole should be on the safe

side even if a failure of a Sensor Controller or an error due to an external factor occurred. An

abnormal operation may result in serious accident.

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal conductor disconnection and/or momentary power interruption.

An abnormal operation may result in a serious accident.

Caution

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal conductor disconnection and/or momentary power interruption.

An abnormal operation may result in a serious accident.

FH/FHV Series Vision System User’s Manual (Z365-E1)

19

Page 22

Precautions for Safe Use

Precautions for Safe Use

Condition of the Fitness of OMRON Products

• Please do not use this product to directly or indirectly use to detect the human body for the purpose

of ensuring the safety. In the same application, please use the safety sensor that is published on our

sensor catalog.

• Omron products are designed and manufactured as general-purpose products for use in general industrial applications. They are not intended to be used in the following critical applications. If you are

using Omron products in the following applications, Omron shall not provide any warranty for such

Omron products, unless otherwise specifically agreed or unless the specific applications are intended by Omron.

a) Applications with stringent safety requirements, including but not limited to nuclear power control

equipment, combustion equipment, aerospace equipment, railway equipment, elevator/lift equipment, amusement park equipment, medical equipment, safety devices and other applications

that could cause danger/harm to people's body and life.

b) Applications that require high reliability, including but not limited to supply systems for gas, water

and electricity, etc., 24 hour continuous operating systems, financial settlement systems and other applications that handle rights and property.

c) Applications under severe condition or in severe environment, including but not limited to out-

door equipment, equipment exposed to chemical contamination, equipment exposed to electromagnetic interference and equipment exposed to vibration and shocks.

d) Applications under conditions and environment not described in specifications.

(1) In addition to the applications listed from (a) to (d) above, Omron products (see definition) are not

intended for use in vehicles designed human transport (including two wheel vehicles). Please do

NOT use Omron products for vehicles designed human transport. Please contact the Omron

sales staff for information on our automotive line of products.

(2) The above is part of the Terms and Conditions Agreement. Please use carefully read the contents

of the guarantee and disclaimers described in our latest version of the catalog, data sheets and

manuals.

Installation Environment (FH series)

• Do not use the product in areas where flammable or explosive gases are present.

• Install the product so that air can flow freely through its cooling vents.

• Clean the ventilation holes and fan outlet regularly to prevent dust and particles from clogging them.

If they are blocked, heat is trapped inside, causing a malfunction.

• Do not install the product close to high-voltage devices and power devices in order to secure the

safety of operation and maintenance.

• Make sure to tighten all installation screws securely.

• When mounting the Sensor Controller using the DIN rail mounting bracket, make sure the screw is

tightened.

• Make sure to mount the product on DIN-rail securely.

20

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 23

Installation Environment (FHV series)

• Do not use the product in areas where flammable or explosive gases are present.

• Do not install the product close to high-voltage devices and power devices in order to secure the

safety of operation and maintenance.

• Do not install the product to a place where vibrations and/or impacts are expected.

• Do not install the product near to a device causing noises. if the product is installed in a noisy environment and operational errors are caused, be sure to take shielding measures.

Power Supply and Wiring (FH series)

• Make sure to use the product with the power supply voltage specified by this manual or Instruction

sheet.

• Do not connect AC power source to Sensor Controller. If connects AC power source, it might be a

cause of the failure.

• Use the wire of a suitable size (AWG 16 to 12) according to the current consumption.

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage

circuits on the secondary side).

• Keep the power supply wires as short as possible.

• Do the following confirmations again before turning on the power supply.

- Is the voltage and polarity of the power supply correct? (24 VDC)

- Is not the load of the output signal short-circuited?

- Is the load current of the output signal appropriate?

- Is not the mistake found in wiring?

- Is the voltage and polarity of the encoder power (ENC0_VDD/GND ENC1_VDD/GND) supply?

(5VDC)

• The recommended power supply for FH-L series is the S8VS- £££ 24 (manufactured by OMRON)

or S8VK-G- £££ 24 (manufactured by OMRON).

Precautions for Safe Use

Power Supply and Wiring (FHV series)

• Make sure to use the product with the power supply voltage specified. If a DC voltage exceeding the

rating or an AC voltage is applied, the circuit parts may be burnt or exploded.

• Do not connect the power supply with polarity reversed.

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage

circuits on the secondary side).

• Use an independent power source for this product. Do not use a shared power source.

• Never apply more than the rated voltage or AC power supply to this product. It may cause malfunction.

• The recommended power supplies are as follows:

- When attaching the lighting module, use S8VK-G06024 (OMRON) or S8VS-06024 (OMRON).

- When not attaching the lighting module, use S8VK-G06024 (OMRON) or S8VS-06024 (OMRON).

• Wire high-voltage cables or power cables separately from the cables of this product. If the same cable or duct is used, the product may receive induction and it may cause malfunctioning or breakage.

• Do not short-circuit load on the open collector output.

• Apply load not exceeding the rating.

• When wiring, put a crimp terminal of the specified size. Do not connect wires simply twisted together

to the power supply or terminal block directly.

FH/FHV Series Vision System User’s Manual (Z365-E1)

21

Page 24

Precautions for Safe Use

• If using an I/O cable 20 m long, confirm that the power supply output is 24 VDC or higher. If it is

lower than 24 VDC, the product does not operate.

• Cut off unnecessary signal wires so that they do not contact any other signal wires.

• After wiring the cables, confirm if the power supply is appropriate, if there is miswiring such as shortcircuit of load, if the load current is appropriate, and if FG is connected appropriately. Otherwise, the

product may be broken due to miswiring etc.

• Take enough safety measures such as a failsafe circuit before using the product.

• Be sure to apply Class D grounding (100Ω or lower grounding resistance) to the case of the smart

camera and the ground wire of the I/O cable.

• Do not share the ground wire with some other devices or connect it to the beam of the building. The

product may be adversely affected.

• Determine the contact point as near as possible to shorten the ground wire as much as possible.

The product may be adversely affected.

Grounding (FH series)

• Make sure the power supply circuit of the Sensor Controller is insulated from the internal circuit. Refer to this manual or Instruction sheet.

• When the connected camera to Sensor Control comes packaged with a base, make sure to mount

with the base. Since the enclosure of the camera main body made of metals is short-circuited with

the internal circuit, the internal circuit might be short-circuited with FG if no base is used, so that

failures or malfunctions may be caused.

Perform Class D grounding (with a grounding resistance of 100 Ω or less). Keep the ground line as

short as possible by setting the grounding point as close as possible. Ground the Sensor Controller

independently. If sharing the ground line with other devices or connecting it with a building beam,

the Sensor Controller might be adversely effected.

• Check wiring again before turning on the Sensor Controller.

• Do not ground the plus (+) terminal when the FH series Sensor Controller is connected to the FHSC12/FH-SM12. Doing so may cause a short circuit of the internal circuit, resulting in a malfunction.

The internal circuit is possible to be given damage, it can be cause the failure.

• FH-1000 series

• FH-2000 series

• FH-3000 series

• FH-5000 series

• FH-L series

• Do not ground the plus (+) terminal of the 24 VDC power source when the FH series Sensor Controller is connected to the FH-MT12 with a USB cable. Doing so may cause a short circuit of the

internal circuit, resulting in a malfunction.

• FH-1000 series

• FH-2000 series

• FH-3000 series

• FH-5000 series

• FH-L series

22

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 25

Mounting (FHV series)

• When doing the following, be sure to turn OFF the power of the smart camera main unit or connected peripheral devices. Not doing so leads to a product failure.

- Cable connection and wiring

- Connector mounting/removal

- Lighting module mounting/removal

- Lens module mounting/removal

• Tighten the mounting screws securely using the defined torque and order described in the Setup

Manual.

• Mount the lens module in the correct direction. Mounting it in the wrong direction may cause malfunction of the device or injury.

• After removing the cable, be sure to put the connector cap. If the connector cap is not put, the product may malfunction or be broken due to entering of foreign materials.

• For the component with a lock mechanism, be sure to confirm that it is locked before using the product.

• Do not apply torsional stress to the cable. Doing so may cause cable breakage.

• Secure the minimum bending radius of the cable. If it cannot be secured, the cable may be broken.

• Assemble as avoiding the waterproof packings and harnesses from being caught by the case, etc.

• Do not use any damaged waterproof packings and light shielding sheet or assemble the product

with foreign materials attached to or caught in.

• Mount the lens module and lighting model in the correct direction. Mounting them in the wrong direction may cause broken or malfunction of the device, or injury.

• Do not touch the lens or image sensor with bare hands. Doing so may lead to malfunctioning or

breakage.

Assemble the lens and image sensor with a correct combination. if not, malfunction may result.

Precautions for Safe Use

Others (FH series)

• Use only the camera and cables designed specifically for the product. Use of other products may

result in malfunction or damage of the product.

• Always turn OFF the power of the Sensor Controller and peripheral devices before connecting or

disconnecting a camera or cable. Connecting the cable with power supplied may result in damage of

the camera or peripheral devices.

• For the cable that is flexed repeatedly, use the robotic cable type (Bend resistant camera cable) to

prevent damages.

• Do not apply torsion stress to the cable. It may damage the cable.

• Secure the minimum bending radius of the cable. Otherwise the cable may be damaged.

• Do not attempt to dismantle, repair, or modify the product.

• Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and contact

your OMRON representative.

• While the power is ON or immediately after the power is turned OFF, the Sensor Controller and

camera case are still hot. Do not touch the case.

• When disposing of the product, treat it as an industrial waste.

• Do not drop the product nor apply excessive vibration or shock to the product. Doing so may cause

malfunction or burning.

• This product is heavy. Be careful not to drop it while handling.

• A lithium battery is incorporated, so a severe injury may rarely occur due to ignition or explosion.

FH/FHV Series Vision System User’s Manual (Z365-E1)

23

Page 26

Precautions for Safe Use

• Be sure to take fail-safe measures externally when controlling stages and robots by using the measurement results of the Sensor Controller (axis movement output by calibration and alignment measurement).

Others (FHV series)

• Use only the dedicated cable (FHV-VN £/FHV-VD £), camera-mount lighting controller (FL-TCC £/

FLV-TCC £), lighting module (FHV-LTM- £), and lens module (FHV-LEM- £). Otherwise, the product may malfunction or be broken.

• If anything abnormal occurs, for example, strange smell/sound is detected, the main unit gets very

hot, or a smoke comes, stop using the product, turn OFF the product, and consult OMRON’s branch

or sales office.

• Do not disassemble, deform by pressurizing, incinerate, repair, or alter this product.

• When disposing of the product, treat as industrial waste.

• Do not drop the product or expose it to abnormal vibration or impact. Doing so may lead to product

failure.

• If using the measurement result of the smart camera to operate the stage or robot (output of axis

moving distance by calibration and alignment measurement), be sure to take failsafe measures externally.

• The waterproof packing and light shielding sheet are rubber products. Avoid storing them in a location where rubber deteriorates.

24

FH/FHV Series Vision System User’s Manual (Z365-E1)

Page 27

Precautions for Correct Use

Precautions for Correct Use

Installation and Storage Sites (FH-1000/2000/3000/5000 series)

Install and store the product in a location that meets the following conditions:

• Surrounding temperature of 0 to +50°C *1

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 35 to 85%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight