Omron FHV Series, FHV7-S Series, FH-5 Series, FHV7-C Series, FH-1 Series Operation Manual

...Page 1

Vision Sensor

FH/FHV Series

Vision System

Operation Manual for Sysmac Studio

FH-1£££/FH-1£££-££

FH-2£££/FH-2£££-££

FH-3£££/FH-3£££-££

FH-5£££/FH-5£££-££

FHV7£-£££££-C

FHV7£-£££££-S££/FHV7£-£££££-S££-££

FHV7£-£££££-H££/FHV7£-£££££-H££-££

Z343-E1-10

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

,

• QR Code is a registered trademark of DENSO W

AVE INCORPORATED.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the FH/FHV Series.

This manual contains information that is necessary to use the FH/FHV Series.

Please read this manual and make sure you understand the functionality and performance of the

FH/FHV Series before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• FH-1£££

• FH-1£££-££

• FH-2£££

• FH-2£££-££

• FH-3£££

• FH-3£££-££

• FH-5£££

• FH-5£££-££

• FH-L£££

• FH-L£££-££

• FHV7£-£££££-C

• FHV7£-£££££-S££/FHV7£-£££££-S££-££

• FHV7£-£££££-H££/FHV7£-£££££-H££-££

Part of the specifications and restrictions are given in other manuals. Refer to Relevant Manuals on

Relevant Manuals on page 2 and Related Manuals on page 18.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

1

Page 4

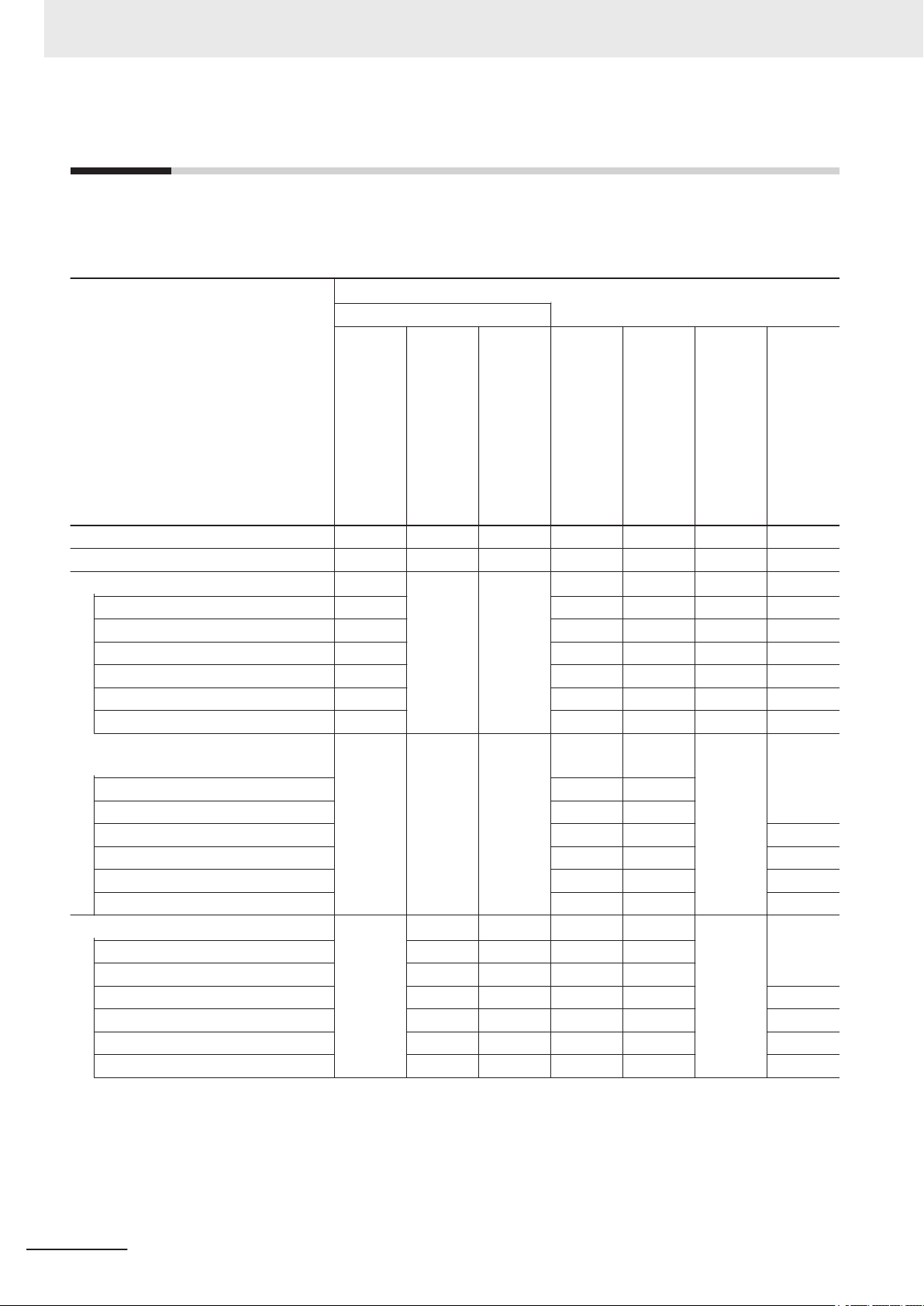

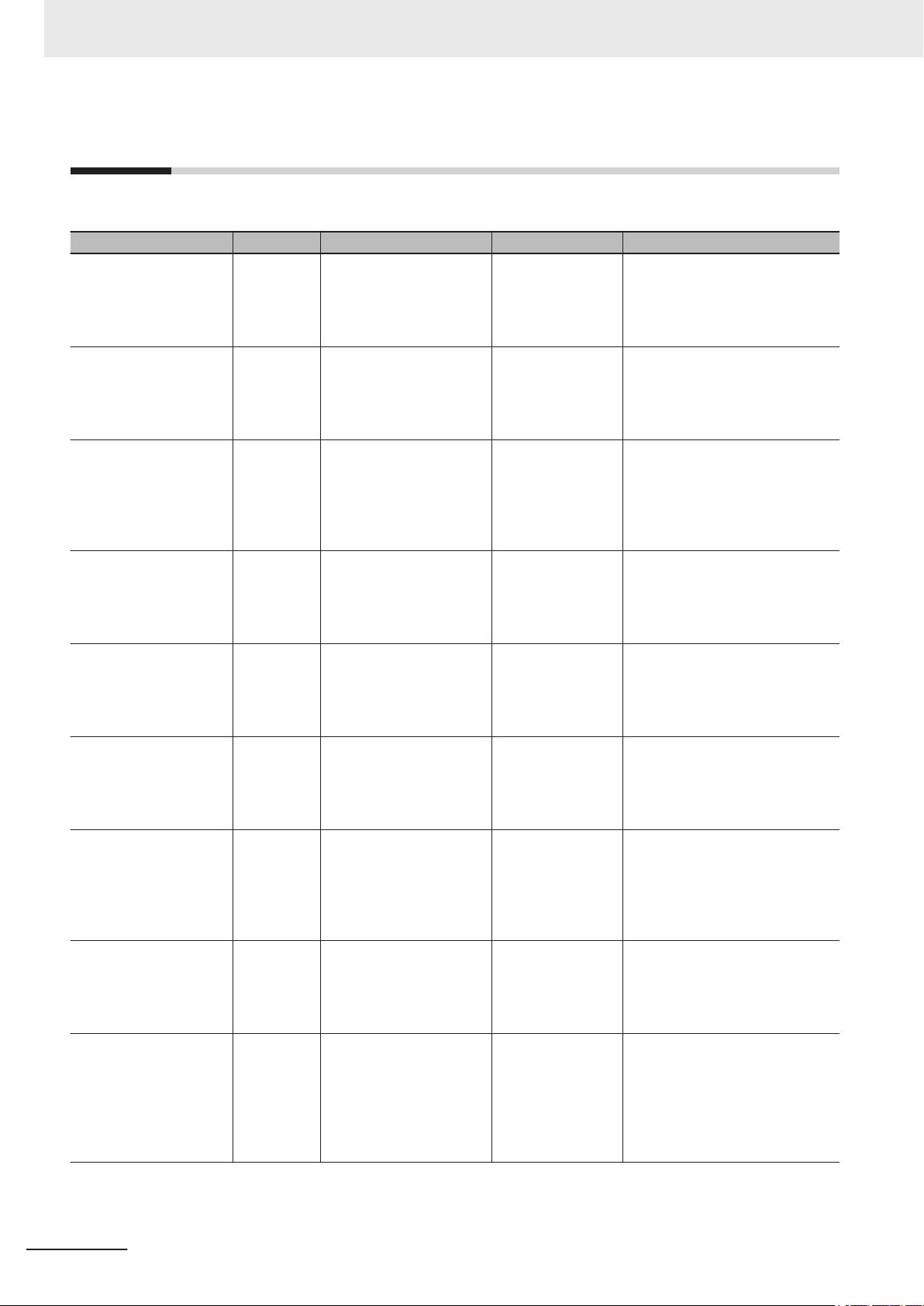

Relevant Manuals

Relevant Manuals

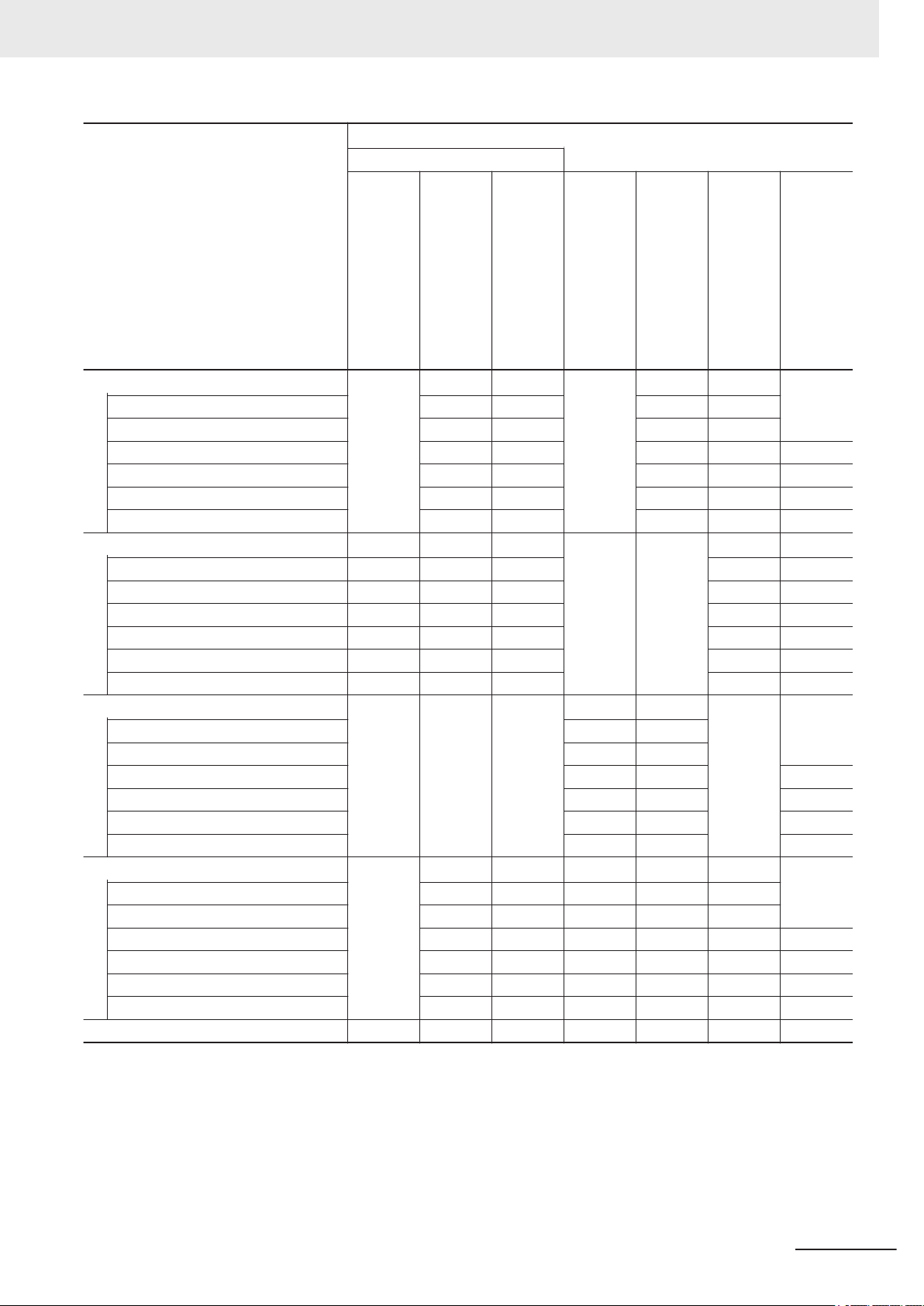

The following table provides the relevant manuals for the FH/FHV Series.

Read all of the manuals that are relevant to your system configuration and application before you use

the FH/FHV Series.

User's Manual

Purpose of use

Basic information

FH/FHV Series Vision System

FH Series Vision System

Hardware Setup Manual

Manual

FHV Series Smart Camera

Setup Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

Programming Manual

FH/FZ5 Series Vision System

Macro Customize Functions

FH/FHV Series Vision System

User’s Manual

for Communications Settings

FH/FHV Series Vision System

Operation Manual

for Sysmac Studio

Overview of FH series

Overview of FHV7 series

Setup and Wiring

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the communication setting of Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

l l

l l

l l

l

l l l l

l

l l

2

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 5

Purpose of use

Basic information

FH/FHV Series Vision System

User's Manual

Hardware Setup Manual

FH Series Vision System

FHV Series Smart Camera

Setup Manual

Relevant Manuals

Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

FH/FZ5 Series Vision System

Macro Customize Functions

Programming Manual

FH/FHV Series Vision System

User’s Manual

for Communications Settings

FH/FHV Series Vision System

Operation Manual

for Sysmac Studio

Create and Set the Scene

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Optimizing the Scene Flow

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Connecting the Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Using Helpful Functions

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Troubleshooting and Problem Solving

l

l l

l l

l

l l l l

l

l

l

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

3

Page 6

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simpl y b y p res sin g t he Un it s to ge th e r

and locking the sliders by moving them toward the back of the Units . The End Co v er is connect ed in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

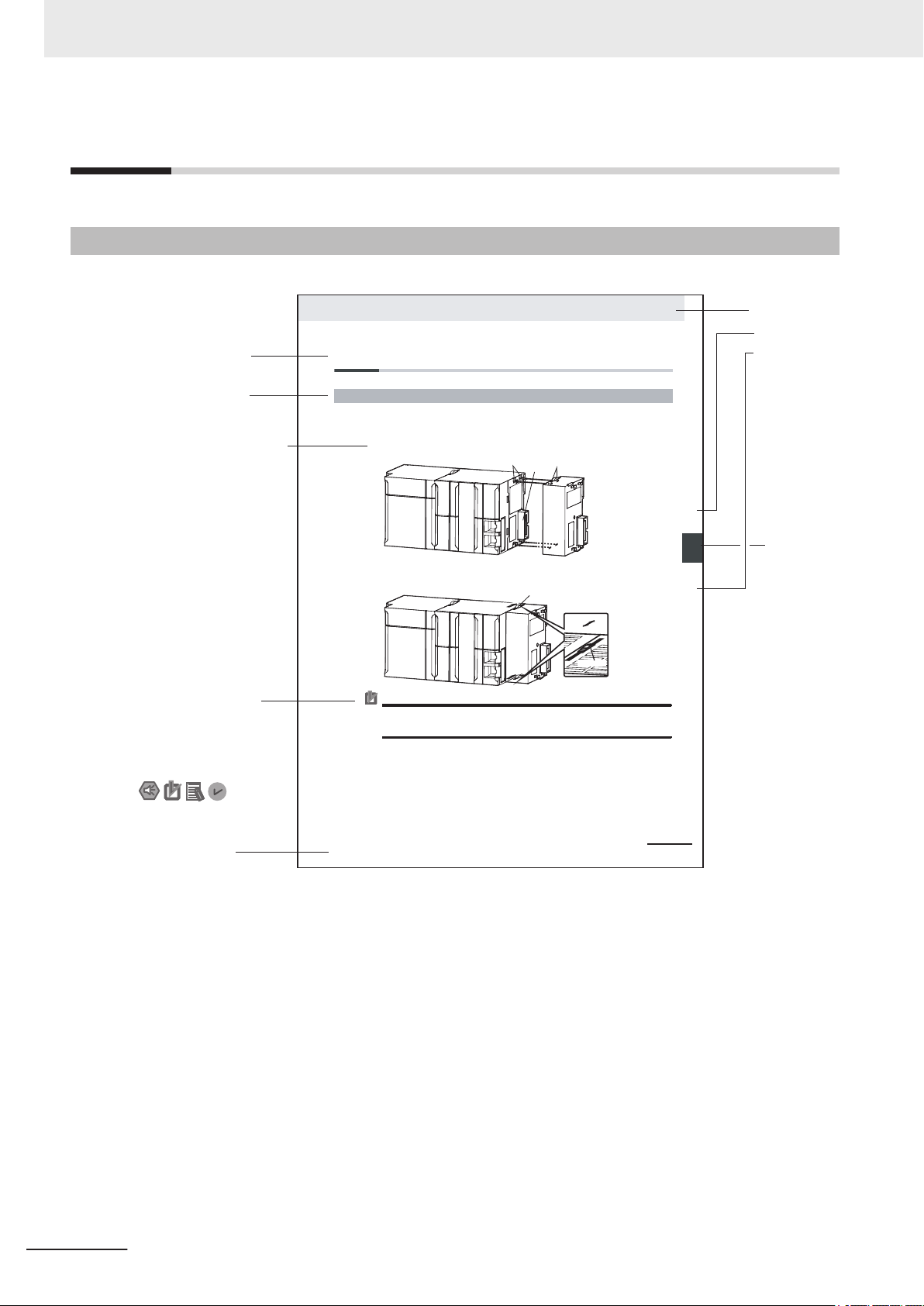

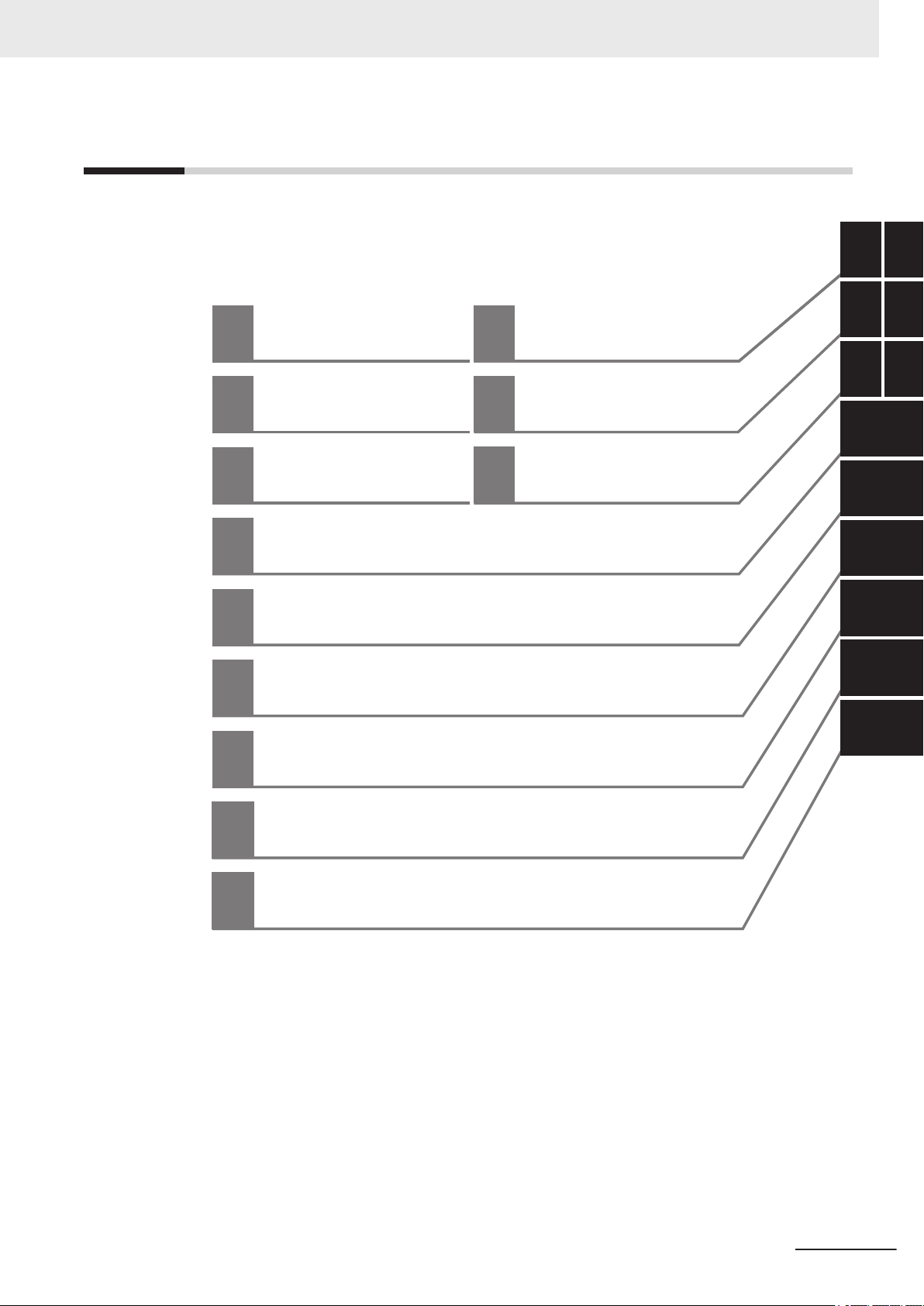

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

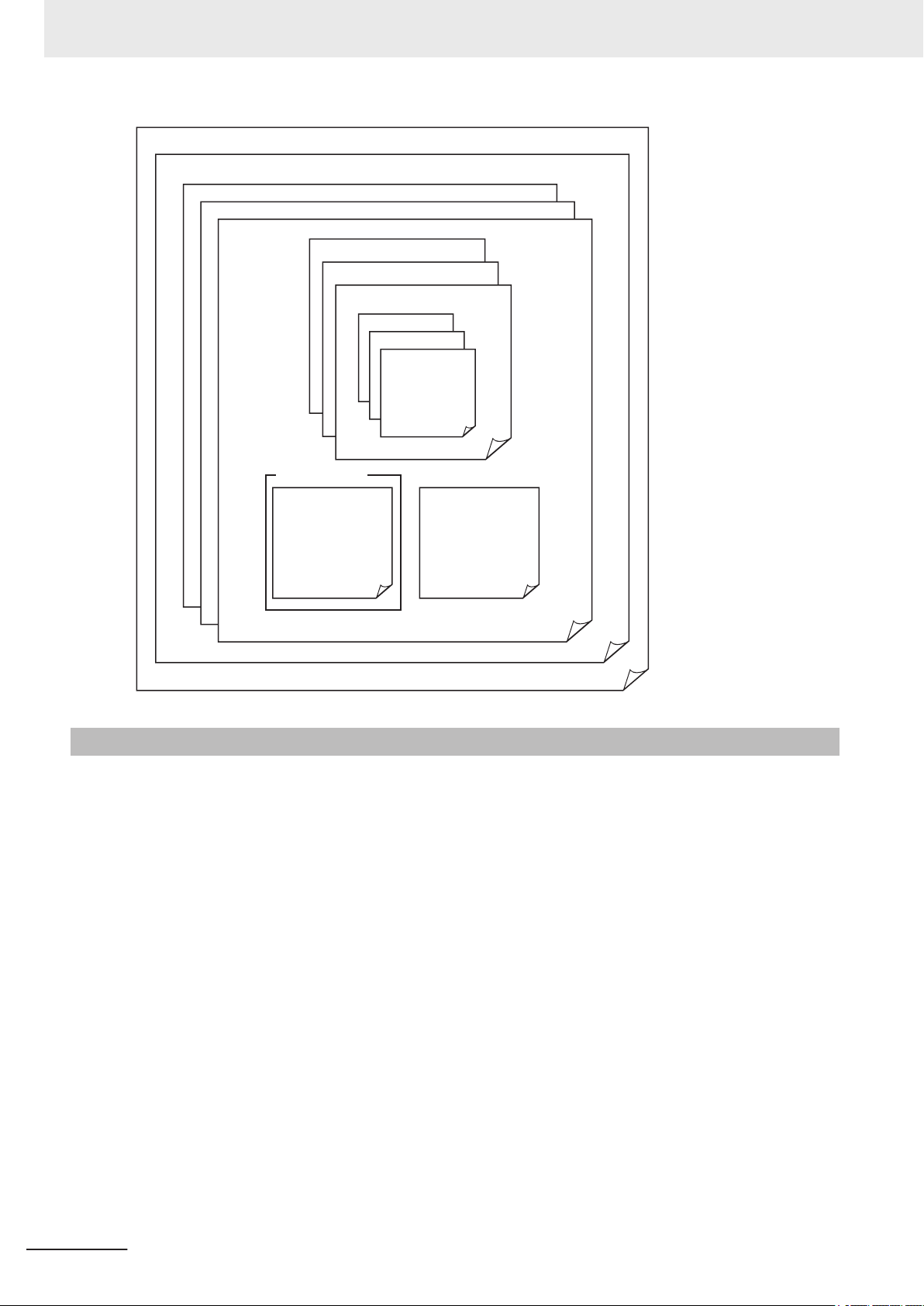

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier

Manual Structure

.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

5

Page 8

Manual Structure

6

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 9

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

Terms and Conditions Agreement........................................................................ 11

Warranty, Limitations of Liability .................................................................................................................... 11

Application Considerations ............................................................................................................................12

Disclaimers ....................................................................................................................................................12

Safety Precautions................................................................................................. 14

CONTENTS

...........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 15

Precautions for Correct Use ................................................................................. 16

Regulations and Standards .................................................................................. 17

Related Manuals..................................................................................................... 18

Terminology............................................................................................................ 20

Revision History..................................................................................................... 21

Sections in This Manual ........................................................................................ 23

Section 1 Overview

1-1 Supported Models................................................................................................................1 - 2

Project Management............................................................................................................1 - 3

1-2

1-2-1 Project data ...............................................................................................................................1 - 3

1-2-2 Project Data Handling in Different System Configurations........................................................1 - 4

Section 2 Basic Operations

2-1 Basic Design Flow 1 ............................................................................................................2 - 3

Basic Design Flow 2 ............................................................................................................2 - 5

2-2

2-3 Creating a New Project........................................................................................................2 - 7

2-3-1 Creating a New Project File from the Project Window ..............................................................2 - 7

2-3-2 Adding FH/FHV Device to a Project..........................................................................................2 - 8

2-3-3 Deleting FH/FHV Device from a Project....................................................................................2 - 9

2-4 Description of Screen Components.................................................................................2 - 10

2-4-1 Application Window.................................................................................................................2 - 10

2-4-2 Menu Bar.................................................................................................................................2 - 10

2-4-3 Toolbar .................................................................................................................................... 2 - 11

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

7

Page 10

CONTENTS

2-5 Basic Operations of Scene Data.......................................................................................2 - 31

2-6 Basic Operations of Flow Editing.....................................................................................2 - 35

2-7 Function List ......................................................................................................................2 - 39

2-8 Precautions on Synchronization through an NJ/NX/NY-series Controller...................2 - 44

2-4-4 Multiview Explorer ...................................................................................................................2 - 11

2-4-5

2-4-6 Toolbox ....................................................................................................................................2 - 29

2-5-1 Switching Scenes....................................................................................................................2 - 31

2-5-2 Managing Scenes ...................................................................................................................2 - 32

2-5-3 Entering Scene Information.....................................................................................................2 - 32

2-5-4 Searching for a Scene.............................................................................................................2 - 33

2-5-5 Switching Scene Groups.........................................................................................................2 - 33

2-5-6 Managing Scene Groups ........................................................................................................2 - 33

2-5-7 Entering Scene Group Information..........................................................................................2 - 34

2-6-1 Adding a Processing Unit........................................................................................................2 - 35

2-6-2 Managing Processing Units ....................................................................................................2 - 36

2-6-3 Searching for a Processing Unit..............................................................................................2 - 38

2-7-1 List of Functions Provided with the FH/FHV Tool ....................................................................2 - 39

2-7-2 Comparison with FH Series Unit Functions ............................................................................2 - 41

2-7-3 Comparison with FHV Series Unit Functions ..........................................................................2 - 42

2-8-1 Synchronized Project Data......................................................................................................2 - 44

2-8-2 Saving and Loading the Settings Data for the FH/FHV Sensor Controller..............................2 - 45

2-8-3 Transferring Data from the Sysmac Studio .............................................................................2 - 46

2-8-4 Transferring Data to the Sysmac Studio .................................................................................2 - 47

Edit Pane.................................................................................................................................2 - 13

Section 3 Connecting with a Vision Sensor

3-1 Connecting with a Vision Sensor ....................................................................................... 3 - 2

3-2

Adding FH/FHV Series Vision Sensor on the Network to a Project ................................3 - 3

3-3 Establishing an Online Connection with a Vision Sensor ...............................................3 - 4

3-3-1 Establishing an Online Connection from the Sensor Connection Screen .................................3 - 4

3-3-2 Establishing an Online Connection from the Multiview Explorer...............................................3 - 5

3-4 Synchronizing Project Data and Sensor Setting Data......................................................3 - 7

3-4-1 Transferring Project Data to the Sensor....................................................................................3 - 7

3-4-2 Transferring Setting data in the Sensor to a Project .................................................................3 - 8

3-5 Ending a Connection with a Vision Sensor.....................................................................3 - 10

3-5-1 Ending a Connection in the Sensor Connection Screen .........................................................3 - 10

3-5-2 Ending a Connection in the Multiview Explorer.......................................................................3 - 10

3-6 Logging in to a Registered User's Account ....................................................................3 - 11

Section 4 Configuring Measurement Settings

4-1 Overview of Processing Units ............................................................................................4 - 2

4-1-1

4-1-2 Measurement ............................................................................................................................4 - 2

4-1-3 Compensate Image...................................................................................................................4 - 2

4-1-4 Support Measurement...............................................................................................................4 - 3

4-1-5 Branch.......................................................................................................................................4 - 3

4-1-6 Output Result ............................................................................................................................4 - 3

4-1-7 Display Result ...........................................................................................................................4 - 3

4-2 Editing a Processing Unit ...................................................................................................4 - 5

4-2-1 Parameter Settings ...................................................................................................................4 - 5

4-2-2 Editing an Area..........................................................................................................................4 - 7

4-2-3 Color Extraction.......................................................................................................................4 - 10

4-2-4 Color........................................................................................................................................ 4 - 11

4-2-5 Binary ......................................................................................................................................4 - 11

Input Image ...............................................................................................................................4 - 2

8

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 11

4-2-6 Detection Point/Reference Point .............................................................................................4 - 11

4-2-7

4-2-8 Image Control Area .................................................................................................................4 - 12

List...........................................................................................................................................4 - 12

Section 5 Designing Exchange with External Devices

5-1 Designing Exchange with External Devices......................................................................5 - 2

5-2

Setting Procedure ................................................................................................................ 5 - 3

Section 6 Online Debugging

6-1 Performing Test Measurement ...........................................................................................6 - 2

6-1-1

6-1-2 Measuring File Images in the RAMDisk or the External Memory, i.e. USB Memory of

6-1-3 Measuring Logging Images in the Vision Sensor Memory........................................................6 - 3

6-2 Checking Measurement Results.........................................................................................6 - 4

6-2-1 Checking Detailed Results ........................................................................................................6 - 4

6-2-2 Changing the Image Display Settings .......................................................................................6 - 5

6-2-3 Checking Multiple Measurement Images at the Same Time.....................................................6 - 6

6-3 Checking Result Output ...................................................................................................... 6 - 7

6-4 Saving Measurement Results ............................................................................................. 6 - 8

6-5 Saving Settings Data ...........................................................................................................6 - 9

6-6 Loading Settings Data ....................................................................................................... 6 - 10

Measuring Camera Images.......................................................................................................6 - 2

the Vision Sensor ......................................................................................................................6 - 3

CONTENTS

Section 7 Offline Debugging

7-1 Performing Offline Simulation of Sensor Measurement Operation ................................7 - 2

7-2 Offline Debugging of the Sensor Control Program and Sensor Operation (Only

When Using EtherCAT Connection) ...................................................................................7 - 3

7-2-1 Control Signals Supported with Offline Debugging ...................................................................7 - 3

7-2-2 Offline Debugging Procedure for the Sensor Control Program.................................................7 - 4

Section 8 Other Useful Functions

8-1 Using the Command Customize Setting Tool ...................................................................8 - 2

Using the Calibration Support Tool....................................................................................8 - 3

8-2

8-3 Using the File Save Tool......................................................................................................8 - 4

8-3-1 Opening the File Save Tool .......................................................................................................8 - 4

8-3-2 Copying a File ...........................................................................................................................8 - 4

8-3-3 Saving a Logging Image as a File.............................................................................................8 - 5

8-4 Using the User Data Setting Tool .......................................................................................8 - 6

8-5 Changing the System Environment ...................................................................................8 - 7

8-6 Help .......................................................................................................................................8 - 9

8-7 Using the Security Setting Tool ........................................................................................8 - 10

8-8 Using the Scene Group Saving Destination Setting Tool .............................................. 8 - 11

8-9 Using the Image File Save Tool ........................................................................................8 - 12

8-9-1 Opening the Image File Save Tool ..........................................................................................8 - 12

8-9-2 Saving the Image File .............................................................................................................8 - 12

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

9

Page 12

CONTENTS

8-9-3 Saving the Logged Images to Files.........................................................................................8 - 13

8-10

Using the Registered image Manager..............................................................................8 - 15

8-11 Using the Update Standard Position Tool .......................................................................8 - 16

8-12 Using the Conversion Scene Group Data Tool ...............................................................8 - 17

8-13 Using the Scene Control Macro Tool ...............................................................................8 - 18

8-14 Print the Settings ...............................................................................................................8 - 19

8-15 Using the Conveyor Panorama Display tool ...................................................................8 - 20

8-16 Using the Conveyor Calibration Wizard tool...................................................................8 - 21

8-17 Using the Calibration Plate Print tool ..............................................................................8 - 22

Section 9 Limitations

9-1 Limitations............................................................................................................................9 - 2

9-2

Synchronization with the NJ/NX/NY-series Controllers ................................................... 9 - 8

Section 10 Troubleshooting

10-1 Troubleshooting for EtherCAT.......................................................................................... 10 - 2

10-2

Sysmac Error Status..........................................................................................................10 - 3

Appendices

A-1 Sysmac Device Features.................................................................................................... A - 2

A-1-1 Sysmac Error Status ................................................................................................................ A - 2

A-1-2 Saving the Node Address Setting ............................................................................................ A - 2

A-1-3 Serial Number Display ............................................................................................................. A - 3

A-1-4 Compliance with ESI Specification (ETG.2000 S (R) V1.0.1) .................................................. A - 3

A-1-5 SII Data Check ......................................................................................................................... A - 3

Index

10

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

l

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

l

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

l

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

11

Page 14

Terms and Conditions Agreement

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

W

ARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

’s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIP-

MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

. It may represent the result of

12

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

, some specifications of the Product may

Page 15

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’

time to confirm actual specifications of purchased Product.

s representative at any

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

13

Page 16

Safety Precautions

Safety Precautions

For details of Safety Precautions, refer to Safety Precautions in the Vision System FH/FHV Series Us-

er's Manual (Cat. No. Z365).

14

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 17

Precautions for Safe Use

For details of Precautions for Safe Use, refer to Precautions for Safe Use in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

Precautions for Safe Use

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

15

Page 18

Precautions for Correct Use

Precautions for Correct Use

For details of Precautions for Correct Use, refer to Precautions for Correct Use in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

16

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 19

Regulations and Standards

For details of Regulations and Standards, refer to Regulations and Standards in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

Regulations and Standards

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

17

Page 20

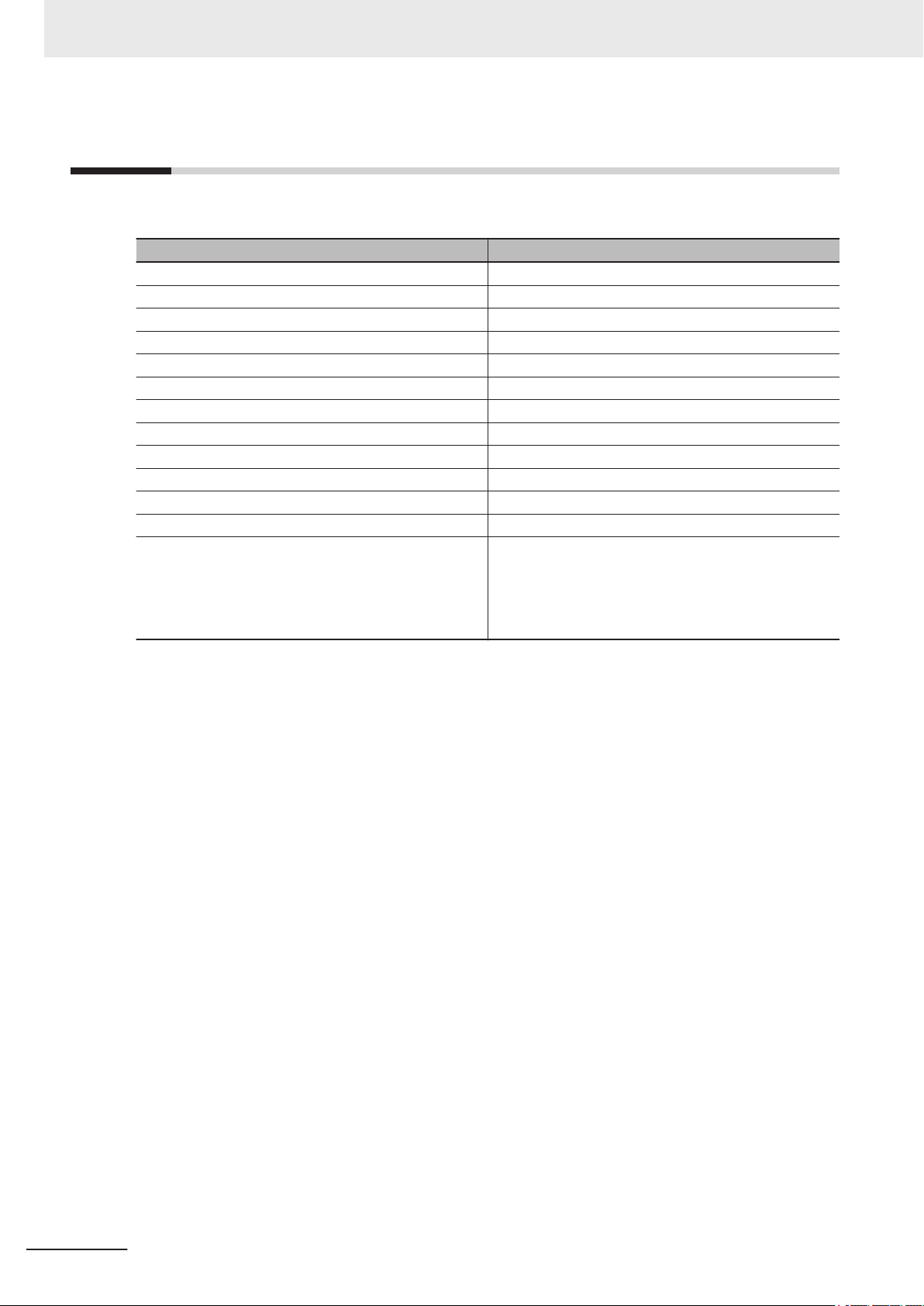

Related Manuals

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

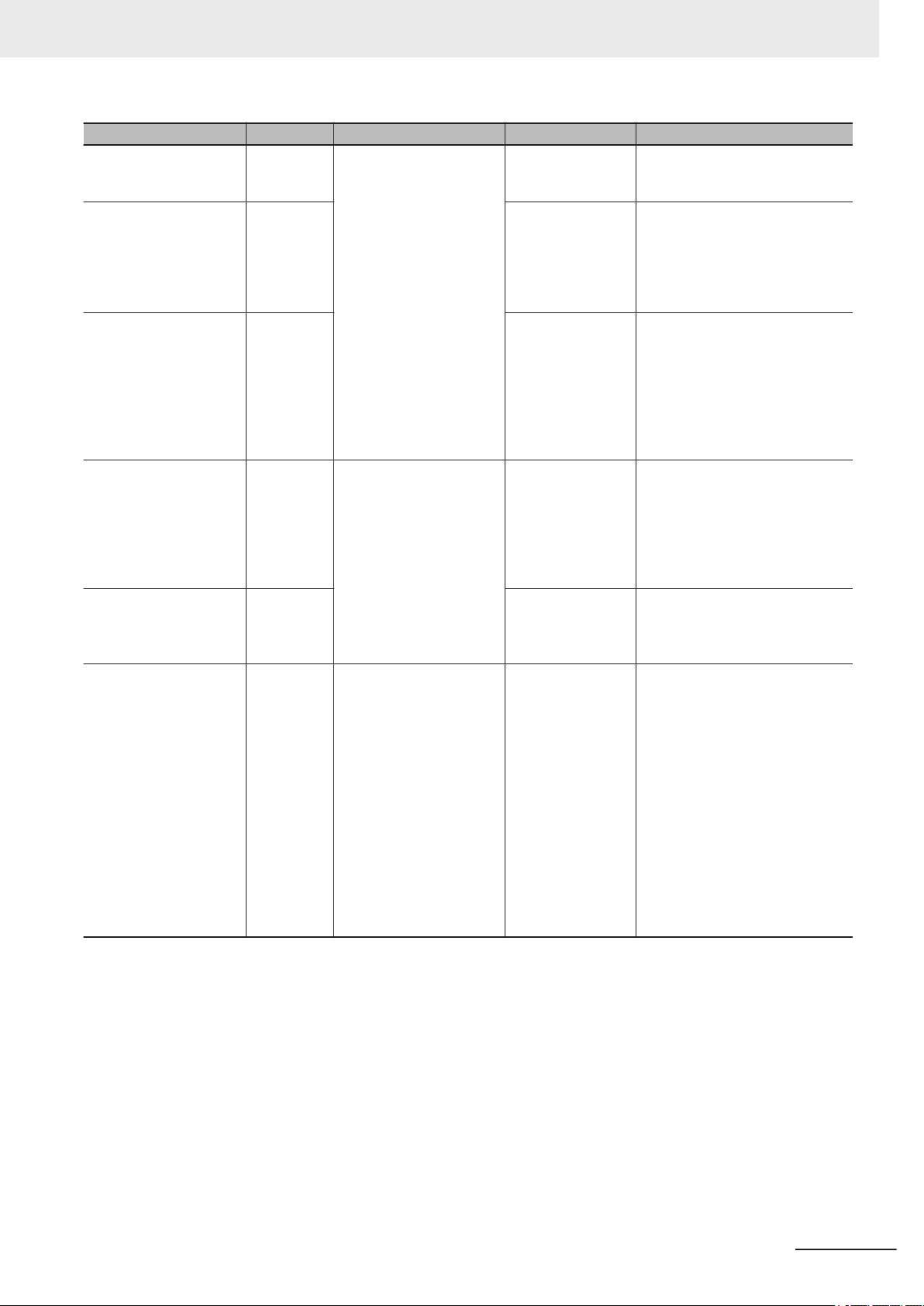

Name of Manual Cat. No.. Model Purpose Contents

Vision System

FH Instruction Sheet

Vision System

FH Instruction Sheet

Vision System

FH-L Instruction Sheet

Smart Camera

FHV Instruction Sheet

Smart Camera

Lighting Module

-LTM Instruction Sheet

FHV

Smart Camera Lens Module

-LEM-S Instruction

FHV

Sheet

Smart Camera High-Speed

Lens Module

-LEM-H Instruction

FHV

Sheet

Smart Camera Data Unit

FHV Instruction Sheet

FHV Series

Smart Camera

Setup Manual

9608337-2

3102269-4

9606631-1

3129404-0

3129276-4

3128622-5

3129408-2

3130057-0

Z408

FH-1£££

FH-1£££-££

FH-3£££

FH-3£££-££

FH-2£££

FH-2£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FHV7£-£££££-C

FHV-LTM££

FHV-LEM-S££

FHV-LEM-H££

FHV-SDU££

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller.

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller.

To confirm the safety

and usage precautions of the V

System FH-Lite series Sensor Controller.

To confirm the safety

and usage precautions of the Smart

Camera FHV7 series.

To confirm the safety

and usage precautions of the Smart

camera lighting module FHV-LTM.

To confirm the safety

and usage precautions of the Smart

camera lens module

FHV-LEM-S.

To confirm the safety

and usage precautions of the Smart

camera high-speed

lens module FHVLEM-H.

To confirm the safety

and usage precautions of the Smart

Camera Data Unit.

When User want to

know about the hardware specifications

or to setup the Smart

camera FHV series.

ision

ision

ision

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH

series in the manual.

To confirm the safety and usage precautions of the Vision System FH

series Sensor Controller.

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH-L

series in the manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

FHV7 series in the manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lighting module FHV-LTM in the

manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lens module FHV-LEM-S.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the high-speed lens module FHVLEM-H.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the Smart Camera Data Unit in the

manual.

Describes FHV series specifications,

dimensions, part names, I/O information, installation information, and

wiring information.

18

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 21

Name of Manual Cat. No.. Model Purpose Contents

Vision System

FH/FHV Series

User's Manual

Vision System

FH/FHV/FZ5 series

Processing Item Function

Reference Manual

Vision System

FH/FHV/FZ5 Series

User's manual for Communications Settings

Vision System

FH/FZ5 series

Hardware Setup Manual

Vision System

FH series

Macro Customize Functions Programming Manual

Vision System

FH/FHV Series

Operation Manual

for Sysmac Studio

Z365

Z341 When User confirm

Z342 When User confirm

Z366

Z367 When User operate

Z343

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

When User want to

know about the

FH/FHV series.

the details of each

processing items at

the create the measurement flow or operate it.

the setting of communication functions.

When User want to

know about the

Hard-ware specifications or to setup the

Sensor Controller of

ision System

the V

FH/FZ5 series.

or programming using Macro Customize

functions.

When User connect

to NJ series via

T communi-

EtherCA

cation.

Describes the soft functions, setup,

and operations to use FH/FHV series/

Describes the software functions,

settings, and operations for using

FH/FHV/FZ5 series.

Describes the functions, settings,

and communications methods for

communication between

FH/FHV/FZ5 series and PLCs.

The following communications protocol are described.

Parallel, PLC Link, EtherNet/IP

EtherCAT, and Non-procedure.

Describes FH/FZ5 series specifications, dimensions, part names, I/O

information, installation information,

and wiring information.

Describes the functions, settings,

and operations for using Macro Customize function of the FH series.

Describes the operating procedures

for setting up and operating FH/FHV

series Vision Sensors from the Sysmac Studio FH/FHV Tools.

Related Manuals

,

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

19

Page 22

Terminology

Terminology

• For descriptions of the Controller terms that are used in this manual, refer to information on terminol-

ogy in the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

• For descriptions of the FH/FHV Series terms that are used in this manual, refer to information on

terminology in the FH/FHV Series Vision System User's Manual (Cat. No. Z365).

20

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 23

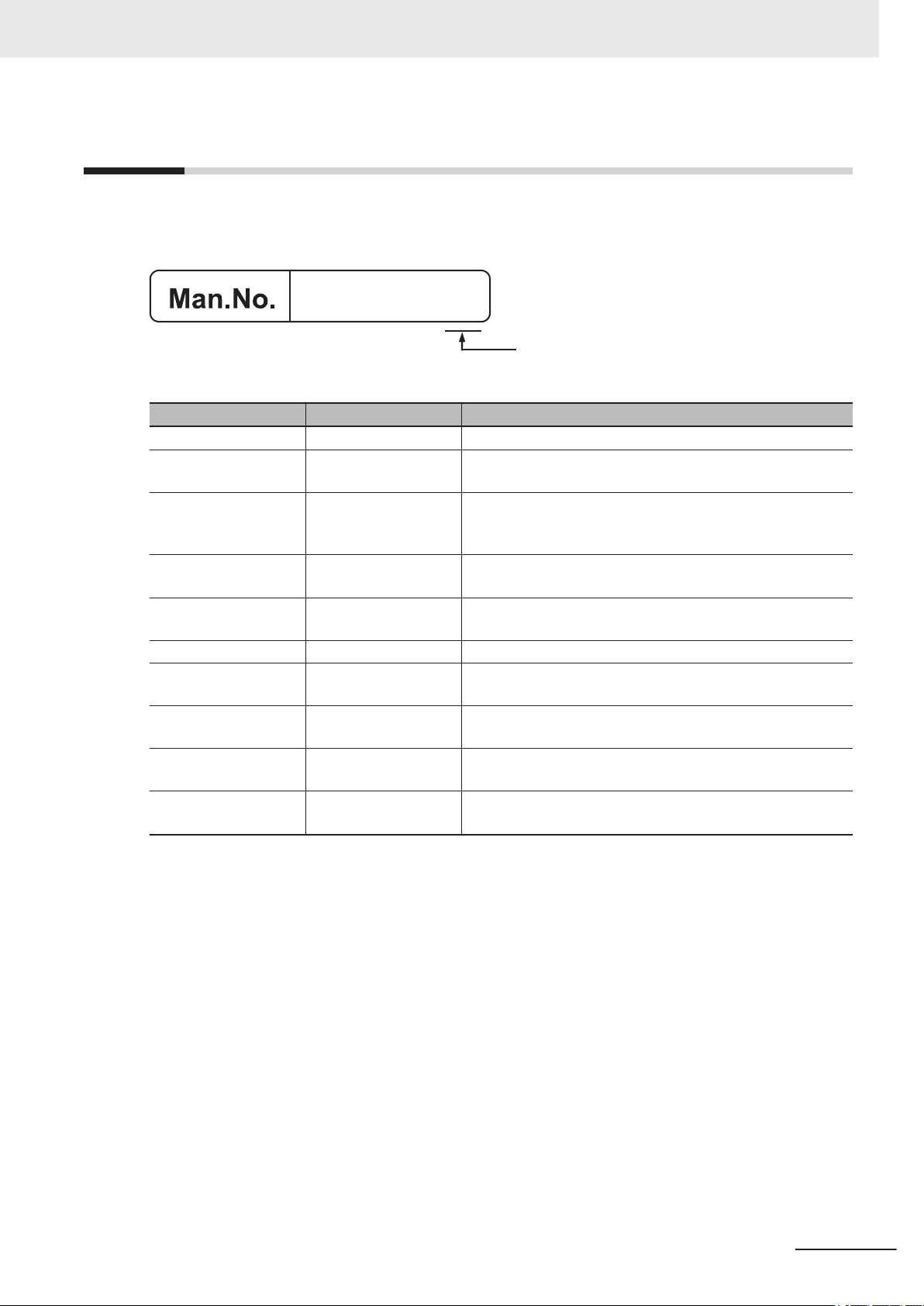

Revision History

Z343-E1-10

Revision Code

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Rev. Code Rev. Date Revision Contents

01 Jun. 2013 First edition.

02 Sep 2013 Added offline debugging function, Support for software ver-

03 Jan. 2014 Added additional supported processing units, added support

04 Jul. 2014 Additions for software version upgrade. Support for software

05 Oct. 2015 Additions for software version upgrade and FH Sensor Con-

06 Apr. 2016 Corrections sentences related other manuals.

07 Apr. 2017 Additions for software version upgrade and FH Sensor Con-

08 Jun. 2017 Additions for software version upgrade and FH Sensor Con-

09 Jul. 2018 Additions for software version upgrade and FH Sensor Con-

10 Oct. 2019 Additions for software version upgrade, FHV Smart Camera

Revision History

sion 5.1 of the FH sensor controller

for multiple FH unit settings, added a security function, expanded data transfer functions.

version 5.20 of the FH sensor controller

troller ver

troller ver

troller ver

troller ver

ver

.5.50.

.5.71.

.5.72.

.6.10.

.6.30 and FH Sensor Controller ver.6.20, 6.30.

.

.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

21

Page 24

Revision History

22

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 25

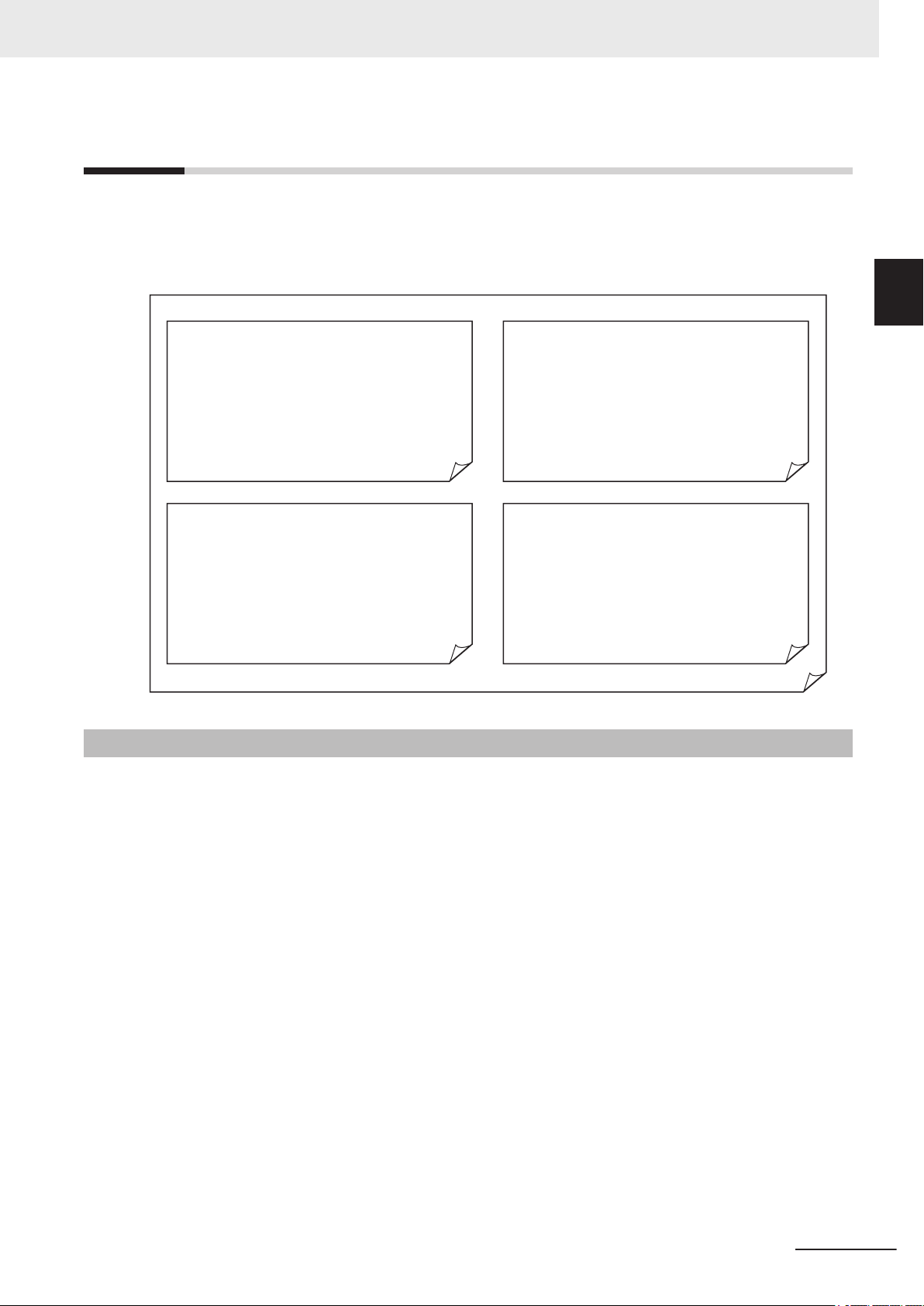

Sections in This Manual

1

10

2

3

4

5

6

7

8

9

1

10

2

3

A

I

4

5

6

7

8

9

Overview Troubleshooting

Basic Operations Appendices

Connecting with

a Vision Sensor

A

I

Index

Designing Exchange with External Devices

Configuring Measurement Settings

Online Debugging

Offline Debugging

Other Useful Functions

Limitations

Sections in This Manual

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

23

Page 26

Sections in This Manual

24

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 27

Overview

This Chapter describes the functional specifications of the Sysmac Studio FH/FHV

tools (hereinafter referred to as "FH/FHV tools").

1-1

1-2 Project Management ....................................................................................1 - 3

1

Supported Models........................................................................................ 1 - 2

1-2-1 Project data................................................................................................... 1 - 3

1-2-2 Project Data Handling in Different System Configurations ........................... 1 - 4

1

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

1 - 1

Page 28

1 Overview

1-1

Supported Models

The FH/FHV tools support the following models in the FH/FHV Vision Sensor series.

Connection Device Type Description

FH-5050 High-speed controller for 2-channel camera type

FH-5050-10 High-speed controller for 4-channel camera type

FH-5050-20 High-speed controller for 8-channel camera type

FH-3050 High-speed controller for 2-channel camera type

FH-3050-10 High-speed controller for 4-channel camera type

FH-3050-20 High-speed controller for 8-channel camera type

FH-2050 High-speed controller for 2-channel camera type

FH-2050-10 High-speed controller for 4-channel camera type

FH-2050-20 High-speed controller for 8-channel camera type

FH-1050 Standard controller for 2-channel camera type

FH-1050-10 Standard controller for 4-channel camera type

FH-1050-20 Standard controller for 8-channel camera type

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-££

FHV7£-£££££-H££

FHV7£-£££££-H££-££

Smart Camera

1 - 2

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 29

Project data

Data related to the NJ/NX/NY-series Controller Data related to the FH/FHV sensor

Data related to Servo Drives Data related to other vision sensors

1 Overview

1-2 Project Management

1-2

Project Management

Sysmac Studio manages the configuration information of each of the controller, servo, and vision sen-

sor devices on a project basis.

Here, we describe the contents of the project data related to the FH/FHV Series and how the data is

managed.

1

1-2-1 Project data

1-2-1

Project data

Eight FH/FHV vision sensor series devices can be registered to one project.

In the FH/FHV Series, the following types of data provided by Sysmac Studio are managed as project

data.

Scene group data (scene data)

•

• System data

• Tool data (communications command macros, security settings, and other data)

By using the Multi-line Random-trigger Mode, the FH sensor controller independently processes multi-

ple processing lines at the same time. In Multi-line Random Trigger mode, the above data is controlled

separately for each line. (It can not be used with the FHV series.)

Project data manages this data together as one batch. These data can also be exported and imported

individually as file data.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

1 - 3

Page 30

Sensor

Line

Project data

Line

Line

Scene group data

Scene group data

Command

customize

data

System

data

Tool data

Scene data

Scene group data

Scene data

Scene data

1 Overview

1-2-2

Project Data Handling in Different System Configurations

The contents of the Sysmac Studio project data and the data being synchronized varies depending on

the connection method (i.e., Ethernet direct connection or connection through an NJ/NX/NY

Controller) between the FH/FHV sensor and the computer that runs Sysmac Studio. Particularly with

the connection through an NJ/NX/NY-series Controller, there are restrictions on some Sysmac Studio

functions. Be sure you understand the following before operation.

For details, refer to the 2-8 Precautions on Synchronization through an NJ/NX/NY-series Controller on

page 2 - 44.

-series

1 - 4

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 31

USB/Ethernet

EtherCAT

Sysmac Studio NJ/NX/NY-series Controller

FH/FHV

Ethernet

Sysmac Studio

FH/FHV

Configurations and Setup

Configurations and Setup

EtherCAT

CPU/Expansion

Racks

POUs Data

System data

Tool data

Tasks

I/O Map

Controller Setup

Task SetupEvent Setup

Motion Control

Setup

Cam Data

Settings

Scene group

data

Data that the NJ/NX/NY-series

Controller manages

Data that the FH/FHV

sensor manages

Project data

System data

Tool data

Scene group

data

Data that the FH/FHV

sensor manages

Project data

1 Overview

1-2 Project Management

System configuration

Project data that the

Sysmac Studio

manages

Connection through an NJ/NX/NY-series

Controller (when executing an

NJ/NX/NY project)

The sensor data unit (FHV-SDU30) is required for EtherCA

T connection between

NJ/NX/NY-series Controller and FHV sensor.

For details, refer to FHV Series Smart

Camera Setup Manual (Cat. No. Z408).

There are two types of data: the data that

the NJ/NX/NY

-series Controller manages

and the data that the FH/FHV sensor manages.

Ethernet direct connection

(when executing an FH/FHV project)

1

1-2-2 Project Data Handling in Different System Configurations

There is the data that the FH/FHV sensor

manages.

Data to be

synchronized with

Sysmac Studio

Available functions

in Sysmac Studio

that control the

FH/FHV sensor

Online

Available functions

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

in Sysmac Studio

that control the

FH/FHV sensor

fline

Of

The data that the NJ/NX/NY-series Controller manages within the project data that

Sysmac Studio manages is synchronized.

Because the data that the FH/FHV sensor

manages (i.e., the settings data for the

FH/FHV sensor) is not synchronized, the

settings for the FH/FHV sensor need to be

synchronized separately

.

For details, refer to the 2-8 Precautions on

Synchronization through an NJ/NX/NY-series Controller on page 2 - 44.

Checking the data output from the FH/FHV

sensor sent through EtherCA

T is possible.

Making setting changes, and creating and

adjusting the measurement flows for the

FH/FHV are not possible.

Checking the data output from the FH/FHV

sensor sent through EtherCAT is possible.

Making setting changes on the FH/FHV

sensor, creating and adjusting the measurement flows for the FH/FHV in addition to

checking the output data from the FH/FHV

sensor are all possible.

The data that the FH/FHV sensor manages

(i.e., the settings data for the FH/FHV sensor) within the project data that Sysmac

Studio manages is synchronized.

For details, refer to the 3-4 Synchronizing

Project Data and Sensor Setting Data on

page 3 - 7.

Making setting changes on the FH/FHV

sensor, creating and adjusting the measurement flows for the FH/FHV in addition to

checking the output data from the FH/FHV

sensor are all possible.

Making setting changes on the FH/FHV

sensor, creating and adjusting the measurement flows for the FH/FHV in addition to

checking the output data from the FH/FHV

sensor are all possible.

1 - 5

Page 32

1 Overview

Downloading the

settings data for the

FH/FHV sensor

Uploading the settings data for the

FH/FHV sensor

Connection through an NJ/NX/NY-series

Controller (when executing an

NJ/NX/NY project)

The settings data for the FH/FHV sensor is

not downloaded.

Performing the data downloading from

Sysmac Studio will not download the data

that the FH/FHV sensor manages within

the project data that Sysmac Studio manages. Therefore, the settings for the

FH/FHV sensor will not be overwritten.

There are following two methods to download the FH/FHV settings data to the

FH/FHV sensor

.

• Directly connecting to the FH/FHV sen-

sor and downloading the data.

• Extracting the data from Sysmac Studio

and loading it to the FH/FHV sensor via

the external memory.

The settings data for the FH/FHV sensor is

not uploaded.

After performing the data uploading to Sysmac Studio, all the FH/FHV settings data

values (i.e., the scene group data, the system data, the communications command

macros, and the security settings data) that

the FH/FHV sensor manages within the

project data that Sysmac Studio manages

will be reset to the factory defaults.

The device variables related to the FH/FHV

sensor in the I/O Map are uploaded.

There are following two methods to transfer the settings data for the FH/FHV sensor

to Sysmac Studio.

• Directly connecting to the FH/FHV sen-

sor and uploading the data.

• Save the settings data in the FH/FHV

sensor in the external memory and load

it to Sysmac Studio via the external

memory.

Ethernet direct connection

(when executing an FH/FHV project)

Downloading the FH/FHV settings data

from Sysmac Studio is possible.

If the FH/FHV sensor is connected to the

computer that runs Sysmac Studio via

Ethernet, downloading the FH/FHV settings

data from Sysmac Studio to the FH/FHV

sensor is possible by transferring the

project data that the Sysmac Studio manages to the FH/FHV sensor via the Ethernet.

If not connected, right-click the FH/FHV

sensor in the Multiview Explorer and select

Save file from the menu to save the data in

the external memory. Then, load the data

in the external memory to the FH/FHV sensor.

Uploading the settings data for the FH/FHV

sensor to Sysmac Studio is possible.

If the FH/FHV sensor is connected to the

computer that runs Sysmac Studio via

Ethernet, loading the data in the FH/FHV

sensor to Sysmac Studio project is possible by transferring the FH/FHV settings data to the project via Ethernet.

If not connected, connect the external

memory that holds the FH/FHV settings data to the computer that runs Sysmac Studio. Then, right-click the FH/FHV sensor in

the Multiview Explorer and select Load

from file from the menu to load the data.

1 - 6

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 33

Configurations and Setup

Configurations and

Setup

EtherCAT

CPU/Expansion Racks

Data

System data

Tool data

Tasks

I/O Map

Controller Setup

Task Setup

Event Setup

Motion Control Setup

Cam Data Settings

Scene group data

Data that the NJ/NX/NY-series Controller manages

Data that the FH/FHV sensor manages

Project data

1 Overview

Precautions for Correct Use

The data that the NJ/NX/NY-series Controller manages and the data that the FH/FHV sensor

manages are handled separately on Sysmac Studio except for the I/O Map data that the

NJ/NX/NY

FH/FHV sensor manages. Because of this, the information in the I/O Map will be updated and

changed after editing the data that the FH/FHV sensor controller manages (i.e., the settings data for the FH/FHV sensor).

-series Controller manages. The I/O Map is associated to the system data that the

1-2 Project Management

1

1-2-2 Project Data Handling in Different System Configurations

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

1 - 7

Page 34

1 Overview

1 - 8

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 35

2

2

Basic Operations

This chapter describes the basic design flow and design items for using Sysmac Studio.

Note:

•

The contents of the Sysmac Studio project data and the data being synchronized

varies depending on the connection method (i.e., Ethernet direct connection or connection through an NJ/NX/NY-series Controller) between the FH/FHV sensor and

the computer that runs Sysmac Studio.

• For information on connection through an NJ/NX/NY-series Controller, refer to

2-8 Precautions on Synchronization through an NJ/NX/NY-series Controller on page

2 - 44.

2-1 Basic Design Flow 1 .................................................................................... 2 - 3

2-2 Basic Design Flow 2 .................................................................................... 2 - 5

2-3 Creating a New Project ................................................................................2 - 7

2-3-1 Creating a New Project File from the Project Window.................................. 2 - 7

2-3-2 Adding FH/FHV Device to a Project ............................................................. 2 - 8

2-3-3 Deleting FH/FHV Device from a Project ....................................................... 2 - 9

2-4 Description of Screen Components ......................................................... 2 - 10

2-4-1 Application Window .................................................................................... 2 - 10

2-4-2 Menu Bar .................................................................................................... 2 - 10

2-4-3 Toolbar .........................................................................................................2 - 11

2-4-4 Multiview Explorer........................................................................................2 - 11

2-4-5 Edit Pane .................................................................................................... 2 - 13

2-4-6 Toolbox ....................................................................................................... 2 - 29

2-5 Basic Operations of Scene Data............................................................... 2 - 31

2-5-1 Switching Scenes ....................................................................................... 2 - 31

2-5-2 Managing Scenes ....................................................................................... 2 - 32

2-5-3 Entering Scene Information ........................................................................ 2 - 32

2-5-4 Searching for a Scene ................................................................................ 2 - 33

2-5-5 Switching Scene Groups ............................................................................ 2 - 33

2-5-6 Managing Scene Groups ............................................................................ 2 - 33

2-5-7 Entering Scene Group Information ............................................................. 2 - 34

2-6 Basic Operations of Flow Editing............................................................. 2 - 35

2-6-1 Adding a Processing Unit ........................................................................... 2 - 35

2-6-2 Managing Processing Units ........................................................................ 2 - 36

2-6-3 Searching for a Processing Unit ................................................................. 2 - 38

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

2 - 1

Page 36

2 Basic Operations

2-7 Function List............................................................................................... 2 - 39

2-7-1

2-7-2 Comparison with FH Series Unit Functions ................................................ 2 - 41

2-7-3 Comparison with FHV Series Unit Functions.............................................. 2 - 42

List of Functions Provided with the FH/FHV Tool ....................................... 2 - 39

2-8 Precautions on Synchronization through an NJ/NX/NY-series

Controller ..................................................................................................... 2 - 44

2-8-1 Synchronized Project Data ......................................................................... 2 - 44

2-8-2 Saving and Loading the Settings Data for the FH/FHV Sensor Controller . 2 - 45

2-8-3 Transferring Data from the Sysmac Studio................................................. 2 - 46

2-8-4 Transferring Data to the Sysmac Studio..................................................... 2 - 47

2 - 2

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 37

2 Basic Operations

2-1

Basic Design Flow 1

This section describes the flow for designing a system that uses NJ/NX/NY-series CPU Unit as a con-

troller.

For details on the program on the NJ/NX/NY-series CPU Unit side, task design, and debugging, refer

to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Precautions for Correct Use

The settings data for the FH/FHV sensor cannot be synchronized with the data in the Sysmac

Studio project via an NJ/NX/NY-series Controller.

For details, refer to 2-8 Precautions on Synchronization through an NJ/NX/NY-series Controller

on page 2 - 44.

To synchronize them, directly connect the FH/FHV sensor to the computer that runs Sysmac

Studio via Ethernet.

For details, refer to 3-4 Synchronizing Project Data and Sensor Setting Data on page 3 - 7.

New project settings

Create a project file.

2-1 Basic Design Flow 1

2

(1) Starting Sysmac Studio

Start Sysmac Studio.

For details, refer to Starting and Exiting the Sysmac Studio in the Sysmac Studio Version 1

Operation Manual (Cat. No. W504).

(2) Designing a new project

Create a new project.

For details, refer to Creating a Project File in the Sysmac Studio Version 1 Operation Manual

(Cat. No. W504).

Controller configuration and settings

• Controller configuration:

Creating an EtherCAT configuration

(1)

Register FH/FHV as an EtherCAT slave in EtherCAT.

For details, refer to EtherCAT Configuration and Settings in the Sysmac Studio Version 1

Operation Manual (Cat. No. W504).

Registering device variables

(2)

When using or using after editing device variables for the user defined variables to connect the

FH/FHV I/O information and program, register the device variables in I/O Map.

For details, refer to Creating Device Variables in the Sysmac Studio Version 1 Operation

Manual (Cat. No. W504).

• Controller settings:

Editing slave parameters

(1)

Edit the Operation Settings of the slaves.

For details, refer to Creating the EtherCAT Slave Terminal Configuration in the Sysmac Studio

Version 1 Operation Manual (Cat. No. W504).

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

2 - 3

Page 38

2 Basic Operations

Sensor connection

Establish an online connection with the sensor.

(1) Connecting a sensor

For details, refer to S

Design

Create the processing flow.

(1) Creating flow

For details, refer to 2-6 Basic Operations of Flow Editing on page

(2) Editing processing units

For details, refer to 4-2 Editing a Processing Unit on page 4 - 5.

ection 3 Connecting with a Vision Sensor on page 3 - 1.

2 - 35.

Online debugging of sensor

Perform debugging using the actual device.

(1) Performing test measurement

Perform test measurement on sample work. Adjust the parameters if necessary

For details, refer to Section 6 Online Debugging on page 6 - 1.

.

2 - 4

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 39

2 Basic Operations

2-2

Basic Design Flow 2

This section describes the flow for designing a system that uses a controller other than NJ/NX/NY-ser-

ies CPU Unit.

New project settings

Create a project file.

(1) Starting Sysmac Studio

Start Sysmac Studio.

For details, refer to Starting and Exiting the Sysmac Studio in the Sysmac Studio Version 1

Operation Manual (Cat. No. W504).

(2) Designing a new project

Create a new project.

Select a vision sensor for the category and FH/FHV for the device.

For details, refer to 2-3 Creating a New Project on page 2 - 7.

(3) Selecting sensor type

Select the sensor type and then establish an online connection.

For details, refer to the step 3 on 2-3-1 Creating a New Project File from the Project Window on

page 2 - 7.

2-2 Basic Design Flow 2

2

Sensor configuration and settings

• Sensor configuration:

(1) Creating an interface configuration for the sensor

Edit the interface configuration.

For details, refer to 5-2 Setting Procedure on page 5 - 3.

• Sensor settings:

(1) Editing the communication conditions

Edit the communication conditions of the sensor.

For details, refer to 5-2 Setting Procedure on page 5 - 3.

Design

Create the processing flow.

(1) Creating flow

For details, refer to 2-6 Basic Operations of Flow Editing on page 2 - 35.

(2) Editing processing units

For details, refer to 4-2 Editing a Processing Unit on page 4 - 5.

Online debugging of sensor

Perform debugging using the actual device.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

2 - 5

Page 40

2 Basic Operations

(1) Performing test measurement

Perform test measurement on sample work. Adjust the parameters if necessary

For details, refer to Section 6 Online Debugging on page 6 - 1.

.

2 - 6

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 41

2 Basic Operations

2-3

2-3-1

Creating a New Project

This section describes how to create a new project file. For details on the basic operations, refer to

Creating a Project in the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Here, we describe how to create a new project for the FH/FHV vision sensor (hereinafter referred to as

"FH/FHV project").

Creating a New Project File from the Project Window

1 Click the New Project button in the project window

2 In the Project Properties dialog box, enter the information in Project name, Author (option-

al), and Comment (optional), select the following device from Category and Device of Select

Device, and click the Create button.

Item Setting

Category Vision sensor

Device

.

• FH

• FHV

2-3 Creating a New Project

2

2-3-1 Creating a New Project File from the Project Window

3 Select the FH/FHV vision sensor to connect to.

When establishing an online connection, click Search for sensors and then click the Search

button. The found sensors are displayed in a list. Select the sensor you wish to connect to and

then click the OK button.

If you know the IP address of the sensor you wish to connect to beforehand or will connect to a

sensor via a router

dress in IP address. After input is complete, click the OK button.

If you wish to edit the settings offline, click Enter the type, select the Type and Version items

for the sensor you wish to edit, and then click the OK button.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

, select the Specify the IP address check box and then enter the IP ad-

2 - 7

Page 42

2 Basic Operations

4 A new project is created.

The project file is created and the next screen appears.

2-3-2

2 - 8

Precautions for Correct Use

• An online connection cannot be established if the FH/FHV device registered to the project

and the actual device are not the same type and version.

•

If there is already a different FH/FHV slave device in the project with an established online

connection, you will not be able to establish an online connection for a new FH/FHV slave

device. To establish an online connection for a new FH/FHV slave device, switch the other

FH/FHV slave device from online to offline.

Adding FH/FHV Device to a Project

You can add an FH/FHV device to a project.

Right-click the Device Group and select Add - FH or Add - FHV.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 43

The sensor selection screen appears. Select the sensor type.

The selected FH/FHV device is registered.

2 Basic Operations

2-3 Creating a New Project

2

2-3-3 Deleting FH/FHV Device from a Project

2-3-3

Deleting FH/FHV Device from a Project

You can delete FH/FHV device from a project.

Right-click the FH/FHV vision sensor you wish to delete and select Delete.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

2 - 9

Page 44

4)

2 Basic Operations

2-4

2-4-1

Description of Screen Components

This section describes the screen components in FH/FHV project.

For a description of the screen components in NJ/NX/NY-series CPU Unit project, refer to Parts of the

Window in the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Application Window

2-4-2

No. Name

1 Menu Bar

2 Toolbar

3 Multiview Explorer

4 Edit Pane

5 Toolbox

Menu Bar

Menu Name Description

File Close Closes the project.

Save Saves the project.

Save As Saves the project with a different name.

Save As New Number Saves the project with a new update number.

Import Imports an exported file so that it can be edited in the tool.

Export Saves the project as an external file.

Exit Closes Sysmac Studio.

Edit Copy Copies the selected item.

Paste Pastes the copied item.

Delete Deletes the selected item.

2 - 10

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 45

Menu Name Description

View Multiview Explorer Displays the Multiview Explorer.

Toolbox Displays the Toolbox.

Reset Window Layout Resets the window layout.

Insert Controller Inserts an NJ or NX project.

Displacement Sensor Inserts a ZW project.

Vision Sensor Inserts an FH or FHV project.

Tools Options Displays the Options menu.

Help Help Contents Displays V

Sysmac Studio (Cat. No. Z343).

Keyboard Mapping Reference Displays the shortcut key reference.

Online Registration Performs online registration.

About Sysmac Studio Displays the version of Sysmac Studio.

ision System FH/FHV Series Operation Manual

2 Basic Operations

2-4 Description of Screen Components

2

2-4-3 Toolbar

2-4-3

2-4-4

Toolbar

Button Name Description

Copy Copies the selected item.

Paste Pastes the copied item.

Delete Deletes the selected item.

Help Displays V

Sysmac Studio (Cat. No. Z343).

ision System FH/FHV Series Operation Manual

Multiview Explorer

• This pane will be the access point for all data of the FH/FHV series.

•

You can right-click any data item that can be set and select an item from the menu (context menu).

You can also display various editing screens in the Edit Pane.

• Multiview Explorer can be displayed or hidden by clicking the display/hide bar on the left side of the

window. Even when hidden, it can be displayed temporarily by placing the mouse pointer over the

display/hide bar. Moving the mouse pointer away from the bar returns the Multiview Explorer to the

hidden state.

Item list that make up the Multiview Explorer and the menu items displayed by right-clicking

Tree View Items Menu Item Description

Device Group Add - FH/FHV Adds a sensor to the project.

Rename Changes the device group name.

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

2 - 11

Page 46

2 Basic Operations

Tree View Items Menu Item Description

Type Edit Displays the main screen in the Edit Pane.

Line X

(X=0,1,,,7)

Scene data Edit Displays the scene data editing screen in the Edit

System data Edit Displays the system data editing screen in the Edit

Tools Communica-

tion Command

Macro

Delete Deletes the sensor from the project.

Restart Restarts the sensor.

Online Switches the connection state with the sensor to on-

line.

Offline Switches the connection state with the sensor to off-

line.

Stop offline editor Ends the offline editor.

Ends the following application.

• FZ-CoreRA<current_line_number_0_to_7>.exe

Change Version Changes the sensor version.

When the version is changed, the setting data is initialized.

This menu item only appears in NJ/NX/NY Project.

Monitor window Displays the monitor window in the Edit Pane.

Scene maintenance window

Save data Saves the sensor settings data to non-volatile memory.

Copy Copies setting data of the line.

Paste Pastes the copied setting data of the line.

Rename Changes the line name.

Save to file Saves scene group 0 + system data to a file.

Load from file Loads scene group 0 + system data from a file.

Print Displays the print settings parameters in the Edit

Copy Copies the scene group data.

Paste Pastes the scene group data.

Delete Deletes the scene group data.

Save to file Saves the scene group data to a file.

Load from file Loads the scene group data from a file.

Copy Copies the system data.

Paste Pastes the system data.

Delete Deletes the system data.

Save to file Saves the system data to a file.

Load from file Loads the system data from a file.

Edit Displays the communication command macro tool in

Copy Copies the communication command macro data.

Paste Pastes the communication command macro data.

Delete Deletes the communication command macro data.

Save to file Saves the communication command macro data to a

Load from file Loads the communication command macro data from

Displays the Scene maintenance window in the Edit

Pane.

Pane.

Pane.

Pane.

the Edit Pane.

file.

a file.

2 - 12

FH/FHV Series Vision System Operation Manual for Sysmac Studio (Z343-E1)

Page 47

2 Basic Operations

Tree View Items Menu Item Description

Calibration

Support T

User Data Edit Displays the user data tool in the Edit Pane.

Save file Edit Displays the file saving tool in the Edit Pane.

Conveyor

Panorama

Display

Image file

save

Scene Control

macro tool

Conveyor Calibration Wizard

Scene Group

Saving Destination Settings

Calibration

Plate Print

Security settings

Registered image

Manager

Update standard position

tool

Conversion

scene group

data tool Edit

Edit Displays the calibration support tool in the Edit Pane.

ool

Edit Displays the Conveyor Panorama Display tool in the

Edit Pane.