Page 1

Vision Sensor

FHV Series

Smart Camera

Setup Manual

FHV7H-££££

Z408-E1-01

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

• QR Code is a registered trademark of DENSO WAVE INCORPORATED.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the FHV Series Smart Camera.

This manual contains information that is necessary to use the FHV Series Smart Camera.

Please read this manual and make sure you understand the functionality and performance of the FHV

Series Smart Camera before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• FHV7H-££££

Part of the specifications and restrictions are given in other manuals. Refer to Relevant Manuals on

Relevant Manuals on page 2 and Related Manuals on page 23.

FHV Series Smart Camera Setup Manual (Z408-E1)

1

Page 4

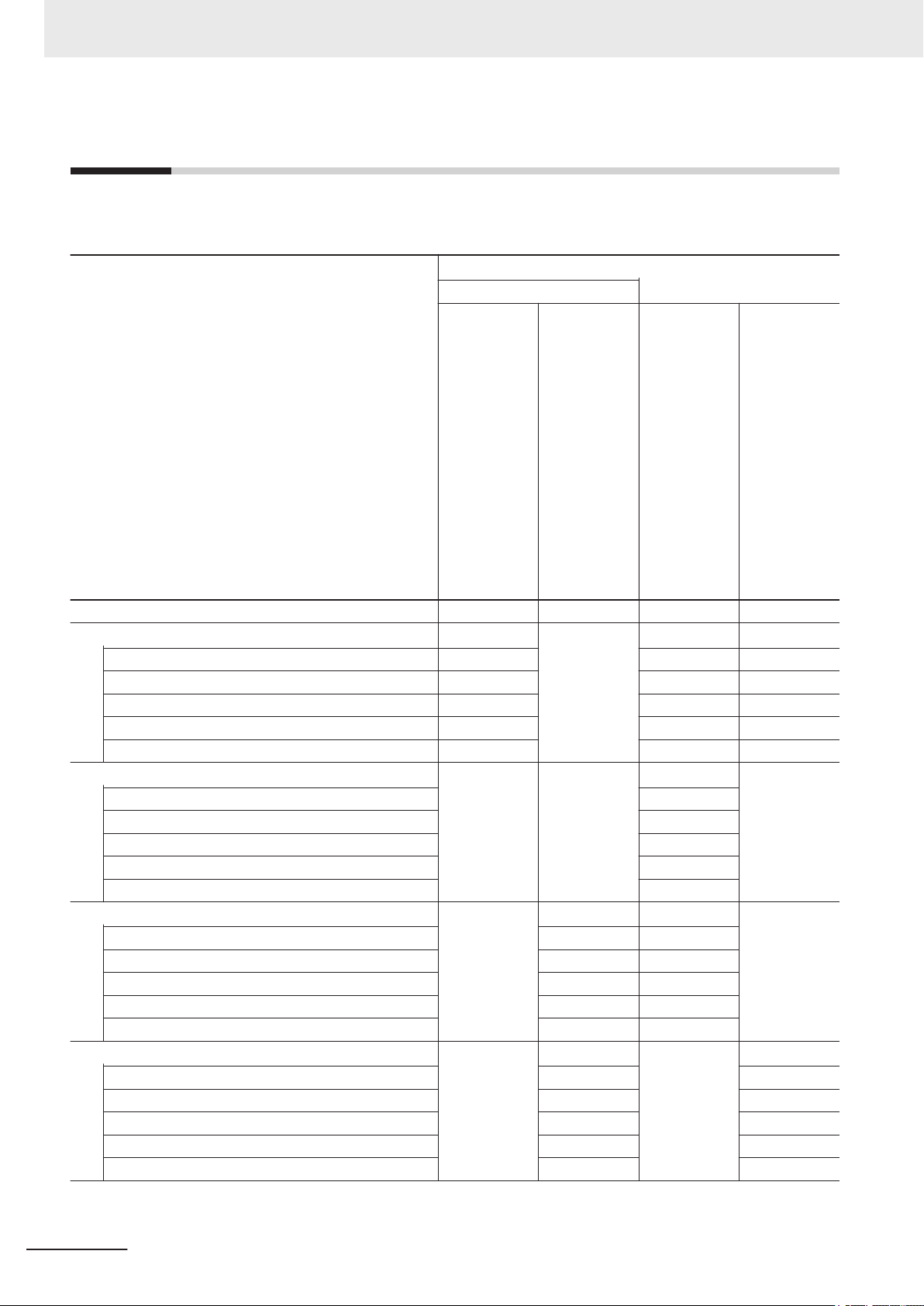

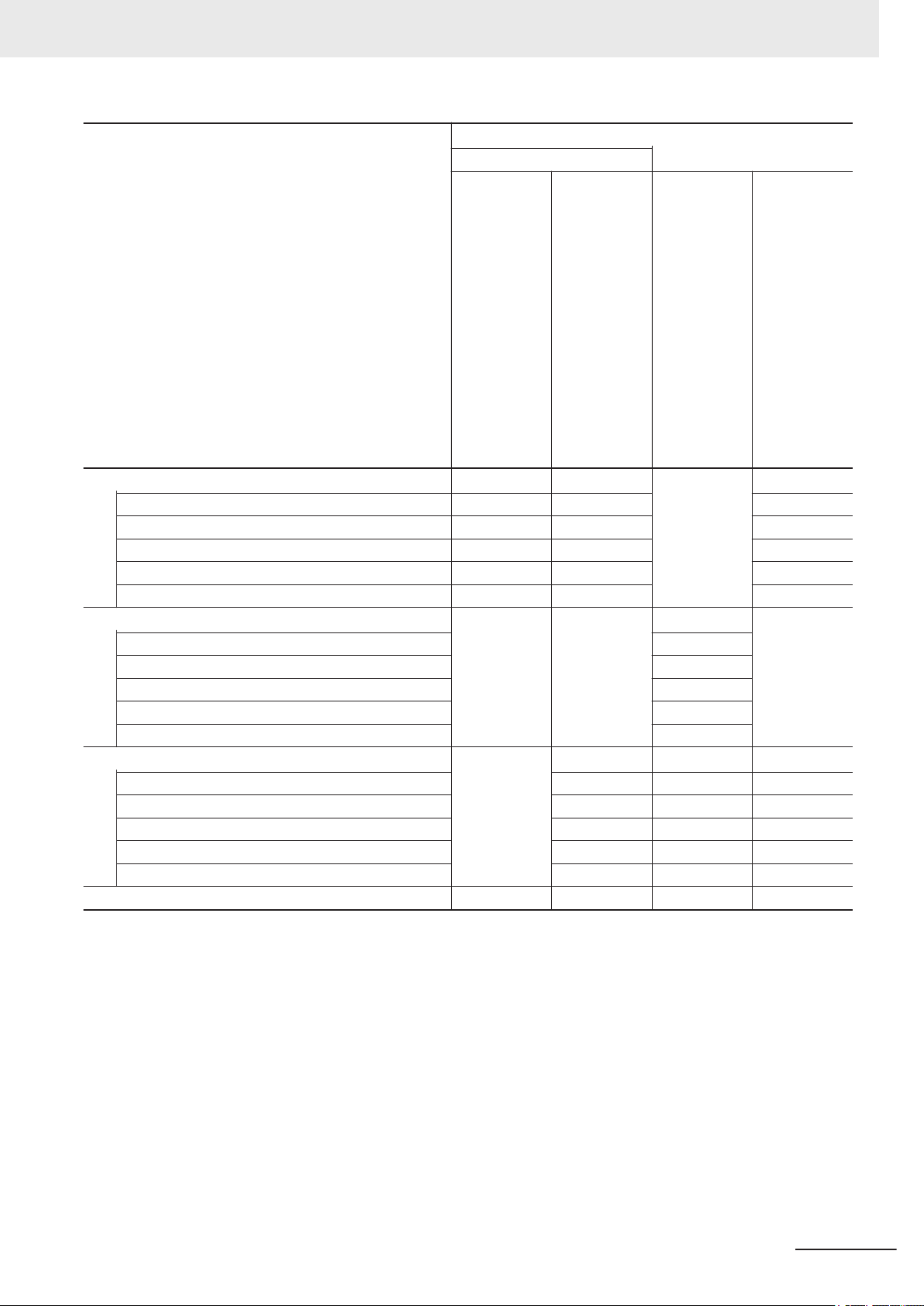

Relevant Manuals

Relevant Manuals

The following table provides the relevant manuals for this product. Read all of the manuals that are

relevant to your system configuration and application before you use this product.

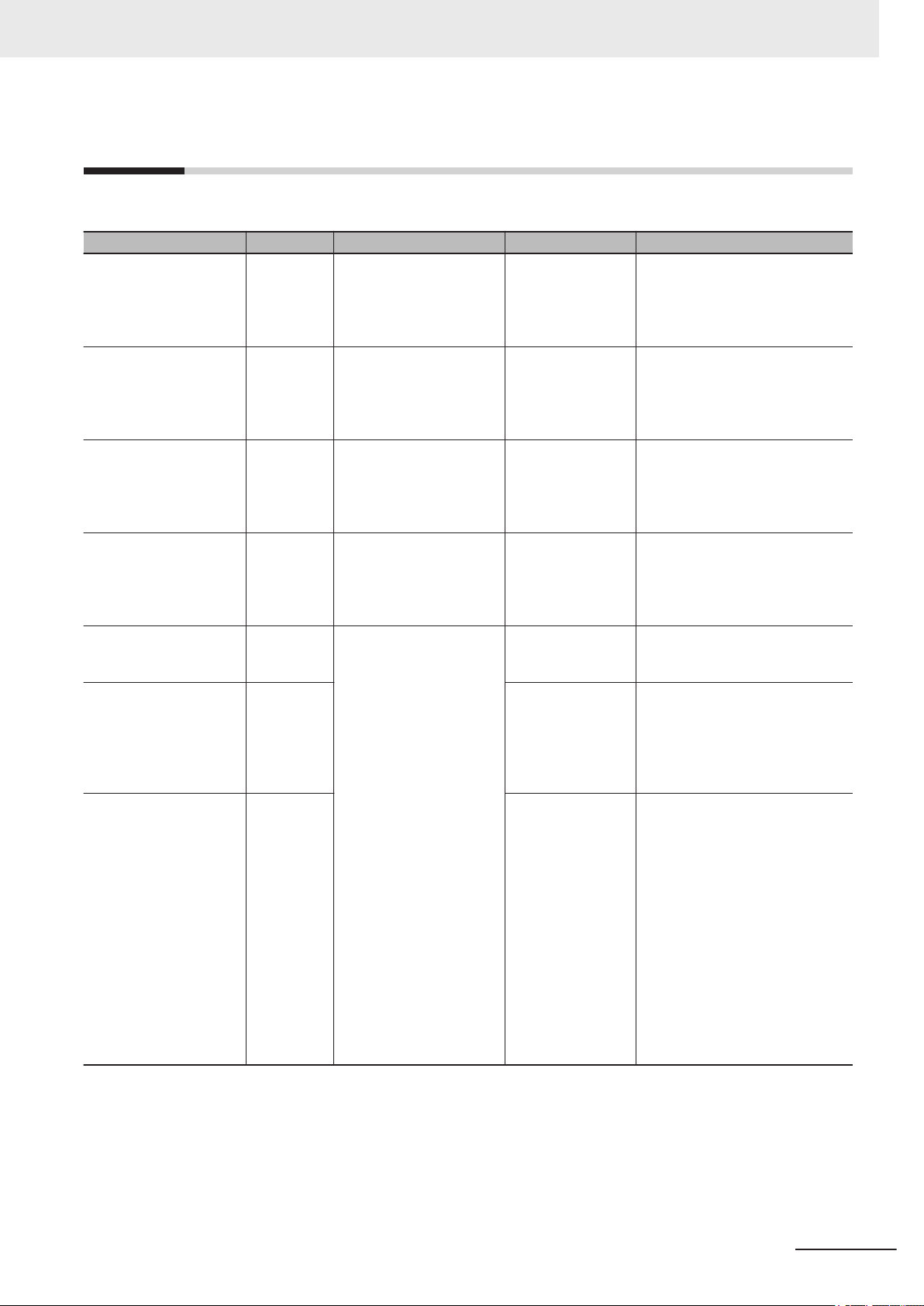

Information Reference Matrix

Manual

Basic information

Vision System FH/FHV/FZ5 Series

User's Manual

Vision System FHV Series

Smart Camera

Setup Manual

Vision System FH/FHV/FZ5 Series

Processing Item Function

Reference Manual

Vision System FH/FHV/FZ5 Series

User’s Manual for Communications Settings

Overview of FHV7 series

Setup and Wiring

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the communication setting of Smart Camera

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the Smart Camera

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Create and Set the Scene

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

l l

l

l l l

l l

l l

2

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 5

Information Reference Matrix

Optimizing the Scene Flow

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Connecting the Controller

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Using Helpful Functions

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Troubleshooting and Problem Solving

Relevant Manuals

Manual

Basic information

Vision System FH/FHV/FZ5 Series

User's Manual

l l l

l

l

Vision System FHV Series

Smart Camera

Setup Manual

Reference Manual

Vision System FH/FHV/FZ5 Series

Processing Item Function

l

Vision System FH/FHV/FZ5 Series

User’s Manual for Communications Settings

FHV Series Smart Camera Setup Manual (Z408-E1)

3

Page 6

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

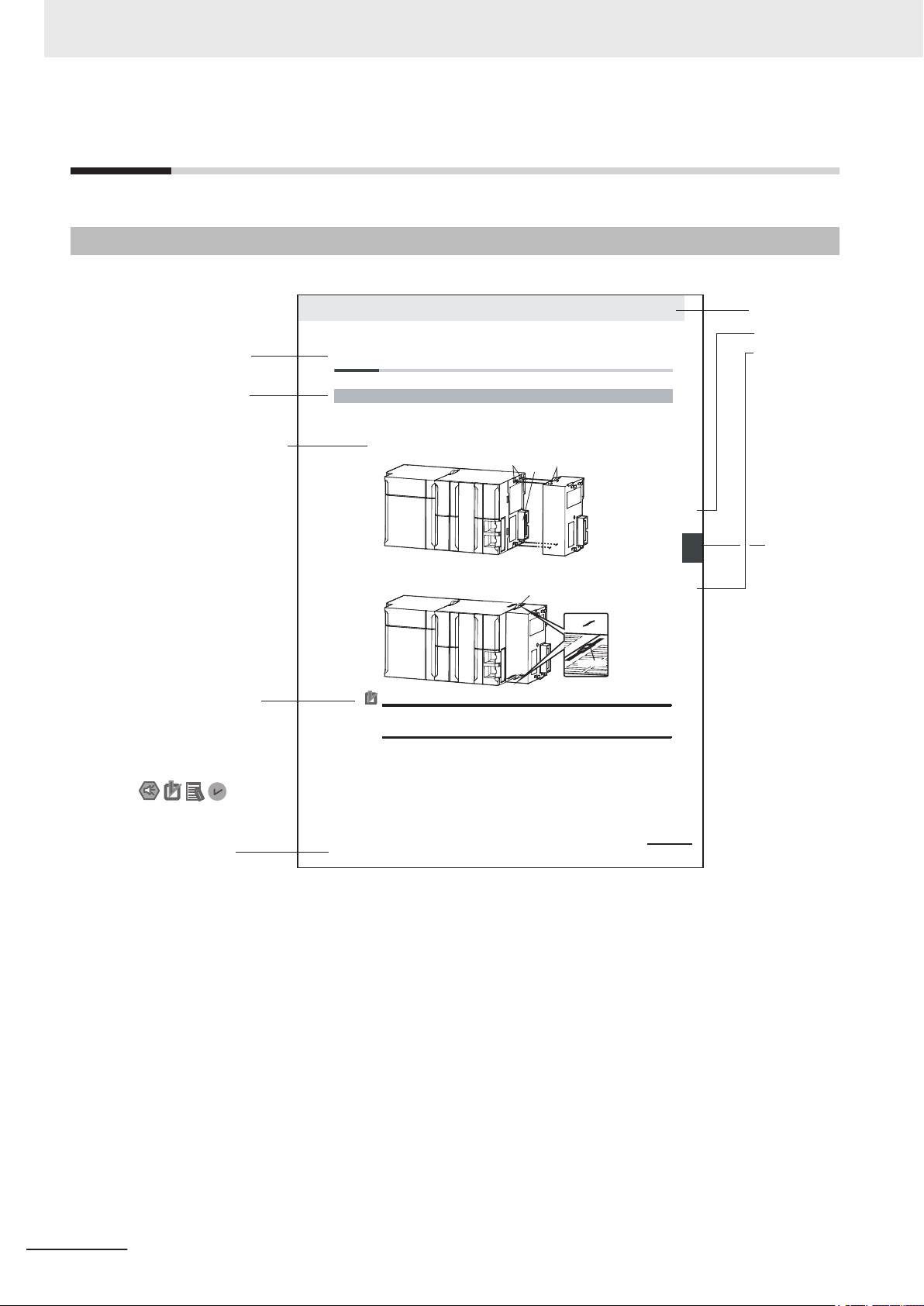

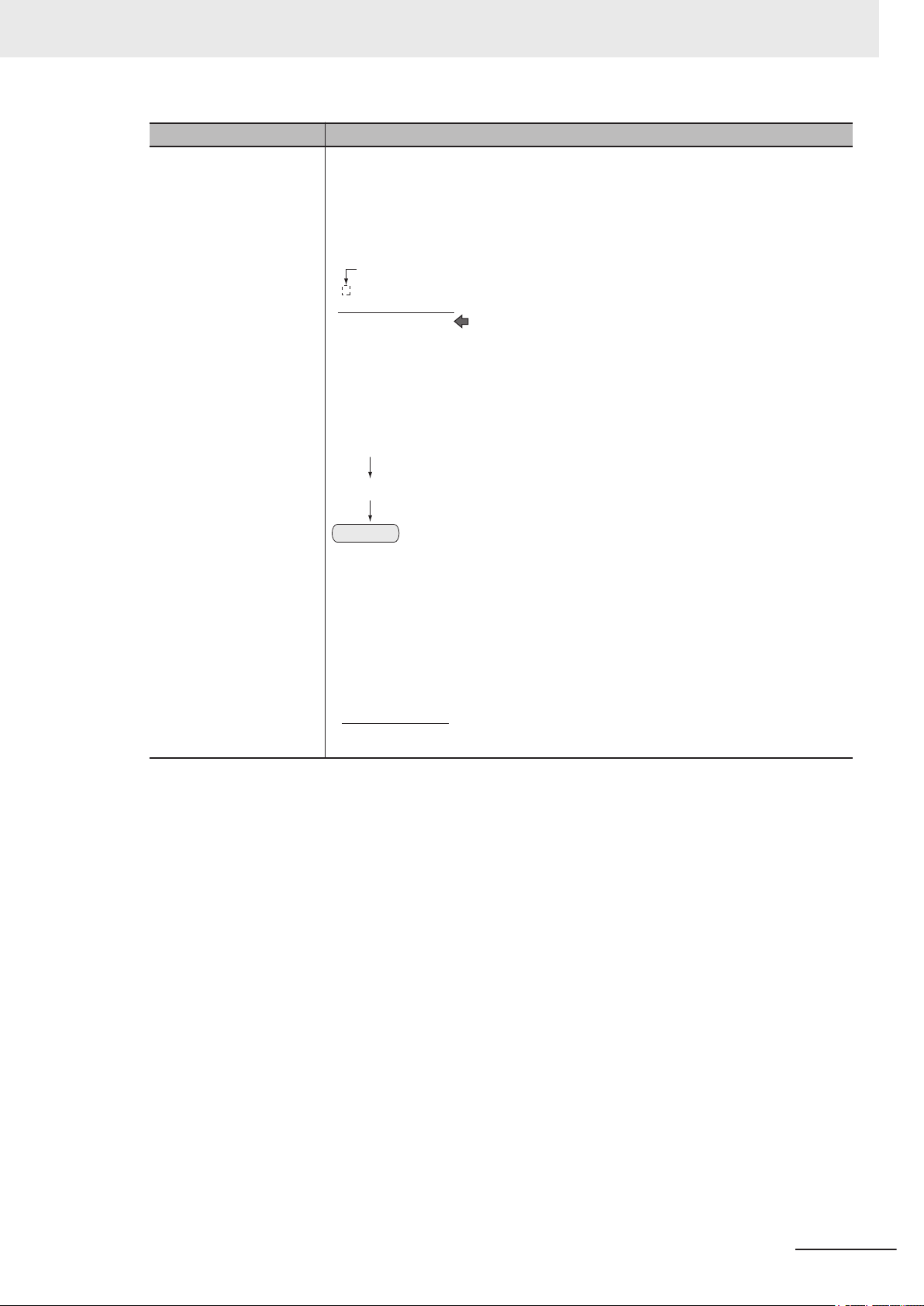

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

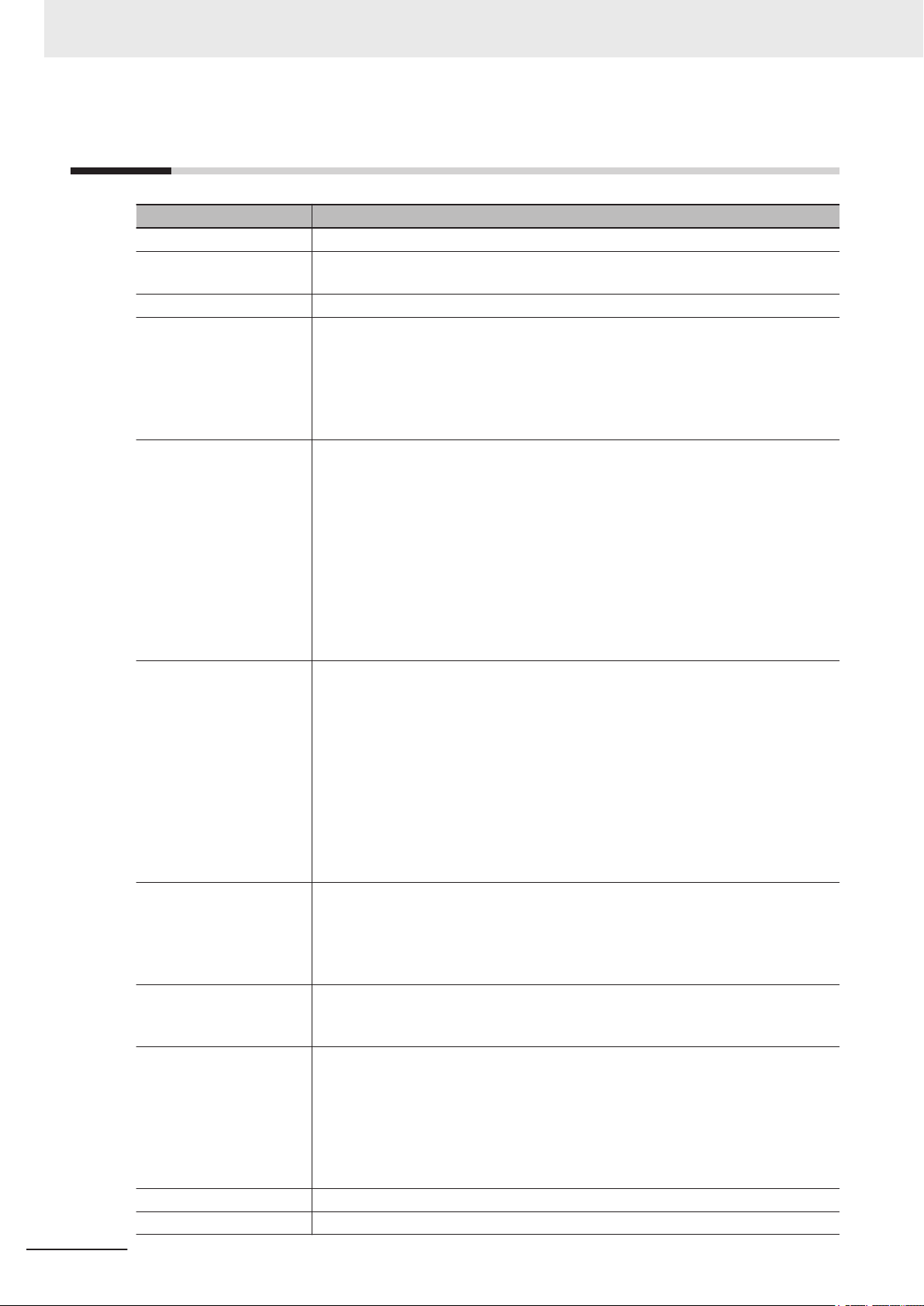

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

FHV Series Smart Camera Setup Manual (Z408-E1)

5

Page 8

6

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 9

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products ......................................................................................................................................... 1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

................................................................................................................................... 6

Sections in This Manual ........................................................................................ 29

Terms and Conditions Agreement........................................................................ 10

Warranty, Limitations of Liability ....................................................................................................................10

Application Considerations ............................................................................................................................11

Disclaimers ....................................................................................................................................................11

CONTENTS

Safety Precautions................................................................................................. 13

Symbols and the Meanings for Safety Precautions Described in This Manual .............................................13

Meanings of Alert Symbols ............................................................................................................................ 13

Warning..........................................................................................................................................................14

Precautions for Safe Use ...................................................................................... 15

Condition of the Fitness of OMRON Products ............................................................................................... 15

Installation Environment ................................................................................................................................15

Power Supply and Wiring ..............................................................................................................................15

Mounting ........................................................................................................................................................ 16

Others ............................................................................................................................................................ 17

Precautions for Correct Use ................................................................................. 18

Installation Location ....................................................................................................................................... 18

Power Supply, Connection, and Wiring..........................................................................................................18

Maintenance ..................................................................................................................................................19

Beam .............................................................................................................................................................19

Image Sensor ................................................................................................................................................19

Communications with Upper Equipment........................................................................................................ 19

Failsafe Measures .........................................................................................................................................20

Warm-up ........................................................................................................................................................ 20

Camera Installation........................................................................................................................................20

Others ............................................................................................................................................................ 20

LED Safety..................................................................................................................................................... 21

Regulations and Standards .................................................................................. 22

Using Product Outside Japan ........................................................................................................................ 22

Conformance to KC Standards......................................................................................................................22

Conformance to EC/EU Directives ................................................................................................................22

Related Manuals..................................................................................................... 23

Terminology............................................................................................................ 24

Revision History..................................................................................................... 28

FHV Series Smart Camera Setup Manual (Z408-E1)

7

Page 10

CONTENTS

Section 1 Confirm the Package

1-1 Smart Camera.......................................................................................................................1 - 2

1-1-1 FHV7H-□□□□□-C Series ...........................................................................................................1 - 2

1-1-2 FHV7H-□□□□□-S□□ Series .......................................................................................................1 - 2

1-1-3 FHV7H-□□□□□-S□□-□□ Series..................................................................................................1 - 3

1-2 Sold Separately ....................................................................................................................1 - 4

1-2-1 Cables .......................................................................................................................................1 - 4

1-2-2 Modules.....................................................................................................................................1 - 5

1-2-3 Accessories...............................................................................................................................1 - 6

1-2-4 Lighting and Lighting Controller ................................................................................................1 - 8

1-2-5 Software ....................................................................................................................................1 - 8

Section 2 Overview of FHV Series

2-1 Overview of System.............................................................................................................2 - 2

2-1-1 Basic System of Measurement .................................................................................................2 - 2

2-2 Flow of Use Procedure ........................................................................................................2 - 7

Section 3 Configuration

3-1 Smart Camera.......................................................................................................................3 - 2

3-1-1 FHV Series................................................................................................................................3 - 2

3-2 Cables .................................................................................................................................3 - 10

3-2-1 I/O Cables ...............................................................................................................................3 - 10

3-2-2 Ethernet Cables ......................................................................................................................3 - 13

3-3 Lens Modules .....................................................................................................................3 - 15

3-3-1 Specifications ..........................................................................................................................3 - 15

3-3-2 Meaning of Optical Chart ........................................................................................................3 - 17

3-4 C Mount Lenses .................................................................................................................3 - 20

3-4-1 Specifications ..........................................................................................................................3 - 20

3-4-2 Meaning of Optical Chart ........................................................................................................3 - 30

3-5 Lighting Modules ...............................................................................................................3 - 37

3-5-1 Specifications ..........................................................................................................................3 - 37

3-5-2 Dimensions .............................................................................................................................3 - 38

3-6 Optical Filters .....................................................................................................................3 - 39

3-6-1 Specifications ..........................................................................................................................3 - 39

3-6-2 Dimensions .............................................................................................................................3 - 39

3-7 Waterproof Hoods..............................................................................................................3 - 41

3-7-1 Specifications ..........................................................................................................................3 - 41

3-7-2 Dimensions .............................................................................................................................3 - 42

3-8 Mounting Fixtures..............................................................................................................3 - 46

3-8-1 Specfications...........................................................................................................................3 - 46

3-8-2 Dimensions .............................................................................................................................3 - 46

3-9 Software..............................................................................................................................3 - 48

3-9-1 Remote Operation Tool ...........................................................................................................3 - 48

3-9-2 Simulation Software ................................................................................................................3 - 48

Section 4 Handling and Installation Environment

4-1 Warning.................................................................................................................................4 - 2

8

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 11

Section 5 Installation

5-1 Assembling Equipment ....................................................................................................... 5 - 2

5-1-1 C Mount Lens / IP40 Configuration ...........................................................................................5 - 2

5-1-2 C Mount Lens / IP67 Configuration ...........................................................................................5 - 3

5-1-3 Lens Module / IP40 Configuration.............................................................................................5 - 5

5-1-4 Lens Module / IP67 Configuration.............................................................................................5 - 8

5-1-5 Lens Module / Internal Lighting / IP67 Configuration ..............................................................5 - 10

5-2 Installing the Smart Camera .............................................................................................5 - 14

5-2-1 How to Connect.......................................................................................................................5 - 14

5-2-2 When Connecting the Smart Camera to a Lighting Controller ................................................5 - 18

Section 6 Power Supply and I/O Interface

6-1 When Turning Power ON and OFF .....................................................................................6 - 2

6-2 Fail-safe Measures...............................................................................................................6 - 4

6-3 Precautions for I/O Interface...............................................................................................6 - 5

6-4 I/O Cable Interface (Power Supply, I/O, RS-232C).............................................................6 - 6

6-4-1 Recommended Power Supply for FHV Series ..........................................................................6 - 6

6-4-2 Cables .......................................................................................................................................6 - 7

6-4-3 Pin Layout .................................................................................................................................6 - 8

6-4-4 Interface Specifications .............................................................................................................6 - 9

6-4-5 I/O Interface Input / Output Circuit Diagram............................................................................6 - 12

6-4-6 RS-232C Interface ..................................................................................................................6 - 14

6-5 Ethernet Interface ..............................................................................................................6 - 15

6-5-1 Cables .....................................................................................................................................6 - 16

6-5-2 Pin Layout ...............................................................................................................................6 - 17

6-6 Inserting and Removing the MicroSD Card.....................................................................6 - 18

6-6-1 How to Insert / Remove the MicroSD Card .............................................................................6 - 18

CONTENTS

Section 7 Software Setup

7-1 Setting up the Software.......................................................................................................7 - 2

7-1-1 Recommended Operational Environment .................................................................................7 - 2

7-1-2 Installation .................................................................................................................................7 - 2

7-1-3 Windows....................................................................................................................................7 - 3

7-1-4 Use Procedures ........................................................................................................................7 - 4

7-2 Operating the Smart Camera Remotely [Remote Operation Tool] ................................7 - 10

7-2-1 Summary.................................................................................................................................7 - 10

7-2-2 Environment Settings .............................................................................................................. 7 - 11

7-2-3 Network Settings for the Remote Operation PC .....................................................................7 - 11

7-2-4 Network Settings for the Smart Camera .................................................................................7 - 12

7-2-5 Network Settings for the Smart Camera with Remote Operation Tool ....................................7 - 14

7-2-6 Launching the Remote Operation ...........................................................................................7 - 14

7-2-7 Terminating the Remote Operation .........................................................................................7 - 17

7-3 Using the Simulation Software [Simulation Software] ................................................... 7 - 18

7-3-1 Introduction .............................................................................................................................7 - 18

7-3-2 Available Image Formats.........................................................................................................7 - 18

7-3-3 Operational Precautions..........................................................................................................7 - 18

Index

FHV Series Smart Camera Setup Manual (Z408-E1)

9

Page 12

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

l

Omron’s exclusive warranty is that the Products will be free from defects in materials and work-

manship for a period of twelve months from the date of sale by Omron (or such other period ex-

pressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

l

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

l

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be re-

sponsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Compa-

nies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

10

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 13

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At Buy-

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the par-

ticular Product with respect to Buyer’s application, product or system. Buyer shall take application re-

sponsibility in all cases.

Terms and Conditions Agreement

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIP-

MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual per-

formance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and oth-

er reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may

FHV Series Smart Camera Setup Manual (Z408-E1)

11

Page 14

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or estab-

lish key specifications for your application. Please consult with your Omron’s representative at any

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

12

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 15

Safety Precautions

Safety Precautions

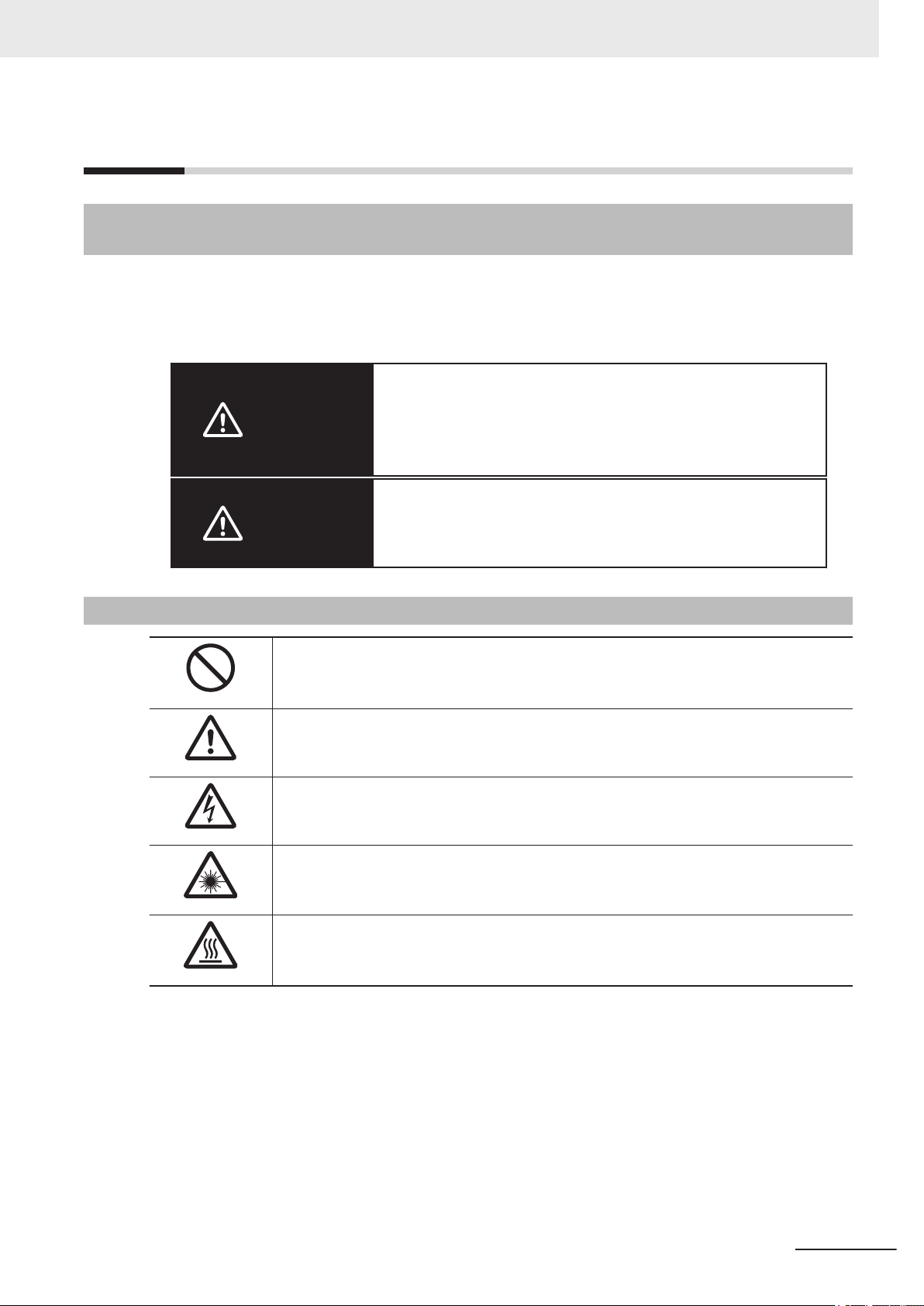

Symbols and the Meanings for Safety Precautions Described in This Manual

The following notation is used in this manual to provide precautions required to ensure safe usage of a

Sensor Controller. The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoid-

WARNING

ed, will result in minor or moderate injury, or may result in seri-

ous injury or death.

Additionally there may be significant property damage.

Caution

Meanings of Alert Symbols

General Prohibition

Indicates general prohibitions, including warnings, for which there is no specific

symbol

General Caution

Indicates general cautions, including warnings, for which there is no specific symbol.

Electrical Hazard

Indicates the possible danger of electric shock under specific conditions.

LED light Hazard

Indicates the possible danger of LED radiation or light.

High Temperature Caution

Indicates the possible danger of injury by high temperature under specific conditions.

Indicates a potentially hazardous situation which, if not avoid-

ed, may result in minor or moderate injury or in property dam-

age.

FHV Series Smart Camera Setup Manual (Z408-E1)

13

Page 16

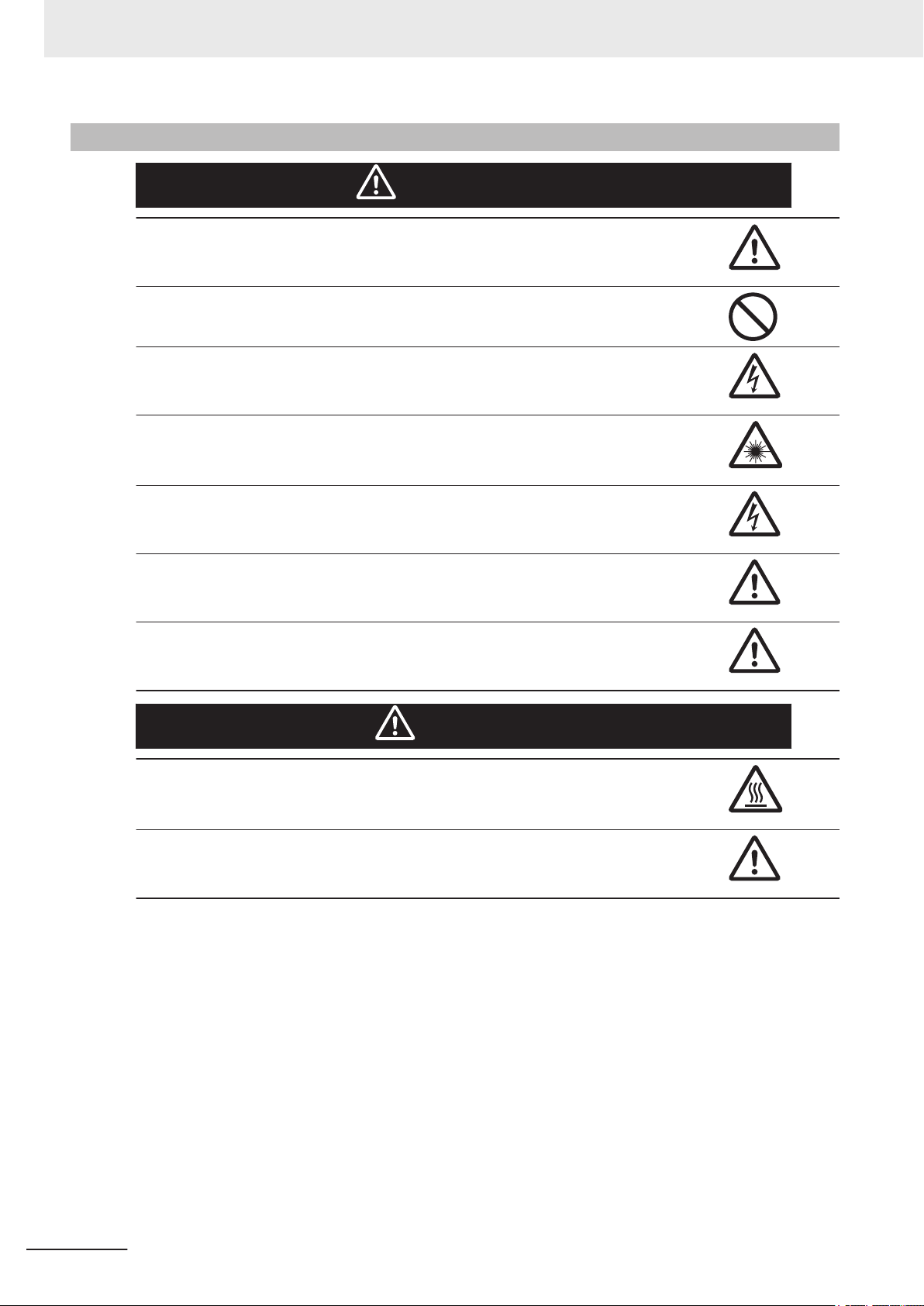

Safety Precautions

Warning

This product must be used according to this manual and Instruction Sheet.

Failure to observe this may result in the impairment of functions and performance of the

product.

This product is not designed or rated for ensuring the safety of persons.

Do not use it for such purposes.

Never connect the AC power supply with this product. When the AC power supply is connected, it causes the electric shock and a fire.

If you keep watching the LED light, it may have an adverse effect on the eyes, do not stare

directly into the light emitted from the LED. If a specular object is used, take care not to allow

reflected light to enter your eyes.

WARNING

Do not touch the terminals while the power supply is ON.

Doing so may result in electrical shock.

Please take external safety measures so that the system as a whole should be on the safe

side even if a failure of a smart camera or an error due to an external factor occurred. An

abnormal operation may result in serious accident.

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal conductor disconnection and/or momentary power interruption.

An abnormal operation may result in a serious accident.

Caution

Danger of burns. Do not touch the case while the power is ON or just after power is turned

OFF, since it remains extremely hot.

When mounting the lighting module, lens module, and covers, make sure that the screws are

tightened securely. If not, the product may break or malfunction, or injury may result.

14

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 17

Precautions for Safe Use

Condition of the Fitness of OMRON Products

• Please do not use this product to directly or indirectly use to detect the human body for the purpose

of ensuring the safety. In the same application, please use the safety sensor that is published on our

sensor catalog.

• Omron products are designed and manufactured as general-purpose products for use in general in-

dustrial applications. They are not intended to be used in the following critical applications. If you are

using Omron products in the following applications, Omron shall not provide any warranty for such

Omron products, unless otherwise specifically agreed or unless the specific applications are intend-

ed by Omron.

a) Applications with stringent safety requirements, including but not limited to nuclear power control

equipment, combustion equipment, aerospace equipment, railway equipment, elevator/lift equip-

ment, amusement park equipment, medical equipment, safety devices and other applications

that could cause danger/harm to people's body and life.

b) Applications that require high reliability, including but not limited to supply systems for gas, water

and electricity, etc., 24 hour continuous operating systems, financial settlement systems and oth-

er applications that handle rights and property.

c) Applications under severe condition or in severe environment, including but not limited to out-

door equipment, equipment exposed to chemical contamination, equipment exposed to electro-

magnetic interference and equipment exposed to vibration and shocks.

d) Applications under conditions and environment not described in specifications.

Precautions for Safe Use

(1) In addition to the applications listed from (a) to (d) above, Omron products (see definition) are not

intended for use in vehicles designed human transport (including two wheel vehicles). Please do

NOT use Omron products for vehicles designed human transport. Please contact the Omron

sales staff for information on our automotive line of products.

(2) The above is part of the Terms and Conditions Agreement. Please use carefully read the contents

of the guarantee and disclaimers described in our latest version of the catalog, data sheets and

manuals.

Installation Environment

• Do not use the product in areas where flammable or explosive gases are present.

• Do not install the product close to high-voltage devices and power devices in order to secure the

safety of operation and maintenance.

• Do not install the product to a place where vibrations and/or impacts are expected.

• Do not install the product near to a device causing noises. if the product is installed in a noisy envi-

ronment and operational errors are caused, be sure to take shielding measures.

Power Supply and Wiring

• Make sure to use the product with the power supply voltage specified. If a DC voltage exceeding the

rating or an AC voltage is applied, the circuit parts may be burnt or exploded.

• Do not connect the power supply with polarity reversed.

FHV Series Smart Camera Setup Manual (Z408-E1)

15

Page 18

Precautions for Safe Use

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage

circuits on the secondary side).

• Use an independent power source for this product. Do not use a shared power source.

• Never apply more than the rated voltage or AC power supply to this product. It may cause malfunc-

tion.

• The recommended power supplies are as follows:

- When attaching the lighting module, use S8VK-G12024 (OMRON) or S8VS-12024 (OMRON).

- When not attaching the lighting module, use S8VK-G06024 (OMRON) or S8VS-06024 (OMRON).

• Wire high-voltage cables or power cables separately from the cables of this product. If the same ca-

ble or duct is used, the product may receive induction and it may cause malfunctioning or breakage.

• Do not short-circuit load on the open collector output.

• Apply load not exceeding the rating.

• When wiring, put a crimp terminal of the specified size. Do not connect wires simply twisted together

to the power supply or terminal block directly.

• If using an I/O cable 20 m long, confirm that the power supply output is 24 VDC or higher. If it is

lower than 24 VDC, the product does not operate.

• Cut off unnecessary signal wires so that they do not contact any other signal wires.

• After wiring the cables, confirm if the power supply is appropriate, if there is miswiring such as short-

circuit of load, if the load current is appropriate, and if FG is connected appropriately. Otherwise, the

product may be broken due to miswiring etc.

• Take enough safety measures such as a failsafe circuit before using the product.

• Be sure to apply Class D grounding (100Ω or lower grounding resistance) to the case of the smart

camera and the ground wire of the I/O cable.

• Do not share the ground wire with some other devices or connect it to the beam of the building. The

product may be adversely affected.

• Determine the contact point as near as possible to shorten the ground wire as much as possible.

The product may be adversely affected.

Mounting

• When doing the following, be sure to turn OFF the power of the smart camera main unit or connect-

ed peripheral devices. Not doing so leads to a product failure.

- Cable connection and wiring

- Connector mounting/removal

- Lighting module mounting/removal

- Lens module mounting/removal

• Tighten the mounting screws securely using the defined torque and order described in the Setup

Manual.

• Mount the lens module in the correct direction. Mounting it in the wrong direction may cause mal-

function of the device or injury.

• After removing the cable, be sure to put the connector cap. If the connector cap is not put, the prod-

uct may malfunction or be broken due to entering of foreign materials.

• For the component with a lock mechanism, be sure to confirm that it is locked before using the prod-

uct.

• Do not apply torsional stress to the cable. Doing so may cause cable breakage.

• Secure the minimum bending radius of the cable. If it cannot be secured, the cable may be broken.

• Assemble as avoiding the waterproof packings and harnesses from being caught by the case, etc.

16

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 19

• Do not use any damaged waterproof packings and light shielding sheet or assemble the product

• Mount the lens module and lighting model in the correct direction. Mounting them in the wrong direc-

• Do not touch the lens or image sensor with bare hands. Doing so may lead to malfunctioning or

Others

• Use only the dedicated cable (FHV-VN/FHV-VD), camera-mount lighting controller (FL-TCC/

• If anything abnormal occurs, for example, strange smell/sound is detected, the main unit gets very

• Do not disassemble, deform by pressurizing, incinerate, repair, or alter this product.

• When disposing of the product, treat as industrial waste.

• Do not drop the product or expose it to abnormal vibration or impact. Doing so may lead to product

• If using the measurement result of the smart camera to operate the stage or robot (output of axis

• The waterproof packing and light shielding sheet are rubber products. Avoid storing them in a loca-

Precautions for Safe Use

with foreign materials attached to or caught in.

tion may cause broken or malfunction of the device, or injury.

breakage.

Assemble the lens and image sensor with a correct combination. if not, malfunction may result.

FLV-TCC), lighting module (FHV-LTM-), and lens module (FHV-LEM-). Otherwise, the product

may malfunction or be broken.

hot, or a smoke comes, stop using the product, turn OFF the product, and consult OMRON’s branch

or sales office.

failure.

moving distance by calibration and alignment measurement), be sure to take failsafe measures ex-

ternally.

tion where rubber deteriorates.

FHV Series Smart Camera Setup Manual (Z408-E1)

17

Page 20

Precautions for Correct Use

Precautions for Correct Use

Installation Location

In order to prevent the product from becoming inoperable or malfunction, and to prevent other adverse

effects to the performance or equipment, please observe the following.

• A location where the ambient temperature does not exceed the rated range (operating: 0 to 40°C,

storage: -25 to 65°C).

• A location where the temperature does not vary sharply (condensation occurs).

• A location where relative temperature does not exceed a range of 35-85%RH.

• A location not exposed to corrosive gases or combustible gases.

• A location not exposed to dust, salt, or metal powder.

• A location not exposed to direct vibration or impact.

• A location not exposed to strong disturbance light (laser light, arc welding light, or ultraviolet light).

• A location not near a heating appliance or exposed to direct sunlight.

• A location not exposed to mist of water, oil, or chemicals or misty atmosphere.

• A location not exposed to strong magnetic/electric fields.

• A location not near a high-voltage device or power device

• A location where rubber quality is not deteriorated.

Power Supply, Connection, and Wiring

• If using a commercially available switching regulator, earth the frame ground terminal.

• If the power supply line has surge, connect a surge absorber according to the operational environ-

ment to use the product.

• After wiring the cables, confirm if the power supply is appropriate, if there is miswiring such as short-

circuit of load, or if the load current is appropriate. Otherwise, the product may be broken due to

miswiring etc.

• Do not put load on the cables and connectors before wiring them.

• Do not turn OFF the power supply while data are being saved in the smart camera. Otherwise, data

on the memory is broken, so the product does not operate normally when started up next time.

• When turning OFF the power, confirm that data have been saved completely before starting opera-

tions.

- When data are saved by operating the sensor controller, the saving process must have been com-

pleted and the following user operations must be possible.

- When data are saved using communication commands, processing of the applicable commands

must have been completed and the busy state is OFF.

• If contacting a terminal or a signal cable inside the connector, use a wrist strap to take antistatic

measures to prevent breakage due to static electricity.

• If removing the microSD card, confirm that data are not being read or written before removing it.

• Do not insert the microSD card inversely, obliquely, or as twisting it.

• While data are being read in or written to the microSD card, the SD ACCESS LED on the Smart

Camera main unit is turned on for a while. Remove the card after confirming that the LED is com-

pletely turned off.

• Except when inserting or removing the microSD card, put the cover of the microSD card inserting

connector and screw it up before using the product.

18

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 21

• When a message indicating that processing is being executed is displayed on the screen, do not

turn OFF the power. Otherwise, data on the memory is broken, so the product does not operate nor-

mally when started up again.

• Do not use the product in environments subject to water droplets when an external lighting is con-

nected. The main unit may be broken.

• The RS-232C communication standard defines the maximum cable length as 15 m. Implement this

communication using an I/O cable 2/3/5/10 m long.

• When connecting cables, align terminals and connect them straightly. If not, the terminals bent and

may cause malfunction or unable to communicate normally.

Maintenance

• Turn OFF the power and confirm safety before starting maintenance.

• Remove dirt on the lens using the special cloth for lens or an air brush.

• If a large dust attaches to the image sensor, use the blower brush (for the camera lens) to blow it off.

Do not blow it off with your exhaled air.

• Do not use thinner, alcohol, benzene, acetone, or kerosene to clean his product.

• When the lens or lens module is not being mounted, be sure to attach the C mount cap to the lens

mounting part. If a dust attached to the image sensor, the product may sense incorrectly or be bro-

ken.

• Wipe off dirt on this product with a soft cloth gently.

• Be sure to put the cap/cover onto the connector not used. Otherwise, the product may malfunction

or get out of order due to entering of foreign materials.

Precautions for Correct Use

Beam

• The beam center may vary product by product. When mounting this module, be sure to confirm the

center position of the video on the monitor.

The beam center of this product may vary over a couple of pixels due to the variation of ambient

temperature because of the material characteristics.

• Select the model by confirming the field of view and camera installation distance on the optical dia-

gram. In addition, the field of view may vary product by product.

When mounting this product, be sure to confirm video using the monitor.

Image Sensor

• For this product, a line may appear depending on the measurement condition or sensitivity because

of the specification of the image sensor.

However, this is not a fault or failure of the product. In addition, although there may be multiple de-

fective pixels, this is not a fault or failure of the product. Use the product as confirming the actual

image.

Communications with Upper Equipment

• Implement communications with upper equipment after confirming that this product has been started

up. In addition, when this product is being started up, unstable signals may be issued by the upper

FHV Series Smart Camera Setup Manual (Z408-E1)

19

Page 22

Precautions for Correct Use

interface. In the initial operation, take action such as clearing the receiving buffer of the equipment

used.

Failsafe Measures

• When operating a stage or robot using measurement results of the Smart Camera (axis moving dis-

tance output by the calibration or alignment measurement), take measures as follows: Be sure to

operate the stage or robot after confirming the measurement result data on the stage or robot side

that the data are within the movable range of the stage or robot.

Warm-up

• Turn ON the power and wait for 60 minutes or more before conducting precise inspection. The cir-

cuit is not stable directly after the power is turned ON, so brightness may vary gradually.

Camera Installation

• In an environment exposed to high humidity and sharp temperature fluctuation, the inside of the

lighting cover may become cloudy in rare cases. If it becomes cloudy, remove the lighting cover and

wipe off the inside with a soft cloth.

• If installing smart camera main units side by side, secure a space of 30 mm or more wide between

them.

Others

• For better heat radiation, use the separately sold fitting (FHV-XMT-7) or mount the product to the

metal frame (recommended size: 100×110 mm or more and thickness: 10 mm or more).

• Do not assemble the lighting module or waterproof hood in a hot and humid environment. Other-

wise, condensation may occur. If it becomes cloudy, remove the lighting cover and wipe off the

moisture with an absorbent, but soft cloth so as not to damage the product.

• There are two types of polarizing filters: FHV-XPL (for visible light) and FHV-XPL-IR (for both visible

and infrared lights). Use the appropriate option according to the illumination light source.

• If switching the focus for a long period of time continuously except when installing and adjusting the

product, performance may be degraded due to heat generation or abrasion of inner parts.

• When the lens module is mounted to the product, the specificatins of vibration tolerance are

changed.

• Do not touch the lens module after it is mounted. Otherwise, it may be broken.

• If using this product without attaching the lighting module in an environment needing waterproof, use

waterproof hood FHV-XHD series.

• Operate the product by using Calculation and Branch processing items on the Smart Camera side

additionally and creating a check flow, for example, if the stage or robot is within a range of -xxxxx to

xxxxx from its movable range, data are not output to outside.

• The lighting module and lens module are fixed to the smart camera with dropout preventing screws.

Do not remve them from the product.

• When turning on the FHV series, the date/time settings always returns to the default. Therefore, you

need to re-set the date/time with an operation or a communication command every time at startup.

20

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 23

For details of communication commands, refer to each communication command in the Vision

System FH/FZ5 Series User's Manual for Communications Settings (Cat. No.Z342).

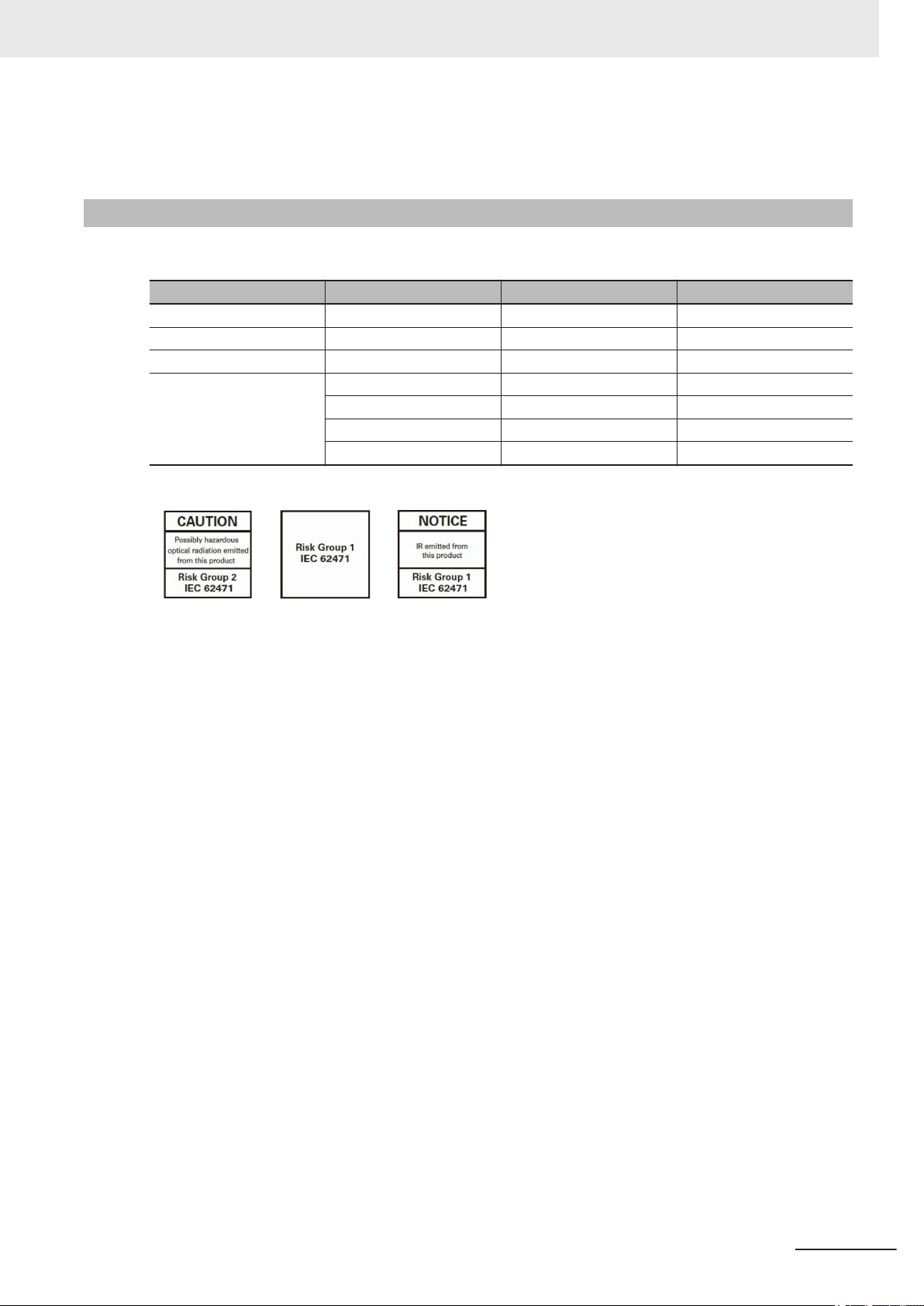

LED Safety

This product is classified into the following risk groups by IEC62471.

FHV-LTM-W White Risk group 2 A

FHV-LTM-R Red Risk group 1 B

FHV-LTM-IR Infrared light Risk group 1 C

FHV-LTM-MC

Precautions for Correct Use

Model Color LED safety Display

Red Risk group 1 B

Green Risk group 2 A

Blue Risk group 2 A

Infrared light Risk group 1 C

A B C

FHV Series Smart Camera Setup Manual (Z408-E1)

21

Page 24

Regulations and Standards

Regulations and Standards

Using Product Outside Japan

If you export (or provide a non-resident with) this product or a part of this product that falls under the

category of goods (or technologies) specified by the Foreign Exchange and Foreign Trade Control

Law as those which require permission or approval for export, you must obtain permission or approval

or service transaction permission) pursuant to the law.

Conformance to KC Standards

Observe the following precaution if you use this product in Korea.

• Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in pla-

ces other than homes. Sellers and/or users need to take note of this.

Conformance to EC/EU Directives

The product is compliant with the standards below:

• EU Directive 2014/30/EU (After April 20 2016)/EU EN61326-1

Electromagnetic environment : Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall ma-

chine conform to EMC standards.

22

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 25

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Name of Manual Man. No.. Model Purpose Contents

Smart Camera

FHV Instruction Sheet

Smart Camera

Lighting Module

FHV-LTM Instruction Sheet

Smart Camera Lens Module

FHV-LEM-S Instruction

Sheet

FHV Series

i-Smart Camera

Setup Manual

Vision System

FH/FHV/FZ5 Series

User's Manual

Vision System

FH/FHV/FZ5 Series Processing Item Function Reference Manual

Vision System

FH/FHV/FZ5 Series

User's manual for Communications Settings

3129404-0

3129276-4

3128622-5

Z408

Z365

Z341 When User confirm

Z342 When User confirm

FHV7£-££££-C

FHV-LTM££

FHV-LEM-S££

FHV7£-££££-C

FHV7£-££££-S-££

FHV7£-££££-S-££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FHV7£-££££-C

FHV7£-££££-S-££

FHV7£-££££-S-££-££

FZ5-L35£

FZ5-L35£-££

FZ5-6££

FZ5-6££-££

FZ5-8££

FZ5-8££-££

FZ5-11££

FZ5-11££-££

FZ5-12££

FZ5-12££-££

To confirm the safety

and usage precautions of the Smart

Camera FHV7 series.

To confirm the safety

and usage precautions of the Smart

camera lighting module FHV-LTM.

To confirm the safety

and usage precautions of the Smart

camera lens module

FHV-LEM.

When User want to

know about the hardware specifications

or to setup the Smart

camera FHV series.

When User want to

know about the

FH/FHV/FZ5 series.

the details of each

processing items at

the create the measurement flow or operate it.

the setting of communication functions.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

FHV7 series in the manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lighting module FHV-LTM in the

manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lens module FHV-LEM.

Describes FHV series specifications,

dimensions, part names, I/O information, installation information, and

wiring information.

Describes the soft functions, setup,

and operations to use FH/FHV/FZ5

series/

Describes the software functions,

settings, and operations for using

FH/FHV/FZ5 series.

Describes the functions, settings,

and communications methods for

communication between

FH/FHV/FZ5 series and PLCs.

The following communications protocol are described.

Parallel, PLC Link, EtherNet/IP,

EtherCAT, and Non-procedure.

Related Manuals

FHV Series Smart Camera Setup Manual (Z408-E1)

23

Page 26

Terminology

Terminology

Term Definition

FHV Series All FHV series model names.

Measurement flow (abbreviated as “flow”)

Measurement processing Executing processing items for inspections and measurements.

Measurement ID Measurement time: YYYY-MM-DD_HH-MM-SS-XXXX

Processing item Any of the individual items for vision inspections that are partitioned and packaged

Scene A unit for changing the measurement flow that consists of a combination of proc-

Processing unit (abbreviated as unit)

Measurement trigger A trigger for executing measurements.

Test measurement A measurement that is performed to manually test (check) measurements under

Single measurement A measurement that is executed only once in synchronization with the trigger input.

Continuous measurement Measurements are executed repeatedly and automatically without a trigger input.

A continuous flow of measurement processing. A measurement flow consists of a

scene created from a combination of processing items.

(YYYY: Calendar,, MM: Month, DD: Day, HH: Hour, MM: Minutes, SS: Second,

XXXX: Millisecond and Line number.)

• Example:

Measurement time: 11:10:25.500 AM, December 24, 2007 and Line 0, the measurement ID is "2007-12-24_11-10-25-5000".

so that they can be flexibly combined.

These include the Search, Position Compensation, and Fine Matching items.

Processing items can be classified for image input ([Input image]), inspection/

measurement ([Measurement]), image correction ([Compensate image]), inspection/measurement support ([Support measurement]), process branching ([Branch]),

results external output ([Output result]), resulting image display ([Display result]),

etc.

You can freely classify processing items to handle a wide range of applications.

A scene (i.e., a unit for changing the measurement flow) is created by registering

the processing items as units.

essing items.

Scene is used because of the correspondence to the scene (i.e., type of measurement object and inspection contents) where measurements are performed.

A scene is created for each measurement or measurement contents.

You can easily achieve a changeover simply by changing the scene when the

measurement

object or inspection content changes.

Normally you can set up to 128 scenes. If you need more than 128 scenes, you

can separate them into different groups or use the Conversion Scene Group Data

Tool to create a scene group that contains over 128 scenes.

A processing item that is registered in a scene.

Numbers are assigned to processing units in order from the top and they are executed in that order.

Processing items are registered for the processing units to create a scene (i.e., a

unit for changing the measurement flow).

With a parallel interface, the STEP signal is used. With a serial interface, an Execute One Measurement or a Start Continuous Measurement command is used.

the conditions that are set in the currently displayed scene.

Test measurements can be executed on an Adjustment Window. Processing is

completed inside the Controller and the measurement results are not normally output on an external interface.

However, you can select Output in Test measurement to output the measurement

results after executing measurements.

24

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 27

Term Definition

Operation mode

• Double Speed Multi-input

A mode that processes the measurement flow for the first trigger and then processes the measurement flow in parallel for the second trigger to achieve a highspeed trigger input interval. It is used together with the multi-input function.

• Non-stop adjustment mode

A mode that allows you to adjust the flow and set parameters while performing

measurements.

The enables adjustments without stopping the line or stopping inspections.

• Standard

A logging mode that allows complete parallel processing of measurements and

logging.

Traditionally, logging was not possible while processing measurements. Either

measurements or logging had to be given priority and the other one had to wait.

With this mode, you can save the measurement images in external storage without affecting the transaction time.

Parallel processing (an

option for any of the

above operation modes)

Multi-input function A function that is used to consecutively and quickly input images.

Parallel processing splits part of the measurement flow into two or more tasks, and

processes each task in parallel to shorten the transaction time.

Processing items for parallel processing are used so that the user can specify the

required parallel processing.

It allows the next STEP signal to be acknowledged as soon as the image input

processing is completed. There is no need to wait for measurement processing to

be completed.

You can check whether image input processing has been completed with the status

of the READY signal. Even if the READY signal is ON when measurement processing is being executed, the next STEP signal can be acknowledged.

Terminology

FHV Series Smart Camera Setup Manual (Z408-E1)

25

Page 28

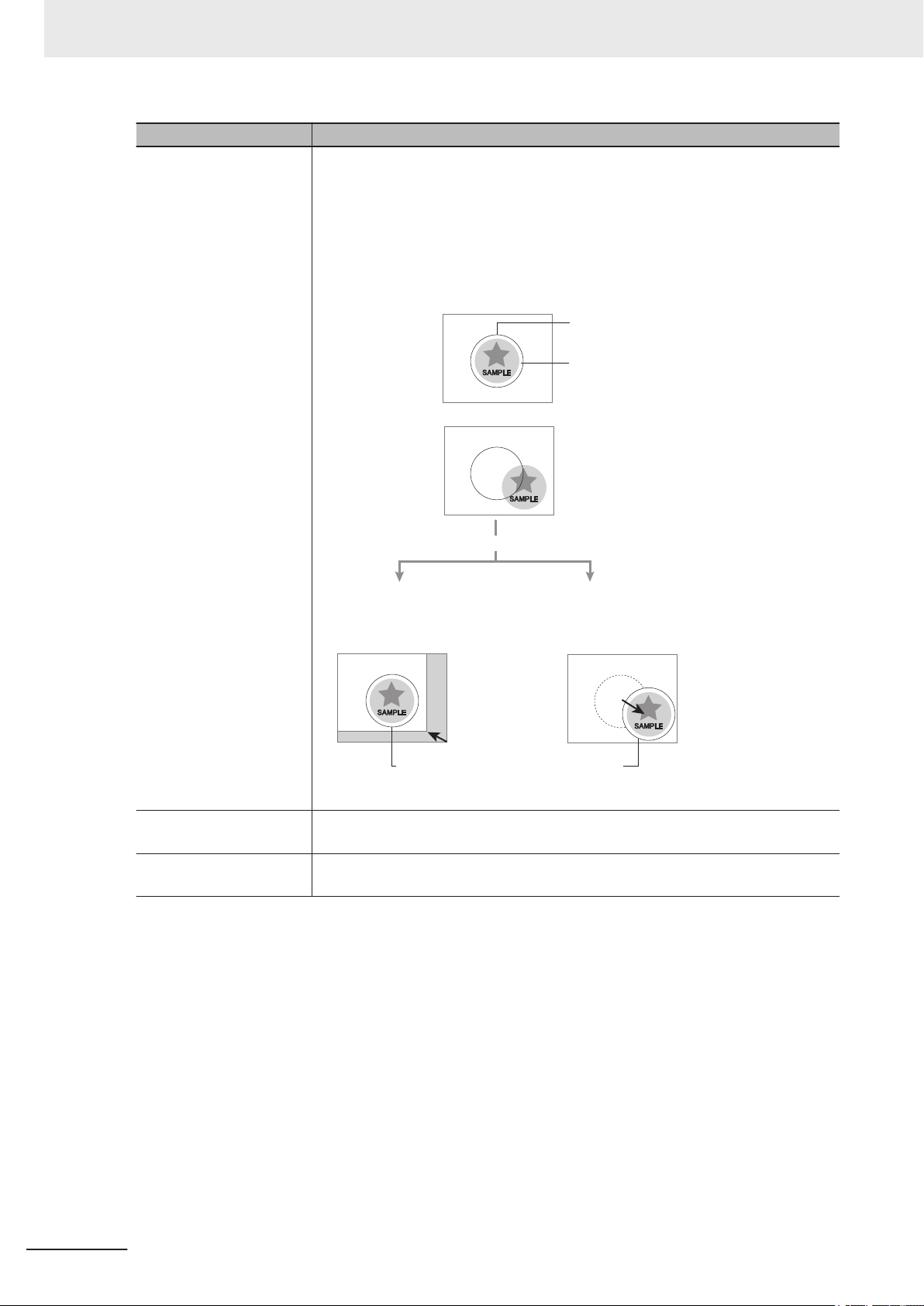

When position of object to be measured is deflected

When position deflection correction is set in advance:

Object to be measured

overflows Measurement area.

Reference position

Measurement area and objects to be measured

are correctly aligned.

Object to be measured

Measurement area

Measurement will be carried out

after measured object enters into Measurement area.

Measurement will be carried out after

moving the Measurement area for a

corresponding deflection.

Measurement will be carried out

after moving the image for a

corresponding deflection and

returning to the reference position.

Terminology

Position compensation When the location and direction of measured objects are not fixed, the positional

Term Definition

deviation between reference position and current position is calculated and measurement is performed after correcting.

Please select processing items that are appropriate to the measurement object

from processing items that are related to position compensation.

Reference position The point that is always the reference. If the location of the registered model is dif-

Model The image pattern that serves as the inspection target. Characteristics portions are

ferent from the reference position, the setting should be changed in Ref. setting.

extracted from images of the object and registered as model registration.

26

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 29

Term Definition

−“1” expresses with 2’s Complement (for 8 bits)

00000000 (= 0)

-)

(In the case of 1, minus 1)

00000001 (= 1)

11111111 (=-1)

00000001 (= 1)

11111110

11111111 (=-1)

Invert all bits

Plus 1

11111111 (= -1)

00001001 (= 9)

+)00001010 (= 10)

2's complement Binary numbers are generally used to represent negative numbers.

Negative numbers are expressed by Inverting all bits of a positive number and

adding 1 to the result.

Ex. -1 is expressed as 2's complement.

-1 can be calculated by 0-1.

There are methods for simple calculation without performing this kind of computation.

For instance, Negative number = inverting all bits of a positive number and then

adding 1 to the result.

Terminology

The first digit is used to judge whether the number is positive or negative.

• When 0: Positive number (or 0)

• When 1: Negative number

The advantage of two's complement numbers is that positive and negative numbers can be used as is in calculations.

Ex. When -1+10=9

FHV Series Smart Camera Setup Manual (Z408-E1)

27

Page 30

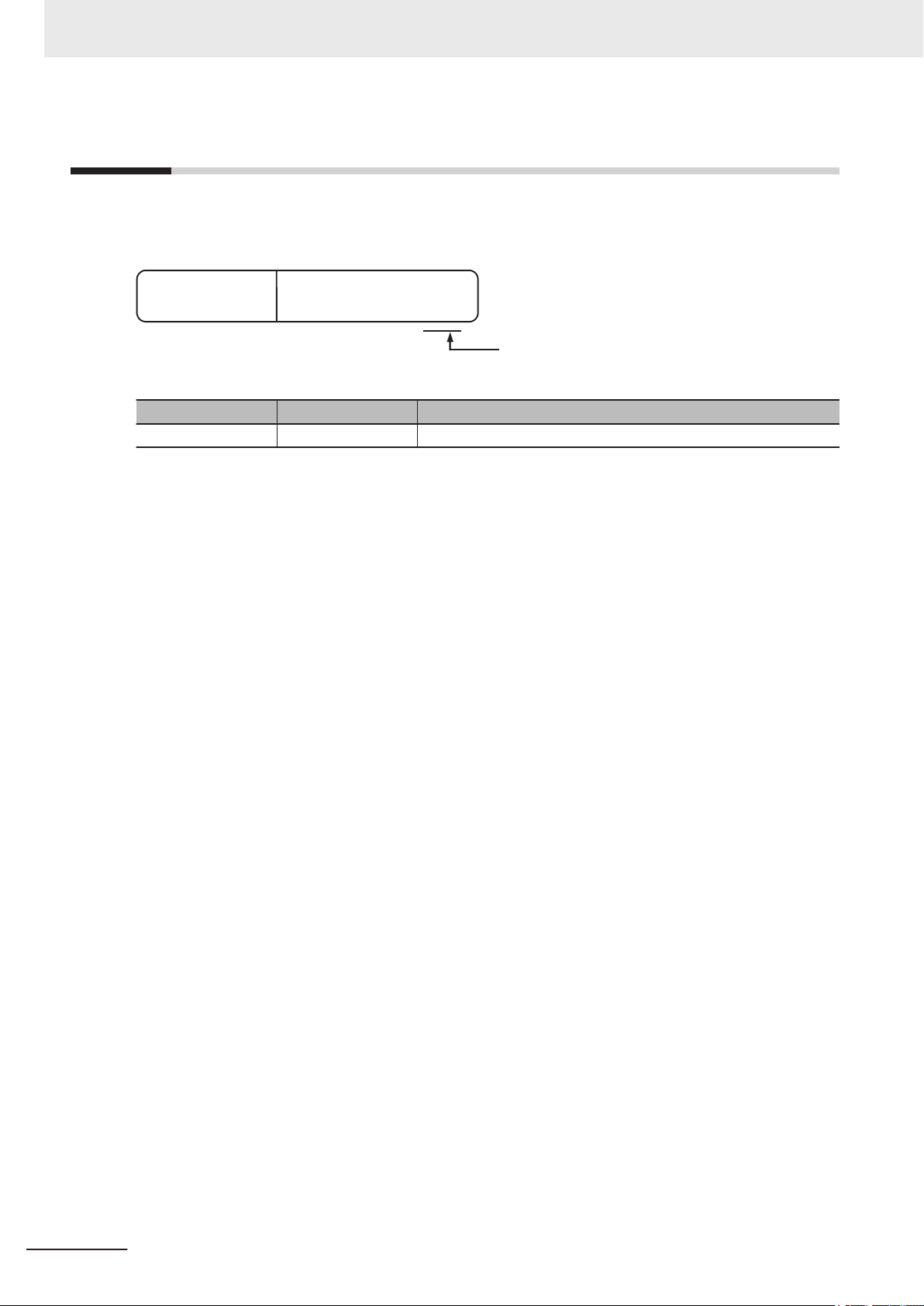

Z408-E1-01

Revision code

Cat. No.

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

A Nov. 2018 Original production

28

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 31

Sections in This Manual

1

2

3

4

5

1

2

3

4

5

I

Confirm the Package

Overview of FHV series

Configuration

Handling and Installation Environment

Installation

I

6

7

Index

6

7

Power Supply and I/O Interface

Software Setup

I

Sections in This Manual

FHV Series Smart Camera Setup Manual (Z408-E1)

29

Page 32

Sections in This Manual

30

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 33

Confirm the Package

1-1 Smart Camera............................................................................................... 1 - 2

1-1-1 FHV7H-□□□□□-C Series ............................................................................... 1 - 2

1-1-2 FHV7H-□□□□□-S□□ Series........................................................................... 1 - 2

1-1-3 FHV7H-□□□□□-S□□-□□ Series ..................................................................... 1 - 3

1-2 Sold Separately ............................................................................................1 - 4

1-2-1 Cables........................................................................................................... 1 - 4

1-2-2 Modules ........................................................................................................ 1 - 5

1-2-3 Accessories .................................................................................................. 1 - 6

1-2-4 Lighting and Lighting Controller .................................................................... 1 - 8

1-2-5 Software........................................................................................................ 1 - 8

1

1

FHV Series Smart Camera Setup Manual (Z408-E1)

1 - 1

Page 34

1 Confirm the Package

1-1

1-1-1

Smart Camera

First, please check to see if the package has all the necessary Smart Camera parts.

FHV7H-□□□□□-C Series

• Smart Camera

FHV7H-□□□□□-C: 1

• Connector cap for Ethernet cable (mounted on the body): 1

• Connector cap for an external lighting (mounted on the body): 1

• C mount cap (mounted on the body): 1

• C mount cover (mounted on the body): 1

• Instruction sheet: 1

• Membership registration: 1

• Compliance sheet: 1

1-1-2

FHV7H-□□□□□-S□□ Series

• Smart Camera

FHV7H-□□□□□-S□□: 1

• Connector cap for Ethernet cable (mounted on the body): 1

• Connector cap for an external lighting (mounted on the body): 1

• Special cover for FHV-LEM-S (mounted on the body): 1

• Instruction sheet: 1 each (Body, and lens module)

• Membership registration: 1

• Compliance sheet: 1

1 - 2

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 35

1 Confirm the Package

1-1-3

FHV7H-□□□□□-S□□-□□ Series

• Smart Camera

FHV7H-□□□□□-S□□-□□: 1

• Connector cap for Ethernet cable (mounted on the body): 1

• Connector cap for an external lighting (mounted on the body): 1

• Instruction sheet: 1 each (Body, lens module, and lighting module)

• Membership registration: 1

• Compliance sheet: 1

1-1 Smart Camera

1

1-1-3 FHV7H-□□□□□-S□□-□□ Series

FHV Series Smart Camera Setup Manual (Z408-E1)

1 - 3

Page 36

1 Confirm the Package

1-2

1-2-1

Sold Separately

Cables

I/O Cables

Appearance Description Model

I/O cable straight

Cable length: 2 m, 3 m, 5 m, 10 m, 20 m

I/O cable right-angle

Cable length: 2 m, 3 m, 5 m, 10 m, 20 m

FHV-VDB □□M

FHV-VDLB □□M

Ethernet Cables

Appearance Description Model

Ethernet cable straight

Cable length: 2 m, 3 m, 5 m, 10 m, 20 m

Ethernet cable right-angle

Cable length: 2 m, 3 m, 5 m, 10 m, 20 m

FHV-VNB □□M

FHV-VNLB □□M

1 - 4

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 37

1 Confirm the Package

1-2-2

Modules

Lens Modules

Appearance Focal distance Model Package contents

6 mm FHV-LEM-S06

9 mm FHV-LEM-S09

12 mm FHV-LEM-S12

16 mm FHV-LEM-S16

25 mm FHV-LEM-S25

• Main unit: 1

• Special cover for FHV-LEM-S: 1

• Screws: M3×8 mm: 5 (including one

spare piece)

• Instruction sheet : 1

• Compliance sheet: 1

If purchasing the Smart Camera with integrated lens module, refer to 1-1-2 FHV7H-□□□□□-S□□ Series

on page 1 - 2 and 1-1-3 FHV7H-□□□□□-S□□-□□ Series on page 1 - 3.

Lighting Modules

Appearance Color

White - LED FHV-LTM-W

Red Typ. 630 nm LED FHV-LTM-R

Infrared light Typ. 850 nm LED FHV-LTM-IR

Multi-color R: Typ. 630 nm

Peak

wavelength

G: Typ. 525 nm

B: Typ. 465 nm

IR:Typ. 850 nm

Source Model Package contents

• Main unit: 1

• Waterproof packing

(small) FHV-XWPCAM:1

• Waterproof packing

(large) FHV-XWPLTM: 1

• Light shielding sheet

FHV-XLS-LTM: 1

LED FHV-LTM-MC

• Lighting cover FHV-

XCV: 1

• Hexagonal wrench

(length: 60 mm): 1

• Instruction sheet: 1

• Compliance sheet: 1

1-2 Sold Separately

1

1-2-2 Modules

If purchasing the Smart Camera with integrated lighting module, refer to the 1-1-3 FHV7H-□□□□□-

S□□-□□ Series on page 1 - 3.

FHV Series Smart Camera Setup Manual (Z408-E1)

1 - 5

Page 38

1 Confirm the Package

1-2-3

Accessories

Optical Filters

Appearance Type Supported wavelength Model

Polarization filter Visible FHV-XPL

Polarization filter Visible to infrared FHV-XPL-IR

Diffusion filter FHV-XDF

Lighting cover FHV-XCV

Waterproof Hoods

Appearance Description Model Package contents

For C mount lens

3Z4S-LE SV-V

series

For C mount lens

3Z4S-LE SV-H

series

FHV-XHD-S

FHV-XHD-L

• Hood cover: 1

• Hood base: 1

• Waterproof packing, FHV-XWP-CAM: 1

• Screws, M3×8 mm: 5

For lens module FHV-XHD-LEM

• Hood cover: 1

• Hood base: 1

• Waterproof packing FHV-XWP-CAM: 2

• Hexagonal wrench: (length: 60 mm): 1

Mounting Fixtures

Appearance Description Model Package contents

For Smart Camera body

and lighting controller

mounting

For lighting controller

mounting

FHV-XMT-7 None

FHV-XMT-7-TCC Screws: M5×8 mm: 5

Waterproof Packings

Appearance Description Model

For camera: 5

*1

FHV-XWP-CAM

1 - 6

For internal lighting: 5

*1

FHV-XWP-LTM

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 39

1 Confirm the Package

Appearance Description Model

For hood: 5

*1. After this was used once, replace this with the new one when mounting and dismounting lens or lighting

module.

*1

FHV-XWP-HD-SL

Waterproof Caps

Appearance Description Model

For lighting connector FHV-XWC-LCN

For Ethernet connector FHV-XWC-ECN

Light-shielding Sheet

Appearance Description Model

For lighting module: 3

*1

FHV-XLS-LTM

1-2 Sold Separately

1

1-2-3 Accessories

*1. After this was used once, replace this with the new one when mounting and dismounting lens or lighting

module.

FHV Series Smart Camera Setup Manual (Z408-E1)

1 - 7

Page 40

1 Confirm the Package

1-2-4

Lighting and Lighting Controller

Appearance Description Model

-

External lighting - FLV series

- FL series

Lighting Controller

(Required to control

external lighting form

a Smart Camera)

For FLV series Camera mount

lighting controller

Analog lighting

controller

For FL series Camera mount

lighting controller

Digital lighting

controller

FLV-TCC series

FLV-ATC series

FL-TCC series

FL-STC series

1-2-5

For the setting method of lighting controllers, refer to those instruction sheets respectively.

Software

Appearance Description Model

- FH_FHV Remote Operation Tool -

The Remote Operation tool and the simulation software are possible to download with free by doing

the member registration after purchasing the Smart Camera. For details, refer to the membership reg-

istration sheet packed with the Smart Camera.

1 - 8

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 41

2

2

Overview of FHV Series

2-1 Overview of System .....................................................................................2 - 2

2-1-1 Basic System of Measurement ..................................................................... 2 - 2

2-2 Flow of Use Procedure ................................................................................2 - 7

FHV Series Smart Camera Setup Manual (Z408-E1)

2 - 1

Page 42

2 Overview of FHV Series

2-1

2-1-1

Overview of System

Basic System of Measurement

FHV series use pre-built packages that contain all the processing tasks (for image input, measurement

processing, displays, outputs, etc.) that are required for vision inspections.

Users arrange these packaged processes to make measurement flows with in order of execution of

the vision inspection.

An FHV executes vision inspections according to user-created flows.

Additional Information

In the FHV settings, a flow containing packaged processes that are arranged in order of execution of processing items and image processing is called a measurement flow.

Processing items and measurement flows can have more than one setting. You can switch the

setting based on the scene to inspect.

For details, refer to the Vision System FH/FHV/FZ5 series User's Manual (Cat. No. Z365).

2 - 2

FHV Series Smart Camera Setup Manual (Z408-E1)

Page 43

Defect

Search

Measurement flow

FHV

Output Unit

Image Sensor

Measurement

trigger

• Judgement

result

• Measured

values

Measurement

results are

output

The measurement flow is executed basically in

order of the unit numbers.

Image input

from the

Camera

Measurement

processing of

the input image

PLC or other external device

Image Input

2 Overview of FHV Series

Concept of Measurement Processing

When the FHV receives a measurement trigger from the PLC or other external device, the image input

from a Camera, measurement processing, and output of measurement results (e.g., OK/NG judge-

ment results) are executed in the order that those processing items are registered in the measurement

flow.

2-1 Overview of System

2

2-1-1 Basic System of Measurement