Page 1

Vision Sensor

FH/FZ5 Series

Vision System

User’s Manual

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ5-6

FZ5-6-

FZ5-11

FZ5-11-

FZ5-L35

FZ5-L35-

Z365-E1-02

Page 2

Introduction

Thank you for purchasing the FH/FZ5.

This manual provides information regarding functions, performance and operating methods that

are required for using the FH/FZ5.

When using the FH/FZ5, be sure to observe the following:

• The FH/FZ5 must be operated by personnel knowledgeable in electrical engineering.

• To ensure correct use, please read this manual thoroughly to deepen your understanding of the

product.

• Please keep this manual in a safe place so that it can be referred to whenever necessary.

NOTE

• All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system, or transmitted, in any form, or by any means, mechanical,

electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

• No patent liability is assumed with respect to the use of the information

contained herein. Moreover, because OMRON is constantly striving to improve

its high-quality products, the information contained in this manual is subject

to change without notice. Every precaution has been taken in the preparation of

this manual. Nevertheless, OMRON assumes no responsibility for errors or omis

sions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

Trademarks

•

Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation

in Japan and other countries for OMRON factory automation products.

•

This software is based in part on the work of the Independent JPEG Group.

Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trade-

•

marks or trademarks of Microsoft Corporation in the United States and other countries.

Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other

•

countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

•

Automation GmbH, Germany.

•

ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

The SD and SDHC logos are trademarks of SD-3C, LLC.

•

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

•

•

MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks

or registered trademarks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

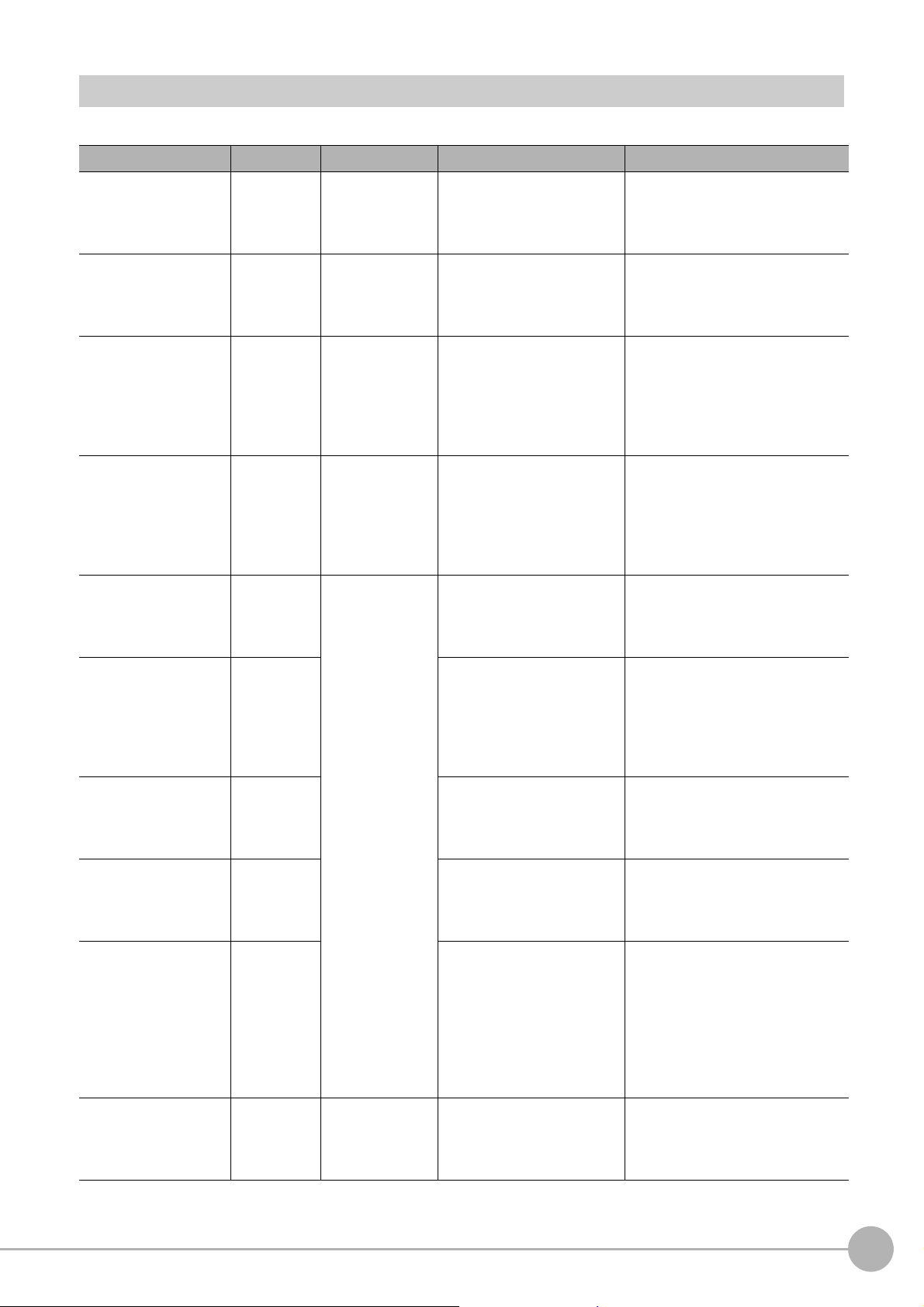

Structure of FH/FZ5 Manuals

The following table gives the manual configuration of the FH/FZ5.

Name of Manual Cat. No. Model Proposes Contents

Vision System FH

Instruction Sheet

Vision System FH-L

Instruction Sheet

Vision System FZ5

Instruction Sheet

Vision System FZ5-L

Instruction Sheet

Vision System FH/FZ5

Series User’s Manual

Vision System FH/FZ5

series Hardware Setup

Manual

Vision System FH/FZ5

series Macro Customize

Functions Programming

Manual

Vision System FH/FZ5

series Processing Item

Function Reference

Manual

Vision System FH/FZ5

Series User’s Manual

for Communications

Settings

Vision System FH

Series Operation

Manual for Sysmac

Studio

9607479-9

9606631-1

9524422-4

9910002-2

Z365

Z366

Z367

Z341

Z342

Z343

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ5-6

FZ5-6-

FZ5-11

FZ5-11-

FZ5-L35

FZ5-L35-

FH-1

FH-1-

FH-3

FH-3-

FH-L

FH-L-

FZ5-L35

FZ5-L35-

FZ5-6

FZ

5-6-

FZ5-11

FZ5-11-

FH-1

FH-1-

FH-3

FH-3-

To confirm the safety and

usage precautions of the

Vision System FH series

Sensor Controller.

To confirm the safety and

usage precautions of the

Vision System FH-Lite series

Sensor Controller.

To confirm the setup

procedures, safety and

usage precautions of the

Vision System FZ5 series

Sensor Controller, including

I/O setup and wiring

To confirm the setup

procedures, safety and

usage precautions of the

Vision System FZ5-L Series

Sensor Controller, including

I/O setup and wiring.

When User want to know how

to setup the Sensor Controller

of the Vision System FH/FZ5

series.

When User want to know

about the Hard-ware

specifications or to setup the

Sensor Controller of the

Vision System FH/FZ5

series.

When User operate or

programming using Macro

Customize functions.

When User confirm the details

of each processing items at

the create the measurement

flow or operate it.

When User confirm the

setting of communication

functions.

When User connect to NJ

series via EtherCAT

communication.

Describes the definitions of basic

terms, meaning of signal words,

and precautions for correct use of

FH series in the manual.

Describes the definitions of basic

terms, meaning of signal words,

and precautions for correct use of

FH-L series in the manual.

Describes the definitions of basic

terms, meaning of signal words,

and precautions for correct use of

FZ5 series in the manual.

Describes the definitions of basic

terms, meaning of signal words,

and precautions for correct use of

FZ5-L series in the manual.

Describes the soft functions, setup,

and operations to use Sensor

Controller of the Vision System FH/

FZ5 series.

Describes FH/FZ5 series

specifications, dimensions, part

names, I/O information, installation

information, and wiring information.

Describes the functions, settings,

and operations for using Macro

Customize function of the FH/FH5series.

Describes the software functions,

settings, and operations for using

FH/FH5-series.

Describes the functions, settings,

and communications methods for

communicating between FH/FH5

series.

The following communication

protocol are described.

Parallel, PLC Link, EtherNet/IP,

EtherCAT, and Non-procedure

Describes the operating

procedures for setting up and

operating FH series Vision Sensors

from the Sysmac Studio FH Tools.

Vision System FH/FZ5 Series

User’s Manual (Z365)

1

Page 4

Conventions Used in This Manual

Symbols

The symbols used in this manual have the following meanings.

IMPORTANT

Note

Indicates relevant operational precautions that must be followed.

Indicates operation-related suggestions from OMRON.

Use of Quotation Marks and Brackets

In this manual, menus and other items are indicated as follows.

[ ] Menu Indicates the menu names or processing items shown in the menu bar.

“ ” Item name Indicates the item names displayed on the screen.

2

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 5

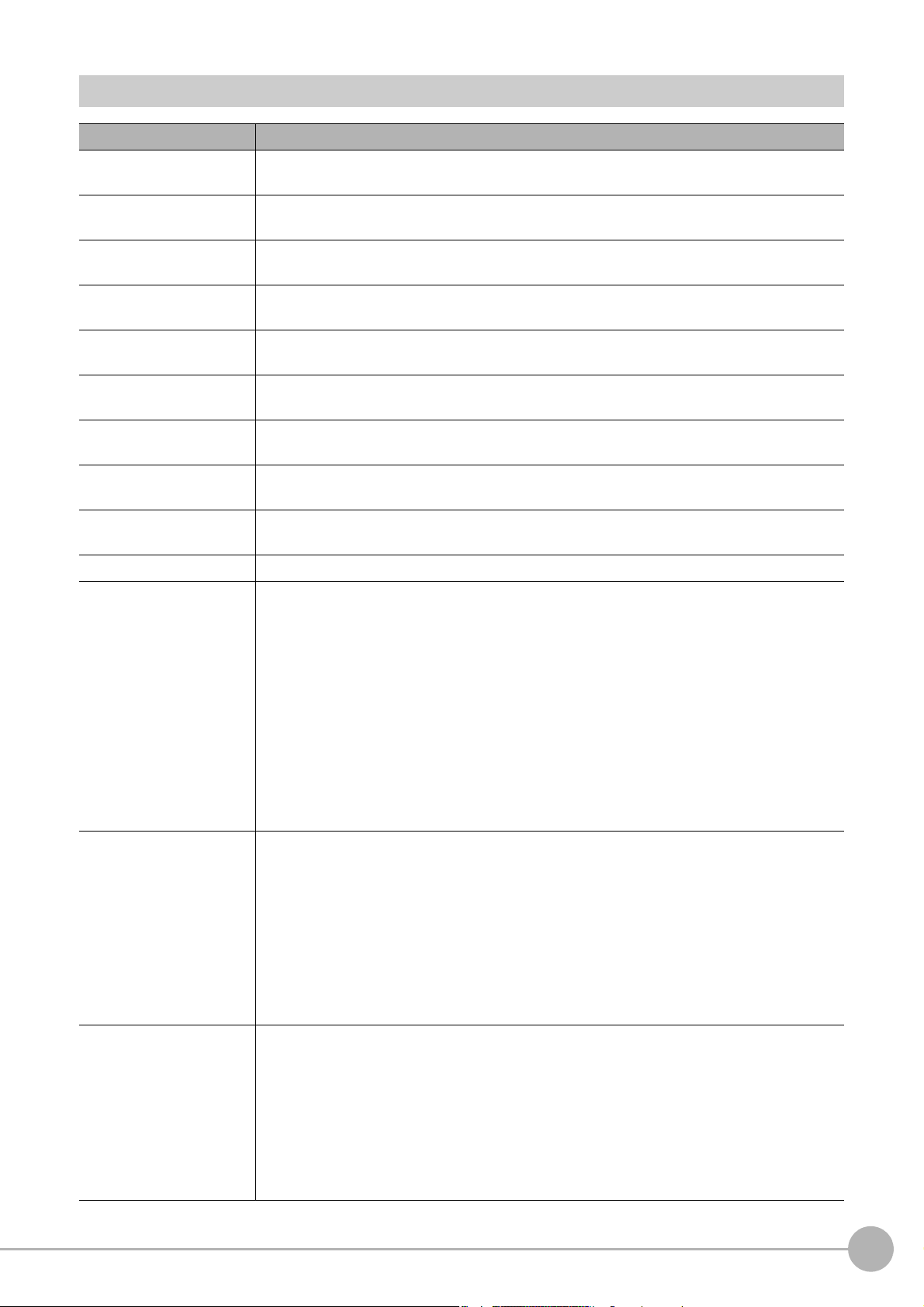

Definitions of Basic Terms

Ter m Definition

FH series

All FH series model names as follows:

FH-1, FH-1-, FH-3, FH-3-, FH-L, FH-L-

FH-1000 series

FH-3000 series

FH-L series

FZ5 series

FZ5-600 series

FZ5-1100 series

FZ5-L series

measurement flow

(a

measurement processing Executing processing items for inspections and measurements.

Measurement ID

processing item

bbrevia

ted as “flow”)

All FH-1 series model names as follows:

FH-1, FH-1-

All FH-3 series model names as follows:

FH-3, FH-3-

All FH-L series name the following:

FH-L, FH-L-

All FZ5 series name shows the following:

FZ5-6, FZ5-6-, FZ5-11, FZ5-11-, FZ5-L35, FZ5-L35-

All FZ5-6 series name the following:

FZ5-6, FZ5-6-

All FZ5-11 series name the following:

FZ5-11, FZ5-11-

All FZ5-L35 series name the following:

FZ5-L35, FZ5-L35-

A continuous flow of measurement processing. A measurement flow consists of a scene

created from a combination of processing items.

Information of time when the sensor controller receives the measurement trigger and the line no.

Format of measurement ID: YYYY-MM-DD_HH-MM-SS-XXXX

YYYY: Year (4 digits)

MM: Month

DD: Date

HH: Hour

MM: Minute

SS: Second

XXXX: Millisecond

Example:

Measured time: 12/24/2007, 11:10:25.500:

Line: 0

Measurement ID: 2007-12-24_11-10-25-5000

Any of the individual items for vision inspections that are partitioned and packaged so that they

can be flexibly combined.

These include the Search, Position Compensation, and Fine Matching items.

Processing items can be classified for image input ([Input image]), inspection/measurement

([Measurement]), image correction ([Compensate image]), inspection/measurement support

([Support measurement]), process branching ([Branch]), results external output ([Output

result]), resulting image display ([Display result]), etc.

You can freely classify processing items to handle a wide range of applications.

A scene (i.e., a unit for changing the measurement flow) is created by registering the

processing items as units.

A unit for changing the measurement flow that consists of a combination of processing items.

“Scene” is used because of the correspondence to the scene (i.e., type of measurement object

and inspection contents) where measurements are performed.

A scene is created for each measurement or measurement contents.

scene

Vision System FH/FZ5 Series

User’s Manual (Z365)

You can easily achieve a changeover simply by changing the scene when the measurement

object or inspection content changes.

Normally you can set up to 128 scenes. If you need more than 128 scenes, you can separate

them into different groups or use the Conversion Scene Group Data Tool to create a scene

group that contains over 128 scenes.

3

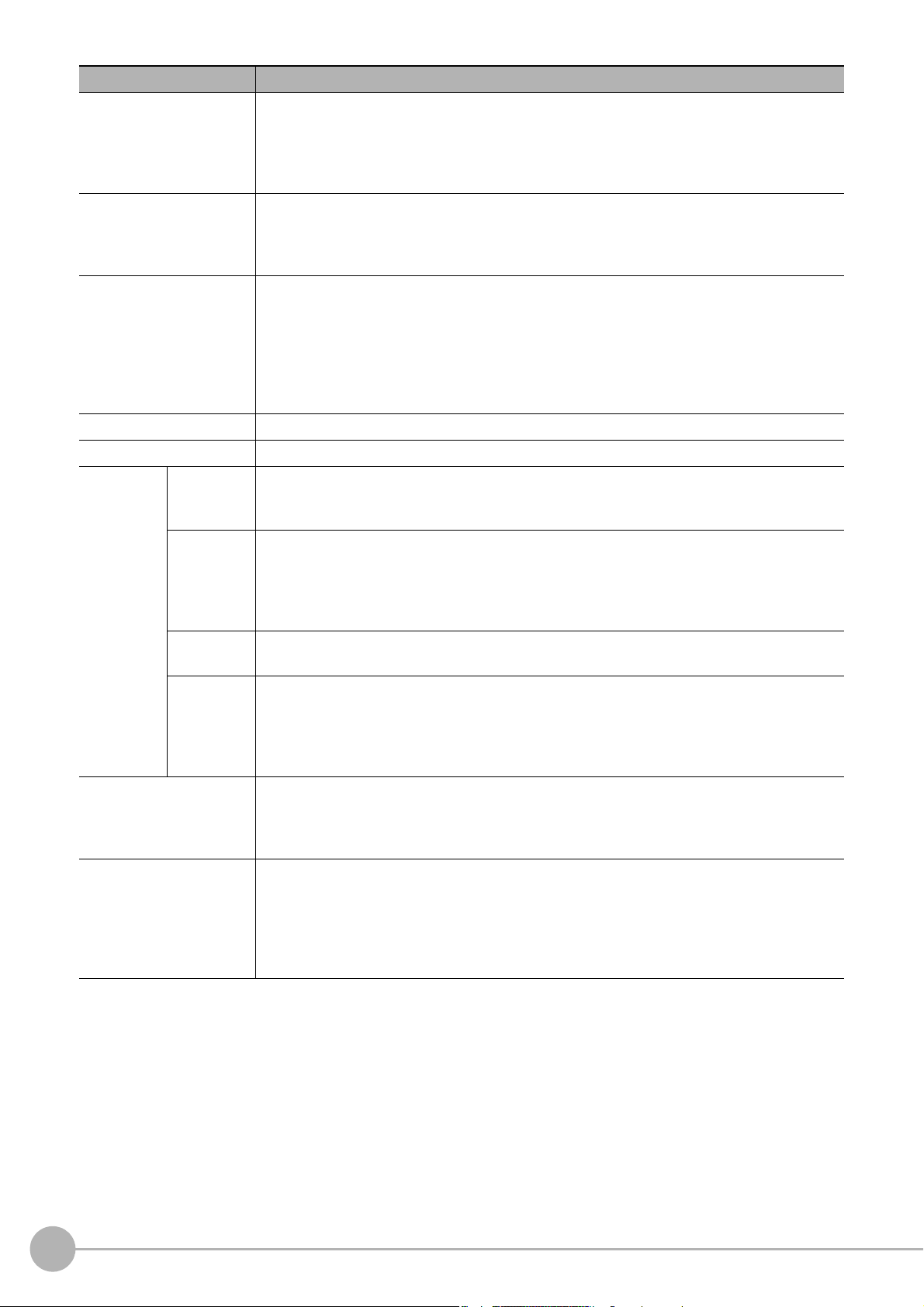

Page 6

Ter m Definition

A processing item that is registered in a scene.

processing unit

(abbreviated as “unit”)

measurement trigger

test measurement

single measurement A measurement that is executed only once in synchronization with the trigger input.

continuous measurement Measurements are executed repeatedly and automatically without a trigger input.

Double

Speed Multiinput

Multi-line

Randomtrigger

operation

modes

Non-stop

Adjustment

Standard

parallel processing (an

option for any of the above

operation modes)

Numbers are assigned to processing units in order from the top and they are executed in that

order.

Processing items are registered for the processing units to create a scene (i.e., a unit for

changing the measurement flow).

A trigger for executing measurements.

With a parallel interface, the STEP signal or command 00 (Continuous Measurement) is used. With

a serial interface, an Execute One Measurement or a Start Continuous Measurement command is

used.

A measurement that is performed to manually test (check) measurements under the conditions

that are set in the currently displayed scene.

Test measurements can be executed on an Adjustment Window. Processing is completed

inside the Controller and the measurement results are not normally output on an external

interface.

However, you can select [Output] in [Test measurement] to output the measurement results

after executing measurements.

A mode that processes the measurement flow for the first trigger and then processes the

measurement flow in parallel for the second trigger to achieve a high-speed trigger input

interval. It is used together with the multi-input function.

A trigger mode that allows you to independently processing multiple measurement flows.

With traditional image processing, two or more triggers cannot be acknowledged at the same

time.

In Multi-line Random-trigger Mode, you can randomly input multiple triggers into one Controller

to independently process multiple scenes in parallel.

A mode that allows you to adjust the flow and set parameters while performing measurements.

The enables adjustments without stopping the line or stopping inspections.

A logging mode that allows complete parallel processing of measurements and logging.

Traditionally, logging was not possible while processing measurements. Either measurements

or logging had to be given priority and the other one had to wait.

With this mode, you can save the measurement images in external memory without affecting

the transaction time.

Parallel processing splits part of the measurement flow into two or more tasks, and processes

each task in parallel to shorten the transaction time.

Processing items for parallel processing are used so that the user can specify the required

parallel processing.

multi-input function

4

A function that is used to consecutively and quickly input images.

It allows the next STEP signal to be acknowledged as soon as the image input processing is

completed. There is no need to wait for measurement processing to be completed.

You can check whether image input processing has been completed with the status of the

READY signal. Even if the READY signal is ON when measurement processing is being

executed, the next STEP signal can be acknowledged.

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 7

Ter m Definition

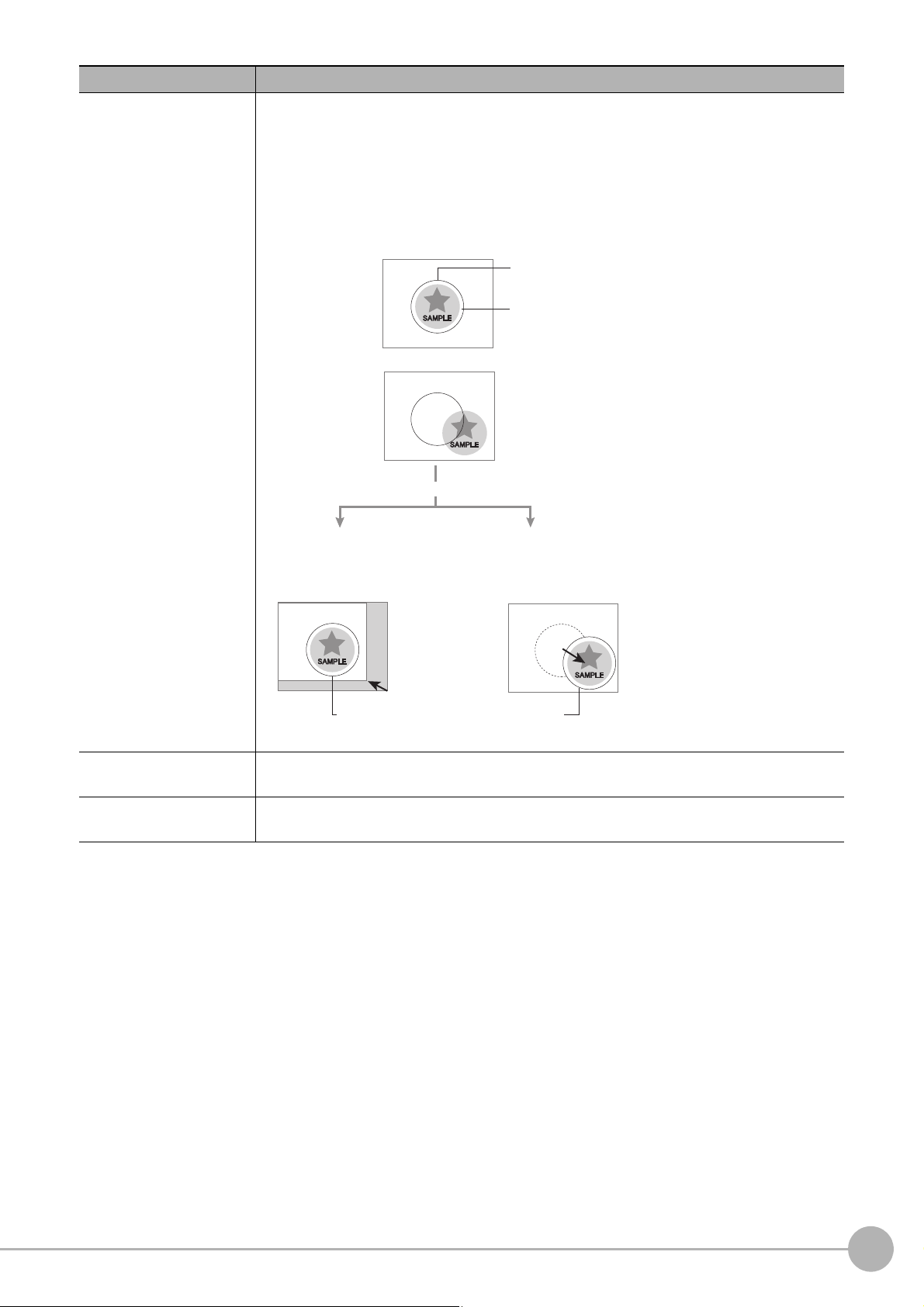

When position of object to be measured is deflected

When position deflection correction is set in advance:

Object to be measured

overflows Measurement area.

Reference position

Measurement area and objects to be measured

are correctly aligned.

Object to be measured

Measurement area

Measurement will be carried out

after measured object enters into Measurement area.

Measurement will be carried out after

moving the Measurement area for a

corresponding deflection.

Measurement will be carried out

after moving the image for a

corresponding deflection and

returning to the reference position.

Position compensation

When the locatio

between reference position and current position is calculated and measurement is performed

after correcting.

Please select processing items that are appropriate to the measurement object from

processing items that are related to position compensation.

n and direction of measured objects are not fixed, the positional deviation

Reference position

Model

The point that is always the reference. If the location of the registered model is different from

the reference position, the setting should be changed in [Ref. setting].

The image pattern that serves as the inspection target. Characteristics portions are extracted

from images of the object and registered as model registration.

Vision System FH/FZ5 Series

User’s Manual (Z365)

5

Page 8

Ter m Definition

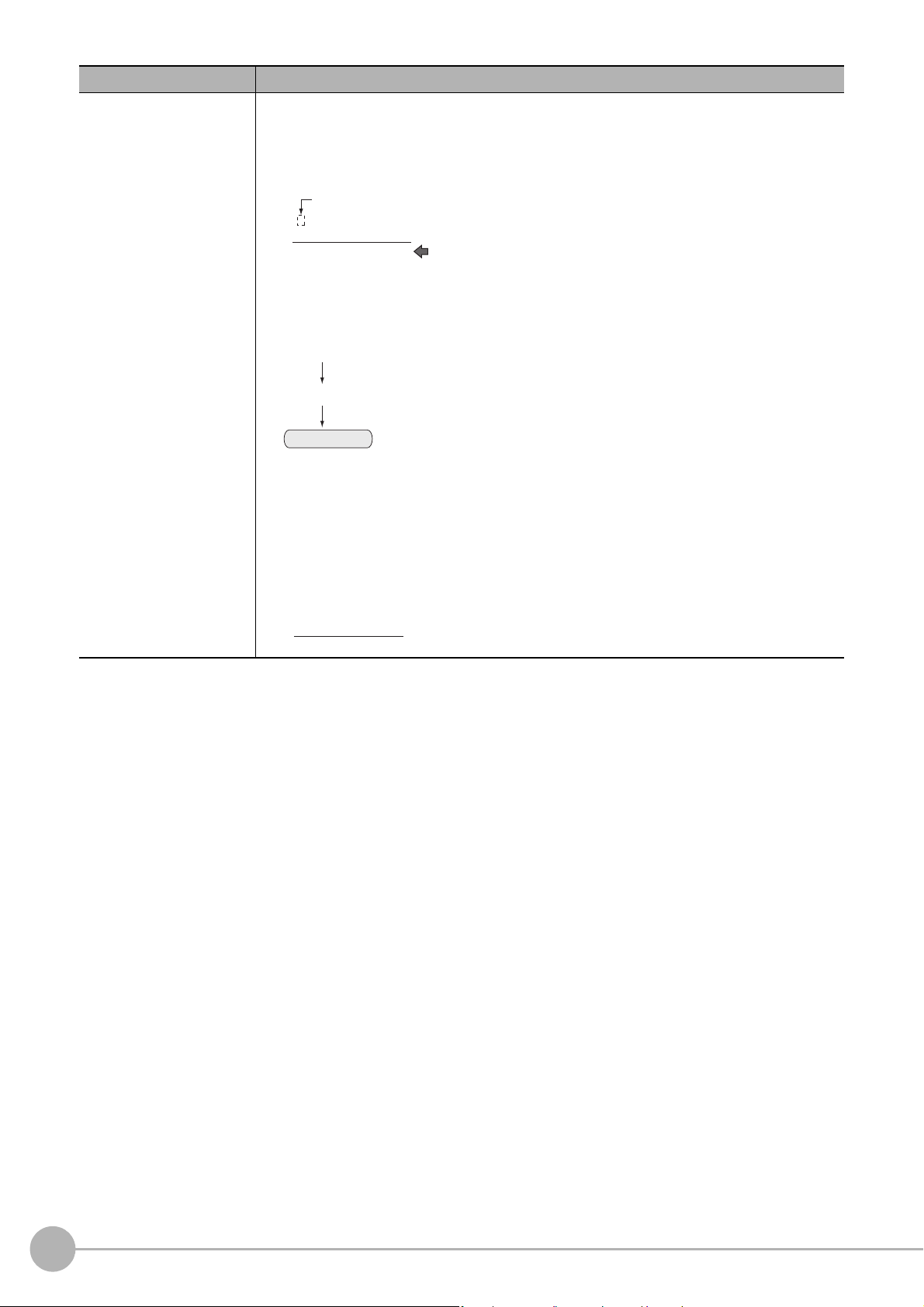

−“1” is expresses with 2’s Complement (for 8 bits)

00000000 (= 0)

−

)

(In the case of 1, minus 1)

00000001 (= 1)

11111111 (=−1)

(

2's complement

Binary numbers are generally used to represent negative numbers.

Negative numbers are expressed by "Inverting all bits of a positive number and adding 1 to the

result".

(Example) "−1" is expressed as 2's complement

"−1" can be calculated by "0-1".

There are methods for simple calculation without performing this kind of computation.

For instance, "Negative number = inverting all bits of a positive number and then adding 1 to

the result".

00000001 (= 1)

Invert all bits

11111110

Plus 1

11111111 (=−1)

The first digit is used to judge whether the number is positive or negative.

• When 0: Positive number (or 0)

• When 1: Negative number

The advantage of two's complement numbers is that positive and negative numbers can be

used as is in calculations.

(Example) When −1+10=9

1

1111111 (= −1)

+)00001010 (= 10)

00001001

= 9)

6

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 9

Contents

Structure of FH/FZ5 Manuals ............................................................................................................... 1

Conventions Used in This Manual ........................................................................................................ 2

Definitions of Basic Terms .................................................................................................................... 3

Terms and Conditions Agreement ...................................................................................................... 13

Safety Precautions .............................................................................................................................. 15

Precautions for Safe Use .................................................................................................................... 17

Precautions for Correct Use ............................................................................................................... 20

Regulations and Standards ................................................................................................................ 23

1. Before Operation ..........................................................................................................................27

Overview .................................................................................................................................................. 28

Basic Mechanism for Measurements .................................................................................................. 28

Support for a Variety of Scenes and Measurement Lines .................................................................. 29

Flow of Application ................................................................................................................................... 31

Windows .................................................................................................................................................. 33

Types of Windows .............................................................................................................................. 33

Overview of Window Navigation ......................................................................................................... 34

Main Window (Layout 0): Adjustment Window (Default) .................................................................... 35

Main Window (Layout 1): Run Window (Default) ................................................................................ 41

Menu List ............................................................................................................................................ 42

Checking the System Configuration ......................................................................................................... 44

System Configuration ......................................................................................................................... 44

Functional Comparison between the FH-series and FZ5-series Controllers ...................................... 45

Saving Settings before Turning OFF the Power and Restarting .............................................................. 49

Restarting the Controller: [System Restart] ........................................................................................ 49

Turning OFF the LCD ......................................................................................................................... 50

Accuracy .................................................................................................................................................. 51

Initializing the Controller ........................................................................................................................... 52

Initializing the Controller: [System initialization] .................................................................................. 52

2. Setting Scenes (Measurement Flows) ........................................................................................53

What Is a Scene? ..................................................................................................................................... 54

Example of a Scene ............................................................................................................................ 55

What Is a Scene Group? .......................................................................................................................... 57

Creating a Scene ..................................................................................................................................... 58

Editing Processing Units in Scenes ......................................................................................................... 59

Displaying and Checking Processing Branches in a Scene .................................................................... 62

Changing the Scene or Scene Group ...................................................................................................... 66

Changing the Scene ........................................................................................................................... 66

Changing Scene Groups .................................................................................................................... 66

Editing Scenes ......................................................................................................................................... 68

Copying Scenes .................................................................................................................................. 68

Deleting Scenes .................................................................................................................................. 68

Renaming a Scene and Adding a Description .................................................................................... 69

Editing Scene Groups .............................................................................................................................. 70

Copying and Deleting Scene Groups ................................................................................................. 70

Changing the Scene Group Name ...................................................................................................... 71

Vision System FH/FZ5 Series

User’s Manual (Z365)

7

Page 10

3. Performing Test Measurement/Starting Operation ...................................................................73

Adjustment Windows and Run Windows ................................................................................................. 74

Main Window (Layout 0): Adjustment Window (Default) .................................................................... 74

Main Window (Layout 1): Run Window (Default) ................................................................................ 75

Main Window (Layout 1): Changing to the Run Window .................................................................... 75

Main Window (Layout 1): Changing to the Adjustment Window ......................................................... 75

Preparing the Controller and Cameras .................................................................................................... 76

Camera Setup ..................................................................................................................................... 76

Preparing a Controller ......................................................................................................................... 78

Adjusting the Camera ......................................................................................................................... 78

Executing Test Measurements ................................................................................................................ 79

Key Points for Adjustment ........................................................................................................................ 80

Stabilizing Measurements ................................................................................................................... 80

Shortening Processing Time ............................................................................................................... 81

Arranging Windows .................................................................................................................................. 83

Arranging Window Elements (Layout Modification) ............................................................................ 83

Setting the Behavior of Output Signals for Each Layout (Layout Settings) ........................................ 98

Changing Layout Numbers in the Main Window ................................................................................. 98

Troubleshooting .................................................................................................................................. 99

Arranging the Window Display ............................................................................................................... 100

Changing the Image Mode and Other Display Contents .................................................................. 100

Custom Dialogs ...................................................................................................................................... 103

Flow of Use ....................................................................................................................................... 103

Custom Dialog Tool .......................................................................................................................... 104

Launching Your Custom Dialog Box ................................................................................................. 115

Useful Functions for Operation .............................................................................................................. 116

Remeasuring Saved Images ............................................................................................................ 116

Improving Adjustment Efficiency ....................................................................................................... 117

Changing Judgement Conditions without Stopping Measurement ................................................... 118

Changing Regions as a Batch [Shift area] ........................................................................................ 119

Monitoring Measurement Value Trends ............................................................................................120

Logging Measurement Values and Measurement Images ............................................................... 120

Analyzing Logged Data ..................................................................................................................... 132

Clearing Measurement Results ........................................................................................................ 134

Clearing Saved Images .................................................................................................................... 134

Capturing Screen Images ................................................................................................................. 134

Checking the Memory Consumption and Percentage of Memory Used ........................................... 136

Using the Operation Log ................................................................................................................... 137

Operation Log Format ....................................................................................................................... 139

Saving Data to an External Device ................................................................................................... 140

8

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 11

4. Using Tools .................................................................................................................................143

Limiting user operations (Security settings) ........................................................................................... 144

Setting Accounts (Account List) ........................................................................................................ 144

Setting Layout Restrictions ............................................................................................................... 146

Setting User Group Operation Restrictions ......................................................................................147

Saving/Loading/Deleting the Security Settings ................................................................................. 149

Changing between user accounts .......................................................................................................... 155

Logging in ......................................................................................................................................... 155

Logging Out ...................................................................................................................................... 155

Saving Scene groups in external memory (Scene Group Saving Destination settings) ........................ 156

Analyzing inspection and measurement results (NG analyzer) ............................................................. 158

Layout of NG Analyzer Window ........................................................................................................ 159

Using Method of NG Analyzer .......................................................................................................... 160

Sharing data within the controller (User data tool) ................................................................................. 163

Setting Procedure for User Data ....................................................................................................... 163

Outputting a List of Scene Data Set Values (Settings download and upload tools) .............................. 165

Downloading Set Values ................................................................................................................... 165

About Downloaded CSV Files .......................................................................................................... 165

Uploading Set Values ....................................................................................................................... 167

Saving Image files to a RAMDisk, or External memory device (Image file save) .................................. 168

Managing images used for model registration and reference (Registered Image Manager) ................. 170

Registering Images ........................................................................................................................... 170

Loading an Image ............................................................................................................................. 171

Customizing communication commands (Communication command macro) ....................................... 172

Displaying a measurement flow as a flowchart while editing it (Flow viewer) ........................................ 173

Verifying calibration results (Calibration support tool) ............................................................................ 174

Updating the referenced position data for a unit in the measurement flow

(Update standard position tool) .............................................................................................................. 175

Increasing the number of scenes in a group to more than 128 scenes

(Conversion scene group data tool) ....................................................................................................... 177

Create a customized settings dialog box (Custom dialog tool) .............................................................. 180

Extending the functions in a measurement flow, or scene (Scene Control Macro Tool) ....................... 181

Backing up Sensor Controller setting data (Configuration copy) ........................................................... 182

Before backing up ............................................................................................................................. 182

Backing up Sensor Controller settings .............................................................................................. 184

Restoring settings with saved settings data ...................................................................................... 194

Troubleshooting ................................................................................................................................ 197

Changing settings for each line in Multi-line Random-trigger mode (Line Maintenance) ....................... 199

Before use of Line Maintenance ....................................................................................................... 199

Line Maintenance tool operations ..................................................................................................... 202

Operating with Functional Limitations ............................................................................................... 209

Troubleshooting ................................................................................................................................ 213

Remotely operating the controller (Remote Operation) ......................................................................... 214

Overview ........................................................................................................................................... 214

Operation Environment Condition ..................................................................................................... 215

How to Start ...................................................................................................................................... 217

Vision System FH/FZ5 Series

User’s Manual (Z365)

9

Page 12

5. Saving Data to the FH series/FZ5 series ..................................................................................221

Saving Data to the FH series/FZ5 series ............................................................................................... 222

About Saving Areas .......................................................................................................................... 222

External Drive Names ....................................................................................................................... 223

Using External Memory Devices (FH series/FZ5-1100 series only) ................................................. 224

Shared folder on a computer connected to the network ................................................................... 224

Saving Settings Data to the Flash Memory and Restarting ................................................................... 225

Saving Settings Data to the Controller RAMDisk or an External Memory Device ................................. 226

Saving Logged Images in the Controller Memory (RAM) to a RAMDisk or

an External Memory Device ................................................................................................................... 227

Copying or Moving Files between the Controller RAMDisk and an External Memory Device ............... 228

Loading Settings Data from the Controller RAMDisk or an External Memory Device to the

Sensor Controller ................................................................................................................................... 229

6. Changing the System Environment .........................................................................................231

Setting the Camera Conditions .............................................................................................................. 232

Checking the Camera Connections: [Camera Connection] .............................................................. 232

Setting the Trigger Delay: [Inter-camera setting] ..............................................................................232

Setting the SHTOUT Signal: [Output Signal Settings] ...................................................................... 235

Setting the Conditions That Are Related to Operation during Measurement ......................................... 237

Setting the Operation Mode ................................................................................................................... 238

Selection Guide for Operation mode ................................................................................................ 239

Double Speed Multi-input ................................................................................................................. 240

Multi-line Random-trigger Mode ....................................................................................................... 244

Non-stop Adjustment Mode .............................................................................................................. 250

Standard (Operation Mode) .............................................................................................................. 252

Parallel Processing ................................................................................................................................ 253

Parallel Processing Settings (Automatic Parallelization) .................................................................. 253

Parallel Processing Settings (Manual Parallelization) ...................................................................... 253

Specific Example of Parallel Processing .......................................................................................... 255

Restrictions ....................................................................................................................................... 256

Setting Procedures ........................................................................................................................... 259

Multi-trigger Imaging Processing Function ............................................................................................. 263

Settings for Multi-trigger Imaging ...................................................................................................... 264

Restrictions ....................................................................................................................................... 266

Setting Methods ................................................................................................................................ 267

About Multi-input function (Multi-trigger Imaging) .............................................................................271

Troubleshooting ................................................................................................................................ 276

Setting the Operating Environment of the System ................................................................................. 277

Selecting Language [Startup Settings] ............................................................................................. 277

Setting the Status at Startup [Startup Settings] ................................................................................ 278

Setting Communication [Startup Settings] ........................................................................................ 280

Setting Operation mode [Startup Settings] ....................................................................................... 284

Date-time setting [Other] ................................................................................................................... 285

Fan control setting [Other] ................................................................................................................ 285

STEP setting [Other] ......................................................................................................................... 286

Encoder trigger setting [Other] .......................................................................................................... 287

Network drive setting [Other] ............................................................................................................ 289

Error Setting [Other] .......................................................................................................................... 291

Checking System Information [System Information] ......................................................................... 293

10

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 13

7. Appendices ................................................................................................................................297

Alignment ............................................................................................................................................... 298

Overview ........................................................................................................................................... 298

Execution of Calibration .................................................................................................................... 301

Troubleshooting ................................................................................................................................ 308

Alignment .......................................................................................................................................... 309

Alignment Processing Items ............................................................................................................. 316

Error Messages and Troubleshooting .................................................................................................... 317

FAQ ........................................................................................................................................................ 323

During Start-up ................................................................................................................................. 323

During Operation .............................................................................................................................. 324

For Measurement ............................................................................................................................. 325

About Parallel Interface ................................................................................................................... 326

Serial Interface (RS-232C/422 Connection) ..................................................................................... 327

Camera with Lighting Controller ....................................................................................................... 327

Measurement Mechanism ...................................................................................................................... 328

Color Processing Mechanism .......................................................................................................... 328

Search Processing Mechanism ....................................................................................................... 329

Edge Detection Measurement .......................................................................................................... 332

Defect Detection Measurement ........................................................................................................ 335

Handling Coordinates ...................................................................................................................... 336

Basic Knowledge about Operations ....................................................................................................... 337

Inputting Values ............................................................................................................................... 337

Inputting Text ................................................................................................................................... 337

Selecting Files and Folders ............................................................................................................. 338

Available Operations in Select File Window ....................................................................................340

Using the Zoom Function .................................................................................................................. 341

Setting Figures ....................................................................................................................................... 342

Layout of Figure Setting Area .......................................................................................................... 342

Setting Methods ............................................................................................................................... 343

About OR Setting/NOT Setting ......................................................................................................... 349

Image file ............................................................................................................................................... 350

About Number of Logging Images ......................................................................................................... 352

About Limits on the Number of Image Input Processing Items Used .................................................... 355

About Max. Number of Loading Images during Multi-input .................................................................... 356

Character Code Table ............................................................................................................................ 357

About Memories Usable with FH series/FZ5 series ............................................................................... 358

Memory Usage Guidance For Processing Items ................................................................................... 359

Memory Display Image on PLC I/O ....................................................................................................... 364

Operation log input information list ........................................................................................................ 366

Manual Revision History ........................................................................................................................ 379

Vision System FH/FZ5 Series

User’s Manual (Z365)

11

Page 14

12

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 15

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a

period of twelve months from the date of sale by Omron (or such other period expressed in writing by

Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on

infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally shipped

with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii)

repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price of the

non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity

or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or

inappropriate modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of

Products in combination with any electrical or electronic components, circuits, system assemblies or any

other materials or substances or environments. Any advice, recommendations or information given orally or

in writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which

liability is asserted.

Vision System FH/FZ5 Series

User’s Manual (Z365)

13

Page 16

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying ratings and limitations of use

which apply to the Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to

Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any

consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user

in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test

conditions, and the user must correlate it to actual application requirements. Actual performance is subject to

the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the Product may be changed

without any notice. When in doubt, special part numbers may be assigned to fix or establish key

specifications for your application. Please consult with your Omron’s representative at any time to confirm

actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical or proofreading errors or omissions.

14

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 17

Safety Precautions

CAUTION

Symbols and the meanings for safety precautions described in this manual.

In order for the product to be used safely, the following indications are used in this book to draw your attention

to the cautions. The cautions with the indications describe the important contents for safety.

Indicates a potentially hazardous situation which, if not avoided, will result in minor or moderate

WARNING

injury, or may result in serious injury or death.

Additionally there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or in property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

General Prohibition

Indicates general prohibitions, including warnings, for which there is no specific symbol.

General Caution

Indicates general cautions, including warnings, for which there is no specific symbol.

Electrical Hazard

Indicates the possible danger of electric shock under specific conditions.

Explosion Hazard

Indicates the possible danger of explosion under specific conditions.

Laser Radiation Hazard

Indicates the possible danger of laser radiation or light.

High Temperature Caution

Indicates the possible danger of injury by high temperature under specific conditions.

Vision System FH/FZ5 Series

User’s Manual (Z365)

15

Page 18

Alert statements in this Manual

WARNING

The following alert statements apply to the products in this manual. Each alert statement also appears at the

locations needed in this manual to attract your attention.

This product must be used according to this manual or Instruction sheet.

Failure to observe this may result in impairment of functions and performance of the product.

This product is not designed or rated for ensuring safety of persons. Do not use it for such purposes.

Never connect the AC power supply with this product.

When the AC power supply is connected, it causes the electric shock and a fire.

A lithium battery is built into the Controller and may occasionally combust, explode, or burn if not

treated properly. Dispose of the Controller as industrial waste, and never disassemble, apply

pressure that would deform, heat to 100°C or higher, or incinerate the Controller.

Since camera that can be connected with this product emits a visible light that may have an adverse

effect on the eyes, do not stare directly into the light emitted from the LED. If a specular object is

used, take care not to allow reflected light enter your eyes.

Do not touch the terminals while the power supply is ON. Doing so may result in electrical shock.

Please take external safety measures so that the system as a whole should be on the safe side even

if a failure of a Sensor Controller or an error due to an external factor occurred. An abnormal

operation may result in serious accident.

Please take fail-safe measures on your side in preparation for an abnormal signal due to signal

conductor disconnection and/or momentary power interruption. An abnormal operation may result in

a serious accident.

CAUTION

Danger of burns. Do not touch the case while the LED is ON or just after power is turned OFF, since

it remains extremely hot.

16

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 19

Precautions for Safe Use

Condition of the fitness of OMRON products

• Please do not use this product to directly or indirectly use to detect the human body for the purpose of

ensuring the safety. In the same application, please use the safety sensor that is published on our sensor

catalog.

• Omron products are designed and manufactured as general-purpose products for use in general industrial

applications. They are not intended to be used in the following critical applications. If you are using Omron

products in the following applications, Omron shall not provide any warranty for such Omron products,

unless otherwise specifically agreed or unless the specific applications are intended by Omron.

(a) Applications with stringent safety requirements, including but not limited to nuclear power control

equipment, combustion equipment, aerospace equipment, railway equipment, elevator/lift equipment,

amusement park equipment, medical equipment, safety devices and other applications that could

cause danger/harm to people’s body and life.

(b) Applications that require high reliability, including but not limited to supply systems for gas, water and

electricity, etc., 24 hour continuous operating systems, financial settlement systems and other

applications that handle rights and property.

(c) Applications under severe condition or in severe environment, including but not limited to outdoor

equipment, equipment exposed to chemical contamination, equipment exposed to electromagnetic

interference and equipment exposed to vibration and shocks

(d) Applications under conditions and environment not described in specifications

*1 In addition to the applications listed from (a) to (d) above, Omron products (see definition) are not intended

for use in vehicles designed human transport (including two wheel vehicles). Please do NOT use Omron

products for vehicles designed human transport. Please contact the Omron sales staff for information on our

automotive line of products.

*2 The above is part of the Terms and Conditions Agreement. Please use carefully read the contents of the

guarantee and disclaimers described in our latest version of the catalog, data sheets and manuals.

Installation Environment

• Do not use the product in areas where flammable or explosive gases are present.

• Install the product so that air can flow freely through its cooling vents.

• Clean the ventilation holes and fan outlet regularly to prevent dust and particles from clogging them. If they

are blocked, heat is trapped inside, causing a malfunction.

• Do not install the product close to high-voltage devices and power devices in order to secure the safety of

operation and maintenance.

• Make sure to tighten all installation screws securely.

• When mounting the Sensor Controller using the DIN rail mounting bracket, make sure the screw is

tightened.

• Make sure to mount the product on DIN-rail securely.

Vision System FH/FZ5 Series

User’s Manual (Z365)

17

Page 20

Power Supply and Wiring

• Make sure to use the product with the power supply voltage specified by this manual or Instruction sheet.

• Do not connect AC power source to Sensor Controller. If connects AC power source, it might be a cause of

the failure.

• Use the wire of a suitable size (AWG 16 to 12) according to the current consumption.

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-voltage circuits

on the secondary side).

• Do the following confirmations again before turning on the power supply.

− Is the voltage and polarity of the power supply correct? (24 VDC)

− Is not the load of the output signal short-circuited?

− Is the load current of the output signal appropriate?

− Is not the mistake found in wiring?

− Is the voltage and polarity of the encoder power (ENC0_VDD/GND ENC1_VDD/GND) supply? (5 VDC)

• The recommended power supply is the S8VS-24 (manufactured by OMRON) or S8VK-G-24

(manufactured by OMRON).

Ground

• Make sure the power supply circuit of the FH Sensor Controller is insulated from the internal circuit.

Refer to this manual or Instruction sheet.

• When the connected camera to Sensor Control comes packaged with a base, make sure to mount with the

base. Since the enclosure of the camera main body made of metals is short-circuited with the internal

circuit, the internal circuit might be short-circuited with FG if no base is used, so that failures or

malfunctions may be caused.

Perform Class D grounding (with a grounding resistance of 100 Ω or less).

Keep the ground line as short as possible by setting the grounding point as close as possible.

Ground the FH Sensor Controller independently. If sharing the ground line with other devices or

connecting it with a building beam, the Sensor Controller might be adversely effected.

• Check wiring again before turning on the FH Sensor Controller.

• Do not ground the plus (+) terminal when the FH series Sensor Controller is connected to the FH-SC12/

FH-SM12. Doing so may cause a short circuit of the internal circuit, resulting in a malfunction.

The internal circuit is possible to be given damage, it can be cause the failure.

− FH-1000 series

− FH-3000 series

− FH-L series

• Do not ground the plus (+) terminal of the 24VDC power source when the FH series Sensor Controller is

connected to the FH-MT12 with a USB cable. Doing so may cause a short circuit of the internal circuit,

resulting in a malfunction.

− FH-1000 series

− FH-3000 series

− FH-L series

18

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 21

Other

• Use only the camera and cables designed specifically for the product. Use of other products may result in

malfunction or damage of the product.

• Always turn OFF the power of the Sensor Controller and peripheral devices before connecting or

disconnecting a camera or cable. Connecting the cable with power supplied may result in damage of the

camera or peripheral devices.

• For the cable that is flexed repeatedly, use the robotic cable type (Bend resistant camera cable) to prevent

damages.

• Do not apply torsion stress to the cable. It may damage the cable.

• Secure the minimum bending radius of the cable. Otherwise the cable may be damaged.

• Do not attempt to dismantle, repair, or modify the product.

• Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and contact your

OMRON representative.

• While the power is ON or immediately after the power is turned OFF, the Sensor Controller and camera

case are still hot. Do not touch the case.

• When disposing of the product, treat it as an industrial waste.

• Do not drop the product nor apply excessive vibration or shock to the product. Doing so may cause

malfunction or burning.

• This product is heavy. Be careful not to drop it while handling.

• A lithium battery is incorporated, so a severe injury may rarely occur due to ignition or explosion.

• Be sure to take fail-safe measures externally when controlling stages and robots by using the

measurement results of the Sensor Controller (axis movement output by calibration and alignment

measurement).

Vision System FH/FZ5 Series

User’s Manual (Z365)

19

Page 22

Precautions for Correct Use

Installation and Storage Sites for FH-1000 series/FH-3000 series/FZ5-1100 series/

FZ5-600 series/FZ5-L series

Install and store the product in a location that meets the following conditions:

• Surrounding temperature of 0 to +50°C

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 35 to 85%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

Installation and Storage Sites for FH-L series

Install and store the product in a location that meets the following conditions:

• Surrounding temperature of 0 to +55°C (-25 to +70°C in storage)

• No rapid changes in temperature (place where dew does not form)

• Relative humidity of between 10 to 90%

• No presence of corrosive or flammable gases

• Place free of dust, salts and iron particles

• Place free of vibration and shock

• Place out of direct sunlight

• Place where it will not come into contact with water, oils or chemicals

• Place not affected by strong electro-magnetic waves

• Place not near to high-voltage, or high-power equipment

Orientation of Product

• For good heat dissipation, install the product only in the position written this manual or Instruction sheet so

as not to block the ventilation holes.

Ambient Temperature

• For good heat dissipation, keep the distance written this manual or Instruction sheet.

• Do not install the product immediately above significant heat sources, such as heaters, transformers, or

large-capacity resistors.

• Do not let the ambient temperature exceed an operating temperature range.

• Provide a forced-air fan cooling or air conditioning if the ambient temperature is near the upper range of

operating temperature range so that the ambient temperature never exceeds the upper range of operating

temperature range.

Noise Resistance

• Do not install the product in a cabinet containing high-voltage equipment.

• Do not install the Sensor Controller within 200 mm of power cables.

20

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 23

Component Installation and Handling

• Touching Signal Lines

To prevent damage from static electricity, use a wrist strap or another device for preventing electrostatic

discharges when touching terminals or signal lines in connectors.

• Handling a USB Memory/SD memory card.

Refer to Using External Memory Device in the Vision System FH/FZ5 series User’s Manual (Cat. No.

W365).

• Do not insert an SD memory card in the reverse orientation, at an angle, or in a twisting manner.

Before removing a USB memory device or SD memory card, make sure that data is not being read or

written to them.

For a USB memory device, the memory device's LED flashes while data is being read or written. Make

sure that the LED stops flashing before removing the memory device.

For an SD memory card, the SD BUSY LED of Sensor Controller flashes while data is being read or

written. Make sure that the LED stops flashing before removing the card.

• Turning OFF the Power

When a message is displayed indicating that a task is in progress, do not turn OFF the power. Doing so

causes the data in the memory to be corrupted, resulting in the product not operating properly upon the

next start-up.

When turns OFF, conform the followings proceedings have completed. and then operate again.

− When saves using Sensor Controller:

Confirm the save processing is completed and next operation is possible.

− When saves using communication command:

Intended command is completed. BUSY signal is turned OFF

• Setting of Power Source

The power source need to be supplied from DC power source apparatus which is taken a save ultra-low

voltage circuit: to protect high voltage.

Maintenance

• Turn OFF the power and ensure the safety before maintenance.

• Clean the lens with a lens-cleaning cloth or air brush.

• Lightly wipe off dirt with a soft cloth.

• Dirt on the image element must be removed using an air brush.

• Do not use thinners or benzene.

• To ensure safe access for operation and maintenance, separate the Sensor Controller as much as

possible from high-voltage equipment and power machinery.

Communication with High-order Device

• After confirming that this product is started up, communicate with the high-order device. When this product

has started up, an indefinite signal may be output from the high-order interface. To avoid this problem,

clear the receiving buffer of your device at initial operations.

Fail-Safe Measures

• When controlling stages and robots using the measurement results from the Sensor Controller (axis

movement output based on calibration and alignment measurement), always take fail-safe measures

within the stage and robot systems, such as checking whether the data obtained from the measurement

results is within the range of movement of the stages and robots.

• On a FH Sensor Controller side, supplementary use operations and branches of the Sensor Controller to

configure a check flow such as “data should not be externally provide if the data is in a range from

-XXXXX to XXXXX” based on the stage/robots range of movement.

Vision System FH/FZ5 Series

User’s Manual (Z365)

21

Page 24

Connecting the Sensor Controller and Monitor with a Switcher and Splitter

• Do not use devices that make the Sensor Controller recognize the monitor again when switching operation

is performed. Re-recognition process in switching operation has an effect such as a delay in measurement

time.

22

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 25

Regulations and Standards

All Series

Using Product Outside Japan

This regulation applies to FH/FZ5 sensor controller and peripheral devices.

If you export (or provide a non-resident with) this product or a part of this product that falls under the category

of goods (or technologies) specified by the Foreign Exchange and Foreign Trade Control Law as those which

require permission or approval for export, you must obtain permission or approval or service transaction

permission) pursuant to the law.

U.S. California Notice:

This product contains a lithium battery for which the following notice applies: Perchlorate Material - special

handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

Conformance to KC Standards

This regulation applies to FH/FZ5 sensor controller and peripheral devices.

Observe the following precaution if you use this product in Korea.

• Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places other

than homes. Sellers and/or users need to take note of this.

Vision System FH/FZ5 Series

User’s Manual (Z365)

23

Page 26

FH-1000/FH-3000 series

Conformance to EC/EU Directives

This regulation applies to FH-1000/FH-5000 series Sensor Controller and peripheral devices.

The FH-1000/FH-5000 series Sensor Controller is compliant with the standards below:

• EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1

Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• Also, the following condition is applied to the immunity test of this product.

− If the level of disturbance of the video is such that characters on the monitor are readable, the test is a

pass.

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall machine

conform to EMC standards.

• If there is a need to respond to the EC / EU directive, please use by an analog RGB output.

Conformance to UL Standards

This regulation applies to FH-1000 and FH-3000 series Sensor Controller and peripheral devices.

This product complies with UL Standards.

• UL508

FH-L series

Conformance to EC/EU Directives

This regulation applies to FH-L series Sensor Controller and peripheral devices.

The FH-L series Sensor Controller is compliant with the standards below:

• EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1

Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• Also, the following condition is applied to the immunity test of this product.

− If the level of disturbance of the video is such that characters on the monitor are readable, the test is a

pass.

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall machine

conform to EMC standards.

• If there is a need to respond to the EC / EU directive, please use by an analog RGB output.

Conformance to UL Standards

This regulation applies to FH-L series Sensor Controller and peripheral devices.

This product complies with CSA Standards.

• UL 61010-2-201

24

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 27

FZ5/FZ5-L series

Conformance to EC/EU Directives

This regulation applies to FZ5/FZ5-L series Sensor Controller and peripheral devices.

The FZ5/FZ5-L series Sensor Controller is compliant with the standards below:

• EC Directive 2004/108/EC (Until April 19 2016) / EU Directive 2014/30/EU (After April 20 2016)

EN61326-1

• Electromagnetic environment: Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• Also, the following condition is applied to the immunity test of this product.

− If the level of disturbance of the video is such that characters on the monitor are readable, the test is a

pass.

• This product complies with EC/EU Directives. EMC-related performance of the OMRON devices that

comply with EC/EU Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel on which the OMRON devices are installed.

• The customer must, therefore, perform the final check to confirm that devices and the overall machine

conform to EMC standards.

Conformance to CSA Standards

This regulation applies to FZ5/FZ5-L Sensor Controller and peripheral devices.

This product complies with CSA Standards.

• CSA C22.2 No.61010-1

Vision System FH/FZ5 Series

User’s Manual (Z365)

25

Page 28

MEMO

26

Vision System FH/FZ5 Series

User’s Manual (Z365)

Page 29

Before Operation

This section describes the basic flow and preparations that are necessary to start

operation.

Overview............................................................................. 28

Flow of Application ........................................................... 31

Windows............................................................................. 33

Checking the System Configuration................................ 44

Saving Settings before Turning OFF the Power and

Restarting........................................................................... 49

Accuracy ............................................................................ 51

Initializing the Controller .................................................. 52

1

Before Operation

Page 30

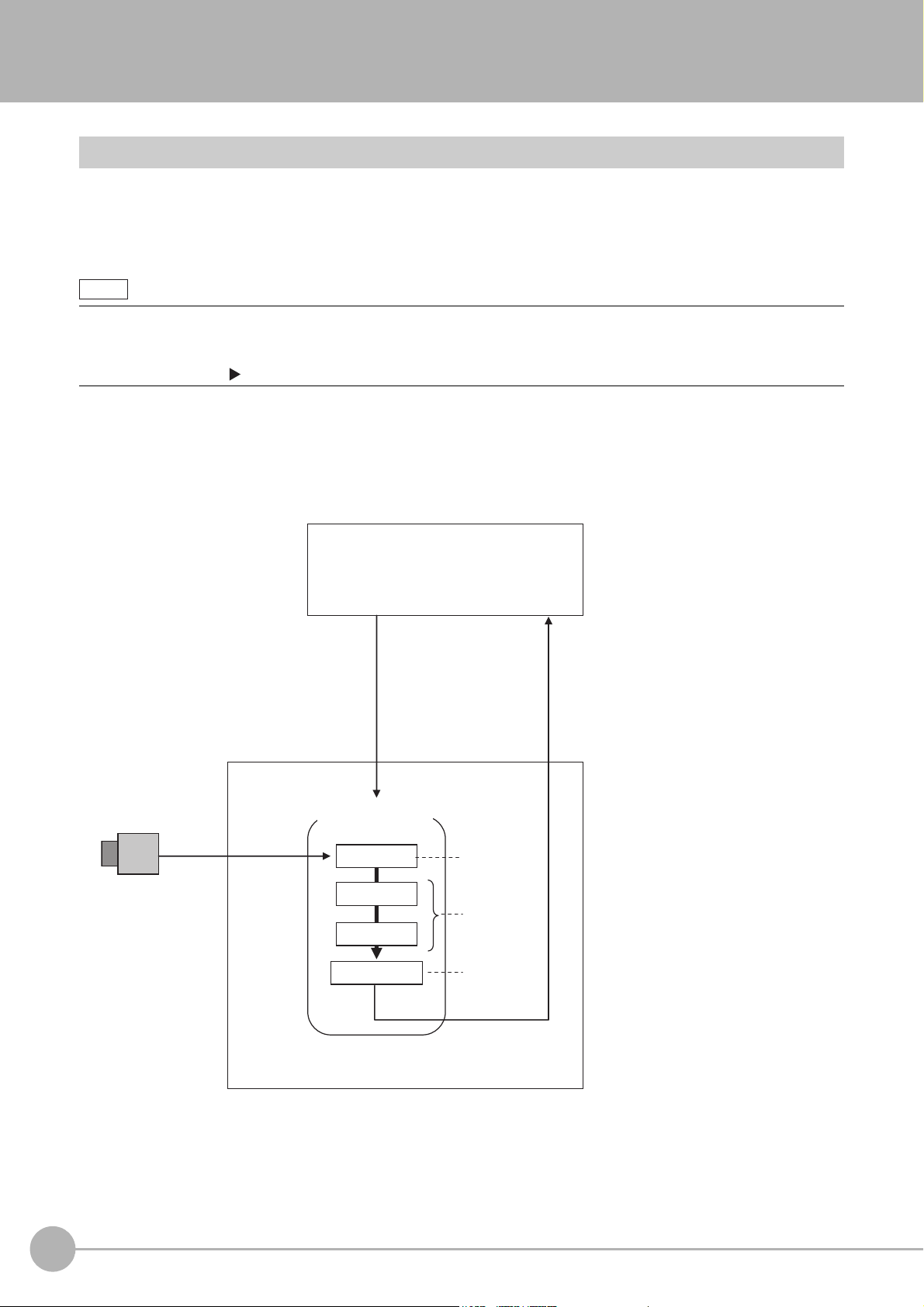

Overview

Note

PLC or other external device

Image Input

Defect

Search

Measurement flow

FH/FZ5

Output Unit

Camera

Measurement

trigger

The measurement flow is executed basically in

order of the unit numbers.

Measurement

results are

output.

Measurement

processing of