Page 1

Vision Sensor

FH Series

Vision System

Robot Connection Guide

OMRON TM Series Edition

Z447-E1-01

Page 2

NOTE

Trademarks

•

and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

•

•

•

•

•

•

• QR Code is a registered trademark of DENSO WAVE INCORPORATED.

•

Other company names and product names in this document are the trademarks or

-

marks of their respective companies.

Copyrights

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover,

because OMRON is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every precaution has been taken in

the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or

omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Sysmac

and other countries for OMRON factory automation products.

This software is based in part on the work of the Independent JPEG Group.

Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Microsoft product screen shots used with permission from Microsoft.

registered trade

Page 3

CONTENTS

Introduction ............................................................................................................................................ 2

T erms and Conditions Agreement ....................................................................................................... 3

Safety Precautions ................................................................................................................................ 5

Waring ..................................................................................................................................................... 6

Precautions for Safe Use ...................................................................................................................... 7

Precautions for Correct Use ................................................................................................................. 8

Regulations and Standards .................................................................................................................. 9

Related Manuals .................................................................................................................................. 10

Revision History ...................................................................................................................................11

1. Overview ....................................................................................................................................... 12

1.1. Overview................................................................................................................................. 12

1.2. Instructions for Building a 3D Robot Vision Application ......................................................... 12

1.3. Robot Programs Covered in this Manual ............................................................................... 13

2. System Configuration .................................................................................................................. 14

2.1. Cautions for Robot Equipment ............................................................................................... 14

2.2. When Using Vision Sensor FH Series 3D Vision Sensor....................................................... 14

3. Connecting Vision Sens or to Rob ot Controller ........................................................................ 16

3.1. Setting Communications for Robot controller......................................................................... 17

3.2. Connecting and Checking Vision Sensor and Robot Controller ............................................ 20

3.3. Verify Commands Sent/Received .......................................................................................... 22

4. Coordinate System ...................................................................................................................... 26

4.1. Name of Coordinate System .................................................................................................. 26

5. How to Start the Setup Program ................................................................................................ 28

6. Description of the Sample Programs ......................................................................................... 29

6.1. Initialization of the Sample Program ...................................................................................... 31

6.2. Switching Scenes on the Vision Sensor ................................................................................. 32

6.3. Moving Robot to Robot Image Position .................................................................................. 34

6.4. Register the Current Robot Position in the Vision Sensor ..................................................... 36

6.5. Executing Measurements on Vision Sensor .......................................................................... 36

6.6. Getting the Measurement Results .......................................................................................... 38

6.7. Moving Robot to Robot Command Position at Measurement ................................................ 39

7. Component Reference ................................................................................................................. 41

7.1. List of Components ................................................................................................................ 41

7.2. Error Message ........................................................................................................................ 41

7.3. Component Details ................................................................................................................. 42

1

Page 4

Introduction

Thank you for purchasing the FH Series.

This manual contains information that is necessary to use the FH Series.

Please read this manual and make sure you understand the functionality and

performance of the FH Series before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during

operation.

2

Page 5

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

● Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing

by Omron). Omron disclaims all other warranties, express or implied.

●

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclai ms all warrant ies and respo nsibility of any type for cl aims or expens es based on

infringement by the Products or otherwise of any intellectual property right.

● Buyer Remedy

Omron’s sole obligation her eunder shall be, at Omron’s election, to (i) replace ( in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying

Product, (ii) repair t he non-complying Product, or (iii) repay or credit Buyer an amount equal t o the

purchase price of the non-complying Product; provid ed that in n o event shall Omron be res ponsible for

warranty, repair, inde mnity or any other claims or expenses regardin g the Products unless Omron’s

analysis confirms that th e Products were properly handl ed, stored, installed and mainta ined and not

subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by Buyer

must be approved in writ ing by Omron befor e shipment. Omron Companies shal l not be liable for the

suitability or unsuitabi lity or the results from the use o f Products in combination with a ny electrical or

electronic components, circuits, system assemblies or any other materials or substances or

environments. Any advice, recommendations or information given orally or in writing, are not to be

construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/

or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR CO MMERCIAL LOSS IN

ANYWA Y CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT ,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companie s exceed the individua l price of the Product o n

which liability is asserted.

3

Page 6

Application Consider a t ions

Suitability of Use

Omron Companies shall n ot be responsible for conformity with any standar ds, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At Buyer’s

request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply t o the Product. This inf ormation by its elf is not sufficie nt for a comple te

determination of the suit abi l ity of the Product in combination wit h the e nd pr o duc t, mac hine, sy s tem, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with res pect to Buyer’s appl ication, product or sys tem. Buyer shall take applicatio n

responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE Q UANTITIES WI THOUT ENSUR ING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall no t be r espons i ble f or t he use r’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Comp any websites, catalo gs and other materials is provided as a guide for

the user in deter mining suitability and does n ot constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specificat ions and ac cess ories may be c hang ed at a ny t ime base d on impr oveme nts and other reasons. It is our practic e to change par t numbers when published ratings or features are c hanged,

or when significant cons truction c hanges ar e made. How ever, some specification s of the Produc t may

be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application . Please c onsult w ith your Omr on’s represe ntative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

4

Page 7

Safety Precautions

For details on Safety Precautions, refer to Safety Precautions in the Vision System

FH Series 3D Robot Vision Application Construction Guide (Cat. No. Z446).

5

Page 8

Waring

For details on Waring, refer to Waring in the Vision System FH Series 3D Robot

Vision Application Construction Guide (Cat. No. Z446).

6

Page 9

Precautions for Safe Use

For details on Precautions for Safe Use, refer to Precautions for Safe Use in the

Vision System FH Series 3D Robot Vision Application Construction Guide (Cat. No.

Z446).

7

Page 10

Precautions for Correct Use

For details on Precautions for Correct Use, refer to Precautions for Correct Use in

the Vision System FH Series 3D Robot Vision Application Construction Guide (Cat.

No. Z446).

8

Page 11

Regulations and Standards

For details on Regulations and Standards, refer to Regulations and Standards in the

Vision System FH Series 3D Robot Vision Application Construction Guide (Cat. No.

Z446).

9

Page 12

Name of Manual

Cat. No.

Model

Purpose

Contents

Regular Payload

Series Hardware

Installation Manual

I623

RT6-0□□□□□□

When User

Robot

Describes the

Medium & Heavy

Payload Series

Hardware

Installation Manual

I624

When User

Robot

Describes the

TMflow Software

Manual

-

When User

to configure

TMflow

Describes the software

TECHMAN ROBOT

Safety System 3.

Safety Manual

-

When User

Robot

Describes the safety

Name of Manual

Cat. No.

Model

Purpose

Contents

V

F

3

Application

Construction

Guide

Z446

FH-5050

When User

know about

Describes the soft

Related Manuals

<Application Construction Guide>

ision Sensor

H Series

D Robot Vision

<Robot Manual>

FH-SMDA-GS050B

RT6-1□□□□□□

RT6-2□□□□□□

want to

the FH

series 3D

robot vision

system.

want to

know the

setup and

hardware

specification

s of the TM

want to

know the

setup and

hardware

specification

s of the TM

functions, setup,

and operations to use FH

series 3D

robot vision system.

specifications, external

dimensions, names of

parts, I/O, installation,

and wiring of the

cooperative robot TM5.

specifications, external

dimensions, names of

parts, I/O, installation,

and wiring of the

cooperative robot TM12,

TM14.

3

I626

I648

want to

know how

Want to

Know the

Safety

Features of

the TM

functions, settings, and

operations for using the

collaborative robot TM.

functions in Collaborative

robot TM.

10

Page 13

Cat. No.

Z447-E1-01

Revision History

A manual revision code appears as a suffix to the c atalog n umber on t he front and bac k cover s

of the manual.

Rev. Code Rev. Date Revision Contents

01 Feb. 2021 Original product

Revision code

11

Page 14

Procedure

Reference

Construction Guide] Chapter 6

Construction Guide] Chapter 7

Setting Communications for Robot controller

Refer to Chapter 3.1

Refer to Chapter 3.3

Construction Guide] Chapter 8

Description of the sample programs

Refer to Chapter 6

1. Overview

1.1. Overview

This manual describes procedures for connections and settings required for

constructing robot vision applications by connecting your robot controller to the

Vision Sensor FH (hereafter referred to as Vision Sensor).

Utilizing this manual and Robot Vision Application Construction Guide can reduce

man-hours to connect the Vision Sensor to your robot controller, set the Vision Sensor,

and create robot programs.

1.2. Instructions for Building a 3D Robot Vision Application

Please follow the flow below for constructing 3D robot vision applications

Creating Data Set for Robot Vision

↓

System Settings for the Vision Sensors

↓

↓

Connecting Vision Sensor to Robot Controller

↓

Robot Vision Settings for Vision Sensors

↓

[3D Robot Vision Application

[3D Robot Vision Application

Refer to Chapter 3.2

[3D Robot Vision Application

12

Page 15

Program

Project Name

Detail

Vision Sensor.

(hand) and to place the workpiece.

1.3. Robot Programs Covered in this Manual

The two types of robot programs covered in this manual are output from the Robot

Vision Dataset Output Tool. Each program is used for a different purpose.

Setup Program FHSETUPMAIN This program allows the Vision Sensor to

give operating instructions to the robot to

configure the Vision Sensor for robot

vision.

This program consists of the following

functions

- Send the current robot position to the

Vision Sensor.

- Move to the indicated position on the

Sample Program FHSAMPLEMAIN This program is a sample of the basic

program flow for a pick application.

In this program, the robot gives control

instructions to the Vision Sensor.

The program consists of the following

functions

- Connecting to the Vision Sensor

- Scene switching of the Vision Sensor

- Moving to the measurement position

- Registering the current robot position to

the Vision Sensor

- Execute measurement instructions to

the Vision Sensor

- Receives the position of the workpiece to

be recognized

- Move to approach position

- Move to the target work location

(grasping position)

Based on this program, a pick-and-place

application is built by adding the robot

movement to operate the end-effector

13

Page 16

Device name

Manufacture

Name

Model

Remarks

supported.

Vision Sensor

LAN Cable

(Straight cable)

Data set output tool

for 3D Robot Vision

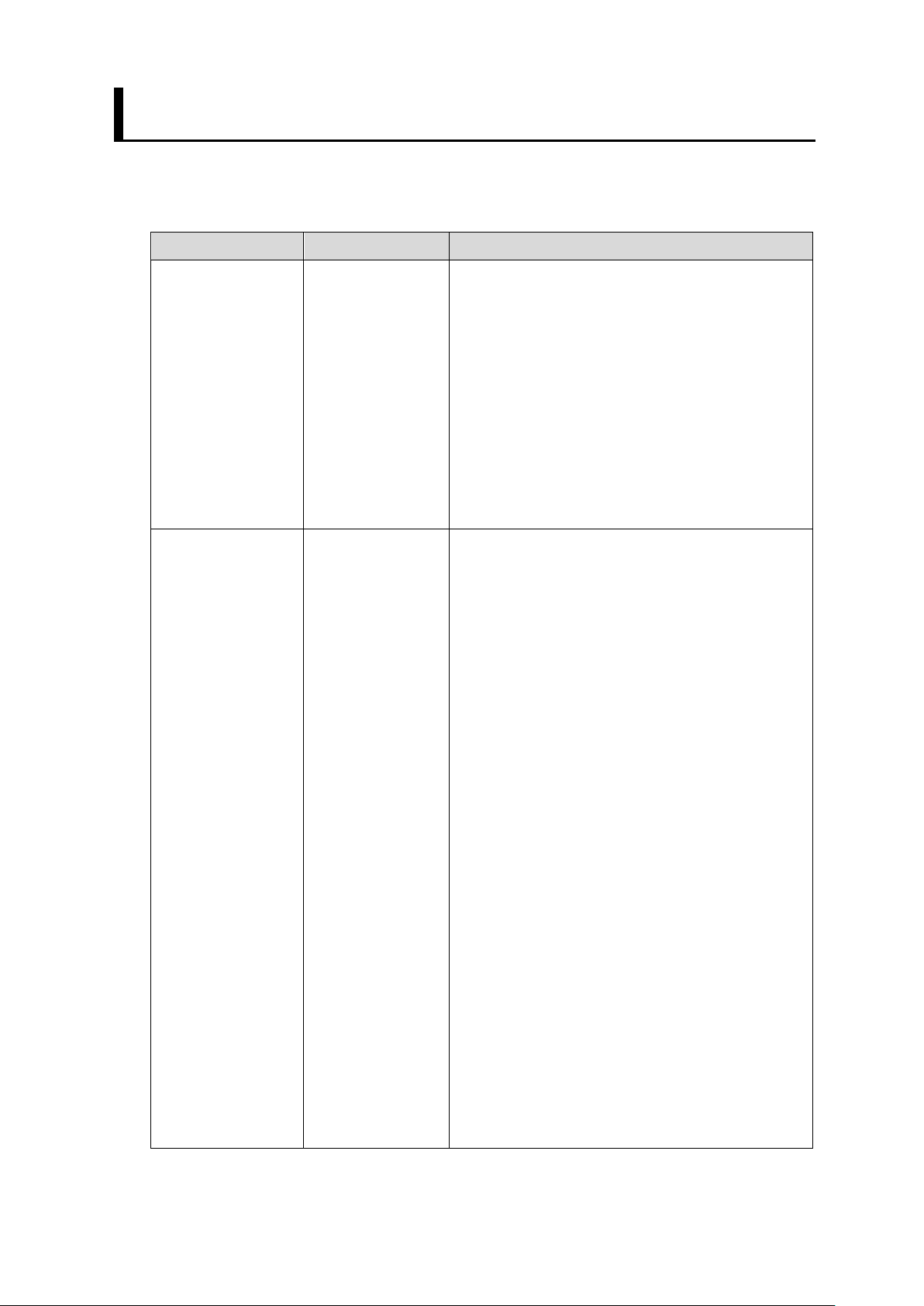

2. System Configuration

This chapter describes the system configuration and target devices to construct robot

vision applications.

2.1. Cautions f or Robot Equipment

[RobotBase] and [NOTOOL] have been selected for the robot controller's coordinate

system.

2.2. When Using Vision Sensor FH Series 3D Vision Sensor

2.2.1. System Configuration

Switching hub

PC

USB memory

Calibration Target

3DCamera

Robot

2.2.2. Target Devices

TeachingPendant

Robot Controller

TMflow

PC Software

Vision Sensor OMRON

Ve r. 6 . 40 or

later

Vision Sensor

FH Series

FH-5050

Controllers

other than

FH-5050 are

not

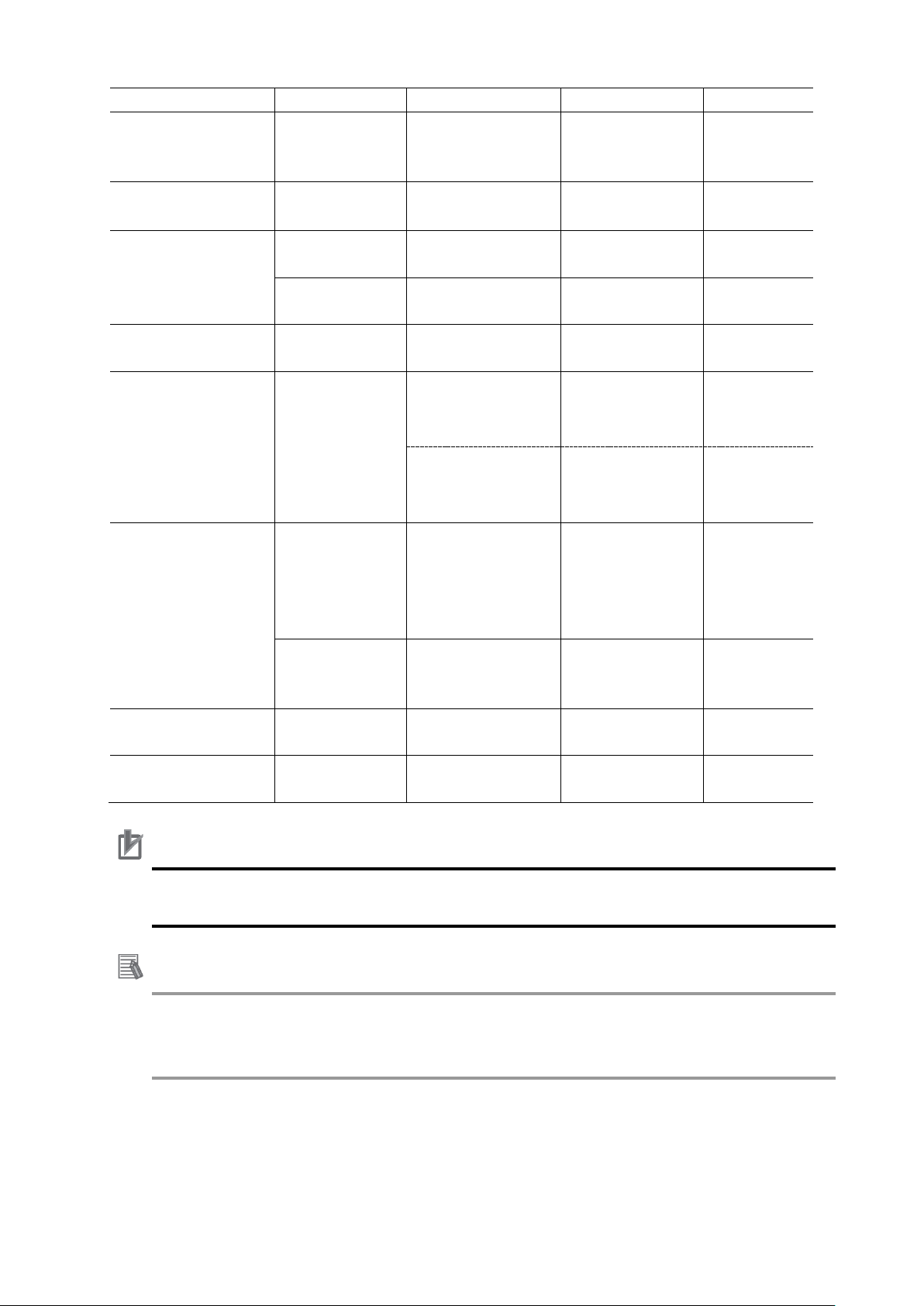

14

Page 17

3D Camera

OMRON

3D Vision Sensor

FH-SMDA-GS050B

resistance

FH-VSDX-LBX□M

Tar g e t

Tar g e t

Robot Vision

Software Installer

it.

obot Programing

TMflow

hub

d product

d product

evice except mentioned above for each device of the system

configuration.

For details, refer to manuals noted in Related Manuals.

Camera Cable OMRON

Camera I/O cable OMRON

OMRON

Calibration target

OMRON

3D Software OMRON

Robot OMRON

OMRON

PC software

Ethernet cable

super bending

I/O cable super

bending resistance

Handeye Calibration

Camera Calibration

3D

Collaborative Robot

TM5-700

TM5-900 RT6-0□□90□□

Data set output tool

for 3D robot vision

FHV-VNBX□M

FHV-VNLBX□M

FH-VSDX-BX□M

FH-XCAL-R -

FH-XCAL-S

FH-UM3D1 -

RT6-0□□70□□

-

-

-

-

Ver.1.00

Please

contact us for

how to obtain

R

OMRON

Switching hub OMRON

USB memory OMRON USB memory FZ-MEM8G

Environment

Industrial switching

-

W4S1-□□□

Precautions for Correct Use

Do not use any d

Additional Information

This manual does not provide operations, installation, and wiring methods for each

device.

Ver.1.80.530

0 or later

Recommende

Recommende

15

Page 18

Vision sensor. ▼

Communication

using PING command.

▼

sending and receiving commands.

3. Connecting Vision Sensor to Robot Controller

This chapter describes procedures to connect the Vision Sensor to the robot controller.

Please follow the flow below for the settings.

The IP address of each device is described below.

Vision Sensor : 10.5.5.100

Robot controller: 10.5.5.101

To change the robot's communication

settings, connect the monitor,

keyboard, and mouse to the robot

3.1

3.2

3.3 Verify Commands Sent/Received

Setting communications for the

robot controller

Verifying Ethernet

control box and activate the robot.

Use TMflow to change the robot's

default IP address to match the

communication settings set for the

Check the connection status of Ethernet

Run a robot program for startup to

establish the TCP/IP connection

between the Vision Sensor and the

robot controller.

Check the communication status by

16

Page 19

3.1. Setting Communications for Robot controller

Please follow the procedures below to set the communications for the robot controller.

Connect a monitor, keyboard, and mouse to the robot's control box, and turn on the

robot's power.

Click [Get Control] on the

robot startup screen to make

the settings available.

1

If the robot is in auto mode,

switch to manual mode.

Click the icon in the top left

menu to display a list of the

function menu.

2

Click [System] – [Network].

Click [Local Area Connection

X] in Network setting.

Set the IP Address and Subnet

Mask.

Set the IP address that does

3

not overlap with the Vision

Sensor and the PC where

TMflow is running.

17

Page 20

setting.

Vision to the USB memory.

"TMROBOT".

Click [OK] and Click an icon

enclosed in red square on the

right figure to close to Network

Copy the "TM_Export" folder in

the "RobotProgram" folder of

the data output from the Data

4

Set Output Tool for Robot

Change the device name of

the USB memory to

5

Connect the USB memory to

the USB port of the robot

controller.

6

Click the icon in the top left

menu to display a list of the

function menu.

7

Click

[System] – [Import/Export]

Click [import] in the top left

corner.

The right dialog will be

displayed, select “Configure

Controller” and click [Finish].

8

18

Page 21

For details, refer to manuals noted in Related Manuals.

In Robot List ,

select FHRobotVision and click

[OK].

Select all files that appear in

Project, Component.

Click [Import] at the bottom

right.

9

When the import is complete

and "Import complete" is

displayed, click [OK].

Additional Information

The device name of the USB flash drive is “TMROBOT”.

The program cannot be read with any other device name.

This manual does not provide operation, installation, and wiring methods for each

device.

19

Page 22

cables.

3.2. Connecting and Checking Vision Sensor and Robot Controller

Follow the procedures below to connect the Vision Sensor and the robot controller

and to check the connection status.

3.2.1. Verifying Ethernet Communication (FH Series Vision Sensor)

Connect the Vision Sensor and

the robot controller with LAN

1

(Operation of the Vision

Sensor)

Move the mouse cursor to

lower left of the window to

display [Start]. Select [Start]

2

- [All Programs] -

[Accessories] - [Command

Prompt] to launch [Command

Prompt].

(Operation of the Vision

Sensor)

Execute PING command to

the IP address of the robot

3

controller.

(Operation of the Vision

Sensor)

When 32-byte data could be

successfully sent/received

four times as shown in the

figure on the right, that

4

means that the

communications have been

established and the wiring and

settings of Ethernet is

correctly done.

20

Page 23

correct.

When 32-byte data cannot be

sent/received four times and

PING command timed out,

check whether or not the

robot controller is turned on,

the wiring was correctly done,

or communication settings are

21

Page 24

3.3. Verify Commands Sent/Received

Execute the setup program on the robot controller and follow the steps below to

confirm that commands can be sent and received from the Vision Sensor.

(Operation of TMflow)

On the robot controller side,

select [Project].

1

(Operation of TMflow)

Like shown on the right

figure,

On the project editing screen,

click the icon.

2

Select [FHSETUPMAIN] from

the list of projects and click

[OK] to load the setup

program.

(Operation of TMflow)

Like shown on the right

figure,

Click the icon to open the

configuration dialog for

[fhsetup] node.

3

22

Page 25

dialog.

save your network settings.

(Operation of TMflow)

Select [RecvString] to open

the Network Settings dialog.

Make sure that [Choose

Device] is set to FH.

Click [Edit Device] to open the

Device Settings screen.

4

Set the IP address and port

number of the Vision Sensor.

Click [Done] to save the

settings.

(Operation of TMflow)

Select [SendString] to open

the Network Settings dialog.

Make sure that [Choose

5

Device] is set to FH.

After confirming, close the

[fhsetup] node configuration

(Operation of TMflow)

Like shown on the right

figure,

6

Click the icon to save the

[FHSETUPMAIN] project to

23

Page 26

Vision Sensor

TMflow

W

Rx

P

Ry

R

Rz

(Operation of Robot Stick)

Press the [Play/Pause] button

on the robot stick to run the

project.

7

When the project is in the

running state, the robot's ring

will flash green.

(Operation of the Vision

Sensor and TMflow)

Like shown on the right

figure, when [Get] is clicked

on the Main Window of the

Vision Sensor and the current

robot position on TMflow is

displayed at the same position

on the Main Window of the

Vision Sensor,

sending/receiving commands

between them have been

succeeded.

8

* The current robot position

can be checked by clicking

[Controller] on the project

editing toolbar.

* Correspondence relation of

notation

24

Page 27

others.

stick to stop the project.

For details, refer to manuals noted in Related Manuals.

(Operation of the Vision

Sensor)

Like shown on the right

figure,

9

If the [Robot Error] button

turns red, the connection has

failed. Check the wiring and

(Operation of Robot Stick)

When the Vision Sensor and

the robot controller have

10

exchanged commands, press

the [Stop] button on the robot

Additional Information

This manual does not provide operation, installation, and wiring methods for each

device.

25

Page 28

Coordinate System

Meaning

System

origin

Local Coordinate System

User-defined coordinate system

of the robot

flange coordinates system.

and the Z axis is the optical axis of the camera.

4. Coordinate System

This chapter describes the coordinate system handled by the robot vision application.

4.1. Name of Coordinate System

The robot coordinate system of the Vision Sensor uses the name shown in the table

below.

Robot Base Coordinate

Flange Coordinate system Coordinate system defined on the flange surface

Tool Coordinate System The coordinate system is defined in the tool

Camera Coordinate System With the optical center of the camera as the

Coordinate system with the robot base as the

center point by offsetting the origin of the

starting point, the X and Y axes are the

horizontal and vertical directions of the image,

26

Page 29

Vision Sensor

OMRON TM Series

Local Coordinate System

Base Coordinate System

Tool Coordinate System

Tool Coordinate System

The orientation of the coordinate axes of each coordinate system depends on the robot.

Please refer to the instruction manual for each robot.

There are the following differences between the names of the coordinate system in the

Vision Sensor and the coordinate system in the OMRON TM series.

27

Page 30

the list of projects and click

to load the setup

Press the [Play/Pause] button

on the robot stick to run the

5. How to Start the Setup Program

This chapter describes how to start the setup program. To set the robot vision of

the Vision Sensor, the setup program must be running on the robot side. Establish

the connection between the Vision Sensor and the robot controller by [3. Connecting

Vision Sensor to Robot Controller]

(Operation of TMflow)

Like shown on the right figure,

On the project editing screen,

click the icon.

Select [FHSETUPMAIN] from

1

[OK]

program.

(Operation of Robot Stick)

project.

2

When the project is in the

running state, the robot's ring

will flash green.

28

Page 31

Connecting the Vision Sensor to the robot controller

Switching scenes on the Vision Sensor

Moving the robot to the image position

Register the current robot position in the Vision Sensor

Executing measurements on the Vision Sensor

Getting the measurement results

Moving the robot to the robot command position at measurement

(Driving the robot etc.)

2) Command response

(Measurement value etc.)

(Measurement etc.)

Program

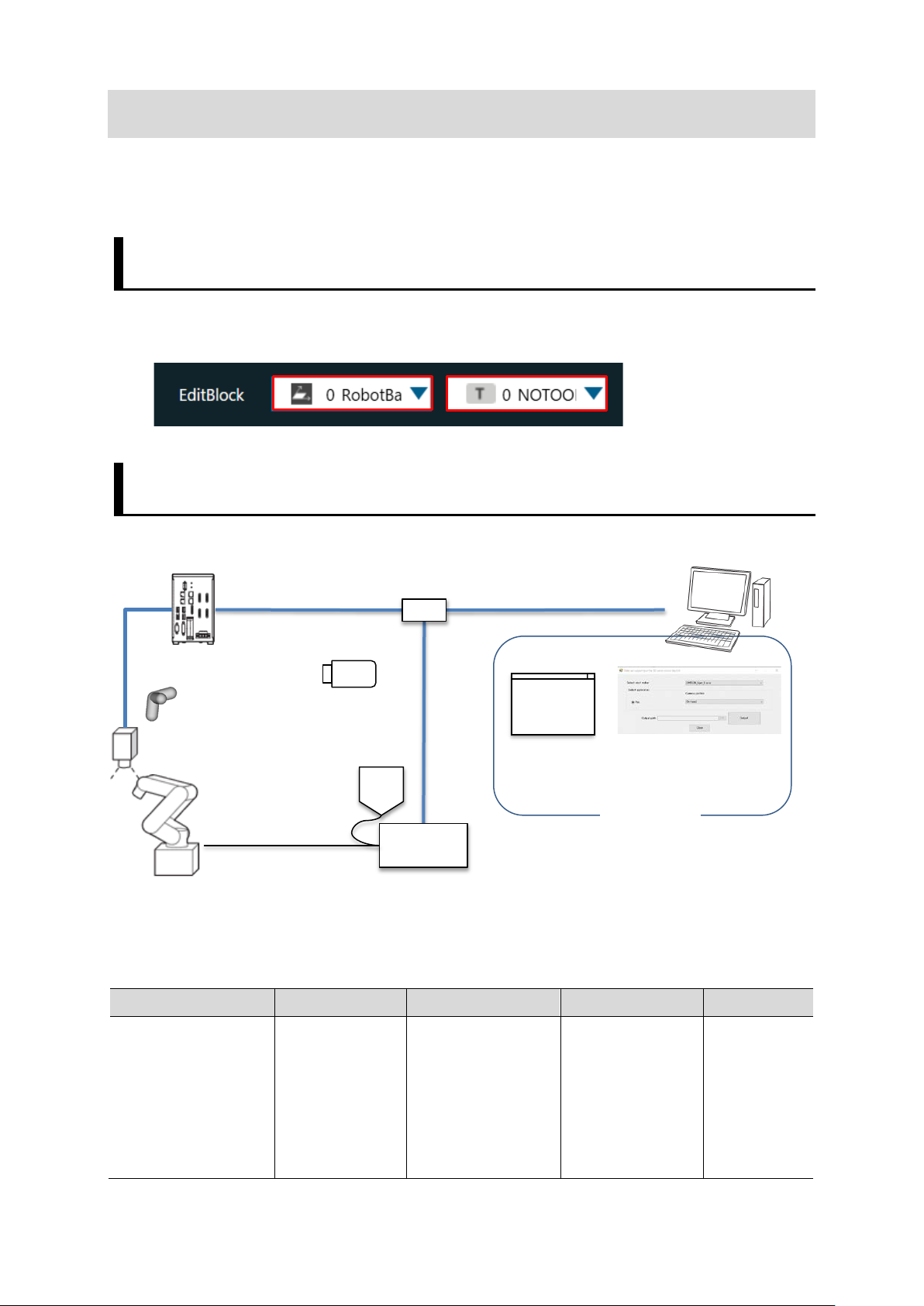

6. Description of the Sample Programs

This chapter describes design examples of robot programs to construct applications

using the sample program.

You can understand how to implement a robot program to control the Vision Sensor

as shown in the following figure.

Vision Sensor

Robot

3) Command execution

Switching hub

Robot controller

1) Control command

Execution

Sample

PC

The sample program is implemented with the following procedures. When building

an actual application, design, implement and test the robot program, utilizing the

functions described in Chapter 7.

6.1

6.2

▼

▼

6.3

▼

6.4

▼

6.5

▼

6.6

▼

6.8

29

Page 32

Precautions for Correct Use

measurement values.

The implementation procedures for robot programs noted in this chapter are a

reference. You should design, implement, and test actually operating robot programs

based on your specific environment and applications.

In the Main Window or “Layout setup” of the Vision Sensor, check that the “Output”

of the current layout is ON. If the setting were OFF, the Vision Sensor will not output

30

Page 33

setting for each node.

fhrunsendcmd Component

fhdefglobal Component

6.1. Initialization of the Sample Program

This section describes how to initialize global variables, set the IP address and port

number of the Vision Sensor.

Open [FHSAMPLEMAIN] sub-

1

flow in the Project Edit page.

The [fhdefglobal] component

is placed at the beginning of

the flow.

This component initializes the

2

global variables needed to

communicate with the Vision

Sensor.

Select the ChangeScene node

on the flow and click the

pencil icon to open the

settings dialog box.

Click [SendString] and make

sure that [Choose Device] is

" F H ".

Click Edit Device and set the

3

IP address and port number

of the Vision Sensor.

Click [Done] to close the

dialog box.

The communication device

“FH” is commonly used in the

sample program.

It is not necessary to

configure the communication

31

Page 34

rCode].

Number of command

Commad

S

fhrunsendcmd Component

6.2. Switching Scenes on the Vision Sensor

Sends a scene switching command to the Vision Sensor and receives the response to

that command.

Select the [ChangeScene]

node on the flow and click the

1

pencil icon to open the

settings screen.

Click [input Argument] to

open the configuration dialog

box.

Click [Variables(7)] to open

the Variables configuration

dialog box.

Make sure that [cmdName] is

2

[SCENE].

Sets the scene number to be

used for [cmdArg[0]]

argument.

arguments

Non-procedure

Communication

cene Number

3

Check for the error in the

[ChangeScene] node.

The error is stored in the

global variable

[g_FHRobotVision_OMRON_er

32

Page 35

proceed to the next node.

next node.

fhrunrecvres Component

If the error code is 0 (zero),

proceed to the next node.

The [RecvResponse] node

receives the response to the

4

scene switching command.

Check for the error in the

[RecvResponse] node.

The error is stored in the

global variable

5

[g_FHRobotVision_OMRON_er

rCode].

If the error code is 0 (zero),

Check the execution result

(command response) of the

[RecvResponse] node.

The result of the execution is

stored in the global variable

6

[g_FHRobotVision_OMRON_p

aram[0]].

If the result of the execution

is 1 (OK), then proceed to the

33

Page 36

6.3. Moving Robot to Robot Image Position

Move the robot to the imaging position and register the imaging position in the

variable.

Move the robot to the imaging

position.

1

Click [Point Manager] to open

the dialog box.

Select [imgPos] and click the

pencil icon.

2

Click [Overwrite new pose to

this point] to record the

current robot position in

[imgPos]

34

Page 37

Point Node

Click [X] to close the Point

Manager dialog.

At the [imgPos] point node,

the robot moves to the

imaging position.

WARNING

3

These operations drive the robot.

Operate the robot in the state whereby pressing the

[Emergency stop] button can stop its motion anytime.

In the base list, select [RobotBase] as the current base.

In the tool list, select [NOTOOL] as the current tool.

35

Page 38

proceed to the next node.

fhsample_regpos Component

fhrunsendcmd Component

6.4. Register the Current Robot Position in the Vision Sensor

To register the current robot position to the Vision Sensor, use "fhsample_regpos".

The [RegistCurPos] node

registers the current robot

1

position to the Vision Sensor.

Check for the error in the

[RegistCurPos] node.

The error is stored in the

global variable

2

[g_FHRobotVision_OMRON_err

Code].

If the error code is 0 (zero),

6.5. Executing Measurements on Vision Sensor

Send the measurement command to the Vision Sensor and receives a response to

that command.

Click the [MEASURE] node to

open the configuration dialog

1

box.

Click the [inputArgument] to

open the configuration dialog

box.

2

Click [Variables(7)] to open

the Variables configuration

dialog box.

36

Page 39

proceed to the next node.

proceed to the next node.

fhrunrecvres Component

Number of command

Make sure that [cmdName] is

[MEASURE].

By executing the [MEASURE]

arguments

node, measurement command

is sent to the Vision Sensor.

Check for the error in the

[MEASURE] node.

The error is stored in the

global variable

3

[g_FHRobotVision_OMRON_err

Code].

If the error code is 0 (zero),

The [RecvResponse] node

receives the response to the

4

measurement command.

Non-procedure

Communication

Commad

Check for the error in the

[RecvResponse] node.

The error is stored in the

global variable

5

[g_FHRobotVision_OMRON_err

Code].

If the error code is 0 (zero),

37

Page 40

next node.

If the error code is 0 (zero),

fhrunrecvval Componrnt

Check the execution result

(command response) of the

[RecvResponse] node.

The result of the execution is

stored in the global variable

6

[g_FHRobotVision_OMRON_pa

ram[0]].

If the result of the execution is

1 (OK), then proceed to the

6.6. Getting the Measurement Results

The Vision Sensor measurements are received using "fhrunrecvval". In this sample

program, it is assumed that the Vision Sensor measurements are sent in the order

"TJG X Y Z W P R".

The [RecvVal] node receives

the measurement result of the

Vision Sensor and stores it in

the

g_FHRobotVision_OMRON_par

am[0-6].

1

Each element contains the

measurement results as shown

in the table on the right.

g_FHRobotVision_OMRON_param[0]

g_FHRobotVision_OMRON_param[1]

g_FHRobotVision_OMRON_param[2]

g_FHRobotVision_OMRON_param[3]

g_FHRobotVision_OMRON_param[4]

g_FHRobotVision_OMRON_param[5]

g_FHRobotVision_OMRON_param[6]

TJG

X

Y

Z

W

P

R

Check for the error in the

[RecvResponse] node.

The error is stored in the

global variable

2

[g_FHRobotVision_OMRON_err

Code].

38

Page 41

the program.

Set Node

Set Node

proceed to the next node.

Check the TJG of the Vision

Sensor measurement result.

The TJG of the Vision Sensor

measurement result is stored

in the global variable

[g_FHRobotVision_OMRON_pa

3

ram[0]].

If TJG is OK (1), proceed to

the next node, otherwise exit

6.7. Moving Robot to Robot Command Position at Measurement

Using the measurement results of the Vision Sensor the robot is moved to Robot

Command Position via the approach position.

The [SetCmdPos] node sets

the results of the Vision Sensor

measurements to the point

variable [resCmdPos].

You can grip the Robot

Command position of the point

1

variable [resCmdPos].

Select the [SetApproDist] node

and click the pencil icon to

open the Settings dialog box.

2

Click [Variables(1)] and set the

approach distance to

var_approDist.

39

Page 42

base coordinate system.

Point Node

Point Node

Set Node

The approach position is the

point of access to the Robot

Command position.

The approach distance is the

offset value in the Z

direction(mm) in the robot

The [SetApproPos] node

calculates the approach

position by adding the

approach distance in the Z+

3

direction from the robot

command position.

The [aproPos] node moves the

robot to the approach position.

Then, move to the robot

command position

[resCmdPos]. At this position,

the workpiece can be grasped.

The sample program ends

after moving to the robot

4

command position.

These operations drive the robot.

Operate the robot in the state whereby pressing the

[Emergency stop] button can stop its motion anytime.

WARNING

In the base list, select [RobotBase] as the current base.

In the tool list, select [NOTOOL] as the current tool.

40

Page 43

Component Name

Description

Reference

fhdefglobal

Initialize a global variable.

Chapter 7.3.1

Register the current robot coordinates to the

Vision Sensor

Sensor

Sensor

fhrunrecvval

Receive numerical data from the Vision Sensor

Chapter 7.3.5

7. Component Reference

This chapter describes the functions for building a robot vision application

7.1. List of Components

This is a list of functions that can be used by the actual driving robot program.

fhsampleregpos

fhrunsendcmd Send a no-procedure command to the Vision

fhrunrecvres Receive a command response from the Vision

7.2. Error Message

The error message will be displayed on the DisplayBoard of TMflow.

Chapter 7.3.2

Chapter 7.3.3

Chapter 7.3.4

41

Page 44

Initialize global variables

7.3. Component Details

7.3.1. fhdefglobal

Function

Initialize a global variable.

Input Parameters

None

Output Parameters

None

Exit Process

This component has one exit node as follows

NoError : Normal termination.

Remarks

Define the global variables that are necessary to use the robot application.

Return Value

None

Precautions

Be sure to call this function before using any other function.

Example

The following example initializes a global variable.

42

Page 45

Communication Settings for the Vision

Sensors

WaitTime

int

Communication waiting time(ms)

Communication Settings for the Vision

Sensors

WaitTime

int

Communication waiting time(ms)

Er r. N o .

Error Message

Description

0 - normal termination

1800

-1601

ERROR:fhsendstring():NO_DATA:-1601

Send string length 0

1601

1602

-1301

ERROR:fhrecvstring():NO_CONNECT-1301

Unconnected state

7.3.2. fhsampleregpos

Function

Register the current robot position to the Vision Sensor.

Input Parameters

Setting Node Setting Target Data Typ e Description

SendString ChooseDevice device

RecvString ChooseDevice device

Output Parameters

None

Exit Process

There are two exit nodes in this component as follows

NoError : Normal termination.

Error : Abnormal termination (Please check the message displayed in the view window.)

Remarks

Get the current position of the robot in accordance with the selected coordinate system

number and register the current position to the Vision Sensor.

Return an error if this function is called while the Vision Sensor is not connected.

Returns an error if a response of current position registration failure is received from the

Vision Sensor.

Return value

-1800

-1601 ERROR:fhsendstring():NO_CONNECT:-

-1602 ERROR:fhsendstring():STRING_LEN:-

ERROR:fhsampleregpos():Trigger NG:-

Response NG

Unconnected state

Send string length over

43

Page 46

-1301

ERROR:fhrecvstring():NO_DATA:-1301

Receive data length 0

-1302

ERROR:fhrecvstring():STRING_LEN:-1302

Receive data length over

Registration of the current robot position in the Vision Sensor

Precautions

None

Example

In the following example, the current robot position is registered to the Vision Sensor.

44

Page 47

Type

ChooseDevice

device

Communication Settings for the Vision Sensors

WaitTime

int

Communication waiting time(ms)

to be sent to the Vision Sensor (0 to 5)

procedural commands to be sent to the

Vision Sensor

to the Vision Sensor(string).

to the Vision Sensor(string).

to the Vision Sensor(string).

to the Vision Sensor(string).

to the Vision Sensor(string).

command

argument 1

argument 1

argument n(*2)

7.3.3. fhrunsendcmd

Function

Send a no-procedure command to the Vision Sensor

Input Parameters

Setting Node Setting Target Data

Description

SendString

inputArgument cmdArgNum int Number of no-procedural command arguments

cmdName String No-

cmdArg[0] String Argument 1 of the no-procedure command sent

cmdArg[1] String Argument 2 of the no-procedure command sent

cmdArg[2] String Argument 3 of the no-procedure command sent

cmdArg[3] String Argument 4 of the no-procedure command sent

cmdArg[4] String Argument 5 of the no-procedure command sent

Output Parameters

None

Exit Process

There are two exit nodes in this component as follows

NoError : Normal termination.

Error : Abnormal termination (Please check the message displayed in the view window.)

Remarks

Sends a no-procedure command to the Vision Sensor, concatenating the parameters

according to the following format.

If the number of no-protocol command arguments is out of the input range, an error is

returned.

<Format>

No-protocol

SP(*1)

Command

SP

Command

SP …

Command

45

Page 48

Er r. N o .

Error Message

Description

0 - normal termination

input range.

-1601

ERROR:fhsendstring():NO_CONNECT:-1601

Unconnected state

-1601

ERROR:fhsendstring():NO_DATA:-1601

Send string length 0

-1602

ERROR:fhsendstring():STRING_LEN:-1602

Send string length over

No-procedure command name

argument 1

*1: “SP” is space

*2: The command argument n depends on the number of non-procedural command

arguments.

Return Value

-1506 ERROR:fhrunsendcmd():Invalid Command

Argument No.:-1506

The number of non-

procedural command

arguments is out of the

Precautions

The length of the string of the no-stepping command that can be sent is 127 bytes (not

including the delimiter).

Set the input parameters so that the string length of the no-procedure command does

not exceed 127 bytes.

Example

In the following example, we will switch to scene number 5.

Number of arguments of the no-

procedure command

No-procedure command

46

Page 49

Setting Node

Setting Target

Data Type

Description

Communication Settings for the Vision

Sensors

WaitTime

int

Communication waiting time(ms)

Type

than "OK")

Other than 0: Error)

Er r. N o .

Error Message

Description

0 - normal termination

-1301

ERROR:fhrecvstring():NO_CONNECT:-1301

Unconnected state

-1301

ERROR:fhrecvstring():NO_DATA:-1301

Receive data length 0

-1302

ERROR:fhrecvstring():STRING_LEN:-1302

Receive data length over

7.3.4. fhrunrecvres

Function

fhrunrecvres

Input Parameters

RecvString ChooseDevice device

Output Parameters

Variable Name Data

g_FHRobotVision_OMRON_param float[] param[0] : Command Response Results

g_FHRobotVision_OMRON_errCode int Execution Result(0: Normal termination

Exit Process

There are two exit nodes in this component as follows

NoError : Normal termination.

Error : Abnormal termination (Please check the message displayed in the view window.)

Remarks

Receive the response (command response) to the no-procedure command sent to the

Vision Sensor.

If the command response is OK, assign 1 to the global variable

Description

(1: Command response "OK" - 1: other

g_FHRobotVision_OMRON_param[0].

If the command response is not OK, assign "-1" t o the global variable

g_FHRobotVision_OMRON_param[0].

Return Value

47

Page 50

Precautions

None

Example

In the following example, the response to the measurement command is received and if

the command response is not OK, the program is terminated.

Send MEASURE Command

Receives a command response to “MEASURE” command.

Check if the error number is 0.

The expression "g_FHRobotVision_OMRON_param[0] == 1"

to check if the command response is OK

48

Page 51

Setting Node

Setting Target

Data Type

Description

Communication Settings for the Vision

Sensors

WaitTime

int

Communication waiting time(ms)

Type

param[9] : Received numeric

data 0 - 9)

Other than 0: Error)

The string before conversion

The result of the analysis after conversion

abc

0

123abc

123

abc123

0

1.00E+03

1000

7.3.5. fhrunrecvval

Function

Receive numerical data from the Vision Sensor

Input Parameters

RecvString ChooseDevice device

Output Parameters

Variable Name Data

g_FHRobotVision_OMRON_param float[] param[0] -

g_FHRobotVision_OMRON_errCode int Execution Result(0: Normal termination

Exit Process

There are two exit nodes in this component as follows

NoError : Normal termination.

Error : Abnormal termination (Please check the message displayed in the view window.)

Remarks

This function stores the numerical data sent from the Vision Sensor into the global

variable "g_FHRobotVision_OMRON_param".

This function outputs up to 10 values.

If there are more than 11 numbers, this function outputs only the first 10.

Description

If the length of the segmented string is longer than 12 bytes, this function returns an

error of abnormal parameter length.

Returns an error if the number of numeric data is zero.

The following is an example of the output when a string is included.

<Conversion example>

49

Page 52

Er r. N o .

Error Message

Description

0 - normal termination

-1301

ERROR:fhrecvstring():NO_CONNECT:-1301

Unconnected state

-1301

ERROR:fhrecvstring():NO_DATA:-1301

Receive data length 0

-1302

ERROR:fhrecvstring():STRING_LEN:-1302

Receive data length over

Result Output (Message) Processing Item

measurement results

Setting Target

Setting details

Output device

IoModule2: Serial (Ethernet)

-

Termination string

∖r (Carriage Return)

-

Delimiter string

∖x20 (Space)

-

[9]

Return Value

Precautions

The maximum length of the string to be received is 127 bytes (not including the delimiter).

if more than 128 bytes are received, an error is returned.

The measurement result received from the Vision Sensor will be stored in the

g_FHRobotVision_OMRON_param.

To get the measurement result with this function, Result Output (Message) must be

placed in the flow, and the settings must be as follows

The destination of the received

Output Data 0 - 9 numerical data(*1) g_FHRobotVision_OMRON_param

[0] -

g_FHRobotVision_OMRON_param

*1: The output data format should be set as follows

- Data type: Number

- Digits of integer: 6

- Digits of decimal: 4

50

Page 53

Example

In the following example, the robot moves after receiving the measurement result of the

Vision Sensor (grasping position X, Y, Z, W, P, R).

Receive the results of the Vision Sensor measurements

Check if the error number is 0.

Store the received results in a Point

Move Robot

51

Page 54

Authorized Distributor:

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. Z447-E1-01

0221

© OMRON Corporation 2021 All Rights Reserved.

OMRON Corporation Industrial Automation Company

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

Contact: www.ia.omron.com

Kyoto, JAPAN

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Loading...

Loading...