Omron F500 DATASHEET

Vision Sensor

F500

Network-compatible

Sensor supports

everything from highprecision detection to

production and

quality control

F500

Features

The F500 enables high-precision inspections and measurements in the factory and then goes

further to support easy construction of a production and quality control system for quality

traceability.

High-precision Sensing

1-million-pixel Digital Interface Camera

Clear images are obtained by greatly reducing noise in highresolution video signals.

User Customization for Even Simpler Operation

Various applications are supported through features like flow

menus that flexibly handle even complicated applications and

macros that enable user programming.

A Wealth of Algorithms to Achieve High-precision

Measurements

High-precision measurements are achieved through original

algorithms ideal for lowcontrast mark positioning, minute defect detection, and much more.

terface changes, measurement condition changes, and much

more. Macros can be easily programmed using a simple text

editor.

Storage for Production and Quality Control

Store inspection and measurement data for safe keeping.

Provide feedback to quality control data, or analyze the data

to improve quality. The stored data can be used in many

ways.

Large Storage Capacity

Approximately 200 images minimum can be stored right in the

Controller. Measurement images are stored without alteration

for future use, such as repeating measurements to check

measurement accuracy or attaching images to reports.

Remote Access and Operation

Applications Software

Build Flexible Applications

The F500 provides OMRON's new menu system called Flow

Menus, which enable flexible measurements through menu

settings including multiple filtering operations and conditional

branches based on measurement results.

Easier to Use, Easy to Program

A Macro programming feature is provided to support measurement functions by enabling screen customization, I/O in-

across a Network

Easily achieve a production and quality control system using

an IT environment that provides easy access to the production

site and operating status.

Remote Access and Operation

Data such as the operating status of the Vision Sensor and

images resulting from inspections can be remotely accessed.

Measurements, storage, and communications can be executed independently so that measurements will not stop even

during random remote access.

C-55F500

Flexible User Customization for Any

Purpose

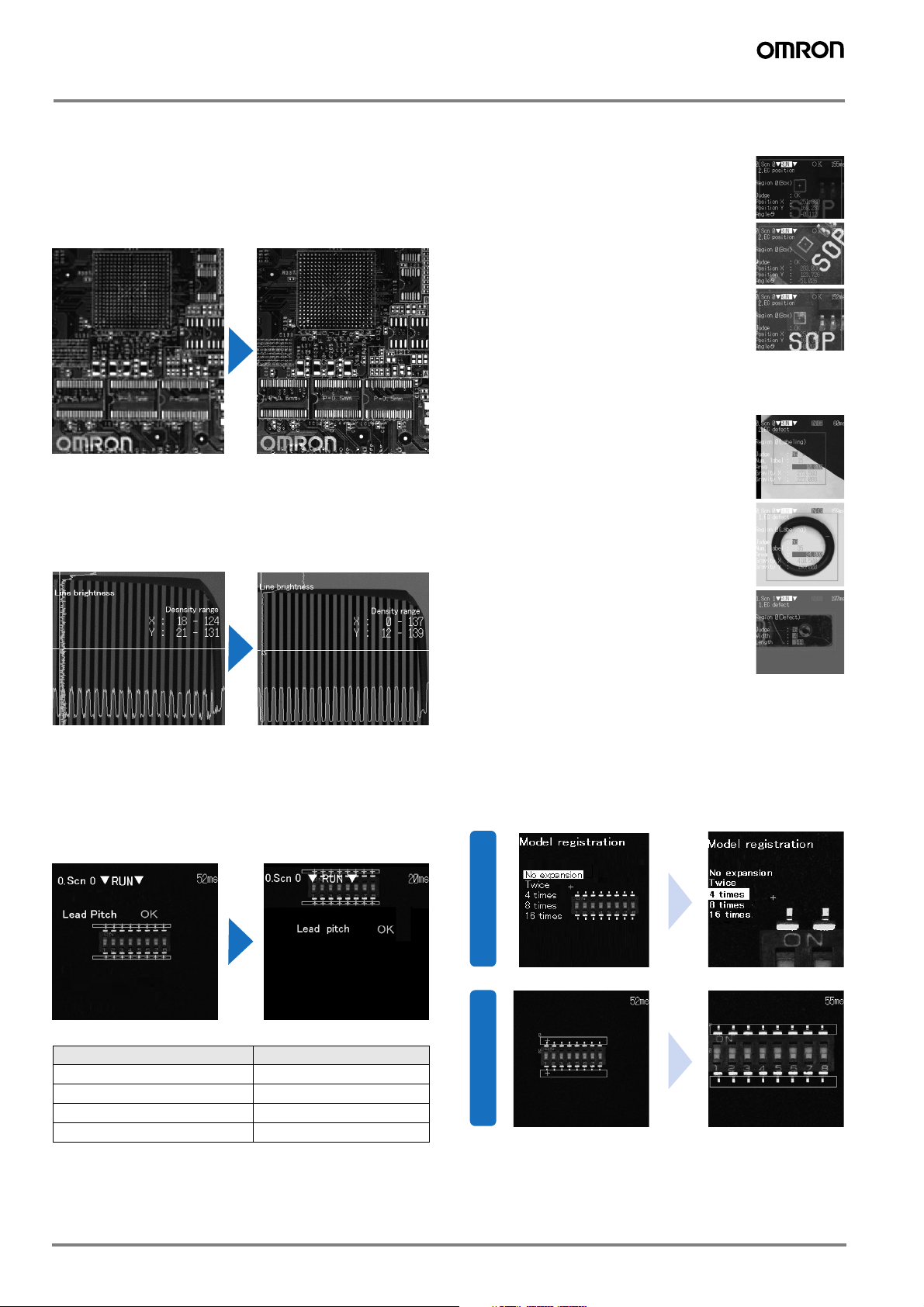

Benefits of Increased Resolution

Doubling the horizontal and vertical resolutions increases total resolution by a factor of four, enabling clear images for

small or complicated workpieces.

250,000 pixels (previous systems) 1 million pixels

1-million-pixel Camera with Digital Interface

The video signal noise that hurt measurement precision has

been greatly reduced to enable inspections of minute foreign

matter or damage as well as highprecision positioning.

Line Brightness Image from an

Analog Interface Camera

Partial Scan Function

Partial scans can be used to reduce the image reading time,

which is often the bottleneck in measurement processing

time.

Line Brightness Image from a

Digital Interface Camera

Advanced Algorithms for High-precision Measurements

Positioning

ECM Searches

Edge code models are used for pattern

searches. ECM searches are not easily affected by deformation and dirt, and can thus

be very effective with low-contrast workpieces.

EC Positioning

Model registration is not required for EC posi-

tioning. Searching is possible with shape information, such as "circle," "rectangle," or

"intersection." This achieves higher precision in measurements than conventional pattern matching methods.

Reference data: Repeatability is within 1/20 pixel (OMRON test data)

Appearance Inspections

EC Defect

Geometric information is used to measure

minute defects or lowcontrast scratches in

the measurement object at high precision.

Stable detection is possible for applications

like measuring deformation in O-rings.

EC Circle Count

Circles are searched for based on a circle of

a specified size. Stable detection is possible

without undue influence by deformation or

dirt.

EC Circle Defect

Defects in circles, such as depressions and

scorching in molded items, can be easily

measured at high precision. The defect in the circle can be extracted even with a patterned background.

Reduced Work with Simple Operations

Zoom Function for 1-million-pixel Images

Zoom in to see detail clearly for easier setting and adjustment

(display enlargement supported).

ZOOM

Setting Screen

Full Frame Reading

Number of Pixels read Reading time

1,024 x 1,024 pixels 48.3 ms

1,024 x 512 pixels 27.6 ms

1,024 x 256 pixels 16.3 ms

1,024 x 128 pixels 10.7 ms

Partial Reading

Entire Screen Display

ZOOM

Measurement Screen

Enlarged Display

High-speed Serial USB Interface

A USB interface simplifies high-speed communications between the Vision Sensor and a computer. Communications

can be used to handle measurement data, setting data, system data, image data, and more.

C-56 Vision Systems

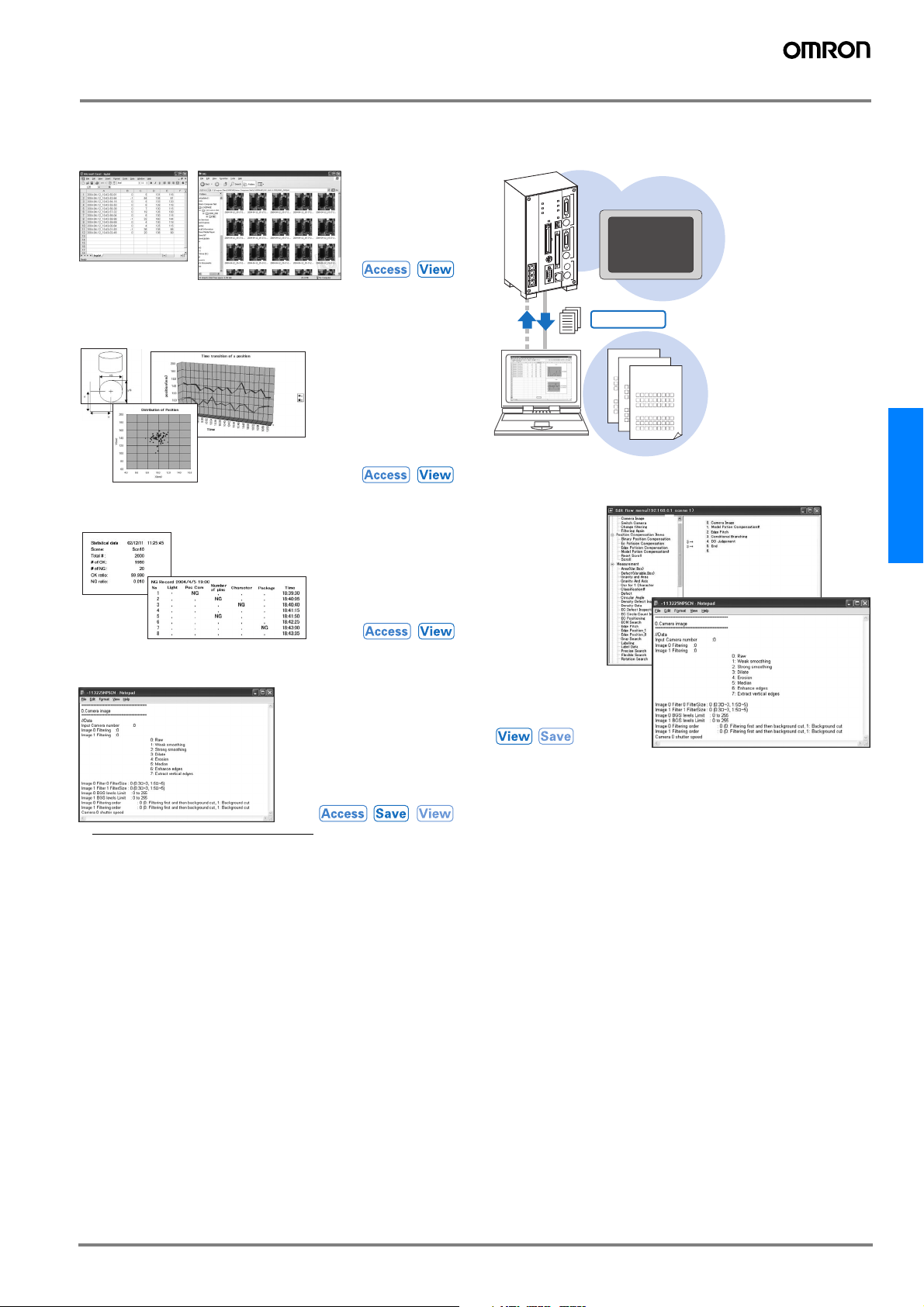

Networking to Access, Save, View and Edit Data

Batched Access and List Viewing of Logged Images

1

Batch File Uploading

1

The data stored in

the Controller can

be displayed in

lists.

Batched Access and List Viewing of Measurement

1

Data

Links can be created to

spreadsheet software to

statistically process

measurement results or

display graphs. All

measurement data can be

saved for feedback to trend

management or to monitor

variations in measurement

data.

Log Production and Quality Control Information

Macros can be used to total production

quantities, production information such as fault

rates, or NG products

according to the type of

inspection.

1

Production 15400 pcs.

Good products 14890 pcs.

NG products 610 pcs.

Batch Transfer

Daily Report

Date:

Daily Report

Production quantity

Date:

Daily Report

Date:

Production quantity

Production quantity

Rate of operation

Rate of operation

Rate of operation

Display and Edit Scene Data

Scene data set in

Vision Sensors

connected to the

network can be

viewed and edited.

The scene data

displayed on the

computer can also

be printed.

The data saved in the Controller can be transferred

to a computer as a batch

upload. This function is

useful when determining

judgement values for initial settings or to back up

data.

And because measurements and communications are executed independently, files can be uploaded without affecting the

Vision Sensor's measurement operation.

1

F500

Managing and Transferring Setting Data

Files containing Vision Sensor

setting data (such as scenes

and system data) can be sent

and received.

The software version of the

Vision Sensor can also be

easily upgraded.

1

Scheduled for release soon.

1

C-57F500

Loading...

Loading...