Page 1

Page 2

F400

Color Vision Sensor

Introduction Manual

Produced June 1999

1

Page 3

About this Manual:

This manual describes the features and basic operations of the F400 Color Vision

Sensor. This is one of three manuals used to operate the F400. Refer to the following

table for the contents of each manual.

Manual

1: Introduction Manual

2: Setup Manual

3: Operation Manual

Please read the above manuals carefully and be sure you understand the information provided before attempting to install

or operate the F400.

Describes F400 capabilities and basic

operating procedures for beginners by

using typical applications.

Provides information on system hardware

and installation.

Describes operation of the F400, including

setting of criteria, communication with

external devices, etc.

Contents Catalog No.

Z131-E1-1

Z130-E1-1

Z135-E1-1

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and related

sections before attempting any of the procedures or operations given.

2

Page 4

TABLE OF CONTENT

General Precautions, Visual Aids 4

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

SECTION 1 FEATURES 5

1-1 Pickup Mode 6

1-2 Color Filter Mode 8

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

SECTION 2 MEASUREMENT 11

2-1 Starting and Quitting 12

2-2 Surface Def ects on Bottle Caps 14

2-2-1 Changing Operating Mode 15

2-2-2 Selecting Scene Mode 16

2-2-3 Adjusting Images 17

2-2-4 Setting Measurement Region 19

2-2-5 Measuring Objects 21

Fore more stable measurements 22

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

2-3 Ice Cream Separation 24

2-3-1 Changing Operating Mode 25

2-3-2 Selecting Scene Mode 26

2-3-3 Adjusting Images 27

2-3-4 Setting Measurement Region 29

2-3-5 Setting Output 32

2-3-6 Checking Measurements 35

2-3-7 Measuring Objects 37

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

SECTION 3 Appendix - Peculiarity of Color 39

SECTION 4 Samples of Measurement Objects 44

3

Page 5

General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the manual or applying the product to nuclear control

systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines,

safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if

used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and

equipment, and be sure to provide the systems, machines, and equipment with double safety mechanisms.

Visual Aids

The following headings will help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

Indicates pages where additional information can be found.

Indicates a procedure. The step numbers in the procedure correspond to the numbers in any

1

related illustrations.

© OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON. No patent liability is assumed with

respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without notice. Ever y precaution has been taken in the preparation of this manual.

Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

4

Page 6

SECTION 1

F400 measures the image using color information of color image.

Select a scene mode out of two processing modes, "color pickup

mode" and "color filter mode", according to the application.

The information contained in this section is about scene mode.

FEATURES

5

Page 7

1-1 Color Pickup Mode

Possible to measure the several colors at the same time.

<Applications>

● Separation by colors

OMRON

Ice Cream

Vanilla

OMRON

Ice Cream

Strawberry

OMRON

Ice Cream

Lemon

Ice creams will be separated by the colors of the lids.

● Miswiring check of wire harnesses

Settings -> p.24

Miswiring can be checked b y registering all colors of

the wire harnesses.

6

Page 8

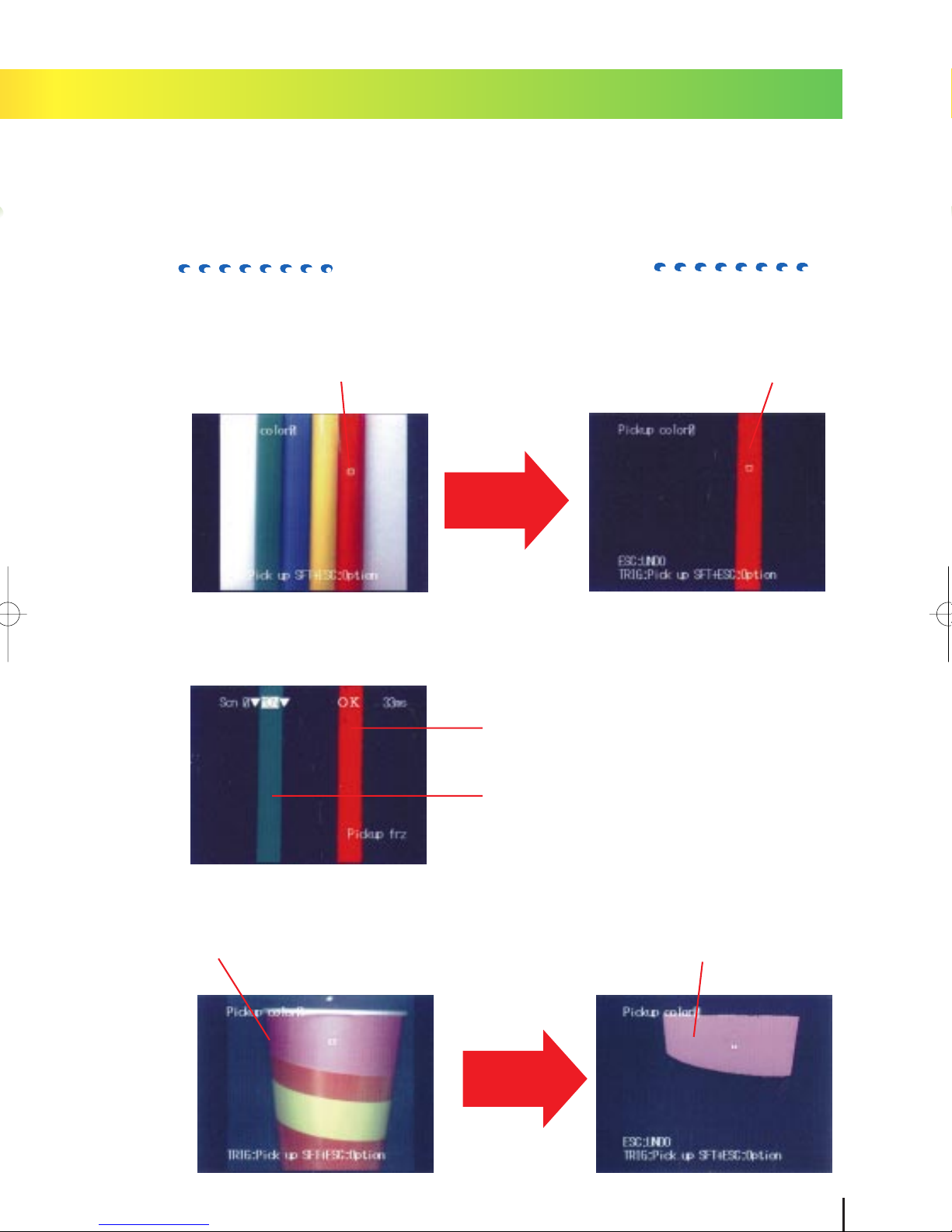

<How to convert the image>

●

Select the color to be picked up from color image. (Up to 8 colors can be registered.)

(Ex.) When red is selected.

Binarized

● Select the color to be inspected by region.

Region 0: Only red will be regarded as

inspection object.

Region 1: Only green will be regarded

as inspection object.

Only red will be picked up .

Other colors will turn black.

● Can distinguish between "shaded pink" and "red".

Even if at the end of a part of pink faded out. Only pink will be picked up.

7

Page 9

1-2 Color Filter Mode

Stable measurement of the object that is

hardly detected in monochrome image.

<Applications>

● Detection of surface defect

Surface defects on bottle caps .

● Amount of adhesive.

Inspect the amount of adhesive that has been coated on metal board.

Settings -> p.14

8

Page 10

<How to convert the image>

●Can convert the image into gray image enhancing specific color using the

built-in color filter.

Camera

F400

Convert into gray

image of 256 gradations.

Color filter can be switched electrically

Variety of color filter is

on the next page.

The color to be detected will be displayed

lightly .

●For only light and shade are used to process in former monochrome image, detection is hardly executed.

9

Page 11

Blue filter

Gray filter

<Color filters>

Color image read by camera

Red filter

Take an effect the same as using optical red filter.

Red will be displayed lightly.

Take an effect the same as using optical green filter.

Green will be displayed lightly.

Colorgray filter

The filter can be arranged according to the color

to be detected. Light will be changed in accordance with hue.Use the filter with understanding of peculiarity of color.

Appendix

(Ex.) Measured color: red

Peculiarity of color (p .39)

Green filter

Take an effect the same as using

optical blue filter.

Blue will be displayed lightly.

Gray filter will conver t the image into former

gray image (monochrome image based on light

and shade of color).Use this filter when measurement monochromatic image such as black,

white and gray.

10

Page 12

SECTION 2

This section describes basic operations of F400 with typical applications.

MEASUREMENT

11

Page 13

2-1 Starting and Quitting

2-1-1 Starting

Be sure that the basic F400 components have been connected correctly.

1

NOTE: Read "Setup Manual" before attempting to setup or wire the F400 components.

Appendix

Turn ON the power supply on the monitor .

2

Turn ON the power supply on the F400.

3

The opening screen will appear.

See "Setup Manual" for camera setting distance and

the details of lens.

Appendix

Setup Manual "2-4 Camera"

Setup Manual "2-2 Connections", "2-3 Power Supply and Ground"

Vision Inspection System

F400-C10 Series

Color-Gray Menu Software

Ver. 2.00

(C) Copyright OMRON Corporation

1998-1999

All Rights Reserved

The image has been taken b y camera will be display ed.

4

The following screen will appear the first

time power is turned ON.

The reversed part of the display is called

cursor. Use the cursor keys to select

items.

Trouble shooting

Camera images do not appear on the screen.

*The Camera Cable is not properly connected.

*The lens cap has not been removed.

*The lens diaphragm is opened or closed too far.

12

Cursor

Page 14

Console

The F400 is operated with selecting functions from the screen and the console is used to

perform menu operations. Be sure to familiarize yourself with console operations before

actually using the menus.

TRIGger key

2-1-2 Quitting

ESC TRIG

ESCape key

ENT

ENTer key

Up, Down, Left,

and Right keys

SHIFT key

SHIFT

Menu operations can be performed with computer via RS-232C port.

Appendix

Operation Manual "6-2 RS-232C Port"

The power can be turned OFF in any mode.

But do not turn OFF the power while saving or loading the data, and be sure to save the data

before turning OFF the power so as not to lose the data. See "Operation Manual" for saving the

setting data.

Appendix

Operation Manual "2-2-5 Quitting"

NOTE: Do not turn OFF the power while saving the measurement conditions in the following

procedure.Data in flash memory may be lost, and the F400 may not operate properly the next time

when it is started.

13

Page 15

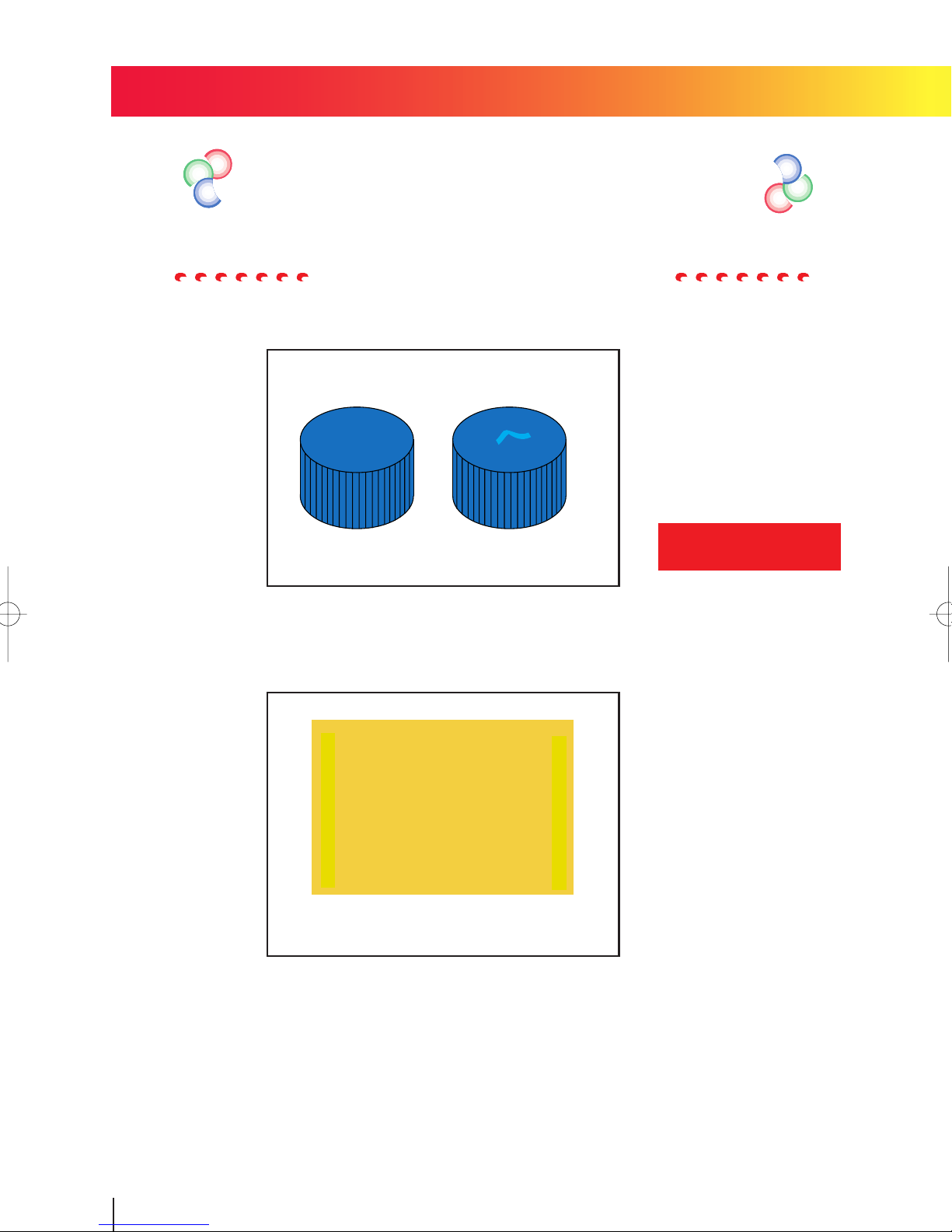

2-2 Surface Defects on Bottle Caps

This section describes functions and setting steeps with the application of surface def ects of bottle

caps. Read this section with actual operation using the picture of measurement object at the end

of this manual.

Setting example

Camera

Extension Tube 1(mm)

Lens 25 (mm)

Camera

distance

OK

NG

320 (mm)

(acceptable) (unacceptable)

1. Change the operating mode.

2. Select the scene mode.

3. Adjust the image.

Field of vision 50(mm)

Select "SET" mode.

Select "Color filter" mode.

Select "Colorgray" for the color filter.

4. Set the measurement region.

5. Measure the objects.

14

Set the region with "surface defect".

Select "RUN" mode.

Page 16

2-2-1 Changing Operating Mode

Select "SET" mode to set measurement condition.

The following screen will be display ed when the pow er

1

is turned ON.

Use the Right Key to move the cursor to "MONitor"

2

and press the ENTer key.

Select "SET" mode

2-2 Surface Defect on Bottle Caps

Use the Up Key to move the cursor to "SET" mode

3

and press the ENTer key.

The screen enters setting mode.

After a short pause, the screen to select the scene mode will appear.

15

Page 17

2-2-2 Selecting Scene Mode

Measurement conditions, such as the type of measurement object and the contents of the inspection, are

input under "scenes". Up to 16 scenes can be set. "Color pickup mode" and "Color filter mode" are called

scene mode. One of these will be selected to inspect in each scene. Difference between "Color pickup

mode" and "Color filter mode" is described in the beginning of the book.

NOTE: Scene mode cannot be changed if scene 0 is already set.

Clear the scene or switch into another scene.

Select "Color filter" and press the ENTer key.

1

"Color filter" has been set to scene 0. After a short pause, basic screen for "SET"

mode will appear.

Clear the scene before changing the setting already registerd.

Select "Color filter" mode.

<How to clear the scene>

Press the ESCape key.

1

Leaves "SET" mode.

Select "Scene 0" and press the ENTer key.

2

A selection of 9 scenes (0 to 8) will be

displayed.

Press the SHIFT+ESCape keys at scene 0.

3

A selection of "Copy" and "Clear" will

be displayed.

Select "Clear" and press the ENTer key.

4

A confirmation message will be displayed.

5 Select "Execute" and press the ENTer key .

2

3

4

Scene data will be cleared and the display will return to the screen of .

2-2-1 Changing Operating Mode —>P.15

16

2

5

Page 18

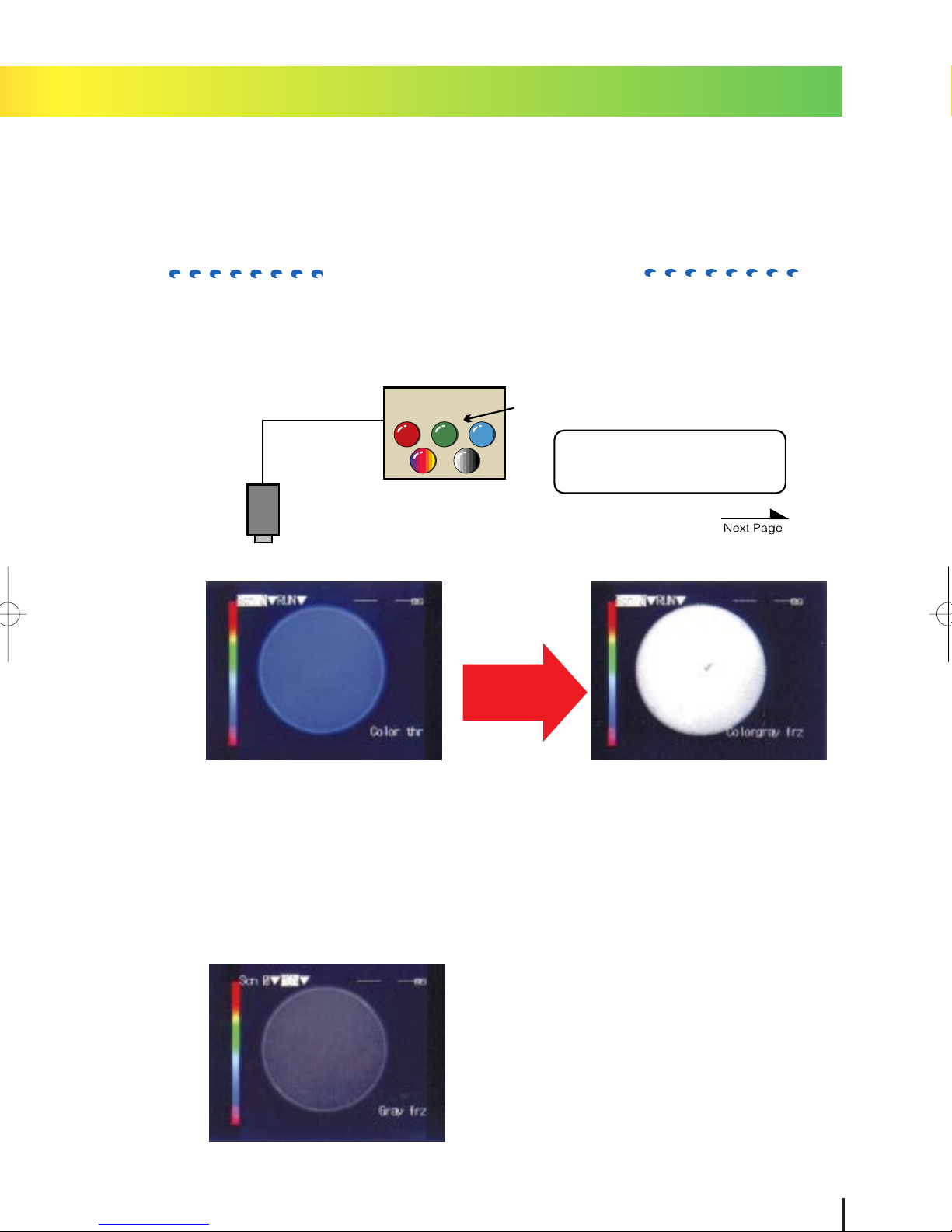

2-2-3 Adjusting Images

The image read by camera will be processed into the image can be easily measured.

Confirming the displayed image on the monitor, process it into "Colorgray filter" to get high-contrast

between the defect and the background.

1Select "Adjust" and press the ENTer key.

2Select "Colorgray" and press the ENTer key .

Select "Colorgray" for Color filter.

2-2 Surface Defect on Bottle Caps

3 Press the ENTer key to set the color filter.

Select "Color select" and press the ENTer key .

4

The screen to set the colorgray filter

will be displayed.

17

Page 19

Use the Up and Down Keys to move the cursor parameter to

5

the color bar pointer.

The selected color will be lighted.

Adjust the position of cursor to get

highest contrast.

Press the ENTer key.

6

The screen of 4 will appear.

Press the ESCape key and the screen of

7

will appear.

1

18

Page 20

2-2-4 Setting Measurement Region

Set the measurement region in which the inspection is to be performed.

Select "Surface defect" to detect surface defect on the measurement object.

<About surface defect>

A measurement method detected by dispersion of light (density) on the object. Extremely dark or

light part of the object will be detected as defect. Degree of defect will be shown by "defect" 0 to 255.

Make output light for hue of measured color as close as registered color.

Setting of the Measurement Region

Select "Measurement region" and press the ENTer key.

1

Set the measurement region with "Surface defect".

2-2 Surface Defect on Bottle Caps

Select "0." and press the ENTer key.

2

Select "Surface defect" and press the ENTer key.

3

Select "Box" and press the ENTer key.

4

Select "Region" and press the ENTer key.

5

19

Page 21

Specify upper-left corner of the measurement region.

6

Use the cursor keys to move the cursor and press the

ENTer key.

6

Specify lower-right corner of the measurement region.

7

Use the cursor keys to move the cursor and press the

ENTer key.

The measurement region will be indicated by

dotted line on the screen.

Setting the Judgement

Select "Conditions" and press the ENTer key.

8

Change the value of defect into "30" and press the

9

ENTer key.

Change the numeral with a one-digit cursor appeared on the display.

Use the Left and Right Keys to move the

cursor to the digit to be input.

Use the Up and Down Keys to change the

numeral.

Judgement value

for displayed image.

Judgement

condition

7

9

11

<Judgement condition>

Judgement condition is set for surface defect with the model to enable checking whether or not the

model with no defect has been found. If the defect is larger than judgement condition, surface defect

may be found.

Judgement condition is set at "10" regarding defect deg ree of displayed image as criterion.

Press the ENTer key after changing the numeral.

10

Select "End" and press the ENTer key.

11

=mкЙлл=нЬЙ=bp`~йЙ=вЙу=лЙоЙк~д=нбгЙл=~еЗ=нЬЙ=лЕкЙЙе=зС=1==пбдд=~ййЙ~кK

12

(Ex.) Sample B Sample C

Defect degree 10

Sample A

Judgement

condition

40

OK

(acceptable) (unacceptable) (unacceptable)

72 168

NG NGJudgement

20

Page 22

2-2-5 Measuring Objects

Input measurement trigger and the measurement will be performed according

to the conditions set for the current scene.

The results will be output to OR terminal of the terminal block.

Press the ESCape key in following screen to leave

1

"SET" mode.

Select "MONitor" to enter "RUN" mode and press the

2

ENTer key.

Select"RUN"mode.

2-2 Surface Defect on Bottle Caps

Select "RUN" and press the ENTer key .

3

The screen enters measurement mode.

Press the TRIGger k e y.

4

One measurement will be performed.

21

Page 23

For more stable measurements

1. Additional Measurement Region

Circle cannot be measured wholly by box measurement region.

Whole object will be measured with one more measurement region.

See "Operation Manual".

Appendix

Operation Manual "3-3 Measurement Methods"

Measurement object

To measure the wholly object

Measurement

Region 0 (Box)

Measurement

Region 1

(Circumference)

Out of measurement

The measurement object will be measured wholly.

Measurement Region

0 + Measurement

Region 1

22

Page 24

2. Position Compensation

Use the position compensation function when the orientation and displacement of the measurement objects are not consistent. If the measurement object is not in a consistent position, the image read by the

camera and the measurement region will not be aligned properly and a correct judgement will not be

obtained. See "Operation Manual"

Measurement

region

Appendix

Operation Manual "3-2 Position Compensation"

WRONG OK

Scroll

the image

2-2 Surface Defect on Bottle Caps

Measurement object is out of

the screen.

The part of the measurement

region is correctly positioned

in measurement region.

"Area & gravity" will be av ailab le for this application.

Position compensation will be performed with the gravity of white pixels in measurement region. The

image must be converted (binarized) to black (0) and white (1) pix els beforehand.

Binarized image

Position

Gravity of white pixels

compensation region

23

Page 25

2-3 Ice Cream Separation

This section describes functions and setting steps with the application of ice cream separation.

Read this section with actual operation using the picture of measurement object at the end of

this manual.

OMRON

Ice Cream

Vanilla

OMRON

Ice Cream

Strawberry

Ice Cream

1. Change the operating mode.

OMRON

Lemon

Setting example

Camera

distance 370 (mm)

Field of vision 80 (mm)

Select "SET" mode.

Camera

Lens 16 (mm)

2. Select the scene mode.

3. Adjust the image.

4. Set the measurement region.

5. Set the output.

6. Check the measurement.

7. Measure the objects.

Select "Color pickup".

Register the color to be picked up.

Set the region with "Area & gravity".

Select "Judge".

Select "MONitor" mode.

Select "RUN" mode.

24

Page 26

2-3-1 Changing Operating Mode

Select "SET" mode to set measurement condition.

The following screen will be displa y ed after the po wer is

1

turned ON.

Use the Right Key to move the cursor to "MONitor" and

2

press the ENTer key.

Select "SET" mode.

OMRON

Ice Cream

OMRON

Ice Cream

Strawberry

Vanilla

OMRON

Ice Cream

Lemon

Select "SET" and press the ENTer key.

3

The screen enters setting mode.

After a short pause, the screen to select the scene mode will appear.

2-3 Ice Cream Separation

25

Page 27

2-3-2 Selecting Scene Mode

Measurement conditions, such as the type of measurement object and the contents of the inspection,

are input under "scenes". Up to 16 scenes can be set. "Color pickup mode" and "Color filter mode" are

called scene mode. One of these will be selected to inspect in each scene . Difference between "Color

pickup mode" and "Color filter mode" is described in the beginning of the book.

NOTE: Scene mode cannot be changed if scene 0 is already set.

Clear the scene or switch into another scene.

Select "Color pickup" and press the ENTer key.

1

"Color pickup" has been set to scene 0.

After a short pause, basic screen for "Set"

mode will appear.

Clear the scene before changing the setting already registered.

Select "Color pickup" mode.

<How to Clear the Scene>

Press the ESCape key.

1

Leaves "SET" mode.

Select "Scene 0" and press the ENTer key.

2

A selection of 9 scenes (0 to 8) will be

displayed.

Press the SHIFT+ESCape keys at scene 0.

3

A selection of "Copy" and "Clear" will

be displayed.

Select "Clear" and press the ENTer key.

4

A confirmation message will be displayed.

Select "Execute" and press the ENTer key.

5

2

3

4

Scene data will be cleared and the display will return to the screen of .

2-3-1 Changing Operating Mode —>P.25

26

2

5

Page 28

2-3-3 Adjusting Images

Register the color to be picked up.

Confirming the displayed image on the monitor , register the colors (three colors) of ice cream lid in

"Pickup color ".

Select "Adjust" and press the ENTer key.

1

Select "Pickup color" and press the ENTer key.

2

Registering screen of pickup color 0 will

be displayed.

OMRON

Ice Cream

OMRON

Ice Cream

Strawberry

Vanilla

OMRON

Ice Cream

Lemon

3

Press the ENTer key to register the color of "V anilla" in

"Pickup color 0".

Use the Left and Right Keys to switch the

picked up color number can be switched.

Other colors will be registered for picked

up color 1 to 2. Picked up color 1: Register the color of "strawberry". Picked up

color 2: Register the color of "lemon".

Use the cursor keys to move the box to the color to be

4

picked up.

Press the SHIFT+ENTer keys to change

the size of box on the screen.

Press the TRIGger k e y.

5

Color to be picked up will be displayed.

Repeat above steps

to 5 to make the

4

color to be picked up to be wholly displayed.

2-3 Ice Cream Separation

27

Page 29

Press the ENTer key.

6

The color inside the box will be registered

and the screen of

Use the Right Key to switch the pickup color number.

7

Register other colors repeating above steps

to 6.

3

Press the ESCape key several times and the

8

screen of

will appear.

1

will appear.

3

28

Page 30

2-3-4 Setting Measurement Region

Set the measurement region with "Area & gravity".

Set the measurement region in which the inspection is to be performed.

Set three measurement regions with "Area & gravity" which can be measured the area of the measurement object.

<Area & gravity >

The pixels of picked up color will be counted in the measurement region. The counted pixels are called

"Area". Set the box of the same size at the same position in the measurement region 0 to 2. (Set the

measurement region in space of no letter.) Counted area can tell the color being measured.

Measurement region 0

(Color pickup 0)

OMRON

Ice Cream

Vanilla

The area will be counted

only when "vanilla" ice

creams are under measured.

1

Select "Measurement region" and

press the ENTer key.

The table of measurement region number will be displayed.

Measurement region 1

(Color pickup 1)

Measurement region

The area will be counted

only when "strawberry"

ice creams are under

measured.

OMRON

Ice Cream

Strawberry

Measurement region 2

(Color pickup 2)

Measurement region

Ice Cream

The area will be counted

only when "lemon" ice

creams are under measured.

OMRON

Lemon

OMRON

Ice Cream

OMRON

Ice Cream

Strawberry

Vanilla

OMRON

Ice Cream

Lemon

Select "0." and press the ENTer key.

2

Select "Area & gravity" and press the ENTer key.

3

2-3 Ice Cream Separation

29

Page 31

Selecting color to be picked up

Select "Color no." and press the ENTer key.

4

Use the Left and Right Keys to select color to be picked

5

up, and press the ENTer key.

Pickup color 0 will be selected for the

measurement region 0.

Setting the Region

Select "Region" and press the ENTer key.

6

Select "New" and press the ENTer key.

7

Select "Box" and press the ENTer key.

8

Select "OR" and press the ENTer key.

9

"OR" is for setting the region, "NO T" is for

partly erasure.

30

Page 32

Specify upper-left corner of the measurement region. Use

10

the cursor keys to mov e the cursor and press the ENTer key .

Specify lower-right corner of the measurement region.

11

Use the cursor keys to move the cursor and press the

ENTer key.

The measurement region will be indicated by

dotted line on the screen.

Press the ESCape key se veral times and the

12

screen of

will appear.

2

10

11

Select "1." and press the ENTer key.

13

Repeat above steps

to 12 and set the

3

measurement region 1 to 2.

Press the ESCape key several times and the screen

14

of

will appear.

1

OMRON

Ice Cream

Vanilla

OMRON

Ice Cream

Lemon

OMRON

Ice Cream

Strawberry

2-3 Ice Cream Separation

31

Page 33

2-3-5 Setting Output

Select "Judge".

Set the output for external device.

Set so as to the results of measurement region 0 to 2 will be output to the terminal block DO_0 to 2. The

color will be inspected depending on the region of OK (acceptable) result.

<Setting Judgement Condition>

Judgement condition is set for measuring the area of color pick up and of no pic k ed up color. Refer to

the measurement for the displayed image. The picked up color in the measurement region of OK

result will be under inspection.

(Ex.) Yellow (lemon) is under inspection.

Measurement region 0

(DO_0)

Area=8

Measurement region Measurement region

Measurement region 1

(DO_1)

Area=3

Measurement region 2

(DO_2)

Area=3720

OMRON

Ice Cream

Lemon

Judgement

NG NG OK

(unacceptable) (unacceptable) (acceptable)

For counting the area may be influenced by noise, set the value a little higher.

pЙдЙЕн=?bсйкЙллбзе?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

1

pЙдЙЕн=?gмЗЦЙ?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

2

pЙдЙЕн=?MK?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

3

"0." indicates DO_0 of terminal block.

32

Page 34

pЙдЙЕн=x===z=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

4

pЙдЙЕн=?oM?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

5

"R0" indicates measurement region 0.

pЙдЙЕн=?^кЙ~=j^?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

6

R0.MA will be set.

pЙдЙЕн=?lh?=~еЗ=йкЙлл=нЬЙ=bkqЙк=вЙуK

7

OMRON

Ice Cream

Vanilla

OMRON

Ice Cream

Lemon

OMRON

Ice Cream

Strawberry

2-3 Ice Cream Separation

Operational expression will be set.

Then set the judgement condition.

33

Page 35

Select "Upper" and press the ENTer key.Then change

8

the numeral by digits.

8

See p.32 to set the judgement condition.

Change the numeral with a one-digit cursor appeared on the display.

Use the Left and Right Keys to move the

cursor to the digit to be input.

Use the Up and Down Keys to change the

numeral.

Press the ENTer key, after changing the numeral.

9

Select "Lower" and press the ENTer key.

10

Press the ESCape key and the screen of 3 will

11

appear.

First 8 letters of expression that had been

set will be displayed.

Select "1." and press the ENTer key.

12

10

Repeat the steps 4 to 11, set "1." to

"R1.MA" and set "2." to "R2.MA".

Press the ESCape key sev er al times and the

13

screen of

will appear.

1

34

Page 36

2-3-6 Checking Measurements

Select "MONitor" mode.

With practical operation, check that the measurement would be performed correctly with

the conditions already set. The results will be just displayed on the screen. Not be output

to the terminal block. Measurement condition can be adjusted referring to the judgement.

Press the ESCape key in following screen to leave

1

"SET" mode.

Operation will be in monitor mode auto-

matically.

Press the SHIFT+ESCape keys, to confirm out-

2

put result in terminal block, to confirm output

result in terminal block.

Select "Display result: None" and press the ENTer key .

3

OMRON

Ice Cream

Vanilla

OMRON

Ice Cream

Lemon

OMRON

Ice Cream

Strawberry

2-3 Ice Cream Separation

Select "All judges" and press the ENTer key.

4

35

Page 37

Select "End" and press the ENTer key.

5

Press the TRIGger k e y.

6

Results of DO_0 to 2 will be displayed.

Ice

Terminal

block

DO_0

DO_1

DO_2

Vanilla

OK

NG

NG

Strawberry

Lemon

NG

OK

NG

NG

NG

OK

"Refer to "Operation Manual - 4-1 Checking Measurements"

36

Page 38

2-3-7 Measuring Objects

Input measurement trigger and the measurement will be performed according to the conditions set for the current scene.

The results will be output to terminal block DO_0 to 2.

Select "MONitor" to enter "RUN" mode and press

1

the ENTer key.

Select "RUN" and press the ENTer key.

2

The screen enters measurement mode.

Select "RUN" mode.

OMRON

Ice Cream

OMRON

Ice Cream

Strawberry

Vanilla

OMRON

Ice Cream

Lemon

Press the TRIGger ke y.

3

One measurement will be performed.

Terminal

block

DO_0

DO_1

DO_2

Ice

Vanilla

OK

NG

NG

Strawberry

Lemon

NG

OK

NG

NG

NG

OK

2-3 Ice Cream Separation

37

Page 39

Memo

38

Page 40

SECTION 3

Appendix - Peculiarity of color -

39

Page 41

Color is expressed by hue, saturation and value.

Saturation

(Chroma)

The degree of the vividness of color

Low : Monotone color

High : Close to pure color

Value

(Lightness)

The degree of light and the

shade of color

`çäçê=`ìÄÉ

Color Pickup Mode

Hue

The color attributes such

as red, blue, and green

In color pickup mode, color image will be converted into binary image by three parameters - hue, saturation and value.

Specifying picked up color, its corresponding part of the space in color cube will be converted into "1", and the other "0".

Monotone color that cannot be treated by color gray filter, can be e xtracted in color pickup mode.

The picked up color will be

converted into "1".

The part of "1" will be

displayed by picked up

color in F400.

The colors excluding picked up

color will be converted into "0".

The part of "0" is displayed by

black at default, but it can be

converted into 5 colors "from

black to white".

40

Page 42

Colorgray filter in color filter mode

In colorgray filter, color image will be converted into gray image using hue and saturation, but lightness isn't

considered during conversion.

The density of gray image after conversion depends on the point on hue/ saturation plane of color image.

Low

Hue

High

Hue/saturation plane

Saturation

Density of colorgray image

= Saturation of measured color - (Hue of registered color - Hue of measured color)

(Ex.) Registered color: blue

Registered color

Blue

Light blue

Red

Select registered color out of 256 hues. Color bar displayed left side of a screen indicates hue.

Highest chroma colors in each hue are lined up on the color bar.

So blue must be selected on the color bar when light blue is to be registered.

As measured color is as close as registered color

and high chroma, it will be white in gray image.

Though hue is registered color, it will be gray in

gray image because of low saturation.

As measured color is as far as registered color, it

will be black in gray image though high

saturation.

See next page for the setting of color g r ay filter.

41

Page 43

1

2

How to set of colorgray filter

3

(Hue: STEP 1 to 2, Saturation: STEP 3)

Step

Step

Selecting the Registered Color

Select a color to be expressed brightly in gra y image .

"Hue of registered color - Hue of measured color" will be converted to 256 lev els in gr ay image.

Make output dark for hue of measured color as f ar as registered color.

Registered color

Low

Converting the color bar into color

circle will make it easy to understand.

High High

Low

Hue of registered color

- Hue of measured color

Switching the Color Band

HLJNUM=ЗЙЦкЙЙл

Centering the registered color, convert

the colors of +/-180 degrees into gray

image of 256 gradations.

Registered color (255)

Centering the registered color , convert the colors of

+/-90 degrees into gray image of 256 gradations.

Other colors will be converted into black.

+/- 90 degrees

Registered color (255)

Step

(0)

(0)

Adjusting the Range of Chroma

Chroma means the vividness of color. Color of lower tone will be converted into darker.

Higher tone than upper limit of the range will be white.

High

Chroma

Low

Lower tone than lower limit will be black.

Monotone

Upper limit

Gray image of 256 gradations

Lower limit

(0)

42

Page 44

43

Page 45

OMRON Corporation

Industrial Automation Company

Advanced Sensors Division

Sensing Devices and Components Division H.Q.

28th Fl., Crystal Tower Bldg.,

1-2-27, Shiromi, Chuo-ku,

Osaka 540-6028 Japan

Tel: (81)6-6949-6105/Fax: (81)6-6949-6149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS, INC.

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel: (65)835-3011/Fax: (65)835-2711

OMRON (CHINA) CO. LTD.

21F, Beijing East Ocean Center

No. 24A Jian Guo Men Wai Da Jie

Chao Yang District, Beijing, 100022

China

Tel: (86)10-6515-5778/Fax: (86)10-6515-5810

Page 46

Loading...

Loading...