Page 1

Cat. No. Z135–E1-1

F400

OPERATION MANUAL

Color Vision Sensor

Page 2

i

F400 Color Vision Sensor

Operation Manual

Produced June 1999

Page 3

!

!

!

ii

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual.

Always heed the information provided with them. Failure to heed precautions can result in

injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury, or property damage.

Visual Aids

The following headings will help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the

product.

Indicates pages where additional information can be found.

1. Indicates a procedure. The step numbers in the procedure correspond to the

numbers in any related illustrations.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every precaution has been taken in

the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information

contained in this publication.

Page 4

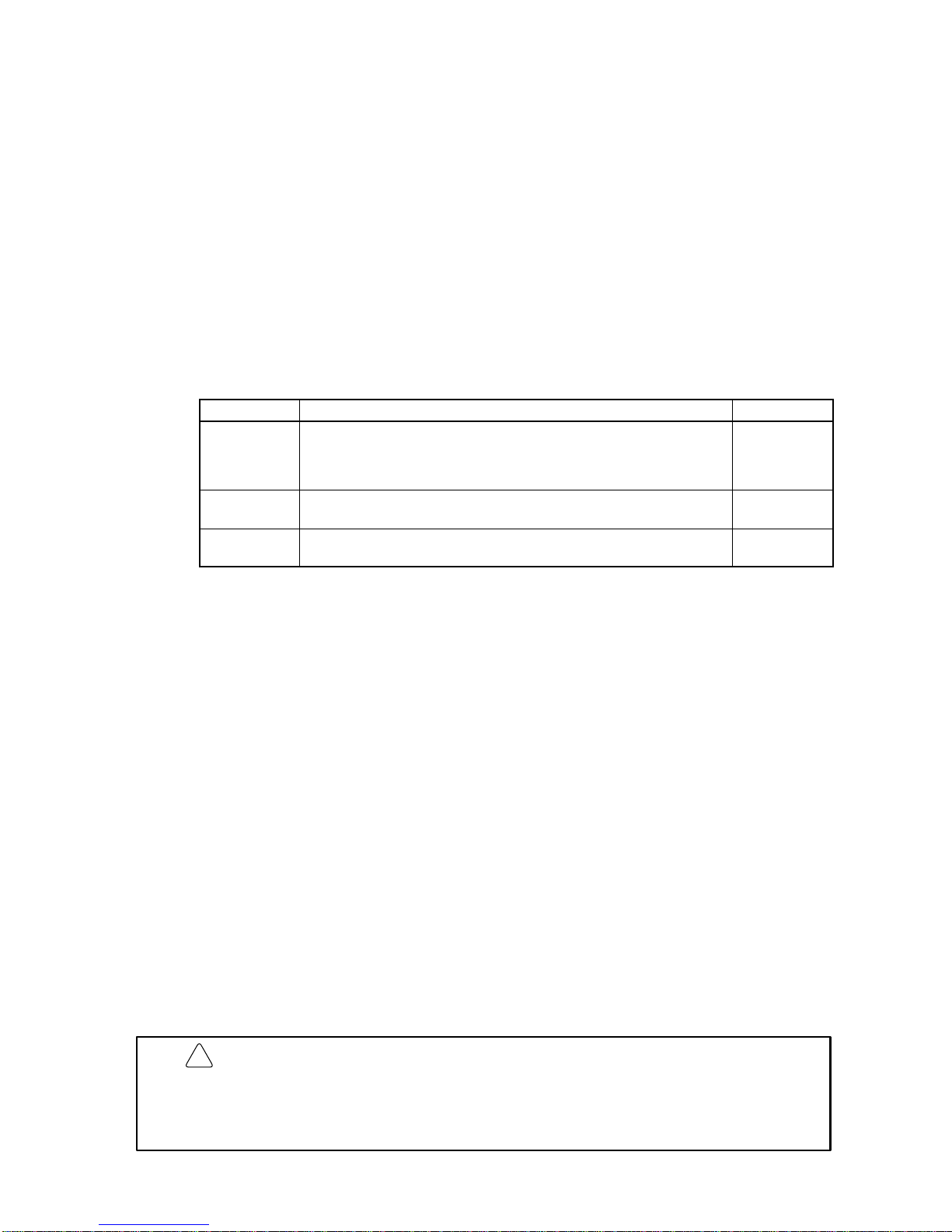

iii

About this Manual:

This manual describes the measurement conditions, settings, and external device communications methods for the F400 Color Vision Sensor. The F400 can take measurements using color information.

The F400 supports two scene modes that can be used for measurement: Color Pickup Mode and Color

Filter Mode. The features of these two scene modes are as follows:

Color Pickup Mode: Only the specified color is extracted and measured.

Color Filter Mode: A color filter is applied to create an easily measurable image. Color combinations

that are hard to distinguish in gray images because of low contrast in brightness,

such as green and yellow, can be recognized and measured.

Please read this manual and other related manuals carefully and be sure to understand the information

provided before attempting to install or operate the F400. The manuals for the F400 are outlined in the following table.

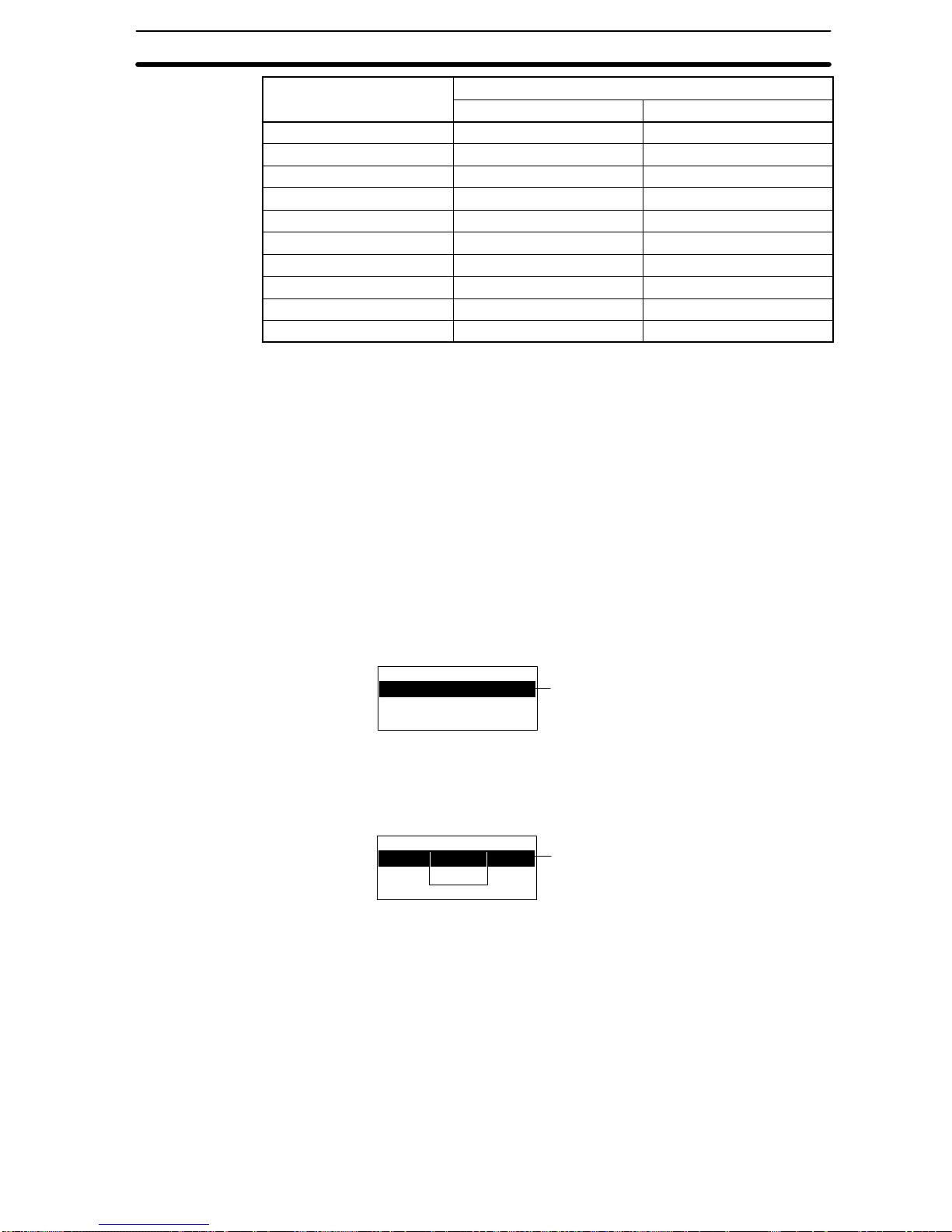

Manual

Contents Cat. No.

Introduction

Manual

Provides introductory information about the F400. This manual is

designed for first-time users of the F400 and describes features of

color gray measurement, basic operations of the F400, and the

main F400 applications.

Z131-E1-1

Setup

Manual

Describes hardware, wiring, and connections required to install the

F400.

Z130-E1-1

Operation

Manual

Describes F400 functions. Explains measurement settings and

methods for communications with external devices.

Z135-E1-1

Section 1 Introduction

describes features, measurement modes, and menu tree of the F400

Color Vision Sensor.

Section 2 Basic Operations

describes the overall flow of F400 application and basic opera-

tions.

Section 3 Settings

describes how to set measurement conditions for F400 visual inspections.

Section 4 Checking and Executing Measurements

describes how to monitor if correct measurements are being performed with the set measurement conditions. It also describes how to

perform measurements.

Section 5 System Settings

describes the system setting procedures for the F400.

Section 6 Communications with External Devices

describes the communications settings

and I/O formats for communications with external devices.

Section 7 T roubleshooting

lists the errors that may occur during F400 operation, along with

their probable causes and remedies.

WARNING Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the

information provided in the section and related sections before attempting

any of the procedures or operations given.

!

Page 5

v

TABLE OF CONTENTS

PRECAUTIONS vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Safety Precautions viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii. . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – Introduction 1. . . . . . . . . . . . . . . . . . . . . . .

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Measurement Modes 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Color Pickup and Color Filter Modes 4. . . . . . . . . . . . .

1-2-2 Additional Color Filter Mode 4. . . . . . . . . . . . . . . . . . .

1-3 Menu Trees 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Basic Operations 7. . . . . . . . . . . . . . . . . . .

2-1 Menu Operations 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Screen Displays 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Input Devices 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Menu Tree 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-4 Inputting Values 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-5 Drawing Measurement Regions 12. . . . . . . . . . . . . . . . . .

2-2 Starting and Quitting 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Starting 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Selecting Scene Modes 15. . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Changing Scenes 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Copying and Clearing Scenes 17. . . . . . . . . . . . . . . . . . .

2-2-5 Quitting 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – Settings 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Adjusting Images 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-1 Shutter Speed 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-2 Applying Color Filters 24. . . . . . . . . . . . . . . . . . . . . . . . .

3-1-3 Creating a Color Filter 26. . . . . . . . . . . . . . . . . . . . . . . . .

3-1-4 Picking Up Measurement Colors 28. . . . . . . . . . . . . . . . .

3-1-5 Filtering 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-6 Background Suppression 34. . . . . . . . . . . . . . . . . . . . . . .

3-1-7 Output Calibration 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Position Compensation 37. . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Adjusting Images for Easier Position Compensation 38. .

3-2-2 Setting Position Compensation Regions 38. . . . . . . . . . .

3-2-3 Searches 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-4 Position Compensation using Edges 43. . . . . . . . . . . . . .

3-2-5 Area and Center of Gravity, and Center of

Gravity and Axis Angle 46. . . . . . . . . . . . . . . . . . . . . . . .

3-3 Measurement Methods 50. . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Measurement Regions 50. . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of contents

vi

3-3-2 Surface Defects 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-3 Searches 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-4 Edge Processing 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-5 Area and Center of Gravity, and Center of

Gravity and Axis Angle 67. . . . . . . . . . . . . . . . . . . . . . . .

3-4 Expressions 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – Checking and Executing Measurements 83

4-1 Checking Measurements 84. . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Adjusting Evaluation Criteria while

Viewing Measurements 85. . . . . . . . . . . . . . . . . . . . . . . .

4-2 Measuring 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 Adjusting Evaluation Criteria during Measurement 93. . .

SECTION 5 – System Settings 95. . . . . . . . . . . . . . . . . . . .

5-1 White Balance 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Output Destination 97. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Backup 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-1 Operations Using the F400 97. . . . . . . . . . . . . . . . . . . . .

5-3-2 Operation Examples for the Personal Computer 99. . . . .

5-4 Display Settings 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-1 Measurement Screen Settings 100. . . . . . . . . . . . . . . . . . .

5-4-2 Changing the Display Image 103. . . . . . . . . . . . . . . . . . . .

5-5 Key Allocation 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Startup Mode 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Error Settings 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Version 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – Communications with External Devices 111

6-1 Terminal Blocks 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-1 I/O Format 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-2 Terminal Signal Operation and Timing 112. . . . . . . . . . . .

6-1-3 Setting Communications (Terminal Block) 118. . . . . . . . .

6-2 RS-232C Port 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1 Flowcharts 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2 Setting Communications (RS-232C) 121. . . . . . . . . . . . . .

6-2-3 Input Command List 122. . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-4 I/O Format 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – Troubleshooting 135. . . . . . . . . . . . . . . . . . . .

Glossary 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

vii

PRECAUTIONS

This section provides general precautions for using the F400 Color Vision Sensor.

The information contained in this section is important for the safe and reliable application of the F400 Color

Vision Sensor. You must read this section and understand the information contained before attempting to

set up or operate a F400 Color Vision Sensor.

1 Safety Precautions viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions viii. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

!

!

!

!

!

!

!

!

!

!

!

!

PRECAUTIONS

viii

1 Safety Precautions

WARNING Cover the terminal blocks with the Terminal Block Protection Covers.

Uncovered terminal blocks can result in electric shock.

WARNING Use DC power supplies with safe extra low-voltage circuits on the

secondary side for the main F400 power supply and power supplies for

the terminal blocks. Excessively high voltages can result in electric

shock.

Caution Do not touch fluorescent or halogen lights while the power is ON or

immediately after the power is turned OFF. These lights generate heat

and can cause burns.

Caution Do not use the F400 in environments with flammable or explosive gases.

Caution Install the F400 away from high-voltage equipment or motors to ensure safety during

operation and maintenance.

Caution Use the power supply cables and crimp terminals of specified sizes.

Caution Use at the power supply voltages specified in this manual.

Caution Be sure to securely tighten the screws when mounting F400 components.

Caution Do not dismantle, repair or modify any F400 components.

Caution Dispose of F400 components as industrial waste.

Caution To prevent damage from static electricity, use a wrist strap or another device for pre-

venting electrostatic charges when touching terminals or connector signal lines.

Caution Do not turn OFF the power while a message is being displayed indicating that proces-

sing is being performed. Data in memory will be destroyed, and the F400 may not

operate correctly the next time it is started.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines, and equipment that may have a serious

influence on lives and property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems,

machines, and equipment with double safety mechanisms.

Page 9

1

SECTION 1

Introduction

This section describes features, measurement modes, and menu tree of the F400 Color Vision Sensor.

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Measurement Modes 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Color Pickup and Color Filter Modes 4. . . . . . . . . . . . .

1-2-2 Additional Color Filter Mode 4. . . . . . . . . . . . . . . . . . .

1-3 Menu Trees 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

1-1SectionFeatures

2

1-1 Features

Color Images

Color information from a color image can be used when performing measurements.

Select one of the two F400 measurement modes, called scene modes, depending on

the application. The two modes are Color Pickup Mode and Color Filter Mode.

Refer to t h e

Introduction Manual (Z131)

for information on color (hues and saturation)

and applications.

Color Pickup Mode

The Color Pickup mode is used to extract only specified colors. Simply click the color

to be displayed on the screen to register it as a pickup color. Up to 8 colors can be

registered per scene.

Applications include separation by color, such as for ice cream separation or for wiring checks.

Color Filter Mode

A color filter can be applied to create an easily measurable image. There are five color

filters: Red, green, blue, colorgray, and gray. The colorgray filter is used to convert a

color image to a grayscale image with 256 gradations by using hue and saturation

settings. The colorgray filter enables measurement of color combinations, such as

green and yellow, with low contrast in brightness making them hard to distinguish in

gray images.

Applications include detection of small defects, such as surface defects on bottle

caps, and inspection free from background distortion, such as inspecting the amount

of adhesive that has been coated on a surface.

Page 11

1-1SectionFeatures

3

• Position and orientation of object can be compensated before measurement. → p. 37

There are four methods: Using search, edge, area and center of gravity, or center of gravity

and axis angle.

• Color of object and color read by camera can be adjusted automatically using white balance.

→ p. 96 Adjust white balance each

time lighting is changed.

• Camera image can be adjusted to facilitate measurement.

Filtering: Edges of object are enhanced and noise reduced.

→ p.

33

Background suppression: Background of object, such as pat-

terns, is excluded from measurement.

→ p. 34

Color filter: Contrast of measurement area is increased

→ p.24

• Up to 8 specified colors can be picked up.

→ p. 28

• Images can be checked on screen. Up to 16 images can be stored

in memory to confirm past images to see what problems have

occurred. Images can be backed up on a computer.

→ p. 100

• Setup can be changed smoothly.

→ p. 16 Each of 16 scenes can be

set up for different inspection

conditions. Change scenes to

setup a different measurement

object.

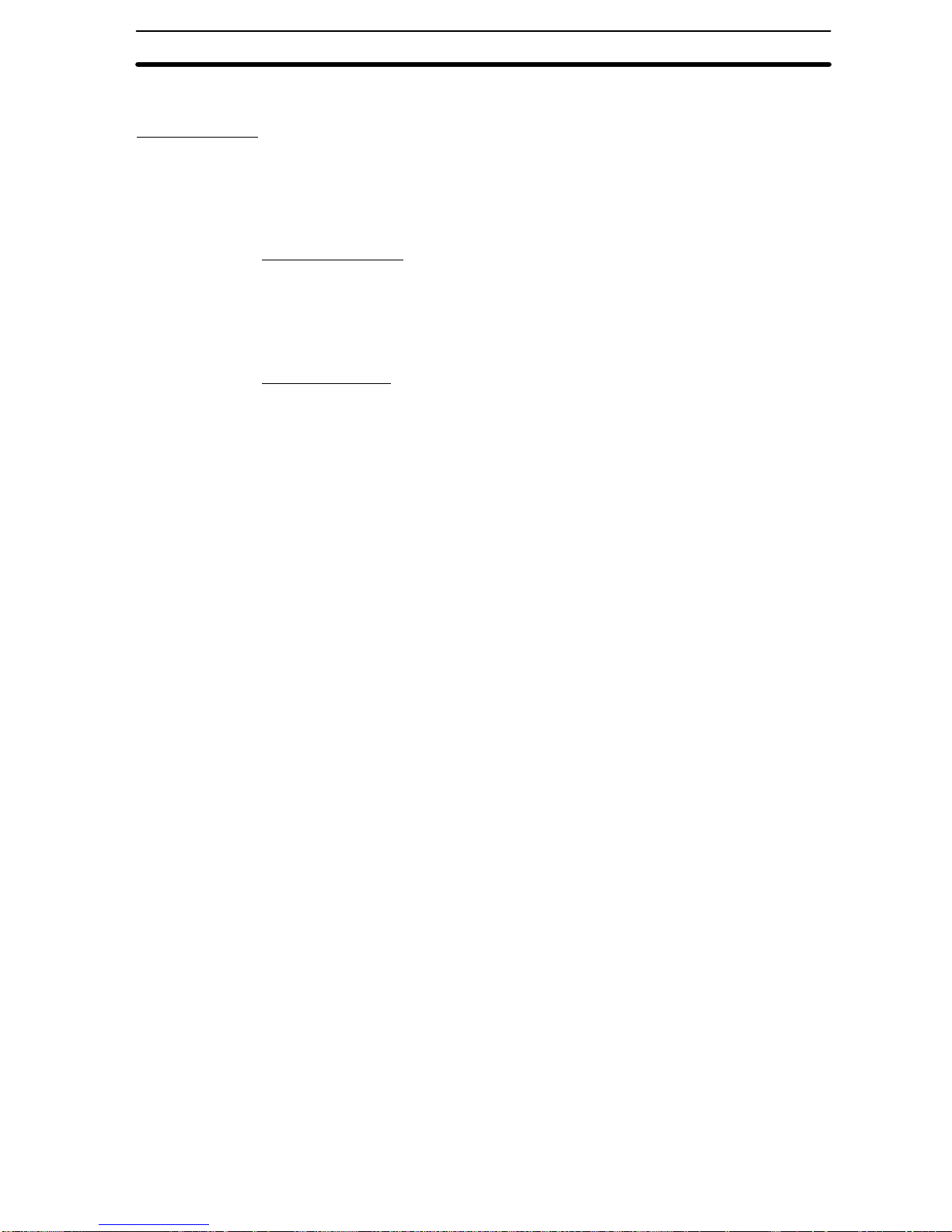

Camera

Sync sensor

Monitor

Programmable Controller

Personal computer

• Shutter speed can be adjusted to speed of measurement object.

→ p. 24

F400

• Communications with external devices is possible through a

terminal block or RS-232C port. Refer to the table on the next

page.

•The distance between two regions or the maximum value

can be obtained by calculating measured values or by

using functions.

→ p. 75

Input/Output Terminal block RS-232C

Trigger input Yes Yes

Measurement values output No Yes

Judgement output (OK/NG) Yes No

Terminal blocks:

→ p. 112

RS-232C port:

→ p. 119

Page 12

1-2SectionMeasurement Modes

4

1-2 Measurement Modes

There are five measurement modes. Different modes are available depending on the

scene mode.

1-2-1 Color Pickup and Color Filter Modes

Search → p. 55, 144

Density searches are used when inspecting the shape of specific objects. The object

is measured using a registered measurement pattern called a model. The position of

the object and the degree of conformity, called the correlation, with the model are calculated.

Edge

→ p. 63, 140

The edge measurements are used to find the coordinates of edges of the measurement object. The width of an object can be calculated by using an equation to subtract

edge coordinates.

Area and Center of Gravity

→ p. 67, 147

The binary center of gravity and area can be used to calculate the size (i.e., the area)

and the position (i.e., the center of gravity) of the measurement object.

Center of Gravity and Axis Angle

→ p. 67, 147

The binary axis angle can be used to calculate the orientation (i.e., the binary axis) of

the measurement object, in addition to the center of gravity and area. Binary axis

searches increase processing time, so binary center of gravity and area searches

should be used when only the center of gravity and area are required.

1-2-2 Additional Color Filter Mode

Surface Defects → p. 52, 142

The measurement object can be inspected for surface defects. Areas that are largely

different in densities are detected as defects.

Page 13

1-3SectionMenu Trees

5

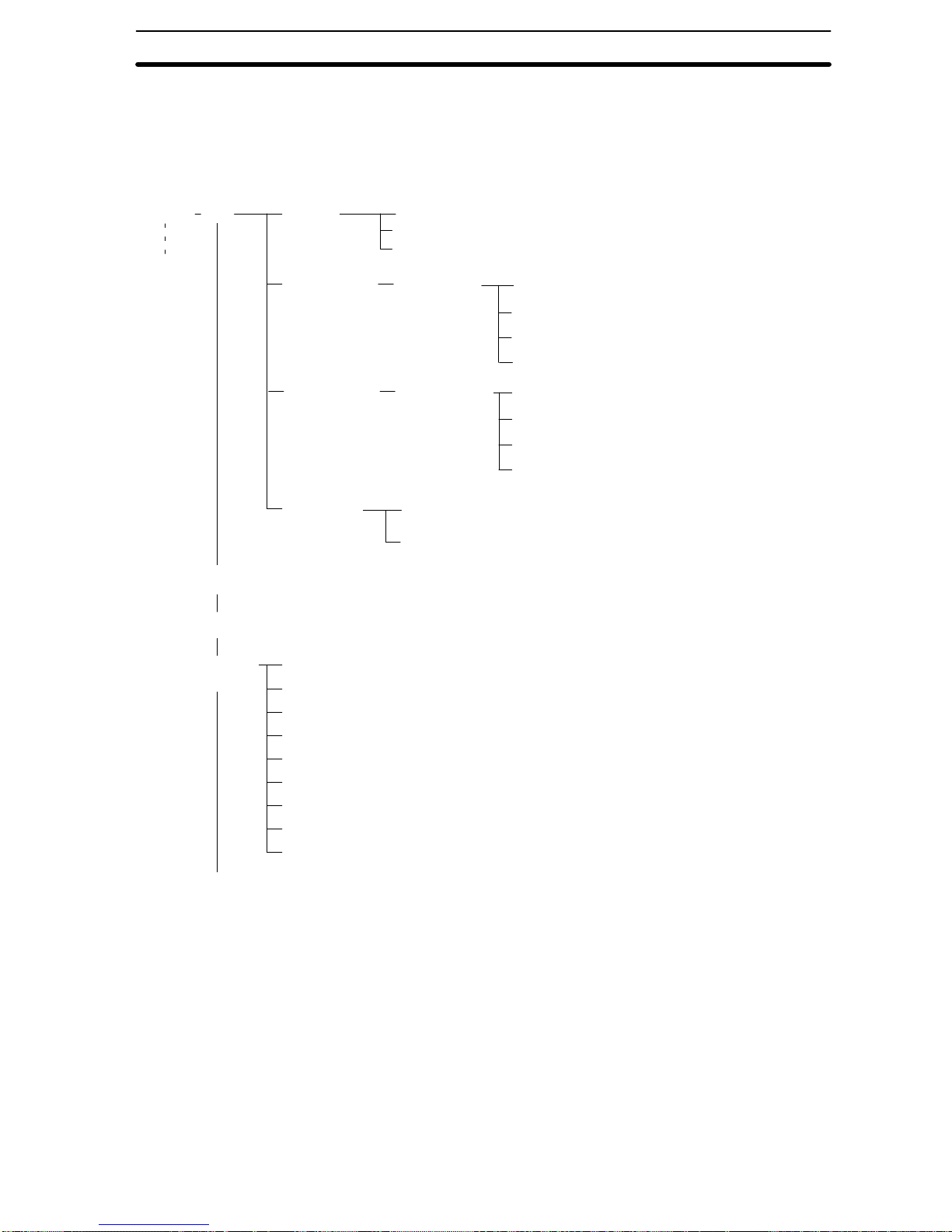

1-3 Menu Trees

Color Pickup and Color Filter Modes have different menu hierarchies. The menu hierarchies are outlined in the following diagrams. The same hierarchy exists under each

scene.

Color Pickup

Shutter speed → p. 24

Pickup color

→ p. 28

Calibration

→ p. 36

Position

compensation

Area & gravity

→ p. 46

Measurement

region

Judge

→ p. 75

Data

→ p. 75

SET

MON (Monitor) → p. 84

RUN

→ p. 92

Scene 0

Scene 15

→ p. 16

Gravity & axis → p. 46

Edge → p. 43

Search → p. 40

Area & gravity

→ p. 67

Gravity & axis → p. 67

Edge → p. 63

Search → p. 55

White balance → p. 96

SYS

(System)

Communications settings→ p. 118, 121

Backup → p. 97

Display settings → p. 100

Startup mode → p. 107

Error method → p. 108

Version → p. 110

SAVE → p. 18

Region 0

Region 1

Measurement

region 0 to 15

Output → p. 97

Set key operation

→ p. 106

Expression

Adjust

Page 14

1-3SectionMenu Trees

6

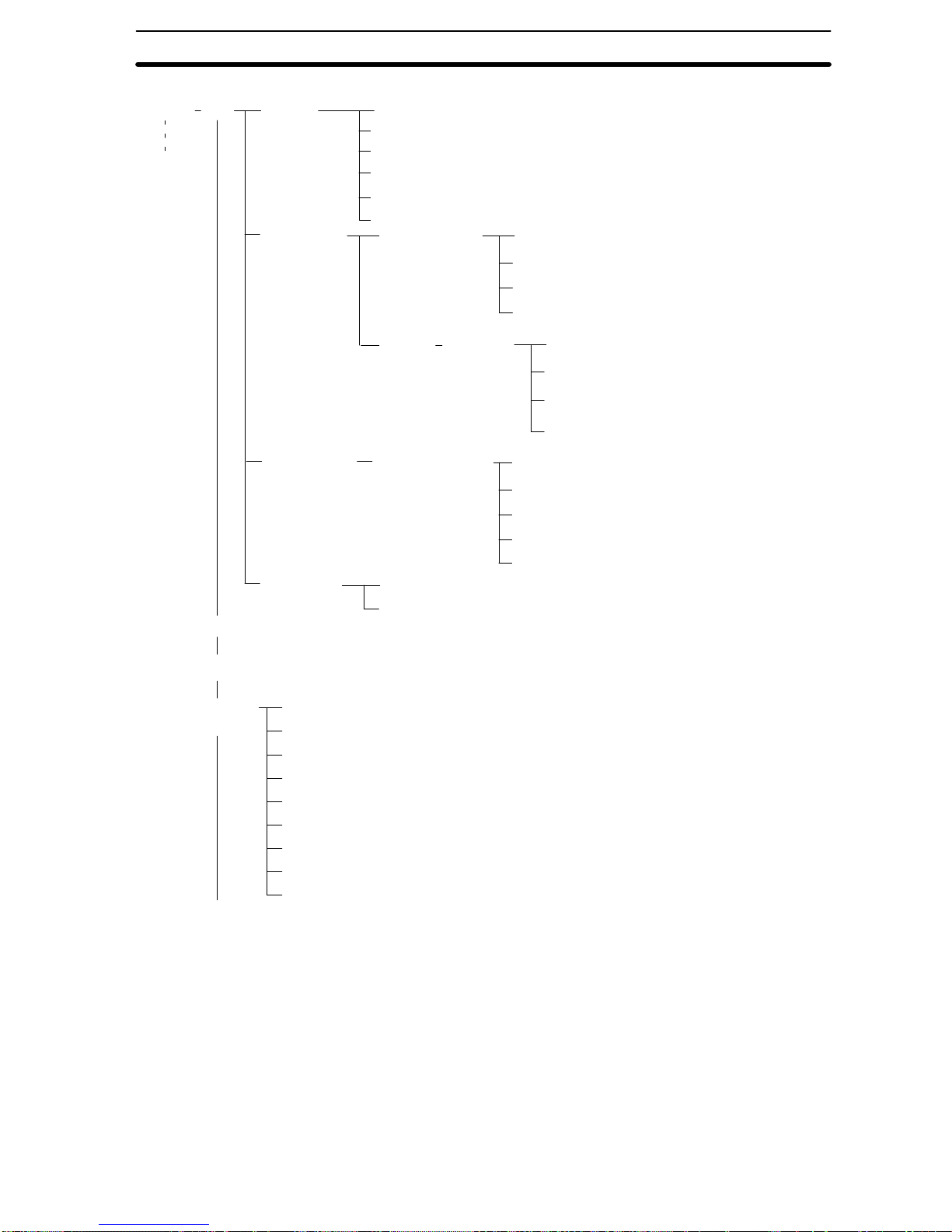

Color Filter

Shutter speed → p. 24

Color filter

→ p. 24

Calibration

→ p. 36

Position

compensation

Color filter

→ p. 37

Measurement

region

Judgement

→ p. 75

Data

→ p. 75

SET

MON (Monitor) → p. 84

RUN

→ p. 92

Scene 0

Scene 15

→ p. 16

Color select → p. 37

Filtering → p. 37

Background suppression level → p. 37

Surface defects

→ p. 52

Search → p. 55

Edge → p. 63

Area & gravity → p. 67

White balance → p. 96

SYS

(System)

Communications settings → p. 118, 121

Backup → p. 97

Display settings → p. 100

Startup mode → p. 107

Error method → p. 108

Version → p. 110

SAVE → p. 18

Background suppression level → p. 34

Color select

→ p. 26

Filtering → p. 33

Adjust

Region

Search → p. 55

Edge → p. 63

Area & gravity → p. 67

Gravity & axis → p. 67

Gravity & axis → p. 67

Region 0

Region 1

Measurement

region 0 to 15

Output→ p. 97

Set key operation

→ p. 106

Expression

Adjust

Page 15

7

SECTION 2

Basic Operations

This section describes the overall flow of F400 application and basic operations.

2-1 Menu Operations 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Screen Displays 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Input Devices 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 Menu Tree 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-4 Inputting Values 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-5 Drawing Measurement Regions 12. . . . . . . . . . . . . . . . .

2-2 Starting and Quitting 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Starting 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Selecting Scene Modes 15. . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Changing Scenes 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Copying and Clearing Scenes 17. . . . . . . . . . . . . . . . . . .

2-2-5 Quitting 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 16

2-1SectionMenu Operations

8

2-1 Menu Operations

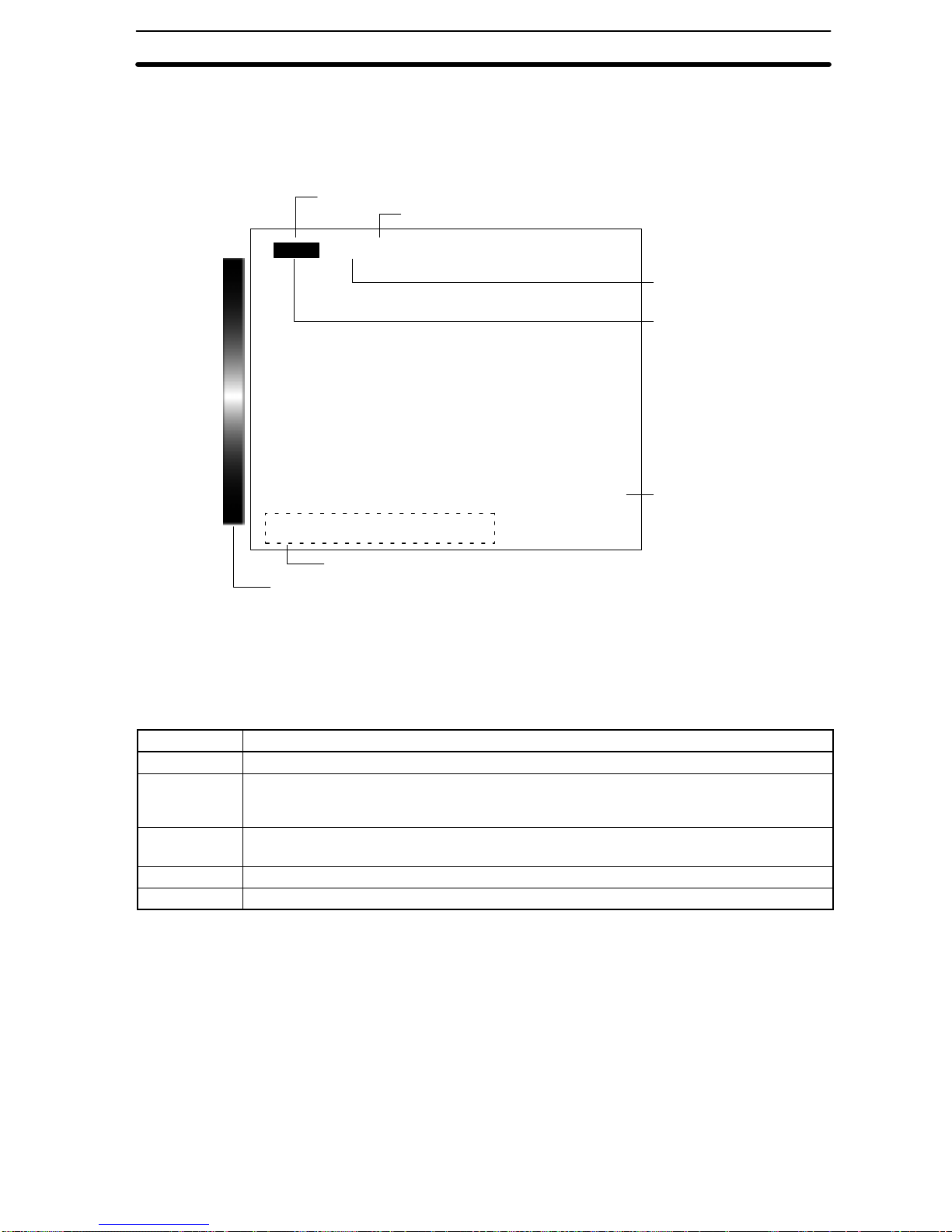

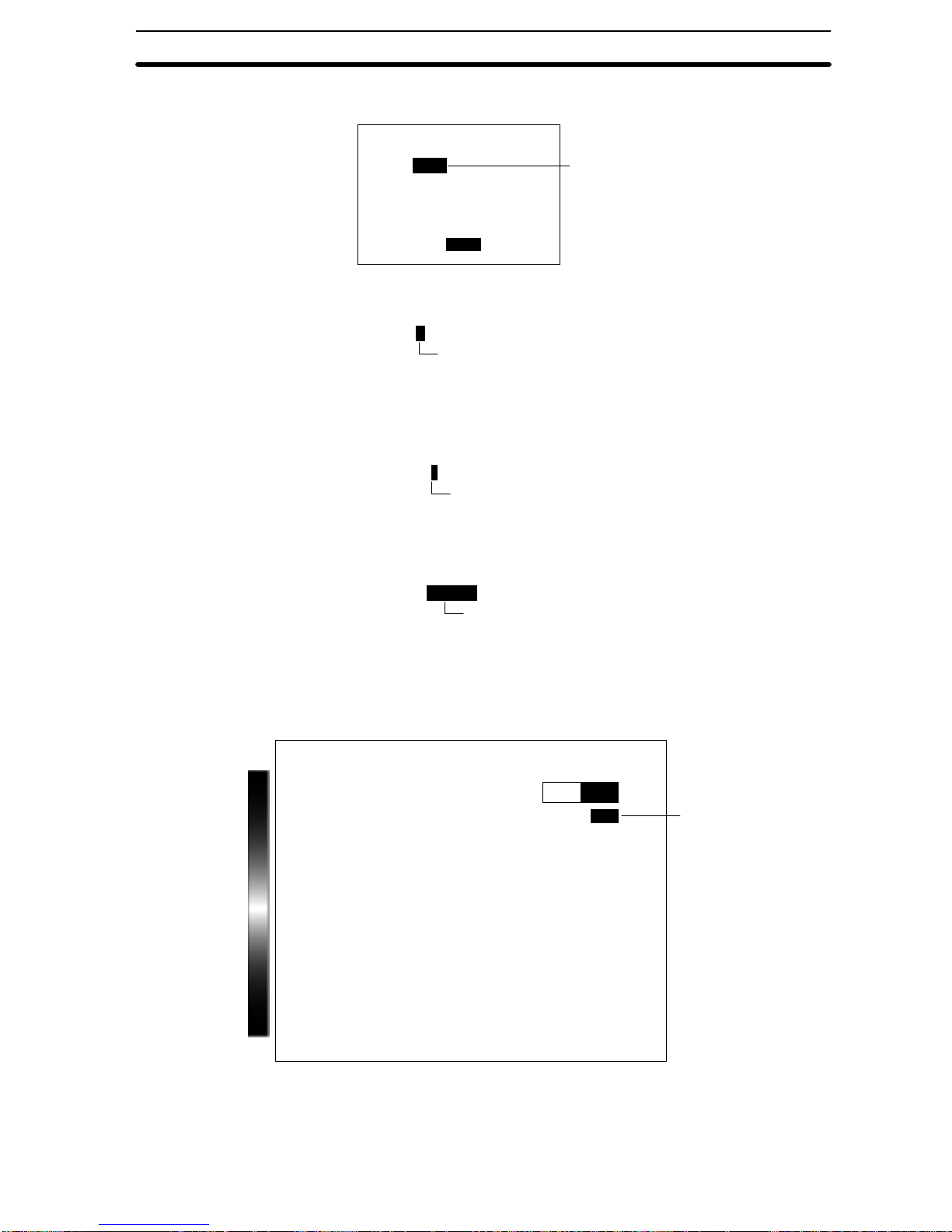

2-1-1 Screen Displays

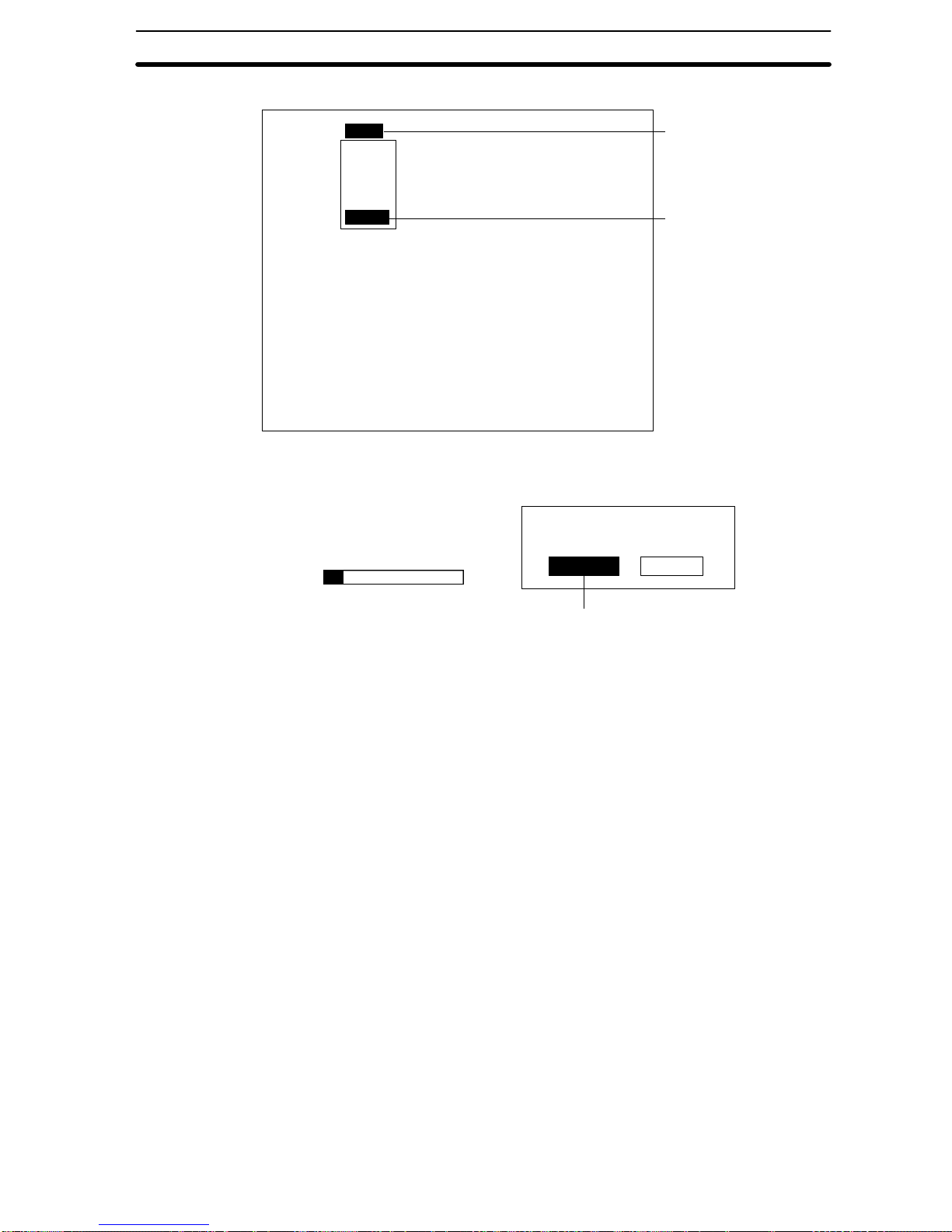

The F400 is operated by selecting functions from the screen. Highlighted text indicates the current cursor position. The screen is shown in the following diagram.

Scene number

Mode

Key operations

B Mark

Color bar

Cursor

position

Displayed

image

---- --ms

Color thr

Scn 0BMONB

The current scene number is displayed. There are 16 scenes that can be created to

change the measurement conditions easily.

Options will appear when an item with the B mark is selected.

The current operating mode is displayed. The modes are Set, Monitor, Run, System,

and Save. The operating modes are described in the following table.

Mode Meaning

SET Used to set measurement conditions.

MON (Monitor) Used to confirm whether or not the measurement is being performed correctly under the set

conditions and make adjustments if required. In this mode, measurement results are

displayed on the video monitor only and are not output to an external device.

RUN Used to perform object measurements. Outputs measurement results to an external device

via terminal blocks or RS-232C.

SYS (System) Used to make F400 system settings.

SAVE Saves settings to flash memory. Always save altered settings before exiting.

The selected text is highlighted.

The type of image displayed on the video monitor is shown. Refer to

Section 5-4-2

Changing Displayed Images

. →p. 103

The keys that can be used and their corresponding functions are displayed at the bottom of the screen.

The F400 will be in Color Filter Mode if the color bar is displayed and in Color Pickup

Mode if the color bar is not displayed.

2-1-2 Input Devices

The menu operations are performed from either the Console or the RS-232C port.

— Filter/Pickup —

Scene

Number

B Mark

Mode

Cursor

Position

Displayed

Image

Key

Operations

Color Bar

— Filter/Pickup —

Page 17

2-1SectionMenu Operations

9

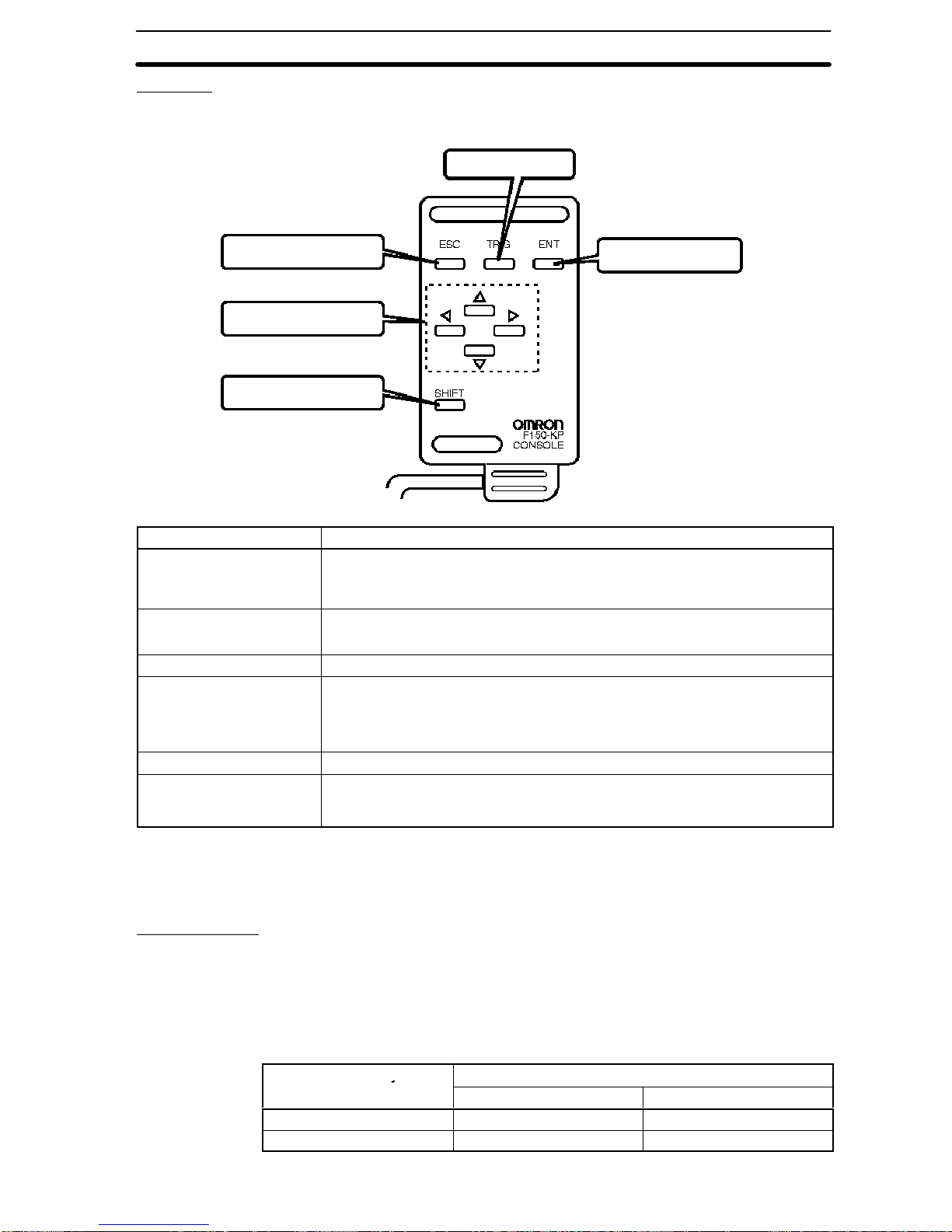

Console

The Console is used to perform menu operations. Be sure to familiarize yourself with

Console operations before actually using the menus.

TRIG (trigger) Key

ESC (escape) Key

Up, Down, Left, and

Right Cursor Keys

SHIFT Key

ENT (enter) Key

Key Function

ESC: Escape Key ESC Key functions differ depending on the screen currently displayed. Refer to

the explanations for individual screens. (See note.)

Interrupts processing and returns the user to the previous menu display.

TRIG: Trigger Key Starts object measurement.

Picks up a color when in Color Pickup Mode.

ENT: Enter Key Executes a function or sets a value.

Up and Down Keys Used to move the cursor up and down to select items.

The Up Key will increase a value by 1 and the Down Key will decrease a value

by 1. Continue pressing the Up or Down Key to quickly increase or decrease a

value.

Left and Right Keys Used to move the cursor left or right to select items.

SHIFT Key Must be pressed in combination with another key to have any effect. Specific

functions are assigned to SHIFT +

another key

for specific screens. (See note.)

Refer to the explanations for individual screens.

Note Possible to change assigned key functions or to assign new functions such as chang-

ing scenes or displays. Changed key allocations are effective only in the Monitor or

Run mode. Refer to

Section 5-5 Key Allocation

. →p. 106

RS-232C Port

There are keyboard key combinations for input via RS-232C that correspond to the

Console keys when in Run Mode. Refer to

Section 6-2-3 Input Command List

.

→p. 122

The keyboard key combinations are shown in the following table. The key codes

shown on the right in the following table can be input from an external device to perform the same functions as the Console keys shown on the left.

Console key

RS-232C input

Co so e ey

Key Code

ESC CTRL + [ ($1B)

TRIG CTRL + A ($01)

Page 18

2-1SectionMenu Operations

10

Console key RS-232C inputConsole key

CodeKey

ENT CTRL + M ($0D)

Up Key CTRL + E ($05)

Down Key CTRL + X ($18)

Left Key CTRL + S ($13)

Right Key CTRL + D ($04)

SHIFT + ESC TAB, CTRL + I ($09)

SHIFT + TRIG CTRL + T ($14)

SHIFT + ENT CTRL + R ($12)

SHIFT + Up Key CTRL + W ($17)

SHIFT + Down Key CTRL +Z ($1A)

Note 1. Commands cannot be input during menu operation.

2. Input CTRL + Q to re-input commands to change from the menu operation to

command input.

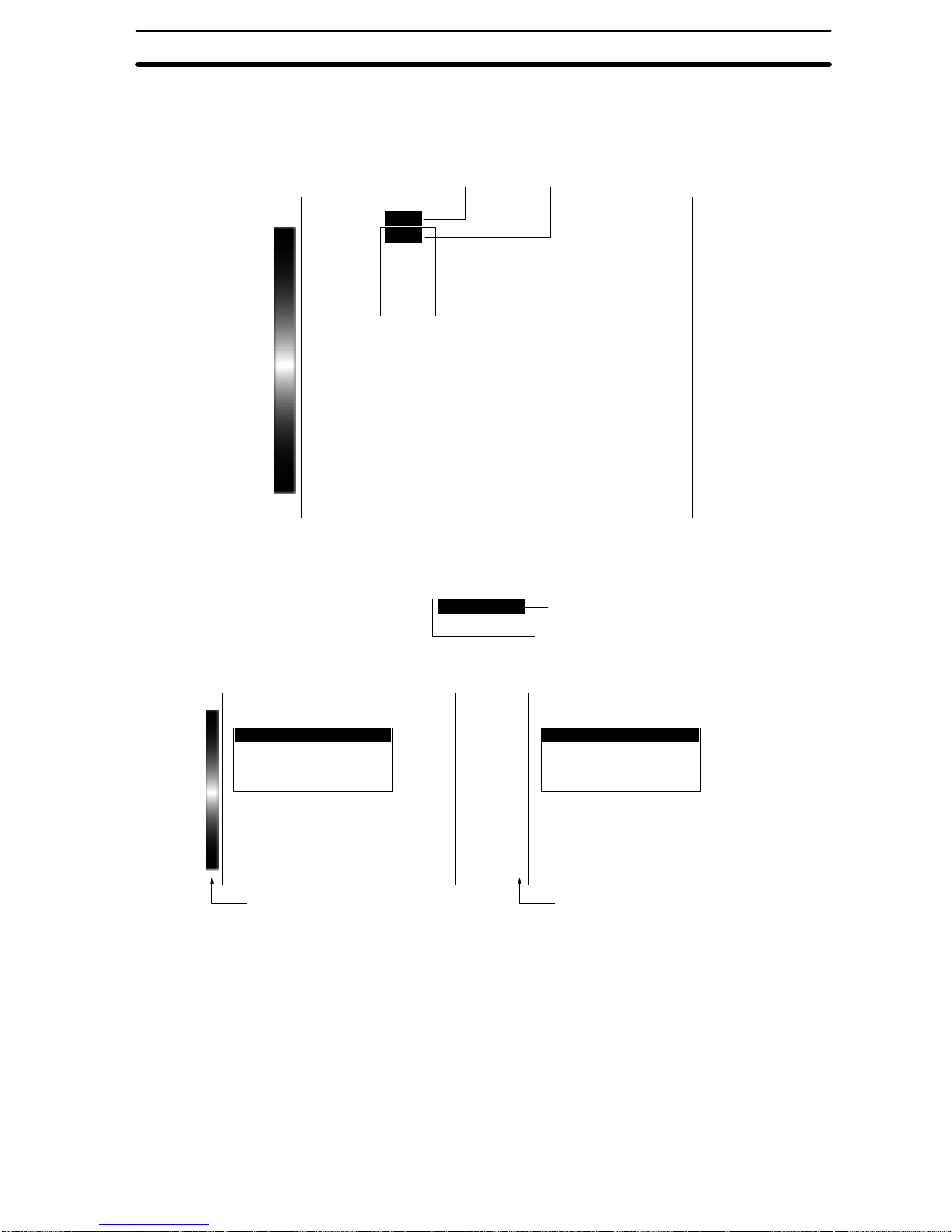

2-1-3 Menu Tree

F400 menus are hierarchical. The cursor is moved to the required functions to set

measurement conditions. Use the following procedure to move around the menu

tree.

Menu Tree:

→p. 5

1. Move the cursor to the desired function using the Up, Down, Left, and Right

Cursor Keys.

1

Adjust

Position compensation

Measurement region

Expression

2. Press the ENT Key. In this example, the cursor will move to the Adjust menu.

Repeat this step to move to lower levels.

2

Adjust

Position compensation

Measurement region

Expression

Adjust

Region

3. Press the ESC Key. The display will move to the previous menu level (i.e., the

screen shown in step (1)).

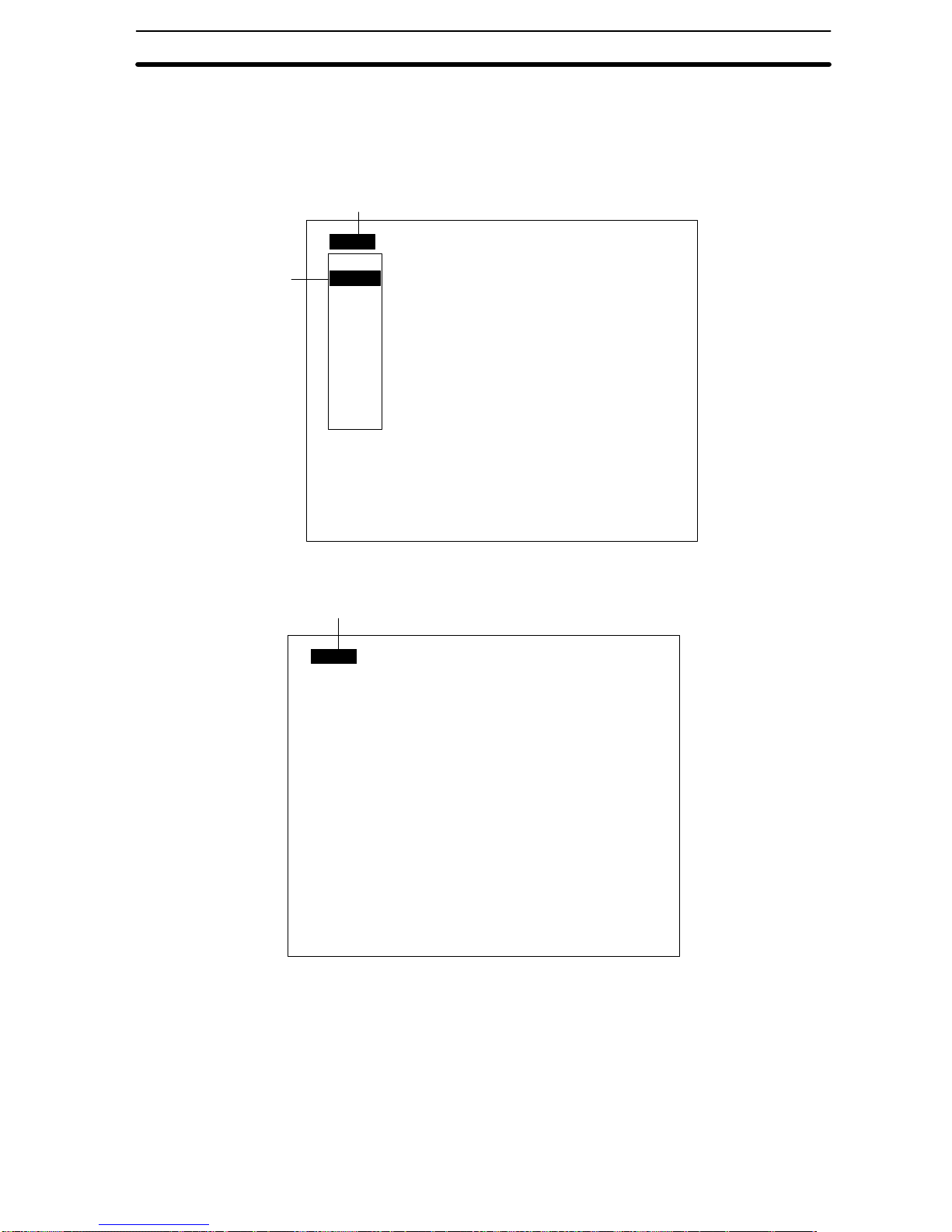

2-1-4 Inputting Values

This section explains how to input numeric values when setting measurement conditions. There are two input methods.

Specifying the Input Digit

Specifying the input digit is used mainly for setting judgements and system conditions.

— Filter/Pickup —

— Filter/Pickup —

Page 19

2-1SectionMenu Operations

11

1. Move the cursor to the item for which a value is to be changed and press the ENT

Key. The cursor size will change to a cursor the size of a single digit.

1

Correlation : 79 [80:100]

Position X : 180.000

[ 0.000 : 511.000]

Position Y : 30.000

[ 0.000 : 483.000]

Speed : 2B

End

2. Using the Left and Right Keys, move the cursor to the digit to be changed.

2

Position X: 180.000

[00000.000: 511.000]

3. Use the Up and Down Keys to change the value.

The Up Key will increase the value by 1 and the Down Key will decrease the

value by 1.

3

Position X: 180.000

[00100.000: 511.000]

4. Press the ENT Key when all digits have been changed as desired. The value will

be set.

4

Position X: 180.000

[190.000: 511.000]

Increasing and Decreasing Values

Values are increased or decreased mainly when setting binary levels and background suppression levels.

1. Move the cursor to the item for which the value is to be changed.

1

Binary level

↑↓:Move ←→:Change

Upper[255]

Lower[128]

Reverse

Auto

OK

2. Using the Left and Right Keys, change the numeric value. The Right Key will

increase the value by 1 and the Left Key will decrease the value by 1. The SHIFT

+ Right Key will increase the value by 10. The SHIFT + Left Key will decrease the

value by 10.

Page 20

2-1SectionMenu Operations

12

3. Use the Up and Down Keys to move to the next item. The numeric value will be

set.

3

Upper[200]

Lower[128]

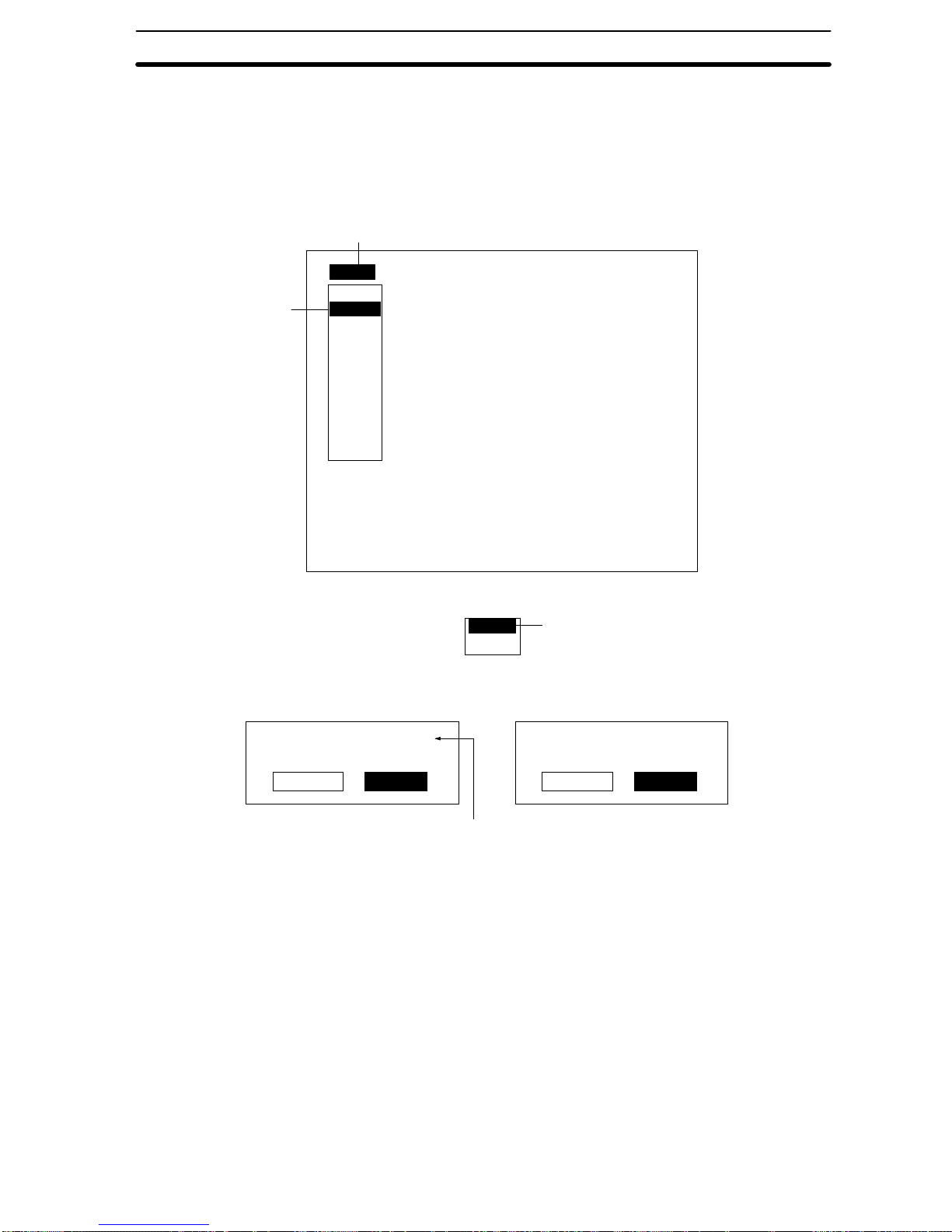

2-1-5 Drawing Measurement Regions

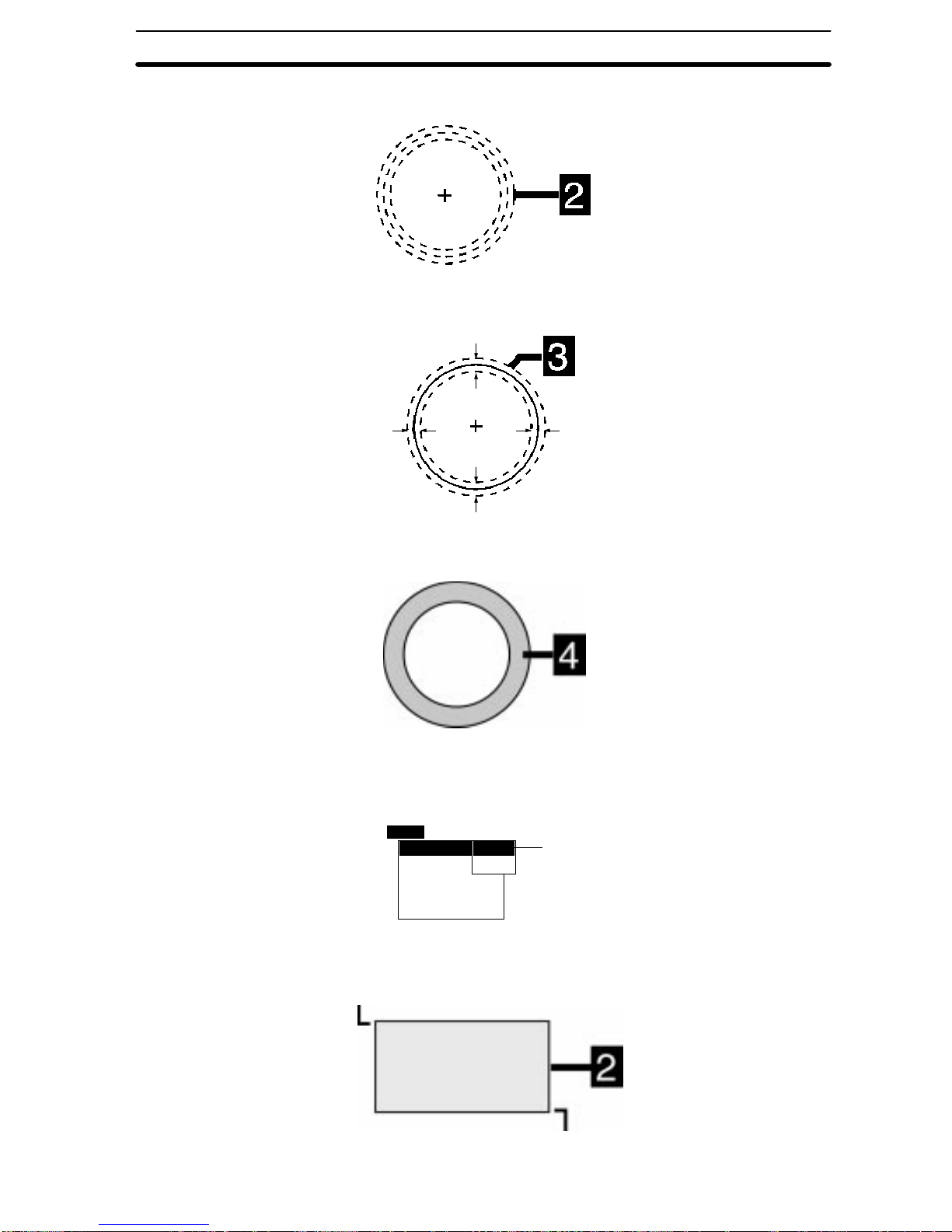

This section explains drawing methods for model and measurement regions.

Use the Up, Down, Left, or Right Keys to move from one drawing point to another.

Press the Shift Key together with any one of these keys to move at a faster rate.

Types of Drawings

Type Drawing method

Box Set two diagonally opposing corners.

Ellipse Set two diagonally opposing corners of a rectangle enclosing the

ellipse.

Circle Set the center and radius.

Circumference Set the center and radius. and then the line width.

Polygon Specify up to 10 neighboring vertices. After specifying the last point,

press the ENT Key twice and it will be joined to the first point and the

region will be drawn.

Note The type and number of drawings that can be created depends on the function in

which the drawings are being used.

Drawing Method (OR/NOT)

Drawing mode Meaning

OR Registers drawings as models or regions. If multiple drawings are made, all drawings will

be registered as one region.

NOT Used to delete part of a region.

2nd figure (NOT)

1st figure (OR) 2nd figure (OR)

1st figure (NOT)

Example 1: Drawing a Circumference

1. Using the Cursor Keys, set the center of the circle and press the ENT Key. The

center of the circle will be set. Use the SHIFT + Cursor Keys to move the cursor

quickly.

The middle line is

the base of the

circumferences.

— Filter/Pickup —

Page 21

2-1SectionMenu Operations

13

2. Use the Up and Down Keys to specify the radius and press the ENT Key. The

arrows for specifying the line width for the circumference will be displayed.

3. Use the Up and Down Keys to set the line width. The arrows for specifying the

line width will be displayed.

4. Press the ENT Key. The drawing will be set and the drawn region will be displayed in white.

Example 2: Deleting Part of a Drawing

1. Select OR mode in the first drawing (a box for this example) and press the ENT

Key. The arrow for drawing a box will be displayed.

1

Box

Ellipse

Circle

Circumference

Polygon

OR

NOT

New

2. Set two diagonally opposing corner points to draw the box. Use the SHIFT + Cur-

sor Keys to move the cursor quickly.

1st point

2nd point

Page 22

2-2SectionStarting and Quitting

14

3. Select NOT mode in the second drawing (an ellipse in this example) and press

the ENT Key. The arrow for drawing an ellipse will be displayed.

3

Box

Ellipse

Circle

Circumference

Polygon

OR

NOT

Add

4. Set two diagonally opposing corner points of a rectangle enclosing the ellipse to

draw the ellipse.

The overlapping section of the box and ellipse will be deleted.

This section will be the region.

2-2 Starting and Quitting

2-2-1 Starting

Use the following procedure to start and quit operation.

Note Be sure to refer to the

Setup Manual (Z130)

when connecting components or wiring

the power supply or grounding the unit.

Setup Manual→2-2 Connections

and

2-3 Power Supply and Ground

1. Be sure that the basic F400 components have been connected correctly.

→

Setup Manual

2. Turn ON the power supply to the monitor.

— Filter/Pickup —

Page 23

2-2SectionStarting and Quitting

15

3. Turn ON the power supply to the F400.

The title page will be displayed.

2

Vision Inspection System

F400-C10 Series

Color-Gray Menu Software

Ver.2.00

(C)Copyright OMRON Corporation

1998-1999

All Rights Reserved

4. After a short pause, the main F400 screen will be displayed.

The following screen will appear the first time power is turned ON.

3

---- --ms

Color thr

Scn 0BMONB

Note The startup scene and startup mode that appear when power is turned ON can be set.

Use these settings to make daily operation more efficient once the F400 is ready for

actual operation.

→

Startup Mode

on p. 107

2-2-2 Selecting Scene Modes

The F400 has two scene modes: Color Filter and Color PickUp. Select the appropriate measurement mode for the application.

Refer to

Features

in the

Introduction Manual (Z131)

→p. 5

Select the scene mode when setting conditions for a scene for the first time.

1. Select MON (Monitor) and press the ENT Key

— Filter/Pickup —

Page 24

2-2SectionStarting and Quitting

16

2. Select SET to display a list of scene processing options. The options will not be

displayed if measurement conditions are already set for the selected scene number. The scene number must be changed or the settings cleared before the

options can be changed.

12

---- --ms

Color thr

Scn 0BMONB

SET

MON

RUN

SYS

SAVE

3. Select either

Color filter

or

Color pickup

and press the ENT Key. The settings

screen for the selected scene mode will be displayed.

3

Settings screen for Color Filter Mode

Settings screen for Color Pickup

Mode

Color bar displayed. No color bar displayed.

Color filter

Color pickup

Settings

Adjust

Position compensation

Measurement region

Expression

Color thr

Settings

Adjust

Position compensation

Measurement region

Expression

Color thr

Note Changing between Color Filter and Color Pickup Modes

To change the scene mode for selected scenes, clear the scene and then change the

scene mode.

→

Copying and Clearing Scenes

on p. 17

2-2-3 Changing Scenes

All the settings for measurement conditions are input for a specific scene. Up to 16

scenes can be set, numbered from 0 to 15. Scenes can be changed to switch between

different measurement conditions for different measurement setups or measurement

objects. Scene 0 will be displayed by default when the power is turned ON. Setup can

be changed by simply changing scenes. Refer to

Scene

in the

Glossary

on page 145.

— Filter/Pickup —

Page 25

2-2SectionStarting and Quitting

17

1. Place the cursor on the scene number displayed on the screen (Scn 0 in this

example) and press the ENT Key. A list of scene numbers will be displayed.

Move the cursor using the Down Key to display the next group of scene numbers

from 9 to 15.

2. Select a new scene number.

1

2

---- --ms

Color thr

Scn 0BMONB

Scn 0

Scn 1

Scn 2

Scn 3

Scn 4

Scn 5

Scn 6

Scn 7

Scn 8

↑ ↓

3. Press the ENT Key to display the selected scene.

3

---- --ms

Color thr

Scn 2BMONB

Note Commands to switch scenes can be input from external devices when in Monitor or

Run Mode.

Refer to

I/O Format

in

6-1 Terminal Blocks

and

List of Input Commands

in

RS-232C

. →p. 112, 122

2-2-4 Copying and Clearing Scenes

This section explains how to copy and clear scene data. Clear scene data before

changing the scene mode to either Color Filter or Color Pickup Mode.

— Filter/Pickup —

Page 26

2-2SectionStarting and Quitting

18

1. Place the cursor on the scene number displayed on the main screen (Scn 0 in this

example) and press the ENT Key. A list of scene numbers will be displayed.

Move the cursor using the Down Key to display the next group of scene numbers

from 9 to 15.

2. Press SHIFT + ESC Keys on the scene number to be copied or cleared. The two

processing options will be displayed.

1

2

---- --ms

Color thr

Scn 0BMONB

Scn 0

Scn 1

Scn 2

Scn 3

Scn 4

Scn 5

Scn 6

Scn 7

Scn 8

↑ ↓

3. Select

Copy

or

Clear

. A confirmation message will be displayed.

3

When

Copy

is selected

When

Clear

is selected

Place the cursor on Scn 0 and press

the ENT Key to display a list of scene

numbers.

Copy

Clear

Original scene : Scn 0B

Execute Cancel

This scene data

will be cleared.

Execute Cancel

4. Move the cursor to Execute and press the ENT Key. The data for the selected

scene will be copied or cleared and the display will return to the main screen.

2-2-5 Quitting

The user can quit the F400 and turn OFF the power at any time except while saving or

loading data. Save all measurement settings to flash memory before quitting. The

data in flash memory is loaded each time the F400 is started. Any changes made will

be lost unless they are saved to the flash memory.

Note The measurement images and sample images in memory are also cleared when the

power is turned OFF. These images cannot be saved to flash memory, but they can be

backed up on a computer if required. Refer to

5-3 Backup

. →p. 97

1. Move the cursor to

MON

and press the ENT Key . A list of operation modes will be

displayed.

— Filter/Pickup —

Page 27

2-2SectionStarting and Quitting

19

2. Select

SAVE

. A confirmation message will be displayed.

1

2

---- --ms

Color thr

Scn 0BMONB

SET

MON

RUN

SYS

SAVE

3. Move the cursor to Execute and press the ENT Key. The save will be executed

and a progress box will be displayed.

3

Saving data

Setting data will be saved.

Execute Cancel

Note Do not input the RESET command or turn OFF the power while saving data. The data

may be lost, and the F400 may not operate properly the next time it is started.

When the data has been saved, the display will return to the main screen.

4. Turn OFF the power to the F400.

Page 28

21

SECTION 3

Settings

This section describes how to set measurement conditions for F400 visual inspections.

The following headings are used in this section to indicate the measurement modes to which an operation is appli-

cable.

3-1 Adjusting Images 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-1 Shutter Speed 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-2 Applying Color Filters 24. . . . . . . . . . . . . . . . . . . . . . . .

3-1-3 Creating a Color Filter 26. . . . . . . . . . . . . . . . . . . . . . . .

3-1-4 Picking Up Measurement Colors 28. . . . . . . . . . . . . . . .

3-1-5 Filtering 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1-6 Background Suppression 34. . . . . . . . . . . . . . . . . . . . . .

3-1-7 Output Calibration 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Position Compensation 37. . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Adjusting Images for Easier Position Compensation 38.

3-2-2 Setting Position Compensation Regions 38. . . . . . . . . . .

3-2-3 Searches 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-4 Position Compensation using Edges 43. . . . . . . . . . . . .

3-2-5 Area and Center of Gravity, and Center of

Gravity and Axis Angle 46. . . . . . . . . . . . . . . . . . . . . . .

3-3 Measurement Methods 50. . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Measurement Regions 50. . . . . . . . . . . . . . . . . . . . . . . .

3-3-2 Surface Defects 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-3 Searches 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-4 Edge Processing 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-5 Area and Center of Gravity, and Center of

Gravity and Axis Angle 67. . . . . . . . . . . . . . . . . . . . . . .

3-4 Expressions 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

— Color Filter —

— Color Pickup —

— Filter/Pickup —

Page 29

3-1SectionAdjusting Images

22

3-1 Adjusting Images

Images displayed on the video monitor can be adjusted for easier measurement.

Before adjusting the image on the monitor , however, adjust lighting and camera focus

to clearly display the measurement object in the center of the screen.

Note White Balance

Depending on the inspection environment and type of lighting, even white images

read by the camera may appear somewhat colored. Refer to the

2-6 Lighting

in the

Setup Manual (Z130)

for information on lighting methods. Adjust the white balance

before setting the light and adjusting the image.

White Balance

→ p. 96

Different adjustments are possible depending on the scene mode and type of image.

Refer to the following table for items that can be adjusted.

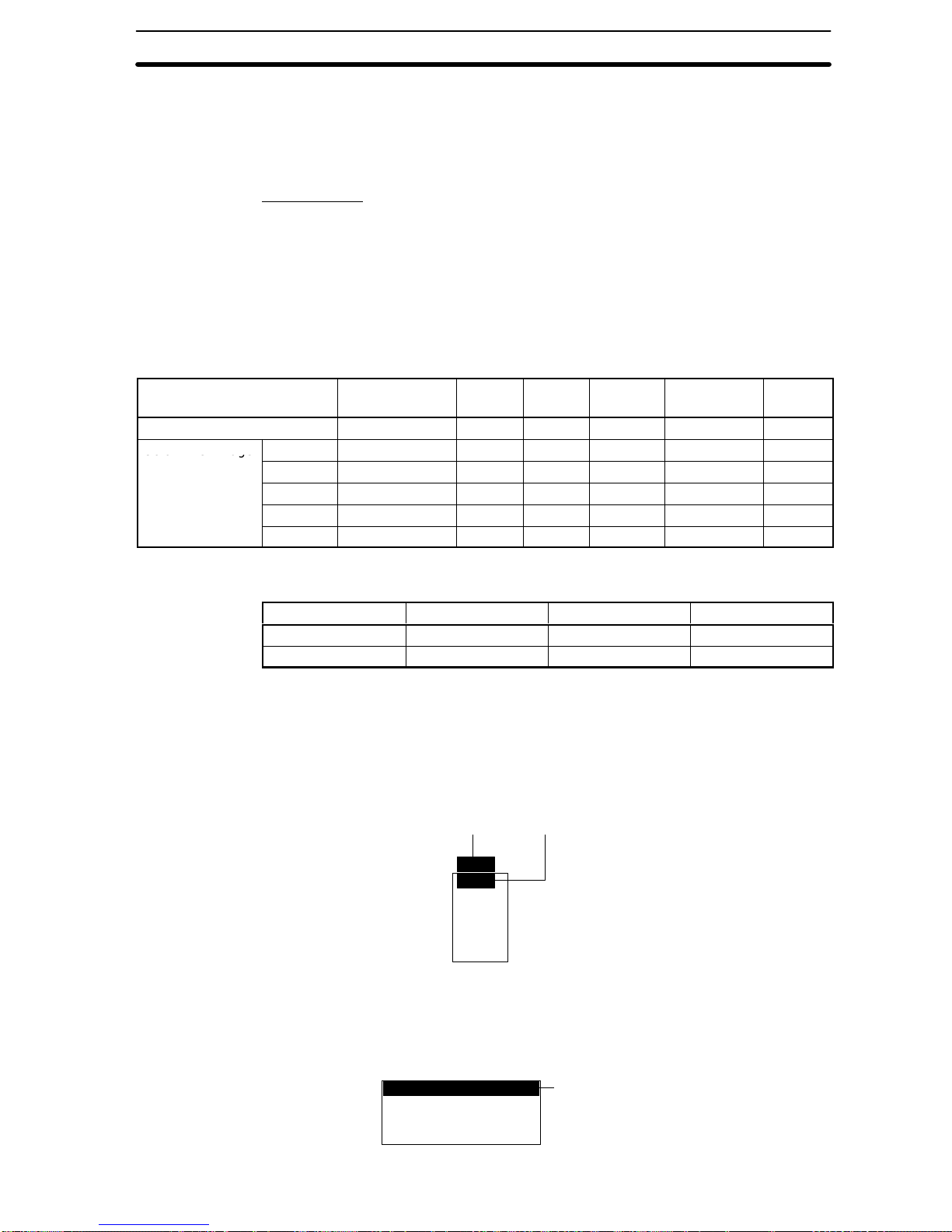

Color Filter Mode

Image Color filter Shutter

speed

Calibra-

tion

Color

selection

Background

suppression

Filtering

Color Yes Yes Yes No No No

Color Filter Image

Colorgray No Yes Yes Yes Yes Yes

Co o e age

Red No Yes Yes No Yes Yes

Green No Yes Yes No Yes Yes

Blue No Yes Yes No Yes Yes

Gray No Yes Yes No Yes Yes

Color Pickup Mode

Image Shutter speed Color pickup Calibration

Color Yes Yes Yes

Pickup color Yes Yes Yes

1. Move the cursor to the operation mode in the main screen (Monitor in this example) and press the ENT Key. A list of modes will be displayed.

2. Move the cursor to

SET

and press the ENT Key. A list of setting modes will be

displayed.

12

Scn 0BMONB

SET

MON

RUN

SYS

SAVE

3. Move the cursor to

Adjust

and press the ENT Key. The Adjust (image adjust-

ment) Window will be displayed.

3

Adjust

Position compensation

Measurement region

Expression

Settings

Page 30

3-1SectionAdjusting Images

23

Color Filter Mode

Color Pickup Mode

Filtering

OFF

BGS levels

0:255

Shutter

1/2000s

Calibration

512.000

Colorgray thr

Color select

Pickup color

Shutter

1/2000s

Calibration

512.000

Pick up thr

Adjustment items are underlined. Use Left or

Right Key to change the displayed item.

Adjust

Color thr

←→:Switch

Color filter

Colorgray

Shutter

1/2000s

Calibration

512.000

←→

Adjust

Color thr

←→:Switch

Pickup color

p

Shutter

1/2000s

Calibration

512.000

←→

Note 1. If adjustment items are hard to read, use the SHIFT + ESC Keys to switch

between clear and filled backgrounds. Select the background that makes the

screen most legible. Refer to

5-4 Display Settings.

2. When temporarily switching between through or freeze images while performing

image adjustment, use the SHIFT + Up Key or SHIFT + Down Key to select the

appropriate type of display for the image.

Page 31

3-1SectionAdjusting Images

24

3-1-1 Shutter Speed

Change the shutter speed when the object is moving quickly, causing the image to be

blurred. The shutter speed can be changed for any displayed image.

Movement speed Shutter speed

1/100 s

1/500 s

1/2000 s*

1/10000 s

Slow

Fast

*Default value

1. Move the cursor to

Shutter

on the screen for the image to be adjusted and press

the ENT Key. The Shutter Speed Window will be displayed. Use the Left and

Right Keys to change the list of options if

Shutter

does not appear on the list.

1

Adjust

Color thr

←→:Switch

Color filter

Colorgray

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to change the shutter speed. Check the image

while changing the shutter speed.

2

1/100 s 1/500 s 1/2000 s 1/10000 s

Shutter

1/2000s

3. Press the ENT Key. The shutter speed setting will be saved and the display will

return to the Adjust (image adjustment) Window.

3-1-2 Applying Color Filters

A color filter can be applied to the image read by the camera to emphasize particular

colors and make a grayscale image for easier measurement. The F400 has five color

filters. Select a filter color that will make the color to be detected lighter (e.g., surface

defects or marks). This section explains how to select color filters.

Refer to the

Introduction Manual (Z131)

for information on colors. → p. 39

— Filter/Pickup —

— Color Filter —

Page 32

3-1SectionAdjusting Images

25

Color Function

Red Emphasizes (lightens) red.

Green Emphasizes (lightens) green

Blue Emphasizes (lightens) blue.

Gray Changes to a grayscale image (standard black and white image).

Colorgray Creates a filter to suit the color to be detected.

1. Move the cursor to the color filter (Colorgray in this example) and press the ENT

Key. The Color Filter Window will be displayed. Use the Left and Right Keys to

change the list of options if

Color Filter

does not appear on the list.

1

Adjust

Color thr

←→:Switch

Color filter

Colorgray

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to change the color filter . Check image while changing the color filter.

Colorgray Red Green Blue Grey

2

Color filter

Colorgray

3. Press the ENT Key. The color filter setting will be saved and the display will return

to the Adjust (image adjustment) Window.

Note The selected color filter will be used for measurement. A different color filter can be

set for position displacement compensation.

Refer to

3-2-1 Adjusting Images for Easier Position Compensation

→ p. 38

Page 33

3-1SectionAdjusting Images

26

3-1-3 Creating a Color Filter

When the F400 color filters cannot emphasize a particular color in an image, a new

filter is created to suit the detection color. The color image is converted to a grayscale

image based on the hue and saturation settings. Adjust the hue and saturation settings while referring to the displayed image and create a filter that best emphasizes

the detection color. This section explains the procedure for creating color filters.

Refer to the

Introduction Manual (Z131)

for information on colors. → p. 39

Hue The colors red, yellow, green, blue, and purple. Select the color that

will highlight the section to be detected in the gray image.

Color band The range of colors to be measured based on the set color.

Saturation The vividness of the color. Areas outside the saturation range are

changed to white or black and excluded from measurement. The

saturation range is set using upper and lower limits.

Color filters are created by selecting the Colorgray filter function. Set a colorgray filter

in advance using the Color Filter settings.

Refer to

3-1-2 Applying Color Filters

→ p. 24

1. Move the cursor to

Color select

and press the ENT Key. The Color Selection

Window will be displayed. The image will be converted to a color grayscale

image and a A mark will appear on the color bar . Use the Left and Right Keys to

change the list of options if

Color select

does not appear on the list.

1

Adjust

Colorgray thr

←→:Switch

Color select

Filtering

OFF

BGS levels

0:255

Shutter

1/2000s

Calibration

512.000

2. Use the Up and Down Keys to move the A mark and select the color. The image

displayed on the screen will change as the A mark scrolls through the colors.

Press SHIFT + Up and Down Keys to scroll through the colors quickly. Use the

Left and Right Keys to switch to a color image and check the color.

— Color Filter —

Page 34

3-1SectionAdjusting Images

27

3. Press the SHIFT + ENT Keys to select the color band. Pressing the SHIFT + ENT

Keys will alternately change between ±90_ and ±180_.

3

2

↑↓:Select SFT+ENT:Band

Color band

±90°

39

A

The number indicates the cursor position. Use this

number as reference for setting the filter color.

(For example: set to the same filter color for position adjustment and measurement.

Adjust (Color select)

4. Press the ENT Key. The set color and color band settings will be saved. Perform

steps 5 to 9 to set the saturation range, otherwise go straight to step 10.

Note The selected color filter is used for measurement. A different color filter can be set for

position displacement compensation.

Refer to

3-2-1Adjusting Images for Easier Position Compensation

→ p. 38

Setting the Chroma Range

5. Press the SHIFT + ESC Keys. The Saturation Range Settings Window will be

displayed.

Page 35

3-1SectionAdjusting Images

28

6. User the Left and Right Keys to change the upper limit. The displayed image will

change as the setting is changed. Use the SHIFT + Left and Right Keys to

increase or decrease the value by 10.

6

7

8

Color select (Saturation range)

↑↓:Move ←→:Change

Lower limit Upper limit

Saturation Range Settings

Upper [80]

Lower [ 0]

OK

7. Repeat the same operation to change the lower limit.

8. Move the cursor to

OK

and press the ENT Key. The display will return to the Color

Selection Window.

9. Press the ENT Key again. The saturation range will be saved.

10. Press the ESC Key to close the Color Selection Window. The display will return

to the Adjust (image adjustment) Window.

3-1-4 Picking Up Measurement Colors

Simply click the desired color to extract and measure it. All other colors will be treated

as background. The extracted color is called the pickup color. Up to 8 pickup colors

can be registered. Display the Adjust (image adjustment) Window for Color Pickup

Mode before starting color pickup.

Refer to

2-2-2 Selecting Scene Modes.

→ p. 15

Selecting a Color

First, select the color to be picked up in the color image. The F400 will extract the

selected color and will automatically switch to a pickup color image. All other areas of

the image will be changed to black in the display. Repeat the color selection process

until all the desired colors have been extracted.

Color image

Move the cursor to the color to

be selected.

Pickup color image

Only the selected color will be

displayed.

Pickup color0 Pickup color0

TRIG:Pick up SFT+ESC:Option

ESC:UNDO

TRIG:Pick up SFT+ESC:Option

Press TRIG Key.

— Color Pickup —

Page 36

3-1SectionAdjusting Images

29

Changing Cursor Size

If the cursor size does not match the size of section to be extracted, press the SHIFT +

ENT Keys to change the cursor size. (Max. 64 x 64 pix.)

Changing Background Color of Pickup Color

If the image is hard to see because the pickup color is similar to the background color,

press the SHIFT + TRIG Keys to change the background color that is available in five

different gradations.

Display Image and Margin

Press the SHIFT + ESC Keys on the color pickup display to display a dialog. Using

this dialog, change the display image or set the color parameter range for extracting

colors considering noise.

End

Display image : ColorB

Margin : 3B

Display Image

Colors can be extracted though monitoring image colors while switching the display

image between color image and two types of pickup color images.

Color image Pickup image

Pickup image for all pickup

colors

The pickup color

currently being

extracted will be

displayed.

All of the registered pickup

colors will be displayed.

Pickup color registered during the

zero extraction.

Pickup color1

TRIG:Pick up SFT+ESC:Option

Pickup color1

TRIG:Pick up SFT+ESC:Option

Pickup color1

TRIG:Pick up SFT+ESC:Option

The color image

is displayed.

Margin

When the margin is positive (+): Color parameter range will be widened by the set

margin for color pickup.

When the margin is negative (–): Color parameter range will be narrowed by the set

margin for color pickup and the colors outside the range will be treated as noise.

• If all the colors subject to measurement cannot be

picked up, set the margin to a positive value.

• If colors not subject to measurement are also picked

up with much noise, set the margin to a negative value.

–3

–2

–1

0

+1

+2

+3

Narrow

Wide

Margin

Page 37

3-1SectionAdjusting Images

30

1. Move the cursor to

Pickup color

and press the ENT Key. The Pickup Color Num-

ber Selection Window will be displayed.

1

Adjust

Color thr

←→:Switch

Pickup color

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to select the pickup color number to be registered.

The image read by the camera will not be displayed if no pickup colors have been

registered for the selected number. The pickup image will be displayed for registered pickup color numbers.

2

Use the Left and Right Keys to scroll through the pickup

color numbers 0 to 7 in order.

Pickup

color 0

Pickup

color 1

Pickup

color 7

Color pickup

←→:Change

Color 0

3. Press the ENT Key. The Color Pickup Window will be displayed and the color

pickup cursor will appear.

4. Move the cursor to the section for which the color is to be extracted and press the

TRIG Key . Color pickup will be performed for the specified section of the image.

The image will then change to a pickup color image and the selected color will be

displayed.

If the picked up color is hard to see, press the SHIFT + TRIG Keys to select one of

Page 38

3-1SectionAdjusting Images

31

five background gradations. Select the background gradation that will show the

pickup color in greatest contrast.

To change the display image or pickup color margin, press the SHIFT + ESC

Keys.

4

Registered pickup color number

Color pickup cursor

Pickup color0

TRIG:Pick up SFT+ESC:Option

5. Move the cursor to the next section to be extracted and press the TRIG Key.

Repeat this procedure to pick up all the colors for measurement.

Press the ESC Key to cancel colors selected using the TRIG Key. The last pickup

color selection will be canceled.

4

Pickup color0

ESC:UNDO

TRIG:Pick up SFT+ESC:Option

6. Press the ENT Key when all the desired colors have been extracted. The pickup

colors will be registered and the display will return to the Pickup Color Number

Selection Window. Repeat steps 2 to 5 to register more pickup colors.

Page 39

3-1SectionAdjusting Images

32

Changing and Clearing Pickup Colors

1. Move the cursor to

Pickup color

and press the ENT Key. The Pickup Color Num-

ber Selection Window will be displayed.

1

Adjust

Color thr

←→:Switch

Pickup color

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to display the pickup color number to be changed or

cleared and press the ENT Key. The processing options will be displayed.

2

Pickup color

←→:Change

Color 0

Page 40

3-1SectionAdjusting Images

33

3. Select either

Correct

or

Clear

and press the ENT Key.

3

4

When

Correct

is selected When

Clear

is selected

The color pickup cursor

is displayed.

A confirmation message is

displayed.

Next, perform the same steps as for

color pickup.

Correct

Clear

Pickup color0

TRIG:Pick up SFT+ESC:Option

Color 0 will be cleared.

Execute Cancel

4. When Clear has been selected, move the cursor to

Execute

and press the ENT

Key. The selected pickup color settings will be cleared and the display will return

to the Adjust (image adjustment) Window.

3-1-5 Filtering

The image read by the Camera can be manipulated to create an image that is easier

to measure, by using smoothing or edge enhancement.

Smoothing displays a smoothed image with reduced noise. Smoothing allows suppression of the effects of uneven lighting due to an uneven or damaged surface.

Edge enhancement displays an image with enhanced edges between bright and dark

regions to compensate for blurred images.

Filtering can be performed only on images to which a color filter has been applied.

Filtering method Function

OFF No filtering.

Smoothing Displays a smooth image with reduced noise. Select either weak or

strong smoothing.

Enhance edges Displays an image with enhanced edges between bright and dark

regions.

Extract edges Displays an image with the edges between the bright and dark

regions extracted.

— Color Filter —

Page 41

3-1SectionAdjusting Images

34

1. Move the cursor to the

Filtering

method (OFF in this example) and press the

ENT Key. The Filtering Window will be displayed. Use the Left and Right Keys to

change the list of options if

Filtering

does not appear on the list.

1

Adjust

Red thr

←→:Switch

Filtering

OFF

BGS levels

0:255

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to select the filtering method. Check the image

while selecting the appropriate filtering method.

2

Use the Left and Right Keys to switch between weak smoothing,

strong smoothing, edge enhancement, and edge extraction.

OFF

Weak

smoothing

Strong

smoothing

Enhance

edges

Extract

edges

Filtering

OFF

3. Press the ENT Key. The filtering settings will be saved and the display will return

to the Adjust (image adjustment) Window.

Note The selected filtering method is used for measurement. Different filtering can be set

for position displacement compensation.

Refer to

3-2-1 Adjusting Images for Easier Position Compensation

→ p. 38

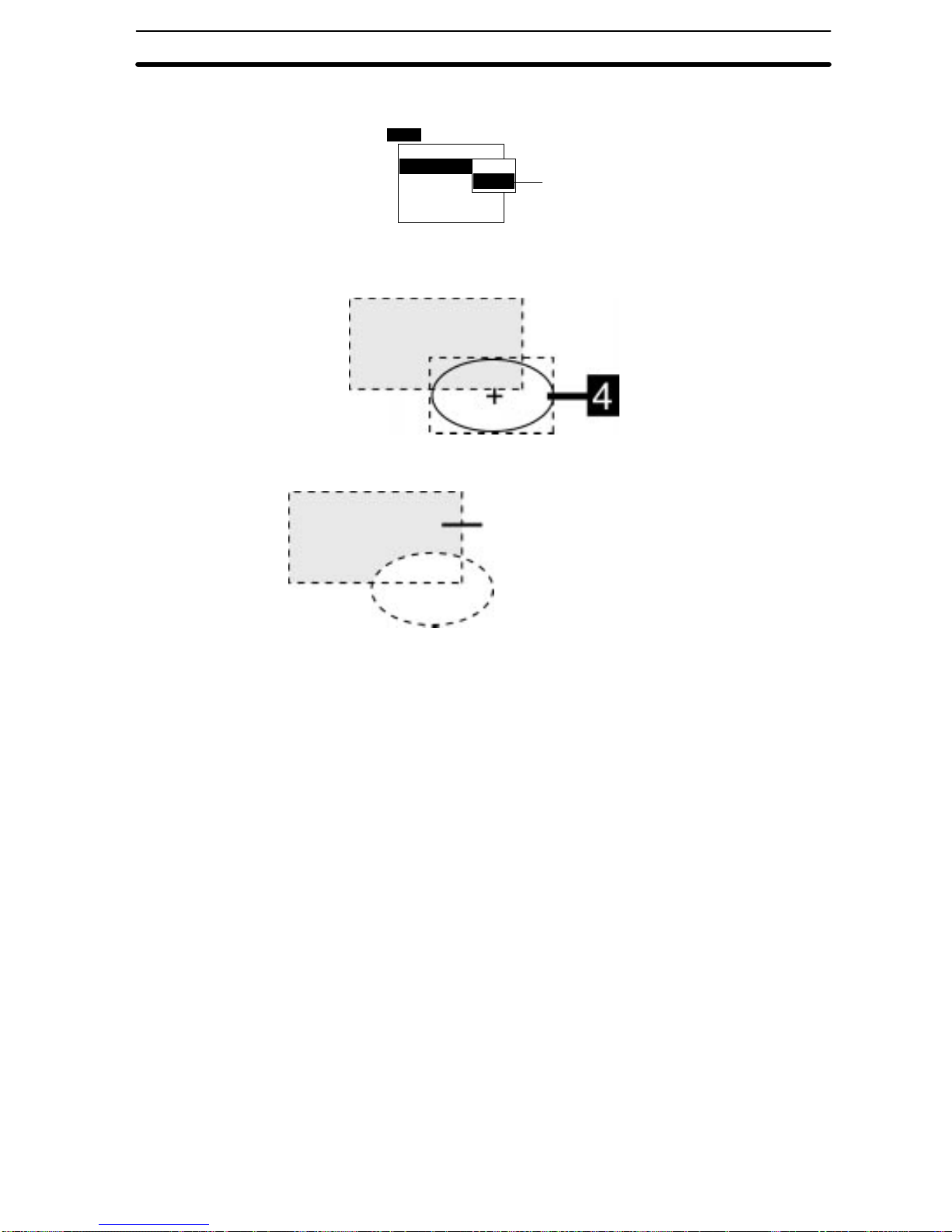

3-1-6 Background Suppression

Background suppression (BGS) changes image areas with densities below the lower

limit to 0, and image areas with densities above the upper limit to 255. Image areas

with densities between the lower and upper limits are graded from 0 to 255 so that

only images with densities between the lower and upper limits are measured.

Monitor the image and set the upper and lower limits of the density to eliminate the

background.

— Color Filter —

Page 42

3-1SectionAdjusting Images

35

Example

Lower limit: 150 Upper limit: 255

Measurement object Density

Image areas with densities of 149 or lower

will not be measured and the density will

be changed to 0.

Only image areas with densities between

150 and 255 will be measured. The whole

image is graded from 0 to 255.

Background Background density (cut)

1. Move the cursor to

BGS levels

(0:255 in this example) and press the ENT Key .

The BGS Levels Setting Window will be displayed. Use the Left and Right Keys

to change the list of options if

BGS levels

does not appear on the list.

1

Adjust

Red thr

←→:Switch

Filtering

OFF

BGS levels

0:255

Shutter

1/2000s

Calibration

512.000

2. Use the Left and Right Keys to alter the upper limit. The displayed image will

change when the numeric values are changed. Use the SHIFT + Left and Right

Keys to increase or decrease the numeric value by 10.

3. Change the lower limit the same way.

2

3

4

Upper[200]

Lower[100]

OK

Lower limit Upper limit

BGS Level Setting

4. Move the cursor to OK and press the ENT Key.

Note The selected BGS level is used for measurement. Different BGS levels can be set for

position displacement compensation.

Refer to

3-2-1 Adjusting Images for Easier Position Compensation

→ p. 38

Page 43

3-1SectionAdjusting Images

36

3-1-7 Output Calibration

Calibration can be set to output the measurement results in physical units, such as

mm.

Set the relationship between the physical coordinates and the camera coordinates to

convert the measurement results from pixels to physical units, such as µm, mm, or

cm.

If calibration data is not set, the default settings will remain, and measurements using

the camera coordinates will be output.

For details, refer to

Glossary

. → p. 142

Default Settings

Origin

Coordinate system: Left-handed

Origin: Upper left corner of screen

Magnification: 1.000

Units: mm/pix

484 mm

(= 484 pixels)

512 mm (= 512 pixels)

Setting

Options Meaning

Origin Upper left*

Lower left

Center

Select the position of the origin (0,0) of the coordinate system on the

screen.

Upper left

Lower left

Center

Coordinate

system

Right-handed

Left-handed*

Select the coordinate system. The positive direction for angles will

depend on the coordinate system.

Left-handed System

Right-handed System

Upper

-left

origin

Forward

direction

Lowerleft origin

Forward

direction

Center

origin

Forward

direction

Upper

-left

origin

Forward

direction

Lowerleft origin

Forward

direction

Center

origin

Forward

direction

Magnification 0.001 to 9.999

(1.000*)

Set the actual measurement to which 1 pixel will correspond.

For example, an actual length of 10 mm could correspond to 100

pixels on the screen.

10 (mm)/100 (pix) = 0.1 (mm/pix). The magnification, therefore, would

be 0.1.

Units

µm/pix,

mm/pix*, or

cm/pix

Set the units for conversion.

Note The default settings are indicated by an asterisk (*).

— Filter/Pickup —

Page 44

3-2SectionPosition Compensation

37

1. Move the cursor to

Calibration

and press the ENT Key. The Calibration Setting

Window will be displayed. Use the Left and Right Keys to change the list of

options if

Calibration

does not appear on the list.

1

Adjust

Red thr

←→:Switch

Filtering

Red

Shutter

1/2000s

Calibration

512.000

2. Move the cursor to the item to be changed and press the ENT Key. Options are

available for items indicated by a Bmark. The magnification is changed by

changing the numeric value.

3. Press the ENT Key. The settings will be saved.

2, 3

5

Origin : Upper leftB

Coordinate : LefthandB

Magnification: [1.000]

Unit : mm/pixB

End

4. Repeat steps 2 and 3 to change other settings.

5. When all settings have been made, move the cursor to

End

and press the ENT

Key. The calibration settings will be saved and the display will return to the Adjust

(image adjustment) Window.

3-2 Position Compensation

Use position displacement compensation when the position and orientation of the

measurement objects are not consistent. The position of the measurement object is

compared to a reference position, the amount of displacement is calculated, and the

image is scrolled by that amount before a measurement is performed.

Page 45

3-2SectionPosition Compensation

38

Flow of Operation

1. Adjusting Images for Easier Position Compensation → p. 38

2. Setting Position Compensation Regions

→ p. 38

3. Searches

→ p. 40

4. Position Compensation using Edges

→ p. 43

5. Area and Center of Gravity, and Center of Gravity and

Axis Angle

→ p. 46

Adjust the image for easier position compensation.

Set the measurement region for

position compensation.

Select the position compensation

method.

Set the position compensation

conditions.

3-2-1 Adjusting Images for Easier Position Compensation

Different image conditions can be set for measurement and position compensation.

Refer to the procedures for setting measurement image conditions; the setting methods are the same.

Applying Color Filters to Images

Different color filters can be applied for measurement and for position compensation.

Refer to

3-1-2 Applying Color Filters

→ p. 24

Creating a Color Filter

Different color filters can be created for measurement and for position compensation.

Refer to

3-1-3 Creating a Color Filter

→ p. 26

Filtering

Different filtering can be performed for measurement and for position compensation.

For example, smoothing may be selected to reduce noise for measurement and edge

enhancement may be selected for position compensation to highlight the edges of the

measurement object.

Refer to

3-1-5 Filtering

→ p. 33

Background Suppression

Different background suppression can be performed for measurement and for position compensation.

Refer to

3-1-6 Background Suppression

→ p. 34

3-2-2 Setting Position Compensation Regions

The F400 has four methods of position compensation: Search, edge enhancement

and extraction (edge), area and center of gravity, and center of gravity and axis angle.

A measurement region must be set before position compensation can be performed.

Up to two regions can be set for each scene.

— Color Filter —

— Filter/Pickup —

Page 46

3-2SectionPosition Compensation

39

1. Move the cursor to

SET/Position compensation/Region

and press the ENT

Key. The Position Compensation Selection Window will be displayed. The window shown in step 2 will be displayed if

Position compensation

is selected in

Color Pickup Mode.

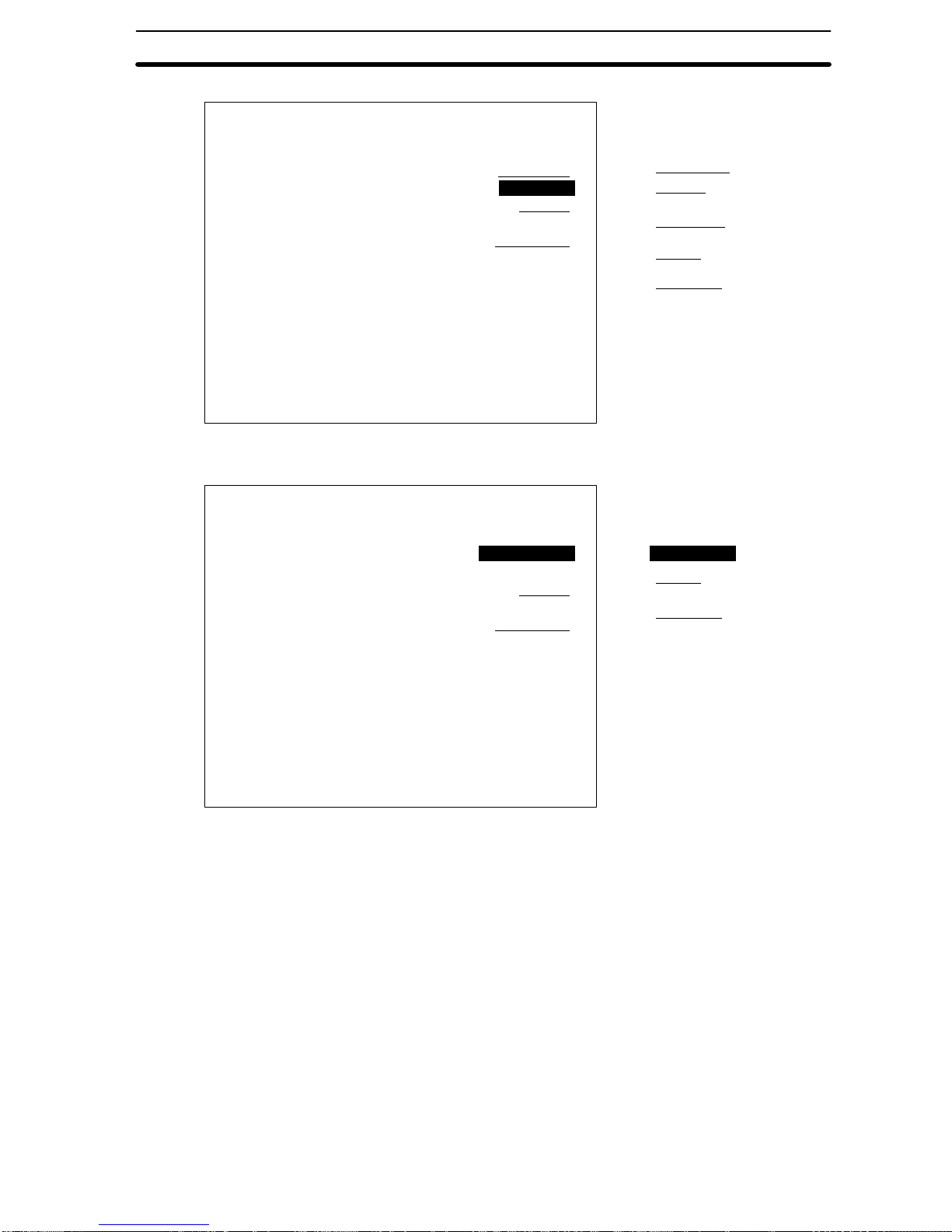

1

1

Color Filter Mode Color Pickup Mode

Settings

Adjust

Position compensation

Measurement region

Expression

Adjust

Region

Color frz

Settings

Adjust

Position compensation

Measurement region

Expression

Color frz

2. Select the position compensation method and press the ENT Key. The setting

options for the selected method of position compensation will be displayed. The

method selected here will be registered for region 0. Refer to the procedures for

each position compensation method for subsequent steps.

2

These options are not displayed

when the second region is registered.

Color Filter Mode Color Pickup Mode

Search

Edge

Area & gravity

Gravity & axis

Area & gravity

Gravity & axis

Edge

Search

2

Changing and Clearing Measurement Regions

Settings for registered position compensation methods are changed and cleared on

the Settings Window for the measurement region number. To change the position

compensation method, clear the selected method and then register another method.

1. Move the cursor to

Set/Position compensation/Region

and press the ENT

Key. If region 0 has been registered, the window for selecting measurement

region numbers will be displayed.

2. Select either

Change settings

or

Clear

as desired and press the ENT Key.

2

3

0.Search

1.

Change settings

Clear

Region (Position compensation)

Changing Settings

The settings window for the selected position compensation method will be displayed. Refer to the procedures for each position compensation method for subsequent steps.

Clearing Settings

A confirmation message will be displayed.

Page 47

3-2SectionPosition Compensation

40

3. If

Clear

has been selected, move the cursor to

Execute

and press the ENT Key .

4

This region will be cleared.

Execute Cancel

Note The measurement regions selected here are for position compensation. Separate

measurement regions can be set for measurement.

Refer to

3-3-1 Measurement Regions

→ p. 50

3-2-3 Searches

This section explains position displacement compensation using searches. The

search method must be selected for the position compensation region in advance.

Refer to

3-2-2 Setting Position Compensation Regions

→ p. 38

Searches

Position compensation is performed using a registered measurement pattern called a

model. The area of the image that most highly correlates with the model is found, the

amount of displacement is calculated, and the image is scrolled by the detected

amount of displacement before measurements are performed.

Reference position (position

where the model is registered.)

Displacement X

Displacement Y

Input image

— Filter/Pickup —

Page 48

3-2SectionPosition Compensation

41

Procedure

1. Select the color pickup number

for position compensation (for

Color Pickup Mode only).

2. Register a search model.

3.Set the search range.

4.Set the evaluation criteria for

position compensation.

Note 1. Searches selected here are for position compensation.

Refer to

3-3-3 Searches

for measurement applications. → p. 55

2. Position compensation methods are changed or cleared in the Region Settings

Window.

Refer to

3-2-2 Setting Position Compensation Regions

. → p. 38

Selecting Color Pickup Numbers for Position Compensation (Color Pickup

Mode Only)

Select a color for position compensation from the registered pickup colors. The procedure is the same as for measurement.

Refer to

Selecting Color Pickup Numbers for Measurement

under

3-3-3 Searches

→ p. 56

Pickup color number currently displayed

Color selection

Color 0

←→:Change

Registering a Model

A characteristic part of the measurement image, such as a mark or corner, is registered as a model. The model can be of any size.

Since the position in which the model is registered serves as a reference position for

position compensation, place the object so that it is properly located within the screen

before registering it as a model. The procedure is the same as for measurement.

Page 49

3-2SectionPosition Compensation

42

Refer to

Registering a Model

under

3-3-3 Searches

→ p. 58

OK: Section to be

inspected is located

properly within the

screen.

WRONG:

Measurement object

is off the screen.

Model

(Up to 3 figures can be drawn in combination.)

Setting the Search Region

Set a range in which to search for the model. The search can be made on the whole

input screen. However , the search range can be limited to reduce the processing time

and increase the accuracy. The procedure is the same as for measurement.

Refer to

Setting the Search Region

under

3-3-3 Searches

→ p. 61

The model is displayed in solid lines.

Search region is displayed in dotted

lines.

The range to search for the model.

Search region 250,260

Setting Evaluation Criteria

Criteria are set for the correlation with the model to enable checking whether or not

the correct position compensation model has been found. If the correlation with the

model is too low, the wrong position may be found. Set the upper and lower limits for

the correlation.

The procedure is the same as for measurement.

Refer to

Setting Evaluation Criteria

under

3-3-3 Searches

→ p. 62

Page 50

3-2SectionPosition Compensation

43

Evaluation and Processing

Evaluation Processing

OK Position compensation is performed before measurement.

NG The object is measured without position compensation. Regardless

of the measurement result, however, an overall evaluation of NG will

be output to the OR terminal.

Correlation range for OK evaluation