Page 1

1

UV Power Monitor F3UV

Monitor the Output of a UV Light Source

through an Optical Fiber Cable

Monitors with Optical Fibers

Head Unit withstands temperatures of up to

300°C.

Easy-to-read digital display of measurement

values.

Harmful UV light converted to visible light before

performing measurements. This feature prevents

deterioration of the Amplifier’s light receiving

element.

Monitors with Built-in Amplifiers

Deterioration due to UV light prevented by

protective structure.

Confirm the output status of the UV light source

with an operation indicator.

Filtering Cover (reduces light intensity by 1/6.5)

also available.

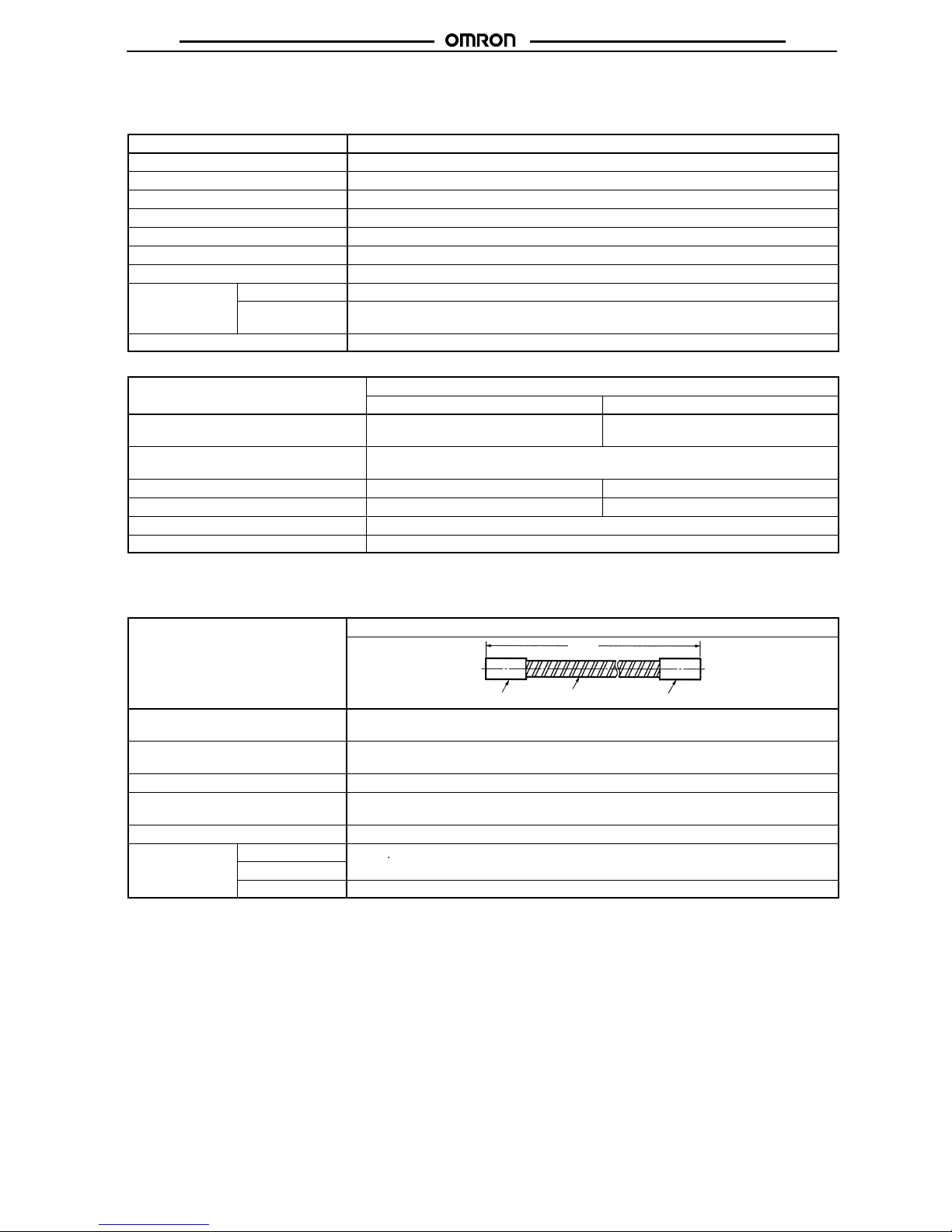

Ordering Information

Monitors with Built-in Amplifiers

Main Unit

Appearance

Intensity range of incident light

Output

Model number

1 to 30 mW/cm

2

Analog voltage output (1 to 5 V)

F3UV-A30

0.2 to 3 mW/cm

2

F3UV-A03

Note:

Does not function as a sensor

.

Monitors with Optical Fibers

Amplifier

Appearance

Connection

method

Outputs T

ransistor type

Model number

Pre-wired cable

•

Judgement output

• Answer-back output

NPN F3UV-XW11

•

Anal

og current or voltage

output

PNP F3UV-XW41

Head Unit

Appearance

W

avelength range of

incident light

Max. temperature

Model number

Remarks

200 to 370 nm

300_C

(Use at temperatures below

the Fiber Unit’

s rated

operating temperature.)

F3UV-HM

Includes two M8 nuts

and one mounting plate.

Page 2

F3UV

F3UV

2

Fiber Units

Compatible

Amplifier Units

Compatible

Head Units

Appearance Max.

temperature

Intensity range of

incident light

(see note)

Model number

Quantity

F3UV-XW11,

F3UV-XW41

F3UV-HM

M4 threads, 2 m

300_C

10 to 300 mW/cm2F32-300

1

M4 threads, 2 m

70_C

10 to 300 mW/cm2F32-70

Note: The

values given are for a standard UV

light source with a central wavelength of 360 nm, measured with a standard illumination meter

(and

for use in combination with the specified Amplifier and Head Unit). The

power range is one for which teaching to 100% is possible.

Accessories (Sold Separately)

Accessories for Monitors with Built-in Amplifiers

Appearance Name Model

number

Protective T

ube (Protects the cord.)

F39-CU1M

Protective Cover (Protects the display.) F39-HU2

1/6.5 Filtering Cover

F39-HU1

Mounting Bracket

F39-L9

Accessories for Monitors with Optical Fibers

Appearance Name Model

number

Quantity

Applicable Fiber Units

Protective Tube

(Protects the fiber

.)

F39-FU1M 1 F32-70

Page 3

F3UV

F3UV

3

Specifications

Ratings/Characteristics

Monitors with Built-in Amplifiers (Main Unit)

Item F3UV-A30 F3UV-A03

Incident

light power range

1

1 to 30 mW/cm

2

0.2 to 3 mW/cm

2

Incident light wavelength range

200 to 370 nm

Power indicator

Green LED

Operation indicator

Orange LED (lights with an output between 4 and 5 V)

Sensitivity adjustment

One-turn variable adjuster

Power supply voltage

12 to 24 VDC

±10%

Current consumption

15 mA max.

Response time

2

300 ms max. 400 ms max.

Output

3

1 to 5 V (with an of

fset voltage of 0.2 V min.)

Connection impedance

100 kΩ min.

Repetitive accuracy

±

2% F

.S. max.

T

emperature drift

0.2% of F

.S./°C max.

Ambient operating illumination4Fluorescent light 1,000 lx max.

Fluorescent light 500 lx max.

Ambient temperature

Operating: –10° to 70°CStorage: –25° to 80

°C

Ambient humidity

Operating:

35% to 85%

Insulation resistance

20 MΩ min. (at 500 VDC)

Dielectric strength

1,000 V AC 50/60 Hz for 1 min

V

ibration resistance

10 to 150 Hz, 0.1-mm amplitude in X, Y

, and Z directions

(8 minutes of vibration × 10 repetitions= total time 80 minutes)

Shock resistance

150 m/s2 three times each in the ±X, ±Y, and ±Z directions

Degree of protection

Conforms to IEC IP30

Connection method

Pre-wired cable with a standard length of 2 m

W

eight (packed)

78 g

Material Casing: Die-cast zinc

Window: Synthetic quartz glass

Accessories

Operation Manual

Note: 1.

Using a standard UV light source and UV illumination meter in a power range for which analog output can be set to 5 V

.

2.

The response time is the rise time of the output signal to 10 to 90%.

3. An

output voltage up to 6 V can be output. Adjust the sensitivity so

that the output is less than 5 V

. The output is 0.2 to 1 V when there

is

no incident UV light.

4.

This value is the illumination at the receiver window maintaining an of

fset voltage of 1 V max. with the fluorescent light.

Page 4

F3UV

F3UV

4

Accessories (Sold Separately)

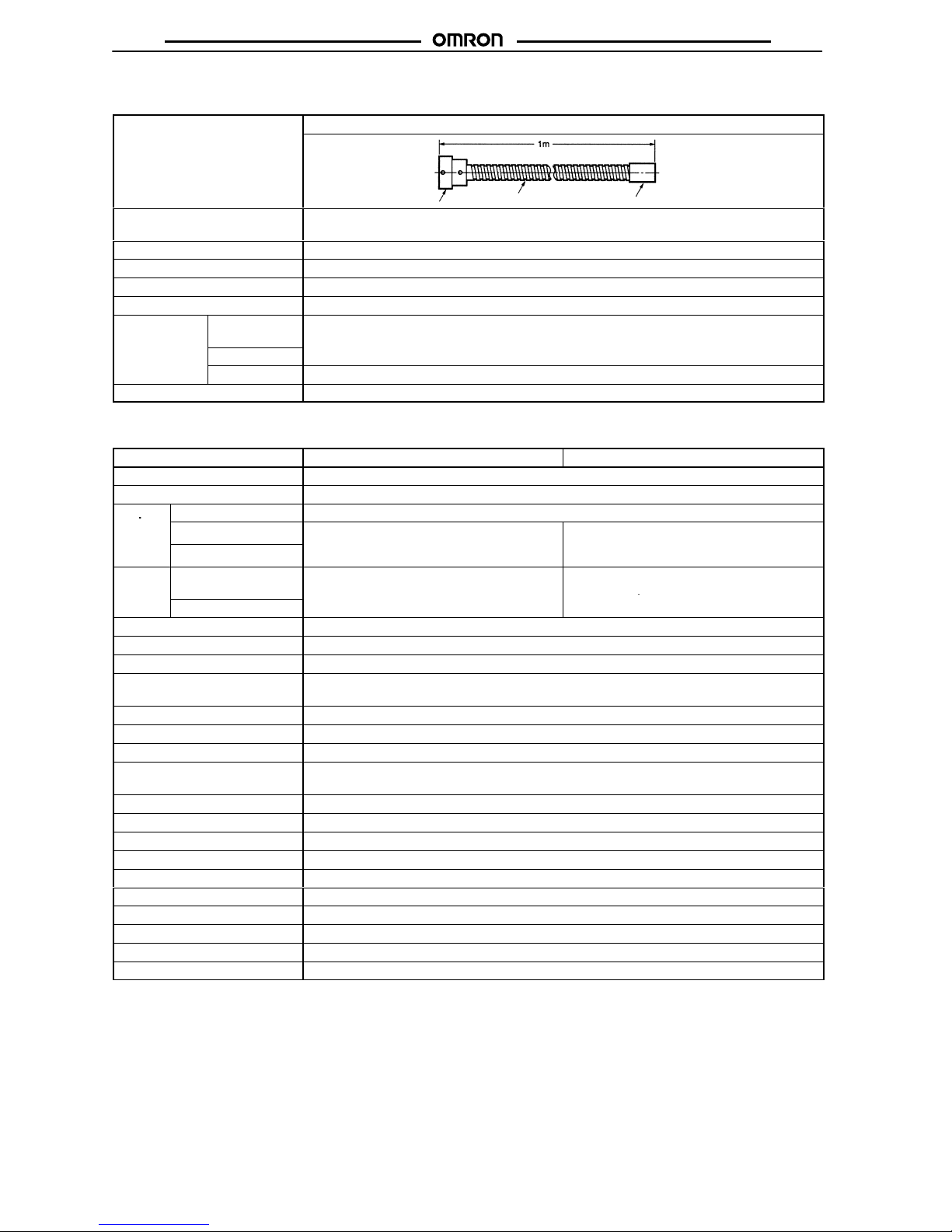

Protective Tube (Protects the Cord.)

Item

F39-CU1M

Head connector

Flexible tube

End cap

Ambient

temperature

–40°

to 100°C for operation and storage

(Use within the specified operating temperature range for the Monitor

.)

Ambient humidity

Operating:

35% to 85%

Storage: 35% to 95%

Bending radius

24 ± 5 mm

Max. pulling force

2 N-m max. between the head connector and tube, end cap and tube, or on the tube itself

Crush weight

9.8 N-m max. load on the side of the tube

Material

Head

connector

Nickel-plated brass

End cap

Tube

Stainless (SUS304)

Attachment M2 screws

Monitors with Optical Fibers

Amplifiers

Item

F3UV-XW11 F3UV-XW41

Power

supply voltage

12 to 24 VDC

±10%

Current consumption

75 mA max.

Outputs

Analog output

Current (4 to 20 mA) or voltage (1 to 5 V) (Monitoring mode or integral mode)

p

Judgement output

NPN open collector output, 100 mA max.,

PNP open collector output, 100 mA max.,

Answer-back output

residual voltage 1 V max.

(Monitoring mode or integral mode)

residual voltage 2 V max.

(Monitoring mode or integral mode)

Inputs

Remote teaching

input

ON:

0 V short-circuit (current 1 mA max.)

ON:

Power supply voltage short-circuit or 9 to

24 V (open-circuit current: 3 mA max.)

Reset input

OFF:

Open (open or 9 to 24 V)

(p )

OFF:

Open (open or 1.5 V max.)

Protective circuits

Reversed power supply polarity protection and output short-circuit protection

Response time

1

500 ms max.

Sensitivity setting

T

eaching function

Indicators Power supply/T

eaching indicator (green/red), Operation indicator (orange), 7-segment digital

percentage display (red), 7-segment digital threshold display (red)

Repetitive accuracy

±

2% F

.S. max.

Ambient operating illumination2Fluorescent light 1,000 lx max.

T

emperature drift

±

0.1% of F

.S./°C max.

Ambient temperature

Operating: –25 to 55°C (with no icing or condensation) Storage: –40 to 70°C (with no icing or

condensation)

Ambient humidity

Operating or storage: 35% to 85%

Insulation resistance

20 MΩ min. (at 500 VDC)

Dielectric strength

1,000 V AC 50/60 Hz between the leads and the case

V

ibration resistance

10 to 150 Hz, 0.1-mm amplitude or 15 m/s2 in X, Y

, and Z directions each for 2 hours

Shock resistance

150 m/s2 three times each in the X, Y

, and Z directions

Degree of protection

Conforms to IEC 60529 standards IP30

Connection method

Pre-wired cable with a standard length of 2 m

W

eight (packed)

Approx. 270 g

Material ABS plastic

Accessories

Operation Manual

Note: 1.

The response time is the rise time or fall time of the output signal to 10 to 90%.

2. The

ambient operating illumination is the illumination that changes the analog output +5% F

.S. at 200 lx; it is not the operational limit.

3. An

analog output of up to 6 V (or 24 mA) can be output. The output is 1 V (or 4 mA) when there is no incident UV light.

4. F

.S. stands for full scale. For a current output, full scale is 16 mA (4 to 20 mA). For a voltage output, full scale is 4 V (1 to 5 V).

Page 5

F3UV

F3UV

5

5. Definition

of the luminous energy integral: The physical unit of the luminous energy integral is energy (J:

joules) and this value is

calculated

by multiplying the UV intensity (mV)

by the time of exposure (s), but it is dimensionless when this sensor’s analog output

value

(V) is used for the UV intensity

. The integral is measured with an 1

1 ms sampling time.

Head Unit

Item

F3UV-HM

Incident light wavelength range

200 to 370 nm

T

emperature drift

–0.15%/°C max.

Ambient temperature

Operating or storage: –40° to 300°C (with no icing or condensation)

Ambient humidity

Operating or storage: 35% to 85% (with no icing or condensation)

W

eight (packed)

Approx. 300 g

V

ibration resistance

10 to 55 Hz, 0.75-mm amplitude or 10 m/s

2

Shock resistance

500 m/s

2

Material

Protective casing

Stainless steel (SUS303)

Fluorescent fiber

path

Functional fluoroglass

Accessories

M8 nut and mounting bracket

Fiber Units

Item

Model

F32-300 F32-70

Ambient temperature

(with no icing or condensation)

Operating: –40°

to 300

°C

*1

Storage: –40°

to 1

10°C

Operating: –40°

to 70

°C

Storage: –40°

to 70

°C

Ambient humidity

(with no icing or condensation)

Operating:

35 to 85%

Storage:

35 to 95%

Bending radius

25 mm min. 25 mm min.

Fiber outer sheathing material

SUS

Black polyethylene

Degree of protection

Conforms to IEC IP67

Standard fiber length

2 m

Note:

The maximum temperature is lower near the amplifier unit. See the Dimensions for details.

Accessories (Sold Separately)

Protective Tube (Protects the Fiber

.)

Item

F39-FU1M

1,000

Head connector

Flexible tube

End cap

Ambient

temperature

–40°

to 150°C for operation and storage

(Keep the ambient temperature within the range specified for the fiber within the tube.)

Ambient humidity

Operating:

35 to 85%

Storage:

35 to 95%

Bending radius

30 mm min.

Max. pulling force

1.5 N-m max. between the head connector and tube, 1.5 N-m max. between the end cap and

tube, and 2 N-m on the tube itself

Crush weight

29.4 N-m max. on the tube

Head connector

Nickel-plated brass

End cap

p

Tube

Stainless (SUS304)

Page 6

F3UV

F3UV

6

Engineering Data

Monitors with Built-in Amplifiers

Output Characteristics

F3UV-A30

(Output

characteristics when the output is

set at 5 V for a UV intensity of 30 mW/cm2.)

F3UV-A03

(Output characteristics when the output is

set at 5 V for a UV intensity of 3 mW/cm2.)

Angular Characteristics

F3UV-A30/-A03

F3UV-A30/-A03

and F39-HU1 Cover (Sold Separately)

UV power monitor output (V)

UV intensity (mW/cm2)

Relative sensitivity (%)

Angle (degrees)

X-axis relative sensitivity (%)

Relative sensitivity (%)

Angle

(degrees)

UV power monitor output (V)

UV intensity (mW/cm2)

X-axis relative sensitivity (%)

Y-axis relative

sensitivity (%)

Y-axis relative

sensitivity (%)

Monitors with Optical Fibers

Output Characteristics

F3UV-XWj1

+ F3UV

-HM + F32-300

(Output characteristics when the sensitivity

is

set at 300 mW/cm2.)

Angular Characteristics (Y-direction)

F3UV-HM

The

output variation in the X-direction is less than

±

10% of F

.S. in a full 360_ rotation.

Sensor output (V)

UV intensity (mW/cm2)

Relative value (%)

Angle (degrees)

Sensitivity Characteristics

All

F3UV Models

Intensity (relative)

W

avelength (nm)

Page 7

F3UV

F3UV

7

Nomenclature

Monitors with Built-in Amplifiers

F3UV-A30/-A03

Operation

indicator

(orange)

Power

indicator

(green)

Sensitivity

adjuster VR

Functions

Name

Function

Display

functions

Power indicator

Lit green when power supply

is ON.

Operation indicator

Lit orange when the analog

output is between 4 and 5 V

.

Output

functions

Analog output

Outputs a voltage (1 to 5 V)

proportional to the incident

light. (The of

fset voltage is

0.2 V min.)

Sensitivity adjuster

Sensitivity can be set to the

desired level with this

one-turn adjuster

.

Monitors with Optical Fibers

F3UV-XW11/-XW41

Operation

indicator

Lit orange:

Judgement output ON

Fiber lock

Digital display

Sensitivity setting/threshold up

Light intensity monitor mode (MON)

TEACH:

Sensitivity setting

ADJ:

Threshold adjustment

(Up button)

Light intensity integral mode (ITG)

TEACH:

Stop integration

Zero point setting/threshold down

Light intensity monitor mode (MON)

TEACH:

Zero point setting

ADJ:

Threshold adjustment

(Down button)

Light intensity integral mode (ITG)

TEACH:

Start integration

Measurement/T

eaching indicator

Lit green:Teaching OK

RUN

Flashing red:Teaching error

Lit red:

Start light intensity

integration

Processing mode switch

Light intensity monitor mode

TEACH:

Zero point setting/

sensitivity setting

ADJ:

Threshold adjustment

RUN:

Measure light intensity

Light intensity integral mode

TEACH:

Start/stop integration

RUN (ADJ):

Light intensity integral

Output selection switch

IOUT:

Current output (4 to 20 mA)

VOUT: V

oltage output (1 to 5 V)

Operation mode switch

MON:

Light intensity monitor mode

ITG:

Light intensity integral mode

Page 8

F3UV

F3UV

8

Functions

Name

Function

Indicator functions

Measurement/

teaching

indicator

•

Lit green:

T

eaching OK

RUN

•

Flashing red:Teaching error

•

Lit red:

Start light intensity

integration

Operation

indicator

•

Lit orange:

Judgement output ON

Digital display

• Percentage display when operating in

light

intensity monitor mode

HI: Greater than 124%

LO: Less than 0%

Output functions

Analog output

(switchable)

• Outputs

a current (4 to 20 mA) or voltage

(1 to 5 V) that is proportional to the

incident

light intensity

.

Select

current or voltage output with

the

output selection switch.

Judgement

output

• ON when the incident light intensity is

below

the set threshold value.

• OFF when the incident light intensity is

above

the set threshold value.

(Includes a short-circuit protection function.)

Answer-back

output

• A one pulse output (1 sec) is generated

when remote teaching has been completed

normally

.

Input functions

Reset input

• This trigger signal starts integration

when

the Unit is

in integral mode and the

processing

mode is set to “RUN”.

Remote

teaching input

• When the Unit is in monitor mode or

integral mode, teaching is performed

when

a pulse signal is input here.

Threshold setting

function (monitor

mode only)

• The

desired

threshold value can be set

by pressing the Up and Down buttons.

(The digital display will change in 1%

increments

when the value is set.)

Sensitivity setting function (monitor mode only)

Zero point

setting

• Sets

the zero point reference when

the

UV

light source is OFF

.

After teaching, the digital display will

read

“0%”.

Sensitivity

setting

• Sets the initial sensitvity when the UV

light source is ON.

After teaching, the digital display will

read

“100%”.

Max. sensitivity

setting

• Sets the sensor sensitivity to the

maximum sensitivity.

Min. sensitivity

setting

• Sets the sensor sensitivity to the

minimum sensitivity.

Light intensity

monitor function

(Part of the

current/voltage

output switching

function.)

• Displays the digital (%) value

corresponding to the incident light

intensity and outputs the analog

and

judgement outputs.

Light intensity

integral function

(Part of the

current/voltage

output switching

function.)

• Calculates the light intensity integral

value

(I) from the incident light intensity

(P) and time (T) using the following

equation:

I = P × T

.

Also outputs the integral’s analog

output

simultaneously and displays

the

digital

(%) value. (Output ON at 100%.)

Page 9

F3UV

F3UV

9

Operation

I/O Circuit Configuration

Monitors with Built-in Amplifiers

Monitors with Optical Fibers

Main

Brown

Black

Power supply

(12 to 24 VDC)

Output (1 to 5 V)

Power Operation

Power

(green)

Operation

(orange)

Display

Reset input

Remote teaching input

Answer-back

output

Judgement

output

Controller,

etc.

Shield

Black

Load

Load

Brown

12 to 24 VDC

Analog output

0 V

Gray

Internal

circuit

F3UV-XW11 (NPN Output)

Purple

Pink

Blue

White

Main

circuit

Black

Blue

Output (1 to 5 V)

0 V

Sensitivity adjuster

Measurement/

teaching

(green/red)

Operation

(orange)

Display

Reset input

Remote teaching

input

Answer-back

output

Judgement

output

Shield

White

Black

Load

Load

Brown

12 to 24 VDC

Analog

output

0 V

Gray

F3UV-XW41 (PNP Output)

Purple

Pink

Blue

Controller,

etc.

Analog GND

Internal

circuit

Monitors with Built-in Amplifiers

Analog Indications such as Voltage or Current Signals

F3UV-A30/-A03

UV Power Monitor

Black

Blue

K3NX-VD2A-T1

+–

Brown

Page 10

F3UV

F3UV

10

Dimensions

Note: All

units are in millimeters unless otherwise indicated.

Monitors with Built-in Amplifiers

Main Units

F3UV-A30/-A03

Light receiving window

Mounting holes (3.5 dia.)

7.4 dia.

4 dia.

9.5 dia.

Protective cover screw

hole (M2, depth 6)

Power/Operation

indicators

Sensitivity adjuster

Two, M3

Mounting Hole Dimensions

Accessories (Sold Separately)

Protective Tube (Protects Cord.)

F39-CU1M

End Cap (Note 1)

5 dia.

Two, M2

7 dia.

Tube (Note 2)

Head Connector (Note 1)

15 dia.

9.75 dia.

12 dia.

15 dia.

7 dia.

Tube internal

diameter: 5

8.5 dia.

Hex head

set screws

Note: 1. Material:

C3504 (nickel-plated brass)

2. Material:

Stainless steel (SUS304)

3.

M2 securing screws are included.

Installed Protective T

ube

Protective Cover (Protects Display.)

F39-HU2

1/6.5 Filtering Cover

F39-HU1

Material: Stainless steel (SUS304-CSP)

t = 0.2

Material: Stainless steel (SUS304-CSP)

t = 0.2

Installed Protective Cover

Installed 1/6.5 Filtering Cover

Two light receiving windows

2.5 dia.

Two, dia. 1

Two, 3.5 dia.

Optical

axis

F39-L9 Mounting Bracket (sold separately)

Optical axis

Page 11

F3UV

F3UV

11

Mounting Bracket

F39-L9

Material: Stainless steel (SUS304-CP)

t = 0.2

Optical

axis

Optical axis

Optical axis

Monitors with Optical Fibers

Main Units

Amplifier

F3UV-XW11/-XW41

Fiber insertion opening

Measurement/teaching

indicator (green/red)

Operation indicator (orange)

RUN/ADJ/TEACH mode switch

Sensitivity setting/threshold value up button

Zero-point setting/threshold value up button

Monitor/Integral mode switch

Current/Voltage output switch

7-segment display

Fiber lock button

Vinyl-insulated round cable 5.8 dia., 7 conductors

(Conductor cross sectional area: 0.2 mm

2

, diameter

of insulator: 1.1 mm) Standard length 2 m

9.9 dia.

Two, M4

Mounting

Hole Dimensions

Page 12

F3UV

F3UV

12

Base Unit

F3UV-HM

Fiber Unit

F32-300

Fiber Unit

F32-70 (Cuttable)

Detection surface

Lock washer Lock nuts (2)

M8 ×

1

6 dia.

15 dia.

5 dia.

M2.6

× 0.45

Hex nuts (2)

Lock washers (2)

Detection head*

1

M4 ×

0.7

Flexible tube, 2.8 dia. (Stainless)

Hex fastener

Sleeve

1 dia.

4 dia.

4 dia.

5 dia.

Note: The max. temperature is

300_C in section A and

110_C in section B, which

connects

to the Main Unit.

The

part of section

B that is

actually inserted into the

Main Unit must remain within the Main Unit’s rated

operating temperature

range.

Material:

Stainless steel (SUS303)

*1: Material: Stainless steel (SUS303)

1 dia.

M2.6

× 0.45

Hex nuts (2)

Lock washers (2)

Detection head*

M4 ×

0.7

Optical fiber, 2.2 dia.

*Material: Nickel-plated brass

Note:

The “cuttable” Fiber Units can be cut to length. Units that are not marked “cuttable” cannot be cut to length.

Accessories (Sold Separately)

Protective Tube (Protects the Fiber.)

F32-FU1M

M4

× 0.7,

depth 4

Head Connector

*1

End Cap

*1

Tube

*2

(5.6 dia.)

7 dia.

4 dia.

Note: 1. Material: Nickel-plated brass

2. Material:

Stainless steel

(SUS304)

Page 13

F3UV

F3UV

13

Precautions

Be

sure to observe the precautions listed here. These precautions

are

essential for safe operation.

• Do

not

use these Units in locations with flammable or explosive

gases.

• Do

not use these Units in water

.

• Do not attempt to disassemble, repair, or improve these

products.

• Always use a power supply voltage that is within the specified

operating

range. Do not use with an AC power supply

.

• Be sure that wiring is correct, such as the polarity of the power

supply leads.

•

Connect loads properly

.

•

Do not short-circuit the load’

s terminals.

• Do not mount the Amplifier Unit in a location where it will be

exposed

to UV light.

Precautions Common to the F3UV-series

Wiring

Connections

Make

sure that the power supply voltage is below the maximum volt

-

age

before turning the power ON.

Be sure that the terminal polarity and wiring are correct.

Never

share a conduit that is used for high-voltage or power lines.

Use extension cords with a minimum thickness of 0.3 mm2, less

than

5 m long, and check operation before using.

Power Supply

When using a commercial switching regulator, ground the FG

(frame

ground) and G

(ground) terminals. Output signal noise will be

excessive

if the power supply is not grounded.

After

turning on the power supply

, wait for at least one second

until

consistent

detections can be performed before using the Monitor

. If

separate

power supplies are used for

the F3UV and connected de

-

vices,

always turn ON the F3UV’

s power supply first.

Installation and Operation

Installation

UV

light is harmful, so be sure to turn OFF the UV light source before

installing

the F3UV

.

Sensitivity Setting

The

analog output value will change due to temperature drift. If the

temperature is rising, wait for the temperature to stabilize before

setting the sensitivity.

Precautions for the F3UV-A30/A03

Installation

Installation Torque

T

orque the sensor’s Main Unit screws to 0.49 N-m max.

Precautions Regarding UV Light

The

sensor’s display and

cord are not protected against UV expo

-

sure.

If these parts will be exposed to UV light, protect

them with the

F39-HU2

Protective Cover and F39-CU1M Protective T

ube.

When

UV light will be in the

user’s field of vision or directly contact

the

skin during adjustment, use a shield or other protective device

to

prevent

injury

.

Adjustment

Sensitivity Adjustment

Use

the following procedure to adjust the analog output to 5 V before

initial

operation or after replacing the UV light source.

1. Set up the Sensor and the UV light source to be monitored.

The sensitivity adjuster is factory set to its minimum setting

(all

the way to the left).

2. T

urn ON the UV light source.

3. Check

whether the operation indicator (orange) of the Sensor

is lit. The operation indicator will light if the analog output

value is between 4 and 5 V. If it does not light, adjust in the

following way.

4.

Rough Adjustment

The

operation indicator will light if the analog output value is

between

4 and

5 V

. In this case, proceed to

Fine Adjustment

below. If the operation indicator is not lit, check whether the

operation indicator can be made to light by turning the

sensitivity adjuster. If the operation indicator still does not

light, then the UV intensity is either too high (i.e., exceeds

Sensor specifications, with an analog output value greater

than

5 V), or is too low

. If the UV intensity is too high, make the

operation

indicator light by

either using the F39-HU1 Filtering

Cover (sold separately), or moving the Sensor farther away

from

the UV light source. If the UV intensity is too low

, move

the Sensor closer to the UV light source, until the operation

indicator

lights.

5.

Fine Adjustment

Adjust

the sensitivity adjuster until the analog output value is

5 V. If it not possible to obtain a value of 5 V this way

, then the

distance between the Sensor and the UV light source is

inappropriate. Move the Sensor either closer to, or farther

away

from the UV light source.

Cleaning

Never

use paint thinner or mineral spirits of any kind. If there is de

-

bris

or dust on the light-receiving window

, wipe it of

f with a soft

cloth

or

blow it of

f with a low-pressure air sprayer

.

Precautions for the F3UV-XW11/XW41

Installation

1. Installation Torque

T

orque the sensor’s Main Unit screws to 0.49 N-m max.

2. Using DIN Track

(Installation)

1.

Hook the top of the Unit onto the DIN T

rack.

2.

Snap the bottom of the Unit onto the DIN T

rack.

Note:

Do not reverse steps 1 and 2.

(Removal)

When

removing the Unit from the DIN T

rack, pull the

mount

-

ing

hook forward to release it.

Page 14

F3UV

F3UV

14

DIN

Track

Mounting hook

(2)

(1)

Precautions Regarding UV Light

The Amplifier itself is not protected against UV exposure. Do not

install

the Amplifier in

locations where it will be exposed to UV light.

Adjustment

Basic

Operating Procedures

1.

Install the Amplifier Unit.

2.

Connect the Fiber Unit to the Amplifier Unit.

3. T

urn ON the power supply

.

4. Select an operating mode with the operation mode switch.

(Light

intensity monitor mode

or light intensity integral mode)

5. When using the analog output, select current or voltage

output

with the output selection switch.

6. Set the processing mode switch to TEACH and perform the

teaching operation.

•

Light Intensity Monitor Mode

Make

the zero-point setting

when the indicator is not lit and

make

the sensitivity setting when the indicator is lit. (Make

the

sensitivity setting after the temperature has

stabilized.)

• Light

Intensity Integral Mode

Use

the start setting at the start of illumination and the stop

setting when completed. Teaching can be performed by

pressing

the buttons or with codes.

7. When

changing the threshold value in light intensity monitor

mode,

set the processing mode switch to ADJ and adjust the

threshold value. The judgement output will go ON when the

light intensity is below the threshold value. The threshold

value

is set to 50 at the factory

.

8. Set the processing mode switch to RUN to start

measurement. In light intensity integral mode, start

integration

with the Reset input.

Cleaning

Never use paint thinner or mineral spirits of any kind.

Fiber Unit/Base Unit

Installation

Installing

the Head Unit

When

connecting the Head Unit and Fiber Unit, tighten to

a torque of

0.78

N-m max. When installing the

Head Unit, be sure to turn OFF

the

UV light source and check that it is safe to install the Unit.

Head Unit

(F3UV-HM)

M8 nuts

(included)

M4 nut

(included)

Mounting panel

W

ashers (included)

Fiber Unit

(F32-300)

Installing the Fiber Unit and Amplifier Unit

The

quality of the connection between the Fiber Unit and Amplifier

Unit

has a major impact on the operating characteristics, so be sure

to connect these Units securely.

Securing the Fiber Unit

1.

Cutting the Fiber (F32-70 only)

• Insert the fiber into the hole of the cutting tool and set the

tool

at the desired length.

• Press

down on the blade and cut the fiber

. Do not stop when

the

fiber is only partially cut; make one clean cut.

• Once a hole has been used to cut a fiber, do not use that

hole

again. The cut surface may not be clean enough and

the

detection characteristics may be degraded.

2.

Installing the Fiber

With

the lock button in the release position, insert the fiber

into

the

Unit and press the button until you hear a click. This click

is

the sound of the fiber being locked.

Locked position

Release position

3.

Removing the Fiber

Press

the lock

button again. The lock will be released, the lock

button

will pop up, and it will be possible to remove the fiber

.

Do

not force the lock button up by pulling on it. (T

o maintain

the fiber’s characteristics, check whether the lock is out of

place.)

4. Fiber

Insertion Location

When

inserting the Fiber Unit into the Amplifier Unit, always

Page 15

F3UV

F3UV

15

insert the Fiber Unit completely as shown in the following

diagram.

Fiber

Unit

(Example:

F32-300)

Fiber Unit

(Example:

F32-70)

5.

Fiber Unit Installation/Removal Precautions

Install and remove the Fiber Unit only when the ambient

temperature

is between –40 and 40

_C.

6.

Protecting the Fiber Unit

When the outer sheathing of a FIber Unit other than the

F32-300 will be exposed to UV light, protect the fiber by

covering

it with the F39-FU1M Protective T

ube.

Page 16

F3UV

F3UV

16

OMRON Corporation

Industrial

Automation Company

Industrial Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530, Japan

Tel: (81)75-344-7068/Fax: (81)75-344-7107

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To

convert millimeters into inches, multiply by 0.03937. T

o convert grams into ounces, multiply by 0.03527.

Cat. No. E315-E1-1 In the interest of product improvement, specifications are subject to change without notice.

Printed

in Japan

0301-1M (0700) (O)

Loading...

Loading...