Page 1

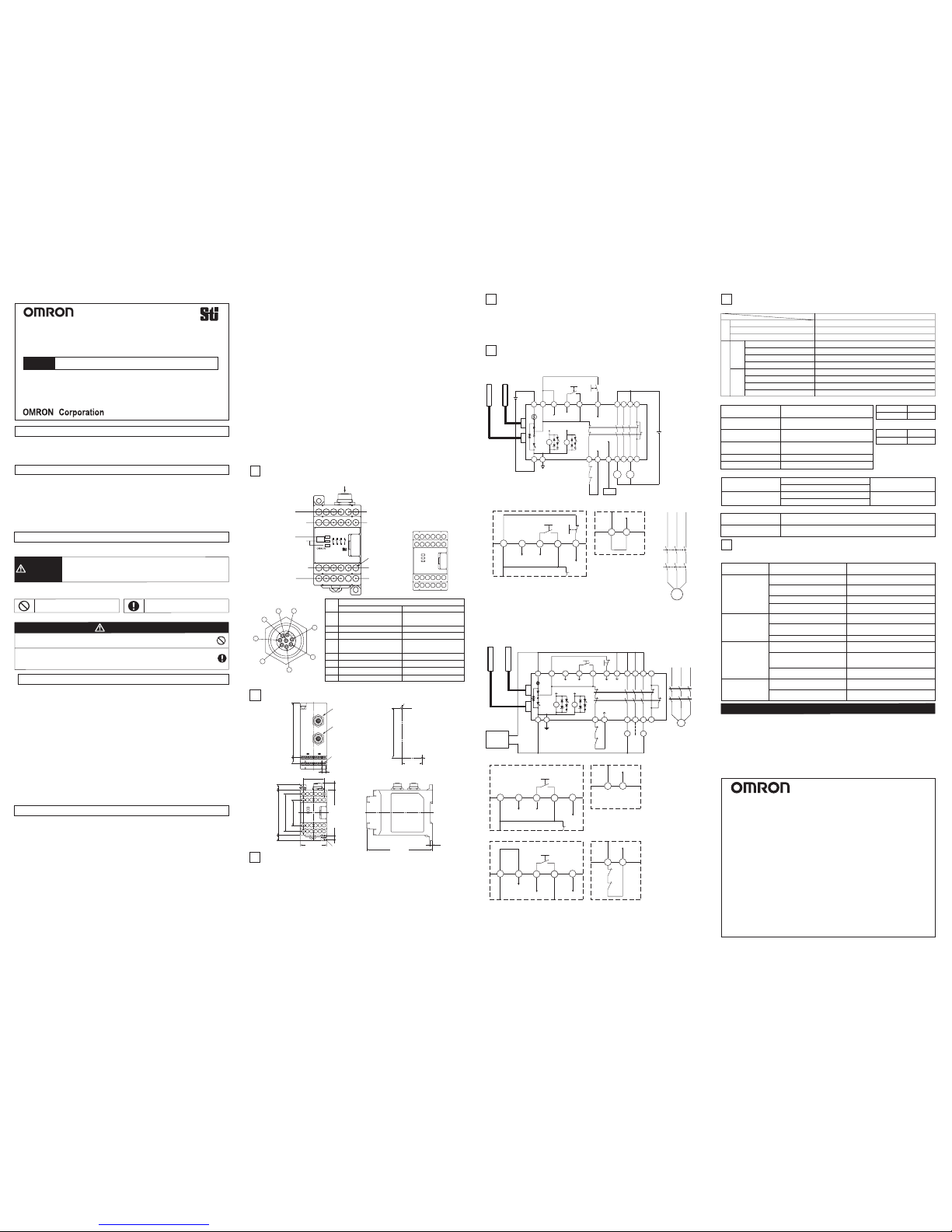

*S1 Open: Normal light emission.

Close: Stop light emission.

●Wiring for Auto-reset mode.

●Wiring for Manual reset mode and the EDM function enabled

●Wiring when the EDM is not used.

●Wiring when the EDM is not used.

*S3 If the switch is not necessary,

connect between X1 and H1.

4

Functions

Designation

The F3SP-B1P can construct the condition conforming to cat. 4 / PLe or cat.2 / PLc requested by EN

ISO13849-1 with combination as follows:

- Category 4 / PLe: Type F3SN-A□□□□P□□ or F3SH-A09P03 or F3SR-430B□□□□

or F3SJ-A□□□□P□□ or F3SJ-B□□□□P25

- Category 2 / PLc: Type F3SN-B□□□□P□□

Note: Category is not judeged only by the condition above, but is judged by the

condition of the whole control system.

- In order to be cat. 4/ PLe, or cat. 2/ PLc

1. The NC contact from a contactor is required to feed back signal.

(Refer to the application examples. For category 2, it is not mandatory.)

2. PE terminal should be connected to protective earth.

3. In application with long term operation of devices, the F3SP-B1P must have cyclic

operation every 24 hours at least in order to detect failures and a failure

accumulation.

Application examples

5

●Wiring for the Manual reset mode and the EDM function.

5-1 When in combination with the F3SN/F3SH/F3SJ

5-2 When in combination with the F3SR

Specications

●Characteristics

(1) When ready for wiring, the power source should be disconnected rst. Further, at operating

this unit, the terminal cover should be closed correctly in orde to prevent an electrical shock.

(2) Do not wire in case threat of Lightning. otherwise an electric shock may occur.

(3) Do not apply any excessive voltage or current to the input or output circuit the F3SP-B1P.

Doing so may result in damage to the F3SP-B1P or cause are.

(4) Do not apply any variable voltage, otherwise F3SP-B1P may malfunction.

(5) Do not connect any overload to the output circuit, otherwise the F3SP-B1P in operation will

generate excessive heat and the output elements of the F3SP-B1P may short-circuit or re

may result.

(6) The lifetime of F3SP-B1P depends on the conditions of switching of its outputs. Be sure to

conduct its test operation under actual operating conditions in advance and use it within

appropriate switching cycles. Change the F3SP-B1P before expected operation. Over

operation may cause may short-circuit or may malfunction.

(7) Do not operate the F3SP-B1P with ammable or explosive gass. An arc with operation and

the heat of relay will cause a re or an explosion.

(8) Do not disassemble, repair, or modify the F3SP-B1P, otherwise an electric shock may occur or

the F3SP-B1P may malfunction.

(9) Use protective device (Fuse etc) for short-circuit protection and ground fault protection,

otherwise a re may occur or the F3SP-B1P may malfunction.

(10) Be sure to wire correctly. The sensor connector is the same both the emitter and the

receiver.

(11) Do not dismantle, repair, or modify F3SP-B1P. it may lead to loss of its safety functions.

(1) For malfunctions in case that the power supply picks up gradually.

Malfunctions in case that the power supply picks up gradually. In case that the input circuits

close before the power supplies, internal logic may malfunction.

(2) Handling

Do not drop the F3SP-B1P or shock or vibrate the F3SP-B1P excessively. Doing so may result

in damage to the F3SP-B1P or cause F3SP-B1P to malfunction.

(3) For adhesion of solvent

Adhesion of solvent, likely Alcohol, Thinner, Trichloroethane, Gasoline, on the product should

be prohibited. Such solvent cause erasing the marking and being inferior of the parts.

(4)Take appropriate and sucient countermeasures when installing systems in the following

locations. Inappropriate and insucient measures may result in malfunction.

1. Locations subject to static electricity or other forms of noise.

2. Locations subject to possible exposure to radioactivity.

3. Locations close to power supplies.

(5) Wiring

1. Use the following to wire the F3SP-B1P.

- Stranded wire (Flexible wire): 0.75 to 1.5mm

2

- Solid wire: 1.0 to 1.5mm

2

2. The F3SP-B1P may malfunction or generate heat.

- Tighten each screw to a torque of 0.78 to 1.18N・m

3. PE is a ground terminal. When machine is grounded at the positive, the PE terminal

should not be grounded.

4. NC terminals do not have any function. Do not wire them.

The following functions of the sensor can be used. Refer to the instruction manual of

the sensor for detailed information.

・ Auto reset/Manual reset (Interlock function)

・ External device monitoring (EDM)

・ External test (Light emission stop function by test input)

・ Auxiliary output (PNP transistor output)

(*)

*When in combination with the F3SR, "auxiliary output" can not be used.

The F3SP-B1P received the following approvals in combination with the

F3SN/F3SH/F3SR/F3SJ:

・ From EU accredited body TUV-SUD Product Service GmbH:

- EC Type-examination in accordance with the EU Machinery Directive

Approved standards: EN61496-1, CLC/TS 61496-2 (IEC61496-2)

・ From the Third Party Assessment Body UL:

- UL Listed to U.S. and Canadian safety standards

Approved standards: IEC61496-1, IEC61496-2,

UL508, CAN/CSA C22.2 No.14, CAN/CSA C22.2 No.8

●Ratings

6

Thank you for purchasing F3SP-B1P Control Unit.

Please read and understand this manual before using the products.

Keep this manual ready to use whenever needed.

Only qualied person trained in professional electrical technique should handle F3SP-B1P.

Since this instruction sheet only provides general infomation, refer to the instruction

manual of the sensor.

Please consult your OMRON representative if you have any questions or comments.

USER'S MANUAL

Type F3SP-B1P

Jul. 2011

English

WARNING

Precaution for Safe Use

Indicates a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, or may

result in serious injury or death.

Additionally there may be signicant property damage.

Meanings of Signal Words

The following signal words are used in this manual.

Meaning of Alert Symbols

The following alert symbols are used in this manual.

Serious injury may possibly occur due to breakdown of safety outputs.

Do not connect loads beyond the rated value tothe safety outputs.

Serious injury may possibly occur due to loss of required safety functions.

Wire F3SP-B1P properly so that supply voltages or voltages for loads do

NOT touch the safety inputs accidentally or unintentionally.

WARNING

Alert Statements

Control Unit

F

or

F3SN-A □□□□P□□, F3SN-B □□P□□, F3SH-A09P03,

F3SR-430B □□□□, F3SJ-A □□□□P□□, F3SJ-B □□□□P25

Indicates prohibited actions

Indicates mandatory actions

Precautions for Safe Use

Precautions for Correct Use

●Life expectancy

Electrical endurance

Mechanical endurance

100,000 operations MIN. Rated load

Switching frequency 1,800 operations/h

5,000,000 operations MIN.

Switching frequency 18,000 operations/h

●Isolation specication

Insulation resistance

Dielectric strength

Between dierent poles of output

Between dierent poles of output

Between inputs and outputs

Between inputs and outputs

100Mohm MIN.

(by 500VDC Megger)

2,500VAC 1min.

7

Failure detection

Type F3SP-B1P can detect the failure for the safety of internal circuit, parts condition and

external wiring.

K1 and K2 LED

do not turn on.

Failures of the parts

of the internal circuits.

Replace with a new product.

Failures involving the wiring

of External input. (input line)

Failure indication

by LED

Failure condition

K1 or K2 LED

does not turn on.

Power LED

does not turn on.

Checking points and measures

to take

Failures involving the wiring

of External input. (input line)

Failures of the parts of the

External devices. (Contactor etc)

Failures of the parts

of the internal circuits.

Replace with a new External devices.

(Contactor etc)

Failures of the parts

of the internal circuits.

Replace with a new product.

Supply voltage outside

the rated value.

Check the supply voltage to

Expansion.

Failures involving the wiring

of External input. (output line)

Replace with a new product.

Check the wiring to External input.

(input line)

Check the wiring to External input.

(output line)

Check the wiring to External input.

(input line)

Failures of the parts of the

Protective device. (Fuse etc)

Replace with a new Protective device.

(Fuse etc)

All LED turn on.

but the safety

output doesn't on.

Failures involving the wiring

of External input.

(input line / power line)

Check the wiring to External input.

(input line/power line)

Failures of the Sensor.

Failures of the Sensor.

Check the Sensor.

Check the Sensor.

S1: External test switch

S2: Interlock / Lockout reset switch

S3: Lockout reset switch

KM1,KM2: Magnet contactor

M: 3-phase motor

S1: External test/Lockout reset switch

S2: Interlock reset switch

KM1,KM2: Magnet contactor

M: 3-phase motor

E1: 24 VDC power supply (S82K)

1.7W MAX. (Exclude sensor power)

24VDC

25VAC 60VDC

5A

AC: 1250VA DC: 150W

AC: 125VA DC: 150W

TYPE F3SP-B1P

Rated power consumption

Rated supply voltage

Operating voltage range

Input

Rated load

Rated carry current

Max. switching voltage

Max. switching capacity

Output

For North

America

Rated load

Rated carry current

Max. switching voltage

Max. switching capacity

For Europe

5A

250VAC 5A cosφ=1 30VDC 5A L/R=0ms

250VAC 125VDC

-15% to +10% of rated supply voltage

25VAC 5A cosφ=1 30VDC 5A L/R=0ms

OMRON shall not be responsible for conformity with any standards, codes, or

regulations that apply to the combination of the products in the customer's

application or use of the product.

Take all necessary steps to determine the suitability of the product for the

systems, machines, and equipment with which it will be used. Know and

observe all prohibitions of use applicable to this product.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK

TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Suitability for Use

OMRON EUROPE B.V. (Representative in EU)

Wegalaan 67-69, NL-2132 JD Hoofddorp

THE NETHERLANDS

PHONE 31-2356-81-300 FAX 31-2356-81-388

OMRON SCIENTIFIC TECHNOLOGIES INC.

6550 Dumbarton Circle, Fremont CA 94555-3605

U.S.A

PHONE 1-510-608-3400 FAX 1-510-744-1442

OMRON ASIA PACIFIC PTE. LTD.

438A Alexandra Road # 05-05/08,

Alexandra Technopark Singapore 119967

SINGAPORE

PHONE 65-6-835-3011 FAX 65-6-835-2711

Note: Specications subject to change without notice.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530

JAPAN

Original instructions

EC Declaration of Conformity

Standards

OMRON declares that Type F3SP-B1P is in conformity with the requirements of

the following EC Directives:

- EMC Directive: 2004/108/EC

- Machinery Directive: 2006/42/EC

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

PHONE 86-21-5037-2222 / FAX 86-21-5037-2200

●Protection class

Operation time

100ms MAX.

(exclude sensor response time)

Destruction: 300 m/s

2

Malfunction: 100 m/s

2

Ambient humidity

Ambient temperature

Shock resistance

Vibration resistance

Response time

-10 to 55 ℃

10ms MAX.

(exclude sensor response time)

35 to 85%RH

10 to 55Hz 0.35mm single amplitude

(0.7mm double amplitude)

IP20

IP40

3

2

Enclosure

Terminals

●Pollution degree

External

Internal

(6) Mounting multiple units

When mounting multiple units close to each other, the rated current will be 3A.

Do not apply a current higher than 3A.

(7) Operating and Storage Environment

Do not operate or store the F3SP-B1P under the following conditions.

Doing so may result in damage to the F3SP-B1P or cause the F3SP-B1P to malfunction.

1. The places with direct sunlight.

2. The places with ambient temperature ranges not within -25 to 55℃.

3. The places with rapid temperature changes resulting in condensation or relative humidity

ranges not within 35 to 85%RH.

4. The places with atmospheric pressure out of the range 86 to 106kpa.

5. The places with corrosive or inammable gas.

6. The places with water, oil, or chemical sprayed on the F3SP-B1P.

7. The places with vibration or shock aecting the F3SP-B1P.

8. The places with atmosphere containing dusts, saline or metal powder.

(8) DC power supply units

In order to conform to IEC61496-1 and UL508, DC power supply unit must satisfy all the

conditions mentioned in the instruction manual the sensor.

(9) Installation

1. Cabinet of F3SP-B1P should meet IP54 protection.

2. The F3SP-B1P is exclusively for F3SN-A□□□□P□□, F3SN-B□□□□P□□,

F3SH-A09P03, F3SR-430B□□□□, F3SJ-A□□□□P□□, F3SJ-B□□□□P25 series.

3.The following functions are set with two short pieces when delivered. Change wirings

depending on necessary functions.

- H1-X1 short: Auto reset mode.

- T31-T32 short: EDM function is inactive.

*

These combinations of wiring and function are for the use with the F3SN/F3SH or F3SJ.

When in combination with the F3SR, refer to Section 5.

(10) For feedback purpose use devices with contacts capable of switching micro loads of

24VDC, 5mA.

(11) This is a class A product. In residential areas it may cause radio interference, in which case

the user may be required to take adequate measures to reduce interference.

KM1

24VDC

KM1 KM2

KM2

S2

S1

PLC

EMITTER

RECEIVER

K1

K2

K1

K2

A1

H1

L1 J1

H1 X1

A2

PE

T31

T32

P1

41

33

23

13

42

34

24

14

INTERLOCK

TEST

RESET

AUXILIARY

EDM

OSSD2

OSSD1

S3

S1

H1

L1 J1

H1

X1

T31

T32

INTERLOCK

TEST

RESET

KM1

M

KM2

●Wiring when the EDM is used.

●Wiring for Auto-reset mode.

●Wiring for Auto-reset mode.

S1

S2

A1 H1 L1 J1 H1 X1 P1 13 23 33 41

KM1

KM2

Function

select input

TEST

RESET

Operating

range

select input

OSSD 1 OSSD 2

K1

K2

K1 K2

A2 PE T31 T32

EDM

14 24 34 42

KM1

KM2

KM1

KM2

F3SP-B1P

E1

24VDC

0V

M

Emitter

Receiver

Function

select input

TEST

RESET

S1

H1

L1 J1

H1

X1

T31

T32

EDM

H1

Function

select input

TEST

RESET

S1

L1 J1

H1

X1

T31

T32

EDM

H1

1

External Physical Dimensions

2

●Unit

For safety category and PL

3

43

63

76 MAX.

9

7×5=35

13 MAX.

45 MAX.

R2.3

111 MAX.

5

5.6

9

4.6 dia.

35±0.3

5.9

24-M3

Emitter

Receiver

10.5

91

84

±0.3

Two,4.2 dia. or M4

Mounting holes

Sensor connectors For Receiver(Black)

For Emitter(Gray)

Output terminals

Power input

terminal

Output terminals

Power input

terminal

Earth terminal

I/O terminals

Input power

indicator

Relay operation

indicators

I/O terminal

I/O terminals

I/O terminals

Type F3SP-B1P

13 23 33 41 H1 J1

NC NC

L1 H1 X1 A1

14132423343342

41

P134 422414

A2

PE

T32T31

NCNCNC

PWR

K1

K2

No.

13 23 33 41

14 24 34 42

T31 T32

A1X1H1

H1 J1

L1NC NC

PENC NC A2

P1NC

24 VDC

SAFETY LIGHT CURTAIN

CONTROL UNIT

F3SP-B1P

●Connector

Pin

No.

Signal Name

Receiver

1

2

4

5

6

7

3

RS-485 (A)

Auxiliary output

(* Operating rangeselect input)

OSSD 1

+24V

OSSD 2

EDM input

*Names used when connecting with the F3SR

0V

RS-485(B

)

NC

RS-485(B

)

RS-485(A

)

Reset input

Test input

+24V

Interlock selection input

(* Function select input)

Emitter

0V

8

1

2

7

6

5

4

3

8

KM1

KM2

Page 2

OMRON CANADA, INC. • HEAD OFFICE

Toronto, ON, Canada • 416.286.6465 • 866.986.6766 • www.omron247.com

OMRON ELECTRONICS DE MEXICO • HEAD OFFICE

México DF • 52.

55.59.01.43.00

• 01-800-226-6766 • mela@omron.com

OMRON ELECTRONICS DE MEXICO • SALES OFFICE

Apodaca, N.L. • 52.81.11.56.99.20 • 01-800-226-6766 • mela@omron.com

OMRON ELETRÔNICA DO BRASIL LTDA • HEAD OFFICE

São Paulo, SP, Brasil • 55.11.2101.6300 • www.omron.com.br

OMRON ARGENTINA • SALES OFFICE

Cono Sur • 54.11.4783.5300

OMRON CHILE • SALES OFFICE

Santiago • 56.9.9917.3920

OTHER OMRON LATIN AMERICA SALES

54.11.4783.5300

Authorized Distributor:

F57I-E-01 06/12 Note: Specifications are subject to change. © 2014 Omron Electronics LLC Printed in U.S.A.

Printed on recycled paper.

Automation Control Systems

• Machine Automation Controllers (MAC) • Programmable Controllers (PLC)

• Operator interfaces (HMI) • Distributed I/O • Software

D

rives & Motion Controls

• Servo & AC Drives • Motion Controllers & Encoders

Temperature & Process Controllers

• Single and Multi-loop Controllers

Sensors & Vision

• Proximity Sensors • Photoelectric Sensors • Fiber-Optic Sensors

• Amplified Photomicrosensors • Measurement Sensors

• Ultrasonic Sensors • Vision Sensors

Industrial Components

• RFID/Code Readers • Relays • Pushbuttons & Indicators

• Limit and Basic Switches • Timers • Counters • Metering Devices

• Power Supplies

S

afety

• Laser Scanners • Safety Mats • Edges and Bumpers • Programmable Safety

Controllers • Light Curtains • Safety Relays • Safety Interlock Switches

OMRON AUTOMATION AND SAFETY • THE AMERICAS HEADQUARTERS • Chicago, IL USA • 847.843.7900 • 800.556.6766 • www.omron247.com

OMRON EUROPE B.V. •

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands.

•

+31 (0) 23 568 13 00

•

www.industrial.omron.eu

Loading...

Loading...