Omron F3SL-A0871P30, F3SL-A0351P30, F3SL-A1046P30, F3SL-A1219P30, F3SL-A1394P30 Instruction Manual

...Page 1

Safety Light Curtain

INSTRUCTION MANUAL

Cat. No. SCEE712-E2-1

INSTRUCTION MANUAL

Safety Light Curtain

F3SL Series

Cat. No. SCEE712-E2-1

Page 2

Page 3

i

Introduction

Thank you for purchasing the F3SL Series Safety Light Curtain.

Always heed the following points when using the F3SL:

• Make sure that personnel operating the F3SL are knowledgeable about the machine on which it is installed

• Read this manual completely and be sure you understand the information provided before attempting to

operate the F3SL

• Keep the manual in a secure and convenient location and refer to it as necessary.

(1) The F3SL has not received the type approval provided by Article 44-2 of the Industrial Safety and Health

Law of Japan. Therefore, it cannot be used in Japan as a safety device for pressing or shearing machines

provided by article 42 of that law.

(2) F3SL an equipment conforming to ESPE (Electro Sensitive Protective Equipment) specified in the 1st

Clause of Safety Component, Annex IV B in the EU (European Union) Machinery Directive. F3SL also conforms to the following overseas regulations and standards.

EU regulations and technical standards:

- Machinery Directive: No. 98/37/EC

- EMC Directive: No. 89/336/EEC

- EN 61496-1(06/98) (Type4 ESPE)

IEC standard

- IEC 61496-2(11/97) (Type 4 AOPD)

(3) F3SL has been received the following certification from EU authorized institutions.

"EC Type Approval (TYPE 4 ESPE)" in accordance with the Machinery Directive, from TÜV Rheinland.

If you use the F3SL under the condition or environment shown below, be sure to use it by leaving a margin for each rating and function and taking system safety into consideration.

(1) Use of the F3SL under any condition or environment not described in this manual.

(2) Use of the F3SL for devices and facilities requiring special safety (e.g., nuclear control, railway, aerospace,

automobile, combustion facility, medical system, space development, and large-scale amusement machinery).

General conventions for safe use

The following conventions are used for precautionary items in this manual in order to ensure safe and proper

use of the F3SL. Items listed here are critical for safety and must be heeded at all times.

Regulations and Standards

Notice

Precaution on Safety

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates prohibited actions.

Page 4

ii

WARNING

A F3SL should only be installed, checked out and maintained by a qualified person. It is important that the

user be familiar with the installation requirements, safe mounting distance, controls and features before

using the F3SL.

If the F3SL is used as a safety device, the user has the responsibility to insure that applicable national, federal and local safety rules, codes and regulations are satisfied. In addition, the user should insure that all

machine operators, maintenance personnel, electricians, supervisors, etc. are familiar with and understand

all instructions regarding the use of the F3SL, the machinery on which it is installed and the appropriate

safety regulations.

Perimeter guarding installations must not allow a machine or robot to restart automatically. Use a start switch

placed outside and within view of the hazardous area.

Disconnect power before removing end caps.

Use of Exact Channel Select and/or Floating Blanking will make the F3SL system less sensitive to objects in

the detection zone. Improper use of either can result in severe injury to personnel. Exact Channel Select

may require a hard barrier guard (see “9-2-1 Additional Guarding” on page 9-2-1 Additional Guarding 19),

Exact Channel Select or Floating Blanking may require an increase in the safety distance. Read the following section carefully.

Using Exact Channel Select with Floating Blanking is an advanced feature. All situations which may occur to

the F3SL system detection zone must be carefully considered. The F3SL system may be less sensitive to

objects in the detection zone. The safety distance must be increased. Failure to do so may cause serious

injury.

To prevent a hand or other objects to enter the channel-selected part, provide a physical guard such as a

fence.

This product is designed for use on a 24 VDC, negative ground (protective earth) electrical system only.

Never connect the F3SL to a positive ground (protective earth) system. With a positive ground (protective

earth) wiring scheme, certain simultaneous shorts of both safety outputs may not be detected and the

guarded machine may not stop resulting is severe operator injury.

Never install a F3SL system without regard to the safety distance. If the F3SL system is mounted too close

to the point of operation hazard, the machine may not stop in time to prevent an operator injury.

Install the F3SL system so as not to be affected by the reflection from the reflective surface. Failure to do so

may cause the system undetectable, resulting in severe operator injury.

Never use only a single safety output to control the machine. Should this single output fail, the machine may

not stop, resulting in severe operator injury. The machine must be connected using both safety outputs.

The tests outlined in the Test Procedure in Appendix B must be performed at installation, according to the

employer’s regular inspection program and after any maintenance, tooling change, set up, adjustment, or

modification to the F3SL system or the guarded machine. Where a guarded machine is used by multiple

operators or shifts, it is suggested that the test procedure be performed at each shift or operation change.

Testing ensures that the light curtain and the machine control system work properly to stop the machine.

Failure to test properly could result in serious injury to personnel.

Page 5

iii

Table of Contents

1 Important Safety Warnings ....................................................................................................................... 1

2 Theory of Operation ................................................................................................................................... 2

2-1 F3SL System Specifications .................................................................................................................. 2

2-2 Technical Specifications ........................................................................................................................ 2

3 System Components and Indicators ........................................................................................................ 4

4 System Operation ...................................................................................................................................... 6

4-1 Operating States .................................................................................................................................... 6

4-1-1 Machine Run ................................................................................................................................... 6

4-1-2 Machine Stop ................................................................................................................................... 6

4-1-3 Interlock ........................................................................................................................................... 6

4-1-4 Alarm ............................................................................................................................................... 6

4-2 Operating Modes ................................................................................................................................... 6

4-2-1 Automatic Start ................................................................................................................................ 6

4-2-2 Start Interlock .................................................................................................................................. 6

4-2-3 Start/Restart Interlock ...................................................................................................................... 6

4-3 Operating Mode Selection ..................................................................................................................... 7

5 Detection Options ...................................................................................................................................... 8

5-1 Exact Channel Select (ECS) .................................................................................................................. 8

5-2 Floating Blanking ................................................................................................................................... 8

5-3 Using Exact Channel Select with Floating Blanking .............................................................................. 9

5-3-1 The Effect of Exact Channel Select and Floating Blanking on Minimum Object Resolution ......... 10

5-4 Activating and Programming Exact Channel Select ............................................................................ 10

5-5 Activating Floating Blanking ................................................................................................................. 11

6 DIAGNOSTIC AND TEST FEATURES ..................................................................................................... 12

6-1 Upper Most/ Lower Most Beam Indicators ........................................................................................... 12

6-2 Synchronization Beam ......................................................................................................................... 12

6-3 Machine Primary Control Element (MPCE) Monitoring ........................................................................ 12

6-3-1 Activating and Deactivating MPCE Monitoring .............................................................................. 12

7 Outputs ..................................................................................................................................................... 13

7-1 Safety Outputs ..................................................................................................................................... 13

7-2 Auxiliary Output ................................................................................................................................... 13

8 Safe Mounting Distance .......................................................................................................................... 14

8-1 European Safety Distance Formulas ................................................................................................... 14

8-1-1 Safety Distance Formula for Systems with a Minimum Object Resolution of 40 mm or Less .......................... 14

8-1-2 Safety Distance Formula for Systems with a Minimum Object Resolution Greater Than 40 mm ..................... 15

8-1-3 Factors Affecting the Safety Distance Formula ............................................................................. 15

8-2 US Safe Distance Formulas ................................................................................................................ 15

9 Installation ................................................................................................................................................ 17

9-1 Reflective Surface Interference ........................................................................................................... 17

9-2 General Considerations ....................................................................................................................... 19

9-2-1 Additional Guarding ....................................................................................................................... 19

9-2-2 Installation of Multiple Systems ..................................................................................................... 19

9-2-3 Access to Configuration Switches ................................................................................................. 20

9-2-4 Detection Zone .............................................................................................................................. 20

9-2-5 Alignment ....................................................................................................................................... 20

9-2-6 Cable Assemblies .......................................................................................................................... 21

9-2-7 Input Power Requirements/Connections ....................................................................................... 21

9-2-8 Special Requirements for Perimeter Guarding .............................................................................. 21

9-2-9 Marking Minimum Object Resolution ............................................................................................. 21

9-2-10 Presence Sensing Device Initiation ............................................................................................. 21

Page 6

iv

10 Connecting To The Machine Control Circuit ....................................................................................... 22

110-1 Connecting Via Two Force-Guided Relays ...................................................................................... 22

10-2 Connection with OMRON safety relay unit Model G9SA ................................................................... 23

11 Checkout and Test Procedures ............................................................................................................ 24

11-1 Checkout Procedure .......................................................................................................................... 24

11-2 Test Procedure .................................................................................................................................. 24

11-3 Using the Test Object ........................................................................................................................ 24

12 Cleaning .................................................................................................................................................. 24

13 Dimensional Drawings and Patents ..................................................................................................... 25

13-1 Dimensional Drawings ....................................................................................................................... 25

13-2 Patents ............................................................................................................................................... 25

14 Troubleshooting ..................................................................................................................................... 26

14-1 Receiver Endcap Indicator Lights ...................................................................................................... 26

14-1-1 Receiver Troubleshooting ............................................................................................................ 26

14-2 Emitter Endcap Indicator Light ........................................................................................................... 26

14-2-1 Troubleshooting the Emitter ........................................................................................................ 26

Appendix A —Checkout Procedure .......................................................................................................... 27

A-1 Checkout Procedure Log ..................................................................................................................... 27

Appendix B —Test Procedure ................................................................................................................... 28

B-1 Test Procedure Log ............................................................................................................................. 28

Page 7

1 Important Safety Warnings

1

1 Important Safety Warnings

A F3SL system is a general purpose presence sensing device designed to guard personnel working around

moving machinery.

Whether a specific machine application and F3SL system installation complies with safety regulations depends

on the proper application, installation, maintenance and operation of the F3SL system. These items are the responsibility of the purchaser, installer and employer.

The employer is responsible for the selection and training of personnel to properly install, operate, and maintain

the machine and its safeguarding systems. A F3SL system should only be installed, verified and maintained by

a qualified person.A qualified person is defined as "a person or persons who, by possession of a recognized

degree or certificate of professional training, or who, by extensive knowledge, training or experience, has successfully demonstrated the ability to solve problems relating to the subject matter and work." (ANSI B30.2-1983)

To use a F3SL system the following requirements must be met:

• The guarded machine

must be able to stop anywhere in its cycle. Do not use a safety light curtain on a press

with a full-revolution clutch.

• The guarded machine must not present a hazard from flying parts.

• The guarded machine must have a consistent stopping time and adequate control mechanisms.

• Severe smoke, particulate matter and corrosives may degrade the efficiency of a safety light curtain. Do not

use the F3SL system in this type of environment.

• All applicable governmental and local rules, codes, and regulations must be satisfied. This is the employer’s

responsibility.

• All safety-related machine control elements must be designed so that a alarm in the control logic or failure

of the control circuit does not lead to a failure to danger.

• Additional guarding may be required for access to dangerous areas not covered by the F3SL system.

• Perform the OMRON test procedure at installation and after maintenance, adjustment, repair or modification

to the machine controls, tooling, dies or machine, or the F3SL system.

• Perform only the test and repair procedures outlined in this manual.

• Follow all procedures in this manual for proper operation of the F3SL system.

The enforcement of these requirements is beyond the control of OMRON. The employer has the sole responsibility to follow the preceding requirements and any other procedures, conditions and requirements specific to his

machinery.

WARNING

Please read this information completely before starting the installation procedure. A F3SL should only be

installed, checked out and maintained by a qualified person. It is important that the user be familiar with the

installation requirements, safe mounting distance, controls and features before using the F3SL.

If the F3SL is used as a safety device, the user has the responsibility to insure that applicable national, federal and local safety rules, codes and regulations are satisfied. In addition, the user should insure that all

machine operators, maintenance personnel, electricians, supervisors, etc. are familiar with and understand

all instructions regarding the use of the F3SL, the machinery on which it is installed and the appropriate

safety regulations.

Page 8

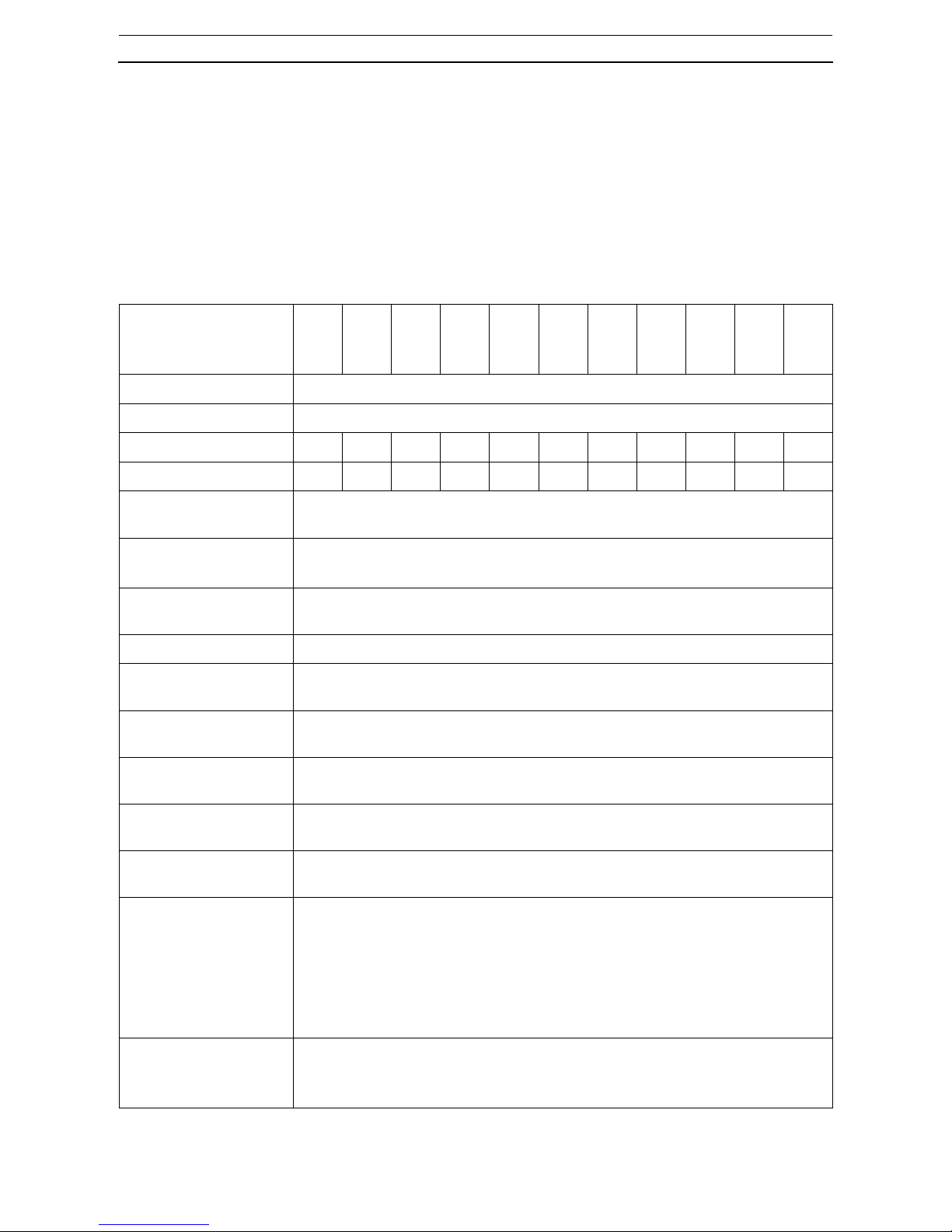

2-1 F3SL System Specifications

2 Theory of Operation

2

2 Theory of Operation

2-1 F3SL System Specifications

The F3SL is a long-range, single-beam infrared safety light curtain designed for machine perimeter guarding

from personal access.A “redundant” microprocessor design combined with extensive fault mode and effects

analysis provides safe, control reliable operation.

A F3SL system consists of one emitter and one receiver. No interconnecting cables or separate control enclosure are required.

2-2 Technical Specifications

Model

Item

Model

F3SLA0351

P30

Model

F3SLA0523

P30

Model

F3SLA0700

P30

Model

F3SLA0871

P30

Model

F3SLA1046

P30

Model

F3SLA1219

P30

Model

F3SLA1394

P30

Model

F3SLA1570

P30

Model

F3SLA1746

P30

Model

F3SLA1920

P30

Model

F3SLA2095

P30

Operating range 0.3-20 m

Optical axis pitch 22 mm

No. of optical axes 16 24 32 40 48 56 64 72 80 88 96

Protective Height

351mm 523mm 700mm 871mm 1,046mm 1,219mm 1,394mm 1,570mm 1,746mm 1,920mm 2,095mm

Minimum Object

Resolution

Opaque object,ø30 mm or more ( ø52/ø74 for floating blanking)

Effective Aperture Angle

Emitter and receiver: ±2.5° maximum, at operating range longer than 3 m

(IEC61496-2).

Light source (emission

waveform)

Infrared LED (850 nm)

Power supply voltage 24 VDC±20%, ripple (p-p) 5% or less

Rise time after power ONWithin 3 seconds

Current consumption Emitter: 285 mA max.

Receiver: 1.4A max.

Control output PNP transistor output x 2 outputs, load current 500 mA or less (residual voltage

2V or less) (excluding voltage drop due to cable extension), ON at light ON.

Auxiliary output Same signal as control output: PNP transistor output x 1 output (non-safety out-

put), load current 100 mA (excluding voltage drop due to cable extension)

Protective circuit Output load is short-circuit protected, inverted power supply connection is pro-

tected.

Safety related features • Start/restart interlock feature [valid/invalid selectable by select switch]

• Blanking feature

(1) Channel select (fix blanking)

(2) Floating blanking

(3) No blanking (at ex-factory)

Either of the above modes is selectable by the select switch. Blanking beam of

(1) is determined by programming button for teaching.

Diagnostic features • Self-diagnostic feature at power ON

• External relay (MPCE) monitoring feature (connect external relay monitor input

line to contact b of external relay, 50 mA, 24 VDC)

Page 9

2 Theory of Operation

2-2 Technical Specifications

3

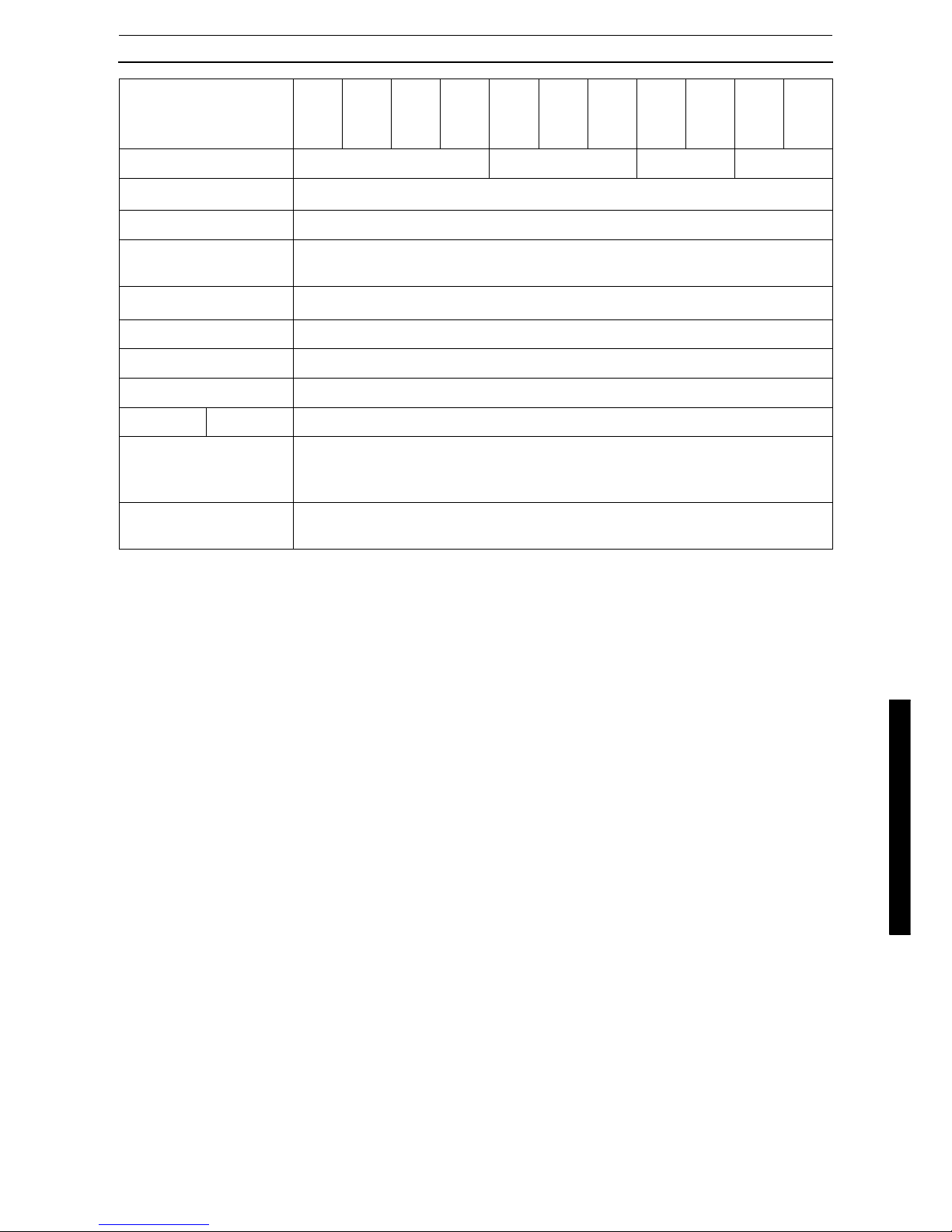

*1. ESPE(Electro-Sensitive Protective Equipment)

*2. AOPD(Active Opto-electronic Protective Devices)

*Specifications subject to change without notice.

Response time (ON-->OFF)

20 ms or shorter 25 ms or shorter 30 ms or shorter 35 ms or shorter

Ambient temperature

0-55

°C at operation and storage (non-icing, non-condensing)

Ambient humidity 35-95% RH at operation and storage (non-condensing)

Resistance to vibration

Malfunction and durability: 10-55 Hz, double amplitude 0.7 mm, X, Y and Z-direction, 20 sweeps

Shock resistance

Malfunction and durability: 100 m/s

2

, X, Y and Z-direction, 1000 times

Protective structure IEC60529 IP65

Connecting method M12 connector type

Weight (packaged) 11 kg or less

Material

Case

Aluminum

Accessories Test rod(ø30), mounting hardware (top, bottom), operating instructions, hexago-

nal wrench exclusive for program button access, 2 load resistors for test (10 k ),

2 surge killer

Applicable standard IEC(EN)61496-1 TYPE4 ESPE *1

IEC61496-2 TYPE4 AOPD *2

Model

Item

Model

F3SLA0351

P30

Model

F3SLA0523

P30

Model

F3SLA0700

P30

Model

F3SLA0871

P30

Model

F3SLA1046

P30

Model

F3SLA1219

P30

Model

F3SLA1394

P30

Model

F3SLA1570

P30

Model

F3SLA1746

P30

Model

F3SLA1920

P30

Model

F3SLA2095

P30

Ω

Page 10

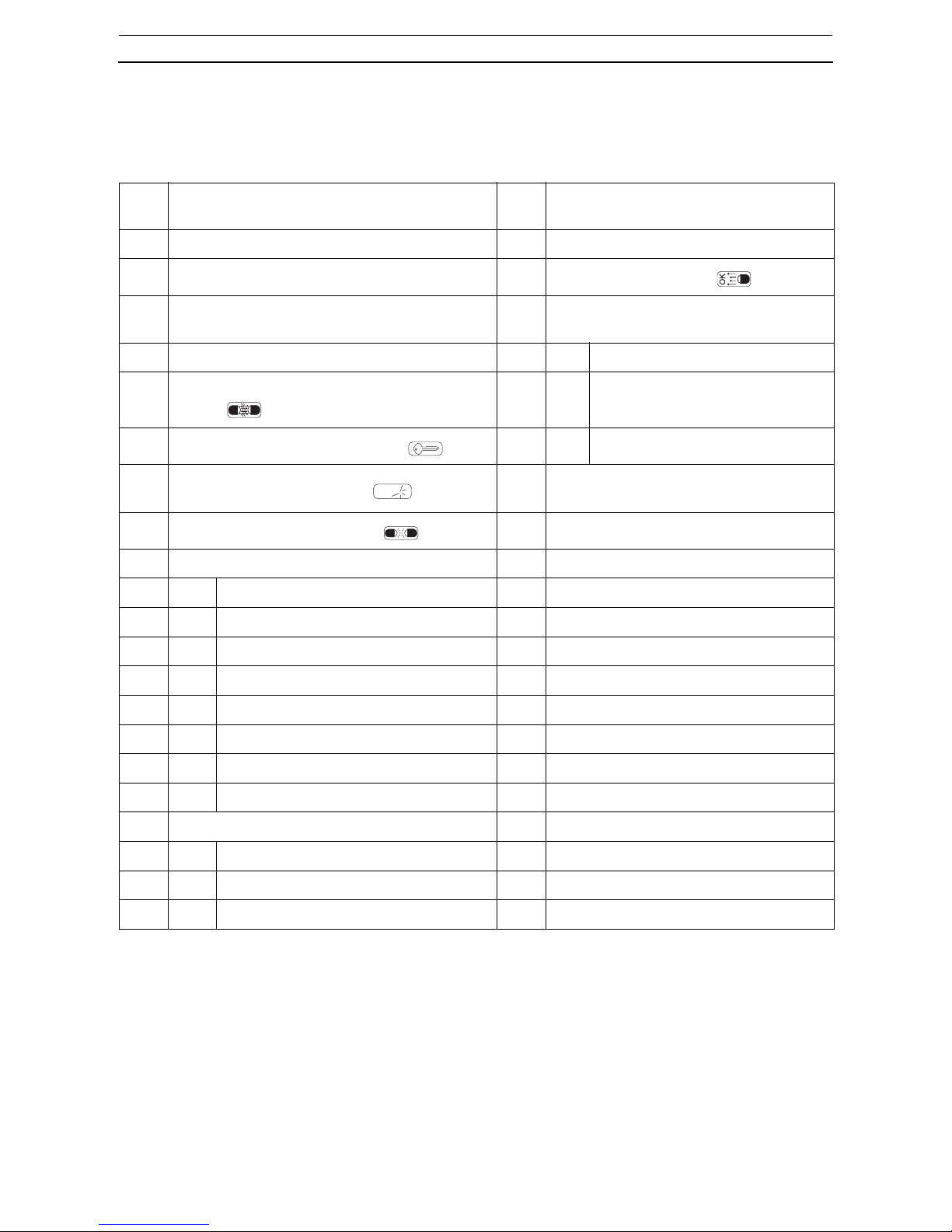

3 System Components and Indicators

4

3 System Components and Indicators

Refer to “Figure 3-1” on page 5 for the location of the components and indicators listed below.

Table 3-1 System Components Identification

Note: OSSD outputs must have a minimum load or the F3SL system will enter an alarm condition. For the pur-

pose of testing prior to final installation, this load can be supplied by a 10K ohm resistor (included in documentation kit). See Figure 7-1 for details.

Chart

#

Chart

#

C RECEIVER N EMITTER

D

Upper Most/Lower Most Beam Indicators - Red

O

Status Indicator - Yellow

E

Removable End Cap. Access to configuration

switches

P

Emitter connections

F Program button (must remove security screw) 10 Drain - Shield(Uninsulated) Wire

G

Channel Select or Floating Blanking Indicator Yellow

11 +24VDC - White Wire

H

Interlock or Fault Indicator - Yellow

12 0VDC(GND) - Brown Wire

I

Machine Stop Indicator - Red

Q

Synchronization Beam

J

Machine Run Indicator - Green

R

Optical axis

K Receiver connections S Protective height (detection zone)

1 OSSD1 - Orange Wire (see note below)

2 0VDC(GND) - Brown Wire

3 Drain - Shield(Uninsulated) Wire

4 +24VDC - White Wire

5 Auxiliary Out - Violet Wire

6 MPCE - Pink Wire

7 Start - Gray Wire

8 OSSD2 - Yellow Wire (see note below)

L Inside Receiver End Cap

B Switch B

A Switch A

M Connector

☛

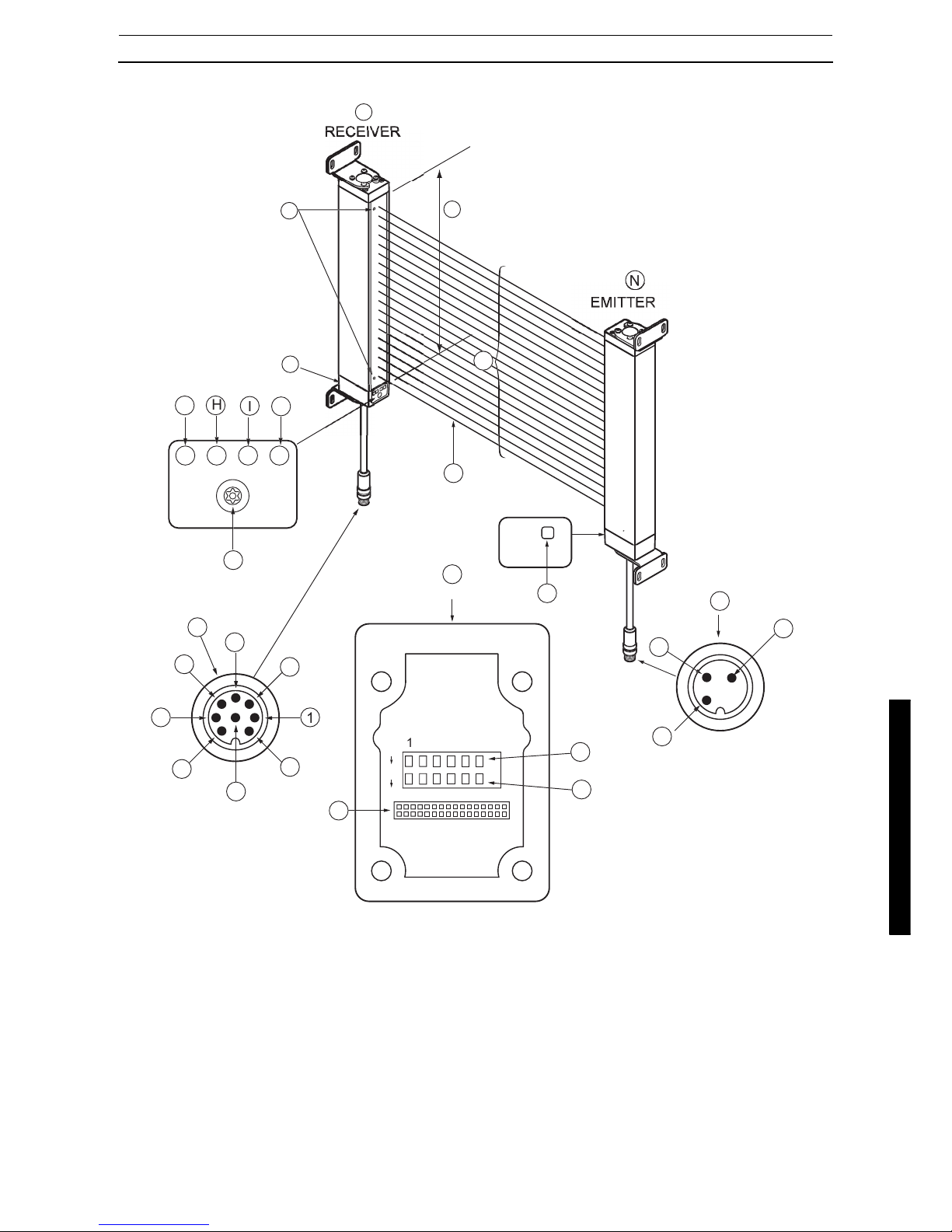

Page 11

3 System Components and Indicators

5

Figure 3-1 System Drawing

O

C

INDICATOR SIDE

1

3456

Page 12

4-1 Operating States

4 System Operation

6

4 System Operation

A F3SL system is a microprocessor-controlled, infrared transmitted-beam safety light curtain. The system consists of a receiver assembly and a emitter assembly. The receiver and emitter assemblies are not physically interconnected.

F3SL system is often used where personnel protection is required. Typical applications include robotic work

cells, filter presses, injection molders, food processing equipment and automated assembly equipment.

4-1 Operating States

The operating condition of a F3SL system is described in terms of states. The following operating states exist

for the F3SL system.

4-1-1 Machine Run

The two receiver safety outputs are in the ON state, the green machine run indicator is lit, and the auxiliary output

is in a state consistent with its configuration. See Section 7-2 on page 13. The protected machine is allowed to

operate. Pressing and releasing the start button has no effect.

4-1-2 Machine Stop

The two receiver safety outputs are in the OFF state, the red machine stop indicator is lit, and the auxiliary output

is in the follow state consisitent with the safety outputs. See Section 7-2 on page 13. The protected machine is

not allowed to operate.

4-1-3 Interlock

The two receiver safety outputs are in the OFF state, the red machine stop indicator and yellow interlock indicator are lit. The auxiliary output is in the follow state consisitent with the safety outputs. See Section 7-2 on page

13. The interlock state does not allow the protected machine to operate until the detection zone is clear of obstructions and the start button is pressed and released.

4-1-4 Alarm

The two receiver safety outputs are in the OFF state, the red machine stop indicator is lit, the yellow interlock

indicator is flashing, and the auxiliary output is in the OFF state. The alarm state does not allow the protected

machine to operate. The primary difference between alarm and interlock is that the F3SL system will remain in

the alarm state until the alarm is corrected, regardless of power cycling or an external start button press and

release.

4-2 Operating Modes

System operating modes determine the start-up and operating behavior of a F3SL system. Operating mode definitions rely on the operating states presented above. Operating mode selection is performed via configuration

switches in the removable cap on the bottom of the receiver.

Note: If internal alarms are detected by the F3SL system during power-up or operation, it will enter the alarm

state with its safety outputs in the OFF state.

4-2-1 Automatic Start

A F3SL system will power-up with its safety and auxiliary outputs OFF, and, if the detection zone is not obstructed, enter the machine run state. In this state, when an object is sensed entering the detection zone, the F3SL

system will change from machine run to machine stop and remain in this state until the obstruction is removed.

Once the detection zone is clear, the F3SL system will automatically change from machine stop to machine run.

4-2-2 Start Interlock

The F3SL system will power-up with its safety outputs OFF, and, if no alarms are detected, enter the interlock

state. To enter the machine run state, the detection zone must be clear (or an Exact Channel Select pattern satisfied), and then the operator must press and release the Start button. In the machine run state, when an object

is sensed entering the detection zone the F3SL system will change from machine run to machine stop. Once the

detection zone is clear, the F3SL system will automatically change from machine stop to machine run.

4-2-3 Start/Restart Interlock

A F3SL system will power-up with its safety outputs OFF, and, if no alarms are detected, enter the interlock state.

To enter the machine run state, the detection zone must be clear (or an Exact Channel Select pattern satisfied),

☛

Page 13

4 System Operation

4-3 Operating Mode Selection

7

and then the operator must press and release the Start button. In the machine run state, when an object is

sensed entering the detection zone the F3SL system will change from machine run to interlock. The F3SL system will remain in the interlock state even after the obstruction is removed from the detection zone. To enter the

machine run state, the operator must press and release the start button. If any obstruction is present in the detection zone when the start button is pressed and released, the F3SL system will remain in the interlock state.

Note: The definitions above mention a start button. See Section 10–“Connecting To The Machine Control Cir-

cuit” for wiring of the start button.

4-3 Operating Mode Selection

Operating mode is selected by setting positions 1 and 2 of Switches A and B, located inside the receiver end

cap. Refer to Table 4-1. Any mismatch between the settings of Switch A and B will result in an alarm condition.

To access Switches A and B, remove the four captive screws which secure the largest receiver end cap. Set

these switches before mounting the recieiver.

WARNING

Perimeter guarding installations must not allow a machine or robot to restart automatically. Use a start switch

placed outside and within view of the hazardous area.

WARNING

Disconnect power before removing end caps.

Table 4-1 Operating Mode Switch Settings

SWITCH A SWITCH B

OPERATING MODE1212

Automatic Start (default setting) ON ON ON ON

Start interlock OFF ON OFF ON

Start/Restart interlock OFF OFF OFF OFF

Not Allowed ON OFF ON OFF

Page 14

5-1 Exact Channel Select (ECS)

5 Detection Options

8

5 Detection Options

5-1 Exact Channel Select (ECS)

ECS disables selected, fixed areas of the detection zone by masking off specific, fixed beam locations. ECS is

helpful when stationary objects such as tooling and fixtures permanently obstruct a portion of the detection zone.

ECS requires that any portion of the detection zone which is blocked remain blocked. If the obstruction is removed the F3SL system will enter a machine stop state. The synchronization beam (the beam nearest to the

cable) cannot be selected. Also, one additional beam must remain unblocked. A channel is defined as one emitter/receiver pair or “beam”.

See "Table 5-1 System Response to Exact Channel Select" on page 8 for a diagram of F3SL system response

during operation with ECS active.

5-2 Floating Blanking

Up to two channels can be disabled at any location in the detection zone (except for the synchronization beam)

without the F3SL system going to the machine stop state. The disabled channels are not fixed at a single location

but “float” through the detection zone.

See Table 5-2 for a diagram of F3SL system response during operation with Floating Blanking active.

WARNING

Use of Exact Channel Select and/or Floating Blanking will make the F3SL system less sensitive to objects in

the detection zone. Improper use of either can result in severe injury to personnel. Exact Channel Select

may require a hard barrier guard (see “9-2-1 Additional Guarding” on page 19), Exact Channel Select or

Floating Blanking may require an increase in the safety distance. Read the following section carefully.

Table 5-1 System Response to Exact Channel Select

Channel Select

Status

Exact Channel Select

Inactive

Exact Channel Select

Inactive

Exact Channel Select

Active

Exact Channel Select

Active

Exact Channel Select

Active

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5...

System

Response

machine run machine stop machine run machine stop machine stop

Page 15

5 Detection Options

5-3 Using Exact Channel Select with Floating Blanking

9

5-3 Using Exact Channel Select with Floating Blanking

When both Exact Channel Select and Floating Blanking are selected, the floating channels are allowed to occur

anywhere within the detection zone (except for the beam nearest the cable), even within the area selected by

Exact Channel Select. In these areas, a channel that should normally be blocked is allowed to be clear.

Table 5-2 System Response to Floating Blanking

Floating

Blanking

Inactive

1

Channel

Floating

Blanking

Active

1

Channel

Floating

Blanking

Active

1

Channel

Floating

Blanking

Active

1

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

2

Channel

Floating

Blanking

Active

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5...

System Response

1

Exception

machine stop

0

Exceptions

machine

run

1

Exception

machine

run

2

Exceptions

machine stop

2

Exceptions

machine stop

0

Exceptions

machine

run

1

Exception

machine

run

2

Exceptions

machine

run

2

Exceptions

machine

run

3

Exceptions

machine stop

3

Exceptions

machine stop

3

Exceptions

machine stop

Table 5-3 Icon Key for Tables 5-1 and 5-2

Symbol Description

= Optical channel is not blocked.

= Optical channel is blocked.

= Optical channel is selected by Exact Channel Select.

= Optical channel is selected by Exact Channel Select and is blocked.

WARNING

Using Exact Channel Select with Floating Blanking is an advanced feature. All situations which may occur to

the F3SL system detection zone must be carefully considered. The F3SL system may be less sensitive to

objects in the detection zone. The safety distance must be increased. Failure to do so may cause serious

injury.

To prevent a hand or other objects to enter the channel-selected part, provide a physical guard such as a

fence.

Page 16

5-4 Activating and Programming Exact Channel Select

5 Detection Options

10

5-3-1 The Effect of Exact Channel Select and Floating Blanking on Minimum Object

Resolution

When Exact Channel Select and/or Floating Blanking is active, the safety distance is affected. Exact Channel

Select and Floating Blanking desensitize the light curtain and increase the size of the minimum object detected.

The increase is equal to the channel spacing distance for each channel that is disabled.

• A F3SL system with one channel disabled has a minimum object sensitivity of:

30mm + 22mm =52mm (2.05 inches).

• A F3SL system with two channel disabled has a minimum object sensitivity of:

30mm + 22mm + 22mm =74mm (2.91 inches).

If the size of the object detected by the F3SL system increases, the minimum safe distance must increase. Use

the minimum object sensitivity given in to determine the new figure to use when computing the safety distance.

5-4 Activating and Programming Exact Channel Select

Exact Channel Select is activated by setting position 4 of Switches A and B, located inside the receivere end

cap. Refer Figure 3-1 and Table 5-5. Any mismatch between the settings of Switches A and B will result in a

alarm condition. To access Switches A and B, remove the four captive screws which secure the largest receiver

end cap. Set these switches before mounting the receiver.

To program an ECS pattern, the F3SL system must be in the machine stop state. An ECS pattern is stored by

blocking the appropriate area of the detection zone and pressing, then releasing the program button (See Figure

3-1 for location).

The F3SL system will then enter the interlock or machine stop condition, regardless of the operating mode. The

Start button may be pressed-and-released or power may be cycled to enter the machine run state. Subsequent

power cycles will result in operation in accordance with the configured operating mode.

A new ECS pattern is recorded when the system is in the machine stop state with no alarms, the configuration

switches are correctly set, and the Program button is pressed and released. If the configuration switches are

subsequently set to disable ECS, the stored ECS pattern is cleared.

Note: The Program button is accessed by removing a tamper-resistant screw. A wrench which matches this

screw is provided in the receiver hardware package. This wrench should be kept under supervisor control. The tamper-resistant screw must be replaced to maintain the environmental integrity of the F3SL

system.

Table 5-4 Sample and D

pf

Factors

Total Number of Beams

Disabled by Exact Channel

Select and/or Floating Blanking

Minimum Object Resolution d Depth Penetration Factor, Dpf

for use with ANSI Formula (Dpf

= 3.4 (d-7.0) mm)

None 30 mm (1.18 inches) 78.2mm (3.08 inches)

1 Beam 52 mm (2.05 inches) 153.0 mm (6.02 inches)

2 Beams 74 mm (2.91 inches) 227.8 mm (8.97 inches)

3 Beams 96 mm (3.78 inches) 302.6 mm (11.91 inches)

4 Beams 118 mm (4.65 inches) 377.4 mm (14.86 inches)

5 Beams 140 mm (5.51 inches) 452.2 mm (17.80 inches)

etc...

WARNING

Disconnect power before removing end cap.

Page 17

5 Detection Options

5-5 Activating Floating Blanking

11

5-5 Activating Floating Blanking

Floating Blanking (either one- or two- beam) is activated by setting positions 5 and 6 of Switches A and B located

inside the receiver end cap. Refer to Figure 3-1 and Table 5-5. Any mismatch between the settings of Switch A

and B will result in an alarm condition. To access Switches A and B, remove the four captive screws which secure the largest receiver end cap. Set these switches before mounting the receiver. Use of the program button

is not required.

Note: When ECS or Floating Blanking is active, the amber ECS/FB Indicator will illuminate to indicate that the

F3SL system is operating in a less sensitive state.

Table 5-5 Detection Option Switch Settings

SWITCH A SWITCH B

OPERATING MODE 456456

Exact Channel Select Active ON

ON

Exact Channel Select Inactive

(default setting)

OFF

OFF

One-channel Floating Blanking Active ON OFF ON OFF

Two-channel Floating Blanking Active OFF ON OFF ON

Floating Blanking Inactive (default setting) OFF OFF OFF OFF

Not Allowed – alarm Condition ON ON ON ON

Page 18

6-1 Upper Most/ Lower Most Beam Indicators

6 DIAGNOSTIC AND TEST FEATURES

12

6 DIAGNOSTIC AND TEST FEATURES

6-1 Upper Most/ Lower Most Beam Indicators

The F3SL system has a visible, red Upper Most/Lower Most Beam Indicators (BI), adjacent to one for upper most

and another one for lower most infrared beam. These BI are located on the receiver. The BI will light when the

infrared beam fails to meet the conditions necessary for the F3SL system to remain in the machine run state.

When the synchronization beam is broken, all BI will light.

BI are not a safety critical component. An BI failure will not cause a alarm condition and the F3SL system will

continue to operate.

6-2 Synchronization Beam

Synchronization between the F3SL system emitter and receiver is optical. The beam closest to the cable connector supplies this signal. When this beam is blocked, the system will enter a machine stop state and both

Beam Indicators (BI) will light. When the beam is cleared, the system will resynchronize itself and enter a state

consistent with its operating mode.

6-3 Machine Primary Control Element (MPCE) Monitoring

MPCE monitoring is an important safety function. It monitors the F3SL system interface to the guarded machine

and checks to ensure that the control elements are responding correctly to the light curtain and to detect any

inconsistency between the two machine MPCE. This is necessary to detect a malfunction within the interface

which presents a stop signal from reaching the machine controller.

Connections for MPCE monitoring are made at the receiver. On power-up, the F3SL system looks for an MPCE

closed condition. If this is found, it will enter a state consistent with the selected operating mode. When the F3SL

system enables its safety outputs, it monitors the MPCE for a closed-to-open transition. This transition must occur within 300 ms or the F3SL system considers the MPCE alarmed. The F3SL system will then enter an alarm

state. Additionally, if the MPCE connectors are incorrectly wired, the F3SL system will enter an alarm state.

Note: For proper operation of the F3SL system when MPCE is not active, the MPCE input must be wired to the

F3SL system ground.

6-3-1 Activating and Deactivating MPCE Monitoring

MPCE monitoring is activated by setting position 3 of Switches A and B located inside the receiver end cap. Refer to Figure 3-1 and Table 6-1. Any mismatch between the settings of Switches A and B will result in an alarm

condition. To access Switches A and B, remove the four captive screws which secure the largest receiver end

cap. Set these switches before mounting the receiver.

WARNING

Disconnect power before removing end caps.

Table 6-1 MPCE Switch Settings

Switch A Switch B

MPCE MONITORING

ACTIVE OR NOT ACTIVE

33

Active OFF OFF

Not Active (default setting) ON ON

Page 19

7 Outputs

7-1 Safety Outputs

13

7 Outputs

7-1 Safety Outputs

The F3SL system receiver supplies two independent PNP-type, safety outputs to provide run/stop signals to the

guarded machine. In the machine run state, the safety outputs are electrically conducting and source 500 milliamps of current at 24 VDC. In the machine stop state, the outputs are not electrically conducting.

Note: The safety outputs must have a minimum load or the F3SL system will enter a alarm condition. For the

purpose of testing prior to final installation, this load can be supplied by a 10K ohm resistor (included in

documentation kit). See Figure 7-1 for details

.

Figure 7-1 Connection of load to safety outputs for testing.

7-2 Auxiliary Output

This is not a safety output. F3SL systems suplies one PNP-type auxiliary output.In the on state, this Auxiliary

output will source up to 100mA, and will be on when the safety outputs are on. (Follow mode)

WARNING

This product is designed for use on a 24 VDC, negative ground (protective earth) electrical system only.

Never connect the F3SL to a positive ground (protective earth) system. With a positive ground (protective

earth) wiring scheme, certain simultaneous shorts of both safety outputs may not be detected and the

guarded machine may not stop resulting is severe operator injury.

24 VDC

SUPPLY

OSSD1 OSSD2 0 V

24 V+

10K ohm 10K ohm

Page 20

8-1 European Safety Distance Formulas

8 Safe Mounting Distance

14

8 Safe Mounting Distance

A F3SL system must be mounted far enough from the machine danger zone so the machine will stop before a

hand or other body part reaches the hazardous area. This distance is called the safety distance. It is a calculated

number based on a formula. See Figure 8-1 for an illustration of the safety distance.

Figure 8-1 Safe Mounting Distance

Regardless of the calculated distance, a F3SL system should never be mounted closer than 5.5 inches

(140 mm) from the point of operation hazard. This is required by Table 0-10 in OSHA 1910.217.

8-1 European Safety Distance Formulas

The following discussion is based on standard EN999:1998 and applies to light curtains used in industrial

environments.

8-1-1 Safety Distance Formula for Systems with a Minimum Object Resolution

of 40 mm or Less

When the minimum object resolution of the system is 40 mm or less, use the following formula:

S = (K x T) + C

where:

S = the minimum distance in millimeters, from the danger zone to the detection point, line, plane or zone.

K = 2000 mm/s

T = the overall system stopping performance in seconds.

T = t

m

+ t

s

tm = maximum stopping time of the machine is seconds.

t

s

= response time of the safety light curtain in seconds.

This response time is given in 2-2 Technical Specifications.

C = 8(d-14 mm), but not less than zero.

d = the minimum object detection of the F3SL system in millimeters.

i.e.:

S = (2000 mm/s x T) + 8(d – 14 mm)

WARNING

Never install a F3SL system without regard to the safety distance. If the F3SL system is mounted too close

to the point of operation hazard, the machine may not stop in time to prevent an operator injury.

Light Curtain

D

s

Ds is the minimum safe distance

between the light curtain sensing

field and the point of operation

hazard (pinch point).

Page 21

8 Safe Mounting Distance

8-2 US Safe Distance Formulas

15

<Calculation example>

Under the conditions of T

m

= 0.05s, Ts=0.02s and d=30 mm,

S = 2000 mm/s x (0.05

s

+0.02s) + 8 (30 mm-14 mm)

= 268 mm

This formula applies for all minimum distances of S up to and including 500 mm. The minimum value of S shall

not be less than 100 mm.

If S is found to be greater than 500 mm using the formula above, then the formula below can be used. In this

case the minimum value of S shall not be less than 500 mm.

S = (1600 mm/s x T) + 8(d – 14 mm)

8-1-2 Safety Distance Formula for Systems with a Minimum Object Resolution Great-

er Than 40 mm

When the minimum object resolution of the system is greater than 40 mm, use the following formula:

S = (K x T) + C

where:

S = the minimum distance in millimeters, from the danger zone to the detection point, line, plane or zone.

K = 2000 mm/s

T = the overall system stopping performance in seconds.

T = t

m

+ t

s

tm = maximum stopping time of the machine is seconds.

t

s

= response time of the safety light curtain in seconds.

This response time is given in Section 2-2—Technical Specifications.

C = 850 mm.

i.e.:

S = (1600mm x T) + 850mm

8-1-3 Factors Affecting the Safety Distance Formula

When light curtains are used for machine initiation, their minimum object resolution must be 30 mm or smaller

(based on EN 999, other standards may vary). In this case the formula given in Section 8-1-1 applices except

that the minimum distance S shall be greater than 150 mm./

For parallel approach the formula for C becomes:

C = 1200 mm – (0.4 x H), but not less than 850 mm

H = the height of the detection zone above the floor in mm.

8-2 US Safe Distance Formulas

In the United States two formulas exist to properly determine the safety distance. OMRON recommends the formula provided by the American National Standards Institute (ANSI) which incorporates additional factors when

compared to the formula required by OSHA.

The ANSI formula given below is for a normal approach to the light curtain.

D

s

= K x (Ts + Tc + Tr + Tbm) + D

pf

Where:

Ds = minimum safety distance, in inches, between the F3SL detection zone and the nearest point of operation

hazard.

K = hand speed constant in inches per second. The ANSI standard value is 63 inches/second which assumes

the operator starts a hand motion toward the point of operation from rest. According to ANSI B11.19-1990, “The

value of the hand speed constant, K, has been determined by various studies and although these studies indicate speeds of 63 in./sec. to over 100 in./sec., they are not considered conclusive determinations. The user

should consider all factors, including the physical ability of the operator, when determining the value of K to be

used.”

Page 22

8-2 US Safe Distance Formulas

8 Safe Mounting Distance

16

T

s

= the stop time of the press (or machine) in seconds, measured from the final de-energized control element.

Measured at maximum closing velocity.

T

c

= the response time, in seconds, of the press or machine control circuit to activate the machine’s brake.

Note: T

s

+ Tc is usually measured together by a stop time measuring device.

T

r

= the response time of the F3SL system, in seconds.

This response time is given in 2-2 Technical Specifications on page 2.

T

bm

= the additional stopping time, in seconds, allowed by the brake performance monitor before it detects stop

time deterioration.

The T

bm

factor allows consideration for brake wear, adding extra stop time allowed by the brake monitor. There-

fore, T

bm

= Brake monitor set point - (Ts + Tc).

Note: If the guarded machine is not equipped with a stop time performance monitor, a percentage increase fac-

tor should be applied to the stop time of the machine to allow for braking system wear. Contact your machine manufacturer for information.

D

pf

= This is related to the minimum object sensitivity of the F3SL system. By knowing the minimum object sen-

sitivity, S, of the F3SL system, D

pf

is read directly from Table 5-4 depending on the F3SL model being installed.

Page 23

9 Installation

9-1 Reflective Surface Interference

17

9 Installation

9-1 Reflective Surface Interference

A reflective surface adjacent to the detection zone can deflect the optical beam and may cause an obstruction

in the zone not to be detected. (See Figure 9-2 and Figure 9-3.) The reflective surface may be part of the machine, mechanical guard or workpiece. Therefore, a minimum distance (d) must exist between the reflective object and the center line of the F3SL detection zone. The Test Procedure (Appendix B) must be used to test for

this condition.

Figure 9-1 Correct Mounting Example with Proper Alignment

.The interruption is clearly detected. The reflective object is outside of the beam angle.

Figure 9-2 Unsafe Mounting Example

The interruption is not detected because of the reflection. The reflective object is inside the beam angle.

WARNING

Install the F3SL system so as not to be affected by the reflection from the reflective surface. Failure to do so

may cause the system undetectable, resulting in severe operator injury.

Emitter

Receive

r

Approach direction

Central beam

Light beam interrupted

d

Reflective Surface

Perimeter of danger area

Interruption

a

Beam Angle, a

Operating Range, R

Emitter

Receiver

Approach direction

Central beam

Light beam interrupted

d

Reflective Surface

Perimeter of danger area

Reflection

Interruption

a

Beam Angle, a

Page 24

9-1 Reflective Surface Interference

9 Installation

18

Figure 9-3 Unsafe Mounting Example

Interruption is not detected because of the reflection. Reflective surface interference may also appear above and

below the sensing field.

Figure 9-4 Worst Case Alignment Example

This example shows the minimum distance from the reflective surface, d, to one side of the beam center line.

Figure 9-5 Minimum Distance from a Reflective Surface as a Function of Range

Receiver

Reflective Surface

Perimter of danger area

Reflection

Interruption

a

Sensing Field

Emitter

Emitter

Receiver

Beam Angle, a

d

Reflective Surface

Operating Range, R

a

a

Perimeter of danger area

0

100

300

500

700

900

2m

4m

6m

8m

10m

12m

14m

16m

Minimum distance

Range (m)

18m

20m

1.1m

1.3m

0.3m

d(mm)

Page 25

9 Installation

9-2 General Considerations

19

9-2 General Considerations

9-2-1 Additional Guarding

Areas of access to the point of hazardous operation not guarded by the F3SL system must be protected by suitable means such as a fixed barrier guard, an interlocked guard or a safety mat. See Figure 9-6.

Figure 9-6 Correct Light Curtain Installation Example

9-2-2 Installation of Multiple Systems

When two or more F3SL systems are mounted in close proximity and in alignment with each other, precautions

should be taken to avoid one curtain interfering with another. This can be corrected by mounting the emitters

and receivers back-to-back or stacked. See Figure 9-7 for reference.

Hazard

Zone

D

s

LIGHT CURTAIN

Mechanical

Barrier

Supplemental

Guarding

Example

Page 26

9-2 General Considerations

9 Installation

20

Figure 9-7 Multiple Light Curtain Installation Configurations

9-2-3 Access to Configuration Switches

Switches to configure the F3SL system operating features are located inside the end cap of the receiver and

Exact Channel Select is programmed via a push button accessed from the front of this end cap. If it will be necessary to change the configuration or Exact Channel Select program during operation, access to this cap must

be maintained. When reinstalling end caps, tighten the four slotted end cap screws in a diagonal pattern to a

torque of 7 to 9 in-lbs. (0.8 to 1 Nm)

9-2-4 Detection Zone

The F3SL system detection zone is delineated by the inside edge of the emitter and receiver endcaps. The area

outside these marks is not protected. Position the F3SL system so that it is only possible to access the danger

point through the detection zone.

9-2-5 Alignment

Physical alignment of the emitter and receiver units is easiest when the F3SL system is in the automatic start

operating mode with Exact Channel Select inactive. The units should be in the same plane and at equal height.

The Upper Most/ Lower Most Beam Indicators will light when a beam is out of alignment. See Section 6-1—Upper Most/ Lower Most Beam Indicators for details.

WARNING

Isolate power before removing end cap.

Emitter

Receiver

Machine 2Machine 1

Emitter

Receiver

NOT RECOMMENDED INSTALLATION

This arrangement may be subject

to interference between the two

light curtains.

Emitter

Receiver

Machine 1

Emitter

Receiver

Machine 2

PREFERRED INSTALLATION

The receivers are mounted

back to back.

Machine 1

Receiver

Receiver

Emitter

Emitter

PREFERRED INSTALLATION

An alternating receiver to

transmitter orientation

is suggested.

Page 27

9 Installation

9-2 General Considerations

21

9-2-6 Cable Assemblies

Receiver cable connections are color coded red and emitter cable connections are black. Details of the pin-out

connections for the OMRON-supplied connector are provided in Table 3-1.

9-2-7 Input Power Requirements/Connections

The F3SL system operates directly from 24 VDC ±20%. Power to the F3SL system must come from a dedicated

power supply which meets the requirements of IEC 60204-1 and IEC 61496-1. The F3SL system internally generates voltages for its own use. No other devices should be connected to these voltages.

9-2-8 Special Requirements for Perimeter Guarding

In perimeter guarding applications the F3SL system detection zone is placed around the outside perimeter of a

guarded machine or robot. This placement leaves space for personnel to stand between the detection zone and

the hazardous machine.

In this case, the guarded machine must only be restarted using a switch located outside and with a full view of

the area of hazardous motion. Operation of the F3SL system in the start/restart interlock operating mode is suitable for perimeter guarding.

9-2-9 Marking Minimum Object Resolution

Serial number labels on the emitter and receiver indicate three possible minimum object resolutions. During installation, use a permanent marker to obscure the object resolutions not set. This will depend on whether no

floating blanking, 1-beam or 2-beam floating blanking is set. See Section 5-3-1 for information.

9-2-10 Presence Sensing Device Initiation

Using the light curtain to initiate a machine after an object is removed from the sensing area is called Presence

Sensing Device Initiation (PSDI). Use of PSDI places additional requirements on the guarding and safety controls. It can restrict advanced light curtain features such as Floating Blanking and Exact Channel Select. Good

sources of reference for PSDI include: ANSI RIA 15.06-1999, OSHA 1910.217(h), and ANSI B11.2-1995.

Page 28

10-1 Connecting Via Two Force-Guided Relays

10 Connecting To The Machine Control Circuit

22

10 Connecting To The Machine Control

Circuit

10-1 Connecting Via Two Force-Guided Relays

OMRON model G7SA relays provides force-guided relay outputs for machine control. See Figure 10-1 for the

preferred connection method using two force-guided relays.

Figure 10-1 Connection Method(Connecting Via Two Force-guided Relays)

WARNING

This product is designed for use on a 24 VDC, negative ground (protective earth) electrical system only.

Never connect the F3SL system to a positive ground (protective earth) system. With a positive ground (protective earth) wiring scheme, certain simultaneous shorts of both safety outputs may not be detected and the

guarded machine may not stop resulting is severe operator injury.

Never use only a single safety output to control the machine. Should this single output fail, the machine may

not stop, resulting in severe operator injury. The machine must be connected using both safety outputs.

0V

Ground

MPCE

2

S1

MPCE1MPCE2

Emitter

Receiver

Star t(gr ay)

+24V(white)

0V(brown)

Aux.Output(violet)

Shield

+24V(white)

0V(brown)

Control output 1(orange)

Control output 2(yellow )

M:Machine drive (e.g. three-phase motor)

S1:Start switch for interlock reset (NC contact)

MPCE1 and MPCE2: safety relay with 2 force-guided relays (recommended model: G7SA) and contactor

Shield

PLC

(PNP input)

,et c.

+24

VDC

Power

supply

Note 3

Note 1

Note 5

Note 5

Note 4

Note 1: In regards to MPCE1 and MPCE2, which perform final control of the machine, use safety relays equipped

with a force-guide function (e.g. OMRON model G7SA).

Note 2: If the MPCE monitor function is not used, short circuit the MPCE monitor line (pink) to 0V power supply.

Note 3: When the load is not connected to control outputs 1 and 2, this system will enter error state and not

operate properly. For testing during installation, connect the 10 KW resistor (included in documentation kit)

to the MPCE1 and MPCE2 position.

Note 4: When using this system in automatic start mode, short circuit the start line (gray) to 0V power supply.

Note 5: When wiring, be sure to connect the proper color cords. Note that colors of the power supply lines are

white for +24 VDC; brown for 0V,differing from those of ordinary sensors.

Note 6: Connect the attached surge-killer in parallel to MPCE1 and MPCE2.

Surge-killer

Surge-killer

Note 6

Page 29

10 Connecting To The Machine Control Circuit

10-2 Connection with OMRON safety relay unit Model G9SA

23

10-2 Connection with OMRON safety relay unit Model G9SA

When using in combination with Model G9SA-301, nullify the start/restart interlock and the external relay (MPCE) monitoring

features which are integrated in F3SL, before using the feature equivalent to Model G9SA-301

.

Figure 10-2 Connection Method(

Example of connection to Model G9SA-301 Safety Relay

Unit)

E1

0V

Ground

TH

SA

E2

Emitter

Receiver

Feedback loop

Model F3SL

Light ON

Blocked

Reset switch S1

Contacts K1 & K2 a

Contacts K1 & K2 b

Contacts KM1 & KM2 a

Contacts KM1 & KM2 b

PLC input

PLC output

KM3

S1:Reset switch

KM1 and KM2:Magnet contactor (model LP1D)

KM3:Solid-state contactor (model G3J)

M:3-phase motor

E1 and E2:24VDC power supply (model S82K)

Operation Chart

Star t(gr ay)

+24V(white)

0V(brown)

Aux.Output(violet)

Shield

+24V(white)

0V(brown)

Control output 1(orange)

Control output 2(yellow )

Shield

+24

VDC

MPCE

monitor(pink)

Page 30

11-1 Checkout Procedure

11 Checkout and Test Procedures

24

11 Checkout and Test Procedures

11-1 Checkout Procedure

Once the F3SL system has been configured, mounted, aligned and properly connected to the machine control

system, the initial Checkout Procedure detailed in Appendix A must be performed by qualified personnel. A copy

of the checkout results should be kept with the machine records.

11-2 Test Procedure

The Test Procedure must be performed by qualified personnel. To test the F3SL system with Exact Channel

Select and Floating Blanking disabled, use the OMRON-supplied test object. For applications where Exact

Channel Select or Floating Blanking are enabled, see Table 5-4 to determine the proper size test object.

11-3 Using the Test Object

When using the test object, guide it through the detection zone as shown below.

Figure 11-1 Test Object Pattern

12 Cleaning

Accumulation of oil, dirt and grease on the front filter of the F3SL emitter and receiver can effect the system operation. Clean filters with a mild detergent or glass cleaner. Use a clean, soft, lint-free cloth. Painted F3SL surfaces may be cleaned with a mild de-greasing cleaner or detergent.

WARNING

The tests outlined in the Test Procedure in Appendix B must be performed at installation, according to the

employer’s regular inspection program and after any maintenance, tooling change, set up, adjustment, or

modification to the F3SL system or the guarded machine. Where a guarded machine is used by multiple

operators or shifts, it is suggested that the test procedure be performed at each shift or operation change.

Testing ensures that the light curtain and the machine control system work properly to stop the machine.

Failure to test properly could result in serious injury to personnel.

ST

AR

T

ST

OP

Page 31

13 Dimensional Drawings and Patents

13-1 Dimensional Drawings

25

13 Dimensional Drawings and Patents

13-1 Dimensional Drawings

Figure 13-1 Dimensional Drawing

13-2 Patents

Elements of the electoronics and optics essential to meet the specifications and performance standards of

OMRON controls are covered by one or more of the following U.S.Patent Numbers:5015840; 5281809.

Table 13-1 Emitter and Receiver Lengths

Model A (mm) B (mm) C (mm)

F3SL-A0351P30 351 415 435.3

F3SL-A0523P30 523 587 607.3

F3SL-A0700P30 700 764 784.3

F3SL-A0871P30 871 935 955.3

F3SL-A1046P30 1046 1110 1130.3

F3SL-A1219P30 1219 1283 1303.3

F3SL-A1394P30 1394 1458 1478.3

F3SL-A1570P30 1570 1634 1654.3

F3SL-A1746P30 1746 1810 1830.3

F3SL-A1920P30 1920 1984 2004.3

F3SL-A2095P30 2095 2159 2179.3

ATI

ON

1.4

5

.

8

.

8

2.

00

L

G

1

6

1

6

MTG

)

1.

38

.

0

.

0

1.

97

.D

.

1

FRONT VIEW

IDE VIEW

.2

0

.

1

.4

5

11

LOTS (4

)

.

9

1.

35

4.

3

.2

8

.

0

.

3

.

37

1.

00

25.

4

.

1

2.

33

MTG

)

TO-CENTER

)

SLOT

ENTER

-

16.

6

.

66

10.

2

.4

0

1

7.

3

DETECTION ZONE

)

26.

7

1.

05

.

1

1.

50

4.0

5.

7

2.52

0.2

3

=

262.9/10.35 SHOWN

)

A = DETECTION ZON

E

4.

3

= A

+

.

32

mm (.3

)

INCHES (.01

)

Page 32

14-1 Receiver Endcap Indicator Lights

14 Troubleshooting

26

14 Troubleshooting

14-1 Receiver Endcap Indicator Lights

1. GREEN – The guarded machine is operating.

2. RED - The light curtain is blocked and the guarded machine is not operating.

3. YELLOW interlock- The light curtain is waiting for the start button to be pushed. The guarded machine is not

operating. If the LED is blinking, the light curtain is in a alarm condition.

4. AMBER FB or CS – The light curtain is operating in a reduced resolution mode.

14-1-1 Receiver Troubleshooting

If the yellow interlock LED is blinking:

1. Check the configuration for MPCE Monitoring. If MPCE Monitoring is inactive (via receiver endcap DIP

switches), the input (pink wire) must be connected to system ground. If MPCE is active, the input must be

connected to the normally closed contacts of the control relays of the guarded machine or the monitor terminal of the RM module. See Section 10—Connecting To The Machine Control Circuit for an example.

2. Make sure both DIP switches in the receiver endcap have been set properly and identically.

See Tables 4-1, 5-4 and 6-1 in manual.

3. Verify the power supply is within specified limits (+24V ± 20%).

4. Verify the light curtain is properly connected to the control relays of the guarded machine. If the light curtain

is not intended to be connected to control relays, see Section 7-1—Safety Outputs of manual for instruction.

5. Verify the control relays are within operating limits of the safety outputs. See Section 2-2—Technical Specifications.

6. Verify the cable lengths from the light curtain to the control relays are within specified limits.(Max.60 m is

possible.)

7. Call OMRON.

If the red LED is always on:

1. Verify the yellow LED on the emitter is on.

2. Realign the light curtain.

3. Verify the first beam (synchronization beam) is not obstructed.

14-2 Emitter Endcap Indicator Light

Yellow – The Emitter is active. If the LED is blinking, the light curtain is in a alarm condition.

14-2-1 Troubleshooting the Emitter

If the yellow LED is off:

1. Verify the cable is connected.

2. Verify the power supply is within limits (+24V ± 20%).

3. Call OMRON.

If the yellow LED is blinking:

1. Verify the power supply is within limits (+24V ± 20%).

2. Call OMRON.

Page 33

Appendix A —Checkout Procedure

A-1 Checkout Procedure Log

27

Appendix A —Checkout Procedure

A-1 Checkout Procedure Log

The following checkout procedure must be performed by qualified personnel during initial F3SL system installation and at least every three months or more frequently depending on machine usage and company guidelines.

Machine Identification:

Date:

Technician Signature:

Item Condition Comments

1. Verify that the guarded machine is compatible with the type of machine

which maybe used with the F3SL system. See Section 1—Important

Safety Warnings for further information.

Pass

Fail

2. Verify that the mounting distance of the F3SL system is equal to or

greater than the minimum safe distance from the danger point. See Section 8—Safe Mounting Distance for further information.

Pass

Fail

3. Determine that all access to the danger point not protected by the F3SL

system is guarded by other means, such as gates, fencing or other

approved methods. Verify that all additional guarding devices are installed

and operating properly.

Pass

Fail

4. Make sure the operator is not able to stand between the F3SL system

detection zone and the machine danger point. Verify that the light curtain

can only be reset from a position outside and within view of the hazardous

machine area.

Pass

Fail

5. Inspect the electrical connections between the guarded machine’s con-

trol system and the F3SL system. Verify that they are properly connected

to the machine such that a stop signal from the F3SL system results in an

immediate halt of the machine’s cycle. See Section 10—Connecting To

The Machine Control Circuit.

Pass

Fail

6. If the MPCE monitoring feature is not used, proceed to step 7. To test

the MPCE feature, verify that the feature has been enabled. Turn the

machine power on. Cycle the machine. Place a temporary jumper wire

between the MPCE connections. The F3SL should enter a alarm condition. Remove the temporary jumper. Press and release the start button.

Pass

Fail

7. Record the test results in the machine log, then perform the Test Proce-

dure.

Pass

Fail

Page 34

B-1 Test Procedure Log

Appendix B —Test Procedure

28

Appendix B —Test Procedure

B-1 Test Procedure Log

The following test procedure must be performed by qualified personnel during initial F3SL system installation,

according to the employer’s regular inspection program and after any maintenance, adjustment or modification

to the F3SL system or the guarded machine. Testing ensures that the light curtain, safety system, and machine

control system work together to properly stop the machine. Failure to test properly could result in serious injury

to personnel. To test the F3SL system, use the correct size test object.

Machine Identification:

Date:

Technician Signature:

Item Condition Comments

1. Disable the guarded machine. Apply power to the F3SL system. Pass

Fail

2. Visually inspect the machine to ensure that access to the danger point is

only through the F3SL detection zone. If not, additional guarding, including

mechanical barriers may be required. Verify that all additional guarding

devices and barriers are installed and operating properly.

Pass

Fail

3. Verify that the mounting distance of the F3SL system is equal to or

greater than the calculated minimum safety distance from the danger

point. See Section 8—Safe Mounting Distance for further information.

Ensure that the operator is not able to stand between the F3SL detection

zone and the danger point.

Pass

Fail

4. Check for signs of external damage to the F3SL system, the machine

and the electrical cables and wiring. If damage is found, lock the machine

off and report to the supervisor.

Pass

Fail

5. Interrupt the F3SL system detection zone with the proper size test

object. Move the test object inside the perimeter (along the top, sides and

bottom) of the detection zone and up and down through the center. At least

one Individual Beam Indicator must be lit while the test object is anywhere

in the detection zone. If in automatic start mode, verify that the red

machine start light is lit. If in start/restart interlock mode, verify that the red

machine stop and yellow interlock lights are on. Press and release start

button before proceeding to step 6.

Pass

Fail

6. Start the machine. While the machine is in motion, interrupt the detec-

tion zone with the test object. The machine should stop immediately. Never

insert the test object into the dangerous parts of the machine. With the

machine at rest, interrupt the detection zone with the test object. Verify that

the machine will not start with the test object in the detection zone.

Pass

Fail

7. Verify that the braking system is working properly. If the machine does

not stop fast enough, adjust the braking system or increase the distance

from the detection zone to the danger point.

Pass

Fail

8. If the safety devices or the machine fails any of these tests, do not run

the machine. Immediately tag or lockout the machine to prevent its use

and notify the supervisor.

Pass

Fail

Loading...

Loading...