Omron E5CD-**2**M-004 Series, E5CD-**2**M-002 Series, E5ED-**4**M-004 Series, E5ED-**4**M-022 Series, E5ED-**4**M-008 Series Connection Manual

...Page 1

Machine Automation Controller NJ-series

General-purpose Serial

Connection Guide

(RS-485 CompoWay/F)

OMRON Corporation

Digital Temprature Controller

(E5□D / E5□C / E5□C-T)

P520-E1-02

Page 2

About Intellectual Property Rights and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

Sysmac is a trademark or registered trademark of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

Company names and product names in this guide are the t rademarks or registered trademarks

of their respective companies.

Page 3

Table of Contents

1. Related Manuals ........................................................................................ 1

2. Terms and Definitions ............................................................................... 1

3. Precautions ................................................................................................ 2

4. Overview .................................................................................................... 3

5. Applicable Devices and Device Configuration ....................................... 4

Applicable Devices ............................................................................. 4 5.1.

Device Configuration .......................................................................... 6 5.2.

6. Serial Communications Settings ............................................................. 8

Parameters ........................................................................................ 8 6.1.

Cable Wiring ...................................................................................... 9 6.2.

7. Serial Communications Connection Procedure ................................... 10

Work Flow ........................................................................................ 10 7.1.

Digital Temperature Controller Setup ................................................ 11 7.2.

Controller Setup ............................................................................... 15 7.3.

Serial Communication Status Check ................................................ 30 7.4.

8. Initialization Method ................................................................................ 32

Initializing a Controller ...................................................................... 32 8.1.

Initializing a Digital Temperature Controller ...................................... 33 8.2.

9. Program .................................................................................................... 34

Overview .......................................................................................... 34 9.1.

Destination Device Command .......................................................... 40 9.2.

Error Detection Processing .............................................................. 43 9.3.

Variables .......................................................................................... 44 9.4.

ST Program ...................................................................................... 46 9.5.

Timing Charts ................................................................................... 51 9.6.

Error Processing .............................................................................. 52 9.7.

10. Revision History .................................................................................. 56

Page 4

1.Related Manuals

1

for NJ-series CPU Unit

1. Related Manuals

To ensure system safety, make sure to always read and follow the information provided in all

Safety Precautions and Precautions for Saf e Use in the manuals for each device which is

used in the system.

The table below lists the manuals pertaining to t his guide.

Cat. No. Model Manual name

W500 NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

W501 NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

W502 NJ501-□□□□

NJ301-□□□□

NJ101-□□□□

W504 SYSMAC-SE2□□□ Sysmac Studio Version 1 Operation Manual

W494 CJ1W-SCU□2 CJ-series

NJ-series

CPU Unit

Hardware User's Manual

NJ/NX-series

CPU Unit

Software User's Manual

NJ/NX-series

Instructions Reference Manual

Serial Communications Units

Operation Manual

H225 E5□D Digital Temperature Controllers

Communications Manual

H224 E5□D Digital Temperature Controllers User’s Manual

H175 E5□C Digital Temperature Controllers

Communications Manual

H174 E5□C Digital Temperature Controllers User’s Manual

H186 E5□C-T Digital Temperature Controllers

Programmable Type

Communications Manual

H185 E5□C-T Digital Temperature Controllers

Programmable Type User’s Manual

2. Terms and Definitions

Term Explanation and Definition

Serial Gateway

mode

This is a function of PLC that performs serial communic ations by

automatically converting a message (command data) to a specified

protocol (CompoWay/F, Modbus-RTU, or Modbus-ASCII), depending on

the type of message.

Page 5

3.Precautions

2

Indicates a potentially hazardous situation whi ch, if not avoided,

damage.

Precautions for Correct Use

Additional Information

Symbol

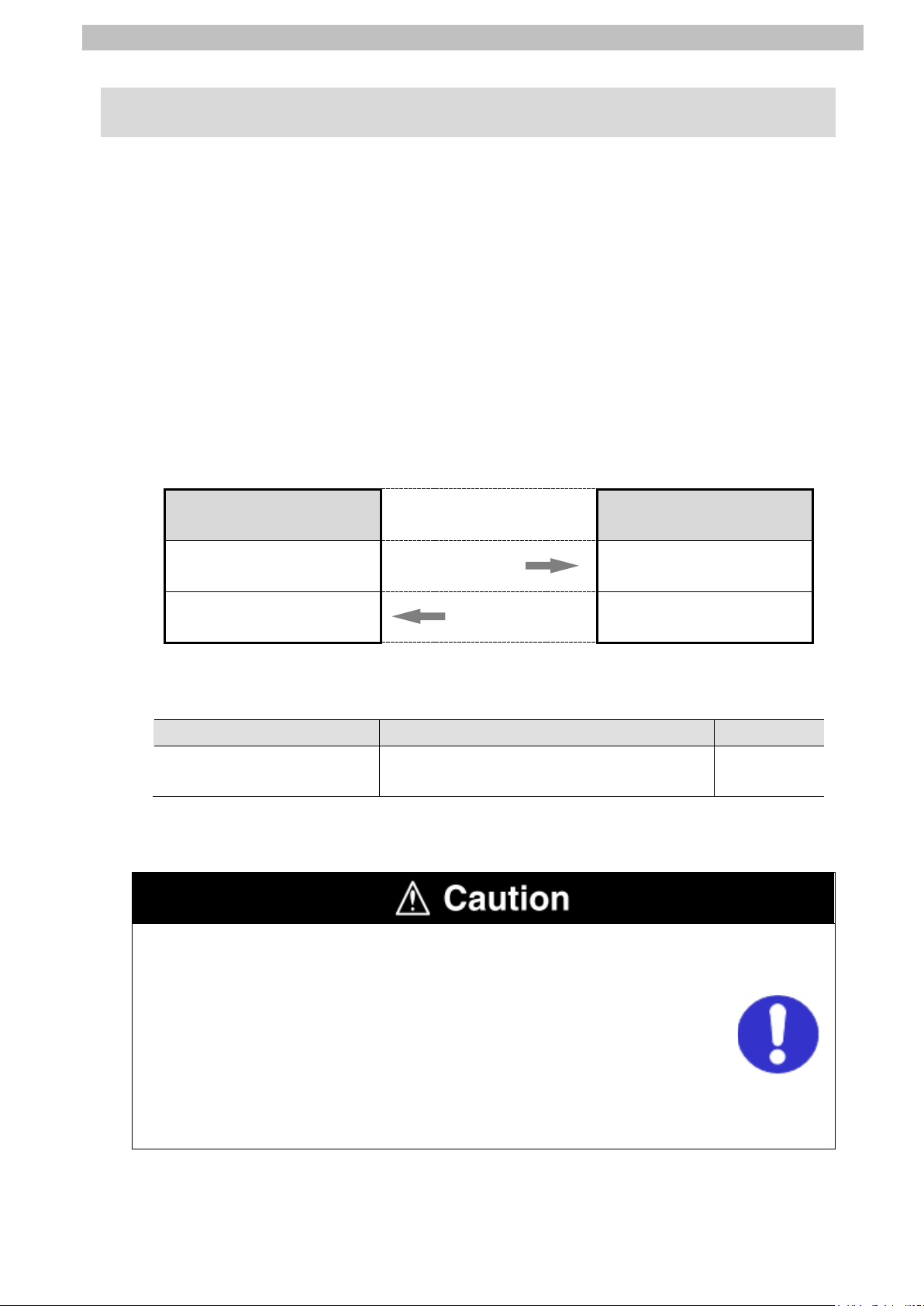

3. Precautions

(1) Understand the specifications of devices which are used in the system. Allow some

margin for ratings and performance. Provide saf ety measures, such as installing a safety

circuit, in order to ensure safety and minimize the risk of abnormal occurrence.

(2) To ensure system safety, make sure to always read and follow the information provided in

all Safety Precautions and Precautions for Safe Use in the manuals for each device

which is used in the system.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or the whole of this guide

without the permission of OMRON Corporation.

(5) The information contained in this guide is current as of March 2018. It is subject to

change for improvement without notice.

The following notations are used in this guide.

may result in minor or moderate injury, or may result in serious

injury or death. Additionally there may be significant property

Indicates a potentially hazardous situation whi ch, if not avoided,

may result in minor or moderate injury or property damage.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase unders tanding or make operation easier.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circl e and explained in the text.

This example shows a general precaution for something t hat you must do.

Page 6

4.Overview

3

Name

File name

Version

Command data

Response data

4. Overview

This guide describes procedures for connecting a Digital Temperature Controller (E5□D,

E5□C or E5□C-T) to an NJ-series Machine Automation Controller + Serial Communications

Unit (hereinafter referred to as the "Controller") via serial communications, both produced by

OMRON Corporation (hereinafter referred to as "OM RO N"), and for checking their

communication status.

Refer to Section 6. Serial Communications Set tings and Section 7. Serial Communications

Connection Procedure to understand setting methods and key points to send or receive a

message via serial communications.

The program in the prepared Sysmac Studio project file is used to check the serial connection

by sending or receiving a message of ''Read Controller Attributes'' to/from the Digital

Temperature Controller.

■The send/receive messages of "Read Controller Attributes''

Controller

Sending command data Executing the command

Receiving response data

and storing in memory

Prepare the Sysmac Studio project file with a lat est version beforehand.

To obtain the Sysmac Studio project file, contact your OMRON representative.

Sysmac Studio project file

(extension: csm2)

Hereinafter, the Sysmac Studio project file is referred to as “the project file".

This guide aims to explain wiring methods and communications settings

necessary to connect corresponding devic es and provides the setting

procedures. The program used in this guide is not designed to be cons tantly

used at a site but is designed to check if the c onnection is properly established.

Both functionalities and performances are therefore not fully considered for the

program.

When you actually construct a system, please us e the wiring methods,

communications settings and setting procedures described in this guide as a

reference, and design a program according to you r appl ication needs.

Serial communications

(RS-485)

Returni ng response data

P520_NJ_CWF485_OMRON_E5CD_V100.

csm2

Digital Temperature

Controller

Ver.1.00

Page 7

4

5. Applicable Devices and Device Configuration

OMRON

NJ-series CPU Unit

NJ501-□□□□

NJ101-□□□□

OMRON

Serial Communications Unit

CJ1W-SCU□2

E5CD-□□2□□M-002

E5EC-T□□4□SM-022

5.Applicable Devices and Device Configuration

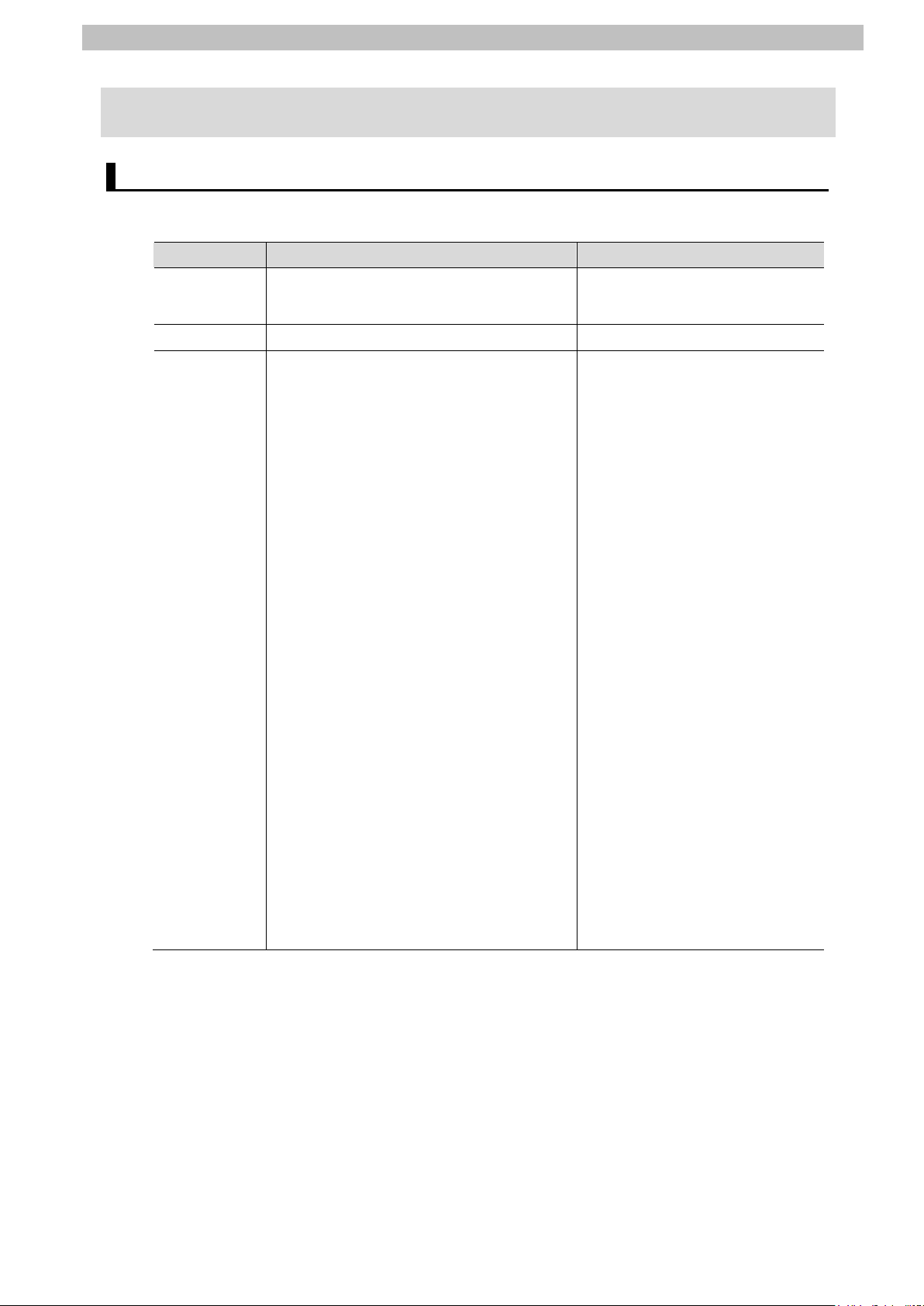

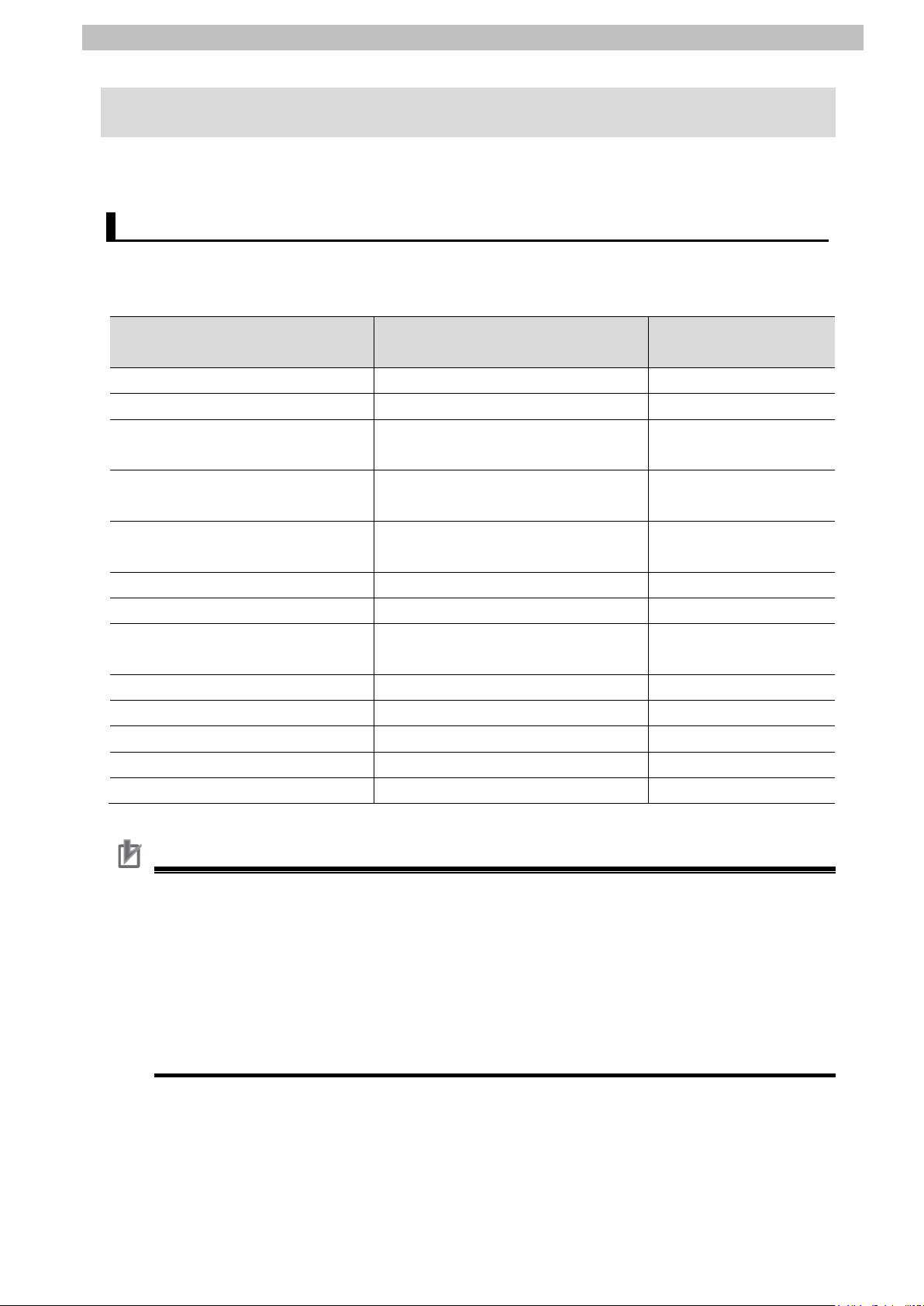

Applicable Devices 5.1.

The applicable devices are as follows:

Manufacturer Name Model

NJ301-□□□□

OMRON Digital Temperature Controller

E5CD-□□2□□M-004

E5ED-□□4□□M-004

E5ED-□□4□□M-008

E5ED-□□4□□M-022

E5CC-□□□□□M-002

E5CC-□□□□□M-003

E5CC-□□□□□M-004

E5AC-□□□□SM-004

E5AC-□□□□SM-008

E5AC-□□□□SM-009

E5AC-□□□□SM-012

E5AC-□□□□SM-014

E5EC-□□□□□M-004

E5EC-□□□□□M-008

E5EC-□□□□□M-009

E5EC-□□□□□M-012

E5EC-□□□□□M-014

E5DC-□□□□□M-002

E5DC-□□□□□M-015

E5GC-□□□□□M-015

E5CC-T□□3□SM-002

E5CC-T□□3□SM-003

E5CC-T□□3□SM-004

E5AC-T□□4□SM-004

E5AC-T□□4□SM-008

E5AC-T□□4□SM-020

E5AC-T□□4□SM-022

E5EC-T□□4□SM-004

E5EC-T□□4□SM-008

E5EC-T□□4□SM-020

Page 8

5.Applicable Devices and Device Configuration

5

Precautions for Correct Use

Additional Information

In this guide, the devices with models and versions listed in 5.2. Device Configuration are

used as examples of applicable devices to des cribe the procedures for connecting the

devices and checking their connection.

You cannot use devices with versions lower than the versions list ed i n 5.2.

To use the above devices with models not listed in 5.2. or versions higher than those listed in

5.2., check the differences in the specifications by referring to t he manuals before operating

the devices.

This guide describes the procedures for establi shing the network connection.

It does not provide information on operation, installation, wiring method, device functional it y,

or device operation, which is not related to the connection procedures.

Refer to the manuals or contact your OMRON representative.

Page 9

5.Applicable Devices and Device Configuration

6

OMRON

Serial Communications Unit

CJ1W-SCU42

Ver.2.0

OMRON

Sysmac Studio

SYSMAC-SE2□□□

Ver.1.21

-

Serial cable (RS-485)

-

Precautions for Correct Use

Precautions for Correct Use

Precautions for Correct Use

Personal computer

NJ501-1500+

CJ1W-SCU42

Serial cable

E5CD-RX2A6M-002

USB cable

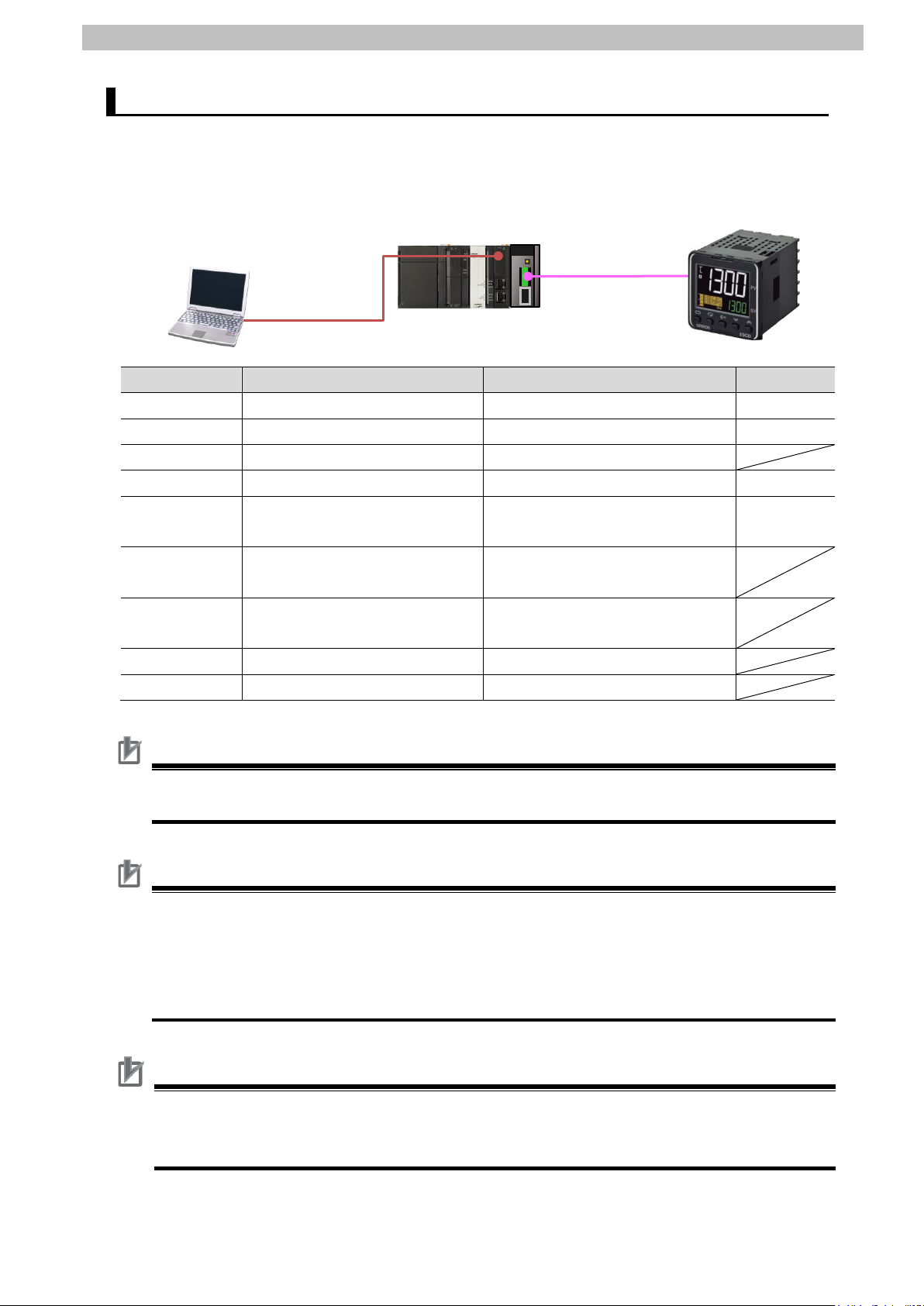

Device Configuration 5.2.

The hardware components to reproduce the connect i on procedures in this guide are as

follows:

(Sysmac Studio installed,

OS: Windows 7)

Manufacturer Name Model Version

OMRON NJ-series CPU Unit NJ501-1500 Ver.1.16

OMRON Power Supply Unit NJ-PA3001

(RS-485)

OMRON Sysmac Studio project file P520_NJ_CWF485_OMRON_E

Ver.1.00

5CD_V100.csm2

- Personal computer

-

(OS: Windows 7)

- USB cable

-

(USB 2.0 type B connector)

OMRON Digital Temperature Controller E5CD-RX2A6M-002

Prepare the project file with a latest version beforeh and.

To obtain the project file, contact your OMRON representative.

Update Sysmac Studio to the version speci fied in this Clause 5.2. or to a higher version.

If you use a version higher than the one specified, the procedures and related screenshots

described in Section 7. and the subsequent sections may not be applicable.

In that case, use the equivalent procedures described in this guide by referring to the Sysmac

Studio Version 1 Operation Manual (Cat. No. W504).

Turn ON the terminating resistance switch on the Serial Communications Unit and connect

120 Ω (1/2 W) terminating resistance to the terminals of the Digital Temperature Controller at

either end of the RS-422A/485 transmission path.

Page 10

7

Additional Information

Operation Manual (Cat. No. W504).

For information on the serial cable (RS-485), refer to 3-3 RS-232C and RS-422A/485 Wiring

of the CJ-series Serial Communications Units Operation Manual for NJ-series CPU Unit (Cat.

No. W494).

Additional Information

The system configuration in this guide uses USB for the connection between the personal

computer and the Controller. For information on how to install the USB driver, refer to A-1

Driver Installation for Direct USB Cable Connection of the Sysmac Studio Version 1

5.Applicable Devices and Device Configuration

Page 11

6.Serial Communications Settings

8

(transmission character)

Baud rate

9,600 bps (default)

9,600 bps (default)

6. Serial Communications Settings

This section describes the parameters and cable wiri ng, which are set up in this guide.

Parameters 6.1.

The following parameters are required to connect t he Controller and the Digital Temperature

Controller via serial communications .

Setting item

Device name J01 Unit No. 0 Communications Unit No.

(slave address)

Serial communications port

(connection)

Terminating resistance Terminating resistance ON

2-wire or 4-wire 2-wire (WIRE: 2) 2-wire (fixed)

Serial communications mode Serial Gateway Data length

(Serial Communications Unit)

- 1 (default)

Port 1 (RS-422A/485) -

(TERM: ON)

7 bits (default) 7 bi ts (default)

Controller

Digital Temperature

Controller

-

Stop bits 2 bits (default) 2 bi ts (default)

Parity (parity bit) Even (default) Even (default)

Communications method - CompoWay/F (default)

Send data wait time - 20 ms (default)

Precautions for Correct Use

The connection procedure described in this gui de assumes that the following Serial

Communications Unit, port and setting values are used.

Model: CJ1W-SCU42

Serial communications port: Port 1

Unit No.: 0

Device name: J01

If you connect devices under different conditions, refer to Section 9. Program and create a

program by changing the variable names and sett i ng values .

Page 12

6.Serial Communications Settings

9

Pin No.

Signal name

Input/Output

5 (See note 2.)

FG

Shield

-

SDB+

4

Additional Information

refer to their respective manuals.

Ter minating r esistance

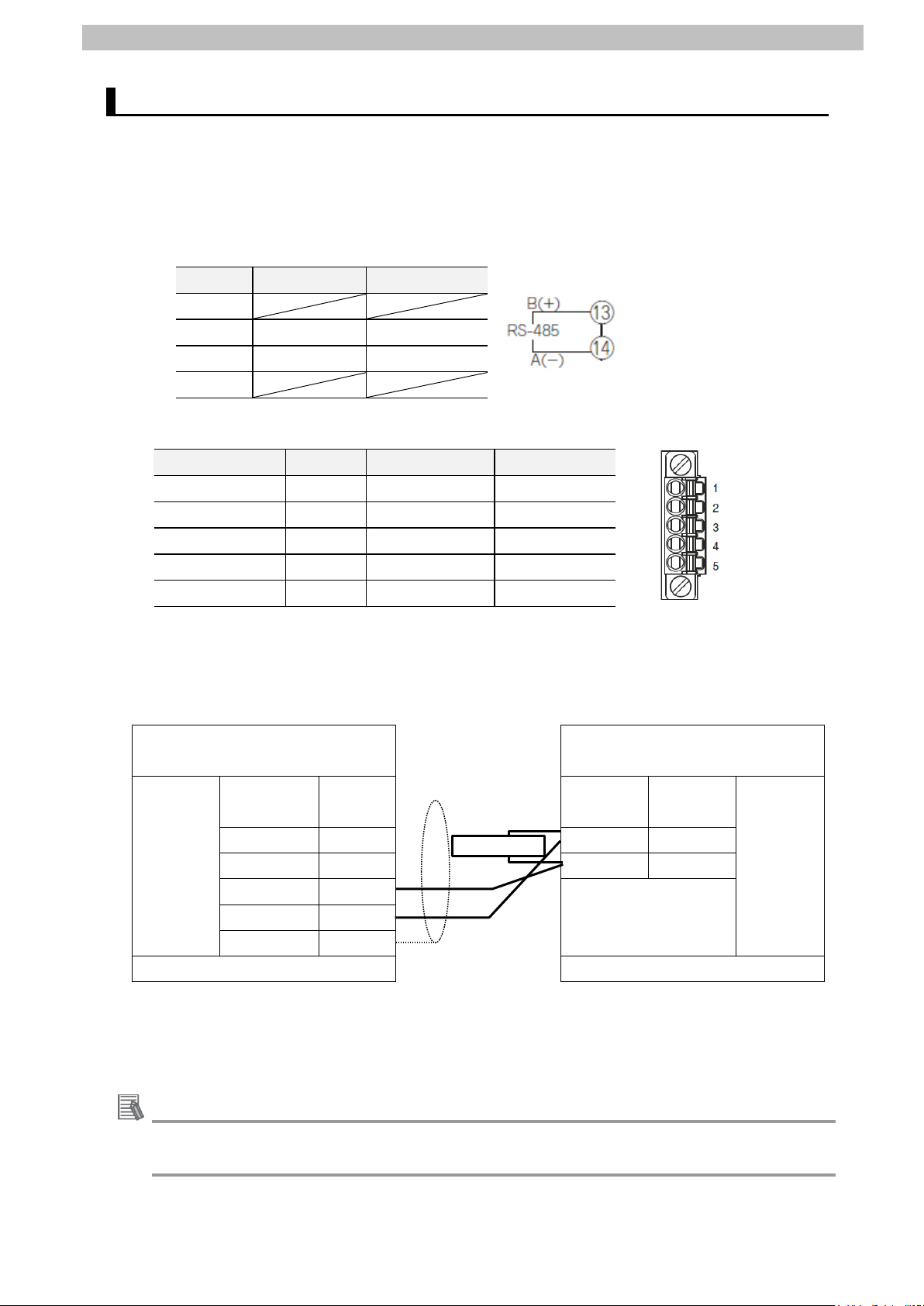

Cable Wiring 6.2.

Refer to Section 3 Installation and Wiring of the CJ-series Serial Communications Units

Operation Manual for NJ-series CPU Unit (Cat. No. W494) for details on cable wiring.

Check the connector configurations and pin assignments before wiring.

■Connector configuration and pin assignment

Digital Temperature Controller (E5CD) applicable connector: Termi nal block

1-12

13 B(+) Input/Output

14 A(-) Input/Output

15-18

Serial Communications Unit (CJ1W-SCU42) applicable connector: Terminal block

Pin No. Symbol Signal name Input/Output

1 (See note 1.) RDA Receive data - Input

2 (See note 1.) RDB Receive data + Input

3 (See note 1.) SDA Send data - Output

4 (See note 1.) SDB Send data + Output

Note 1: For 2-wire connection, use either pins 1 and 2 or pins 3 and 4.

2: Pin 5 (Shield) is connected to the GR terminal on the Power Supply Unit though the

Serial Communications Unit. The cable shield can thus be grounded if you ground the

GR terminal of the Power Supply Unit.

■Cable and pin assignment

Serial Communications

Digital Temperature Controller

Unit (CJ1W-SCU42)

RS-422A/

485

interface

Signal

name

Pin No. Terminal

No.

RDA- 1 13 B(+)

RDB+ 2 14 A(-)

SDA- 3

FG 5

Terminal block Terminal block

Connect 120 Ω (1/2 W) terminating resistance

between B(+) and A(-) of the Digital Temperature

Controller that is connected at the end of the

network.

(E5CD)

Signal

name

RS-485

interface

For information on the connector configurations and pin assignments of the other models,

Page 13

7.Serial Communications Connection Procedure

10

Setup

Set up the Digital Temperature Controller.

Set parameters for the Digital Temperature

Controller.

7.3. Controller Setup

Set up the Controller.

Set the hardware switches on the Serial

Communications Unit and connect the cables .

Importing the Project File

Start Sysmac Studio and import the project f i le.

Check the parameters of the Serial

on the project data, and build the project programs.

Go online with Sysmac Studio and transfer t he

Transfer the setting data of the Serial

Communications Unit.

Check

Start the send/receive processing and confirm t hat

Check that correct data is written to the variables of

the Controller in Sysmac Studio.

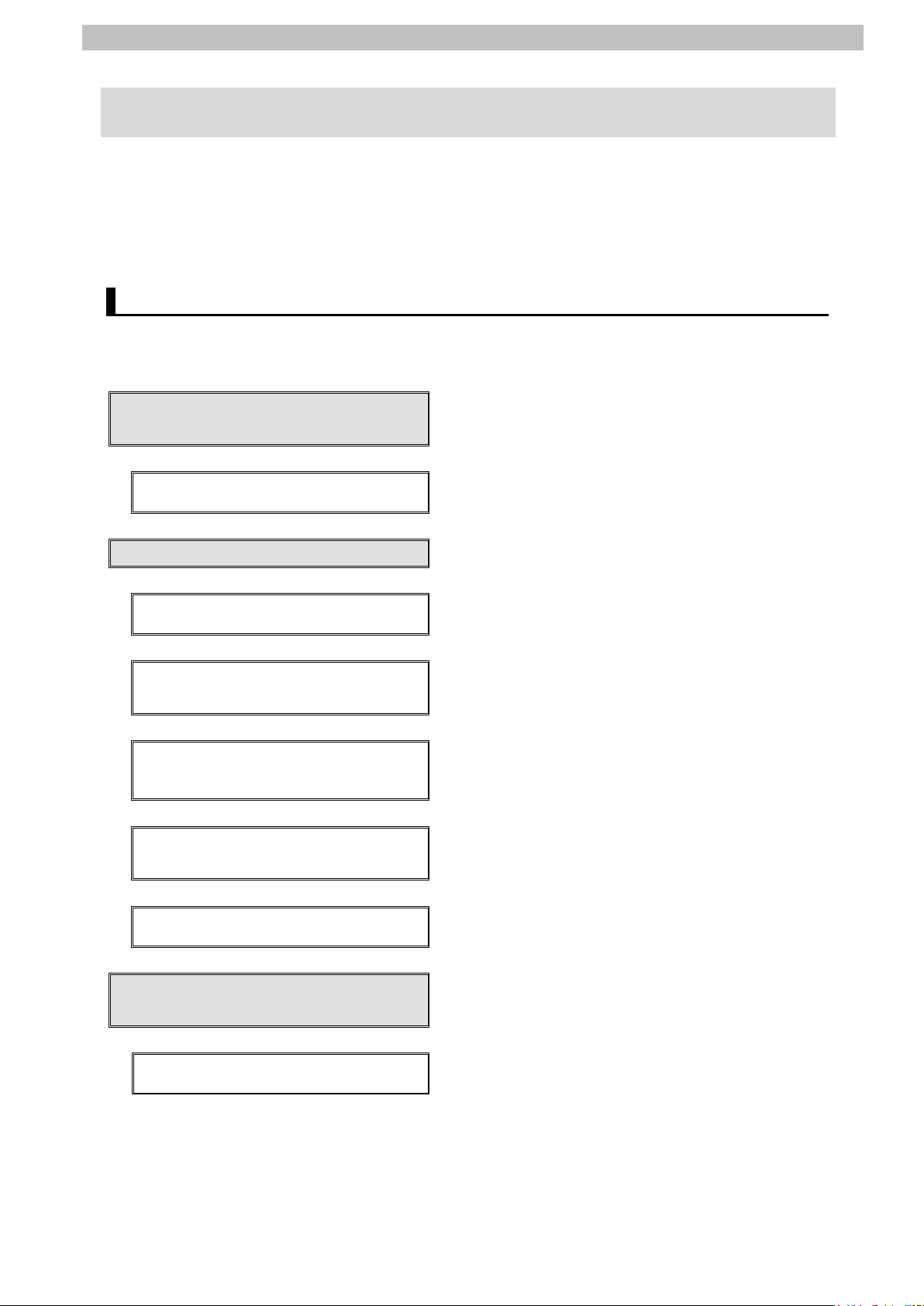

7. Serial Communications Connection Procedure

This section describes the procedures for connecting the Controller to the Digital Temperature

Controller via serial communications . The procedures f or setting up the Controller and the

Digital Temperature Controller in this guide are based on the f actory default settings.

For the initialization, refer to Section 8. Initialization Method.

Work Flow 7.1.

Take the following steps to connect the Controller and the Digital Temperature Controller via

serial communications and to send or receive a message.

7.2. Digital Temperature Controller

↓

7.2.1. Parameter Settings

↓

↓

7.3.1. Hardware Settings

↓

7.3.2. Starting Sysmac Studio and

↓

7.3.3. Checking the Parameters and

Building Programs

↓

7.3.4. Going Online and Transferring

the Project Data

Communications Unit, execute the program check

project data to the Controller.

↓

7.3.5. Transferring the Unit Settings

↓

7.4. Serial Communication Status

↓

7.4.1. Checking Received Data

serial communications performs normall y.

Page 14

7.Serial Communications Connection Procedure

11

1

manuals.

2

(Down) Key

3

4

Serial cable

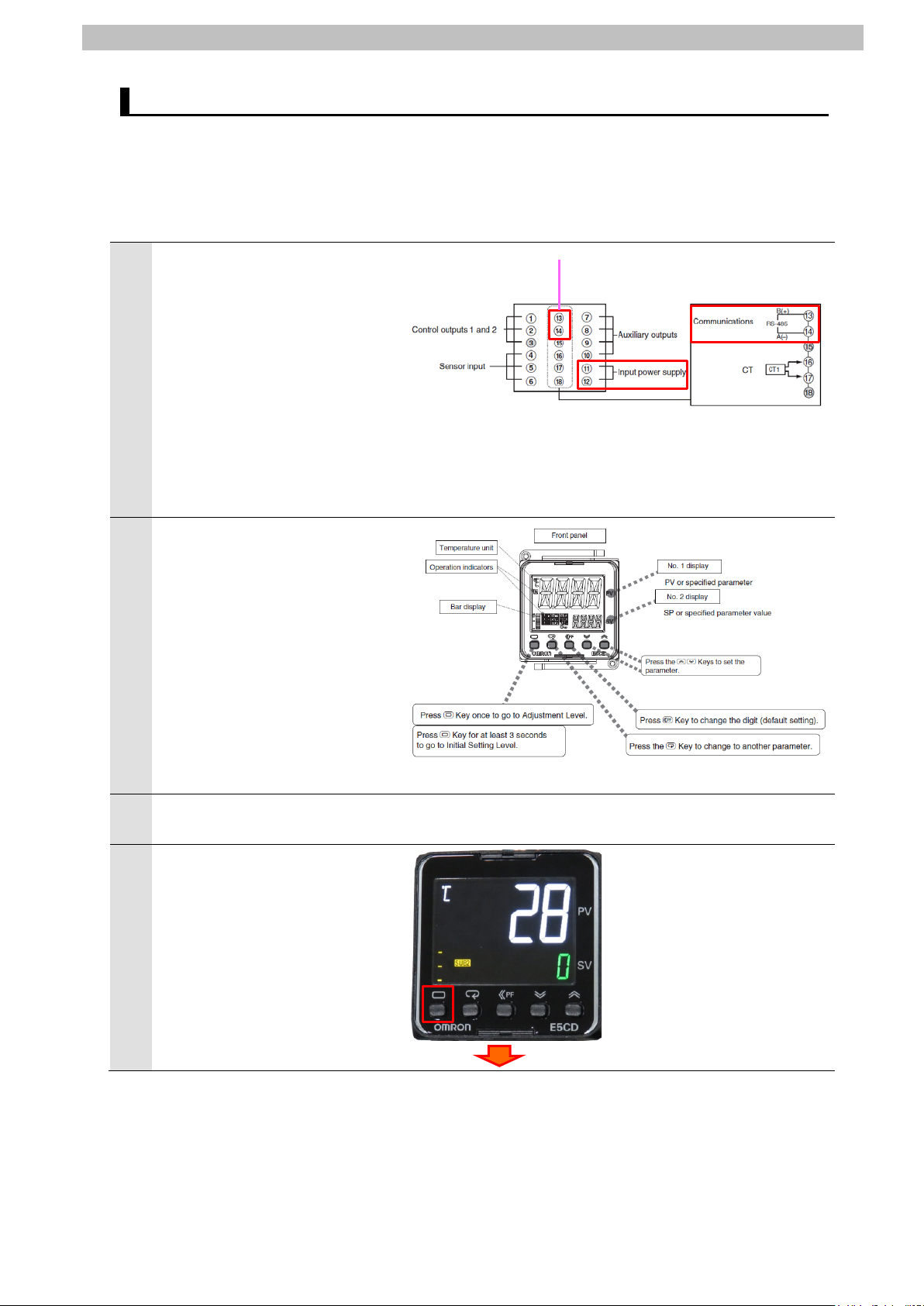

Digital Temperature Controller Setup 7.2.

Set up the Digital Temperature Controller.

7.2.1. Parameter Settings

Set parameters for the Digital T emperature Controller.

Connect the power supply and a

serial cable to the terminal block

located on the back of Digital

Temperature Controller.

*Only the parameters in

Communications Setting Level

are described in this guide.

If you use the parameters in

Adjustment Level that is

specific to each of the models,

refer to their respective

(RS-485)

Check the positions of each of

the keys, No.1 and No. 2

displays and Operation

indicators.

In this guide, the keys are

described as follows:

L (Level) Key

M (Mode) Key

U (Up) Key

D

Turn ON Digital Temperature

Controller.

The current temperature is

displayed on No. 1 display once

Digital Temperature Controller is

turned ON. (Operation Level)

Press the L (Level) Key for at

least 3 seconds.

L (Level) Key for at least 3 seconds

Page 15

7.Serial Communications Connection Procedure

12

"in-t" (Initial Setting Level) is

5

displayed on No. 1 display.

Press the L (Level) Key again

for less than 1 second.

The display changes to

6

Communications Setting Level.

"psel" (Protocol Setting) and

"cwf" (CompoWay/F) are

displayed on No. 1 and No. 2

displays, respectively.

*If the setting value is different,

press the U (Up) or D (Down)

Key to change the parameter.

Press the M (Mode) Key.

"u-no" (Communications Unit

7

No.) is displayed.

Check that Communications

Unit No. is 1.

*If the setting value is different,

change it in the same way as

step 6.

Press the M (Mode) Key.

"bps" (Communications Baud

8

Rate) is displayed.

Check that Communications

Baud Rate is 9.6 kbps.

*If the setting value is different,

change it in the same way as

step 6.

Press the M (Mode) Key.

L (Level) Key

< Setting value>

CWF / Mod

(default: CWF)

CWF: CompoWay/F

Mod: Modbus-RTU

M (Mode) Key

<Setting value>

0 to 99 (default: 1)

M (Mode) Key

<Setting value>

9.6, 19.2, 38.4 or

57.6 kbps

(default: 9.6)

M (Mode) Key

Page 16

7.Serial Communications Connection Procedure

13

"len" (Communications Data

9

Length) is displayed.

Check that Communications

Data Length is 7 bits.

*If the setting value is different,

change it in the same way as

step 6.

Press the M (Mode) Key.

"sbit" (Communications Stop

10

Bits) is displayed.

Check that Communications

Stop Bits is 2 bits.

*If the setting value is different,

change it in the same way as

step 6.

Press the M (Mode) Key.

"prty" (Communications Parity)

11

is displayed.

Check that Communications

Parity is EVEN.

*If the setting value is different,

change it in the same way as

step 6.

Press the M (Mode) Key.

"sdwt" (Send Data Wait Time) is

12

displayed.

Check that Send Data Wait Time

is 20.

*If the setting value is different,

change it in the same way as

step 6.

Press the L (Level) Key for less

than 1 second.

<Setting value>

7 or 8 bits (default: 7)

M (Mode) Key

<Setting value>

1 or 2 bits (default: 2)

M (Mode) Key

<Setting value>

NONE, EVEN or ODD

(default: EVEN)

M (Mode) Key

<Setting value>

0 to 99 ms (default: 20)

L (Level) Key.

Page 17

7.Serial Communications Connection Procedure

14

15

"in-t" ((Initial Setting Level) is

13

displayed.

Press the L (Level) Key for at

least 1 second.

The display returns to Operation

14

Level as shown in step 4.

Turn OFF Digital Temperature

Controller.

L (Level) Key for at least 1 second

Page 18

7.Serial Communications Connection Procedure

15

be applicable.

2

3

4

5

・TERM

・WIRE (2-wire or 4-wire switch)

2: 2-wire, 4: 4-wire

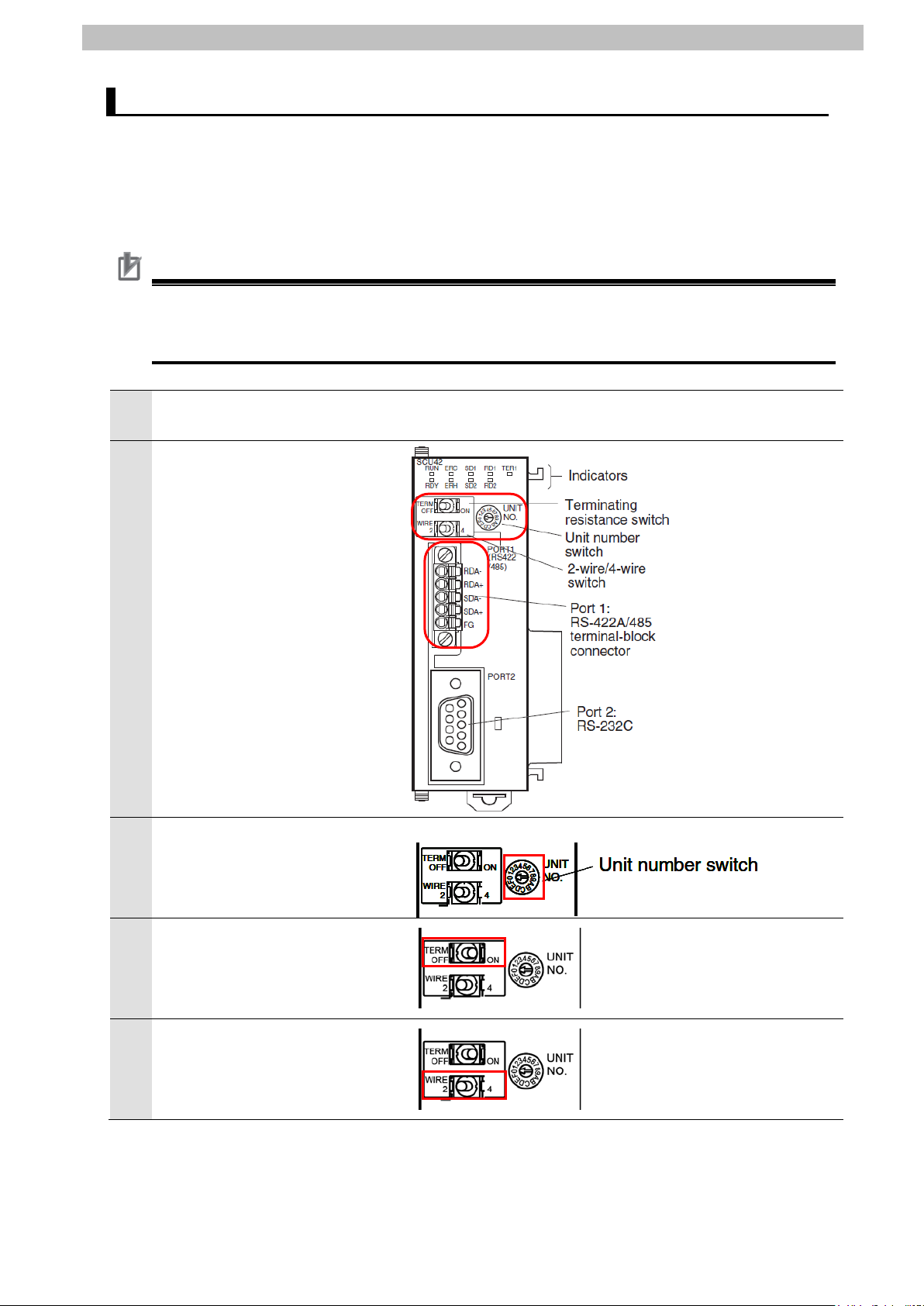

Controller Setup 7.3.

Set up the Controller.

7.3.1. Hardware Settings

Set the hardware switches on the Serial Communications Unit and connect the cables.

Precautions for Correct Use

Make sure that the power supply is OFF when you set up.

If it is ON, the settings described in the following steps and subsequent proc edures may not

Make sure that Controller is

1

powered OFF.

Check the positions of the

hardware switches and Port 1

on the front panel of Serial

Communications Unit by

referring to the figure on the

right.

Set Unit number switch to 0.

*The unit number is set to 0 as

the factory default setting.

Set Terminating resistance

ON/OFF switch to ON.

(Terminating resistance ON)

Set 2-wire or 4-wire switch to 2.

(2-wire)

(Terminating resistance ON/OFF switch)

OFF: Terminating resistance OFF

ON: Terminating resistance ON

Page 19

7.Serial Communications Connection Procedure

16

Serial cable

(RS-485)

Serial Communications Unit

USB

Cable

Controller

End Cover

Power Supply Unit

CPU Unit

Personal

Connect Serial Communications

6

Unit to Controller as shown on

the right.

Connect Digital T emperature

Controller and Port 1 on Serial

Communications Unit with the

serial cable.

Connect Personal computer and

Controller with a USB cable.

computer

Page 20

7.Serial Communications Connection Procedure

17

1

Sysmac Studio.

2

7.3.2. Starting Sysmac Studio and Importing the Project File

Start Sysmac Studio and import the project f i le.

Install Sysmac Studio and the USB driver on your pers onal computer beforehand.

Start Sysmac Studio.

*If the User Account Control

Dialog Box is displayed at start,

make a selection to start

Click Import.

The Import file Dialog Box is

3

displayed.

Select P520_NJ_CWF485_

OMRON_E5CD_V100.csm2

and click Open.

*Obtain the project file from

OMRON.

Page 21

18

The P520_NJ_CWF485_

Controller

Toolbox

Edit Pane

Multiview

Output T ab

Build T ab

4

OMRON_E5CD_V100 project is

displayed.

The following panes are

displayed in this window.

Left: Multiview Explorer

Top right: T oolbox

Bottom right: Controller Status Pane

Top middle: Edit Pane

The following tabs are displayed

in the bottom middle of this

window.

Output T ab Page

Build T ab Page

7.Serial Communications Connection Procedure

Explorer

Page

Page

Status

Pane

Page 22

7.Serial Communications Connection Procedure

19

1

2

Settings.

3

7.3.3. Checking the Parameters and Building Programs

Check the parameters of the Serial Communic ations Unit, exec ute the program chec k on the

project data, and build the project programs.

Double-click CPU/Expansion

Racks under Configurations

and Setup in the Multiview

Explorer.

The CPU/Expansion Racks Tab

Page is displayed in the Edit

Pane.

Select Serial Communications

Unit as shown on the right.

The setting values of

CJ1W-SCU42 are displayed.

Check that the device name is

J01 and that the unit No. is 0.

*If the setting values are

different from the above,

change the values.

Click Edit Special Unit

The 0 [Unit 0] : CJ1W-SCU42

(J01) Tab Page is displayed.

Select Port1: Serial Gateway

Settings from the pull-down list

of Parameter group to show.

Page 23

20

Parameter group to show is set

Apply.

5

6

4

to Port1: Serial Gateway

Settings.

The setting items of Port1: Serial

Gateway Settings are shown.

Check that Port1: Port settings

is set to User settings and that

the other settings are the same

as those listed in 6.1.

Parameters.

*If the setting values are

different, select the values from

the pull-down list. After

changing the values, click

7.Serial Communications Connection Procedure

Double-click I/O Map under

Configurations and Setup in

the Multiview Explorer.

The I/O Map Tab Page i s

displayed, and then the

parameters of Serial

Communications Unit are listed.

Check that the variable names

in the Variable Column start with

J01 and that "Global Variables"

is set for each of them in the

Variable Type Column.

*If the settings are different from

the above, right-click

CJ1W-SCU42 and select

Create Device Variable.

Page 24

21

Double-click Task Settings

8

9

10

12

13

7

under Configurations and

Setup in the Multiview Explorer.

The Task Settings Tab Page is

displayed in the Edit Pane.

Click the Program Assignment

Settings Button. Check that

Program0 is set in the Primary

Task Field and that Run is set as

the initial status.

Select Check All Programs

from the Project Menu.

The Build Tab Page is displayed.

Check that "0 Errors" and "0

Warnings" are displayed.

7.Serial Communications Connection Procedure

Select Rebuild Controller from

11

the Project Menu.

A confirmation dialog box is

displayed. Check the contents

and click Yes.

Check that "0 Errors" and "0

Warnings" are displayed on the

Build Tab Page.

Page 25

7.Serial Communications Connection Procedure

22

Unit.

1

Temperature Controller.

2

3

4

7.3.4. Going Online and Transferring the Project Data

Go online with Sysmac Studio and transfer t he proje ct data to the Controller.

Always confirm safety at the destination node before you transfer a user

program, configuration data, setup data, devi ce variables, or values in memory

used for CJ-series Units from Sysmac Studio. The devices or machines may

perform unexpected operation regardless of t he operating mode of the CPU

Always confirm safety before you reset the Controll er or any components.

Turn ON Controller and Digital

Select Change Device from the

Controller Menu.

The Change Device Dialog Box

is displayed.

Check that the Device and

Version Fields are set as shown

on the right.

Click Cancel.

*If the settings are different,

select the setting items from

the pull-down list, and click OK.

Select Communications Setup

from the Controller Menu.

Page 26

23

The Communications Setup

6

processing.

Additional Information

8

5

Dialog Box is displayed.

Select Direct connection via

USB in the Connection type

Field.

Click OK.

Select Online from the

Controller Menu.

The dialog box on the right is

displayed, check the contents

and click Yes.

*The contents of the dialog box

vary depending on the status of

Controller. Check the contents

and click on an appropriate

button to proceed with the

7.Serial Communications Connection Procedure

When an online connection is

7

established, a yellow line is

displayed under the toolbar.

For details on the online connections to the Controller, refer to Section 6. Online Connections

to a Controller of the Sysmac Studio Version 1 Operation Manual (Cat. No. W504).

Select Synchronize from the

Controller Menu.

Page 27

7.Serial Communications Connection Procedure

24

10

The Synchronization Dialog Box

9

is displayed.

Check that the data to transfer

(NJ501 shown on the right) is

selected.

Click Transfer To Contro ller.

*After executing "Transfer To

Controller", the Sysmac Studio

data is transferred to

Controller, and the data is

synchronized.

A confirmation dialog box is

displayed. Confirm that there is

no problem, and click Yes.

A screen is displayed stating

"Synchronizing".

A confirmation dialog box is

displayed. Confirm that there is

no problem, and click No.

*Do not return to RUN mode.

Page 28

7.Serial Communications Connection Procedure

25

from step 1.

Precautions for Correct Use

As shown in the figure on the

11

right, the font color that is used

to display the synchronized data

changes to the same color as

the one used to specify

"Synchronized". Check that a

message is displayed stating

"The Synchronization process

successfully finished".

Confirm that there is no

problem, and click Close.

*When the Sysmac Studio

project data coincides with the

Controller data, a message is

displayed stating "The

synchronization process

successfully finished".

*If the synchronization fails,

check the wiring and repeat

Always confirm safety before you reset the Controll er or any components in step 13 and

subsequent steps.

Page 29

26

Select Reset Controller from

13

14

15

12

the Controller Menu.

*”Reset Controller” cannot be

selected when the operating

mode of Controller is RUN

Mode. In this case, select

Mode - PROGRAM Mode from

the Controller Menu to change

to PROGRAM mode, and then

perform this step.

7.Serial Communications Connection Procedure

A confirmation dialog box is

displayed. Check the contents

and click Yes.

A confirmation dialog box is

displayed. Check the contents

and click Yes.

The Controller is reset, and

Sysmac Studio goes offline.

The yellow line under the toolbar

disappears.

Page 30

7.Serial Communications Connection Procedure

27

1

4

5

Settings

7.3.5. Transferring the Unit Settings

Transfer the setting data of the Serial Communications Unit.

Select Online from the

Controller Menu.

When an online connection is

2

established, a yellow line is

displayed under the toolbar.

Select Mode - PROGRAM

3

Mode from the Controller Menu.

A confirmation dialog box is

displayed. Confirm that there is

no problem, and click Yes.

PROGRAM mode is displayed

in the Controller Status Pane.

Double-click CPU/Expansion

6

Racks under Configurations

and Setup in the Multiview

Explorer.

Select Serial Communications

Unit displayed on the CPU Rack

configuration.

Click Edit Special Unit

.

Page 31

28

The 0 [Unit 0] : CJ1W-SCU42

8

Yes

9

10

7

(J01) Tab Page is displayed.

Click Transfer to Controller.

A confirmation dialog box is

displayed. Check the contents

and click Yes.

A dialog box is displayed

indicating that transferring is

being performed. After that, the

dialog box on the right is

displayed. Check the contents

and click

The Port Selection Dialog Box is

displayed.

Select All ports and click OK.

.

7.Serial Communications Connection Procedure

A confirmation dialog box is

displayed. Check the contents

and click OK.

Page 32

29

Select Port1: Serial Gateway

11

Settings from the pull-down list

of Parameter group to show.

Click Compare.

Check that "≠" (mismatch) is

12

not shown within the red oval in

the figure on the right.

7.Serial Communications Connection Procedure

Page 33

7.Serial Communications Connection Procedure

30

change the variable values on a Watch Tab

Precautions for Correct Use

1

2

3

Serial Communication Status Check 7.4.

Start the send/receive processing and confirm that serial communications performs norm al ly.

If you change the variable values on a Watch Tab Page when Sysmac Studio is

online with the CPU Unit, the devices connected to the Controller may operat e

regardless of the operating mode of the CPU Unit.

Always ensure safety before you

Page when Sysmac Studio is online with the CPU Unit.

Check that the serial cable is connected before performing the following procedure.

If not, turn OFF both devices, and then connect the seri al cable.

7.4.1. Checking Received Data

Check that correct data is written to the variables of the Controller in Sysmac Studio.

Select Mode - RUN Mode from

the Controller Menu.

The dialog box on the right is

displayed. Confirm that there is

no problem, and click Yes.

RUN mode is displayed in the

Controller Status Pane.

Page 34

31

Select Watch Tab Page from

5

6

variable.

7

pull-down list.

9

Communications start switch

String data

The number of data bytes

4

the View Menu.

Select the Watch (Project)1

Tab.

Check that the variables shown

on the right are displayed in the

Name Column.

*Click Input Name to add a

7.Serial Communications Connection Procedure

Check that the display format of

Output_recvByteSize is

Decimal.

*If not, select Decimal from the

Click TRUE in the Modify

8

Column for Input_Start.

The online value of Input_Start

changes to True, and the

communications processing

starts.

Check received data on the

Watch Tab Page of Sysmac

Studio.

*The example on the right shows

that the online values of

Output_recvByteSize (the

number of data bytes) and

Output_recvCWFdata (string

data) are 28 bytes and “01 00

00 0503 0000 E5CD-RX2A6

00D9”, respectively.

The response data varies

depending on the device used.

・・・

Response data

01= Node No.

00= Subaddress

00= End code

0503= Command (MRC, SRC)

0000= Response (MRES, SRES)

E5CD-RX2A6 = Receive data (Controller Attributes)

00D9 = Buffer size

Page 35

8.Initialization Method

32

8. Initialization Method

The setting procedures in this guide are based on the f actory default settings.

Some settings may not be applicable unless you use the devices with the factory default

settings.

Initializing a Controller 8.1.

To initialize the settings of a Controller, it is necessary to initialize a Serial Communications

Unit and a CPU Unit. Change the operating mode of the Controller to PROGRAM mode

before the initialization.

8.1.1. Serial Communications Unit

To initialize the settings of a Serial Communications Unit, select the displayed Serial

Communications Unit (CJ1W-SCU42) and click Edit Special Unit Settings on the

CPU/Expansion Racks Tab Page of Sysmac Studio.

Click Return to default and Apply. Then, click Transfer to Controller.

Page 36

8.Initialization Method

33

8.1.2. CPU Unit

To initialize the settings of a CPU Unit, select Clear All Memory from the Controller Menu in

Sysmac Studio.

The Clear All Memory Dialog Box is displayed. Check the contents and click OK.

Initializing a Digital Temperature Controller 8.2.

To initialize the settings of a Digital Tem perature Controll er, refer to Parameter Initialization in

6-8 Advanced Function Setting Level of the Digital Temperature Controllers User's Manual

(Cat. No. H224/H174/H185).

Page 37

9.Program

34

Additional Information

9. Program

This section describes the details on the program in the project file that is used in this guide.

Overview 9.1.

The following explains the specificat i ons and functions of the program that are used to check

the connection between the Digital Temperature Controller (hereinafter referred to as the

"Destination Device") and the Controller (Serial Communications Unit (hereinafter referred t o

as the "SCU")).

This program performs communications via CompoWay/F using the Serial Gateway function

of the SCU, to send/receive the "Read Controller Attributes" command to/from the Destination

Device and detect a normal end or an error end.

A normal end of the send/receive processing means a normal end of communications via

CompoWay/F.

An error end means an error end of communications via Com poWay/F and an error of the

Destination Device (identified in the response data from the Destination Device).

Here, the prefix "10#" (possible to omit) is added to decimal data and the prefix "16#" is added

to hexadecimal data when it is necessary to distinguis h between decimal and hexadecimal

data. (e.g., "1000" or "10#1000" for decimal dat a and "16#03E8" for hexadecimal data)

The prefix "<data type>#" is also added to deci m al or hexadecimal data when specifying a

specific data type. (e.g.,"WORD#16#03E8")

OMRON has confirmed that normal communic ations can be performed using this program

under the conditions of 5.2. Device Configuration. However, we do not guarantee the normal

operation under disturbances such as electri cal noise or device performance variation.

Page 38

9.Program

35

Controller

CPU Unit

SCU

ST program

setting area

Serial Gateway

function

(1) Executes the send command

Command data

Response data

storage area

(2) Sends command data.

(3) Executes the

(4) Receives the response data

9.1.1. Outline of Processing

The following figure shows the data flow from when the Controller (SCU) sends CompoWay/F

command to the Destination Device until the Controller receives response data from the

Destination Device.

(1)The ST program executes the send command instruction (SendCmd instruction) for which

CompoWay/F is specified.

(2)The Controller sends command data of "Read C ontroller Attributes" to the Digital

Temperature Controller using communications via CompoWay/F.

(3)The Digital Temperature Controller executes the command by receiving the command data

from the Controller, and returns response data to the Controller.

(4)The Controller receives the response data f rom the Digital Temperature Controller and

stores in the specified variable.

Controller

RS-485

Digital Temperature

IF …. THEN

……….

ELSE

……….

End_IF

instruction.

SendCmd(…

(SendCmd instruction)

(Specifying CompoWay/F)

Local_cmddata

Command data

Local_recvdata

Response data

(Communications via

CompoWay/F)

command

and returns

response data.

and stores it at the specified

variable in the memory.

Page 39

9.Program

36

Additional Information

(Cat.No. W502).

Name

Function block

Description

Command

Gateway and sends a command to SCU.

9.1.2. SendCmd Instruction and Send/Receive Messages

The following describes the function block for sending a command (hereinafter referred to as

"the SendCmd instruction") and the general operation of sending/receiving a message.

For details on the SendCmd instruction, refer t o Serial Communications Instructions in

Section 2. Instruction Descriptions of the NJ/NX-series Instructions Reference Manual

●SendCmd instruction

Send

SendCmd

●SendCmd instruction argument data

The SendCmd instruction uses a Serial

Page 40

37

[DstNetAdr: Destination network addres s]

= 16#A9

a destination unit address.

The following table shows the variables that store a destination network address.

Variable Setting item Data type Description

DstNetAdr

Destination

network address

Network

NetNo

address

NodeNo Node address USINT

UnitNo Unit address BYTE

_sDNET_

Destination network address

ADR

USINT USINT#16#00 (fixed): Local network

USINT#16#00 (fixed): Communications in local

Controller

Make the following setting.

Serial port's unit address

For SCU

Port 1: 16#80 + 16#04 x [Unit number (hex)]

Port 2: 16#81 + 16#04 x [Unit number (hex)]

For example, when the unit number (No. 10) port 2 is

used, the unit address of serial port is as follows:

= 16#81 + 16#04 x 16#0A = 16#81 + 16#28

9.Program

[CommPort: Destination serial port]

The following table shows the variable that stores a destination serial port number.

Variable Sett i ng item Data type Description

_NONE: The destination is not a serial port i n H os t

CommPort

Destination

_ePORT

serial port

Link Mode.

Set _NONE to specify the serial port unit address as

[CmdSize: Command data size]

The following table shows the variable that stores the number of command data bytes (send

data).

Variable Sett i ng item Data type Description

CmdSize

Command data

UINT

size

Sets the number of command data bytes.

(UNIT#2 to maximum data length)

[Option: Response]

The following table shows the variables that store settings to receive a response.

Variable Sett i ng item Data type Description

Option Response

isNonResp No response BOOL

TimeOut Timeout time UINT

Retry Retry count USINT Sets USINT#0 to 15 (0 to 15 times).

_sRESPO

Response monitoring and retry spec ifications

NSE

TRUE: Response is not required.

FALSE: Response is required.

Sets UINT#1 to 65535 (indicates 0.1 t o 6553.5

seconds). (UINT#0: 2 seconds (default))

Page 41

9.Program

38

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

28

03

AA

BB

CC

DD

EE

FF

GG

HH

II

**

**

**

CompoWay/F

Node No.

Subaddress

SID

Command

Text

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

28

03

aa

bb

AA

BB

CC

DD

cc

dd

FF

GG

HH

II

ee

ff

gg

hh

**

CompoWay/F

Comm-

code

Command

Response

[CmdDat[] array: Command array (send data)]

With this program, the command data (send data), after bei ng set with the STRING array

variable (Local_cmdCWFdata), is c onverted and stored in the BYTE array variable

(Local_cmddata), and then transferred to t he command array (CmdDat[]).

Command array

・・・・・・

command

The CompoWay/F command (16#2803) is a command that can be executed when using

CompoWay/F with the Serial Gateway function of the SCU.

The shaded areas of the command data (from AA onwards) are expressed in ASCII codes.

[RespDat[] array: Response storage array (receive data)]

With this program, the response data (receive data), after being received in the response

storage array (RespDat[]), is stored in the BYT E array v ari able (Local_recvdata).

The data is then converted into the STRING array variable (Output_recvCWFdata) and is

checked.

Response storage array

command

and end

Node

No.

Sub

address

End code

The shaded areas of the response data (from AA onwards) are expressed in ASCII codes.

The response data that are not boxed with thick lines such as AA will be the same values as

those of the command code.

The response data boxed with thick lines (cc, dd, ee to hh) will be stored in the following

variables as Destination Device error codes when a Destination Device error occurs.

For details, refer to 9.7.2. Destination Device Error.

Ouitput_CWFErrCode1: End code

Ouitput_CWFErrCode2: Response (MRES, SRES)

"aa" and "bb" command end codes are not used in this guide or this program.

MRC SRC

MRC SRC MRES SRES

・・

Text

Page 42

39

●Send/Receive Messages

STX

Node

No.

Sub

address

Command

ETX

16#02

MRC

SRC

16#03

STX

Node

No.

Sub

address

End

code

Command

Response

ETX

16#02

MRC

SRC

MRES

SRES

16#03

Local_cmd

CWFdata

Command

MRC

SRC

Local_cm

ddata

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

28

03

AA

BB

CC

DD

EE

FF

GG

HH

II

**

CPU

SCU

CompoWay/F

Node No.

Subaddress

SID

Command

Text

SCU

(send data)

STX

Command

ETX

Destination

data)

Local_re

cvdata

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

28

03

aa

bb

AA

BB

CC

DD

cc

dd

FF

GG

HH

II

ee

ff

gg

hh

**

SCU

Compo

command

Comm-

code

Node No.

Sub

End code

Command

Response

Text

MRC

SRC

MRES

SRES

Output_rec

Node

No.

Sub

address

End

code

Command

Response

MRC

SRC

MRES

SRES

Controller

Destination

Device

[Frames of send/receive messages]

Send message (command)

SID

Text

9.Program

BCC

Reception message (response)

Text

BCC

[Relationship between send command (S endCm d instruction operand) and send message]

Node No. Subaddress SID

→

command

MRC

SRC

→

Destination

Device

Node

16#02 MRC SRC 16#03

No.

Sub

address

SID

Text

[Relationship between receive response (S endCmd instruction operand) and receive

message]

Device →

SCU

(receive

STX

Node

16#02 MRC SRC MRES SRES 16#03

No.

Sub

address

End

code

Command Response

Text

Text

・・

BCC

ETX

BCC

・

→

CPU

Way/F

and end

address

vCWFdata

Text

Page 43

40

Destination Device Command 9.2.

Read Controller Attributes

Reads the attributes of the Destination Device.

The following describes the Destination Device command used in this program.

9.2.1. Overview of the Command

This program reads the Destination Device information by using the "Read Controller

Attributes" command.

Command name Description

9.2.2. Detailed Description of the Function

The following describes the "Read Controller Attributes" command.

●SendCmd instruction send data

[DstNetAdr: Destination network addres s]

Variable Setting item Data type Setting value

DstNetAdr

NetNo Network address USINT 16#00 Fixed: Local network

NodeNo Node address USINT 16#00 Fixed: Within local controller

UnitNo Unit address BYTE 16#80 Unit number 0 + Port number 1

Destination network address

_sDNET_ADR -

9.Program

[CommPort: Destination serial port]

Variable Setting item Data type Setting value

CommPort

Destination serial port

_ePORT _NONE Fixed

[CmdSize: Command data size]

Variable Setting item Data type Setting value

CmdSize Command data size UINT 11 11 bytes

[Option: Response]

Variable Setting item Data type Setting value

Option Response _sRESPONSE -

isNonResp

TimeOut Timeout time UINT 0 Default: 2 sec

Retry Retry count USINT 3 3 times

Response is not

BOOL FALSE Response is re qui red.

required.

Page 44

41

[CmdDat[ ]: Command array]

Variable

Setting item

Data type

Setting value

CmdDat

Element

number

0

CompoWay/F

command

BYTE

16#28

1 BYTE

16#03

2

BYTE

16#30

"01": Unit No. of Destination

Device

3 BYTE

16#31

4

BYTE

16#30

5 BYTE

16#30 6

SID

BYTE

16#30

"0": Fixed (Not used)

7

BYTE

16#30

8 BYTE

16#35

9

BYTE

16#30 10

BYTE

16#33

" ": The setting is not required f or

this command.

Variable

Storing item

Data type

Storing value

RespDat

Element

number

0

CompoWay/F

command

BYTE

16#28

Fixed: Same as CmdDat[0]

1 BYTE

16#03

Fixed: Same as CmdDat[1]

2

BYTE

16#**

End code of CompoWay/F

command

3 BYTE

16#** 4

BYTE

16#30

"01": Unit No. of Destination

Device

5 BYTE

16#31 6

BYTE

16#30

7 BYTE

16#30

8

BYTE

16#**

"xx": End code

("00": Normal end)

9 BYTE

16#** 10

BYTE

16#30

11

BYTE

16#35 12

BYTE

16#30

13

BYTE

16#33 14

BYTE

16#**

15

BYTE

16#**

16

BYTE

16#** 17

BYTE

16#**

:

Text

BYTE

16#**・・

"xxxx

"

9.Program

: Text BYTE・・・ 16#00

Command array

Node No.

Subaddress

MRC

Command

SRC

ARRAY[0..255

] OF BYTE

-

Fixed

"00": Fixed (Not used)

"0503": "Read Controller

Attributes" command

After the data boxed in red above is set with the following STRING array variable, it is

transferred to the command array (CmsDat[]).

Variable Data type Data

CONCAT(NodeNo, SubAddress,SID,

Local_cmdCWFdata STRING[256]

MRCSRC, SendText);

●SendCmd instruction receive data

[RespDat[ ]: Response storage array]

Response storage

array

Command end code

Node No.

Subaddress

End code

Command

Response

MRC

SRC

MRES

SRES

ARRAY[0..255

] OF BYTE

・・・

-

"00": Fixed (Not used)

"0503": "Read Controller

Attributes" command

"xxxx"

("0000": Normal end)

・・・

Page 45

9.Program

42

02

30

31

30

30

30

30

35

30

33 03

xx

STX

Node No.

Subaddress

SID

Command

MRC

Command

SRC

Text

(Not used)

ETX

BCC

02

30

31

30

30

30

30

30

35

30

33

30

30

30

30

STX

Node No.

Subaddress

End code

Command

MRC

Command

SRC

Response

MRES

Response

SRES

**

**

**

**

**

**

**

**

**

**

**

**

**

**

Model number

Buffer size

03

**

ETX

BCC

02

30

31

30

30

**

**

30

35

30

33

**

**

**

**

STX

Node No.

Subaddress

End code

Command

MRC

Command

SRC

Response

MRES

Response

SRES

03

**

ETX

BCC

Additional Information

●Send message

This is the command frame of the message that is sent by the Controller to the Destination

Device according to the setting of the "Read Controller Attributes" command.

・Except for STX, ETX and BCC, ASCII codes are sent.

・STX, ETX and BCC are automat ically added to the send message by the SCU.

・Data not used is moved forward.

●Receive message (at normal operation)

This is the response frame of the normal message received by the Controller from the

Destination Device according to the setting of the "Read Controller Attributes" command.

・Except for STX, ETX and BCC, ASCII codes are received.

・STX, ETX and BCC are automatically removed from the receive message by the SCU.

・Data not used is moved forward.

●Receive message (at error operation)

This is the response frame of the error message rec eived by the Controller from the

Destination Device.

・Except for STX, ETX and BCC, ASCII codes are received.

・STX, ETX and BCC are automatically removed from t he receive message by the SCU.

For details on the end codes and response codes, refer to 9.7.2 Destination Device Error.

For details on the Destination Device comm and and data format, refer to Chapter 3

Communications Data for CompoWay/F of the Digital Temperature Controllers

Communications Manual (Cat. No. H225/ H175/H186).

Page 46

9.Program

43

Local

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

28

03

aa

bb

AA

BB

CC

DD

cc

dd

FF

GG

HH

II

ee

ff

gg

hh

**

CompoWay/F

Comm-

code

Node

Subad-

End code

Command

Response

Text

Serial cable

Controller

Destination Device

(1)

(2)

Error Detection Processing 9.3.

With this program, the error detection processing is performed according to the following

descriptions (1) and (2).

For information on error codes, refer to 9.7. Error Processing.

(1)Errors at the execution of the SendCmd ins truction (SendCmd instruction errors)

Errors such as a Unit error, a command format error and a parameter error are detected as

SendCmd instruction errors when executing the SendCmd instruction. If an error occurs,

the error code ErrorID or ErrorIDEx of the SendCmd instruction will be generated to identify

the error. If an error in communications with the Destination Device is caused by a

transmission error due to, for example, a character corruption or unmatched baud rate

setting, the transmission error status (J01_P1_TransErrSta) that is the allocated variable

area of the SCU will be stored in the output variable to show the communication error

status.

(2)Errors in the Destination Device (Destinat i on Device errors)

Destination Device errors include a command err or, a parameter error and an execution

failure in the Destination Device. An error is identified in the response data (receive data)

that is returned from the Destination Device. If an error occurs in the Destination Device, the

corresponding error code will be st ored in the end code or response of the receive data.

_recv

data

command

and

end

No.

dress

・

Page 47

9.Program

44

Variable name

Data type

Description

Communications start switch (The program is started when this

switch changes from FALSE to TRUE.)

Input_NodeNo

STRING[3]

Destination node address

Command execution code

Read Controller Attributes: "0503"

Command parameter

Read Controller Attributes: " " (no parameter)

Output_recvByteSize

UINT

The number of receive data bytes

Output_recvCWFdata

STRING[256]

An area that stores receive data. (STRING type: 256 characters)

An area that stores an error code of SendCmd instruction.

Normal end: 16#0000

An area that stores an expansion error code of SendCmd

instruction. Normal end: 16#00000000

Transmission error status when a communication error occurs.

Normal end: 16#0000

An area that stores the Destination Device end code when a

Normal end: 16#0000

An area that stores the response cod e when a Destination

Normal end: 16#0000

Variable name

Data type

Description

J01_P1_TransErr

BOOL

Transmission error

J01_P1_TransErrSta

BOOL

Transmission error status

Additional Information

For details on the device variables for the SCU, ref er to 2-3. Device Variable for CJ-series

(Cat. No. W494).

Network Communications Instruc tion Enabled Flag

TRUE: A port is available. FALSE: A port is not available.

Additional Information

For information on the system-defined variables for the SendCmd instruction, refer to Serial

Instructions Reference Manual (C at. No. W502).

Variables 9.4.

The variables used in this program are listed below.

9.4.1. Lists of Variables

The following tables list the external variables (user-defined global variables, device variables

for CJ-series Unit and system-defined varia bles) and internal variables, which are both used

in this program.

●External variables

[User-defined global variables]

Input_Start BOOL

Input_MRCSRC STRING[5]

Input_SendText STRING[128]

Output_CmdErrorID WORD

Output_CmdErrorIDEx DWORD

Output_TransErrCode WORD

Output_CWFErrCode1 WORD

Output_CWFErrCode2 WORD

Storage area of J01_P1_TransErrSta

Destination Device error occurs.

Device error occurs.

[Device variables for CJ-series Unit] (SCU)

Unit of the CJ-series Serial Communications Uni ts Operation Manual for NJ-series CPU Unit

[System-defined variable]

Variable name Data type Description

_Port_isAvailable BOOL

Communications Instructions in Section 2. Instruction Descriptions of the NJ/NX-series

Page 48

9.Program

45

Variable name

Data type

Description

This function block sends a comm and to the SCU using the

Serial Gateway function.

Additional Information

No.W502).

Variable name

Data type

Description

Communications processing st atus flag

(Communications processing in pr ogress)

Communications processing st atus flag

(Communications processing normal end)

Communications processing st atus flag

(Communications processing error end)

Local_State

DINT

Processing number

Local_ExecFlgs

BOOL

Communications instruction e xecution flag

Local_DstNetAdr

_sDNET_ADR

Destination address for SendCmd instruction setting

Destination serial port specific ation for SendCmd

instruction setting

Local_sendSize

UINT

Send command data size for SendCmd inst ruction setting

Local_Option

_sRESPONSE

Response setting for SendCmd instr uction setting

Local_SubAddress

STRING[3]

Subaddress "00" (fixed)

Local_SID

STRING[2]

SID "0" (fixed)

ARRAY[0..255]

OF BYTE

Command array for SendCmd instruction s etting

(256 bytes)

ARRAY[0..255]

OF BYTE

Response storage array for SendCmd instruction setting

(256 bytes)

An area that stores send data

(STRING type: 256 characters)

●Internal variables (instance variables)

The following tables list the internal variables to execute the function block in the progra m.

An internal variable is called an "instance". The name of the function block used is specified

as the data type of the variable.

[Instance for the SendCmd instruction]

SendCmd_instance SendCmd

For details on the SendCmd instruction, refer t o Serial Communications Instructions in

Section 2. Instruction Descriptions of the NJ/NX-series Instructions Reference Manual (Cat.

●Internal variables

Local_Busy BOOL

Local_Done BOOL

Local_Error BOOL

Local_CommPort _ePORT

Local_cmddata

Local_recvdata

Local_cmdCWFdata STRING[256]

Page 49

46

ST Program 9.5.

9.5.1. Functional Components of the Program

The program used in this guide is written in the ST language.

The functional components are as follows:

Major

classification

1.Communications

processing

2.Initialization

processing

3.CompoWay/F

communications

processing

4.Processing

number error

process

1.1. Starting the communications pr ocessing

1.2. Clearing the communications processing

status flags

1.3. Communications processing in progress

status

2.1. Initializing the communications instruction

2.2. Initializing the communications instruction

execution flag

2.3. Initializing the error code storage areas

2.4. Setting the SendCmd instruction control

data

2.5. Setting the send variables

2.6. Initializing the receive dat a storage areas

2.7. Initialization setting end p r ocessing

3.1. Determining the communicat ions

processing status and setting the e xecution

flag

3.2. Executing the communications instruction

- The error processing is performed

Minor classification Description

9.Program

The communications processing

is started.

The receive data storage areas

and the error code storage areas

are initialized.

The parameters and send data

are set for the SendCmd

instruction. (CompoWay/F)

The SendCmd instruction

(CompoWay/F) is executed.

A normal end or an error end of

the execution is detected.

when a non-existent number is

detected.

Page 50

9.Program

47

9.5.2. Program list

The program used in this guide is shown below.

The send data (command data) setting to the Dest ination Device is boxed in red in this

program list.

●Program: Program0 (General-purpose s erial communications connection check program)

1. Communications processing

Page 51

48

2. Initialization processing

9.Program

Page 52

49

3. CompoWay/F communications processing

9.Program

Page 53

50

4. Processing number error process

9.Program

Page 54

9.Program

51

Error end (1)

Error end (2)

Timing Charts 9.6.

The timing charts are shown below.

■Normal end

Input_Start

Local_Status.Busy

Output_recvCWFdata

Local_Status.Done

Local_Status.Error

Output_CmdErrorID

Output_TransErrorCode

Output_CWFErrCode1 and 2

■Error end

instruction error

Input_Start

Local_Status.Busy

Output_recvCWFdata Error Error response

Local_Status.Done

Local_Status.Error

Output_CmdErrorID

Output_TransErrorCode

Output_CWFErrCode1 and 2

*1 If Input_Start changes from TRUE to FALSE during the execution (Busy=ON), a normal end or an error end

is output for one period after the processing is completed (Busy=OFF).

Normal response Normal response

Output for 1 period*

16#FFFF

16#FFFF

16#FFFF

SendCmd

16#FFFF 16#xxxx 16#FFFF 16#FFFF 16#0000 16#FFFF 16#0000

16#FFFF 16#xxxx 16#FFFF 16#FFFF 16#1000 16#FFFF 16#1000

16#FFFF

6#0000

16#0000

16#0000

16#FFFF 16#xxxx 16#FFFF 16#xxxx

16#FFFF

16#0000

16#FFFF

16#FFFF

Destination Device

error

16#0000

16#0000

Output for 1 period*1

Page 55

9.Program

52

output parameter.

Additional Information

Error Processing 9.7.

The errors that may occur during the program exec ution are shown below.

9.7.1. SendCmd Instruction Error

These error codes are generated when the SendCmd i nstruction ends in error.

●SendCmd instruction error code [Output_CmdErrorID, Output_CmdErrorIDEx]

An error code of ErrorID is stored in Output_CmdsErrorID, and an error code of ErrorIDEx is

stored in Output_CmdsErrorIDEx.

[Output_CmdErrorID]

Value Error description

16#0400 An input parameter for an instruction exceeded the valid range for an input

variable.

16#0406 The data position specified for an instruction excee ded the data area range.

16#0407 The results of instruction processing exceeded the data area range of the

16#0800 An error occurred when a FINS command was sent or received.

Detailed information is stored in Output_CmdErrorIDEx.

16#0801 The port is being used.

For details on errors, refer to A-3 Error Code Detail s of the NJ/NX-series Instructions

Reference Manual (Cat. No. W502).

For information on troubleshooting, refer to 9-3 Troubleshooting of the CJ-series Serial

Communications Units Operation Manual for NJ-series CPU Unit (Cat. No. W494).

[Output_CmdErrorIDEx]

For information on error codes to be stored, refer to t he l ist of expansion error code

ErrorIDEx described in SendCmd in Section 2. Instruction Descriptions of the NJ/NX-series

Instructions Reference Manual (Cat . No. W502).

Page 56

9.Program

53

13

1: SendCmd instruction error 0: Normal

8

1: Processing number error 0: Normal

5

1: Timeout error 0: Normal

3

1: Framing error 0: Normal

Value

Description

●Transmission error status [Output_TransErrCode]

The data of J01_P1_TransErrSta transmission error status is stored in

Output_TransErrCode.

When a SendCmd instruction error, a destination device error or a processing number error

occurs, bits 8, 12 and 13 will change to TRUE, respectively.

[Status of each bit at a transmission error]

Bit Description

15 1: Transmission error 0: No transmission error

14 (Not used)

12 1: Destination Device error 0: Normal

9 to 11 (Not used)

7 1: F CS check error 0: FCS check normal

6 (Not used)

4 1: Overrun error 0: Normal

2 1: Parity error 0: Normal

0 and 1 (Not used)

16#0000 and 16#FFFF indicate the following stat us.

16#0000 Normal end

16#FFFF Initialized

Page 57

54

9.7.2. Destination Device Error

Bit

15 8 7

0

#00 Fixed

"**" End code

These error codes are used for errors in the Destination Device.

●Destination Device error code [Output_CWFErrCode1, Output_CWFErrCode2]

[Output_CWFErrCode1] (End code)

End code Name Description Priority

00 Normal completion The command ende d normally without error. None

The specified FINS command could not be

0F FINS command error

10 Parity error

11 Framing error Stop bit is "0". 1

12 Overrun error

13 BCC error

14 Format error

16 Sub-address error

18 Frame length error

executed.

The FINS response code should indicate why

the command could not be executed.

The sum total of bits whose received d ata is "1"

does not match the set value of the

"communications parity" bit.

An attempt was made to transfer new data

when the reception data buffer was already full.

The calculated BCC value is different from t he

received BCC value.

- The command text contains characters other

than 0 to 9, and A to F.

- There was no SID and command text, or there

was no command text.

- "MRC/SRC" not included in command tex t.

- Illegal (unsupported) subaddress

- There was no subaddress, SID and command

text.

- Subaddress was less than two characters,

and there was no SID and command text

The received frame exceeds the specified

(supported) number of bytes.

9.Program

8

2

3

5

7

6

4

Page 58

55

1104

End address out-of-range error

6

1100

Parameter error

9

[Output_CWFErrCode2] (Response code)

Response code Error name Priority

0000 Normal completion None

0401 Unsupported command 1

1001 Command too long 2

1002 Command too short 3

1101 Area type error 4

1103 Start address out-of-range error 5

1003 Number of elements/data mismatch 7

110B Response to o long 8

3003 Read-only error 10

2203 Operation error 11

9.Program

Additional Information

For details and troubleshooting on the Desti nation Device errors, refer to the Digital

Temperature Controllers User's Manual (Cat. No. H224/H 174/H185) and the Digital

Temperature Controllers Communications Manual (Cat. No. H225/H175/H186).

Page 59

10.Revision History

56

code

10. Revision History

Revision

01 January 2013 First edition

02 June 2018 Added the model numbers of the Digital Temperature

Date of revision Description of revi sion

Controller.

Revision and changes associated with upgrades of the

Controller and Sysmac Studio.

Page 60

2013-2018

P-E1-0

0618- (0113)

Loading...

Loading...