前言

E5CZ/AZ/EZ 支持串行通信,包括CompoWay/F, SYSWAY和Modbus。

本用户手册说明了E5CZ/AZ/EZ的通信功能。在使用E5CZ/AZ/EZ之前,请务必通读并理解本手册,以确保

正确的使用。

另外,阅读之后请妥善保管本手册,以便随时取阅。

© OMRON, 2008

保留所有权利。未经欧姆龙书面许可,不得以任何形式,或以机械、电子、影印、记录或其它任何

方式复制本手册的任何部分,或将其存储于检索系统中,或进行传播。

本手册中信息的使用不涉及专利责任。此外,欧姆龙始终致力于提高产品品质,本手册中的内容可

能随时更改,恕不另行通知。本手册在编制过程中已考虑到各注意事项。但对于错误和省略部分以

及任何由于使用本手册的信息而造成的损失,欧姆龙概不承担任何责任。

I

阅读并理解本手册

请在使用产品之前阅读并理解本手册。如有任何问题或建议,请联系您的欧姆龙代表

保证内容和责任限定

保证内容

欧姆龙的唯一保证是产品自售出起一年 (或其它指定时间)内在材料和工艺上没有缺点。

欧姆龙对产品的无侵权、可售性或特殊用途的适用性均无任何明示或暗示性担保。任何购买者或使用者须

承认单独的购买者或使用者决定了产品将适当地符合他们有意使用的需求。欧姆龙拒绝其它所有保证,无

论明确的或暗示的。

责任限定

欧姆龙将不为产品以任何方式造成的特殊、间接的或因此产生的损坏、利益损失或商业损失负责,无论此

主张是基于契约、保证、疏忽或严格赔偿责任。

欧姆龙对已宣称责任的产品的任何超越单价的行为概不负责。

欧姆龙对产品的授权,修理或其它主张决不负责,除非欧姆龙分析确认产品合理操作、储藏、安装和维护

且未遭受污染、滥用、误用或不当更改或修理。

应用注意事项

使用的适宜性

欧姆龙将不对所有应用于客户应用中的产品结合对各个标准、代码或规章的符合性负责。

在客户的需求中,欧姆龙将提供可用的第三方证明文件来确定产品使用的额定值和局限性。

该信息本身对于完全确定产品与其它产品、机器、系统或其它应用或使用的适宜性并不充分。

以下为一些必须特别注意的应用示例。这并不是详尽无遗地罗列了所有可能的产品用途的列表,也并不意

味着所列用途对产品适用:

z 户外使用、遭受潜在化学污染或电干扰处使用、或未在本手册中提及的条件或用途。

z 核能控制系统、燃烧系统、铁路系统、航空系统、医疗器材、娱乐机械、车辆、安全设备和服从分离

工业或政府规章的安装。

z 可能对生命或财产造成风险的系统、机器和设备。

请了解并遵守所有产品可用性的禁止条款。

切勿将本产品用于可能造成严重生命或财产风险且不能保证整个系统设计于从事风险的场合,欧姆龙产品

已为用在整个设备或系统里而适当地额定并已安装。

可编程产品

对于用户在可编程产品上编程,及其导致的任何结果,欧姆龙概不负责。

II

免责条款

规格的变更

产品规格和附件随时可能基于改进和其它原因而更改。

当已公布的额定值或特性改变,或作出重大结构改变时更改型号编号是我们惯例。但是,产品某些规格可

能作出更改而不予通知。如有疑问,可指派特殊型号编号以为您的请求固定或建立关键规格。请在任何时

候联系您的欧姆龙代表以确认所购产品的实际规格。

尺寸和重量

尺寸和重量仅为名义上的,并不能用作制造用途,即使已说明了公差。

性能数据

本手册所给出的性能数据是用作给用户作为确定适用性的向导,并不予以担保。其将可能表现出欧姆龙测

试条件下的结果,用户必须将其与实际应用需求相联系。实际性能服从欧姆龙的保证以及责任限定。

错误和疏忽

本手册中的信息已小心核对并认为正确;但是对记录、印刷或校对错误或疏忽并不指定责任。

III

注意信息的定义

本手册中使用以下记号,以提供确保产品安全使用所需的注意事项。

所提供的安全注意事项对安全特别重要。必须阅读并记住所有安全注意事项中提供的信息。

安全使用注意事项

符号

使用了以下记号:

注意

符号 含义

注意

禁止

强制注意

表示潜在危险,如不加以避免,可能导致轻度或中度人身伤害或

财产损失。

一般注意

不特定的一般的注意、警告、危险提醒标记。

触电注意

在特定的条件下,有触电可能性的提醒标记。。

一般禁止

不特定的一般的禁止提醒标记。

一般注意

不特定的一般的注意、警告、危险提醒标记。

IV

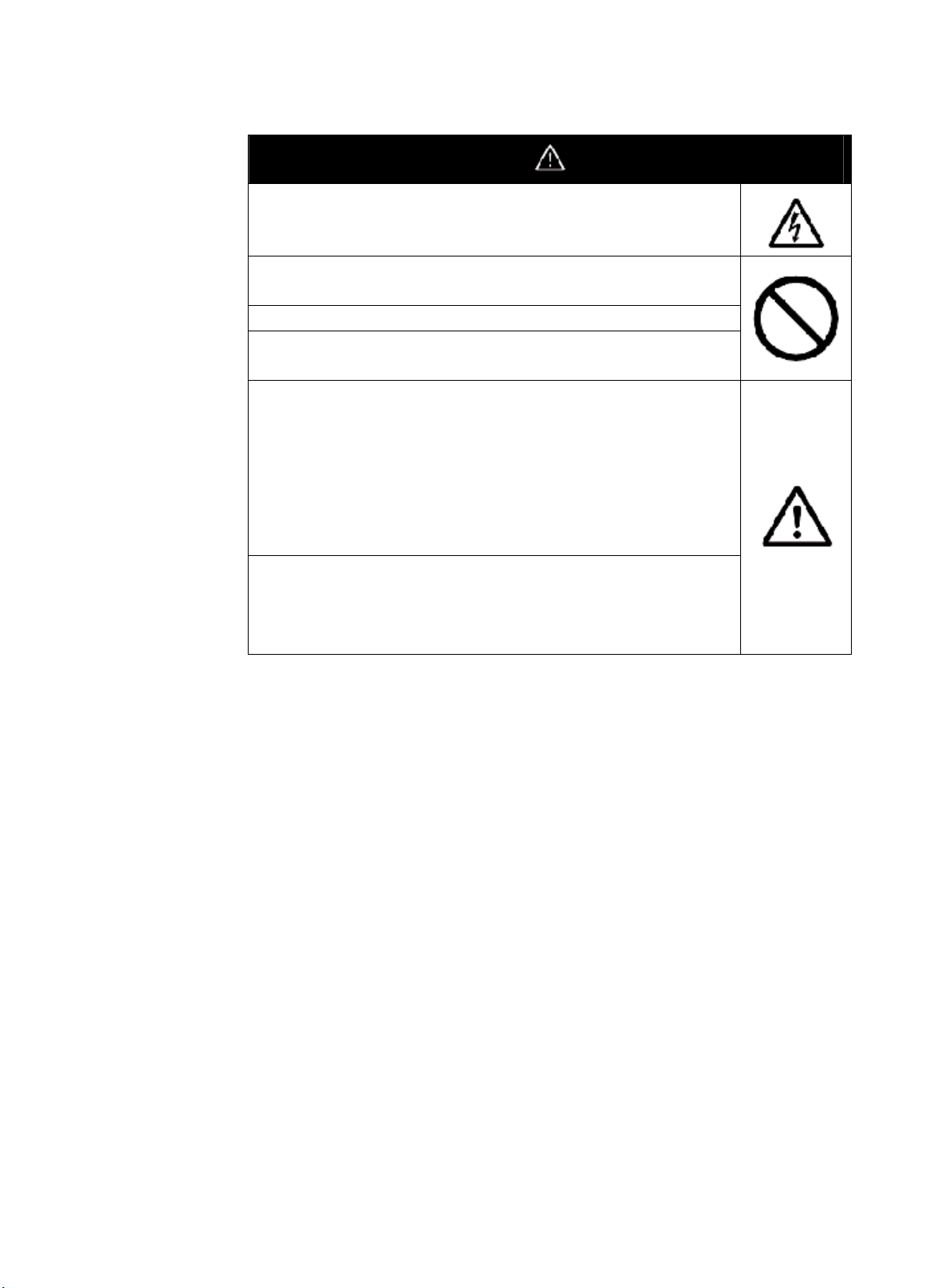

安全注意事项

通电时请不要触及端子。

否则会由于触电而引起轻度的伤害。

制品中请勿有金属或导线、加工的粉屑等进入;否则有触电、火灾、

故障的危险。

请勿在有易燃性、爆炸瓦斯的地方使用;否则可能引起爆炸。

请勿自行分解、修理、改造及触摸端子内部;否则有触电、火灾、故

障的危险。

注意-火灾和触电的危险

a) 本产品作为开放式过程控制设备通过 UL 认证,必须安装在不能向外喷火构

b) 在使用 1 个以上断路器的情况下,在修理点检前,请关闭所有开关,确保

c) 信号输入为 SELV 限制回路。*1

d) 注意:为了降低火灾和触电的危险,请勿在内部连接异于2级回路的输出。

在超过寿命的状态下使用输出电容器,会有接点熔着及烧毁的情况发

生。

输出继电器的寿命会因开关容量、开关条件而有很大的不同,因此必

须考虑实际使用条件,请在额定负载、电气寿命次数内使用

造内使用。

产品处于不通电状态。

*2

注意

*1 SELV回路是一种独立于电源的带有双重绝缘或强制绝缘的电路,不会超过30 V r.m.s. 和42.4 V峰值

或60 VDC。

*2 二级电源是一种通过UL测试和认证的电源,其次级输出的电流和电压被限制在单位级别内。

V

注意

端子螺丝请依规定的扭矩(0.74~0.90N.m)锁紧。螺丝松动,可能会

产生起火。(参见备注)

温控器的各种设定值,请配合控制对象做正确的设定。在设定内容与控

制对象的内容相异的情况下,错误的动作是造成装置的破损与事故的

原因。

当温控器因故障而无法正常运行或影响报警输出时会损坏设备和机

器。为了安全请考量温控器可能的故障,并在系统中安装监视设备。

备注 E5CZ-U 的规定扭矩为 0.5 N·m。

VI

安全使用注意事项

请确保遵守以下注意事项以防止操作失败、故障及对产品的功能和性能产生不利影响。否则可能会导致

意想不到的后果。

1) 本产品专为室内使用而设计。请勿在室外或下列环境中使用。

z 会直接受到加热设备辐射热的地方

z 有水、油等飞溅的地方

z 阳光直射的地方

z 有粉尘、腐蚀性气体(尤其是硫化气体、氨气等)存在的地方

z 温度变化激烈的地方

z 会产生结冰、凝露的地方

z 振动或冲击很强烈的地方

2) 在各型号规定的温度和湿度范围内使用和储藏温控器。

当二个或多个温控器水平紧靠安装或垂直紧安装时,由于温控器的热辐射会导致内部温度上升而降

低使用寿命。这种情况下,需要采取风扇强制冷却或其它通风措施来降低温控器的温度

3) 为了不妨碍散热,温控器周边请勿封闭。温控器本身的通风孔也不要堵塞。

4) 请确认端子的极性,做正确的配线。

5) 配线用压接端子请使用指定尺寸(M3.5 、宽 7.2mm 以下)的端子。明线材料,请使用

2

AWG24~AWG14 的绞线或硬铜线(截面积 0.205~2.081mm

多可以插入两根相同类型和尺寸的配线或两个压接端子。

6) 不使用的端子,请勿连接。

7) 为了避免感应噪声,温控器的接线板的接线应远离高压线或大电流的电源电缆。同样不要让电源线

一起走线或平行于温控器连线,推荐使用单独的管道屏蔽线。

在可能产生噪声的外围设备上安装浪涌吸收器或噪声过滤器,例如电感应设备(如电机、变压器、

螺线管圈、磁性线圈等)。在电源上使用噪声过滤器时,除了确认其电压和电流值外,还应尽可能近

地安装在温控器附近。将温控器及其电源尽可能地远离产生强大的、高频波(如频焊接机、高频机

器等)的设备和产生浪涌的设备。

8) 请在额定负载及电源电压范围内使用本产品。

9) 为了使电源投入时在 2 秒内到达额定电压,请借助开关、继电器等进行瞬间加载。如果电源电压缓

)。(剥线长度 5~6mm。)一个端口最

慢增加,温控器没有复位,可能会发生输出故障。

10) 电源接通后请确保至少有 30 分钟以上的预热时间,然后再开始实际的控制操作,以保证温度显示

的正确性。

VII

11) 使用自整定时,同时打开温度控制器和负载(如加热器),或在温控器打开前接通负载。如果在接通

负载前打开温控器电源,则不能再进行正确的自整定和实现最优控制。

12) 电源开关或断路器应该靠近单元。请设置作业人员能够马上关上电源的开关或断路器,并做适当的

表示。

13) 取出温控器之前需先关闭电源,请绝对不要用手触摸端子或电子元件,或者给予冲击。插回时,请

不要让电子元件与外壳接触。

14) 关于清洁:请勿使用油漆稀释剂,请用标准等级的酒精。

15) 电源启动后经约 2 秒钟输出才开启,在配置控制回路时请给予充分的考虑。

16) 切换到某些菜单时,输出可能会关闭,请考虑到这一点再进行操作。

17) EEPROM 的记入次数是有寿命的。通过通信等频繁记入数据的场合请使用 RAM 记入模式。

VIII

本手册的说明

手册构成

本手册中,按通信方式进行分别说明。

请结合所使用的系统阅读各章节。

概

概要

要

通信数据

Modbus

通

信

数

据

关于相关手册

本用户手册对 E5CZ/AZ/EZ 的通信功能进行说明。

关于控制器功能的详情,请参见各用户手册。

附

附录

录

IX

X

目录

前言········································································ I

阅读并理解本手册 ················································· II

保证内容和责任限定·············································· II

应用注意事项 ························································ II

免责条款······························································· III

安全注意事项 ·······················································IV

安全使用注意事项 ···············································VII

本手册的说明 ·······················································IX

第1章 通信方式············································ ········································································ 1-1

1.1 通信方式的概要 ··············································································································1-2

简介 ·····························································································································1-2

通信规格 ······················································································································1-3

传送顺序 ······················································································································1-3

接口 ·····························································································································1-4

布线 ·····························································································································1-4

通信参数 ······················································································································1-6

第2章 CompoWay/F 通信方式··················· ········································································ 2-1

2.1 数据格式 ·························································································································2-2

命令帧··························································································································2-2

响应帧··························································································································2-3

通信数据 ······················································································································2-4

终止码示例···················································································································2-4

2.2 命令文本构成·················································································································· 2-6

PDU构成······················································································································2-6

区域定义 ······················································································································2-6

类别代码 (变量类别) ···································································································2-6

地址 ·····························································································································2-7

要素数··························································································································2-7

服务一览 ······················································································································2-7

2.3 服务详情 ·························································································································2-9

变量区域读取··············································································································· 2-9

变量区域写入·············································································································2-10

控制器固有属性读取 ··································································································2-12

控制器状态读取 ·········································································································2-13

回传测试 ····················································································································2-14

动作指令 ····················································································································2-15

2.4 响应代码一览················································································································ 2-20

第3章 CompoWay/F 和 SYSWAY的通信数据 ··············································································· 3-1

3.1 变量区域(设定范围)一览·································································································3-2

3.2 状态 ······························································································································3-14

XI

第4章 SYSWAY (E5□J 和 E5□X格式) 通信方式 ····························································· 4-1

4.1 数据格式 ·························································································································4-2

命令帧格式···················································································································4-2

响应帧··························································································································4-3

通信数据 ······················································································································4-3

SYSWAY命令一览·······································································································4-4

4.2 命令解说 ·························································································································4-5

当前值读取···················································································································4-5

设定值写入···················································································································4-6

设定值和操作量监控读取·····························································································4-7

通讯写入切换··············································································································· 4-9

第5章 Modbus 通信方式 ···························· ········································································ 5-1

5.1 数据格式 ·························································································································5-2

命令帧··························································································································5-2

响应帧··························································································································5-4

错误代码 ······················································································································5-5

5.2 功能一览 ·························································································································5-6

5.3 变量区域 ·························································································································5-7

5.4 服务详情 ·························································································································5-9

变量区域读取··············································································································· 5-9

变量区域写入·············································································································5-11

动作指令 ····················································································································5-14

回传测试 ····················································································································5-19

第6章 Modbus的通信数据 ·························· ········································································ 6-1

6.1 变量区域与(设定范围)一览 ·····························································································6-2

6.2 状态 ······························································································································6-13

附录········································································· ··················································································· A-1

ASCII代码表 ··························································································································A-2

故障排除 ································································································································A-3

索引 ········································································································································· I-1

修订纪录 ·································································································································R-1

XII

第1章

通信方式

本章对通信方式及布线方法进行简要说明。在设置设备时请阅读本章。

1.1 通信方式的概要 ·················································1-2

简介···································································· 1-2

通信规格 ····························································1-3

传送顺序 ····························································1-3

接口···································································· 1-4

布线···································································· 1-4

通信参数 ····························································1-6

通信参数设定 ·····················································1-6

通信参数 ····························································1-7

1-1

第 1 章 通信方式

1.1 通信方式概要

简介 通信功能在主机侧进行编程,并由主机监控或设定E5CZ/AZ/EZ的参数。在此,从

主机开始进行说明。

CompoWay/F是欧姆龙通用串行通信中的统一通信方式。具有统一的帧格式,其

命令依据在欧姆龙生产的PLC等中有实际成果的FINS*,便于主机和组件间进行通

信。

概述

*FINS(Factory Interface Network Service)

在欧姆龙FA网络上的控制器间进行信息传递的协议。

Modbus是一种标准通信控制方式,遵循Modicon公司的RTU-模式Modbus协议

(PI-MBUS-300修订版 J)。支持的功能同CompoWay/F,变量区域的读取,变量区

域的写入,动作指令和回传测试功能。

E5CZ/AZ/EZ 支持以下通信功能。

z 参数的读取/写入

z 动作指令

z 设定值的选择

通信功能遵循下列条件:

z 仅当“通讯写入” 参数设为ON(启用)时,参数才能被写入。

1-2

通信规格

1.1 通信方式的概要

传送通路连接 RS-485: 多支路

RS-232C: 点对点

通信方式(参见备注1。) RS-485 (2线式半双工)/RS-232C

同步方式 起停同步

通信波特率(参见备注2。) 1200, 2400, 4800, 9600,19200 或 38400 bps

通信代码 ASCII

通信数据长度(参见备注

7 或 8位

2。)

通信终止位(参见备注2。) 1 或 2位

出错检查 垂直奇偶校验 (无,偶校验,奇校验)

SYSWAY通信时,FCS (帧检测顺序)

CompoWay/F通信时,BCC (块检查字符)

Modbus通信时,CRC-16 (循环冗余检查-16)

流控制 无

接口 RS-485/RS-232C

重启式功能 无

通信缓冲 40 字节

通信响应等待时间 0~99毫秒, 默认时间: 20毫秒

备注1:仅E5AZ和E5EZ支持RS-232C。

概述

备注2:可以使用通信菜单对通信比特率,数据长度,终止位,垂直奇偶校验进行分别设

定。高亮部分为初始值。

传送顺序

主机传送命令帧时,E5CZ/AZ/EZ传送与命令内容对应的响应帧。每个命令帧返回一个响

应帧。命令帧和响应帧的动作如下。

命令帧 命令帧

主机

响应帧

从主机侧接收本机的响应到发送下一个指令之间至少等待 2

毫秒。

1-3

第 1 章 通信方式

接口

通过一个标准的RS-485接口或RS-232C接口和主机进行通信。使用一个K3SC接

口转换器对RS-485和RS-232C接口进行转换。

配线 RS-485

z 连接形态为1对1或1对多。1对多连接时,包括主机最多能连接32台。

z 电缆总长最大为500m。

2

)~AWG14 (截面积2.081 mm2)。

通讯变换器

侧

概述

主机侧

z 请使用屏蔽双绞电缆AWG24(截面积0。205 mm

简称

端子号

简称

屏蔽线

标记

空

终端负载

端子号

终端负载请使用

屏蔽线

侧

简称

包括主机在内的传送通路的两端,必须进行终端的指定(终

规定传输路径的两端,包括主计算机作为端节点

端负载的连接)。使用的终端负载不小于 54Ω。

将主机和E5CZ/AZ/EZ的通信规格设为一致。使用1对多连接时,使所有通信单元的

通信规格保持一致(当然,每个单位的编号是唯一的)。

本章说明E5CZ/AZ/EZ通信规格的设定方法。有关主机的详情,请参见主机附带的

用户手册。

1-4

RS-232C (仅限于E5AZ/E5EZ)

采用1对1连接。电缆总长最大为15m。要延长线路,请使用欧姆龙Z3R RS-232C光

接口。

对于电缆,请使用屏蔽双绞电缆AWG24(截面积:0.205mm

2

)。

主机(IBM PC/AT 或兼容)

2.081mm

主机

PIN

PIN

1.1 通信方式的概要

2

)~AWG14(截面积

概述

电缆参考图

导线横截面

1-5

第 1 章 通信方式

通信参数

在通信菜单中设定E5CZ/AZ/EZ的通信规格。这些参数的设定在E5CZ/AZ/EZ的操作

面板上进行。通信参数及其设定范围如下表所示。

项目 记号 设定内容 设定值

通信协议 CompoWay/F (SYSWAY)/Modbus

通信单元号 0~99 0,,1到99

通信波特率 1.2/2.4/4.8/9.6/19.2/38.4 (kbps) 1.2/2.4/4.8/9.6 /19.2/38.4 (kbps)

概述

通信数据位 7/8位 7 /8位

通信终止位 1/2 1/2

通信奇偶校验 无,偶校验,奇校验

发送数据等待时间 0~99 0~99 ms, 默认时间: 20 毫秒

通信参数设定

高亮部分表示初始值。

使用E5CZ/AZ/EZ进行通信之前,按以下步骤设定通信单元编号,波特率及其他参

数。关于通信参数设定以外的操作方法,请参见所使用机型的用户手册。

1. 按菜单键 3 秒以上,从“操作菜单”转换到“初始菜单”。

2. 按菜单键少于 1 秒,从“初始菜单”转换到“通信菜单”。

3. 用模式键进行参数的切换。

1-6

4

.

使用上调或下调键更改参数设定值。

1.1 通信方式的概要

协议选择

备注:仅当“ 协议设定” 设为

CompoWay/F时显示。

通信单元编号

概述

通信波特率

通信数据位(参见备注.)

通信终止位(参见备注.)

通信奇偶校验

发送数据等待时间

通信参数

通信参数设定值改变后,仅在重新启动电源后才有效,请务必注意。

z 协议设定

通信协议可选。可设为 CompoWay/F(SYSWAY)或 Modbus。

z 通信单元编号

此参数为每一个温控器设定唯一的单元编号。设定单元编号的目的是,在与主

机进行通信时,便于主机识别温控器。能在 0~99 的范围内进行设定。初始值

为 1。当使用 2 个或 2 个以上温控器时,不要设定相同的单元编号。否则,会

影响正常的操作。

z 通信比特率

设定与主机进行通信时的波特率。通信波特率设置如下:1.2

( 1200bps ) ,2.4(2400bps),4.8(4800bps),9.6(9600bps),19.2(19200bps), 和 38.4

(38400bps)

z 通信数据长度

此参数设定通信数据位长度。设为“7 位”或“8 位”。

1-7

第 1 章 通信方式

z 通信终止位

此参数设定通信终止位长度。可设为“1”或“2”。

z 通信奇偶校验

可设定通信奇偶校验。可将奇偶校验设为“无”,“偶校验”或“奇校验”。

z 发送数据等待时间

概述

可设定 1~99 毫秒之间的发送数据等待时间,以 1 毫秒为间隔。

初始值为 20 毫秒。

1-8

第2章

CompoWay/F 通信方式

使用CompoWay/F通信格式时,请阅读本章。

2.1 数据格式 ········································································2-2

命令帧 ······································································2-2

BCC计算示例·····················································2-3

响应帧 ······································································2-3

通信数据···································································2-4

终止码示例 ·······························································2-4

2.2 命令文本构成································································· 2-6

PDU构成 ··································································2-6

区域定义···································································2-6

类别代码 (变量类别) ··············································2-6

地址 ··········································································2-7

要素数 ······································································2-7

服务一览···································································2-7

2.3 服务详情 ········································································2-9

变量区域读取 ··························································· 2-9

变量区域写入 ························································· 2-10

控制器固有属性读取··············································· 2-12

控制器状态读取······················································ 2-13

回传测试·································································2-14

动作指令·································································2-15

2.4 响应代码一览······························································· 2-20

2-1

第 2 章 CompoWay/F 通信方式

2.1 数据格式

在数字前加 H’,表示 16 进制数,如 H’02。不带 H’前缀的数字,表示 ASCII 字符。

在帧的各字段下的数字表示字节数。

命令帧

文本

节点号 子地址

命令文本

计算范围

STX

表示通信帧文本开头的代码。

请在开头字节中设置该字符。

接收期间再一次接收STX时,从已接收STX的地方修正接收。

节点号 z 此编号指定传送对象。

z 指定E5CZ/AZ/EZ的通信单元编号。

z 能进行BCD值设定00~99,和ASCII值“XX”设定。

z 广播发送时,请指定“XX”。广播发送无响应。

z 对于上述以外的节点号,无响应。

子地址 E5CZ/AZ/EZ不使用子地址。请务必设定为“00”。

SID (服务 ID) E5CZ/AZ/EZ不使用SID。请务必设定为“00”。

命令文本 命令文本部分。有关详情,请参见2.2 命令文本的构成。

ETX 表示文本结束的代码。

BCC

块检查字符。

将节点号~ETX的值按每个字节进行XOR(异或)后的值作为BCC。

2-2

BCC计算示例

BCC(块检查字符)由自节点号~ETX 的值按每个字节进行异或计算的结果决定。将该 8 位

数据写入到帧末尾的 BCC 字节中。

2.1 数据格式

节点号

将计算结果(35H)写入 BCC 字节。

子地址 命令文本

表示XOR(异或)计算,H表示16进制。

响应帧

节点号 子地址 终止码 命令文本

终止码 名称 内容 出错检查

00 正常结束 无异常,命令正常结束。 无

OF FINS 命令出错 不能执行指定的 FINS 命令。

有关不执行的详情,请根据 FINS 响应代码进行判断。

10 奇偶校验出错 接收的数据为「1」的位总和与[通信奇偶校验]的设定值不一致。 2

11 帧出错 终止位为「0」 1

12 溢出出错 接收数据已满时,希望传送新的数据。 3

13 BCC 出错 接收的 BCC 值和计算的 BCC 值不一致。 5

14 格式出错 z 命令文本包含0~9、A-F之外的字符。但是,回传测试除外(详

细请参见回传测试)。

z 没有SID和命令文本,或没有命令文本。

z 命令文本不包含「MRC/SRC」。

16 子地址出错 z 子地址不正确(不支持)。

z 没有子地址,SID,命令文本。

z 子地址不满2字符,没有SID和命令文本。

18 帧长度出错 接收帧超过规定的(支持)字节数。 4

z 终止码对本地节点的1个命令帧接收进行回送。

z 到ETX,BCC字符为止没有结束时,则没有响应。

z 出错检查优先顺序表示同时发生多个出错时的顺序。

BCC

优先顺序

8

7

6

2-3

第 2 章

通信数据

CompoWay/F 通信方式

通信

格式

设定(监视)值 负值 小数点

CompoWay/F 8位16进制 2的余数 省略小数点并将结果转化为16进制数。

示例:105.0→1050→H’0000041A

终止码示例

下例所示为命令没有正常结束时的终止码。

示例1) 子地址不正确,没有SID,命令文本时

命令

节点号

子地址

BCC

响应

节点号

子地址

终止码

BCC

终止码为16(子地址出错)

可以接收子地址,因为子地址出错检查的优先级高于格式出错。

示例2) 没有命令文本时

命令

节点号 子地址

SID

BCC

响应

节点号 子地址

终止码

BCC

终止码为14(格式出错)

2-4

示例3) 节点号未提供时

命令

节点号,缺1个字符

响应

没有响应

示例4) 没有子地址,BCC不正确时

命令

2.1 数据格式

节点号

BCC

响应

节点号

子地址

终止码

BCC

子地址设为00

,终止码为13(BCC出错)。

2-5

)

第 2 章

CompoWay/F 通信方式

2.2 命令文本构成

PDU构成 向命令文本传送MRC(主请求代码),SRC(子请求代码)以及与之相连的各个必要数

据。

服务请求PDU

响应帧中,紧接着上述MRC/SRC的传送,传送MRES(主响应代码)和SRES(子响应

代码),接着继续传送数据。

服务响应PDU(正常时)

无法执行指定命令文本时,仅MRC/SRC,MRES/SRES成为目标响应PDU。

服务响应PDU(不执行指定命令文本时)

MRES/SRES提供响应。正常结束时MRES/SRES不输出。

区域定义 仅由变量区域构成。

类别代码(变量类别)

下表所示为变量区域的类别代码。

存取尺寸

11:双字

变量类别(1 字节

区域

0:设定区域 0

1:设定区域 1

读取/写入

0:只能读取

1:可读取/写入

2-6

2.2 命令文本的构成

下表总结了设定区域0和设定区域1。

区域 说明

设定区域 0 此区域包括了保护,手动控制,操作和调整菜单。

设定区域 1 此区域包括了初始,通信和高级功能菜单。

变量类别转换为2字节的ASCII代码,放入帧内。实际存在的变量类别如下所示。

变量类别

内容

C0 双字数据,是设定区域0的只读参数。

C1 双字数据,是设定区域0的可读写参数。

C3 双字数据,是设定区域1的可读写参数。

* 设定区域1没有只读参数,所以没有变量类别 “C2。”

地址

根据变量类别附加地址。地址用2字节16进制表示,请加上存取尺寸单位。

要素数

要素数用2字节16进制表示。要素数的指定范围为“0 ~ 2”。

示例,要素数为“0002,”时,从地址中指定两项数据。

服务一览

MRC SRC 服务名称 处理

01 01 变量区域读取 读取变量区域。

01 02 变量区域写入 写入变量区域。

05 03 控制器固有属性读取 读取型号,通信缓冲器的尺寸。

06 01 控制器状态读取 读取运行状态。

08 01 回传测试 进行回传测试

30 05 动作指令 进行运行/停止,AT(自整定)执行/

中止,转换到设定区域1等。

2-7

第 2 章

CompoWay/F 通信方式

z 在存储器异常(RAM异常)或者控制器初始化时(直到电源接通后控制器读取

当前值为止)不接受任何指令,没有响应。

2-8

2.3 服务详情

变量区域读取

读取变量区域

服务请求PDU

2.3 服务详情

变量

类别

读取开始

地址

位元

位置

要素数

服务请求 CPU

响应代码

读取数据

(要素数部分)

或

(1) 变量类别和读取开始地址

有关变量类别和读取开始地址的详情,请参见第3章 CompoWay/F and SYSWAY

的通信数据。

(2) 位元位置

E5CZ/AZ/EZ 不支持位元存取。固定为“00”

(3) 要素数

要素数 处理

0000 不进行读取操作(不将读取数据添加到服务请求PDU),且

正常结束。

0001到 0002 进行读取操作,且正常结束。

(4) 响应代码

正常结束

响应代码 名称 说明

0000 正常结束 没有异常

发生错误

响应代码 出错名称 原因

1001 命令长度溢出 命令长度过长。

1002 命令长度不够 命令长度不够。

1101 区域类别出错 变量类别错误。

1103 开始地址超出范围 读取开始地址超出范围。

2-9

第 2 章

CompoWay/F 通信方式

响应代码 出错名称 原因

110B 响应长度溢出 超出要素数0002。

1100 参数出错 位元位置在00之外。

2203 动作出错 EEPROM异常。

(5)注意事项

z 报警功能

即使报警在温控器面板上无显示时,但它们在通信功能中仍然有效。

变量区域写入

写入变量区域

服务请求PDU

变量

类别

写入开始

地址

位元

位置

要素数

写入数据

(要素数部分)

服务响应 PDU

(1) 变量类别和写入开始地址

有关变量类别和写入开始地址的详情,请参见第3章 CompoWay/F和SYSWAY的

通信数据。

(2) 位元位置

E5CZ/AZ/EZ不支持位存取。固定为“00”。

(3) 要素数

要素数 处理

0000 不进行写入,为正常结束(请勿将写入数据添加到服务响应

0001到0002 进行写入,为正常结束。

(4) 响应代码

正常结束时

响应代码 名称 说明

0000 正常结束 没有异常

或

响应代码

PDU中)。

2-10

出错时

响应代码 出错名称 原因

1002 命令长度太短 命令长度太短

1101 区域类别出错 变量类别出错。

2.3 服务详情

1103 开始地址超出范围

出错

1104 结束地址超出范围

出错

1003 要素数/ 数据数不

一致

1100 参数出错 z 位元位置不是 “00”

3003 只读数据出错 在变量类别“C0”中进行了写入 。

2203 动作出错 z “通讯写入”参数设为 “OFF” (禁用)。

* 有关AT (自整定)的详情,请参见其他用户手册。

(5) 注意事项

写入开始地址超出范围。

写入结束地址(写入开始地址+要素数)超过变

量区域的最终地址。

数据数与要素数不一致。

z 写入数据在设置范围之外。

z 试图从设定区域0写入到设定区域1的设定

项目中。

z 试图从保护值以外写入保护设定项目中。

z 在AT (自整定)中 。*

z EEPROM异常。

z报警功能

即使报警在控制器显示屏上未显示,但它们在通信功能中仍然有效。

2-11

第 2 章

CompoWay/F 通信方式

控制器固有属性读取

此服务读取型号和通信缓冲器尺寸。

服务请求PDU

服务响应 PDU

(1) 型号

用10字节ASCII代码表示型号,不满10字节时为空格代码。

示例,E5CZ-R2MT使用如下型号(继电器输出,2个报警输出,可选单元功能和

多重TC/Pt输入)。

(2) 缓冲器尺寸

用2字节16进制数表示通信缓冲器尺寸,转换后读取4字节ASCII代码。

缓冲器尺寸:40字节(=H’0028)。

(3) 响应代码

正常结束时

响应代码 名称 内容

响应代码

型号

缓冲器尺寸

2-12

0000 正常结束 没有异常

发生出错时

响应代码 名称 内容

1001 命令长度溢出 命令长度过长

2203 动作出错 EEPROM异常

控制器状态读取

此服务读取控制器的运行状态和异常状态。

服务请求PDU

2 2

服务响应 PDU

2.3 服务详情

(1)运行状态

运行状态 内容

00 进行控制的状态(设定区域为0,没有发生出错,在运行中)

01 未进行控制的状态(除上述以外的状态)。

(2)相关信息

(3)响应代码

响应代码

运行

状态

相关

信息

位元位置

加热器电流值溢出(CT1)

加热器电流值保持(CT1)

加热器断线异常

显示范围溢出

输入异常

正常结束时

响应代码 名称 内容

0000 正常结束 没有异常

发生出错时

响应代码 名称 内容

1001 命令长度溢出 命令长度过长

2203 动作出错 EEPROM异常

2-13

第 2 章

回传测试

CompoWay/F 通信方式

此服务进行回传测试

服务请求PDU

服务响应 PDU

(1)测试数据

将任意测试数据设定在0~23的用户定义范围内。

根据通信数据长度,在以下范围内为测试数据设定某个值。

通信数据长度 测试数据

8位 ASCII代码:H’20~H’7E,H’A1~H’FE

7位 ASCII代码:H’20~H’7E

(2)响应代码

正常结束时

响应代码 名称 内容

0000 正常结束 没有异常

测试数据

响应代码

至

测试数据

至

请勿设置H’40。将会变为无响应。

2-14

发生出错时

响应代码 名称 内容

1001 命令长度溢出 命令长度过长

2203 动作出错 EEPROM异常

动作指令

此服务执行各项操作,如运行/停止,通讯写入,写入模式,保存RAM数据,AT (自

整定) 执行/取消,多重-SP, 转换到设定区域1和软件复位。

服务请求PDU

指令

代码

相关

信息

服务响应 PDU

响应代码

(1)指令代码和相关信息

2.3 服务详情

指令代码 指令内容 相关信息

00 通讯写入 00: OFF (禁用)

01 运行/停止 00: 运行

02 多重-SP 00: 设定点0

03 AT 执行/取消 00: 取消

04 写入模式 00: 备份

05 保存RAM数据 00

06 软件复位(参见备注。) 00

07 转换到设定区域1 00

08 自动/手动切换 00:自动模式

0B 参数初始化 00:初始化至默认值

备注:软件复位中没有响应。

(2)响应代码

正常结束时

01: ON (启用)

01: 停止

01: 设定点1

02: 设定点2

03: 设定点3

01: AT 执行

01: RAM

01:手动模式

响应代码 名称 内容

0000 正常结束 没有异常

2-15

第 2 章

发生出错时

CompoWay/F 通信方式

响应代码 出错名称 原因

1001 命令长度溢出 命令长度过长。

1002 命令长度太短 命令长度太短。

1100 参数出错 指令代码和相关信息错误。

2203 动作出错 z “通讯写入”参数设为OFF(禁用)。但是:

注意,无论(通讯写入)设为(ON)还是

(OFF),错误信息始终能被接收。

(3)动作指令和注意事项

z 通讯写入

通过设置相关信息将“通讯写入”设为“ON:启用”或“OFF:禁用”。设定区

域0/1均可接收该指令。

z 运行/停止

通过设置相关信息选择控制的运行/停止。设定区域0/1的双方均可接收该指令。

z 多重-SP

事先在调整菜单中设置4个设定点,以便切换至所需的设定点。设定区域0/1的双方

均可接收该指令。

z AT执行/取消

通过设置相关信息选择AT的执行/取消。只可在设定区域0中进行接收,下列情况

下会发生“动作出错”。

z “运行/停止”参数设为停止时。

z 已由“设定区域1”发布时。

z ON/OFF控制时。

z 写入模式

通过设置相关信息选择备份模式或RAM写入模式,设定区域0/1的双方均可接收该

指令。

z 无法处理。有关详情请参见以下(3)

指令和注意事项

z EEPROM异常。

。

动作

2-16

2.3 服务详情

EEPROM (非易失性只读存储器)的写入次数是有限的。因此,需要频繁覆盖数据

时请使用RAM写入模式。

写入模式 说明

备份模式 由通讯写入操作/调整菜单内的参数(只读参数除外)时,

进行对EEPROM的写入。

RAM写入模式 由通讯写入操作/调整菜单内的参数(只读参数除外)时,

不进行对EEPROM的写入。但是,通过控制器面板上的按

键操作可以改变参数值。

z 从RAM写入模式切换到备份模式时, 操作/调整菜单中的参数(只读参数除外)

写入到EEPROM中。

z 仅当“通讯写入”参数设为“ON”(启用)时,RAM写入模式启用。

z 相应地,当“通讯写入”参数设为“OFF”(禁用)时,操作/调整菜单(只读参

数除外)中的参数写入到EEPROM中,即使模式设为RAM写入模式。

z RAM数据保存

将操作/调整菜单的参数值(只读参数除外)写入EEPROM,设定区域0/1的双方均

可接收该指令。

z 软复位

恢复接通电源时的处理,设定区域0/1的双方均可接收该指令,没有对于该动作指

令的响应。

z 转换到设定区域1

向“设定区域1”转换的动作指令,且设定区域0/1的双方均可接收该指令。如果“初

始化/通信保护”设为“2”,会发生“动作出错”,且禁止转换。

从设定区域0开始转换,显示变为“初始菜单”的“输入类型”,在设定区域1中

发布该动作指令时,显示不会发生变化。

2-17

第 2 章

CompoWay/F 通信方式

在手动模式中转换到设定区域1

在手动模式中发出此动作指令时,会发生“动作出错”,且禁止转换到设定区

域1。

z 自动/手动切换

此动作指令通过设置相关信息,切换手动模式或自动模式。仅设定区域1接受该指

令。在下列情况下会发生“动作出错”:

z 指令在设定区域1中执行时

z 禁用自动/手动切换(不显示)

控制器切换到手动模式时,会显示手动操作量。当控制器从手动模式切换到自动模

式时,会显示操作菜单的顶部参数。如果控制器切换到手动模式时已经处于手动模

式,指令将正常结束,且显示内容不变(内容不刷新)。

将自动/手动状态写入EEPROM

写入模式决定了自动/手动状态是否写入EEPROM。

写入模式 说明

备份模式 由通信切换自动/手动模式时,自动/手动状态写入

EEPROM。

RAM 写入模式

由通信切换自动/手动模式时,自动/手动状态不写入

EEPROM。

可使用控制器按键操作写入状态。

* 通过通信动作指令切换自动/手动模式且控制器处于RAM写入模式时,自动/手动

状态不存入EEPROM。相应的,如果执行软件复位或断开再接通电源,使控制

器重启,自动/手动模式复位到之前保存的状态。

在自整定期间切换到手动模式

如果在自整定(AT)期间切换模式,将取消AT且控制器切换到手动模式。

2-18

z 参数初始化

当前设置返回到初始值并写入EEPROM。此指令仅能在设定区域1中接受。在设定

区域0中发出此指令时,会发生“动作出错”。

在初始化中设定的设定值取决于指令的相关信息设置,如下表所示。

相关信息 说明(初始化值)

00 默认初始化值(有关详情,请参见第3章 CompoWay/F和

2.3 服务详情

SYSWAY

的通信数据

)。

(这些设置与设置数据的设定值初始化中选择FACT时使用

的相同。)

z 设定区域

控制动作在设定区域0中执行。在该状态下,可执行仅在控制中允许的动作或是那

些即使控制运行时执行也不会引起问题的动作。这些动作包括PV读取,SP写入,

和更改运行/停止状态。

但是,设定区域0禁止影响控制的动作,包括在初始菜单中写入数据。(始终允许

读取设置数据)。

在设定区域1中,停止控制动作。在该状态下,可执行在设定区域0中不允许的动

作。这些动作包括在初始菜单中写入数据。

电源接通时,温控器设置在设定区域0中。要转换到设定区域1,请使用“转换到

设定区域1” 指令。要返回至设定区域0,先断开再接通电源,或用“软件复位”

指令。

接通电源

软件复位指令

设定区域 0 设定区域 1

“转换到设定

区域1”指令

控制进行中 控制停止.

2-19

第 2 章

CompoWay/F 通信方式

2.4 响应代码一览

正常结束时

响应代码 名称 内容

0000 正常结束 无异常 无

发生出错时

响应代码 名称 内容

0401 未支持命令 不支持该命令的服务功能。 1

1001 命令长度溢出 命令长度过长。 2

1002 命令长度太短 命令长度太短。 3

1101 区域类别出错 变量类别错误。 4

1103 开始地址范围外出错 读取/写入开始地址在范围之外 5

1104 结束地址范围外出错 写入结束地址(写入开始地址+要素数)超出变量区域

的最终地址。

1003 要素数/数据数不一致 要素数和数据数不一致。 7

110B 响应长度溢出 响应长度超出通信缓冲器尺寸(要素数大于0002时)。 8

1100 参数出错 z 位元位置不为00

z 写入数据在设定范围外。

z 动作指令的指令代码或相关信息错误。

3003 只读数据出错 对变量类别“C0”进行写入。 10

2203 动作出错 z “通讯写入”设为OFF(禁用)。

z 由设定区域0对设定区域1的设定项目进行写入。

z 由保护值以外对保护设定项目进行写入。

z 在AT中进行写入。

z 在动作指令中不能进行处理。

z EEPROM异常。

出错检查

优先顺序

出错检查

优先顺序

6

9

11

2-20

第3章

CompoWay/F 和 SYSWAY的通信数据

本章罗列了CompoWay/F 和 SYSWAY 通信协议中通信数据的详细内容。

3.1 变量区域(设定范围)一览···································· 3-2

3.2 状态 ·································································3-14

3-1

第3章 CompoWay/F 和 SYSWAY的通信数据

3.1 变量区域(设定范围) 一览

以下为变量区域一览。在设定(监控)值一列内用16进制数表示CompoWay/F通信的设定范围。括号内的值

为实际的设定范围(SYSWAY的设定范围,请参见该实际值)。如果设定项有相关参考章节,请阅读相关章

节了解详情。

没有报警输出端子也可以在控制器中使用报警功能。在这种情况下,通过状态数据确认报警发生。

变量

类别

地址 参数名称 设定(监控)值 菜单

C0 0000 当前值 温度:与各传感器的控制范围相同。

C0 0001 状态(参见备注。) 有关详情,请参见:3.2 状态

C0 0002 内部设定点

C0 0003 加热器电流1值监视 H’00000000~H’00000226(0.0~55.0)

通信数据

C0 0004 MV监控(加热) 标准:H’00000000~H’0000041A

C0 0005 MV监控(冷却) H’00000000~H’0000041A(0.0~105.0)

C0 0007 漏电流1值监视 H'00000000~H'00000226 (0.0~55.0)

备注。 不显示在控制器的显示屏上。

操作

模拟:比例下限值-5%FS~比例上限值+5%FS

SP下限值~SP上限值

(参见备注。)

(-5.0~105.0)

加热冷却:H’00000000~H’0000041A

(0.0~105.0)

3-2

3.1 变量区域(设定范围)一览

变量

类别

C1 0000 操作/调整保护 H’00000000(0):在操作和调整菜单中没有限制。

C1 0001 初始化/通信保护 H’00000000(0):允许转换到初始化/通信菜单。

C1 0002 设定值改变保护 H’00000000(0):OFF

C1 0003 设定点 下限设定~上限设定

C1 0004 报警值1 H’FFFFF831~H’0000270F(-1999~9999)

地址 参数名称 设定(监控)值 菜单

H’00000001(1):禁止转换到调整菜单。

H’00000002(2):只允许显示和更改“PV”和“PV/SP”。

H’00000003(3):只允许显示“PV”和“PV/SP”。

(显示转换到高级功能菜单)

H’00000001(1):允许转换到初始化/通信菜单。

(不显示转换到高级功能菜单)

H’00000002(2):禁止转换到初始化/通信菜单。

(允许更改控制器显示屏上的设置)

H’00000000(1):ON

(禁止更改控制器显示屏上的设置)

保护

通信数据

操作

C1 0005 报警值上限1 H’FFFFF831~H’0000270F(-1999~9999)

C1 0006 报警下限值1 H’FFFFF831~H’0000270F(-1999~9999)

C1 0007 报警值2 H’FFFFF831~H’0000270F(-1999~9999)

C1 0008 报警值上限2 H’FFFFF831~H’0000270F(-1999~9999)

C1 0009 报警下限值2 H’FFFFF831~H’0000270F(-1999~9999)

C1 000A 报警值3(参见备注。) H’FFFFF831~H’0000270F(-1999~9999)

C1 000B 报警值上限3(参见备

注。)

C1 000C 报警下限值3(参见备

注。)

H’FFFFF831~H’0000270F(-1999~9999)

H’FFFFF831~H’0000270F(-1999~9999)

备注。 报警3未分配输出时,参数不显示在控制器的显示屏上。

3-3

第3章 CompoWay/F 和 SYSWAY的通信数据

变量

类别

C1 000D 加热器断线1检测 H’00000000~H000001F4(0.0~50.0)

C1 000E 设定点0 SP下限值~SP上限值

C1 000F

C1 0010

C1 0011

C1 0012 温度输入偏移值 H’FFFFF831~H’0000270F(-199.9~999.9)

C1 0013 上限温度输入偏移值 H’FFFFF831~H’0000270F(-199.9~999.9)

C1 0014 下限温度输入偏移值 H’FFFFF831~H’0000270F(-199.9~999.9)

C1 0015 比例带 H’00000001~H’0000270F(0.1~999.9)

C1 0016 积分时间 H’00000000~H’00000F9F(0~3999)

C1 0017 微分时间 H’00000000~H’00000F9F(0~3999)

C1 0018 冷却系数 H’00000001~H’0000270F(0.01~99.99)

通信数据

C1 0019 死区 H’FFFFF831~H’0000270F

地址 参数名称 设定(监控)值 菜单

设定点 1

设定点 2

设定点 3

SP下限值~SP上限值

SP下限值~SP上限值

SP下限值~SP上限值

(TC/Pt通用输入型号:-199.9~999.9)

(模拟输入型号:-19.9~99.99)

调整

C1 001A 手动复位值 H’00000000~H’000003E8(0.0~100.0)

C1 001B 滞后(加热) H’00000001~H’0000270F

(TC/Pt通用输入型号:0.1~999.9)

(模拟输入型号:0.01~99.99)

C1 001C 滞后(冷却) H’00000001~H’0000270F

(TC/Pt通用输入型号:0.1~999.9)

(模拟输入型号:0.01~99.99)

C1 001E HS报警1 H’00000000~H’000001F4(0.0~50.0)

3-4

3.1 变量区域(设定范围)一览

变量

类别

C1 0024 手动MV 标准:H'FFFFFFCE ~ H'0000041A (−5.0 ~105.0)

C1 0025 SP 斜坡设定值 H'00000000 (0): OFF

C1 0026 MV 上限 标准:MV下限+ 0.1 ~H’0000041A (MV 下限 + 0.1~105.0)

C1 0027 MV 下限 标准:H’FFFFFFCE ~MV上限−0.1 (−5.0~ MV上限−0.1)

C3 0000 输入类型 (TC/Pt

地址 参数名称 设定(监控)值 菜单

加热冷却:H'FFFFFBE6~ H'0000041A (−105.0

~ 105.0)

H'00000001 ~H'0000270F (1~ 9999)

加热冷却: H'00000000 ~ H'0000041A (0.0~

105.0)

加热和冷却: H'FFFFFBE6~ H'00000000 (−105.0~ 0.0)

H'00000000 (0): Pt (−200~850℃/−300 ~ 1500°F)

通用输入型号)

(参见备注。)

H'00000001 (1): Pt (−199.9 ~500.0℃/−199.9 ~ 900.0°F)

H'00000002 (2): Pt (0.0 ~ 100.0℃/0.0~210.0°F)

H'00000003 (3): JPt (−199.9~ 500.0℃/−199.9~900.0°F)

H'00000004 (4): JPt (0.0~100.0℃/0.0~210.0°F)

H'00000005 (5): K (−200~1300℃/−300~2300°F)

H'00000006 (6): K (−20.0~500.0℃/0.0~900.0°F)

H'00000007 (7): J (−100~850℃/−100~1500°F)

H'00000008 (8): J (−20.0~400.0℃/0.0~750.0°F)

H'00000009 (9): T (−200~400℃/−300~700°F)

H'0000000A (10): T (−199.9~400.0℃/−199.9~700.0°F)

H'0000000B (11): E (0~600℃/0~1100°F)

H'0000000C (12)

H'0000000D (13): U (−200~400℃/−300~700°F)

H'0000000E (14): U (−199.9~400.0℃/−199.9 to 700.0°F)

H'0000000F (15): N (−200~1300℃/−300~2300°F)

H'00000010 (16): R (0~1700℃/0~3000°F)

H'00000011 (17): S (0~1700℃/0~3000°F)

H'00000012 (18): B (100~1800℃/300~3200°F)

H'00000013 (19): 红外温度探头(K 140 F/60 C)

H'00000014 (20): 非接触式温度传感器(K 240℉/120℃)

H'00000015 (21): 非接触式温度传感器(K 280℉/140℃)

H'00000016 (22): 非接触式温度传感器(K 440℉/220℃)

H'00000017 (23): 0 ~ 50 mV

: L (−100~850℃/−100~1500°F)

备注。 可选择与所连接的传感器匹配的输入类型。

有两种输入类型规格:热电偶/测温电阻体输入和模拟输入。

手动

控制

调整

初始

设置

通信数据

3-5

第3章 CompoWay/F 和 SYSWAY的通信数据

变量

类别

C3 0000

C3 0001

C3 0002

C3 0003

地址 参数名称 设定(监控)值 菜单

输入类型( 模拟输入型

号) (参见备注。)

比例上限 比例下限 + 1~H’0000270F (比例下限+ 1~9,999)

比例下限 H’FFFFF831~比例上限−1 (−1999 ~比例上限−1)

小数点

(TC/Pt通用输入型号)

H'00000000 (0): 4 ~20 mA

H'00000001 (1): 0~ 20 mA

H'00000002 (2): 1~5 V

H'00000003 (3): 0~5 V

H'00000004 (4): 0~10 V

H'00000000~00000001 (0~1)

初始设置

小数点 (模拟输入型号)

C3

C3

C3

0004 温度单位

℃/℉选择

0005 上限设定 值的范围如下(省略小数点):

0006 下限设定 值的范围如下(省略小数点):

通信数据

C3

C3

C3

备注。 可选择与所连接的传感器匹配的输入类型。

0007 PID/开关 H’00000000(0):ON/OFF

0008 标准控制或者加热/冷却

控制

0009 ST H’00000000(0):OFF

有两种输入类型规格:热电偶/测温电阻体输入和模拟输入。

H'00000000~ 00000003 (0~3)

H’00000000(0):℃

H’00000001(1):℉

温度:输入范围下限+1~输入范围上限

模拟:比例下限~SP上限-1

温度:输入范围下限~输入范围上限-1

模拟:比例下限~SP上限-1

H’00000001(1):2自由度PID控制

H’00000000(0):标准

H’00000001(1):加热冷却

H’00000001(1):ON

3-6

3.1 变量区域(设定范围)一览

变量

类别

C3 000A 控制周期(加热) H’00000000(0):0.5

C3 000B 控制周期(冷却) H’00000000(0):0.5

C3 000C 正/逆操作 H’00000000(0):逆动作

C3 000D 报警1类型 H’00000000(0):报警功能关闭

C3 000E 报警 2 类型 H’00000001(1):上下限报警

C3 000F 报警 3 类型(参见备注) 设定与报警2类别相同

地址 项目 设定(监控)值 值名称

H’00000001~H’00000063(1~99)

H’00000001~H’00000063(1~99)

H’00000001(1):正动作

H’00000001(1):上下限报警

H’00000002(2):上限报警

H’00000003(3):下限报警

H’00000004(4):上下限范围报警

H’00000005(5):附待机顺序的上下限报警

H’00000006(6):附待机顺序的上限报警

H’00000007(7):附待机顺序的下限报警

H’00000008(8):绝对值上限报警

H’00000009(9):绝对值下限报警

H’0000000A(10):附待机顺序的绝对值上限报警

H’0000000B(11):附待机顺序的绝对值下限报警

H’0000000C(12):LAB(断路报警)

H’00000002(2):上限报警

H’00000003(3):下限报警

H’00000004(4):上下限范围报警

H’00000005(5):附待机顺序的上下限报警

H’00000006(6):附待机顺序的上限报警

H’00000007(7):附待机顺序的下限报警

H’00000008(8):绝对值上限报警

H’00000009(9):绝对值下限报警

H’0000000A(10):附待机顺序的绝对值上限报警

H’0000000B(11):附待机顺序的绝对值下限报警

初始设置

通信数据

备注。 报警3未分配输出时,参数不显示在控制器的显示屏上。

3-7

第3章 CompoWay/F 和 SYSWAY的通信数据

通信数据

变量

类别

C3 0010 通信单元号(参见备

C3 0011 波特率

C3 0012 数据位

C3 0013 终止位(参见备注。) H’00000001(1):1

C3 0014 奇偶校验(参见备注。) H’00000000(0):无

地址 参数名称 设定(监控)值 菜单

H’00000000~H’00000063(0~99)

注。)

H’00000000(0):1.2

(参见备注。)

(参见备注。)

H’00000001(1):2.4

H’00000002(2):4.8

H’00000003(3):9.6

H’00000004(4):19.2

H’00000005(5):38.4

H’00000007(7):7

H’00000008(8):8

H’00000002(2):2

H’00000001(1):偶校验

H’00000002(2):奇校验

通信设定

备注。 更改通信参数后,复位控制器可以使这些参数生效。

3-8

3.1 变量区域(设定范围)一览

变量

类别

C3 0015 多重-设定点使用数 H'00000000 (0):无多重-SP

C3 0016 事件输入分配1 H'00000000 (0):无

C3 0017 事件输入分配2 H'00000000 (0):无

C3 001A 多重-设定点使用 H'00000000 (0):OFF

C3 001B SP 斜坡时间单位 H'00000000 (0):EU/秒

C3 001C SP斜坡设定值 H'00000000 (0):OFF

C3 001D 待机顺序复位方式 H'00000000 (0):情况 A

C3 001E 报警时报警1 开启 H'00000000 (0):报警时关闭

C3 001F 报警 1 滞后 H'00000001 ~ H'0000270F

C3 0020 报警时报警2 开启 H'00000000 (0):报警时关闭

C3 0021 报警 2滞后 H'00000001 ~ H'0000270F

C3 0022 报警时报警3 开启(参

C3 0023 报警3滞后

C3 0024 HB使用 H'00000000 (0):OFF

C3 0025 加热器断线闩锁 H'00000000 (0):OFF

地址 参数名称 设定(监控)值 菜单

H'00000001 (1):2SP

H'00000002 (2):4SP

H'00000001 (1):运行/停止 (多重-SP使用数设为1或2时,

不能设定。)

H'00000002 (2):自动/手动(多重-SP使用数设为1或2时,

不能设定。)

H'00000001 (1):运 行 /停止 (多重-SP使用数设为2时,不

能设定。)

H'00000002 (2):自动/手动(多重-SP使用数设为2时,不

能设定。)

H'00000001 (1):ON

H'00000001 (1):EU/分钟

H'00000001~ H'0000270F (1 ~ 9999)

H'00000001 (1):情况 B

H'00000001 (1):报警时开启

(TC/Pt 通用输入型号:0.1 ~ 999.9)

(模拟输入型号:0.01~99.99)

H'00000001 (1):报警时开启

(TC/Pt 通用输入型号:0.1 ~ 999.9)

(模拟输入型号:0.01~99.99)

H'00000000 (0):报警时关闭

见备注。)

(参见备注。)

H'00000001 (1):报警时开启

H'00000001 ~ H'0000270F

(TC/Pt 通用输入型号:0.1 ~ 999.9)

(模拟输入型号:0.01~99.99)

H'00000001 (1):ON

H'00000001 (1):ON

高级功能

通信数据

备注。 报警3未分配输出时,参数不显示在控制器的显示屏上。

3-9

第3章 CompoWay/F 和 SYSWAY的通信数据

变量

类别

C3 0026 加热器断线滞后 H'00000001 ~H'000001F4 (0.1 ~ 50.0)

C3 0027 ST稳定范围 H'00000001~H'0000270F (0.1 ~ 999.9)

C3 0028 H'00000000~H'00000064 (0.00 to 1.00)

C3 0029 MV上限 标准:MV下限+ 0.1~H’0000041A (MV 下限+ 0.1~ 105.0)

C3 002A MV 下限 标准:H’FFFFFFCE~MV 上限−0.1 (−5.0~MV上限−0.1)

C3 002B 输入数字滤波器 H'00000000~H'0000270F(0.0 ~999.9)

C3 002C 附加PV 显示 H'00000000 (0):OFF

C3 002D MV 显示 H'00000000 (0):OFF (操作量显示关闭)

C3 002E 显示模式自动返回 H'00000000 (0):OFF

通信数据

C3 002F 报警1 闩锁 H'00000000 (0):OFF

地址 参数名称 设定(监控)值 菜单

高级功能

加热冷却:H'00000000~H'0000041A (0.0~105.0)

加热冷却:H'FFFFFBE6~H'00000000 (−105.0~0.0)

H'00000001 (1):ON

H'00000001 (1):ON (操作量显示开启)

H'00000001 ~ H'00000063 (1 ~ 99)

H'00000001 (1):ON

C3 0030 报警2 闩锁 H'00000000 (0):OFF

H'00000001 (1):ON

C3 0031 报警3 闩锁(参见备

注。)

H'00000000 (0):OFF

H'00000001 (1):ON

备注。 报警3未分配输出时,参数不显示在控制器的显示屏上。

3-10

3.1 变量区域(设定范围)一览

变量

类别

C3 0032 保护菜单转换时间 H'00000001 ~ H'0000001E (1~ 30)

C3 0033 输入错误输出 H'00000000 (0):OFF

C3 0034 冷接点补偿方式 H'00000000 (0):OFF

C3 0035 MB指令逻辑切换

C3 0038 报警 1 ON延时 H'00000000 ~ H'000003E7 (0 ~ 999)

C3 0039 报警 2 ON延时 H'00000000 ~ H'000003E7 (0 ~ 999)

C3 003A 报警 3 ON延时(参

C3 003B 报警 1 OFF延时 H'00000000 ~ H'000003E7 (0 ~ 999)

C3 003C 报警 2 OFF延时 H'00000000 ~ H'000003E7 (0 ~ 999)

C3 003D 报警 3 OFF延时

C3 003E 传送输出类型 H'00000000 (0):OFF

C3 003F 传送输出上限 H'FFFFF831~H'0000270F (−1999~9999) (参见

C3 0040 传送输出下限 H'FFFFF831 ~ H'0000270F (−1999~9999) (参

C3 0041 线性电流输出类型 H'00000000 (0):4~20 mA

C3 0042 输入偏移类型 H'00000000 (0):温度输入1-点偏移

地址 参数名称 设定(监控)值 菜单

H'00000001 (1):ON

H'00000001 (1):ON

H'00000000 (0):OFF

(参见备注2。)

见备注1。)

(参见备注1。)

H'00000001 (1):ON

H'00000000 ~ H'000003E7 (0 ~ 999)

H'00000000 ~ H'000003E7 (0 ~ 999)

H'00000001 (1):设定点

H'00000002 (2):SP斜坡期间的设定点

H'00000003 (3):PV

H'00000004 (4):MV 监视器 (加热)

H'00000005 (5):MV 监视器(冷却)

备注3。)

见备注3。)

H'00000001 (1):0~20 mA

H'00000001 (1):温度输入2-点偏移

高级功能

通信数据

初始设置

高级功能设

定

备注1 报警3未分配输出时,参数不显示在控制器的显示屏上。

备注2 仅MB命令(Sysway)可进行逻辑切换。CompoWay/F的动作指令的代码00(通讯写入)的逻辑不受

影响。

备注3 设定 (监视)范围取决于“传送输出类型”的设定。(详情参见

设定数据一览

。)

3-11

第3章 CompoWay/F 和 SYSWAY的通信数据

变量

类别

C3 0044 自动/手动切换显示附加 H'00000000 (0):OFF

C3 0046 HS报警使用 H'00000000 (0):OFF

C3 0047 HS报警闩锁 H'00000000 (0):OFF

C3 0048 HS报警滞后 H'00000001~ H'000001F4 (0.1~50.0)

C3 0049 LBA检测时间 H'00000000~H'0000270F (0~9999)

C3 004A LBA 级别 H'00000001~H'0000270F

C3 004B LBA带 H'00000000 ~ H'0000270F

通信数据

地址 参数名称 设定(监控)值 菜单

高级功能

H'00000001 (1):ON

H'00000001 (1):ON

H'00000001 (1):ON

(TC/Pt通用输入型号:0.1~999.9)

(模拟输入型号:0.01~ 99.99)

(TC/Pt通用输入型号:0.1~999.9)

(模拟输入型号:0.01~ 99.99)

3-12

3.1 变量区域(设定范围)一览

变量

类别

C3 004C 协议选择(参见备

C3 004D 发送数据等待时间

地址 参数项目 设定(监控)值 菜单

H'00000000 (0):CompoWay/F

注。)

(SYSWAY)

H'00000001 (1):Modbus

H'00000000 ~ H'00000063 (0 ~99)

(参见备注。)

C3 004E 控制输出1指定 控制输出1为线性输出时:

H'00000000 (0):未分配。

H'00000001 (1):

H'00000002 (2):控制输出 (冷却)

控制输出 (加热)

控制输出1为脉冲输出时:

H'00000000 (0):未分配。

H'00000001 (1):

H'00000002 (2):控制输出 (冷却)

H'00000003 (3):报警 1

H'00000004 (4):

H'00000005 (5):报警3

C3 0050 报警输出 1分配 H'00000000 (0):未分配。

H'00000001 (1):控制输出 (加热)

H'00000002 (2):控制输出 (冷却)

H'00000003 (3):报警 1

H'00000004 (4):

H'00000005 (5):报警3

C3 0051 报警输出2 分配 H'00000000 ~ H'00000005 (0 ~ 5)

控制输出 (加热)

报警2

报警2

* 和报警输出1分配的设定相同

C3 0052 显示字符选择 H'00000000 (0):OFF

H'00000001 (1):ON

C3 0056 报警输出 3分配 H'00000000 ~ H'00000006 (0 ~ 6)

和报警输出1分配的设定相同

*

高级功能

通信数据

备注 更改通信参数后,复位控制器可以使这些参数生效。

3-13

第3章 CompoWay/F 和 SYSWAY的通信数据

3.2 状态

状态数据的结构如下图所示。

通信数据

输出

输入异常

异常

位元位置

加热器电流值溢出(CT1)

加热器电流值保持(CT1)

HB (加热器烧毁报警) 异常

HS 报警输出(CT1)

超出显示范围

输入错误

控制输出(加热)

控制输出 (冷却)

3-14

HB (加热器烧毁) 报警输出

(CT1)

报警输出1

报警输出2

报警输出3

3.2 状态

动作状态 事件输入

位元位置

事件输入 1

事件输入 2

写入模式

设定区域

AT执行/取消

运行/停止

通讯写入

自动/手动

通信数据

3-15

第3章 CompoWay/F 和 SYSWAY的通信数据

通信数据

位元位置 状态

位的内容

0 1

0 加热器电流值溢出(CT1) 未发生 发生

1 加热器电流值保持(CT1)(参见备注1) 更新 保持

2 HB(加热器断线报警)异常 未发生 发生

3 HS 报警输出(CT1) OFF ON

4 空 OFF ---

5 显示范围溢出 未发生 发生

6 输入异常 未发生 发生

7 空 OFF ---

8 控制输出 (加热) OFF ON

9 控制输出 (冷却) OFF ON

10 HB(加热器断线)报警输出(CT1) OFF ON

11 空 OFF ---

12 报警输出1 OFF ON

13 报警输出 2 OFF ON

14 报警输出 3 OFF ON

15 空 OFF ---

16 事件输入1 OFF ON

17 事件输入2 OFF ON

18 空 OFF ---

19 空 OFF ---

20 写入模式 备份模式 RAM写入模式

21 EEPROM RAM=EEPROM RAM≠EEPROM

22 设定区域 设定区域0 设定区域1

23 AT执行/取消 AT取消中 AT执行中

24 运行/停止 运行 停止

25 通讯写入 OFF(禁用) ON(启用)

26 自动/手动切换 自动模式 手动模式

27 空 OFF ---

28 空 OFF ---

29 空 OFF ---

30 空 OFF ---

31 空 OFF ---

备注 1。 控制输出ON的时间少于190 ms时,设定为“1” ,且加热器电流值监控中保持之前的值。

备注 2。 “空”位总是关闭。

备注 3。 在设定区域1中读取时,位的状态如下:

z 电流值溢出:保持之前的

z HB出错: 保持之前的值

z 电流值保持: 保持之前的

z 超出显示范围: 保持之前

z 输入出错: 保持之前的值

z HB和HS输出:清除

z 加热冷却输出: 清除

z 报警输出: 清除

3-16

第4章

SYSWAY (E5□J和E5□X格式)

通信方式

该通信方式支持与现有机型(E5□J 和 E5□X)的兼容性。

采用新系统时,建议使用CompoWay/F通信方式。

4.1 数据格式····························································4-2

命令帧格式······················································4-2

FCS计算示例············································ 4-2

响应帧 ·····························································4-3

通信数据 ·························································4-3

SYSWAY命令一览··········································4-4

4.2 命令解说····························································4-5

当前值读取······················································4-5

设定值写入······················································4-6

设定值及操作量监控读取································4-7

通讯写入切换 ··················································4-8

4-1

第4章 SYSWAY (E5□J和E5□X格式)通信方式

4.1 数据格式

命令帧格式

通信

单元

号

标题

代码

数据

代码

文本

终端

负载

计算范围

@ 表示块格式开头的字符(ASCII H’40)。

通信单元号 BCD中可以设为00~99,对于00~99以外的单元编号,无响应。

标题代码 用2个字符表示命令的种类。

数据代码 仅在报警值2写入/读取时为”02”,其余全部为”01”。

文本 保存读取值, 写入值,或状态数据等,根据命令而不同。

FCS 帧检查时序。

对从@开始到文本最终字符为止的值,按每个字符进行XOR(异或),保存转为ASCII代码

的值。

终端负载 表示块格式的结束。

由*和CR(回车=H’0D)构成。

zFCS的计算示例

FCS(帧检查时序)计算机从开始字符“@”到文本的最终字符为止的异或,将该8位

SYSWAY

数据转换为ASCII,设置到FCS处。

开始

字符

通信单元号 标题代码 数据代码

4-2

将计算结果4BH根据各个位转换为ASCII,设置到FCS。

表示XOR(异或)计算,H表示16进制。

响应帧

通信

单元

标题

代码

结束

代码

号

终止码 名称 内容

文本

4.1 数据格式

终端

负载

优先

顺序

10 奇偶校验出错 接收的数据为“1”的位总和与“通信奇偶校验”的设定值不一

1

致。

11 帧出错 终止位为“0” 2

12 溢出出错 接收数据缓存器已满时,进行新的数据传送。 3

13 FCS出错 接收的FCS值和计算的FCS值不同 4

IC* 未定义出错 不能解读命令的标题代码。 5

14 格式出错 命令长度不正确 6

OD 命令不可执行 通讯写入为OFF(禁用)时,进行设定值的写入。

7

当AT执行时写入设定值。

15 未定义数据 写入数据在设定范围之外或不为数值。

数据代码在设定范围之外或不为数值。

00 正常结束 没有异常,正常结束命令 —

8

SYSWAY

*未定义出错的响应格式与通常情况下不同,没有“终止码”,出错代码保存在“标题代码”中,详细情况请

参见以下内容。

未定义出错时的响应格式

通信

单元

标题

代码

终端

负载

号

通信数据

通信格式 设定(监控)值 负值 小数点

SYSWAY 10进制4位 最高位为-1,则将最高位设为A

例:-1999→A999

设为没有小数点。

例:105.0→1050

最高位为:-,则将最高位设为F

例:-10→F010

4-3

第4章 SYSWAY (E5□J和E5□X格式)通信方式

SYSWAY命令一览

分类

标题

代码

数据

命令 写入/读取 数据长度 备注

代码

通讯写入切换 MB 01 通讯写入切换 写入 4B

写入 无

注1。)

ME 01 备份模式选择 写入模式选择(参见备

MA 01 RAM写入模式选择

操作/调整设定值保存 MW 01 操作/调整设定值保存

设定值写入

WS 01 设定点写入

写入 4B

W% 01 报警值1写入

W% 01 报警值2写入

WB 01 比例带写入

WN 01 积分时间写入

WV 01 微分时间写入

WI 01 温度输入偏移值写入

WW 01 加热器断线检测写入

设定值读取及操作量

监控读取

RS 01 设定点读取

R% 01 报警值1读取

读取 4B

R% 02 报警值2读取

RB 01 比例带读取

RN 01 积分时间读取

RV 01 微分时间读取

RI 01 温度输入偏移值读取

RW 01 加热器断线检测读取

RO 01 操作量监控读取

SP上下限值读取 RL 01 SP上下限值读取 读取 8B 上下限

SYSWAY

当前值读取 RX 01 当前值读取 读取 8B 参见备

加热器电流值监控读取 RZ 01 加热器电流值监控读取 读取 8B 参见备

初始状态读取 RU 01 初始状态读取 读取 5B 参见备

z 在内存异常(RAM异常),初始状态(直至求出接通电源时的当前值为止的状态)中,不接受全部服务,没有响应。

z 在内存异常(EEPROM异常)时进行写入时,不进行EEPROM的写入,为”正常结束”。读取和平常一样进行。

备注 1。 EEPROM (非易失性只读存储器) 的写入次数有限。因此,需要频繁覆盖数据时采用RAM。

备注 2。当前值读取范围为各输入的显示范围。

备注 3。状态 (后半部4B)

备注4:状态(前半部2B)

值一次

性读取

注 2。

注 3。

注 4。

位元位置 位元位置

溢出

显示保持

控制模式

输出动作

z 溢出:加热器电流值>55。0A时设为1。

z 显示保持:控制输出ON的时间不满19ms时,设为1,加热器电流保持之前的值。

4-4

1

ON/OFF

正动作

0

PID

逆动作

4.2 命令解说

当前值读取

读取当前值和状态。

命令

标题

代码

数据

代码

通信单

元号

响应

4.2 命令解说

终端

负载

通信单

元号

(1)当前值

请参见

第3章

(2)状态

输入异常 未发生 发生

加热器断线检测 OFF或没有功能 ON

EEPROM RAM=EEPROM RAM≠EEPROM

报警1 OFF或没有功能 ON

报警2 OFF或没有功能 ON

写入模式 备份模式 RAM写入模式

通讯写入 OFF(禁用)或没有功能 ON(启用)

(3)终止码

标题代码结束

代码

当前值

CompoWay/F和SYSWAY

状态

终端

负载

的通信数据

位元位置

输入异常

加热器烧毁检测

EEPROM

报警1

报警2

写入模式

通讯写入

内容 项目

0 1

SYSWAY

终止码“00”时为正常,除此之外的情况下无法进行命令处理,有关终止码的详

情请参见:

响应帧

(第4-3页)。

4-5

第4章 SYSWAY (E5□J和E5□X格式)通信方式

(4) 注意事项

z 即使控制器显示屏不显示报警 1和 2 ,但是通信中的全部功能有效。

z 控制器转换到设定区域1时,保持之前保存的状态。设定区域1整合了初始菜单,

通信菜单和高级功能菜单。

设定值写入

此指令写入设定点,报警值1和2,比例带,积分时间,微分时间,温度输入偏移

值和加热器断线检测。

SYSWAY

(2) 数据代码

命令

通信单

元号

标题代码数据

代码

写入值 FCS

终端

负载

响应

通信单

元号

标题代码结束

代码

终端

负载

(1)标题代码

标题代码 命令

WS

W%

WB

WN

WV

WI

WW

设定点写入

报警值 1/2 写入

比例带写入

积分时间写入

微分时间写入

温度输入偏移值写入

加热器断线检测写入

仅在写入报警值2时,数据代码为 “02” 。其余全部为“01。”

(3) 写入值

4-6

有关写入值(设定值)范围的详情,参见

信数据

。

CompoWay/F 和 SYSWAY

的通

第3章

(4) 注意事项

●报警值1和2

报警1类型设定为“上下限报警”,“上下限范围报警”或“附待机顺序的上下限

报警”,可分别设定上下限报警。报警值1设定禁用,而“报警值上限1”和“报

警值下限1”的设定用作报警设定值。

4.2 命令解说

因此,设定上下限报警时,由通信将值写入到“报警值上限1”和“报警值下限1”,

而不是“报警值1”。“报警值2”也一样。

●温度输入偏移

使用2-点偏移时,“温度输入偏移”禁用,启用“上限温度偏移值”和“下限温度

偏移值”作为“温度输入偏移值”。因此,将值写入“上限温度偏移值”和“下限

温度偏移值”,而不是“温度输入偏移值”。

2-点偏移方式用在下列情况中:

z “输入类型”设为非接触式温度传感器。

z “输入类型”未设为非接触式温度传感器,但是“输入偏移类型”设为2-点偏

移。

●报警

z 仅支持报警1和2。

z 不支持报警3。

●加热器断线检测

写入到“加热器断线1检测”。

设定值及操作量监控读取

读取设定点,报警值1和2,比例带,积分时间,微分时间,温度输入偏移,加热

器断线检测和MV监视器。

命令

响应

通信单

元号

标题代码数据

代码

终端

负载

SYSWAY

通信单

元号 标题代码结束代码

读取值

终端

负载

4-7

第4章 SYSWAY (E5□J和E5□X格式)通信方式

(2)数据代码

(4) 注意事项

(1)标题代码

标题代码 命令

RS 设定点读取

R% 报警值 1/2 读取

RB 比例带读取

RN 积分时间读取

RV 微分时间读取

RI 温度输入偏移值读取

RW 加热器断线检测读取

仅在写入报警值 2 时为「02」,其余全部为「01」。

(3)读取值

有关读取值范围的详情,请参见「

」。

据

RO 操作量监控读取

●报警值1和2

报警1类型设为“上下限报警”,“上下限范围报警”或“附待机顺序的上下限报

第3章

CompoWay/F和 SYSWAY

的通信数

警”时,可分别设定报警的上下限。“报警值1设定”禁用,而“报警值上限1”

和“报警值下限1”设定用作报警设定值。

因此,设定“上下限报警”时,由通信读取的是“报警值上限1”而不是“报警值

1”。“报警值2”也一样。

SYSWAY

●温度输入偏移

使用2-点偏移方法时,“温度输入偏移”禁用,且启用“上限温度输入偏移值”和

“下限温度输入偏移值”参数,作为温度输入偏移设定值。因此,使用2-点偏移时,

读取的是“上限温度输入偏移值”,而不是“温度输入偏移值”。

2-点偏移方法用在以下情况中:

z “输入类型”设为非接触式温度传感器。

z “输入类型”未设为非接触式温度传感器,但是“输入偏移类型”设为2点偏移。

4-8

4.2 命令解说

●报警

只支持报警1和2。

不使用报警 3 。

●加热器断线检测

读取“加热器断线1检测”。

通讯写入切换

通过MB指令逻辑切换设置(高级功能菜单)更改MB指令的逻辑,如下表所示。

MB 指令 (通讯写入切换) 相当于 E5□J 控制器的MB指令 (远程/本地切换)。

MB 命令文本数据

0000 通讯写入启用

(远程模式选择)

0001 通讯写入禁用

(本地模式选择)

z MB 命令逻辑切换的初始值设为 OFF(逻辑与 E5J 相同)

MB 命令逻辑切换的设定

OFF ON

通讯写入禁用

(本地模式选择)

通讯写入启用

(远程模式选择)

SYSWAY

4-9

第4章 SYSWAY (E5□J和E5□X格式)通信方式

4-10

第5章

Modbus 通信方式

采用 Modbus 格式进行通信之前,请阅读本章。

5.1 数据格式 ··················································5-2

命令帧····················································5-2

CRC-16计算示例································5-3

响应帧····················································5-4

正常响应帧 ·········································5-4

错误响应帧 ·········································5-4

错误代码 ················································5-5

无响应················································· 5-5

5.2 功能一览 ··················································5-6

5.3 变量区域 ··················································5-7

地址 ···················································· 5-7

要素数················································· 5-8

设定值················································· 5-8

5.4 服务详情 ··················································5-9

变量区域读取·········································5-9

变量区域写入·······································5-11

动作指令 ··············································5-14

回传测试 ··············································5-19

5-1

ModBus通信方式

5.1 数据格式

数据格式遵循 Modbus (RTU)通信协议。因此,主机发出的命令和 E5CZ/AZ/EZ 返

回的响应都包含在数据块中,定义为帧。

下面对命令帧和响应帧的构成进行说明。

在以下示例中,数值前添加 H 表示十六进制数,如 H’02。不带前缀 H’的数字和字

命令帧

母都表示 ASCII 字符。

在 RTU 模式下,命令帧在至少 3.5 个字符时间的停顿区间后开始,并在至少 3.5

个字符时间的停顿区间后结束。

从机地址

3.5 个字符时间以上的停顿区间。

从机地址

功能码 功能码为 1 字节十六进制码,表示主机发出的指令类型。

数据

CRC-16

功能码 数据

字节

计算范围,

指定单元号。

可在 16 进制数H’00~H’63 之间(十进制 0~99)设定单元编号。

广播发送指定设为 H’00。广播发送无响应。

这是与特定功能码对应的文本数据,用于指定所需的数据,

如变量地址或设定数据。(采用 16 进制数。)

循环冗余码校验

校验码计算从机地址~数据末端的范围。

Modbus

5-2

用 2 字节十六进制数表示。

3.5 个字符时间以上的停顿区间。

zCRC-16计算示例

5.1 数据格式

工作存储器每次处理 1 个字节的消息。(CRC 寄存器即 16 位的寄存器)。

(1) CRC 寄存器初始化为 H’FFFF。

(2) 对 CRC 寄存器的内容和消息的首字节进行 XOR 异或运算,运算结果返回到

CRC 寄存器。

(3) MSB(最高有效位)用零填满,CRC 寄存器向右移 1 位。

(4) 如果 LSB(最低有效位)移过来的那位是“0”,则重复第(3)步(进行下一次移位)。

如果 LSB(最低有效位)移过来的那位是“1”,对 CRC 寄存器内容和 H’A001

进 XOR 异或运算,运算结果返回到 CRC 寄存器。

(5) 重复执行第(3)步和第(4)步,直至移位次数达到 8 次。

(6) CRC 过程一直持续到消息的末端。对 CRC 寄存器内容和消息的下一字节进

行 XOR 异或运算,重复执行第(3)步,运算结果返回到 CRC 寄存器。

(7) CRC 运算结果(CRC 寄存器的存储值)附加在消息的末字节内。

CRC 运算结果添加示例。

如果 CRC 运算结果为 H’1234,按以下图示将 CRC

从机地址

功能码 数据

存储值的附加给命令帧。

低

高

字节

计算范围,

Modbus

5-3

Mod Bus通信方式

响应帧

z正常响应帧

错误响应帧

从机地址

从机地址

从机地址 沿用命令帧中的从机地址,即返回响应单元的编号。

功能码 为接收功能码加上十六进制值 H’80,表示该响应是错误响应。

功能码 数据

计算范围

功能码

计算范围

错误代码

字节

字节

Modbus

5-4

示例:

接收功能码=H’03

发生错误时,响应帧中的功能码=H’83

错误代码 用以表示发生错误的类型。

CRC-16 循环冗余码校验

该校验码计算从机地址~数据末端的范围。

为 2 字节十六进制数。

错误代码

5.1 数据格式

最终代码 名称 说明

H’01 功能码出错 接收到不支持的功能码。 1

H’02 变量地址出错 指定的变量区域地址超出范围。 2

H’03 变量数据出错 数据量和要素数不一致。

字节数不是要素数的两倍。

响应长度超出通信缓冲器容量。

动作指令中的命令码或相关信息出错,或写入数据在设定范

围以外。

H’04 动作出错 在下列操作模式中不允许写入数据:

“通讯写入”参数设为“OFF”(禁用)。

试图由设定区域 0 对设定区域 1 的项目进行写入。

试图将非保护菜单的参数写入保护参数。

AT 执行期间。

不能处理的指令。

出错检测

优先级

3

4

无响应

下列情况中,不处理收到的指令,同时无响应返回。

相应的,主机会发生超时错误。

z 接收指令中的从机地址与通信单元号不一致。

z 由误差传送引起的奇偶校验出错、帧出错或溢出错误。

z 接收命令帧时发生 CRC-16 码出错。

z 命令帧内的数据块之间存在 3.5 个字符时间以上的停顿区间。

另外,对于广播功能将执行指定的功能处理程序,但无响应返回(从机地址=H’00)。

Modbus

5-5

Mod Bus通信方式

5.2 功能一览

功能码 名称 处理过程

03(H’03) 变量读取(多项) 该功能读取变量区域内的变量。

16(H’10) 变量写入(多项) 该功能将变量写入变量区域。

06(H’06) 变量写入(动作指令) 此功能写入一条动作指令。

08(H’08) 回传测试 此功能执行一次回传测试。

下表列出了各种功能码。

功能码一览

可读取两个或多个连续的变量。

可写入两个或多个连续的变量。

可广播此功能(广播发送)。

可广播此功能(广播发送)。

Modbus

5-6

5.3 变量区域

5.3 变量区域

变量区域是一块用于在通信时与 E5CZ/AZ/EZ 交换数据的存储区域。

变量区域可执行的动作包括读取当前值和读取/写入参数。

另一方面,动作指令不使用变量区域。

动作指令等

读取/写入

微机

变量区域

访问变量区域时,变量在区域中的位置由字标识符、区域编号和区域内地址共同指

定。

z地址 根据变量类别添加地址。地址用 2 字节十六进制数表示,并按规定的访问大小进行

附加。每个地址由一个字标识符、区域编号和区域内地址构成。

区域编号(00~3F)

字标识符(0~3)

Modbus 地址与 CompoWay/F 设定区域 0 和设定区域 1 相对应。

设定区域 0 和设定区域 1 并不直接与 Modbus 地址相对应,但下表给出了粗略的

对应关系和一个例外。

设定区域

设定区域 0

00~0B 0000~0BFE

地址(2 字节)

Modbus 地址

区域编号 地址范围

*Modbus 地址对应的部分例外情况

滞后(加热)、滞后(冷却),控制周期(加热)和控制周期(冷却)参数分配给连续地址,

但控制周期参数为设定区域 1 的参数。

区域内地址(00~FE):128 个变量

Modbus

5-7

B

Mod

us通信方式

因此,从设定区域0侧写入控制周期(加热或冷却)参数时会发生动作出错,如从操

作菜单。

z要素数 要素数用 2 字节十六进制数表示。要素数的设定范围根据指令的不同而变化。

示例:要素数为 0010 时,表示该地址下的八个数据项。

Modbus 协议中,一个要素占 2 字节数据,但设定数据占 4 字节。

z设定值 从变量区域读取或向变量区域写入值时采用十六进制数,小数点忽略(负值用二进

制补码格式表示)。

示例:D’150.0ÆH’0000041A

变量为 8 位十六进制数。负值用二进制补码格式表示。变量值为忽略小数点的十六

进制值。

示例:E5CZ/AZ/EZ 的当前值为 105.0 时,读取值为

H’0000041A(105.0Æ1050ÆH’0000041A)。

Modbus

5-8

5.4 服务详情

变量区域读取

命令帧

从机地址

功能码

如图所示为读取变量区域,在命令帧中设定所需数据。

读取开始地址

名称 说明

从机地址 指定 E5CZ/AZ/EZ 的单元编号。

可在 H’01~H’63 之间设定单元编号 (十进制 1~99)。

要素数

字节

5.4 服务详情

功能码 变量区域读取功能的功能码为 H’03。

读取开始地址 指定将要读取数据的地址。

有关地址的详情,请参见第六章 Modbus

要素数 规定设定数据数为读取要素数的两倍。要素数的设定范围是

H’0002~H’0010(2~16)。

示例:

读取两项设定数据时,要素数应设为 H’0004。

CRC-16 此校验码计算从机地址~数据末端的范围。

有关 CRC-16 计算的详情,请参见 5.1

计算示例(

5-3

页)

。

通信数据

数据格式

中的 CRC-16

Modbus

5-9

Mod Bus通信方式

响应帧

读取数据

从机地址 功能码

从机地址 沿用命令帧中的从机地址。

功能码 此为接收的功能码。

字节数 包含读取数据的字节数。

要素数 包含读取的设定数据项的数量

CRC-16 此校验码计算从机地址~数据末端的范围。

响应代码

字节数 数据 1

最高位字节

数据 n

最高位字节 最低位字节

名称 说明

如果功能正常结束,功能码保持不变。如果发生出

错,将十六进制数 H’80 加入功能码,表示该响应是

出错响应。

示例:

接收的功能码=H’03

发生错误时,响应帧中的功能码=H’83

有关 CRC-16 计算的详情,请参见 5.1

的 CRC-16

数据 1

最低位字节

要素数×2 字节

数据 n

计算示例(

5-3

页)

。

数据格式

中

Modbus

5-10

功能码 错误代码 出错名称 原因

H’83

H’03 --- 正常结束 无异常。

读取隐藏参数

可读取由于显示设置原因而不显示的参数,和控制器上不会显示的参数。

指令和响应示例

如下所示为读取当前值时的指令和响应。(本例中,从机地址为 H’01)

当前值

z 地址:H’0000;读取数据:H’000003E8(100.0℃)

指令:

响应:

H’02 变量地址出错 起始变量地址读取不正确。

• 变量区域编号不正确。

H’03 变量数据出错 要素数超出范围。

变量区域写入

命令帧

从机地址 功能码

如图所示为,向变量区域写入数据,在命令帧中设定所需数据。

写入开

始地址

要素数

字节数

最高位字节

读取数据

数据 1

数据 1

最低位字节

5.4 服务详情

数据 n

最高位字节

要素数×2 字节

数据 n

最低位字节

从机地址 指定 E5CZ/AZ/EZ 的单元编号。

功能码 变量区域写入功能的功能码为 H’10。

写入开始地址 指定将写入的设定数据的起始地址。

要素数 规定设定数据数为写入要素数的 2 倍。要素数的设定范围

字节数 指定写入数据的字节数。

CRC-16 此校验码计算从机地址~数据末端的范围。

名称 说明

可在 H’01~H’63 之间设定单元编号。(十进制 1~99)。

有关地址的详情,请参见第六章 Modbus

是 H’0002~H’0010(2~16)。

示例:

写入两项设定数据时,要素数应设为 H’0004。

有关 CRC-16 计算的详情,请参见 5.1

通信数据

数据格式

中的

CRC-16

计算示例(

5-3

页)

。

Modbus

5-11

Mod Bus通信方式

响应帧

从机地址 功能码

名称 说明

从机地址 沿用命令帧中的从机地址。

功能码 为接收的功能码。

写入开始地址 为接收的写入开始地址。

要素数 为接收的要素数。

CRC-16 此校验码计算从机地址~数据末端的范围。

写入开

始地址

要素数

如果功能正常结束,功能码保持不变。如果发生出错,

将十六进制数 H’80 加入功能码,表示响应为出错响

应。

示例:

接收的功能码=H’10

发生出错时,响应帧中的功能码=H’90

CRC-16

字节

Modbus

有关 CRC-16 计算的详情,请参见 5.1

CRC-16

计算示例(

5-3

页)

。

数据格式

中的

5-12

5.4 服务详情

响应代码

功能码 错误代码 出错名称 原因

H’90

H’10 --- 正常结束 无异常。

写入隐藏参数

H’02 变量地址出错 起始变量地址写入不正确。

z 变量区域编号不正确。

H’03 变量数据出错 数据量与要素数不一致。

字节数不是要素数的两倍。

写入数据超出范围。

H’04 动作出错 控制器在下列操作状态下无法进行

数据写入。

“通讯写入”参数设为

“OFF”(禁用)。

试图由设定区域 0 对设定区域 1

的项目进行写入。

试图将非保护菜单的参数写入

保护参数。

AT 执行期间。

可写入由于显示设置原因而不显示的参数,和控制器上不会显示的参数。

指令和响应示例

如下所示为写入“上限报警 1”和“下限报警 1”参数的指令和响应。(本例中,从机地

址为 H’01)

上限报警 1

z 地址:H’010A, 写入数据:H’000003E8(1,000)

下限报警 1

z 地址:H’010C, 写入数据:H’FFFFFC18(-1,000)

指令:

响应:

Modbus

5-13

第5章 MODBUS通信方式

动作指令

命令帧

Modbus

该功能执行如下指令,通讯写入、运行/停止、多重 SP、AT(自整定)执行/取消、

写入模式、RAM 数据保存、软件复位、转换到设定区域 1、自动/手动模式、初始

化设定和解除报警闩锁。

从机地址 功能码

响应帧

从机地址 功能码

(1) 指令代码和相关信息

指令代码 指令内容 相关信息

00 通讯写入 00:OFF(禁用)

01 运行/停止 00:运行

02 多重设定点(SP) 00:设定点 0

03 AT 执行/取消 00:取消

04 写入模式 00:备份

05 保存 RAM 数据 00

06 软件复位 00

07 转换到设定区域 1 00

09 自动/手动切换 00:自动模式

0B 参数初始化 00:初始化为默认值

*软件复位执行时无响应。

写入开

始地址

写入开

始地址

写入数据

写入数据

字节

字节

01:ON(启用)

01:停止

01:设定点 1

02:设定点 2

03:设定点 3

01:AT 执行

01:RAM

01:手动模式

5-14

5.4 服务详情

(2) 响应代码

正常结束

功能码 错误代码 名称 说明

H’06 --- 正常结束 无异常

发生错误时

功能码 错误代码 名称 说明

H’86

H’02 变量地址出错 写入变量地址不是“0000”。

H’03 变量数据出错 写入数据不正确。

z 指令代码或相关信息不正确。

H’04 动作出错 控制器在下列操作状态下无法写入数据

z “通讯写入”参数设为“OFF”(禁用)。无论

“通讯写入”参数设为(ON/OFF) 都能接

收该指令。

z 进程无法执行。有关详情,请参见下文

中的(4)动作指令和注意事项。

(3) 指令和响应示例:

如下所示为停止命令的指令和响应(本例中,从机地址是 H’01。)

停止命令(指令代码:01;相关信息:01)

z 地址:H’0000(固定地址)

写入数据:H’0101(运行/停止,停止命令)

Modbus

指令:

响应:

5-15

第5章 MODBUS通信方式

(4) 动作指令和注意事项

z 通讯写入

通过设置相关信息将“通讯写入”参数设定为“ON”(启用)或“OFF”(禁用)。

设定区域 1 和设定区域 0 都可接受该指令。

z 运行/停止

通过设置相关信息将控制设为“运行”或“停止”。

设定区域 1 和设定区域 0 都可接受该指令。

z 多重设定点(SP)

在调整菜单内预先设置四个设定点,便于切换到所需的设定点。

设定区域 1 和设定区域 0 都可接受该指令。

z AT 执行/取消

通过设置相关信息将 AT(自整定)设为“执行”或“取消”。仅设定区域 0 可接受该指令。

下列情况中,会发生“动作出错”。

z “运行/停止”参数设为“停止”

z 在“设定区域 1”中执行该指令

z ON/OFF 控制正在运行

z 写入模式

Modbus

通过设置相关信息选择“备份模式”或“RAM 写入模式”。设定区域 1 和设定区域 0 都

接受该指令。

EEPROM(非易失性只读存储器)的写入次数有限。因此,需要频繁覆盖数据时请使

用 RAM 写入模式。

写入模式 说明

备份模式 操作/调整菜单中的参数(只读参数除外)由通信方式写

入时,数据写入 EEPROM。

RAM 写入模式 操作/调整菜单中的参数(只读参数除外)由通信方式写

入时,数据不写入 EEPROM。

z 从 RAM 写入模式转换到备份模式时,操作/调整菜单中的参数(只读参数除外)

写入 EEPROM。

z 仅当“通讯写入”参数设为“ON”(启用)时,RAM 写入模式可用。

可通过控制器的按键操作更改参数值。

5-16

5.4 服务详情

相应的,“通讯写入”参数设为“OFF”(禁用)时,即使 RAM 写入模式为“禁用”,操作/

调整菜单中的参数(只读参数除外)也写入 EEPROM。

z RAM 数据

此命令将操作/调整菜单中的参数(只读参数除外)写入 EEPROM。设定区域 1 和设

定区域 0 都接受该指令。

z 软件复位

电源接通时执行重启。设定区域 1 和设定区域 0 都可接受该指令。此操作无响应。

z 转换到设定区域 1

此命令执行转换到设定区域 1。设定区域 1 和设定区域 0 都接受该命令。如果“初

始化/通信保护”设为“2”,会发生“动作出错”,且禁止转换到设定区域 1。

如果在设定区域 0 中执行此转换,“初始菜单”会显示“输入类型”。如果在设定区域

1 执行此转换,显示内容不变。

手动模式下转换到设定区域 1

如果在手动模式下发出此操作命令,会发生“动作出错”,且禁止转换到设定区域 1。

Modbus

5-17

第5章 MODBUS通信方式

z 自动/手动切换

此命令通过设置相关信息,执行手动/自动模式间的切换。仅设定区域 0 接受该命

令。下列情况会发生“动作出错”:

• 在“设定区域 1”中执行该指令

• 禁用自动/手动切换期间(不显示)

控制器切换至手动模式时,会显示“手动操作量”。控制器从手动模式切换至自动模

式时,会显示操作菜单的顶部参数。如果切换至手动模式时控制器已处于手动模式,

命令将正常结束,显示内容不变(不刷新显示内容)。

z 将自动/手动状态写入 EEPROM

写入模式决定是否将自动/手动状态写入EEPROM。

写入模式 说明

备份模式 使用通信切换自动/手动模式时,自动/手动模式状

态写入 EEPROM。

RAM 写入模式 使用通信切换自动/手动模式时,自动/手动模式状

Modbus

态不写入 EEPROM。可通过控制器的按键操作写

入状态信息。

*如果用通信功能的动作指令切换自动/手动模式且控制器的写入模式设为 RAM,

则自动/手动模式状态不存入 EEPROM 中。相应的,如果执行软件复位或断开后

接通电源后控制器执行重启,自动/手动模式设为之前保存的状态。

自整定期间切换到手动模式

如果在自整定(AT)期间进行模式切换,AT 将被取消,且控制器切换至手动模式。

z 参数初始化

参数设置回到初始值并写入 EEPROM。仅设定区域 1 接受该指令。如果在设定区

域 0 发出该指令,会发生“动作出错”。

5-18

5.4 服务详情

初始化时设定的设定值取决于命令中相关信息的设定,如下表所示。

相关信息 说明(初始化值)

00 默认设定值(详情请参见第3章CompoWay/F和SYSWAY

通信数据

“FACT”所使用的内容相同。)

)。(这些设置与初始化设置数据的设定值时选择

z 设定区域

控制动作在设定区域 0 中执行。在此状态下,可执行仅在控制期间允许的动作,或

着是那些即使在控制运行时执行也不会产生问题的动作。这些动作包括当前值读

取,设定点写入及改变运行/停止状态。

但是,设定区域 0 禁止执行影响控制的动作,包括在初始菜单中写入数据。(始终

允许读取设定数据。)

在设定区域 1 中,控制动作停止。在此状态下,可执行在设定区域 0 内禁止的动

作,这些动作包括在初始菜单中写入数据。

接通电源时,温度控制器设在设定区域 0。要转换到设定区域 1,可使用“转换到设

定区域 1”命令。要返回设定区域 0,先断开再接通电源,或执行 “软件复位”命令。

接通电源

软件复位命令

回传测试

设定区域 0

控制运行中

命令帧

从机地址 功能码

响应帧

从机地址 功能码

*命令正常执行时,响应帧返回和命令帧内一致的数据。

写入开

始地址

写入开

始地址

“转换到设定

区域 1”命令

测试数据

测试数据

设定区域 1

控制停止

字节

字节

Modbus

5-19

第5章 MODBUS通信方式

(1) 测试数据

输入任意 2 字节十六进制数。

(2) 响应代码

功能码 出错代码 名称 说明

H’88 H’03 变量数据出错 功能码之后的数据不是固定数据(H’00,

H’00)

H’08 --- 正常结束 无异常

(3) 指令和响应示例

以下示例为指令/响应的回传测试命令。

(本例中,测试数据为 H’1234。)

(本例中,从机地址为 H’01。)

指令:

响应:

Modbus

5-20

第6章

Modbus 的通信数据

本章罗列了 Modbus 通信协议中通信数据的详细信息。

6.1 变量区域(设定范围)一览······························ 6-2

6.2 状态 ······························································ 6-13

6-1

第 6 章 Modbus 的通信数据

6.1 变量区域(设定范围)一览

下表列出了变量区域。“设定(监视)值”一列中用十六进制数表示的值为 Modbus 中

规定的设定范围。括号“()”中的值为实际设定范围。

如果设定项有相关参考章节,请阅读参考章节了解详细内容。

如果不使用报警输出端子,也可以使用控制器的报警功能。这种情况下,可通过状

态数据确认报警发生。

地址 参数名称 设定(监视)值 菜单

0000 PV 温度:使用各传感器的规定范围。

模拟:比例下限-5% FS~比例上限+5% FS

0002 状态(参见备注。) 有关详情请参见

0004 内部设定点

(参见备注。)

0006 加热器电流 1 值

监视

下限设定~上限设定

H’00000000~H’00000226(0.0~55.0)

通信规格

操作

0008 MV 监视(加热) 标准:H’FFFFFFCE~H’0000041A(-5.0~105.0)

加热冷却:H’00000000~H’0000041A(0.0~105.0)

000A MV 监视(冷却) H’00000000~H’0000041A(0.0~105.0)

0106 设定点 下限设定~上限设定

0108 报警值 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

010A 报警值上限 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

010C 报警值下限 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

010E 报警值 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0110 报警值上限 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0112 报警值下限 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0404 PV 温度:在各传感器的规定范围内使用。

Modbus

0406 内部设定点

(参见备注。)

040C 状态(参见备注。) 有关详情,请参见

备注 控制器上不显示。

模拟:比例下限-5% FS~比例上限+5% FS

下限设定~上限设定

通信规格。

操作

6-2

(

6.1 变量区域

地址 参数名称 设定(监视)值 菜单

0500 操作/调整保护 H’00000000(0):在操作和调整菜单中无限制

H’00000000(1):禁止转换到调整菜单

H’00000000(2):仅允许显示和更改“PV”和“PV/SP”参数

H’00000000(3):仅允许显示“PV”和“PV/SP”参数

0502 初始化/通信保护 H’00000000(0):允许转换到初始化/通信菜单。(显示转

换到高级功能菜单)

H’00000000(1):允许转换到初始化/通信菜单。(不显示

转换到高级功能菜单)

H’00000000(2):禁止转换到初始化/通信菜单。

0504 设定值改变保护 H’00000000(0):OFF(允许更改控制器的设置)

H’00000000(1):ON(禁止更改控制器的设置)

设定范围)一览

保护

Modbus

6-3

第 6 章 Modbus 的通信数据

地址 参数名称 设定(监视)值

0600 手动 MV 标准:H’FFFFFFCE 到 H’0000041A(-5.0 到 105.0)

加热冷却:H’FFFFFBE6 到 H’0000041A(-105.0 到 105.0)

0602 设定点 下限设定~上限设定

0608 加热器电流 1 值

监视

060A MV 监视(加热) 标准:H’FFFFFFCE 到 H’0000041A(-5.0 到 105.0)

060C MV 监视(冷却) H’00000000 到 H’0000041A(0.0 到 105.0)

0700 冷却系数 H’00000001 到 H’0000270F(0.01 到 99.99)

0708 死区 H’FFFFF831 到 H’0000270F

070A 手动复位值 H’00000000 到 H’000003E8(0.0 到 100.0)

070C 滞后(加热) H’00000001 到 H’0000270F

070E 滞后(冷却) H’00000001 到 H’0000270F

0710 控制周期(加热) H’00000000(0):0.5

0712 控制周期(冷却) H’00000000(0):0.5

0718 SP 斜坡时间单位 H’00000000(0):EU/秒

071A SP 斜坡设定值 H’00000000(0):OFF

072C 下限温度输入偏

移值

0730 上限温度输入偏

移值

0734 加热器电流 1 值

Modbus

0736 加热器断线检测1 H’00000000 到 H’000001F4(0.0 到 50.0)

监视

H’00000000 到 H’00000226(0.0 到 55.0)

加热冷却:H’00000000 到 H’0000041A(0.0 到 105.0)

(TC/Pt 通用输入型号为-199.9 到 999.9)

(模拟输入型号为-19.99 到 99.99)

(TC/Pt 通用输入型号为 0.1 到 999.9)

(模拟输入型号为 0.01 到 99.99)

(TC/Pt 通用输入型号为 0.1 到 999.9)

(模拟输入型号为 0.01 到 99.99)

H’00000001 到 H’00000063(1 到 99)

H’00000001 到 H’00000063(1 到 99)

H’00000001(1):EU/分钟

H’00000001 到 H’0000270F(1 到 9999)

H’FFFFF831 到 H’0000270F(-199.9 到 999.9)

H’FFFFF831 到 H’0000270F(-199.9 到 999.9)

H’00000000 到 H’00000226(0.0 到 55.0)

菜单

操作

调整

初始设定

高级功能

调整

操作

调整

0738 漏电流 1 值监视 H’00000000 到 H’00000226(0.0 到 55.0)

073A HS 报警 1 H’00000000 到 H’000001F4(0.0 到 50.0)

0746 温度输入偏移值 H’FFFFF831 到 H’0000270F(-199.9 到 999.9)

6-4

操作

调整

(

6.1 变量区域

地址 参数名称 设定(监视)值 菜单

0800 输入数字滤波器 H’00000000 到 H’0000270F(0.0 到 999.9) 高级功能

0900 设定点 0 下限设定~上限设定 调整

0904 报警值 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0906 报警值上限 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0908 报警值下限 1 H’FFFFF831 到 H’0000270F(-1999 到 9999)

090A 报警值 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

090C 报警值上限 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

090E 报警值下限 2 H’FFFFF831 到 H’0000270F(-1999 到 9999)

0910 报警值 3

(参见备注)

0912 报警值上限 3

(参见备注)

0914 报警值下限 3

H’FFFFF831 到 H’0000270F(-1999 到 9999)

H’FFFFF831 到 H’0000270F(-1999 到 9999)

H’FFFFF831 到 H’0000270F(-1999 到 9999)

设定范围)一览

操作

(参见备注)

091C 设定点 1 下限设定~上限设定

0938 设定点 2 下限设定~上限设定

0954 设定点 3 下限设定~上限设定

0A00 比例带 H’00000001 到 H’0000270F(0.1 到 999.9)

0A02 积分时间 H’00000000 到 H’00000F9F(0 到 3999)

0A04 微分时间 H’00000000 到 H’00000F9F(0 到 3999)

0A0A MV 上限 标准:MV 下限+0.1~H’0000041A(MV 下限+0.1~105.0)

0A0C MV 下限 标准:H’FFFFFFCE~MV 上限-0.1 (-5.0~MV 上限-0.1)

加热冷却:H’FFFFFBE6~H’00000000(-105.0~0.0)

备注 报警 3 未分配输出时,此参数不显示在控制器的显示屏上。

调整

Modbus

6-5

第 6 章 Modbus 的通信数据

地址 参数名称 设定(监视)值 菜单

0C00 输入类型(TC/Pt 通

用输入型号)( 参见

备注。)

0C02 温度单元

0C12 比例下限 H’FFFFF831~比例上限-1

0C16 比例上限 比例下限+1~H’0000270F

Modbus

备注 可选择与所连接的传感器匹配的输入类型。

H’00000014 (20):非接触式温度传感器(K 240°F/120°C)

输入类型(模拟输入

型号)

(参见备注)

℃/℉选择

小数点 (TC/Pt 通用

输入型号)

小数点

(模拟输入型号)

有两种输入类型 :热电偶/测温电阻体输入和模拟输入。

H’00000000 (0): Pt (−200 到 850°C/−300 到500°F)

H’00000001 (1): Pt (−199.9 到 500.0°C/−199.9 到900.0°F)

H’00000002 (2): Pt (0.0 到 100.0°C/0.0 到 210.0°F)

H’00000003 (3): JPt (−199.9 到 500.0°C/−199.9 到 900.0°F)

H’00000004 (4): JPt (0.0 到 100.0°C/0.0 到 210.0°F)

H’00000005 (5): K (−200 到 1300°C/−300 到 2300°F)

H’00000006 (6): K (−20.0 到 500.0°C/0.0 到 900.0°F)

H’00000007 (7): J (−100 到 850°C/−100 到 1500°F)

H’00000008 (8): J (−20.0 到 400.0°C/0.0 到 750.0°F)

H’00000009 (9): T (−200 到 400°C/−300 到 700°F)

H’0000000A (10):T (−199.9 到 400.0°C/−199.9 到 700.0°F)

H’0000000B (11):E (0 到 600°C/0 到 1100°F)

H’0000000C (12):L (−100 到 850°C/−100 到 1500°F)

H’0000000D (13):U (−200 到 400°C/−300 到 700°F)

H’0000000E (14)

H’0000000F (15):N (−200 到 1300°C/−300 到 2300°F)

H’00000010 (16):R (0 到 1700°C/0 到 3000°F)

H’00000011 (17):S (0 到 1700°C/0 到 3000°F)

H’00000012 (18):B (100 到 1800°C/300 到 3200°F)

H’00000013 (19):非接触式温度传感器(K 140°F/60°C)

H’00000015 (21):非接触式温度传感器(K 280°F/140°C)

H’00000016 (22):非接触式温度传感器(K 440°F/220°C)

H’00000017 (23): 0到50 mV

H’00000000 (0):4到20 mA

H’00000001 (1):0到20 mA

H’00000002 (2):1到5 V

H’00000003 (3):0到5 V

H'00000004 (4):0到10 V

H’00000000 (0):°C

H’00000001 (1):°F

(-1999到比例上限-1)

(比例下限+1~9999)

H’00000000到00000001 (0到1) 0C18

H’00000000到00000003 (0到3)

:U (−199.9 到 400.0°C/−199.9 到 700.0°F)

初始

设置

6-6

6.1 变量区域(设定范围)一览

地址 参数名称 设定(监视)值 菜单

0D06 线性输出类型 H’00000000 (0):4 到 20 mA

H’00000001 (1):0 到 20 mA

0D1E 上限设定 值的范围如下(省略小数点):

温度:下限设定+1~输入范围上限

模拟:下限设定+1~比例上限

0D20 下限设定 值的的范围如下(省略小数点):

温度:输入范围下限值~上限设定-1

模拟:比例下限~上限设定-1

0D22 标准控制或加热/

冷却控制

0D24 正/逆动作 H’00000000(0):逆动作

0D28 PID/ 开关 H’00000000(0):开/关

0D2A ST 自调节 H’00000000(0):关

0E00 传送输出类型 H’00000000(0):关

0E0C 控制输出 1 指定 控制输出 1 为线性输出时:

0E14 事件输入分配 1 H’00000000(0):无

H’00000002(2):自动/手动(“多重设定点使用数”为 1 或 2

0E16 事件输入分配 2 H’00000000(0):无

H’00000000(0):标准

H’00000001(1):加热冷却

H’00000001(1):正动作

H’00000001(1):2 自由度 PID 控制

H’00000001(1):开

H’00000001(1):设定点

H’00000002(2):SP 斜坡期间设定点

H’00000003(3):PV

H’00000004(4):MV 监视(加热)

H’00000005(5):MV 监视(冷却)

H’00000000(0):不分配

H’00000000(1):控制输出(加热)

H’00000000(2):控制输出(冷却)

控制输出 1 为脉冲输出时:

H’00000000(0):不分配

H’00000001(1):控制输出(加热)

H’00000002(2):控制输出(冷却)

H’00000003(3):报警 1

H’00000004(4):报警 2

H’00000005(5):报警 3

H’00000001(1):运行/停止(“多重设定点使用数”为 1 或 2

时不能设定。)

时不能设定。)

H’00000001(1):运行/停止(“多重设定点使用数”为 2 时不

能设定。)

H’00000002(2):自动/手动(“多重设定点使用数”为 2 时不

能设定。)

初始

设置

高级功能

Modbus

6-7

第 6 章 Modbus 的通信数据

地址 参数名称 设定(监视)值 菜单

0E20 报警输出 1 指定 H’00000000(0):不分配

H’00000001(1):控制输出(加热)

H’00000002(2):控制输出(冷却)

H’00000003(3):报警 1

H’00000004(4):报警 2

H’00000005(5):报警 3

0E22 报警输出 2 指定 H’00000000 到 H’00000005(0 到 5)(设定同报警输出分配 1)

0E24 报警输出 3 指定 H’00000000 到 H’00000005(0 到 5)(设定同报警输出分配 1)

0E28 传送输出上限 H’FFFFF831 到 H’0000270F(-1999 到 9999)(参见备注)

0E2A 传送输出下限 H’FFFFF831 到 H’0000270F(-1999 到 9999)(参见备注)

备注 设定(监视)值的范围取决于“转换输出类型”的设置。(有关详情,请参见

设定数据一览

)

初始设置

Modbus

6-8

(

6.1 变量区域

地址 参数名称 设定(监视)值 菜单

0F00 报警 1 类型 H’00000000(0):报警功能关闭

H’00000001(1):上下限报警

H’00000002(2):上限报警

H’00000003(3):下限报警

H’00000004(4):上下限范围报警

H’00000005(5):附待机顺序的上下限报警

H’00000006(6):附待机顺序的上限报警

H’00000007(7):附待机顺序的下限报警

H’00000008(8):绝对值上限报警

H’00000009(9):绝对值下限报警

H’0000000A(10):附待机顺序的绝对值上限报警

H’0000000B(11):附待机顺序的绝对值下限报警

H’0000000C(12):LBA(断路报警)

0F02 报警 1 闩锁 H’00000000(0):OFF

H’00000001(1):ON

0F04 报警 1 滞后 H’00000001 到 H’0000270F

(TC/Pt 通用输入型号为 0.1 到 999.9)

(模拟输入型号为 0.01 到 99.99)

0F06 报警 2 类型 H’00000000(0):报警功能关闭

H’00000001(1):上下限报警

H’00000002(2):上限报警

H’00000003(3):下限报警

H’00000004(4):上下限范围报警

H’00000005(5):附待机顺序的上下限报警

H’00000006(6):附待机顺序的上限报警

H’00000007(7):附待机顺序的下限报警

H’00000008(8):绝对值上限报警

H’00000009(9):绝对值下限报警

H’0000000A(10):附待机顺序的绝对值上限报警

H’0000000B(11):附待机顺序的绝对值下限报警

0F08 报警 2 闩锁 H’00000000(0):关

H’00000001(1):开

0F0A 报警 2 滞后 H’00000001 到 H’0000270F

(TC/Pt 通用输入型号为 0.1 到 999.9)

(模拟输入型号为 0.01 到 99.99)

0F0C 报警 3 类型

(参见备注)

设定同报警 2 类型

设定范围)一览

初始

设置

高级功能

初始

设置

Modbus

高级功能

设定

初始

设置

备注 报警 3 未分配输出时,此参数不显示在控制器的显示屏上。

6-9

第 6 章 Modbus 的通信数据

地址 参数名称 设定(监视)值 菜单

0F0E 报警 3 闩锁

(参见备注)

0F10 报警 3 滞后

(参见备注)

0F18 待机顺序复位方式 H’00000000(0):情况 A

0F1A 报警时报警 1 开启 H’00000000(0):报警时关闭

0F1C 报警时报警 2 开启 H’00000000(0):报警时关闭

0F1E 报警时报警 3 开启

(参见备注)

H’00000000(0):关

H’00000001(1):开

H’00000001 到 H’0000270F

(TC/Pt 通用输入型号为 0.1 到 999.9)

(模拟输入型号为 0.01 到 99.99)

H’00000001(1):情况 B

H’00000001(1):报警时开启

H’00000001(1):报警时开启

H’00000000(0):报警时关闭

H’00000001(1):报警时开启

高级功能

设定

0F22 报警 1 On 延时 H’0000000 到 H’000003E7(0 到 999)

0F24 报警 2 On 延时 H’0000000 到 H’000003E7(0 到 999)

0F26 报警 3 On 延时

(参见备注)

0F2A 报警 1 OFF 延时 H’0000000 到 H’000003E7(0 到 999)

0F2C 报警 2 OFF 延时 H’0000000 到 H’000003E7(0 到 999)

0F2E 报警 3 OFF 延时

(参见备注)

备注 报警 3 未分配输出时,此参数不显示在控制器的显示屏上。

H’0000000 到 H’000003E7(0 到 999)

H’0000000 到 H’000003E7(0 到 999)

Modbus

6-10

(

6.1 变量区域

地址 参数名称 设定(监视)值 菜单