Page 1

R

i

dualvol

t

i

dualvol

t

i

dualvol

t

i

dualvol

t

High-Precision Fiber-optic Amplifier E3X-NH

TheE3X-NHEmploysa16-Bit

Processor as An Industry First

An Automatic Sensitivity Adjustment

H

feature allows stable detection of

objects in frequently changing

environments

H Three teach modes for optimal sensing

H 8-point scaled sensitivity meter is ideal

for high precision sensing and

through-beam applications at long

distances (and clearly displays a

target’s reflectivity level)

H A manual fine tuning sensitivity feature

allows 13 threshold adjustments using

an easy-to-read digital scale

H Ideal for detecting small objects or fine

wires

H NPN/PNP types available

Ordering Information

J AMPLIFIER UNITS

Description General-purpose models Timer-function models

Output NPN PNP NPN PNP

Part number E3X-NH11 E3X-NH41 E3X-NH21 E3X-NH51

Appearance

Light source (Wave length) Red LED (680 nm)

Power supply voltage 12 to 24 VDC ±10%, ripple (p-p) 10% max.

Current consumption 75 mA max.

Output

Response time 1 ms max. for turn-on and turn-off, respectively

Sensitivity setting Teaching method

Fine sensitivity adjustment Automatic or manual fine threshold adjustment (13 levels)

Control

output

Alarm output

NPN open collector,

load current: 50 mA

max., res

1Vmax.

PNP open collector,

load current: 50 mA

age:

max., res

1Vmax.

NPN open collector,

load current: 50 mA

age:

max., res

1Vmax.

PNP open collector,

load current: 50 mA

age:

max., res

1Vmax.

age:

2

Page 2

E3X-NH

p

E3X-NH

Specifications

Description General-purpose models Timer-function models

Part number E3X-NH11 E3X-NH41 E3X-NH21 E3X-NH51

Light source Red (680 nm)

Supply voltage 12--24 VDC +10% ripple (p-p) 10 % max.

Output NPN PNP NPN PNP

Timing —— 40 ms off delay

Indicator Operation indicator (orange LED), 8-level incident level indicator (green LED), 13-level

Circuit protection Output short-circuit protection, reverse polarity on supply

Operation mode Light ON and Dark ON, switch-selectable

Ambient light immunity

Ambient temperature

Ambient humidity Operating 35% to 85% (with no condensation)

Dielectric strength 1,000 VAC at 50/60 Hz for 1 minute

Vibration resistance 10 to 55 Hz, 1.5-mm double amplitude or 300 m/s2(approx. 30G) for 2 hrs each in X, Y, and

Insulation resistance 20 MΩ min. (at 500 VDC)

Shock resistance 500 m/s2(approx. 50G) for 3 times each in X, Y, and Z axis

Enclosure rating IEC IP50

Connection method 2m cable

Material

Weight (with 2 m cable) Approx. 100 g

Accessory Mounting brackets (included)

Incandescen

tlamp

Sunlight 10,000 ℓxmax.

Operating -- 2 5 °Cto55°C(--13°F to 131°F) with no icing

Storage -- 4 0 °Cto70°C(--40°F to 158°F) with no icing

Case PBT

Cover Polycarbonate

threshold indicator (red LED)

3,000 ℓxmax.

Z directions

3

Page 3

E3X-NH

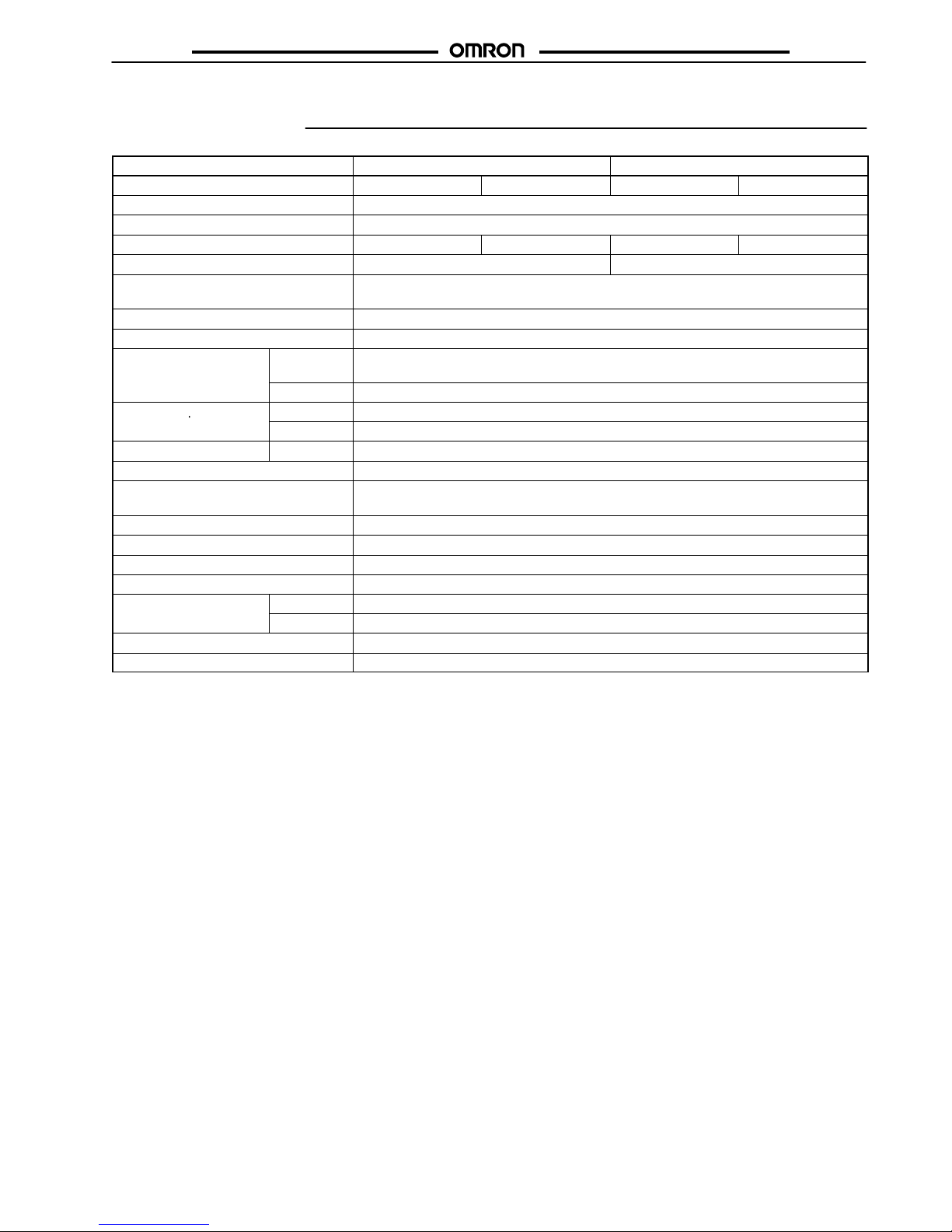

Nomenclature

J E3X-NH11

Operation Indicator (orange)

Lit when output is ON.

Incident Level Indicators

(green, 8 levels)

Lit depending on the incident

light amount.

UP/DOWN Selector

Select UP for increasing the threshold value.

Select DOWN for decreasing the threshold

value.

Operation Mode Selector

Switchable between light-ON and

dark-ON modes.

Threshold Indicators

(red, 13 levels)

Indicates threshold level.

SET Button

For teaching or for fine threshold adjustment

Mode Selector

Switchable among TEACH, ADJ, and

RUN modes.

E3X-NH

Operation

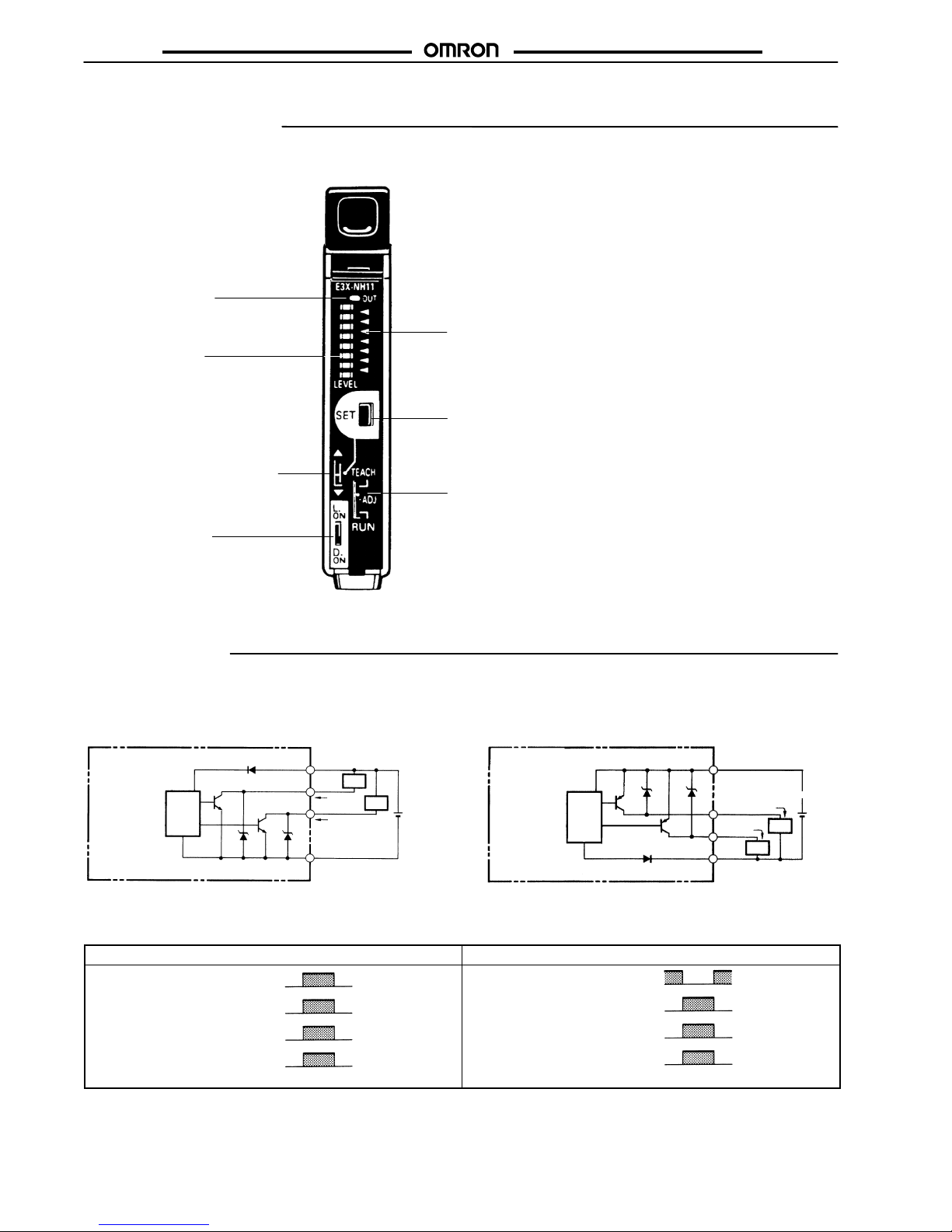

J OUTPUT CIRCUITS

E3X-NH11 (NPN output)

Brown

Load

Photoelectric

sensor

main

circuit

Black

Orange

Blue

Control

output

Alarm output

Load

12 to 24 VDC

J OPERATION MODE

Light-ON Dark-ON

Light received

Light not received

Operation indicator

(orange)

Output

transistor

Load (relay) Operate

ON

OFF

ON

OFF

Release

(Between brown and black)

PNP circuits

Photoelectric

sensor

main

circuit

Light received

Light not received

Operation indicator

(orange)

Output

transistor

Load (relay) Operate

ON

OFF

ON

OFF

Release

(Between brown and black)

Brown

Control output

Black

Alarm

output

Orange

Blue

12 to 24 VDC

Load

Load

4

Page 4

E3X-NH

E3X-NH

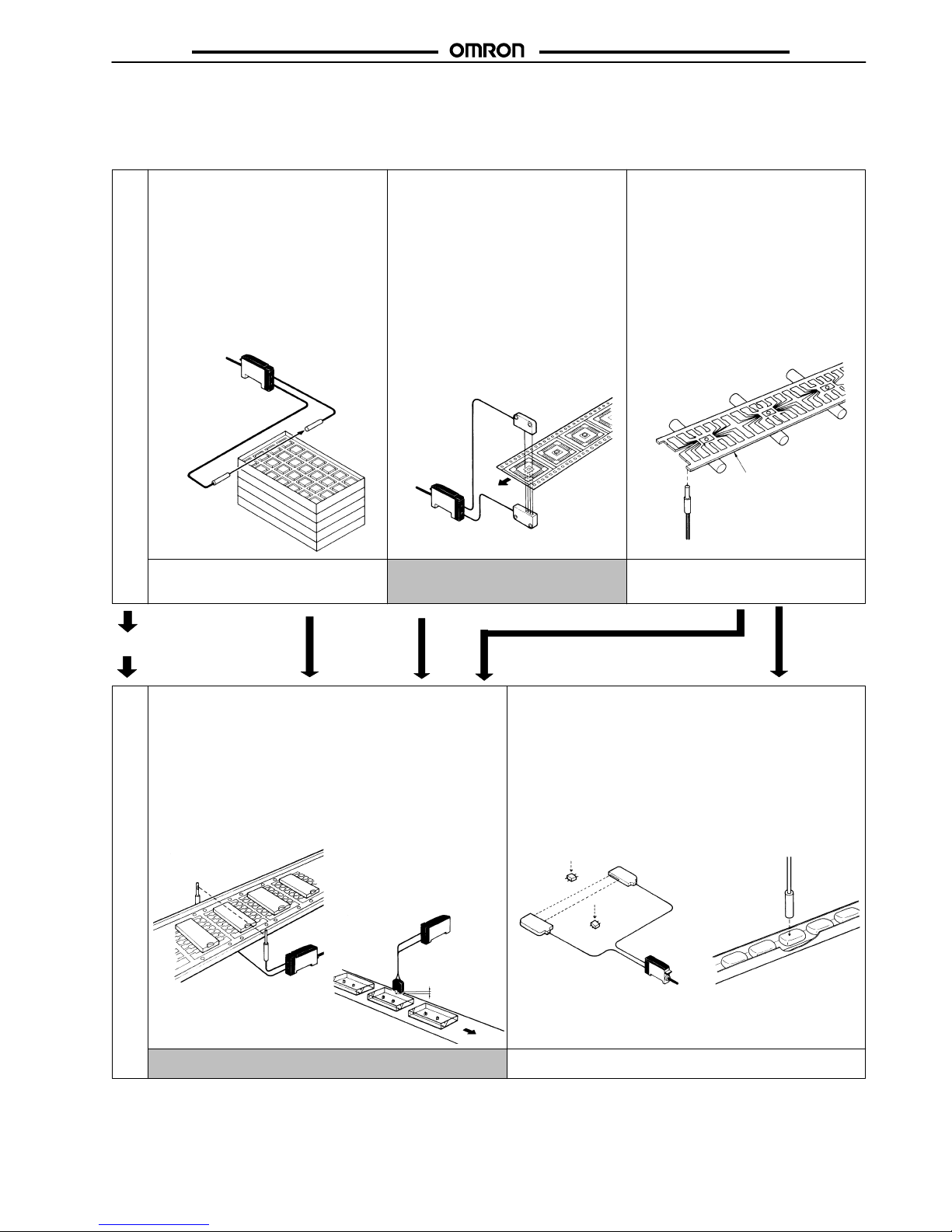

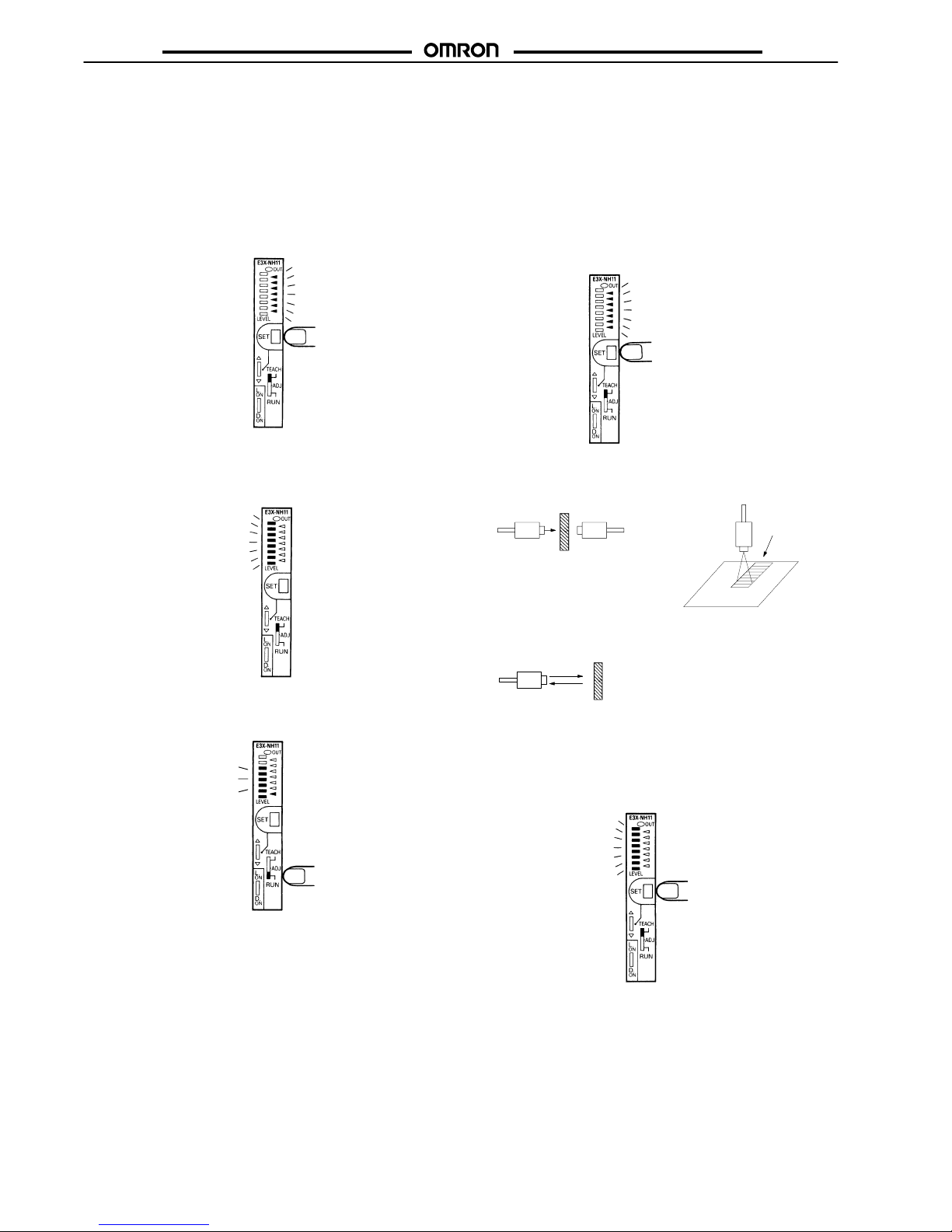

J SENSITIVITY SETTING AND ADJUSTMENT

Refer to the following to select the most suitable sensitivity setting method. We recommend that two-point teaching and manual-tuning be

tried first.

Using the Sensor at the

Maximum Sensitivity

Sensing Slight Differences

Sensitivity Setting

Without Objects

Application Examples

Detection of a passing object with

through-beam fibers.

Checking IC Tray Arrangements

E3X-NH

Sensitivity Setting

Application Examples

Detection of slight differences in

reflection.

Detection of translucent objects.

Detection of object surface irregu-

larities.

Color discrimination.

Detecting IC Chips on Film Sheet

E32-T16P

E3X-NH

Maximum Sensitivity Setting One-point Teach ModeTwo-point Teach Mode

Fine-tuning, if required.

Film sheet

Application Examples

Detection of minute passing objects.

Detection of lead wires.

High-precision positioning.

Detecting Lead Frame Position

Lead frame

E32-D32

Fine-tuning on Production Lines

Reason

Marginal sensitivity adjustment is required considering the

differences in targets.

For high-precision positioning of electronic parts.

Detecting

Lead Frame Rises

E32-T24

E3X-NH

Detecting

Cassette Tape Cases

Ensuring reliable detection

without being influenced by

the difference in color or

mark.

E32-L25A

Sensitivity Adjustment (Fine-tuning)

Manual-tuning (Fine Sensitivity Adjustment)

E3X-NH

3.3 mm

Ideal Operation Under Frequently Changing

Environments

Reason

Dust sticking to the fiber tip.

Targets are slightly different from each other in color or

surface quality.

Detecting

Passing Chip Parts

E32-T16P

E3X-NH

Counting

Number Of Pills

Auto-tuning (Automatic Sensitivity Compensation)

5

Page 5

E3X-NH

E3X-NH

J SENSITIVITY SETTING (TEACHING)

The sensitivity of the E3X-NH is factory-set to maximum. When resetting the sensitivity of the E3X-NH to maximum after with/without-object teaching or positioning/no-object teaching, follow the steps described below.

Maximum Sensitivity Setting

1. Set the mode selector to TEACH.

Hold the SET button down for three seconds. Be sure that all

the threshold indicators (red) are lit. The built-in buzzer will

beep once when the threshold indicator is lit.

Two-point Teach Mode

1. Set the mode selector to TEACH.

Place the target object in the sensing area and press the

SET button once. Be sure that all the threshold indicators

(red) are lit. The built-in buzzer will beep once when the

threshold indicator is lit.

Press for 3 s min.

2. The sensitivity will be set when the built-in buzzer beeps

continuously and all the incident level indicators (green) are

lit.

3. Set the mode selector to RUN. Be sure that only the bottom

threshold indicator is lit.

Press once for 0.5 to 2.5 s

Through-beam Model

Light is

interrupted.

Diffuse Model

2. Remove the object and press the SET button.

If teaching is OK:

All the incident level indicators (green) will be lit. The built-in

buzzer will beep once.

Diffuse Model

Mark

Base

6

Press once for 0.5 to 2.5 s

Page 6

E3X-NH

E3X-NH

If teaching is not stable:

The threshold indicator (red) will flash. The built-in buzzer will

beep 3 times.

Change the position of the object and the sensing distance

that has been set and repeat the process.

Hold set button down

for 0.5 to 2.5 s

Through-beam Model

Light is received.

Diffuse Model

Mark

Base

Diffuse Model

One-point Teach Mode

1. Set the mode selector to TEACH.

Press the SET button once without a target object in the

sensing area. Be sure that all the threshold indicators (red)

are lit. The built-in buzzer will beep once when the threshold

indicators are lit.

Press once for 0.5 to 2.5 s

2. Set the mode selector to RUN. The threshold is set automatically.

3. Set the mode selector to RUN. Be sure that the middle

threshold indicator is lit. The threshold will be set to a 50%

value.

3. The Sensor will automatically compensate for environmental

changes.

7

Page 7

E3X-NH

J SENSITIVITY ADJUSTMENT (TUNING)

Manual-tuning

(Fine Sensitivity Adjustment)

Note: The auto-tuning function will be disabled if manual-tuning is

utilized.

1. After setting the sensitivity of the E3X-NH, select the adjustment direction with the UP/DOWN selector in the ADJ mode.

(2)

(1)

E3X-NH

Auto-tuning

(Automatic Sensitivity Compensation)

1. Set the mode selector to TEACH.

Press the SET button once without a target object in the

sensing area. Be sure that all the threshold indicators (red)

are lit. The built-in buzzer will beep once when the threshold

indicators are lit.

2. Press the SET button in ADJ mode. Be sure that the

threshold-level changes whenever the SET button is

pressed. If two threshold indicators are lit, the threshold will

automatically be set to a middle value equal to the target’s

sensed value.

3. Set the mode selector to RUN.

2. Set the mode selector to ADJ and press the SET button for

three seconds minimum. Be sure that the threshold indicator

(red) flashes. The built-in buzzer will beep continuously when

cycle is complete.

(2)

Press for 3 s min.

(1)

3. Set the mode selector to RUN. The threshold indicator (red)

will continue to flash while the the auto-tuning function is

enabled.

8

Page 8

E3X-NH

E3X-NH

J SENSITIVITY SETTING—THRESHOLD SETTING AND INDICATORS

Threshold

indicators

Level 1 2 3 4 5 6 7 8 9 10 11 12 13

Maximum Sensitivity Setting

• Use Through-beam Fibers for detection of opaque objects.

• Use the Diffuse Fibers for detection of objects with fixed background.

The threshold should be set to a level slightly higher than the Zero point when detecting objects that completely interrupt light.

Diffuse Sensor

The number of incident level indicators that are lit will depend on the location of the object. The bottom indicator of the threshold indicators

will always be lit.

Farther

Light

Closer

Target

Target

Threshold

Incident

level

indicator

Threshold

indicator

2-Point Teach Mode

• Ideal for the detection of object surface irregularities or minute objects.

• Ideal for the detection of objects against a background that reflects light irregularly.

Diffuse Sensor

1. Press the SET button with the target in the sensing area.

Then press the SET button without target in the sensing

area, as illustrated at the right.

Farther

Light

Closer

Fiber

head

Target

Light

Large

Small

Fiber

head

RUN/ADJ Mode

The number of the incident level indicators lit depends

on the position of the target. When using the

manual-tuning function, it is possible to adjust the

threshold in six levels. The default threshold is set to 7.

Farther

Target

Threshold

Light

Large

Light

Threshold

Small

2. Set the threshold to the middle value between the values

obtained with and without the target.

Closer

Incident

level

indicator

Threshold

indicator

9

Page 9

E3X-NH

E3X-NH

One-point Teach Mode

• Ideal if it is impossible to perform teaching with the target

fixed in the sensing area.

• Ideal for high-precision positioning.

• Ideal for detection of bright or dark objects.

Diffuse (Light-ON) Fiber Unit

1. Press the SET button without the target in the sensing

area.

Set the threshold to the value that is ±6% of the incident

level.

Farther

Threshold

Light

Closer

Note: If the target is not present at the time of teaching, the

threshold cannot be set to the position corresponding

to -6% of the incident level. The sensitivity will then be

set to maximum automatically when in RUN mode.

2. Detecting the first object in RUN/ADJ mode.

Farther

6%

6%

Threshold

Target

Incident level without a fixed background

or target.

The number of indicators lit depends on

the position of the target. The threshold

position of the target is set to 7.

Through-beam(Dark-ON)Fiber Unit

1. Press the SET button without target in the sensing area.

Set the threshold to the value that is ±6% of the incident

level.

Farther

Threshold

Light

Closer

6%

6%

Threshold

Incident level without a fixed

background or target.

2. Detecting the first object in RUN/ADJ mode.

Farther

Light

Closer

Target

6%

Threshold

Incident

level

indicator

Threshold

indicator

18%

Tuning

range

18%

The number of indicators lit depends on

the position of the target. The threshold

position of the target is set to 7.

Light

Closer

Threshold

6%

Incident

level

indicator

18%

18%

Threshold

indicator

Tuning

range

10

Page 10

E3X-NH

E3X-NH

J THRESHOLD LEVEL AND INDICATOR LEVELS

Setting the Initial Threshold

• To set the initial threshold, perform One-point teaching by pressing the SET button for a minimum of 3 seconds.

• As a result of target movement during operation, the middle value between the highest and lowest point on the incident scale will be

obtained. The E3X-NH will perform an auto-tuning function within a range of ±18% of this value.

Tuning

Farther

range

Light

Closer

Threshold Compensation

Farther

Light

Closer

Threshold

Initial threshold for

auto-tuning

Threshold compensation

Incident

level

indicator

(see note)

Time

Threshold

indicator

(The

threshold is

set to 7.)

Threshold

indicator

18%

18%

Note: The number of Incident-level

indicators lit depends on the

presence of the target.

• The sensor will perform an Automatic Threshold Compensation within the preset band.

• After the threshold has been compensated, the Threshold Indicator will flash, indicating the adjusted value.

• Threshold compensation occurs at 1, 3, 6, 10, 15, 22, and 30 minutes after turning on the E3X-NH. After the initial 30 minute time-

frame, Threshold Compensation is continually repeated, every 30-minutes.

• Alarm output will occur if the threshold compensation range is not within the tuning range. Perform sensitivity setting again if the alarm

signal turns ON.

11

Page 11

E3X-NH

Dimensions

Unit: mm (inch)

J AMPLIFIER

E3X-NHj1

E3X-NH

Cable: Polyvinyl chloride-covered cord

4-mm dia. (18/0.12 dia), 4 stranded conductors

Standard length: 2 m

Weight: Approx. 100 g

Two, 2.4 dia.

Operation indicator

Two, 3.2 -dia. holes

Threshold indicators

Incident level

indicators

(A) (see note)

Note: The mounting bracket can be at-

Mounting

bracket

Two, mounting holes

tached to this side.

12

Page 12

E3X-NH

Installation

E3X-NH

J CUTTING FIBER

Insert a fiber into the Fiber Cutter and determine the length of the

fiber to be cut.

Press down the Fiber Cutter in a single stroke to cut the fiber.

An insertion mark can be placed on the fiber to serve as a

reference when inserting the fiber into the Amplifier. Use the

following procedure.

Confirm through the Cutter hole that the fiber is inserted beyond

the insertion mark hole so that the insertion mark is properly

indicated, and then press firmly down on the Cutter.

(2)

(1)

Insert the fiber into the Amplifier up to the insertion mark. Proper

fiber performance will not be achieved unless the fiber is inserted

all the way to the insertion mark. (This method is applicable to

standard, 2.2-mm-diameter fibers only.)

J FIBER CONNECTION OR

DISCONNECTION PROCEDURES

The E3X-NH Amplifier has a lock button. Follow these steps to

connect or disconnect the fibers to (or from) the E3X-NH

Amplifier:

Note: The fiber must be locked or released in a temperature

range of --10°Cto40°C(14°F to 104°F).

Connection

Lock button

Fiber insertion mark

Fiber

1. After cutting the fibers (using the E39-F4 Fiber Cutter), place

an insertion mark on the fiber so that it can be correctly inserted into the Amplifier.

2. Insert the fiber into the Amplifier up to this insertion mark.

3. Press the lock button to lock the fiber in that position.

13

Page 13

E3X-NH

E3X-NH

Disconnection

1. Before pulling out the fiber, you MUST first press the lock

button to release (unlock) the fiber, or you may damage

the fiber.

2. Then, pull the fiber from the amplifier.

Protective cover

Unlocked

Locked

Procedure for Inserting the Fiber

If the portion from the tip to the insertion mark of the fiber is

not inserted into the Amplifier Unit, the sensing distance will

be reduced.

2.2-mm-dia. Fiber

Insert to the portion

from the tip to the

insertion mark of

each fiber into the

Amplifier Unit.

Fiber Unit

12.6 mm

Thin Fiber with the E39-F9 Attachment

The portion from the tip to

the insertion mark of each

fiber into the Amplifier Unit.

Fiber Unit

12.6 mm

Fiber with Fixed Length

The portion from the tip to

the insertion mark of each

fiber into the Amplifier Unit.

Amplifier Unit

Amplifier Unit

Amplifier Unit

J BENDING RADIUS

E39-F11 Sleeve Bender

The bending radius of the stainless tube should be as large as

possible. The smaller the bending radius becomes, the shorter

the sensing distance will be.

Insert the tip of the stainless tube to the Sleeve Bender and bend

the stainless tube slowly along the curve of the Sleeve Bender

(refer to the figure).

1.3 dia.

min.

10

1.2 dia.

max.

Stainless tube

10

R10

R5

Fiber tip position mark

Do not bend here.

R12.5

R7.5

90omax.

1.2 dia.

max.

J REFLECTOR

Observe the Following Precautions when Using the

Reflector (E39-R3)

Use detergent, etc., to remove any dust or oil from the surfaces

where tape is applied. Adhesive tape will not be attached

properly if oil or dust remains on the surface.

The E39-R3 cannot be used in places where it is exposed to oil

or chemicals.

12.6 mm

14

Page 14

E3X-NH

E3X-NH

J ATTACHMENT UNITS

Applications

E39-F10 Fiber Connector

Use the following procedure (refer to the figure) to connect fibers

via the Fiber Connector.

Splice

Retention unit

Retention unit

Fiber Unit

Each Fiber Unit should be as close as possible before they are

connected.

Sensing distance will be reduced by approximately 25% when

fibers are connected.

Only fibers with a 2.2-mm dia. can be connected. (Refer to page

NO TAG for applicable Fiber Units.)

Protective Spiral Tube

Insert a fiber to the Protective Spiral Tube from the head

connector side (threaded) of the tube.

Use the attached saddle to secure the end cap of the Protective

Spiral Tube. To secure the Protective Spiral Tube at a position

other than the end cap, apply tape to the tube so that the portion

becomes thicker in diameter.

Saddle

Tube

End cap

J AMPLIFIER UNITS

Mounting

1. Mount the front part (see #1) to the mounting bracket (attach-

ment)oronaDINrail.

2. Press the back part (see #2) onto the mounting bracket or

onto the DIN rail.

Note: DO NOT mount the back part on the mounting bracket or

the DIN rail first and then mount the front part on the mounting bracket on the DIN rail. This could decrease the mounting strength of the Amplifier Unit.

Protective spiral

tube

Fiber Unit

Push the fiber into the Protective Spiral Tube. The tube should be

straight so that the fiber is not twisted when inserted. Then turn

the end cap of the spiral tube.

Protective spiral

tube

Fiber Unit

Secure the Protective Spiral Tube on a suitable place with the

attached nut.

Mounting panel

tube

Hexagon clamping nut

Fiber Unit

Toothed washerProtective spiral

DIN Rail

(1)

Removal

You can remove the Amplifier in one easy step:

1. Press the Amplifier Unit in direction (A) and lift the fiber insertion part in direction (B) as shown here

(B)

DIN Rail

(A)

(2)

15

Page 15

E3X-NH

E3X-NH

When Side-Mounting

Washers

(6 dia. max.)

When side-mounting:

Attach the mounting bracket on the Amplifier first, and secure

the amplifier with M3 screws and washers. The diameter of

the washers should be a maximum of 6 mm.

Insert the fiber into the Amplifier up to the insertion mark. Proper

fiber performance will not be achieved unless the fiber is inserted

all the way to the insertion mark. (This method is applicable to

standard, 2.2-mm-diameter fibers only.)

Insertion mark

12.6

2.2-dia.

The cutting holes cannot be used twice. If the same hole is used

twice, the cutting face of the fiber will be rough and the sensing

distance will be reduced. Always use an unused hole.

Use either one of the two holes on the right (refer to the following

figure) to cut a thin fiber as follows:

1. An attachment is temporarily fitted to a thin fiber before

shipment.

Thin fiber attachment (E39-F9)

Temporarily fitted

2. Secure the attachment after adjusting the position of it in the

direction indicated by the arrow.

4. Finished state (proper cutting state)

Approx.

0.5 mm

Note: Insert the fiber in the direction indicated by the arrow.

Connection

Do not pull or press the Fiber Units. The Fiber Units have a

withstand force of 9.8 N (1 kgf) or 29.4 N (3 kgf) (pay utmost

attention because the fibers are thin).

Do not bend the Fiber Units beyond the permissible bending

radius.

Do not bend the edge of the Fiber Units (excluding the E32-TjR

and E32-DjR).

20 mm min.

Correct

Amplifier Unit

Incorrect

Do not apply excess force on the Fiber Units.

Fiber Unit

Nylon wireholder

Correct

Incorrect

The Fiber Head could be break by excessive vibration. To

prevent this, the following is effective:

Fiber Unit

20 mm min.

Metal holder

3. Insert the fiber into the E39-F4 to cut.

Cutter E39-F4

Two holes for

thin fiber

Three holes for

standard fiber

(2.2-mm dia.)

16

A one-turn loop can

absorb vibrations.

Tape

Turning the Power ON

When the power is turned ON, the operation indicator will be ON

momentarily. Note that this will not have an effect on performance

since no control output will be generated.

When the power is turned ON, the operation indicator will be ON

momentarily. Note that this will not have an effect on performance

since no control output will be generated.

Perform two-point teaching if two to three Fiber Units are closely

mounted together, at which time supply power only to the Unit in

teaching operation in turn or block the emitters of the Fiber Units

not in teaching operation.

Page 16

E3X-NH

Precautions

WARNING

!

The E3X-NH is not a safety component for ensuring the

safety of people as defined in EC Directive 91/368/EEC, or

as covered by separate European standards or by any other

regulations or standards.

E3X-NH

J SENSING A MINUTE OBJECT

This data sheet shows typical examples for detecting minute

objects. These typical examples are for reference use only,

because these example operations were tested on Units sampled

at random from a lot and the values described are average

values. Do not assume that all Units ensure such operations.

J AVOID DAMAGE TO THE E3X-NH

SENSOR

• Do not impose any voltage exceeding the rated voltage on

the E3X-NH.

• Do not impose 100 VAC or more on models that operate with

DC.

• When supplying power to the E3X-NH, make sure that the

polarity of the power is correct.

• Do not short-circuit the load connected to the E3X-NH.

• The load must be connected to the E3X-NH in operation.

J REFLECTOR

Precautions for Using the E39-R3 Reflector

Use detergent, etc., to remove any dust or oil from the surfaces

where tape is applied. Adhesive tape will not be attached

properly if oil or dust remains on the surface.

The E39-R3 cannot be used in places where it is exposed to oil

or chemicals.

J MUTUAL INTERFERENCE PROTECTION

Perform two-point teaching if two to three Fiber Units are closely

mounted together. The mutual interference feature will guard

against false triggering.

J EEPROM WRITING ERROR

Write errors may result at the time of teaching due to power

failure or static noise. If any of these occur, re-teach the

amplifier.

J WHEN THE POWER IS OFF

The moment power is turned off, the E3X-NH may output a pulse

signal which could affect the operation of the devices connected

to it. This will occur more often if power is supplied to the

E3X-NH from an external power supply, thus affecting the

connected timer or counter. We recommend using a separate

power supply to avoid a false signal.

For extending the cable, use wire with 0.3 mm

length of the cable should be a maximum of 100 m.

2

min. The total

J POWER SUPPLY

If a standard switching regulator is used as a power supply, the

frame ground (FG) terminal and the ground (G) terminal must be

grounded, or the Amplifier can malfunction due to the switching

noise of the power supply.

The supplied voltage must be within the rated voltage range.

Unregulated full- or half-wave rectifiers must not be used as

power supplies.

J WIRING

Never wire the Amplifier within the same conduit with power

lines. Doing so will cause induction between the lines, possibly

resulting in faulty operation or damage. Always wire the Amplifier

in a separate, dedicated conduit.

Power line

NOTE: DIMENSIONS SHOWN ARE IN MILLIMETERS. To convert millimeters to inches divide by 25.4.

R

OMRON ELECTRONICS LLC

One East Commerce Drive

Schaumburg, IL 60173

1-800-55-OMRON

Cat. No. CEDSAX4 11/01 Specifications subject to change without notice. Printed in U.S.A.

OMRON ON--LINE

Global -- http://www.omron.com

USA -- http://www.omron.com/oei

Canada -- http://www.omron.com/oci

OMRON CANADA, INC.

885 Milner Avenue

Scarborough, Ontario M1B 5V8

416-286-6465

17

17

Loading...

Loading...