Page 1

Photoelectric switch with built-in amplifier (long distance) in plastic housing

E3G

Retroreflective Models

• Sensing Distance of 10 m, with polarized light to detect shiny objects.

• Operation stability monitored ba the

stability indicator.

Distance-setting Models

• Distance setting models with a long

2 m sensing distance incorporate a

teaching function.

• Set sensing area (zone setting) function allows detection of shiny objects

with uneven surface.

Common Features

• Meets IEC IP67 requirements.

• M12 rotary connector, pre-wired or terminal block connection

E3G

Features

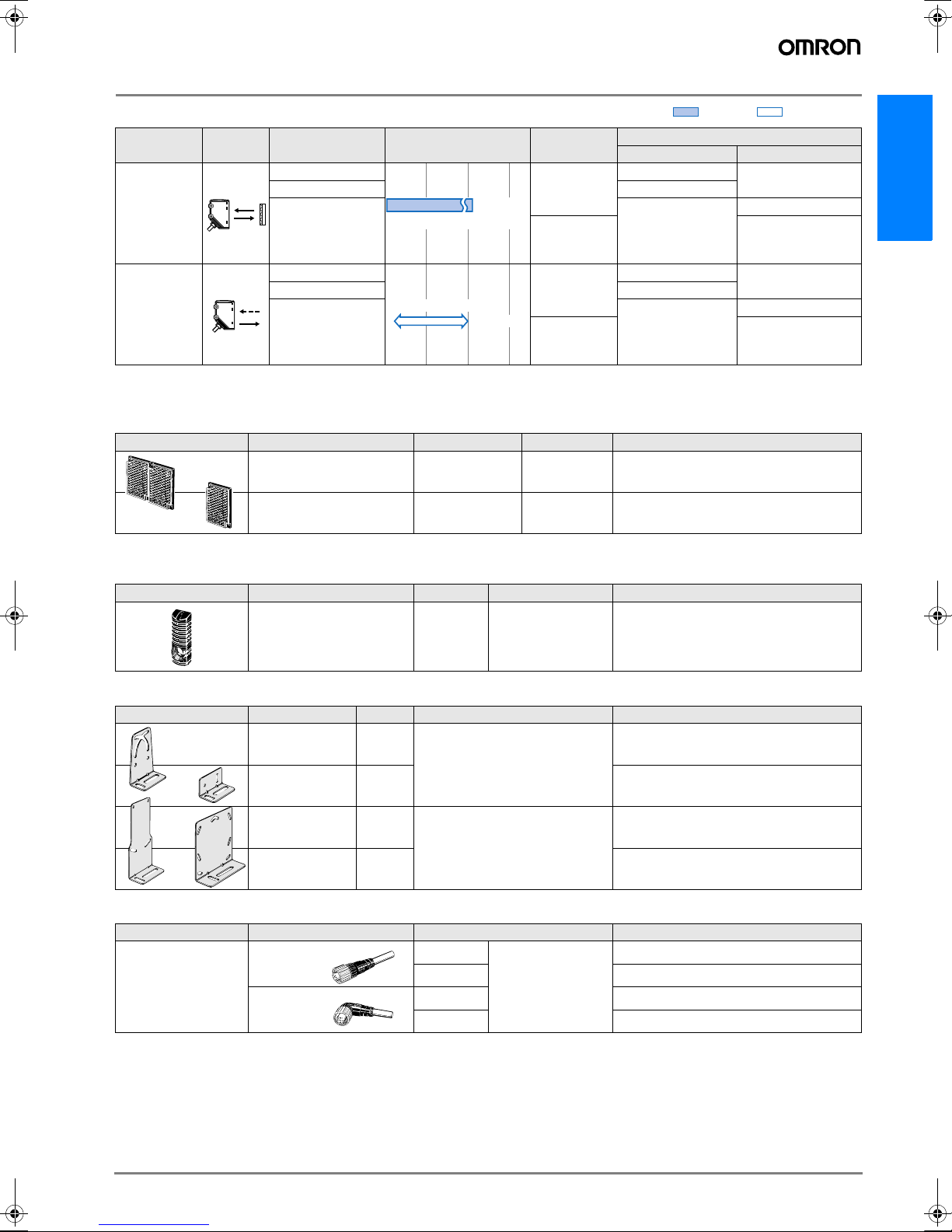

Retroreflective Models

Though the Size Is Compact, the Sensing

Distance Is as Long as 10m.

Replace the conventional through-beam model with the retroreflective model for saving wiring and installation space.

Through-

beam

ConventionalNew product

Retorore-

flective

model

10m

10m

Saves wiring effort

Saves space

Reflector

Easy monitoring of Operation stability by

means of stability indicator.

The stability indicator becomes

darker due to dust on the lens or

improper optical axis adjustment.

A-119E3G

Page 2

Distance-setting

Distance-setting Models with a Long 2-m

Sensing Distance Incorporate a Teaching

Function

Sensitivity adjustment without being influenced by background objects is possible by simply pressing a button. Useful

for teaching without a sensing object.

General

Select either transistor (NPN/PNP selectable) or relay output. Three connection

methods (plus a model with a timer function). Select either a DC power supply or a

variable power

supply: 24 V to 240 VAC or 12 to 240 VDC).

Easy Optimum Sensing Distance Adjustments

Teaching with and without a sensing object ensures highly accurate detection without influence from the background.

Without sensing object With sensing object

ONE

PUSH

ONE

PUSH

Zone Setting Function

Effective for detecting glossy objects, which were difficult to

detect with conventional sensors. (D-ON)

OFF

(Incident)

Teach with only the

background (conveyer).

ON

(Interrupted)

Sensing zone

Approx. ±10%

Since the Sensor can have a threshold value not

only in front of the background but also beyond the

background, it is possible to detect objects such as

mirror-surface objects that do not return light from

the object surface.

IEC Standard IP67 Water Proofing

M12 Rotary Connector Available on Models

with DC Power Supplies

Detection of large works

Retroreflective model can make longdistance detection, saving wiring.

E3G-R13

E3G-L73

A-120 Standard Photoelectric Sensors

Application

Detection of large corrugated cardboard

Just by installing the sensor on one side,

only the boxes to be detected shall be

sensed.

E3G-L73E3G-L73

Detection of cars in multi-story parking lot

10m10m

E3G-R13

E3G-R13

Page 3

Ordering Information

Sensors

Sensor type Shape Connection method Sensing distance Timer function

Pre-wired

Retroreflec-

tive Models

(with M.S.R.

Function)

Distance-

setting

* Values in parentheses indicate the minimum required distance between the sensor and reflector.

Connector type E3G-R17-G

10m

Terminal block ---

Pre-wired

Connector type E3G-L77

White paper 300 ¥ 300 mm

Terminal block ---

[500mm]*

0.2 to 2 m

---

ON or OFF

delay 0 to 5 s

(adjustable)

---

ON or OFF

delay 0 to 5 s

(adjustable)

NPN/PNP selector Relay contact output

E3G-R13-G

E3G-L73

Accessories (Order Separately)

Reflectors

Shape Sensing distance (typical) Model Quantity Remarks

10 m (500 mm) * E39-R2 1 ---

6 m (100 mm) * E39-R1S 1 ---

* Values in parentheses indicate the minimum required distance between the sensor and reflector.

Red light Infrared light

Model

---

E3G-MR19-G

E3G-MR19T-G

---

E3G-ML79-G

E3G-ML79T-G

E3G

Terminal Protection Cover for Side-pullout Cable

Shape Model Quantity Applicable type Remarks

E39-L129-G 1

Mounting Brackets

Shape Model Quantity Applicable type Remarks

E39-L131 1

E39-L132 1 Rear-mounting use

E39-L135 1

E39-L136 1 ---

Sensor I/O Connectors

Cable Shape Cable length Model

Straight

Standard cable

L-shaped

E3G-MR19(T)-G

E3G-ML79(T)-G

E3G-R1#

E3G-L7#

E3G-MR19(T)-G

E3G-ML79(T)-G

2 m

5 m XS2F-D421-GC0-A

2 m XS2F-D422-DC0-A

5 m XS2F-D422-GC0-A

3-wire type

Provided with rubber bushing and cap for

pullout prevention in horizontal direction

---

Cable pulled out downwards

XS2F-D421-DC0-A

A-121E3G

Page 4

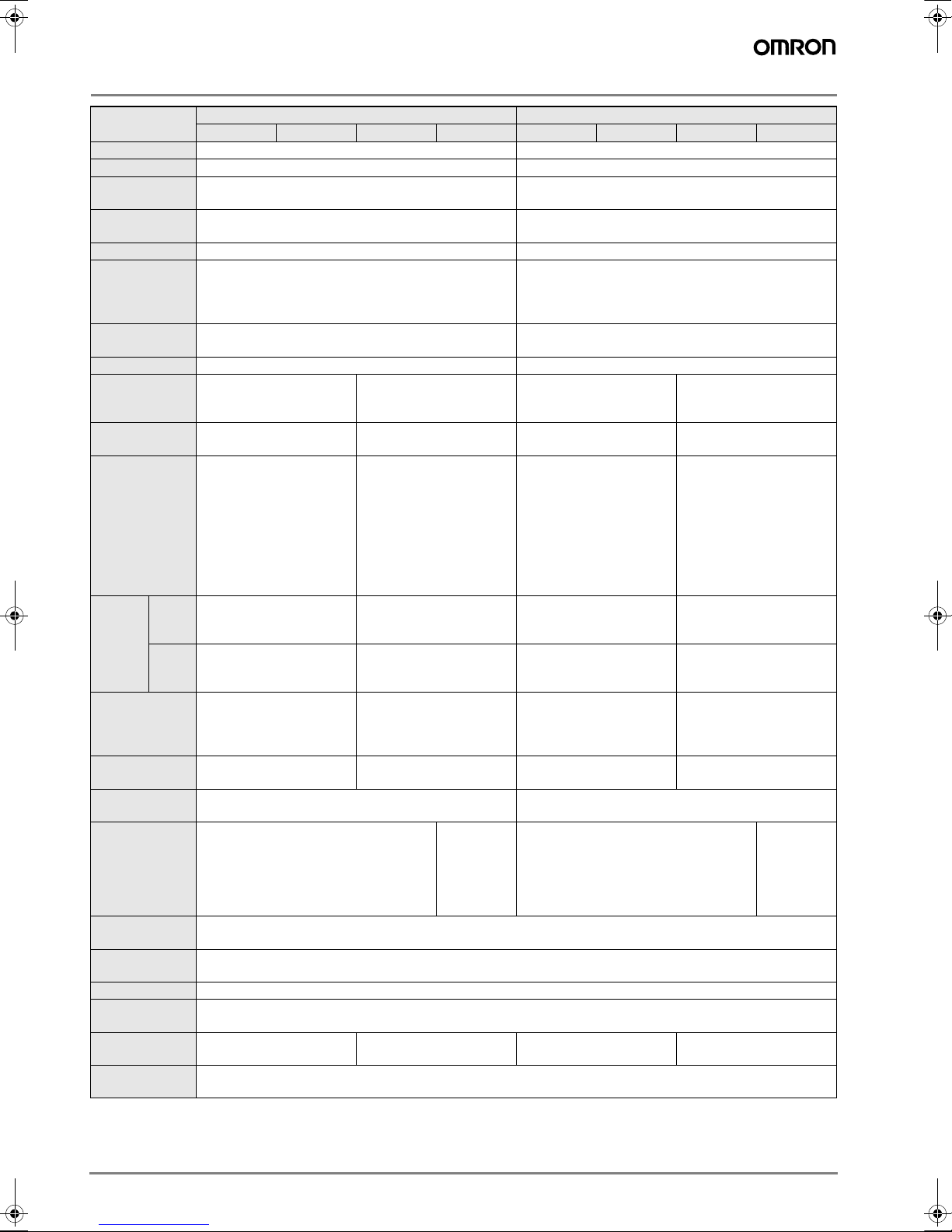

Rating/Performance

Sensor type Retroreflective Models (M.S.R. function) Distance-setting

Item Model E3G-R13-G E3G-R17-G

Sensing distance 10 m (500 mm) * (When using the E39-R2) 0.2 to 2 m (White paper 300 x 300 mm)

Setting distance --- 0.5 to 1.2 m (White paper 300 x 300 mm)

Standard sensing

object

Hysteresis

(typical)

Directional angle Sensor: 1° to 5° --Reflectivity

characteristics

(black/white

error)

Light source

(wave length)

Spot size --- 70 mm dia. max. (At detection distance of 1m)

Power supply

voltage

Current/Power

consumption

Control output

MeLife expectancy (relay

output)

Protective circuits

Response time Operation/reset: 1 ms each

Sensitivity

adjustment

Timer function ---

Ambient

illuminance

Ambient

temperature

Ambient humidity Operating: 35% to 85%RH, Storage: 35% to 95%RH (with no condensation)

Insulation

resistance

Dielectric

strength

Vibration

resistance

* Values in parentheses indicate the minimum required distance between the sensor and reflector.

chani-

cal

Electri-

cal

Opaque: 80 dia. min. ---

Red LED (700 nm) Infrared LED (860 nm)

10 to 30 VDC

[Ripple (p-p) 10% included]

50 mA max. 2 W max. 60 mA max. 2 W max.

Load supply voltage 30

VDC max., load current 100

mA max. (residual

voltage NPN output: 1.2 V

max., PNP output: 2 V

max.) Open collector output

type (NPN/PNP output

switch selectable) L-ON/

D-ON switch selectable

---

---

Reverse polarity protection,

output short-circuit protection, mutual interference

prevention

One-turn adjuster Teaching method (NORMAL mode/ZONE mode)

Incandescent lamp: 3,000 lux max. Sunlight 10,000 lux max.

Operating: -25°C to 55°C, Storage: -30°C to 70°C (with no icing or condensation)

20 M min. at 500 VDC

1,000 VAC at 50/60 Hz for

1 minute

Destruction: 10 to 55 Hz, 1.5 mm double amplitude for 2 hours each in X, Y, and Z directions

E3G-MR19-G

--- 10% of setting distance

--- ±10% max. (At detection distance of 1m)

12 to 240 VDC ±10% ripple

(p-p) : 10% max. 24 to 240

VAC ±10% 50/60 Hz

Relay output: Switch-over

contact 250 VAC 3A

(cos =1) max. 30 VDC 3A

max. L-ON/D-ON switch

selectable

50,000,000 operations min.

(switching frequency:

18,000 operations/h)

100,000 operations min.

(switching frequency: 1,800

operations/h)

Mutual interference prevention function

Operation/reset: 30 ms

each

2,000 VAC at 50/60 Hz for

1 minute

E3G-MR19T-G

ON delay/

OFF delay

0 to 5 s

(Adjuster

variable

system)

E3G-L73 E3G-L77

10 to 30 VDC

(Ripple (p-p) 10% included)

Load supply voltage 30

VDC max., load current 100

mA max. (residual

voltage NPN output: 1.2 V

max., PNP output: 2 V

max.) Open collector output

type (NPN/PNP output

switch selectable) L-ON/

D-ON switch selectable

---

---

Reverse polarity protection,

output short-circuit protection, mutual interference

prevention

Operation/reset: 5 ms each

---

1,000 VAC at 50/60 Hz for

1 minute

E3G-ML79-G

12 to 240 VDC ±10% ripple

(p-p) : 10% max. 24 to 240

VAC ±10% 50/60 Hz

Relay output: Switch-over

contact 250 VAC 3A

(cos =1) max. 30 VDC 3A

max. L-ON/D-ON switch

selectable

50,000,000 operations min.

(switching frequency:

18,000 operations/h)

100,000 operations min.

(switching frequency:

1,800 operations/h)

Mutual interference prevention function

Operation/reset: 30 ms

each

2,000 VAC at 50/60 Hz for

1 minute

E3G-ML79T-G

ON delay/

OFF delay

0 to 5 s

(Adjuster

variable

system)

A-122 Standard Photoelectric Sensors

Page 5

Sensor type Retroreflective Models (M.S.R. function) Distance-setting

Item Model E3G-R13-G E3G-R17-G

E3G-MR19-G

E3G-MR19T-G

E3G-L73 E3G-L77

Shock resistance 500 m/s2 3 times in each of X, Y and Z directions

Protective

structure

Connection

method

Weight

(Packed state)

IEC 60529 IP67 (with Protective Cover attached)

Pre-wired

(standard

length: 2 m)

Approx.

150 g

M12

Connector

Terminal block

Approx. 50 g Approx. 150 g Approx. 50 g Approx. 150 g

Pre-wired

(standard

length: 2 m)

M12

Connector

Case PBT (polybutylene terephthalate)

Mate-

Lens Acrylics (PMMA)

rial

Mounting

Brackets

Stainless steel (SUS304)

Accessories Instruction sheet, and screwdriver for adjustment Instruction sheet

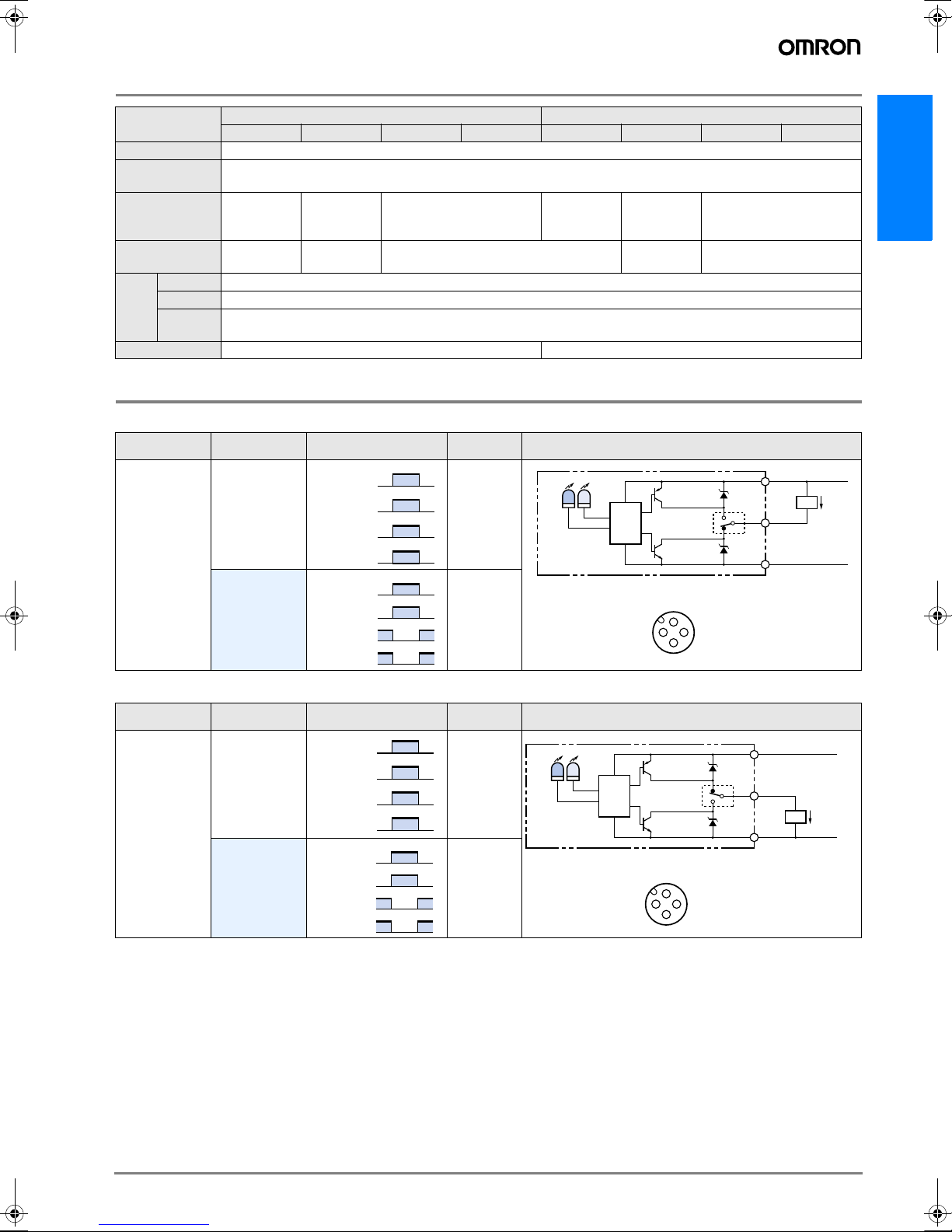

Output Circuit Diagram

NPN output

Model

E3G-R13-G

E3G-R17-G

E3G-L73

E3G-L77

Operating status of

output transistor

Light ON

Dark ON

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Interrupted

Interrupted

Operation

Operation

indicator

indicator

(orange)

(orange)

Output

Output

transistor

transistor

Load

Load

(Relay)

(Relay)

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

Incident

Incident

ON

ON

OFF

OFF

ON

ON

OFF

OFF

Operate

Operate

Reset

Reset

Mode selection

switch

LON

(LIGHT ON)

DON

(DARK ON)

Operation

indicator

(Orange) (Green)

Stability

indicator

Output circuit

Main

NPN or PNP

circuit

output selector

* Set the NPN or PNP selector to NPN

Connector Pin Arrangement

2

E3G-ML79-G

Terminal block

PNP output

transistor

NPN output

transistor

1

4

3

ZD

*

ZD

Note: Terminal 2 is not used.

E3G-ML79T-G

10 to 30 VDC

Brown

Load

Black

Control

output

Blue

Load

current

E3G

0V

PNP output

Model

E3G-R13-G

E3G-R17-G

E3G-L73

E3G-L77

Operating status of

output transistor

Light ON

Dark ON

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Interrupted

Operation

indicator

(orange)

Output

transistor

Load

(Relay)

Timing chart

Incident

ON

OFF

ON

OFF

Operate

Reset

Incident

ON

OFF

ON

OFF

Operate

Reset

Mode selection

switch

LON

(LIGHT ON)

DON

(DARK ON)

Operation

indicator

(Orange) (Green)

Output circuit

Stability

indicator

Main

circuit

* Set the NPN or PNP selector to PNP

PNP output

transistor

NPN or PNP

output selector

NPN output

transistor

Connector Pin Arrangement

1

2

4

3

Note: Terminal 2 is not used.

10 to 30 VDC

Brown

ZD

*

Black

Control output

Load

ZD

Blue

Load current

0V

A-123E3G

Page 6

Relay contact output

2

T

Td

2

2

T

Td

1

Mode selection

switch

(LIGHT ON)

(DARK ON)

1

(LIGHT ON)

1

(DARK ON)

LON

DON

LON

DON

Timer function Model Timing chart

Incident

Interrupted

Operation

ON

indicator

OFF

(orange)

ON

Ta

Operation

indicator

(orange)

Incident

OFF

OFF

Incident

OFF

OFF

Interrupted

ON

ON

ON

ON

Incident

Ta

T

1

T

1

OFF

OFF

OFF

Td

Td

ON

ON

T

1

1

T

1

2

T

T

1

Td2Td

T

T

1

Td

1

2

T2T

2

T

2

2

T

1

Td

1

T2T

1

T

1

Td

1

T2T

2

T2T

T

1

Td

2

None

ON or OFF

delay 0 to 5 s

(adjustable)

* For ON and OFF, delay timers vary independently.

Note: Td1, Td2: Delay time (0 to 5 s), T1: Any period longer than delay time, T2: Any period shorter than delay time

E3G-MR19-G

E3G-ML79-G

E3G-MR19T-G

E3G-ML79T-G

Interrupted

ON delay *

OFF delay *

Interrupted

ON delay *

OFF delay *

Connectors (Sensor I/O connectors)

2

13

4

Terminal No. Wire colors

1

2

3

4

XS2F-D421-DC0-A

XS2F-D421-GC0-A

XS2F-D422-DC0-A

XS2F-D422-GC0-A

Brown

Blue

Black

Note: Pin 2 is not used.

Class

For DC

Wire, outer

jacket color

Brown A

Connector

pin No.

Application

supply (+V)

- B -

Blue C

Power sup-

Black D Output

Power

ply (0 V)

Main

circuit

Output circuit

1

Tc

2

Ta Contact output

3

Tb

4

Power

supply

5

(G6C Relay built in)

24 to 240 VAC

12 to 240 VDC

(no polarity order restricted)

E3G

A-124E3G

Page 7

Characteristic data (typical)

E3G-R/MR Retroreflective Models

Operating Range

500

E-39-R2 reflector

100

10

Incident output excess gain

ON

1

level

0.1

0 5 10 15 20

Distance (m)

E3G-L/ML Distance-setting Models

Spot Diameter vs. Sensing Distance Sensing Zone (in NORMAL mode) Sensing Zone in ZONE Mode

120

Horizontal

Vertical

100

80

Spot diameter (mm)

60

40

20

0

0.5 1 1.5 2 2.5

Distance (m)

Sensing Object Size vs. Setting Distance Sensing Object Angle Characteristics

3

Distance setting: 0.5, 1 and 2 m

2.5

2

Sensing distance (m)

1.5

1

0.5

0

100 200 300 400 500 600

Side length (one side) of sensing object: d (mm)

White paper

Black paper

2m

1m

0.5m

Close-range Characteristics

2.5

2

2.03m

40

Distance setting: 0.5, 1 and 2 m

Sensing object:

30

White paper 300

20

Distance Y (mm)

10

0

−

10

−

20

−

30

40

−

1m

0.5m

0.50 1 1.5 2 2.5

(Up and Down)

20

Sensing object: White paper

Sensing distance: 1 m

15

10

5

0

Sensing distance variation (%)

-

5

-

10

-

15

20

-

-40-30-20-

×

300 mm

X

2m

Distance X (m)

(Upwards

and

Downwards)

Inclination

angle

+Ø

Sensing object

10 0 10 20 30 40

-Ø

Inclination angle (

40

Y

Distance setting: 0.5, 1 and 2 m

Sensing object:

30

White paper 300

20

Distance Y (mm)

10

0

-

10

0.5m

-

20

-

30

40

-

0.50 1 1.5 2 2.5

¥

300 mm

1m

2m

Distance X (m)

Sensing Object Angle (Left and Right)

20

Sensing object: White paper

Sensing distance: 1 m

15

10

5

0

Sensing distance variation (%)

-

5

-

10

-

15

20

-

Ø

˚

)

-40-30-20-

10 0 10 20 30 40

(Left and light)

Sensing object

Inclination angle (

Y

X

Inclination

angle

+Ø

-Ø

E3G

Ø

˚

)

1.5

Sensing distance (m)

1

0.51m

0.5

60mm

0

Black paper

(0.5m)

0.52m

White paper

(0.5m)

1.24m

53mm

43mm

Black paper

Material (teaching distance m)

(2m)

0mm

White paper

(2m)

A-125E3G

Page 8

Nomenclature

Retroreflective Models

E3G-R13-G (Pre-wired model)

E3G-R17-G (Connector model)

Stability indicator

(Green)

Sensitivity adjuster

Operation indicator

(Orange)

PNP/NPN selector

L.ON/D.ON selector

E3G-MR19-G (Terminal Block Model)

E3G-MR19T-G (Terminal Block Model with Timer)

Sensitivity adjuster

ON-delay adjuster *

OFF-delay adjuster *

Operation indicator (Orange)

Stability indicator (Green)

L.ON/D.ON selector

Distance-setting

E3G-L73 (Pre-wired model)

E3G-L77 (Connector model)

Indicators

Stability indicator (Green)

Teaching indicator

(Red and green)

PNP/NPN selector

NORMAL/ZONE selector

Operation indicator

(Orange)

Mode selector

TEACH/

RUN(D•ON)/

RUN(L•ON)

TEACH button

E3G-ML79-G (Terminal Block Model)

E3G-ML79T-G (Terminal Block Model with Timer)

Indicators

Stability indicator (Green)

Teaching indicator

(Red and green)

TEACH button

ON-delay adjuster *

OFF-delay adjuster *

Operation indicator (Orange)

TEACH/RUN selector

L-ON/D-ON selector

NORMAL/ZONE selector

* The ON or OFF de-

lay adjuster is not

available with the

E3G-MR19-G.

* The ON or OFF delay

adjuster is not available with the E3GML79-G.

A-126 Standard Photoelectric Sensors

Page 9

Operation

E3G-L/ML

Adjustment Steps

Pro-

ce-

dure

Install, wire, and turn on the Sensor.

1

Perform distance setting (teaching). Refer to "Distance Setting (Teaching)".

2

Check that the mode selector is set to RUN.

3

Distance Setting (Teaching)

Select the most appropriate teaching method in reference to the following descriptions.

Teaching without sensing

Application

objects (i.e., Teaching the

background).

Operation

Setting a threshold in the

middle between the background and sensing object

for operation.

Detection of glossy objects

in front of the background.

E3G

Setting the maximum

sensing distance of the

Sensor.

Teaching Normal one-point teaching Normal two-point teaching Zone teaching

Setting method

Press the button

TEACH TEACH TEACH TEACH

with the background object.

Press the button

with the background object.

Press the button

with the background object

(conveyor, etc.).

Thresholds (a and b) are

set in the sensing distance

on condition that the difference between these

thresholds is approximately 10% of the whole sens-

Set threshold

Threshold (a) is set to a

distance in front of the

background of 20% of the

background distance.

Threshold (a) is set approximately in the middle

between the background

and sensing object.

ing distance.

Output ON range

La: Distance equivalent to threshold

(a)

Lb: Distance equivalent to threshold

The output is ON between

the Sensor and La.

Normal Mode1. Normal Onepoint Teaching 2. Normal Two-point Teaching

E3G-L/ML

(b)

Normal one-point teaching

Pro-

ce-

Operation

dure

Set the mode selector to .

1

Set the NORMAL/ZONE mode selector to .

2

Press the button with the background.

3

The teaching indicator (red) will turn ON.

Set the mode selector to . (Set to L-ON or D-ON

4

mode.)

Note: Perform normal one-point teaching with the background.

TEACH

TEACH

RUN

Normal two-point teaching

The output is ON between

the Sensor and La.

Threshold a

Background

(La)

ON

NORMAL

The output is ON between

La and Lb.

Threshold a

E3G-L/ML

Background

(La)

Object

ON

Pro-

ce-

dure

Move the sensing object and press the button with

the background.

If the teaching is successful, the teaching indicator

4

(green) will turn ON.

If the teaching is not successful, the teaching indicator

(red) will flash.

When the teaching is successful, the setting is complete.

Set the mode selector to . (Use the operation mode

selector to set L-ON/D-ON.) When the teaching is not

5

successful, change the work position and setting distance

again, and restart the setting from step "3".

Pro-

ce-

Operation

dure

Set the mode selector to .

1

Set the NORMAL/ZONE mode selector to .

2

Press the button with a sensing object.

3

The teaching indicator (red) will turn ON.

TEACH

TEACH

NORMAL

Maximum distance setting

(in normal mode)

Press the button

for longer than three seconds.

The threshold is set in such

manner that the stability indicator will turn ON at approximately 2 m if the

sensing object is white paper.

The output is ON whenever the sensing object is located between the Sensor

and at a distance of 2.2 m.

Zone Mode Zone Teaching

Threshold a

E3G-L/ML

L-ON

D-ON

Background

(La)

OFF

ON ONOFF

Operation

TEACH

RUN

Threshold b

(Lb)

OFFON

A-127E3G

Page 10

Zone teaching

Pro-

ce-

Operation

dure

Set the mode selector to .

1

Set the NORMAL/ZONE mode selector to .

2

Press the button with the background.

The teaching indicator (red) will turn ON and the teaching

3

TEACH

TEACH

ZONE

indicator (green) will then turn ON.

Set the mode selector to . (Set to L-ON or D-ON

4

mode.)

Note: Perform zone teaching with the background.

RUN

Precautions

Correct Use

E3G-R/MR

Design

Power Supply

A full-wave rectification power supply can be used with the

E3G-MR19(T)-G.

Maximum distance setting (in normal mode)

If you want to set the maximum distance of the sensor, set a

maximum distance as depicted in the following procedure.

Pro-

ce-

Operation

dure

Set the mode selector to .

1

Set the NORMAL/ZONE mode selector to .

2

Press the button 3 s or more.

The teaching indicator (red) will turn ON.

3

TEACH

TEACH

NORMAL

In 3 s, the teaching indicator (green) will turn ON.

When the teaching indicator (green) turns ON, the setting

is complete. Set the mode selector to . (Set to L-ON/

4

RUN

D-ON.)

E3G-L/ML

Design

Power Supply

A full-wave rectification power supply can be used with the

E3G-ML79(T)-G.

Wiring Considerations

The tensile strength of the cable during operation should not

exceed the values shown below.

Model Tensile strength

E3G-R13-G

E3G-MR19(T)-G

E3G-R17-G 10 N max.

50 N max.

● For adjustment

Display

• The following graphs indicate the status of each operation

level.

• Set the E3G so that it will work within the stable operation

range.

Stability indicator (green)

Stable

operation

range

(see note)

Unstable

operation

range

(see note)

Stable

operation

range

(see note)

Note: If the operation level is set to the stable operation range, the E3G will operate with

Operation

level x 1.2

Operation

level

Operation

level

x 0.8

the highest reliability and without being influenced by temperature change, voltage

fluctuation, dust, or setting change.

Incident level

ON

OFF

ON

Operation indicator (Orange)

L·ON D·ON

ON

OFF

OFF

ON

Wiring Considerations

The tensile strength of the cable during operation should not

exceed the values shown below.

Model Tensile strength

E3G-L73

E3G-ML79(T)-G

E3G-L77 10 N max.

50 N max.

Miscellaneous

EEPROM Write Error

If a write error occurs (operation indicator flickers) due to power-off, static electricity or other noise in the teaching mode,

perform teaching again.

E3G-M#(T)-G

Wiring Considerations

• The cable with an external diameter of 6 to 8 mm is recommended.

• Securely tighten the cover to maintain water resistance and

dust resistance. The thread size of the conduit socket is PG

13.5

• Do not tighten with the cable caught by the terminal protection cover. Otherwise, the water-resistant structure and like

cannot be maintained.

A-128 Standard Photoelectric Sensors

Page 11

(Recommended example)

Terminal

protection cover

Rubber bushing

33mm

63mm

(4)

Power supply

(5)

(1) Tc

(3) Tb

Output(2) Ta

Washer

Clamping nut

• Changing to Side-pullout Cable from Vertical-pullout Cable

(1)

(2)

(2)

E39-L129-G Terminal

Protection Cover

Rubber bushing

Washer

Clamping nut

All E3G Models

Design

Load Relay Contact

If a load is used that will spark when it is turned OFF (e.g. a

contactor or valve), the usually closed side may be turned ON

before the usually open side is turned OFF or vice versa. If

both usually open output and usually closed output are used

simultaneously, apply an surge suppressor to the load. (Refer

to OMRON's "Switch/Relay/Connector (PCB Product) Catalog" for typical examples of surge suppressors.

Wiring Considerations

Connection/Wiring

The E3G has load short-circuit protection. If load short-circuit

or like has occurred, the output turns OFF. Therefore, recheck

the wiring and switch power on again. This resets the shortcircuit protection circuit. Load short-circuit protection is activated when a current of 2 times or more of the rated load current flows. When using an L load, use the one the inrush

current of which is less than 1.2 times of the rated load current.

E3G

(3)

(4)

Rubber bushing *

Cap *

Note: * Provided with the E39-L129-G

Pro-

ce-

Operation

dure

A Remove the present cover.

Attach the E39-L129-G Terminal Protection Cover for

B

side-pullout cable.

Remove the clamping nut, washer, and rubber bushing

C

of the E3G. These are used for the side-pullout cable.

Attach the rubber bushing and cap provided with the

D

E39-L129-G to the E3G as replacements.

Mounting

• If Sensors are mounted face-to-face, ensure that no optical

axes cross each other. Otherwise, mutual interference may

result.

• Be sure to install the Sensor carefully so that the directional

angle range of the Sensor will not be directly exposed to intensive light, such as sunlight, fluorescent light, or incandescent light.

• Do not strike the Photoelectric Sensor with a hammer or any

other tool during the installation of the Sensor, or the Sensor

will loose its water-resistive properties.

• Use M4 screws for Sensor installation.

• For case installation, tighten it to the torque of 1.2 Nm max.

Water Resistance

Tighten the operation cover screws and terminal block cover

screws to a torque of 0.3 to 0.5 Nm in order to ensure water

resistivity.

A-129E3G

Page 12

Dimensions (Unit: mm)

Sensors

Retroreflective Models

Pre-wired

E3G-R13-G

Connector type

E3G-R17-G

Receiver

18.8

24.4

Emitter

Terminal block

E3G-MR19-G

E3G-MR19T-G

Operation indicator (Orange)

Stability indicator (Green)

12

1.1

R11

R7

22

68.5

67.8

14

12

21

Receiver

12

Operation mode selector

M2.6

Sensitivity

adjuster

47.8

45

43

R11

Two, 4.5 dia.

mounting holes

25

29

Vinyl-insulated round cable with three

conductors, 6 dia. (17

standard length: 2 m

Operation indicator (Orange)

Stability indicator (Green)

Sensitivity adjuster

Mounting

Holes

2-M4

25

x 0.16 dia.);

Operation mode selector

M2.6

OFF-delay adjuster *

ON-delay adjuster *

Two, 4.5 dia.

mounting holes

Note: All dimensions other than the

ones specified below are the

same as the corresponding dimensions of E3G-R13-G.

8

7

10

37 8

43

Note: * The ON or OFF-delay adjuster is

not available with the E3G-MR19.

connector

Mounting Holes

M12

2-M4

10.5 dia.

18.8

35.95

Emitter

R7

22

84.45

84.95

14

6

2.1

12

29

16 37

44

68

Conduit PG 13.5

74

Hexagonal nut (Diagonal: 22)

Application cable: 6 to 8 dia.

37

74

A-130 Standard Photoelectric Sensors

Page 13

Distance-setting

Pre-wired

E3G-L73

Connector type

E3G-L77

TEACH buttonOperation indicator (Orange)

E3G

Receiver

14 dia. lens

12.8

Emitter

Terminal block

E3G-ML79-G

E3G-ML79T-G

Indicators

Stability indicator (Green)

Teaching indicator (Red and green)

14

18

68.5

Receiver

67.8

14

30

13.7

21

47.8

45

43

Indicators

Stability indicator (Green)

Teaching indicator

(Red and green)

M2.6

Operation mode selector

Two, 4.5 dia.

mounting holes

25

29

Vinyl-insulated round cable with three

conductors, 6 dia. (17 x 0.16 dia.);

standard length: 2 m

Operation indicator

(Orange)

TEACH button

Mounting

Holes

Operation mode

M2.6

selector

OFF-delay adjuster *

ON-delay adjuster *

M2.6 nut

2-M4

25

Two, 4.5 dia.

mounting holes

Note: The figures and dimensions not

given are the same as those of

E3G-L73-G shown on the left.

8

7

10

37 8

43

E3G-ML79-G does not equipped ON-delay adjuster

and OFF-delay adjuster.

M12

connector

Mounting Holes

2-M4

10.5 dia.

14 dia.

lens

30

24.4

Emitter

13.7

29

18

84.95

84.45

6

16 37

44

68

74

37

Hexagonal nut (Diagonal: 22)

Conduit PG 13.5

74

A-131E3G

Page 14

Accessories (Order Separately)

Terminal Protection Cover for Side-pullout Cable

E39-L129-G

Terminal Protection Cover for Side-pullout Cable (Example of E3G-MR19-G)

M2.6

19

81.5

Note: 1 . The cover is provided with a rubber bushing and cap

to prevent the cable from being pulled out in vertical

direction.

29

Reflectors and Mounting Brackets

H-3

M2.6

61.8

22

90.3

81

44 Cap (Attach to E39-L129-G)

(Conduit)

Hexagonal nut

(Diagonal: 22)

Applicable cord: 6 to 8 dia.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. E278-E2-04-X

In the interest of product improvement, specifications are subject to change without notice.

A-132 Standard Photoelectric Sensors

Loading...

Loading...