Omron CP1L-L14D Series, CP1L-J14D Series, CP1L-L20D Series, CP1L-M30D Series, CP1L-M40D Series Getting Started Manual

...Page 1

CP1L CPU Unit

Cat. No. W07E-EN-02

CP1L-J14D@-@

CP1L-J20D@-@

CP1L-L10D@-@

CP1L-L14D@-@

CP1L-L20D@-@

CP1L-M30D@-@

CP1L-M40D@-@

CP1L-M60D@-@

GETTING STARTED GUIDE

Page 2

CP1L-J14D-

CP1L-J20D-

CP1L-L10D-

CP1L-L14D-

CP1L-L20D-

CP1L-M30D-

CP1L-M40D-

CP1L-M60D-

CP1L CPU Unit

Getting Started Guide

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some CX-Programmer displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Trademarks

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

SYSMAC is a registered trademark of OMRON’s Programmable Controllers.

Other brand and product names are trademarks or registered trademarks of their respective owners.

© OMRON, 2007

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

2

Page 4

TABLE OF CONTENTS

PRECAUTIONS ............................................................... 9

1 Intended Audience.................................................................................................... 10

2 General Precautions................................................................................................. 10

3 Safety Precautions ................................................................................................... 10

4 Application Precautions ............................................................................................ 10

SECTION 1CP1L Overview ........................................... 11

1-1 CP1L Models ............................................................................................................ 12

1-2 Part Names and Functions ....................................................................................... 15

SECTION 2Designing Systems...................................... 19

2-1 Organization of this Manual...................................................................................... 20

2-2 About the Shutter Control System ............................................................................ 22

2-3 I/O Allocation for the Shutter Control System........................................................... 24

2-4 Example Ladder Program......................................................................................... 26

SECTION 3Mounting and Wiring ................................... 27

3-1 Installation Notes ...................................................................................................... 28

3-2 Mounting onto DIN Tracks ........................................................................................ 31

3-3 Wiring Devices.......................................................................................................... 32

3-4 Power Testing CP1L................................................................................................. 35

SECTION 4Creating Programs ...................................... 37

4-1 Preparing for Programming ...................................................................................... 38

4-2 Creating Ladder Programs ....................................................................................... 44

4-3 Using CX-Programmer ............................................................................................. 47

4-4 Using the Help .......................................................................................................... 50

4-5 Inputting Programs ................................................................................................... 53

4-6 Saving/Loading Programs ........................................................................................ 70

4-7 Editing Programs ...................................................................................................... 73

SECTION 5Transferring and Debugging Programs ....... 77

5-1 Going Online............................................................................................................. 78

5-2 Adjusting/Debugging Online ..................................................................................... 85

Appendix ........................................................................ 95

A-1 Channel/Relay Numbers .......................................................................................... 96

A-2 Instructions ............................................................................................................. 101

A-3 Inner Workings of CP1L ......................................................................................... 105

A-4 CP1L Programming Examples ............................................................................... 114

3

Page 5

About this Manual:

This manual describes installation and operation of the CP-series Programmable Controllers (PLCs)

and includes the sections described below. The CP Series provides advanced package-type PLCs

based on OMRON’s advanced control technologies and vast experience in automated control.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate a CP-series PLC. Be sure to read the precautions provided in the following section.

This manual is intended for first-time users of the SYSMAC CP series. The basic use of the series is

explained based on SYSMAC CP1L.

Circuit configurations, wiring methods, and programs provided in this manual are given strictly as

examples. When constructing an actual system, check the specifications, performance, and safety of

each component by referring to the respective manuals.

Ladder programs in this manual are provided strictly as examples. When designing the actual circuits,

take adequate safety measures.

Precautions provide general precautions for using the Programmable Controller and related devices.

Section 1 introduces the types of CP1L, as well the part names.

Section 2 explains how to construct a CP1L system, using a shutter control system as an example.

Section 3 explains the how to install CP1L onto a DIN track, how to wire power supply and I/O lines,

and how to test operation.

Section 4 explains the basic functions of CX-Programmer creating the ladder program for the shutter

control system.

Section 5 describes how to transfer and debug programs.

The Appendices provide channel/relay numbers, instructions, inner workings of CP1L, and CP1L programming examples.

4

Page 6

Related Manuals

The following manuals are used for the CP-series CPU Units. Refer to these manuals as required.

Cat. No. Manual name Description

W462 SYSMAC CP Series CP1L

CPU Unit User’s Manual

W451 SYSMAC CP Series

CP1H/CP1L CPU Unit Programming Manual

W446 SYSMAC CX-Programmer

Operation Manual

Explains the system configuration, installation, wiring, I/O allocation, pulse/counter functions, and

expansion unit connections in details. Also provides

information on errors, troubleshooting, maintenance, and inspection.

Provides the following information on the CP

Series:

• Programming instructions

• Programming methods

•Tasks

• File memory

• Functions

Use this manual together with the CP1H Program-

mable Controllers Operation Manual (W450).

Provides information on installing and operating the

CX-Programmer for all functions except for function

blocks.

5

Page 7

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in

materials and workmanship for a period of one year (or other period if

specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS

OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF

THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT

THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER

SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE,

OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the

individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY,

REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE

PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND

NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR

INAPPROPRIATE MODIFICATION OR REPAIR.

6

Page 8

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards,

codes, or regulations that apply to the combination of products in the

customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party

certification documents identifying ratings and limitations of use that apply

to the products. This information by itself is not sufficient for a complete

determination of the suitability of the products in combination with the end

product, machine, system, or other application or use.

The following are some examples of applications for which particular

attention must be given. This is not intended to be an exhaustive list of all

possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or

electrical interference, or conditions or uses not described in this

manual.

• Nuclear energy control systems, combustion systems, railroad systems,

aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or

government regulations.

• Systems, machines, and equipment that could present a risk to life or

property.

Please know and observe all prohibitions of use applicable to the

products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT

THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE

RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED

AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a

programmable product, or any consequence thereof.

7

Page 9

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time

based on improvements and other reasons.

It is our practice to change model numbers when published ratings or

features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without

any notice. When in doubt, special model numbers may be assigned to fix

or establish key specifications for your application on your request. Please

consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for

manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user

in determining suitability and does not constitute a warranty. It may

represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is

subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed

to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

8

Page 10

PRECAUTIONS

This section provides general precautions for using the CP-series Programmable Controllers (PLCs)

and related devices.

The information contained in this section is important for the safe and reliable application of

Programmable Controllers. You must read this section and understand the information contained

before attempting to set up or operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9

Page 11

Intended Audience

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance

specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment,

amusement machines, safety equipment, and other systems, machines, and

equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this

manual close at hand for reference during operation.

WARNING It is extremely important that a PLC and all PLC Units be used for the

specified purpose and under the specified conditions, especially in

applications that can directly or indirectly affect human life. You must consult

with your OMRON representative before applying a PLC System to the

above-mentioned applications.

3 Safety Precautions

Caution When power is ON or has just been turned OFF, do not touch the power

supply, I/O terminals, or the surrounding areas. Doing so may result in burns.

After turning the power OFF, wait for the unit to cool down sufficiently before

touching it.

Caution Secure the AC power supply line to the terminal block with a 0.5N

torque. Loosening the screw may result in a fire or malfunction.

Caution Before starting online editing, confirm that the extension of cycle time will

have no adverse effects. Otherwise, input signals may not be read.

4 Application Precautions

Caution Confirm that the facility will not be affected by changing to MONITOR or RUN

mode.

·m of

10

Page 12

SECTION 1

CP1L Overview

This section introduces the types of CP1L, as well the part names

used during operation.

1-1 CP1L Models ........................................................................ 12

1-2 Part Names and Functions ................................................... 15

Page 13

1

CP1L Overview

1

CP1L Overview

1-1 CP1L Models

CP1L programmable controller is a PLC package type, available with 10, 14, 20, 30, 40, or 60 I/O points.

For application examples that use CP1L, refer to appendix A-4 CP1L Programming Examples.

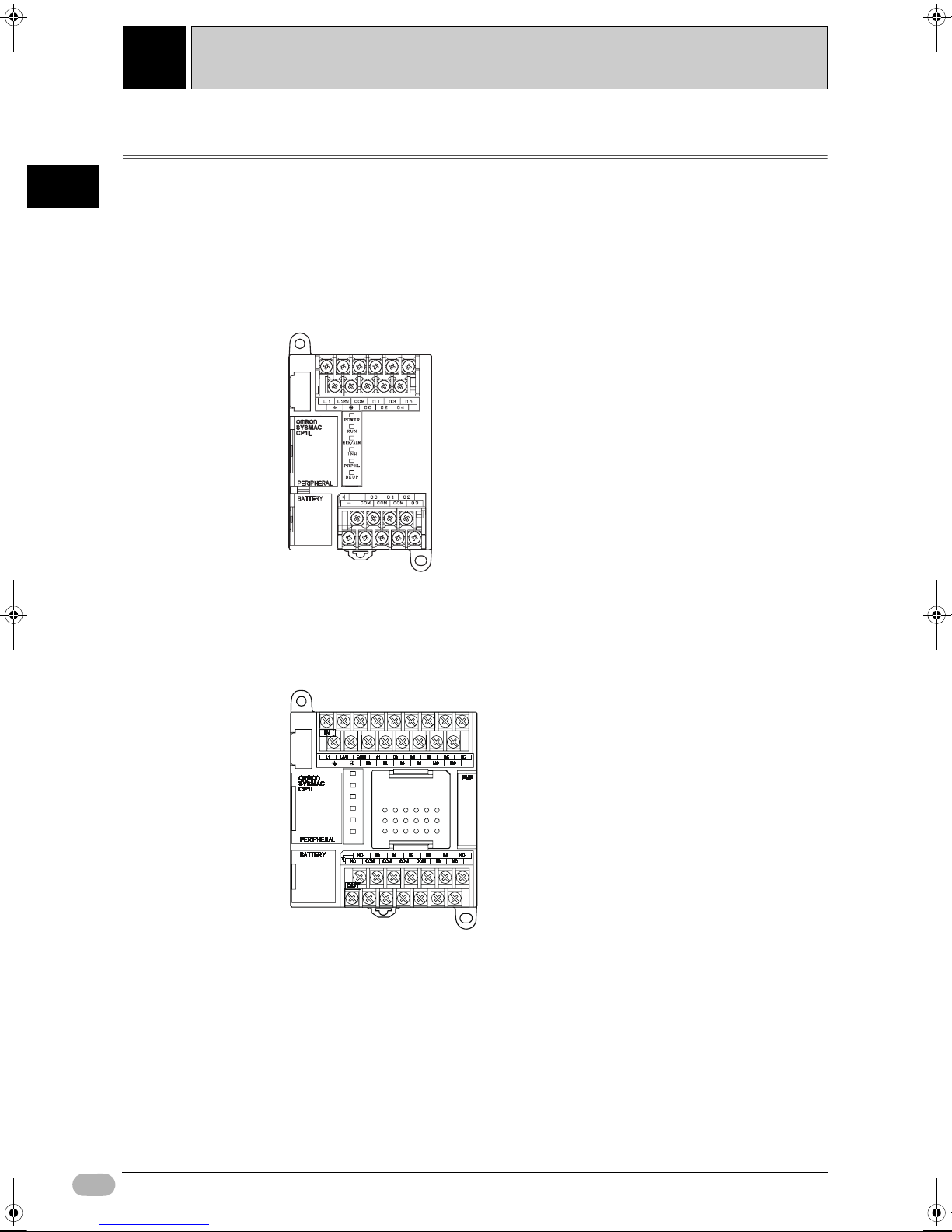

10-point I/O Units (CP1L-L10D-)

• The CPU Unit has 6 inputs and 4 outputs built in.

• The PLC cannot use CP-series Expansion I/O Units to expand the maximum

total of I/O points.

14-point I/O Units (CP1L-L14D-/CP1L-J14D-)

• CPU unit has 8 input points and 6 output points.

• CP-series expansion I/O units can be used to add I/O points, up to a total of

54 I/O points.

12 SYSMAC CP1L Getting Started Guide

Page 14

20-point I/O Units (CP1L-L20D-/CP1L-J20D-)

• CPU unit has 12 input points and 8 output points.

• CP-series expansion I/O units can be used to add I/O points, up to a total of 60 I/

O points.

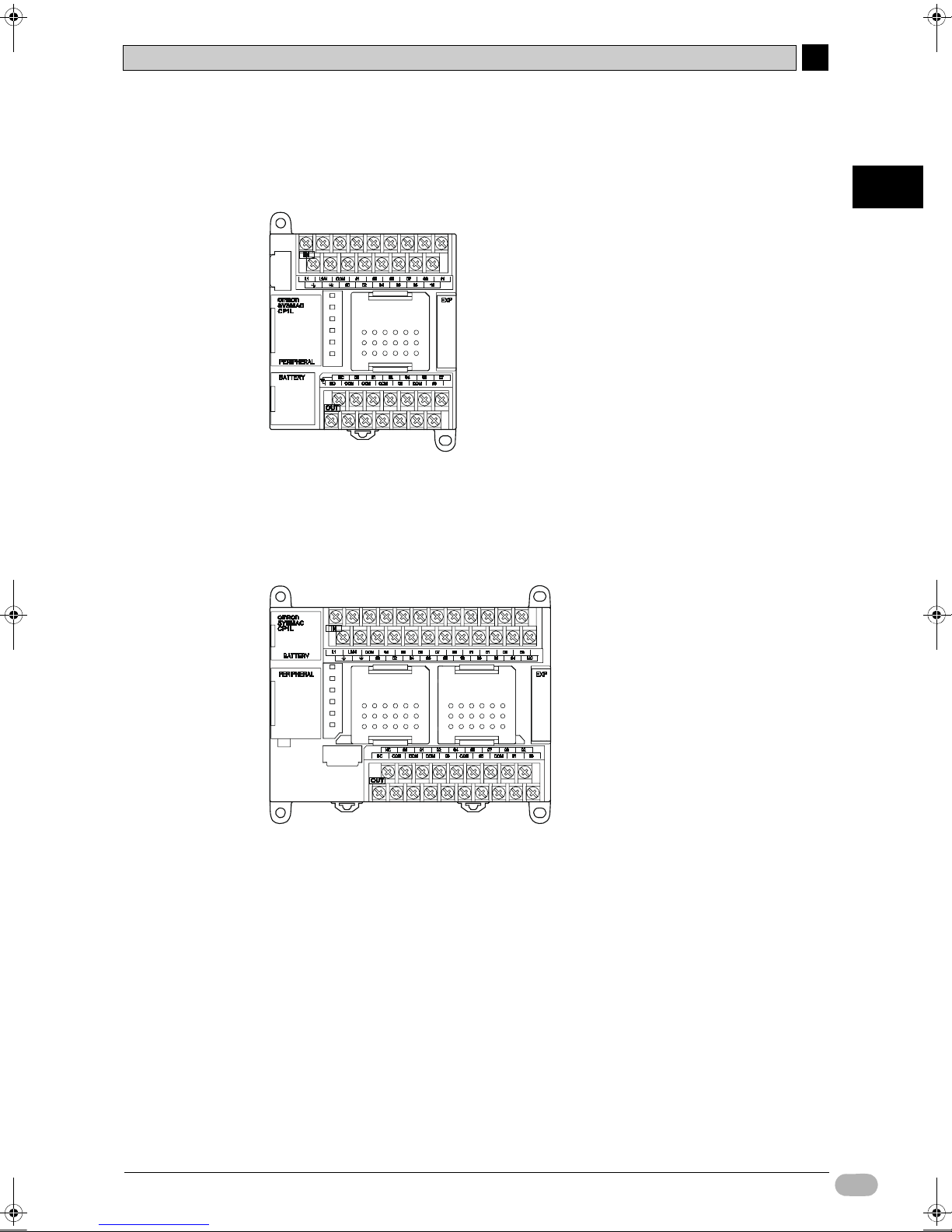

30-point I/O Units (CP1L-M30D-)

• CPU unit has 18 input points and 12 output points.

• CP-series expansion I/O units can be used to add I/O points, up to a total of 150

I/O points .

1-1 CP1L Models

1

1

CP1L Overview

SYSMAC CP1L Getting Started Guide 13

Page 15

1

CP1L Overview

1-1 CP1L Models

1

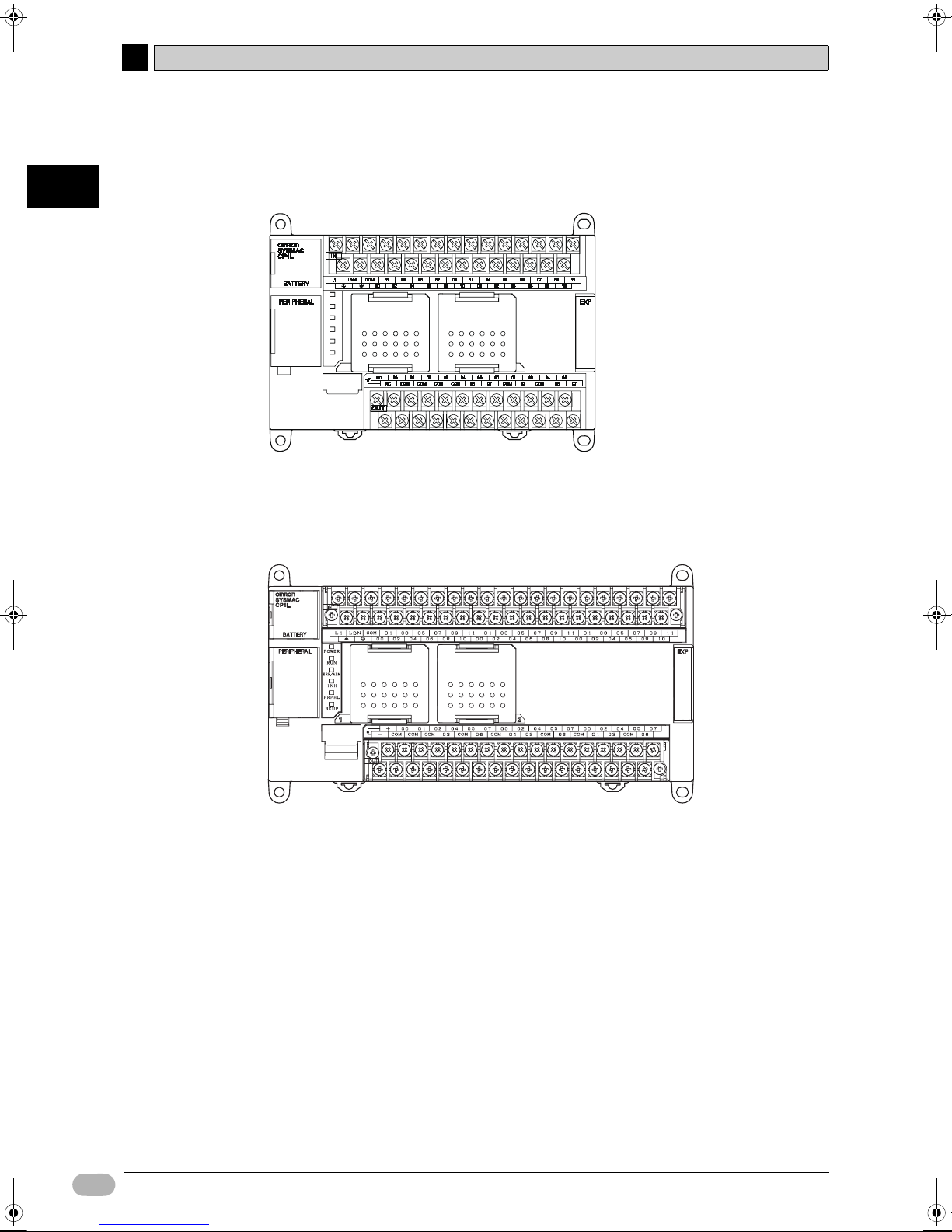

40-point I/O Units (CP1L-M40D-)

• CPU unit has 24 input points and 16 output points.

• CP-series expansion I/O units can be used to add I/O points, up to a total of 160

I/O points.

60-point I/O Units (CP1L-M60D-)

• CPU unit has 36 input points and 24 output points.

• CP-series expansion I/O units can be used to add I/O points, up to a total of 180

14 SYSMAC CP1L Getting Started Guide

Page 16

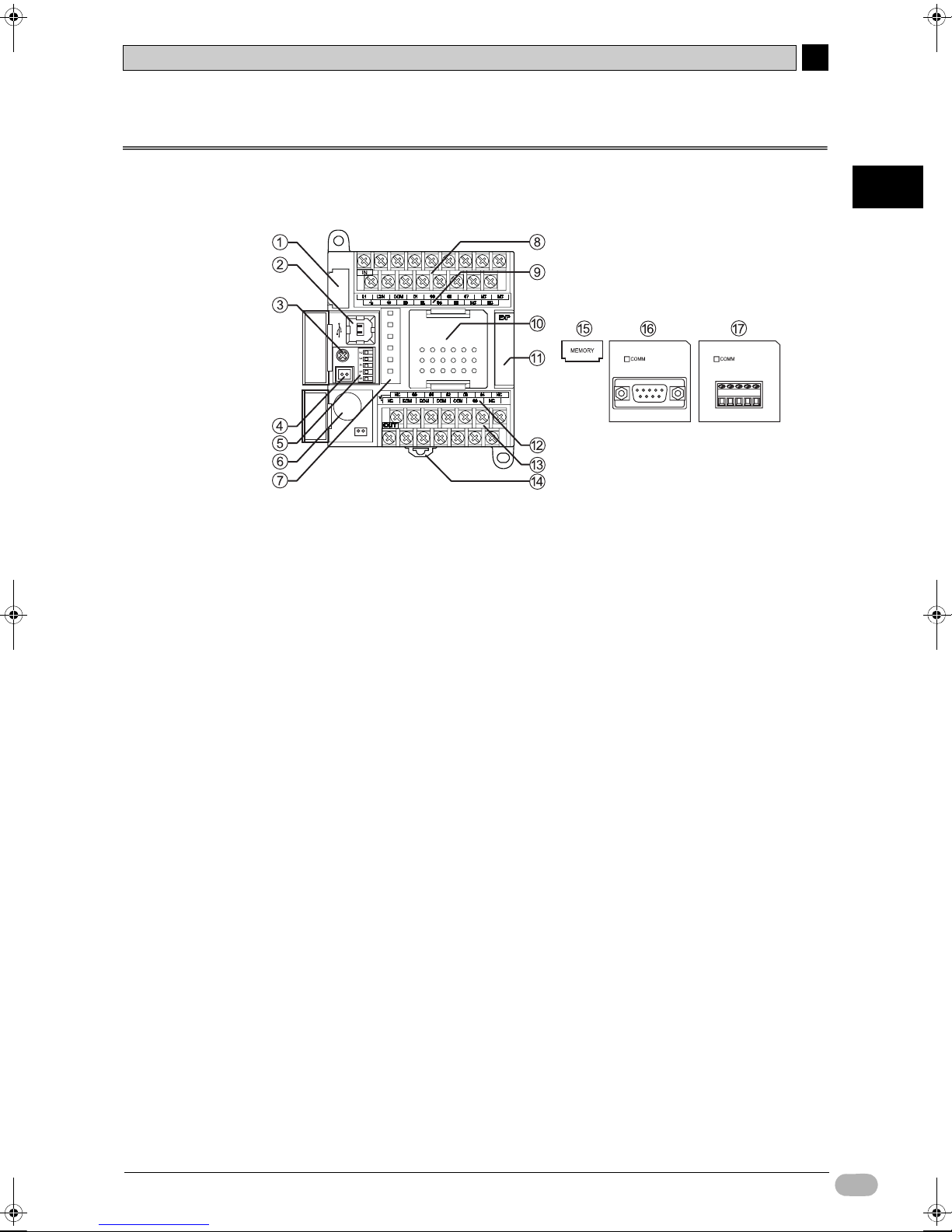

1-2 Part Names and Functions

1-2 Part Names and Functions

This section describes the part names and functions, using the 14-point I/O unit as an example.

14-point I/O Unit

1

1

CP1L Overview

(1) Memory cassette slot

Used to attach a memory cassette (15). Memory cassettes can be used to

store backups for CP1L programs, parameters, and data memory. They also

allow you to copy data to other CP1L units without using a programming tool

(software).

(2) Peripheral USB port

Used for connection to a computer. Computers can be used for programming

and monitoring.

(3) Analog adjuster

Rotate to adjust the value for auxiliary area A642CH to within the 0 to 255

range. Use to change timer and counter settings without using a programming

tool (software).

(4) External analog settings input connector

Takes an external input between 0 and 10V, and changes the value for

auxiliary area A643CH to a value between 0 and 256. This input is not

isolated.

(5) DIP switches

Used for settings such as write-permission on user memory, automatic

transfers from memory cassettes, and tool bus use.

For details, refer to 2-1 Part Names and Functions of CP Series CP1L CPU

Unit User's Manual (W462).

(6) Battery

Maintains the internal clock and RAM contents while the power supply is OFF.

SYSMAC CP1L Getting Started Guide 15

Page 17

1

CP1L Overview

1-2 Part Names and Functions

1

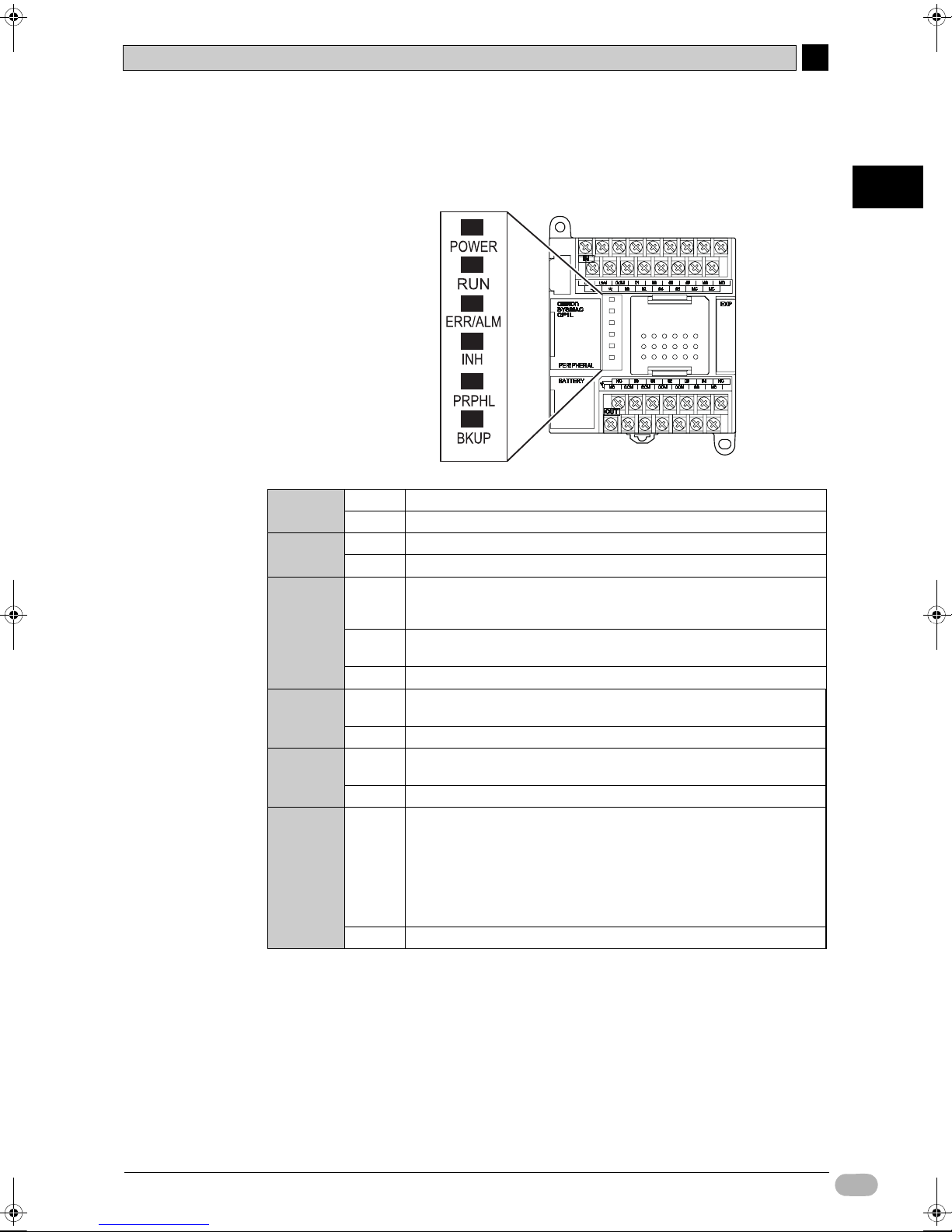

(7) Operation indicators

(8) Power supply, ground, and input terminal block

(9) Input indicators

(10) Option board slot

(11) Expansion I/O unit connector

Indicates the operating status of CP1L. Indicated statuses include power

status, operating mode, errors, and peripheral USB communication status.

Used to connect the power supply line, ground line, and input lines.

Lit when the corresponding input terminal contact is ON.

Used to install an RS-232C option board (16) or an RS-422A/485 option

board (17).

14/20-point I/O units may have 1 serial communication option board installed.

30/40/60-point I/O units may have up to 2 serial communication option boards

installed.

Used to connect CP-series expansion I/O units and expansion units. 14/20point I/O units may have 1 expansion unit connected. 30/40/60-point I/O units

may have up to 3 expansion units connected.

(12) Output indicators

Lit when the corresponding output terminal contact is ON.

(13) External power supply and output terminal block

• External power supply terminal:

Units that use AC power supply have a 24VDC external power supply terminal

with a maximum capacity of 300mA.This can be used as a service power

supply for input devices.

• Output terminals: Used to connect output lines.

(14) DIN track mounting pin

Used for mounting unit to a DIN track.

(15) Memory cassette (optional)

Used to store data from the built-in flash memory. Insert into memory cassette

slot (1).

(16) RS-232C option board

Insert into option board slot (10).

(17) RS-422A/485 option board

Insert into option board slot (10).

16 SYSMAC CP1L Getting Started Guide

Page 18

zIndicator Statuses

This section describes the operating statuses of CP1L as displayed by the

operation indicators.

1-2 Part Names and Functions

1

1

CP1L Overview

POWER

(Green)

RUN

(Green)

ERR/ALM

(Red)

INH

(Yellow)

PRPHL

(Yellow)

BKUP

(Yellow)

Lit Power is ON.

Not lit Power is OFF.

Lit CP1L is executing a program in either RUN or MONITOR mode.

Not lit Operation is stopped in PROGRAM mode, or stopped due to a fatal error.

Lit A fatal error (including FALS execution) or a hardware error (WDT error)

has occurred.

CP1L operation will stop, and all outputs will be turned OFF.

Blinking A non-fatal error (including FAL execution) has occurred.

CP1L operation will continue.

Not lit Operation normal.

Lit The output OFF bit (A500.15) has turned ON.

All outputs will be turned OFF.

Not lit Operation normal.

Blinking Communication (either sending or receiving) is active on the peripheral

USB port.

Not lit Any other state.

Lit • User program, parameter, or data memory is being written to or read

from the built-in flash memory (backup memory).

• User program, parameter, data memory, DM defaults, or comment

memory is being written to or read from the memory cassette.

• User programs, parameters, and data memory are being restored

following a PLC power-on.

Note: Do not turn the PLC power supply OFF while this indicator is lit.

Not lit Any other state.

SYSMAC CP1L Getting Started Guide 17

Page 19

1

CP1L Overview

1-2 Part Names and Functions

1

18 SYSMAC CP1L Getting Started Guide

Page 20

SECTION 2

Designing Systems

This section explains how to construct a CP1L system, using a

shutter control system as an example.

All subsequent sections are written based on the sample program

used in this section.

2-1 Organization of this Manual .................................................. 20

2-2 About the Shutter Control System ........................................ 22

2-2-1 Operation........................................................................ 22

2-2-2 System Components ...................................................... 23

2-3 I/O Allocation for the Shutter Control System ....................... 24

2-4 Example Ladder Program..................................................... 26

Page 21

2

Designing Systems

2-1 Organization of this Manual

Sections 2 through 5 of this manual explain the construction process of a CP1L system, from design to

operation, using a shutter control system as an example. Section contents are as follows:

2

Designing Systems

Section 2: Workflow from design to operation, shutter control system

specifications, components, and I/O allocation.

Section 3: CP1L installation, component wiring, and power testing.

Section 4: Connecting CP1L to a computer, and creating ladder programs.

Section 5: Setting PLC clock and PLC operation mode, transferring data from

computer to CP1L, operation, adjustment, and debugging.

Note Circuit configurations, wiring methods, and programs provided in this manual

are given strictly as examples. When constructing an actual system, check the

specifications, performance, and safety of each component by referring to the

respective manuals.

20 SYSMAC CP1L Getting Started Guide

Page 22

2-1 Organization of this Manual

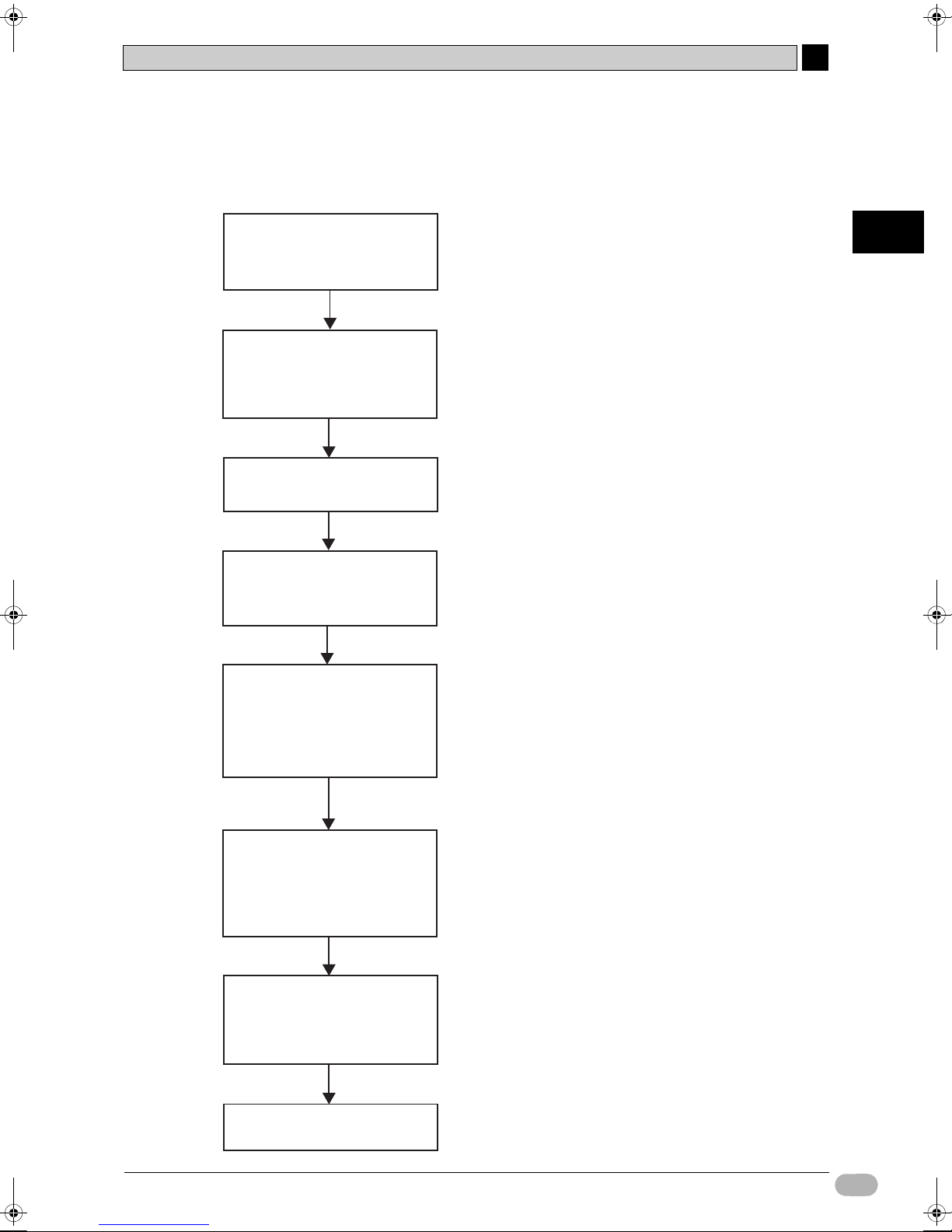

zWorkflow from Design to Operation

The workflow for constructing a CP1L shutter control system is shown below. For details, refer

to the respective sections of the manual.

2

I/O allocation

· Allocate relay numbers

to sensors and switches

Preparing the equipment

· Equipment preparation

· Wire power supply and ground

· Wire I/O devices

Supplying power to CP1L

· Test PLC operation

Preparing to write program

· Install USB driver onto computer

· Connecting CP1L to a computer

Writing programs

· Enter ladder programs

in CX-Programmer

· Compile

· Save

· Edit

Refer to 2-3 I/O Allocation for the Shutter Control

System.

Refer to 3-2 Mounting onto DIN Tracks and 3-3

Wiring Devices.

Refer to 3-4 Power Testing CP1L.

Refer to 4-1 Preparing for Programming.

Refer to 4-2 Creating a Ladder Program, 4-3 Using

CX-Programmer, 4-5 Inputting Programs, 4-6 Saving/

Loading Programs, and 4-7 Editing Programs.

2

Designing Systems

Going online with CP1L

and the computer

· Set the CP1L clock

· Switch to PROGRAM mode.

· Transfer the program

Online debugging

· Monitor power

· Force-set/force-reset commands

· Online Editing

Production run

Refer to 5-1 Going Online.

Refer to 5-2 Adjusting/Debugging Online.

Refer to 5-1 Going Online.

SYSMAC CP1L Getting Started Guide 21

Page 23

2

Designing Systems

2-2 About the Shutter Control System

2

2-2 About the Shutter Control System

This section defines the operation and components of a shutter control system.

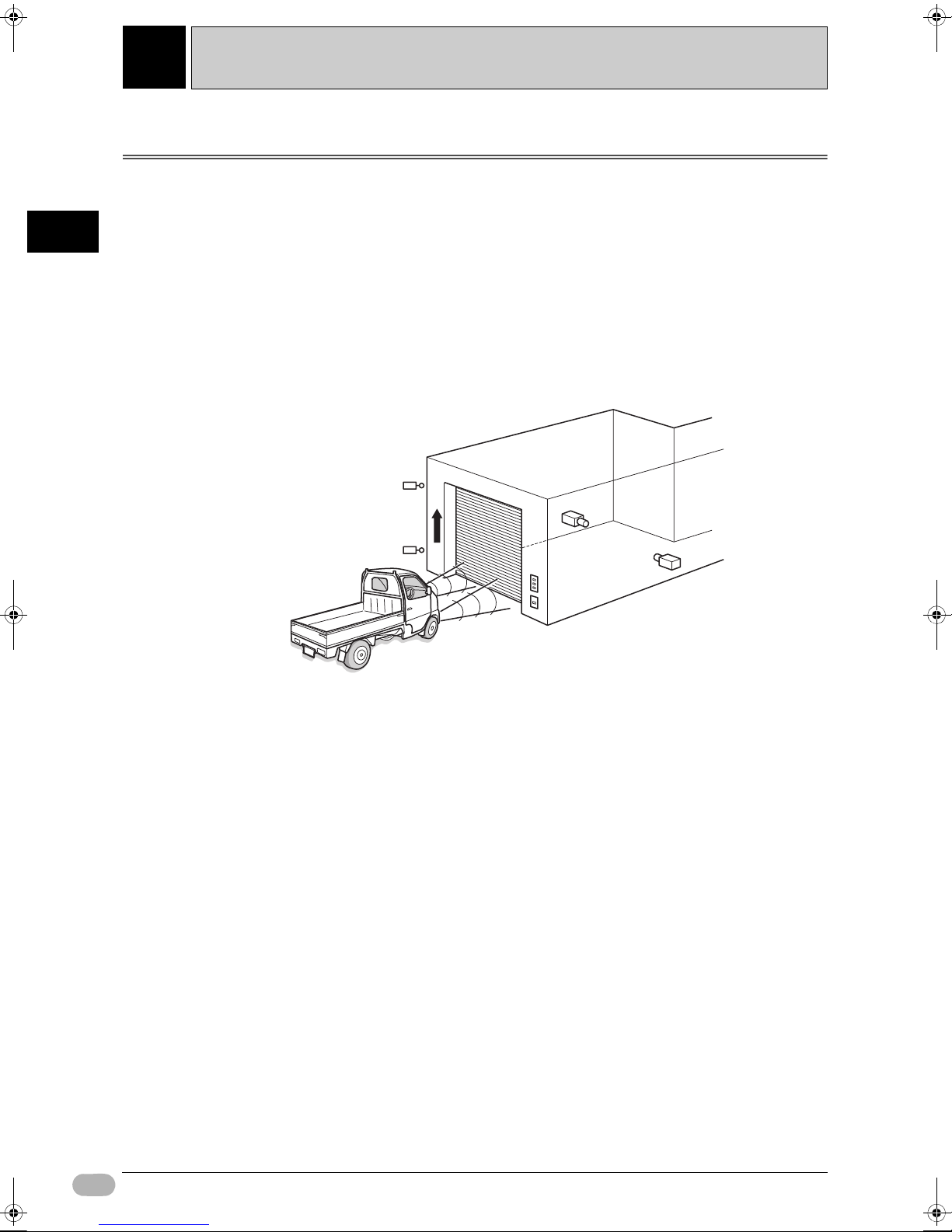

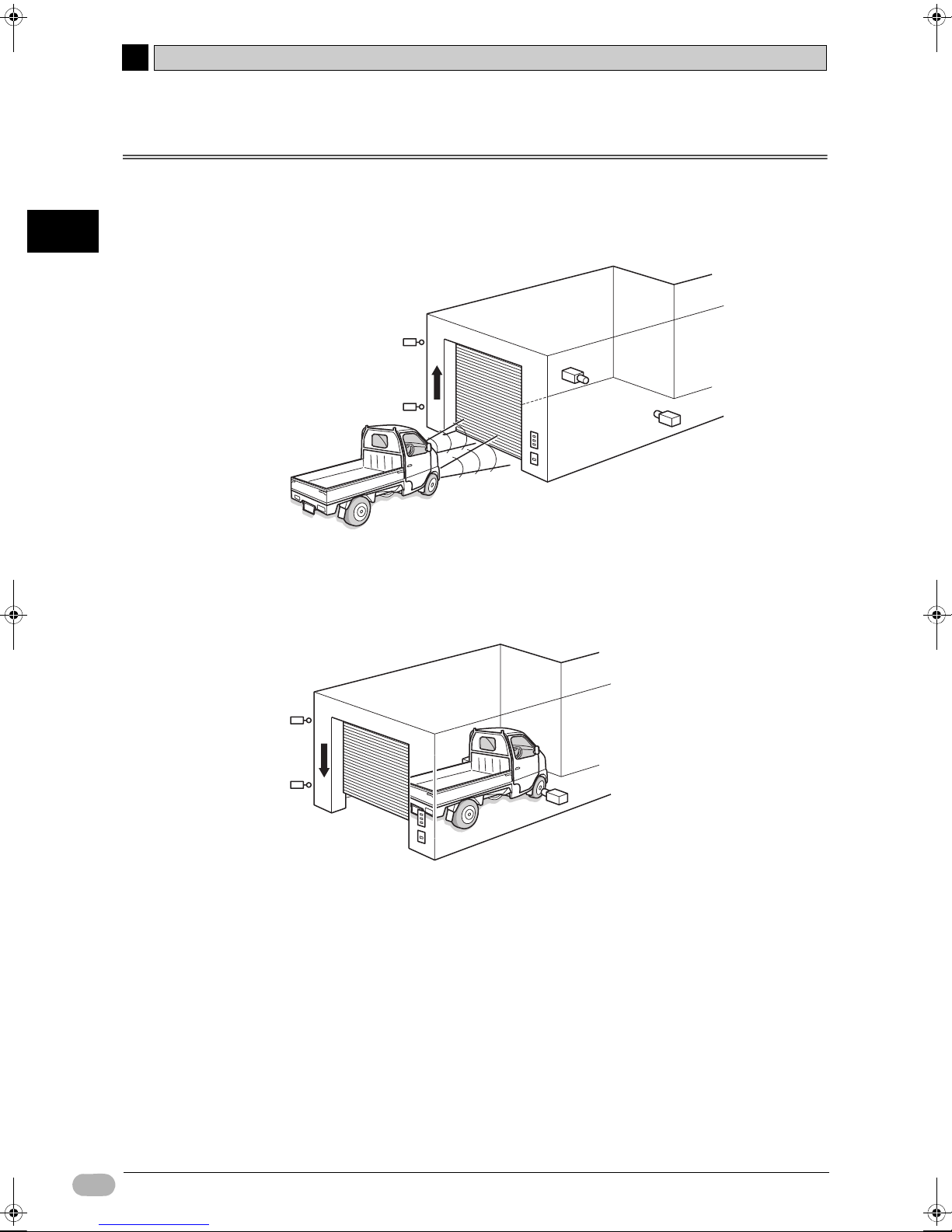

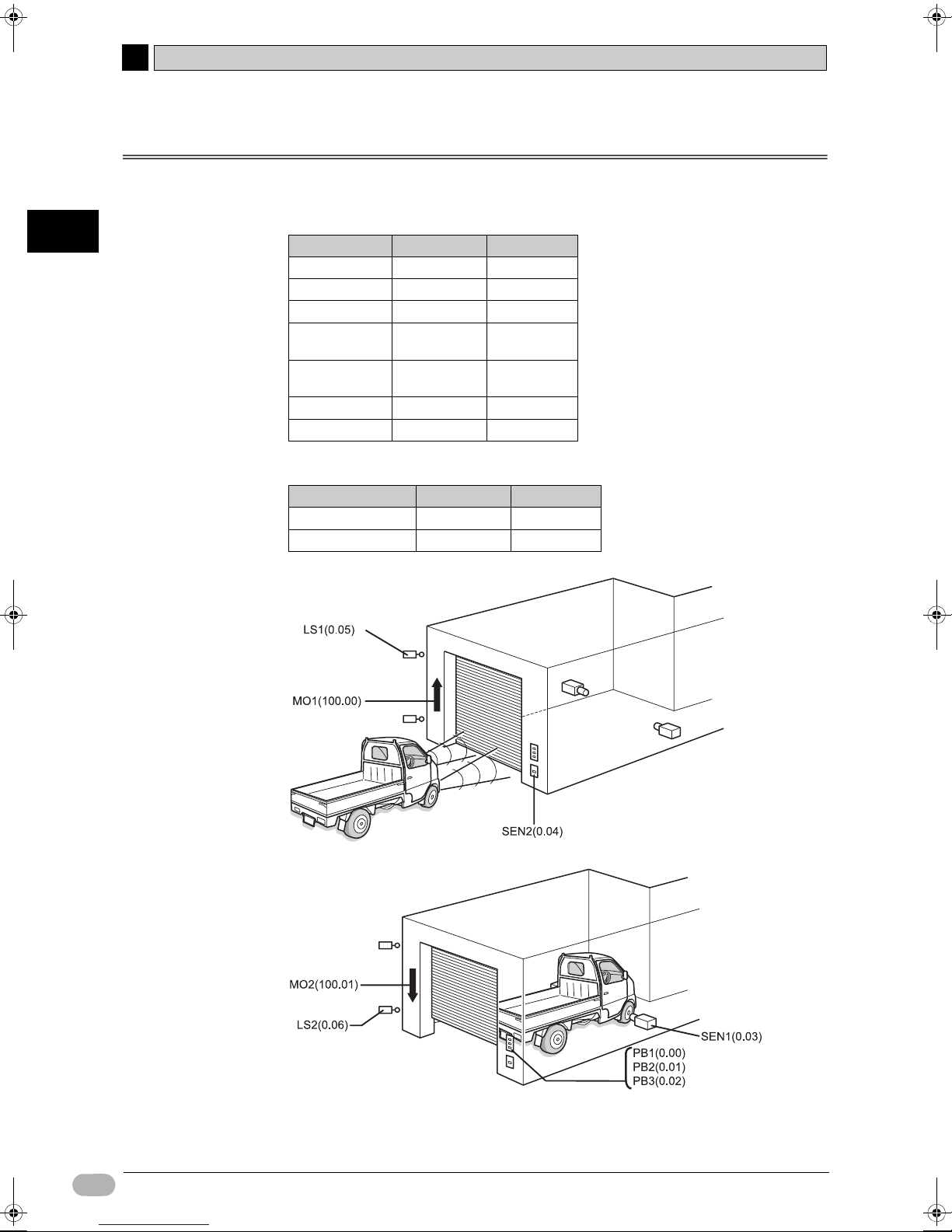

2-2-1 Operation

This section defines the operation of a shutter control system.

A car approaches the shutter.

• When a sensor detects 3 headlight flashes within 5 seconds, the shutter

opens.

• The shutter can also be opened, closed, and stopped with buttons.

• When a sensor detects full car entrance into the garage, the shutter closes.

• When pulling the car out of the garage, use the buttons to operate the shutter.

22 SYSMAC CP1L Getting Started Guide

Page 24

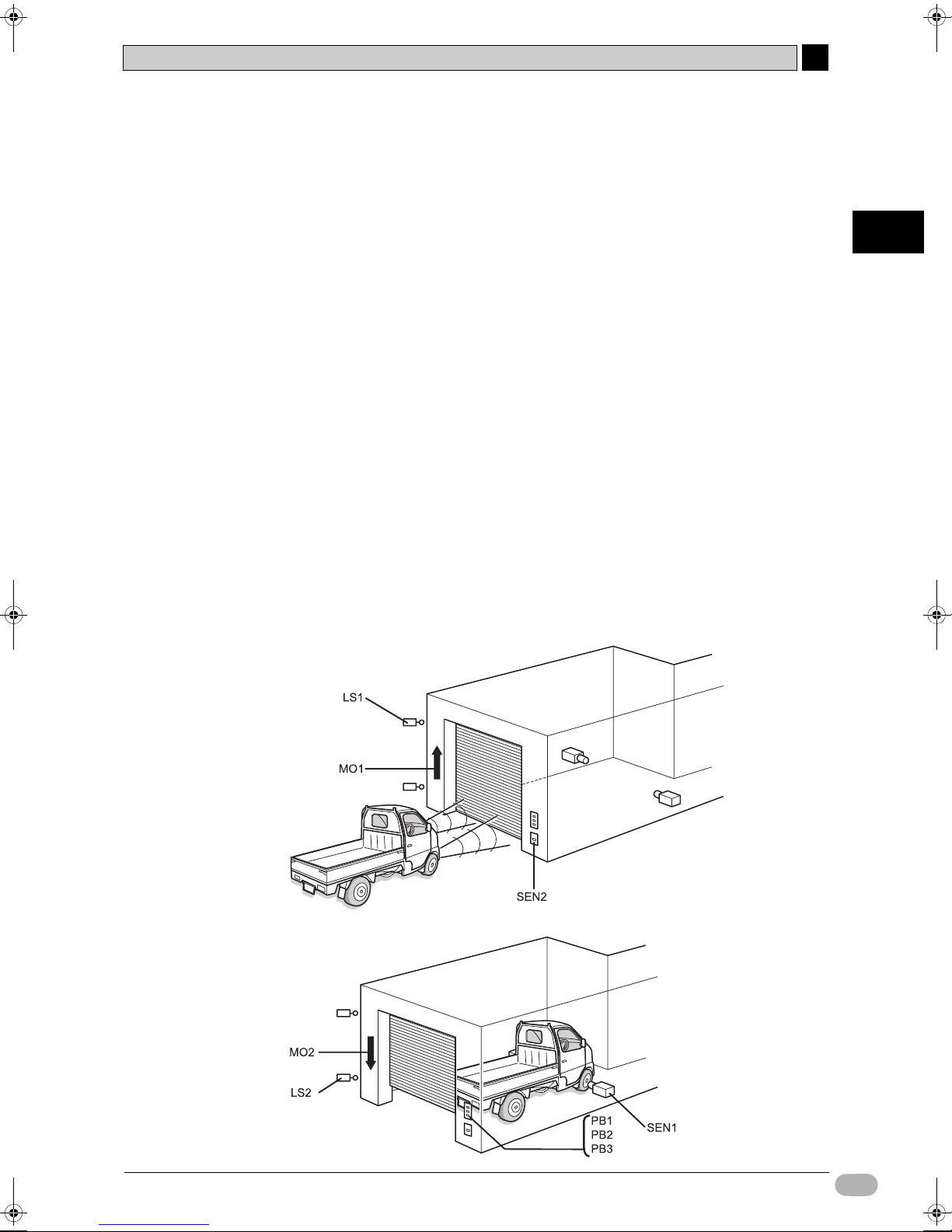

2-2-2 System Components

This section defines components to be used in the shutter control system. The

following components are to be used.

zPLC

• CP1L (14-point I/O unit with AC power supply)

2-2 About the Shutter Control System

2

2

zEquipment and Software for Programming

• CX-Programmer

•Computer

• USB cable (A-B)

zInputs

• Shutter OPEN button : PB1

• Shutter STOP button : PB2

• Shutter CLOSE button : PB3

• Car detection sensor : SEN1

• Headlight detection sensor : SEN2

• Limit switch, turned ON when shutter is fully open : LS1

• Limit switch, turned ON when shutter is fully closed : LS2

zOutputs

• Contact for activating the shutter escalation motor : MO1

• Contact for activating the shutter de-escalation motor : MO2

Designing Systems

SYSMAC CP1L Getting Started Guide 23

Page 25

2

Designing Systems

2-3 I/O Allocation for the Shutter Control System

2

2-3 I/O Allocation for the Shutter Control System

I/O relays on CP1L are allocated to contacts as defined by following.

zInputs

Device Contact Address

OPEN button PB1 0.00

STOP button PB2 0.01

CLOSE button PB3 0.02

Car detection

sensor

Light detection

sensor

Upper limit LS LS1 0.05

Lower limit LS LS2 0.06

zOutputs

Device Contact Address

Escalation motor MO1 100.00

De-escalation motor MO2 100.01

SEN1 0.03

SEN2 0.04

24 SYSMAC CP1L Getting Started Guide

Page 26

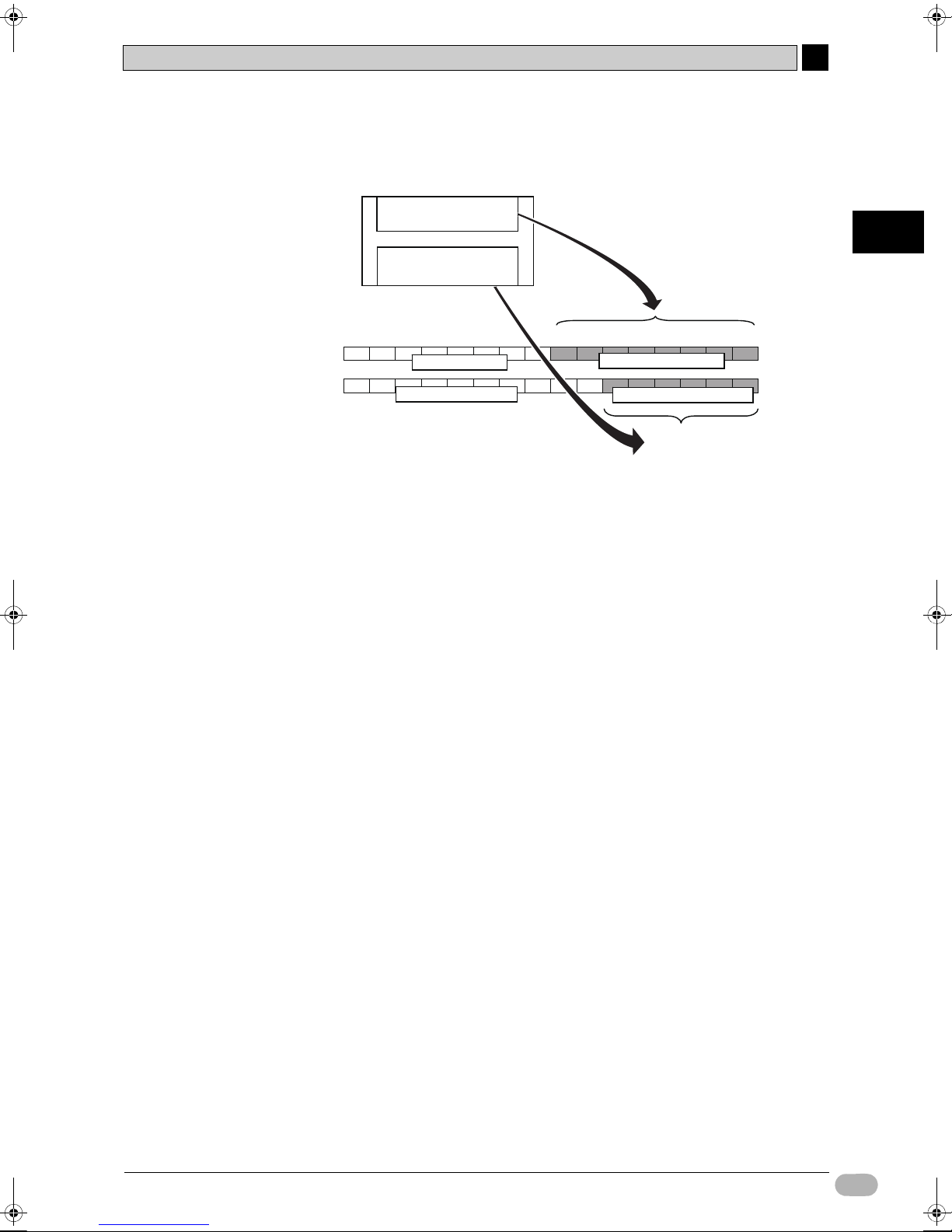

2-3 I/O Allocation for the Shutter Control System

Used as work area

zI/O Allocation on CP1L with 14-point I/O

8 inputs

2

Input Area

Output Area

100 CH

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0 CH

0 CH (0.00~0.07)

100 CH (100.00~100.05)

6 outputs

Not available

Allocate

Allocate

Input area : 8 inputs

Output area : 6 outputs

On 14-point I/O units, 8 inputs, from 0.00 to 0.07 (bits 00 to 07 on 0CH), are

allocated to the input terminal block.

Also, 6 output relays, from 100.00 to 100.05 (bits 00 to 05 on 100CH), are

allocated to the output terminal block.

Unused upper bits on the input channel (bits 08 to 15) cannot be used as a work

area. Unused upper bits on the output channel (bits 06 to 15) , however, can be

used.

2

Designing Systems

SYSMAC CP1L Getting Started Guide 25

Page 27

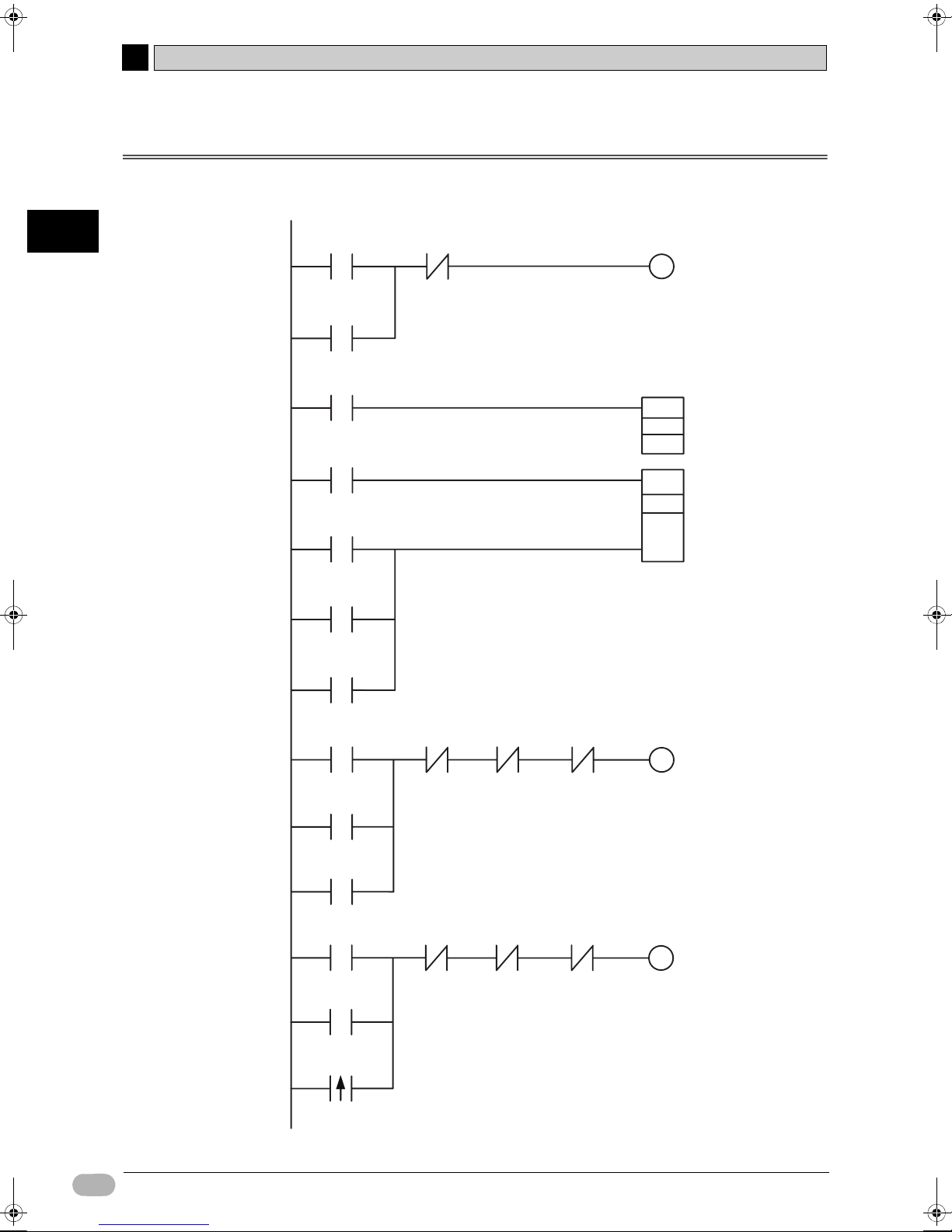

2-4 Example Ladder Program

2

2-4 Example Ladder Program

An example ladder program for the shutter control system is shown below. Program creation is explained

in SECTION 4.

2

Designing Systems

0.04

Light detection

sensor

W0.00

Work area

W0.00

Work area

0.04

Light detection sensor

T0000

Timer

C0000

Counter

A200.11

T0000

Timer

W0.00

Work area

TIM

0000

#50

CNT

0000

#3

Timer

Counter

P_First_Cycle First cycle flag

C0000

Counter

0.00

OPEN button

100.00

Escalation

motor

0.02

CLOSE button

100.01

De-escalation

motor

0.03

Car detection sensor

0.01

STOP button

0.01

STOP button

0.05

Upper

limit LS

0.06

Lower

limit LS

100.01

De-escalation

motor

100.00

Escalation

motor

100.00

Escalation

motor

100.01

De-escalation

motor

26 SYSMAC CP1L Getting Started Guide

Page 28

SECTION 3

Mounting and Wiring

This section explains how to install CP1L onto a DIN track, how to

wire power supply and I/O lines, and how to test operation.

3-1 Installation Notes .................................................................. 28

3-2 Mounting onto DIN Tracks .................................................... 31

3-3 Wiring Devices...................................................................... 32

3-3-1 Connecting Power Supply and Ground Lines ................ 32

3-3-2 Connecting I/O Lines ...................................................... 33

3-4 Power Testing CP1L ............................................................. 35

Page 29

3

Mounting and Wiring

3

Mounting and Wiring

3-1 Installation Notes

For improved reliability and maximized functionality, take the following factors into consideration when

installing a CP1L system.

Installation Location

Do not install in the following locations:

• Locations subject to ambient temperature lower than 0°

°C.

55

• Locations subject to dramatic temperature changes, causing possible

condensation.

• Locations subject to relative humidity lower than 10%RH or higher than

90%RH.

• Locations subject to corrosive or flammable gases.

• Locations subject to excessive dust, salt, or metal powder.

• Locations subject to shock or vibration.

• Locations exposed to direct sunlight.

• Locations subject to water, oil, or chemical reagent splashes.

C or higher than

Shield the system sufficiently when installing in the following locations:

• Locations subject to static electricity and other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible radioactive exposure.

• Locations in close proximity to close to power lines.

Installation into Cabinets and Control Panels

When installing CP1L into a cabinet or control panel, ensure adequate

environment resistance, as well as sufficient accessibility for operation and

maintenance.

zTemperature Control

The ambient operating temperature for CP1L is 0 to 55°C. The following

precautions apply.

• Provide adequate space for air flow.

• Do not install above equipment, which generates significant heat (i.e. heaters,

transformers, high-capacity resistors).

• If the ambient temperature is to exceed 55

conditioner.

°C, install a cooling fan or air

28 SYSMAC CP1L Getting Started Guide

Page 30

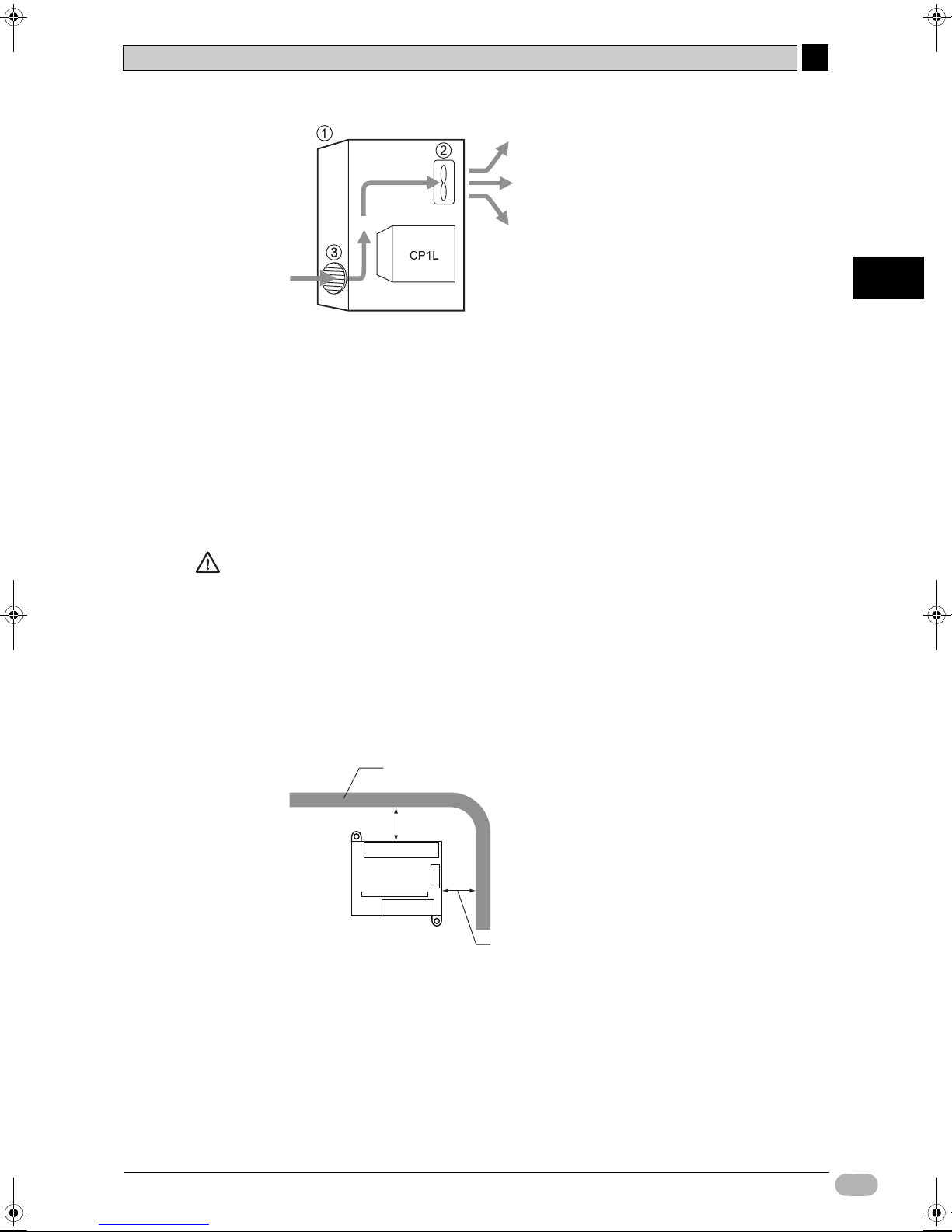

(1) Control panel

(2) Fan

(3) Louver

zAccessibility for Operation and Maintenance

• For safety during operation and maintenance, separate the unit as far as

possible from high-voltage equipment and power machinery.

• For ease of operation, mount the unit onto the control panel at a height of

1,000 to 1,600mm.

3-1 Installation Notes

3

3

Mounting and Wiring

Caution When power is ON or has just been turned OFF, do not touch the power supply,

I/O terminals, or the surrounding areas. Doing so may result in burns.

After turning the power OFF, wait for the unit to cool down sufficiently before

touching it.

zImproving Noise Resistance

• Avoid installing into a cabinet, which also has high-voltage equipment

installed.

• Secure at a distance of 200mm or more from power lines.

Power Line

200mm min.

CP1L

• Properly ground the mounting plate between the unit and the mounting

surface.

200mm min.

SYSMAC CP1L Getting Started Guide 29

Page 31

3

Mounting and Wiring

3-1 Installation Notes

3

zMounting

For heat dissipation, mount CP1L in the orientation shown below.

External Dimensions

DIN Track

Model W1 W2

CP1L-L10D- 66 56

CP1L-L14D- 86 76

CP1L-L20D- 86 76

CP1L-L30D- 130 120

CP1L-L40D- 150 140

CP1L-M60D- 195 185

Secure the DIN track onto the control panel, using at least 3 screws.

• Use M4 screws at intervals of 210mm (6 holes) or less. Screw torque is

·m.

1.2N

For details on installing CP1L, refer to SECTION 3 Installation and Wiring of CP

Series CP1L CPU Unit User’s Manual (W462).

30 SYSMAC CP1L Getting Started Guide

Page 32

3-2 Mounting onto DIN Tracks

This section explains how to mount CP1L onto a DIN track.

1. Pull out the DIN track mounting pin (1).

2. Hook the rear panel of CP1L onto the DIN track (1), as shown.

3-2 Mounting onto DIN Tracks

3

3

Mounting and Wiring

3. Push in the DIN track mounting pin (1) to secure CP1L.

SYSMAC CP1L Getting Started Guide 31

Page 33

3

Mounting and Wiring

3-3 Wiring Devices

3

3-3 Wiring Devices

This section explains how to wire CP1L (14-point I/O unit with AC power supply).

Protective Label

Wire scraps may be scattered during wiring. To prevent them from entering the

unit, leave the protective label (adhered on the top surface of the unit) on until

wiring is done.

When wiring is complete, remove the label to ensure proper heat dissipation.

3-3-1 Connecting Power Supply and Ground Lines

This section explains how to wire the power and ground lines.

Units with AC Power Supply

Power and ground terminals (A) are located near the top of CP1L.

Terminal block layout at (A)

4

1

2

(1) Power supply terminal

Supply 100 to 240VAC voltage at 50/60Hz.

The acceptable supply voltage range is 85 to 264VAC.

• Use separate circuits for the power supply circuit and the motor circuit, in

order to prevent voltage drops due to starting currents and inrush currents

from other equipment.

• Use a twisted-pair of power supply cables to prevent noise from the power

supply line. Adding a 1:1 isolating transformer will further reduce electrical

noise.

3

NC

NC

NC

NC

6.2mm max.

32 SYSMAC CP1L Getting Started Guide

Page 34

3-3 Wiring Devices

• In consideration of voltage drops and allowable current, use the thickest

electrical wire possible.

(2) LG

LG is a functional ground terminal (noise-filtered neutral terminal). To

resolve errors and electrical shocks caused by noise, short the LG and GR

terminals for a class D grounding (ground resistance of 100 or less).

3

(3) GR

GR is a protective ground terminal. To prevent electrical shocks, use a

dedicated ground line (2mm

resistance of 100 or less).

• To prevent electrical shocks and noise, always ground the terminal with

class D grounding (ground resistance of 100 or less).

• If the power supply has a grounded phase, connect the grounded phase to

the L2/N terminal.

• Do not share the ground line with other equipment, or connect it to building

structure beams. The results may be unfavorable.

(4) Recommended crimp terminal

When wiring the AC power supply, use ring-type crimp terminals to prevent

unintended disconnection.

WARNING Secure the AC power supply line to the terminal block with 0.5N·m of torque.

Loosening the screw may result in a fire or malfunction.

3-3-2 Connecting I/O Lines

14-point I/O Units

CP1L has input terminals located at the top, and output terminals located at the

bottom.

2

or thicker) for a class D grounding (ground

3

Mounting and Wiring

(1) Input terminal

(2) Output terminal

SYSMAC CP1L Getting Started Guide 33

Page 35

3

Mounting and Wiring

3-3 Wiring Devices

3

zWiring Inputs

zWiring Outputs

1. Wire the inputs as shown, while referring to 2-3 I/O Allocation for the

Shutter Control System.

1. Wire the outputs as shown, while referring to 2-3 I/O Allocation for the

Shutter Control System.

For details on wiring, refer to 3-5-4 I/O Wiring for CPU Units with 14 I/O Points

of CP Series CP1L CPU Unit User’s Manual (W462).

34 SYSMAC CP1L Getting Started Guide

Page 36

3-4 Power Testing CP1L

After wiring CP1L, perform a power test.

Turning Power ON

Supply power to CP1L, and then check the status with the indicators.

3-4 Power Testing CP1L

3

1. Turn the power OFF for all components (escalation motor,

de-escalation motor, etc.).

2. Turn the power ON for CP1L.

3. Wait 2 seconds for the CP1L to initialize.

4. Check the indicators on CP1L. If [POWER] and [RUN] are lit, CP1L is

operating normally.

Note When CP1L is turned ON, it will go into RUN mode automatically.

3

Mounting and Wiring

5. Turn the power OFF for CP1L.

SYSMAC CP1L Getting Started Guide 35

Page 37

3

3-4 Power Testing CP1L

3

Note Battery

• Using a battery

The battery maintains the internal clock and retained regions of I/O memory

while the power supply is OFF.

If no battery is installed, or if the installed battery is running low, the internal

clock will stop, and data in the retained regions of I/O memory will be lost.

Data such as user programs and PLC system settings are not lost even when

the power is OFF and no battery is installed.

Mounting and Wiring

For details on replacing the battery, refer to 10-2 Replacing User-servicable

Parts of CP Series CP1L CPU Unit User’s Manual (W462).

• Battery-free operation

If there is no need to reference the PLC clock and RAM data, CP1L can be

used without a battery (battery-free operation).

For details, refer to 6-5 Battery-free Operation of CP Series CP1L CPU Unit

User’s Manual (W462).

36 SYSMAC CP1L Getting Started Guide

Page 38

SECTION 4

Creating Programs

In this section, the steps for creating ladder programs essential to

CP1L operation will be shown, using CX-Programmer. In creating

the ladder program for the shutter control system, the basic

functions of CX-Programmer will be explained.

4-1 Preparing for Programming................................................... 38

4-1-1 What is CX-Programmer? .............................................. 38

4-1-2 Connecting to a Computer

and Installing the USB Driver ......................................... 39

4-2 Creating Ladder Programs ................................................... 44

4-2-1 Operation........................................................................ 44

4-2-2 Ladder Program.............................................................. 46

4-3 Using CX-Programmer.......................................................... 47

4-3-1 Starting CX-Programmer ................................................ 47

4-3-2 Operation Screens.......................................................... 48

4-4 Using the Help ...................................................................... 50

4-5 Inputting Programs ............................................................... 53

4-5-1 Creating New Projects.................................................... 53

4-5-2 Inputting Contacts........................................................... 56

4-5-3 Inputting Output Coils ..................................................... 59

4-5-4 Inputting Timers.............................................................. 61

4-5-5 Inputting Counters .......................................................... 63

4-5-6 Inputting Auxiliary Areas................................................. 66

4-5-7 Inputting Differentiated Up Contacts............................... 68

4-5-8 END Instruction .............................................................. 69

4-6 Saving/Loading Programs .................................................... 70

4-6-1 Compiling Programs ....................................................... 70

4-6-2 Saving Programs ............................................................ 71

4-6-3 Loading Programs .......................................................... 72

4-7 Editing Programs .................................................................. 73

4-7-1 Editing I/O Comments .................................................... 73

4-7-2 Inputting Rung Comments.............................................. 74

4-7-3 Editing Rungs ................................................................. 75

Page 39

4

Creating Programs

4

Creating Programs

4-1 Preparing for Programming

This section explains the necessary preparations, such as connecting CP1L to a computer and installing

the USB driver, in order to begin creating ladder programs.

4-1-1 What is CX-Programmer?

CX-Programmer is a programming tool (software) for creating the ladder

programs that are to be executed by CP1L.

In addition to programming functions, it also offers other useful functions for CP1L

setup and operation, such as debugging programs, address and values display,

PLC setup and monitoring; and remote programming and monitoring via the

network.

CX-Programmer can be run on computers running Windows 98 SE, Me, NT 4.0

(SP6a), 2000 (SP3 or later), or XP.

For details on installing CX-Programmer, refer to 1-1 Installation of CX-

Programmer of CX-Programmer Introduction Guide (R132).

For details on using CX-Programmer, refer to CX-Programmer Operation Manual

(W446).

38 SYSMAC CP1L Getting Started Guide

Page 40

4-1 Preparing for Programming

4-1-2 Connecting to a Computer and Installing the USB Driver

To use CX-Programmer, you must connect CP1L to a computer, which has CXProgrammer installed. This section explains how to connect CP1L to a computer.

The computer to be connected to must have CX-Programmer Ver.7.1 or later

installed.

You will also need a USB cable to connect CP1L to the computer.

Furthermore, a USB driver must be installed for CP1L to be recognized by the

computer.

4

zItems Required for Connection

Operating system Windows 98, Me, 2000, or XP

Software CX-One (i.e. CX-Programmer)

USB driver Included with software

USB cable USB 1.1 (or 2.0) cable (A-B), 5m or shorter

zRestrictions on USB Connections

Due to limitations of the USB specifications, the following restrictions apply when

connecting CP1L to a computer.

• Only 1 CP1L can be connected to a computer at any given time. You cannot

connect multiple CP1Ls simultaneously.

• Do not disconnect the USB cable while the system is online. Before

disconnecting the USB cable, switch the application to offline status. If the USB

cable is disconnected while online, the following will occur:

[Windows 2000, XP]

Simply reconnecting the USB cable will not restore CX-Programmer to online

status. First switch CX-Programmer to offline status, reconnect the USB cable,

and then switch CX-Programmer back to online status.

[Windows 98, Me]

If the USB cable is disconnected while the system is online, a blue error

screen may be displayed. In this case, you will need to reboot the computer.

4

Creating Programs

SYSMAC CP1L Getting Started Guide 39

Page 41

4

Creating Programs

4-1 Preparing for Programming

4

Connecting to a Computer and Installing the USB Driver

This section explains how to connect CP1L to a computer running Windows XP.

For details on connecting CP1L to a computer running Windows 2000, refer to

1-3-1 Connecting with a Commercially Available USB Cable of CP Series CP1L

CPU Unit User’s Manual (W462).

1. Turn the power ON for CP1L and the computer.

2. Using a USB cable (2), connect the peripheral USB port (3) on CP1L to a

USB port on the computer

(1).

When the computer detects CP1L, the following message will be displayed.

The Found New Hardware Wizard dialog box will be displayed. This screen will be

used to install the USB driver.

Note The programming console is not available for CP1L.

3. On the Found New Hardware Wizard dialog box, select [No, not this time],

and click [Next].

Depending on computer environment, the Found New Hardware Wizard dialog box

may not be displayed. If it is not displayed, proceed to step 4.

40 SYSMAC CP1L Getting Started Guide

Page 42

4-1 Preparing for Programming

4

4. Select [Install from a list of specific location (Advanced)], and click [Next].

5. Confirm that [Include this location in the search] is checked, and that

[C:\Program Files\OMRON\CX-Server\USB\Win2000_XP\Inf] is displayed

in the location field. Click [Next].

Driver installation will begin.

When the installation is complete, a dialog box will be displayed, confirming that

installation is complete.

4

Creating Programs

SYSMAC CP1L Getting Started Guide 41

Page 43

4

Creating Programs

4-1 Preparing for Programming

4

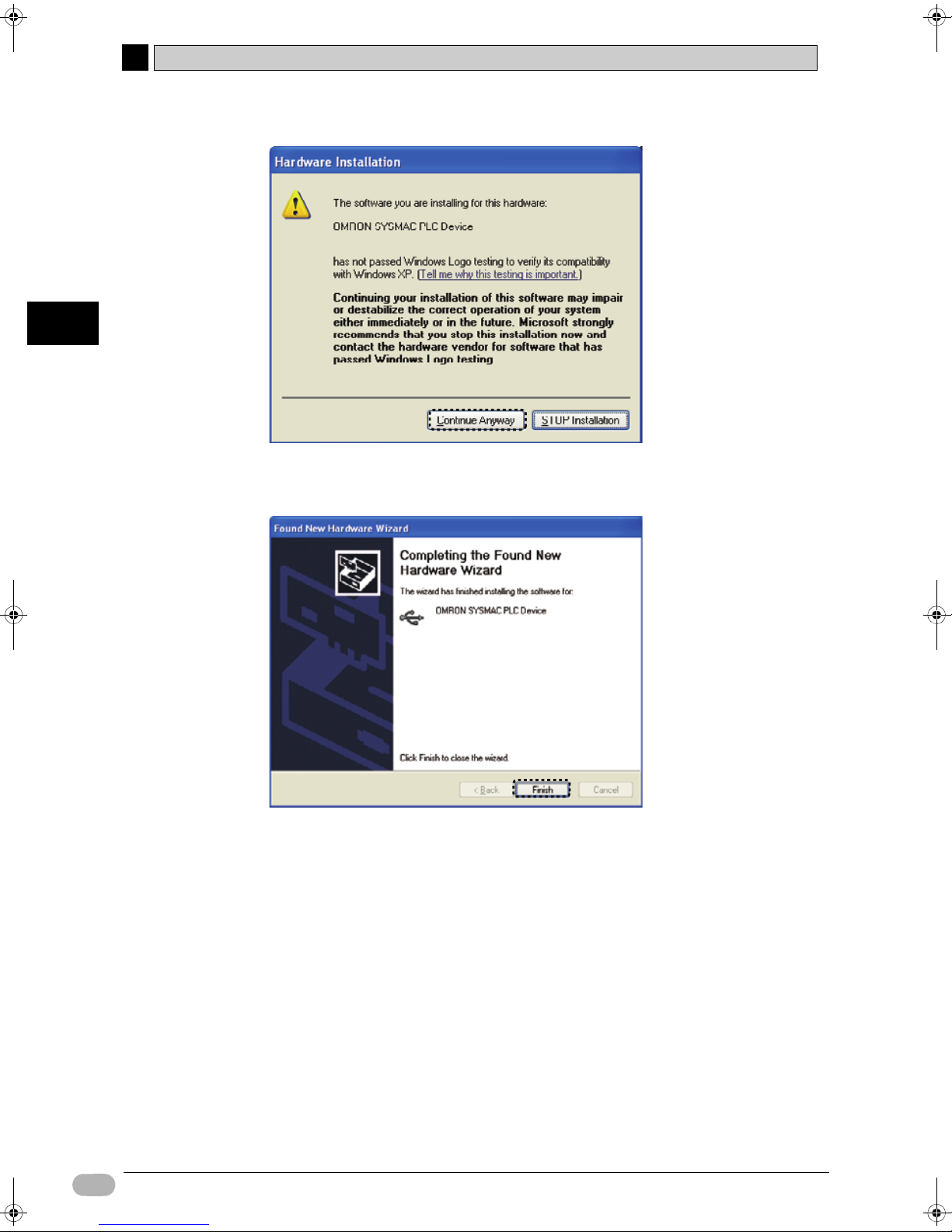

If the Hardware Installation dialog box is displayed, click [Continue Anyway].

6. Click [Finish].

USB driver installation is now complete.

p

42 SYSMAC CP1L Getting Started Guide

Page 44

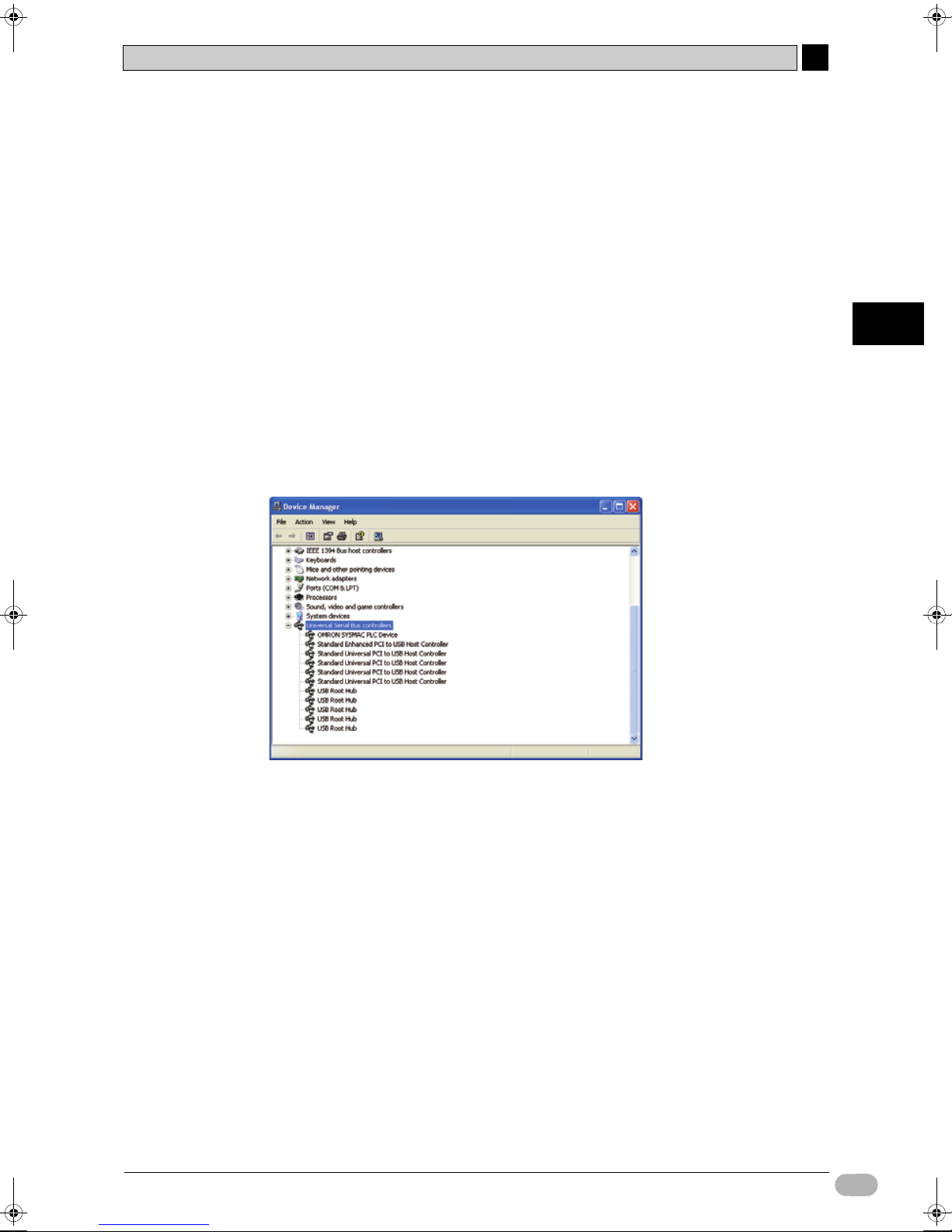

Confirming Installation

Confirm that the driver has been installed properly.

1. On the desktop, select [Start], and then right-click [My Computer].

A context menu will be displayed.

2. Select [Properties].

The System Properties dialog box will be displayed.

4-1 Preparing for Programming

4

3. Select the Hardware tab, and click [Device Manager].

The Device Manager dialog box will be displayed.

4. Double-click [Universal Serial Bus controllers].

5. Confirm that [OMRON SYSMAC PLC Device] is displayed.

If so, the USB driver has been installed successfully.

4

Creating Programs

6. Close the Device Manager dialog box, and then the System Properties

dialog box.

If [OMRON SYSMAC PLC Device] is not displayed, reinstall the USB driver.

For details on reinstalling the USB driver, refer to 1-3-1 Connecting with a

Commercially Available USB Cable of CP Series CP1L CPU Unit User’s

Manual (W462).

SYSMAC CP1L Getting Started Guide 43

Page 45

4-2 Creating Ladder Programs

4

4-2 Creating Ladder Programs

A ladder program can now be created for the example introduced in SECTION 2 System Design. First,

however, the functions of the ladder program will be described.

4-2-1 Operation

The ladder program to be created will open and close a garage shutter.

For details on the example application, refer to 2-2-1 Operation.

4

Creating Programs

zEntering the Garage

2

2

1

3

The component functions and operations will be defined in detail below.

(1) Push-buttons:

• The shutter can be opened, closed, and stopped with buttons.

• The OPEN and CLOSE buttons will continue operating the shutter even when

they are not held down. A self-maintaining bit is used to achieve this.

(2) Limit switches:

• When the shutter is fully opened or fully closed, it will be stopped by a limit

switch.

• When the shutter is opening, the de-escalation motor will be interlocked to

prevent damage.

(3) Light detection sensor:

• A light detection sensor detects light from headlights pointed at the garage.

When 3 headlight flashes are detected by a counter instruction, the shutter

escalation motor is activated.

• After the first headlight flash, a timer is activated by a timer instruction. After 5

seconds, a reset command is given to the counter instruction.

• The present value of the counter instruction is retained even when CP1L is

powered OFF. To prevent malfunction, a reset command is given to the

counter instruction when CP1L is powered ON.

44 SYSMAC CP1L Getting Started Guide

Page 46

zAfter Entering the Garage / Exiting the Garage

(1) Car detection sensor:

• A car detection sensor will detect full car entrance into the garage, and activate

the shutter de-escalation motor.

(2) Push-buttons:

• When pulling the car out of the garage, use the buttons to operate the shutter.

• When pulling the car out of the garage, a differentiated up contact should be

used as the car detection sensor, so that the shutter does not close

immediately upon fully opening.

4-2 Creating Ladder Programs

4

4

Creating Programs

A ladder program will be set forth hereafter based on the description above.

SYSMAC CP1L Getting Started Guide 45

Page 47

4-2 Creating Ladder Programs

4

4-2-2 Ladder Program

The ladder program for the example application is shown below.

4

Creating Programs

0.04

Light detection

sensor *1

W0.00

Work area *2

W0.00

Work area

0.04

Light detection sensor

T0000

Timer

C0000

Counter

A200.11

T0000

Timer *3

W0.00

Work area *4

*1 Refer to Inputting Contacts of 4-5-2 Inputting Contacts.

*2 Refer to Inputting OR Circuits of 4-5-2 Inputting Contacts.

*3 Refer to Inputting Closed Contacts of 4-5-2 Inputting Contacts.

*4 Refer to 4-5-3 Inputting Output Coils.

TIM

0000

Timer *5

#50

CNT

Counter *6

0000

#3

*5 Refer to 4-5-4 Inputting Timers.

*6 Refer to 4-5-5 Inputting Counters..

*7 Refer to 4-5-6 Inputting Auxiliary Areas.

P_First_Cycle First cycle flag *7

C0000

Counter

0.00

OPEN button

100.00

Escalation

motor

0.02

CLOSE button

100.01

De-escalation

motor

0.03

Car detection sensor *8

0.01

STOP button

0.01

STOP button

0.05

Upper

limit LS

0.06

Lower

limit LS

100.01

De-escalation

motor

100.00

Escalation

motor

*8 Refer to 4-5-7 Inputting Differentiated Up Contacts.

100.00

Escalation

motor

100.01

De-escalation

motor

Creating the program in CX-Programmer will be explained in the next section.

46 SYSMAC CP1L Getting Started Guide

Page 48

4-3 Using CX-Programmer

This section explains CX-Programmer start-up and operation screens..

4-3-1 Starting CX-Programmer

1. On the desktop, select [Start] - [All Programs] - [OMRON] - [CX-One] - [CX-

Programmer] - [CX-Programmer].

CX-Programmer will start.

The title screen will be displayed, followed by the main window.

4-3 Using CX-Programmer

4

4

Creating Programs

Note For details on installing CX-Programmer, refer to Chapter 1 Overview and

Installation of CX-One of CX-One Introduction Guide (R145).

SYSMAC CP1L Getting Started Guide 47

Page 49

4

Creating Programs

4-3 Using CX-Programmer

4

4-3-2 Operation Screens

This section explains the functions available on the CX-Programmer main window.

For details on using CX-Programmer, refer to CX-Programmer Operation Manual

(W446).

zMain Window

1

2

3

4

5

6

9

7

8

10

(1) Title bar

Displays the data file name, created in CX-Programmer.

(2) Main menu

Used to select CX-Programmer functions.

(3) Toolbars

Displays icons for frequently used functions. Place the mouse cursor over an

icon to display the corresponding function name.

Select View - Toolbars from the main menu to show/hide toolbars. Drag the

toolbars to change their position.

(4) Project tree / (6) Project workspace

Used to manage programs and settings. Drag & drop items to copy the data.

Select [View] - [Windows] - [Workspace] from the main menu to show/hide the

workspace.

(5) Section

Programs can be split into and managed as multiple parts.

(7) Diagram workspace

Used to create and edit ladder programs.

(8) I/O comment bar

Displays the name, address/value, and I/O comment for the variable selected

by the mouse cursor.

48 SYSMAC CP1L Getting Started Guide

Page 50

4-3 Using CX-Programmer

(9) Output window

Select [View] - [Windows] - [Output] from the main menu to show/hide the

output window. Displays the following information:

Compile:

Displays program check results.

Find Report:

Displays search results for contacts, instructions, and coils.

Transfer:

Displays errors which occurred while loading a project file.

4

(10) Status bar

Displays information such as PLC name, offline/online status, and active cell

position.

If an online connection error or other errors occur and are recorded by the

error log while online, a blinking red error message will be displayed. Select

[View] - [Windows] - [Status Bar] from the main menu to show/hide the status

bar.

zDiagram Workspace

(1) Rung number

(2) Program address

4

Creating Programs

(3) Rung header

If a rung is incomplete, a red line will be displayed to the right of its rung

header.

(4) Bus bar

zInformation Window

Displays basic shortcut keys used in CX-Programmer.

Select [View] - [Windows] - [Information Window] from the main menu to show/hide

the information window.

SYSMAC CP1L Getting Started Guide 49

Page 51

4

Creating Programs

4-4 Using the Help

4

4-4 Using the Help

CX-Programmer Help provides information on the CX-Programmer screens, and explains all operations

including basic functions, program creation, and monitoring. Instructions, as well as formats and operand

functions, are also explained.

Referencing CX-Programmer Help

1. While using CX-Programmer, press the [F1] key.

The help window will be displayed.

CX-Programmer Help can also be displayed in several other ways.

zFrom the Desktop Menu

1. On the desktop, select [Start] - [All Programs] - [OMRON] - [CX-One] - [CX-

Programmer] - [CX-Programmer Help].

CX-Programmer Help will be displayed.

50 SYSMAC CP1L Getting Started Guide

Page 52

zFrom CX-Programmer

1. Select [Help] - [Help Contents] from the main menu.

CX-Programmer Help will be displayed.

Referencing PLC Instruction Sets

For details on instructions used in ladder programs, refer to PLC Instruction Sets.

4-4 Using the Help

4

4

Creating Programs

SYSMAC CP1L Getting Started Guide 51

Page 53

4

Creating Programs

4-4 Using the Help

4

zFrom CX-Programmer

1. Select [Help] - [Instruction Reference] - [CS/CJ-Series and CP-Series]

from the main menu.

CP-Series PLC Instruction Sets will be displayed.

zWhile Creating Ladder Programs

1. While creating a ladder program instruction, click [Instruction Help] on

the New Instruction dialog box.

CP-Series PLC Instruction Sets will be displayed.

Note When selecting a special instruction, Instruction Help will be displayed.

52 SYSMAC CP1L Getting Started Guide

Page 54

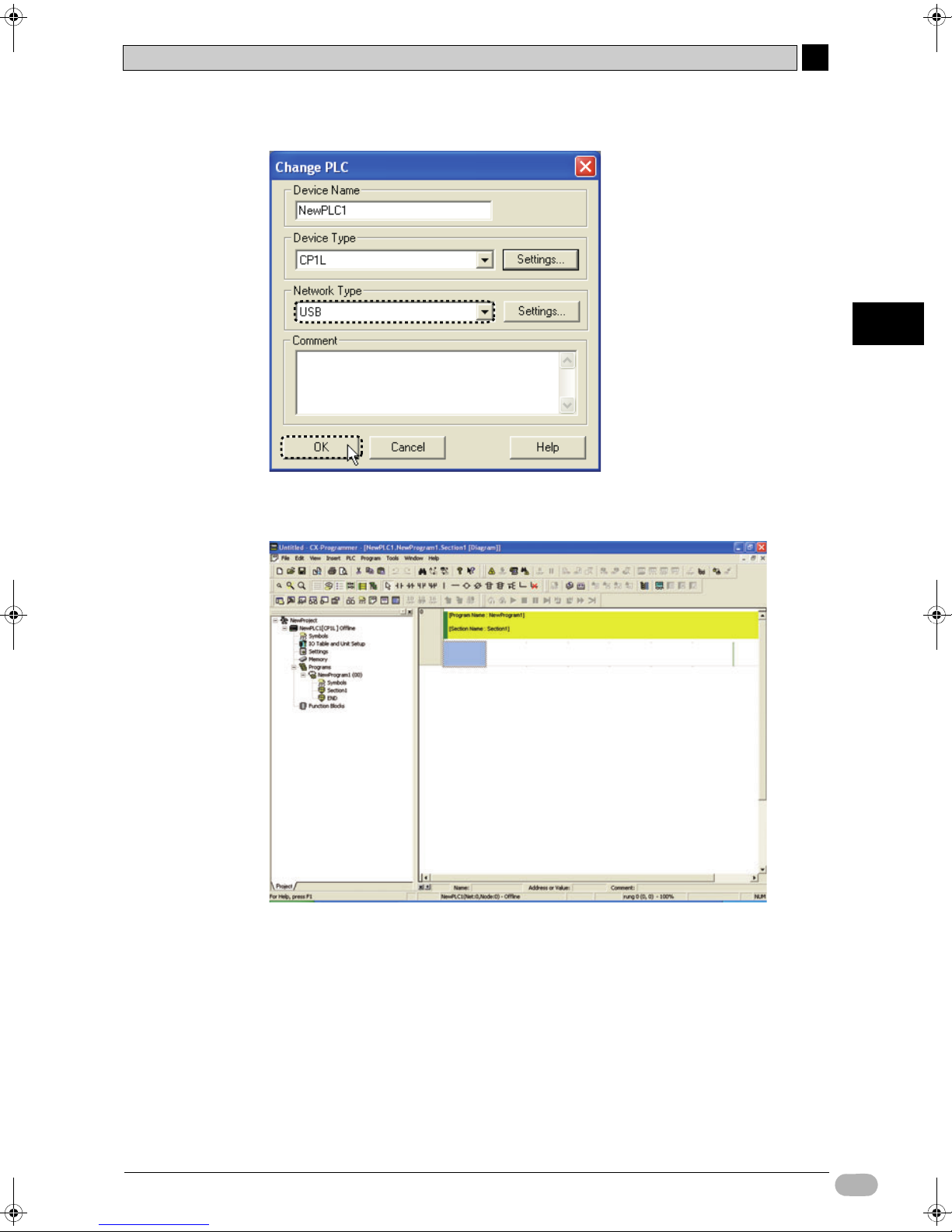

4-5 Inputting Programs

4-5 Inputting Programs

Using the commands available in CX-Programmer, create a program for the example application.

4-5-1 Creating New Projects

When using CX-Programmer for the first time, you will need to create a new

project. When creating a new project, you must set the target device type and CPU

type for the program and data being created.

4

1. Select [File] - [New] from the main menu.

The Change PLC dialog box will be displayed.

2. Select [CP1L] from the Device Type drop-down list.

4

Creating Programs

SYSMAC CP1L Getting Started Guide 53

Page 55

4

Creating Programs

4-5 Inputting Programs

4

3. Click [Settings].

The Device Type Settings dialog box will be displayed.

4. Select the CPU from the CPU Type drop-down list. Click [OK].

The Device Type Settings dialog box will be closed.

54 SYSMAC CP1L Getting Started Guide

Page 56

4-5 Inputting Programs

5. Confirm that [USB] is displayed for Network Type. Click [OK].

The Change PLC dialog box will be closed. Main window for the new project will be

displayed.

4

4

Creating Programs

If [USB] is not displayed for Network Type, refer to 4-1-2 Connecting to a Computer

and Installing the USB Driver and confirm that the USB driver has been installed

properly.

SYSMAC CP1L Getting Started Guide 55

Page 57

4

Creating Programs

4-5 Inputting Programs

4

4-5-2 Inputting Contacts

Input a contact. For details on ladder programs, refer to 4-2-2 Ladder Program.

Inputting Contacts

1. Press the [C] key.

The New Contact dialog box will be displayed.

2. Input address "4". Press the [Enter] key.

"4" is entered. The Edit Comment dialog box will be displayed.

3. Input "Light detection sensor" as the I/O comment. Press the [Enter] key.

A contact representing input from the light detection sensor will be displayed on the

ladder program.

Next, input an OR circuit.

56 SYSMAC CP1L Getting Started Guide

Page 58

Inputting OR Circuits

1. Place the cursor on the program. Press the [Enter] key.

A space for inserting an OR circuit will be created.

2. Press the [W] key.

The New Contact OR dialog box will be displayed.

4-5 Inputting Programs

4

4

Creating Programs

3. Input address "W0". Press the [Enter] key.

"W0" is entered. The Edit Comment dialog box will be displayed.

4. Input "Work Area" as the I/O comment. Press the [Enter] key.

An OR circuit representing the work area contact will be displayed.

Next, input a closed contact.

SYSMAC CP1L Getting Started Guide 57

Page 59

4

Creating Programs

4-5 Inputting Programs

4

Inputting Closed Contacts

1. Press the up arrow key.

The cursor is moved upward.

2. With the cursor in the up position, press the [/] key.

The New Closed Contact dialog box will be displayed.

3. Input address "T0". Press the [Enter] key.

"T0" is entered. The Edit Comment dialog box will be displayed.

4. Input "Timer" as the I/O comment. Press the [Enter] key.

An AND circuit representing the timer closed contact will be displayed.

Next, input a work area output.

58 SYSMAC CP1L Getting Started Guide

Page 60

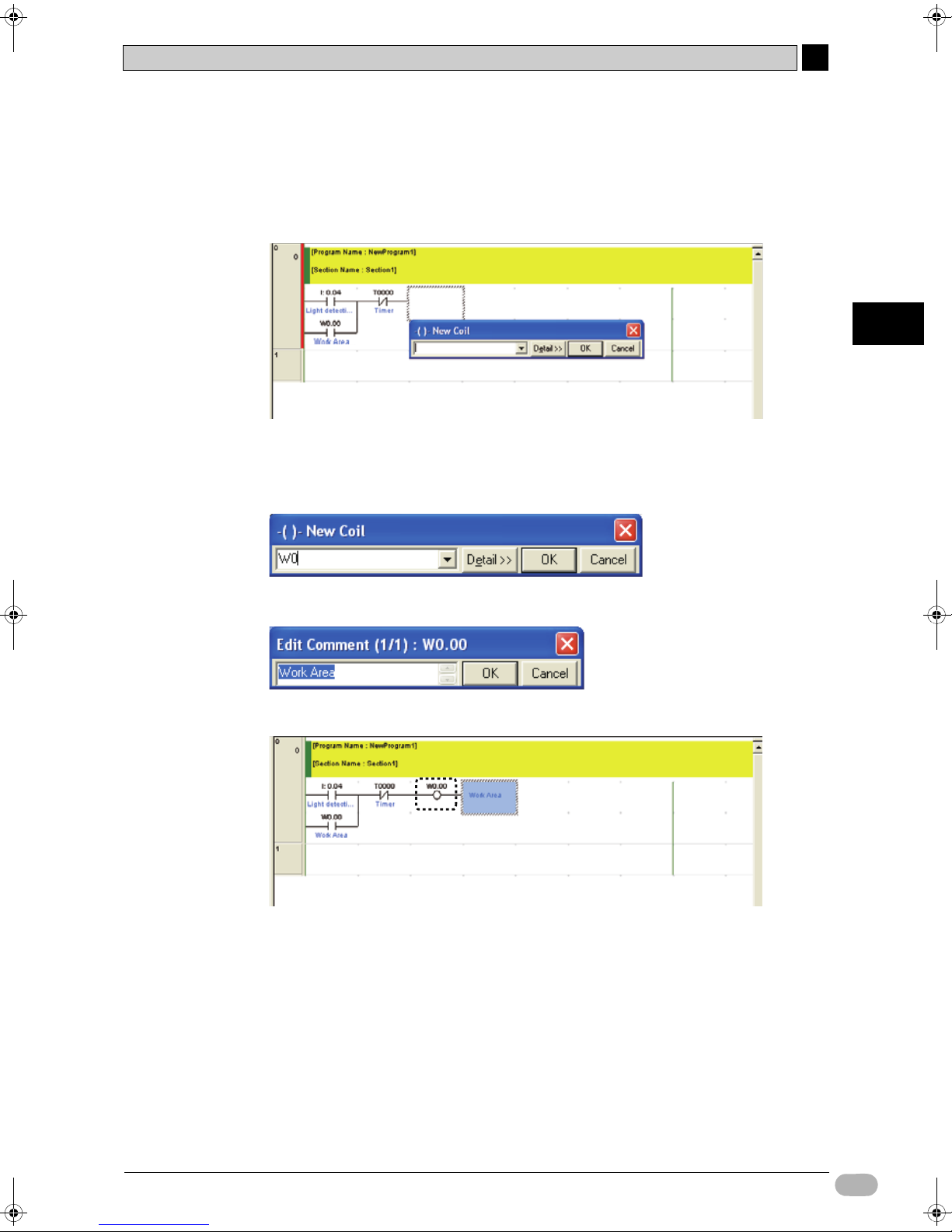

4-5-3 Inputting Output Coils

Input an output coil for the work area.

1. Press the [O] key.

The New Coil dialog box will be displayed.

2. Input address "W0". Press the [Enter] key.

"W0" is entered. The Edit Comment dialog box is displayed with the I/O comment

already entered.

4-5 Inputting Programs

4

4

Creating Programs

3. Press the [Enter] key.

An output coil for the work area will be displayed on the ladder program.

SYSMAC CP1L Getting Started Guide 59

Page 61

4

Creating Programs

4-5 Inputting Programs

4

4. Press the down arrow key 2 times.

Note Duplicated Coils

When the cursor is positioned on the next rung, the current rung input is complete.

Next, input a timer instruction.

Do not duplicate coils.

If the same address is specified for multiple outputs, only the rung closer to the

END instruction will be valid.

This is because programs are executed sequentially from top to bottom. Invalid

rungs caused by duplicated coils will be detected by CX-Programmer as an error.

E.g. A program with duplicated coils

The error may be resolved by modifying the program as shown below.

60 SYSMAC CP1L Getting Started Guide

Page 62

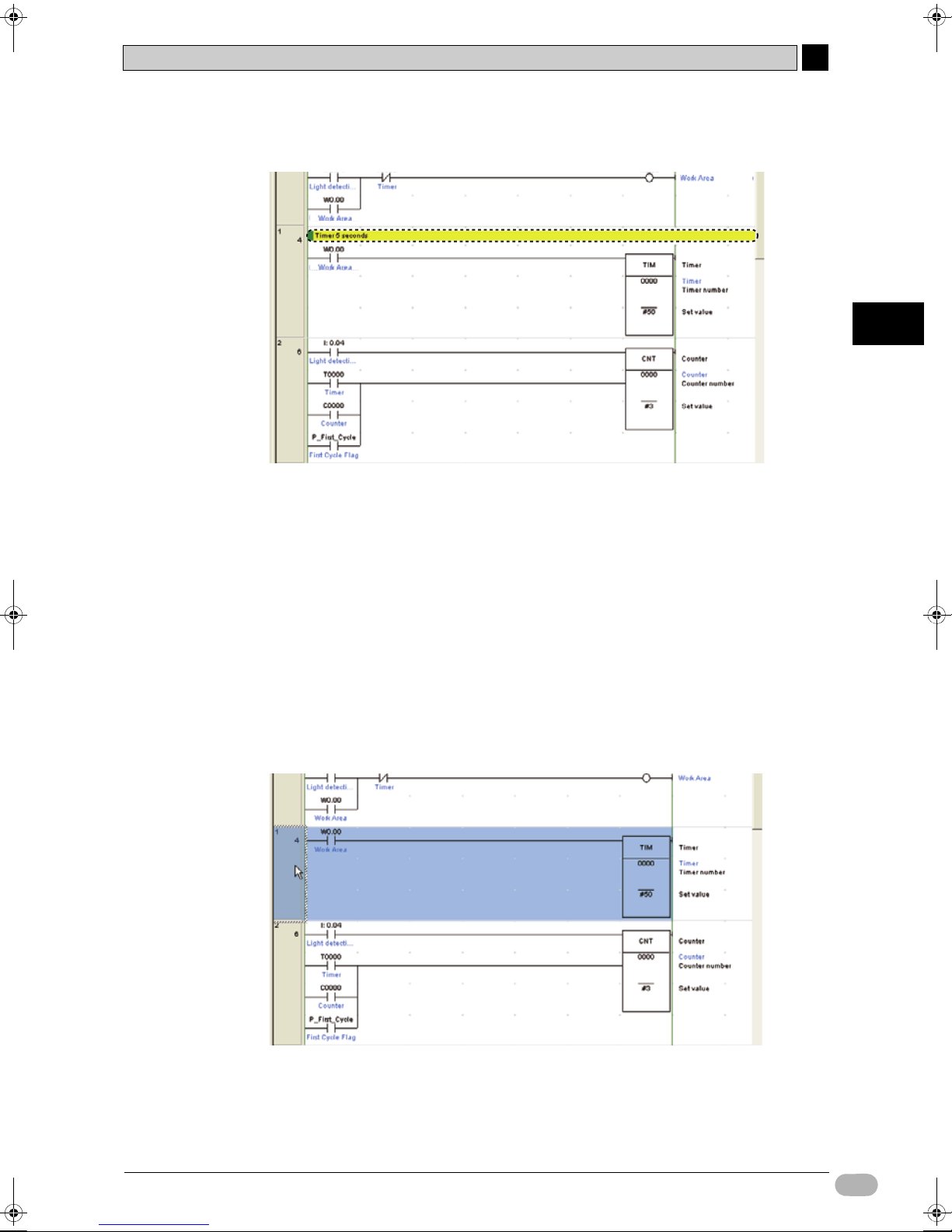

4-5-4 Inputting Timers

1. Press the [C] key. Input contact "W000". Then, press the [Enter] key

while the Edit Comment dialog box is up.

For details on inputting a contact, refer to 4-5-2 Inputting Contacts.

2. Press the [I] key.

The New Instruction dialog box will be displayed.

4-5 Inputting Programs

4

4

Creating Programs

3. Input timer instruction "TIM 0 #50". Press the [Enter] key.

"TIM 0 #50" is entered. The Edit Comment dialog box is displayed with the I/O

comment already entered.

"TIM 0 #50" indicates a 5.0 second delay timer, with a timer completion flag of

T0000.

SYSMAC CP1L Getting Started Guide 61

Page 63

4

Creating Programs

4-5 Inputting Programs

4

4. Press the [Enter] key.

A timer instruction will be displayed on the ladder program.

5. Press the down arrow key 3 times.

When the cursor is positioned on the next rung, timer instruction input is complete.

Next, input a counter instruction.

62 SYSMAC CP1L Getting Started Guide

Page 64

4-5-5 Inputting Counters

1. Press the [C] key. Input contact "004". Then, press the [Enter] key while

the Edit Comment dialog box is up.

For details on inputting a contact, refer to 4-5-2 Inputting Contacts.

2. Press the [I] key.

The New Instruction dialog box will be displayed.

4-5 Inputting Programs

4

4

Creating Programs

3. Input counter instruction "CNT 0 #3". Press the [Enter] key.

"CNT 0 #3" is entered. The Edit Comment dialog box is displayed with the I/O

comment already entered.

"CNT 0 #3" indicates a decrementing counter starting at count 3, with a counter

completion flag of C0000.

SYSMAC CP1L Getting Started Guide 63

Page 65

4

Creating Programs

4-5 Inputting Programs

4

4. Input "Counter" as the I/O comment. Press the [Enter] key.

A counter instruction will be displayed on the ladder program.

Next, input a reset input for the counter instruction.

The timer contact (TIM 0000) will be used as the reset input.

5. Place the cursor below the contact created in step 1.

64 SYSMAC CP1L Getting Started Guide

Page 66

4-5 Inputting Programs

6. Input contact "T0000".

7. Press the down arrow key 2 times.

When the cursor is positioned on the next rung, counter instruction input is

complete.

4

4

Creating Programs

Next, input an auxiliary area.

SYSMAC CP1L Getting Started Guide 65

Page 67

4

Creating Programs

4-5 Inputting Programs

4

4-5-6 Inputting Auxiliary Areas

Auxiliary area is a relay with a specific purpose.

The first cycle flag will be ON for only 1 cycle after the PLC has been powered ON.

Here, it will be used to reset the counter when CP1L is powered ON.

1. Press the [W] key. Input an OR circuit contact "C0000". Then, press the

[Enter] key while the Edit Comment dialog box is up.

For details on inputting a contact, refer to 4-5-2 Inputting Contacts.

2. Press the [Enter] key.

A space for inserting an OR circuit will be created.

66 SYSMAC CP1L Getting Started Guide

Page 68

3. Press the left arrow key.

4. Press the [W] key.

The New Contact OR dialog box will be displayed.

5. Input address "A20011". Press the [Enter] key.

4-5 Inputting Programs

4

A first cycle flag will be displayed on the ladder program.

4

Creating Programs

SYSMAC CP1L Getting Started Guide 67

Page 69

4

Creating Programs

4-5 Inputting Programs

4

4-5-7 Inputting Differentiated Up Contacts

1. While referring to 4-2-2 Ladder Programs, enter a ladder program,

extending to de-escalation motor contact,

2. Press the [Enter] key.

A space for inserting an OR circuit will be created.

3. Press the [W] key.

The New Contact OR dialog box will be displayed.

"10001".

4. Input address "3". Press the [Enter] key.

The Edit Comment dialog box will be displayed.

5. Input "Car detection sensor" as the I/O comment. Press the [Enter] key.

A contact representing input from the car detection sensor will be displayed as an

OR circuit.

6. Double-click contact "003".

The Edit Contact dialog box will be displayed.

68 SYSMAC CP1L Getting Started Guide

Page 70

7. Click [Detail].

8. Select [Up] for Differentiation. Click [OK].

4-5 Inputting Programs

4

4

Creating Programs

An upward arrow representing a differentiated up condition will be displayed on the

contact.

4-5-8 END Instruction

Ladder programs must be terminated with an END instruction.

When a new program is created in CX-Programmer, a section inclusive of an END

instruction will be inserted automatically. Hence, there is no need to input an END

instruction manually.

To confirm the ladder program containing only the END instruction, double-click the

[END] section.

SYSMAC CP1L Getting Started Guide 69

Page 71

4

Creating Programs

4-6 Saving/Loading Programs

4

4-6 Saving/Loading Programs

Created ladder programs must be saved. This section explains how to check, save, and load ladder

programs.

4-6-1 Compiling Programs

By compiling, you can check for errors in the program.

1.

Select [PLC] - [Compile All PLC Programs] from the main menu.

The compilation is started.

When the compilation is complete, program check results will be displayed in the

output window.

2. If an error has been detected, double-click the error message in the

output window.

The cursor is moved to where the error was detected. Correct the error.

70 SYSMAC CP1L Getting Started Guide

Page 72

4-6-2 Saving Programs

Save the created ladder program. Programs are saved in groups for each project.

1. Select [File] - [Save As] from the main menu.

The Save CX-Programmer File dialog box will be displayed.

2. Specify the save location, and input a file name. Click [Save].

The CX-Programmer project file will be saved.

4-6 Saving/Loading Programs

4

4

Creating Programs

SYSMAC CP1L Getting Started Guide 71

Page 73

4

Creating Programs

4-6 Saving/Loading Programs

4

4-6-3 Loading Programs

Load a saved ladder program into CX-Programmer. Programs are loaded in groups

for each project.

1. Select [File] - [Open] from the main menu.

The Open CX-Programmer Project dialog box will be displayed.

2. Specify the save location and file. Click [Open].

The CX-Programmer project file will be opened, and the saved programs will be

displayed.

72 SYSMAC CP1L Getting Started Guide

Page 74

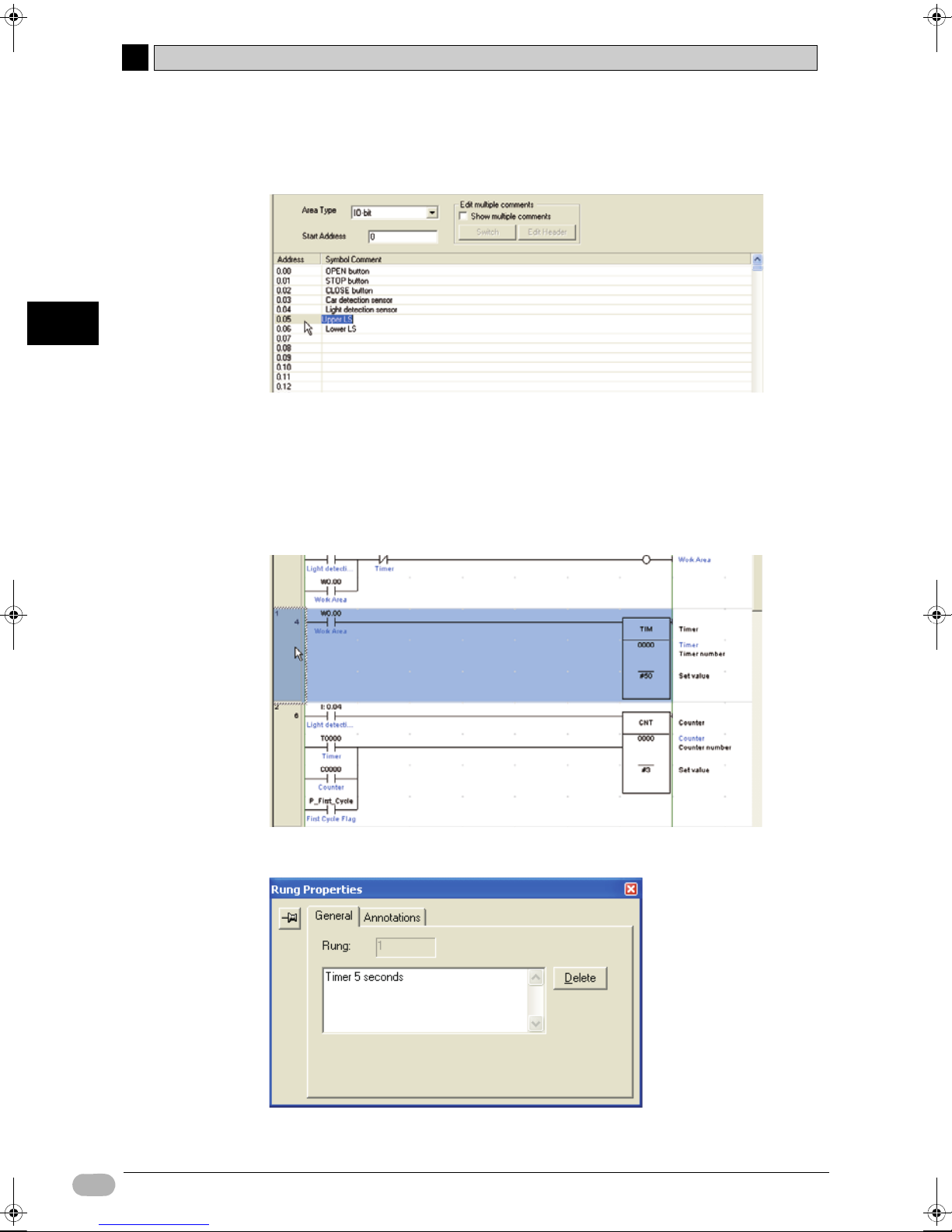

4-7 Editing Programs

4

4-7 Editing Programs

Created ladder programs can be edited in CX-Programmer. I/O comments and rung comments can also

be added or edited.

4-7-1 Editing I/O Comments

I/O comments can be added and edited via a list of addresses.

1. Select [Edit] - [I/O Comment] from the main menu.

4

Creating Programs

The I/O comment window will be displayed.

SYSMAC CP1L Getting Started Guide 73

Page 75

4

Creating Programs

4-7 Editing Programs

4

2. Double-click the address for which you wish to input or edit the I/O

comment.

The I/O comment field will become editable. Input or edit the I/O comment.

4-7-2 Inputting Rung Comments

Comments can be added to each rung of a ladder program.

1. Double-click the rung header for the rung you wish to add a comment to.

The Rung Properties dialog box will be displayed.

2. On the General tab, input the comment into the comment field.

74 SYSMAC CP1L Getting Started Guide

Page 76

3. Close the Rung Properties dialog box.

The entered rung comment will be displayed on the ladder program.

4-7 Editing Programs

4

4

Creating Programs

4-7-3 Editing Rungs

Created ladder programs can be edited.

Deleting

zContacts/Instructions

1. Place the cursor on a contact or on an instruction. Press the [Delete] key.

The selected contact or instruction will be deleted.

zRungs

1. Click a rung header.

The whole rung will be selected.

2. Press the [Delete] key.

The selected rung will be deleted.

SYSMAC CP1L Getting Started Guide 75

Page 77

4

Creating Programs

4-7 Editing Programs

4

Creating Vertical/Horizontal Lines

Vertical and horizontal connection lines can be created.

Vertical lines are created as follows:

1. Position the cursor at the starting point of the vertical line.

2. Hold down the [Ctrl] key, and press the up/down arrow key.

Horizontal lines can be created in the same manner.

(1) Starting point

(2) Cursor

• Creating a line from right to left:

Hold down the [Ctrl] key and press the left arrow key.

• Creating a line from left to right:

Hold down the [Ctrl] key and press the right arrow key.

• Creating a line from bottom to top:

Hold down the [Ctrl] key and press the up arrow key.

• Creating a line from top to bottom:

Hold down the [Ctrl] key and press the down arrow key.

Note Repeating the process over an existing connection line will delete it.

Copying/Pasting Contacts/Instructions/Rungs

zContacts/Instructions

1. Place the cursor on a contact or an instruction.

2. Hold down the [Ctrl] key and press the [C] key.

The selected contact or instruction will be copied to the clipboard.

3. Move the cursor to where you wish to paste. Hold down the [Ctrl] key and

press the [V] key.

The contact or instruction on the clipboard will be pasted.

zRungs

1. Click the rung header of the rung you wish to copy.

The whole rung will be selected.

2. Hold down the [Ctrl] key and press the [C] key.

The selected rung will be copied to the clipboard.

3. Move the cursor to the rung where you wish to paste. Hold down the [Ctrl]

key and press the [V] key.

The rung on the clipboard will be pasted.

76 SYSMAC CP1L Getting Started Guide

Page 78

SECTION 5

Transferring and Debugging

Programs

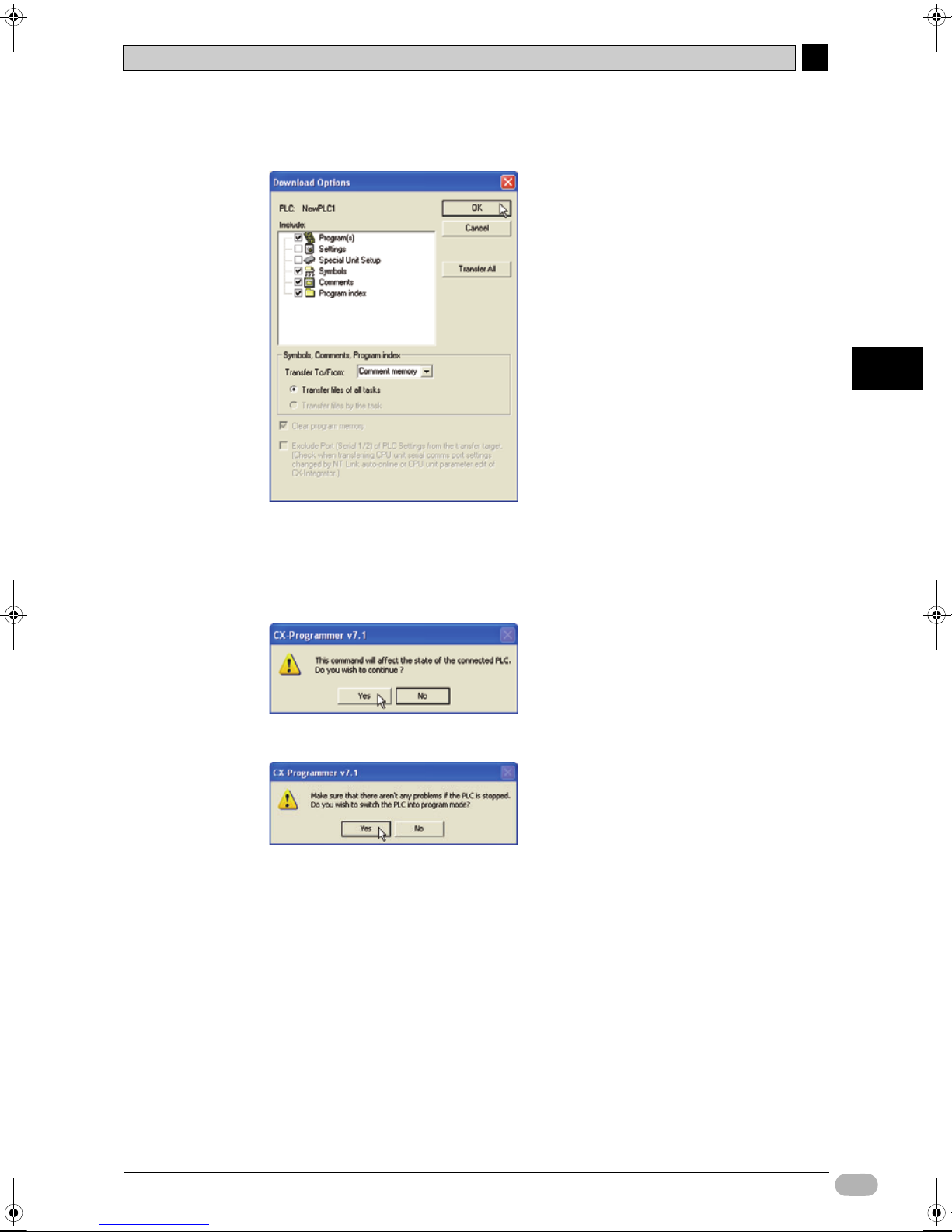

To transfer data from a computer to CP1L, the computer and CP1L

must first be online.

Monitoring and debugging programs executed on CP1L are also

performed with the computer and CP1L online.

5-1 Going Online......................................................................... 78

5-1-1 Setting the CP1L Clock .................................................. 79

5-1-2 Changing the Operating Mode ....................................... 80

5-1-3 Transferring Programs.................................................... 82

5-1-4 Executing Operations ..................................................... 84

5-2 Adjusting/Debugging Online ................................................. 85

5-2-1 Monitoring....................................................................... 85