Page 1

OPERATION MANUAL

CP1H CPU Unit

SYSMAC CP Series

CP1H-X40D@@-

@@

CP1H-XA40D@@-

@@

CP1H-Y20DT-D

Cat. No. W450-E1-02

Page 2

CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

CP1H CPU Unit

Operation Manual

Revised May 2006

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially ha zardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which ap pears in some displays and on some OMRON produ cts, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some CX-Programmer displays to mean Programmable Contr oller.

Visual Aids

The following headings appear in the le ft column of the manual to help you locate different types of

information.

OMRON, 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or tran smit ted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

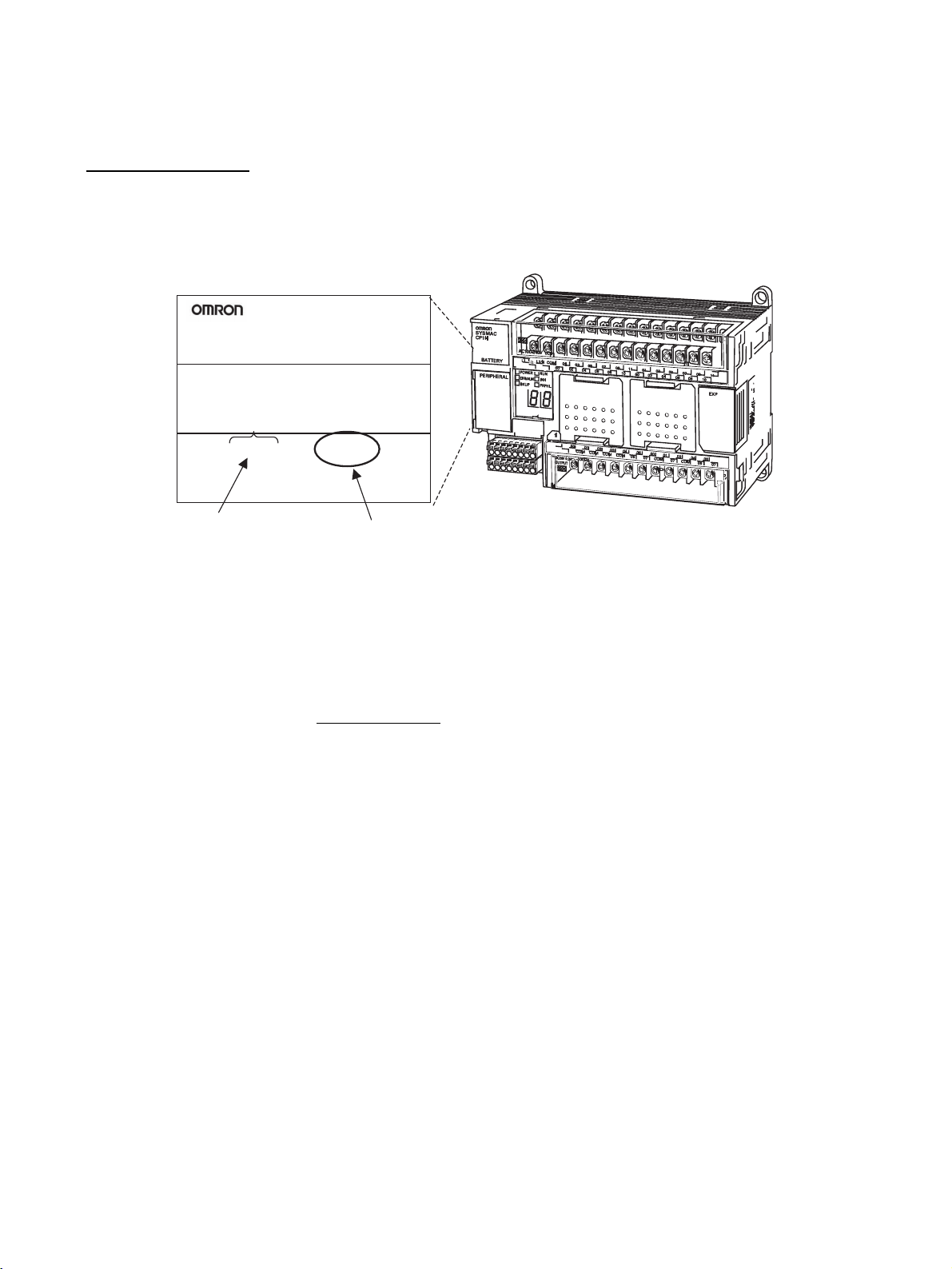

Unit Versions of CP-series CPU Units

Unit Versions A “unit version” has been introduced to manage CPU Units in the CP Se ries

according to differences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

Product nameplate

CPU UNIT

Lot No. 28705 0000 Ver.1.0

OMRON Corporation MADE IN JAPAN

Lot No.

CP1H-XA40CDR-A

Confirming Unit Versions

with Support Software

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

CP-series CPU Unit

Unit version (Example for Unit version 1.0)

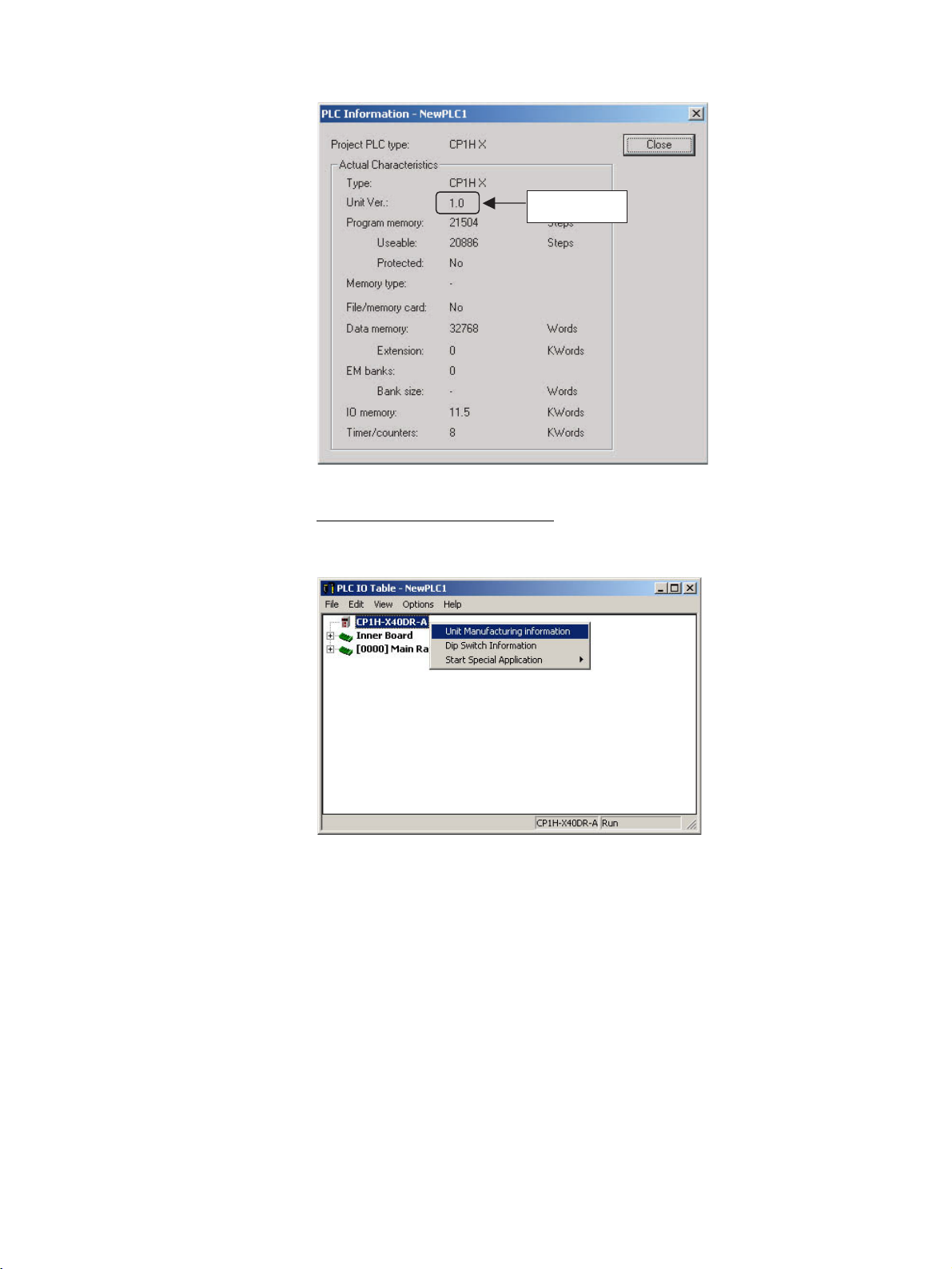

CX-Programmer version 6.1 or highe r ca n be us ed t o c onfi rm the unit version

using one of the following two methods. (See note.)

• Using the PLC Information

• Using the Unit Manufacturing Information

Note CX-Programmer version 6.1 or lower cannot be used to conf irm un it versions

for CP-series CPU Units.

PLC Information

• If you know the device type and CP U type, select them in the Change

PLC Dialog Box, go online, and sel ect P LC - Edit - Information from the

menus.

• If you don't know the device type and CPU type but are connected directly

to the CPU Unit on a ser ial line, select PLC - Auto Online to go onlin e,

and then select PLC - Edit - Information from the menus.

In either case, the following PLC Information Dialog Box will be displayed.

vi

Page 6

Unit version

Use the above display to confirm the unit version of the CPU Unit.

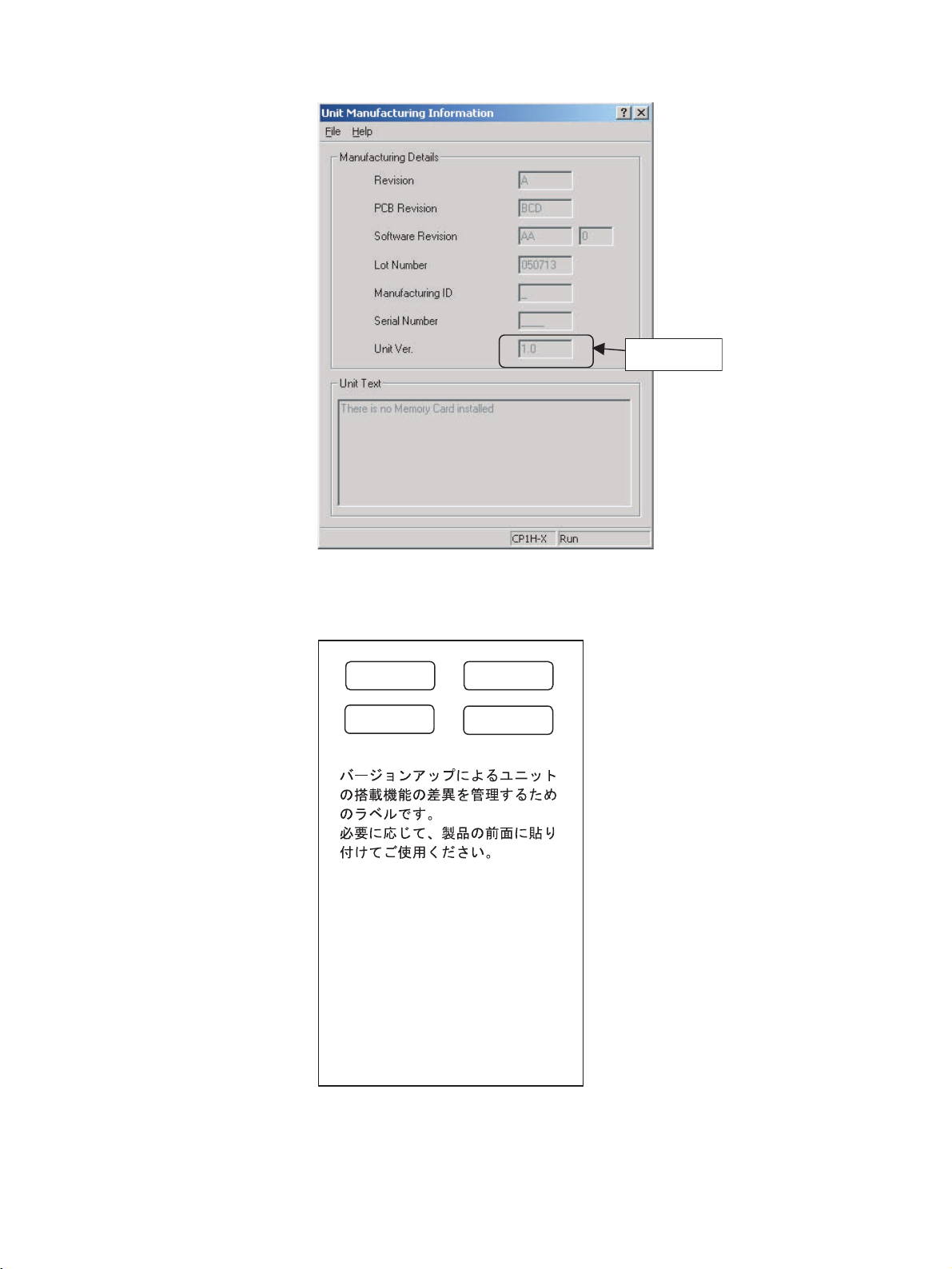

Unit Manufacturing Information

In the IO Table Window, right-click and sel ect Unit Manufacturing information - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

vii

Page 7

Unit version

Use the above display to confirm the uni t version of the CPU Unit connected

online.

Using the Unit Version

Labels

The following unit version labels are provided with the CPU Unit.

Ver.

Ver.

Ver.

1.0

Ver.

1.0

These Labels can be used

to manage differences

in the available

functions among the Units.

Place the appropriate label

on the front of the Unit to

show what Unit

version is actually being

used.

viii

These labels can be attached to the fron t of previous CPU Units to d ifferentiate between CPU Units of different unit versions.

Page 8

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Features and Main Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-3 Connecting Programming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-4 Function Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-5 Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SECTION 2

Nomenclature and Specifications . . . . . . . . . . . . . . . . . . . . . 41

2-1 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

2-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2-3 CP1H CPU Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2-4 CPU Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2-5 CPU Unit Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

2-6 Power OFF Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

2-7 Computing the Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3-1 Fail-safe Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3-2 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3-3 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3-4 Wiring CP1H CPU Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

3-5 Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

3-6 CPM1A Expansion I/O Uni t Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

ix

Page 9

TABLE OF CONTENTS

SECTION 4

I/O Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4-1 Overview of I/O Memory Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4-2 I/O Area and I/O Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

4-3 Built-in Analog I/O Area (XA CPU Units Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4-4 Data Link Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4-5 CPU Bus Unit Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4-6 Special I/O Unit Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

4-7 Serial PLC Link Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

4-8 DeviceNet Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

4-9 Internal I/O Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

4-10 Holding Area (H). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

4-11 Auxiliary Area (A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

4-12 TR (Temporary Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

4-13 Timers and Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

4-14 Data Memory Area (D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

4-15 Index Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

4-16 Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

4-17 Task Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

4-18 Condition Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

4-19 Clock Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

SECTION 5

Basic CP1H Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

5-1 Interrupt Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

5-2 High-speed Counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

5-3 Pulse Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5-4 Quick-response Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

5-5 Analog I/O (XA CPU Units). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

SECTION 6

Advanced Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

6-1 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

6-2 Analog Adjuster and External Analog Setting Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353

6-3 7-Segment LED Dis play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .355

6-4 Battery-free Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

6-5 Memory Cassette Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

6-6 Program Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

6-7 Failure Diagnosis Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

6-8 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

x

Page 10

TABLE OF CONTENTS

SECTION 7

Using CPM1A Expansion Units and Expansion I/O Units. 381

7-1 Connecting CPM1A Expansion Units and Expansion I/O Units . . . . . . . . . . . . . . . . . . . . . 382

7-2 Analog Input Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

7-3 Analog Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

7-4 Analog I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

7-5 Temperature Sensor Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .423

7-6 CompoBus/S I/O Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

7-7 DeviceNet I/O Link Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .444

SECTION 8

Program Transfer, Trial Operation, and Debugging . . . . . 451

8-1 Program Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

8-2 Trial Operation and Debugging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 452

SECTION 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 459

9-1 Error Classification and Confirmation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 460

9-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

9-3 Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

9-4 Troubleshooting Unit Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .478

SECTION 10

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 481

10-1 Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482

10-2 Replacing User-serviceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 489

B Dimensions Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .497

C Auxiliary Area Allocations by Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

D Auxiliary Area Allocations by Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 525

E Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

F Connections to Serial Communications Option Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

G PLC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 599

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 629

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 635

xi

Page 11

TABLE OF CONTENTS

xii

Page 12

About this Manual:

This manual descr ibes installation and operat ion of the CP-series Program mable Controllers (PLCs)

and includes the sections described below. The CP Series p rovid es advanced package-type PLCs

based on OMRON’s advanced control technologies and vast experience in automated control.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or opera te a CP-series P LC. Be sure to read the precautions provided in the following section.

Definition of the CP Series

The CP Series is centered around the CP1H CPU Units and is designed with the same basic architecture as the CS and CJ Series. The Special I/O Uni ts and CPU Bus Unit s of the CJ Ser ies ca n thus be

used. CJ-series Basic I/O Units, however, cannot be used. Always use CPM1A Expansion Un its and

CPM1A Expansion I/O Units when expanding I/O capacity.

I/O words are allocated in the same way as the CPM1A/CPM2A PLCs, i.e., using fixed areas for inputs

and outputs.

CS Series

CS1-H CPU Units

CS1H-CPU@@H

CS1G-CPU@@H

CS1 CPU Units

CS1H-CPU@@ (-V1)

CS1G-CPU@@ (-V1)

CS1D CPU Units

CS1D CPU Units for

Duplex-CPU System

CS1D-CPU

CS1D CPU Units for

Single-CPU System

CS1D-CPU S

CS1D Process CPU Units

CS1D-CPU

CS-series Basic I/O Units

CS-series Special I/O Units

CS-series CPU Bus Units

CS-series Power Supply Units

Note: Products specifically for the CS1D

Series are required to use CS1D

CPU Units.

CS/CJ/CP Series

CJ Series

CJ1-H CPU Units

CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G -CPU@@P

(Loop CPU Unit)

CJ1M CPU Unit

CJ1M-CPU@@

@@H

@@

@@P

CJ1 CPU Unit

CJ1G-CPU@@

CJ-series Basic I/O Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

CJ-series Power Supply Units

CPM1A Expansion I/O Units

CPM1A Expansion Units

CJ-series Special I/O Units

CJ-series CPU Bus Units

CP Series

CP1H CPU Units

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

xiii

Page 13

Precautions provides general precautions for using the Programmable Controller and related devices.

Section 1 introduces the features of the CP1 H and describes its config uration. It also describes th e

Units that are available and connection methods for Programming Devices and other peripheral

devices.

Section 2 describes the names and functions of CP1H parts and provides CP1H specifications.

Section 3 describes how to install and wire the CP1H.

Section 4 describes the structure and functions of the I/O Memory Areas and Parameter Areas.

Section 5 describes the CP1H’s interrupt and high-speed counter functions.

Section 6 describes all of the advanced functions of the CP1H that can be used to achieve specific

application needs.

Section 7 describes how to use CPM1A Expansion Units and Expansion I/O Units

Section 8 describes the processes used to transfer the program to the CPU Unit and the functions that

can be used to test and debug the program.

Section 9 provides information on hardware and software errors that occur during CP1H operation

Section 10 provides inspection and maintenance information.

The Appendices provide product lists, dimensions, tables of Auxiliary Area allocations, and a memory

map.

xiv

Page 14

Related Manuals

The following manuals are used for the CP-series CPU Units. Refer to these manuals as required.

Cat. No. Model numbers Manual name Description

W450 CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

W451 CP1H-X40D@-@

CP1H-XA40D@-@

CP1H-Y20DT-D

W342 CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCU21

CS1W-SCB21-V1/41-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CP1H-CPU@@

CJ1G-CPU@@

CJ1W-SCU21-V1/41-V1

W446 WS02-CXPC1-E-V70 SYSMAC CX-Pro-

W447 WS02-CXPC1-E-V70 SYSMAC CX-Pro-

W444 CXONE-AL@@C-E CX-One FA Inte-

W445 CXONE-AL@@C-E CX-Int egrator Opera-

W344 WS02-PSTC1-E CX-Protocol Opera-

SYSMAC CP Series

CP1H CPU Unit

Operation Manual

SYSMAC CP Series

CP1H CPU Unit Programming Manual

SYSMAC CS/CJseries Communica tions Commands Reference Manual

grammer

Ver. 7.0 Operation

Manual

grammer Ver. 7.0

Operation Manual

Function Blocks

grated Tool Package

Setup Manual

tion Manual

tion Manual

Provides the f o llo wing in f o rmation on th e CP Se ries:

•Overview, design, installation, maintenance, and

other basic specifications

•Features

• System confi guration

•Mounting and wiring

•I/O memory allocation

• Troubleshooting

Use this manual together with the CP1H Program-

mable Controllers Programming Manual (W451).

Provides the f o llo wing in f o rmation on th e CP Se ries:

•Programming instructions

• Programming methods

•Tasks

• File memory

•Functions

Use this manual together with the CP1H Program-

mable Controllers Operation Manual (W450).

Describes commands addressed to CS-series and

CJ-series CPU Units , incl uding C-mod e comm ands

and FINS commands.

Note This manual describes on commands

address to CPU Units regardless of the communications path. (CPU Unit serial por ts,

Serial Communications Unit/Board ports, and

Communications Unit ports can be used.)

Refer to the relevant operation manuals for

information on commands addresses to Special I/O Units and CPU Bus Units.

Provides inf ormation on instal ling a nd oper at ing the

CX-Programmer f o r al l fun ct ion s except for function

blocks.

Provides specifications and oper ating proc edures

for function blocks. Function blocks can be used

with CX-Programmer Ver. 6.1 or highe r and either a

CS1-H/CJ1-H CPU Unit with a uni t v ersi on of 3.0 or

a CP1H CPU Unit. Refer to W446 for operating procedures for functions other than function blocks.

Provides an overview of the CX-One FA Integrated

Tool and installation procedures.

Describes CX-Integrator operating procedures and

provides inf ormatio n on ne tw ork config ur ation (data

links, routing tables, Communications Units setup,

etc.

Provides operat ing proc edures f or crea ting pro tocol

macros (i.e., communications sequences) with the

CX-Protocol and other information on protocol macros.

The CX-Protocol is required to create prot oc ol ma cros for user-specific serial communications or to

customize the standard system protocols.

xv

Page 15

xvi

Page 16

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xvii

Page 17

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THA T THE OMRON PR ODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xviii

Page 18

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xix

Page 19

xx

Page 20

PRECAUTIONS

This section provides general precautions for using the CP-series Programmable Controllers (PLCs) and related devices.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this s ection and understand t he information contained before attempting to se t up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-4 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xxix

6-5 Conditions for Meeting EMC Directives

when Using CPM1A Relay Expansion I/O Units. . . . . . . . . . . . . . . xxx

xxi

Page 21

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, me dical equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides informat ion for programming and operat ing the Un it. B e

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely impor tant that a PLC and al l PLC Units b e used for the spec i-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to th e above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the te r minals o r ter minal blocks while the power is bein g

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), includin g the following items, to ensure safety in the system if an

abnormality occurs due to malfunc tion of the PLC or anoth er external factor

affecting the PLC operation. Not doing so may result in serious accidents.

xxii

• Emergency stop cir cuits, inter lock circui ts, limit cir cuits, and sim ilar safety

measures must be provided in external control circuits.

Page 22

Safety Precautions 3

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a counterme asure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC or outputs may remain ON or OFF due to deposits on or burning

of the output relays, or destruc tio n of th e ou tpu t transis to rs. As a c ou ntermeasure for such problems, extern al safety measures must be provide d

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or shor t-circuited, the voltage may drop and result in the out puts

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power in terruptions, or other causes. Not doing so may result in

serious accidents.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Other wise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or editing the I/O area. Doing either of thes e withou t confir m ing

safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC power supply to the torque

specified in this manual. The loose s crews may result in burning o r malfunction.

!Caution Do not touch anywhere near the power supply parts or I/O terminals while the

power is ON, and immediately after tur ning OFF the power. The hot surface

may cause burn injury.

!Caution Pa y careful attention to the polarities (+/-) when wiring the DC power supply . A

wrong connection may cause malfunction of the system.

!Caution When connecting the PLC to a computer or other peripheral device, either

ground the 0 V side of the external power supply or do not ground the external

power supply at all. Otherwise the external power supply may be shorted

depending on the connection methods of the peripheral device. DO NOT

ground the 24 V sid e of the exter nal power suppl y, as shown in t he following

diagram.

Non-insulated DC power supply

24 V

Twisted-pair

cable

FG

0 V

0 V

CPU Unit

FG

FG

0 V

Peripheral device

FG

xxiii

Page 23

Operating Environment Precautions 4

!Caution After programming (or repr ogrammi ng) using the IOWR instruction, confir m

that correct operation is possible with the new ladder program and data before

starting actual operation. Any irregularities may cause the product to stop

operating, resulting in unexpected operation in machinery or equipment.

!Caution The CP1H CPU Units automatically back up the user program and parameter

data to flash memor y when these are written to the CPU Unit. I/O memory

(including the DM Area , counter present values and Completion Flags, an d

HR Area), however, is not written to flash memory. The DM Area, counter

present values and Completion Flags, and HR Area can be held during power

interruptions with a ba ttery. If there is a batter y error, the contents of these

areas may not be accurate af ter a power interruption. If the con tents of the

DM Area, counter present values and Completion Flags, and HR Area are

used to control external outputs, prevent inappropriate outputs from being

made whenever the Battery Error Flag (A402.04) is ON.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and su fficient counterm easures when installing sys tems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of th e PLC S ystem c an have a large effect on th e

longevity and reliability of the sy stem. Improper operating environme nts can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Make sure that the operating environment is within the specified conditions at installati on and remains within the specifi ed conditions during the

life of the system.

xxiv

Page 24

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PLC System.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to 100

to a ground of 100

• Always turn OFF the power su pply to the PLC before attempting a ny of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Expansion Units or any other Units

• Connecting or removing the Memory Cassette or Option Board

• Setting DIP switches or rotary switches

• Connecting or wiring the cables

• Connecting or disconnecting the connectors

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or co uld dam age the PLC or PLC Uni ts. Always heed

these precautions.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures agai nst short-circuiting may result in burning.

• Mount the Unit only after checking the connectors and terminal blocks

completely.

• Be sure that all the terminal screws and cable connector screws are tightened to the torque s pecified in the relevant manuals. Incorrect tig htening

torque may result in malfunction.

• Wire all connections correctly according to instructions in this manual.

• Always use the power supply voltage specified in the operati on manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate m easures to ensure that the specified power with the

rated voltage and frequency is supplied. Be partic ularly car eful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Do not apply voltages to the in put terminals in excess of the rated input

voltage. Excess voltages may result in burning.

• Do not apply voltages o r connect loads to the output ter minals in excess

of the maximum switching capac i ty. Excess voltage or loads may result in

burning.

Ω or less when installing the Units. Not connecting

Ω or less may result in electric shock.

xxv

Page 25

Application Precautions 5

• Be sure that the ter minal blocks, connectors, Option Boards, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Wire correctly and double-check all the wiring or the setting switches

before turning ON the power suppl y. Incorrect wir ing may result in burning.

• Check that the DIP switches and data memory (DM) are properly set

before starting operation .

• Check the user program for proper execution before actually running it o n

the Unit. Not checking the program may result in an unexpected operation.

• Resume operation only after transferring to the new CPU Unit and/or Special I/O Units the contents of the DM, HR, and CNT A reas required for

resuming operation. Not doing so may result in an unexpected operation.

• Confirm that no ad verse effect will occur in the system before attemptin g

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC ( includi ng the se tting of th e

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• When replacing p arts, be sure to confi rm that the rating of a new par t is

correct. Not doing so may result in malfunction or burning.

• Before touching the Unit, be su re to firs t to uc h a grounde d m etal li c obj ec t

in order to discharge a ny static buildup. Not doing so may result in malfunction or damage.

• Do not touch the Expansion I/ O Unit Conn ec tin g Cable while the power is

being supplied in order to prevent malfunction due to static electricity.

• Do not turn O FF the power supply to the Uni t while data is being tran sferred.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• Do not touch the mounted par ts or the rear surface of PCBs because

PCBs have sharp edges such as electrical leads.

• Double-check the pin numbers when assembling an d wiring t he connectors.

• Wire correctly according to specified procedures.

• Do not connect pin 6 (+5V) on the RS-232C Opti on Board on the CPU

Unit to any external device other than the NT-AL001 or CJ1W-CIF11 Conversion Adapter. The external device and the CPU Unit may be damaged.

• Use the dedicated conne cting cables specified in this manual to connect

the Units. Using commerc ially avai lable RS-232C computer cables may

cause failures in external devices or the CPU Unit.

xxvi

Page 26

Application Precautions 5

• Check that data link tables an d parameters are p roperly set before star ting operation. Not doing so may result in un expe cted operation. Even if

the tables and parameters are properly set, confirm that no adverse

effects will occur in the system before running or stopping data links.

• Transfer a routing table to the CPU Unit only after confirming that no

adverse effects will be caused by restarting CPU Bus Units, which is automatically done to make the new tables effective.

• The user program and param eter a r ea data i n th e C PU Uni t i s backed up

in the built-in flash memory. The BKUP indicator will light on the fr ont of

the CPU Unit when the backup operation i s in progress. Do not tur n OFF

the power supply to the CPU Unit when the BKUP indicator is lit. The data

will not be backed up if power is turned OFF.

• Do not turn OFF the power supply to the PLC while the Memory Cassette

is being accessed. Doin g so may cor rupt the data in the Memory Cassette. The 7-segment LED will light to indicate writing progress while the

Memory Cassette is being accessed. Wait for the LED display to go out

before turning OFF the power supply to the PLC.

• Before replacing the batter y, supply power to the CPU Unit for at least 5

minutes and then complete battery repla cement within 5 minutes of tu rn

OFF the power supply. Memory data may be corrupted if this precaution is

not observed.

• Always use the following size wire when connecting I/O Units, Spec ia l I/O

Units, and CPU Bus Units: AWG22 to AWG18 (0.32 to 0.82 mm

• UL standards required that batteries be replaced only by experienced

technicians. Do not allow unqualified pe rsons to replace batteries. Also,

always follow the replacement procedure provided in the manual.

• Never short-circuit the positive and negative terminals of a battery or

charge, disassemble, heat, or incinerate the battery. Do not s ubject the

battery to str ong shocks or defor m the barr y by apply ing pressu re. Doing

any of these may result in leakage, ruptur e, heat gene ration, or ig nit ion of

the battery. Dispose of any battery that has been dropped on the f loor or

otherwise subjected to excessive shock. Batteries that have been subjected to shock may leak if they are used.

• Always construct external circuits so that the power to the PLC it turne d

ON before the power to the control system is turned ON. If the PLC power

supply is turned ON afte r the c ontrol power su pply, temporary errors may

result in control system signals bec ause the outpu t ter minals on DC Output Units and other U nits will mo mentar ily tur n ON when power is tur ned

ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be

turned OFF and will maintain their previous status when the PLC is

switched from RUN or MONITOR mode to PROGRAM mode. Make sure

that the external loads will not produce dangerous conditi ons when this

occurs. (When operation stops for a fatal error, including those produced

with the FALS(007) instruction, all outputs from Outpu t Unit will be turned

OFF and only the internal output status will be maintained.)

2

).

xxvii

Page 27

Conformance to EC Directives 6

• Dispose of the product and batteries according to local ordinances as

they apply.

Have qualified specialists properl y dispose o f used batter ies as ind ustrial

waste.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the r elated

EMC standards so tha t they can be more e as ily built in to ot her d evices or th e

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the custo mer, however, must be che cked by

the customer.

EMC-related perfor ma nce o f th e O M RON devices that c omp ly wi th EC Di re ctives will vary depending on the configuration, wi ring, and oth er conditions of

the equipment or control panel on which the OMRON devices are installed .

The customer must, therefore, perform the fina l check to conf ir m th at devices

and the overall machine conform to EMC standards.

Note The applicable EMC (Electromagnetic Compatibility) standard is EN61131-2.

Low Voltage Directive

Always ensure that devices operating at voltage s of 50 to 1,00 0 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

6-3 Conformance to EC Directives

The CP1H PLCs comply with E C Directives. To ensure that the machine or

device in which the CP1H PLC is us ed complies with EC Direc tives, the PLC

must be installed as follows:

1,2,3... 1. The CP1H PLC must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for I/O Units and CPU Units requiring DC power. The output

holding time must be 10 ms minimum for the DC power supply connected

to the power supply terminals on Units requiring DC power.

3. CP1H PLCs complying with EC Directive s also conform to EN61131-2.

Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to

the control panel, wiring, and other conditions. You must therefore confirm

that the overall machine or equipment complies with EC Directives.

xxviii

Page 28

Conformance to EC Directives 6

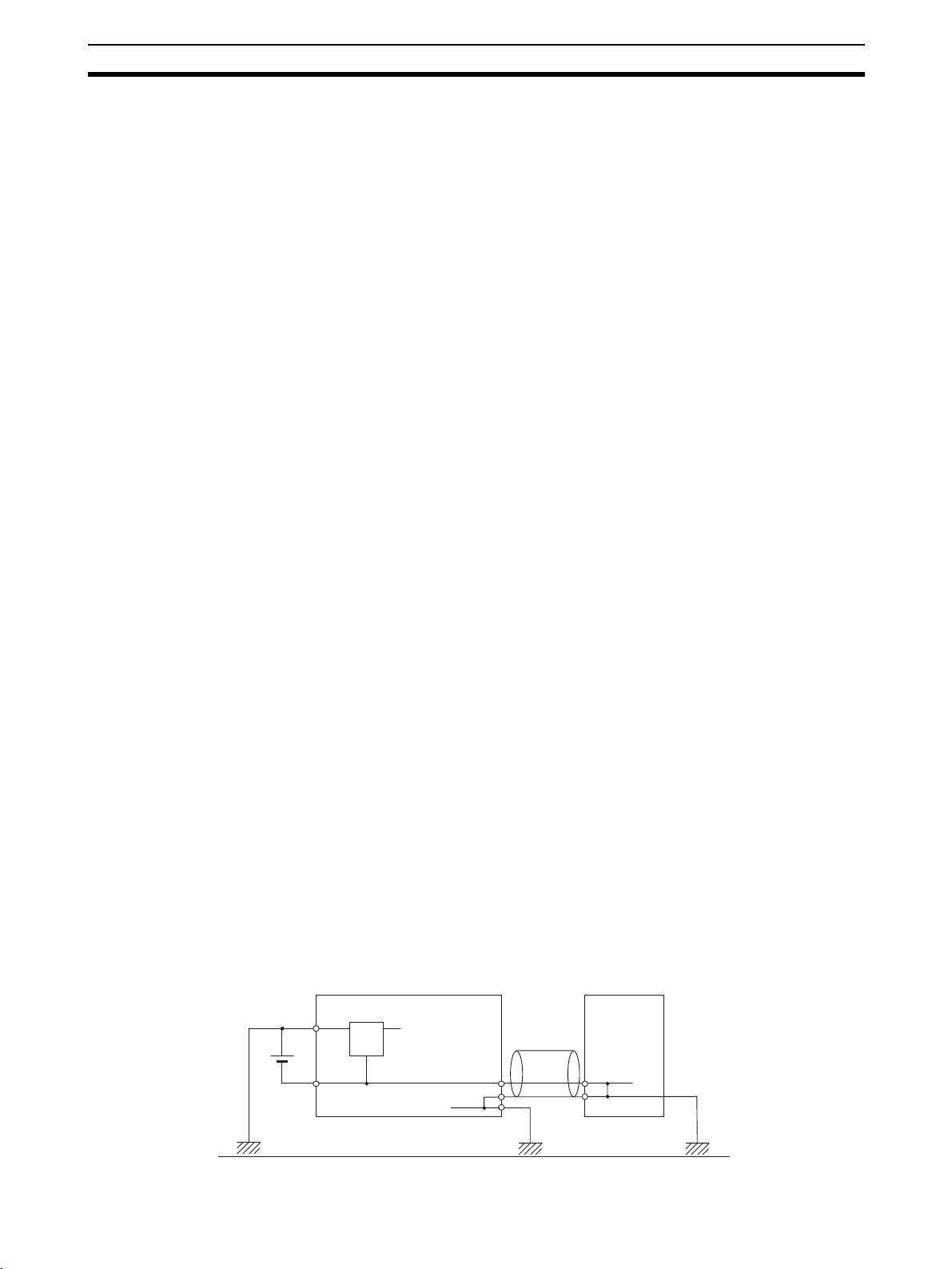

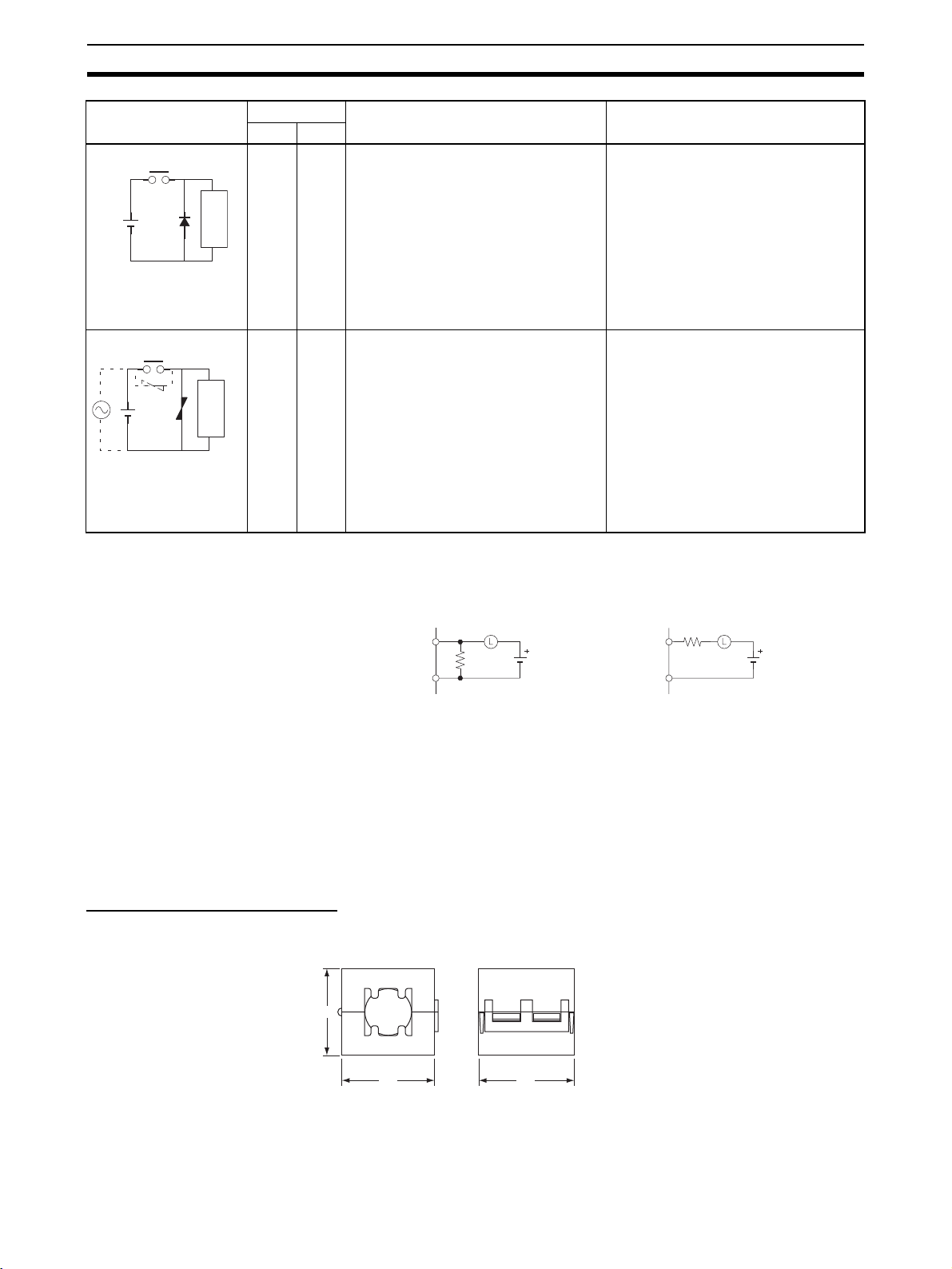

6-4 Relay Output Noise Reduction Methods

The CP1H PLCs conforms to the Commo n Emissi on Stand ards (EN61131- 2)

of the EMC Directives. However, noise generated by relay output switching

may not satisfy these Standards. In such a ca se, a noise filter must be connected to the load side o r other appropriate counter measures must be provided external to the PLC.

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, co nfi guration of mac hi nes, etc . Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

Countermeasur es are not required if the f requency of load switching for the

whole system with the PLC included is less than 5 times per minute.

Countermeasures are required if the frequency of load switching for the whole

system with the PLC included is more than 5 times per minute.

Note Refer to EN61131-2 for more details.

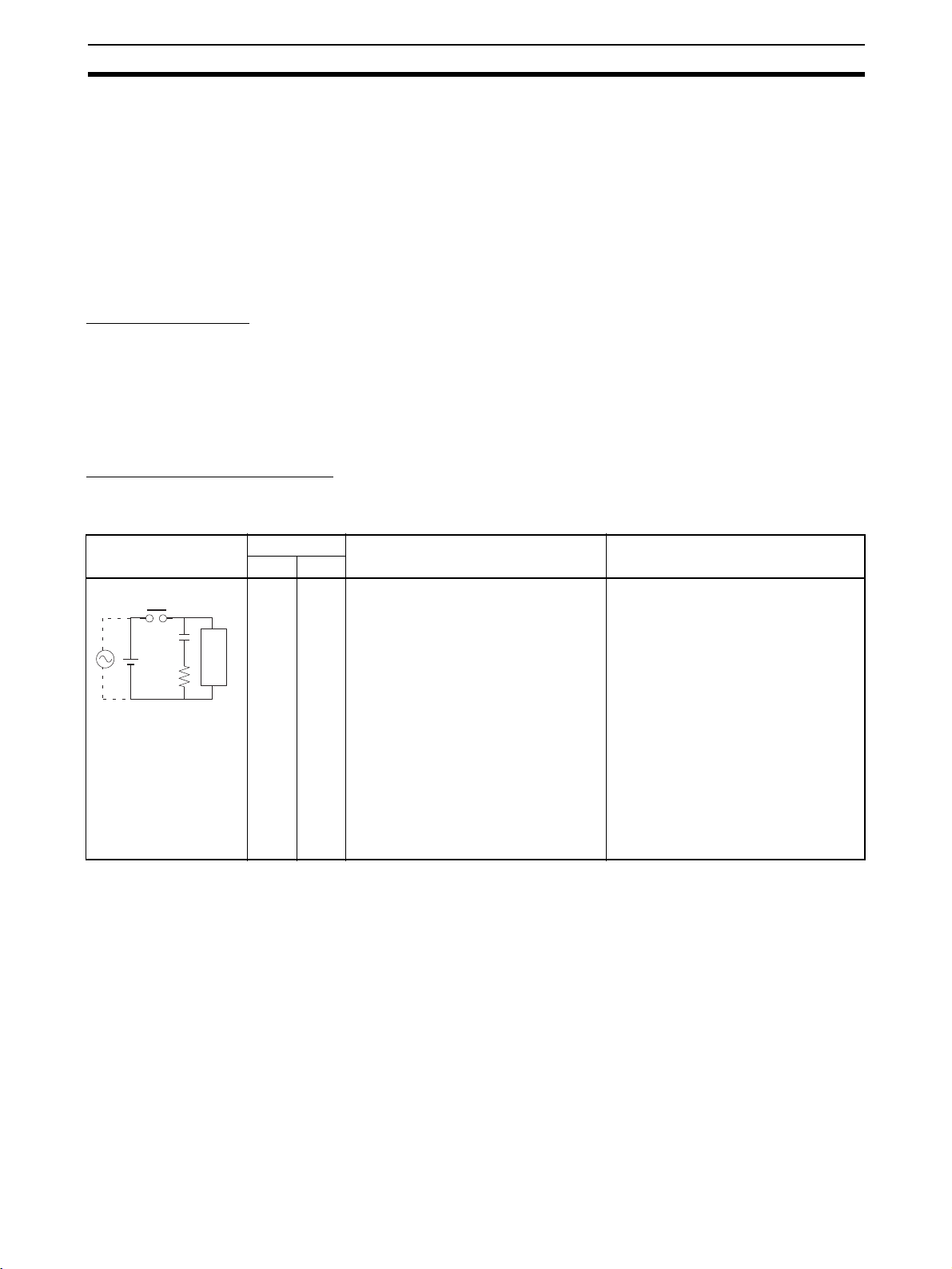

Countermeasure Examples

When switching an inductive load, co nne ct a n su r ge pr ot ec tor, diodes, etc., in

parallel with the load or contact as shown below.

Circuit Current Characteristic Required element

CR method

Powe r

supply

AC DC

Yes Yes If the load is a relay or soleno id, there is

C

R

Inductive

load

a time lag between the moment the circuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V , insert

the surge protector in parallel with the

load. If the supply voltage is 100 to

200 V, insert the surge protector

between the contacts.

The capacitance of the c apacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact v oltag e of 1V.

These values, however, vary with the

load and the characteristics of the

relay. Decide these values from experiments, and take into consideration that

the capacitance suppresses spark discharge when the contacts are separated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 30 0 V. If the circ uit i s an

AC circuit, use a capacitor with no

polarity.

xxix

Page 29

Conformance to EC Directives 6

Circuit Current Characteristic Required element

AC DC

Diode method

Powe r

supply

Varistor method

Power

supply

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so tha t the current will

be converted into Joule heat by the

Inductive

load

resistance of the inductive load.

This time lag, betw een the m om ent the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

Yes Yes The varistor method prevents the impo-

sition of high voltage between the contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the cir-

Inductive

load

cuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V , insert

the varistor in parallel with the load. If

the supply voltage is 100 to 200 V,

insert the varistor between the contacts.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

---

When switching a load with a high inr ush current such as an incandescent

lamp, suppress the inrush current as shown below.

Countermeasure 1

OUT

R

COM

Providing a dark current of

approx. one-third of the rated

value through an incandescent

lamp

Countermeasure 2

R

OUT

COM

Providing a limiting resistor

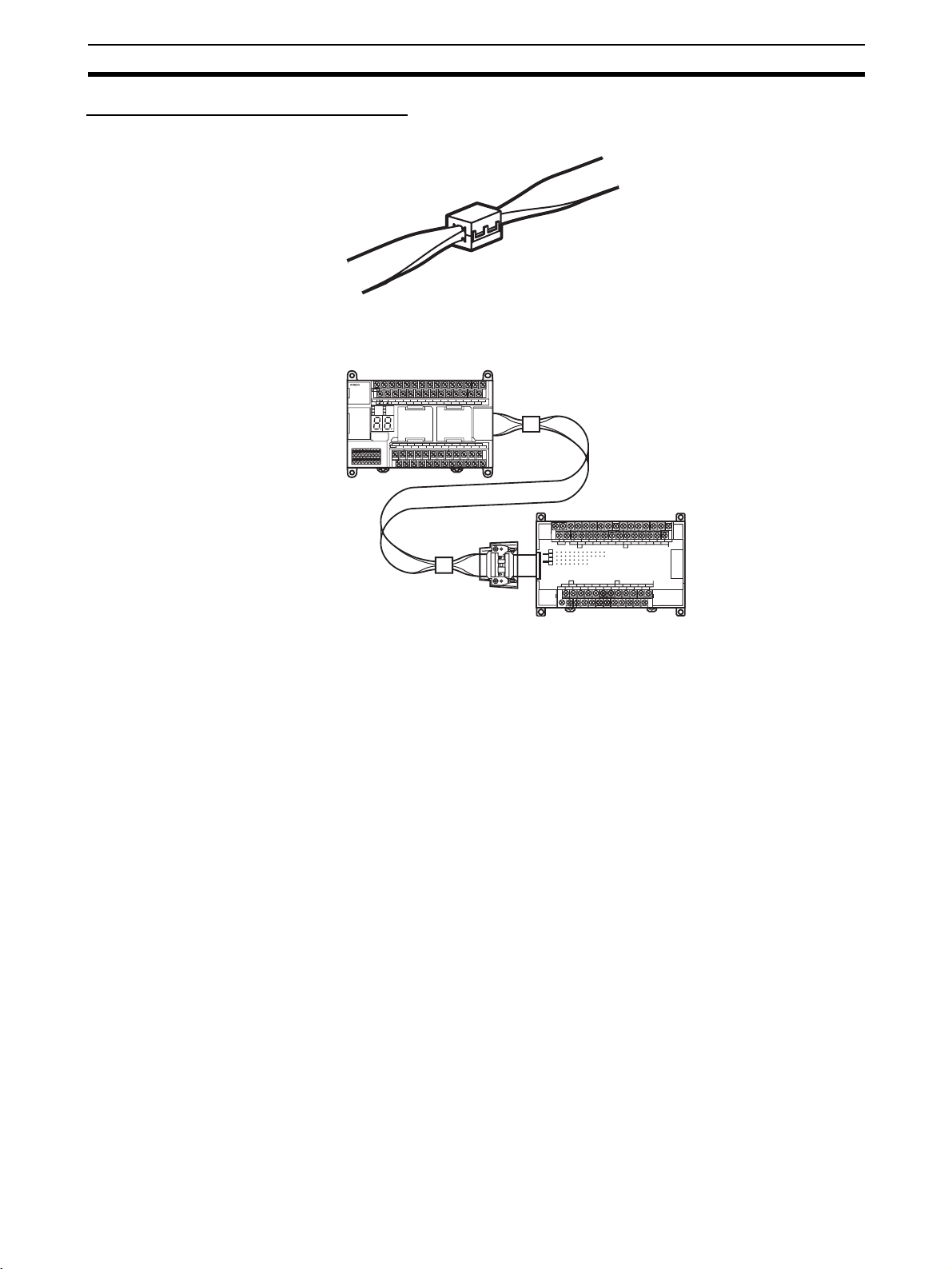

6-5 Conditions for Meeting EMC Directives when Using CPM1A Relay

Expansion I/O Units

EN61131-2 immunity testing conditions when using the CPM1A-40EDR or

CPM1A-16ER with a CP1W-CN811 I/O Connecting Cable are given be low.

Recommended Ferrite Core

Ferrite Core (Data Line Filter) : 04 43-164151 manufactured by Nisshin Electric

Minimum impedance: 90 Ω at 25 MHz, 160 Ω at 100 MHz

30

xxx

32 33

Page 30

Conformance to EC Directives 6

Recommended Connection Method

1,2,3... 1. Cable Connection Method

2. Connection Method

As shown below, connect a ferrite core to each end of the CP1W-CN811

I/O Connecting Cable.

SYSMAC

IN

CP1H

AC100-240V

L1 L2/N COM 01 03 05 07 09 11 01 03 05 07 09 11

BATTERY

00 02 04 06 08 10 00 02 04 06 08 10

POWER

PERIPHERAL

ERR/ALM

BKUP

MEMORY

00 01 02 03 04 06 00 01 03 04 06

COM COM COM COM 05 07 COM 02 COM 05 07

100CH 101CH

OUT

EXP

1CH

NCNCNC

COM

01 03 05 07 09 11 01 03 05 07 09 11

NC

00 02 04 06 08 10

CH CH

CH

IN

CH

CH

0706050403020100

OUT

CH

0706050403020100

CH CH

NC

00 01 02 04 05 07 00 02 04 05 07

NC

COM COM COM COM COM COM03 06 01 03 06

111009080706050403020100

111009080706050403020100

00 02 04 06 08 10

40EDR

EXP

xxxi

Page 31

Conformance to EC Directives 6

xxxii

Page 32

SECTION 1

Features and System Configuration

This section introduces the features of the CP1H and describes its configuration. It also describes the Units that are available

and connection methods for the CX-Programmer and other peripheral devices.

1-1 Features and Main Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 CP1H Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-2-1 Basic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-2-2 System Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-2-3 System Expansion with CJ-series Units. . . . . . . . . . . . . . . . . . . . . . 20

1-2-4 Restrictions on System Configuration . . . . . . . . . . . . . . . . . . . . . . . 22

1-3 Connecting Programming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-3-1 Connecting to a USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-3-2 Connecting to a Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1-4 Function Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-5 Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-5-1 Overview of Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-5-2 Advantages of Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1

Page 33

Features and Main Functions Section 1-1

1-1 Features and Main Functions

1-1-1 CP1H Overview

The SYSMAC CP1H is a n advanced high-speed, package-type Programmable Controller. While the CP1H employs the same architecture as the CS/CJ

Series and provides the same I/O capacity of 40 I/O points as the CPM2A, the

CP1H is approximately ten times faster.

There are three typ es of CP1H CPU Units to select from: a basi c CPU Unit

(X), a CPU Unit with built-in analog I/O terminals (XA), and a CPU Unit with

Dedicated Pulse I/O Terminals (Y).

Basic CPU Units: X The X CPU Units are the standard models in the CP1H Series.

24 built-in inputs (Functions

can be assigned.) (See note.)

Normal inputs (24)

Interrupt inputs (8)

Quick-response inputs (8)

16 built-in outputs (Functions

can be assigned.) (See note.)

Normal outputs (16)

High-speed counter

(4 axes)

100 kHz (single phase)

Unit Ver. 1.0 or Earlier Unit Ver. 1.1 or Later

2 pulse outputs

100 kHz

2 pulse outputs

30 kHz

4 pulse outputs

100 kHz

2 PWM outputs

2 PWM outputs

• The CPU Unit has 24 inputs and 16 outputs built in.

• High-speed counters and pulse outputs can be used on four axes with the

CPU Unit alone.

• The CP1H can be expanded to a maximum total of 320 I/O points by

using CPM1A Expansion I/O Units.

• Using CPM1A Expansion Units also allows extra functions (such as temperature sensor inputs) to be added.

• Installing an Option Board enables RS-232C and RS-422A/485 communications for Programmable Terminals, Bar Code Readers, Inverters, etc.

• Using CJ-seri es CPU B us Uni ts ena bles co mmunica tions with higher an d

lower level devices.

2

Page 34

Features and Main Functions Section 1-1

Note Settings in the PLC Setup dete rmine whether each input point is to be u sed

as a normal input, interrupt input, quick-response input, or high-speed

counter. The instruction used to control each output point determines whether

it is used as a normal output, pulse output, or PWM output.

CPU Units with Builtin Analog I/O

Terminals: XA

The XA CPU Unit adds analog I/O functionality to the X CPU Unit capabilities.

24 built-in inputs (Functions

can be assigned.) (See note.)

Normal inputs (24)

High-speed counter

(4 axes)

100 kHz (single phase)

Unit Ver. 1.0 and Earlier

2 pulse outputs

100 kHz

2 pulse outputs

30 kHz

2 PWM outputs

Unit Ver. 1.1 and Later

4 pulse outputs

100 kHz

2 PWM outputs

4 analog inputs

2 analog outputs

Interrupt inputs (8)

Quick-response inputs

(8)

16 built-in outputs (Functions

can be assigned.) (See note.)

Normal outputs (16)

• The CPU Unit has 24 inputs and 16 outputs built in.

• High-speed counters and pulse outputs can be used on four axes with the

CPU Unit alone.

• The CPU Unit has 4 analog voltage/curr ent inputs and 2 analog voltage/

current outputs built in.

• The CP1H can be expanded to a maximum total of 320 I/O points by

using CPM1A Expansion I/O Units.

• Using CPM1A Expansion Units also allows extra functions (such as temperature sensor inputs) to be added.

• Installing an Option Board enables RS-232C and RS-422A/485 communications for connecting to Programmable Term inals, Bar Code Readers,

Inverters, etc.

• Using CJ-seri es CPU B us Uni ts ena bles co mmunica tions with higher an d

lower level devices.

Note Settings in the PLC Setup dete rmine whether each input point is to be u sed

as a normal input, interrupt input, quick-response input, or high-speed

counter. The instruction used to control each output point determines whether

it is used as a normal output, pulse output, or PWM output.

3

Page 35

Features and Main Functions Section 1-1

CPU Unit with

Dedicated Pulse I/O

Terminals: Y

In place of the X CPU Units' more numerous built-in I/O points, the Y CPU

Unit provides dedicated pulse I/O terminals (1 MHz).

12 built-in inputs (Functions

Pulse inputs

2 high-speed counters

1 MHz (single phase)

Pulse outputs

2 pulse outputs

1 MHz

can be assigned.) (See note.)

Normal inputs (12)

Interrupt inputs (6)

Quick-response inputs

(6)

8 built-in outputs (Functions

can be assigned.) (See note.)

Normal outputs (8)

High-speed counter

(2 axes)

100 kHz (single phase)

2 pulse outputs

100 kHz

2 PWM outputs

• The CPU Unit has 12 inputs and 8 outputs built in.

• High-speed counters and pulse outputs can be used on four axes with the

CPU Unit alone.

The CPU Unit provides a h igh-speed pulse output of up to 1 MHz, and

can handle linear servos.

• The CP1H can be expanded to a maximum total of 300 I/O points by

using CPM1A Expansion I/O Units.

• Using CPM1A Expansion Units also allows extra functions (such as temperature sensor inputs) to be added.

• Installing an Option Board enables RS-232C and RS-422A/485 communications for connecting to Programmable Term inals, Bar Code Readers,

Inverters, etc.

• Using CJ-seri es CPU B us Uni ts ena bles co mmunica tions with higher an d

lower level devices.

Note Settings in the PLC Setup dete rmine whether each input point is to be u sed

as a normal input, interrupt input, quick-response input, or high-speed

counter. The instruction used to control each output point determines whether

it is used as a normal output, pulse output, or PWM output.

4

Page 36

Features and Main Functions Section 1-1

CP1H CPU Unit Models

Model X CPU Units XA CPU Units Y CPU Units

CP1H-X40DR-A

(relay outputs)

Power supply 100 to 240 VAC

50/60 Hz

Program capacity 20K steps

Max. number of I/O points

320 300

(See note.)

Normal I/O I/O points 40 20

Input points 24 12

Input specifica-

24 VDC

tions

Interrupt or

8 max. 6 max.

quick-response

inputs

Output points 16 8

Output specifica-

Relay output Transis tor out-

tions

Highspeed

High-speed

counter inputs

4 axes, 100 kHz (single phase)/50 kHz (differential phases) 2 axes, 1 MHz

counter

inputs

Dedicated high-

None 2 axes, 1 MHz

speed counter

input terminals

Pulse outputs

Built-in I/O terminal allocation

Dedicated pulse

Unit version 1.0 and earlier: 2 axes; 100 kHz, 2 axes, 30 kHz

Unit version 1.1 and later: 4 axes, 100 kHz

None 2 axes, 1 MHz

output terminals

Built-in analog I/O None Analog voltage/current inputs: 4

CP1H-X40DT-D

(transistor

outputs,

CP1H-XA40DR-

A (relay

outputs)

sinking)

CP1H-X40DT1-

D (transistor

outputs,

sourcing)

24 VDC 100 to 240 VAC

50/60 Hz

Relay output Transistor out-

put

Analog voltage/current outputs: 2

CP1H-XA40DT-

D (transistor

outputs,

sinking)

CP1H-

XA40DT1-D

CP1H-Y20DT-D

(transistor

outputs,

sinking)

(to be released

soon)

(transistor

outputs,

sourcing)

24 VDC 24 VDC

Transistor out-

put

put

(single phase)/

50 kHz (differential phases)

(single phase)/

500 kHz (differential phases)

2 axes, 100 kHz

None

Note When CPM1A Expansion I/O Units are used.

Interpreting CP1H CPU Unit Model Numbers

Class

X: Basic model

XA: Built-in analog I/O terminals

Y: Dedicated pulse I/O terminals

Number of built-in

normal I/O points

40: 40

20: 20

Input classification

D: DC inputs

CP1H-@@@@@@-@

Power supply

A: AC

D: DC

Output classification

R: Relay outputs

T: Transistor outputs (sinking)

T1: Transistor outputs (sourcing)

5

Page 37

Features and Main Functions Section 1-1

k

1-1-2 Features

This section describes the main features of the CP1H.

Basic CP1H Configuration

CP1H CPU Unit (Example: XA)

CX-One

Two-digit 7-segment LED display

Input terminal bloc

Output terminal block

USB cable

Peripheral

USB port

Analog adjuster

External analog

settings input

Built-in analog

inputs

Built-in analog

outputs

(XA models only)

USB port

ON

123

4

Memory Cassette

Battery (CJ1W-BAT01)

Two Option Board slots

Faster Processing

Speed (All Models)

Option Board

CP1W-ME05M

Memory Cassette

One RS-232C port

CP1W-CIF01 RS-232C

Option Board

One RS-422A/485 port

CP1W-CIF11 RS-422A/485

Option Board

• Top-class performance has been achieved in a micro PLC, with an

instruction processing speed equivalent to the CJ1M.

• Approximately 500 instructions are processed at high speed.

• Program creation and contro l are simplifi ed by using function blocks (FB)

and tasks.

6

Page 38

Features and Main Functions Section 1-1

Full Complement of

High-speed Counter

Functions (All

Models)

High-speed counter inp uts can be enabled by connecting rota ry encoders to

the built-in inputs. The ample number of high-speed counter inputs ma kes it

possible to control a multi-axis device with a single PLC.

• X and XA CPU Units

Four 100-kHz (single phase)/50-kHz (differential phases) high-speed

counter inputs are provided as a standard feature. (See note.)

24 built-in inputs

(Functions can be assigned.)

High-speed counter

(4 axes)

100 kHz (single phase)

Note Settings in the PLC Setup determine whether each input point is to

be used as a normal input, interrupt input, quick-response input, or

high-speed counter.

• Y CPU Units

Along with two 100-kHz ( single phase)/50-k Hz (differential phases) highspeed counter inputs, two 1-MHz (single phase)/500-kHz (differential

phases) dedicated high-speed counter terminals are provided.

Dedicated pulse

inputs

Two high-speed

counters

1 MHz (for single phase)

12 built-in inputs

(Functions can be assigned.)

High-speed counter

(2 axes)

100 kHz (single phase)

Note Settings in the PLC Setup determine whether each input point is to

be used as a normal input, interrupt input, quick-response input, or

high-speed counter.

7

Page 39

Features and Main Functions Section 1-1

Full Complement of Highspeed Counter Functions

(All Models)

Versatile Pulse

Control (All Models)

High-speed Processing for High-speed Counter Present Value (PV)

Target Values or Range Comparison Interrupts

An interrupt ta sk can be star te d when the count r eaches a s pecified value or

falls within a specified range.

High-speed Counter Input Frequency (Speed) Monitoring

The input pulse fr equency can be moni tored using the PRV instruc tion (one

point only).

High-speed Counter PV Holding/Refreshing

It is possible to toggle between holding and refreshing the high-speed counter

PV by turning ON and OFF the High-speed Counter Gate Flag from the ladder

program.

Positioning and speed control by a pulse-in put servo driver is enabled by outputting fixed duty ratio p ulse output signals fr om the CPU Unit's built-in o utputs.

Four axes (X,Y, Z, and

θ) can be controlled. A 1 -M Hz s pee d pu ls e rate i s als o

possible for Y CPU Units.

• X and XA CPU Units

Pulse outputs for 4 axes at 10 0 kHz maximum ar e provided as st andard

features. (See note.) (Unit version 1.0 or earlier: Pulse outputs for 2 axes

at 100 kHz maximum and 2 axes at 30 kHz maximum.)

16 built-in inputs

(Functions assigned.)

Unit Ver. 1.0 or Earlier

2 pulse outputs

100 kHz

2 pulse outputs

30 kHz

Unit Ver. 1.1 or Later

4 pulse outputs

100 kHz

Note The instruction used to control each output point determines

whether it is used as a normal output, pulse output, or PWM output.

8

Page 40

Features and Main Functions Section 1-1

• Y CPU Units

Along with pulse outputs for two axes at 100 kHz maximum, dedicated

pulse output ter minals for two axes at 1 MHz are provided as standard

features. (See note.)

High-speed, high-p recision positioning by linear ser vomotor, d irect drive

motor, etc., is enabled using 1-MHz pulses.

Full Complement of Pulse

Output Functions (All

Models)

Dedicated pulse

outputs

2 pulse outputs

1 MHz

8 built-in I/O points

(Functions assigned)

2 pulse outputs

100 kHz

Note The instruction used to control each output point determines

whether it is used as a normal output, pulse output, or PWM output.

Select CW/CCW Pulse Outputs or Pulse Plus Direction Outputs for the

Pulse Outputs

The pulse outputs ca n be selected to m atch the pulse in put specification s of

the motor driver.

Easy Positioning with Absolute Coordinate System Using Automatic

Direction Setting

For operations in an absolute coordinate system (i.e., when the origin is

established or when the PV is ch anged by the INI instruc tion), the CW/CCW

direction can be automatically set when PULSE OUTPUT instructions are

executed according to whether the specifie d numbe r of output pulses i s more

or less than the pulse output PV.

Triangular Control

If the amount of output puls es required for acce leration and deceleration (th e

target frequency times the time to reach the target frequency) exceeds the

preset target number of output pulses during positioning (when the ACC

instruction in independent mode or the PLS2 instruction is executed), the

acceleration and d eceleration will be s hor tened and trian gular control w ill be

executed instead of trapezoidal control. In other words, the trapezoida l pulse

output will be eliminated, with no period of constant speed.

Target Position Changes during Positioning (Multiple Start)

While positioning using a PUL SE OUTPU T (PLS2) ins tructio n is in progre ss,

the target position, targe t speed, accelerati on rate, and deceleration rate can

be changed by executing another PLS2 instruction.

Positioning Changes during Speed Control (Interrupt Feeding)

While speed control in continuous mode is in effect, it is possible to change to

positioning in independent mode by executing a PULSE OUTPUT (PLS2)

instruction . By this means, int errupt feedin g (moving a spe cified am ount) ca n

be executed under specified conditions.

9

Page 41

Features and Main Functions Section 1-1

T ar get Speed, Acceleration Rate, and Deceleration Rat e Changes during

Acceleration or Deceleration

When a PULSE OUTPU T instr uct ion with trapezoidal acc elerat ion and de celeration is executed (for speed control or positioning), the target speed and

acceleration and deceleration rates can be changed during acceleration or

deceleration.

Lighting and Power Control by Outputting Variable Duty Ratio Pulses

Operations, such as lighting and power con trol, can be handl ed by outputting

variable duty ratio pulse (PWM) output signals from the CPU Unit's built-in

outputs.

Origin Searches (All

Models)

Input Interrupts (All

Models)

Note For each input point, a selection in the PLC Setup dete rm ines whether it is to

Quick-response

Inputs (All Models)

Note For each inp ut, a PL C Setu p pa r ame ter det ermines whe the r i t is t o be used as

Origin Search and Origin Return Operations Using a Single Instruction

An accurate origi n s ear c h co mb ini ng all I/O si gnals (origin pr oximity input signal, origin input sign al, positioning compl eted signal, error counte r reset output, etc.) can be executed with a sin gl e ins truction. It is also pos s ible to move

directly to an established origin using an origin return operation.

In direct mode, an interrupt task can be started when a built-in input tur ns ON

or OFF. In counter m ode, the rising or falling edges of built-in inputs can be

counted, and an interrupt task started when the count reaches a specified

value. The maximum number of points i s 8 for X and XA CPU Unit s and 6 for

Y CPU Units. (See note.)

be used as a normal input, interrupt input, quick-response input, or highspeed counter. The interrupt input re sponse frequ ency in count er mode must

be 5 kHz or less total for all interrupts.

By using quick-response i nputs, built-in inputs up to a minimum input signal

width of 30

µs can be read regardless of the cycle time.

The maximum number of points is 8 for X and XA CPU Units and 6 for Y CPU

Units. (See note.)

a normal input, interrupt input, quick-response input, or high-speed counter.

Analog I/O Function

(XA CPU Units Only)

10

XA CPU Units have analog I/O functionality, with 4 analog voltage/current

inputs and 2 analog voltage/current outputs built in.

4 analog inputs

ON

123

4

0 to 5 V, 1 to 5 V,

0 to 10 V, −10 to 10 V

0 to 20 mA, 4 to 20 mA

Inverter, etc.

2 analog outputs

0 to 5 V, 1 to 5 V,

0 to 10 V, −10 to 10 V

0 to 20 mA, 4 to 20 mA

• A wide range of applications is possible at a resolution of 6,000 or 12,000.

• Application is also possible for process-control sensor input or Inverter

control without using Expansion I/O Units.

Page 42

Features and Main Functions Section 1-1

Analog Settings (All Models)

Changing Settings Using

Analog Adjustment

Changing Settings Using

External Analog Setti ng

Inputs

By adjusting the analog adjuster with a Phillips screwdriver, the value in the

Auxiliary Area can be changed to any value between 0 and 255. This makes it

easy to change s et values s uc h as t ime rs and counters without Programming

Devices.