Page 1

CK3M-series

Programmable Multi-Axis Controller

Hardware

User's Manual

CK3M-CPU1£1

CK3W

CK3W-AX1313£/-AX1414£/-AX1515£/-AX2323£

CK3W-MD71£0

CK3W-AD£100

CK3W-EXM01/-EXS02

-PD048

Programmable Multi-Axis Controller

O036-E1-02

Page 2

NOTE

• All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or oth-

erwise, without the prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein.

Moreover

tion contained in this manual is subject to change without notice.

, because OMRON is constantly striving to improve its high-quality products, the informa-

• Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON as-

sumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Microsoft, Windows, Excel, and V

crosoft Corporation in the United States and other countries.

• EtherCAT

GmbH, Germany.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

®

is registered trademark and patented technology, licensed by Beckhoff Automation

isual Basic are either registered trademarks or trademarks of Mi-

Copyrights

• Microsoft product screen shots reprinted with permission from Microsoft Corporation.

• This product incorporates certain third party software. The license and copyright information associ-

ated with this software is available at

http://www.fa.omron.co.jp/nj_info_e/.

Page 3

Introduction

Thank you for purchasing a CK3M-series Programmable Multi-Axis Controller (may be called Motion

Controller hereinafter).

This manual contains information that is necessary to use the CK3M-series Programmable Multi-Axis

Controller. Please read this manual and make sure you understand the functionality and performance

of the product before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (electrical engineers or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• CK3M-series Programmable Multi-Axis Controller

CK3M-CPU1£1

CK3W-PD048

CK3W-AX1313£/-AX1414£/-AX1515£/-AX2323£

CK3W-MD71£0

CK3W-AD£100

CK3W-EXM01/-EXS02

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

1

Page 4

4-9

4

Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

s

t

i

n

U

gnitn

u

oM

3-4

4

s

t

ne

no

p

m

o

C

rel

l

o

r

t

n

oC

g

n

i

tc

e

n

noC

1

-

3-

4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

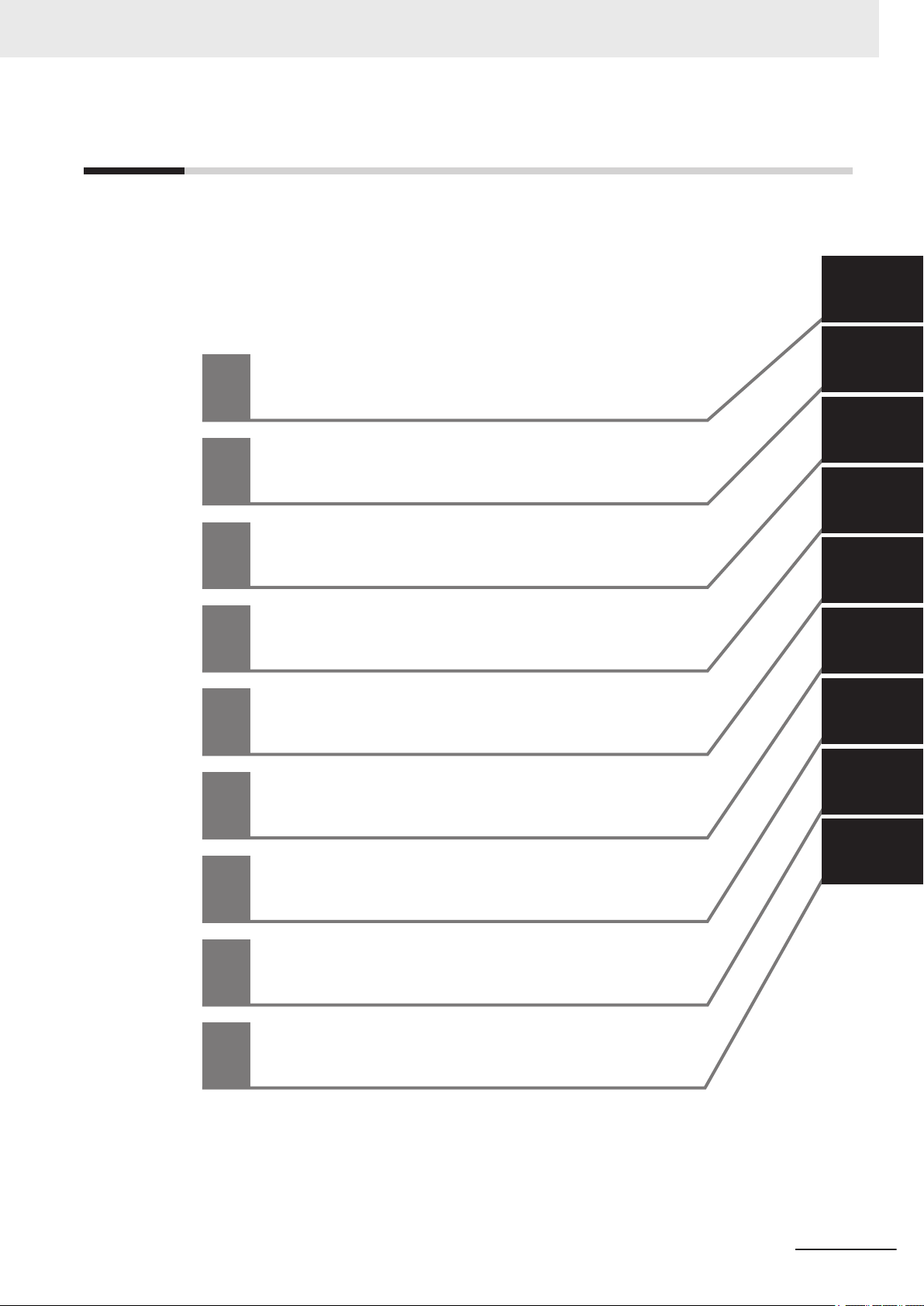

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU

Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

2

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 5

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure correct operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding and make operation easier

Manual Structure

.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

3

Page 6

Manual Structure

4

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 7

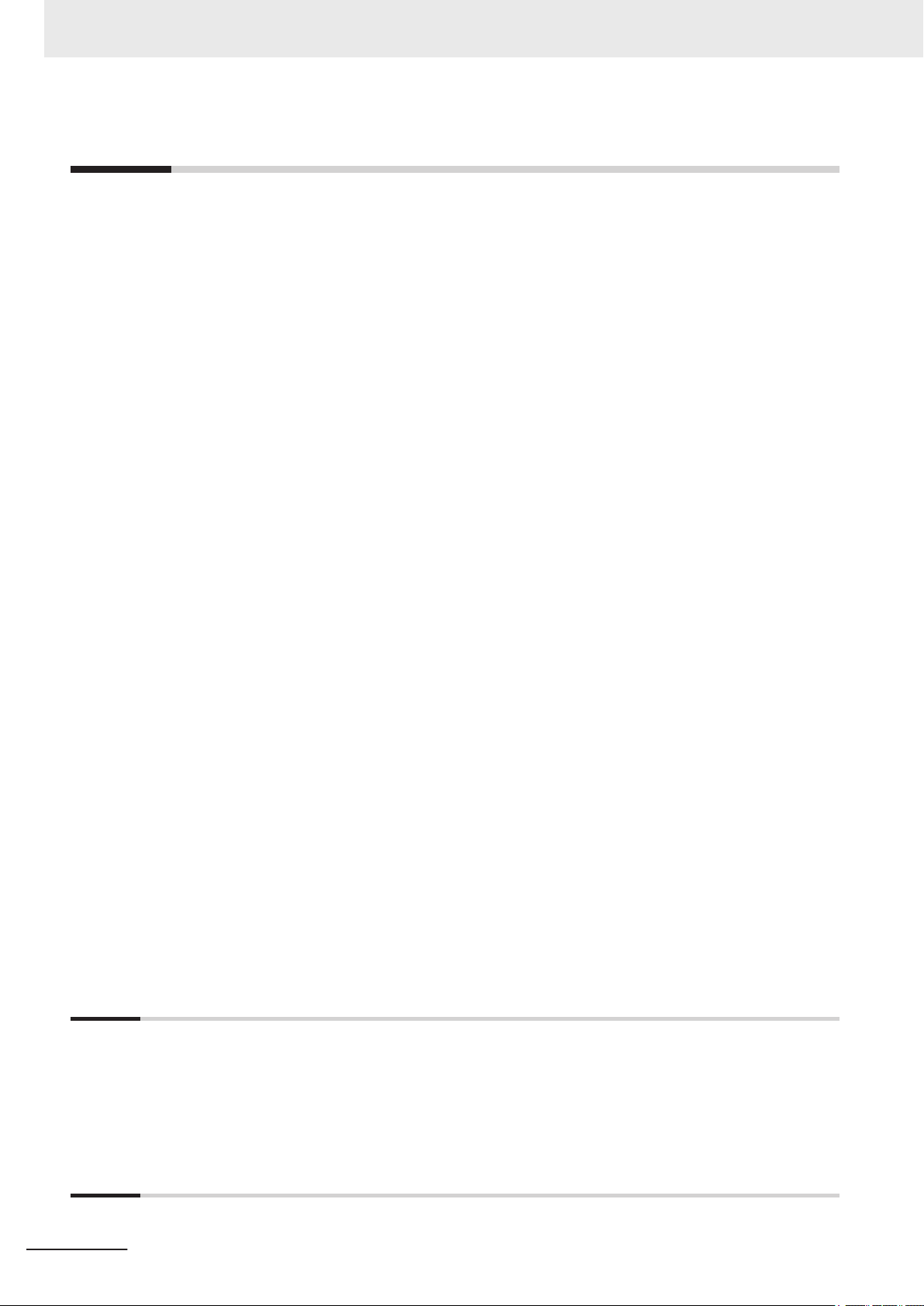

Sections in this Manual

1

2

3

4

5

1

2

3

4

5

A

Introduction to Motion Controllers

System Configuration

Configuration Units

Installation

W

iring

A

6

7

Appendices

6

7

Troubleshooting

Inspection and Maintenance

I

I

Index

Sections in this Manual

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

5

Page 8

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience

Applicable Products ......................................................................................................................................... 1

Manual Structure...................................................................................................... 2

Page Structure.................................................................................................................................................2

Special Information .......................................................................................................................................... 3

Sections in this Manual ........................................................................................... 5

Terms and Conditions Agreement........................................................................ 10

Warranty, Limitations of Liability ....................................................................................................................10

Application Considerations ............................................................................................................................11

Disclaimers ....................................................................................................................................................11

Safety Precautions................................................................................................. 13

Definition of Precautionary Information.......................................................................................................... 13

Symbols ......................................................................................................................................................... 13

WARNING......................................................................................................................................................14

Cautions.........................................................................................................................................................16

...........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 17

Precautions for Correct Use ................................................................................. 22

Regulations and Standards .................................................................................. 24

Conformance to EU Directives ......................................................................................................................24

Condition for Compliance with EU Directives ................................................................................................25

Conformance to UL and CSA Standards.......................................................................................................25

Conformance to KC Certification ...................................................................................................................25

Versions.................................................................................................................. 26

Checking Versions.........................................................................................................................................26

Related Manuals..................................................................................................... 27

Terminology............................................................................................................ 28

Revision History..................................................................................................... 29

Section 1 Introduction to Motion Controllers

1-1 Features and System Configuration ....................................................................................1-2

1-1-1

1-1-2 Introduction to the System Configurations ..................................................................................1-2

1-1-3 Support Software ........................................................................................................................1-4

1-2 CK3M-series Operating Procedure ......................................................................................1-5

Motion Controller Features..........................................................................................................1-2

Section 2 System Configuration

2-1 Basic Configuration...............................................................................................................2-2

6

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 9

2-1-1 CK3W Unit Configuration ............................................................................................................2-2

2-1-2

EtherCAT Network Configuration................................................................................................2-3

2-2 Connecting to the Power PMAC IDE .................................................................................... 2-5

2-3 Ethernet Network Configuration...........................................................................................2-6

Section 3 Configuration Units

3-1 CPU Unit .................................................................................................................................3-3

3-1-1

3-1-2 Part Names and Functions..........................................................................................................3-5

3-1-3 Operation Status Indicators.........................................................................................................3-6

3-1-4 Watchdog Output Terminal Block................................................................................................3-7

3-1-5 USB Memory Device...................................................................................................................3-8

3-2 Power Supply Unit ...............................................................................................................3-10

3-2-1 Models and Specifications ........................................................................................................3-10

3-2-2 Part Names and Functions........................................................................................................ 3-11

3-3 Axis Interface Unit ...............................................................................................................3-12

3-3-1 Models and Specifications ........................................................................................................3-12

3-3-2 Part Names and Functions........................................................................................................3-14

3-3-3 Operation Status Indicators.......................................................................................................3-15

3-3-4 Address Switch Setting .............................................................................................................3-16

3-3-5 Encoder Connector Specifications ............................................................................................3-16

3-3-6 Encoder Loss Detection ............................................................................................................3-21

3-3-7 Pulse Input Timing Specifications for Digital Quadrature Encoder............................................3-22

3-3-8 Input Specifications for Sinusoidal Encoder..............................................................................3-24

3-3-9 OutFlag Function.......................................................................................................................3-26

3-3-10 Amplifier Connector Specifications ...........................................................................................3-27

3-3-11 DA Output Method ....................................................................................................................3-30

3-3-12 DirectPWM Output Method .......................................................................................................3-31

3-3-13 Flag Connection Terminal Block Specifications ........................................................................3-32

3-3-14 General Digital I/O Connection Terminal Block Specifications..................................................3-36

3-4 Digital I/O Unit ......................................................................................................................3-43

3-4-1 Models and Specifications ........................................................................................................3-43

3-4-2 Part Names and Functions........................................................................................................3-47

3-4-3 Operation Indicators..................................................................................................................3-48

3-4-4 Address Switch Setting .............................................................................................................3-48

3-4-5 Terminal Arrangement...............................................................................................................3-49

3-4-6 I/O Data.....................................................................................................................................3-50

3-5 Analog Input Unit ................................................................................................................. 3-52

3-5-1 Models and Specifications ........................................................................................................3-52

3-5-2 Part Names and Functions........................................................................................................3-53

3-5-3 Operation Indicators..................................................................................................................3-54

3-5-4 Address Switch Setting .............................................................................................................3-54

3-5-5 Terminal Arrangement...............................................................................................................3-55

3-5-6 Analog Input Data .....................................................................................................................3-56

3-5-7 Input Filter .................................................................................................................................3-57

3-6 Expansion Master Unit and Expansion Slave Unit ...........................................................3-59

3-6-1 Models and Specifications ........................................................................................................3-59

3-6-2 Part Names and Functions........................................................................................................3-60

3-6-3 Operation Indicators..................................................................................................................3-60

3-6-4 System Configuration................................................................................................................3-60

Models and Specifications ..........................................................................................................3-3

CONTENTS

Section 4 Installation

4-1 Processing at Power ON and Power OFF............................................................................4-2

4-1-1

4-1-2 Power OFF Operation .................................................................................................................4-2

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Power ON Operation...................................................................................................................4-2

7

Page 10

CONTENTS

4-2 Fail-safe Circuits .................................................................................................................... 4-4

4-3

Mounting Units.......................................................................................................................4-5

4-3-1 Installation in a Control Panel .....................................................................................................4-5

4-3-2 Connecting Adjacent Units..........................................................................................................4-9

4-3-3 Mounting to DIN Track ..............................................................................................................4-10

4-3-4 DIN Track and Accessories.......................................................................................................4-12

4-3-5 Assembled Appearance and Dimensions .................................................................................4-13

4-4 Control Panel Installation....................................................................................................4-17

4-4-1 Temperature ..............................................................................................................................4-17

4-4-2 Humidity ....................................................................................................................................4-18

4-4-3 Vibration and Shock ..................................................................................................................4-19

4-4-4 Atmosphere...............................................................................................................................4-19

4-4-5 Electrical Environment ..............................................................................................................4-19

4-4-6 Grounding .................................................................................................................................4-24

Section 5 Wiring

5-1 Power Supply Wiring ............................................................................................................. 5-2

5-1-1

5-1-2 Power Supply Used.....................................................................................................................5-2

5-1-3 Applicable Wires .........................................................................................................................5-2

5-1-4 Grounding ...................................................................................................................................5-3

5-1-5 Required Tools ............................................................................................................................5-4

5-1-6 Connecting Ferrules....................................................................................................................5-4

5-1-7 Connecting Twisted Wires/Solid Wires .......................................................................................5-4

5-1-8 Removing Wires..........................................................................................................................5-5

5-2 CPU Unit Wiring .....................................................................................................................5-7

5-2-1 Laying the EtherCAT Network .....................................................................................................5-7

5-2-2 Laying the Ethernet Network.....................................................................................................5-12

5-2-3 Watchdog Timer Output Wiring .................................................................................................5-15

5-2-4 USB Memory Device Connection..............................................................................................5-17

5-3 Axis Interface Unit Wiring ...................................................................................................5-18

5-3-1 Encoder Connector Wiring ........................................................................................................5-18

5-3-2 Amplifier Connector Wiring .......................................................................................................5-24

5-3-3 Flag Terminal Block/General I/O Terminal Block Wiring............................................................5-26

5-4 Digital I/O Unit Wiring .......................................................................................................... 5-33

5-4-1 Wiring the Terminals..................................................................................................................5-33

5-4-2 Precautions When Connecting a Two-wire DC Sensor.............................................................5-36

5-4-3 Precautions When Connecting to Digital Output.......................................................................5-38

5-5 Analog Input Unit Wiring.....................................................................................................5-40

5-5-1 Wiring the Terminals..................................................................................................................5-40

5-6 Expansion Master Unit and Expansion Slave Unit Wiring ............................................... 5-44

Power Supply Unit CK3W-PD048 ...............................................................................................5-2

Section 6 Troubleshooting

6-1 Types of Errors.......................................................................................................................6-2

6-2

Using the Indicators to Check Errors ..................................................................................6-3

6-2-1 Indicator Types............................................................................................................................6-3

6-2-2 Procedure for Identifying Errors ..................................................................................................6-3

6-3 Troubleshooting for Errors ................................................................................................... 6-5

6-3-1 Fatal Errors in the CPU Unit........................................................................................................6-5

6-3-2 Non-fatal errors in the CPU Unit .................................................................................................6-6

6-3-3 Initialization of CPU Unit Using USB Memory.............................................................................6-8

6-4 Sys.Status Register ...............................................................................................................6-9

6-4-1 Sys.Status Register List ..............................................................................................................6-9

6-4-2 Details of Flags ...........................................................................................................................6-9

8

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 11

Section 7 Inspection and Maintenance

7-1 Cleaning and Maintenance....................................................................................................7-2

7-1-1

7-1-2 Periodic Inspections ....................................................................................................................7-2

7-2 Maintenance Procedures ......................................................................................................7-4

7-2-1 Unit Replacement Precautions....................................................................................................7-4

7-2-2 Backup ........................................................................................................................................7-4

7-2-3 Unit Replacement........................................................................................................................7-4

Cleaning ......................................................................................................................................7-2

Appendices

A-1 General Specifications ......................................................................................................... A-2

A-2

Dimensions............................................................................................................................ A-3

A-2-1 CPU Unit .................................................................................................................................... A-3

A-2-2 Power Supply Unit...................................................................................................................... A-4

A-2-3 Axis Interface Unit ...................................................................................................................... A-4

A-2-4 CK3W-MD and CK3W-AD Units ................................................................................................ A-5

A-2-5 Expansion Master Unit and Expansion Slave Unit..................................................................... A-6

A-2-6 End Cover .................................................................................................................................. A-7

A-3 Restrictions on Using the NX-series EtherCAT Coupler Unit........................................... A-8

A-4 OMRON Servo Drive Connection Example......................................................................... A-9

A-5 Version Information ............................................................................................................ A-10

A-6 How to Read the Lot Number............................................................................................. A-11

CONTENTS

Index

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

9

Page 12

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return

of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or any other

materials or substances or environments. Any advice, recommendations or information given orally

or in writing, are not to be construed as an amendment or addition to the above warranty.

10

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 13

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

W

ARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer

er’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

Terms and Conditions Agreement

’s application or use of the Product. At Buy-

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

. It may represent the result of

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

, some specifications of the Product may

11

Page 14

Terms and Conditions Agreement

be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for your application. Please consult with your Omron’

time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however

, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

s representative at any

12

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 15

Safety Precautions

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Additionally, there may be severe property

damage.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate

injury, or property damage.

WARNING

C

aution

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the CK3M-series Programmable Multi-Axis Controller.

The safety precautions that are provided are extremely important for safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

Safety Precautions

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the

This example indicates that disassembly is prohibited.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the

This example indicates a precaution for electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the

This example shows a general precaution for something that you must do.

circle and explained in text.

triangle and explained in text.

triangle and explained in text.

circle and explained in text.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

13

Page 16

WARNING

Internal

power

supply

circuit

(Non-isolat-

ed)

Power Supply Unit

Cable

External device

External power supply

Power supply

connection

terminal block

Non-isolated DC

power supply

CK3W Unit

+

-

Safety Precautions

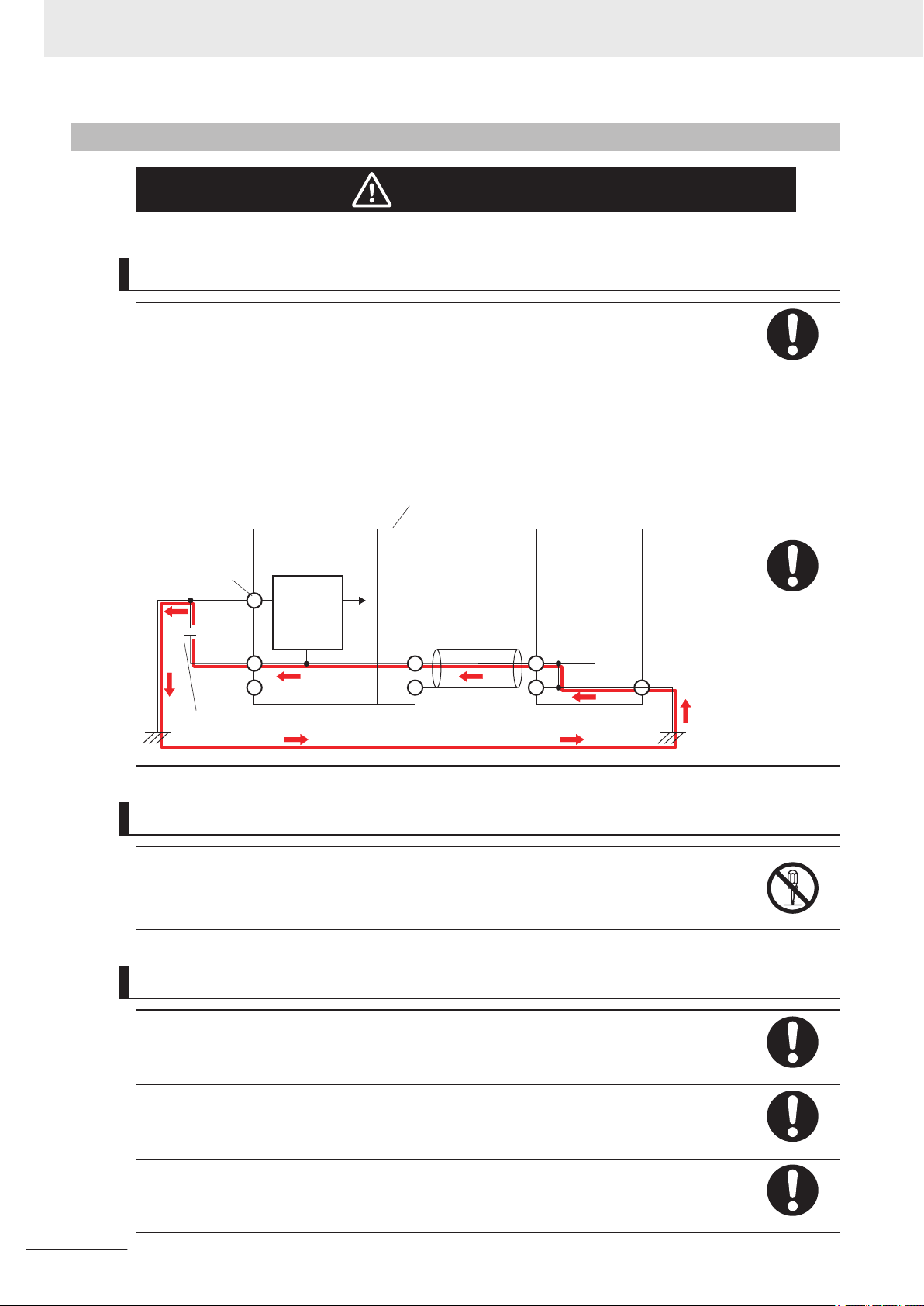

WARNING

Wiring

Connect this Controller correctly to the servo amplifier, encoder, and limit sensors according to the instructions in this manual. Not doing so may cause the motor to run

away

, resulting in serious accidents.

For the Power Supply Unit or any other power supply connected to peripheral devices,

connect the 0-V side to ground, or do not ground them at all.

Depending on how devices connected to the non-insulated circuit are grounded, the

power supply may be short-circuited.

Never ground the 24-V side of the power supply

, as shown in the following figure.

14

During Power Supply

Do not attempt to take any Unit apart.

In particular

, high-voltage parts are present in the Power Supply Unit while power is

supplied or immediately after power is turned OFF. Touching any of these parts may

result in electric shock. There are sharp parts inside the Unit that may cause injury.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if an abnormality occurs due to malfunction of the products or due to other external factors af

ing operation. Not doing so may result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures

must be provided in external control circuits.

You must take fail-safe measures to ensure safety in the event of incorrect, missing, or

abnormal signals caused by broken signal lines, momentary power interruptions, or

other causes.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

fect-

Page 17

Safety Precautions

The UPS used enables normal operation to continue for a certain period of time if a

momentary power interruption occurs. This means that the CK3M-series Controller

may receive incorrect signals from external devices that are also af

interruption. Accordingly, take suitable actions, such as establishing external fail-safe

measures and interlock conditions, to monitor the power supply voltage of the external

device as required.

Unintended outputs may occur if an error occurs in internal data of the Controller. As a

countermeasure for these problems, external safety measures must be provided to ensure safe operation of the system.

The Controller will turn OFF all outputs of output units in the following cases and the

slaves will operate according to the settings in the slaves.

•

If a power supply error occurs

• If the connected power supply is faulty

• If a CPU Unit error (watchdog timer error) or CPU Unit reset occurs

• If a major fault level Controller error occurs

• While the Controller is on standby until RUN mode is entered after the power is

turned ON

• If a system initialization error occurs

External safety measures must be provided to ensure safe operation of the system in

such cases.

The outputs may remain ON or OFF due to welding or burning of the output relays or

destruction of the output transistors. As a countermeasure for these problems, external

safety measures must be provided to ensure safe operation of the system.

fected by the power

To ensure safe use of the Controller, correctly make the limit settings for the position,

speed, acceleration, jerk, current, and following error

tection.

For devices that move in a vertical direction, use a motor brake to prevent them from

falling down when the servo control is stopped.

, as well as the encoder loss de-

Downloading

Always confirm safety at the destination before you transfer a user program, configuration data, or setup data from the Power PMAC IDE.

The devices or machines may perform unexpected operation regardless of the operating mode of the Controller

After you transfer the user program, the Controller is restarted and communications

with the EtherCA

cording to the slave specifications.

The time that communications are cut off depends on the EtherCAT network configuration.

Before you transfer the user program, confirm that the system will not be adversely affected.

T slaves are cut off. During that period, the slave outputs behave ac-

.

Test Run

Before you start a Test Run, make sure that the operation parameters are set correctly.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

15

Page 18

Caution

Safety Precautions

Actual Operation

Check the user program, servo algorithm, data, and parameter settings for proper execution before you use them for actual operation.

Cautions

Design

To control the motor safely and correctly, the servo algorithm design and gain setting

work must be performed by engineers who understand control theories and the specifications of this product.

Test Run

When you perform a test run, take fail-safe measures and run the motor at a sufficiently low speed to ensure safety

.

Downloading

Before you download a project written in C language, execute the re-initialization command ($$$***).

If you download a validated program to a different product, check the operation of the

program again on the product because it may have dif

ferent settings.

16

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 19

Precautions for Safe Use

Transporting

• Do not drop any Unit or subject it to abnormal vibration or shock. Doing so may result in Unit malfunction or burning.

Mounting

• Be sure that the terminal blocks, connectors, and other items with locking devices are correctly

locked into place before use.

• When connecting the Power Supply Unit, CPU Unit, and CK3W Unit, connect the Units together,

then slide the sliders on the top and bottom until they click into place, and lock securely.

• Always mount an end cover for use. Note that if an end cover is not mounted, the Unit may not function satisfactorily.

• The number of CK3W Units connected to the CPU Unit must be within the specified range.

Precautions for Safe Use

Installation

• Always connect to a ground of 100 Ω or less when installing the Units.

• For DIN Track installation, correctly follow the instructions in this manual.

Wiring

• Follow the instructions in this manual to correctly perform terminal block and connector wiring and

insertion.

Double-check all wiring and connector insertion before turning ON the power supply.

• If the external power supply to a digital output or a slave has polarity, connect it with the correct polarity.

If the polarity is reversed, current may flow in the reverse direction and damage the connected devices regardless of the operation of the Controller.

• Before you connect a computer to the Controller, disconnect the power supply plug of the computer

from the AC outlet.

Also, if the computer has an FG terminal, connect it such that the FG terminal has the same electrical potential as the FG on the product.

A difference in electrical potential between the computer and the Controller may cause a failure or

malfunction.

• Do not pull on the cables or bend the cables beyond their natural limit.

• Do not place heavy objects on top of the cables or other wiring lines. Doing so may break the cables.

• Always use power supply wires with sufficient wire diameters to prevent voltage drop and burning.

Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be generated.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

17

Page 20

Precautions for Safe Use

When cross-wiring terminals, the total current for all the terminals will flow in the wire. When wiring

cross-overs, make sure that the current capacity of each of the wires is not exceeded.

•

Do not allow wire clippings, shavings, or other foreign material to enter the Controller. Otherwise,

Controller burning, failure, or malfunctions may occur.

Cover the Controller or take other suitable countermeasures, in particular when carrying out wiring

work.

• To ensure safe use of the functions of the CK3W Units, observe the following points when wiring to

avoid the effects of the noise.

a) Use twisted-pair shielded wire for the encoder connection lines, amplifier connection lines, and

analog input lines.

b) Wire the encoder connection lines, amplifier connection lines, and analog input lines separately

from the AC power lines, motor power lines, and other power lines, and do not insert into the

same duct.

c) If there are noise effects from power supply lines when using the same power supply to power

an electrical welder or an electric discharge machine, or there is a high-frequency source nearby,

insert a noise filter into the power supply input section.

Power Supply Design

• In the system, only use a power supply within the rated supply capacity range specified in this manual.

•

Install external breakers and take other safety measures against short-circuiting and overcurrents in

external wiring.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

• Do not apply voltages or connect loads to the Output Units in excess of the maximum switching capacity.

Turning ON the Power Supply

• It takes approximately several tens of seconds to enter RUN mode after the power supply is turned

ON. During that time, outputs will be OFF or the values will be as according to settings in the Unit or

slaves. Also, external communications will not be able to be performed. Implement fail-safe circuits

so that external devices do not operate incorrectly

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to this user's manual for surge current specifications.

• Configure the external circuits so that the power supply to the digital output turns ON only after the

power supply to the Controller has turned ON.

If the power supply to the Controller is turned ON after the digital output power supply, the digital

output may suddenly malfunction when the power supply is turned ON to the Controller.

.

18

Actual Operation

• Build a program such that the Sys.Status flag is constantly monitored and safe operations are taken

if any errors occur

.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 21

Precautions for Safe Use

Turning OFF the Power Supply

• Do not turn OFF the power supply or remove the USB memory device while the Controller is accessing the USB memory device. Data may become corrupted, and the Controller will not operate

correctly if it uses corrupted data.

•

Always turn OFF the power supply before you attempt any of the following.

a) Mounting or removing the Units

b) Assembling the Units

c) Setting rotary switches

d) Connecting cables or wiring the system

e) Connecting or disconnecting the terminal blocks or connectors

• Do not disconnect the cable or turn OFF the power supply to the product when downloading data or

programs from the Support Software. You may be unable to download the correct data, which could

result in malfunctions.

• Do not turn OFF the power supply when performing write processes to the built-in flash memory.

Data may be corrupted, which could result in malfunctions.

Operation

Confirm that no adverse effects will occur in the system before you attempt any of the following.

•

Changing the operating mode of the Controller (including changing operation mode setting when

power is turned ON)

• Changing the user program or settings

• Changing set values or present values

EtherCAT Communications

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCA

Do not connect EtherCAT communication to EtherNet/IP, a standard in-house LAN, or other networks. An overload may cause the network to fail or malfunction.

• If the Fail-soft Operation Setting parameter is set to Stop, process data communications will stop

for all the slaves when an EtherCAT communications error is detected in a slave. This means that if

a Servo Drive is connected, the Servo turns OFF for all the axes. At that time, the Servo Drive will

operate according to the Servo Drive specifications. Make sure that the fail-soft operation setting results in safe operation when a device error occurs.

• If noise occurs or an EtherCAT slave is disconnected from the network, any current communications

frames may be lost. If frames are lost, slave I/O data is not communicated, and unintended operation may occur. The slave outputs will behave according to the slave specifications. For details, refer

to the manual for the slave.

• When an EtherCAT slave is disconnected or disabled, communications will stop and control of the

outputs will be lost not only for the disconnected slave, but for all slaves connected after it. Confirm

that the system will not be adversely affected before you disconnect or disable a slave.

• You cannot use standard Ethernet hubs or repeater hubs with EtherCAT communications. If you use

one of these, a major fault level error or other error may occur.

T are within specifications.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

19

Page 22

Precautions for Safe Use

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables and the EtherCA

program to confirm that I/O data communications are established before attempting control operations.

• If you need to disconnect the cable from an EtherCAT slave during operation, first reset the EtherCAT and EtherCAT slaves that are connected after it to the Init state, then disconnect the EtherCAT

slave.

• For EtherCAT and EtherNet, use the connection methods and cables that are specified in this manual. Otherwise, communications may be faulty.

• Make sure that all of the slaves to be restored are participating in the network before you reset the

EtherCAT Master Function Module. If any slave is not participating in the network when any of these

errors is reset, the EtherCAT Master Function Module may access a slave with a different node address than the specified node address, or the error may not be reset correctly.

• There is a time lag between the moment when this Controller sends a command value to the EtherCAT type Servo Drive and the moment when it receives the feedback value. Perform servo control

taking this time lag into consideration.

T Coupler Unit device variables in the user

Motion Control

• The motor is stopped if communications are interrupted between the Power PMAC IDE and the

Controller during a T

tem will not be adversely affected before you perform a Test Run.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are established before attempting control operations.

• When you create a servo algorithm, take fail-safe measures in the user program which includes the

servo algorithm.

est Run. Connect the communications cable securely and confirm that the sys-

Unit Replacement

• Make sure that the required data, including the user program, configurations, settings, and variables, is transferred to the Controller that was replaced and to externally connected devices before

restarting operation.

Upgrading the Power PMAC IDE

20

• After you upgrade a project file created with an older version of the Power PMAC IDE for use with a

newer version of Power PMAC IDE, perform a test run before use to check that the project file was

upgraded correctly

.

Maintenance

• Do not attempt to disassemble, repair, or modify the Controller. Doing so may result in a malfunction

or fire.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 23

Precautions for Safe Use

• Do not use corrosive chemicals to clean the Controller. Doing so may result in a failure or malfunction of the Controller

• Dispose of the product according to local ordinances as they apply.

.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

21

Page 24

Precautions for Correct Use

Precautions for Correct Use

Storage and Installation

• Follow the instructions in this manual to correctly perform installation.

• Do not operate or store the Controller in the following locations. Doing so may result in burning, in

operation stopping, or in malfunction.

a) Locations subject to direct sunlight

b) Locations subject to temperatures or humidity outside the range specified in the specifications

c) Locations subject to condensation as the result of severe changes in temperature

d) Locations subject to corrosive or flammable gases

e) Locations subject to dust (especially iron dust) or salts

f) Locations subject to exposure to water, oil, or chemicals

g) Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Controller in the following locations.

a) Locations subject to strong, high-frequency noise

b) Locations subject to static electricity or other forms of noise

c) Locations subject to strong electromagnetic fields

d) Locations subject to possible exposure to radioactivity

e) Locations close to power lines

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up.

• Install the Controller away from sources of heat and ensure proper ventilation. Not doing so may result in malfunction, in operation stopping, or in burning.

Wiring

• Use the rated power supply voltage for the products.

Task Settings

• If a Task Period Exceeded error occurs, shorten the programs to fit in the task period or increase the

setting of the task period.

During Operation

• Do not disconnect the communications cable while the system is running. Doing so may result in a

failure or malfunction of the system.

Motion Control

• Do not download motion control settings during a Test Run.

22

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 25

Precautions for Correct Use

EtherCAT Communications

• Set the Servo Drives to stop operation if an error occurs in EtherCAT communications between the

Controller and a Servo Drive.

•

Always use the specified EtherCAT slave cables. If you use any other cable, the EtherCAT master

or the EtherCAT slaves may detect an error and one of the following may occur.

a) Continuous refreshing of process data communications will not be possible.

b) Continuous refreshing of process data communications will not end during the set cycle

USB Devices

• Always use USB memory devices that comply with the USB standards.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

23

Page 26

Regulations and Standards

Regulations and Standards

Conformance to EU Directives

Applicable Directives

• EMC Directives

Concepts

EMC Directives

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*1

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with

EU Directives will vary depending on the configuration, wiring, and other conditions of the equipment or control panel on which the OMRON devices are installed. The customer must, therefore,

perform the final check to confirm that devices and the overall machine conform to EMC standards.

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows: EMS (Electromagnetic Suscept-

ibility): EN61326 EMI (Electromagnetic Interference): EN61326 (Radiated emission: 10-m regulations).

Conformance to EU Directives

The CK3M-series Units comply with EU Directives. To ensure that the machine or device in which

the CK3M-series Units are used complies with EU Directives, the following precautions must be observed.

• The CK3M-series Units must be installed within a control panel.

• You must use double or reinforced insulation power supply for the DC power supplies that are

connected as the Unit power supplies for the CK3M-series Units.

We recommend that you use the OMRON S8VK-S series DC Power Supplies. EMC standard

compliance was confirmed for the recommended Power Supplies.

• The CK3M-series Units that comply with EU Directives also conform to the Common Emission

Standard (EN61326). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment in which the CK3M-series

Units are used complies with EU Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate

measures.

24

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 27

Condition for Compliance with EU Directives

The immunity test condition for the CK3M-series Analog Input Units is as shown below.

Unit type Overall accuracy

Analog Input Unit +6%/-6%

To connect an Analog Input Unit, use 2-core twisted-pair shielded wire. Note that compliance was confirmed with the shielded wire grounded at both ends.

Conformance to UL and CSA Standards

The CK3M-series Units comply with UL and CSA standards.

For how to make your machine or device compliant with these standards, refer to the INSTRUCTION

SHEET

The INSTRUCTION SHEET provides usage conditions to make it compliant with the standards.

included with the product.

Regulations and Standards

Conformance to KC Certification

When you use this product in South Korea, observe the following precautions.

This product meets the electromagnetic compatibility requirements for business use. There is a risk of

radio interference when this product is used in home.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

25

Page 28

Enter “vers”

Versions

Versions

PMAC firmware revisions are used to manage the motion control firmware in CK3M-series CPU Units.

The PMAC firmware revision is updated each time there is a change in motion control firmware. Even

when two CPU Units have the same model number, they will have functional or performance differences if they have different PMAC firmware revisions.

Checking Versions

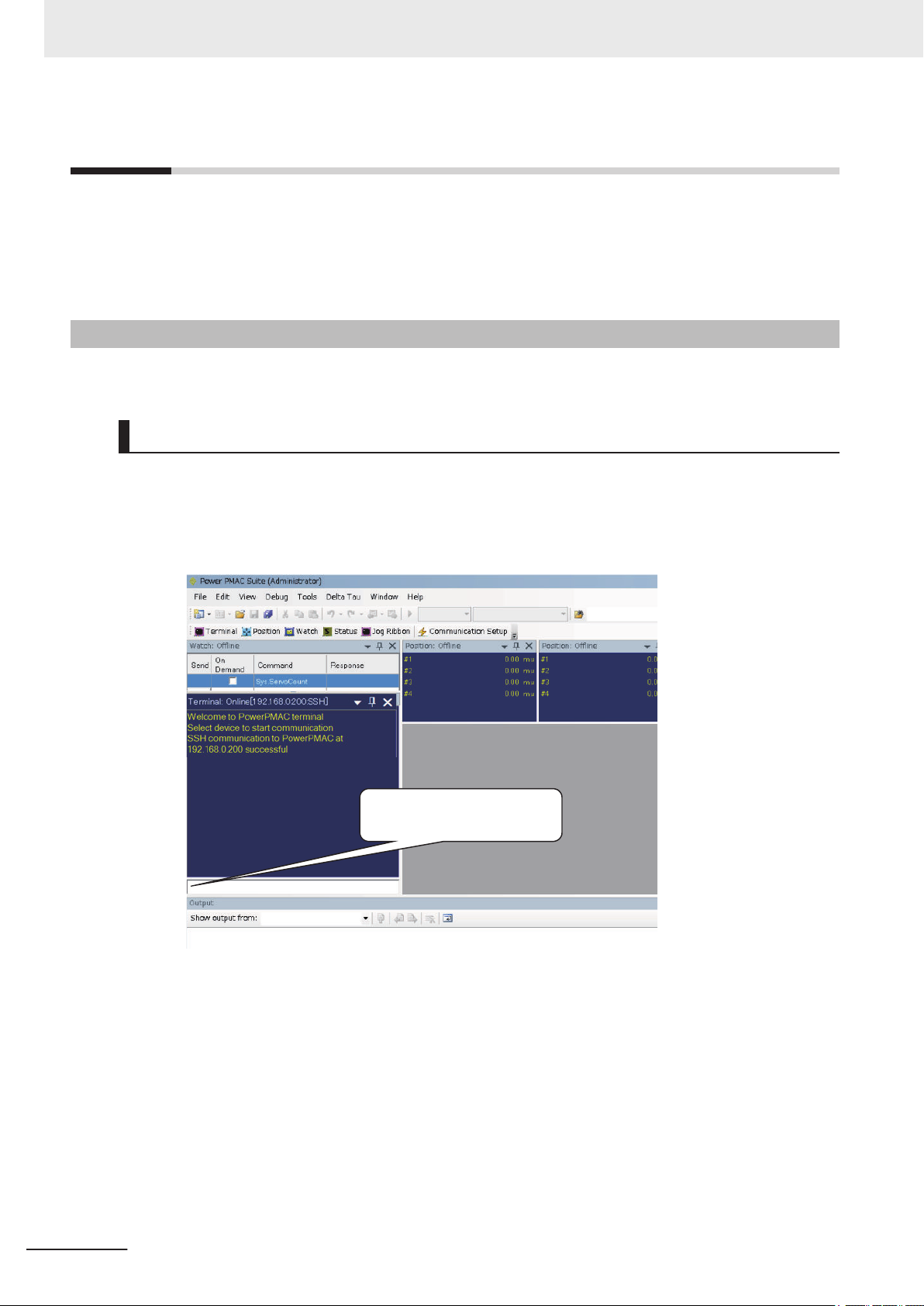

You can check the PMAC firmware revision in Power PMAC IDE.

Checking with Power PMAC IDE

1 Connect the CK3M-series CPU Unit and Power PMAC IDE online.

2 Input vers to the terminal window

.

26

The firmware revision is displayed on the command line.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 29

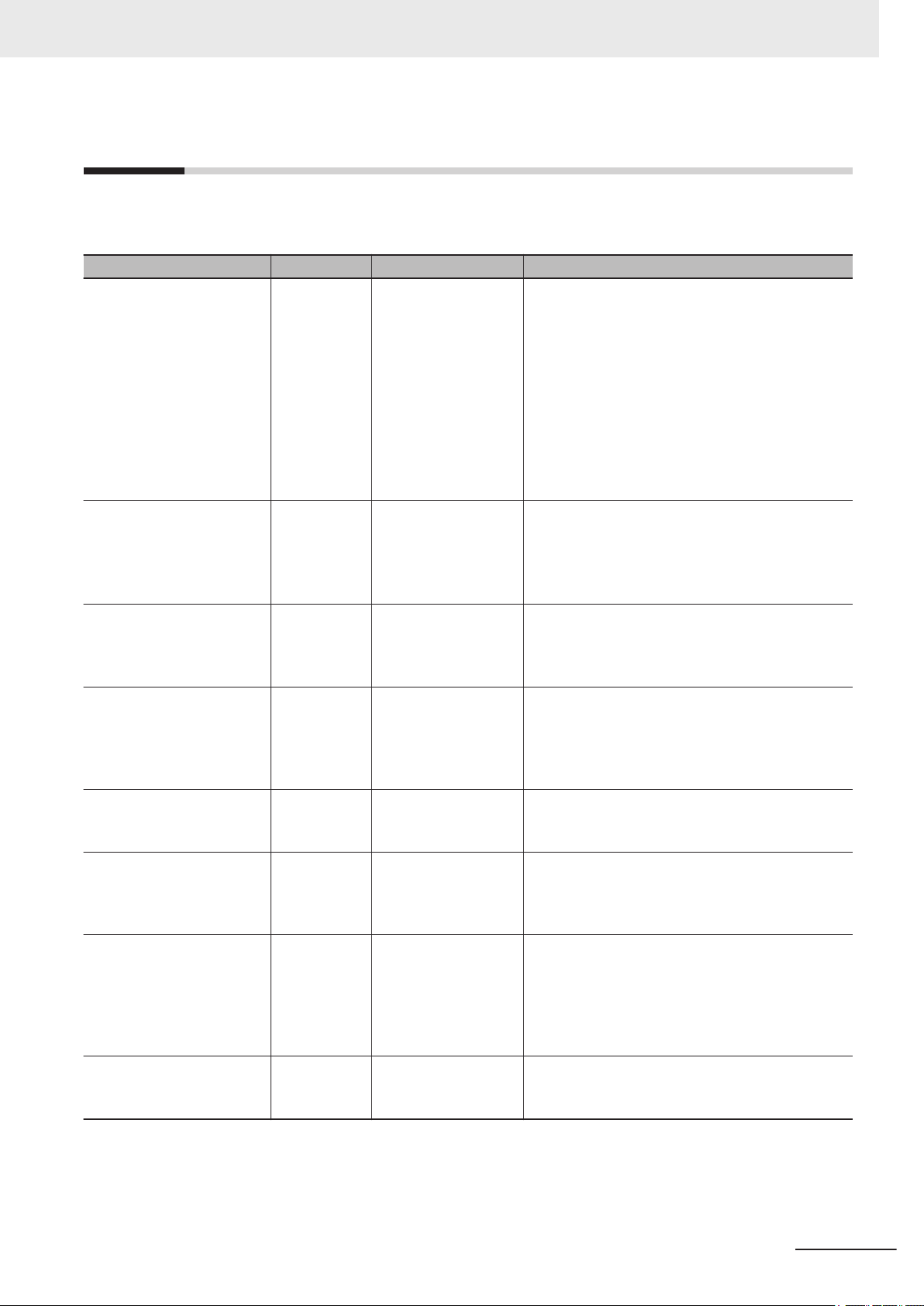

Related Manuals

The following manuals are related. Use these manuals for reference. Contact your OMRON representative for information on how to procure these manuals.

Manual name Cat. No. Application Description

CK3M-series Programmable Multi-Axis Controller

Hardware User

Power PMAC User’s Manual

Power PMAC Software Reference Manual

Power PMAC IDE User

Manual

Power PMAC-NC-16 Quick

Start Manual

Power PMAC-NC16 .ini

Configuration Manual

Power PMAC-NC16 Software User Manual

Power PMAC-NC16 Mill GCode Manual

’s Manual

O036 Learning the basic

O014 Learning the features

O015 Learning how to pro-

O016 Learning how to oper-

O017 Briefly understanding

O018 Configuring an appli-

O019 Learning about usage

O020 Creating programs for

specifications of the

CK3M-series Programmable Multi-Axis

Controller, including

introductory information, design, installation, and maintenance.

Mainly hardware information is provided.

and usage examples

of the

CK3M-series

Programmable MultiAxis Controller.

gram a CK3M-series

Programmable MultiAxis Controller

ate Power PMAC IDE,

the integrated development environment

of the Controller.

the basic usage of

Power PMAC-NC16.

cation for CNC devices by using Power

PMAC-NC16.

and features of Power

PMAC-NC16, Support

Software required to

use the Controller for

CNC devices.

CNC devices by using

Power PMAC-NC16.

.

Related Manuals

An introduction to the entire CK3M-series system

is provided along with the following information.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided on the

CK3M-series Programmable Multi-Axis Controller.

• Basic functions

• Setup examples

• Programming examples

The following information is provided on the

CK3M-series Programmable Multi-Axis Controller.

• Details of commands

• Details of data structure

Describes the operating procedures of Power

PMAC IDE, and examples of how to start the system.

Describes the Quick setup procedure to run Power

PMAC-NC16 on a desktop PC by showing some

examples.

Describes how to set up PowerPmacNC.ini, the

setup data file to be loaded when Power PMACNC16 starts.

The following information is provided on Power

PMAC-NC16.

• How to use the software

• Features included in the software

• Features that can be customized

Describes the basic G-code set that can be used

for Power PMAC-NC16, and relevant instructions.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

27

Page 30

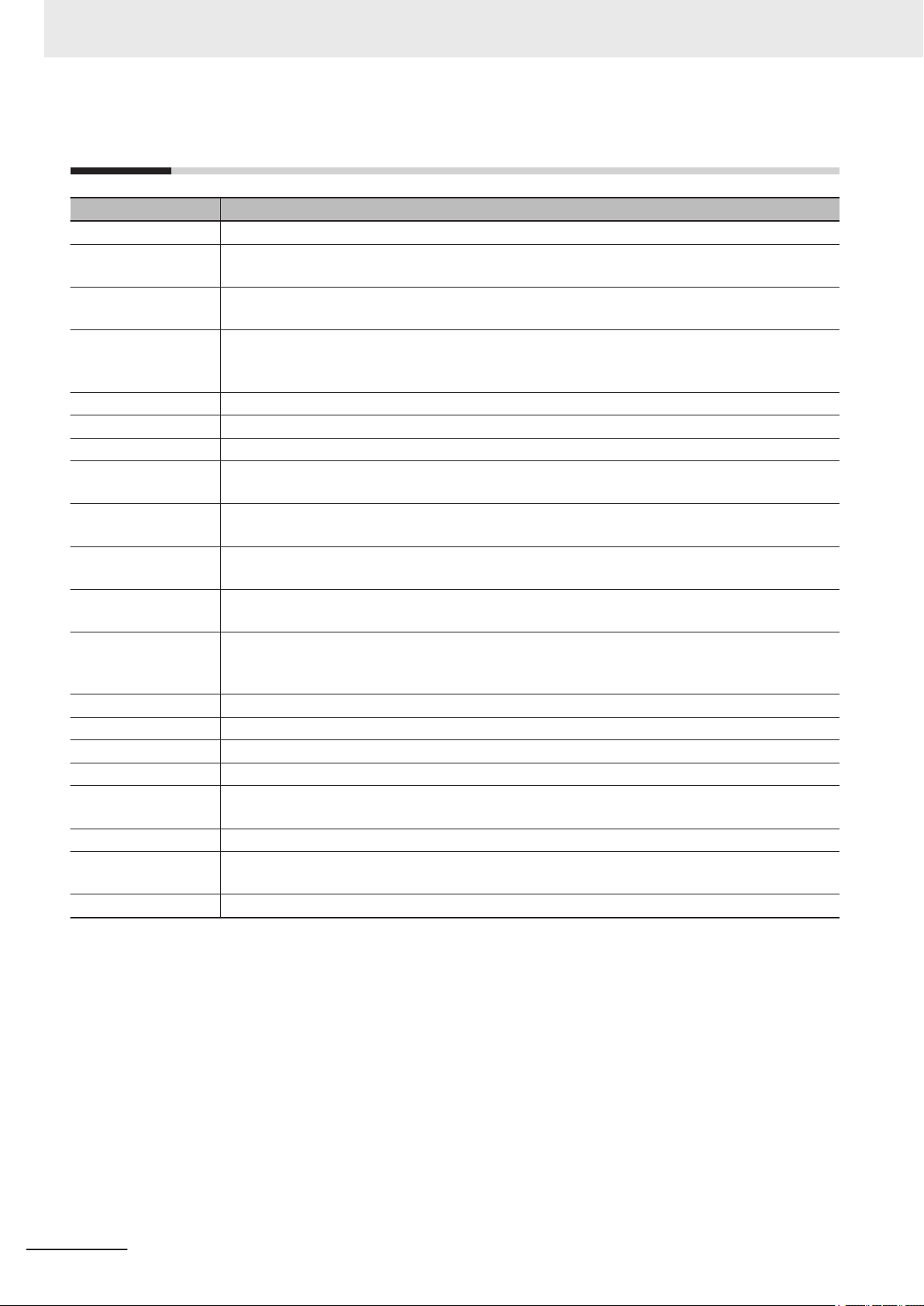

Terminology

Terminology

Term Description

PMAC The acronym for Programmable Multi-Axis Controller.

Motion control Motion control can achieve intended operation by providing a target value to the axis to be con-

trolled, or by controlling state transitions.

Axis A functional unit within the Motion Control Function Module. An axis is assigned to the drive

mechanism in an external Servo Drive, etc.

NC The acronym for Computerized Numerical Control.

A method to numerically control machining processes in production by using computers. CNC has

been further automatized over conventional numerical control machine tools (NC machine tools).

G-code A type of language used to create NC programs.

CPU Central Processing Unit. Hardware that executes instructions from computer programs.

MODBUS/TCP A protocol used for the Modbus communications on TCP/IP.

EtherCAT The acronym for Ethernet for Control Automation Technology.

EtherCA

ENI file ENI is the acronym for EtherCAT Network Information.

The ENI file contains the network configuration information related to EtherCA

ESI file ESI is the acronym for EtherCAT Slave Information.

The ESI file contains information unique to the EtherCA

PMAC3 Style

DSPGate3 IC

Gate3 index IC index for PMAC3 Style DSPGate3 IC.

DirectPWM A Servo Drive interface unique to Delta Tau Data Systems, Inc.

FilteredPWM Method for creating analog output by smoothing the PWM pulse.

TrueDAC Method for creating analog output using a DA converter.

Serial encoder An encoder that uses communications to perform data transfer.

Digital quadrature encoder

Sinusoidal encoder A type of encoder that outputs SIN/COS waveforms at 1 Vpp.

Encoder loss detection function

Hall sensor A sensor that detects the rotor position of the motor by detecting the magnetic field.

Motion control IC developed by the U.S. company Delta Tau Data Systems, Inc.

Gate3 index is set with the DIP switch of the Unit.

If index is i, the CPU Unit accesses the CK3W Unit with Gate3[i] data structure.

A type of encoder that outputs pulse signals.

Function that detects if encoder is not connected.

T is the real-time Ethernet protocol standards.

T slaves.

T slaves in XML format.

28

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 31

Revision History

O036-E1-02

Revi

sion code

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision History

Revision

code

01 July 2018 Original production

02 July 2019

Date Revised content

• Made changes accompanying the addition of CK3W

MD71£0/-AD£100/-EXM01/-EXS02 Units.

• Corrected mistakes.

-AX1313£/-AX2323£/-

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

29

Page 32

Revision History

30

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 33

1

Introduction to Motion Controllers

This section describes the features, system configuration, and operating procedure of

a CK3M-series Programmable Multi-Axis Controller

1-1 Features and System Configuration ............................................................ 1-2

1-1-1 Motion Controller Features ............................................................................. 1-2

1-1-2 Introduction to the System Configurations...................................................... 1-2

1-1-3 Support Software ............................................................................................ 1-4

1-2 CK3M-series Operating Procedure............................................................... 1-5

.

1

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

1-1

Page 34

1 Introduction to Motion Controllers

1-1

1-1-1

Features and System Configuration

This section describes the features and basic system configuration of the CK3M-series Programmable

Multi-Axis Controller and Support Software.

Motion Controller Features

Fast Multi-Axis Control

The Motion Controller uses the Programmable Multi Axis Controller, developed by Delta Tau Data Systems, Inc. (hereinafter referred to as “Delta Tau”), a manufacturer specializing in motion controllers.

This enables control of a maximum of 16 axes of an analog input type or DirectPWM type Servo Drive

(when using four CK3W-AX£££££ Units and an Expansion Rack) at high speeds using the Axis

Interface Unit.

Constructing Systems with Greater Flexibility

Programs for the Motion Controller can be written in G-code, C language, or Programmable Multi-Axis

Controller specific language. This function design flexibility allows you to create functions that are optimized for your equipment.

arious EtherCAT-compatible products such as image sensors and I/O as well as motion controls can

V

be connected, allowing you to construct original systems to suit the equipment.

1-1-2

Compactness

The Controller is compact and has less wiring due to the use of the EtherCAT network, which helps to

downsize devices.

Introduction to the System Configurations

The Motion Controller supports the following system configurations.

The basic configurations include the CK3W Unit configuration, EtherCA

net network configuration, and Support Software.

T network configuration, Ether-

Basic Configuration

• CK3W Unit Configuration

Up to four CK3W Units (or up to two CK3W

Unit type Model

Axis Interface Unit

Digital I/O Unit

Analog Input Unit

CK3W-AX1313£/-AX1414£/-AX1515£/-AX2323£

CK3W-MD71£0

CK3W-AD£100

-AX Units) can be connected to the CPU Unit.

1-2

In addition to the CPU Rack, an Expansion Rack can be used to install additional CK3W Units.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 35

1 Introduction to Motion Controllers

You can add up to four CK3W Units (or up to two CK3W-AX Units) with the Expansion Rack.

1-1 Features and System Config-

By connecting an analog input type or DirectPWM type Servo Drive to a

CK3W-AX Unit, high-speed

axis control is enabled.

One CK3W-AX Unit controls up to four axes.

With the Expansion Rack, one CK3M-series CPU Unit can connect up to four CK3W-AX Units and

control a maximum of 16 axes in total.

A digital quadrature encoder, serial encoder, or sinusoidal encoder may be connected to the CK3WAX Units as encoder input for feedback. The CK3W-AX Units have general digital I/O with 16-point

input and 16-point output.

• EtherCAT Network Configuration

By using the EtherCAT master communications port on the CPU Unit, EtherCAT slaves such as servo drives, inverters, machine vision systems, digital and analog I/O, and other general-purpose

slaves can be connected.

The CPU Unit also supports connections with EtherCAT Slave Terminals. The EtherCAT Slave Terminal helps you to save space and construct flexible systems using a broad range of types of NX

Units.

However, when OMRON NX-series EtherCAT Coupler Units are used for the EtherCAT Slave Terminal, there are restrictions on the models and unit versions of EtherCAT Coupler Units that can be

connected.

Refer to A-3 Restrictions on Using the NX-series EtherCAT Coupler Unit on page A-8 for details.

uration

1

1-1-2 Introduction to the System Configurations

• Ethernet Network Configuration

The Ethernet communications port on the CPU Unit supports the Modbus-TCP protocol. It can be

connected to devices such as PLCs and programmable terminals that support the Modbus-TCP protocol.

• Support Software

Connect a computer with the Support Software installed to the Motion Controller via the Ethernet

network.

Refer to 1-1-3 Support Software on page 1-4 for details of the Support Software.

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

1-3

Page 36

Encoder (Digital quadrature encoder, serial encoder)

Servo drive (analog input type)

or Stepper motor

EtherCAT network

Support Software

PLC

Industrial

Ethernet

switch

Programmable

terminal

Ethernet

Networks

Modbus-TCP

Slave

terminal

Servo

drive/

Encoder

input

slaves

General-

purpose

slaves

1 Introduction to Motion Controllers

1-1-3

Support Software

The following table shows the Support Software used to configure, monitor, program, and debug the

Motion Controller

Configuration software Application How to Procure

Power PMAC IDE

Power

PMAC-NC16

*1. Refer to A-5 V

*2. Contact your OMRON representative for information on how to procure.

.

*1

Power

PMAC-NC16

SDK

Power

PMAC-NC16

Runtime

ersion Information on page A-10 for the supported Power PMAC IDE versions.

This computer software is used to configure

the Motion Controller

and debug the programs.

This computer software is used to control

working machines and other CNC machines

with the Motion Controller

to customize HMI screens. The product contains extension source codes for customization.

This computer software is used to control

working machines and other CNC machines

with the Motion Controller

when you do not customize HMI screens.

, create user programs,

. Use this software

. Use this software

This is free software.

*2

This is non-free software.

This is non-free software.

*2

*2

1-4

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

Page 37

1 Introduction to Motion Controllers

1-2 CK3M-series Operating Pro-

1-2

CK3M-series Operating Procedure

This section describes the procedure to construct a motion control system by using the CK3M-series

Programmable Multi-Axis Controller.

No. Step Description Reference

1 Preparation for

work

Check for specification compatibility

Check compatibility with specifications of

each Unit.

• General specifications

A-1 General Specifications on

A-2

page

• Mounting direction

2 Mounting and

wiring of the

tion Controller

3 Settings and wir-

ing of the Ether-

T slave hard-

CA

ware

Mo-

*1

Selection of peripheral devices

Preparation of

Support Software

Mounting Mount the Motion Controller.

Address switch

setting

Wiring Perform Motion Controller wiring. Section 5 Wiring on page

Node address

settings

Mounting Mount EtherCAT slaves. Refer to the manual for the

Wiring Wire EtherCAT slaves.

Select peripheral devices to be used with

the Motion Controller.

Procure and install the Support Software

required for the system.

• Connecting adjacent Units

• Mounting to DIN Track

Set the address switches for the CK3W

Units.

Use the hardware switches on all of the

EtherCAT slaves in the network to set the

node addresses.

• Wiring of the unit power supply

1-1-3 Support Software on page

4

1-

4-3 Mounting Units on page

4-5

3-3-4 Address Switch Setting on

page 3-16

5-1

Refer to the manual for the

EtherCAT slave.

EtherCA

Refer to the manual for the

EtherCA

T slave.

T slave.

• I/O wiring

4

EtherCAT communications wiring

5 Turn ON the power supply to Ether-

T slaves.

CA

6 Construction of

the EtherCA

network

*1

Installation of ESI

T

files

EtherCAT slave

settings

Activation of the

EtherCA

*1

T network

Perform wiring for the EtherCAT communications cables.

Turn on the power to the devices configuring the system.

Install the ESI files of EtherCAT slaves to

be connected.

Configure the EtherCAT communications

settings. Then, create an ENI file used to

download the configured settings to the

Motion Controller

Use Power PMAC IDE to download the

ENI file to the Motion Controller.

Make sure that the ENI file has been correctly downloaded, and then activate the

EtherCAT network.

.

5-2-1 Laying the EtherCAT Network on page 5-7

Refer to Power PMAC IDE User

Manual (Cat. No. O016) for de-

tails.

For information on the ESI file,

refer to the manual for the

EtherCAT slave.

Refer to Power PMAC IDE User

Manual (Cat. No. O016) for details.

Refer to Power PMAC IDE User

Manual (Cat. No. O016) for details.

cedure

1

CK3M-series Programmable Multi-Axis Controller User's Manual Hardware (O036)

1-5

Page 38

1 Introduction to Motion Controllers

No. Step Description Reference

7 Preparation for