Page 1

CK3E-series

Programmable Multi-Axis Controller

Hardware

User’s Manual

CK3E-110

Programmable Multi-Axis Controller

I610-E1-01

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing a CK3E-series Programmable Multi-Axis Controller.

This manual contains information that is necessary to use the CK3E-series Programmable Multi-Axis

Controller. Please read this manual and make sure you understand the functionality and performance

of the CK3E-series Programmable Multi-Axis Controller before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (ie: be of the rank of electrical engineer or equivalent).

• Personnel in charge of introducing FA devices.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA devices.

• Personnel in charge of managing FA facilities.

Introduction

Applicable Products

This manual covers the following products.

• CK3E-series Programmable Multi-Axis Controller

Model CK3E-

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

1

Page 4

Manual Structure

Manual Structure

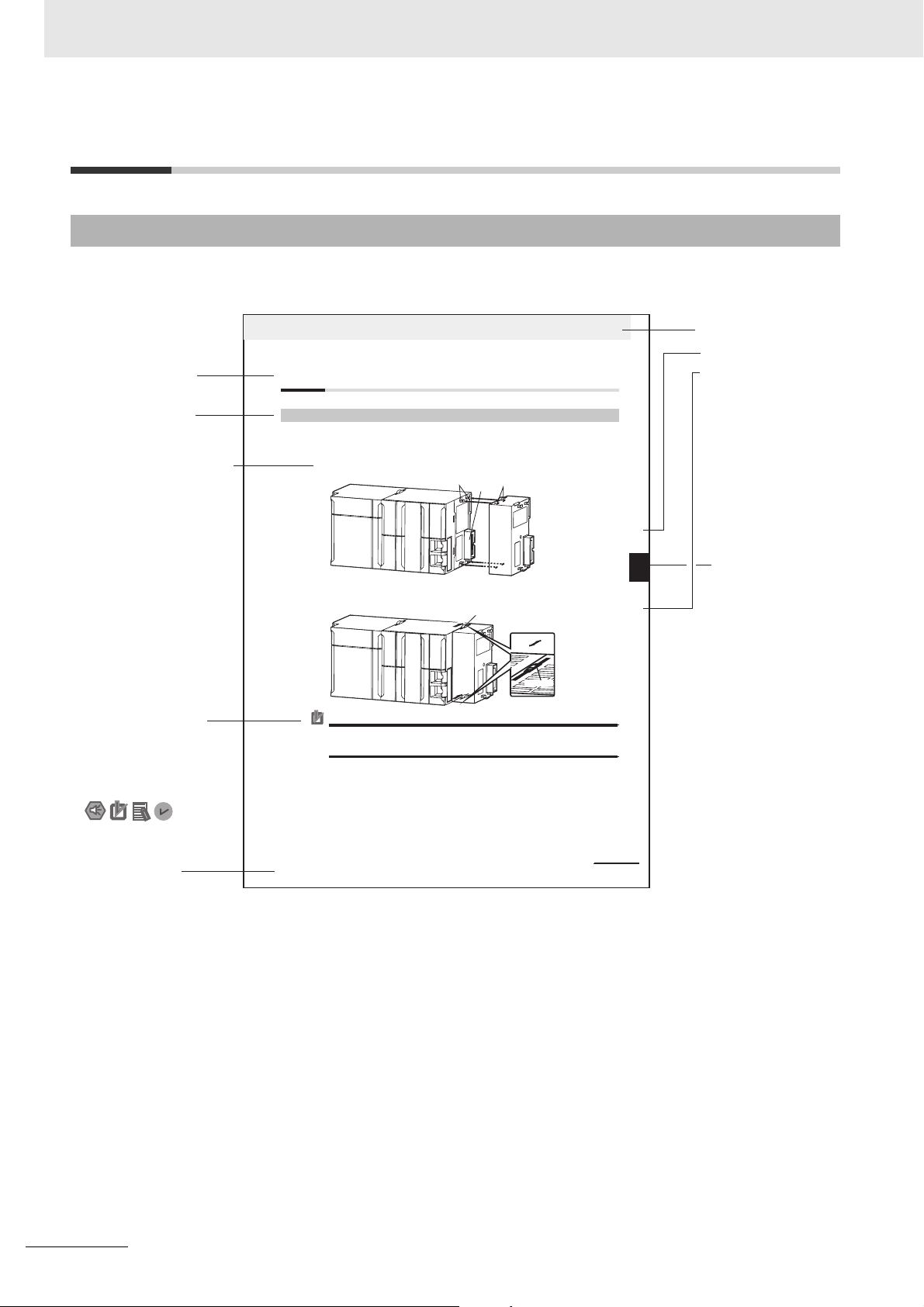

Page Structure and Icons

The following page structure and icons are used in this manual.

Level 2 heading

Level 3 heading

A step in a procedure

Indicates a procedure.

Special information

Icons indicate

precautions, additional

information, or reference

information.

4 Installation and Wiring

4-3 Mounting Units

4-3-1 Connecting Controller Components

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locki ng the slide rs by moving the m toward the back of the U nits. The End Cover is connect ed in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Hook

Connector

Move the sliders toward the back

until they lock into place.

Hook holes

Release

Lock

Slider

Level 1 heading

Level 2 heading

Level 3 heading

Gives the current

headings.

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

Page tab

Gives the number

of the main section.

Manual name

Note This illustration is provided as a sample only. It may not literally appear in this manual.

2

NJ-series CPU Unit Hardware User’s Manual (W500)

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

4-9

Page 5

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure correct operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

Note References are provided to more detailed or related information.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

3

Page 6

CONTENTS

CONTENTS

Introduction ..............................................................................................................1

Intended Audience....................................................................................................................................... 1

Applicable Products ..................................................................................................................................... 1

Manual Structure ......................................................................................................2

Page Structure and Icons ............................................................................................................................ 2

Special Information ...................................................................................................................................... 3

CONTENTS................................................................................................................4

Terms and Conditions Agreement..........................................................................7

Warranty, Limitations of Liability .................................................................................................................. 7

Application Considerations .......................................................................................................................... 8

Disclaimers .................................................................................................................................................. 8

Safety Precautions...................................................................................................9

Definition of Precautionary Information........................................................................................................ 9

Symbols....................................................................................................................................................... 9

WARNING ................................................................................................................................................. 10

Precautions for Safe Use.......................................................................................12

Precautions for Correct Use..................................................................................15

Regulations and Standards ...................................................................................17

Conformance to EU Directives .................................................................................................................. 17

Software Licenses and Copyrights ............................................................................................................ 17

Related Manuals .....................................................................................................18

Terms and Acronyms.............................................................................................19

Revision History .....................................................................................................20

Sections in this Manual .........................................................................................21

Section 1 Features and System Configuration

1-1 Features.................................................................................................................................. 1-2

1-2 Introduction to the System Configurations ........................................................................ 1-3

1-3 Support Software................................................................................................................... 1-5

1-4 Application Procedure .......................................................................................................... 1-6

Section 2 Specifications

2-1 Programmable Multi-Axis Controller ................................................................................... 2-2

2-1-1 Model ..........................................................................................................................................2-2

2-1-2 General Specifications ................................................................................................................2-3

2-1-3 Features and Performance Specifications ..................................................................................2-4

2-2 Specifications of Peripherals ............................................................................................... 2-5

2-2-1 USB Memory Device...................................................................................................................2-5

2-2-2 Power Supply.............................................................................................................................. 2-5

4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 7

Section 3 Part Names and Functions

3-1 Part Names............................................................................................................................. 3-2

3-2 Operation Indicators ............................................................................................................. 3-3

3-3 ID Information Indication Label............................................................................................ 3-4

Section 4 Mounting and Wiring

4-1 Mounting the Programmable Multi-Axis Controller ........................................................... 4-2

4-1-1 Mounting the Programmable Multi-Axis Controller..................................................................... 4-2

4-1-2 Mounting Direction in Control Panels ......................................................................................... 4-3

4-1-3 Mounting Method in Control Panels............................................................................................ 4-3

4-2 Power Supply Wiring............................................................................................................. 4-4

4-2-1 Power Supply Connector Specifications..................................................................................... 4-4

4-2-2 Wiring the Power Supply Connector........................................................................................... 4-4

4-3 Laying the EtherCAT Network .............................................................................................. 4-7

4-3-1 Supported Network Topologies................................................................................................... 4-7

4-3-2 Installation Precautions............................................................................................................... 4-8

4-3-3 Installing EtherCAT Communications Cables ............................................................................. 4-9

4-4 Laying the Ethernet Network.............................................................................................. 4-12

4-4-1 Installation Precautions............................................................................................................. 4-12

4-4-2 Installing Ethernet Networks..................................................................................................... 4-13

4-5 USB Memory Device Connection ....................................................................................... 4-16

CONTENTS

4-6 Grounding ............................................................................................................................ 4-17

4-6-1 Considerations for Earthing Methods ....................................................................................... 4-17

4-6-2 Earthing Methods...................................................................................................................... 4-18

Section 5 Error Processing

5-1 Classification of Errors ......................................................................................................... 5-2

5-2 Using the Indicators to Check Errors .................................................................................. 5-3

5-2-1 Indicator Types ........................................................................................................................... 5-3

5-2-2 Procedure for Determining Errors............................................................................................... 5-4

5-3 Corrective Actions for Errors ............................................................................................... 5-5

5-3-1 Fatal Errors in the Programmable Multi-Axis Controller ............................................................. 5-5

5-3-2 Non-fatal Errors in the Programmable Multi-Axis Controller....................................................... 5-6

Section 6 Inspection and Maintenance

6-1 Cleaning and Maintenance ................................................................................................... 6-2

6-1-1 Cleaning...................................................................................................................................... 6-2

6-1-2 Periodic Inspections.................................................................................................................... 6-2

6-2 Maintenance Procedures ...................................................................................................... 6-4

6-2-1 Unit Replacement Precautions ................................................................................................... 6-4

6-2-2 Backup........................................................................................................................................ 6-4

6-2-3 Unit Replacement....................................................................................................................... 6-4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

5

Page 8

CONTENTS

Appendices

A-1 Dimension Diagram ...............................................................................................................A-2

A-2 Restrictions on Using the OMRON NX-Series EtherCAT Coupler Unit ............................A-3

Index

6

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 9

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

7

Page 10

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

8

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 11

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the CK3E-series Programmable Multi-Axis Controller.

The safety precautions that are provided are extremely important to help ensure safety. Always read

and heed the information provided in all safety precautions.

The following notation is used.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

could result in death or serious injury. Additionally, there may be

severe property damage.

Safety Precautions

Symbols

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

Caution

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates that disassembling is prohibited.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a precaution against electric shock.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in text.

This example shows a general precaution for an action you must carry out.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

9

Page 12

Safety Precautions

WARNING

During Power Supply

Do not attempt to take any Unit apart.

In particular, high-voltage parts are present in the product while power is supplied or immediately after power is turned OFF. Touching any of these parts may result in electric shock.

There are sharp parts inside the Unit that may cause injury.

Fail-safe Measures

Provide safety measures in external circuits to ensure safety in the system if an abnormality

occurs due to malfunction of the system due to other external factors affecting operation.

Not doing so may result in serious accidents due to incorrect operation.

Emergency stop circuits, interlock circuits, limit circuits, and similar safety measures must

be provided in external control circuits.

WARNING

You must take fail-safe measures to ensure safety in the event of incorrect, missing, or

abnormal signals caused by broken signal lines, momentary power interruptions, or other

causes. Not doing so may result in serious accidents due to incorrect operation.

The use of an Uninterruptible Power Supply (UPS) allows normal operation to continue

even if a momentary power interruption occurs, possibly resulting in the reception of an

erroneous signal from an external device affected by the momentary power failure. Take

external fail-safe measures. Where necessary, monitor the power supply voltage on the

system for external devices and use it as an interlock condition.

Unintended behavior may occur when an error occurs in internal memory of the product.

As a countermeasure for such problems, external safety measures must be provided to

ensure safe operation of the system.

The Controller will turn OFF all outputs from Output Units in the following cases. The slaves

will operate according to the settings in the slaves.

• If a power supply error occurs

• If the power supply connection becomes faulty

• When a CPU error (watchdog timer error) or CPU reset occurs

• If a Controller error in the major fault level occurs

• While the Controller is in startup status until RUN mode is entered after the power is

turned ON.

• If a system initialization error occurs

External safety measures must be provided to ensure safe operation of the system in such

cases.

10

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 13

Safety Precautions

Transferring

Always confirm the safety status at the destination before you transfer a user program, configuration data, or setup data from POWER PMAC IDE. The devices or machines may perform unexpected operations regardless of the operating mode of the Controller.

After you transfer the user program, the Controller is restarted and communications with

the EtherCAT slaves are cut off. During that period, the slave outputs behave according to

the slave specifications.

The time that communications are cut off depends on the EtherCAT network configuration.

Before you transfer the user program, confirm that the system will not be adversely

affected.

Test Run

Before you start a Test Run, make sure that the operation parameters are set correctly.

Actual Operation

Check the user program, data, and parameter settings for proper execution before you use

them for actual operation.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

11

Page 14

Precautions for Safe Use

Precautions for Safe Use

Transporting

• Do not drop the Controller or expose it to abnormal vibration or shock. Doing so may result in the

Controller malfunctioning or burning.

Mounting

• Be sure that the connectors and other items with locking devices are correctly locked into place.

Installation

• Always connect to a ground of 100 Ω or less when installing the Controller.

Wiring

• Follow the instructions in this manual to correctly perform connector wiring and insertion. Double-check all wiring and connector insertion before turning ON the power supply.

• If the external power supply to a slave has polarity, connect it with the correct polarity. If the polarity is

reversed, current may flow in the reverse direction and damage the connected devices regardless of

the operation of the Controller.

• Before you connect a computer to the Controller, disconnect the power supply plug of the computer

from the AC outlet. Also, if the computer has an FG terminal, make the connections so that the FG

terminal has the same electrical potential as the FG on the product. A difference in electrical potential

between the computer and Controller may cause a failure or malfunction.

• Do not pull on the cables or bend the cables beyond their natural limit.

• Do not place any objects on top of the cables or other wiring lines. Doing so may cause the cables to

break.

• Always use power supply wires with sufficient wire diameters to prevent voltage drop and burning.

Make sure that the current capacity of the wire is sufficient. Otherwise, excessive heat may be generated. When cross-wiring terminals, the total current for all the terminals will flow in the wire. When

wiring cross-overs, make sure that the current capacity of each of the wires is not exceeded.

Power Supply Design

• In the system, only use the power supply within the rated supply capacity range specified in this manual.

12

Turning ON the Power Supply

• It takes approximately several tens of seconds to enter RUN mode after the power supply is turned

ON. During that time, outputs will be OFF or the values will be as according to settings in the Unit or

slaves. Also, external communications will not be able to be performed. The outputs during this

period will behave according to the slave and Unit specifications. Implement fail-safe circuits so that

external devices do not operate incorrectly.

• Surge current occurs when the power supply is turned ON. When selecting fuses or breakers for

external circuits, consider the above precaution and allow sufficient margin in shut-off performance.

Refer to this manual for surge current specifications.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 15

Precautions for Safe Use

Turning OFF the Power Supply

• Do not turn off the power supply or remove the USB memory device while the Controller is accessing

the USB memory device. Data may become corrupted, and the Controller will not operate correctly if

it uses corrupted data.

• Always turn OFF the power supply before you attempt any of the following.

Connecting cables or wiring the system

Connecting or disconnecting the connectors

• If the product experiences a sudden loss of power or disconnecting the cable while saving a setting

or transfer of data is underway, the changes may not be stored and unexpected behavior may occur.

Operation

Confirm that no adverse effects will occur in the system before you attempt any of the following.

• Changing the operating mode of the Controller (including changing the setting of the Startup Mode)

• Changing the user program or settings

• Changing set values or present values

EtherCAT Communications

• Make sure that the communications distance, number of nodes connected, and method of connection for EtherCAT are within specifications.

Do not connect EtherCAT communications to EtherNet/IP, a standard in-house LAN, or other networks. An overload may cause the network to fail or malfunction.

• If the Fail-soft Operation parameter is set to stop operations, process data communications will stop

for all slaves when an EtherCAT communications error is detected in a slave. For this reason, if

Servo Drives are connected, the Servos for all axes will be turned OFF. At that time, the Servo Drive

will operate according to the Servo Drive specifications. Make sure that the Fail-soft Operation

parameter setting results in safe operation when a device error occurs.

• If noise occurs or an EtherCAT slave is disconnected from the network, any current communications

frames may be lost. If frames are lost, slave I/O data is not communicated, and unintended operation

may occur. The slave outputs behave according to the slave specifications. For details, refer to relevant manuals for each slave.

• When an EtherCAT slave is disconnected or disabled, communications will stop and control of the

outputs will be lost not only for the disconnected slave, but for all slaves connected after it. Confirm

that the system will not be adversely affected before you disconnect or disable a slave.

• You cannot use standard Ethernet hubs or repeater hubs with EtherCAT communications. If you use

one of these, a major fault level error or other error may occur.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables and the EtherCAT Coupler Unit device variables in the user

program to confirm that I/O data communications are established before attempting control operations.

• If you need to disconnect the cable from an EtherCAT slave during operation, first reset the EtherCAT

and EtherCAT slaves that are connected after it to the Init state, then disconnect the EtherCAT slave.

• For EtherCAT and EtherNet, use the connection methods and cables that are specified in this manual. Otherwise, communications may be faulty.

• Make sure that all of the slaves to be restored are participating in the network before you reset the

EtherCAT Master Function Module. If any slave is not participating when any of these errors is reset,

the EtherCAT Master Function Module may access a slave with a different node address than the

specified node address, or the error may not be reset correctly.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

13

Page 16

Precautions for Safe Use

Motion Control

• The motor is stopped if communications are interrupted between POWER PMAC IDE and the Controller during a Test Run. Connect the communications cable securely and confirm that the system

will not be adversely affected before you perform a Test Run.

• EtherCAT communications are not always established immediately after the power supply is turned

ON. Use the system-defined variables in the user program to confirm that communications are established before attempting control operations.

Unit Replacement

• After replacing the Controller, make sure that the required data, including the user program, configurations, settings, and values of variables, has been transferred to the Controller that was replaced, as

well as to externally connected devices before restarting operation.

Maintenance

• Do not attempt to disassemble, repair, or modify the Controller. Doing so may result in a malfunction

or fire.

• Do not use corrosive chemicals to clean the Controller. Doing so may result in a failure or malfunction

of the Controller.

14

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 17

Precautions for Correct Use

Storage and Installation

• Follow the instructions in this manual to correctly perform installation.

• Do not operate or store the Controller in the following locations. Doing so may result in a malfunction

or halt operations.

a) Locations subject to direct sunlight

b) Locations subject to temperatures or humidity outside the range specified in the specifications

c) Locations subject to condensation as a result of severe changes in temperature

d) Locations subject to corrosive or flammable gases

e) Locations subject to dust (especially iron dust) or salts

f) Locations subject to exposure to water, oil, or chemicals

g) Locations subject to shock or vibration

• Take appropriate and sufficient countermeasures when installing the Controller in the following locations.

a) Locations subject to strong, high-frequency noise

b) Locations subject to static electricity or other forms of noise

c) Locations subject to strong electromagnetic fields

d) Locations subject to possible exposure to radioactivity.

e) Locations close to power lines

• Install the Controller away from sources of heat and ensure appropriate ventilation. Not doing so may

result in a malfunction, operations halting, or burning.

• Always touch a grounded piece of metal to discharge static electricity from your body before starting

an installation or maintenance procedure.

Precautions for Correct Use

Wiring

• Do not allow wire clippings, shavings, or other foreign material to enter the Controller. Otherwise, the

Controller may experience a failure, malfunction, or ignite. Cover the Controller or take other suitable

countermeasures, in particular when carrying out wiring work.

• Always ensure the rated supply voltage is connected to the Controller.

Task Settings

• If a Task Period Exceeded error occurs, shorten the programs to fit in the task or increase the setting

of the task period.

Operation

• Do not disconnect the communications cable while the system is running. Doing so may result in a

failure or malfunction of the system.

Motion Control

• Do not download motion control settings during a Test Run.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

15

Page 18

Precautions for Correct Use

EtherCAT Communications

• Set the Servo Drives to stop operation if an error occurs in EtherCAT communications between the

Controller and a Servo Drive.

• Always use the specified EtherCAT slave cables. If you use any other cable, the EtherCAT master or

the EtherCAT slaves may detect an error and one of the following may occur.

a) Continuous refreshing of process data communications will not be possible.

b) Continuous refreshing of process data communications will not end during the set cycle.

USB Device

• Always use USB memory devices that comply with the USB standards.

16

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 19

Regulations and Standards

Conformance to EU Directives

Applicable Directives

•EMC Directives

Concepts

z EMC Directives

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*1

Regulations and Standards

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

*1. Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61326

EMI (Electromagnetic Interference): EN 61326 (Radiated emission: 10-m regulations).

z Conformance to EU Directives

The CK3E-series Controllers comply with EU Directives. To ensure that the machine or device in

which the CK3E-series Controllers are used complies with EU Directives, the following precautions

must be observed.

• The CK3E-series Controllers must be installed within a control panel.

• You must use SELV power supply for the DC power supplies that are connected as the Unit power

supplies and I/O power supplies for the CK3E-series Controllers.

We recommend that you use the OMRON S8JX-series Power Supplies. EMC standard compliance was confirmed for the recommended Power Supplies.

• CK3E-series Controllers that comply with EU Directives also conform to the Common Emission

Standard (EN 61326). Radiated emission characteristics (10-m regulations) may vary depending

on the configuration of the control panel used, other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment in which the CK3E-series Controllers are used complies with EU Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference. If radio interference occurs, the user may be required to take appropriate measures.

• Attach a clamp core to the Ethernet communications cable. Refer to Recommended Clamp Core

and Attachment Procedure on page 4-15 for details of the procedure to attach the clamp core.

Software Licenses and Copyrights

This product incorporates certain third party software. The license and copyright information associated

with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

17

Page 20

Related Manuals

Related Manuals

The following manuals are related. Contact your OMRON representative for information on how to procure these manuals. Use these manuals for reference.

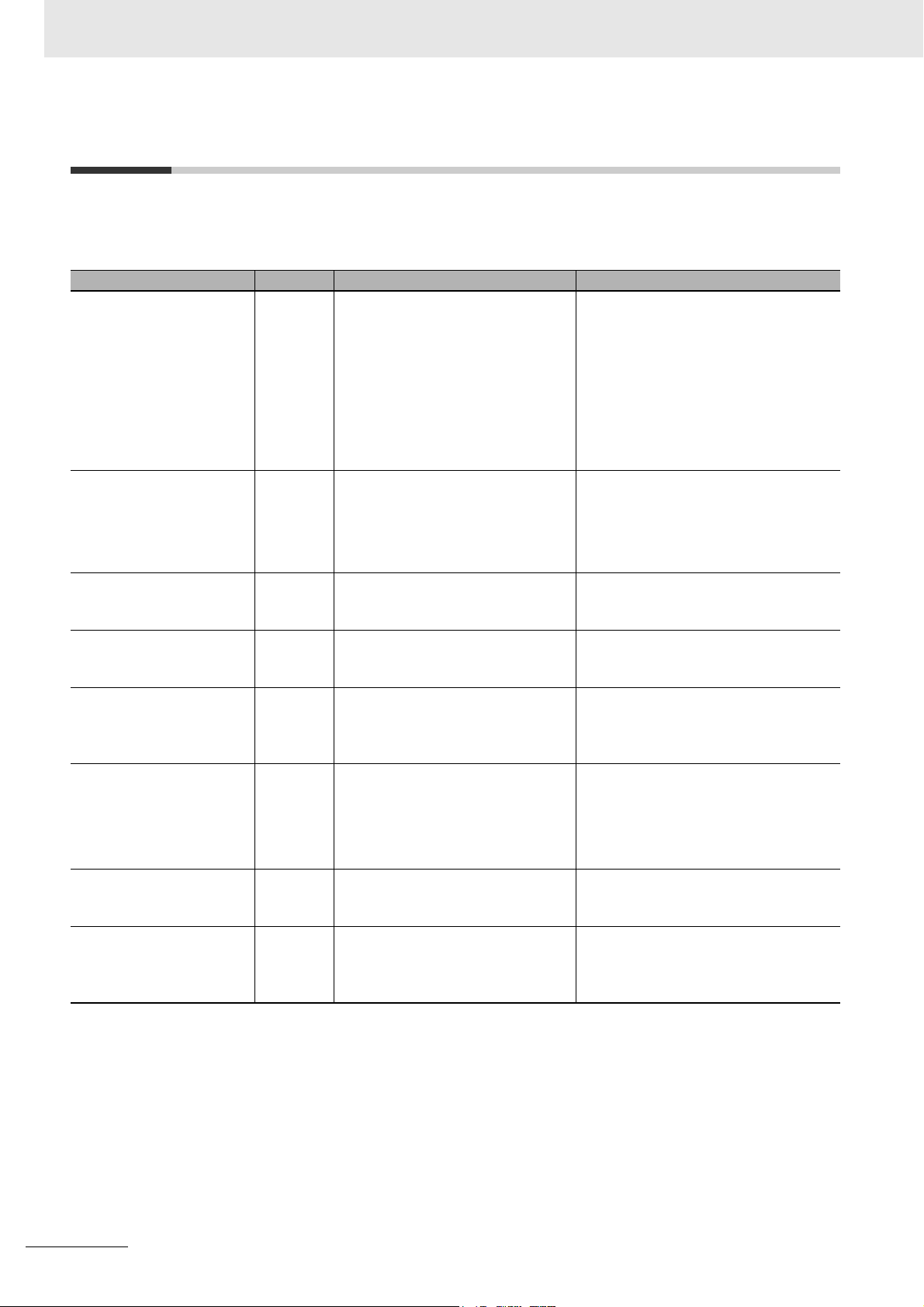

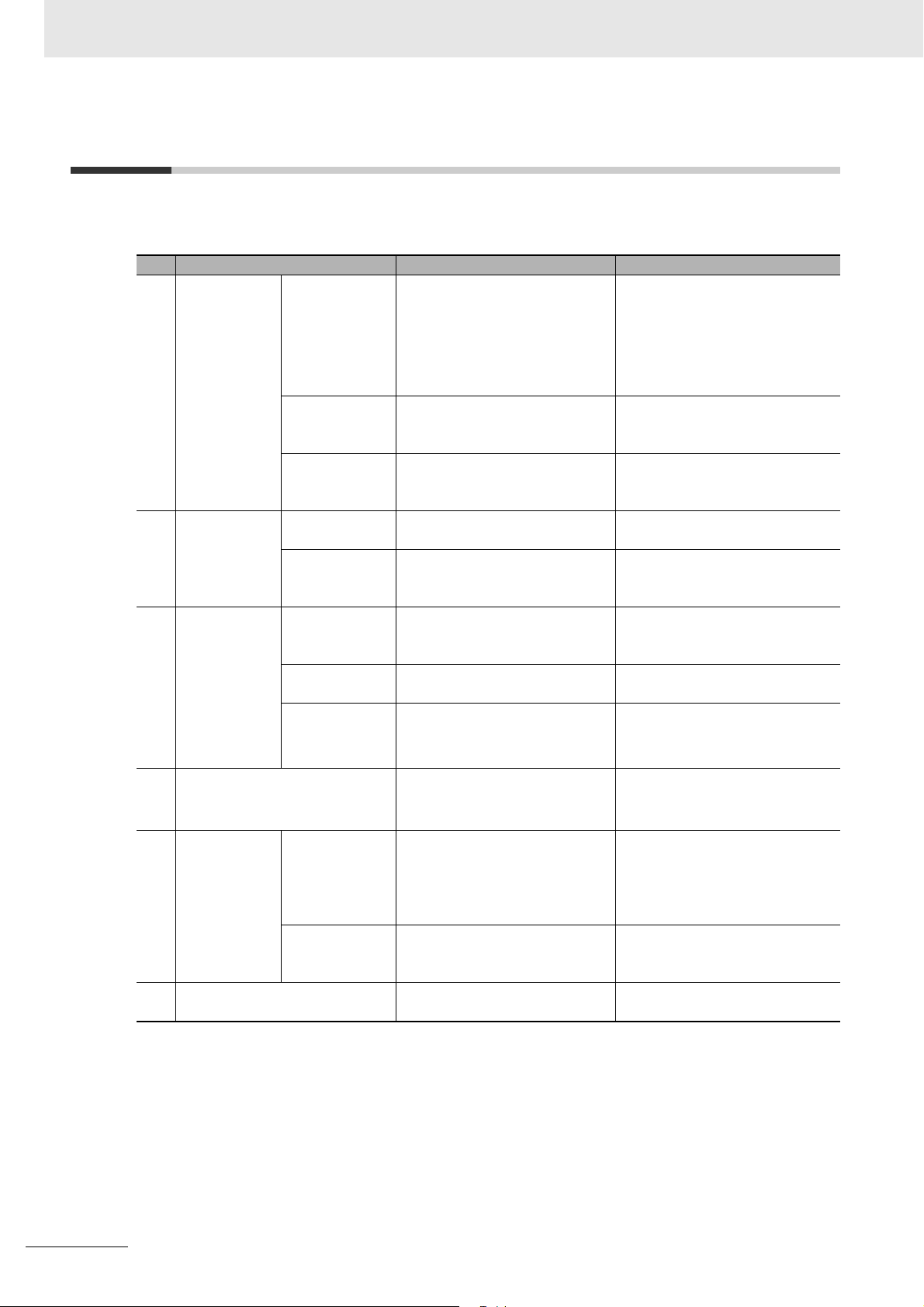

Manual name Cat.No. Application Description

Power PMAC User’s

Manual

Power PMAC Software

Reference Manual

Power PMAC IDE User

Manual

Power PMAC-NC16 Quick

Start Manual

Power PMAC-NC16 .ini

Configuration Manual

Power PMAC-NC16

Software User Manual

Power PMAC-NC16 Mill

G-Code Manual

Acontis EC-Engineer

manual

O014 Learning the features and usage

examples of the CK3E-series Programmable Multi-Axis Controller.

O015 Learning how to program a

CK3E-series Programmable

Multi-Axis Controller.

O016 Learning how to operate Power

PMAC IDE, the integrated development environment of the Controller.

O017 Understanding the basic usage of

Power PMAC-NC16 quickly.

O018 Constructing an application for CNC

devices by using Power

PMAC-NC16.

O019 Learning about usage and features

of Power PMAC-NC16, Support Software required when using the Controller for CNC devices.

O020 Creating programs for CNC devices

by using Power PMAC-NC16.

--- Configuring an EtherCAT network by

using a CK3E-series Programmable

Multi-Axis Controller as the EtherCAT

master.

The following information is provided on

a CK3E-series Programmable Multi-Axis

Controller.

• Basic features of the motion controller

Power Programmable Multi-Axis Controller possessed by the Programmable Multi-Axis Controller.

• Setup examples

• Programming examples

The following information is provided on

a CK3E-series Programmable Multi-Axis

Controller.

• Details of commands

• Details of data structure

Describes the operating procedures of

Power PMAC IDE, and examples of how

to start the system.

Describes a Quick setup procedure to

run Power PMAC-NC16 on a desktop

PC by using an example.

Describes how to set up

“PowerPmacNC.ini”, the setup data file

to be loaded when Power PMAC-NC16

starts.

The following information is provided on

Power PMAC-NC16.

• How to use the software

• Features included in the software

• Features that can be customized

Describes the basic G-code set and the

instructions that can be used for Power

PMAC-NC16.

Operating procedure of Support Software used for EtherCAT network configuration is described.

18

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 21

Terms and Acronyms

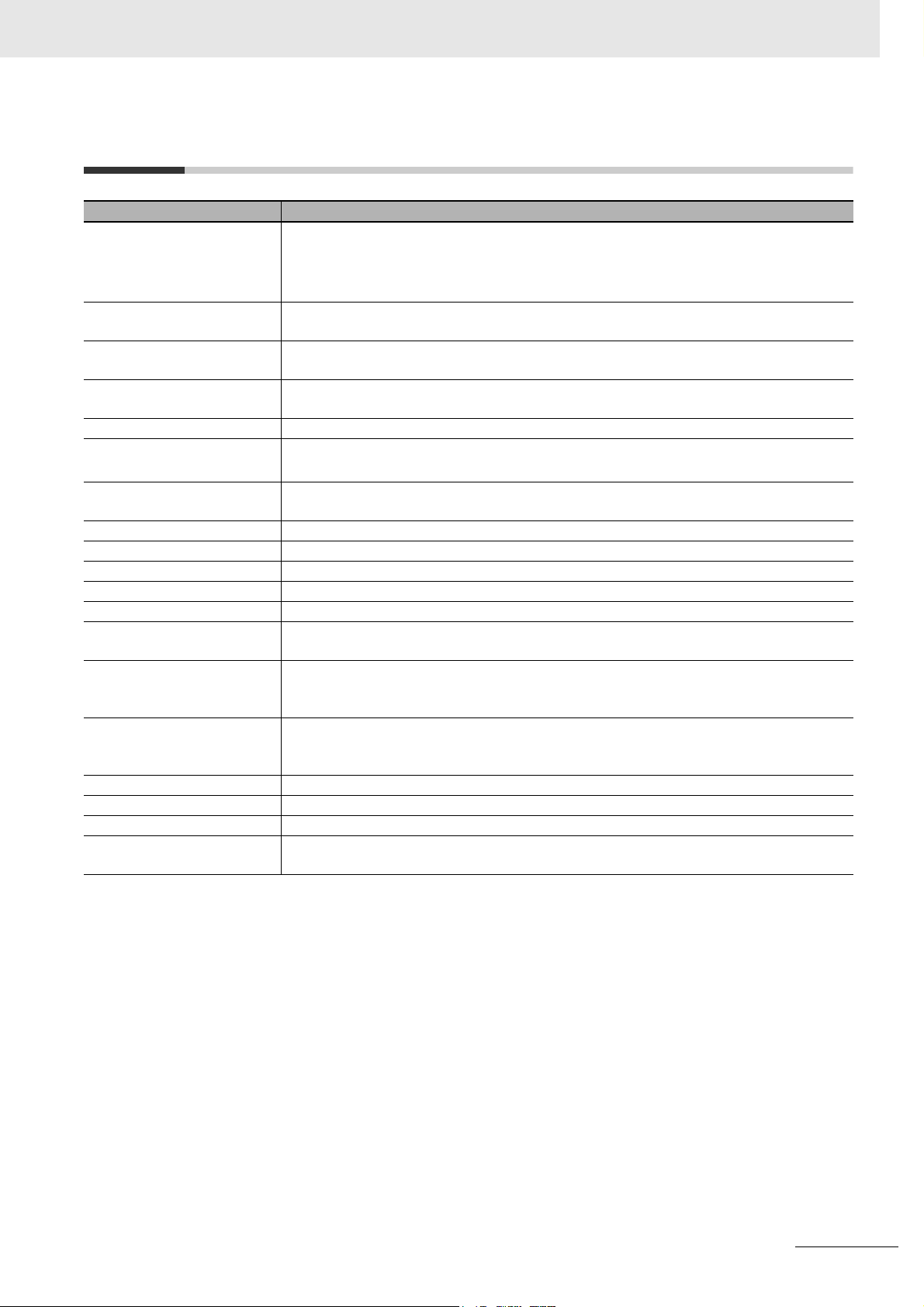

Terms and Acronyms

Term or acronym Description

CNC The acronym for Computerized Numerical Control.

A method to numerically control machining processes in production by using computers.

CNC has been further automatized over conventional numerical control machine tools (NC

machine tools).

CPU Central Processing Unit. Core hardware mounted in computers that executes instructions

from computer programs.

ESI file ESI is the acronym for EtherCAT Slave Information. The ESI file contains information

unique to the EtherCAT slaves in XML format.

ENI file ENI is the acronym for EtherCAT Network Information. The ENI file contains the network

configuration information related to EtherCAT slaves.

Ethernet A network communications protocol used in TCP/IP networks.

EtherCAT The acronym for Ethernet for Control Automation Technology.

EtherCAT is the real-time Ethernet protocol standards.

EtherCAT master The EtherCAT master node that manages the EtherCAT network, monitors the status of

slaves, and exchanges I/O data with slaves. It has one output port.

G-code A type of language used to create NC programs.

Modbus/TCP A protocol used for the Modbus communication on TCP/IP.

PLC Programmable Logic Controller

PMAC The acronym for Programmable Multi-Axis Controller

USB Universal Serial Bus

Servo Drive/Encoder input

slave

Vision sensor A sensor that calculates the area, center of gravity, length, position, and other feature quan-

Axis A functional unit within the Motion Control Function Module. An axis is assigned to the drive

Node address The node address is used to identify Units connected to EtherCAT.

General-purpose slave Any of the EtherCAT slaves that cannot be assigned to an axis.

Programmable terminal A human-machine interface used to facilitate the operation and control of machines.

Motion control Motion control can achieve intended operation by providing a target value to the axis to be

Any of the EtherCAT slaves that is assigned to an axis.

tities of objects by processing images captured using a camera, and outputs the data and

judgment results.

mechanism in an external Servo Drive or the sensing mechanism in an external Encoder

Input Slave Unit.

controlled, or by controlling state transitions.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

19

Page 22

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

I610-E1-01

Revision code

Revision

code

01 August 2016 Original production

Date Revised content

20

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 23

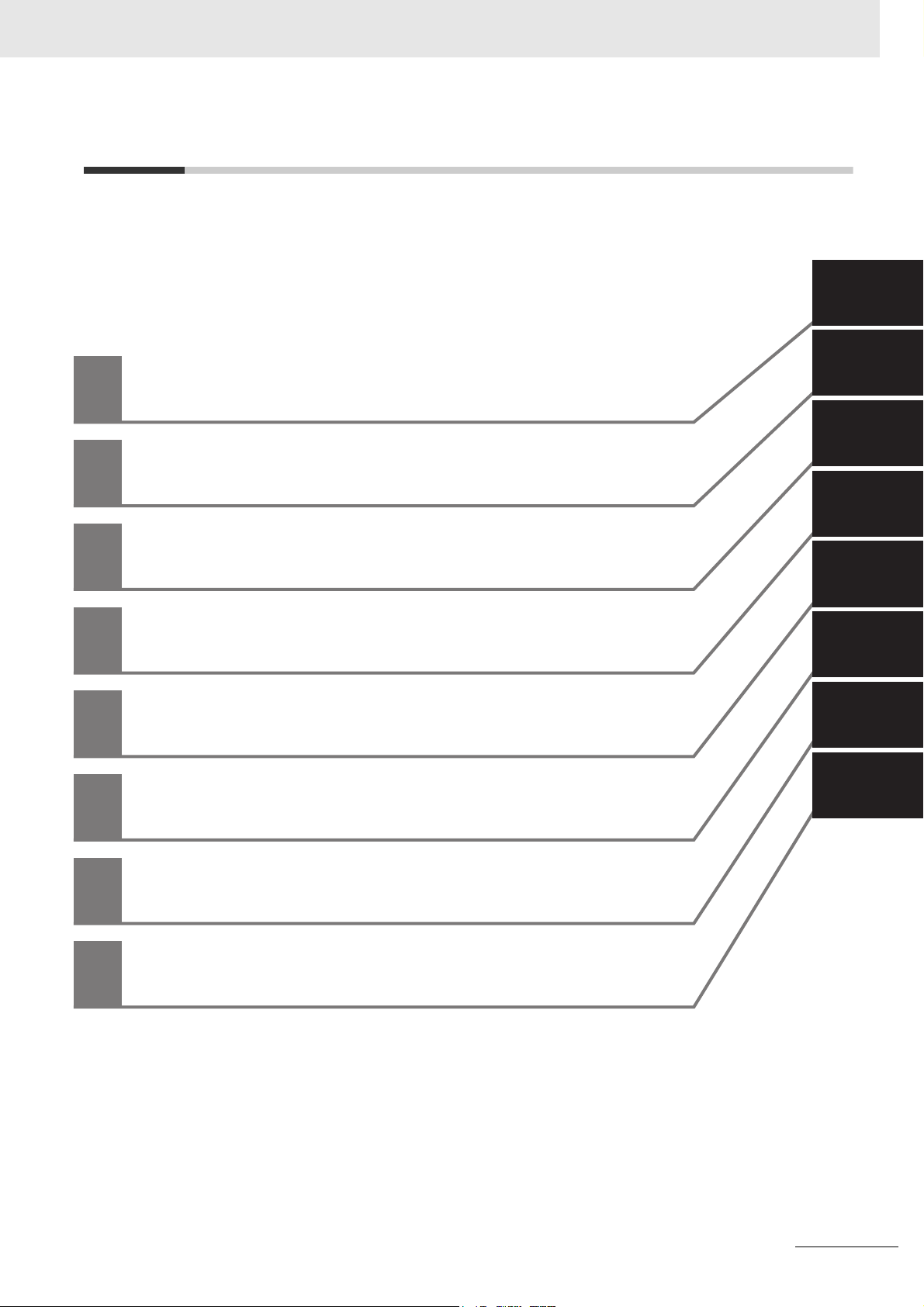

Sections in this Manual

Sections in this Manual

1

Features and System

1A

2I

3

4

5

6

Configuration

Specifications

Part Names and

Functions

Mounting and Wiring

Error Processing

Inspection and Maintenance

2

3

4

5

6

A

I

A

I

Appendices

Index

9

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

9

21

Page 24

Sections in this Manual

22

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 25

1

Features and System Configuration

This section describes the features and system configuration of the Programmable

Multi-Axis Controller.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Introduction to the System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4 Application Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

1 - 1

Page 26

1 Features and System Configuration

1-1 Features

The CK3E-series is the Programmable Multi-Axis Controller that supports the EtherCAT master functions.

The CK3E-series Programmable Multi-Axis Controller has the following features.

Fast Multi-Axis Control

The Controller uses Programmable Multi-Axis Controller, developed by Delta Tau Data Systems, Inc., a

manufacturer specializing in motion controllers.

It allows for multi-axis control of up to 32 axes per unit (when CK3E-1410 is used), and the fast control

which motion control period is 250 μs or more.

Constructing Systems with Greater Flexibility

Programs can be written in G-code, C language, or Programmable Multi-Axis Controller specific language for the Controller. Such function design flexibility allows you to create functions that are optimized for your equipment.

Various EtherCAT-compatible products such as vision sensors and I/O as well as motion controls can

be connected, allowing you to construct original systems to suit the equipment.

Compactness

The Controller is compact and has less wiring due to the use of the EtherCAT network, which helps to

downsize devices.

Additional Information

What is EtherCAT?

EtherCAT is an Ethernet (IEEE802.3) compliant, open, and super-fast industrial network system.

Each node achieves a short communications cycle time by transmitting Ethernet frames at high

speed. A mechanism that allows sharing of clock information enables high-precision synchronized control with low communications jitter.

1 - 2

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 27

1 Features and System Configuration

1-2 Introduction to the System

1-2 Introduction to the System Configu-

rations

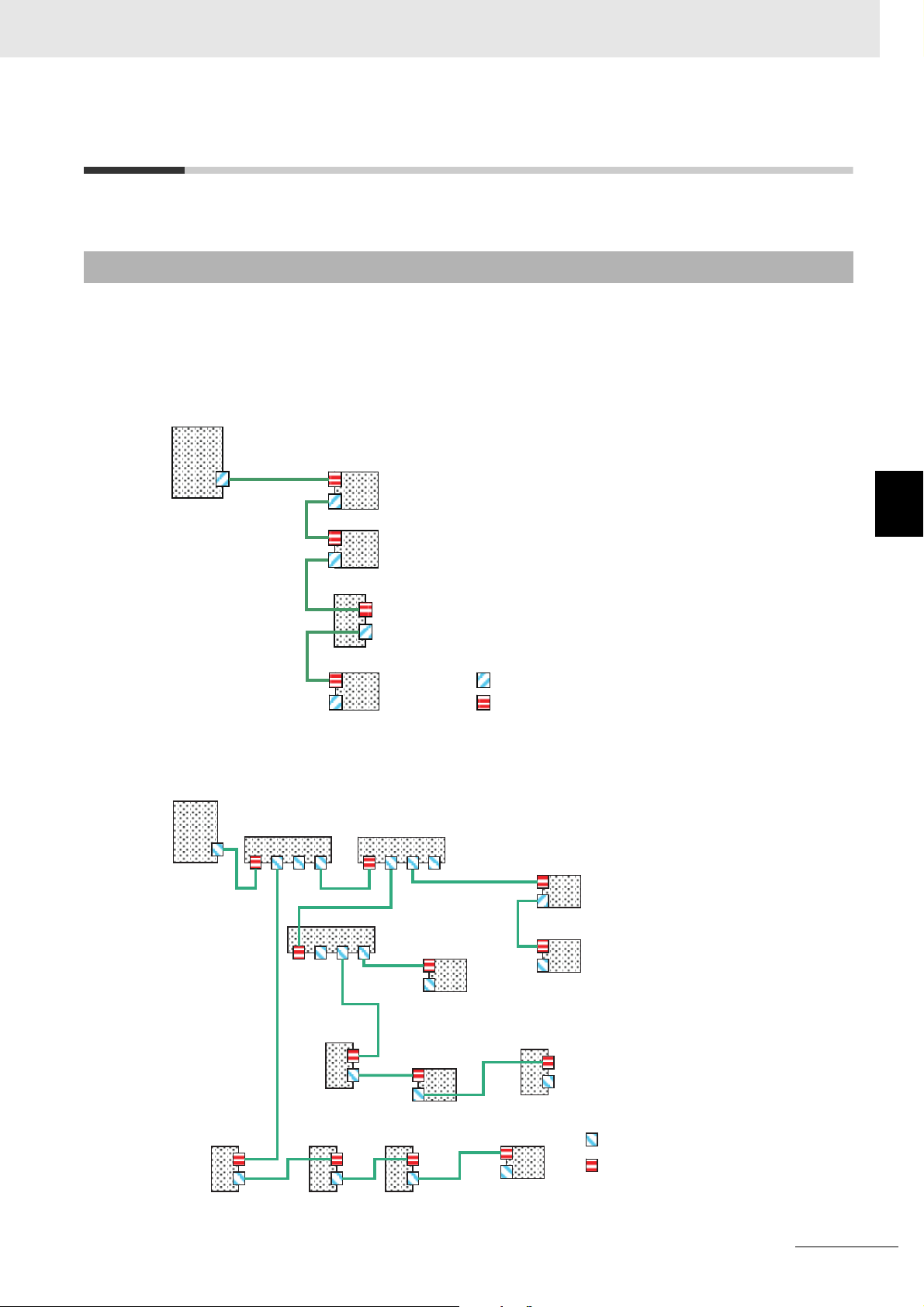

The following shows the configurations of motion control systems using a Programmable Multi-Axis

Controller. The basic configurations include the EtherCAT network configuration, Ethernet network configuration, and Support Software.

EtherCAT Network Configuration

By using the EtherCAT master communications port on the Programmable Multi-Axis Controller, EtherCAT slaves such as servo drives, frequency inverters, machine vision systems, digital and analog I/O,

and other general-purpose slaves can be connected.

The Controller also supports EtherCAT Slave Terminals. The EtherCAT Slave Terminal helps you to

save space and construct flexible systems using a broad range of types of NX Units.

However, when OMRON NX-series EtherCAT Coupler Units are used for the EtherCAT Slave Terminal,

only limited models and unit versions of EtherCAT Coupler Units can be connected. Refer to A-2

Restrictions on Using the OMRON NX-Series EtherCAT Coupler Unit on page A-3.

Ethernet Network Configuration

Configurations

1

The Ethernet communications port on the Programmable Multi-Axis Controller supports the MODBUS-TCP protocol. It can be connected to devices such as a PLC or a programmable terminal that supports the MODBUS-TCP protocol.

Support Software

Connect a personal computer with the Support Software installed to the Programmable Multi-Axis Controller via the Ethernet network. Refer to 1-3 Support Software on page 1-5 for details of the Support

Software.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

1 - 3

Page 28

1 Features and System Configuration

Support Software

PLC

Programmable terminal

Programmable terminal

Modbus-TCP

Ethernet network

Industrial

Ethernet

switch

Slave

terminal

CK3E-series Programmable

Multi-Axis Controller

EtherCAT network

Servo drive/

Encoder

General-purpose

input slaves

slaves

1 - 4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 29

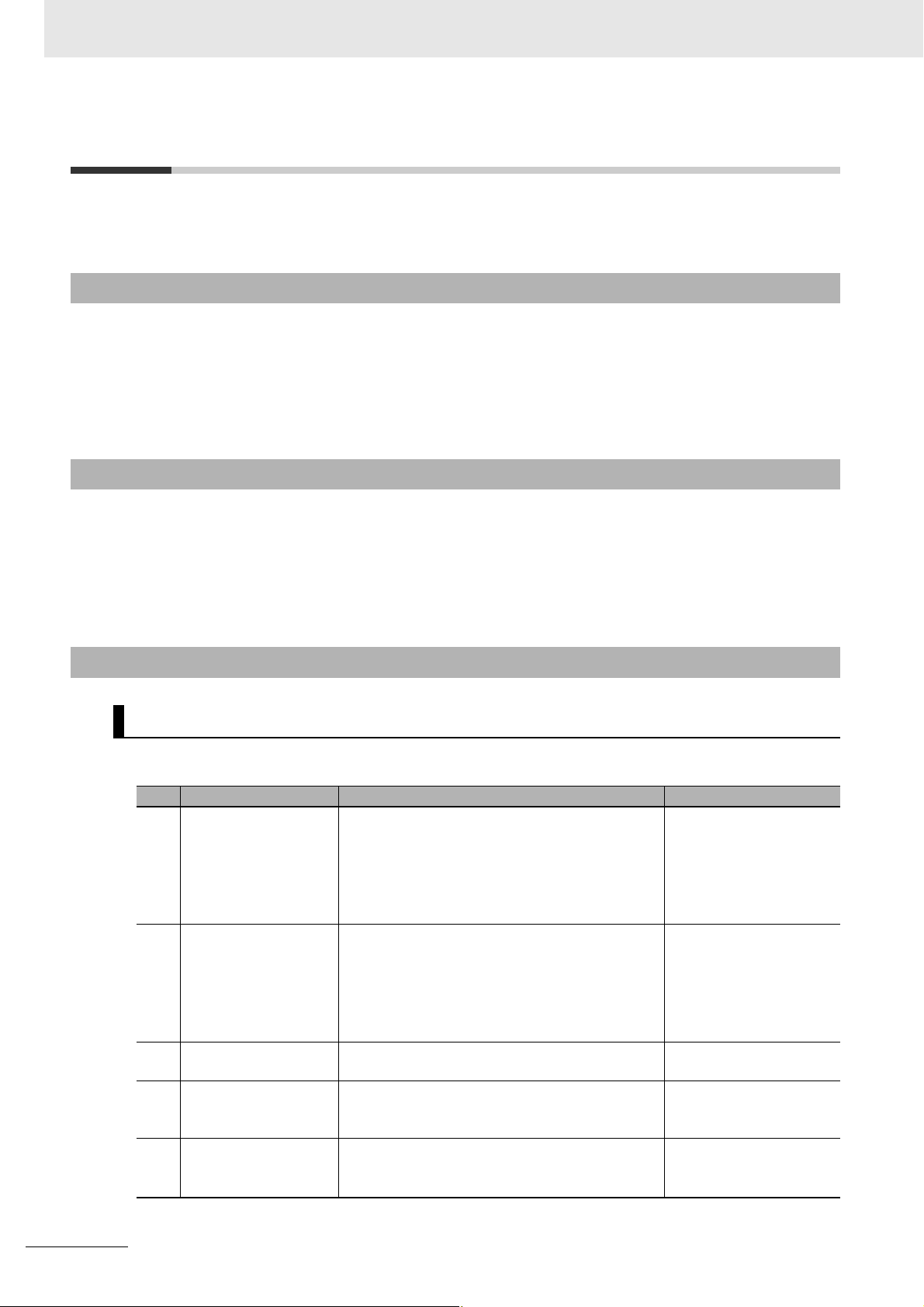

1-3 Support Software

The following table shows the Support Software used to configure, monitor, program, and debug the

Programmable Multi-Axis Controller.

Software Name Application How to Procure

Power PMAC IDE

Power

PMAC-NC16

EC-Engineer This computer software is used to configure

*1. Use Power PMAC IDE Ver.2.2 or a later version.

*1

Power

PMAC-NC16

SDK

Power

PMAC-NC16

Runtime

This computer software is used to configure

the Controller, create user programs, and

debug the programs.

This computer software is used to control

working machines and other CNC machines

with the Controller. Use this software when you

want to customize the HMI screen. The product contains extension source codes used for

customization.

This computer software is used to control

working machines and other CNC machines

with the Controller. Use this software when you

do not customize the HMI screen.

and monitor the EtherCAT network by using

the Controller as the EtherCAT master.

1 Features and System Configuration

This is free software. Contact

your OMRON representative for information on how to

procure.

This is non-free software.

Contact your OMRON representative for information on

how to procure.

This is non-free software.

Contact your OMRON representative for information on

how to procure.

This is free software. Contact

your OMRON representative for information on how to

procure.

1-3 Support Software

1

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

1 - 5

Page 30

1 Features and System Configuration

1-4 Application Procedure

This section describes the procedure to construct a motion control system by using the Multi-Axis Controller.

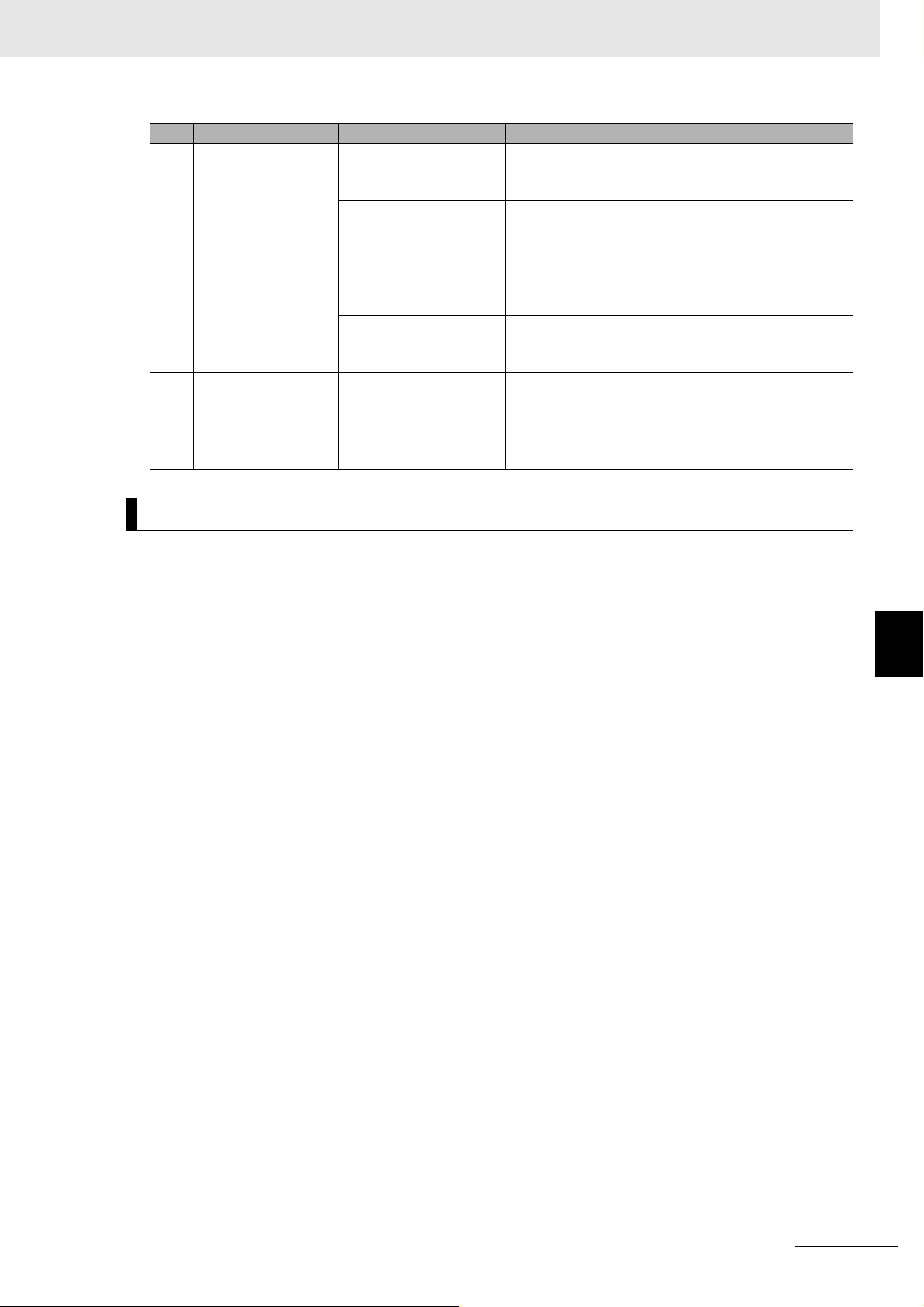

No. Step Description Reference

1 Preparation

before carrying

out work

2 Mounting and

wiring of the

Programmable Multi-Axis

Controller

3 Settings and

wiring of the

EtherCAT

slave hardware.

4 Wiring of the EtherCAT communi-

cation and grounding of the system

5 Preparation for

setting the

Programmable Multi-Axis

Controller

6 Turning the Power ON Turn on the power to the devices

Check for speci-

fication compati-

bility

Selection of

peripheral

devices

Preparation of

Support Soft-

ware

Mounting Mount the Programmable

Wiring Connect the unit power supply of

Node address

settings

Mounting Mount EtherCAT slaves. Refer to the manual for the Ether-

Wiring Wire EtherCAT slaves.

Creation of a

new project

Initialization of

the Controller

Check whether the system is

compatible with specifications of

the Programmable Multi-Axis

Controller.

• General specifications

• Mounting direction

Select peripheral devices to be

used for the Programmable

Multi-Axis Controller.

Procure and install the Support

Software required for the system.

Multi-Axis Controller.

the Programmable Multi-Axis

Controller.

Use the hardware switches on all

of the EtherCAT slaves in the network to set the node addresses.

• Wiring of the unit power supply

• I/O wiring

Ground and wire the EtherCAT

communication cable.

Connect the computer with the

Support Software installed to the

Programmable Multi-Axis Controller. Then start Power PMAC

IDE and create a new project.

Initialize the Programmable

Multi-Axis Controller by using

Power PMAC IDE.

configuring the system.

2-1-2 General Specifications on

page 2-3

2-2 Specifications of Peripherals

on page 2-5

1-3 Support Software on page 1-5

4-1 Mounting the Programmable

Multi-Axis Controller on page 4-2

4-2 Power Supply Wiring on page

4-4

Refer to the manual for the EtherCAT slave.

CAT slave.

Refer to the manual for the EtherCAT slave.

4-3 Laying the EtherCAT Network

on page 4-7

4-6 Grounding on page 4-17

Refer to “Power PMAC IDE User

Manual” for details.

Refer to “Power PMAC IDE User

Manual” for details.

---

1 - 6

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 31

1 Features and System Configuration

No. Step Description Reference

7 Construction

of the EtherCAT network

8 Settings of the

Programmable Multi-Axis

Controller

operation

9 Transferring project data and

checking the operation

Installation of

ESI files

EtherCAT slave

settings

Activation of the

EtherCAT network

Programming Create user programs on Power

Motor settings Set the motor operations for the

Install the ESI files of EtherCAT

slaves to be connected to

EC-Engineer.

Configure the EtherCAT communication settings by using

EC-Engineer. Then, create an

ENI file used to download the

configured settings to the Programmable Multi-Axis Controller.

Download the ENI file to the Programmable Multi-Axis Controller

by using Power PMAC IDE. Make

sure that the ENI file has been

correctly downloaded, and then

activate the EtherCAT network.

PMAC IDE.

Programmable Multi-Axis Controller by using Power PMAC IDE.

Transfer the created project data

and check that operations work

as expected.

Refer to “Acontis EC-Engineer

manual” for details.

For information on the ESI file,

refer to the manual for the EtherCAT slave.

Refer to “Acontis EC-Engineer

manual” for details.

Refer to “Power PMAC IDE User

Manual” for details.

Refer to “Power PMAC User’s

Manual” and “Power PMAC Software Reference Manual” for

details.

Refer to “Power PMAC IDE User

Manual” for details.

Refer to “Power PMAC IDE User

Manual” for details.

1-4 Application Procedure

1

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

1 - 7

Page 32

1 Features and System Configuration

1 - 8

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 33

Specifications

This section describes the specifications of the Programmable Multi-Axis Controller

and configuration devices.

2-1 Programmable Multi-Axis Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-1 Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-1-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-1-3 Features and Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-2 Specifications of Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2-1 USB Memory Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-2-2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2

2

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

2 - 1

Page 34

2 Specifications

2-1 Programmable Multi-Axis Controller

The following provides the models and major specifications of the Programmable Multi-Axis Controller

and configuration devices.

2-1-1 Model

Model Naming

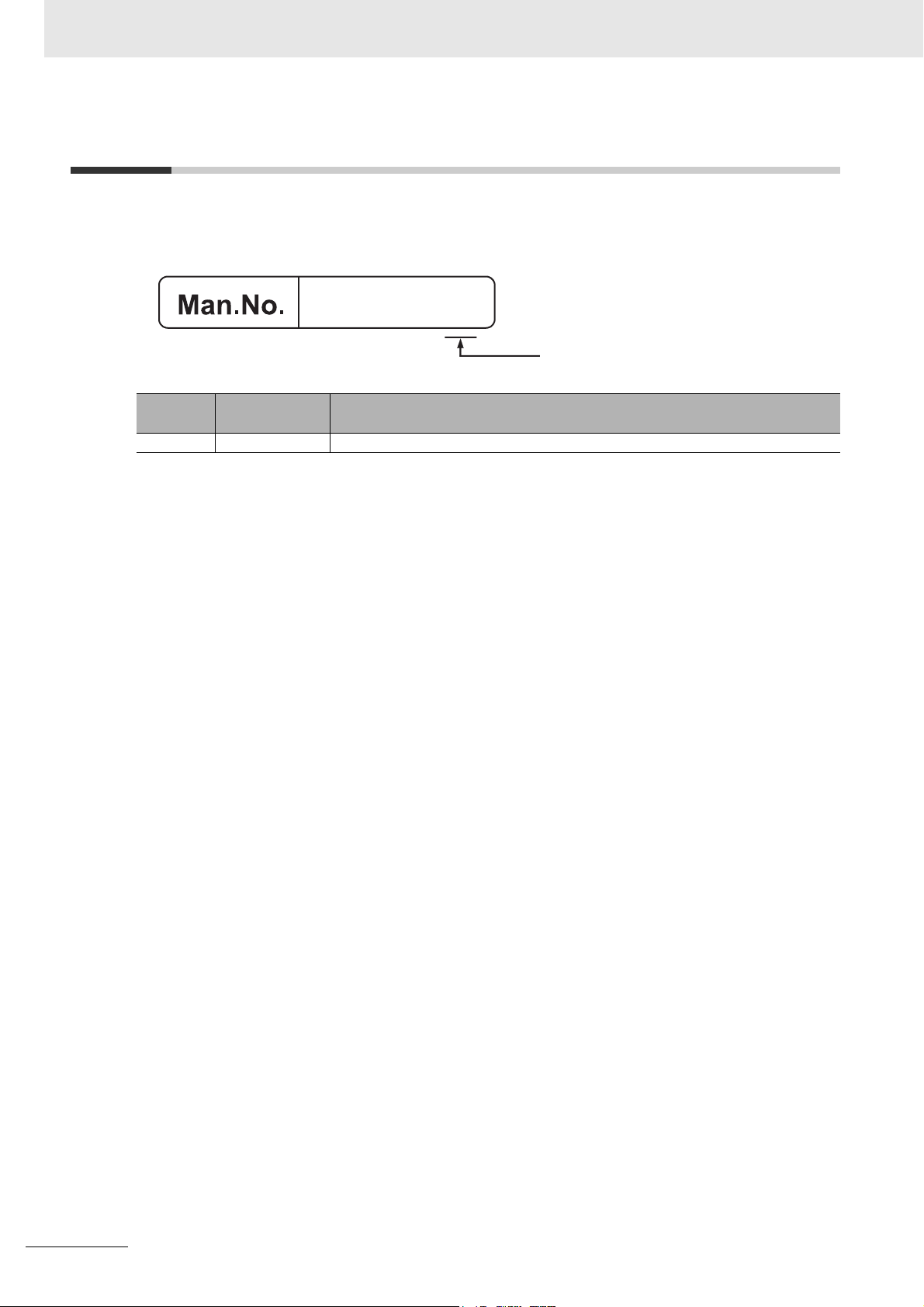

CK3E-series Programmable Multi-Axis Controller model names are assigned according to the following

rule.

Maximum number of controlled axes

12 : 8 axes

13 : 16 axes

14 : 32 axes

Number of EtherCAT ports

1 : 1 port

Always 0

Model List

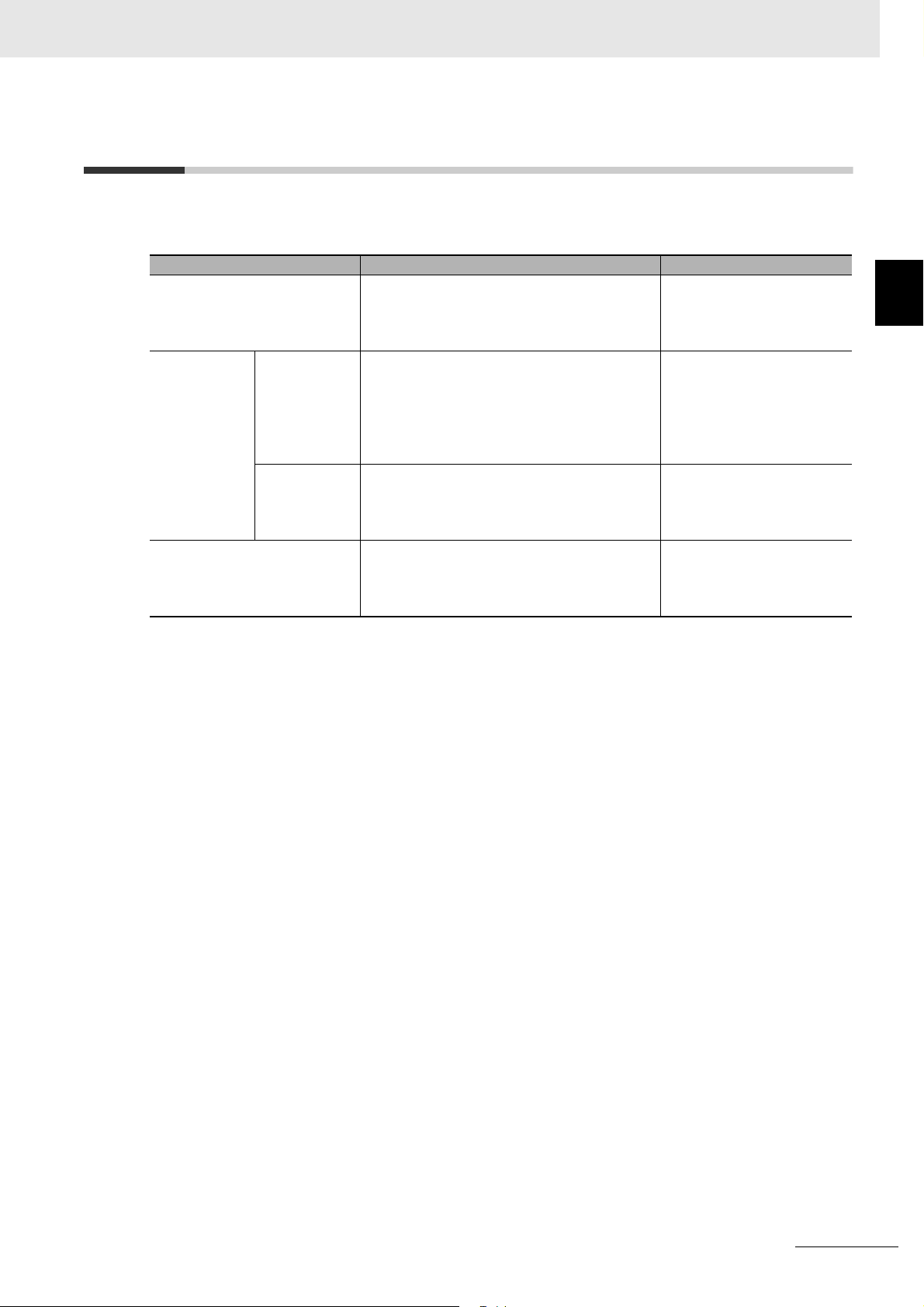

Specifications

Model

CK3E-1210 Main memory: 1 GB

CK3E-1310 16 axes

CK3E-1410 32 axes

Memory Port

Flash memory: 1 GB

Ethernet port: 1

EtherCAT port: 1

Maximum

number of

controlled axes

8 axes

2 - 2

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 35

2 Specifications

2-1-2 General Specifications

Item

Model CK3E-1210 Model CK3E-1310 Model CK3E-1410

Enclosure Mounted in a panel

Grounding methods Ground of 100 Ω or less

Dimensions (height × depth × width) 130.4 × 28.6 × 170.9 mm (H × D × W)

Weight 540 g or less

Unit power supply rated voltage 24 VDC (20.4 to 26.4 VDC)

Unit power current consumption 660 mA or less

Operating

environment

Ambient operating

temperature

Ambient operating

0 to 45°C

10 to 95% RH (without condensation and icing)

humidity

Atmosphere Must be free of corrosive gases.

Ambient storage tem-

-25 to +70°C (without condensation and icing)

perature

Vibration resistance Conforms to IEC 60068-2-6.

5 to 8.4 Hz with 3.5-mm amplitude, 8.4 to 150 Hz, acceleration of 9.8 m/s

X, Y, and Z directions

100 min (10 sweeps of 10 min each = 100 min total)

Shock resistance

Conforms to IEC 60068-2-27, 147 m/s

Applicable standards *1 EU: EN 61326, RCM

*1. For the latest applicable standards for each model, visit the OMRON website (www.fa.omron.co.jp or

www.ia.omron.com), or contact your OMRON representative.

Specifications

2

, 3 times each in X, Y, and Z directions

2

each in

2-1 Programmable Multi-Axis Controller

2

2-1-2 General Specifications

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

2 - 3

Page 36

2 Specifications

2-1-3 Features and Performance Specifications

Item

Memory Main memory: 1 GB

External terminals [Communications connector]

Motion control

EtherCAT

communications

specifications

Ethernet

communications

specifications

USB port Physical layer USB 3.0 compliant, type A connector. Output voltage: 5 V, 0.9 A max.

Maximum number of

controlled axes

Motion control period 250 μs or more

Control method Issuing control commands using EtherCAT communications

Communications protocol

Baud rate 100 Mbps

Physical layer 100BASE-TX (IEEE 802.3)

Topology Line, daisy chain, and branching

Transmission media Twisted-pair cable of category 5 or higher (double-shielded cable with aluminum

Transmission distance Distance between nodes: 100 m or less

Maximum number of

slaves

Range of node

addresses that can be

set

Physical layer 1000BASE-T/100BASE-TX

Frame length 1,514 bytes max.

Media access method CSMA/CD

Modulation Baseband

Topology Star

Transmission media Twisted-pair cable of category 5, 5e, or higher (shielded cable)

Maximum transmission distance between

Ethernet switch and

node

Maximum number of

cascade connections

Transmission distance 3 m max.

Model CK3E-1210 Model CK3E-1310 Model CK3E-1410

Flash memory: 1 GB

For EtherCAT communications

•RJ45 × 1 (Shield supported)

For Ethernet communications

•RJ45 × 1 (Shield supported)

[Power supply input terminal]

For unit power supply × 1

[USB port]

For external memory connection, USB 3.0 host × 1 Type A

8 axes 16 axes 32 axes

EtherCAT protocol

tape and braiding)

32

1 to 32

100 m

There are no restrictions if an Ethernet switch is used.

Specifications

2 - 4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 37

2-2 Specifications of Peripherals

2-2-1 USB Memory Device

The following shows details of the recommended USB memory device.

OMRON is not responsible for the operation, performance, or write life of any other USB memory

devices.

Recommended USB

memory

Model FZ-MEM2G OMRON USB memory device (2 GB)

Model FZ-MEM8G OMRON USB memory device (8 GB)

You can use the USB memory device for the following applications.

• Uploading data

• Downloading data

• Saving relevant data

Description

2 Specifications

2-2 Specifications of Peripherals

2

2-2-1 USB Memory Device

2-2-2 Power Supply

The following shows details of the recommended power supply.

Recommended power supply: Model S8JX series (OMRON)

For specifications and manuals of Model S8JX, visit the OMRON website

(http://www.fa.omron.co.jp/products/family/1989/lineup.html).

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

2 - 5

Page 38

2 Specifications

2 - 6

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 39

3

Part Names and Functions

This section describes the names and functions of the Programmable Multi-Axis Controller.

3-1 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Operation Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 ID Information Indication Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

3 - 1

Page 40

3 Part Names and Functions

3-1 Part Names

(C)

(B)

(A)

(D)

(E)

(J)

(I)

Letter Name Function

(A) USB 3.0 connector The connector of USB 3.0 interface, used to connect a USB

memory device.

(B) Maintenance mode LED Not used. Used for maintenance.

(C) Maintenance mode enter button Not used. Used to enter Maintenance mode. The user does

not use it.

(D) USB 2.0 connector Not used. Used for maintenance. The user does not use it.

(E) Power supply connector Connects to the Unit power supply.

(F) EtherCAT communications port opera-

tion indicators

(G) Ethernet communications port opera-

tion indicators

(H) Unit operation indicators Show the operation status of the Unit using multiple indicators.

(I) Ethernet communications connector Connects to an Ethernet network communications cable.

(J) EtherCAT communications connector Connects to an EtherCAT network communications cable.

Show the operation status of EtherCAT.

Show the operation status of Ethernet.

(F)

(G)

(H)

3 - 2

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 41

3-2 Operation Indicators

The Programmable Multi-Axis Controller is equipped with indicators to show the current operations status of the Unit.

(A)

(B)

3 Part Names and Functions

3-2 Operation Indicators

3

(C)

(D)

(E)

(F)

(G)

The operating statuses corresponding to colors and status of the indicators are shown below.

Letter Indicator Color Status Description

(A) DIAG.MODE Green Lit Not used.

(B) ECAT LINK Orange Lit The EtherCAT link is established.

Not lit The EtherCAT link is not established.

(C) ECAT ACT Yellow Lit The EtherCAT link is established.

Flashing Data communications are in progress after the

EtherCAT link is established.

Flashes every time data is sent or received.

Not lit The EtherCAT link is not established.

(D) Ethernet LINK Green/

Orange

(E) Ethernet ACT Yellow Lit The Ethernet link is established.

(F) PWR/ERR Green/Red Lit in green Power is supplied to the Unit.

(G) RDY Green Lit Power is supplied to the Unit, and the Unit is in

Lit in green The Ethernet link is established at 1 Gbps.

Lit in orange The Ethernet link is established at 100 Mbps.

Not lit The Ethernet link is not established.

Flashing Data communications are in progress after the

Ethernet link is established.

Flashes every time data is sent or received.

Not lit The Ethernet link is not established.

Lit in red Watchdog or another hardware error

Not lit Power is not supplied to the Unit.

operation-ready status.

Not lit Power is not supplied to the Unit, or initial pro-

cessing is in progress.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

3 - 3

Page 42

3 Part Names and Functions

3-3 ID Information Indication Label

The ID information indication label provides information relevant to the Programmable Multi-Axis Controller.

(A)

(B)

(C)

(D)

(E)

Item Name Description

(A) Model Refer to 2-1-1 Model on page 2-2.

(B) Product name Motion Controller

(C) Power supply rat-

ing

(D) Standard logos Logos used to represent applicable standards

(E) Lot number Information on the date of manufacturing.

Details of power supply rating

The lot number of the C3KE-series Programmable Multi-Axis Controller is specified

in the form of DDMYY,where “DD” is the day, “M” is the month, and “YY” is the

year the product is manufactured. “” is a character used by OMRON. For “M”,

digits “1” to “9” respectively represent January to September, “X” represents October, “Y” November, and “Z” December.

3 - 4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 43

Mounting and Wiring

This section describes the procedures for mounting the Programmable Multi-Axis Controller, wiring the power supply used for the Programmable Multi-Axis Controller, and

wiring the Programmable Multi-Axis Controller.

4-1 Mounting the Programmable Multi-Axis Controller . . . . . . . . . . . . . . . . . . 4-2

4-1-1 Mounting the Programmable Multi-Axis Controller . . . . . . . . . . . . . . . . . . . . . 4-2

4-1-2 Mounting Direction in Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-1-3 Mounting Method in Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-2 Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-2-1 Power Supply Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-2-2 Wiring the Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 Laying the EtherCAT Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3-1 Supported Network Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3-2 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-3-3 Installing EtherCAT Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-4 Laying the Ethernet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-4-1 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-4-2 Installing Ethernet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-5 USB Memory Device Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4

4

4-6 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-6-1 Considerations for Earthing Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4-6-2 Earthing Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

4 - 1

Page 44

4 Mounting and Wiring

4-1 Mounting the Programmable

Multi-Axis Controller

4-1-1 Mounting the Programmable Multi-Axis Controller

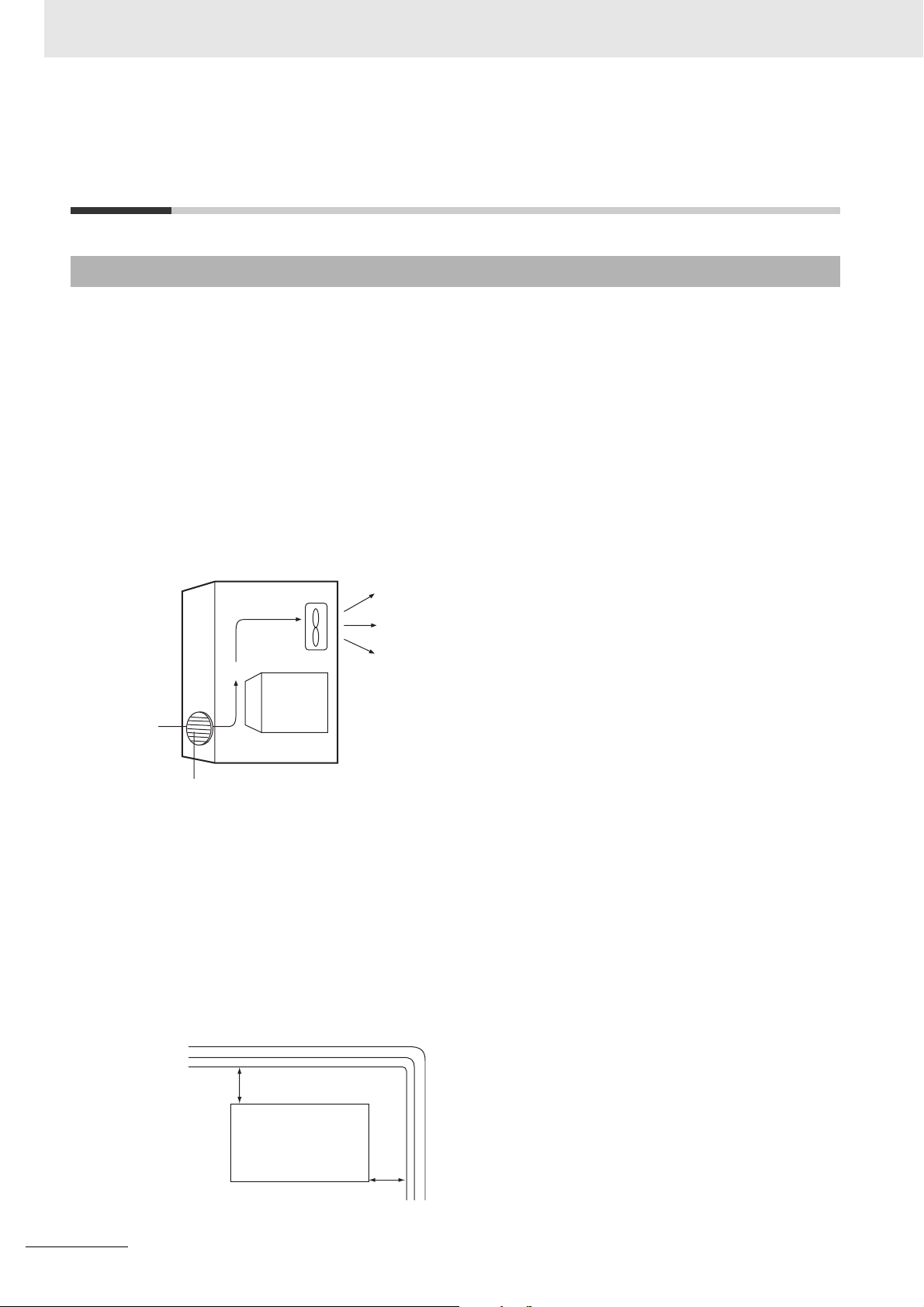

z Installation in Cabinets or Control Panels

When installing the Programmable Multi-Axis Controller in a cabinet or control panel, consider the

ambient temperature, accessibility for operation and maintenance, noise immunity, as well as the

mounting direction.

z Temperature Control

The allowable ambient operating temperature range of the Programmable Multi-Axis Controller is 0

to 45°C. When necessary, take the following steps to maintain the appropriate temperature.

• Provide sufficient space for adequate air flow.

• Do not install the Controller directly above equipment that generates a large amount of heat such

as heaters, transformers, or high-capacity resistors.

• If the ambient temperature exceeds 45°C, install a cooling fan or air conditioner.

Control

panel

Louver

Fan

CK3E-series

Programmable

Multi-Axis

Controller

z Accessibility for Operation and Maintenance

• To ensure safe access for operation and maintenance, move the Controller as far away as possible from high-voltage equipment and electrical machinery.

• It will be easy to operate the Controller if it is mounted at a height of 1,000 to 1,600 mm above the

floor.

z Improving Noise Resistance

• Do not mount the Controller in a control panel containing high-voltage equipment.

• Install the Controller at least 200 mm away from power lines.

Power lines

4 - 2

200 mm min.

CK3E-series

Programmable

Multi-Axis Controller

200 mm min.

• Ground the mounting plate between the Controller and the mounting surface.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 45

4 Mounting and Wiring

4-1-2 Mounting Direction in Control Panels

The Programmable Multi-Axis Controller can be installed facing the front or sideways.

The Controller must be mounted in an upright position to provide appropriate cooling.

Front mounting Sideways mounting

4-1 Mounting the Programmable Multi-Axis Controller

4

4-1-2 Mounting Direction in Control Panels

4-1-3 Mounting Method in Control Panels

The following shows the mounting method of the Programmable Multi-Axis Controller. It is recommended that M4 screws be used for mounting.

1 Create holes for the screws used to mount the Programmable Multi-Axis Controller.

The screw positions are as follows.

Front mounting Sideways mounting

88±0.5

119±0.5

119±0.5

2 Insert the screws into the designated positions to mount the Programmable Multi-Axis Control-

ler.

3 Tighten the screws with 1.2 N-m torque to secure.

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

4 - 3

Page 46

4 Mounting and Wiring

4-2 Power Supply Wiring

4-2-1 Power Supply Connector Specifications

The following power supply connector is used for the Programmable Multi-Axis Controller.

One power supply connector is included in the Programmable Multi-Axis Controller package.

Model Manufacturer

MVSTBW 2.5/3-ST-5,08 (1792760) Phoenix Contact

The following shows the pin assignment of the power supply connector used for the Programmable

Multi-Axis Controller.

123

Pin Description

124 VDC

20 VDC

3 Functional ground terminal

4-2-2 Wiring the Power Supply Connector

Compatible Wires

Wires that can be connected to terminal holes of the power supply connector are bar terminals attached

to twisted wires, twisted wires, and solid wires.

Select a power supply conductor by considering voltage drops and heat due to the cable length within

your installation environment. The following table provides information about the conductors that are

compatible with this connector.

Wire type

Solid wire

Twist ed wire

Twisted wire with bar terminal, without plastic sleeve

Twisted wire with bar terminal, with plastic sleeve

Conductor cross-sec-

tional area

0.2 to 2.5 mm

0.2 to 2.5 mm

0.25 to 2.5 mm

0.25 to 2.5 mm

2

2

2

2

Conductor length

(stripping length)

7 mm

7 mm

7 mm

7 mm

4 - 4

CK3E-series Programmable Multi-Axis Controller Hardware User’s Manual (I610)

Page 47

4 Mounting and Wiring

Grounding

The type of ground terminal on the Programmable Multi-Axis Controller is a functional ground terminal.

A functional ground terminal takes protective measures for device and system functions, including prevention of noises from external sources, and prevention of noises from devices or equipment that may

have harmful effects on other devices or equipment.

• Ground to 100 Ω or less, and as possible use a separate ground from those of other devices.

• If using an independent ground is not possible, then use a common ground. Connect to the ground

pole of the other device.

• Never use a common ground particularly with a motor, inverter, or other type of high-power equipment. Use an independent ground so that they do not affect each other.

• To reduce the risk of receiving an electric shock, do not connect devices to ground poles to which

multiple devices are connected.