Page 1

(ZW-7000 series)

CJ Series

EtherNet/IP

Connection Guide

OMRON Corporation

Displacement Sensor

TM

P661-E1-01

Page 2

About Intellectual Property Rights and Trademarks

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

ODVA and EtherNet/IP

TM

are trademarks of ODVA.

Company names and product names in this document are t he trademarks or registered

trademarks of their respective companies.

Page 3

Table of Contents

1. Related Manuals ........................................................................................ 1

2. Terms and Definitions ............................................................................... 2

3. Precautions ................................................................................................ 3

4. Overview .................................................................................................... 4

5. Applicable Devices and Device Configuration ....................................... 5

5.1. Applicable Devices ............................................................................. 5

5.2. Device Configuration .......................................................................... 6

6. EtherNet/IP Settings .................................................................................. 8

6.1. Parameters ........................................................................................ 8

6.2. Tag Data Link Settings ....................................................................... 9

7. EtherNet/IP Connection Procedure ........................................................ 12

7.1. Work Flow ........................................................................................ 12

7.2. Sensor Controller Setup ................................................................... 14

7.3. PLC Setup ........................................................................................ 25

7.4. Network Settings .............................................................................. 35

7.5. EtherNet/IP Communication Status Check ...................................... 48

8. Initialization method ................................................................................ 55

8.1. Initializing PLC ................................................................................. 55

8.2. Initializing Sensor Controller ............................................................ 56

9. Revision History ...................................................................................... 57

Page 4

1.Related Manuals

1

1. Related Manuals

To ensure system safety, make sure to always read and follow the information provided in all

Safety Precautions and Precautions for Saf e Use in the manuals for each device which is

used in the system.

Cat. No. Model Manual name

W472 CJ2M-CPU[][]

CJ2H-CPU6[]

CJ2H-CPU6[]-EIP

W473 CJ2M-CPU[][]

CJ2H-CPU6[]

CJ2H-CPU6[]-EIP

W465 CJ1W-EIP21

CJ2M-CPU3[]

CJ2H-CPU6[]-EIP

W446 CXONE-AL[][]C-V4

/ AL[][]D-V4

0969584-7 W4S1-05[]

W4S1-03B

Z362 ZW-7000[] Displacement Sensor ZW-7000 series

Z363 ZW-7000[] Displacement Sensor ZW-7000 series

CJ-series

CJ2 CPU Unit

Hardware USER'S MANUAL

CJ-series

CJ2 CPU Unit

Software USER'S MANUAL

CJ Series

EtherNet/IP

OPERATION MANUAL

CX-Programmer

OPERATION MANUAL

Switching Hub

W4S1-series

Users Manual

Confocal Fiber Type

Displacement Sensor User’s Manual

Confocal Fiber Type Displacement

Sensor User’s Manual for

Communications Settings

TM

Units

Page 5

2.Terms and Definitions

2

network.

address, and it is assigned to the memory area of each device.

Corporation.

This standard feature on EtherNet/IP is called a tag data link .

between the specified nodes concurrently.

than one node.

and the node that receives the request is called a "target " .

parameter

It includes the data to set tags, tag sets, and connect ions.

and the parameters that can be set via EtherNet/IP.

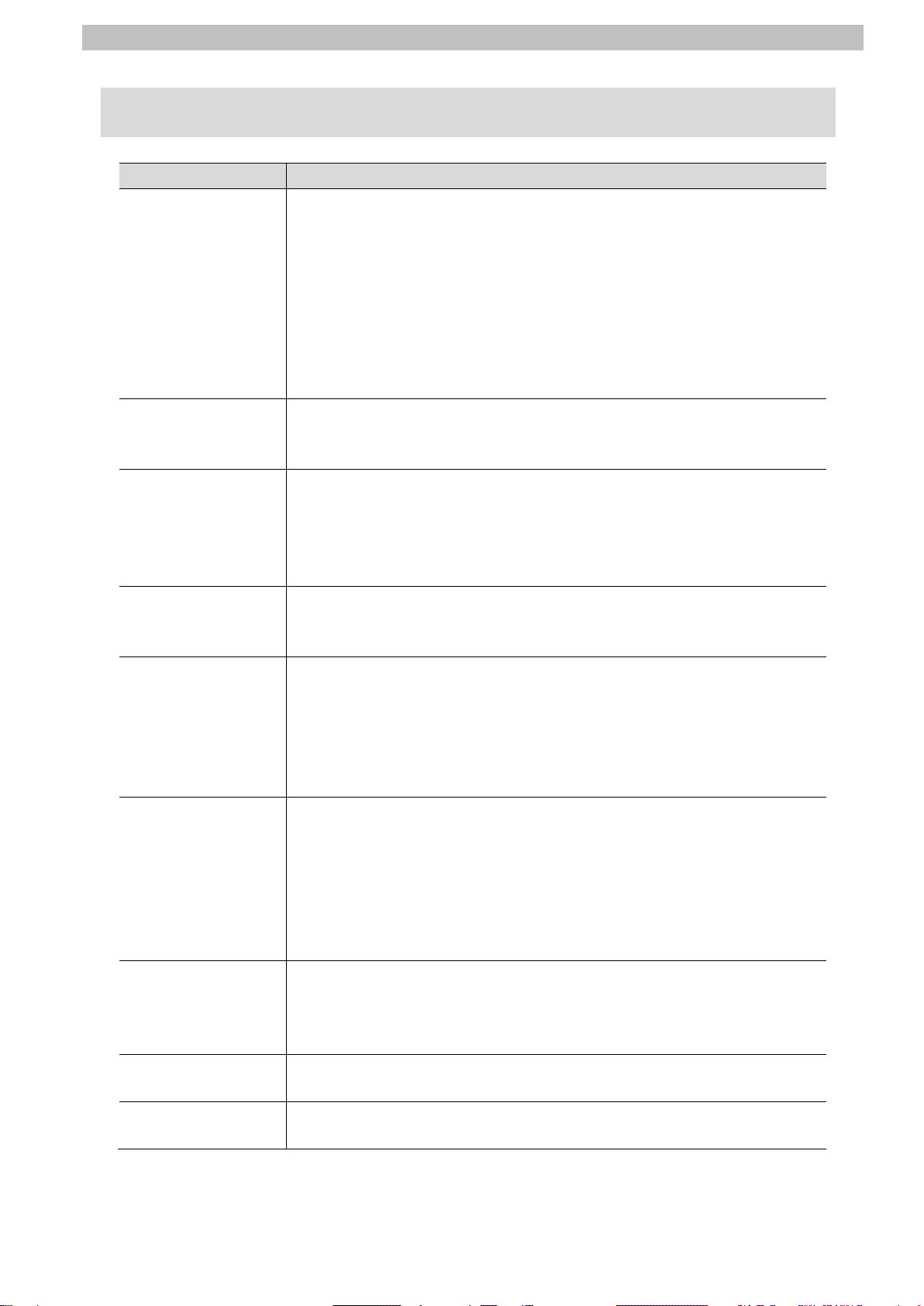

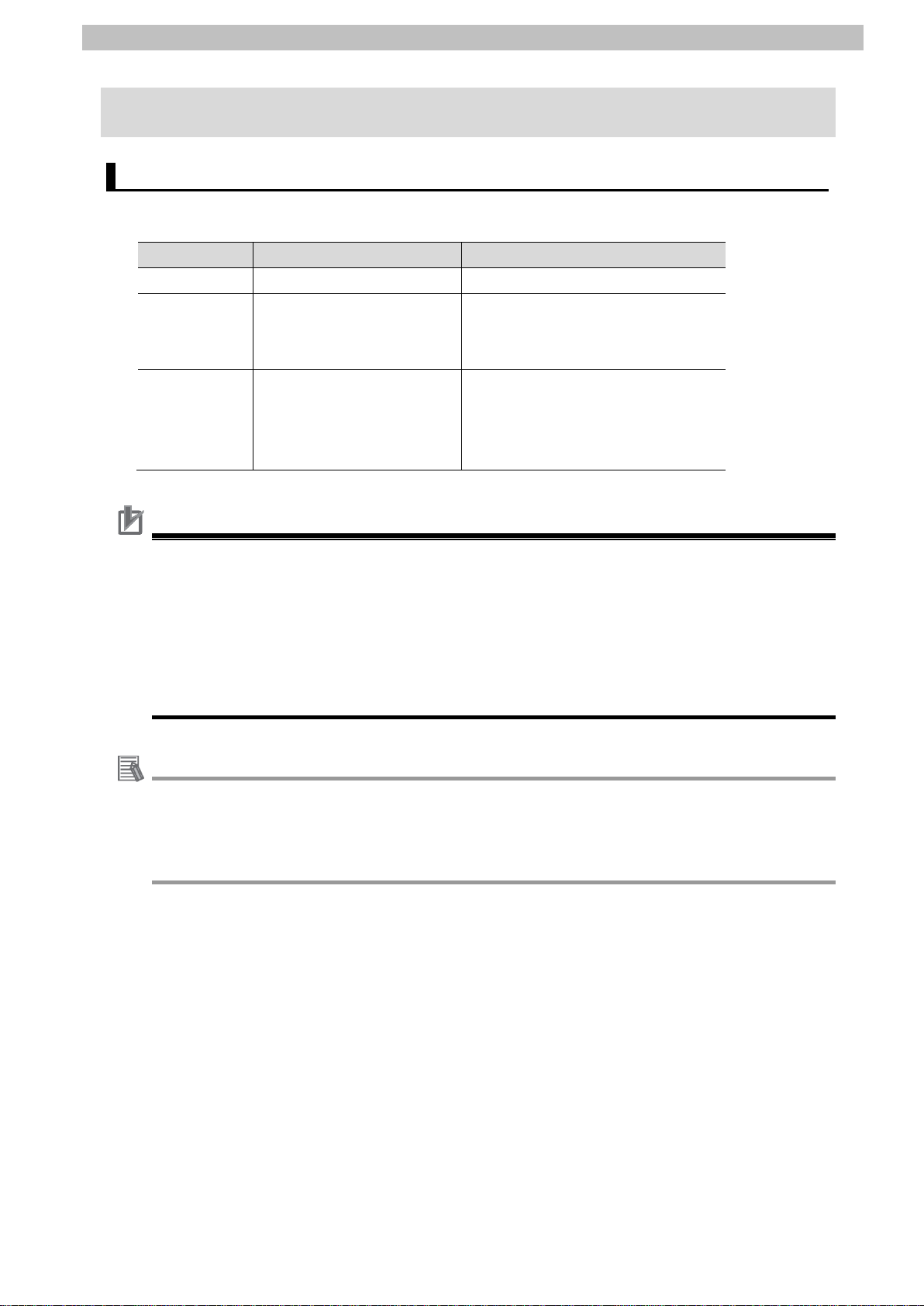

2. Terms and Definitions

Term Explanation and Definition

Node A programmable controller and a device are connected to an EtherNet/IP

network via EtherNet/IP ports. EtherNet/IP recognizes each EtherNet/IP

port connected to the network as one node.

When a device with two EtherNet/IP ports is connected to the

EtherNet/IP network, EtherNet/IP recognizes this device as two nodes.

EtherNet/IP achieves the communications between programmable

controllers or the communications between a pro grammable controller

and a device by exchanging data between these nodes connected to the

Tag A minimum unit of the data that is exchanged on the EtherNet/IP network

is called a tag. The tag is defined as a network variable or as a physical

Tag set In the EtherNet/IP network, a data unit that consists of two or more tags

can be exchanged. The data unit consisting of two or more tags f or the

data exchange is called a tag set. Up to eight tags can be confi gured per

tag set for the programmable controllers produced by OMRON

Tag data link In EtherNet/IP, the tag and tag set can be exchanged cyclically between

nodes without using a user program.

Connection A connection is used to exchange data as a unit within which data

concurrency is maintained. The connection consists of tags or tag sets.

Creating the concurrent tag data link between the specified nodes is

called a "connection establishment". When the connection is established,

the tags or tag sets that configure the connection are excha nged

Connection type There are two kinds of connection types for the tag data li nk connection.

One is a multi-cast connection, and the other is a unicast (point-to-point)

connection. The multi-cast connection sends an output tag set in one

packet to more than one node. The unicast connection separately sends

one output tag set to each node. Therefore, multi-cast connections can

decrease the communications load if one output tag set is sent to more

Originator and

Target

To operate tag data links, one node requests the opening of a

communications line called a "connection".

The node that requests to open the connection is cal led an "originator",

Tag data link

EDS file A file that describes the number of I/O points for the EtherNet/IP device

A tag data link parameter is the setting data to operate tag data links.

Page 6

3.Precautions

3

Precautions for Correct Use

Additional Information

Symbol

3. Precautions

(1) Understand the specifications of devices which are used in the system. Allow some

margin for ratings and performance. Provide saf ety measures, such as installing a safety

circuit, in order to ensure safety and minimize the risk of abnormal occurrence.

(2) To ensure system safety, make sure to always read and follow the information provided in

all Safety Precautions and Precautions for Safe Use in the manuals for each device

which is used in the system.

(3) The user is encouraged to confirm the standards and regulations that the system must

conform to.

(4) It is prohibited to copy, to reproduce, and to distribute a part or the whole of this

document without the permission of OMRON Corporat ion.

(5) The information contained in this document is current as of July 2016. It is subject to

change for improvement without notice.

The following notations are used in this docum ent.

Indicates a potentially hazardous situation whi ch, if not avoided,

may result in minor or moderate injury or property damage.

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase unders tanding or make operation easier.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in the text.

This example indicates a general precaution.

Page 7

4.Overview

4

4. Overview

This document describes the procedures f or connecting Displacement Sensor (hereinafter

referred to as Sensor Controller) to CJ-seri es Programmable Controller + EtherNet/IP Unit

(hereinafter referred to as PLC) via EtherNet/ IP, both produced by OMRON Corporation

(hereinafter referred to as OMRON), and for check ing their connections.

Refer to Section 6. EtherNet/IP Settings and Section 7. EtherNet/IP Connection Procedure to

understand setting methods and key points to operate EtherNet/IP tag data links.

In this document, CJ-series EtherNet/IP Unit and the built-in EtherNet/IP port of CJ-series CJ2

CPU Unit are collectively called as "EtherNet/IP Unit''.

Page 8

5.Applicable Devices and Device Configuration

5

Additional Information

5. Applicable Devices and Device Configuration

5.1. Applicable Devices

The applicable devices are as follows:

Manufacturer Name Model

OMRON CJ2 CPU Unit CJ2[]-CPU[][]

OMRON EtherNet/IP Unit CJ1W-EIP21

CJ2H-CPU6[]-EIP

CJ2M-CPU3[]

OMRON Confocal Fiber Type

Displacement Sensor

Sensor Controller

Sensor Head

ZW-7000[]

ZW-S70[][]

Precautions for Correct Use

In this document, the devices with models and versions listed in 5.2. Device Configuration are

used as examples of applicable devices to des cribe the procedures for connecting the

devices and checking their connections.

You cannot use devices with versions lower than the versions list ed in 5.2.

To use the above devices with models not listed in 5.2. or versions higher than thos e listed in

5.2., check the differences in the specifications by referring to t he manuals before operating

the devices.

This document describes the procedures f or establishing the network connections.

It does not provide information on operation, installation, wiring method, device functional it y,

or device operation, which is not related to the connection procedures.

Refer to the manuals or contact the device manufac turer.

Page 9

5.Applicable Devices and Device Configuration

6

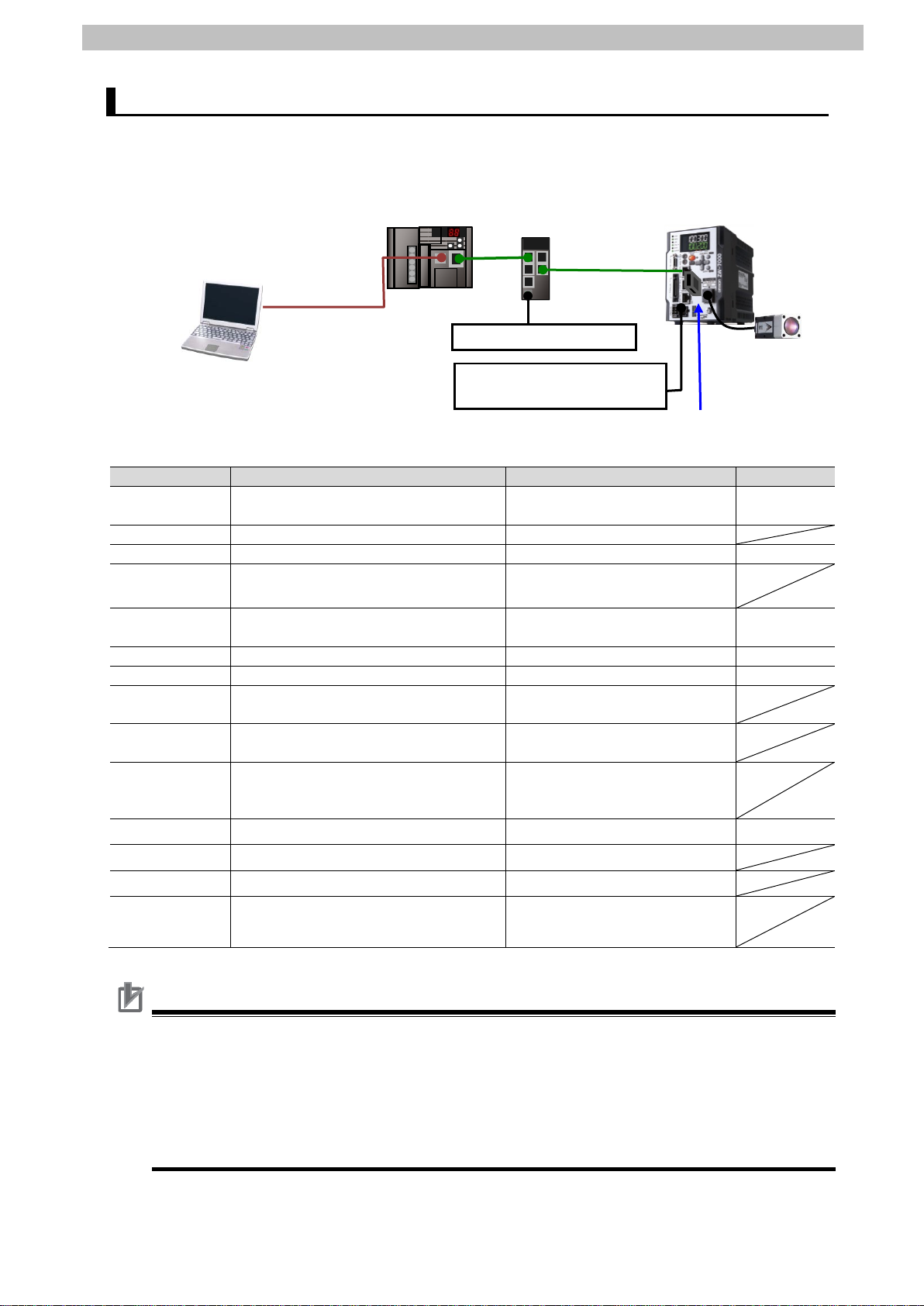

Manufacturer

Name

Model

Version

OMRON

CJ2 CPU Unit

(Built-in EtherNet/IP port)

CJ2M-CPU32

Ver.2.0

(Ver.2.12)

OMRON

Power Supply Unit

CJ1W-PA202

OMRON

Switching hub

W4S1-05C

Ver.1.00

-

24 VDC power supply

-

OMRON

CX-One

CXONE-AL[][]C-V4

/AL[][]D-V4

Ver.4.[][]

OMRON

CX-Programmer

(Included in CX-One)

Ver.9.61

OMRON

Network Configurator

(Included in CX-One)

Ver.3.59c

-

Personal computer

(OS: Windows 7)

-

-

USB cable

(USB 2.0 type B connector)

-

-

LAN cable (STP (shielded,

category 5 or higher)

-

OMRON

S8VS-06024

Precautions for Correct Use

ZW-7000

24 VDC power supply

Calibration ROM

CJ2M-CPU32

Personal computer

24 VDC power supply

LAN cable

W4S1-05C

5.2. Device Configuration

The hardware components to reproduce the connect i on procedures in this document are as

follows:

(CX-One installed,

OS: Windows 7)

USB cable

(Built-in EtherNet/IP port)

(for Sensor Controller)

(for Switching hub)

twisted-pair) cable of Ethernet

OMRON Sensor Controller ZW-7000 Ver.2.020

OMRON Sensor Head ZW-S7030

OMRON Calibration ROM (Supplied with Sensor Head)

24 VDC power supply (for Sensor

Controller) (24 VDC, 2.5A, 60W)

Update CX-Programmer and Network Configurator to the version specified in this Clause 5.2.

or to a higher version. If you use a version higher than the one specified, the procedures and

related screenshots described in Section 7. and subsequent sections may not be applicable.

In that case, use the equivalent procedures described i n this document by referring the

CX-Programmer OPERATION MANUAL (Cat. No. W446) and Network Configurator Online

Help.

Page 10

7

Additional Information

Additional Information

For specifications of 24 VDC power supply available for Switching hub, refer to the Switching

Hub W4S1-series Users Manual (Cat. No. 0969584-7).

For specifications of 24 VDC power supply available for Sensor Controller, refer to the

Displacement Sensor ZW-7000 series Confocal Fiber Type Displacement Sensor User ’s

Manual (Cat. No. Z362).

Additional Information

The system configuration in this document uses USB for the connection between Personal

computer and PLC. For information on how to install the USB driver, refer to A-5 Installing the

USB Driver of the CJ-series CJ2 CPU Unit Hardware Us er's Manual (Cat. No. W472).

5.Applicable Devices and Device Configuration

Page 11

6.EtherNet/IP Settings

8

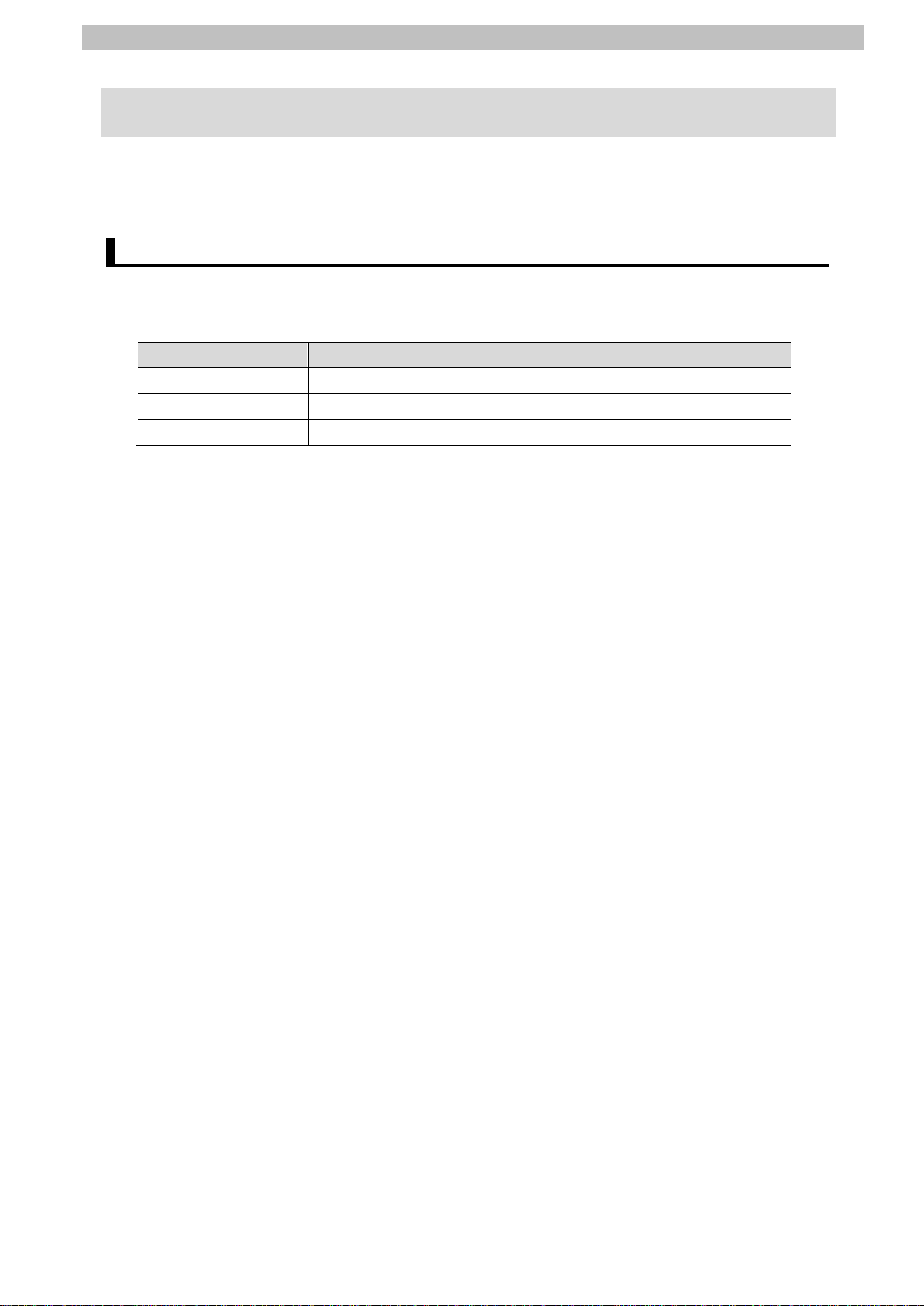

6. EtherNet/IP Settings

This section describes the contents of parameter and tag data link settings that are all defined

in this document.

6.1. Parameters

The parameters required for connecting PLC to Sensor Controller via EtherNet/IP are shown

below.

Item PLC (Node 1) Sensor Controller (Node 50)

IP address 192.168.250.1 192.168.250.50

Subnet mask 255.255.255.0 255.255.255.0

Fieldbus - EtherNet/IP

Page 12

6.EtherNet/IP Settings

9

Address

Bit

Function name

Sensor head control signal 1 (lower 16 bits)

0 Control command execution

1 to 15

Reserved

Sensor head control signal 1 (upper 16 bits)

0 Error clear

1 to 15

Reserved

Sensor head control signal 2 (lower 16 bits)

0 Timing

1 Reset

2 Light metering OFF

4 to 15

Reserved

Sensor head control signal 2 (upper 16 bits)

0 TASK1 Zero reset execution

1 TASK2 Zero reset execution

2 TASK3 Zero reset execution

3 TASK4 Zero reset execution

4 TASK1 Zero reset cancel

5 TASK2 Zero reset cancel

6 TASK3 Zero reset cancel

7 TASK4 Zero reset cancel

8 to 15

Reserved

D10004

0 to 15

Extended area (lower 16 bits)

D10005

0 to 15

Extended area (upper 16 bits)

D10006

0 to 15

Command code (lower 16 bits)

D10007

0 to 15

Command code (upper 16 bits)

D10008

0 to 15

Command parameter 1

D10009

0 to 15

Command parameter 2

D10010

0 to 15

Command parameter 3 (lower 16 bits)

D10011

0 to 15

Command parameter 4 (upper 16 bits)

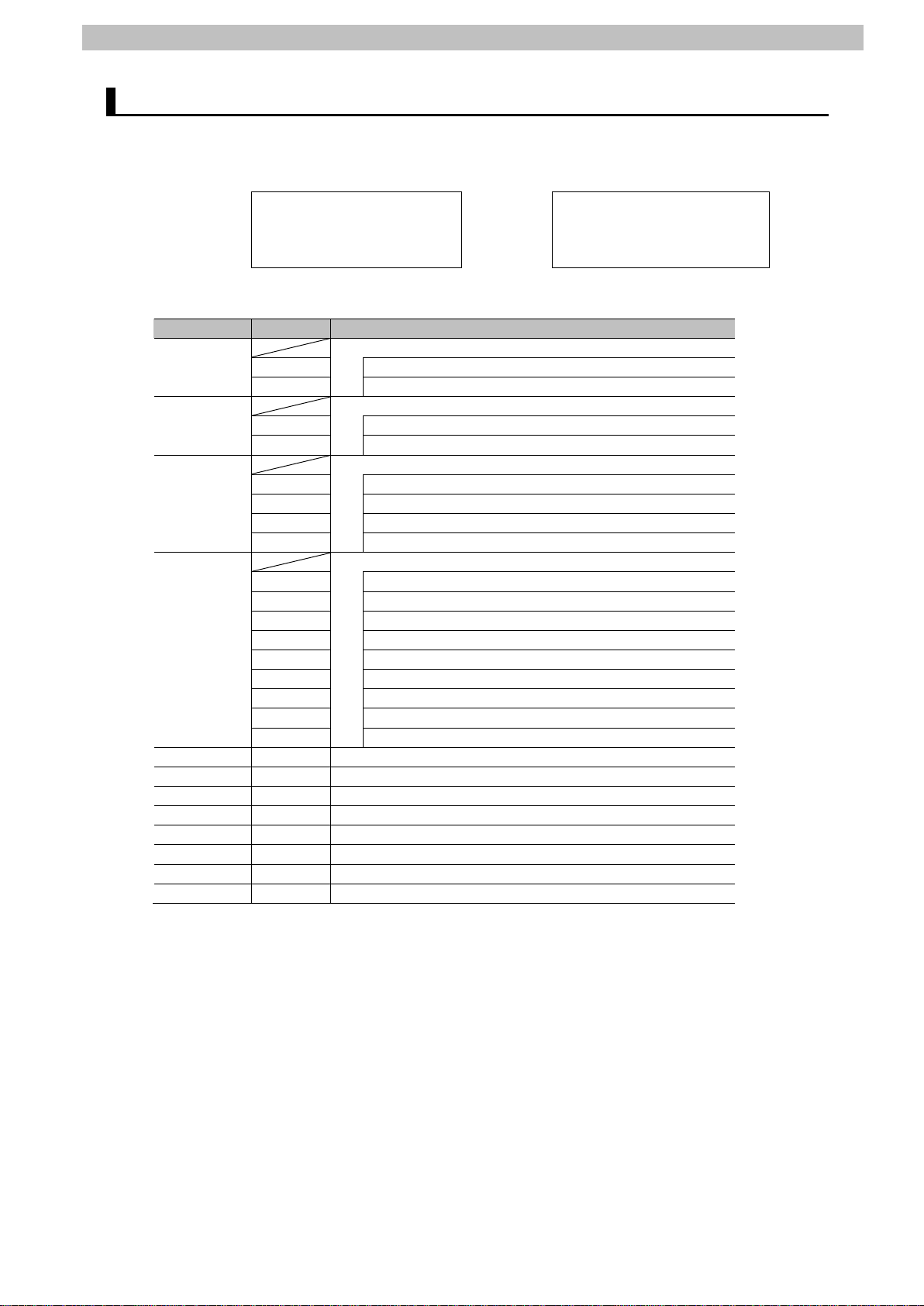

6.2. Tag Data Link Settings

The following shows the content of tag data link settings for Sensor Controller.

Output area Input area

D10000

(PLC to Sensor Controller)

24 bytes

D10011

■Output area

D10000

D10001

D10100

(Sensor Controller to PLC)

56 bytes

D10127

D10002

D10003

Page 13

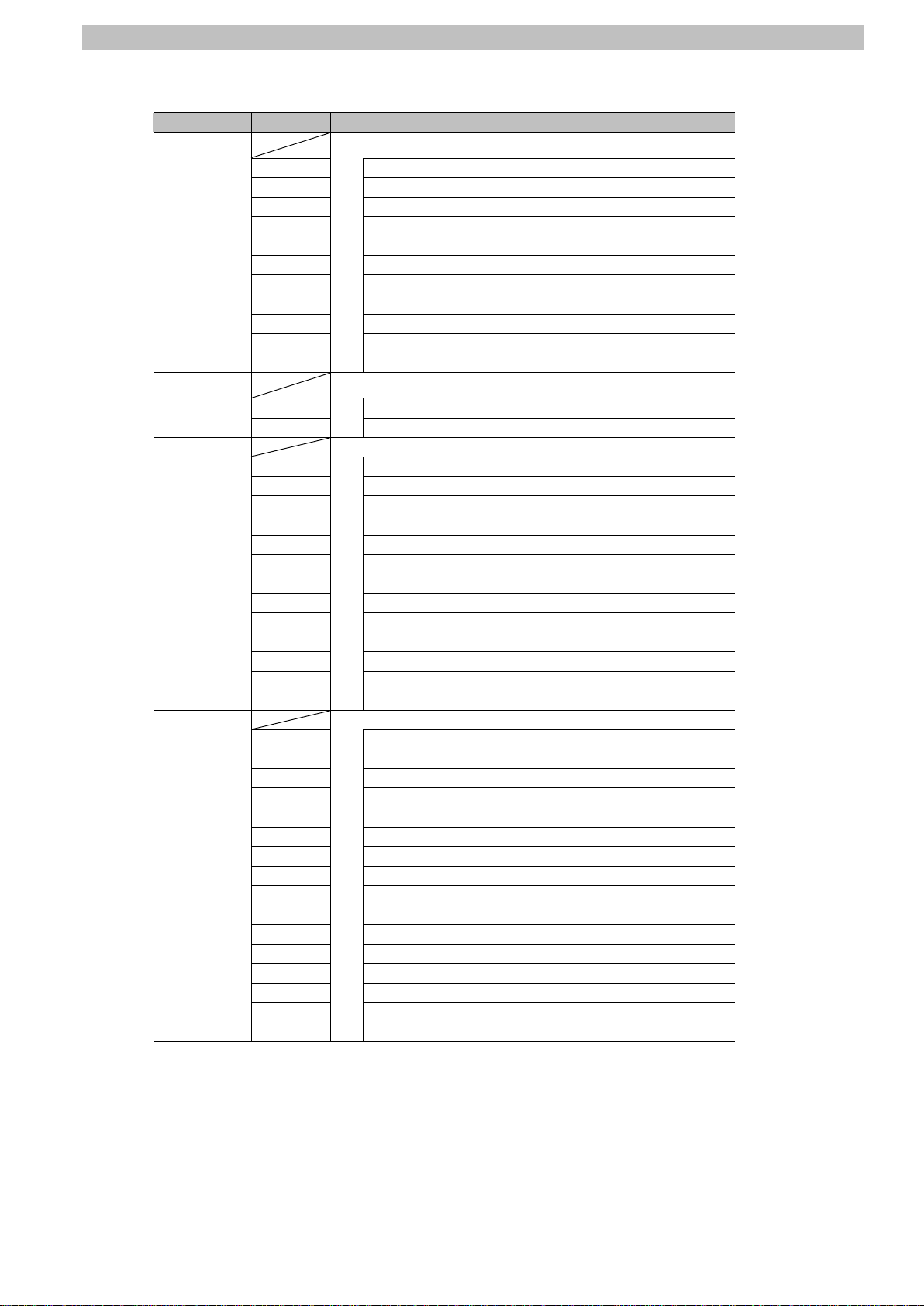

10

■Input area

Address

Bit

Function name

0 Control command completion

1 Reserved

2 Ready

3 Reserved

4 Run screen

5 to 10

Reserved

11 Current bank number bit0

12 Current bank number bit1

13 Current bank number bit2

14 Current bank number bit3

15 Current bank number bit4

0 Error

1 to 15

Reserved

Sensor head status signal 2 (lower 16 bits)

0 Hold execution status

1 Reset execution state

2 Logical beam lighting state

3 Measurement position

4 Measurement state

5 Data output completed

6 Overall judgment result

7 Reserved

8 TASK1 TASK status

9 TASK2 TASK status

10 TASK3 TASK status

11 TASK4 TASK status

12 to 15

Reserved

Sensor head status signal 2 (upper 16 bits)

0 TASK1 Zero reset state

1 TASK2 Zero reset state

2 TASK3 Zero reset state

3 TASK4 Zero reset state

4 TASK1 HIGH output

5 TASK1 PASS output

6 TASK1 LOW output

7 TASK2 HIGH output

8 TASK2 PASS output

9 TASK2 LOW output

10 TASK3 HIGH output

11 TASK3 PASS output

12 TASK3 LOW output

13 TASK4 HIGH output

14 TASK4 PASS output

15 TASK4 LOW output

D10100

D10101

6.EtherNet/IP Settings

Sensor head status signal 1 (lower 16 bits)

Sensor head status signal 1 (upper 16 bits)

D10102

D10103

Page 14

6.EtherNet/IP Settings

11

Address

Bit

Function name

D10104

0 to 15

Extended area (lower 16 bits)

D10105

0 to 15

Extended area (upper 16 bits)

D10106

0 to 15

Command code echo (lower 16 bits)

D10107

0 to 15

Command code echo (upper 16 bits)

D10108

0 to 15

Response code (lower 16 bits)

D10109

0 to 15

Response code (upper 16 bits)

D10110

0 to 15

Response data (lower 16 bits)

D10111

0 to 15

Response data (upper 16 bits)

D10112

0 to 15

Output data 0 (lower 16 bits)

D10113

0 to 15

Output data 0 (upper 16 bits)

D10114

0 to 15

Output data 1 (lower 16 bits)

D10115

0 to 15

Output data 1 (upper 16 bits)

D10116

0 to 15

Output data 2 (lower 16 bits)

D10117

0 to 15

Output data 2 (upper 16 bits)

D10118

0 to 15

Output data 3 (lower 16 bits)

D10119

0 to 15

Output data 3 (upper 16 bits)

D10120

0 to 15

D10121

0 to 15

D10122

0 to 15

D10123

0 to 15

D10124

0 to 15

D10125

0 to 15

D10126

0 to 15

D10127

0 to 15

Reserved

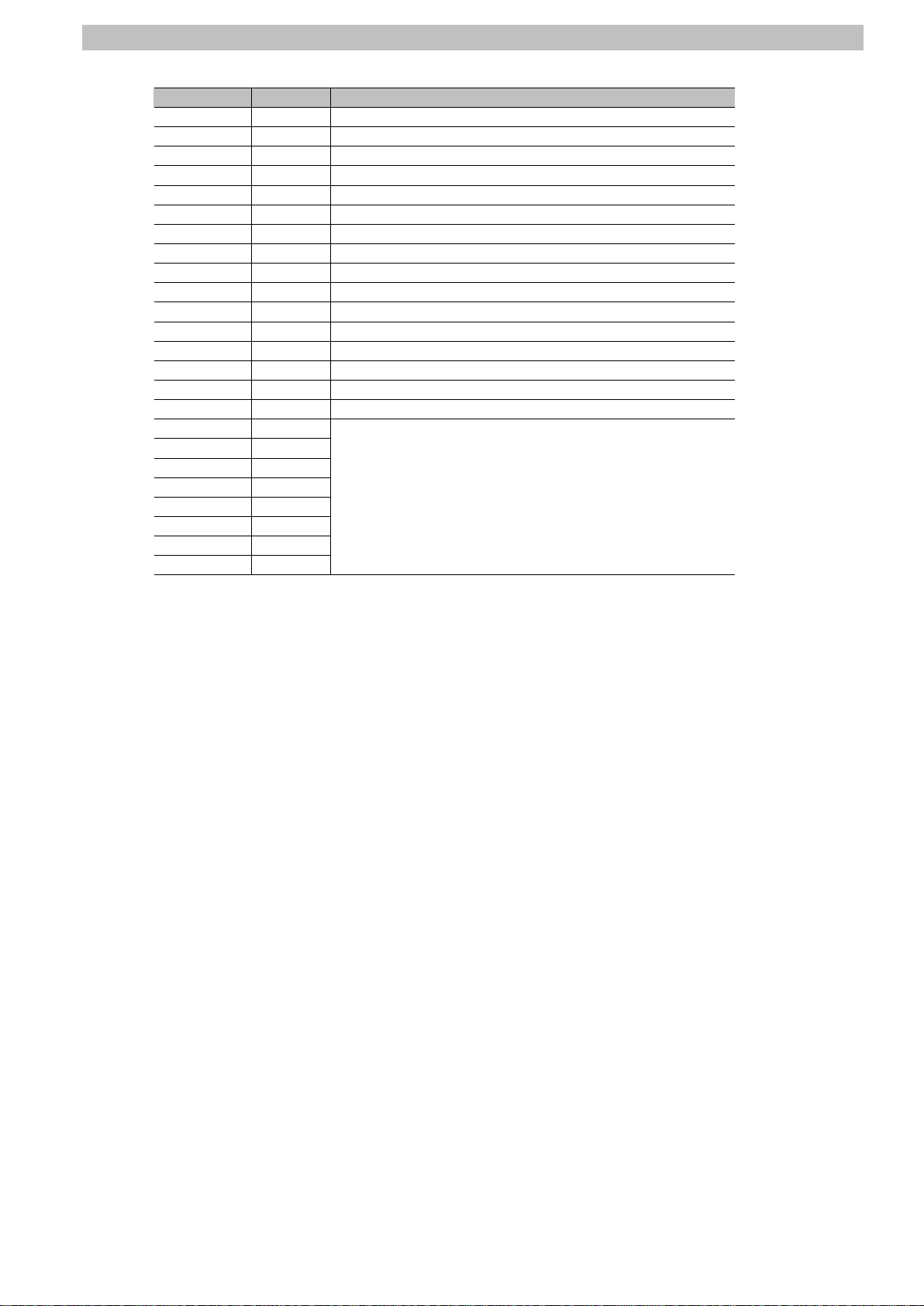

Page 15

7.EtherNet/IP Connection Procedure

12

7.2. Sensor Controller Setup

Set up Sensor Controller.

7.2.1. Hardware Settings

Connect cables and others to Sensor Controller.

Set the parameters for Sensor Controller.

7.3. PLC Setup

Set up PLC.

Set the hardware switches on EtherNet/IP Unit and

wire the network.

Start CX-Programmer and connect online with

Create the I/O table and set the IP address of PLC.

7.4. Network Settings

Set the EtherNet/IP tag data links.

Start Network Configurator and connect onli ne wi th

Upload the network configuration.

Register tags for input (consume) and output

(produce).

7. EtherNet/IP Connection Procedure

This section describes the procedures for connecting PLC and Sensor Controller on the

EtherNet/IP network.

The explanations of procedures for setting up PLC and Sensor Controller given in this

document are based on the factory default settings.

For the initialization, refer to Section 8. Initialization Method.

7.1. Work Flow

Take the following steps to operate tag data links by connecting PLC and Sensor Contr oller

via EtherNet/IP.

↓

↓

7.2.2. Parameter Settings

↓

↓

7.3.1. Hardware Settings

↓

7.3.2. Starting CX-Programmer and

Connecting Online with PLC

↓

7.3.3. Creating the I/O Table and

Setting the IP Address

↓

↓

PLC.

7.4.1. Starting Network Configurator

and Connecting Online with

PLC

↓

7.4.2. Uploading the Network

Configuration

↓

7.4.3. Setting the Tags

↓

PLC.

Page 16

13

Associate the tags of the target device with the

tags of the originator device.

Transfer the set tag data link parameters to PLC.

Check

Confirm that the EtherNet/IP tag data links operate

Check the connection status of the EtherNet/IP

network.

Check that the correct data are sent and received.

7.4.4. Setting the Connections

7.EtherNet/IP Connection Procedure

↓

7.4.5. Transferring the Tag Data Link

Parameters

↓

7.5. EtherNet/IP Communication Status

↓

7.5.1. Checking the Connection Status

↓

7.5.2. Checking the Sent and

Received Data

normally.

Page 17

14

7.2. Sensor Controller Setup

1

may not be applicable.

3

connector

block

Set up Sensor Controller.

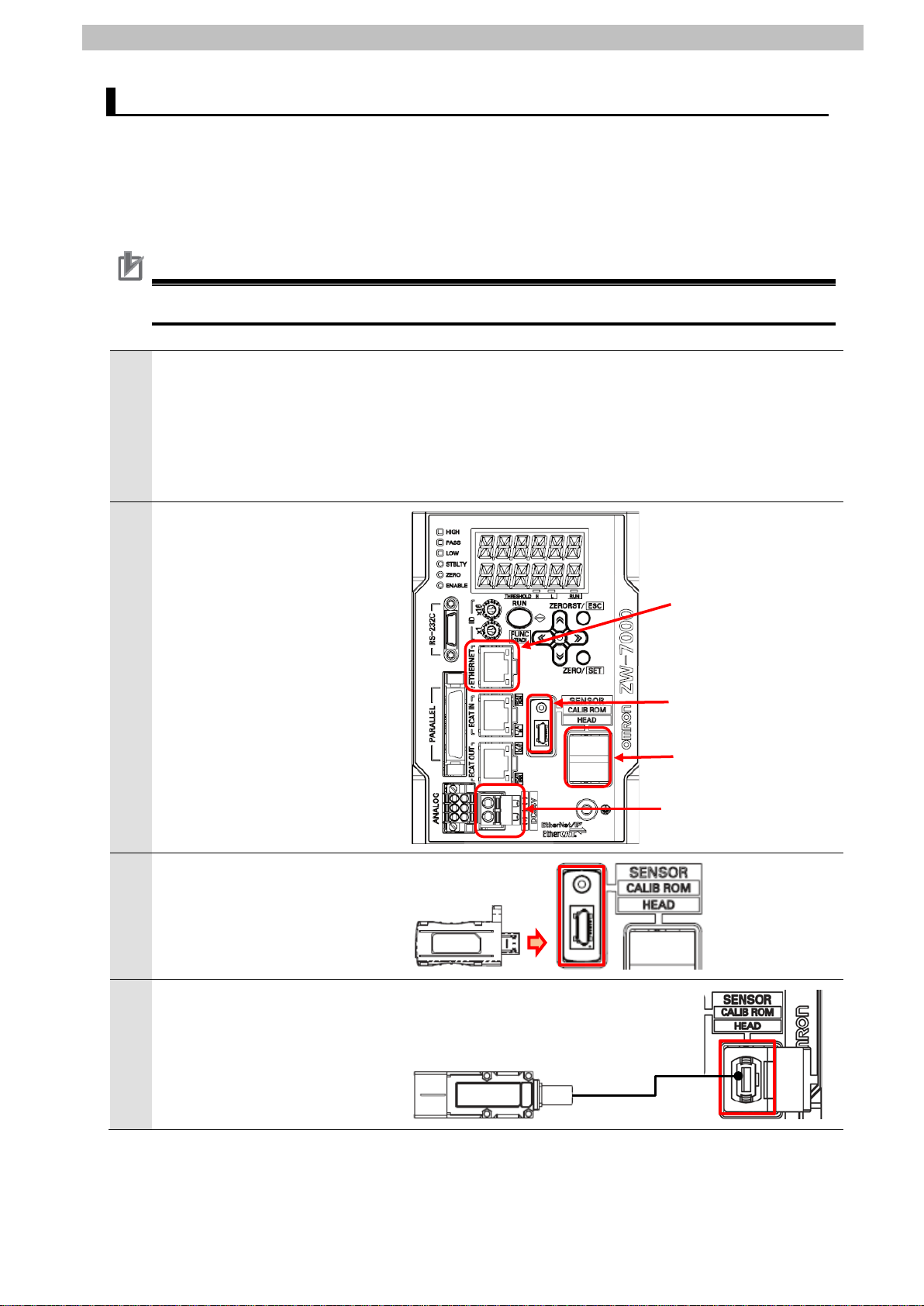

7.2.1. Hardware Settings

Connect cables and others to Sensor Controller.

Precautions for Correct Use

Make sure that the power supply is OFF when you set up.

Make sure that Sensor

Controller is powered OFF.

*If it is ON, the settings

described in the following steps

and subsequent procedures

7.EtherNet/IP Connection Procedure

Check the position of

2

connectors on Sensor Controller

by referring to the figure on the

right.

Connect the calibration ROM to

ROM connector.

Ethernet

ROM connector

Fiber adapter

24V input terminal

4

Connect Fiber connector on

Sensor Head to Fiber adapter.

Page 18

7.EtherNet/IP Connection Procedure

15

24 VDC power supply

6

Manual (Cat. No. Z362).

Connect Switching hub and

5

Ethernet connector on Sensor

Controller with a LAN cable.

Connect 24 VDC power supply

(for Switching hub) to Switching

hub.

Connect 24 VDC power supply

to 24 V input terminal block.

*For details on specifications of

24 VDC power supply available

for Sensor Controller, refer to

the Displacement

SensorZW-7000 series

Confocal Fiber Type

Displacement Sensor User’s

LAN cable

24 VDC power supply

Page 19

16

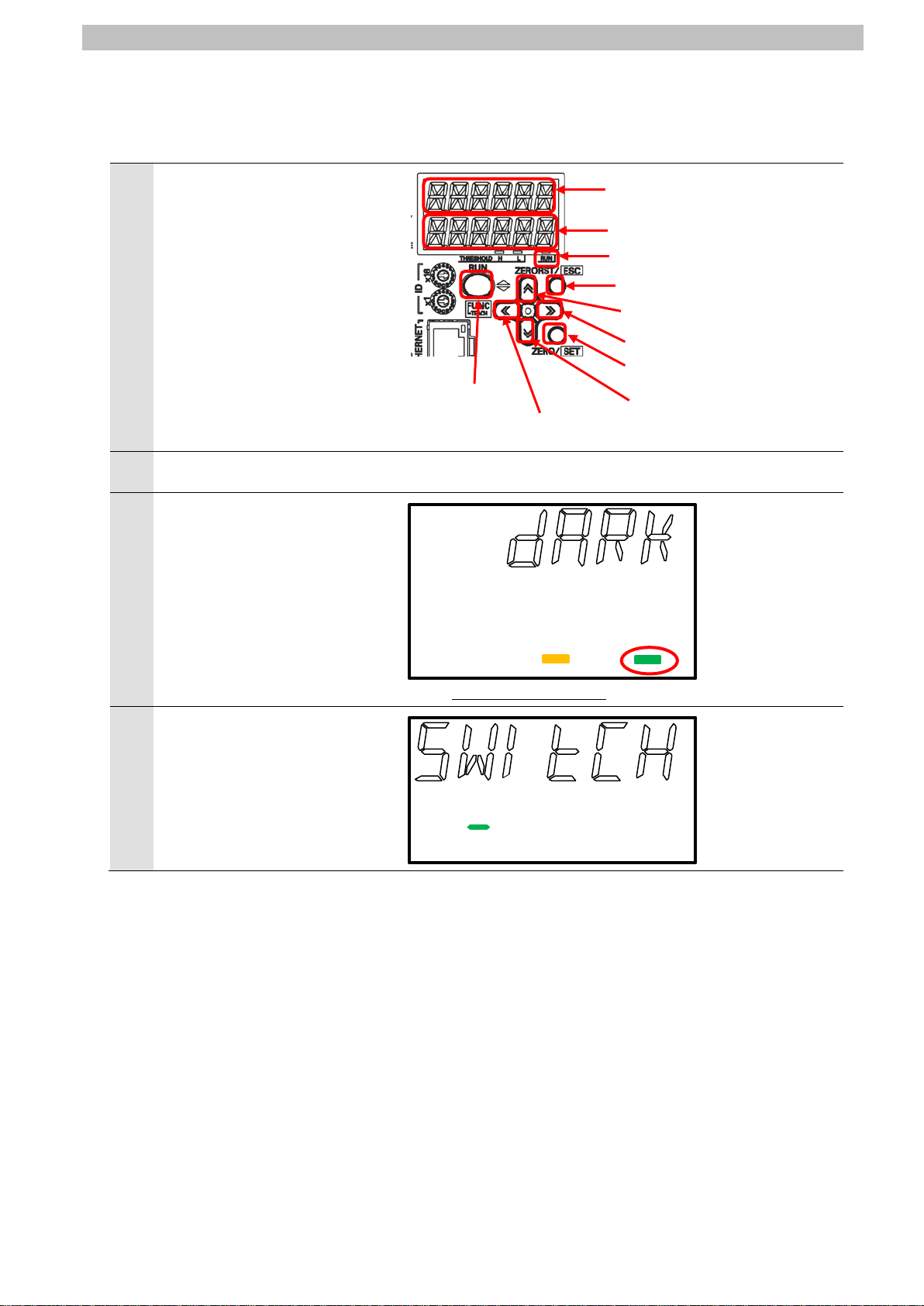

7.2.2. Parameter Settings

1

2

3

4

0kzcan

RUN Indicator (Green)

ZERORST/ESC Key

ZERO/SET Key

(DOWN) Key

↑(UP) Key

(RIGHT) Key

(LEFT) Key

Mode Switching

Set the parameters for Sensor Controller.

Check the positions of each key

and displays to use for

parameter settings.

7.EtherNet/IP Connection Procedure

Main Display (White)

Sub-display (Green)

Turn ON Sensor Controller.

The system enters the RUN

mode after displaying “INIT” for

a few seconds.

*The RUN Indicator is lit in the

RUN mode.

Press and hold the Mode

Switching Key for two seconds.

OK/CAN is displayed.

Press the ZERO/SET Key.

Key

←

*5000

THRESHOLD H L RUN

→

↓

Page 20

17

The operation mode is switched

←

6

←

7

→

5

to the FUNC mode, and SENS

is displayed on Main Display.

*The RUN Indicator goes out in

the FUNC mode.

Keep pressing the →(RIGHT)

or the

(LEFT) Keys until

SYSTEM is displayed.

Press the ZERO/SET Key.

H.CALIB is displayed on Main

Display.

Keep pressing the →(RIGHT )

or the

(LEFT) Keys until

COM is displayed.

Press the ZERO/SET Key.

7.EtherNet/IP Connection Procedure

THRESHOLD H L RUN

RS232C is displayed on Main

Display.

Change the menu from RS232C

to ETN by pressing the

(RIGHT ) Key.

Press the ZERO/SET Key.

Page 21

18

9

→

↑

IPADDR is displayed on Main

8

Display.

Press the ZERO/SET Key.

IP1 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 192 is displayed on

Sub-display.

*The set value here is the first

octet "192" of the IP address

192.168.250.50.

*If the value is different, press

the ZERO/SET Key.

The Sub-display changes to

the editing mode that enables

you to edit the value.

An editable digit of the value

blinks.

Select the digit you want to

change by pressing the

(RIGHT ) or the ←(LEFT)

Keys.

Change the value by pressing

the

Keys.

Press the ZERO/SET Key

again to fix the set value.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again

Press the →(RIGHT ) Key.

(UP) or the ↓(DOWN)

7.EtherNet/IP Connection Procedure

192

000192

192

Page 22

7.EtherNet/IP Connection Procedure

19

11

10

IP2 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 168 is displayed on

Sub-display.

*The set value here is the

second octet "168" of the IP

address 192.168.250.50.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the →(RIGHT ) Key.

168

IP3 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 250 is displayed on

Sub-display.

*The set value here is the third

octet "250" of the IP address

192.168.250.50.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the →(RIGHT ) Key.

250

Page 23

7.EtherNet/IP Connection Procedure

20

13

→

12

IP4 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 50 is displayed on

Sub-display.

*The set value here is the fourth

octet "50" of the IP address

192.168.250.50.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the ZERORST/ESC Key.

50

IPADDR is displayed on Main

Display.

Change the menu to SUBNET

by pressing the

Press the ZERO/SET Key.

(RIGHT) Key.

Page 24

7.EtherNet/IP Connection Procedure

21

14

SUB1 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 255 is displayed on

Sub-display.

*The set value here is the first

octet "255" of the subnet mask

255.255.255.0.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the →(RIGHT ) Key.

255

15

SUB2 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 255 is displayed on

Sub-display.

*The set value here is the

second octet "255" of the

subnet mask 255.255.255.0.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the →(RIGHT ) Key.

255

Page 25

7.EtherNet/IP Connection Procedure

22

16

SUB3 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 255 is displayed on

Sub-display.

*The set value here is the third

octet "255" of the subnet mask

255.255.255.0.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the →(RIGHT ) Key.

255

17

SUB4 is displayed on Main

Display.

Press the ZERO/SET Key.

Check that 0 is displayed on

Sub-display.

*The set value here is the fourth

octet "0" of the subnet mask

255.255.255.0.

*If the value is different, change

the value in the same way as

step 9.

Press the ZERORST/ESC Key.

The first menu shown in this

step is displayed again.

Press the ZERORST/ESC Key

twice.

0

Page 26

7.EtherNet/IP Connection Procedure

23

→

19

Switching

18

ETN is displayed on Main

Display.

Change the menu to MEMLNK

by pressing the

twice.

Press the ZERO/SET Key.

E-CAT is displayed on

Sub-display.

Press the ↑(UP) Key to

change the menu to EIP in

blinking.

EIP stops blinking when

pressing the ZERO/SET Key.

*The memory link function is set

to EtherNet/IP.

Press and hold the Mode

Key for two seconds.

(RIGHT) Key

e-cat

elp

Page 27

7.EtherNet/IP Connection Procedure

24

21

22

valid after power cycling.

20

OK/CAN is displayed.

Press the ZERO/SET Key.

SAVE is displayed on Main

Display.

Press the ZERO/SET Key.

The operation mode is switched

to the RUN mode.

0kzcan

0kzcan

*5000

THRESHOLD H L RUN

Power cycle Sensor Controller.

*The saved setting data become

Page 28

7.EtherNet/IP Connection Procedure

25

1

applicable.

2

3

The unit number is used to identify individual CPU Bus Units when more than

4

switches.

With the FINS communications service, when there are multiple EtherNet/IP

7.3. PLC Setup

Set up PLC.

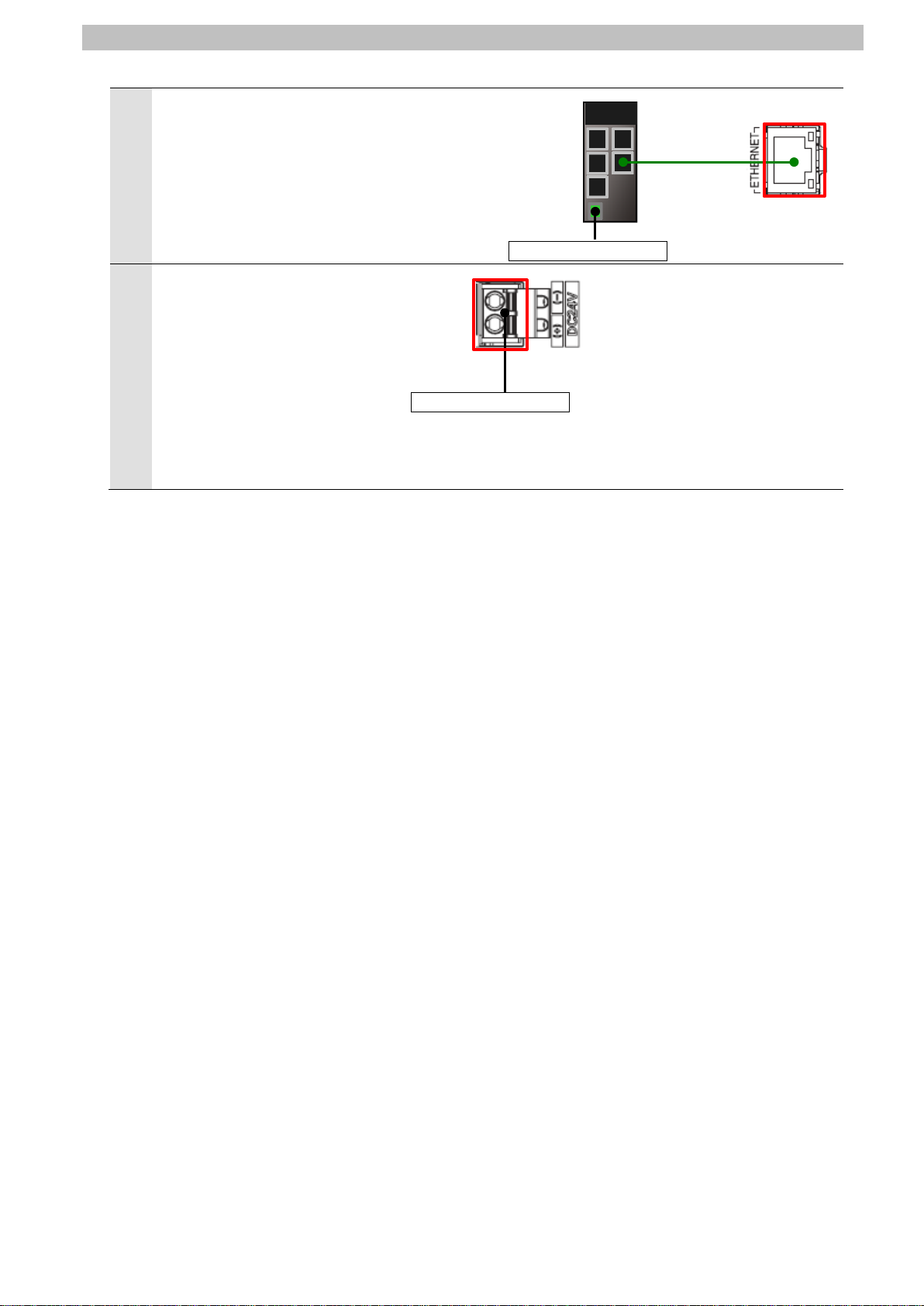

7.3.1. Hardware Settings

Set the hardware switches on EtherNet/IP Unit and wire the network.

Precautions for Correct Use

Make sure that the power supply is OFF when you set up.

Make sure that PLC and

Switching hub are powered

OFF.

*If either of them is ON, the

settings described in the

following steps and subsequent

procedures may not be

Check the position of the

hardware switches on the front

panel of EtherNet/IP Unit by

referring to the figure on the

right.

Set Unit number setting switch

to 0.

Set Node address setting

switches to the following default

settings.

NODE No.x16

NODE No.x16

1

0

: 0

: 1

*The IP address is set to

192.168.250.1.

one CPU Bus Unit is mounted to the same PLC. Use a small screwdriver to

make the setting, taking care not to damage the rotary switch. The unit

number is factory-set to 0.

Units connected to the Ethernet network, the EtherNet/IP Units are identified

by node addresses. Use the node address switches to set the node address

between 01 and FE hexadecimal (1 to 254 decimal).Do not set a number that

has already been set for another node on the same network.

The left switch sets the sixteens digit (most significant digit) and the right

switch sets the ones digit (least significant digit).The node address is

factory-set to 01.

Default IP address = 192.168.250.node address

With the factory-default node address setting of 01, the default IP address is

192.168.250.1.

*By default, the first to third

octets of the local IP address

are fixed to 192.168.250. The

fourth octet is a value that is set

with Node address setting

Page 29

7.EtherNet/IP Connection Procedure

26

6

hub.

7

Personal

24 VDC power supply

LAN cable

PLC

Power Supply Unit

Switching hub

CPU Unit

Connect a LAN cable to the

5

EtherNet/IP port on PLC, and

connect a USB cable to the USB

port. As shown in 5.2. Device

Configuration, connect Personal

computer and Switching Hub to

PLC.

Turn ON PLC and Switching

The set IP address is displayed

on the seven-segment LED

indicators. Afterwards, the last

digit of the IP address is

displayed in hexadecimal during

normal operation.

computer

USB cable

Page 30

7.EtherNet/IP Connection Procedure

27

1

CX-Programmer.

2

3

4

7.3.2. Starting CX-Programmer and Connecting Online with PLC

Start CX-Programmer and connect online with PLC.

Install CX-One and the USB driver on Personal computer beforehand.

Start CX-Programmer.

*If the User Account Control

Dialog Box is displayed at start,

make a selection to start

CX-Programmer starts.

Select Auto Online - Direct

Online from the PLC Menu.

The Direct Online Dialog Box is

displayed.

Select USB connection as

Connection Type.

Click Connect.

Page 31

28

The dialog box on the right is

6

7

during online connection.

Additional Information

Additional Information

5

displayed. Check the contents

and click No.

The dialog box on the right is

displayed.

CX-Programmer and PLC are

automatically connected.

Check that CX-Programmer and

PLC are normally connected

online.

7.EtherNet/IP Connection Procedure

*The icon is press ed down

If PLC cannot be connected online, check the cable c onnection.

Or, return to step 1, check the settings and repeat each step.

For details, refer to Connecting Directly to a CJ2 CPU Unit Using a USB Cable of the

CX-Programmer OPERATION MANUAL (Cat. No. W446).

The dialog boxes explained in the following procedures may not be displayed depending on

the environmental settings of CX-Programmer.

For details on the environmental settings, refer to Options and Preferences in CHAPTER 3

Project Reference in PART 1: CX-Programmer of the CX-Programmer OPERATION

MANUAL (Cat. No. W446). This document explains the setting procedures when ''Confirm all

operations affecting the PLC'' is selected.

Page 32

7.EtherNet/IP Connection Procedure

29

1

2

7.3.3. Creating the I/O Table and Setting the IP Address

Create the I/O table and set the IP address of PLC.

If the operating mode of PLC is

Run Mode or Monitor Mode,

change it to Program Mode by

following the steps below.

(1)Select Operating Mode -

Program from the PLC

Menu in CX-Programmer.

(2)The dialog box on the right is

displayed. Confirm that there

is no problem, and click Yes.

*Refer to Additional Information

on the previous page for the

settings concerning the dialog

display.

(3)Check that Stop/Program

Mode is displayed on the

right of the PLC model in the

Project Workspace of

CX-Programmer.

Select Edit - I/O Table and Unit

Setup from the PLC Menu in

CX-Programmer.

The PLC IO Table Window is

displayed.

(Project Workspace)

Page 33

7.EtherNet/IP Connection Procedure

30

Precautions for Correct Use

3

The PLC is reset after creating and transferring the I/O table in step 3 and subsequent steps.

Always confirm safety before creating and transferring the I/O table.

Select Create from the Options

Menu in the PLC IO Table

Window.

The dialog box on the right is

displayed. Confirm that there is

no problem, and click Yes.

The dialog box on the right is

displayed. Confirm that there is

no problem, and click Yes.

Page 34

7.EtherNet/IP Connection Procedure

31

The Transfer from PLC Dialog

4

Box is displayed.

Select IO Table and SIO Unit

Parameters.

Click Transfer.

When the transfer is completed,

the Transfer Results Dialog Box

is displayed.

Check that the transfer is

successfully completed by

referring to the message in the

dialog box.

When the I/O table is created

normally, the dialog box displays

as follows:

Transfer Success: 1 Unit

Transfer Unsuccessful: 0 Unit

Click OK.

Page 35

32

In the PLC IO Tabl e Window,

5

click + to the left of Built-in

Port/Inner Board to display

CJ2M-EIP21.

*The figure on the right displays

CPU Unit (Built-in EtherNet/IP

port) specified in 5.2. Device

Configuration. If you use an

other applicable EtherNet/IP

Unit, the display position and

name are different from the

figure on the right.

Right-click CJ2M-EIP21 and

select Unit Setup.

7.EtherNet/IP Connection Procedure

The Edit Parameters Dialog Box

6

is displayed.

Select the TCP/IP Tab.

Make the following settings in

the IP Address Field.

・Use the following address:

Select

・IP address: 192.168.250.1

・Subnet mask: 255.255.255.0

Click Transfer[PC to Unit].

Page 36

33

The dialog box on the right is

8

7

displayed. Confirm that there is

no problem, and click Yes.

Check that a message is

displayed stating "Transfer

successful". Click Close.

7.EtherNet/IP Connection Procedure

The dialog box on the right is

displayed. Check the contents

and click Yes.

When the Unit is restarted, the

dialog box on the right is

displayed. Check the contents

and click OK.

Page 37

34

Click Compare to check that the

10

11

9

IP address is correctly changed.

Check that a message is

displayed stating "Compare

successful". Click Close.

7.EtherNet/IP Connection Procedure

Click OK in the Edit Parameters

Dialog Box.

Page 38

7.EtherNet/IP Connection Procedure

35

1

2

7.4. Network Settings

Set the EtherNet/IP tag data links.

7.4.1. Starting Network Configurator and Connecting Online with PLC

Start Network Configurator and connect onli ne wi th PLC.

Right-click CJ2M-EIP21 in the

PLC IO Table Window, and

select Start Special

Application - Start with

Settings Inherited.

The Select Special Application

Dialog Box is displayed.

Select Network Configurator and

click OK.

Network Configurator starts.

Page 39

7.EtherNet/IP Connection Procedure

36

Precautions for Correct Use

3

4

6

Check that the LAN cables are connected before performing the following steps.

If they are not connected, turn OFF each of the devices, and then connect the LAN cables.

Select Select Interface - CJ2

USB/Serial Port from the

Option Menu.

Select Connect from the

Network Menu.

The Setup Interface Dialog Box

5

is displayed,

Check that the following settings

are made.

Port Type: USB

Port: OMR0

Baud Rate: 115200 Bit/s

Click OK.

The Select Connect Network

Port Dialog Box is displayed.

Select BackPlane CJ2M-EIP21 - TCP:2.

Click OK.

Page 40

37

The Select Connected Network

8

7

Dialog Box is displayed.

Check the contents and click

OK.

When an online connection is

established normally, the color

of the icon changes to blue as

shown on the right.

7.EtherNet/IP Connection Procedure

Additional Information

If PLC cannot be connected online, check the cable c onnection.

Or, return to step 3, check the settings and repeat each step.

For details, refer to 6-2-9 Connecting the Network Configurator to the Network in SECTION 6

Tag Data Link Functions of the EtherNet/IP

TM

Units OPERATION MANUAL (Cat. No. W465).

Page 41

7.EtherNet/IP Connection Procedure

38

1

3

4

7.4.2. Uploading the Network Configuration

Upload the network configuration.

Select Upload from the Network

Menu to upload the device

information on the network.

The dialog box on the right is

2

displayed. Confirm that there is

no problem, and click Yes.

The Target Devic e Di alog Box is

displayed. Select 192.168.250.1

and 192.168.250.50.

Click OK.

*If 192.168.250.1 and

192.168.250.50 are not

displayed in the dialog box,

click Add to add the

addresses.

*A displayed address depends

on the status of Network

Configurator.

The device parameters are

uploaded. When the uploading

is completed, the dialog box on

the right is displayed.

Check the contents and click

OK.

Page 42

39

After uploading, check that the

5

IP addresses of uploaded nodes

are updated in the Network

Configuration Pane as follows:

IP Address of node 1:

192.168.250.1

IP address of node 50:

192.168.250.50

7.EtherNet/IP Connection Procedure

Page 43

7.EtherNet/IP Connection Procedure

40

1

3

7.4.3. Setting the Tags

Register tags for input (consume) and output (produc e).

The following explains the receive and send s ettings of the target device in order.

In the Network Configuration

Pane of Network Configurator,

right-click the node 1 device and

select Parameter - Edit.

The Edit Device Parameters

2

Dialog Box is displayed.

Select the Tag Sets Tab.

The data on the Tag Sets Tab

Page is displayed.

Select the In-Consume Tab and

click Edit Tags.

Page 44

41

The Edit Tags Dialog Box is

5

6

4

displayed.

Select the In - Consume Tab

and click New.

Here, register a tag for the area

where the node 1 consumes

data from the node 50.

7.EtherNet/IP Connection Procedure

The Edit Tag Dialog Box is

displayed. Enter the following

values of the parameters.

Name: D10100 (Start address

of the input data to node 1)

Size: 56 (Byte)

After entering, click Regist.

The Edit Tag Dialog Box is

displayed again. Click Close.

Page 45

42

Select the Out - Produce Tab

8

9

7

and click New.

Here, register a tag for the area

where the node 1 produces data

to the node 50.

7.EtherNet/IP Connection Procedure

The Edit Tag Dialog Box is

displayed. Enter the following

values of the parameters.

Name: D10000 (Start address

of the output data from node

1)

Size: 24 (Byte)

After entering, click Regist.

The Edit Tag Dialog Box is

displayed again. Click Close.

Page 46

43

When you finish the registration,

11

10

click OK in the Edit Tags Dialog

Box.

7.EtherNet/IP Connection Procedure

The dialog box on the right is

displayed. Confirm that there is

no problem, and click Yes.

Page 47

44

The Edit Device Parameters

12

Dialog Box is displayed again.

Select the Connections Tab.

7.EtherNet/IP Connection Procedure

Page 48

7.EtherNet/IP Connection Procedure

45

1

3

Connection configuration

Set value

Connection I/O Type

Consume Data From

/Produce Data T o

Originator Device

Input Tag Set

D10100-[56 Byte]

Connection Type

Multi-cast connection

Output Tag Set

D10000-[24 Byte]

Connection Type

Point to Point connection

Target Device

Output Tag Set

Input_101-[56 Byte]

Input Tag Set

Output_100-[24 Byte]

7.4.4. Setting the Connections

Associate the tags of the target device (that rec ei ves the open request) with the tags of the

originator device (that requests for openi ng).

Select 192.168.250.50 in the

Unregister Device List Field.

Click the Down Arrow Button

that is shown in the dialog box.

192.168.250.50 is registered in

2

the Register Device List Field.

Select 192.168.250.50 and click

New.

The Edit Connection Dialog Box

is displayed.

Check that Consume Data

From/Produce Data To is

selected from the pull-down list

of Connection I/O Type.

Set the values listed in the

following table in the Originator

Device and the Target Device

Fields.

■Connection configuration settings

Page 49

46

Check that the settings are

5

6

4

correct.

Click Regist.

The Edit Connection Dialog Box

is displayed again. Click Close.

The Edit Device Parameters

Dialog Box is displayed again.

Click OK.

7.EtherNet/IP Connection Procedure

When the connection is

7

completed, the registered node

address is displayed under the

device icon of node 50 in the

Network Configuration Pane.

Page 50

7.EtherNet/IP Connection Procedure

47

1

3

4

7.4.5. Transferring the Tag Data Link Parameters

Transfer the set tag data link parameters to PLC.

Right-click the device icon of

node 1 in the Network

Configuration Pane and select

Parameter - Download.

The dialog box on the right is

2

displayed. Confirm that there is

no problem, and click Yes.

The tag data link parameters are

downloaded from Network

Configurator to PLC.

The dialog box on the right is

displayed. Check the contents

and click OK.

Page 51

7.EtherNet/IP Connection Procedure

48

1

2

3

7.5. EtherNet/IP Communication Status Check

Confirm that the EtherNet/IP tag data links operate normally.

7.5.1. Checking the Connection Status

Check the connection status of the EtherNet/IP network.

Check with LED indicators on PLC

(EtherNet/IP Unit) that the

EtherNet/IP tag data links operate

normally.

The LED indicators in normal status

are as follows:

MS: Green lit

NS: Green lit

COMM: Yellow lit

100M or 10M: Yellow lit

Check the LED indicators on Sensor

Controller.

The LED indicators in normal status

are as follows:

Red LED: Lighting

Green LED: Lighting

The normal operation of tag data

links is confirmed through the status

information in the Monitor Device

Dialog Box of Network Configurator.

Right-click the device icon of node 1

in the Network Configuration Pane

and select Monitor.

Page 52

49

The dialog box on the right displays

5

6

blue to gray as shown on the right.

7

4

the Status 1 Tab Page in the Monitor

Device Dialog Box.

When the same check boxes are

selected as shown on the right, the

tag data links are normally in

operation.

Click Close.

7.EtherNet/IP Connection Procedure

Number: Node number

Blue: Connection normal

Select Disconnect from the

Network Menu to go offline.

The color of the icon changes from

Select Exit from the File Menu to

close Network Configurator.

Page 53

7.EtherNet/IP Connection Procedure

50

1

setting IP Address.

2

3

7.5.2. Checking the Sent and Received Data

Check that the correct data are sent and received.

If the PLC memory is changed by malfunction during monitoring power flow and

present value status in the Ladder Section Window or in t he Watch Window, the

devices connected to output units may malfunction, regardless of the operating

mode of CPU Unit.

Always ensure safety before monitoring power fl ow and present value status in

the Ladder Section Window or in the Watch Window.

Check that the operating mode of

PLC is in Stop/Program Mode.

*If the PLC is not in Stop/Program

Mode, change to Stop/Program

Mode by referring to step 1 of

7.3.3. Creating the I/O Table and

Select Edit - Memory from the PLC

Menu.

The PLC Memory Window is

displayed. Double-click D on the

Memory Tab of the PLC Memory

Window.

Page 54

51

Select Display - Hexadecimal from

6

7

4

the View Menu.

Select Monitor from the Online

5

Menu.

7.EtherNet/IP Connection Procedure

The Monitor Memory Areas Dialog

Box is displayed.

Check that D is selected.

Click Monitor.

Enter 10000 in the Start Address

Field of the D Window.

Check that the start address

changes to D10000.

Select the value of +6 (D10006) in

8

the D10000 Row of the D Window.

Check that the value in the Start

Address Field changes to 10006.

Page 55

52

Click SetValue.

10

(system data acquisition) is set.

12

13

decimal point) is set.

9

The Set Value Dialog Box is

displayed.

Enter 4000 in the Value Field.

Click OK.

The value of D10006 changes to

4000.

7.EtherNet/IP Connection Procedure

In the same way as step 10, change

11

the value of D10007 to 0040.

*The command code 4000 0040

Select Display - Decimal from the

View Menu.

In the same way as steps 8 to 10,

change the value of D10008 to 900.

*The system data number 900

(number of digits displayed past

Page 56

53

Select Display - Binary from the

15

16

execution

17

completion

18

19

echo

14

View Menu.

7.EtherNet/IP Connection Procedure

Enter 10000 in the Start Address

Field of the D Window.

Check that the start address

changes to D10000.

Select the bit 0 value of D10000 in

the D Window.

Click On.

The bit 0 value of D10000 changes

to 1.

*D10000 Bit 0: Control command

Enter 10100 in the Start Address

Field of the D Window.

Check that the start address

changes to D10100 and that the bit

0 value of D10100 is 1.

*D10100 Bit 0: Control command

Select Display - Hexadecimal from

the View Menu.

Check that the values of D10106

and D10107 show the command

values set in steps 10 and 11,

respectively.

*D10106, D10107: Command code

Page 57

7.EtherNet/IP Connection Procedure

54

-1(FFFF FFFF): NG) is reflected.)

21

Additional Information

Additional Information

Communications Settings (Cat. No. Z363).

20

Check that the values of D10108

and D10109 are both 0.

*D10108, D10109: Response code

(Command execution result (0: OK,

Check that the value of D10110 is 1.

*D10110: Response data

(lower 16 bits)

(The number of digits displayed

past decimal point is 1 (default).)

For details on commands, refer to 4-1 EtherNet/IP Connection of the Displacement Sensor

ZW-7000 series Confocal Fiber Type Displacement Sensor User's Manual for

Communications Settings (Cat. No. Z363).

For details on system data, refer to 8-2 System data li st of the Displacement Sensor

ZW-7000 series Confocal Fiber Type Displacement Sensor User's Manual for

Page 58

8.Initialization method

55

8. Initialization method

The setting procedures in this document are based on the factory default settings.

Some settings may not be applicable unless you use the devices with the factory default

settings.

8.1. Initializing PLC

To initialize the PLC settings, it is necessary to initialize EtherNet/IP Unit and CPU Unit.

Change the operating mode of PLC to PROGRAM mode before the initialization.

8.1.1. EtherNet/IP Unit

To initialize the EtherNet/IP Unit settings, select Edit - I/O T able and Unit Setup from the PLC

Menu in CX-Programmer, and follow the steps below.

(1)Right-click EtherNet/IP Unit in the PLC IO Table Window and select Unit Setup from the

menu.

(2)Click Restart in the Edit Parameters Di alog Box.

(3)An execution confirmation dialog box is di splayed. Confirm that there is no problem, and

click Yes.

Page 59

8.Initialization method

56

(4)The Restart Unit Dialog Box is displayed. Selec t Return to out-of-box configuration, and

then emulate cycling power, and click OK.

(5)A dialog box is displayed indicating that the execution is completed. Check the contents

and click OK.

8.1.2. CPU Unit

To initialize the CPU Unit settings, select Clear All Memory Areas from the PLC Menu in

CX-Programmer. Select Initialize in the Confirm All Memory Area Clear Dialog Box and click

OK.

8.2. Initializing Sensor Controller

For information on how to initialize Sensor Controller, refer to Initializing Settings in 8-11

Setting the System in 8. Sensor controller oper ations of the Displacement Sensor Z W-7000

series Confocal Fiber Type Displacement Sensor User’s Manual (Cat. No. Z362).

Page 60

57

9. Revision History

code

Revision

01 July 7, 2016 First edition

Date of revision Description of revision

9.Revision History

Page 61

58

Page 62

2016

P661-E1-01

0716-(-)

Loading...

Loading...