Omron CJ2H-CPU64-EIP, CJ2H-CPU65-EIP, CJ2H-CPU67-EIP, CJ2H-CPU66-EIP, CJ2H-CPU68-EIP DATASHEET

Page 1

SYSMAC CJ-series CJ2H (Built-in EtherNet/IP) CPU Units

CJ2H-CPU6@-EIP

CSM_CJ2H-CPU-EIP_DS_E_2_1

Flagship PLCs with Built-in

Multifunctional Ethernet Port

• Small, Fast, Flexible:

The CJ2 CPU Units inherit and improve CJ1 features

while also adding EtherNet/IP as a standard feature for

high-speed, high-capacity Ethernet-based networking.

CJ2H-CPU6@-EIP

Features

• High-speed, high-capacity EtherNet/IP is built into every model.

• The CIP communications protocol is supported for direct access to multivendor devices.

• Tag memory provided for easy access from host PCs and PTs.

• Even more program memory and data memory.

• Superior high-speed control performance: LOAD instructions execute in 16 ns, SINE instructions in 0.59 μs.

1

Page 2

CJ2H-CPU6@-EIP

Ordering Information

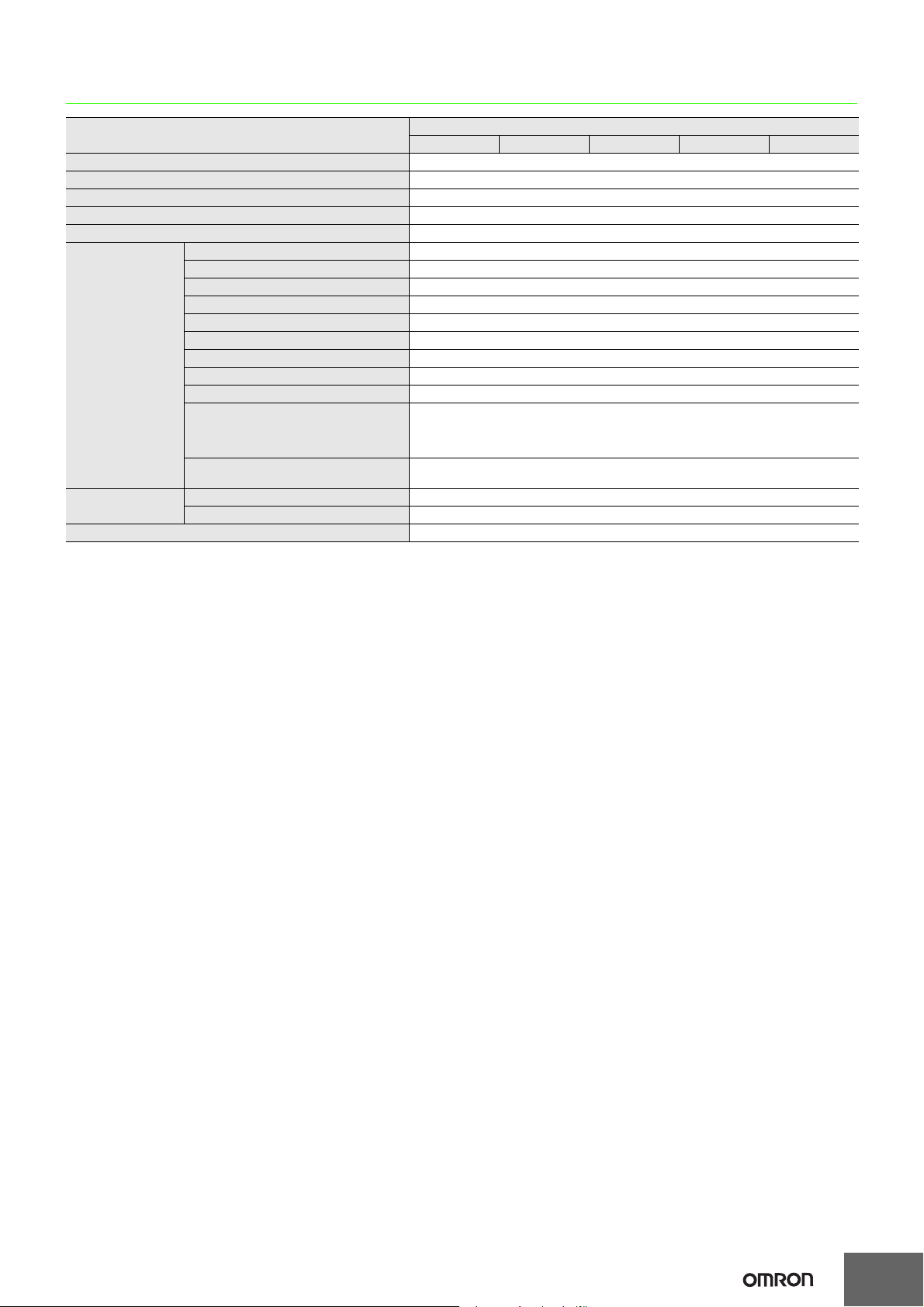

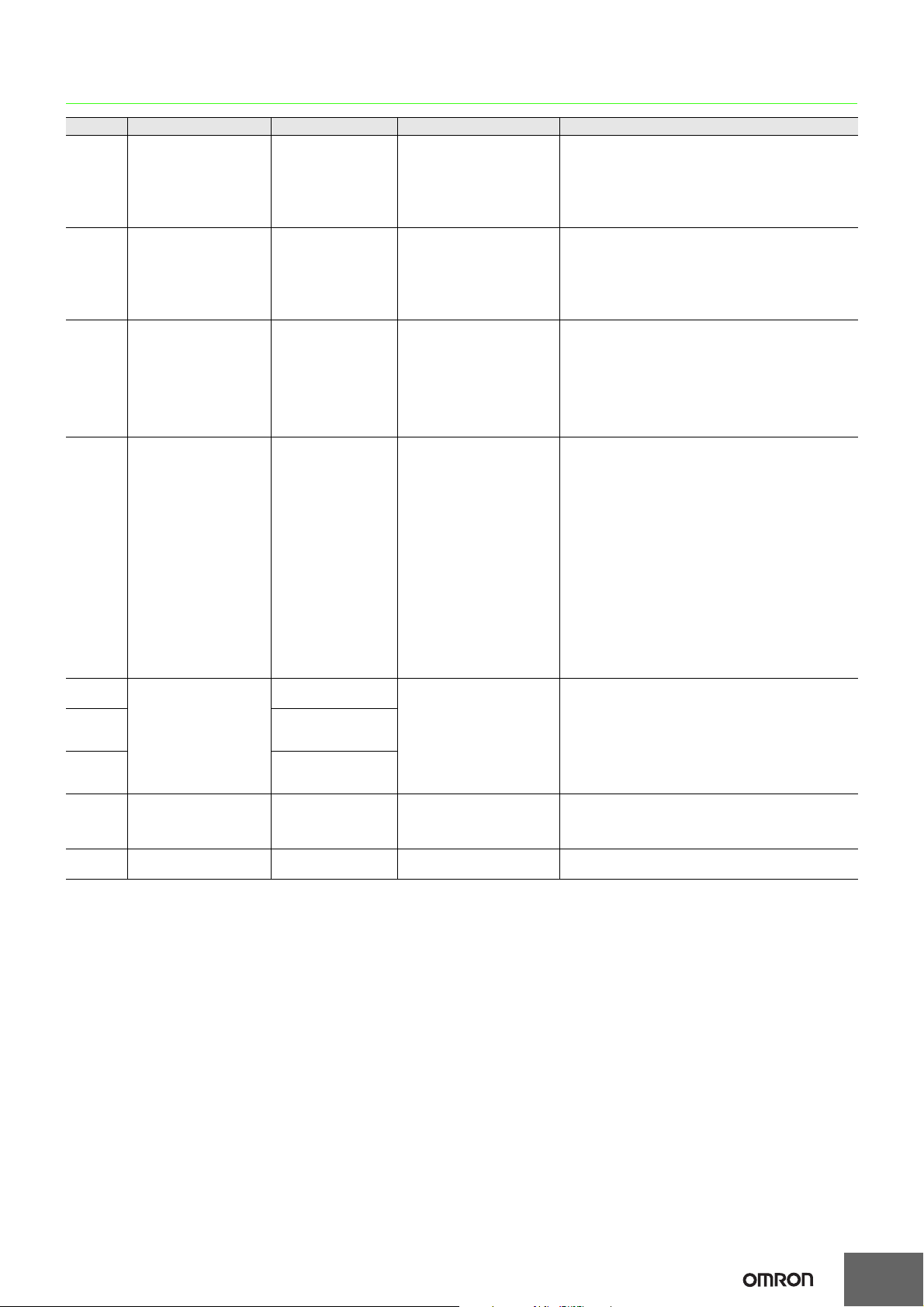

CJ2H (Built-in EtherNet/IP) CPU Units

Specifications

Product

name

CJ2H

(Built-in

EtherNet/IP)

CPU Units

I/O capacity/Mountable

Units (Expansion Racks)

2,560 points / 40 Units

(3 Expansion Racks max.)

Program

capacity

400K steps

250K steps

150K steps

100K steps

50K steps

Data memory capacity

832K words

DM: 32K words

EM: 32K words × 25 banks

512K words

DM: 32K words

EM: 32K words × 15 banks

352K words

DM: 32K words

EM: 32K words × 10 banks

160K words

DM: 32K words

EM: 32K words × 4 banks

160K words

DM: 32K words

EM: 32K words × 4 banks

LD

instruction

execution

time

0.016 μs

Note: Add 0.15 A per Adapter when using NT-AL001 RS-232C/RS-232A Adapters.

Add 0.04 A per Adapter when using CJ1W-CIF11 RS-422A Adapters.

International Standards

• The standards indicated in the "Standards" column are those current for UL, CSA, cULus, NK, and Lloyd standards and EC Directives as of the end of April 2008.

The standards are abbreviated as follows: U: UL, U1: UL (Class I Division 2 Products for Hazardous Locations), C: CSA, UC: cULus, UC1: cULus (Class I Division

2 Products for Hazardous Locations), CU: cUL, N: NK, L: Lloyd, and CE: EC Directives

• Ask your OMRON representative for the conditions under which the standards were met.

Current

consumption (A)

5 V 24 V

0.82

(See

note.)

−

Model Standards

CJ2H-CPU68-EIP

CJ2H-CPU67-EIP

CJ2H-CPU66-EIP

CJ2H-CPU65-EIP

CJ2H-CPU64-EIP

UC1, N, L,

CE

Accessories

The following accessories come with CPU Unit:

Item Specification

Battery CJ1W-BAT01

End Cover CJ1W-TER01 (necessary to be mouned at the right end of CPU Rack)

End Plate PFP-M (2 pcs)

Serial Port (RS-232C) Connector Connector set for serial port connection (D-SUB 9-pin male connector)

2

Page 3

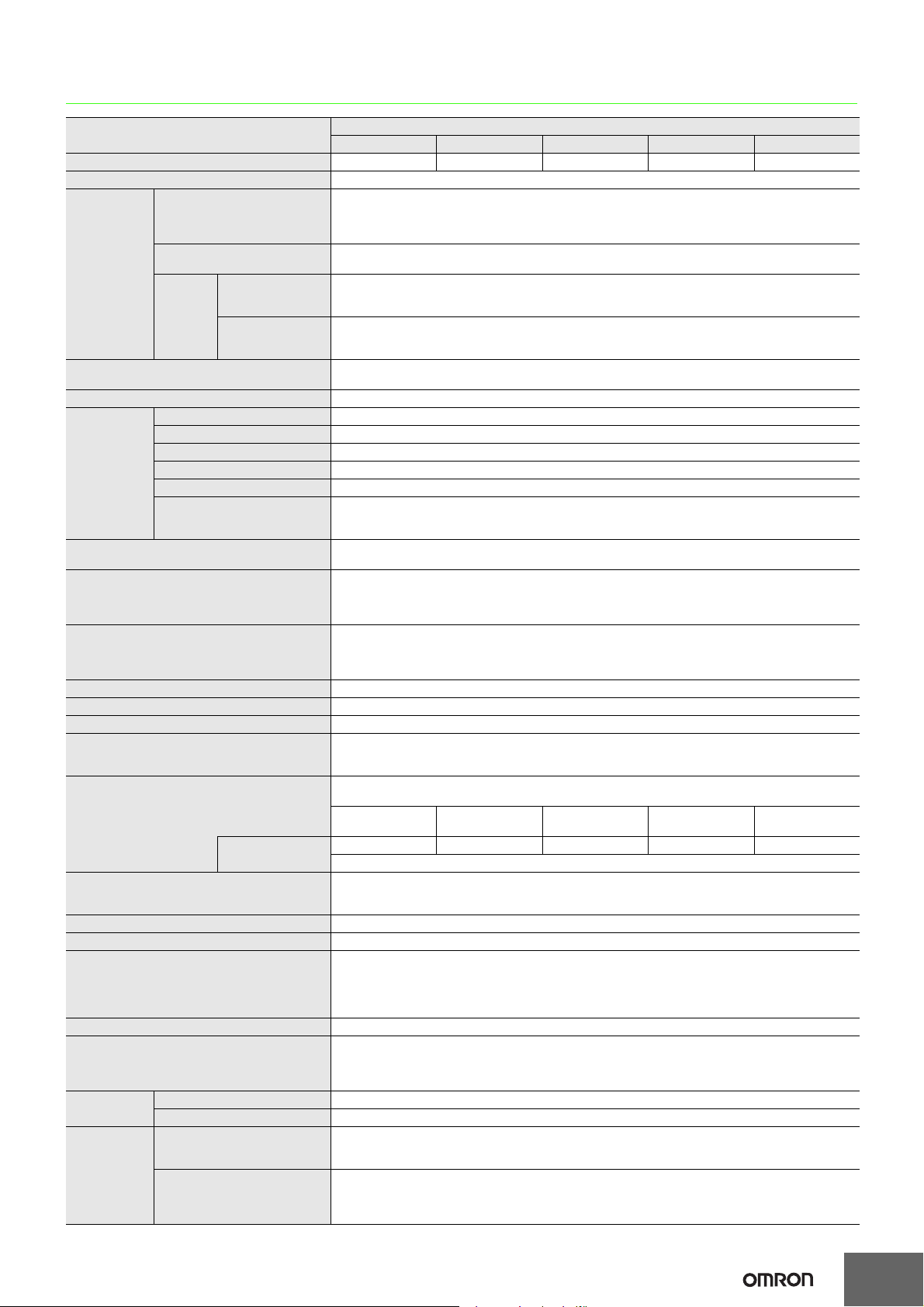

General Specifications

CJ2H-CPU6@-EIP

Item

Enclosure Mounted in a panel

Grounding Less than 100 Ω

CPU Rack Dimensions 90 mm × 65 mm × 80 mm (H × D × W)

Weight 280 g or less

Current Consumption 5 VDC, 0.82 A

Ambient Operating Temperature 0 to 55°C

Ambient Operating Humidity 10% to 90%

Atmosphere Must be free from corrosive gases.

Ambient Storage Temperature −20 to 70°C (excluding battery)

Altitude 2,000 m or less

Pollution Degree 2 or less: Conforms to JIS B3502 and IEC 61131-2.

Use Environment

Battery

Applicable Standards Conforms to cULus and EC Directives.

Noise Immunity 2 kV on power supply line (Conforms to IEC 61000-4-4.)

Overvoltage Category Category II: Conforms to JIS B3502 and IEC 61131-2.

EMC Immunity Level Zone B

Vibration Resistance

Shock Resistance

Life 5 years at 25°C

Model CJ1W-BAT01

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

Conforms to JIS C60068-2-6.

5 to 8.4 Hz with 3.5-mm amplitude, 8.4 to 150 Hz

Acceleration of 9.8 m/s

100 min total)

Conforms to JIS C60068-2-27.

2

, 3 times in X, Y, and Z directions (100 m/s2 for Relay Output Units)

147 m/s

2

for 100 min in X, Y, and Z directions (10 sweeps of 10 min each =

CJ2H-

3

Page 4

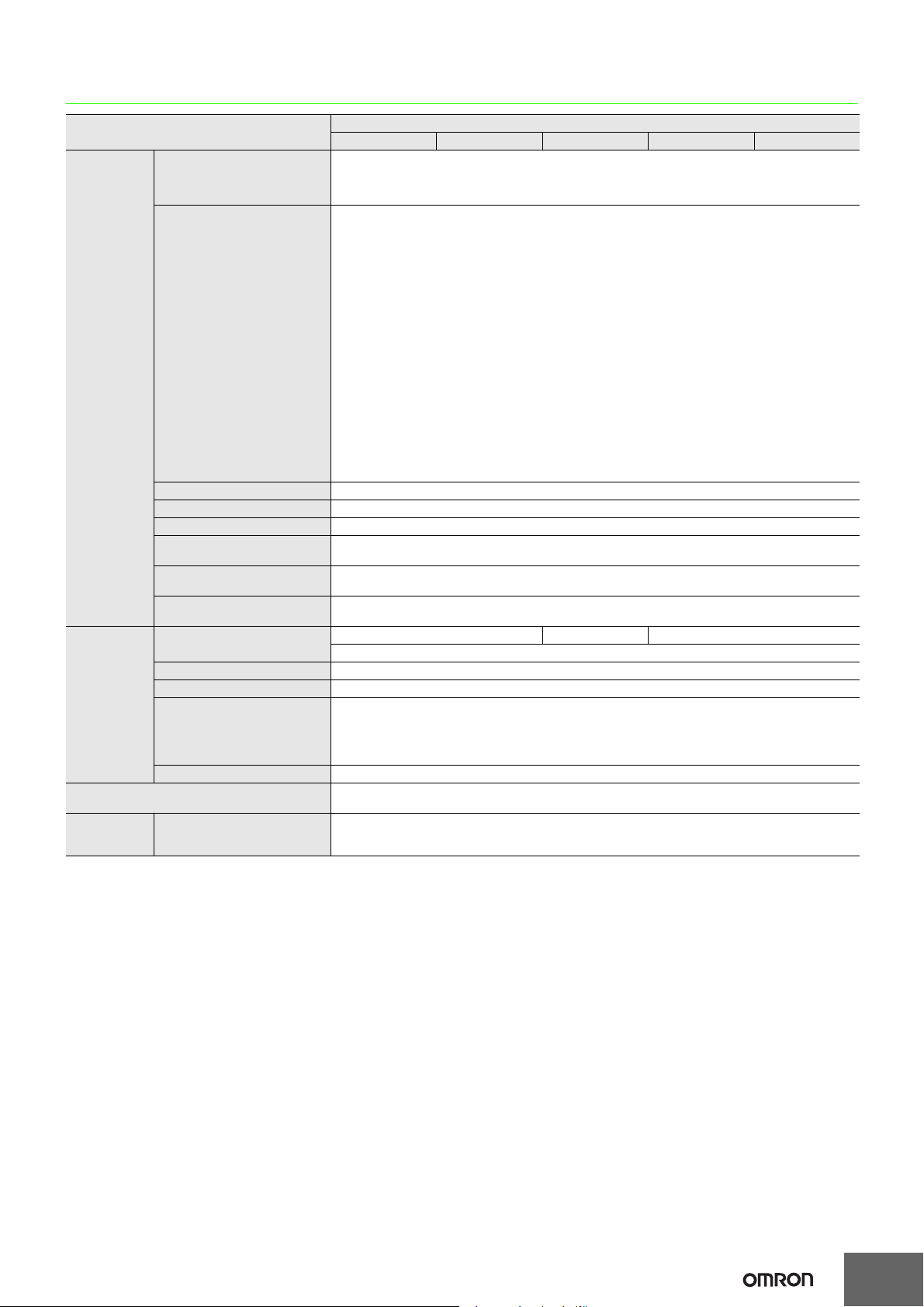

Performance Specifications

CJ2H-CPU6@-EIP

Items

User Memory 50K steps 100K steps 150K steps 250K steps 400K steps

I/O Bits 2,560 bits

Overhead Processing Time

Processing

Speed

Maximum Number of Connectable Units

Maximum Number of Expansion Racks 3 max.

CIO Area

Work Area

Holding Area

Auxiliary Area

Temporary Area 16 bits: TR0 to TR15

Timer Area 4,096 timer numbers (T0000 to T4095 (separate from counters))

Counter Area 4,096 counter numbers (C0000 to C4095 (separate from timers))

DM Area

EM Area

Index Registers

Cyclic Task Flag Area 128 flags

Memory Card 128 MB, 256 MB, or 512 MB

Operating Modes

Execution Mode Normal Mode

Programming Languages

Function

Blocks

Tasks

Execution Time

I/O Interrupts and

Interrupts

I/O Area 2,560 bits (160 words): Words CIO 0000 to CIO 0159

Link Area 3,200 bits (200 words): Words CIO 1000 to CIO 1199

CPU Bus Unit Area 6,400 bits (400 words): Words CIO 1500 to CIO 1899

Special I/O Unit Area 15,360 bits (960 words): Words CIO 2000 to CIO 2959

DeviceNet Area 9,600 bits (600 words): Words CIO 3200 to CIO 3799

Internal I/O Area

Maximum number of definitions 2,048

Maximum number of instances 2,048

Type of Tasks

Number of Tasks

External Interrupts

Scheduled

Interrupts

Force-set/reset

Enabled Banks

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

Normal Mode: 200 μs

(If tag data links are used with EtherNet/IP, add the following to the above time: 100 μs + Number of transferred

words × (0.33 μs or 0.87 μs *))

* When High-speed interrupt function is used

Basic Instructions: 0.016 μs min.;

Special Instructions: 0.048 μs min.

Start time of interrupt task : 26 μs or 17 μs * (30 μs in unit Ver.1.0)

Return time to cyclic task : 11 μs or 8 μs * (15 μs in unit Ver.1.0)

* When High-speed interrupt function is used

Start time of interrupt task : 22 μs or 13 μs * (27 μs in unit Ver.1.0)

Return time to cyclic task : 11 μs or 8 μs * (15 μs in unit Ver.1.0)

* When High-speed interrupt function is used

Total per CPU Rack or Expansion Rack: 10 Units max.;

Total per PLC: 40 Units max.

3,200 bits (200 words): Words CIO 1300 to CIO 1499

37,504 bits (2,344 words): Words CIO 3800 to CIO 6143

Cannot be used for external I/O.

8,192 bits (512 words): Words W000 to W511

Cannot be used for external I/O.

8,192 bits (512 words): Words H000 to H511

Bits in this area maintain their ON/OFF status when PLC is turned OFF or operating mode is changed.

Words H512 to H1535: These words can be used only for function blocks. They can be used only for function

block instances (i.e., they are allocated only for internal variables in function blocks).

Read-only: 31,744 bits (1,984 words)

• 7,168 bits (448 words): Words A0 to A447

• 24,576 bits (1,536 words): Words A10000 to A11535

Read/write: 16,384 bits (1,024 words) in words A448 to A1471

32k words (Bits in the DM Area can be addressed either by bit or by word.)

DM Area words for Special I/O Units: D20000 to D29599 (100 words × 96 Units)

DM Area words for CPU Bus Units: D30000 to D31599 (100 words × 16 Units)

32k words/bank × 25 banks max.: E00_00000 to E18_32767 max.

(Bits in the EM Area can be addressed either by bit or by word.)

32K words × 4

banks

EM3 EM3 EM6 to EM9 EM7 to EME EM11 to EM18

Force-setting/resetting is enabled only for areas specified for automatic address allocation.

IR0 to IR15

These are special registers for storing PLC memory addresses for indirect addressing. (Index Registers can

be set so that they are unique in each task or so that they are shared by all tasks.)

PROGRAM Mode: Programs are not executed. Preparations can be executed prior to program execution in

MONITOR Mode: Programs are executed, and some operations, such as online editing, and changes to

RUN Mode: Programs are executed. This is the normal operating mode.

Ladder Logic (LD),

Sequential Function Charts (SFC),

Structured Text (ST), and

Instruction Lists (IL)

Cyclic tasks

Interrupt tasks (Power OFF interrupt tasks, scheduled interrupt tasks, I/O interrupt tasks, and external interrupt

tasks)

Cyclic tasks: 128

Interrupt tasks: 256

(Interrupt tasks can be defined as cyclic tasks to create extra cyclic tasks. Therefore, the total number of cyclic

tasks is actually 384 max.)

32K words × 4

banks

this mode.

present values in I/O memory, are enabled in this mode.

CJ2H-

32K words × 10

banks

32K words × 15

banks

32K words × 25

banks

4

Page 5

CJ2H-CPU6@-EIP

Symbols

(Variables)

Data Tracing

File Memory

Source/

Comment

Memory

Items

Type of Symbols

Data Type of Symbols

Maximum Size of Symbol 32k words

Array Symbols (Array Variables) One-dimensional arrays

Number of Array Elements 32,000 elements max.

Number of Registrable Network

Symbols (Tags)

Length of Network Symbol (Tag)

Name

Encoding of Network Symbols

(Tags)

Memory Capacity

Number of Samplings Bits = 31, one-word data =16, two-word data = 8, four-word data = 4

Sampling Cycle 1 to 2,550 ms (Unit: 1 ms)

Trigger Conditions

Delay Value −32,768 to +32,767 ms

Function block program

memory, comment file, program

index file, symbol tables

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

• Local symbols: Can be used only within a single task in the PLC.

• Global symbols: Can be used in all tasks in the PLC.

• Network symbols (tags): I/O memory in the CPU Unit can be externally accessed using symbols, depending

on parameter settings.

• BOOL (bit)

• UINT (one-word unsigned binary)

• UDINT (two-word unsigned binary)

• ULINT (four-word unsigned binary)

• INT (one-word signed binary)

• DINT (two-word signed binary)

• LINT (four-word signed binary)

• UINT BCD (one-word unsigned BCD) *1

• UDINT BCD (two-word unsigned BCD) *1

• ULINT BCD (four-word unsigned BCD) *1

• REAL (two-word floating-point)

• LREAL (four-word floating-point)

• CHANNEL (word) *1

• NUMBER (constant or number) *1

• WORD (one-word hexadecimal)

• DWORD (two-word hexadecimal)

• LWORD (four-word hexadecimal)

• STRING (1 to 255 ASCII characters)

• TIMER (timer) *2

• COUNTER (counter) *2

*1. Cannot be used in Function blocks

*2. Can be used only in Function blocks

20,000 max.

255 bytes max.

UTF-8

8,000 words 16,000 words 32,000 words

(Up to 32k words × 25 banks when EM is specified in CX-Programmer)

ON/OFF of specified bit

Data comparison of specified word

Data size: 1 word, 2 words, 4 words

Comparison Method: Equals (=), Greater Than (>), Greater Than or Equals (≥), Less Than (<), Less Than or

Equals (≤), Not Equal (≠)

Memory Card (128, 256, or 512 Mbytes) (Use the Memory Cards provided by OMRON.)

EM file memory (Part of the EM Area can be converted for use as file memory.)

Capacity: 3.5 Mbytes

CJ2H-

5

Page 6

CJ2H-CPU6@-EIP

Communications

Item

Logical Ports for

Communications

CIP

Communications

Specification

Peripheral (USB) Port USB 2.0-compliant B-type connector

Baud Rate 12 Mbps max.

Transmission Distance 5 m max.

Serial Port Interface: Conforms to EIA RS-232C.

Communications Method Half-duplex

Synchronization Method Start-stop

Baud Rate 0.3, 0.6, 1.2, 2.4, 4.8, 9.6, 19.2, 38.4, 57.6, or 115.2 (kbps)

Transmission Distance 15 m max.

EtherNet/IP Port −

Media Access Method CSMA/CD

Modulation Baseband

Transmission Paths Star

Baud Rate 100 Mbps (100Base-TX)

Transmission Media Shielded twisted-pair (STP) cable; Categories: 5, 5e

Transmission Distance 100 m (between hub and node)

Number of Cascade Connections No restrictions if switching hub is used.

Transmission Specifications

CIP Communications: Tag Data Links −

Number of Connections 256

Packet Interval (Refresh period)

Permissible Communications Band 6,000 pps *1

Number of Tag Sets 256

Type of Tags CIO, DM, EM, HR, and WR

Number of Tags per Connection 8 (Seven tags if PLC status is included in the segment.)

Maximum Link Data Size per Node 184,832 words

Maximum Data Size per Connection

Number of Registrable Tag Set 256 (1 connection = 1 segment)

Maximum Tag Set Size 722 words (One word is used when PLC status is included in the segment.)

Maximum Number of Tags

Refreshable in a Single Cycle of

CPU Unit *3

Data Size Refreshable in a Single

Cycle of CPU Unit *3

Change of Tag Data Link Parameter

Settings during Operation

Multi-cast Packet Filter *5 OK

Communications Specifications

CIP Communications: Explicit

Messages

Class 3 (Number of Connections) Number of connections: 128

UCMM (Non-connection Type)

CIP Routing OK (CIP routing is enabled for the following remote Units: CJ1W-EIP21 and CJ2H-CPU6@-EIP.)

FINS Communications −

FINS/UDP OK

FINS/TCP 16 connections max.

EtherNet/IP Conformance Test Conforms to A5.

EtherNet/IP Interface

Logical Ports 8 ports (Used for SEND, RECV, CMND, PMCR, TXDU, and RXDU instructions.)

Extended Logical

Ports

Class 3 (Number of

Connections)

UCMM (Nonconnection Type)

CPU64-EIP CPU65-EIP CPU66-EIP CPU67-EIP CPU68-EIP

64 ports (Used for SEND2, RECV2, CMND2, and PMCR2 instructions.)

Number of connections: 64

Maximum number of clients that can communicate at the same time: 32

Maximum number of servers that can communicate at the same time: 40

0.5 to 10,000 ms (Unit: 0.5 ms)

Can be set for each connection. (Data will be refreshed at the set interval, regardless of the number

of nodes.)

252 or 722 words *2

(Data is synchronized within each connection.)

Output/send (CPU Unit to EtherNet/IP): 256

Input/receive (EtherNet/IP to CPU Unit): 256

Output/send (CPU to EtherNet/IP): 6,432 words

Input/receive (EtherNet/IP to CPU): 6,432 words

OK *4

−

Maximum number of clients that can communicate at the same time: 32

Maximum number of servers that can communicate at the same time: 32

10Base-T/100Base-TX

Auto Negotiation/Fixed Setting

CJ2H-

6

Page 7

CJ2H-CPU6@-EIP

*1. "Packets per second" is the number of communications packets that can be processed per second.

*2. Large Forward Open (CIP optional specification) must be supported in order for 505 to 1,444 bytes to be used as the data size. Application is

supported between CS/CJ-series PLCs. When connecting to devices from other manufacturers, make sure that the devices support the Large

Forward Open specification.

*3. If the maximum number is exceeded, refreshing will require more than one CPU Unit cycle.

*4. When changing parameters, however, the EtherNet/IP port where the change is made will be restarted. In addition, a timeout will temporarily

occur at the other node that was communicating with that port, and it will then recover automatically.

*5. The EtherNet/IP port supports an IGMP client, so unnecessary multicast packets are filtered by using a switching hub that supports IGMP

snooping.

Function Specifications

Functions Description

A minimum cycle time can be set.

(0.2 to 32,000 ms; Unit: 0.1 ms)

The minimum cycle time setting can be changed in MONITOR mode. (Unit version 1.1)

The cycle time is monitored.

(0.01 to 40,000 ms; Unit: 0.01 ms)

Instructions with long execution times can be executed over multiple cycles to prevent

fluctuations in the cycle time.

The input response times can be set for Basic I/O Units. The response time can be

increased to reduce the effects of chattering and noise at input contacts. The response

time can be decreased to enable detecting shorter input pulses.

All of the outputs on Basic I/O Units can be turned OFF when an error occurs in RUN or

MONITOR mode.

Alarm information can be read from Basic I/O Units and the number of Units recognized

can be read.

I/O words can be automatically allocated to the Basic I/O Units that are connected in the

PLC to start operation automatically without registering Units into I/O tables.

The current unit configuration can be registered in I/O tables to prevent it from being

changed, to reserve words, and to set words.

The status of I/O memory can be held when the operating mode is changed or power is

turned ON. The forced-set/reset status can be held when the operating mode is changed

or power is turned ON.

Files (such as program files, data files, and symbol table files) can be stored in Memory

Card, EM File Memory, or Comment Memory.

The user program and Parameter Area can be backed up to an internal flash memory

when they are transferred to the CPU Unit.

I/O comments can be stored as symbol table files in a Memory Card, EM file memory,

or comment memory.

A program file and parameter files can be read from a Memory Card when the power is

turned ON.

Data in I/O memory in the CPU Unit can be written to a Memory Card in CSV/TXT format.

Data in CSV/TXT format in the Memory Card can be read to I/O memory in the CPU Unit.

Cycle Time

Management

Unit (I/O)

Management

Memory

Management

Memory

Cards

Minimum Cycle Time

Cycle Time Monitoring

Background Processing

Basic I/O

Units, Special

I/O Units, and

CPU Bus

Units

Basic I/O

Units

Special I/O

Units and

CPU Bus

Units

Configuration

Management

Holding I/O Memory when Changing Operating Modes

File Memory

Built-in Flash Memory

EM File Function Parts of the EM Area can be treated as file memory.

Storing Comments

EM Configuration EM Area can be set as trace memory or EM file memory.

Automatic File Transfer at Startup

Program Replacement during PLC Operation The whole user program can be read from a Memory Card to CPU Unit during operation.

Function for Reading and Writing Data from a Memory

Card

I/O

Refreshing

Unit Recognition at Startup The number of units recognized when the power is turned ON is displayed.

Input Response Time Setting

Load OFF Function

Basic I/O Unit Status Monitoring

Unit Restart Bits to Restart Units A Special I/O Unit or CPU Bus Unit can be restarted.

Automatic I/O Allocation at Startup

I/O Table Creation

Rack/Slot First Word Settings The first words allocated to a Units on the Racks can be set.

Cyclic Refreshing Cyclic refreshing of Basic I/O Units, Special I/O Units, and CPU Bus Units

Immediate Refreshing I/O refreshing by immediate refreshing instructions

Refreshing by IORF I/O refreshing by IORF instruction

7

Page 8

CJ2H-CPU6@-EIP

Function Description

Communications −

Peripheral (USB)

Port

Serial Port −

Host Link (SYSWAY) Communications

No-protocol Communications

NT Link Communications

Peripheral Bus

Serial Gateway This gateway enables receiving and automatically converting FINS to the CompoWay/F.

EtherNet/IP Port

CIP

Communications

Service

FINS

Communications

Service

Scheduled Interrupts

Power OFF Interrupts A task can be executed when CPU Unit's power turns OFF.

Interrupt

Clock

Power

Supply

Management

Function Blocks Standard programming can be encapsulated as function blocks.

Debugging

I/O Interrupt Tasks A task can be executed when an input signal is input to an Interrupt Input Unit.

External Interrupt Tasks

High-speed Interrupt Function Improves performance for executing interrupt tasks with certain restrictions.

Clock Function

Operation Start Time Storage The time when operating mode was last changed to RUN mode or MONITOR mode is stored.

Operation Stop Time Storage

Startup Time Storage The time when the power was turned ON is stored.

Power Interruption Time Storage The time when the power is turned OFF is stored.

Total Power ON Time Calculation The total time that the PLC has been ON is stored in increments of 10 hours.

Power ON Clock Data Storage A history of the times when the power was turned ON is stored.

User Program Overwritten Time Storage The time that the user program was last overwritten is stored.

Parameter Date Storage The time when the Parameter Area was overwritten is stored.

Memory Protection

Power OFF Detection Time Setting

Power OFF Detection Delay Time

Number of Power Interruptions Counter The number of times power has been interrupted is counted.

Languages in Function Block Definitions Ladder programming or structured text

Online Editing

Force-Set/Reset Specified bits can be set or reset.

Differentiate Monitoring ON/OFF changes in specified bits can be monitored.

Data Tracing

Storing Location of Error when an Error Occurs The location and task number where execution stopped for a program error is recorded.

Program Check

Peripheral Bus

Tag Data Links Programless cyclic data exchanges with the devices on the EtherNet/IP network.

Message Communications Any CIP commands can be received from the devices on the EtherNet/IP network.

Message Communications Any FINS commands can be transferred with the devices on the EtherNet/IP network.

Bus for communications with various kinds of Support Software running on a personal

computer. High-speed communications are supported.

Host Link commands or FINS commands placed between Host Link headers and terminators

can be sent from a host computer or PT to read/write I/O memory, read/control the operating

mode, and perform other operations for PLC.

I/O instructions for communications ports (such as TXD/RXD instructions) can be used for

data transfer with peripheral devices such as bar code readers and printers.

I/O memory in the PLC can be allocated and directly linked to various PT functions, including

status control areas, status notification areas, touch switches, lamps, memory tables, and

other objects.

Bus for communications with various kinds of Support Software running on a personal

computer. High-speed communications are supported.

100Base-TX/10Base-T

Protocols: TCP/IP, UDP, ARP, ICMP (ping only), BOOTP

Applications: FINS, CIP, POP3, SMTP, SNTP, DNS (Client), FTP (Server)

Tasks can be executed at a specified interval (minimum of 0.2 ms or 0.1 ms *, Unit: 0.1 ms).

* When High-speed interrupt function is used.

A task can be executed when interrupts are requested from a Special I/O Unit or a CPU Bus

Unit.

Cock data is stored in memory.

Accuracy (Accuracy depends on the temperature.)

Ambient temperature of 55°C: −3.5 to +0.5 min error per month

Ambient temperature of 25°C: −1.5 to +1.5 min error per month

Ambient temperature of 0°C: −3 to +1 min error per month

The last time a fatal error occurred or the last time the operating mode was changed to

PROGRAM mode is stored.

Holding Area data, DM Area data, EM Area data, Counter Completion Flags, and counter

present values are held even when power is turned OFF. CIO Area, Work Area, some Auxiliary

Area data, and Timer Completion Flags, timer present values, index registers, and data

registers can be protected by turning ON the IOM Hold Bit in the Auxiliary Area, and by also

setting the IOM Hold Bit to “Hold” in the PLC Setup.

The detection time for power interruptions can be set.

AC power supply: 10 to 25 ms (variable)

DC power supply: 2 to 5 ms (CJ1W-PD022) or 2 to 20 ms (CJ1W-PD025)

The detection of power interruptions can be delayed: 0 to 10 ms

(Not supported by the CJ1W-PD022.)

The program can be changed during operation (in MONITOR or PROGRAM mode), except for

block programming areas.

The specified I/O memory data can be stored in the trace memory in the CPU Unit. The

triggers can be set.

• The trace data can be uploaded during data tracing using CX-Programmer, which enables

continuously logging the data by constantly uploading the trace data (trace data uploading

during tracing).

• Data tracing can be automatically started when operation is started (i.e., when the operating

mode is changed from PROGRAM mode to MONITOR or RUN mode).

The programs can be checked for items such as no END instruction and FALS/FAL errors at

startup.

8

Page 9

Selfdiagnosis

and

Restoration

Selfdiagnosis

and

Restoration

(Continued

from

previous

page)

CJ2H-CPU6@-EIP

Function Description

Error Log

CPU Error Detection CPU Unit WDT errors are detected.

User-defined Failure Diagnosis

Load OFF Function This function turns OFF all outputs from Output Units when an error occurs.

RUN Output

Basic I/O Load Short-circuit Detection

Failure Point Detection The time and logic of an instruction block can be analyzes using the FPD instruction.

CPU Standby Detection

System FAL Error Detection

(User-defined non-fatal error)

Duplicate Refreshing Error

Detection

Basic I/O Unit Error Detection This function detects the errors in Basic I/O Units.

Backup Memory Error

Detection

PLC Setup Error Detection This function detects setting errors in the PLC Setup.

Non-fatal Error

Detection

Fatal Error

Detection

CPU Bus Unit Error Detection

Special I/O Unit Error

Detection

Tag Memory Error Detection This function detects errors in tag memory.

Battery Error Detection

CPU Bus Unit Setting Error

Detection

Special I/O Unit Setting Error

Detection

Memory Error Detection This function detects errors that occur in memory of the CPU Unit.

I/O Bus Error Detection

Unit/Rack Number

Duplication Error

Too Many I/O Points Error

Detection

I/O Setting Error Detection

Program Error Detection This function detects errors in programs.

Instruction Processing

Error Detection

Indirect DM/EM BCD

Error Detection

Illegal Area Access Error

Detection

No END Error Detection This function detects an error when there is no END instruction at the end of the program.

Task Error Detection

Differentiation Overflow

Error Detection

Invalid Instruction Error

Detection

User Program Area

Overflow Error Detection

Cycle Time Exceeded Error

Detection

A function is provided to store predefined error codes in CPU Unit, error information, and time

at which the error occurred.

Errors can be generated for user-specified conditions: Non-fatal errors (FAL) and fatal errors

(FALS).

Program section time diagnosis and program section logic diagnosis are supported (FPD

instruction).

The RUN output from the CJ1W-PA205R turns ON while CPU Unit is in RUN mode or

MONITOR mode.

This function provides alarm information from Basic I/O Units that have load short-circuit

protection.

This function indicates when the CPU Unit is on standby because all Special I/O Units and

CPU Bus Units have not been recognized at the startup in RUN or MONITOR mode.

This function generates a non-fatal (FAL) error when the user-defined conditions are met in

program.

This function detects an error when an immediate refreshing Instruction in an interrupt task is

competing with I/O refreshing of a cyclic task.

This function detects errors in the memory backup of the user programs and parameter area

(backup memory).

This function detects an error when there is an error in data exchange between the CPU Unit

and a CPU Bus Unit.

This function detects an error when there is an error in data exchange between the CPU Unit

and a Special I/O Unit.

This function detects an error when a battery is not connected to the CPU Unit or when the

battery voltage drops.

This function detects an error when the model of a CPU Bus Unit in the registered I/O tables

does not agree with the model that is actually mounted in the PLC.

This function detects an error when the model of a Special I/O Unit in the registered I/O tables

does not agree with the model of Unit that is actually mounted.

This function detects when an error occurs in data transfers between the Units mounted in

Rack slots and the CPU Unit and detects when the End Cover is not connected to the CPU

Rack or an Expansion Rack.

This function detects an error when the same unit number is set for two or more Units, the

same word is allocated to two or more Basic I/O Units, or the same rack number is set for two

or more Racks.

This function detects an error when the total number of I/O points set in the I/O tables or the

number of Units per Rack exceeds the specified range.

This function detects an error when the number of Units in the registered I/O tables does not

agree with the actual number of Units that is mounted, or an Interrupt Unit has been connected

in the wrong position, i.e., not in slot 0 to 3.

This function detects an error when the given data value is invalid when executing an

instruction, or execution of instruction between tasks was attempted.

This function detects an error when an indirect DM/EM address in BCD mode is not BCD.

This function detects an error when an attempt is made to access an illegal area with an

instruction operand.

This function detects an error when there are no tasks that can be executed in a cycle, there

is no program for a task, or the execution condition for an interrupt task was met but there is

no interrupt task with the specified number.

This function detects an error when too many differentiated instructions are entered or deleted

during online editing (131,072 times or more).

This function detects an error when an attempt is made to execute an instruction that is not

defined in the system.

This function detects an error when instruction data is stored after the last address in user

program area.

This function monitors the cycle time (10 to 40,000 ms) and stops the operation when the set

value is exceeded.

9

Page 10

Selfdiagnosis

and

Restoration

(Continued

from

previous

page)

Maintenance

Security

CJ2H-CPU6@-EIP

Function Description

System FALS Error Detection

Fatal Error

Detection

(Continued from

previous page)

Memory Self-restoration Function This function performs a parity check on the user program area and self-restoration data.

Simple Backup Function

Unsolicited Communications

Remote Programming and Monitoring

Automatic Online Connection via

Network

Read Protection using Password

FINS Write Protection This function prohibits writing by using FINS commands sent over the network.

Unit Name Function

Hardware ID Using Lot Numbers

(User-defined Fatal Error)

Version Error Detection

Memory Card Transfer Error

Detection

Direct

Serial

Connection

Via

Networks

This function generates a fatal (FALS) error when the user-defined conditions are met in

program.

This function detects an error when a user program includes a function that is not supported

by the current unit version.

This function detects an error when the automatic file transfer from Memory Card fails at

startup.

This function collectively backs up the data in CPU Unit (user programs, parameters, and I/O

memory) and internal backup data in the I/O Units.

A function that allows the PLC to use Network Communications Instruction to send required

FINS commands to a computer connected via a Host Link

Host Link communications can be used for remote programming and remote monitoring

through a Controller Link, Ethernet, DeviceNet, or SYSMAC LINK Network. Communications

across network layers can be performed.

Controller Link or Ethernet: 8 layers

DeviceNet or SYSMAC LINK: 3 layers

This function enables automatically connecting to the PLC online when the CX-Programmer

is directly connected by a serial connection (peripheral (USB) port or serial port).

This function enables connecting the CX-Programmer online to a PLC that is connected via an

EtherNet/IP network.

This function protects reading and displaying programs and tasks using passwords.

Write protection: Set using the DIP switch.

Read protection: Set a password using the CX-Programmer.

This function allows the users to give any names to the Units. Names are verified at online

connection to prevent wrong connection

This function sets operation protection by identifying hardware using the user programs

according to lot numbers stored in the Auxiliary Area.

Unit Versions

Units Models Unit version

CPU: Unit version 1.0

CJ2H CPU Units CJ2H-CPU6@-EIP

EIP: Unit version 2.0

CPU: Unit version 1.1

EIP: Unit version 2.0

Function Support by Unit Version

Unit Version 1.1 or Later

CX-Programmer version 8.02 or higher must be used to enable using the functions added for unit version 1.1.

Unit CJ2H CPU Unit

Model CJ2H-CPU6@-EIP

Unit version

Item

High-speed interrupt function

Decreased overhead time for interrupt tasks

Minimum interval setting of 0.1 ms for Scheduled Interrupt Task

Changing the minimum cycle time setting in MONITOR mode Supported. Not supported.

Note: User programs that use functions of CJ2H CPU Units with unit version 1.1 or later cannot be used with CJ2H CPU Units with unit version

1.0 or earlier. If an attempt is made to transfer a program that uses any of these functions from the CX-Programmer to a CPU Unit with unit

version 1.0, an error will be displayed and it will not be possible to download to the CPU Unit. If a program file (extension: .OBJ) that uses

any of these functions is transferred to a CPU Unit with unit version 1.0, a program error will occur when operation starts or when the function

starts and operation of the CPU Unit will stop.

Unit version 1.1 Unit version 1.0

Supported. Not supported.

10

Page 11

CJ2H-CPU6@-EIP

Unit Versions and Programming Devices

The following tables show the relationship between unit versions and CX-Programmer versions.

Unit Versions and Programming Devices

Required Programming Device

CPU Unit Functions

Ver. 7.1 or lower Ver. 8.0 Ver. 8.02 or higher

CJ2H-CPU6@-EIP

Unit version 1.0

CJ2H-CPU6@-EIP

Unit version 1.1

Functions for unit version 1.0 −

Functions

added for unit

version 1.1

Using new functions −−

Not using new

functions

−

Note: 1. CX-Programmer version 8.0 or higher is required to use CJ2H CPU Units (CJ2H-CPU6@-EIP).

2. CX-Programmer version 8.02 or higher is required to use the added functions in CJ2H CPU Units (CJ2H-CPU6@-EIP) with unit version

1.1.

3. It is not necessary to upgrade the version of the CX-Programmer if functionality that was enhanced for the upgrade of the CPU Unit will

not be used.

4. A Programming Console cannot be used with a CJ2H CPU Unit.

Device Type Setting

The unit version does not affect the setting made for the device type on the CX-Programmer. Select the device type as shown in the following table

regardless of the unit version of the CPU Unit.

CX-Programmer

OK

(See note 1.)

OK

(See note 3.)

OK

OK

(See note 2.)

OK

Programming

Console

−

(See note 4.)

Series CPU Unit group CPU Unit model

CJ Series CJ2H CPU Units CJ2H-CPU6@-EIP CJ2H

Device type setting on

CX-Programmer Ver. 4.0 or higher

11

Page 12

CJ2H-CPU6@-EIP

External Interface

A CJ2H CPU Unit (CJ2H-CPU6@-EIP) provides three communications ports for external interfaces: a peripheral (USB) port, a sirial port and an

EtherNet/IP port.

Battery Compartment

Simple Backup/Memory Card

Power Supply Switch

Used to back up Memory

Card data or turn OFF the

power when removing the

Memory Card.

Also, press the Memory Card

Power Supply Switch to

perform an easy backup

operation.

Memory Card Connector

Connects the Memory Card

to the CPU Unit.

Memory Card Eject Button

Press the eject button to

remove the Memory Card

from the CPU Unit.

LED Indicators

Peripheral (USB) Port

Item Specification

Baud Rate 12 Mbps max.

Transmission Distance 5 m max.

Interface USB 2.0-compliant B-type connector

Protocol Peripheral Bus

DIP Switch

(inside the battery compartment)

Memory Card Indicators

Indicates the Memory Card status

(access and power supply).

Peripheral (USB) Port

Connected to Programming Devices,

such as the CX-Programmer

Serial Port

Connected to Programming Devices, Host

Computers, general-purpose external devices,

Programmable Terminals, and other devices.

EtherNet/IP Port

Connected to the information management

system such as Host Computer

Serial Port

Item Specification

Communications method Half duplex

Synchronization Start-stop

Baud rate 0.3/0.6/1.2/2.4/4.8/9.6/19.2/38.4/57.6/115.2 kbps *

Transmission distance 15 m max.

Interface EIA RS-232C

Protocol Host Link, NT Link, 1:N, No-protocol, or Peripheral Bus

* Baud rates for the RS-232C are specified only up to 19.2 kbps. The CJ Series supports serial communications from 38.4 kbps to 115.2 kbps,

but some computers cannot support these speeds. Lower the baud rate if necessary.

Pin No. Signal Name Direction

1 FG Protection earth −

2 SD (TXD) Send data Output

1

5

6

9

Note: Do not use the 5-V power from pin 6 of the RS-232C port on the CPU Unit for anything but the NT-AL001-E Link Adapter. The external

device or the CPU Unit may be damaged.

3 RD (RXD) Receive data Input

4 RS (RTS) Request to send Output

5 CS (CTS) Clear to send Input

6 5 V Power supply −

7 DR (DSR) Data set ready Input

8 ER (DTR) Data terminal ready Output

9 SG (0 V) Signal ground −

Connector hood FG Protection earth −

12

Page 13

CJ2H-CPU6@-EIP

EtherNet/IP Port

Item Specification

Media Access Method CSMA/CD

Modulation Baseband

Transmission Paths Star

Baud Rate 100 Mbps (100Base-TX)

Transmission Media Shielded twisted-pair (STP) cable; Categories: 5, 5e

Transmission Distance 100 m (between hub and node)

Number of Cascade Connections No restrictions if switching hub is used.

Communications

CIP Communications (tag data links, Explicit Messages).

FINS communications

Dimensions (Unit: mm)

CJ2H CPU Unit

CJ2H-CPU6@-EIP

2.7

90

2.7

66.2

65

79.8 74.5

13

Page 14

CJ2H-CPU6@-EIP

Related Manuals

Cat. No. Model Manual Application Description

Describes the following for CJ2 CPU Units:

• Overview and features

• Basic system configuration

• Part nomenclature and functions

• Mounting and setting procedure

• Remedies for errors

• Also refer to the Software User’s Manual (W473).

Describes the following for CJ2 CPU Units:

• CPU Unit operation

• Internal memory

• Programming

• Settings

• Functions built into the CPU Unit

Also refer to the Hardware User’s Manual (W472)

Describes each programming instruction in detail.

Also refer to the Software User’s Manual (W473) when you

do programming.

Describes C-mode commands and FINS commands

Refer to this manual for a detailed description of commands

for communications with the CPU Unit using C mode

commands or FINS commands.

Note: This manual describes the communications

commands that are addressed to CPU Units. The

communications path that is used is not relevant and

can include any of the following: serial ports on CPU

Units, communications ports on Serial

Communications Units/Boards, and Communications

Units. For communications commands addressed to

Special I/O Units or CPU Bus Units, refer to the

operation manual for the related Unit.

Describes operating procedures for the CX-Programmer.

Also refer to the Software User’s Manual (W473) and

Instructions Reference Manual (W474) when you do

programming.

Provides an overview of the CX-One FA Integrated Tool

Package and describes the installation procedure.

W472

W473

W474

W342

W446

W447

W469

W464

W463

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1M-CPU@@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCU@@-V1

CS1W-SCB@@-V1

CJ1H-CPU@@H-R

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

CJ1G-CPU@@

CJ1W-SCU@@-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

WS02-CX@@-V@

CXONE-AL@@C-V@/

CXONE-AL

CXONE-AL@@C-V@/

AL@@D-V@

@@D-V@

CJ-series CJ2 CPU Unit

Hardware User’s

Manual

CJ-series CJ2 CPU Unit

Software User’s Manual

CS/CJ/NSJ-series

Instructions Reference

Manual

CS/CJ/CP/NSJ-series

Communications

Command Reference

Manual

CX-Programmer

Operation Manual

CX-Programmer

Operation Manual

Functions Blocks

CX-Programmer

Operation Manual SFC

Programming

CS/CJ/CP/NSJ-series

CX-Integrator Network

Configuration Software

Operation Manual

CX-One Setup Manual

Hardware specifications for CJ2

CPU Units

Software specifications for CJ2

CPU Units

Information on instructions

Information on communications

for CS/CJ/CP-series CPU Units

and NSJ-series Controllers

Support Software for Windows

computers

CX-Programmer operating

procedure

Network setup and monitoring Describes the operating procedures for the CX-Integrator.

Installing software from the CXOne

14

Page 15

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

•

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

•

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

•

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2009 All Right Reserved.

2009.1

Loading...

Loading...