Page 1

USER’S MANUAL

Cat. No. W472-E1-01

SYSMAC CJ Series

CJ2H-CPU@@-EIP

CJ2 CPU Unit Hardware

Page 2

Page 3

OMRON, 2008

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 4

Page 5

SYSMAC CJ Series

CJ2H-CPU@@-EIP

CJ2 CPU Unit Hardware

User’s Manual

Produced July 2008

Page 6

Page 7

1

CJ2 CPU Unit Hardware User’s Manual

Introduction

Thank you for purchasing a CJ2H-CPU@@-EIP CJ-series CPU Unit. This manual contains information

that is necessary to use the CJ2H-CPU@@-EIP. Please thoroughly read and understand this manual

before you use the CJ2H-CPU@@-EIP.

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

z Definition of CJ Series

In this manual, CJ Series is a general term to refer to the CJ2 CPU Units, CJ1-H CPU Units, CJ1M CPU

Units, and CJ1 CPU Units.

Intended Audience

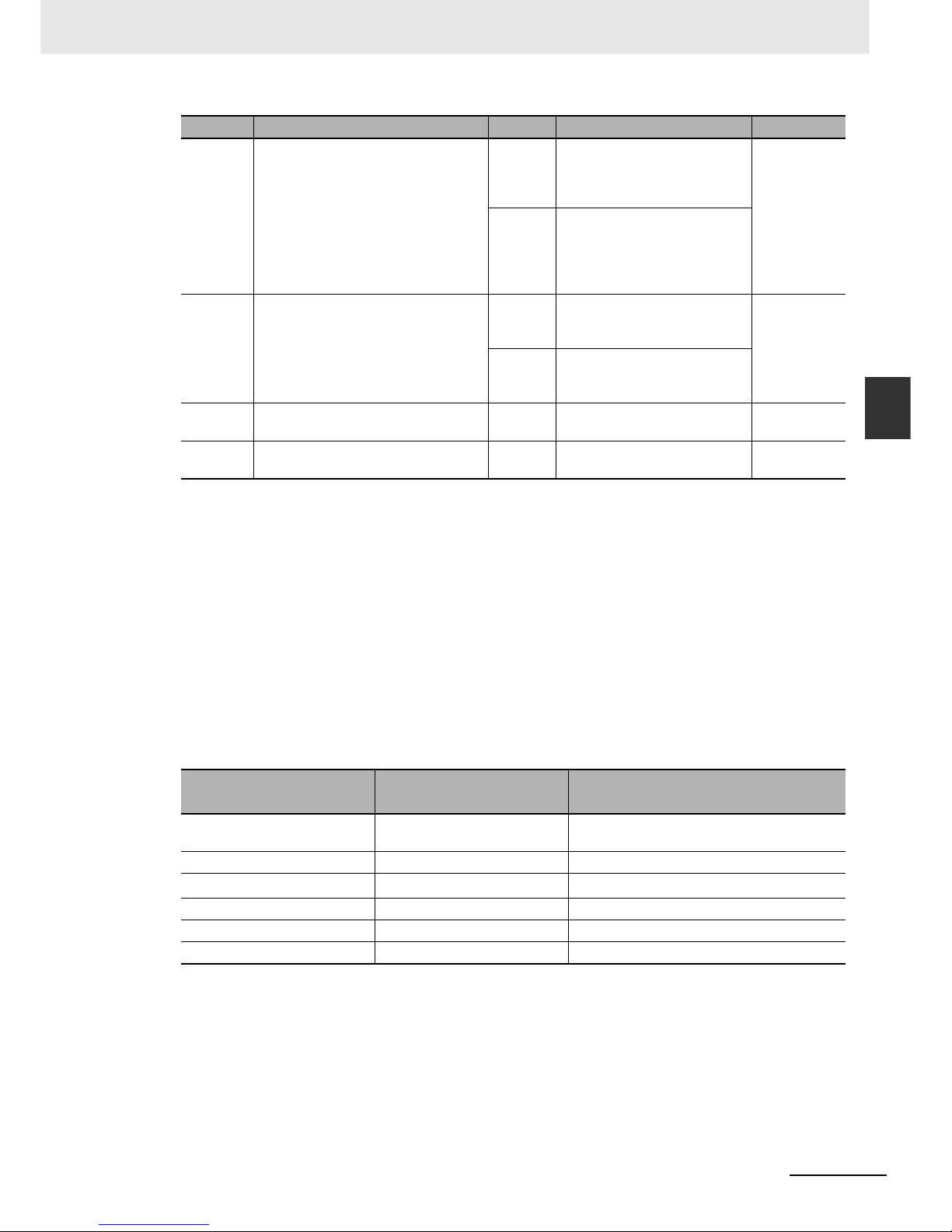

Applicable Products

CS1H-CPU@@H

CS1G-CPU@@H

CS1-H CPU Units

CS-series Power Supply Units

CS-series Basic I/O Units

CS-series CPU Bus Units

CS-series SpecialI/O Units

CS Series

CS1 CPU Units

CS1H-CPU@@(-V)

CS1G-CPU@@(-V)

CS1D CPU Units

CS1D CPU Units

for Duplex Systems

CS1D-CPU@@H

CS1D-CPU@@S

CS1D-CPU@@P

CJ1H-CPU@@H-R

CJ1H-CPU@@H

CJ1G-CPU@@H

CJ1G -CPU@@P

(Loop CPU Units)

CJ1-H CPU Units

CJ-series Power Supply Units

CJ-series Basic I/O Units

CJ-series CPU Bus Units

CJ-series Special I/O Units

CJ1 CPU Units

CJ Series

CJ1G-CPU@@

CJ1M CPU Units

CJ1M-CPU@@

NSJ5-TQ@@(B)-G5D

NSJ5-SQ@@(B)-G5D

NSJ8-TV@@(B)-G5D

NSJ10-TV@@(B)-G5D

NSJ12-TS@@(B)-G5D

NSJ Controllers

NSJ-series Expansion Units

NSJ Series

NSJ5-TQ@@(B)-M3D

NSJ5-SQ@@(B)-M3D

NSJ8-TV@@(B)-M3D

NSJ Controllers

CJ2 CPU Units

CJ2H-CPU@@-@@@

CS1D CPU Units

for Simplex Systems

CS1D Process-control CPU Units

Note: A special Power Supply Unit must

be used for CS1D CPU Units.

Page 8

2

CJ2 CPU Unit Hardware User’s Manual

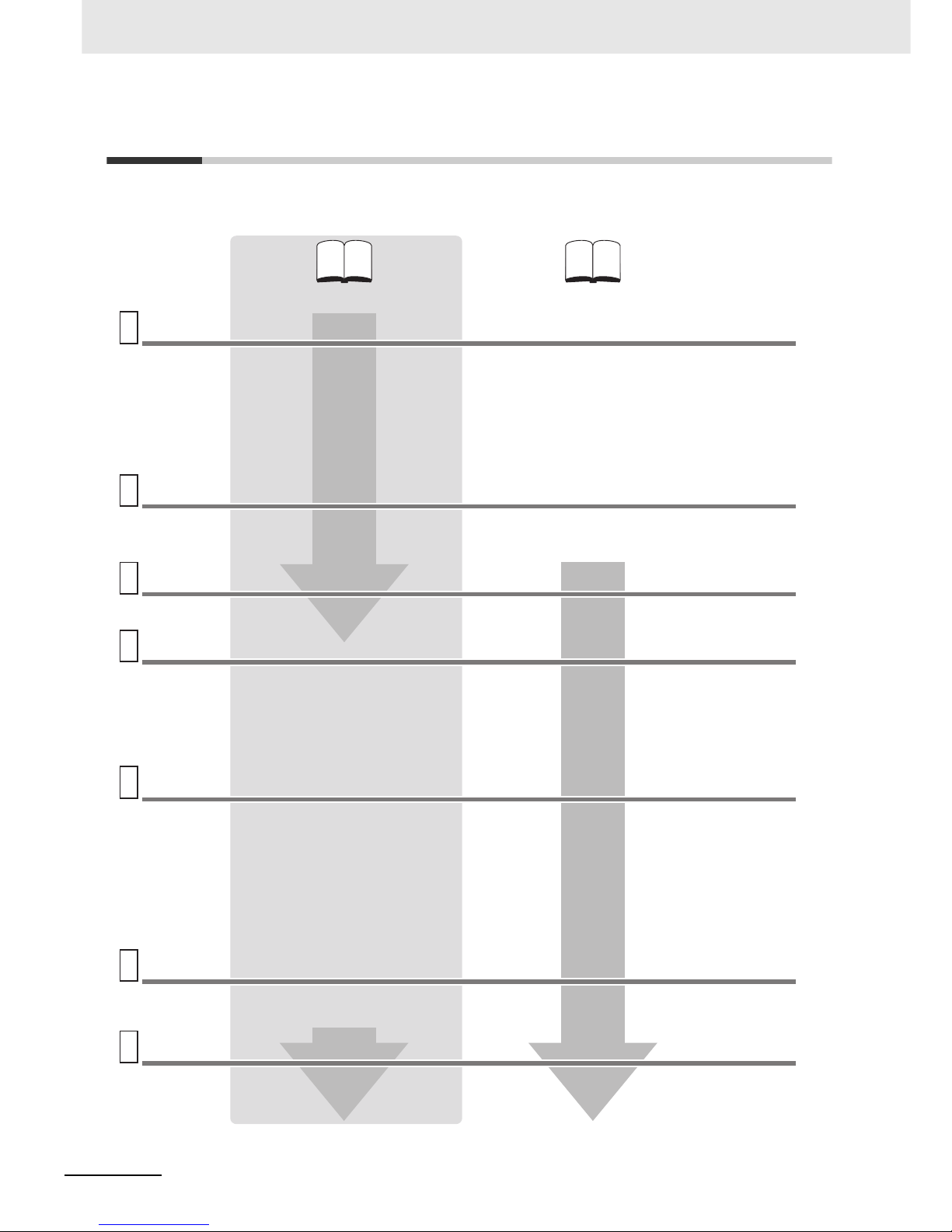

CJ2 CPU Unit Manuals

Information on the CJ2 CPU Units is provided in the following manuals. Refer to the appropriate manual

for the information that is required.

Mounting and Setting Hardware

1

2

3

4

5

6

7

Wiring

Connecting Online to the PLC

Software Setup

Creating the Program

Checking and Debugging Operation

Maintenance and Troubleshooting

CJ-series CJ2 CPU Unit Hardware User’s Manual (W472) CJ-series CJ2 CPU Unit Software User’s Manual (W473)

This Manual

CX-Programmer Support Software

Connecting Cables

Error codes and remedies if a problem

occurs

Procedures for connecting the

CX-Programmer Support Software

Software setting methods for the CPU Unit

(including I/O memory allocation, PLC Setup

settings, Special I/O Unit parameters, CPU Bus

Unit parameters, and routing tables. )

For details on built-in EtherNet/IP port, refer to

the EtherNet/IP Unit Operation Manual (W465)

• Checking I/O wiring, setting the Auxiliary Area

settings, and performing trial operation

• Monitoring and debugging with the

CX-Programmer

• Unit part names and specifications

• Basic system configuration

• Unit mounting procedure

• Setting procedure for DIP switch and rotary

switches on the front of the CPU Unit

For details on built-in EtherNet/IP port, refer

to the EtherNet/IP Unit Operation Manual

(W465)

• Wiring the Power Supply Unit

• Wring Basic I/O Units and external I/O

devices

• Program types and basic information

• CPU Unit operation

• Internal memory

• Data management using file memory in the

CPU Unit

• Built-in CPU functions

• Settings

For details on instructions, refer to the

Instructions Reference Manual (W474).

Page 9

3

CJ2 CPU Unit Hardware User’s Manual

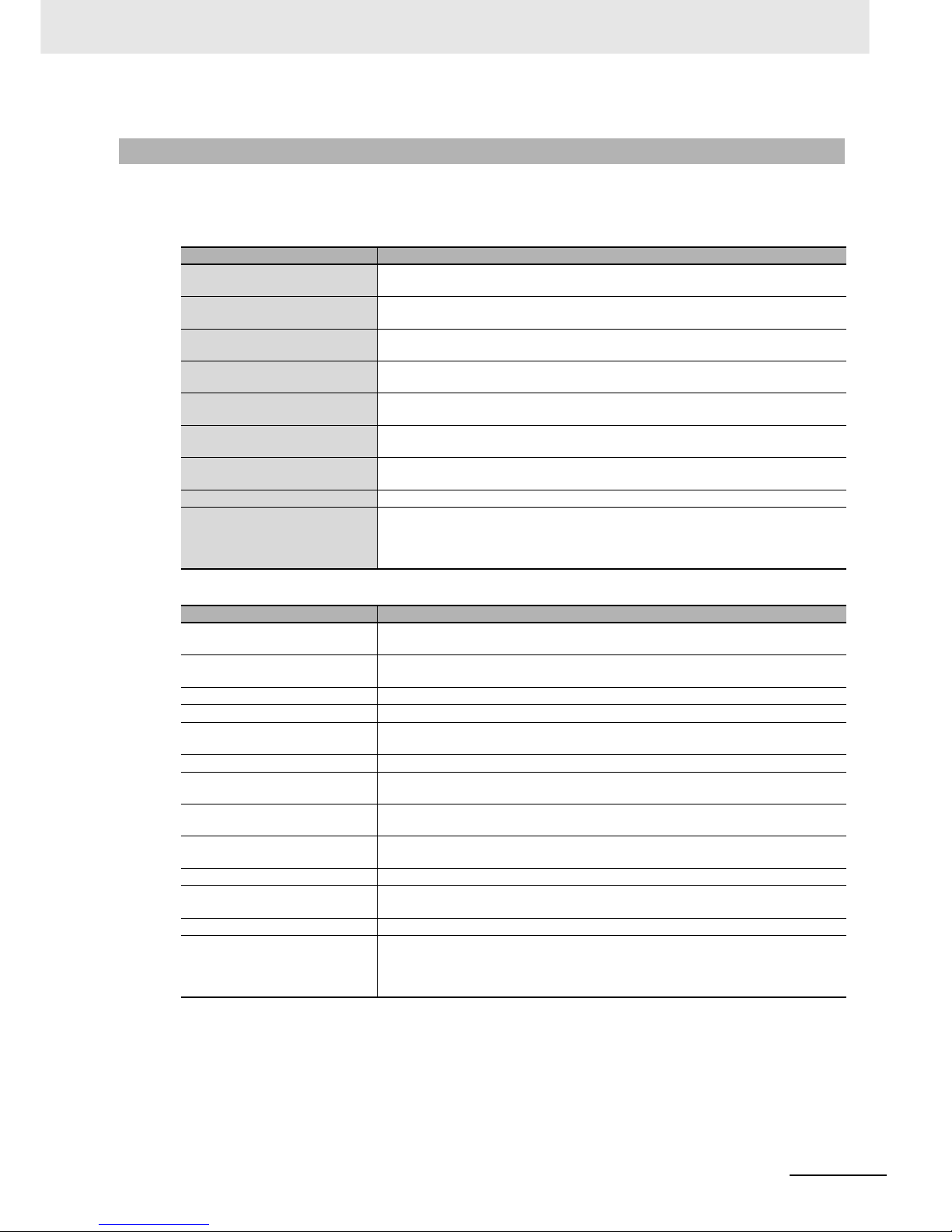

The CJ2 CPU manuals are organized in the sections listed in the following tables. Refer to the appropriate section in the manuals as required.

Manual Configuration

Hardware User’s Manual (W472) (This Manual)

Section Content

Section 1 Overview

This section gives an overview of the CJ2 CPU Units and describes the features and

specifications.

Section 2 Basic System Configuration and Devices

This section describes the system configuration for the CJ2 CPU Unit.

Section 3 Nomenclature and

Functions

This section describes the part names and functions of the CPU Unit and Configuration

Units.

Section 4 Support Software

This section describes the types of Support Software to use to perform programming and

debugging and how to connect the PLC to the Support Software.

Section 5 Installation

This section describes the installation locations and how to wire CPU Units and Configuration Units.

Section 6 Troubleshooting

This section describes how to check the status for errors that occur during system operation and the remedies for those errors.

Section 7 Inspection and Maintenance

This section describes periodic inspection, the service lifes of the Battery and Power

Supply Unit, and how to replace the Battery.

Section 8 Backup Operations This section describes the procedure to back up PLC data.

Appendices

The appendices provide Unit dimensions, details on fatal and non-fatal errors, information on connecting to serial ports on the CPU Unit, the procedure for installing the USB

driver on a computer, and information on load short-circuit protection and line disconnection detection.

Software User’s Manual (W473)

Section Content

Section 1 Overview This section gives an overview of the CJ2 CPU Units and describes the features and

specifications.

Section 2 Internal Memory in the

CPU Unit

This section describes the types of memory in the CPU Unit and the data that is stored.

Section 3 CPU Unit Operation This section describes the internal operation of the CPU Unit.

Section 4 CPU Unit Initialization This section describes the initial setup of the CPU Unit.

Section 5 Understanding Program-

ming

This section describes program types and programming details, such as symbols and

programming instructions.

Section 6 I/O Memory Areas This section describes the I/O memory areas in the CPU Unit.

Section 7 File Operations This section describes the files that can be stored in the CPU Unit, the storage destina-

tion for those files, and file operations.

Section 8 I/O Allocations and Unit

Settings

This section describes the I/O allocations used to exchange data between the CPU Unit

and other Units.

Section 9 PLC Setup This section describes details on the PLC Setup settings, which are used to perform

basic settings for the CPU Unit.

Section 10 CPU Unit Functions This section describes functions that are built into the CPU Unit.

Section 11 Programming Devices

and Communications

This section describes the procedure for connecting the CJ2 CPU Unit to the CX-Pro-

grammer or other Support Software and to other devices.

Section 12 CPU Unit Cycle Time This section describes how to monitor and calculate the cycle time.

Appendices The appendices provide information on programming instructions, execution times, num-

ber of steps, Auxiliary Area words and bits, a memory map of the continuous PLC mem-

ory addresses, I/O memory operation when power is interrupted, and a comparison of

CJ-series and CS-series PLCs.

Page 10

4

CJ2 CPU Unit Hardware User’s Manual

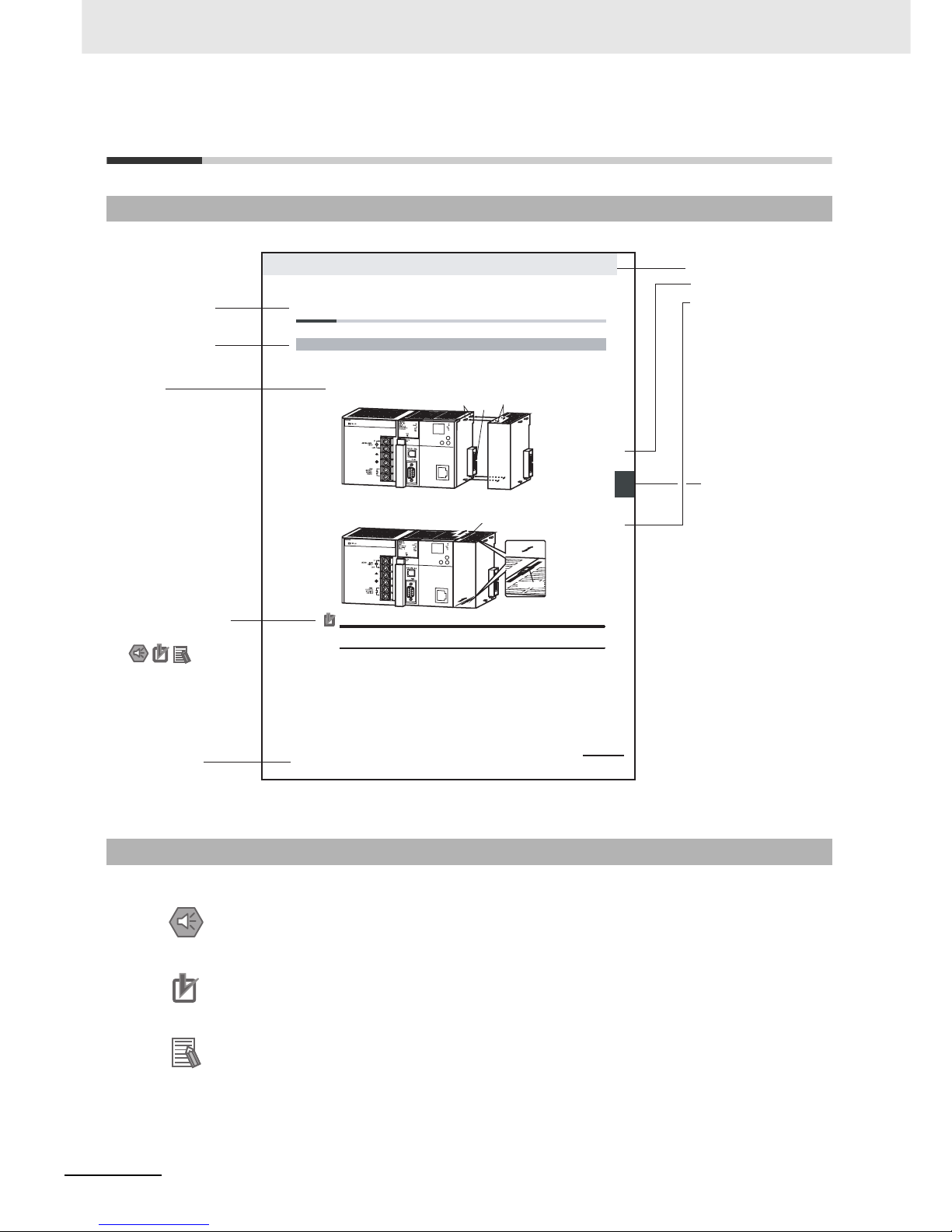

Manual Structure

The following page structure is used in this manual.

Special information in this manual is classified as follows:

Page Structure

Special Information

Precautions for Safe Use

Precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to increase understanding or make operation easier.

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step

in a procedure

Manual name

Level 3 heading

Page tab

Gives the current

headings.

Gives the number

of the section.

This illustration is provided only as a sample and may not literally appear in this manual.

Special Information

(See below.)

5-13

5 Installation

CJ2 CPU Unit Hardware User’s Manual

n

oita

lla

t

s

nI

2-

5

5

s

tn

e

n

o

p

moC CL

P

gn

it

ce

nnoC

1

-2

-

5

5-2 Installation

The Units that make up a CJ-series PLC can be connected simply by pressing the Units together and

locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the PLC.

1. Join the Units so that the connectors fit exactly.

2. The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

If the locking tabs are not secured properly, the connectors may become loose and not function

properly. Be sure to slide the locking tabs until they are securely in place.

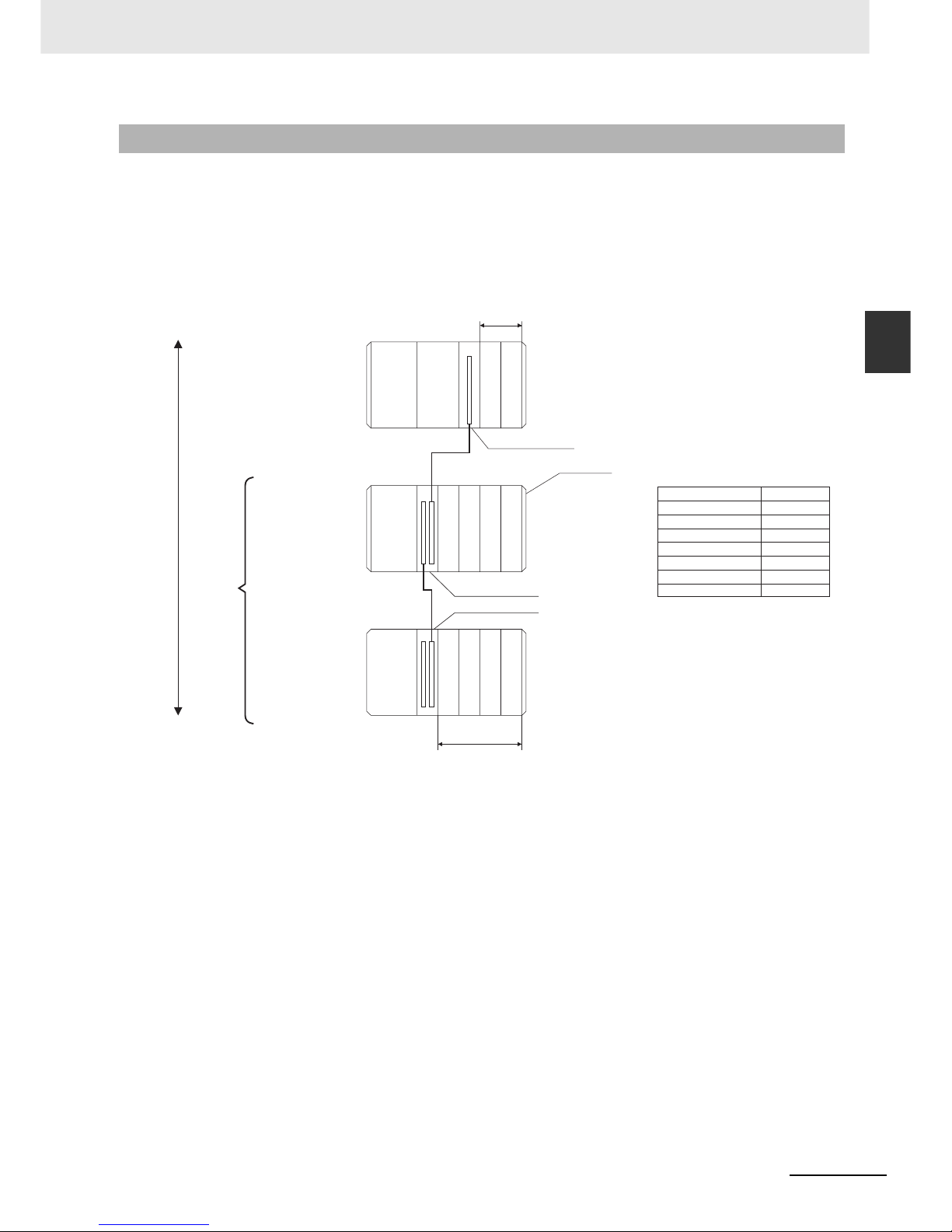

5-2-1 Connecting PLC Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

Page 11

5

CJ2 CPU Unit Hardware User’s Manual

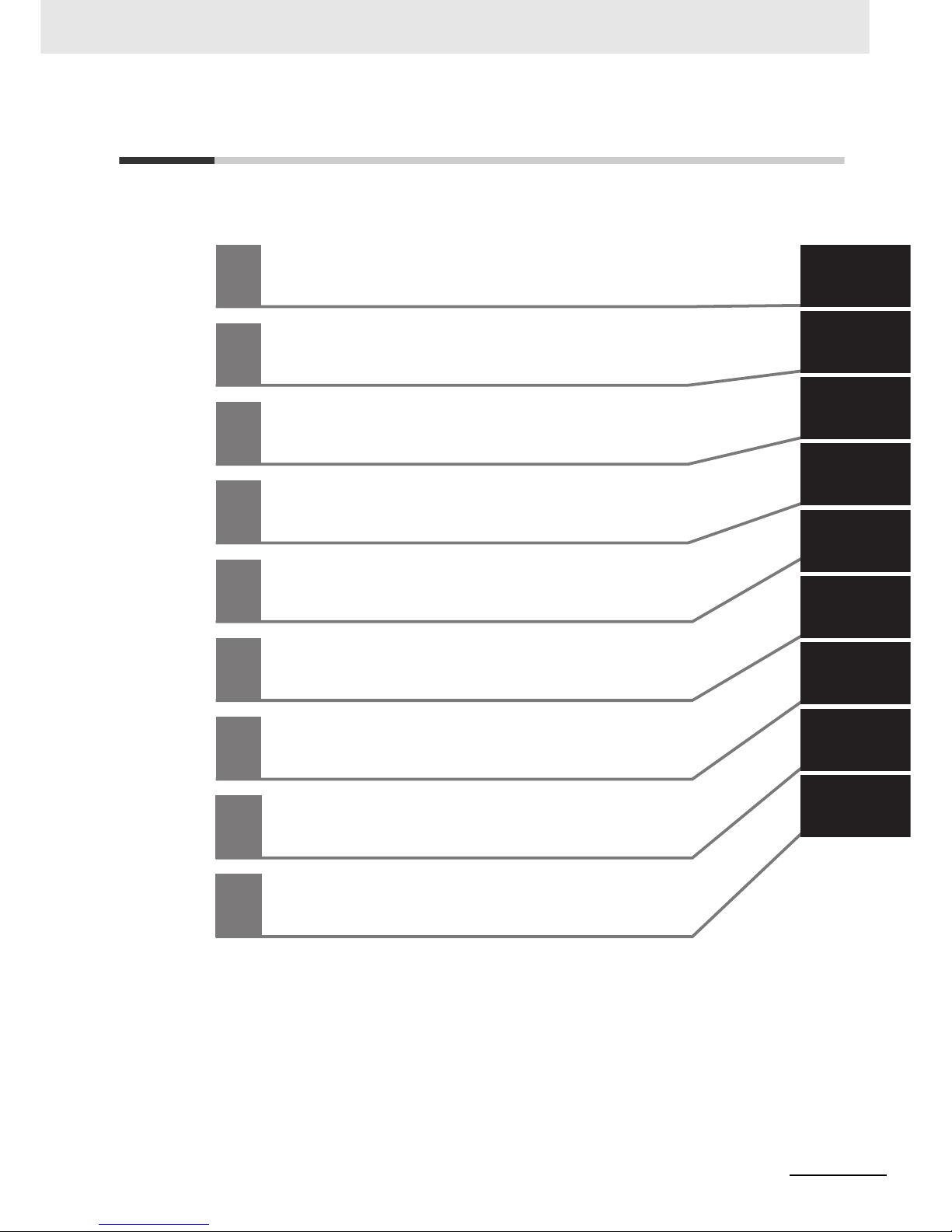

Sections in this Manual

1

2

3

4

5

6

7

8

A

1

2

3

4

5

6

7

8

A

Overview

Basic System Configuration and Devices

Nomenclature and Functions

Support Software

Installation

Troubleshooting

Inspection and Maintenance

Backup Operations

Appendices

Page 12

6

CJ2 CPU Unit Hardware User’s Manual

Page 13

7

CJ2 CPU Unit Hardware User’s Manual

CONTENTS

Introduction............................................................................................................... 1

CJ2 CPU Unit Manuals ............................................................................................. 2

Manual Structure ...................................................................................................... 4

Sections in this Manual............................................................................................ 5

Safety Precautions ................................................................................................. 15

Application Precautions......................................................................................... 21

Operating Environment Precautions .................................................................... 25

Regulations and Standards ................................................................................... 26

Related Manuals ..................................................................................................... 28

Section 1 Overview

1-1 Overview of CJ2 CPU Units ....................................................................................................1-2

1-1-1 Overview..................................................................................................................................... 1-2

1-1-2 CJ2 CPU Unit Features .............................................................................................................. 1-3

1-2 Basic Operating Procedure ....................................................................................................1-7

1-3 Specifications .......................................................................................................................... 1-8

1-3-1 General Specifications................................................................................................................ 1-8

1-3-2 Performance Specifications ........................................................................................................ 1-9

1-3-3 Function Specifications............................................................................................................. 1-13

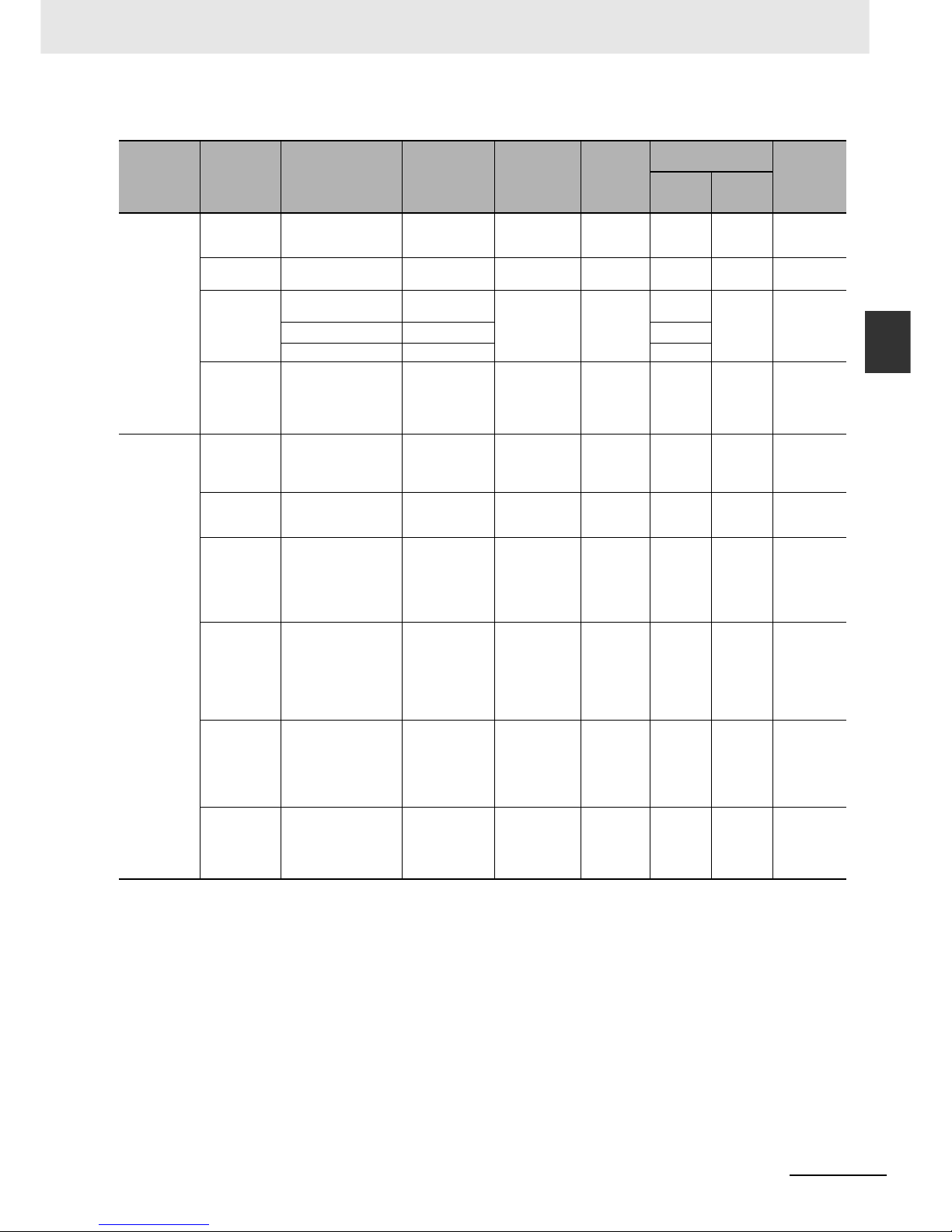

Section 2 Basic System Configuration and Devices

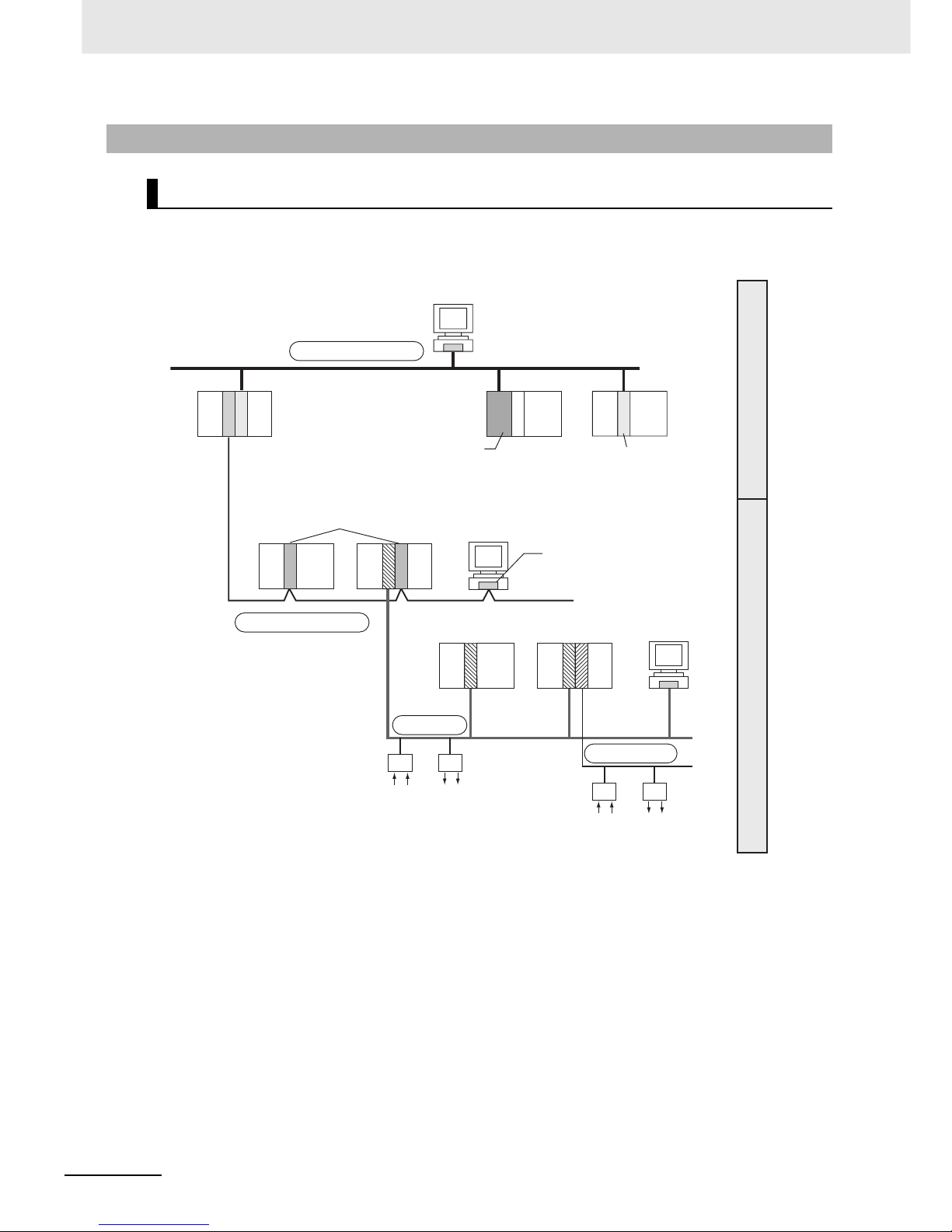

2-1 Basic System Configuration...................................................................................................2-2

2-1-1 Basic System Configuration........................................................................................................ 2-2

2-1-2 CPU Rack................................................................................................................................... 2-3

2-1-3 Expansion Racks........................................................................................................................ 2-7

2-1-4 Configuration Units ................................................................................................................... 2-10

2-1-5 Calculating Unit Current Consumption ..................................................................................... 2-18

2-1-6 Calculating Power Consumption............................................................................................... 2-20

2-2 Expanded System Configuration ......................................................................................... 2-22

2-2-1 Serial Communications............................................................................................................. 2-22

2-2-2 Communications Networks....................................................................................................... 2-24

Section 3 Nomenclature and Functions

3-1 CPU Units ................................................................................................................................. 3-2

3-1-1 CPU Section ............................................................................................................................... 3-2

3-1-2 Built-in EtherNet/IP Section ........................................................................................................ 3-7

3-2 Memory Card.......................................................................................................................... 3-12

3-2-1 Models and Specifications........................................................................................................ 3-12

3-2-2 Operating Procedures............................................................................................................... 3-12

3-2-3 Installing and Removing ........................................................................................................... 3-13

Page 14

8

CJ2 CPU Unit Hardware User’s Manual

3-3 Power Supply Units ............................................................................................................... 3-16

3-3-1 Models and Specifications ........................................................................................................3-16

3-3-2 Components..............................................................................................................................3-19

3-3-3 Selecting a Power Supply Unit..................................................................................................3-21

3-4 CJ-series Basic I/O Units ...................................................................................................... 3-23

3-4-1 Basic I/O Units with Terminal Blocks.........................................................................................3-23

3-4-2 Thirty-two/Sixty-four-point Basic I/O Units with Connectors...................................................... 3-25

3-5 I/O Control Units and I/O Interface Units ............................................................................. 3-26

3-5-1 Component Names ...................................................................................................................3-26

3-5-2 System Configuration................................................................................................................3-26

Section 4 Support Software

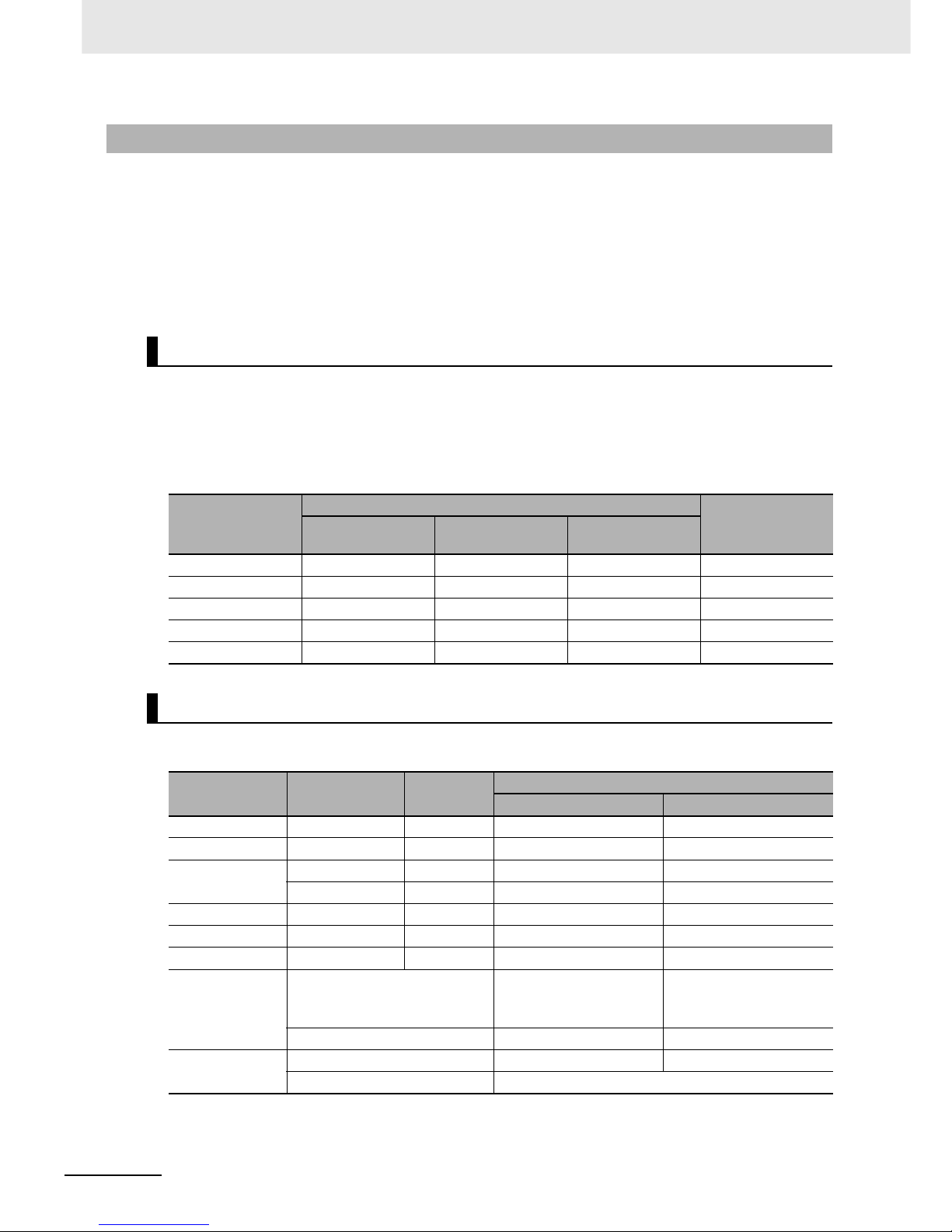

4-1 Support Software..................................................................................................................... 4-2

4-1-1 CX-One FA Integrated Tool Package ..........................................................................................4-2

4-2 Connection Methods ............................................................................................................... 4-6

4-2-1 Connecting by USB.....................................................................................................................4-6

4-2-2 Connecting by RS-232C ............................................................................................................. 4-8

4-2-3 Connecting by Ethernet ............................................................................................................4-10

Section 5 Installation

5-1 Fail-safe Circuits...................................................................................................................... 5-2

5-2 Installation................................................................................................................................ 5-4

5-2-1 Installation and Wiring Precautions.............................................................................................5-4

5-2-2 Installation in a Control Panel .....................................................................................................5-6

5-2-3 Assembled Appearance and Dimensions ................................................................................... 5-8

5-2-4 Connecting PLC Components................................................................................................... 5-11

5-2-5 DIN Track Installation ................................................................................................................5-14

5-2-6 Connecting CJ-series Expansion Racks................................................................................... 5-16

5-3 Wiring ..................................................................................................................................... 5-19

5-3-1 Power Supply Wiring.................................................................................................................5-19

5-3-2 Wiring CJ-series Basic I/O Units with Terminal Blocks ............................................................. 5-25

5-3-3 Wiring Basic I/O Units with Connectors ....................................................................................5-27

5-3-4 Connecting to Connector-Terminal Block Conversion Units or I/O Relay Terminals .................5-31

5-3-5 Connecting I/O Devices ............................................................................................................5-32

5-3-6 Wiring with Ethernet Cable .......................................................................................................5-36

5-4 Control Panel Installation ..................................................................................................... 5-39

5-4-1 Temperature ..............................................................................................................................5-39

5-4-2 Humidity .................................................................................................................................... 5-41

5-4-3 Vibration and Shock..................................................................................................................5-41

5-4-4 Atmosphere............................................................................................................................... 5-41

5-4-5 Electrical Environment ..............................................................................................................5-42

5-4-6 Grounding .................................................................................................................................5-46

Section 6 Troubleshooting

6-1 CPU Unit Errors ....................................................................................................................... 6-2

6-1-1 Errors and Remedies ..................................................................................................................6-2

6-1-2 Checking Errors ..........................................................................................................................6-2

6-1-3 Checking Detailed Status............................................................................................................6-3

6-1-4 Reading Error Log Information....................................................................................................6-3

6-1-5 I/O Table Verification ...................................................................................................................6-5

6-1-6 Types of Errors ............................................................................................................................6-6

6-1-7 Handling Errors ...........................................................................................................................6-7

Page 15

9

CJ2 CPU Unit Hardware User’s Manual

6-2 Built-in EtherNet/IP Port Errors and Remedies................................................................... 6-23

6-2-1 Checking Built-in EtherNet/IP Port Error Status ....................................................................... 6-23

6-2-2 Checking Error Status at the EtherNet/IP Port Seven-segment Display................................... 6-24

6-3 Non-CPU Unit Errors and Remedies.................................................................................... 6-26

6-3-1 Error Causes and Remedies .................................................................................................... 6-26

Section 7 Inspection and Maintenance

7-1 Inspections............................................................................................................................... 7-2

7-1-1 Inspection Points ........................................................................................................................ 7-2

7-1-2 Unit Replacement Precautions ................................................................................................... 7-4

7-2 Replacing the Battery.............................................................................................................. 7-5

7-2-1 Battery Replacement .................................................................................................................. 7-5

7-2-2 Operation When Battery Is Exhausted or Not Installed .............................................................. 7-8

7-3 Power Supply Unit Replacement Time ................................................................................ 7-10

Section 8 Backup Operations

8-1 Backing Up Data ...................................................................................................................... 8-2

8-2 Using a Computer to Back Up Data ....................................................................................... 8-3

8-2-1 PLC Backup Tool ........................................................................................................................ 8-3

8-2-2 PLC Backup Tool Operations...................................................................................................... 8-4

8-3 Simple Backup......................................................................................................................... 8-7

8-3-1 Overview..................................................................................................................................... 8-7

8-3-2 Operating Procedures................................................................................................................. 8-8

8-3-3 Verifying Backup Operations with Indicators ............................................................................ 8-10

8-3-4 Related Auxiliary Bits/Words .................................................................................................... 8-12

8-3-5 Time Required for Simple Backup............................................................................................8-12

8-3-6 Data Backed Up Using Simple Backup..................................................................................... 8-12

Appendices

A-1 Specifications of Basic I/O Units ...........................................................................................A-2

A-1-1 Overview of Units........................................................................................................................A-2

A-1-2 Basic I/O Units............................................................................................................................A-4

A-1-3 Precautions on Contact Output Units .......................................................................................A-51

A-1-4 Connecting Connector-Terminal Block Conversion Units and I/O Relay Terminals.................. A-53

A-2 Dimensions ............................................................................................................................A-86

A-2-1 CJ2H CPU Units.......................................................................................................................A-86

A-2-2 Power Supply Units................................................................................................................... A-86

A-2-3 Basic I/O Units..........................................................................................................................A-89

A-2-4 I/O Control Unit and I/O Interface Unit......................................................................................A-92

A-2-5 I/O Memory Card ......................................................................................................................A-92

A-3 Fatal and Non-fatal Error Details..........................................................................................A-93

A-3-1 Fatal Errors...............................................................................................................................A-93

A-3-2 Non-fatal Errors ........................................................................................................................ A-98

A-4 Connecting to the RS-232C Serial Port on the CPU Unit .................................................A-101

A-4-1 RS-232C Port Specifications ..................................................................................................A-101

A-4-2 Connection Examples.............................................................................................................A-102

A-4-3 Applicable Connectors and Recommended Cables ...............................................................A-105

A-4-4 Example of Recommended RS-232C Wiring .........................................................................A-106

A-4-5 Wiring Connectors ..................................................................................................................A-107

A-5 Installing the USB Driver ....................................................................................................A-110

Page 16

10

CJ2 CPU Unit Hardware User’s Manual

A-6 Load Short-circuit Protection and Line Disconnection Detection for Basic I/O Units..A-115

A-6-1 Load Short-circuit Protection and Line Disconnection Detection for CJ1W-OD202................A-115

A-6-2 Load Short-circuit Protection for CJ1W-OD204/OD212/OD232/MD232.................................A-117

A-7 Relay Output Noise Reduction Methods ...........................................................................A-119

index................................................................................................................ Index-1

Page 17

11

CJ2 CPU Unit Hardware User’s Manual

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON representative

if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 18

12

CJ2 CPU Unit Hardware User’s Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 19

13

CJ2 CPU Unit Hardware User’s Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 20

14

CJ2 CPU Unit Hardware User’s Manual

Page 21

15

CJ2 CPU Unit Hardware User’s Manual

Safety Precautions

The following notation is used in this manual to provide precautions required to ensure safe usage of a

CJ-series PLC. The safety precautions that are provided are extremely important to safety. Always read

and heed the information provided in all safety precautions.

Definition of Precautionary Information

WARINING

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. Additionally, there

may be severe property damage.

Caution

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or property damage.

Precautions for Safe Use

Indicates precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Indicates precautions on what to do and what not to do to ensure proper operation and performance.

Page 22

16

CJ2 CPU Unit Hardware User’s Manual

Symbols

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in

text. This example indicates a precaution for electric shock.

The circle and slash symbol indicates operations that you must

not do. The specific operation is shown in the circle and

explained in text. This example indicates “do not disassemble.”

The filled circle symbol indicates operations that you must do.

The specific operation is shown in the circle and explained in

text. This example shows a general precaution for something

that you must do.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in

text. This example indicates a general precaution.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in

text. This example indicates a precaution for hot surfaces.

Page 23

17

CJ2 CPU Unit Hardware User’s Manual

WARNING

Do not attempt to take any Unit apart while the power is being supplied.

Doing so may result in electric shock.

Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed. As

a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided to

ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety measures must be provided to ensure safety in the system.

Confirm safety before transferring data files stored in the file memory (Memory Card or EM file memory) to the I/O area (CIO) of the CPU Unit using a

peripheral tool. Otherwise, the devices connected to the output unit may malfunction regardless of the operation mode of the CPU Unit.

Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes. Serious accidents

may result from abnormal operation if proper measures are not provided.

Page 24

18

CJ2 CPU Unit Hardware User’s Manual

WARNING

When restoring data, carefully check that the selected data is the correct

data to be restored before executing the restore operation. Depending on the

contents of the selected data, the control system may operate unexpectedly

after the data is restored.

Some Special I/O Units and CPU Bus Units operate with parameters stored

in the CPU Unit (e.g., words allocated in DM Area, data link tables, or Ethernet settings). Information on restrictions will be displayed in the Information

Area in the PLC Backup Tool if there are any restrictions for the selected

CPU Bus Unit or Special I/O Unit. Check the restrictions, and then be sure to

select both the CPU Unit and the CPU Bus Unit or Special I/O Unit when

backing up or restoring data. The control system may operate unexpectedly if

the equipment is started with the data backed up or restored without selecting both Units.

Information on restrictions will be displayed in the Information Area in the

PLC Backup Tool if the data to be stored includes a Unit that has restrictions

on backup. Check the information on restrictions and take the required countermeasures. The control system may operate unexpectedly when the equipment is operated after the data is restored

Before restoring data during PLC operation, be sure that there will be no

problem if PLC operation stops. If the PLC stops at an unexpected time, the

control system may operate unexpectedly.

Be sure to turn the PLC power supply OFF and then back ON after restoring

data. If the power is not reset, the system may not be updated with the

restored data, and the control system may operate unexpectedly.

Data on forced status can be backed up but it cannot be restored. Perform

the procedure to force-set or force-reset bits from the CX-Programmer as

required before starting operation after restoring data that includes forced

status. Depending on the difference in the forced status, the control system

may operate unexpectedly.

Page 25

19

CJ2 CPU Unit Hardware User’s Manual

Caution

Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

The CJ2 CPU Units automatically back up the user program and parameter

data to flash memory when these are written to the CPU Unit. I/O memory

including the DM, EM, and Holding Areas), however, is not written to flash

memory.

The DM, EM, and Holding Areas can be held during power interruptions with

a battery. If there is a battery error, the contents of these areas may not be

accurate after a power interruption. If the contents of the DM, EM, and Holding Areas are used to control external outputs, prevent inappropriate outputs

from being made whenever the Battery Error Flag (A402.04) is ON.

Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the user’s manual. The loose screws may result in burning

or malfunction.

Do not touch the Power Supply Unit when power is being supplied or immediately after the power supply is turned OFF. The Power Supply Unit will be hot

and you may be burned.

Be careful when connecting personal computers or other peripheral devices

to a PLC to which is mounted a non-insulated Unit (CS1W-CLK1@/5@(-V1)

or CS1W-ETN01) connected to an external power supply. A short-circuit will

be created if the 24 V side of the external power supply is grounded and the

0 V side of the peripheral device is grounded. When connecting a peripheral

device to this type of PLC, either ground the 0 V side of the external power

supply or do not ground the external power supply at all.

Page 26

20

CJ2 CPU Unit Hardware User’s Manual

Caution

If a symbol or memory address (only symbols are allowed for ST programming) is specified for the suffix of an array variable in ladder or ST programming, be sure that the specified element number does not exceed the

maximum memory area range. For example, write the program so that processing is executed only when the indirect specification is within the memory

area range by using a symbol comparison instructions or an IF statement.

Specifying an element number that exceeds the maximum range of the

memory area specified for the symbol will result accessing data in a different

memory area, and may result in unexpected operation.

If a symbol or address is specified for an offset in a ladder diagram, program

so that the memory area of the start address is not exceeded when the offset

is specified indirectly using a word address or symbol. For example, write the

program so that processing is executed only when the indirect specification

does not cause the final address to exceed the memory area by using an

input comparison instruction or other instruction.

If a indirect specification causes the address to exceed the area of the start

address, the system will access data in other area, and unexpected operation may occur.

Page 27

21

CJ2 CPU Unit Hardware User’s Manual

Application Precautions

Observe the following precautions when using a CJ-series PLC.

z Power Supply

• Always use the power supply voltages specified in the user’s manuals. An incorrect voltage may

result in malfunction or burning.

• Exceeding the capacity of the Power Supply Unit may prevent the CPU Unit or other Units from

starting.

• Take appropriate measures to ensure that the specified power with the rated voltage and frequency is supplied. Be particularly careful in places where the power supply is unstable. An incorrect power supply may result in malfunction.

• Always turn OFF the power supply to the PLC before attempting any of the following. Not turning

OFF the power supply may result in malfunction or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

• When cross-wiring terminals, the total current for all the terminal will flow in the wire. Make sure

that the current capacity of the wire is sufficient.

• Observe the following precautions when using a Power Supply Unit that supports the Replacement Notification Function.

• Replace the Power Supply Unit within six months if the display on the front of the Power Supply Unit alternates between 0.0 and A02, or if the alarm output automatically turns OFF.

• Keep the alarm output cable separated from power line and high-voltage lines.

• Do not apply a voltage or connect a load exceeding the specifications to the alarm output.

• Whe storing the Power Supply Unit for more than three months, store it at −20 to 30°C and

25% to 70% humidity to preserve the Replacement Notification Function.

• If the Power Supply Unit is not installed properly, heat buildup may cause the replacement notification signal to appear at the wrong time or may cause interior elements to deteriorate or

become damaged. Use only the standard installation method.

• Do not touch the terminals on the Power Supply Unit immediately after turning OFF the power

supply. Residual voltage may cause electrical shock.

• Observe the following precautions to prevent failure due to difference in electrical potential if the

computer is connected to the PLC.

• Before connecting a laptop computer to the PLC, disconnect the power supply plug of the

computer from the AC outlet. Residual current in the AC adaptor may cause difference in electrical potential to occur between the computer and the PLC. After you connect the computer

and PLC, supply the power again from the AC adaptor.

• If the computer has a FG terminal, make the connections so that it has the same electrical

potential as the FG (GR) terminal on the PLC.

• If the computer is grounded to a separate location, difference in electrical potential may occur

depending on the grounding conditions.

z Installation

• Do not install the PLC near sources of strong high-frequency noise.

• Before touching a Unit, be sure to first touch a grounded metallic object in order to discharge any

static build-up. Not doing so may result in malfunction or damage.

Page 28

22

CJ2 CPU Unit Hardware User’s Manual

• Be sure that the connectors, terminal blocks, expansion cables, and other items with locking

devices are properly locked into place. Improper locking may result in malfunction.

• The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

to adjacent Units. The Unit may not operate properly if the sliders are not locked in place. It may

not be possible to achieve proper functionality if the sliders are not locked.

• Always attach the End Cover that comes with the CPU Unit to the right end of the CPU Rack. The

PLC will not operate correctly if the End Cover is not attached.

z Wiring

• Wire all connections correctly.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring

may result in burning.

• Be sure that all terminal screws, and cable connector screws are tightened to the torque specified

in the relevant manuals. Incorrect tightening torque may result in malfunction.

• Do not apply a force exceeding 100 N to the terminal block when tightening it.

• Mount Units only after checking terminal blocks and connectors completely.

• Leave the label attached to the Unit when wiring. Removing the label may result in malfunction if

foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the

label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to terminals. Connection of bare stranded wires may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may

result in burning.

• Always connect to a ground of 100 Ω or less when installing the Units. Not connecting to a ground

of 100 Ω or less may result in electric shock.

• A ground of 100 Ω or less must be installed when shorting the GR and LG terminals on the Power

Supply Unit.

• Fail-safe measures must be taken by the customer to ensure safety in the event of incorrect, missing, or abnormal signals caused by broken signal lines, momentary power interruptions, or other

causes.

• Do not apply voltages or connect loads to the Output Units in excess of the maximum switching

capacity. Excess voltage or loads may result in burning.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing either of these may

break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may break the cables.

• Do not use commercially available RS-232C personal computer cables. Always use the special

cables listed in this manual or make cables according to manual specifications. Using commercially available cables may damage the external devices or CPU Unit.

• Never connect pin 6 (5-V power supply) on the RS-232C port on the CPU Unit to any device other

than an NT-AL001 or CJ1W-CIF11 Adapter. The external device or the CPU Unit may be damaged.

z Handling

• The Power Supply Unit may possibly be damaged if the entire voltage for a dielectric strength test

is applied or shut OFF suddenly using a switch. Use a variable resistor to gradually increase and

decrease the voltage.

• Separate the line ground terminal (LG) from the functional ground terminal (GR) on the Power

Supply Unit before performing withstand voltage tests or insulation resistance tests. Not doing so

may result in burning.

• Make sure that the DIP switches and DM Area are set correctly before starting operation.

Page 29

23

CJ2 CPU Unit Hardware User’s Manual

• Make sure that the required data for the DM Area, Holding Area, and other memory areas has

been transferred to a CPU Unit that has been replaced before restarting operation.

• Confirm that no adverse effect will occur in the system before attempting any of the following. Not

doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so may result in malfunction, fire, or electric shock.

• Do not drop the PLC or subject abnormal vibration or shock to it.

• When replacing parts, be sure to confirm that the rating of a new part is correct. Not doing so may

result in malfunction or burning.

• When transporting or storing Units or Board, static electricity can destroy LSIs or ICs. Cover the

PCBs with a conductive material and maintain the specified storage temperature.

• Do not touch circuit boards or the components mounted to them with your bare hands. There are

sharp leads and other parts on the boards that may cause injury if handled improperly.

• The life of the battery will be reduced if a CPU Unit is left for a period of time without a battery

installed and without power supply, and then a battery is installed without turning ON the power

supply.

• Before replacing the battery, turn ON power for at least 5 minutes before starting the replacement

procedure and complete replacing the battery within 5 minutes of turning OFF the power supply.

Memory contents may be corrupted if this precaution is not obeyed.

• If the Battery Error Flag is used in programming the application, confirm system safety even if the

system detects a battery error before you replace the battery while the power is ON.

• Do not short the battery terminals or charge, disassemble, heat, or incinerate the battery. Do not

subject the battery to strong shocks. Doing any of these may result in leakage, rupture, heat generation, or ignition of the battery. Dispose of any battery that has been dropped on the floor or otherwise subjected to excessive shock. Batteries that have been subjected to shock may leak if they

are used.

• UL standards require that only an experienced engineer can replace the battery.

Make sure that an experienced engineer is in charge of battery replacement. Follow

the procedure for battery replacement given in this manual.

• Unexpected operation may result if inappropriate data link tables or parameters are set. Even if

appropriate data link tables and parameters have been set, confirm that the controlled system will

not be adversely affected before starting or stopping data links.

• CPU Bus Units will be restarted when routing tables are transferred from a Programming Device

to the CPU Unit. Restarting these Units is required to read and enable the new routing tables.

Confirm that the system will not be adversely affected before allowing the CPU Bus Units to be

reset.

• When creating an AUTOEXEC.IOM file from a Programming Device (a Programming Console

or the CX-Programmer) to automatically transfer data at startup, set the first write address to

D20000 and be sure that the size of data written does not exceed the size of the DM Area.

When the data file is read from the Memory Card at startup, data will be written in the CPU

Unit starting at D20000 even if another address was set when the AUTOEXEC.IOM file was

created. Also, if the DM Area is exceeded (which is possible when the CX-Programmer is

used), the remaining data will be written to the EM Area.

• A battery is mounted to a CJ-series CPU Unit when the Unit is shipped from the factory. Also, the

time is set on the internal clock. It is thus not necessary to clear memory and set the clock before

using a CJ-series CPU Unit. This point differs from the CS-series CS1 CPU Units.

Page 30

24

CJ2 CPU Unit Hardware User’s Manual

• The user program and parameter area data in the CJ2 CPU Units are backed up in the built-in

flash memory. The BKUP indicator will light on the front of the CPU Unit when the backup operation is in progress. Do not turn OFF the power supply to the CPU Unit when the BKUP indicator is

lit. The data will not be backed up if power is turned OFF.

• Check the user program and Unit parameter settings for proper execution before actually running

them on the Unit. Not checking the program and parameter settings may result in an unexpected

operation.

• When setting a Special I/O Unit or CPU Bus Unit in the I/O tables, carefully check the safety of the

devices at the connection target before restarting the Unit.

• A CS1 or CJ1 CPU Unit program file (.OBJ) cannot be transferred directly to a CJ2 CPU Unit

using a Memory Card. It must first be converted for use with a CJ2 CPU Unit using the CX-Programmer.

z External Circuits

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the customer.

• Always turn ON power to the PLC before turning ON power to the control system. If the PLC

power supply is turned ON after the control power supply, temporary errors may result in control

system signals because the output terminals on DC Output Units and other Units will momentarily

turn ON when power is turned ON to the PLC.

• Fail-safe measures must be taken by the customer to ensure safety in the event that outputs from

Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• If the I/O Hold Bit is turned ON, the outputs from the PLC will not be turned OFF and will maintain

their previous status when the PLC is switched from RUN or MONITOR mode to PROGRAM

mode. Make sure that the external loads will not produce dangerous conditions when this occurs.

(When operation stops for a fatal error, including those produced with the FALS(007) instruction,

all outputs from Output Unit will be turned OFF and only the internal output status will be maintained.)

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Insufficient safety measures against short-circuiting may result in burning.

• Dispose of the product and batteries according to local ordinances as they apply.

• Do not turn OFF the power supply to the PLC when reading or writing a Memory Card. Also, do

not remove the Memory Card when the BUSY indicator is lit. Doing so may make the Memory

Card unusable.

• To remove a Memory Card, first press the memory card power supply switch and then wait for the

BUSY indicator to go out before removing the Memory Card.

Page 31

25

CJ2 CPU Unit Hardware User’s Manual

Operating Environment Precautions

z Follow the instructions in this manual to correctly perform installation.

z Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

z Take appropriate and sufficient countermeasures when installing systems in the

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Page 32

26

CJ2 CPU Unit Hardware User’s Manual

Regulations and Standards

• EMC Directives

• Low Voltage Directive

z EMC Directives

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of the equipment or control panel on which the

OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices and the overall

machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility):

CS Series: EN 61131-2 and EN 61000-6-2

CJ Series: EN 61000-6-2

* EMI (Electromagnetic Interference):

EN 61000-6-4 (Radiated emission: 10-m regulations)

z Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75 to 1,500 V DC meet

the required safety standards for the PLC (EN 61131-2).

z Conformance to EC Directives

The CJ-series PLCs comply with EC Directives. To ensure that the machine or device in which the

CJ-series PLC is used complies with EC Directives, the PLC must be installed as follows:

• The CJ-series PLC must be installed within a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• CJ-series PLCs complying with EC Directives also conform to the Common Emission Standard

(EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions. You must therefore confirm that the overall machine or equipment complies with

EC Directives.

This product conforms to the following shipbuilding standards. Applicability to the shipbuilding standards is based on certain usage conditions. It may not be possible to use the product in some locations. Contact your OMRON representative before attempting to use a PLC on a ship.

Conformance to EC Directives

Applicable Directives

Concepts

Conformance to Shipbuilding Standards

Page 33

27

CJ2 CPU Unit Hardware User’s Manual

z Usage Conditions for Applications Other Than on the Bridge or Deck

• The PLC must be installed in a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

z Usage Conditions for Bridge and Deck (Certified Only by NK)

• The PLC must be installed in a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

SYSMAC is a registered trademark for Programmable Controllers made by OMRON Corporation.

CX-One is a registered trademark for Programming Software made by OMRON Corporation.

Windows is a registered trademark of Microsoft Corporation.

Other system names and product names in this document are the trademarks or registered trademarks

of their respective companies.

Usage Conditions for NK and LR Shipbuilding Standards

Manufacturer Cosel Co., Ltd.

Model TAH-06-683

Trademarks

Page 34

28

CJ2 CPU Unit Hardware User’s Manual

Related Manuals

Manuals related to a PLC built using a CJ-series CJ2 CPU Unit are listed in the following table. Use

these manuals for reference.

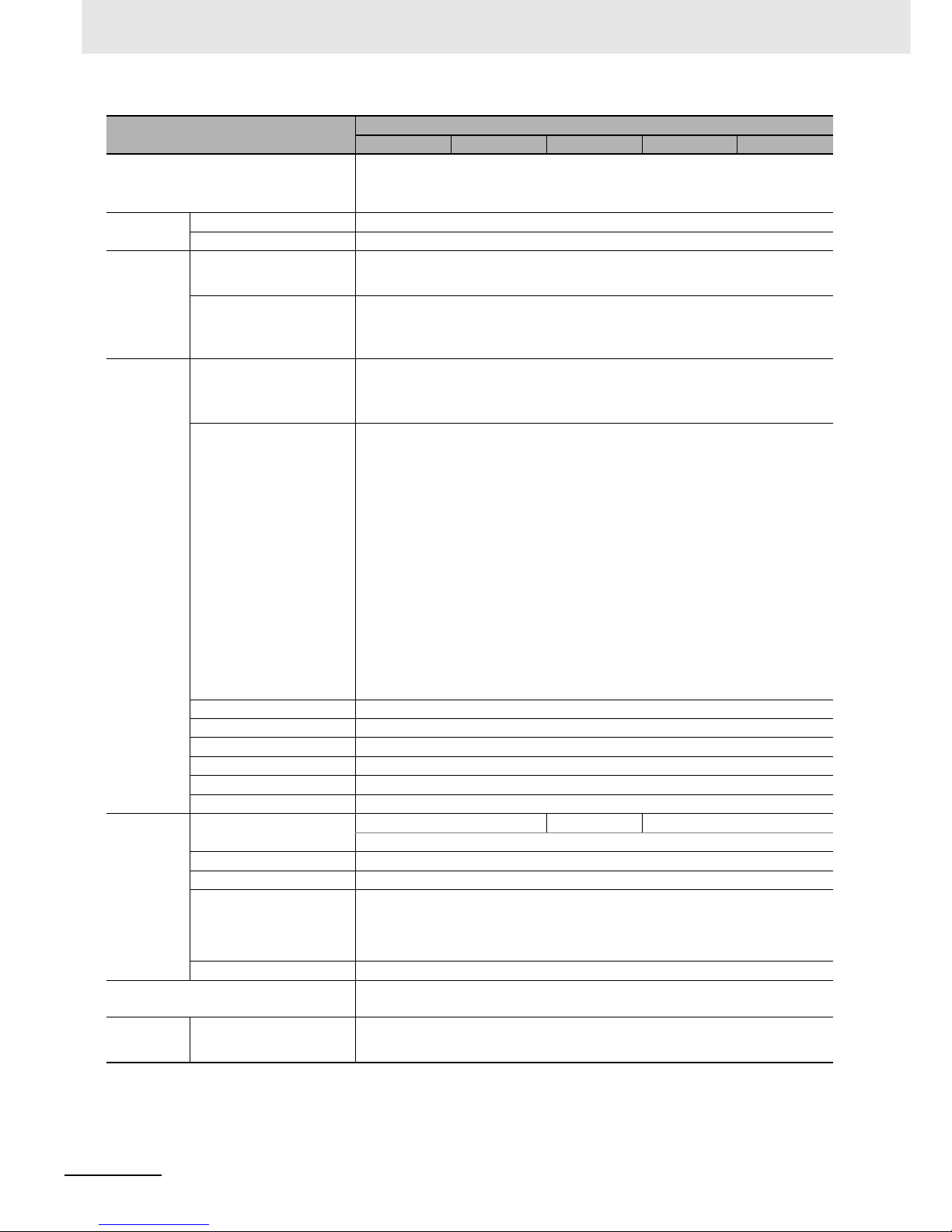

Manual Cat. No. Model Application Description

CJ-series CJ2 CPU

Unit Hardware

User’s Manual (this

manual)

W472 CJ2H-CPU@@-EIP Hardware specifications for

CJ2 CPU Units

Describes the following for CJ2 CPU Units:

• Overview and features

• Basic system configuration

• Part nomenclature and functions

• Mounting and setting procedure

• Remedies for errors

• Also refer to the Software User’s Manual

(W473).

CJ-series CJ2 CPU

Unit Software User’s

Manual

W473 CJ2H-CPU@@-EIP Software specifications for

CJ2 CPU Units

Describes the following for CJ2 CPU Units:

• CPU Unit operation

• Internal memory

• Programming

• Settings

• Functions built into the CPU Unit

Also refer to the Hardware User’s Manual

(W472)

EtherNet/IP Units

Operation Manual

W465 CJ2H-CPU@@-EIP

CS1W-EIP21

CJ1W-EIP21

Using the built-in EtherNet/IP port of the CJ2 CPU

Unit

Describes the built-in EtherNet/IP port and EtherNet/IP Units.

Describes basic settings, tag data links, FINS

communications, and other functions.

CS/CJ/NSJ-series

Instructions Reference Manual

W474 CJ2H-CPU@@-EIP

CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1M-CPU@@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Information on instructions Describes each programming instruction in

detail.

Also refer to the Software User’s Manual (W473)

when you do programming.

CS/CJ/CP/NSJseries Communications Command Reference Manual

W342 CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CS1D-CPU@@H

CS1D-CPU@@S

CS1W-SCU@@-V1

CS1W-SCB@@-V1

CJ1H-CPU@@H-R

CJ1G/H-CPU@@H

CJ1G-CPU@@P

CJ1M-CPU@@

CJ1G-CPU@@

CJ1W-SCU@@-V1

CP1H-X@@@@-@

CP1H-XA@@@@-@

CP1H-Y@@@@-@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

Information on communications for CS/CJ/CPseries CPU Units and NSJseries Controllers

Describes C-mode commands and FINS commands

Refer to this manual for a detailed description of

commands for communications with the CPU

Unit using C mode commands or FINS commands.

Note This manual describes the communica-

tions commands that are addressed to

CPU Units. The communications path that

is used is not relevant and can include any

of the following: serial ports on CPU Units,

communications ports on Serial Communications Units/Boards, and Communications Units. For communications

commands addressed to Special I/O Units

or CPU Bus Units, refer to the operation

manual for the related Unit.

CX-One Setup Manual

W463 CXONE-AL@@C-

V3/AL@@D-V3

Installing software from the

CX-One

Provides an overview of the CX-One FA Integrated Tool Package and describes the installation procedure.

CX-Programmer

Operation Manual

W446 WS02-CX@@-V@ Support Software for Win-

dows computers

CX-Programmer operating

procedure

Describes operating procedures for the CX-Programmer.

Also refer to the Software User’s Manual (W473)

and Instructions Reference Manual (W474)

when you do programming.

CX-Programmer

Operation Manual

Functions Blocks

W447

CX-Programmer

Operation Manual

SFC Programming

W469

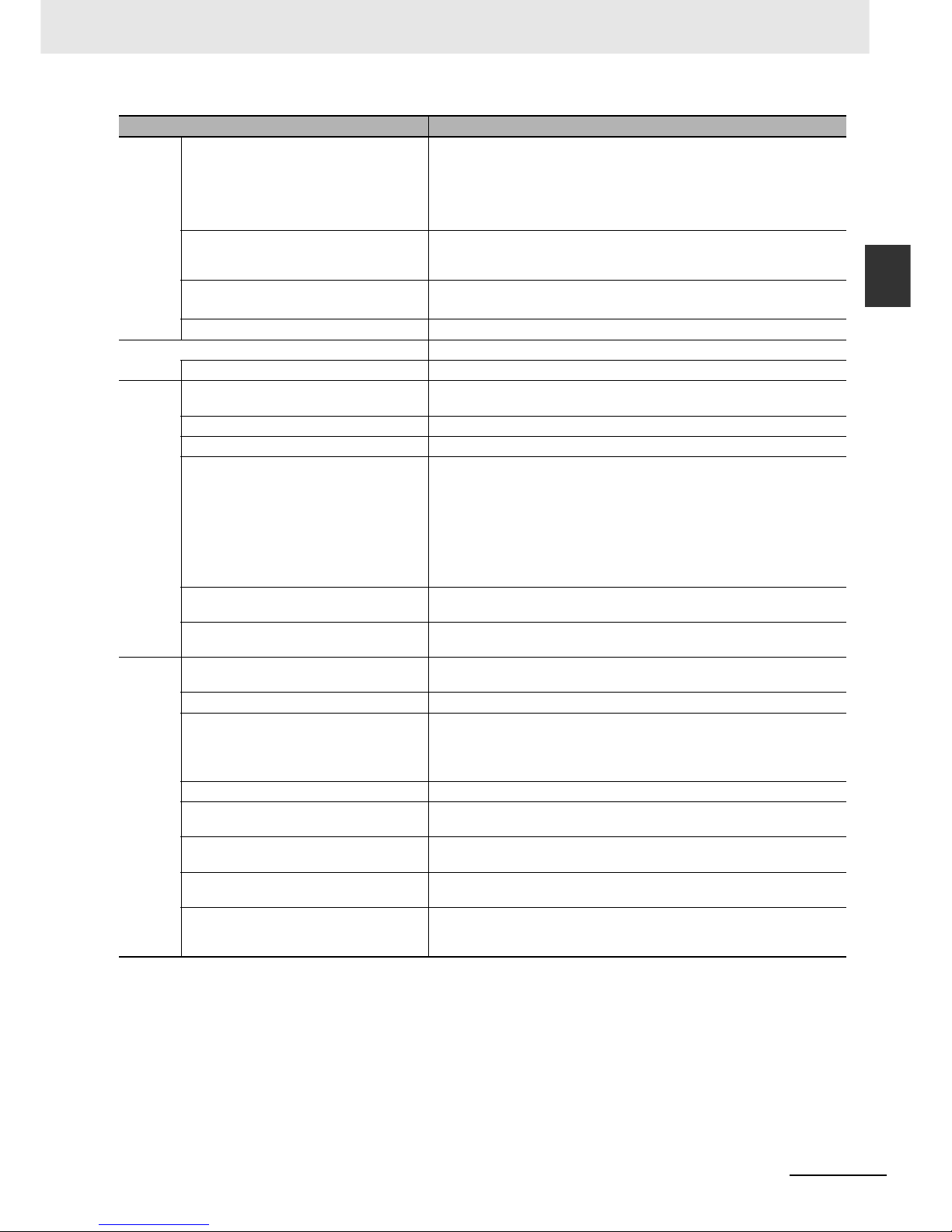

Page 35

29

CJ2 CPU Unit Hardware User’s Manual

CS/CJ/CP/NSJseries CX-Simulator

Operation Manual

W366 WS02-SIMC1-E Operating procedures for

CX-Simulator Simulation

Support Software for Windows computers

Using simulation in the CXProgrammer with CX-Programmer version 6.1 or

higher

Describes the operating procedures for the CXSimulator.

When you do simulation, also refer to the CX-

Programmer Operation Manual (W446), Software User’s Manual (W473), and Instructions

Reference Manual (W474).

CS/CJ/CP/NSJseries CX-Integrator

Network Configuration Software Operation Manual

W464 CXONE-AL@@C-V3/

CXONE-AL@@D-V3

Network setup and monitoring

Describes the operating procedures for the CXIntegrator.

Manual Cat. No. Model Application Description

Page 36

30

CJ2 CPU Unit Hardware User’s Manual

Page 37

1-1

CJ2 CPU Unit Hardware User’s Manual

1

This section provides an overview of the CJ2 PLCs.

1-1 Overview of CJ2 CPU Units ...................................................................................................1-2

1-1-1 Overview .................................................................................................................................... 1-2

1-1-2 CJ2 CPU Unit Features ............................................................................................................. 1-3

1-2 Basic Operating Procedure ...................................................................................................1-7

1-3 Specifications ......................................................................................................................... 1-8

1-3-1 General Specifications ............................................................................................................... 1-8

1-3-2 Performance Specifications ....................................................................................................... 1-9

1-3-3 Function Specifications ............................................................................................................ 1-13

Overview

Page 38

1 Overview

1-2

CJ2 CPU Unit Hardware User’s Manual

1-1 Overview of CJ2 CPU Units

The SYSMAC CJ2 CPU Units are high-speed multi-functional CPU Units with a large memory capacity.

They provide the following features.

z Fast, with Large Memory Capacity

Basic performance is faster and memory capacity has been increased to provide ample capability

for machine control.

z Built-in EtherNet/IP Port

The CJ2 CPU Units support the EtherNet/IP open network as a standard feature. Support Software

connection and universal Ethernet communications, such as data links between PLCs, message

communications between PLCs, and FTP transfers, are all possible.

z General-purpose Networks for Support Software Interface

Support Software and devices can be easily connected using commercially available cable to general-purpose networks via USB and EtherNet/IP ports.

z Tag Access

CJ2 CPU Units have a tag name server to manage tag names and I/O addresses. This enables

access from external devices using tag names, without needing to know the I/O addresses.

z Easier Programming

CJ2 CPU Units offer a highly readable programming environment, including features such as

addressing DM and EM Area bits, setting address offsets, and using array variables.

z Improved Debugging

Online editing and data tracing have been improved, greatly increasing the efficiency of debugging.

1-1-1 Overview

Tag access

Easier programming

General-purpose networks for

Support Software interface

Built-in EtherNet/IP port:

standard equipment

Improved debugging

Faster, with

greater capacity

Page 39

1-3

1 Overview

CJ2 CPU Unit Hardware User’s Manual

1-1 Overview of CJ2 CPU Units

1

1-1-2 CJ2 CPU Unit Features

z High-speed Processing

High-speed processing times of 0.016 µs for basic instructions, 0.048 µs for special instructions, and

0.99 µs for immediate refreshing, are now possible.

z Large Program Capacity

The CJ2 CPU Units provide a large program capacity of up to 400 Ksteps.

z Large Data Memory Capacity

The CJ2 CPU Units provide a large EM Area capacity of up to 800 Kwords (25 banks).

z Up to 128 Cyclic Tasks

The user program can be divided into up to 128 tasks. Using smaller task programs makes it easier

to structure programs and contributes to shorter cycle times.

The CJ2 CPU Units provide as standard equipment a built-in EtherNet/IP port that supports the same

FINS Ethernet functions as an Ethernet Unit (including features such as a FINS server and time coordination) as well as the EtherNet/IP open network.

z High-speed, High-capacity Data Links with User-set Refresh Cycles

The CJ2 CPU Units provide high-speed, high-capacity data links, and refresh cycles can be set individually for each data link area.

In addition, using the EtherNet/IP DataLink Tool makes it possible to set the data links using an interface similar to that of the Controller Link automatic data link setup.

1-1-2 CJ2 CPU Unit Features

Fast, with Large Memory Capacity

Built-in EtherNet/IP Port

EtherNet/IP

High speed

The refresh cycle can be set individually for each area.

High capacity

CJ2 CPU Unit

CJ2 CPU Unit

Page 40

1 Overview

1-4

CJ2 CPU Unit Hardware User’s Manual

z Built-in USB and EtherNet/IP Ports

Commercially available USB cable can be used to connect directly from a USB port on a personal

computer. In addition, a PLC on the EtherNet/IP network can be accessed via USB.

z Prevent Connecting to the Wrong PLC by Using PLC Names from Support

Software

A user-set PLC name can be recorded in a CJ2 CPU Unit. When using Support Software to connect

online to a PLC, verification of the PLC name prevents incorrect connections from the Support Software.

z Network Symbols (Tags) for Flexible Support of Program Changes

The CJ2 CPU Units support network symbols (tags). They have an internal tag name server that

enables them to store tag names and addresses in advance in symbol tables in the CPU Units. Tags

enable the following features.

Data links can be set using tags.

With data links on an EtherNet/IP network, send and receive areas can be specified using symbols

rather than addresses. This enables flexible support for design changes by allowing the data link

areas set by tags to remain unchanged, while simply changing the symbol tables that contain the tag

names and addresses.

Access from host devices is enabled using tags.

Tags can be used for access from host devices, such as touch panel NS-series Programmable Terminals. This makes the creation of host screens and programs at devices such as PTs much more

convenient.

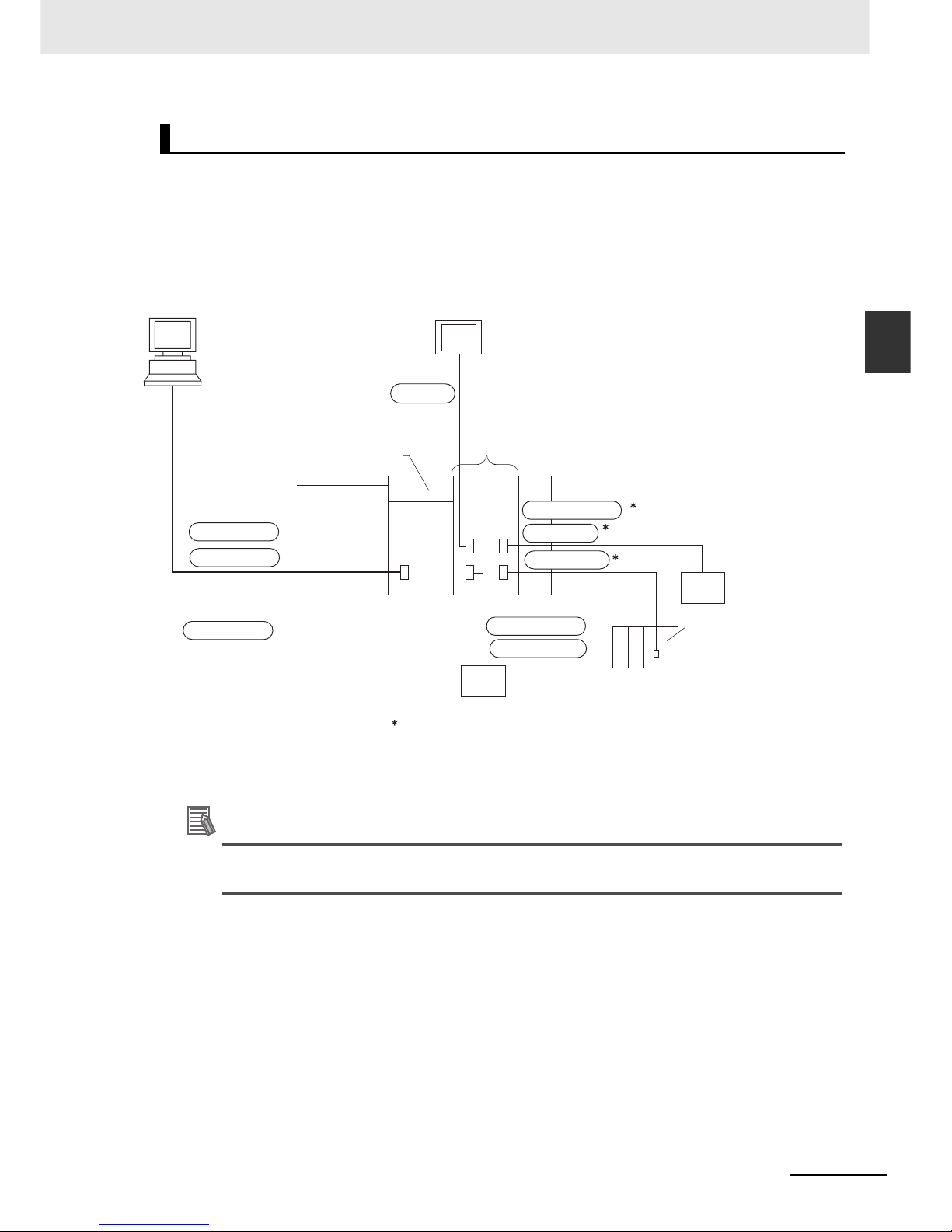

General-purpose Networks for Support Software Interface

Tag Access

Data links enabled by names

EtherNet/IP

Examples:

Inputs from a to b

Inputs from c to d

CJ2 CPU Unit

CJ2 CPU Unit

EtherNet/IP

Touch Panel

NS-series PT

Examples:

Writing to a

Reading from b

Middleware

Supporting EtherNet/IP

CJ2 CPU Unit

CJ2 CPU Unit

Host application, such as SCADA

Access is possible using tags.

Page 41

1-5

1 Overview

CJ2 CPU Unit Hardware User’s Manual

1-1 Overview of CJ2 CPU Units

1

1-1-2 CJ2 CPU Unit Features

Automatic tag allocation makes it unnecessary to know the addresses.

Automatic allocation of tags in the high-capacity EM Area, using automatic address allocation in CXProgrammer symbol tables, enables data link design and access from host devices without having to

pay attention to addresses.

z Address offsets can be specified.

When an address is specified for an instruction operand, an offset can be specified in brackets after

the address to offset it. For example, by setting a word address in brackets to specify the offset, the

address can be dynamically specified according to the contents of that word.

Example

W0.00[D0]: W0.00 is the starting address and the contents of D0 is the offset. If D0 is &3, then

W0.03 is specified.

z Symbols can be specified for array variable subscripts.

By specifying symbols for array variable subscripts, elements can be dynamically specified according to the values of the symbols.

Example

a[b]: The value of symbol b specifies the element for array variable a[ ].

z Bit addresses can be used in the DM Area and EM Area.

Previously the DM Area and the EM Area could be addressed only by words, and bit addresses

could not be specified. The work area for bits can now be expanded by enabling bit addresses in the

DM and EM Areas.

For example, D10.00 specifies bit 00 of D10.

z The format for timer/counter PV refreshing can be selected individually for

each instruction.

Either BCD or binary can be selected individually for each instruction as the format for timer/counter

PV refreshing. For example, the TIM (BCD) and TIMX (binary) instructions can be used together.

Easier Programming

PE

RIFH

ER

A

L

E

R

R

/A

L

M

R

U

N

IN

H

C

O

M

M

B

K

U

P

P

R

P

H

L

C

O

N

TR

OLLE

R

CP

U

6

4-

E

IP

CJ2H

S

Y

S

M

A