Page 1

Cat. No. Z174-E1-02A

SYSMAC CS/CJ Series

CS1W-V600C11

CS1W-V600C12

CJ1W-V600C11

CJ1W-V600C12

ID Sensor Units

Page 2

SYSMAC CS/CJ Series ID Sensor Units

Operation Manual

Revised December 2004

Page 3

iv

Page 4

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON representative if you

have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one

year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER

OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is

asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED,

STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR

INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT DESIGNED OR

RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT

OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated

products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of

products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use that apply to the products. This information by itself is not sufficient for a complete determination of the

suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an

exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the

products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not

described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

v

Page 5

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and does not

constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to actual

application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant

construction changes are made. However, some specifications of the product may be changed without any notice. When in

doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request.

Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product. Please notify us

before copying or reproducing this document in any manner, for any other purpose. If copying or transmitting this document

to another, please copy or transmit it in its entirety.

vi

Page 6

Meanings of Signal Words

The following signal words are used in this manual.

Indicates a potentially hazardous situation which, if not avoided, will result in

!WARNING

minor or moderate injury, or may result in serious injury or death. Additionally

there may be significant property damage.

!CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury or in property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates the possibility of explosion under specific conditions.

Alert Statements in this Manual

The following alert statements apply to the products in this manual. Each alert statement also appears at the

locations needed in this manual to attract your attention.

!WARNING

The SRAM-type Data Carrier has a built-in lithium battery which can combust or

explode if mishandled. Do not disassemble the Data Carrier, or subject it to high

pressure or high temperatures (of 1005C or more), or dispose of it by

incineration.

vii

Page 7

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator and only

for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to an

OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word”

and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming

Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

viii

Page 8

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Precautions for Users of the C200H-IDS01(-V1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

7 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Outline of Features and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Functions by Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 2

CS-series ID Sensor Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-3 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2-4 Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SECTION 3

CJ-series ID Sensor Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-3 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3-4 Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

SECTION 4

Data Exchange with the CPU Unit . . . . . . . . . . . . . . . . . . . . 37

4-1 Outline of Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4-2 Initial Settings Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-3 I/O Data Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION 5

ID Sensor Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5-1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5-2 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5-3 System Settings and Auto Wait Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5-4 Data Carrier Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

ix

Page 9

TABLE OF CONTENTS

5-5 Write Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5-6 Data Carrier Life Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5-7 Data Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SECTION 6

Controlling the ID Sensor Unit . . . . . . . . . . . . . . . . . . . . . . . 73

6-1 ID Sensor Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6-2 Communications Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6-3 Communications Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

SECTION 7

Troubleshooting Alarms and Errors. . . . . . . . . . . . . . . . . . . 93

7-1 Indicators and Error Check Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7-2 ID Sensor Unit Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7-3 CPU Unit Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7-4 Restarting Special I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

7-5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Appendices

A Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

B Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C Data Coding Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

x

Page 10

About this Manual:

This manual describes the installation and operation of the CS1W-V600C11 and CS1W-V600C12 CSseries ID Sensor Units and the CJ1W-V600C11 and CJ1W-V600C12 CJ-series ID Sensor Units, and it

includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate a ID Sensor Unit. Be sure to read the precautions provided in the following section.

Precautions provides general precautions for using the ID Sensor Units, Programmable Controller,

and related devices.

Section 1 describes the features and system configuration of an ID Sensor Unit.

Section 2 describes the specifications, operation, and installation of ID Sensor Units for CS-series

PLCs.

Section 3 describes the specifications, operation, and installation of ID Sensor Units for CJ-series

PLCs.

Section 4 describes the methods used to exchange data with the CPU Unit and the data that is

exchanged.

Section 5 describes the operation of the ID Sensor Units.

Section 6 describes how to control an ID Sensor Unit using commands from the PLC’s CPU Unit.

Section 7 describes troubleshooting errors that can occur during ID Sensor Unit operation.

The Appendices provide dimensions, sample programming, and data coding tables.

!WARNING

Failure to read and understand the information provided in this manual may result in personal injury or death,

damage to the product, or product failure. Please read each section in its entirety and be sure you understand

the information provided in the section and related sections before attempting any of the procedures or operations given.

xi

Page 11

xii

Page 12

PRECAUTIONS

This section provides general precautions for using the ID Sensor Unit, Programmable Controller, and related devices.

The information contained in this section is important for the safe and reliable application of the ID Sensor Unit.

You must read this section and understand the information contained before attempting to set up or operate a ID

Sensor Unit and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

6 Precautions for Users of the C200H-IDS01(-V1). . . . . . . . . . . . . . . . . . . . . . xvii

7 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

7-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

7-4 Relay Output Noise Reduction Methods . . . . . . . . . . . . . . . . . . . . . xix

xiii

Page 13

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON ID Sensor Units. Be sure to read this manual before operation and keep this manual

close at hand for reference during operation.

It is extremely important that a PLC and all PLC Units be used for the specified purpose and under the specified conditions, especially in applications

that can directly or indirectly affect human life. You must consult with your

OMRON representative before applying a PLC system to the above mentioned applications.

3 Safety Precautions

Never attempt to disassemble any Units while power is being supplied.

Doing so may result in serious electrical shock or electrocution.

Never touch any of the terminals while power is being supplied. Doing so

may result in serious electrical shock or electrocution.

The SRAM-type Data Carrier has a built-in lithium

battery which can combust or explode if mishandled.

Do not disassemble the Data Carrier, or subject it to

high pressure or high temperatures (of 100

more), or dispose of it by incineration.

!WARNING

!WARNING

!WARNING

!WARNING

°C or

xiv

Page 14

Operating Environment Precautions 4

!WARNING

Provide safety measures in external circuits, i.e., not in the PLC (CPU Unit

including associated Units), in order to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

!CAUTION

Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Where the PLC is exposed to direct sunlight.

• Where the ambient temperature or humidity is outside the ranges given in

the Unit specifications.

• Where the PLC may be affected by condensation due to radical temperature changes.

• Where there is any corrosive or inflammable gas.

• Where there is excessive dust, saline air, or metal powder.

• Where the PLC is affected by vibration or shock.

• Where any water, oil or chemical may splash on the PLC.

Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

!CAUTION

The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xv

Page 15

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the ID Sensor Unit or the PLC.

!WARNING

Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Performing any of the following with the power supply turned

ON may lead to electrical shock:

• Mounting or removing any Units (e.g., Power Supply Unit, I/O Units,

CPU Unit, etc.) or Memory Cassettes.

• Assembling any devices or racks.

• Setting DIP switches or rotary switches.

• Connecting or disconnecting any cables or wiring.

!CAUTION

Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event that outputs from Output Units remain ON as a result of internal circuit failures, which can occur in relays, transistors, and other elements.

• Always use the power supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Install the Units properly as specified in the operation manuals. Improper

installation of the Units may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Do not attempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

• Check switch settings, the contents of the DM Area, and other preparations before starting operation. Starting operation without the proper settings or data may result in an unexpected operation.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

xvi

Page 16

Precautions for Users of the C200H-IDS01(-V1) 6

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Observe the following precautions when wiring cables.

• Do not bend the cables past their natural bending radius.

• Do not pull on the cables.

• Do not place heavy objects on top of the cables.

• Check terminal blocks sufficiently before mounting them.

• Be sure that the terminal blocks, Memory Units, expansion cables, and

other items with locking devices are properly locked into place. Improper

locking may result in malfunction.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Check all wiring carefully before turning ON the power supply.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• Stop operation and turn OFF the power supply immediately if you smell

any unusual odors, if the surface of the Unit become abnormally hot, if

smoke appears, of if the Unit seems unusual in any other way.

6 Precautions for Users of the C200H-IDS01(-V1)

The CS1W-V600C11, CS1W-V600C12, CJ1W-V600C11, and CJ1WV600C12 (CS/CJ-series) ID Sensor Units cannot be controlled with programming written for the C200H-IDS01 or C200H-IDS01-V1 ID Sensor Unit. Refer

to SECTION 4 Data Exchange with the CPU Unit for details. This section

describes the main differences between these Units.

Command Settings

The CS/CJ-series ID Sensor Units allow the Data Carrier processing command and Data Carrier communications method (i.e., the communications

specification) to be set separately. Commands written for the C200H ID Sensor Units cannot be used without modification. Refer to SECTION 4 Data

Exchange with the CPU Unit for details on designating commands and communications methods.

xvii

Page 17

Conformance to EC Directives 7

New Commands

New commands have been added that allow individual bits to be written and

that allow data to be copied from one Data Carrier to another.

Command name Function

Bit Set Sets the specified bits of the specified area in the Data Carrier.

Bit Clear Clears the specified bits of the specified area in the Data Car-

Mask Bit Write Masks the specified bits in the specified area of the Data Car-

Copy Writes the data read from a Data Carrier by one R/W Head to

rier.

rier and writes data to the bits that are not masked.

the Data Carrier in the communications area of the other R/W

Head. This command is supported by Double-head ID Sensor

Units only.

New Communications Operations

The Repeat Auto communications specification, which repeats the operation

of an Auto specification, has been added. The Repeat Auto specification can

be used with CS/CJ-series ID Sensor Units to place the ID Sensor Unit on

standby waiting for the next Data Carrier after communications with the previous Data Carrier have been finished. Operation is ended when the Abort Bit is

turned ON (refer to 5-2 Communications Specifications).

Changes in Monitoring Function

A switch on the front panel is used to switch between controlling the ID Sensor Unit with the user program in the CS/CJ-series CPU Unit and performing

communications tests. In Test Mode, one byte is read and then written repeatedly. The results of the communications test are confirmed on the status indicators and the Processing Results Monitor (refer to 5-1 Operating Modes).

7 Conformance to EC Directives

7-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

7-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

xviii

Page 18

Conformance to EC Directives 7

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2

EMI (Electromagnetic Interference): EN50081-2

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

7-3 Conformance to EC Directives

The CS/CJ-series PLCs comply with EC Directives. To ensure that the

machine or device in which the CS/CJ-series PLC is used complies with EC

Directives, the PLC must be installed as follows:

1,2,3... 1. The CS/CJ-series PLC must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power supplies.

3. CS/CJ-series PLCs complying with EC Directives also conform to the

Common Emission Standard (EN50081-2). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

7-4 Relay Output Noise Reduction Methods

The CS/CJ-series PLCs conforms to the Common Emission Standards

(EN50081-2) of the EMC Directives. However, noise generated by relay output switching may not satisfy these Standards. In such a case, a noise filter

must be connected to the load side or other appropriate countermeasures

must be provided external to the PLC.

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, configuration of machines, etc. Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

(Refer to EN50081-2 for more details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the PLC included is less than 5 times per minute.

Countermeasures are required if the frequency of load switching for the whole

system with the PLC included is more than 5 times per minute.

xix

Page 19

Conformance to EC Directives 7

Countermeasure Examples

When switching an inductive load, connect an surge protector, diodes, etc., in

parallel with the load or contact as shown below.

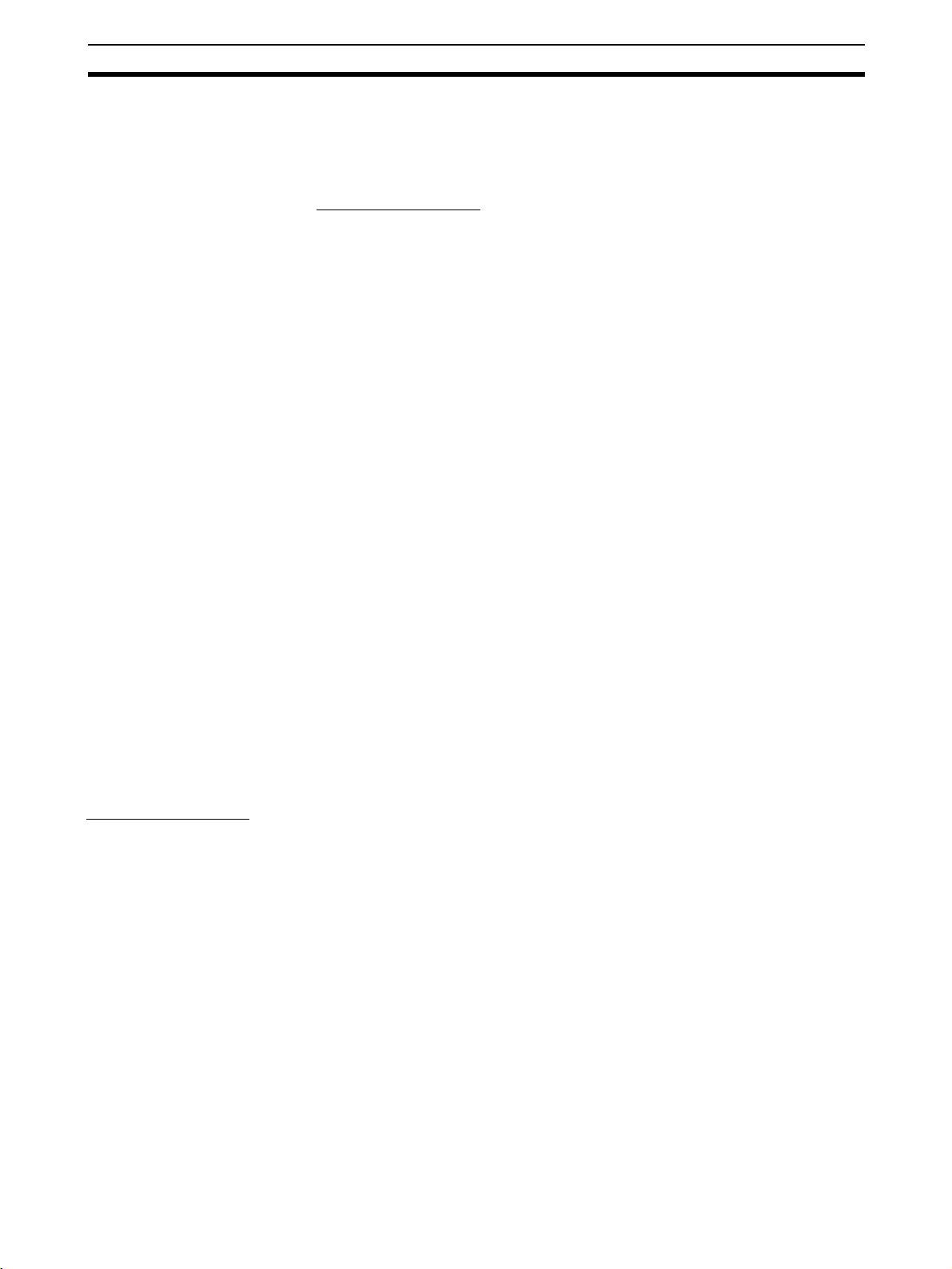

Circuit Current Characteristic Required element

AC DC

CR method

Power

supply

Diode method

Power

supply

Varistor method

Power

supply

Yes Yes If the load is a relay or solenoid, there

is a time lag between the moment the

circuit is opened and the moment the

load is reset.

If the supply voltage is 24 or 48 V,

Inductive

load

insert the surge protector in parallel

with the load. If the supply voltage is

100 to 200 V, insert the surge protector

between the contacts.

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current

will be converted into Joule heat by the

Inductive

load

resistance of the inductive load.

This time lag, between the moment the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

Yes Yes The varistor method prevents the impo-

sition of high voltage between the contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the cir-

Inductive

load

cuit is opened and the moment the load

is reset.

If the supply voltage is 24 or 48 V,

insert the varistor in parallel with the

load. If the supply voltage is 100 to

200 V, insert the varistor between the

contacts.

The capacitance of the capacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact voltage of 1 V.

These values, however, vary with the

load and the characteristics of the

relay. Decide these values from experiments, and take into consideration that

the capacitance suppresses spark discharge when the contacts are separated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is an

AC circuit, use a capacitor with no

polarity.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

---

xx

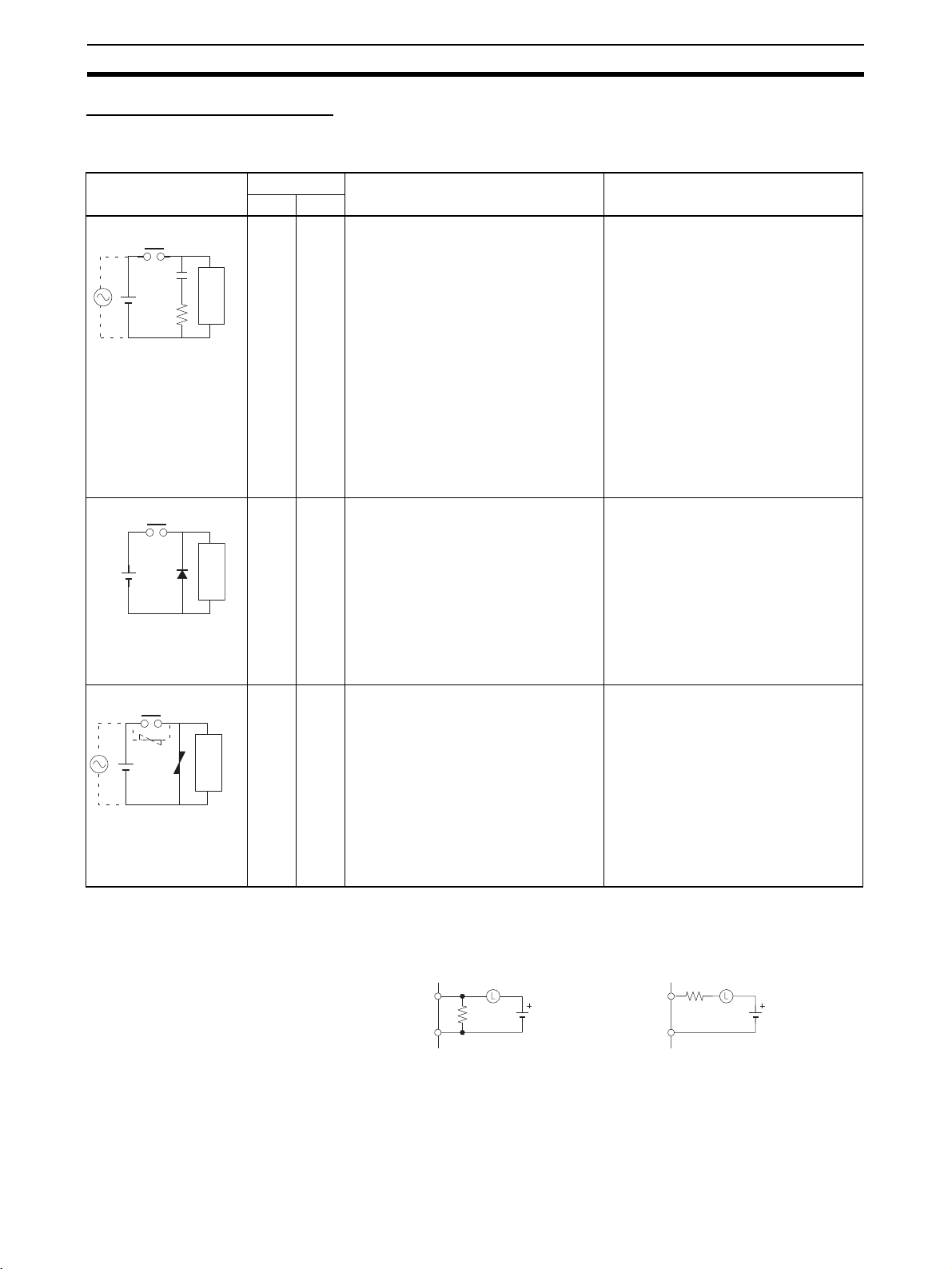

When switching a load with a high inrush current such as an incandescent

lamp, suppress the inrush current as shown below.

Countermeasure 1

OUT

R

COM

Providing a dark current of

approx. one-third of the rated

value through an incandescent

lamp

Countermeasure 2

R

OUT

COM

Providing a limiting resistor

Page 20

Features and System Configuration

This section describes the features and system configuration of an ID Sensor Unit.

1-1 Outline of Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-1 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2 Mounting Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2-3 Mounting Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-4 Unit Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 Functions by Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION 1

1

Page 21

Outline of Features and Functions Section 1-1

1-1 Outline of Features and Functions

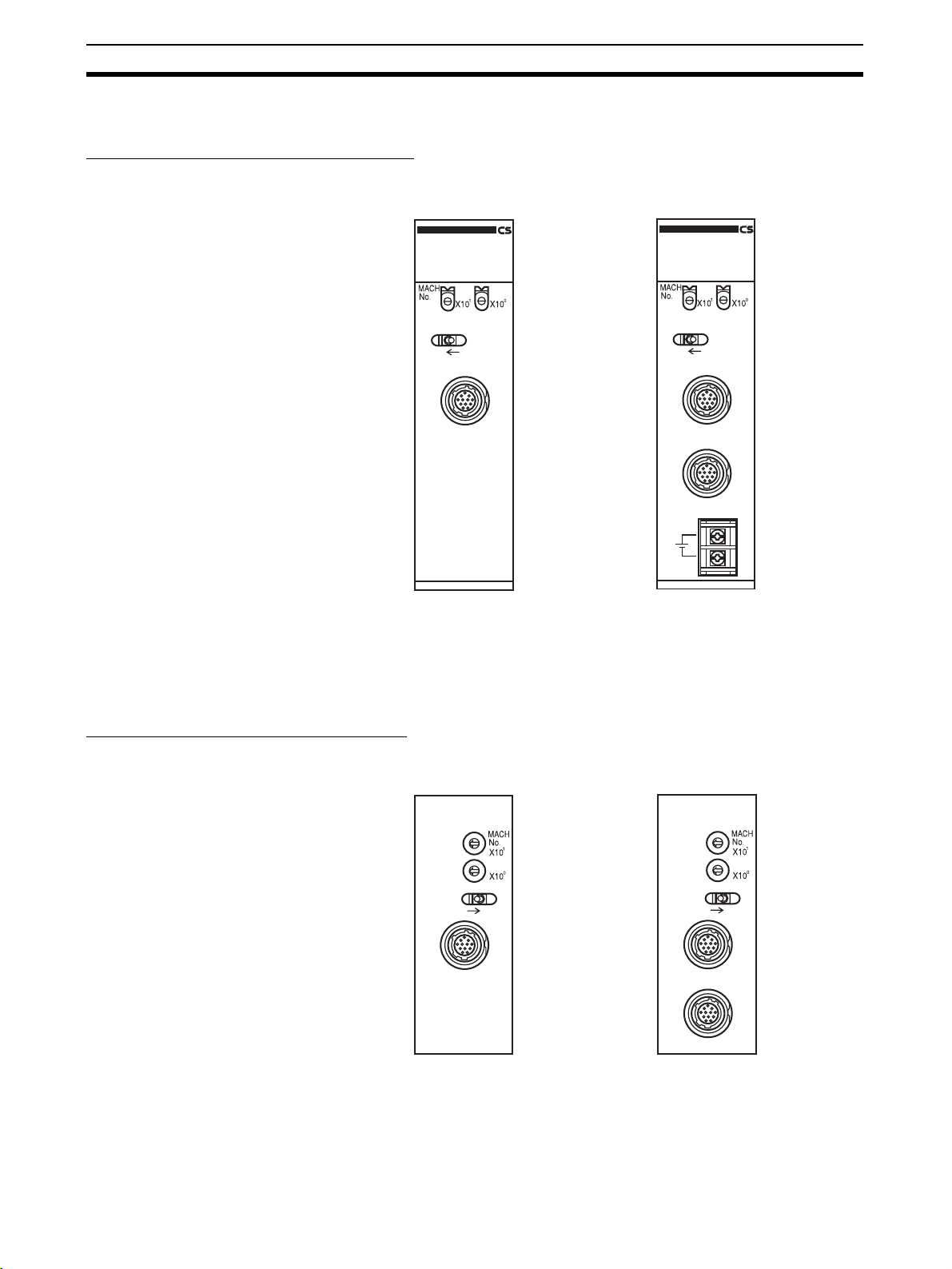

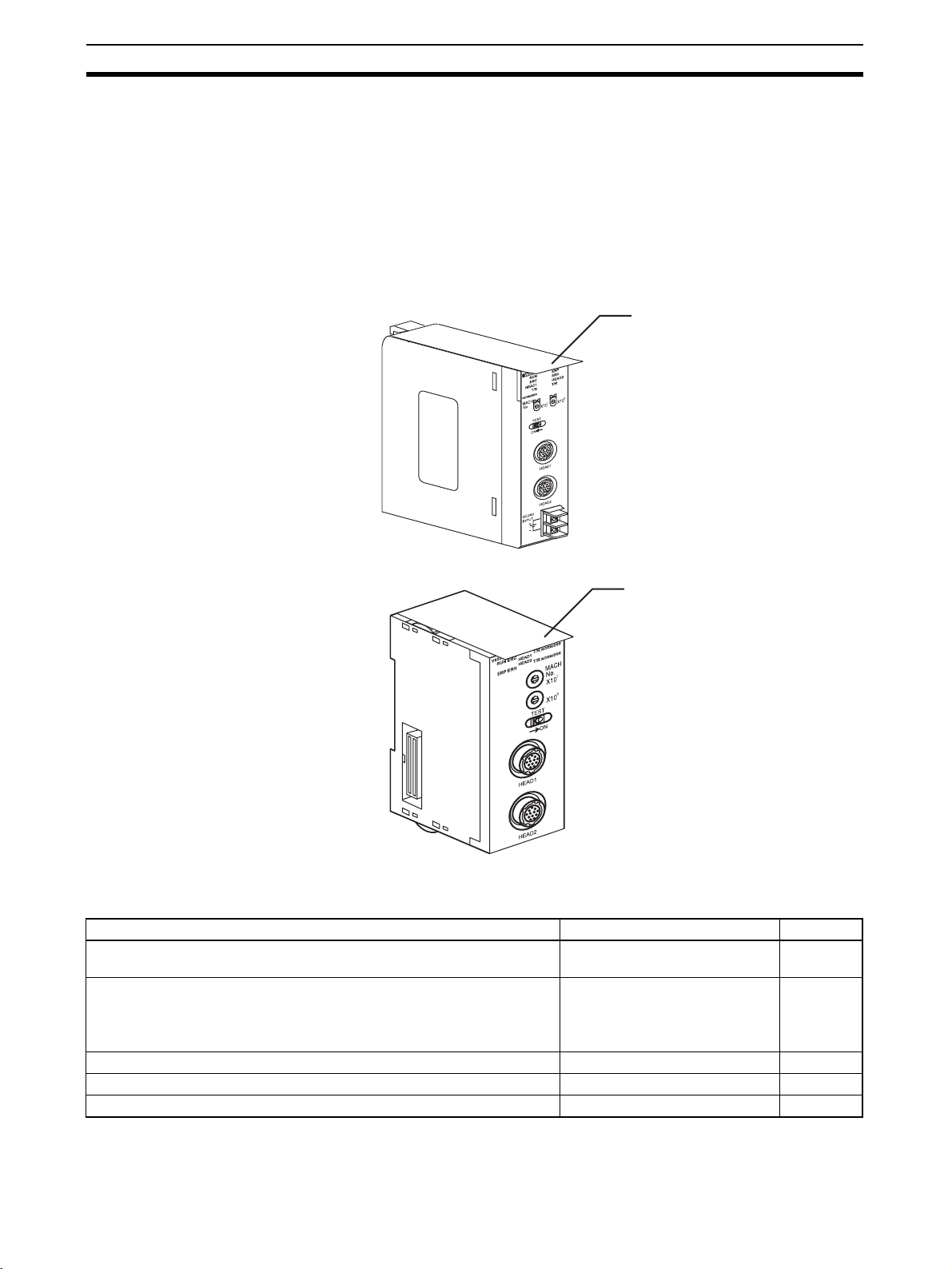

SYSMAC CS-series ID Sensor Units

Single-head ID Sensor Unit

(CS1W-V600C11)

V600C11

RUN

ERP

ERC

ERH

T/R

NORM/ERR

TEST

ON

HEAD

Double-head ID Sensor Unit

(CS1W-V600C12)

V600C12

RUN

ERP

ERC

HEAD1

NORM/ERR

DC24V

INPUT

ERH

HEAD2

T/R

T/R

NORM/ERR

TEST

ON

HEAD1

HEAD2

+

-

These ID Sensor Units read and write data for V600-series Data Carriers for

SYSMAC CS-series PLCs. There are two models: a Single-head ID Sensor

Unit (CS1W-V600C11) and a Double-head ID Sensor Unit (CS1W-V600C12).

CS-series Units can be mounted to a CS-series CPU Rack or CS-series

Expansion Rack.

SYSMAC CJ-series ID Sensor Units

Single-head ID Sensor Unit

These ID Sensor Units read and write data for V600-series Data Carriers for

SYSMAC CJ-series PLCs. There are two models: a Single-head ID Sensor

Unit (CJ1W-V600C11) and a Double-head ID Sensor Unit (CJ1W-V600C12).

CJ-series Units can be connected in a CJ-series CPU Rack or CJ-series

Expansion Rack.

(CJ1W-V600C11)

V600C11

RUN ERC

ERP ERH

T/R NORM/ERR

TEST

ON

HEAD

Double-head ID Sensor Unit

(CJ1W-V600C12)

V600C12

RUN ERC

ERP ERH

HEAD1

HEAD2

HEAD1

HEAD2

T/R NORM/ERR

T/R NORM/ERR

TEST

ON

2

Page 22

Outline of Features and Functions Section 1-1

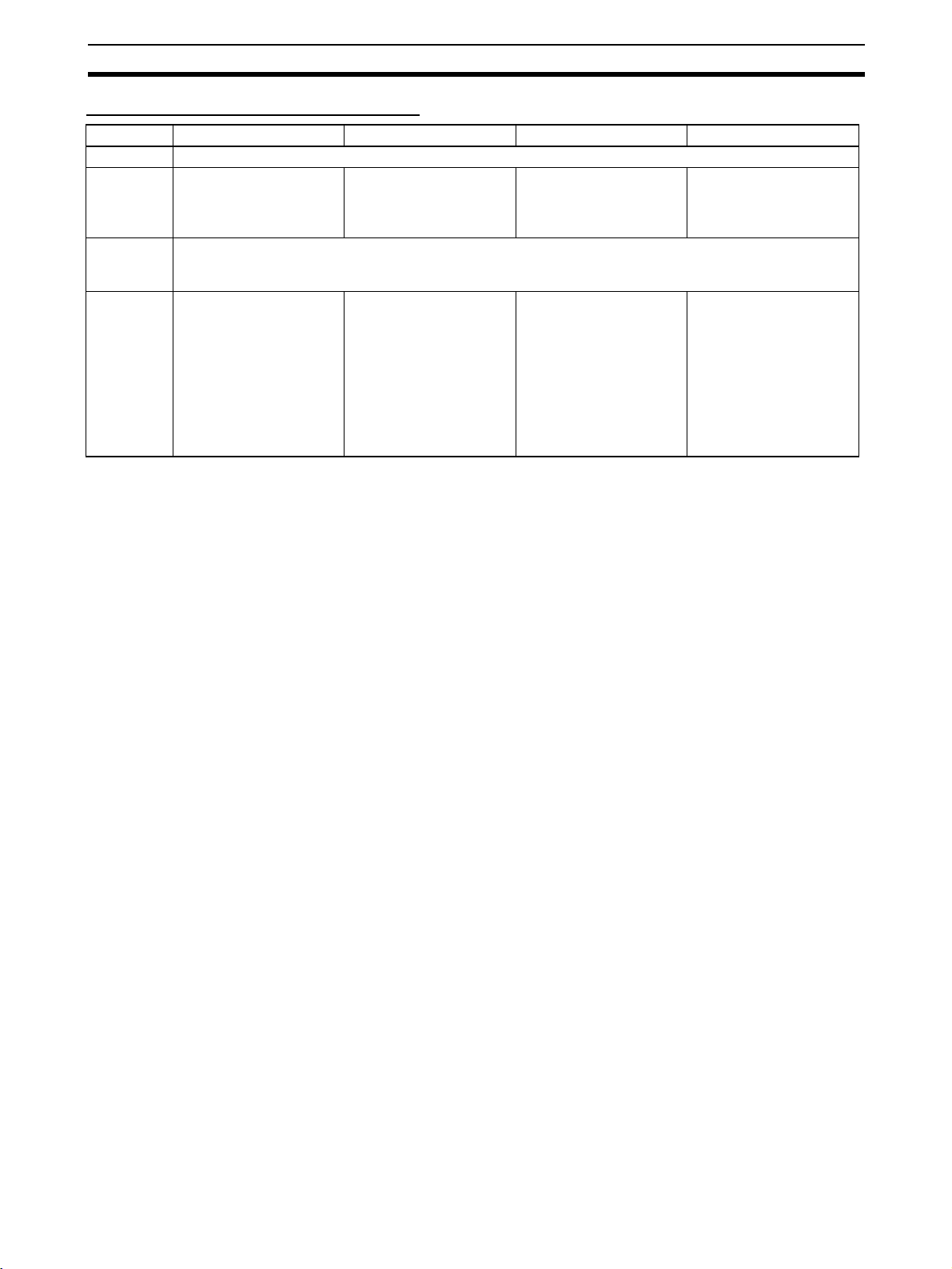

Applicable Products and Commands

CS1W-V600C11 CS1W-V600C12 CJ1W-V600C11 CJ1W-V600C12

R/W Head V600-series (V600-H@@)

Maximum

number of

connected

Heads

Applicable

Data

Carriers

Commands Read

1212

V600-series Data Carriers (V600-D@@R@@ or V600-D@@P@@)

Write

Bit Set

Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Read

Write

Bit Set

Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Copy

Read

Write

Bit Set

Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Read

Write

Bit Set

Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Copy

An RFID system consists of an ID Sensor Unit in a CS-series/CJ-series CPU

Rack or CS-series/CJ-series Expansion Rack, a R/W Head(s) connected to

the ID Sensor Unit, and Data Carriers connected to moving bodies.

The ID Sensor Unit operates through the R/W Head(s) to write data from the

CS/CJ-series CPU Unit to the Data Carriers and read data from the Data Carriers to the CS/CJ-series CPU Unit.

3

Page 23

System Configuration Section 1-2

1-2 System Configuration

1-2-1 Basic System Configuration

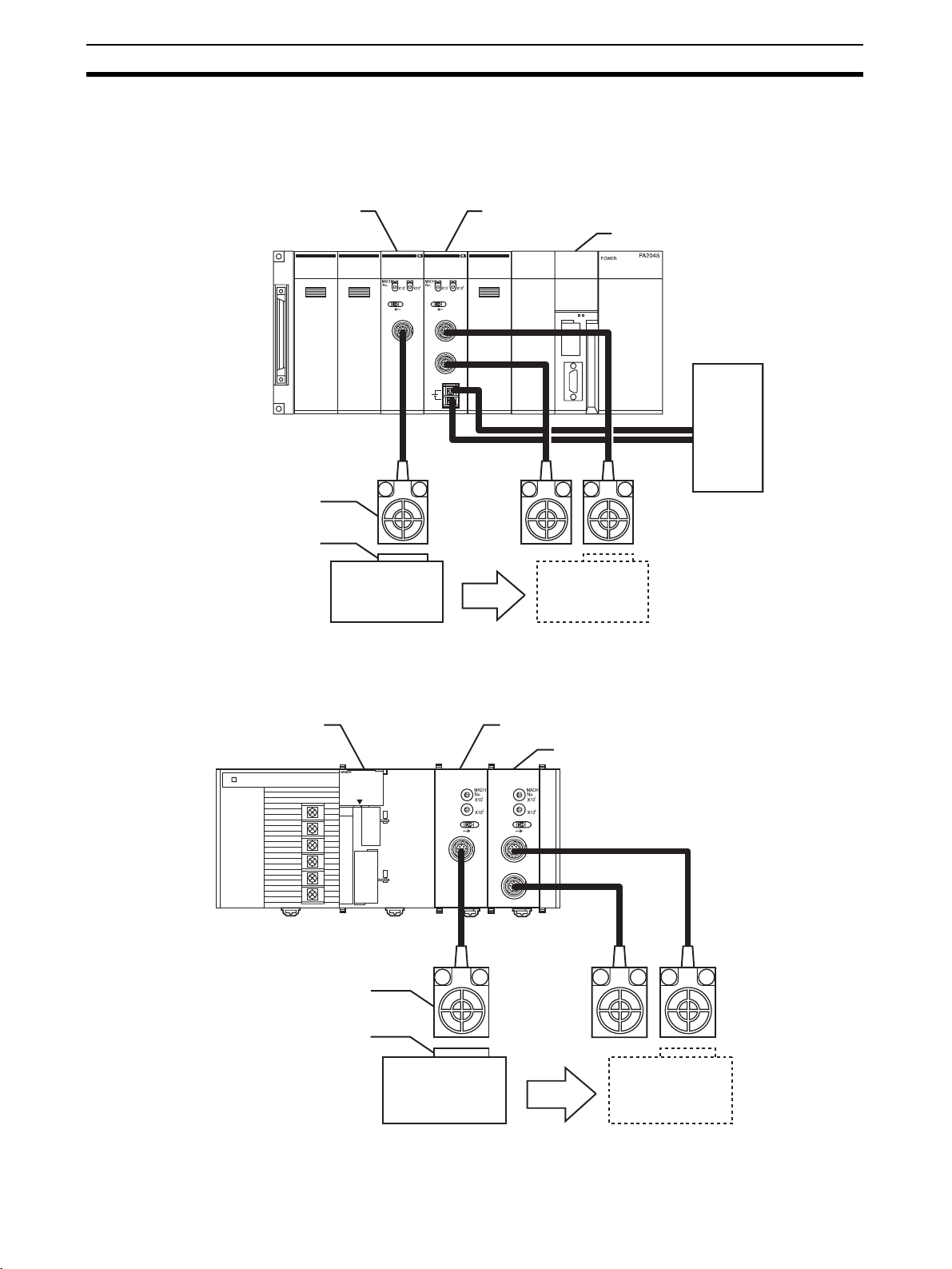

CS-series PLCs

Single-head ID Sensor Unit

R/W Head

NORM/ERR

V600C11

V600C12

RUN

ERP

RUN

ERC

ERH

ERC

HEAD1

T/R

T/R

NORM/ERR

TEST

TEST

ON

ON

HEAD

DC24V

INPUT

+

-

Double-head ID Sensor Unit

ERP

ERH

HEAD2

T/R

NORM/ERR

HEAD1

HEAD2

CPU Unit

24 V DC

power

supply

CJ-series PLCs

Data Carrier

Workpiece

(moving body)

Moves

Workpiece

(moving body)

Note The above example uses one Single-head ID Sensor Unit (CS1W-V600C11)

and one Double-head ID Sensor Unit (CS1W-V600C12).

CPU Unit Single-head ID Sensor Unit

Double-head ID Sensor Unit

SYSMAC

CJ1G-CPU44

PROGRAMMABLE

CONTROLLER

MCPWR

BUSY

R/W Head

OPEN

ERR/ALM

PERIHERAL

PORT

RUN

INH

PRPHL

COMM

V600C11

RUN ERC

ERP ERH

V600C12

T/R NORM/ERR

RUN ERC

T/R NORM/ERR

HEAD1

HEAD2

T/R NORM/ERR

ERP ERH

TEST

HEAD

TEST

ON

ON

HEAD1

HEAD2

Data Carrier

Workpiece

(moving body)

Moves

Workpiece

(moving body)

4

Page 24

System Configuration Section 1-2

Note The above example uses one Single-head ID Sensor Unit (CJ1W-V600C11)

and one Double-head ID Sensor Unit (CJ1W-V600C12).

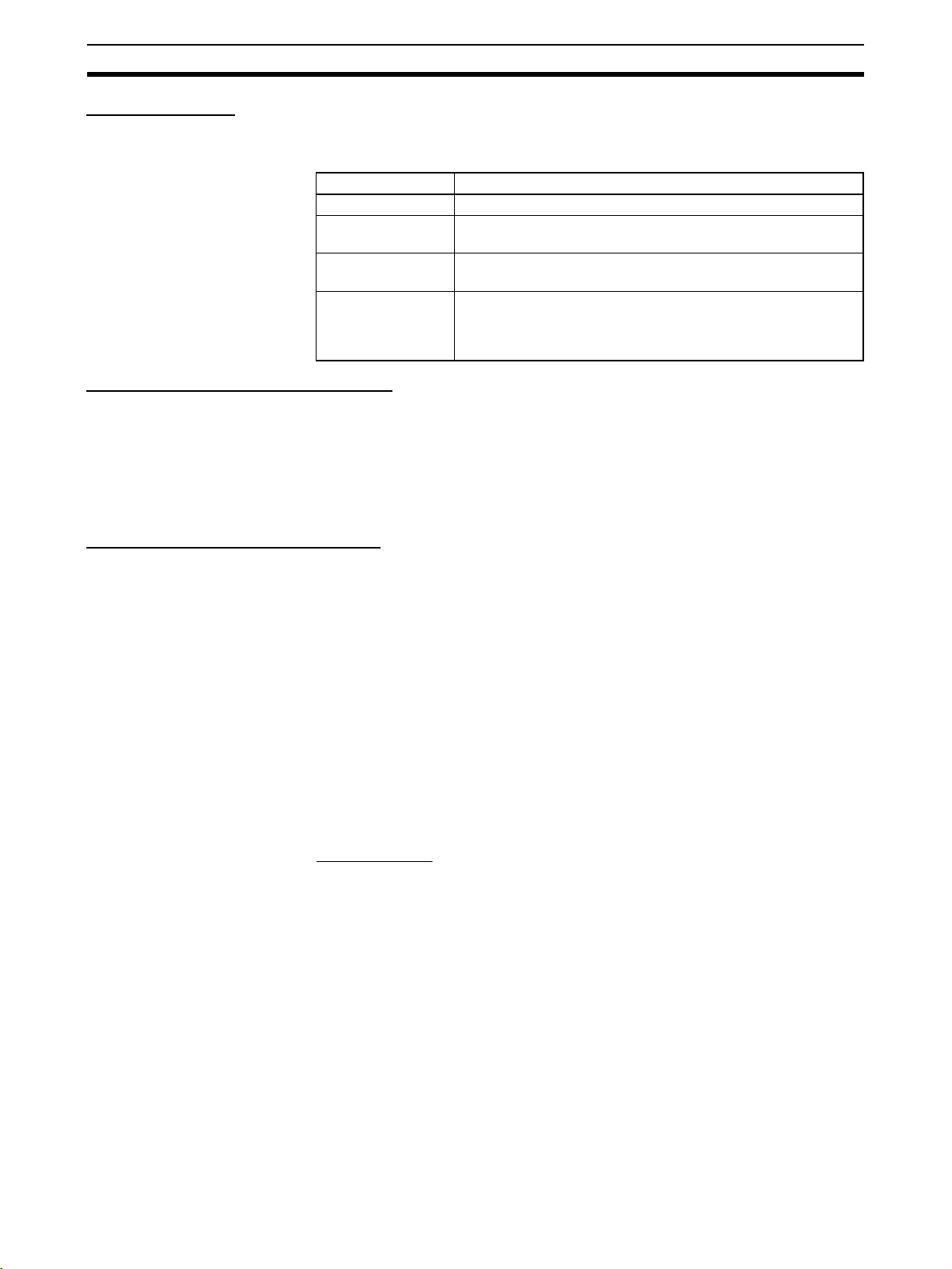

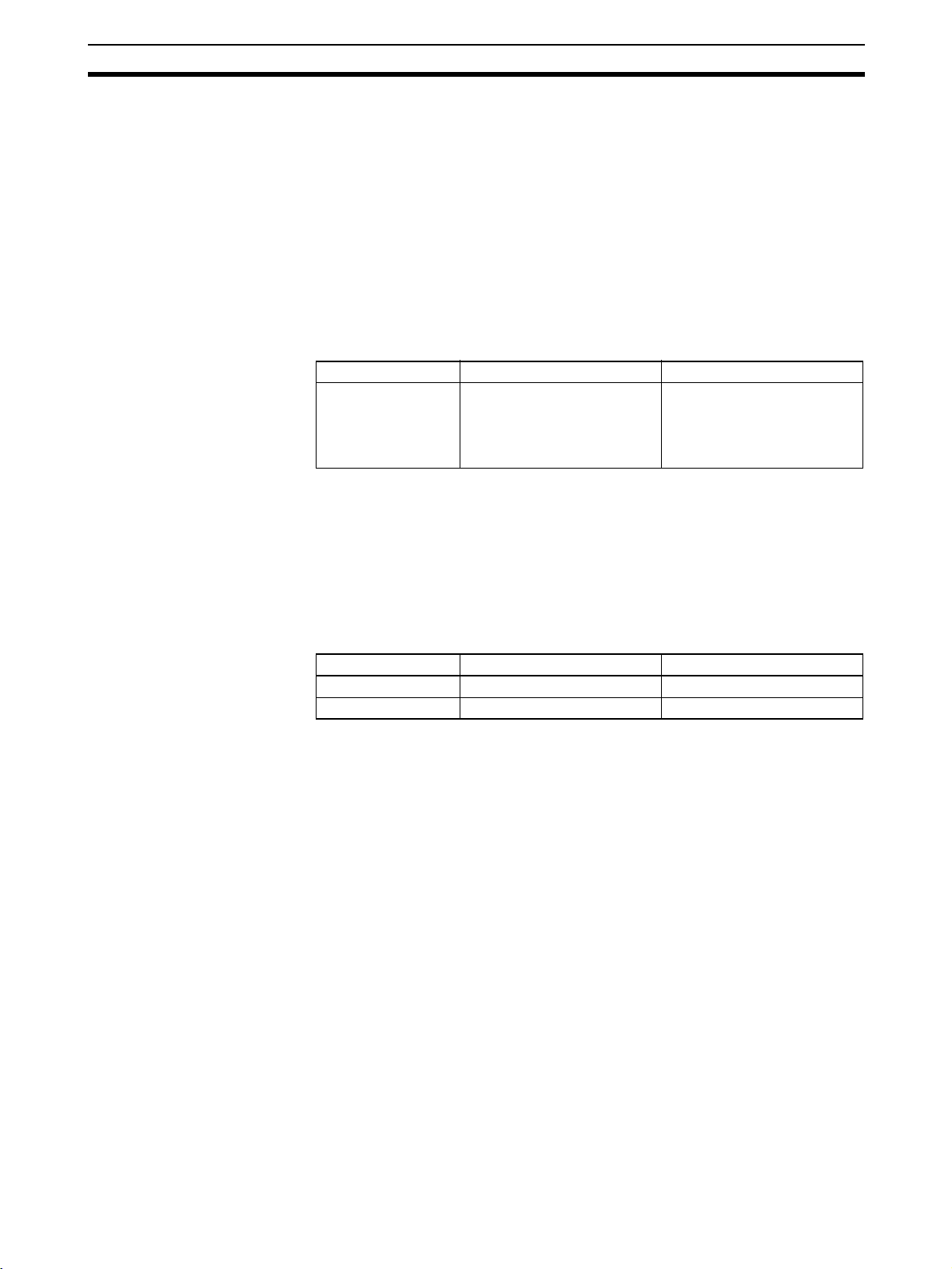

1-2-2 Mounting Restrictions

CS-series PLCs CS-series ID Sensor Units are classified as CS-series Special I/O Units.

• These Units can be mounted to a CS-series CPU Rack or CS-series

Expansion Rack.

• The number of Units per CPU Rack or Expansion Rack depends on the

maximum supply current of the Power Supply Unit and current consumption of other Units on the Rack.

The following table lists the maximum number of Units per Rack when only ID

Sensor Units are mounted.

Power Supply Unit CS1W-V600C11 CS1W-V600C12

C200HW-PA204

C200HW-PA204S

C200HW-PA204R

C200HW-PD204

C200HW-PA209R

CJ-series PLCs CJ-series ID Sensor Units are classified as CJ-series Special I/O Units.

• These Units can be mounted to a CJ-series CPU Rack or CJ-series

Expansion Rack.

• The number of Units per CPU Rack or Expansion Rack depends on the

maximum supply current of the Power Supply Unit and current consumption of other Units on the Rack.

The following table lists the maximum number of Units per Rack when only ID

Sensor Units are mounted.

Power Supply Unit CJ1W-V600C11 CJ1W-V600C12

CJ1W-PA205R 4 2

CJ1W-PA202 2 1

510

Note The I/O words allocated to Special I/O Units are determined by the setting of

the unit number switches on the front of the Unit. They are not affected by the

slots (positions) in which the Units are mounted.

5

Page 25

System Configuration Section 1-2

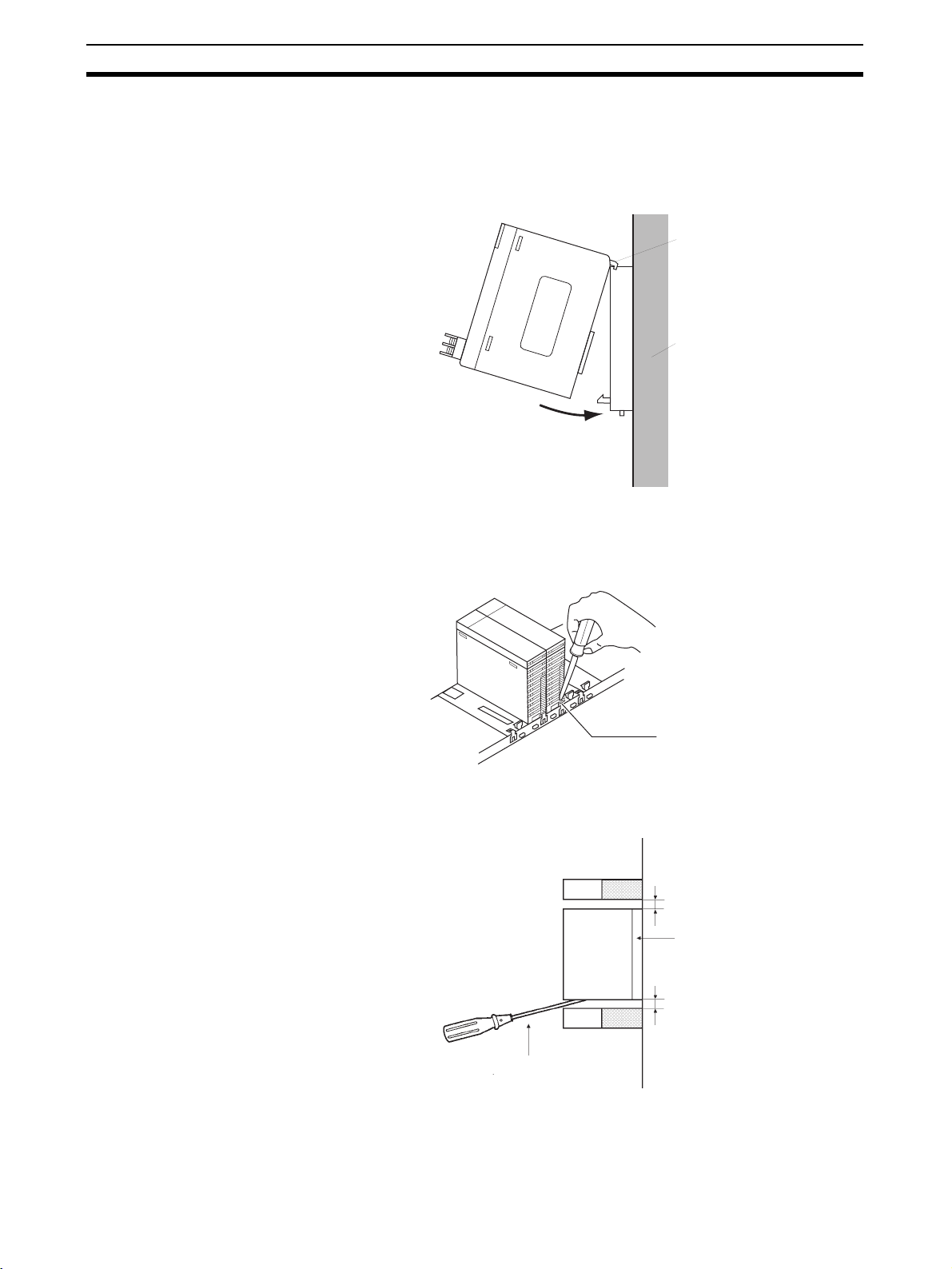

1-2-3 Mounting Units

CS-series PLCs Use the following procedure to mount an ID Sensor Unit to the Backplane.

1,2,3... 1. Lock the top of the ID Sensor Unit into the slot on the Backplane and rotate

the Unit downwards as shown in the following diagram.

Hook

Backplane

2. While making sure to align the Unit properly with the connectors, tighten

the mounting screws securely to a tightening torque of 0.4 N·m.

3. To remove the Unit, first loosen the mounting screws using a Phillips

screwdriver.

Mounting screw

Note Leave enough space below each Rack, as shown in the following diagram, for

mounting and removing the Units.

20 mm min.

Backplane

20 mm min.

Phillips screwdriver

6

Page 26

System Configuration Section 1-2

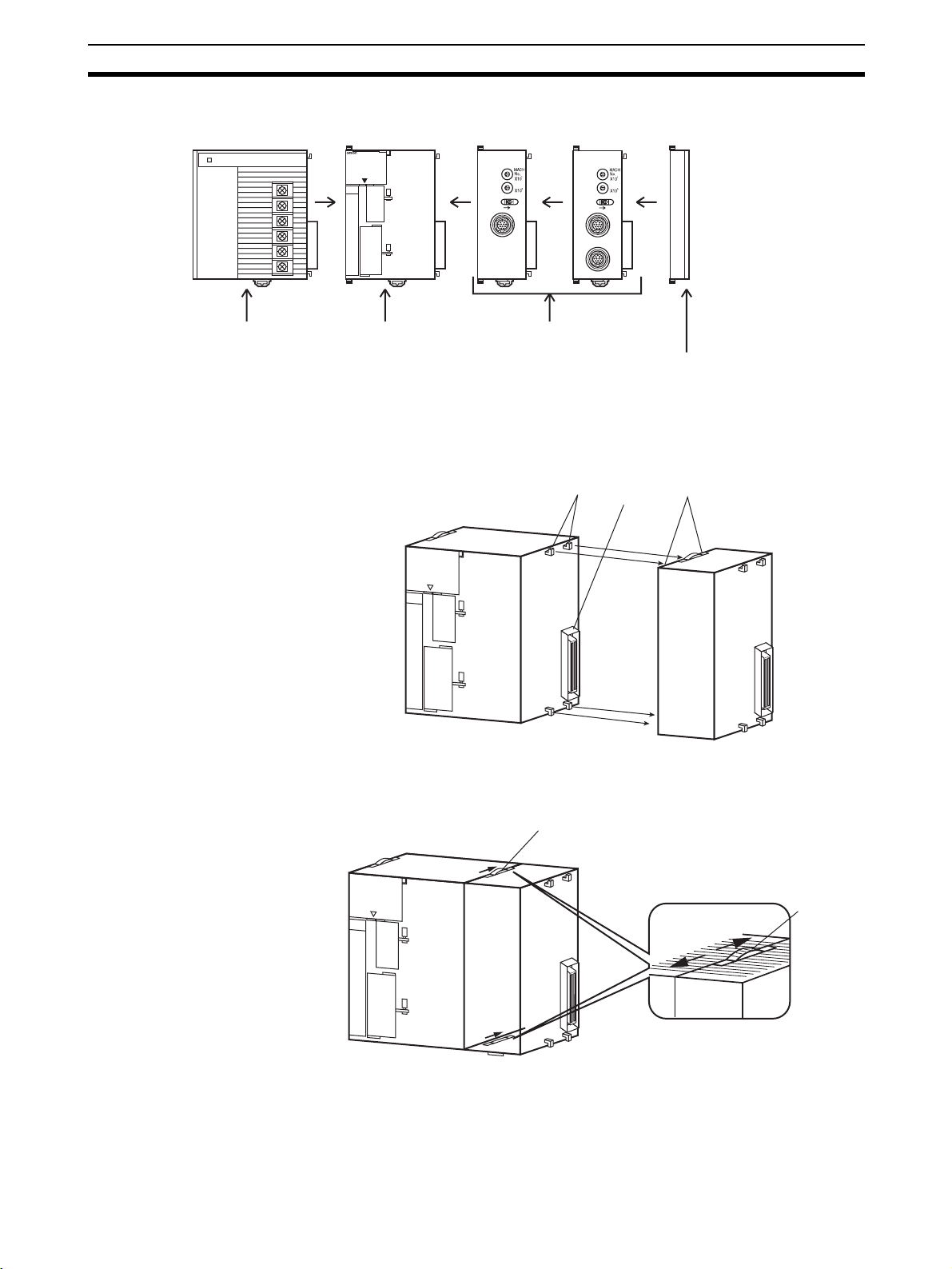

CJ-series PLCs ID Sensor Units are connected as I/O Units in the system configuration, as

shown below.

SYSMAC

CJ1G-CPU44

PROGRAMMABLE

CONTROLLER

RUN

ERR/ALM

INH

PRPHL

COMM

OPEN

MCPWR

BUSY

PERIHERAL

V600C11

RUN ERC

T/R NORM/ERR

ERP ERH

TEST

ON

HEAD

V600C12

RUN ERC

T/R NORM/ERR

HEAD1

HEAD2

T/R NORM/ERR

ERP ERH

TEST

ON

HEAD1

HEAD2

Power Supply Unit

PORT

CPU Unit I/O Units

(10 Units max.)

End Cover

(included with CPU Unit)

Use the following procedure to connect an ID Sensor Unit.

1,2,3... 1. Align the connectors and press in firmly on the Units to connect them com-

pletely.

Hooks

Connector

Hook holes

2. Move the yellow sliders on the top and bottom of the Unit to the lock position to secure the Units. The sliders should click into place.

Move the sliders to the back

until they click into place.

Slider

Locked

Released

3. Attach an End Cover to the Unit on the right end of the Rack.

Note The CJ-series PC may not operate properly if the sliders are not locked firmly

into place.

7

Page 27

Functions by Application Section 1-3

1-2-4 Unit Handling Precautions

Be sure to turn OFF the power supply to the PLC before installing or disconnecting Units, or connecting lines.

To reduce the risk of malfunctioning due to electrical noise, wire input and output lines in separate ducts from high-voltage and power lines.

When wiring a Unit, leave the label in place on the top of the Unit to prevent

wire clippings or other materials from getting inside the Unit. When wiring has

been completed, remove the label to ensure proper heat dissipation.

CS-series PLCs

Remove the label after

wiring has been completed.

CJ-series PLCs

Remove the label after

wiring has been completed.

1-3 Functions by Application

Application Function Reference

Performing communications test with Data Carriers without programming

the CPU Unit

Adjusting communications timing with Data Carriers

Examples:

Communicating with Data Carriers stopped in front of the R/W Head

Communicating with Data Carriers passing by the R/W Head

Protecting Data Carrier memory once it has been written Write protection Page 61

Managing Data Carrier life Data Carrier life check Page 64

Checking the suitability of Data Carrier memory Data check Page 69

Communications test mode Page 52

Communications specifications Page 52

8

Page 28

SECTION 2

CS-series ID Sensor Units

This section describes the specifications, operation, and installation of ID Sensor Units for CS-series PLCs.

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-1-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-1 Overall Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2-2 Operating Procedure Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3-1 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-3-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3-3 Unit Number Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3-4 Communications Test Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4 Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-4-1 Connecting R/W Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-4-2 Wiring the External Power Supply (CS1W-V600C12 Only) . . . . . . 20

2-4-3 Wiring for Safety and Noise Immunity . . . . . . . . . . . . . . . . . . . . . . 21

9

Page 29

Specifications Section 2-1

2-1 Specifications

2-1-1 General Specifications

General specifications conform to those of SYSMAC CS-series Special I/O

Units.

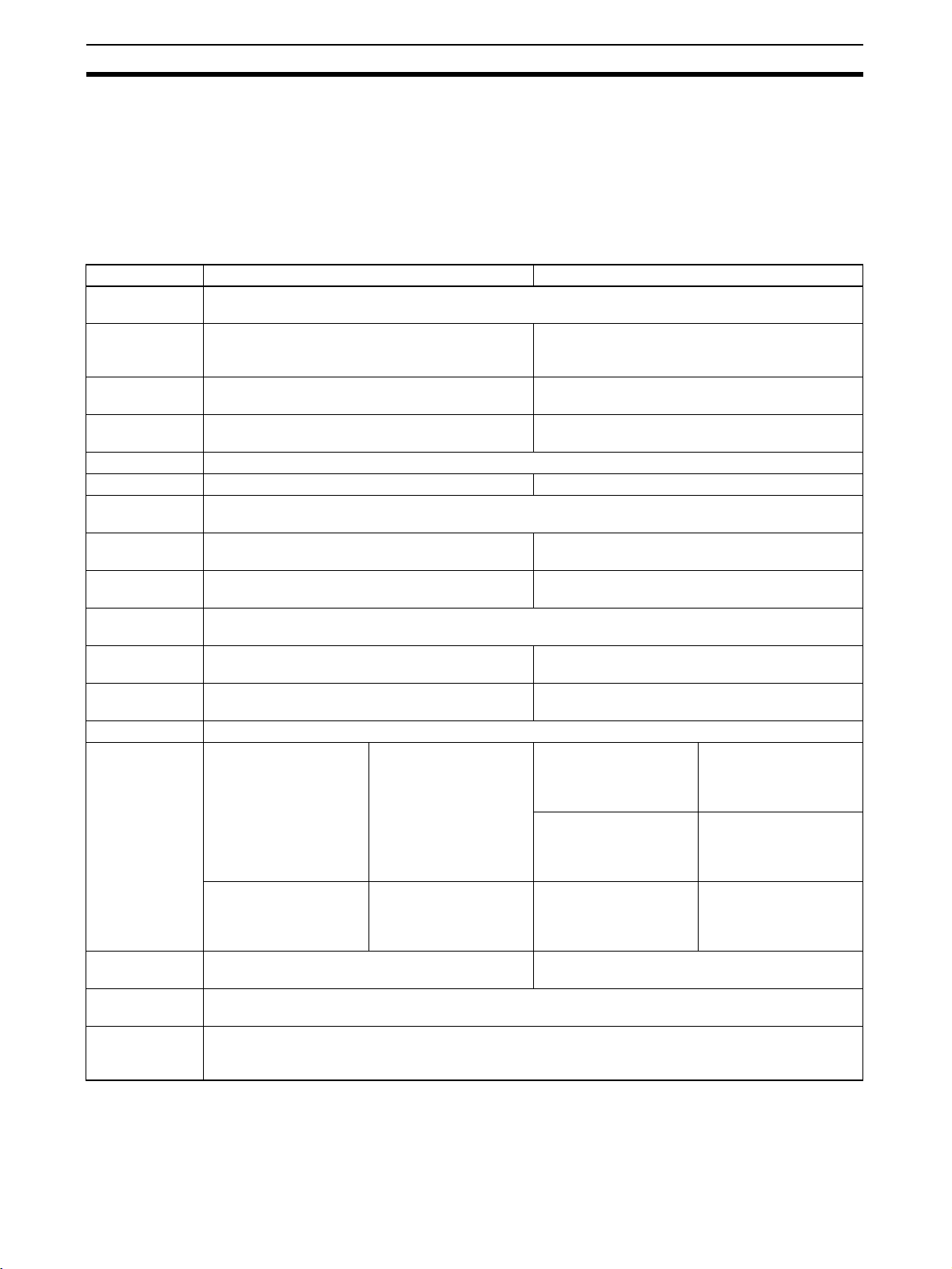

2-1-2 Performance Specifications

CS1W-V600C11 CS1W-V600C12

Unit classification

Influence on

CPU Unit’s cycle

time

Input power supply

Internal current

consumption

Dimensions 35 × 130 × 101 mm (W×H×D)

Weight 180 g max. 300 g max.

Mounting loca-

tion

No. of Units per

Rack

Connectable

Heads

Applicable Data

Carriers

No. of allocated

unit numbers

No. of allocated

words

Control protocol Special protocol

Data exchange

methods with

CPU Unit

Data transfer

quantity

Operating

modes

Diagnostic functions

Special I/O Unit

0.15 ms 0.3 ms

--- 24 V DC +10%/−15%, 360 mA

5 V DC, 260 mA max.; 26 V DC, 120 mA max. 5 V DC, 320 mA max.; 26 V DC, 0 mA max.

CS-series CPU Rack or CS-series Expansion Rack

(Cannot be mounted to C200H Expansion I/O Racks or SYSMAC BUS Slave Racks.)

5 per Rack (CPU Rack or Expansion Rack) 10 per Rack (CPU Rack or Expansion Rack)

V600-series R/W Heads

(V600-H@@) 1 Head

V600-series Data Carriers (V600-D@@)

12

10 words 20 words

Special I/O Unit Area in

CIO Area

CIO 2000 to CIO 2959

Special I/O Unit words

in DM Area

D20000 to D29599

2,048 bytes max.

(160 bytes/scan)

Normal Mode/Test Mode (changed with communications test switch)

(1) ID Sensor Unit error

(2) Communications error detection with Data Carriers

(3) Head 24-V power supply error

Constant data exchange

of 10 words/Unit

100 words/Unit transferred when power is

turned ON or when

restarting the Unit

V600-series R/W Heads

(V600-H@@) 1 or 2 Heads

CPU Unit

→ ID Sensor Unit

ID Sensor Unit

→ CPU Unit

CPU Unit

→ ID Sensor Unit

2,048 bytes max./Head

(160 bytes/scan)

Unit Controls, Communications Processing

specification, Data storage area specification

Unit information,

Results information

Processing results monitor

System Settings

Auto Wait Time Setting

10

Page 30

Specifications Section 2-1

2-1-3 Communications Specifications

CS1W-V600C11 CS1W-V600C12

Communications frequency 530 kHz

Communications controls (1) Changing EEPROM (battery-free) Data Carrier communications mode (distance prior-

ity or time priority)

(2) Write verification

(3) Auto Wait Time Setting

Commands Read

Write

Bit Set/Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Communications specification Trigger, Single auto, Repeat auto

Read

Write

Bit Set/Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Copy

11

Page 31

Operating Procedure Section 2-2

2-2 Operating Procedure

2-2-1 Overall Procedure

The operating procedure for an ID Sensor Unit is shown in the following flowchart.

Installation and settingsTrail operationOperation

Set switch on front of Unit

Wire

Set unit number

Turn ON PLC power

Create I/O tables

Set words allocated in DM Area

Turn PLC power OFF and ON

Set switch on front of Unit

Test communications

Change DIP switch on front of Unit

Turn OFF the communications test switch.

Set unit number switches on front of Unit.

Set communications mode.

Enable/disable verification when writing.

Set auto wait time

OR, turn ON Special I/O Unit Restart Bit.

Turn ON the communications test switch.

Place PLC in PROGRAM mode.

12

Turn ON PLC power

Ladder program operation

OR, turn ON Special I/O Unit Restart Bit.

Note 1. When using CX-Programmer V3.0 or later with the CS1W-V600C12, “I” will

be displayed before addresses for inputs in the ladder diagram and “Q” will

be displayed before addresses for outputs for operation data. In the CXProgrammer’s I/O Table Window, select SIOU/C200H ASCII Unit (A) and

then, from the Enter SIOU Details Window, set the Address per Unit to 2,

the Input Words to 3, and the Output Words to 7, and select the Repeat IN/

OUT for each Address per Unit option.

2. When using CX-Programmer V2.0 or later with the CS1W-V600C11, “I” will

be displayed in the ladder diagram before address for inputs and “Q” will

be displayed before addresses for outputs for operation data.

Page 32

Operating Procedure Section 2-2

2-2-2 Operating Procedure Example

The following is an operating procedure example for the following conditions.

Reading 10 Bytes of Data from Data Carrier Address 0010 Using a Trigger

ID Sensor Unit Settings

1,2,3... 1. Communications Test Switch (Set on Unit’s front panel.)

CS-series CPU Unit

Special I/O

Unit Area

Bit

15

D1000 01 02

D1001 03 04

D1002

D1003

D1004

→: Read data storage order

05 06

07 08

09 0A

Read command

Bit

00

Read data

Special I/O Unit Area Settings

Unit No.: 00

Command: Read

Communications specification: Trigger

Read data storage order: Leftmost

→ Rightmost

First Data Carrier read address: 0010 (hex)

Number of Data Carrier read bytes: 10 bytes

Read data storage destination: D1000 to D1004

CS1W-V600C11

V600C11

RUN

ERP

ERC

ERH

T/R

NORM/ERR

TEST

ON

HEAD

Communications

Data Carrier

Bit

Address

7

(hex)

0010 0 1

0011 0 2

0012 0 3

0013 0 4

0014 0 5

0015 0 6

0016 0 7

0017 0 8

0018 0 9

0019 0 A

Bit

0

2. Mounting and Installation

TEST

ON

Communications test switch

13

Page 33

Operating Procedure Section 2-2

3. Unit No. Setting

0

9

1

8

2

7

3

6

4

5

0

9

1

8

2

7

3

6

4

5

Set the unit number to 0, and the

following words will be allocated

to the Unit as a Special I/O Unit.

• CIO Area: CIO 2000 to CIO 2009

• DM Area: D20000 to D20099

4. PLC Power Supply ON

Power supply ON

Creating I/O Tables Always create the I/O tables after turning ON the PLC power supply. The I/O

tables can be created from the Programming Console or CX-Programmer.

Peripheral port

Programming Console

14

Page 34

Operating Procedure Section 2-2

Initial Settings

1,2,3... 1. Make the settings in the words allocated to Special I/O Units in the DM

Area (refer to page 41).

Peripheral port

Programming Console

First word allocated to Unit in DM Area: m = D20000 + (100

DM

address

D20000 0000Not used Communications

D20001 0000 Auto Wait Time Setting: Infinite

Contents Meaning

1514131211109876543210

test switch enabled

2. PLC Power Supply OFF and ON (or turn ON the Unit Restart Bit)

Ladder Programming

Verification for writing

Peripheral port

× 0) = D20000

Communications

mode: Distance

Programming Console

Set the Command, Communications Specification, Read Data Storage Order, First Data Carrier Read Address, Number of Bytes to Read, and Read

Data Storage Destination in words (n + 1) to (n + 6) allocated in the Special

I/O Unit Area (here, CIO 2001 to CIO 2006).

15

Page 35

Operating Procedure Section 2-2

First word allocated to Unit in CIO Area: CIO 2000 + 10 × 0 = CIO 2000

Word

address

CIO 2001 00 0 0 Command Communications

Contents Meaning

1514131211109876543210

Data order

specification

CIO 2002 00 10 First read address

CIO 2003 00 0A Number of read bytes

CIO 2004 10 00 Read data storage location (rightmost 4 digits)

CIO 2005 0 0 00 Data storage area Bank designation* Read data storage location (leftmost 2

digits)

CIO 2006 00 00 ---

Note *: Always 0 when DM is specified. ---: Ignored.

Execution

input

Waiting for

command

execution

(work bit)

0010.01

ID Busy

2007.00

Test Mode

2007.14

Unit Busy

2007.15

MOV

#0000

2001

MOV

#0010

2002

MOV

#000A

2003

Specification of command,

communications specification,

and read data storage order.

Specification of first read address.

Specification of number of read bytes.

Waiting for command

execution (work bit)

0010.01

Abort input

Waiting for abort

(work bit)

0010.02

Normal End Flag

2007.01

Error End Flag

2007.02

ID

Busy

2007.00

MOVL

#00001000

2004

0010.01

2000.00

2000.02

0010.02

Read data storage location

Waiting for command execution

(work bit)

Command Execution Bit

Abort Bit

Waiting for Abort

(work bit)

Normal end

Used to time getting

read data.

Error end

Used to time getting

resulting information.

16

Page 36

Part Names and Functions Section 2-3

2-3 Part Names and Functions

2-3-1 Part Names

CS1W-V600C11 CS1W-V600C12

V600C11

RUN

ERC

NORM/ERR

(front)

T/R

ERP

ERH

V600C12

RUN

ERC

HEAD1

NORM/ERR

(front)

T/R

ERP

ERH

HEAD2

T/R

NORM/ERR

Status indicators

Unit number switches

ON

TEST

Communications test switch

TEST

ON

R/W Head connector

HEAD

DC24V

INPUT

HEAD1

HEAD2

+

-

R/W Head power terminals

(Back) (Side)

Backplane

connector

Terminal

block

17

Page 37

Part Names and Functions Section 2-3

2-3-2 Indicators

Indicators show the operating status of the Unit. The relationship between the

indicator status and the Unit status is shown in the following table.

Indicator Name Color Meaning

RUN RUN Green Lit The ID Sensor Unit is operating normally.

Not lit The ID Sensor Unit is stopped.

ERC

(Error I/O Controller)

ERH

(Error at Host)

ERP

(Head Power Error)

Head 1 T/R Communicating Yellow Lit Communications are active.

NORM/ERR Normal end Green Lit Communications with the Data Carrier ended

Head 2 T/R Communicating Yellow Lit Communications are active.

NORM/ERR Normal end Green Lit Communications with the Data Carrier ended

Unit error Red Lit An error has occurred in the ID Sensor Unit.

Not lit No error has occurred in the ID Sensor Unit.

CPU Unit error Red Lit An error has occurred in the CPU Unit.

Not lit No error has occurred in the CPU Unit.

Head power error Red Lit An error has occurred in the power supply to the

R/W Head.

Not lit The power supply to the R/W Head is normal.

normally.

Error end Red Lit Communications with the Data Carrier ended in

an error.

normally.

Error end Red Lit Communications with the Data Carrier ended in

an error.

2-3-3 Unit Number Switches

Data exchange between the CPU Unit and ID Sensor Unit is performed using

words allocated to the Unit in the Special I/O Unit Area and in the DM Area.

The words allocated to the ID Sensor Unit in these two areas are determined

by the setting of the unit number switches on the Unit’s front panel.

0

9

1

8

2

7

3

6

4

5

0

9

1

8

2

7

3

6

4

5

Switch

No.

Unit

No.

allocated in

Special I/O

Unit Area

0 Unit 0 CIO 2000 to

CIO 2009

1 Unit 1 CIO 2010 to

CIO 2019

::: : : :

94 Unit 94 CIO 2940 to

CIO 2949

95 Unit 95 CIO 2950 to

CIO 2959

2-3-4 Communications Test Switch

The communications test switch on the Unit’s front panel is used to switch

between Normal Mode and Test Mode.

TEST

ON

Status Description

OFF Normal status (factory setting)

ON Communications test

CS1W-V600C11 CS1W-V600C12

Words

Words

allocated in

DM Area

Words

allocated in

Special I/O

Unit Area

D20000 to

D20099

D20100 to

D20199

D29400 to

D29499

D29500 to

CIO 2000 to

CIO 2019

CIO 2010 to

CIO 2029

CIO 2940 to

CIO 2959

(Cannot be set)

D29599

Words

allocated in

DM Area

D20000 to

D20199

D20100 to

D20299

D29400 to

D29599

18

Page 38

Connections and Wiring Section 2-4

2-4 Connections and Wiring

2-4-1 Connecting R/W Heads

Connection Method

1,2,3... 1. Holding the rubber molding on the connector, align the connector with the

key groove and press in.

2. Press in on the connector until it locks in place.

Rubber molding

Ring

Note The connector will not lock into place if you hold onto the ring. Always hold

onto the rubber molding.

Removal Method Hold onto the ring and pull straight out.

Rubber molding

Ring

Note The connector cannot be removed if you hold onto the rubber molding. Never

pull on the cable with excessive force. The conductors may be broken or damaged.

19

Page 39

Connections and Wiring Section 2-4

2-4-2 Wiring the External Power Supply (CS1W-V600C12 Only)

Wiring the power supply as shown below.

CS1W-V600C12

Connection Example

Line filter

+24 V DC

0 V

M3 self-lifting screws are used as the connection terminals for the power supply. When necessary, use the following crimp terminals. The tightening torque

is approximately 0.59 N·m.

Examples of Applicable Crimp Connectors

Manufacturer Model number Applicable wire size Shape

J.S.T Mfg. Co., Ltd. 1.25-N3A AWG24 to 16 Forked

J.S.T Mfg. Co., Ltd. 1.25-Y3A

6.5 mm max.

Recommended DC Power Supplies (Miniature, by OMRON)

Model number Output capacity Input voltage

S82K-03024 24 V DC, 1.3 A 100/200 V AC

S82J-0224 24 V DC, 1.1 A 100 V AC

Note 1. Although adequate measures have been taken inside the I/O Sensor Unit

for noise entering on the power supply line, supplying power through a line

filter can be used to greatly attenuate ground noise.

2. Although the rated power consumption of the CS1W-V600C12 is 360 mA

at 24 V DC, be sure to consider the surge current when determining capacities.

(For M3 terminal)

20

Page 40

Connections and Wiring Section 2-4

2-4-3 Wiring for Safety and Noise Immunity

R/W Head Cables and I/O

Signal Lines

Countermeasures for

Inductive Loads

Wire the R/W Head cables and I/O signal lines in separate ducts from power

circuit cables both inside and outside the control panel.

(1): I/O cables

(2): Power lines

(1)

(2)

Suspended ducts

(1) (2)

Floor ducts

(1) (2)

Conduits

If the same ducts must be used, shielded cables can be used to increase

resistance to noise. If a shielded cable is used, connect one end of the shield

to ground.

If I/O is connected to an inductive load, connect a surge killer or diode in parallel with the load.

IN

Diode

L

DC input

COM

Relay contact output

Triac output

OUT

COM

L

Surge killer

Noise Countermeasures

for External Wiring

OUT

Relay contact output

Transistor output

COM

Diode

Note Use surge killers and diodes that meet the following conditions:

Surge Killers

Resistance: 50 Ω

Capacitance: 0.47 µF

Voltage: 200 V

Diodes

Inrush withstand voltage: 3 times load voltage min.

Average rectified current: 1 A

Consider the following items when wiring external lines, such as the R/W

Head cables, I/O lines, power supply lines, and high-power lines.

• When using multiconductor cables for signal lines, do not use the same

cable for both I/O lines and other control lines.

+

21

Page 41

Connections and Wiring Section 2-4

• When Racks are installed in parallel with each other, keep them separated by at least 300 mm.

Low-power cables

R/W Head cables and

PLC I/O lines

Control cables

SYSMAC power supply

lines and general

control circuit lines

Power lines

High-power cables

Ground to 100 Ω or less.

• When placing cables in the same duct, separate them with grounded iron

plates.

SYSMAC power supply

lines and general

control circuit lines

Power linesPLC I/O lines

300 mm min.

300 mm min.

Iron plate

200 mm min.

Ground to 100 Ω or less.

22

Page 42

SECTION 3

CJ-series ID Sensor Units

This section describes the specifications, operation, and installation of ID Sensor Units for CJ-series PLCs.

3-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-1-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-1-3 Communications Function Specifications . . . . . . . . . . . . . . . . . . . . 25

3-2 Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2-1 Overall Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2-2 Operating Procedure Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-3 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3-1 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-3 Unit Number Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-4 Communications test Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-4 Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-4-1 Connecting R/W Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-4-2 Wiring for Safety and Noise Immunity . . . . . . . . . . . . . . . . . . . . . . 34

23

Page 43

Specifications Section 3-1

3-1 Specifications

3-1-1 General Specifications

General specifications conform to those of SYSMAC CJ-series Special I/O

Units.

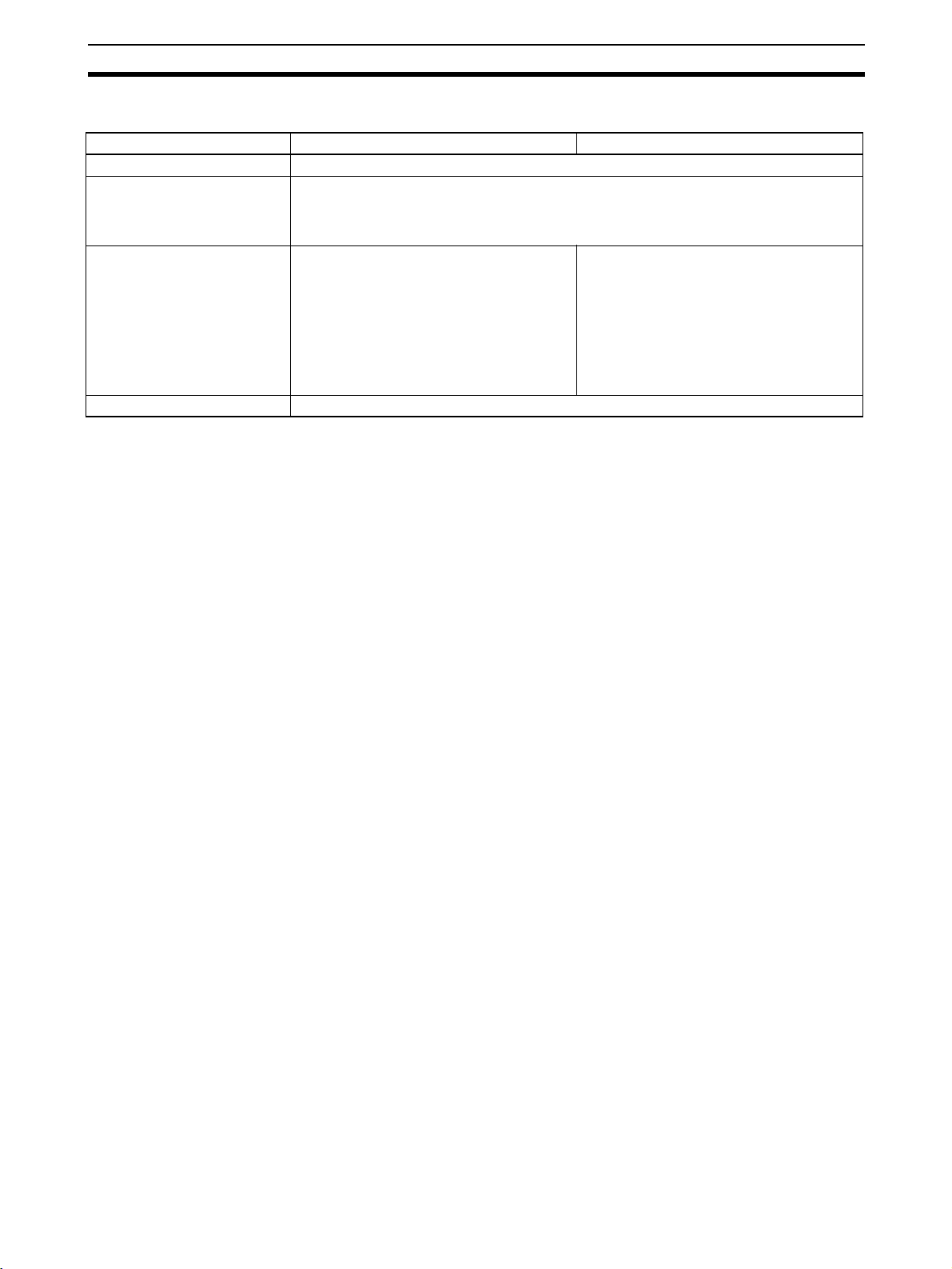

3-1-2 Performance Specifications

CJ1W-V600C11 CJ1W-V600C12

Unit classification

Influence on

CPU Unit’s cycle

time

Internal current

consumption

Dimensions 31 × 90 × 65 mm (W×H×D)

Weight 120 g max. 130 g max.

Mounting loca-

tion

No. of Units per

Rack

Connectable

Heads

Applicable Data

Carriers

No. of allocated

unit numbers

No. of allocated

words

Control protocol Special protocol

Data exchange

methods with

CPU Unit

Data transfer

quantity

Operating

modes

Diagnostic functions

Special I/O Unit

0.15 ms 0.3 ms

5 V DC, 260 mA max.; 24 V DC, 120 mA max. 5 V DC, 320 mA max.; 24 V DC, 240 mA max.

CJ-series Rack or CJ-series Expansion Rack

(Cannot be mounted to C200H Expansion I/O Racks or SYSMAC BUS Slave Racks.)

4 Units maximum per Rack 2 Units maximum per Rack

V600-series R/W Heads

(V600-H@@) 1 Head

V600-series Data Carriers (V600-D@@)

1 unit number 2 unit numbers

10 words 20 words

Special I/O Unit Area

CIO 2000 to CIO 2959

Special I/O Unit words

in DM Area

D20000 to D29599

2,048 bytes max.

(160 bytes/scan)

Normal Mode/Test Mode (changed with communications test switch)

(1) ID Sensor Unit error

(2) Communications error detection with Data Carriers

(3) Head 24-V power supply error

Constant data exchange

of 10 words/Unit

100 words/Unit transferred when power is

turned ON or when

restarting the Unit

V600-series R/W Heads

(V600-H@@) 1 or 2 Heads

CPU Unit

→ ID Sensor Unit

ID Sensor Unit

→ CPU Unit

CPU Unit

→ ID Sensor Unit

2,048 bytes max./Head

(160 bytes/scan)

Unit Controls, Communications Processing

Specification, Data Storage Area Specification

Unit information,

Results Information,

Processing Results

Monitor

System Settings,

Auto Wait Time Setting

24

Page 44

Specifications Section 3-1

3-1-3 Communications Function Specifications

CJ1W-V600C11 CJ1W-V600C12

Communications frequency 530 kHz

Communications control (1) Changing EEPROM (battery-free) Data Carrier communications mode (distance prior-

ity or time priority)

(2) Write verification

(3) Auto Wait Time Setting

Commands Read

Write

Bit Set/Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Communications specification Trigger, Single auto, Repeat auto

Read

Write

Bit Set/Bit Clear

Mask Bit Write

Calculation Write

Data Fill

Data Check

Number of Writes Control

Copy

25

Page 45

Operating Procedure Section 3-2

3-2 Operating Procedure

3-2-1 Overall Procedure

The operating procedure for an ID Sensor Unit is shown in the following flowchart.

Set switch on front of Unit

Set unit number

Turn ON PLC power

Create I/O tables

Installation and settings

Set words allocated in DM Area

Turn PLC power OFF and ON.

Set switch on front of Unit

Test communications

Trail operationOperation

Change DIP switch on front of Unit

Turn OFF the communications test switch.

Wire

Set unit number switches on front of Unit.

Set communications mode.

Enable/disable verification when writing.

Set auto wait time

OR, turn ON Special I/O Unit Restart Bit.

Turn ON the communications test switch.

Place PLC in PROGRAM mode.

26

Turn ON PLC power

Ladder program operation

OR, turn ON Special I/O Unit Restart Bit.

Note 1. When using CX-Programmer V3.0 or later with the CJ1W-V600C12, “I” will

be displayed before addresses for inputs in the ladder diagram and “Q” will

be displayed before addresses for outputs for operation data. In the CXProgrammer’s I/O Table Window, select SIOU/C200H ASCII Unit (A) and

then, from the Enter SIOU Details Window, set the Address per Unit to 2,

the Input Words to 3, and the Output Words to 7, and select the Repeat IN/

OUT for each Address per Unit option.

2. When using CX-Programmer V2.0 or later with the CJ1W-V600C11, “I” will

be displayed in the ladder diagram before address for inputs and “Q” will

be displayed before addresses for outputs for operation data.

Page 46

Operating Procedure Section 3-2

3-2-2 Operating Procedure Example

The following is an operating procedure example for the following conditions.

Reading 10 Bytes of Data from Data Carrier Address 0010 Using a Trigger

ID Sensor Unit Settings

1,2,3... 1. Communications Test Switch (Set on Unit’s front panel.)

CJ-series CPU Unit

Special I/O

Unit Area

Bit

15 00

Read command

Bit

D1000 01 02

D1001 03 04

D1002

D1003

D1004

05 06

07 08

09 0A

Read data

→: Read data storage order

Special I/O Unit Area Settings

Unit No.: 00

Command: Read

Communications specification: Trigger

Read data storage order: Leftmost

→ Rightmost

First Data Carrier read address: 0010 (hex)

Number of Data Carrier read bytes: 10 bytes

Read data storage destination: D1000 to D1004

CJ1W-V600C11

V600C11

RUN ERC

T/R NORM/ERR

ERP ERH

TEST

ON

HEAD

Address

Communications

Data Carrier

Bit

70

(hex)

0010 0 1

0011 0 2

0012 0 3

0013 0 4

0014 0 5

0015 0 6

0016 0 7

0017 0 8

0018 0 9

0019 0 A

Bit

NORM/ERR

R

/

T

1

1

C

0

0

6

V

C

R

E

N

U

R

H

R

E

P

R

E

T

S

E

T

N

O

2. Mounting and Installation

TEST

ON

M

S

Y

S

CJ1G

PROG

ROL

T

N

CO

Communications test switch

/ERR

NORM

T/R

1

1

C

0

V60

N ERC

RU

7

6

5

14 15

34

1

2

6

2

D

15

01

O

ERP ERH

4

910111213

13 1

8

234567

12

I

01

2

91011

8

I

I

3

0

RUN

ALM

/

R

R

E

NH

I

C

A

4

4

U

P

E

C

PRPHL

L

-

B

A

M

M

M

COM

RA

R

E

L

EN

P

O

R

W

MCP

Y

BUS

AL

R

IHE

R

PE

T

R

PO

I

1

I

I

1

20

CN1

3A

0.

V

DC24

1

B/A

TEST

ON

CN2

20

A/B

27

Page 47

Operating Procedure Section 3-2

3. Unit No. Setting

7

8

1

6

2

123

D

0

O

891011 1

I

01

9

8

I

I

0

2

1

N

C

DC24V 0.3A

1

/A A

B

6

9

5

0

4

1

3

2

7

8

6

9

5

0

4

1

3

2

M/ERR

NOR

T/R

1

1

C

0

0

6

V

RUN ERC

7

56

15

4

7

21314

56

5