Page 1

Model

CJ1W-TS561

Thermocouple input unit

INSTRUCTION SHEET

Thank you for purchasing an OMRON product. Read this

instruction sheet thoroughly and familiarise yourself with the

functions and characteristics of the product before using it.

To ensure safe and correct use of this Unit, also read the

Operation- and Programming Manuals for your CJ1 PLC system.

Keep this instruction sheet for future reference.

OMRON MANUFACTURING OF THE NETHERLANDS B.V.

OMRON Corporation 2004 All Rights Reserved

■ General Specifications

Unit classification CJ-series Basic I/O Unit

Compatible Racks CJ-series CPU Rack or

CJ-series Expansion Rack

Max. number of

Units

10 Units/Rack max.

(This requires a CJ1G or CJ1H CPU)

CPU Unit data area

for inputs

Basic I/O area CIO0000 – 0999

(3, 4 or 6 words allocated in IO Table)

Insulation resistance

20 MΩ min. (at 500 V DC) between

input terminals and PLC I/O bus.

Dielectric Strength 500 V AC, 50/60 Hz for 1 min. (detection

current: 1 mA), between Input terminals

and PLC I/O bus.

Internal current

consumption

220 mA max., 5 V DC,

from the PLC I/O bus.

Dimensions 31 x 90 x 65 mm (W x H x D)

Weight 150 g max.

Other

Other general specifications conform to

the CJ-series general specifications.

See Operation Manual W393.

■ Characteristics

■ Unit Description

Thermocouple input K-type or J-type (IEC 60584)

Number of inputs 1 to 6

Measurement range K-type: -200.0 to +1300.0 °C

J-type: -100.0 to +850.0 °C

Indication resolution 0.1 °C

Cold junction

compensation

- Accuracy

Internal measurement of terminal

temperature, once in each scan cycle.

± 2.0 °C in a stable temperature

environment (no direct heat or airflow).

Temperature value

Data representation

16-bit signed integer in units of 0.1 °C:

#F830 = -200.0 °C, #32C8 = +1300.0 °C

Indication accuracy *

over full operational

range (0 – 55 °C

ambient temperature)

± 0.5 % of indicated value or ± 0.7 °C

(whichever is larger) ± 1 digit max.

±2.0 °C ± 1 digit max. using a K-type

thermocouple below –100 °C.

Input response time

(per active input)

40 ms (100 Hz suppression)

67 ms (60 Hz suppression)

80 ms (50 Hz suppression)

400 ms (50+60 Hz suppression)

Input update cycle

time (all active inputs)

[number of active inputs + 1] x [input

response time] + 40 ms

I/O refresh time

(influence on PLC

cycle time)

1-3 inputs (48pt mode): 0.008 ms

4 inputs (64pt mode): 0.011 ms

5-6 inputs (96pt mode): 0.016 ms

The CJ1W-TS561 is a 6-channel input unit for K-type and J-type

thermocouples. It can be installed in any CJ1-series PLC system.

It is classified as a basic I/O unit, occupying 48, 64 or 96 I/O points,

depending on the number of activated inputs.

Always verify that the maximum I/O capacity of the CJ1 CPU is

sufficient for the number of required I/O points.

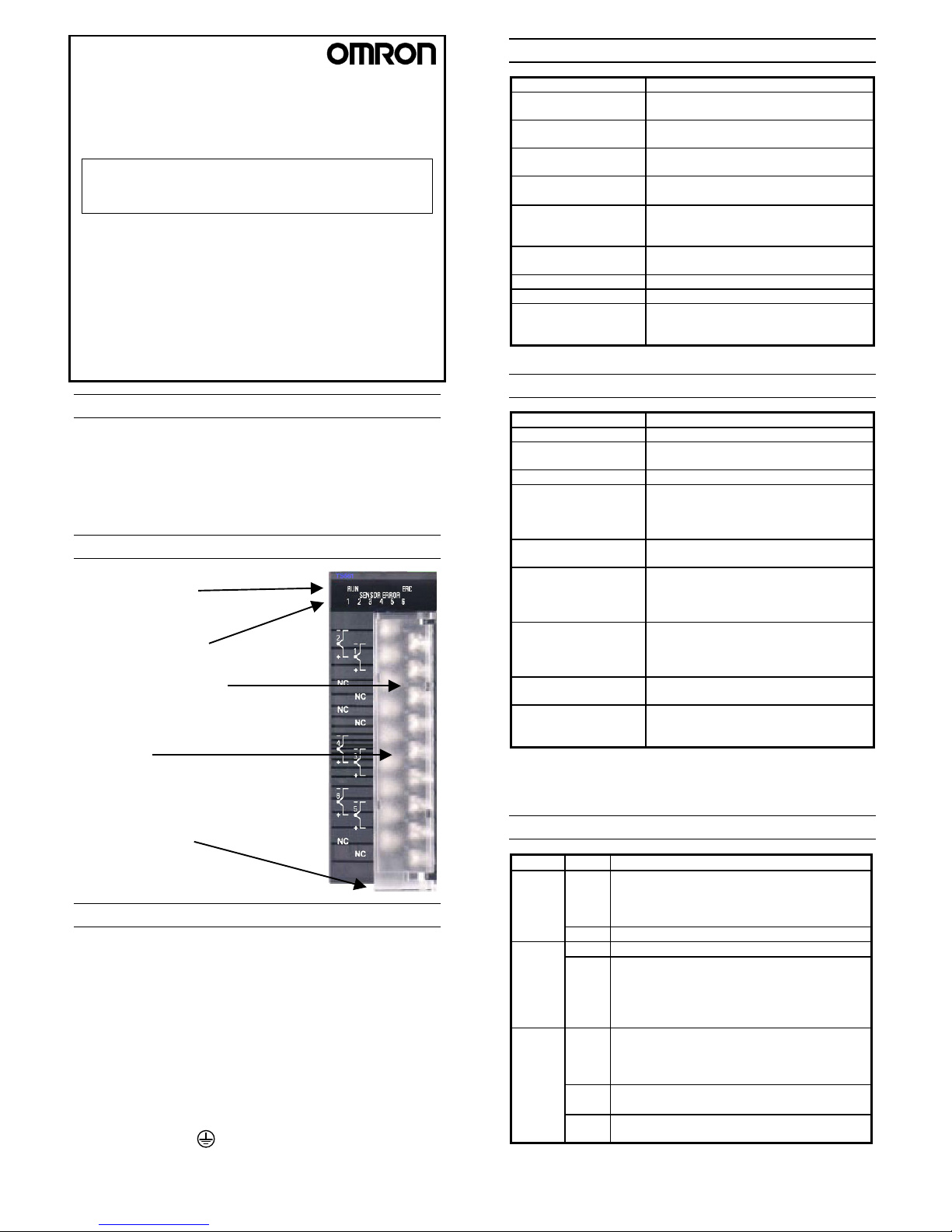

■ Nomenclature

Unit status indicators

• RUN (green)

• ERC (red)

Sensor error indicators

• 1 - 6 (red)

Removable Terminal Block

• Connections for Thermocouples 1 - 6

• CJ1W-TS561: screw terminal

• CJ1W-TS561 (SL): screwless terminal

DIP switches

(remove terminal block for access)

• Select input types (K-type/J-type)

• Select filter functions

• Select number of active inputs (1-6)

Terminal Block latch

• Slide down to remove

• Slide up to lock

* Indication accuracy is guaranteed with the supplied terminal block.

Do not replace the supplied terminal block by a different model (e.g.

screw type by screwless type or vice versa).

■ LED indicators

Name State Description

OFF Fatal error or no power supply.

• Check the host PLC’s CPU status, and the

status of other I/O units. If all other units

function normally, replace the Unit.

RUN

(Green)

ON

Unit functions normally.

OFF

No fatal errors.

ERC

(Red)

ON Incorrect DIP switch setting

Fatal error in the Unit.

• Check the CPU unit for error codes.

• Re-start the PLC system.

• If the ERC LED is still lit, replace the unit.

OFF

• Measurement of the corresponding channel is

within range, or

• Channel has been deactivated by DIP switch

settings

ON

• Measured temperature out-of-range, or

• Thermocouple broken wire

Sensor

Error

1 – 6

(Red)

All ON Calibration data not found or incorrect. The Unit

should be returned to OMRON for calibration.

■ Wiring

• Keep the thermocouple wiring as short as possible to avoid

electrical interference. Shielded wiring is recommended.

• When extending input wiring, always use compensation wires

appropriate for the thermocouple type.

• For activated but unused inputs, short-circuit the + and terminals, to prevent unstable readout on the other inputs.

• Keep the input wiring away from power lines including AC power

supply lines and high-power lines. Do not run the I/O lines in the

same duct or conduit as power lines.

• The input circuits are galvanically isolated from the PLC’s I/O bus,

but there is no galvanic isolation between individual inputs.

• Always ground the terminal on the Power Supply Unit of the

PLC. In case of shielded sensor wiring, connect the shields to the

same grounding point as the PLC.

Page 2

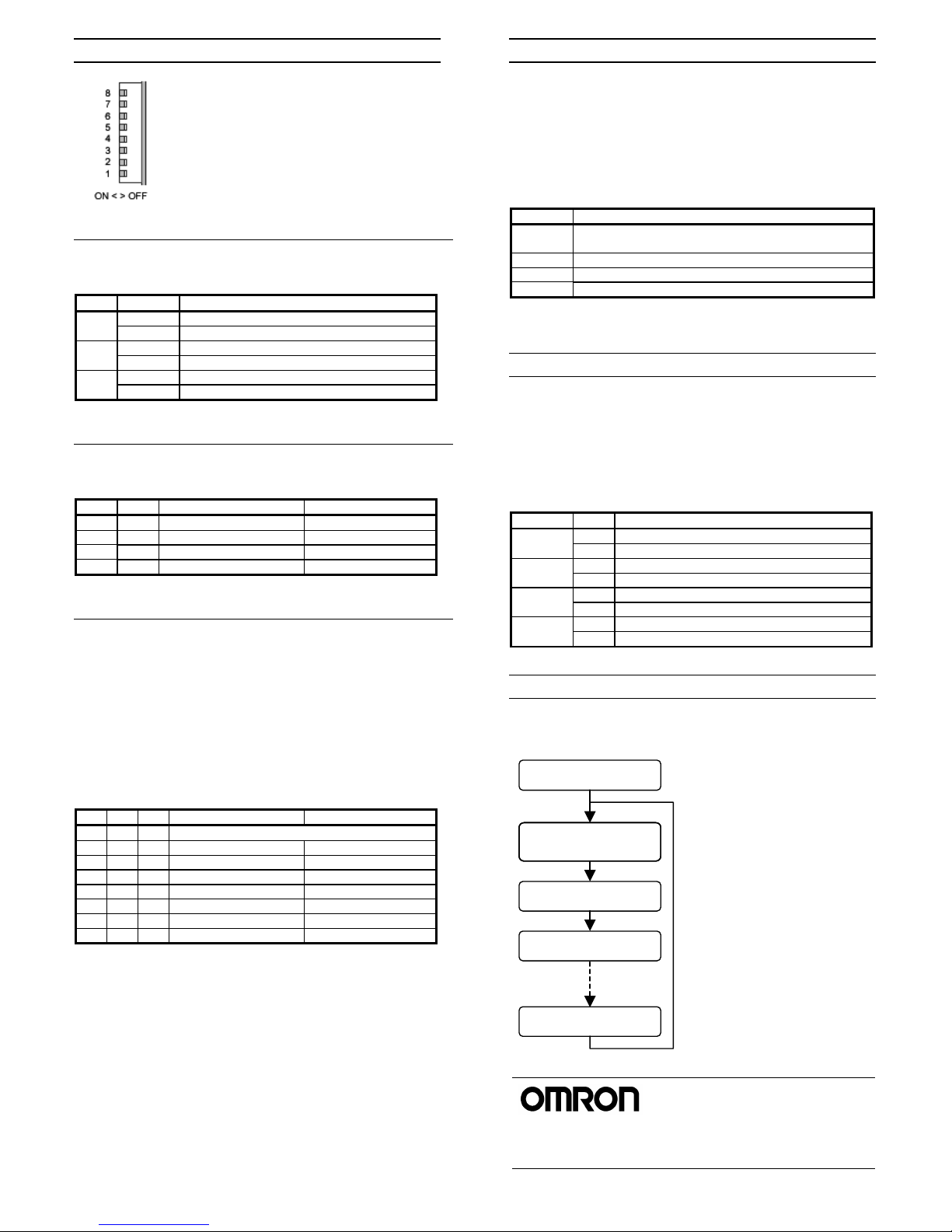

Measure Cold Junction

+ Sensor error check

Measure Channel 1

Measure Channel 2

Measure Channel N

Unit initialisation

■ DIP switches

8 DIP switches are accessible after removing the

front terminal block. Switch settings are processed at

time of power ON, and should not be changed while

the unit is powered.

Default (ex-factory) setting is all switches ON,

i.e. all 6 inputs are active and set to K-type

thermocouple, with filtering at n x 100 Hz. Be sure

to adjust the settings to your requirements before

use.

SW 1, 2 and 3 : Input type selection

Any combination of input types (different numbers of K-type/J-type

sensors) can be set.

SW State Input type selection

OFF Input channel 1 is J-type 1

ON Input channel 1 is K-type

OFF Input channels 2 and 3 are J-type 2

ON Input channels 2 and 3 are K-type

OFF Input channels 4, 5 and 6 are J-type 3

ON Input channels 4, 5 and 6 are K-type

SW 4 + 5 : Input filtering (valid for all active input channels)

Use filtering if the measured value is affected by the mains frequency or

other sources of electrical interference.

SW4 SW5 Filtering Response time

OFF OFF n x 10 Hz suppression 400 ms each input

OFF ON n x 50 Hz suppression 80 ms each input

ON OFF n x 60 Hz suppression 67 ms each input

ON ON n x 100 Hz suppression 40 ms each input

SW 6+7+8 : Input activation

To prevent broken wire indication for unused inputs, and to reduce the

number of input channels occupied in CIO memory, the number of

required inputs can be set by SW 6+7+8.

Input words are allocated in the PLC’s CIO area as Basic I/O Unit, i.e.

sequentially starting at the leftmost unit. See CJ1-series Operation

Manual W393 for details.

Create the I/O table in the PLC after changing the switch settings, to

register the correct number of input words in the PLC CPU. The unit is

registered as 48-point, 64-point, or 96-point input unit, depending on the

number of 16-bit CIO words it occupies.

SW6 SW7 SW8 Active inputs Occupied input words

OFF OFF OFF Not valid, ERC indicator will be ON

ON OFF OFF 1 3 CIO words (1 used)*

OFF ON OFF 1, 2 3 CIO words (2 used)*

ON ON OFF 1, 2, 3 3 CIO words

OFF OFF ON 1, 2, 3, 4 4 CIO words

ON OFF ON 1, 2, 3, 4, 5 6 CIO words (5 used)*

OFF ON ON 1, 2, 3, 4, 5, 6 6 CIO words

ON ON ON 1, 2, 3, 4, 5, 6 6 CIO words

* In these cases, more CIO words will be occupied than required for the

active inputs. The remaining occupied CIO words will be filled with 0’s,

and cannot be used as work bits.

■ Data representation

Measured temperatures are indicated in °C. Each input value

occupies one word (16 bits) in the CIO area and is encoded as a

signed integer, with a resolution of 0.1 °C.

Examples: #0300 = 768 (dec) = 76.8 °C

#FF85 = -123 (dec) = -12.3 °C

Measured values are updated in CIO memory in each I/O refresh cycle.

The following values are to be interpreted as error codes:

Value Description

#7AAA Calibration data invalid or error detected at start-up,

e.g. cold junction temperature out of range.

#7BBB Sensor error, broken wire

#7CCC Measured value out of range (over max. Temperature)

#8CCC Measured value out of range (under min. Temperature)

During initialisation after power ON, data of active inputs will be #0000

until the “Not Ready’ flag turns OFF.

■ ‘Not Ready’ flag

During initialisation after power-on, and in case of internal failure, a

‘Not Ready’ flag will be set in the PLC memory area A050 to A069

(Basic I/O Unit information area, refer to CJ1 Operation Manual W393

for details).

The lower bit of each unit is the Not Ready flag; the error code

indicated in the remaining bits is relevant for repair purposes only.

While this flag is ON, the temperature sensor data indicated by the

unit in the CIO area is invalid.

Address Bit When Bit = ON

00 Unit in rack 0, slot 0 is not ready A050

08 Unit in rack 0, slot 1 is not ready

00 Unit in rack 0, slot 2 is not ready A051

… …

00 Unit in rack 1, slot 0 is not ready A055

… …

00 Unit in rack 3, slot 9 is not ready A069

08 Unit in rack 3, slot 10 is not ready

■ Unit cycle time

The internal processing time for all measurements by the unit is

determined by the number of active channels and the filter type.

The cold junction compensation

measurement and one sensor error

check are executed each cycle.

The cold junction measurement

time depends on the input filter

setting, whereas the sensor error

check takes a fixed 40 ms.

Example:

If 4 inputs are active, and filtering is

set to n x 50 Hz (response time =

80 ms):

Each measurement cycle takes

(4+1) x 80 + 40 ms = 440 ms.

OMRON CORPORATION

Note: Specification subject to change without notice Printed in The Netherlands 1634299-2A

OMRON ELECTRONICS LLC

Phone: 1-847-843-7900 or

1-800-55-OMRON

OMRON CANADA INC.

Phone: 416-286-6465

Phone: 1-514-636-6676 (French)

Loading...

Loading...