Page 1

W903-E2-02

C200HW-MC402-E

Motion Control Unit

Operation Manual

Page 2

C200HW-MC402-E

Motion Control Unit

Operation Manual

Produced June 2001

Page 3

Notice:

OMRON products are manufactured for use according to proper procedu res by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injur y to p eople or damage to property.

!DANGER

!WARNING

!Caution

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch”, which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used a s an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of par ticular interest for efficient and convenient opera-

tion of the product.

1,2,3... Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2001

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information conta ined in this publication.

v

Page 4

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Motion Control Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-6 Comparison with C200HW-MC402-UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SECTION 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-1 Components and Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-4 Servo System Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-5 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SECTION 3

PC Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-1 IR/CIO Area Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-2 Overview of Data Exchanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-3 Details of the Data Exchange Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SECTION 4

Multitasking BASIC Programming . . . . . . . . . . . . . . . . 57

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-2 BASIC Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-3 Motion Control Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4-4 Command Line Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-5 BASIC Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-6 Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

vii

Page 5

TABLE OF CONTENTS

SECTION 5

BASIC Motion Control Programm ing Langua ge . . . . . 71

5-1 Notation Used in this Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5-2 Classifications and Outlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5-3 Command, function and parameter description. . . . . . . . . . . . . . . . . . . . . . . . . . . 84

SECTION 6

Programming Environment . . . . . . . . . . . . . . . . . . . . . . . 157

6-1 Motion Perfect Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

6-2 Motion Perfect Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

6-3 Going Online with the MC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

6-4 Motion Perfect Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

6-5 Motion Perfect Desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

6-6 Motion Perfect Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6-7 Suggestions and Precautions in Using Motion Perfect . . . . . . . . . . . . . . . . . . . . . 177

SECTION 7

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

7-1 Problems and Countermeasures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

7-2 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

7-3 Error Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

7-4 CPU Unit Error Flags and Control Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

SECTION 8

Maintenance and Inspection. . . . . . . . . . . . . . . . . . . . . . . 189

8-1 Routine Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

8-2 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Appendix

Appendix A Upgrading from C200HW-MC402-UK. . . . . . . . . . . . . . . . . . . . . . . . . 193

Appendix B PC Interface Area Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Appendix C Programming Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

viii

Page 6

About this Manual:

This manual describes the installation and operation of the C200HW-MC402-E Motion Control Unit

(MC Unit) and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the MC Unit. Be sure to read t he precautions p rovided in the following

section.

Precautions provides general precautions for using the MC Unit, Programmable Controller (PC), and

related devices.

Section 1

to its operation. Also the specifications and the comparison with previous C200HW-MC402-UK is

shown.

Section 2

Section 3

between the MC Unit and the CPU Unit.

Section 4

which programs are managed for the MC Unit.

Section 5

cation using the MC Unit. All BASIC system, task and axis statements that determine the various

aspects of program execution and MC Unit operation are presented.

Section 6

tor and debug motion based applications for the MC Unit.

Section 7

Section 8

Unit operating in optimum cond ition. It also i ncludes proper procedures when replacing an MC Unit or

battery.

The Appendices provide a guide for upgrading from the C200HW-MC402-UK Unit and the PC Interface Lists. Furthermore, some convenient programming examples are given for the user.

describes the function of the C 200HW-MC402-E Motion Cont rol Unit and concepts related

describes information required for hardware setup and installation.

describes the IR/CIO area allocation and presents the di fferent methods of dat a exchange

gives an overview of the fundamentals of multitasking BASIC programs and the methods by

describes the commands and parameters required for programing the motion control appli-

provides an overview of software package Motion Perfect, which is used to program, moni-

provides procedures on troubleshooting problems that may arise with the MC Unit.

explains the maintenance and inspec tion procedures that must be followed to keep the M C

!WARNING

Failure to read and understand the information provided in this manual may result in personal injury ordeath, damage to the product , or product failure. Please read eachsection

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Motion Control Unit and related devices.

The information contained in this section is important for the safe and reliable application of the Motio n Control

Unit. You must read this section and understand the information contained before attempting to set up o r o perate

a Motion Control Unit and PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-1-1 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

6-1-2 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

xi

Page 8

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the prod uct according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON Motion

Control Units. Be sure to read this manual before operation and keep this

manual close at hand for reference during operation.

!WARNING

It is extremely important that Motion Control Units and related devices be

used for the specified pur pose a nd under t he specified c onditions, especia lly

in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying Motion Control Units

and related devices to the above mentioned applications.

3 Safety Precautions

!WARNING

!WARNING

!WARNING

Never attempt to disassemble any Units while power is being supplied. Doi ng

so may result in serious electrical shock or electrocution.

Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

Provide safety measures in external circuits (i.e., not in the Programmable

Controller or MC Unit) to ensure safety in the system if an abnormal ity occurs

due to malfunction of the PC, malfunction of the MC Un it, or external factors

affecting the operation of the PC or MC Unit. Not providing sufficient safety

measures may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC or MC Unit outputs may remain ON or OFF due to deposits on or

burning of the output relays, or destruction o f the output transistors. As a

counter-measure for such problems, external safety measures must be

provided to ensure safety in the system.

• When the 24-VDC output (service power supply to the PC) is overloaded

or short-circuited, the voltage may drop and result in the outputs bei ng

turned OFF. As a countermeasure for such problems, external safety

measures must be provi d e d to ensure safety in the system.

xii

Page 9

Operating Environment Precautions 4

• It is the nature of high speed motion control and motion control language

programming and multi-tasking systems, that it is not always possible for

the system to validate the inputs to the func tions. It is the responsibility of

the programmer to ensure that various BASIC s tatements are called c orrectly with the correct number of inputs and that the values are correctly

validated prior to the actual calling of the various functions.

!Caution

!Caution

!Caution

Connect the ENABLE output (drivers enable signal) to the Servo Drivers. Otherwise, the motor may run when the power is turned ON or OFF or when an

error occurs in the Unit.

Do not save data into the flash memor y duri ng me mor y operation or while the

motor is running. Otherwise, unexpected operation may be caused.

Do not reverse the polarity of the 24-V power supply. The polarity must be

correct. Otherwise, the motor may star t running unexpectedly and may not

stop.

4 Operating Environment Precautions

!Caution

!Caution

Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation due to radical temperature changes.

• Locations subject to corrosive or inflammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to vibration or shock.

• Locations subject to exposure to water, oil or chemicals.

Take appropriate and sufficient countermeas ures when installing systems in

the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near power supply lines.

!Caution

The operating environment of the P C System c an have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the operating environment is within the specified conditions at installation and rema ins within the spec ified conditions dur ing the life

of the system.

5 Appli c a tion Precau tions

Observe the following precautions when using the Motion Control Unit or the

PC System.

!WARNING

Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or le ss whe n in sta lling the system to

protect against electrical shock.

xiii

Page 10

Application Precautions 5

• Always turn OFF the power supply to the PC before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

• Mounting or dismounting the MC Unit or any other Units.

• Assembling the Units.

• Setting rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution

Failure to abide by the following precautions could lead to faulty operation of

the PC, the MC Unit or the system, or could damage the PC or MC Unit.

Always heed these precautions.

• Maximum 12 of the digital inputs (I0 to I15) should be switched on at any

one time to ensure that the Unit remains within internal temperature specifications. Failure to meet this condition may lead to degradation of performance or damage of components.

• After development of the application programs, be sure to save the program data in flash memory within the MC Unit (using the EPROM command in BASIC). The program data will remain in the S-RAM during

operation and power down, but considering possible battery failure it is

advised to store the data in flash memory .

• It is strongly recommended to store dynamic application data, which can

not be initiated in program, in the PC Unit’s memory considering possible

battery failure.

• Do not turn OFF the power supply to the Unit while data is being written to

flash memory. Doing so may cause problems with the flash memory.

• Confirm that no a dverse effect will occur in the system before attempting

any of the following. Not doing so may result in unexpected operation.

• Changing the operating mode of the PC.

• Changing the present value of any word or any set value in memory.

• Force-setting/force-resetting any bit in memory

• Install external breakers and take other safety measures against short-cir-

cuiting in external wiring. Insufficient safety measures against shor t-circuiting may re s ult in burning.

• Be sure that all mounting screws, terminal screws, and cable connector

screws are tightened securely. Incorrect tightening may result in malfunction.

• Before touching the Unit, be sure to first touch a gro unded m etall ic object

in order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Check the pin numbers before wiring the connectors.

• Be sure that the connectors, terminal blocks, I/O cables, cables between

drivers, and other items with locking devices are properly locked into

place. Improper locking may result in malfunction.

• Always use the power supply voltages specified in this manual. An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be pa rticular ly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfun c tion.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

xiv

Page 11

Conformance to EC Directives 6

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Out put Units in excess of

the maximum switching capacity. Excess voltage or loads may result in

burning.

• Disconnect the functional ground terminal when performing withstand

voltage tests. Not disconnecting the functional ground terminal may result

in burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on t op of the cables or other wir ing lines. Doing so

may break the cables.

• Resume operation only after transferring to the new MC Unit the contents

of the parameters, position data, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Confirm that set parameters and data operate properly .

• Carefully check the user program before actually running it on the Unit.

Not checking the program may result in an unexpected operation.

• Do not attempt to take any Units apart, to repair any Units, or to modify

any Units in any way.

• Perform wiring according to specified procedures.

6 Conformance to EC Directives

6-1 Applicable Directives

• EMC Directives

• Low Vol tage Directiv e

6-1-1 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or machines. The actual products have been checked for conformity to EMC standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer. EMC-related performance of the OMRON devices that comply with

EC Directives will vary depending on the c onfiguration, wiring, and other conditions of the equipment or control panel in which the OMRON devices are

installed. The customer must, therefore, perform final checks to confirm that

devices and the over-all machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN50081-2

(Radiated emission: 10-m regulations)

xv

Page 12

Conformance to EC Directives 6

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC or 75 to

1,500 VDC meet the required safety standards for the PC (EN61131-2).

6-1-2 Conformance to EC Directives

The C200HX/HG/HE ser ies and CS1 ser ies PCs comply with E C Directives.

To ens ure that the machine or device in which a PC is used complies with EC

directives, the PC must be installed as follows:

1,2,3... 1. The PC must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3. PCs complying with EC Directives also conform to the Common Emission

Standard (EN50081-2). When a PC is built into a machine, however , noise

can be generated by switching devices using relay outputs and cause the

overall machine to fail to meet the Standards. If this occurs, surge killers

must be connected or other measures taken external to the PC.

The following methods represent typical methods for reducing noise, and

may not be sufficient in all cases. Required countermeasures will vary depending on the devices connected to the control panel, wiring , the configuration of th e system, a n d othe r conditions.

xvi

Page 13

SECTION 1

Features and System Configuration

This section des cribes the feature s and system conf igur ation of the C200HW-MC402-E Motion Control Unit and co ncepts

related to its operation. It also indi cates the diff erence with the previous C200HW-MC402-UK Unit.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Description of Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Motion Control Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-1 PTP-control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-2 CP-control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-3 EG-Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-4 Other Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-4 Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-1 Feedback Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4-2 Servo System Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-6 Comparison with C200HW-MC402-UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1

Page 14

Features Section 1-1

1-1 Features

1-1-1 Overview

The C200HW-MC402-E Motion Control (MC) Unit is a Special I/O Unit that

can perform

Unit’s multi-tasking BASIC motion control language provides an easy to use

tool for programming advanced motion control applications.

Three types of motion control are possible: point-to-point, continuous path

and electronic gearing.

advanced MC operations on up to four axes simultaneously. The

Point-to-point Control Point-to-point (PTP) control enables positioning independently for each axis.

Axis specific parameters and c ommands are us ed to determi ne the p aths for

the axes.

Continuous Path Control Continuous path (CP) control enables the user not only to control the start and

end positions, but also the path between those points. Possible multi-axis

paths are linear interpolation, circular interpola tion, helical interpolation. Also

user defined paths can be realized with the CAM control.

Electronic Gearing Electronic gearing (EG ) enables controlling an axis as a direct li nk to another

axis. The MC Units supports electronic gear boxing, linked moves and CAM

movements and adding all movements of one axis to another.

The MC Unit can be used in many applications. The following areas have

been identified as applicable areas for the MC Unit.

• Packaging

• Automotive welding

• Coil winding

• Web control

• Cut to length

• Drilling

• Electronic component assembly

• Glue laying

• Flying shears

• Laser guidance

• Milling

• Palletisation

• Tension control

There are many other types of machines that can be controlled by the MC

Unit.

2

Page 15

Features Section 1-1

1-1-2 Descr ip tio n of Feat ures

The MC Unit provides the following features.

Easy Programming with

BASIC Motion Control

Language

A multi-task BASIC motion control language is used to program the MC Unit.

A total of 14 program s can be held i n the Unit an d up to 5 ta sks can be r un

simultaneously. Programs can read a nd writ e to the PC mem ory areas us ing

simple commands from BAS IC or the IORD/IOWR instructions f rom the PC ’s

ladder program.

Windows-based

Programming Software

The MC Unit is programmed using a Windows-based application called

1

Motion Perfect. Motion Perfect allows extremely flexible programming and

debugging.

Virtual Axes The MC Unit contains a total of 8 axes, which consists of 4 servo axes and 4

virtual axes. The virtual axes acts as a perfect servo axes and are used for

computational pur poses for creating profiles. They can be linked directly to

the servo axes.

PC Data Exchange The coordination of the MC Unit with the CPU Unit is largely improved by

modifying the PC Data Exchange interface. The PC Data Exchange interface

now even more allows a centralized control from the PC. The MC Unit uses

the full functionality of the C200HX/HG/HE or CS1 PC. It is now capable of

both exchanging fast control bits via the IR/CIO area as exchanging large

position profile data directly to the MC Unit’s Table array.

Hardware-based

Registration Inputs

There is a high-speed registration input for each axis. On the rising or falling

edge of a registration input, the MC Unit will store the current position in a register. The registered position can then be used by the BASIC program as

required. The registered positions are captured in hardware.

General-purpose Input

and Output Signals

Starting, st opping, limit switching, origin sea rches and many other f unctions

can be controlled without the use of PC I/O. The time required to switch an

output or read an input is thus not dependant on the cycle time. The general

I/O are freely allocable to the different functions.

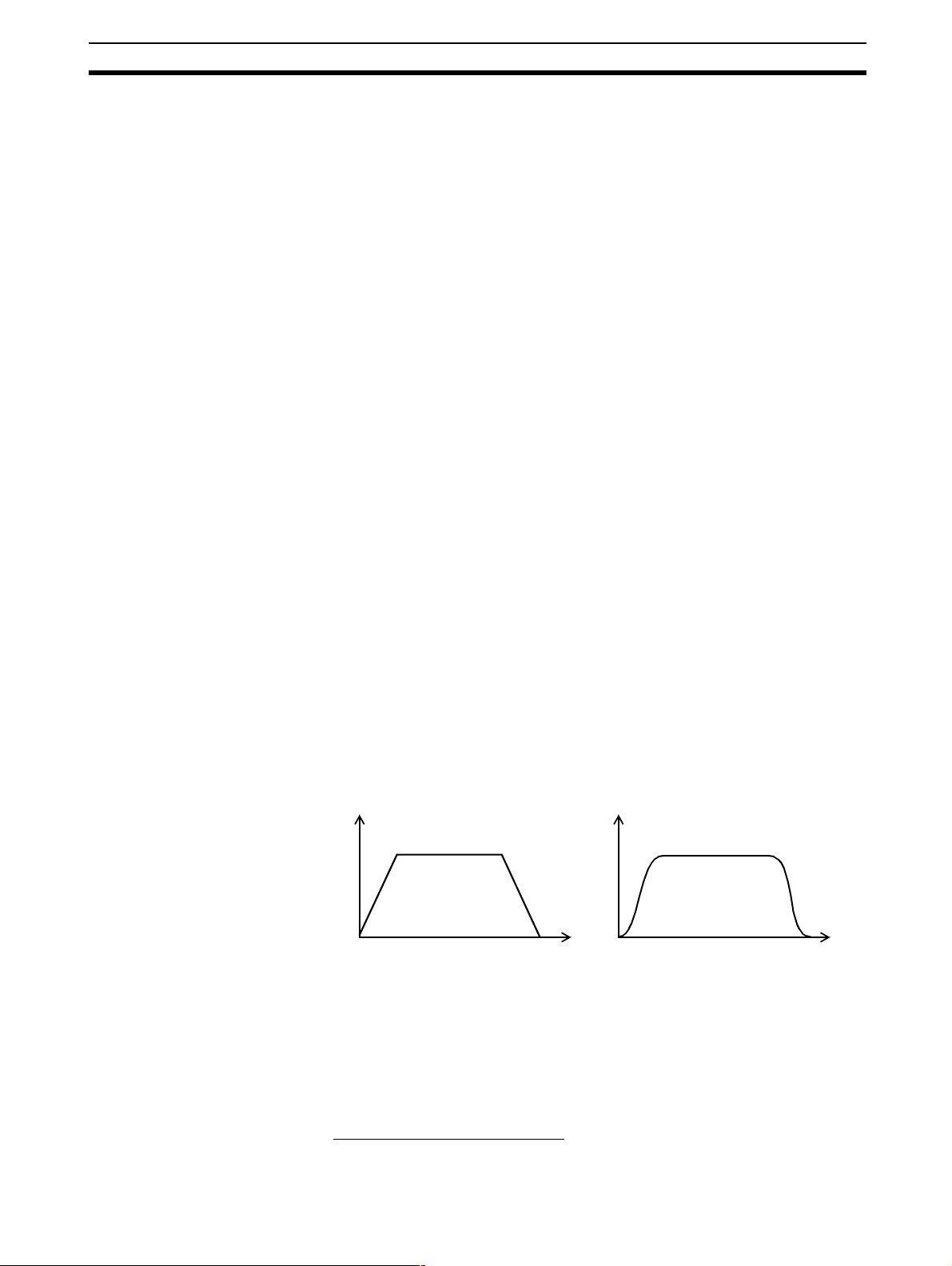

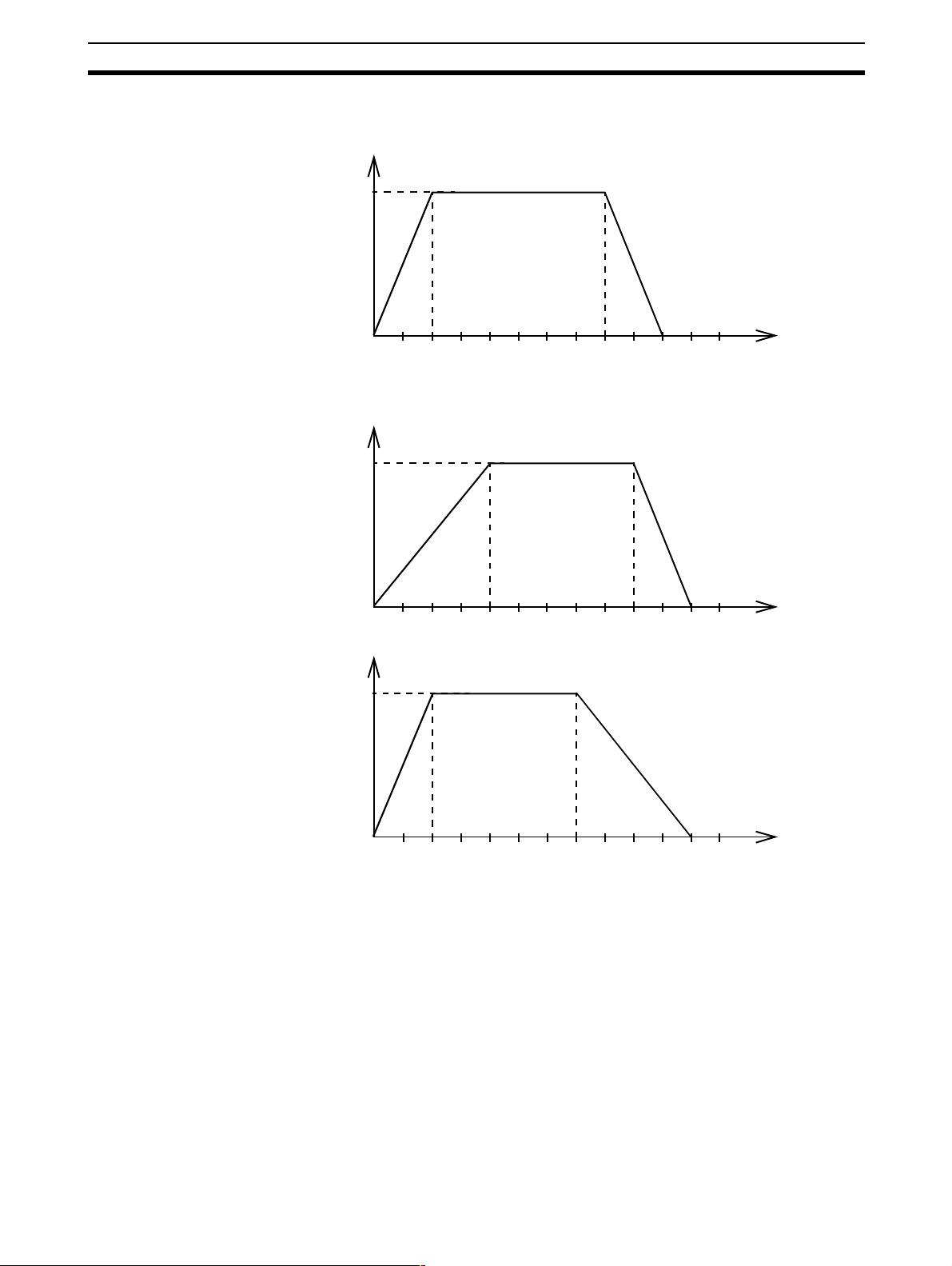

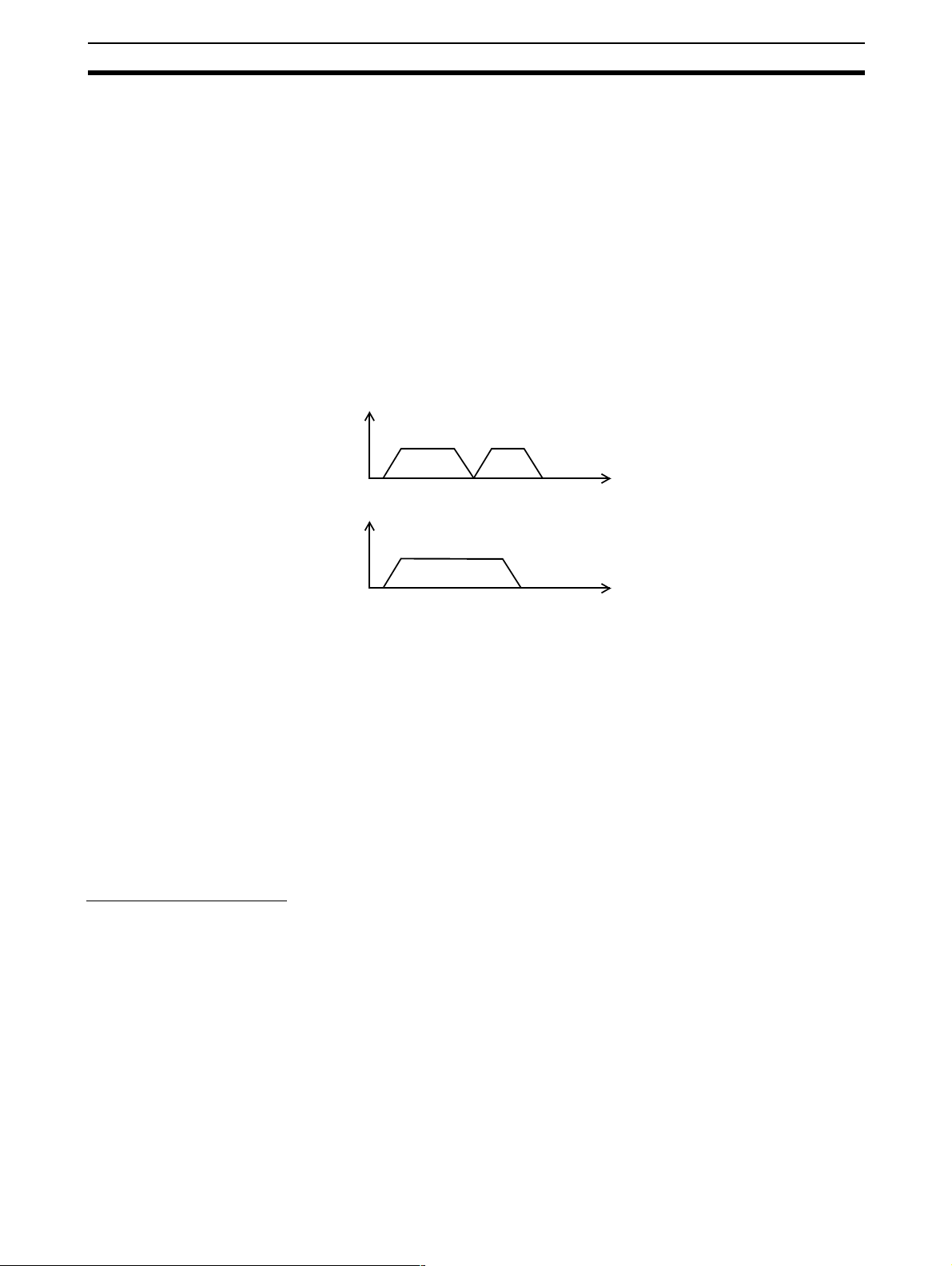

Reduced Machine Wear The traditional trapezoidal speed profile is provided to generate smooth star t-

ing and stopping. The trapezoidal corners can be rounded off to S-curves.

Trapezoidal Speed Profile

with Square Corners

Time

Trapezoidal S pee d Profil e

with S-curve Corners

SpeedSpeed

Time

1.Motion Perfect is a product of Trio Motion Technology Limited.

3

Page 16

System Configuration Section 1-2

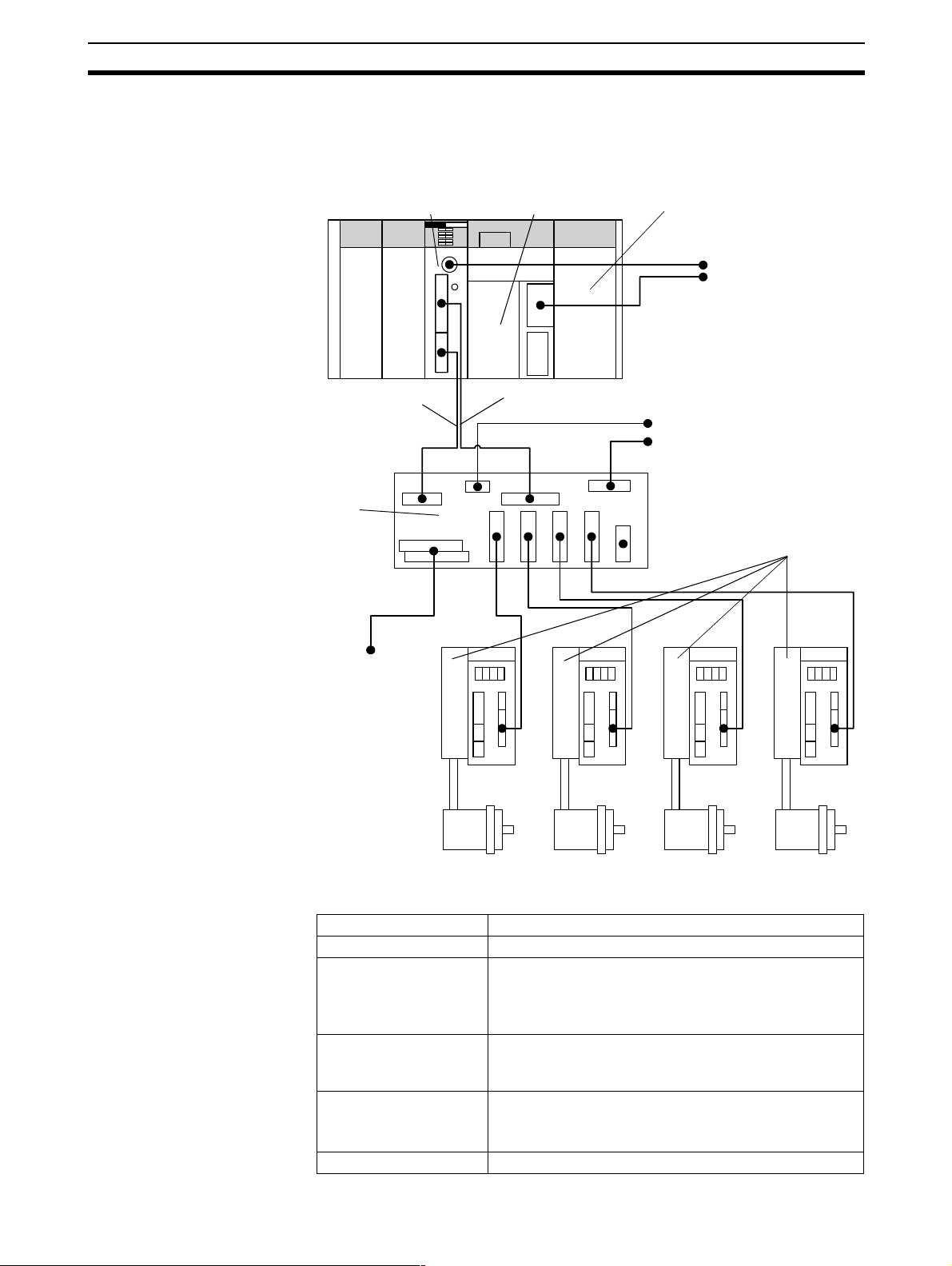

1-2 System Configuration

Basic System

Configuration

The basic system configuration of the MC Unit is shown below. The diagram

shows the basic physical components of a coordinated mot ion control application.

Power Supply Unit

Computer running

• Motion Perfect

• CX-Programmer

or Syswin

Power supply (24-V) for I/O

Power supply (5/24-V) for Axes

Servo Drivers

Termin al

Block

I/O Cable

MC Unit

CPU Unit

Axis Cable

General

Purpose

I/O

The equipment and models which can be used in the system configuration

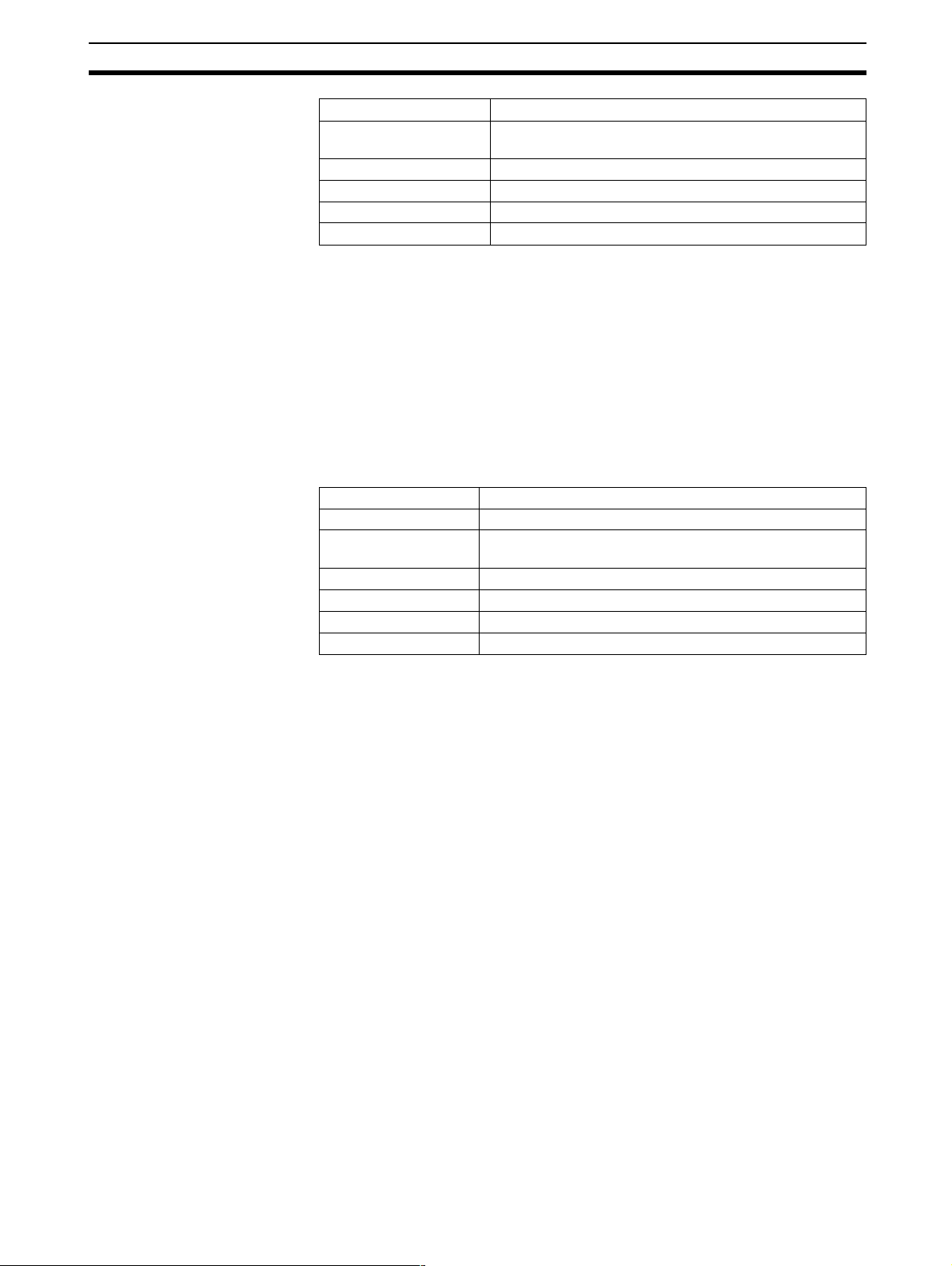

are shown in the following table.

Device Model

Motion Control Unit C200HW-MC402-E

CPU Unit Possible models:

C200HX/HG/HE

C200HS

CS1H/CS1G

Power Supply Unit Possib le models:

C200HW-PA204

C200HW-PA204S

CPU Backplane Possible models:

C200HW-BC031/BC051/BC81/BC101

CS1W-BC023/BC033/BC053/BC083/BC103

Terminal Block R88A-TC04-E

4

Page 17

Motion Control Concepts Section 1-3

Device Model

Personal Computer (for

Motion Perfect)

Motion Perfect Version 2.0 or later

Servo Driver R88D-UA, -UT, -W series

Servomotor R88M-UA, -UT, -W series

Inverter 3G3FV in Flux Vector Control

Note 1. The MC Unit cannot be mounted to a C200H PC.

2. The C200HS CPU Units do not support the IORD/IOWR instructions. The

MC Unit can only communicate with a C200HS CPU Unit using the

PLC_READ and PLC_WRITE commands.

3. The MC Unit cannot be mounted to a SYSMAC BUS Slave Rack.

4. The MC Unit can be mounted next to the CPU Unit on the CPU Rack, but

care must be taken to first deter mine the mounting locations of certain

Communications Unit and other Units that require bus connections to the

CPU Unit.

IBM Pers onal Computer or 100% compatible

Cables to be supplied by

the user

The following standard cables are available. A cable can also be prepared by

the user.

Item Model

R88A-CMX001S-E I/O Connection Cabl e fro m MC Unit to Terminal Block (1m)

R88A-CMX001J1-E Axis Connection Cable fr om MC Unit to Terminal Block

(1m)

R88A-CMU001J2-E Connection from Ter minal Block to UA Servo Driver (1m)

R88A-CMUK001J3-E Connection from Terminal Block to UT Servo Driver (1m)

R88A-CMUK001J3-E2 Connection from Terminal Block to UT/W Servo Driver (1m)

R88A-CCM002P4-E Connection Cable RS-232C from MC Unit to computer (2m)

1-3 Motion Control Concepts

The MC Unit offers the following types positioning control operations.

1. Point-to-point control

2. Continuous Path control

3. Electronic Gearing

This section will introduce some of the commands and parameters as use d in

the BASIC programming of the motion control application. Refer to

SECTION 5 BASIC Motion Control Pro g ramming Language for details.

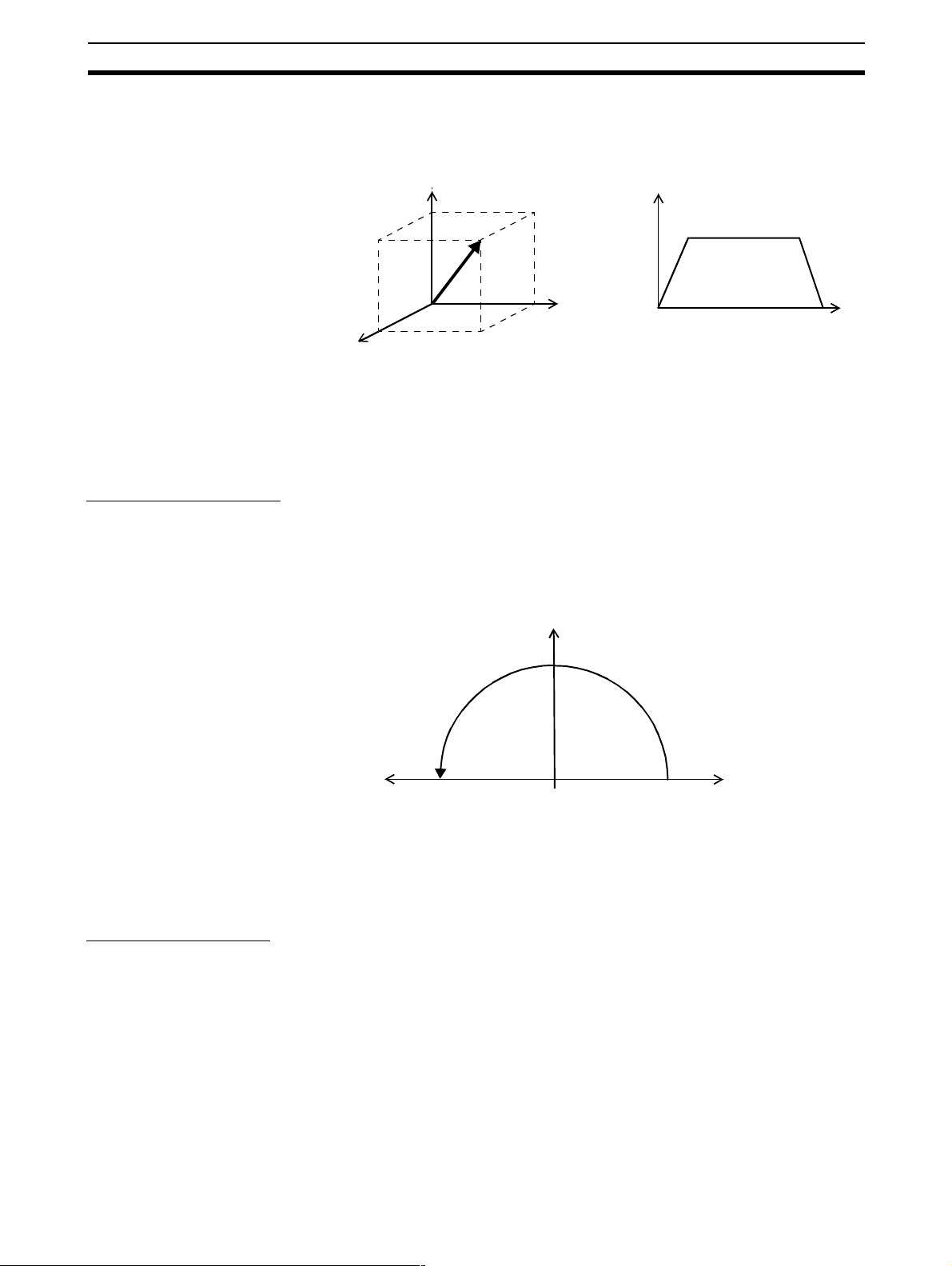

Coordinate System Positioning operations performed by the MC Unit are based on an axis coordi-

nate system. The MC Unit conver ts the encoder edges and pulses from t he

encoder into an internal absolute coordinate system.

The engineering unit which specifies the distanc es of travelling can be freely

defined for each axis separately. The conversion is performed through the

use of the unit conversion factor, which is defined by the UNITS axis parameter. The origin point of the coordinate system can be deter mined using the

DEFPOS command. This com mand re-defines th e current position to zero or

any other value.

A move is defined in either absolute or relative terms. An absolute move takes

the axis to a specific predefined position with respect to the origin point. A relative move takes the axis from the current position to a position that is defined

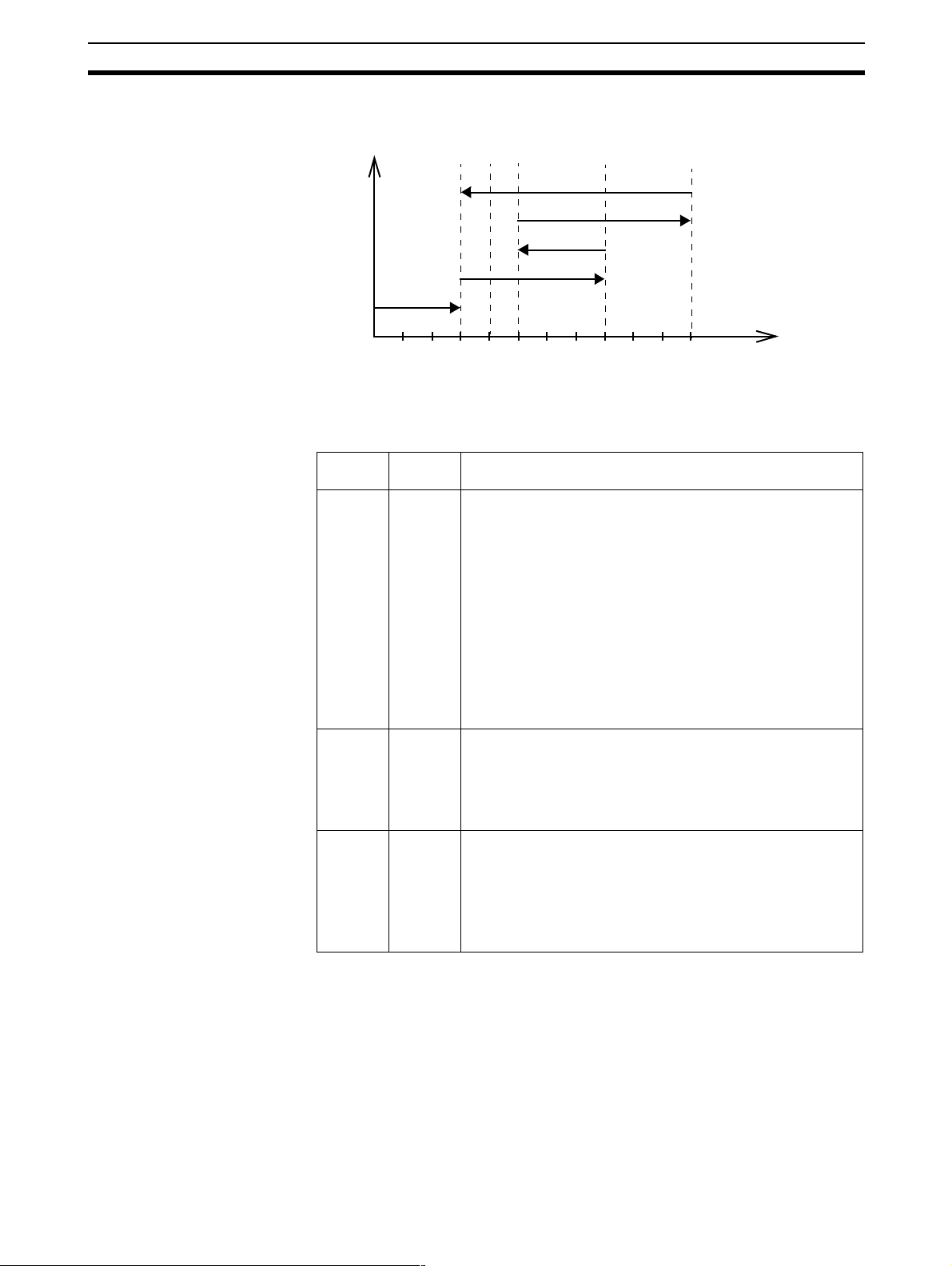

relative to this current position. The following diagram shows gives an exam-

5

Page 18

Motion Control Concepts Section 1-3

ple of relative (command MOVE) and absolute (command M OVEABS) linear

moves.

MOVEABS(30)

MOVE(60)

MOVEABS(50)

MOVE(50)

MOVE(30)

0

50 100

Axis position

Axis Types The MC Unit has 8 axes in tota l, which can be used for different motion con-

trol purposes depending on the application. Th e type of each axis is determined by the ATYPE axis parameter. The following table lists the different

available axis types.

Axis

type

ATYPE

value

Description

Virtual 0 A virtual axis is used for computational purposes to cre-

ate a move profile without physical movement on any

actual Servo Driver. All move commands and axis

parameters available for the servo axis are also available for the virtual axis and the v ir t ual axis behaves like

a perfect servo axis (demanded po sition is eq ual to the

actual position).

Possible application for the virtual axis is having a virtual move profile added to a servo axis or to test a

developed application before controlling the actual

motors.

Axis range: [0, 7]

Servo 2 The servo axis controls the connected Servo Driver.

Based on the calculated movement profile and the

measured position feedback of the Servomotor the

proper speed reference is outputted to the Servo Driver.

Axis range: [0, 3]

Encoder 3 The encoder axis defines an axis which provides an

encoder input without the servo control speed reference

output to the system. An encode r can be c onnected for

measurement, registration and/or synchron ization functions.

Axis range: [0, 3]

Refer to 1-4 Control System for details on the servo system and encoder

feedback signals. Axes 0 to 3 are servo axes by default and axes 4 to 7 are

fixed as virtual axes.

6

Page 19

Motion Control Concepts Section 1-3

1-3-1 PTP-control

In point-to-point positioning, each axi s is moved independently of the other

axis. The MC Unit supports the following operations.

• Relative move

• Absolute mo ve

• Continuous move forward

• Continuous move reverse

Relative and Absolute Moves

To m ove a single axis either the command MOVE for a relative move or the

command MOVEABS for an absolute move is used. Each axis has its own

move characteristics, which are defined by the axis parameters.

Suppose a control program is executed to move from the origin to an axis

no. 0 coordinate of 100 and axis no. 1 coordinate of 50. If the speed parameter is set to be the s ame for both axes and the acceleration and dec eleration

rate are set sufficiently high, the m ovements for axis 0 and axis 1 will be as

illustrated below.

Axis 1

50

MOVEABS(100) AXI S(0)

MOVEABS(50) AXIS(1)

0

50

100

Axis 0

At start, both the axis 0 and axis 1 will move to a coordinate of 50 over the

same duration of time. At this point, axis 1 will stop and the axis 0 will continue to move to a coordinate of 100.

Relevant Axis Parameters As mentioned before the move of a certain axis is determined by the axis

parameters. Some relevant parameters are given in the next table.

Parameter Description

UNITS Unit conver sion factor

ACCEL Acceleration rate of an axis in units/s

DECEL Deceleration rate of an axis in units/s

SPEED Demand speed of an axis in units/s.

2

.

2

.

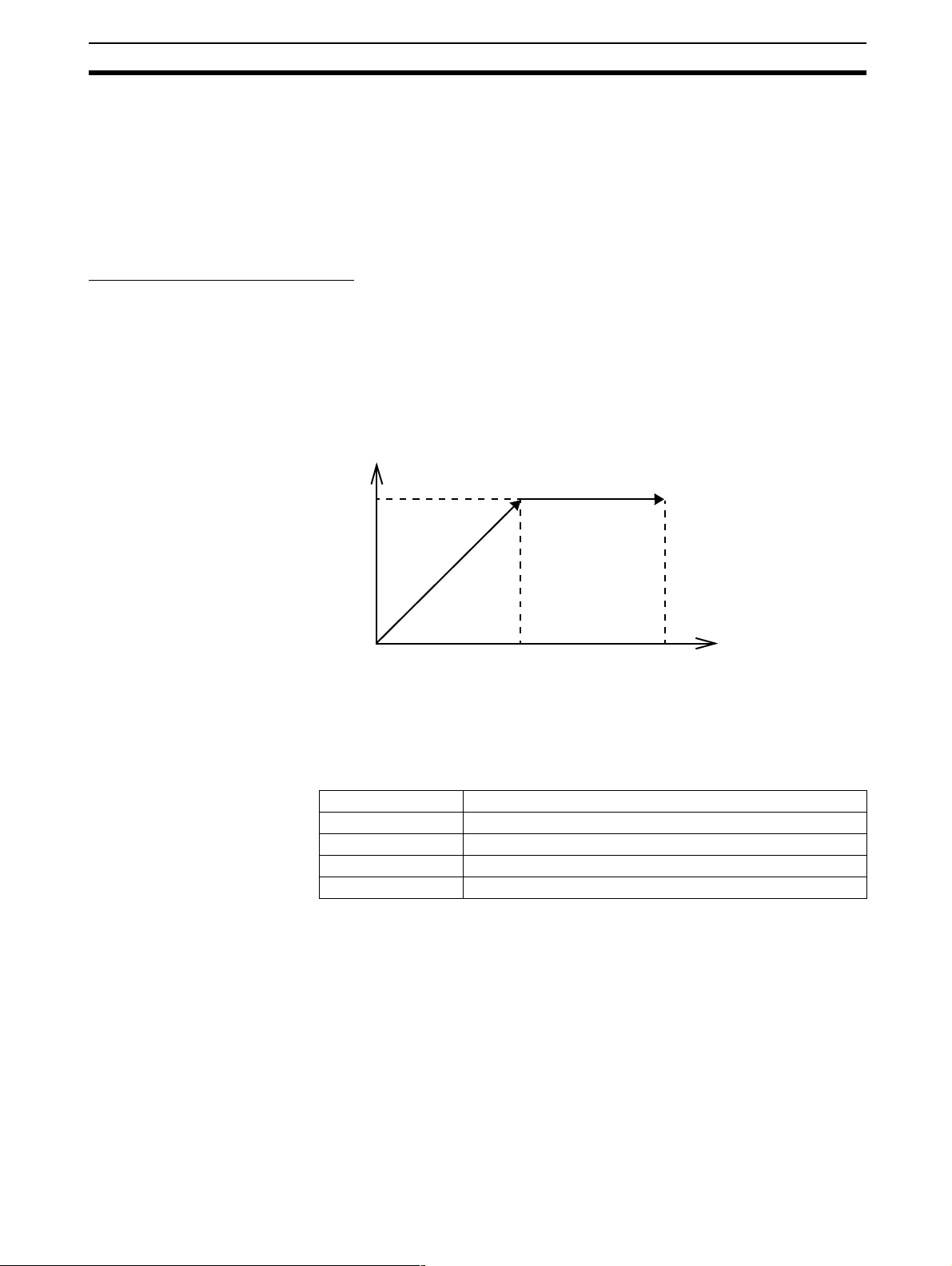

Defining moves The speed profile below shows a simple MOVE operation. The UNITS param-

eter for this axis has been defined for example as meters. The required m aximum speed has been set to 10 m/s. In order to reach this speed in one

second and also to decelerate to zero speed again in one second, both the

acceleration as the deceleration rate have been set to 10 m/s

2

. The total distance travelled is the sum of distances travelled during the acceleration, constant speed and deceleration segm ents. Suppose the distanc e moved by the

7

Page 20

Motion Control Concepts Section 1-3

MOVE command is 40 m, the speed profile will be given by the following

graph.

Speed

ACCEL=10

10

DECEL=10

SPEED=10

MOVE(40)

0

12345

6

Time

The following two speed profiles show the same movement with an acceleration time respectively a deceleration time of 2 seconds.

Speed

ACCEL=5

6

DECEL=10

SPEED=10

MOVE(40)

Time

ACCEL=10

DECEL=5

SPEED=10

MOVE(40)

10

Speed

10

0

12345

0

12345

6

Time

8

Page 21

Motion Control Concepts Section 1-3

D

Vad

Move Calculations The following equations a re used to calculate the total time for the motion of

the axes. Consider the moved distance for the MOVE command as , the

demand speed as , the acceleration rate and deceleration rate .

Acceleration time

V

---=

a

2

Acceleration dist a nc e

V

------=

2a

Deceleratio n time

V

---=

d

2

Deceleration distance

V

------=

2d

Continuous Moves

1-3-2 CP-control

Constant speed distance

V2ad+()

D=

-----------------------–

2ad

D

Total time

The FORWARD and REVERSE commands can be used to start a continuous

movement with constant speed on a cert ain axis. The FORWARD command

will move the axis in positive direction and the REVERSE comman d in negative direction. For these commands also the axis parameters ACCEL and

SPEED apply to specify the acceleration rate and demand speed.

Both movements can be canceled by using either the CANCEL or RAPIDSTOP command. The CANCEL command will cancel the m ove for one axis

and RAPIDSTOP will cancel moves on all axes.

Continuous Path control enables to control a specif ied p ath bet ween t he st art

and end position of a movement for one or multiple axes. The MC Unit supports the following operations.

• Linear interpolation

• Circular interpolation

• Helical interpolation

• CAM control

Va d+()

--- -=

---------------------+

V

2ad

Linear Interpolation

In applications it can be required for a set of motors to perform a move operation from one position to another in a straight line. Linearly interpolated moves

can take place among several axes. The commands MOVE and MOVEABS

are also used for the linear interpolati o n. I n t his c a s e the comma nds will h ave

9

Page 22

Motion Control Concepts Section 1-3

multiple arguments to specify the relative or absolute move for each axis.

Consider the following three axis move in a 3-dimensional plane.

MOVE(50,50,50)

Axis 2

Axis 1

Axis 0

Speed

Time

The speed profile of the motion along the pa th is given in the diagram. T he

three para meters SPEED, AC CEL a n d DECEL w h ich determine the multi axis

movement are taken from the corresponding parameters of the base axis.

The MOVE command computes the various component s of speed demand

per axis.

Circular Interpolation

It may be required that a tool travels from the starting point to the end point in

an arc of a circle. In this instance the motion of two axes is related via a circular interpolated move using the MOVECIRC command. Consider the following

diagram.

Helical Interpolation

MOVECIRC(-100,0,-50,0,0)

-50

Axis 1

0

50

50

Axis 0

The centre point and desired end po int of the trajectory relative to the start

point and the direction of movement are specified. The MOVECIRC command

computes the radius and the angle of rotation. Like the linearly inter polated

MOVE command, the ACCEL, DECEL and SPEED variables associated with

the base axis determine the speed profile along the circular move.

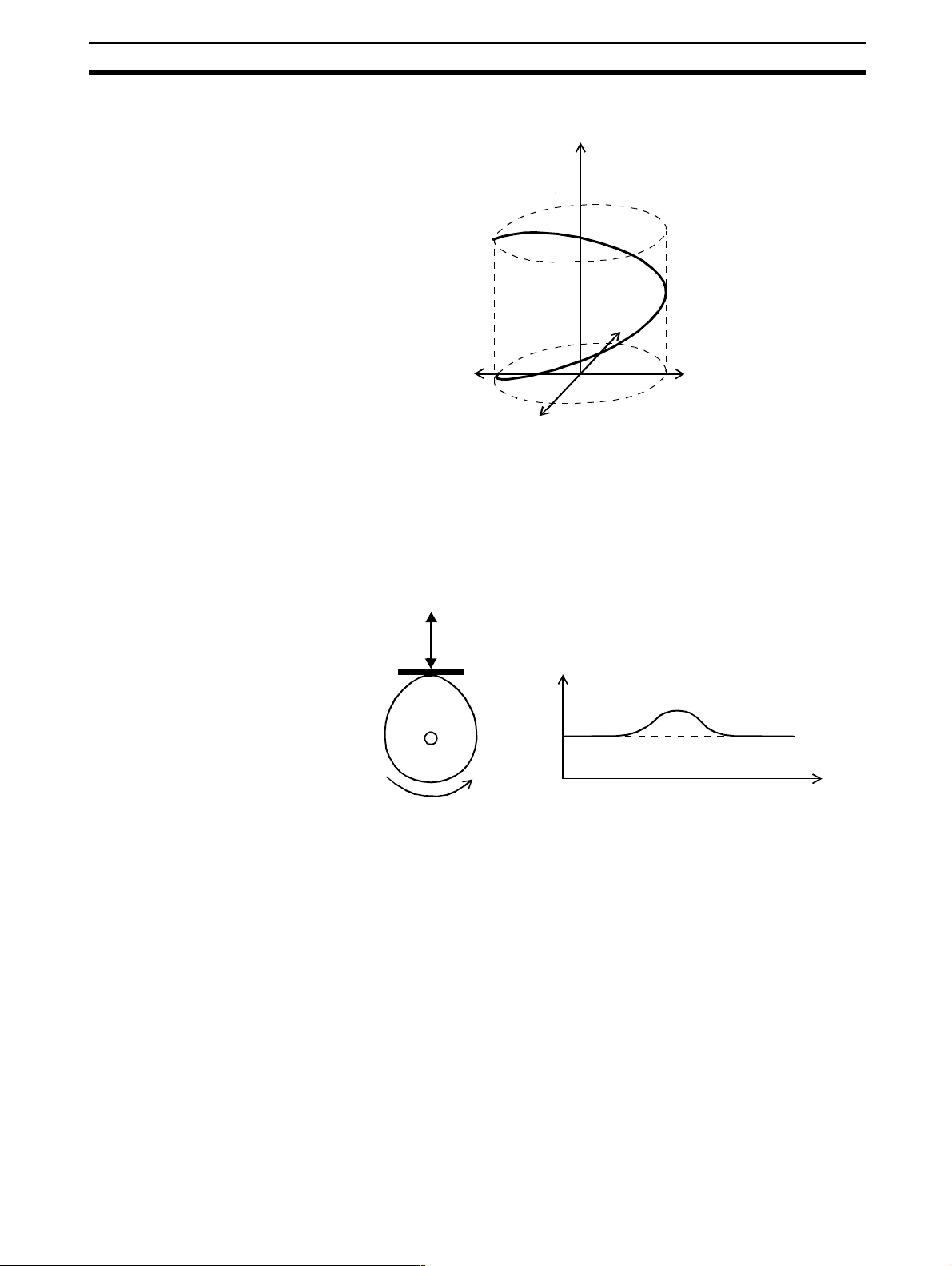

Helical interpolation performs a helical movement on three axes. The motion

control c ommand MHELICA L will perform a circular interpo lation to two axis

and will add a linear move to the third axis. Positioning is performed by again

specifying the centre point, end point and direction for the circular distance

10

Page 23

Motion Control Concepts Section 1-3

and the distance for the third axis. The diagram shows helical interpolation in

a three dimensional plane for axes 0 to 2.

MHELICAL(0,0,0,50,0,150)

Axis 0

Axis 2

Axis 1

CAM Control

Additional to the standard move profiles the MC Unit also provides a way to

define a position profile for the axis to move. The CAM command will move an

axis according to position values stored in the MC Unit Table array. The

speed of travelling through the profile is determ ined by the axis pa rameter s of

the axis.

1-3-3 EG-Control

CAM(0,99,100,20)

Position

Time

Electronic Gearing control allows you to create a direct gearbox link or a

linked move between two axes. The MC Unit supports the following operations.

1. Electronic gearbox

2. Linked CAM

3. Linked move

4. Adding axes

11

Page 24

Motion Control Concepts Section 1-3

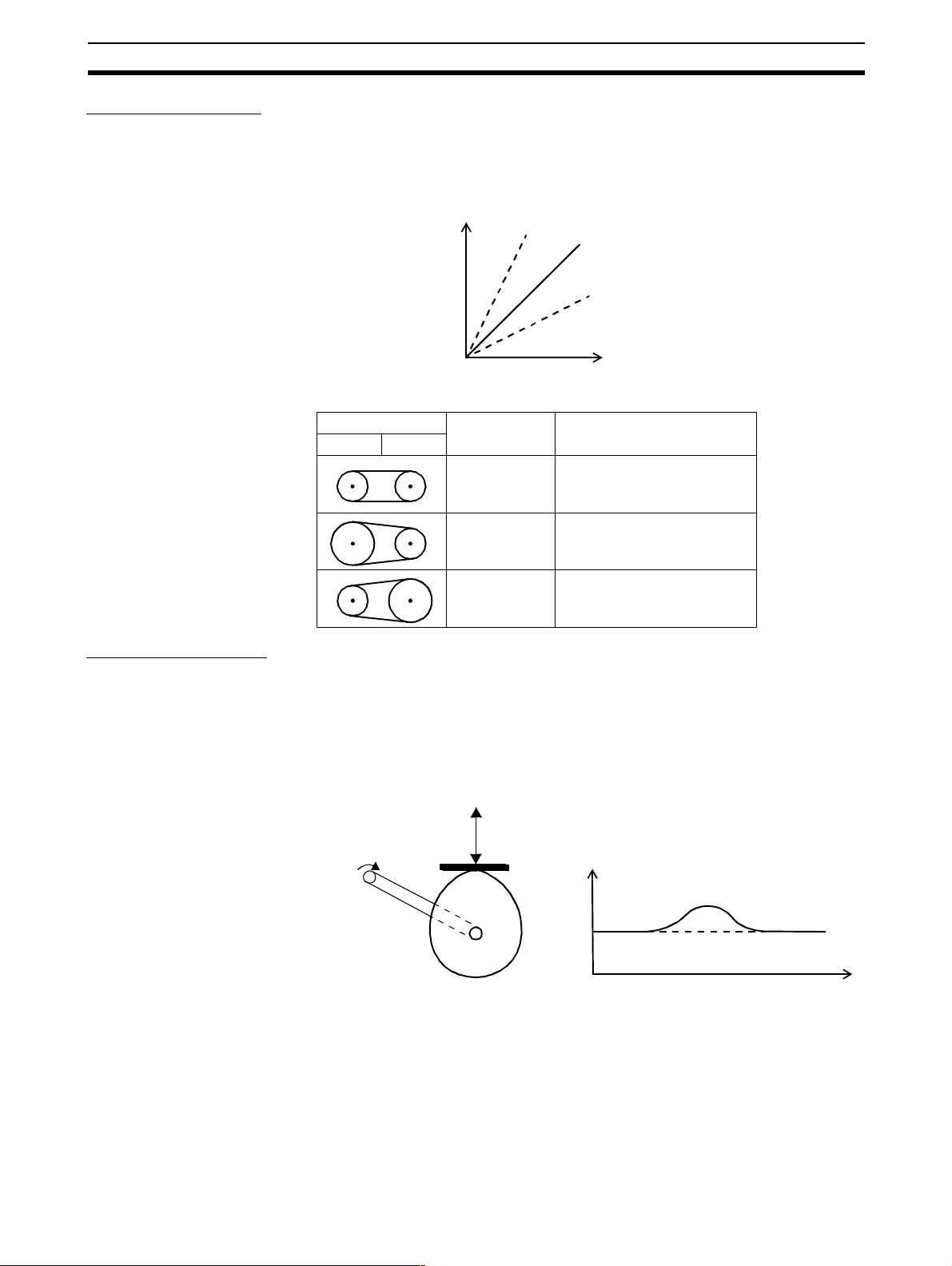

Electronic Gearbox

The MC Unit is able to have a gearbox link from one axis to another as if there

is a physical gearbox connecting them. This can be done using the CONNECT command in the program. In the command the ratio and the axis to link

to are specified.

CONNECT Axis

2:1

Axes Ratio CONNECT command

01

1:1 CONNECT(1,0) AXIS(1)

2:1 CONNECT(2,0) AXIS(1)

1:1

1:2

Master Axis

Linked CAM control

1:2 CONNECT(0.5,0) AXIS(1)

Next to the standard CAM profiling tool the MC Unit also provides a tool to link

the CAM profile to another axis. The command to create the link is called

CAMBOX. The travelling speed through the profile is not deter mined by the

axis parameters of the a xis but by the position of t he linked axis. This is like

connecting two axes through a cam.

CAMBOX(0,99,100,20,0) AXI S(1)

CAMBOX Axis (1) Position

Master Axis (0) Position

12

Page 25

Motion Control Concepts Section 1-3

Linked Move

The MOVELINK command provides a way to link a specified move to a master axis. The move is divided into an acceleration, dece leration and constant

speed part and they are specified in master link distances. This can be particularly useful for synchronizing two axes for a fixed period.

MOVELINK(50,60,10,10,0) AXIS(1)

Speed

Master Ax is (0)

Synchronized

MOVELINK Axis (1)

Time

Adding Axes

It is very useful to be able to add all movements of one axis to another. One

possible application is for instance changing the offset between two axes

linked by an electronic gearbox. The MC Unit provides this possibility by using

the ADDAX command. The movements of the linked axis will cons ists of all

movements of the actual axis plus the additional movements of the master

axis.

Speed axis 0*

BASE(0)

ADDAX(2)

FORWARD

MOVE(100) AXIS(2)

MOVE(-60) AXIS(2)

Speed axis 2

Time

+

Speed axis 0

Time

=

Time

1-3-4 Other Operations

Canceling Moves In normal operation or in case of emergency it can be necessary to cancel the

current movement from the buffers. When the CANCEL or RAP IDSTOP commands are g iven, the selected axis respe ctively all axes will canc el thei r current move.

Origin Search The encoder feedback for controlling the position of the motor is incremental.

This means that all movement must be defined with respect to an origin point.

The DATUM command is used to set up a procedure whereby the MC Unit

13

Page 26

Control System Section 1-4

goes through a sequence and searches for the origin based on digital inputs

and/or Z-marker from the encoder signal.

Print Registration The MC Unit can capture t he position of an axis in a regi ster when an event

occurs. The event is referred to as the print registration input. On the risin g or

falling edge of an input signal, which is either the Z-marker or an input, the MC

Unit captures the position of an axis in hardware. This position can then be

used to correct possible error between the actual position and the desired

position. The print registration is set up by using the REGIST command.

The position is captured in hardware, and therefore there is no software overhead and no interrupt service routines, eliminating the nee d to deal with the

associated timing issues. Each servo axis has one registration input.

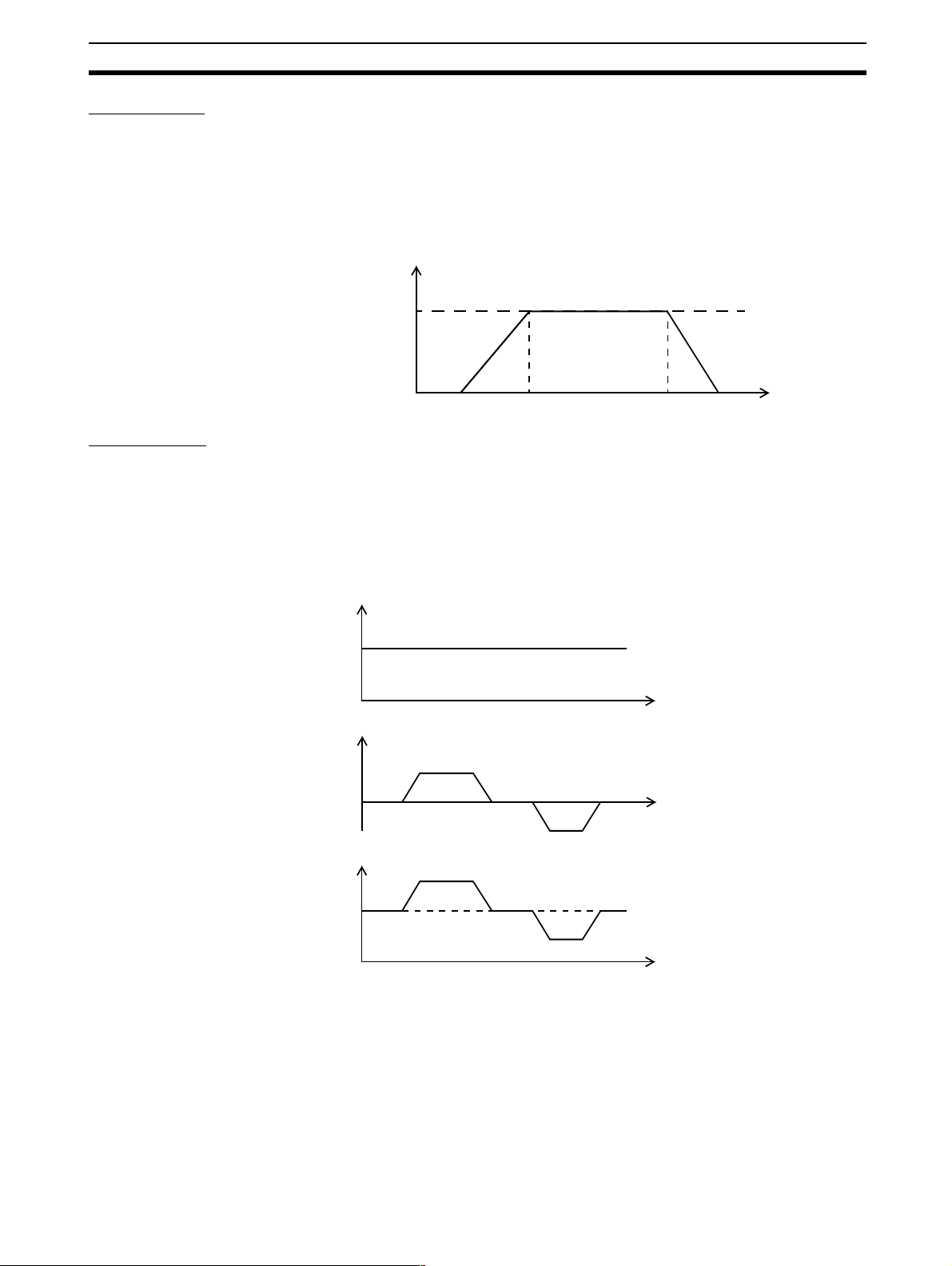

Merging Move s If the MERGE axis parameter is set to 1, a movement will always be followed

by a subsequent movement without stopping. The following illustrations will

show the transitions of two moves with MERGE value 0 and value 1.

Speed

MERGE=0

Time

Speed

MERGE=1

Time

Jogging Jogging moves the axes at a constant speed forward or reverse by manual

operation of the digital in puts. Different speeds are also selectable by input.

Refer to the FWD_JOG, REV_JOG and FAST_JOG axis parameters.

1-4 Control System

1-4-1 Feedback Pulses

The MC Unit is designed to comply with the standard O MRON Servomotors

which have an incremental encoder output. In this section, the signals produced by an incremental optical quadrature encoder are discussed. Incremental encoders are available in linear as well as the more common rot ary

types.

Incremental Encoders

The incremental encoder are e ncoders for which the output pos ition information is relative to a starting position and only the distance moved is measured.

The main components of the rotary incremental encoder are an encoder disk,

light source and photodete ctors, plus an amplification circuitry to “square-up”

the photodetector output. The encoder disk is im printed with marks or slots

evenly spaced around its perimeter. As the disk rotates, light strikes the photodetector at the passing of each slot or mark. Amplifiers then convert the

photodetector output to square wave form.

Quadrature signals are produced by using two photodetectors, one positioned

precisely one half a slot, or marker width, from the other. So quadrature refers

to two periodic functions separated b y a quarter cycle or 90 .

With this arrangement, the direction of rotation can be easily detected by

monitoring the relative phase of bo th signals. For example, if channel A leads

channel B, then counterclockwise (CCW) movement could be indicat ed. Con-

°

14

Page 27

Control Sy st em Section 1-4

versely, if channel B leads channel A, then clockwise (CW) movement would

be indicated.

Ty pically, rotary encoders also provide an additional Z-mar ker or slot on the

disk used to produce a reference pulse. By properly decoding and counting

these signals, the direction of motion, speed, and relative position of the

encoder can be determined.

The number of output pu lses produced per revolution per channel is equivalent to the number of marks around the disk. This position information is

decoded in encoder edges, which is actually the number of pulses multiplied

by four. The resolution is multiplied because the circuit generates a pulse at

any rising or falling edge of either of the two phase signals.

Decoding

Understanding how the signals generated by a quadrature encoder are

decoded will help considerably when applying the quadrature decoder feature

in an actual situation.

The basic task of the decoder is to provide two counter input lines: one that

produces clock pulses when CCW motion is detected and another that produces clock pulses when CW motion is detected. These clock pulses are supplied to counters in the MC Unit, one for CW counts and one for CCW counts.

The contents of the counters can be compared w ith each ot her by software,

and the relative position of the rotary device can be determined f rom the difference.

One advantage of this approach is that the actual counting is done by hardware devices, freeing the MC Unit for other operations. The MC Unit has only

to periodically read the counter values and to make a quick subtraction.

Decoder Th eory of

Operation

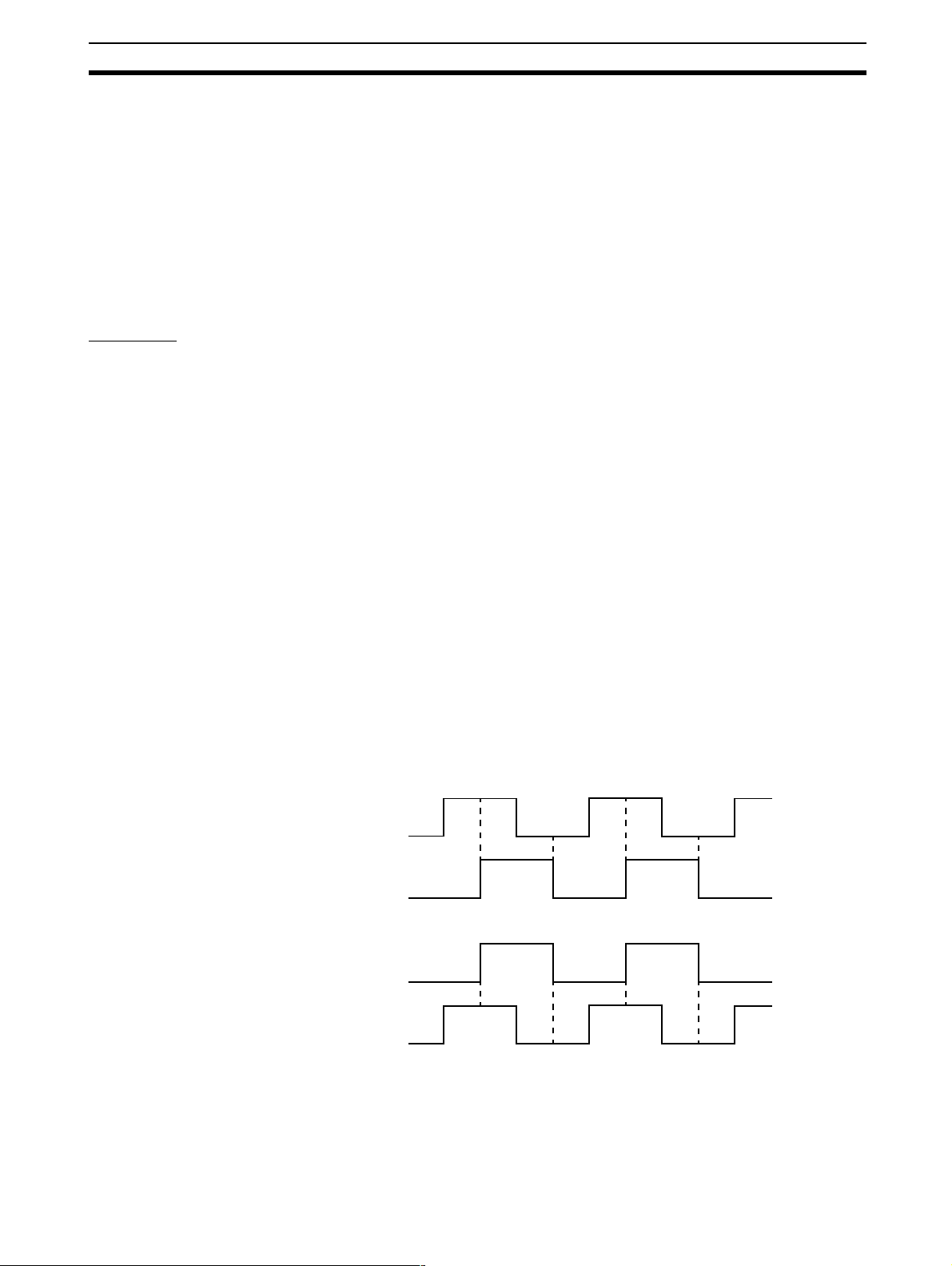

Forward Rotati on

Re vers e Rotat ion

A closer look at the quadrature signals will be helpful. In this example, the

direction of rotation is CCW if phase A leads ph ase B, and CW if phase A

leads phase B.

The decoder circuit detects a transition and generates a pulse on the appropriate counter input channel depending on wheth er the transition is in the CW

or CCW direction. Although time is plotted on the horizontal axis, it is not necessarily linear. The mechanical device may be changing speed as well as

direction.

Phase A

Phase B

Phase A

Phase B

Standard OMRON Servomotors are designed for an advanced A-phase for

forward rotation and an advanced B-phase for reverse rotation. The MC Unit

is designed to comply with this phase advancement, allowing OMRON Ser vo

Driver Connecting Cables to be used without modification.

15

Page 28

Control System Section 1-4

For typical OMRON Servo Drivers, there are 1,000 pulses per revolution. This

implies that there are 4,000 edges per revolution. So there will b e a Z pu lse

every 4,000 edges.

The signals A, B and Z appear physically as A and /A, B and /B and Z and /Z.

These appear as differential signals on twisted-pair wire inputs, ensuring that

common modes are rejected and that the noise level is kept to a minimum.

When using Servomotors by other makers, check carefully the encoder specification for phase advancement. If the definition differs from the ones given

above, reverse the B-phase wiring between the MC Unit and the Servo Driver.

In most case, this should resolve the problem.

1-4-2 Servo System Principles

The servo system used by and the internal operation of the MC Unit are

briefly described be low. Refer to 2-4 Servo System Precautions for precautions related to servo system operation.

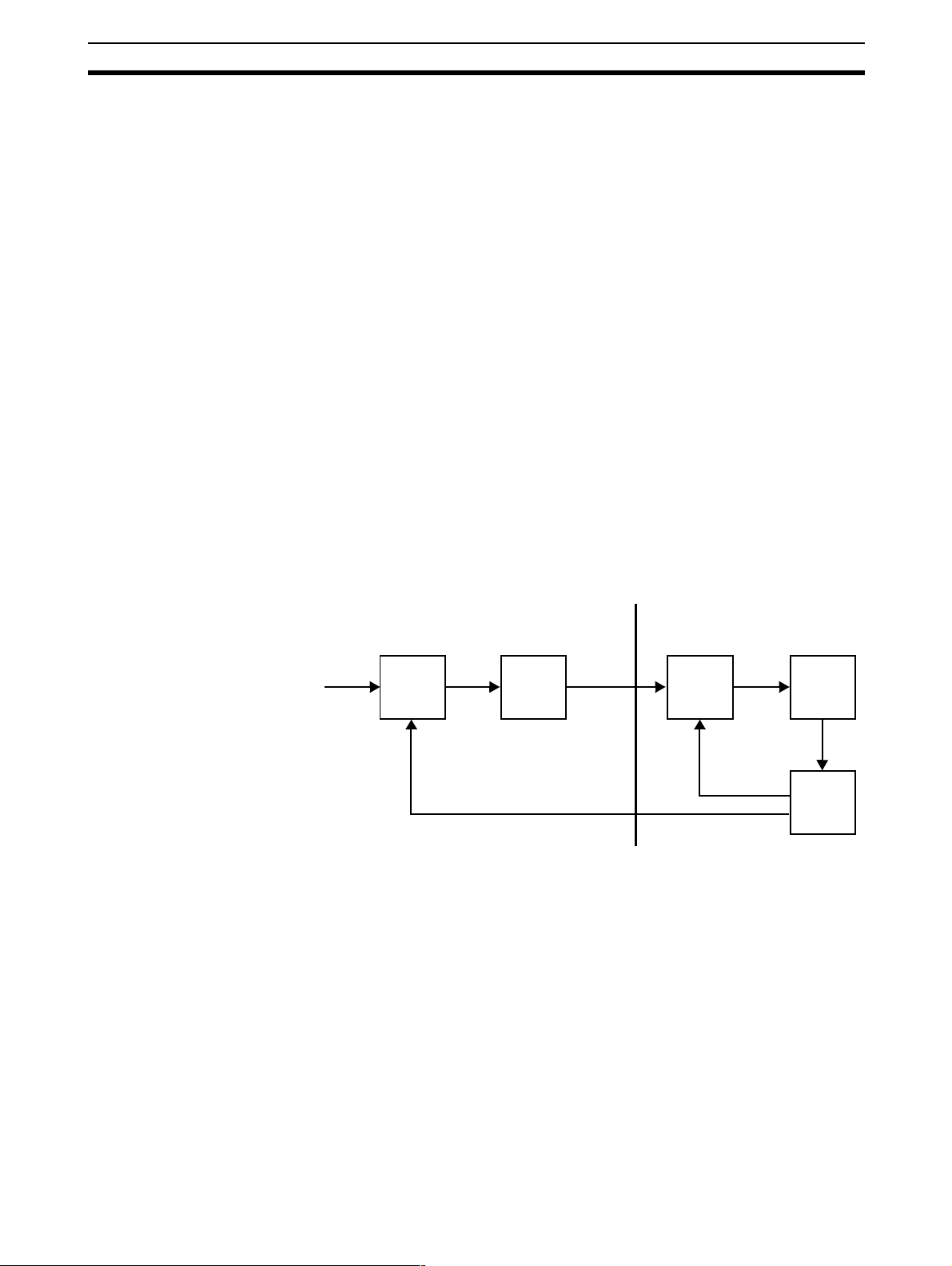

Inferred Closed Loop

System or Semi-closed

Loop System

Internal Operation of the

MC Unit

1,2,3... 1. The MC Unit performs actual position control. It receives encoder pulses

The servo system of the MC Unit uses an inferred closed loop system. This

system detects actual machine movements by the rotation of the motor in

relation to a target value. It calculates the error between the target value and

actual movement, and reduces the error through feedback.

Inferred closed loop systems occupy the mainstream i n modern servo systems applied to positioning devices for industrial applications. Commands to

the MC Unit, speed control voltages to the Servo Drivers, and feedback signals from the encoder are described in the next few pages.

Desired

position

MC Unit

12 3

Error

counter

D/A

Converter

Speed

reference

voltage

Servo System

Speed

Control

Motor

4

Speed

feedback

Encoder

Position

feedback

and calculates the required speed reference from the di fference between

the actual position and the desired position.

2. The calculated desired spee d is directly converted by the D/A converter

into an analogue sp eed reference voltage, which is provided to the Servo

Driver.

3. The Servo Driver controls the rotational speed of the Ser vomotor corresponding to the speed reference input.

4. The rotary encod er will generate the feedback pulses for both the spe ed

feedback within the Servo Driver speed loop and the position feedback

within the MC Unit position loop.

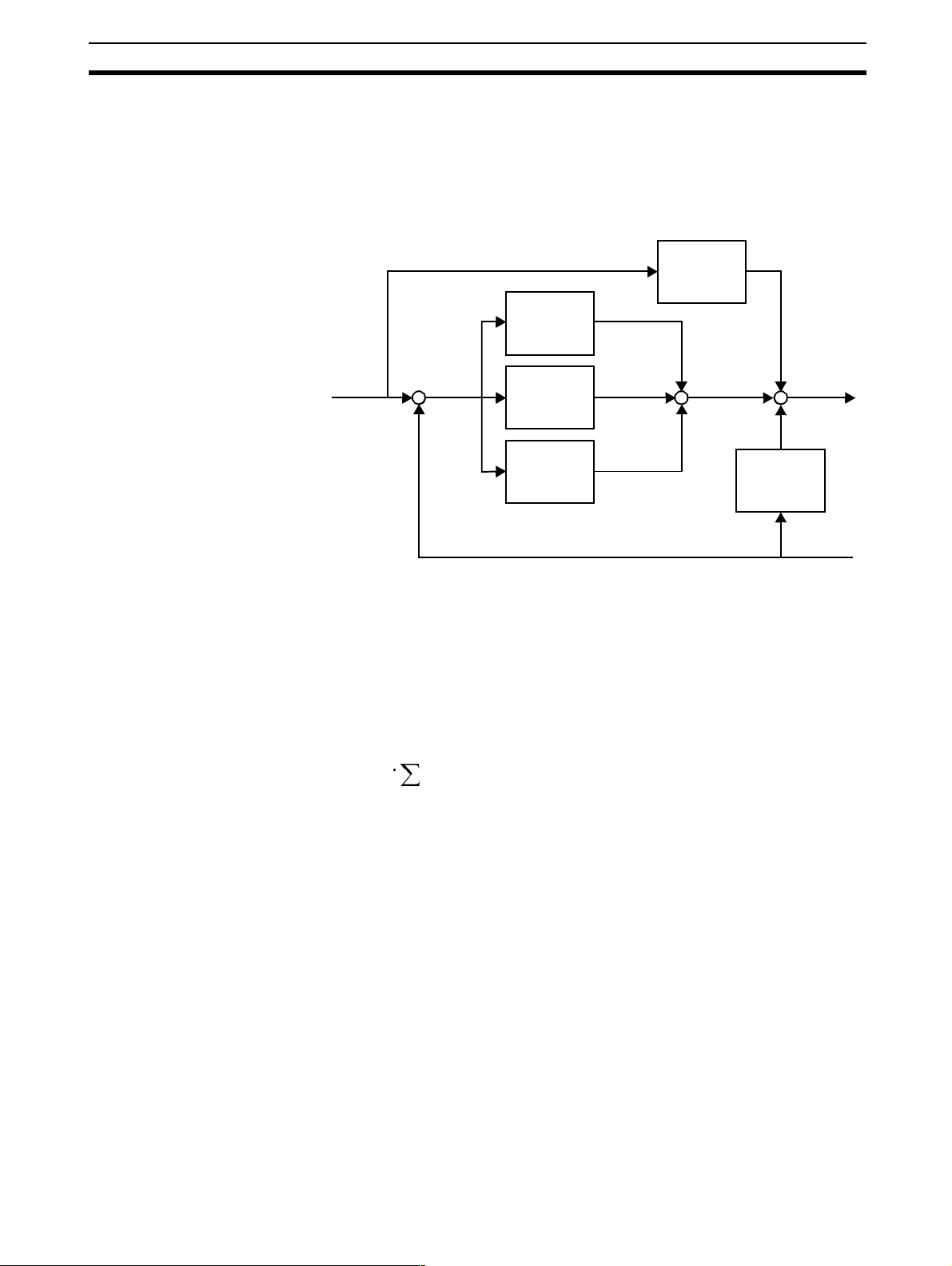

Motion Control Algorithm The servo system controls the motor by continuously adjusting the voltage

output that serves as a spee d reference to the Ser vo Dr iver. The speed reference is calculated by com paring the measured position of the axis from the

encoder with the demand position generated by the MC Unit.

16

Page 29

Control Sy st em Section 1-4

The axis parameters MPOS, DPOS and FE contain the value of respectively

the measured position, demand position and the following error. The following

error is the difference between the demanded and measured position. MC

Unit uses five gain values to control how the servo function generates the voltage output from the following error.

The control algorithm for the motion con trol system of the MC Unit is sho wn in

the diagram below. The five gains are described below.

K

∆

vff

K

p

K

ov

Output

signal

∆

Measured

position

Demand

position

Proportional Gain The proportional gain creates an output that is proportional to the

foll owing er ror .

O

All practical systems use proportional gain. For many just using this gain

parameter alone is sufficient. The proportional gain axis parameter is called

P_GAIN.

Integral Gain The integral gain creates an output t hat is propor tional to the sum of

the following errors that have occurred during the system operation.

O

Integral gain can cause overshoot and so is usually used only on systems

working at constant speed o r with slow accelerations. The integral gain axis

parameter is called I_GAIN.

KpE⋅=

p

K

i

Following

error

+

K

Σ

K

i

∆

d

-

K

p

++

O

p

E

K

i

O

i

E

E

⋅=

i

å

Derivative Gain The derivative gain produces an output that is proportional to the

change in the following error and speeds up the response to changes in

error while maintaining the same relative stability.

O

Derivative gain may create a smoother response. High values may lead to

oscillation. The derivative gain axis parameter is called D_GAIN.

Output Speed Gain The output speed gain produces an output that is proportional to

the change in the measured position and increases system damping.

O

The output speed gain can be us eful for smoothing motions but will gene rate

high following errors. The output speed gain axis parameter is called

OV_GAIN.

d

ov

K

K

d

ov

K

d

E

E∆⋅=

K

ov

P

m

Pm∆⋅=

O

d

O

ov

17

Page 30

Specifications Section 1-5

Speed Feedforward Gain The speed feedforward gain produces an output that is propor-

tional to the change in dem and position and minimizes the following error

K

vff

O

P

d

vff

at high speed.

O

vff

K

vff

Pd∆⋅=

The parameter can be set to minimise the following error at a constant

machine speed after ot her gai ns have been set. Th e speed feed forward gain

axis parameter is called VFF_GAIN.

Default Values The default settings are given below along with the resulting profiles. Frac-

tional values are allowed for gain settings.

Gain Default

Proportional Gain 1.0

Integral Gain 0.0

Der iva tive Gai n 0.0

Output Speed Gain 0.0

Speed Feedforward Gain 0.0

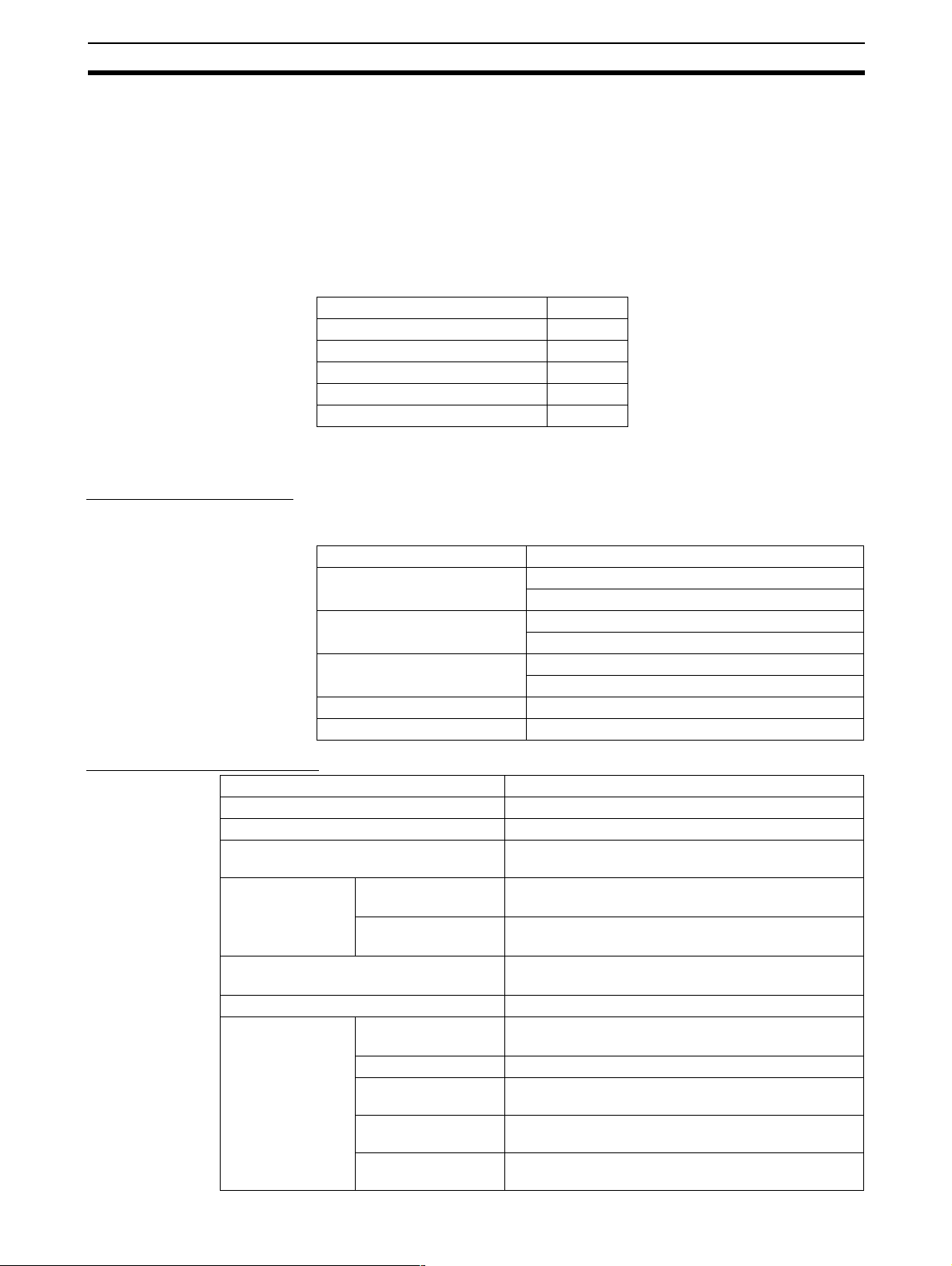

1-5 Specifications

General Specifications

General specifications other than those shown below conform to those for the

SYSMAC C200HS/C200HX/C200HG/C200HE PCs.

Item Specifications

Power supply voltage 5 VDC (from Backplane)

24 VDC (from external power supply)

Voltage fluctuation tolerance 4.75 - 5.25 VDC (from Backplane)

21.6 - 26.4 VDC (from external power supply)

Internal current consu mp tion 600 mA or less for 5 VDC

50 mA or less for 24 VDC

Weight (Connectors excluded) 500 g max.

External Dimensions 130.0 x 35 x 100.5 mm (H x W x D)

Functional Specifications

Type of Unit C200H Special I/O Unit

Applicable PC C200HX/HG/HE and CS1

Backplanes on which MC Unit can be

mounted

Method for data

transfer to CP U

Unit

External connected devices Per sonal computer with Motion Perfect Programming

Controlled Servo Drivers Analogue (speed) input Servo Driver s

Control Control meth od Inferr ed closed loop with incremental encoder and with

18

Item Contents

CPU Backplane

Words allocated in

IR/CIO area

PC and MC Unit

instructions

Maximum No. of axes 8

Maximum No. of

interpolated axes

Maximum No. of

servo axes

Maximum No. of vir-

tual axes

10 words per unit (S ee note 1.)

Any number of words modified by ladder program or

BASIC program instruction

Software

PID , output speed and speed f eed forward gains

8

4

8

Page 31

Specifications Section 1-5

µ

µ

µ

µ

Item Contents

Speed control Speed control of up to 4 axes

Measurement Units User definable

Pos itioning opera-

tions

Encoder interface Line receiver input; maximum response frequency:

Accelerat ion/deceleration curves Trapezoidal or S-curve

External

I/O

Power supply f or general and axis I/O Pr ovided external ly

Task program man-

agement

Linear interpolation Linear interpolation for any number of axes

Circular interpolation Circular interpolation for any two axes

Helical interpolati on Helical interpolation for any three axes

CAM profile CAM profile movement for any axis

Electronic gearbox Electronic gearbox link between any two axes

Linked CAM Linked CAM profile mov em ent for any two axes

Linked move Linked mo ve for any two axes

Adding axes Adding any two axes

250 kp/s (before multiplication)

1 M counts/s (afte r multiplication)

Serial Communication ports

Encoder Line receive inputs:

Servo Driver relationship

General Purpose I/O Up to 16 digital inputs and 8 out puts can be wired to

Registration inputs Each servo axis has a registration input which capture

Programming language

Number of tasks Up to 5 tasks running simultaneously plus the Com-

Max . nu m ber of pr ograms

Data storage capacity 251 (VR) + 16000 (Table) max.

Data transfer to PC

Unit

One RS-232C port for connection to computer wit h the

Motion P erfect software.

One RS-232C port for general purpose.

For four axes (250 kp/s, before mul tiplication)

The foll owing signals are provided.

Inputs:

Driver Alarm Signal (each axis)

Outputs:

Driver Enab le ( all axes)

Speed Reference Voltage (each axis)

Driver Alarm Reset (all axes)

control MC Unit functions. These can include limit

switches, emergency stop switches and proximity

inputs.

the position in hardware. Timing specification (see

note 2):

Digital Input (rising edge): 10 s (max.)

Digital Input (falling edge): 200 s (max.)

Z-marker (rising edge): 2

Z-marker (falling edge): 2

BASIC

mand Line Interface task

14

PLC_READ and PLC_WRITE command in BASIC program, IORD and IOWR instructions in ladder program

in C200HX/HG/HE PCs

s (max.)

s (max.)

19

Page 32

Comparison with C200HW-MC402-UK Section 1-6

Item Contents

Saving program

data

Self diagnostic functions Detection of memory corruption via checksum

MC Unit Battery-backed RAM with flash memory backup.

(See note 3.)

External devi ces Motion Perfect softw are manages a backup on the

hard disk of the personal computer.

Detection of error counter over run

Note 1. The number of MC Units that can be moun ted under on e CPU Unit must

be determined b ased on the maximum number of Special I/O Units that

can be allocated words in the CPU Units, the power supply capacity on the

CPU or Expansion Rack, and the current consumption of the Units mounted to the Rack. Refer to the CPU Unit’s operation manual for details on calculation methods.

2. This specification is the time between the edge in the input signal and the

capture of the position data.

3. The service life for the flash memory is 100,000 writing operations.

1-6 Comparison with C200HW-MC402-UK

The following table shows a comparison between the C200HW-MC402-E Unit

and the previously released C200HW-MC402-UK Unit.

!Caution

The C200HW-MC402-E is not fully backward compatible with the C200HWMC402-UK. Please check Appendix A Upgrading from C200HW-MC402-UK

carefully before upgrading to the C200HW-MC402-E.

Item C200HW-MC402-UK C200HW-MC402-E

Applicable PCs C200HS,C200HX/HG/HE

(HX up to CPU 6 4 )

Supported axes 4 (4 servo) 8 (4 servo and 4 virtual)

Allocated IR/CIO area words 6 words (6 input) 10 words (8 input,

Compatible software Motion Perfect 1.24 and 2.0 Motion Perfect 2.0

Serial Port A Used for Motion Perfect con-

nection and user-defined

communication.

Cyclic Servo Period Set by SERVO_PERIOD

Commands and

instructions

PLC_READ/

PLC_WRITE

IORD/ IOWR Yes

CLEAR_BIT/

SET_BIT/

READ_BIT

param e ter (d efault 1 ms)

Yes Yes

Read/write to MC Unit’s VR

array in one-word format

No Yes

C200HS,C200HX/HG/HE

and CS1

2 output).

- Transfer input and output

words

- General stat us bits shifted

- Modified origin search bits

- Added PC Transfer Error bit

See notes 1 and 2.

Dedicated to Motion Perf ect

connection

Fixed to 1 ms

Also reads/writes al located

IR/CIO area words

Yes

Read/write to MC Unit’s VR

and Table array and oneword and three-word format

supported

Enables bit operation for VR

variables

20

Page 33

Comparison with C200HW- M C402-UK Section 1-6

Item C200HW-MC402-UK C200HW-MC402-E

Commands and

instructions

INPUT/ KEY/

LINPUT

PROC No Yes.

INDEVICE/

OUTDEVICE

CLEAR/ RESET No Yes

APPENDPROG/

AXISVALUES/

EX/

INPUTS0/

INPUTS1/

LOADSYSTEM/

MPE/

STORE

WAIT LOADED/

LIST

No Yes

Added functionality for serial

communications

Allows a process parameter

of a particular task to be

read/written

Yes No

Port 0 is def ault port fo r serial

communication

Commands to clear memory

Yes Commands reserved for

Motion Perfect: descriptions

have been removed from

manual

No Yes

Added functionality

Note 1. The allocation of the IR/C IO area bits has been modi fied in comparison

with the C200HW-MC402-UK. Please refer to 3-1 IR/CIO Area Allocation

and Appendix A Upgrading fr om C200HW-MC402-UK for more information.

2. The names of some IR/CIO area bits have been modified. Unless otherwise indicated, the functionality has not changed. T he names of th e connection pins have been modified without any change in function.

21

Page 34

SECTION 2

Installation

This sectio n des cribes the MC Unit componen ts and provides the information required for installing the MC Unit.

2-1 Components and Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2-1 Installation Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-2-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-3-1 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3-2 I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3-3 Serial Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-3-4 Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-3-5 Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-4 Servo System Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-5 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

23

Page 35

Components and Unit Settings Section 2-1

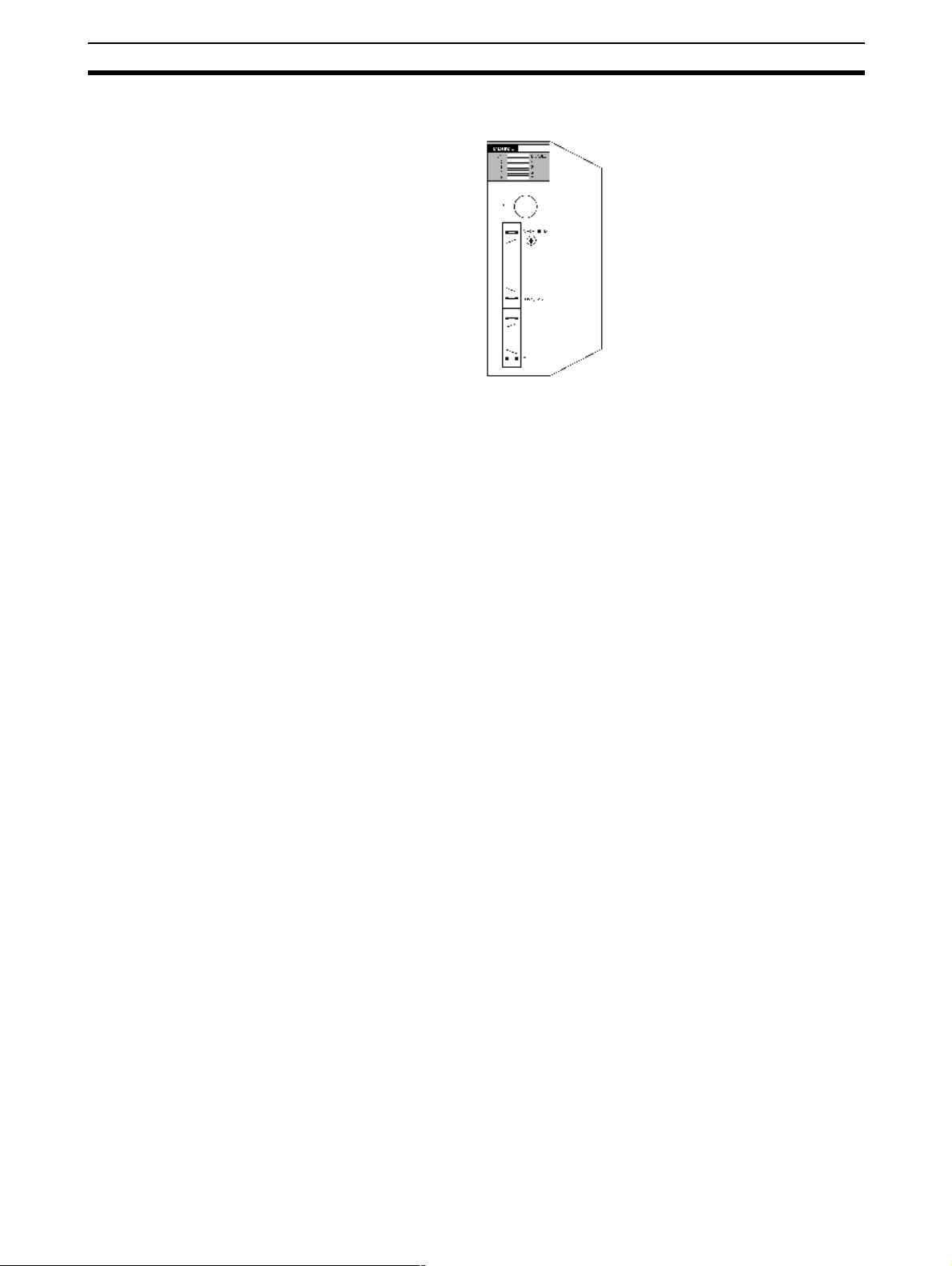

2-1 Com ponents and Unit Se t tings

The following diagram shows the main components of the MC Unit.

MC402-E

RUN DISABLE

4

Indicators

0

5

1

6

2

7

3

Indicators

TOOL

MACHINE No.

Axis Connector

DRV 0,1,2,3

I/O Connector

I/O

Communication

Ports: RS-232C

Unit No. switch

The following table describes the indicators on the front of the MC Unit.

Indicator Color Status Meaning

RUN Green ON The MC Unit is operating normally.

OFF The MC Unit is not recognized by the PC at ini-

tialization or is malfunctioning.

Flashing alone The battery voltage is low.

Flashing with

DISABLE

DISABLE Red ON The axes have been disabled. The Servo

OFF The axes are enabled.

Flashing alone The following error has exceeded the li mit. The

Flashing with

RUN

0 to 7 Orange ON These indicat ors can be control led from the pro-

OFF

An error occurred in the communication

between MC Unit and CPU Unit.

Enable Output is not ON.

Servo Drives ha ve been disabled.

An error occurred in the communication

between MC Unit and CPU Unit.

gram s. R ef e r t o 5-3-53 DISPLAY for details.

Unit No. Switch

24

!Caution

Set the number the unit number between 0 and F.

CPU Unit Unit No. setting range

C200HS-CPU01-E/21-E/31-E/03-E/23-E/33-E

0 to 9

C200HE-CPU11-E/32-E/42-E/11-ZE/32-ZE/42-ZE,

C200HG-CPU33-E/43-E/33-ZE/43-ZE,

C200HX-CPU34-E/44-E/34-ZE/44-ZE

C200HG-CPU53-E/63-E/53-ZE/63-ZE,

0 to F

C200HX-CPU54-E/64-E/54-ZE/64-ZE/85-ZE

CS1H-CPU66-E/65-E/64-E/63-E

CS1G-CPU45-E/44-E/43-E/42-E

Do not change the unit number while power is being supplied to the Unit.

Page 36

Installation Section 2-2

2-2 Installation

2-2-1 Installation Method

1,2,3... 1. Attach the hooks on the upper section of the MC Unit onto the Backplane.

2. Insert the MC Unit connector into the Backplane connector.

!Caution

Do not mount the MC Unit while the power is turned ON to the Rack.

When removing the MC Uni t, lift it out while pressing down on the lock lever

with a screwdriver, as shown in the following illustration.

25

Page 37

Wiring Section 2-3

2-2-2 Dimensions

The basic dimensions of the MC Unit are shown below.

2-3 Wiring

2-3-1 Connector Pin Assignments

I/O Connector

The I/O Connector is used for wiring to external I/O. All I/O are general purpose and functions like limit inputs and origin proximity inputs can be allocated. Inputs I0 / R0 to I3 / R3 can also be used as the Registration Inputs for

axi s 0 to 3. Refer to 2-3-2 I/O Specifications for electrical specifications.

Recommended Connector

and Cable

Connector pin

arrangement

The 3M model numbers are listed below.

Connector IDC plug connector s with

26-pin MDR 10126-6000EC or

10126-6000EL

10326-A200-00

The IDC or soldered connectors can be used with various types of cables.

The following 3M cable is recommended for the MC Unit.

• Round-Jacketed, Shielded, Discrete Wire Cable 3444C-series, 28 AWG

Stranded, Twisted-pair, PVC/PVC.

metal ba ck s h ells

Soldered connector wit h

plastic shells

10126-3000VE or

10126-3000VC

10326-52F0-0086

26

13

25 15

12

26

14

2

1

Page 38

Wiring Section 2-3

I/O Connec tor Pin

Functions

Pin Signal

Name Function

1 24V_IO 24V supply for I/O circuit s

2 O0 Output 0

3 O1 Output 1

4 O2 Output 2

5 O3 Output 3

6 O4 Output 4

7 O5 Output 5

8 O6 Output 6

9 O7 Output 7

10 I0 / R0 Input 0 or Registr ation input for axi s 0

11 I1 / R1 Input 1 or Registr ation input for axi s 1

12 I2 / R2 Input 2 or Registr ation input for axi s 2

13 0V_IO 0V common for I/O circuits

14 I3 / R3 Input 3 or Registr ation input for axi s 3

15 I4 Input 4

16 I5 Input 5

17 I6 Input 6

18 I7 Input 7

19 I8 Input 8

20 I9 Input 9

21 I10 Input 10

22 I11 Input 11

23 I12 Input 12

24 I13 Input 13

25 I14 Input 14

26 I15 Input 15

Axis Connector

Recommended Connector

and Cable

The Axis Connector is used to connect the Servo Drivers for axes 0 to 3.

Refer to 2-3-2 I/O Specifications for electrical specifications.

The 3M model numbers are listed below

Connector IDC plug connector s with

meta l back s h e lls

40-pin MDR 10140-6000EC or

10140-6000EL

10340-A200-00

.

Soldered connector wit h

plastic shells

10140-3000VE or

10140-3000VC

10340-5500-008

The IDC or soldered connectors can be used with various types of cables.

The following 3M cable is recommended for the MC Unit.

• Round-Jacketed, Shielded, Discrete Wire Cable 3444C-series, 28 AWG

Stranded, Twisted-pair, PVC/PVC.

27

Page 39

Wiring Section 2-3

Connector pin

arrangement

Axis Connector Pin

Functions

20

40

39

19

22

2

21

1

Pin Signal

Name Function

1 0V_DRV 0V common for control si gnals

2 /ALARM_0 Alarm input for axis 0

3 /ALARM_1 Alarm input for axis 1

4 /ALARM_2 Alarm input for axis 2

5 A_0 Encoder phase A axis 0

6 /A_0 Encoder phase /A axis 0

7 B_0 Encoder phase B axis 0

8 /B_0 Encoder phase /B axis 0

9 Z_0 Encoder phase Z axis 0

10 /Z_0 Encoder phase /Z axis 0

11 VREF_0 Speed reference signal axis 0

12 0V_ENC 0V common for encoder signal s

13 A_1 Encoder phase A axis 1

14 /A_1 Encoder phase /A axis 1

15 B_1 Encoder phase B axis 1

16 /B_1 Encoder phase /B axis 1

17 Z_1 Encoder phase Z axis 1

18 /Z_1 Encoder phase /Z axis 1

19 VREF_1 Speed reference signal axis 1

20 0V_REF 0V comm on for reference signals

21 /ALARM_3 Alarm input for axis 3

22 ALARMRST Drivers alarm reset signal

23 ENABLE Dr ivers enable signal

24 24V_DRV 24V supply for driver control signals

25 A_2 Encoder phase A axis 2

26 /A_2 Encoder phase /A axis 2

27 B_2 Encoder phase B axis 2

28 /B_2 Encoder phase /B axis 2

29 Z_2 Encoder phase Z axis 2

30 /Z_2 Encoder phase /Z axis 2

31 VREF_2 Speed reference signal axis 2

32 0V_ENC Ground encoder signals

33 A_3 Encoder phase A axis 3

34 /A_3 Encoder phase /A axis 3

35 B_3 Encoder phase B axis 3

36 /B_3 Encoder phase /B axis 3

28

Page 40

Wiring Section 2-3

Pin Signal

Name Function