Page 1

Cat. No. W139-E1-04

SYSMAC

Programmable Controllers

C1000H/C2000H

INSTALLATION GUIDE

Page 2

C1000H/C2000H

Programmable Controllers

Installation Guide

Revised June 2000

Page 3

Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all quotes, agreements, purchase orders, acknowledgments, price lists,

catalogs, manuals, brochures and other documents, whether electronic or in

writing, relating to the sale of products or services (collectively, the "Products

by Omron Electronics LLC and its subsidiary companies (“Omron

objects to any terms or conditions proposed in Buyer’s purchase order or other

documents which are inconsistent with, or in addition to, these Terms.

2. Prices; Payment Terms.

out notice by Omron. Omron reserves the right to increase or decrease prices

on any unshipped portions of outstanding orders. Payments for Products are

due net 30 days unless otherwise stated in the invoice.

3. Discounts.

sent to Buyer after deducting transportation charges, taxes and duties, and will

be allowed only if (i) the invoice is paid according to Omron’s payment terms

and (ii) Buyer has no past due amounts.

4. Interest.

the maximum legal rate, whichever is less, on any balance not paid within the

stated terms.

5. Orders

6. Governmental Approvals.

costs involved in, obtaining any government approvals required for the importation or sale of the Products.

7. Taxes

real property and income taxes), including any interest or penalties thereon,

imposed directly or indirectly on Omron or required to be collected directly or

indirectly by Omron for the manufacture, production, sale, delivery, importation, consumption or use of the Products sold hereunder (including customs

duties and sales, excise, use, turnover and license taxes) shall be charged to

and remitted by Buyer to Omron.

8. Financial.

to Omron, Omron reserves the right to stop shipments or require satisfactory

security or payment in advance. If Buyer fails to make payment or otherwise

comply with these Terms or any related agreement, Omron may (without liability and in addition to other remedies) cancel any unshipped portion of Products sold hereunder and stop any Products in transit until Buyer pays all

amounts, including amounts payable hereunder, whether or not then due,

which are owing to it by Buyer. Buyer shall in any event remain liable for all

unpaid accounts.

9. Cancellation; Etc.

unless Buyer indemnifies Omron against all related costs or expenses.

10. Force Majeure

resulting from causes beyond its control, including earthquakes, fires, floods,

strikes or other labor disputes, shortage of labor or materials, accidents to

machinery, acts of sabotage, riots, delay in or lack of transportation or the

requirements of any government authority.

11. Shipping; Delivery.

a. Shipments shall be by a carrier selected by Omron; Omron will not drop ship

b. Such carrier shall act as the agent of Buyer and delivery to such carrier shall

c. All sales and shipments of Products shall be FOB shipping point (unless oth-

d. Delivery and shipping dates are estimates only; and

e. Omron will package Products as it deems proper for protection against nor-

12. Claims.

Products occurring before delivery to the carrier must be presented in writing

to Omron within 30 days of receipt of shipment and include the original transportation bill signed by the carrier noting that the carrier received the Products

from Omron in the condition claimed.

13. Warranties

Products will be free from defects in materials and workmanship for a period of

twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABIL-

Cash discounts, if any, will apply only on the net amount of invoices

Omron, at its option, may charge Buyer 1-1/2% interest per month or

. Omron will accept no order less than $200 net billing.

. All taxes, duties and other governmental charges (other than general

If the financial position of Buyer at any time becomes unsatisfactory

except in “break down” situations.

constitute delivery to Buyer;

erwise stated in writing by Omron), at which point title and risk of loss shall

pass from Omron to Buyer; provided that Omron shall retain a security interest in the Products until the full purchase price is paid;

mal handling and extra charges apply to special conditions.

Any claim by Buyer against Omron for shortage or damage to the

. (a) Exclusive Warranty. Omron’s exclusive warranty is that the

All prices stated are current, subject to change with-

Buyer shall be responsible for, and shall bear all

Orders are not subject to rescheduling or cancellation

. Omron shall not be liable for any delay or failure in delivery

Unless otherwise expressly agreed in writing by Omron:

. OMRON MAKES NO WARRANTY OR REPRESENTATION,

”). Omron

ITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

")

INTENDED USE. Omron further disclaims all warranties and responsibility of

any type for claims or expenses based on infringement by the Products or otherwise of any intellectual property right. (c) Buyer Remedy

gation hereunder shall be, at Omron’s election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying

Product, or (iii) repay or credit Buyer an amount equal to the purchase price of

the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding

the Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the

use of Products in combination with any electrical or electronic components,

circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://oeweb.omron.com or contact your Omron representative for published information.

14. Limitation on Liability; Etc

FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

15. Indemnities

their employees from and against all liabilities, losses, claims, costs and

expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Omron is a party) which arises

or is alleged to arise from Buyer's acts or omissions under these Terms or in

any way with respect to the Products. Without limiting the foregoing, Buyer (at

its own expense) shall indemnify and hold harmless Omron and defend or settle any action brought against such Companies to the extent based on a claim

that any Product made to Buyer specifications infringed intellectual property

rights of another party.

16. Property; Confidentiality.

sive property of Omron Companies and Buyer shall not attempt to duplicate it

in any way without the written permission of Omron. Notwithstanding any

charges to Buyer for engineering or tooling, all engineering and tooling shall

remain the exclusive property of Omron. All information and materials supplied

by Omron to Buyer relating to the Products are confidential and proprietary,

and Buyer shall limit distribution thereof to its trusted employees and strictly

prevent disclosure to any third party.

17. Export Controls.

licenses regarding (i) export of products or information; (iii) sale of products to

“forbidden” or other proscribed persons; and (ii) disclosure to non-citizens of

regulated technology or information.

18. Miscellaneous

and no course of dealing between Buyer and Omron shall operate as a waiver

of rights by Omron. (b) Assignment

without Omron's written consent. (c) Law.

law of the jurisdiction of the home office of the Omron company from which

Buyer is purchasing the Products (without regard to conflict of law principles). (d) Amendment

Buyer and Omron relating to the Products, and no provision may be changed

or waived unless in writing signed by the parties. (e) Severability

sion hereof is rendered ineffective or invalid, such provision shall not invalidate

any other provision. (f) Setoff

against the amount owing in respect of this invoice. (g) Definitions

herein, “including

nies” (or similar words) mean Omron Corporation and any direct or indirect

subsidiary or affiliate thereof.

. Buyer shall indemnify and hold harmless Omron Companies and

Buyer shall comply with all applicable laws, regulations and

. (a) Waiver. No failure or delay by Omron in exercising any right

. OMRON COMPANIES SHALL NOT BE LIABLE

Any intellectual property in the Products is the exclu-

. Buyer may not assign its rights hereunder

These Terms are governed by the

. These Terms constitute the entire agreement between

. Buyer shall have no right to set off any amounts

” means “including without limitation”; and “Omron Compa-

. Omron’s sole obli-

. If any provi-

. As used

Certain Precautions on Specifications and Use

1. Suitability of Use. Omron Companies shall not be responsible for conformity

with any standards, codes or regulations which apply to the combination of the

Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying

ratings and limitations of use which apply to the Product. This information by

itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application

or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases but the following is a

non-exhaustive list of applications for which particular attention must be given:

(i) Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

(ii) Use in consumer products or any use in significant quantities.

(iii) Energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

(iv) Systems, machines and equipment that could present a risk to life or property. Please know and observe all prohibitions of use applicable to this Product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

iv

ADDRESS THE RISKS, AND THAT THE OMRON’S PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

2. Programmable Products.

user’s programming of a programmable Product, or any consequence thereof.

3. Performance Data

and other materials is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s

test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations

of Liability.

4. Change in Specifications

changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for

your application. Please consult with your Omron’s representative at any time

to confirm actual specifications of purchased Product.

5. Errors and Omissions.

checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical or proofreading errors or omissions.

Omron Companies shall not be responsible for the

. Data presented in Omron Company websites, catalogs

. Product specifications and accessories may be

Information presented by Omron Companies has been

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

©OMRON, 1988

All rights reserved. No part of this publication may be reproduced, photocopied or recorded, stored in a retrieval system or

transmitted in any form or by any means mechanical, electronic, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is con-

stantly striving to improve its high−quality products, the information contained in this manual is subject to change without no-

tice. Every precaution has been taken in the preparation of this manual; nevertheless, OMRON assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 What is a Control System? 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Available Manuals 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Description of All Components 9. . . . . . . . . . . . . . . . . . . . .

2-1 CPU Rack 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 CPU Power Supply 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 I/O Backplane 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Expansion I/O Backplane 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 I/O Power Supply 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Duplex Unit (C2000H Duplex) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 I/O Control Unit 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 I/O Interface Unit 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 File Memory Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 Space Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 I/O Remove Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 I/O Units 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13 Memory Packs 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Assembly 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Mounting the Units 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 C2000H Duplex System 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 C2000H Simplex System 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Memory Packs 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 System Configurations 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

System Connections 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Current Consumption 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 I/O Connections 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Installation Environment 47. . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Cooling 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Mounting Requirements 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Duct Work 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Preventing Noise 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

TABLE OF CONTENTS

SECTION 6

Power Considerations 53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7

Safety Considerations 59. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Inspection and Maintenance 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Specifications 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Standard Models 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 8

About this Manual...

This manual explains how to install C1000H and C2000H C-series Programmable Controllers.

Section 1 is an introduction to Programmable Controllers. General information about what a Programmable Controller can do and how a Programmable Controller works is provided.

Section 2 provides a description of all the components of the C1000H and C2000H. The names of all the

individual parts of each Unit are given.

Section 3 explains how to assemble the C1000H and C2000H. A detailed description of how to mount

each Unit is provided.

Section 4 outlines the system connections involved in installing a C1000H and C2000H Programmable

Controller Systems.

Section 5 contains the requirements for the installation environment of the C1000H and C2000H. Suggestions for preventing electrical noise are included.

Section 6 explains the power considerations involved in installing the C1000H and C2000H.

Section 7 lists safety considerations that should be kept in mind while installing the C1000H and

C2000H.

Appendixes, a Glossary, and an Index are also included.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 9

Page 10

PRECAUTIONS

This section provides general precautions for using the Wired Remote I/O System and related devices.

The information contained in this section is important for the safe and reliable application of the SYSMAC

C1000H/C2000H Programmable Controllers. You must read this section and understand the information contained

before attempting to set up or operate the SYSMAC C1000H/C2000H Programmable Controllers.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 11

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the relevant manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

4Operating Environment Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC system to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

!

torque specified in the operation manual. The loose screws may result in burning

or malfunction.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, the input signals may not be readable.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

4 Operating Environment Precautions

Caution Do not operate the control system in the following locations:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

xii

Page 12

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC system can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC system. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC system.

5Application Precautions

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

• Always ground the system to 100 Ω or less when installing the Units. Not con-

necting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the fol-

lowing. Not turning OFF the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, Memory Units, or any other

Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures in external circuits

(i.e., not in the Programmable Controller) must be provided by the customer.

• Always use the power supply voltages specified in this manual. An incorrect

voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

xiii

Page 13

5Application Precautions

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in this manual. Incorrect tightening torque may result in malfunction.

• Double-check all wiring and switch settings before turning ON the power supply. Incorrect wiring may result in burning.

• Mount Units only after checking terminal blocks and connectors completely.

• Be sure that the terminal blocks, Memory Units, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM Area, HR Area, and other data required for resuming operation. Not

doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so may

break the cables.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching a Unit, be sure to first touch a grounded metallic object in order

to discharge any static built-up. Not doing so may result in malfunction or damage.

• Check the direction and polarity of all terminal blocks and connectors before

attempting to connect them.

xiv

Page 14

SECTION 1

Introduction

This section provides general information about Programmable Controllers (Systems) and how they fit into a Control System.

1-1 What is a Control System? 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 The Role of the PC 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Input Devices 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Output Devices 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 How Does a PC Work? 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Available Manuals 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 15

What is a Control System? Section 1-1

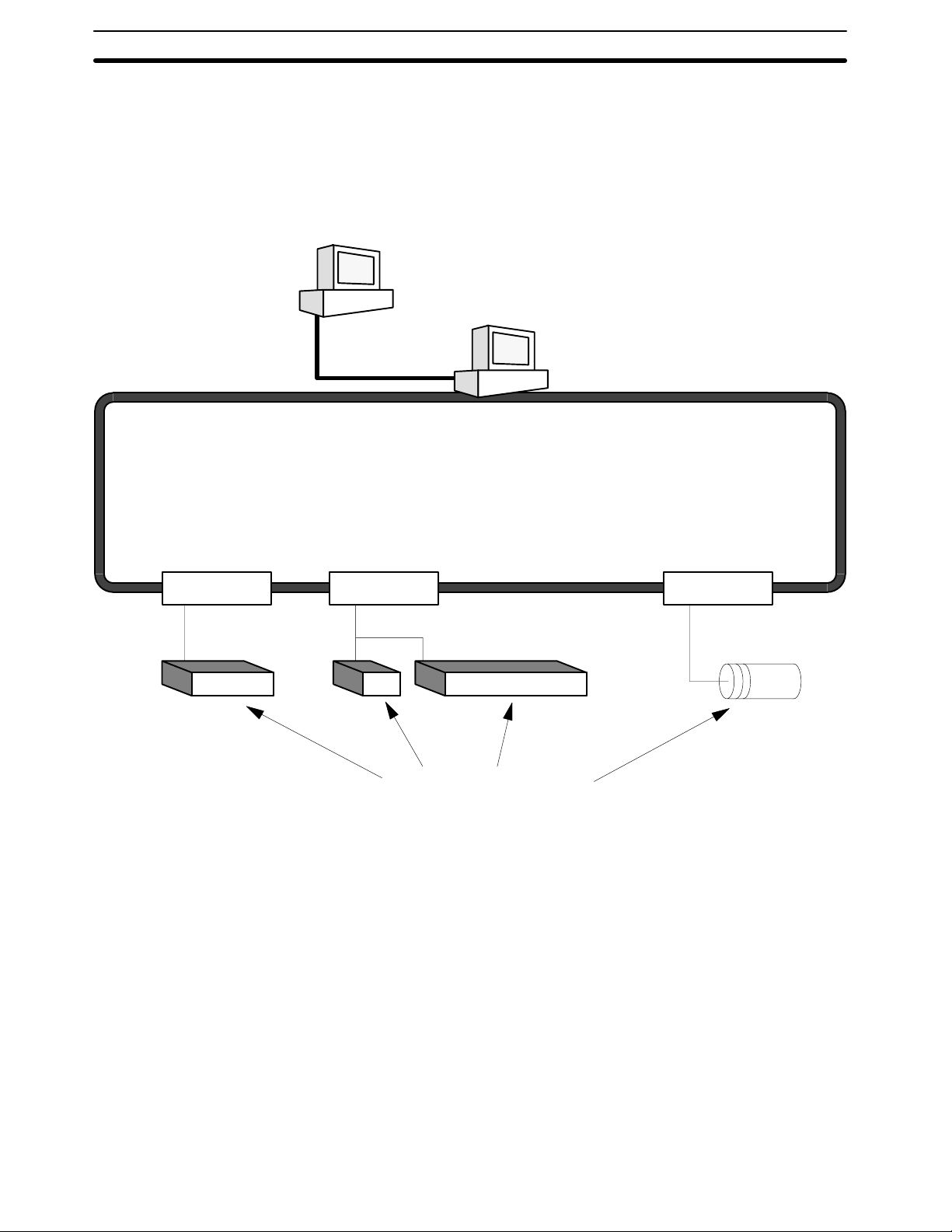

1-1 What is a Control System?

A Control System is the electronic equipment needed to control a particular process. It may include everything from a process control computer, if one is used,

to the factory computer, down through the PCs (and there may be many of them

networked together), and then on down through the network to the control components: the switches, stepping motors, solenoids, and sensors which monitor

and control the mechanical operations.

Process Control Computer

Factory Computer

PCs

PC PC PC

Control Components

A Control System can involve very large applications where many different models of PC are networked together or it could be an application as small as a single

PC controlling a single output device.

2

Page 16

The Role of the PC Section 1-2

A Position Control System

Position Control Unit Input Unit

PC

Signal line for

Servomotor

driver control

Power

source

DC Servomotor

Driver

DC Servomotor

Power

source

DC Servomotor

Driver

DC Servomotor

Handheld

Programming

Console

Control panel

Control switch

In the typical Control System example shown above, a PC controls the movement of the workpiece bed across two horizontal axes using Limit Switches and

Servomotors to monitor and control movement.

1-2 The Role of the PC

The PC is the part of the Control System that directly controls the manufacturing

process. According to the program stored in its memory, the PC accepts data

from the input devices connected to it, and uses this data to monitor the controlled system. When the program calls for some action to take place, the PC

sends data to the output devices connected to it to cause that action to take

place. The PC may be used to control a simple, repetitive task, or it may be connected to other PCs, or to a host computer in order to integrate the control of a

complex process.

3

Page 17

The Role of the PC Section 1-2

1-2-1 Input Devices

PCs can receive input from either automated or manual devices. The PC could

receive data from the user via a pushbutton switch, keyboard, or similar device.

Automated input could come from a variety of devices: micro-switches, timers,

encoders, photosensors, and so on. Some devices, like the Limit Switch shown

below, turn ON or OFF when the equipment actually makes contact with them.

Other devices, like the Photoelectric Switch and Proximity Switch shown below,

use other means, such as light or inductance, in order to get information about

the equipment being monitored.

1-2-2 Output Devices

Photoelectric Switch

Proximity Switch

Limit Switch

A PC can output to a myriad of devices for use in automated control. Almost anything that you can think of could be controlled (perhaps indirectly) by a PC. Some

of the most common devices are motors, Solenoids, Servomotors, Stepping

Motors, valves, switches, indicator lights, buzzers, and alarms. Some of these

output devices, such as the motors, Solenoids, Servomotors, Stepping Motors,

and valves, affect the controlled system directly. Others, such as the indicator

lights, buzzers, and alarms, provide output to notify personnel.

Solenoid

Stepping Motor

Servomotor

4

Page 18

How Does a PC Work? Section 1-3

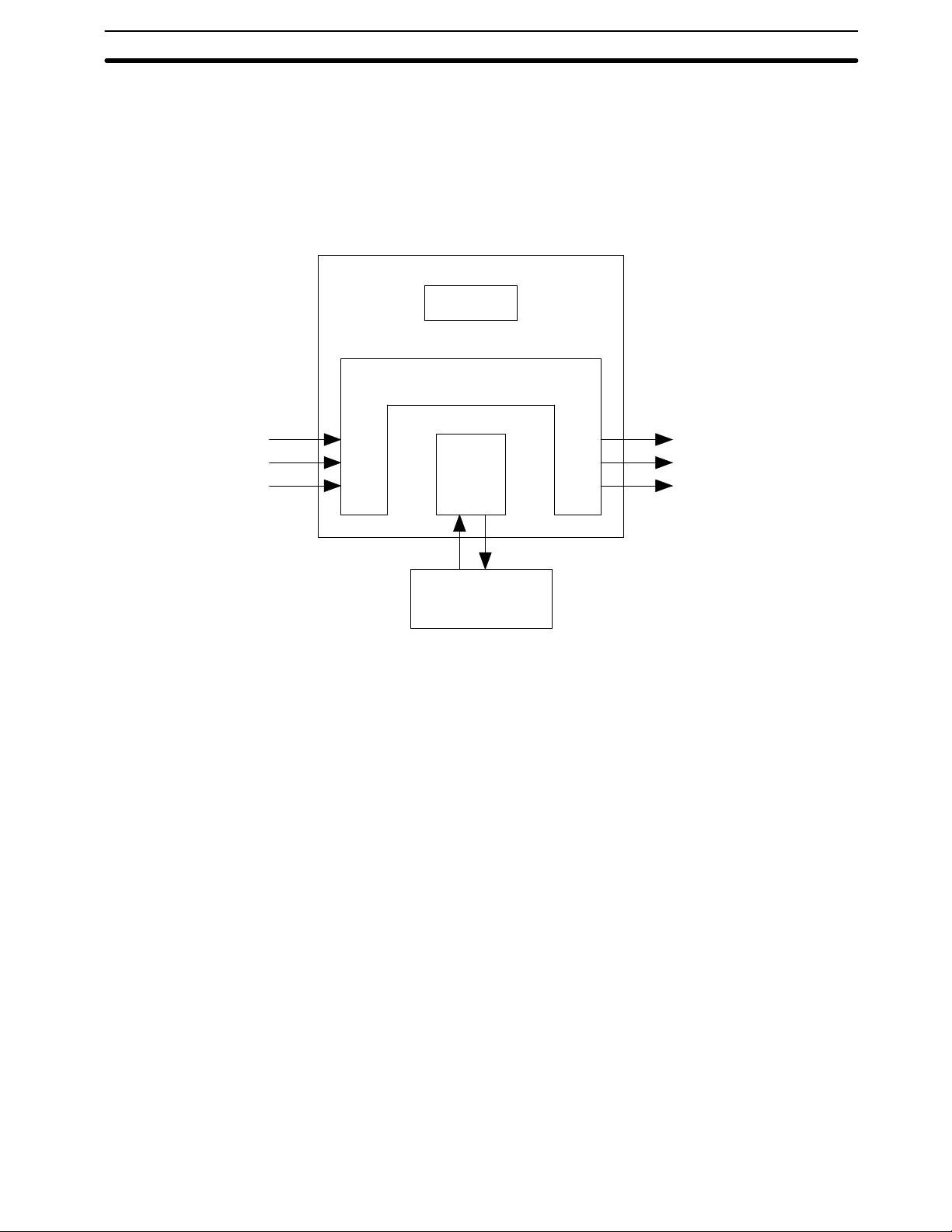

1-3 How Does a PC Work?

PCs operate by monitoring input signals and providing output signals. When

changes are detected in the signals, the PC reacts, through the user-programmed internal logic, to produce output signals. The PC continually scans the

program in its memory to achieve this control.

Block Diagram of PC

Power Supply

Memory

Signals

from

switches,

sensors,

etc.

Input Output

CPU

Programming

Device

Signals to

Solenoids,

motors,

etc.

A program for your applications must be designed, and stored in the PC. This

program is then executed as part of the cycle of internal operations of the PC.

Scanning Cycle When a PC operates, that is, when it executes its program to control an external

system, a series of operations are performed inside the PC. These internal

operations can be broadly classified into the following four categories:

1, 2, 3... 1. Common (or overseeing) processes, such as watchdog timer operation and

testing the program memory.

2. Data input and output.

3. Instruction execution.

4. Peripheral device servicing.

Cycle Time The total time required for a PC to perform all these internal operations is called

the cycle time. The flowchart and diagram on the following page illustrate these

internal operations for a typical PC.

Timing is one of the most important factors in designing a Control System. For

accurate operations, it is necessary to have answers to such questions as these:

• How long does it take for the PC to execute all the instructions in its memory?

• How long does it take for the PC to produce a control output in response to a

given input signal?

The cycle time of the PC can be automatically calculated and monitored, but it is

necessary to have an understanding of the timing relationships within the PC for

effective System design and programming.

5

Page 19

How Does a PC Work? Section 1-3

PC Operation Flowchart

Power application

Initial

Clears data areas and

resets System counters

Checks I/O Unit connection

Resets watchdog timer

Checks hardware and

program memory

processing

on

power

application

Sets error flag and

lights indicator

Error or alarm?

Error

Alarm

No

Check OK?

IR data to Output Units

Processes Remote I/O

Resets watchdog timer

Services peripheral devices

Has the applica-

tion program been completely

executed?

Resets watchdog

timer and application

program counter

Executes the program

End of Program?

No

Yes

No

Common

processes

Out

refresh

Remote

I/O

processes

Servicing

peripheral

devices

PC

cycle

time

Yes

Mathematical

Resets watchdog timer

processes

In refresh

Data from Input

Units to IR Area

6

Page 20

Available Manuals Section 1-4

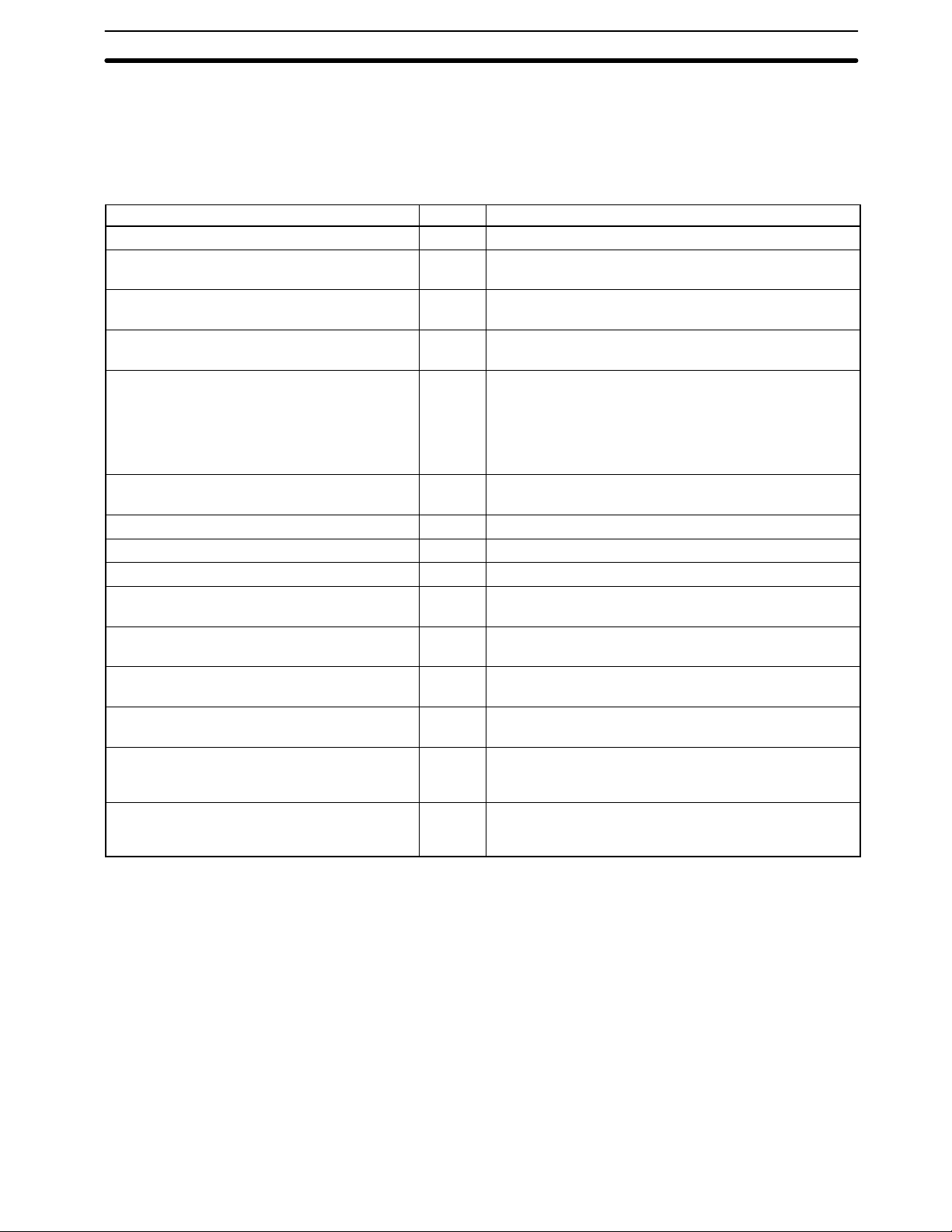

1-4 Available Manuals

The following table lists other manuals that may be required to program

and/or operate the C1000H and C2000H. Operation Manuals and/or Opera-

tion Guides are also provided with individual Units and are required for wiring

and other specifications.

Name Cat. No. Contents

C1000H/C2000H Operation Manual W140 Software specifications

GPC Operation Manual W084 Programming procedures for the GPC (Graphics

Programming Console)

FIT Operation Manual W150 Programming procedures for using the FIT (Factory

Intelligent Terminal

LSS Operation Manual W237 Programming procedures for using LSS (Ladder Support

Software)

SSS Operation Manuals:

Basics W247 Introduction to programming procedures for using SSS

(SYSMAC Support Software)

C Series W248 C-series programming procedures for using SSS

(SYSMAC Support Software)

Data Access Console Operation Guide W173 Data area monitoring and data modification procedures for

the Data Access Console

Printer Interface Unit Operation Guide W107 Procedures for interfacing a PC to a printer

PROM Writer Operation Guide W155 Procedures for writing programs to EPROM chips

Floppy Disk Interface Unit Operation Guide W119 Procedures for interfacing a PC to a floppy disk drive

Wired Remote I/O System Manual W120 Information on building a Wired Remote I/O System to

enable remote I/O capability

Optical Remote I/O System Manual W136 Information on building an Optical Remote I/O System to

enable remote I/O capability

PC Link System Manual W135 Information on building a PC Link System to automatically

transfer data between PCs

Host Link System Manual W143 Information on building a Host Link System to manage

PCs from a ‘host’ computer

SYSMAC NET Link System Manual W114 Information on building a SYSMAC NET Link System and

thus create an optical LAN integrating PCs with

computers and other peripheral devices

SYSMAC LINK System Manual W174 Information on building a SYSMAC LINK System to

enable automatic data transfer, programming, and

programmed data transfer between the PCs in the System

7

Page 21

Page 22

SECTION 2

Description of All Components

This section provides information about the individual Units that make up the C1000H and the C200H Simplex and Duplex

Systems. First the names of all the parts of the three systems are given, followed by any details that apply to the Units that make

up the PC. For a description of how the Units fit together to become a PC, refer to Section 3-5 System Configurations. For

information about the model numbers of any of the parts described in this section, refer to Appendix C Standard Models.

2-1 CPU Rack 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 CPU Power Supply 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 I/O Backplane 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Expansion I/O Backplane 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 I/O Power Supply 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Duplex Unit (C2000H Duplex) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 I/O Control Unit 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 I/O Interface Unit 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 File Memory Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 Space Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11 I/O Remove Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-12 I/O Units 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-13 Memory Packs 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Page 23

CPU Rack Section 2-1

2-1 CPU Rack

The following figures show the names of all the parts of the CPU Racks used in

C1000H and C2000H Systems. Note that the Backplanes used for each system

are different.

C1000H System There are seven models of CPU Racks available for C1000H systems. Choose

a Backplane with 3, 5 (2 models), 6, 8 (2 models), or 9 I/O slots, depending on

your application. Connect the CPU Backplane to an Expansion I/O Rack via the

Expansion I/O Connector.

CPUBackplane

Expansion I/O Connector

Connects the CPU Rack to an

Expansion I/O Rack. When not

used, cover with cap.

I/O Control Unit

An I/O Control Unit must be

mounted to the Rack in order

to connect the CPU Rack to an

Expansion I/O Rack.

I/O Units

(3, 5, 6, 8, or 9 I/O Units depending

on the Backplane used)

CPU Power Supply

C2000H Simplex System The C2000H Simplex CPU Rack is different from the C1000H CPU Rack in that

there are six slots available for I/O Units rather than eight. The CPU Rack for the

Simplex and Duplex Systems have a special slot, to the left of the I/O Units, for

an I/O Remove Unit. Connect the CPU Rack to an Expansion I/O Rack via the

Expansion I/O connector. For more details concerning the Simplex System,

refer to Section 3-3 C2000H Simplex System.

CPU

I/O Remove Unit

When mounted to Rack, standard I/O Units can be

mounted or removed during

CPU operation.

Expansion I/O Connector

Connects the CPU Rack to

an Expansion I/O Rack.

When not used, cover with

cap.

10

I/O Control Unit

An I/O Control Unit must be

mounted to the Rack in order

to connect the CPU Rack to

an Expansion I/O Rack.

Backplane I/O Units (6 I/O Units) CPU Power Supply

Page 24

CPU Rack Section 2-1

C2000H Duplex System The C2000H Duplex CPU Rack is different from both the C1000H and C2000H

Simplex CPU Racks. The CPU Rack houses two CPUs and a Duplex Unit, learning no room for I/O Units. An additional Rack connected to the CPU Rack via the

Expansion I/O Connectors accommodates the I/O Units which would normally

be mounted to the CPU Rack. Note that two connecting cables are required to

connect the CPU Rack to the accompanying I/O Rack that houses the I/O Units.

Just like the Simplex System, the Duplex CPU Rack has a special slot for an I/O

Remove Unit, located on the I/O Backplane.

CPU

Expansion I/O Connectors

Connects the CPU Rack to the

I/O Rack. Use two connecting

cables.

Backplane Duplex Unit CPU Power Supply

11

Page 25

CPU Rack Section 2-1

CPU Two models of CPUs are available. One is used for C1000H Systems and the

other is used for C2000H Systems. The figure below shows the CPU that is used

with C2000H Duplex and Simplex Systems. The CPUs available for the

C1000H/C2000H Systems do not have built-in Power Supplies or Memory

Packs. Choose the Power Supply and memory pack suitable for your application.

Indicators

Peripheral device

mounting screw

Memory Pack

and Battery

Compartment

Peripheral device

connector cover

CPU mounting

screw

mounting screw

Peripheral device

connector cover

Cover storage slotPeripheral device

Peripheral Device Connector The CPU is equipped with one connector for peripheral devices. A peripheral

device, such as the CPU-Mounting Programming Console, can be mounted

directly to the CPU and does not require a connecting cable. To mount the CPUMounting Programming Console or any other peripheral device directly to the

CPU, follow these steps:

12

1, 2, 3... 1. Detach the cover of the peripheral device connector with a standard screw-

driver. Insert the detached cover into the cover storage slot provided at the

bottom of the CPU.

2. Connect the CPU-Mounting Programming Console to the peripheral device

connector.

3. To ensure a positive connection, secure the Programming Console to the

CPU by tightening the mounting screws located on the surface of the CPU.

Page 26

pp y

p

p

to240 VAC

p

CPU Power Supply Section 2-2

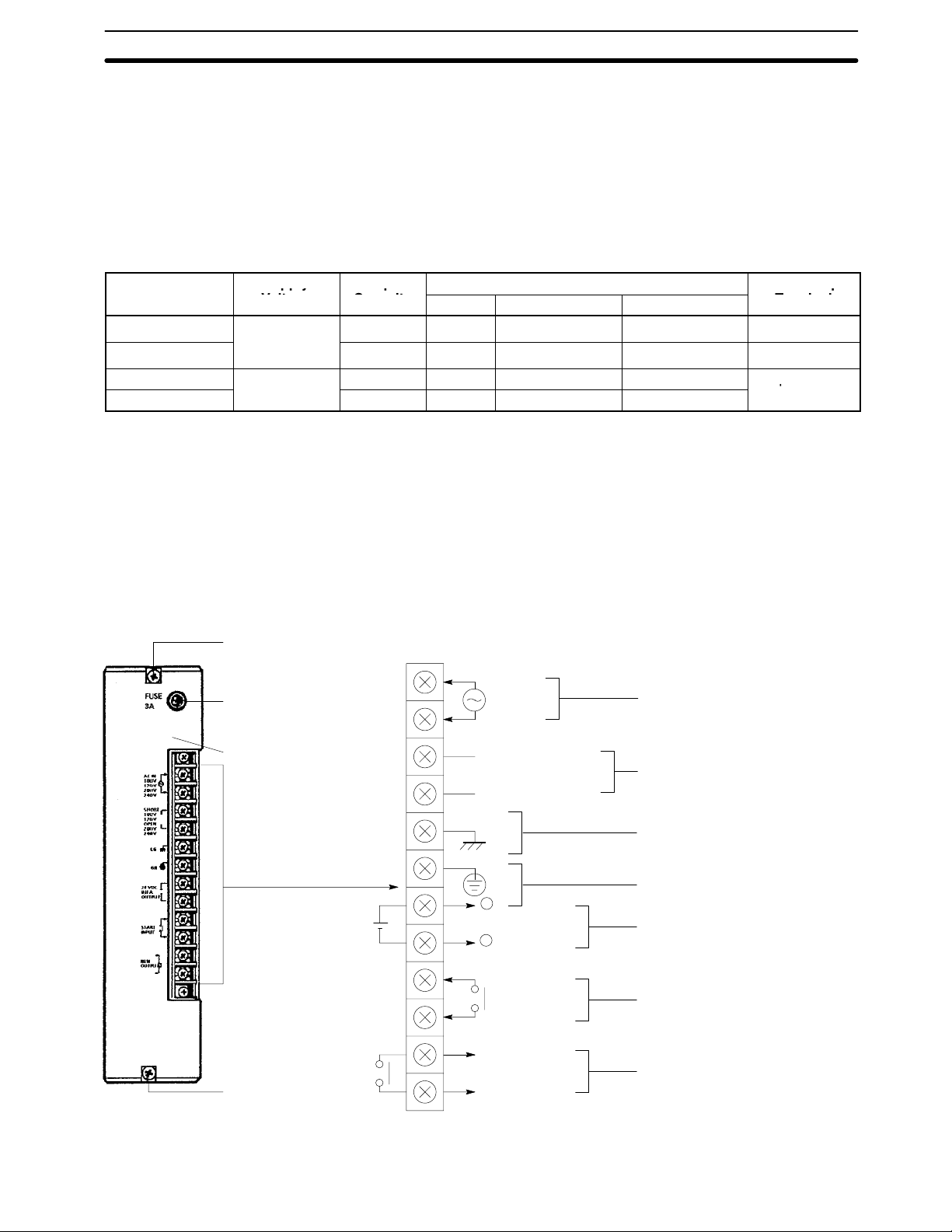

2-2 CPU Power Supply

The CPU Power Supply is mounted to the rightmost slot of the CPU Rack. Three

models of Power Supplies are available: 100 to 120 VAC, 200 to 240 VAC, and

24 VDC. Any one of the three models can be used in the C1000H or C2000H

Simplex Systems: however, the 3G2A5-PS221-E/PS211-E Power Supplies

cannot be used in the C2000H Duplex System. The table below summarizes the

output capacity of the three models and the current available for I/O Units

mounted on the CPU Rack.

Model Supply

3G2A5-PS221-E

3G2A5-PS223-E

3G2A5-PS211-E

Voltage

100 to 120/200

(selectable)

24 VDC

Output

Capacity

C1000H C2000H Simplex C2000H Duplex

7 A 5 VDC 4 A 3 A --- Provided

12 A 5 VDC 9 A 8 A --- Not provided

7 A 5 VDC 4 A 3 A ---

Available Current for I/O Units

24 VDC Output

Terminal

Not provided

C500-PS213-E 9 A 5 VDC 6 A 5 A ---

Note Be sure to keep the total power consumed by all the Units mounted on a Rack

within the value stated in the table above. For example, do not mount I/O Units

with a total current consumption of 5 A to a Rack supplied by a 4 A Power Supply.

As shown in the table above, the available current for I/O Units is only 5 A. For

details concerning current consumption, refer to Section 4 System Connections

3G2A5-PS221-E This Power Supply is used in C1000H and C2000H Simplex Systems.

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

Connect a 100 to 120 VAC or 200 to

240 VAC power source.

Short these terminals to select 100 to

120 VAC. Open them to select 200 to

240 VAC.

Ground this terminal at a resistance of

less than 100 W to improve noise

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100 W to prevent electric

shock.

Use these terminals to supply power

to DC Input Units. Use a separate

Power Supply if the I/O Unit requires

more than 0.8 A. If a current higher

than 0.8 A is output, the PC stops.

These terminals are short-circuited as

a factory-set condition. Remove the

short-circuit bracket to start or stop

the PC with an external signal. Normally, leave them short-circuited.

These terminals are turned ON during RUN operation.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

LG

GR

+

+

0.8 A, 24 VDC output

-

START input

RUN output

13

Page 27

CPU Power Supply Section 2-2

3G2A5-PS223-E This Power Supply is used in C1000H, C2000H Duplex and Simplex Systems.

Mounting screw

Do not loosen this screw.

•

3G2A5-PS211-E

C500-PS213-E

Fuse holder

Contains a MF61NR fuse

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

This Power Supply is used in C1000H and C2000H Simplex Systems.

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

LG

GR

START input

RUN output

Connect a 100 to 120 VAC or 200

to 240 VAC power source.

Short these terminals to select 100

to 120 VAC. Open them to select

200 to 240 VAC.

Ground this terminal at a resistance of less than 100 W to

improve noise immunity or prevent

electric shock.

Ground this terminal at a resistance of less than 100 W to prevent

electric shock.

24 VDC output terminals are not

provided.

These terminals are short-circuited

as a factory-set condition. Remove

the short-circuit bracket to start or

stop the PC with an external signal.

Normally, leave them short-circuited.

These terminals are turned ON

during RUN operation.

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

(6.35-dia. x32)

PS211-E: 125 V, 4 A

•

PS213-E: 125 V, 6.3 A

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

+

-

24 VDC input

LG

GR

START input

RUN output

Connect a 24 VDC power source

(2.3 A min.)

Ground this terminal at a resistance

of less than 100 W to improve noise

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100 W to prevent electric shock.

24 VDC output terminals are not

provided.

These terminals are short-circuited

as a factory-set condition. Remove

the short-circuit bracket to start or

stop the PC with an external signal.

Normally, leave them short-circuited.

These terminals are turned ON during RUN operation.

14

Page 28

I/O Backplane Section 2-3

2-3 I/O Backplane

The I/O Backplane is always paired with the CPU Rack in a C2000H Duplex system. The I/O Backplane houses the I/O Units, which cannot be mounted to the

CPU Rack. Use two cables to connect the I/O Backplane to the CPU Rack. Two

PC Link Units and one Host Link Unit can be mounted to any of the six rightmost

slots on the I/O Backplane. Similar to the C2000H CPU Backplane, the I/O Backplane also has a special slot for an I/O Remove Unit. Use one cable to connect

the I/O Remove Unit on the I/O Backplane to the I/O Remove Unit on the Expansion I/O Rack.

I/O Remove Unit

When mounted to the Rack, I/O Units can be

removed or mounted while the PC is operating.

CPU Connectors

Connects the CPU Rack to the I/O

Rack. Use two connecting cables.

Expansion I/O Backplane Connector

Connects the I/O Rack to an Expansion

I/O Rack. When not used, cover with a

cap.

I/O Units (8 Units max.)I/O Backplane

I/O Control Unit

An I/O Control Unit must be mounted to

the I/O Backplane in order to connect the

I/O Backplane to Expansion I/O Racks.

Expansion I/O

Power Supply

3G2A5-SP001 I/O Cover Unit

When mounting an I/O Cover

Unit, attach the fitting on the I/O

Backplane and the fitting on the

back of the I/O Cover Unit.

15

Page 29

I/O Power Supply Section 2-5

2-4 Expansion I/O Backplane

The Expansion I/O Backplane shown in the following diagram, can be used to

expand the C1000H and C2000H Simplex and Duplex Systems. An Expansion

I/O Rack is just like a CPU Rack, except a CPU is not mounted. However, a

Power Supply is needed for each Expansion I/O Rack. There are three models

of Expansion I/O Backplane available. The Expansion I/O Rack shown below

can only be used with C2000H Systems. This Backplane has a special slot for

the I/O Remove Unit, which allows on-line I/O Unit exchange. two models are

available for C1000H PCs, with either five or eight slots.

I/O Remove Unit

When mounted to the Rack, I/O Units can be

removed or mounted while the PC is operating.

Expansion I/O Power Supply

I/O Units

I/O Interface Unit

An I/O Interface Unit must be mounted to an Expansion

I/O Rack in order to connect the Expansion I/O Rack to

another Expansion I/O Rack.

Expansion I/O Backplane

2-5 I/O Power Supply

Just as a Power Supply must be mounted to the CPU Rack, a Power Supply

must also be mounted to the I/O Backplane and Expansion I/O Backplanes.

There are two Power Supplies available; 100 to 120/200 to 240 VAC and 24

VDC, both of which are explained below. For details, refer to Appendix B Specifi-

cations. Either Power Supply can be used in the C1000H or C2000H Simplex

Systems; however, the 24-VDC Power Supply can not be used in the C2000H

Duplex System.

Model Supply Voltage Output Capacity Available Current for I/O

Units

3G2A5-PS222-E 100 to 120/200 to 240

VAC (selectable)

3G2A5-PS212-E 24 VDC 7 A 5 VDC 6.5 A Not provided

7A 5 VDC 6.5 A Provided

24 VDC Output Terminal

16

Note Be sure to keep the total power consumed by all the Units mounted on a Rack

within the value stated in the table above. For example, do not mount I/O Units

with a total current consumption of 7A to a Rack supplied by a 7 A Power Supply.

As shown in the table above, the available current for I/O Units is only 6.5 A. For

details concerning current consumption, refer to Section 4 System Connections.

Page 30

I/O Power Supply Section 2-5

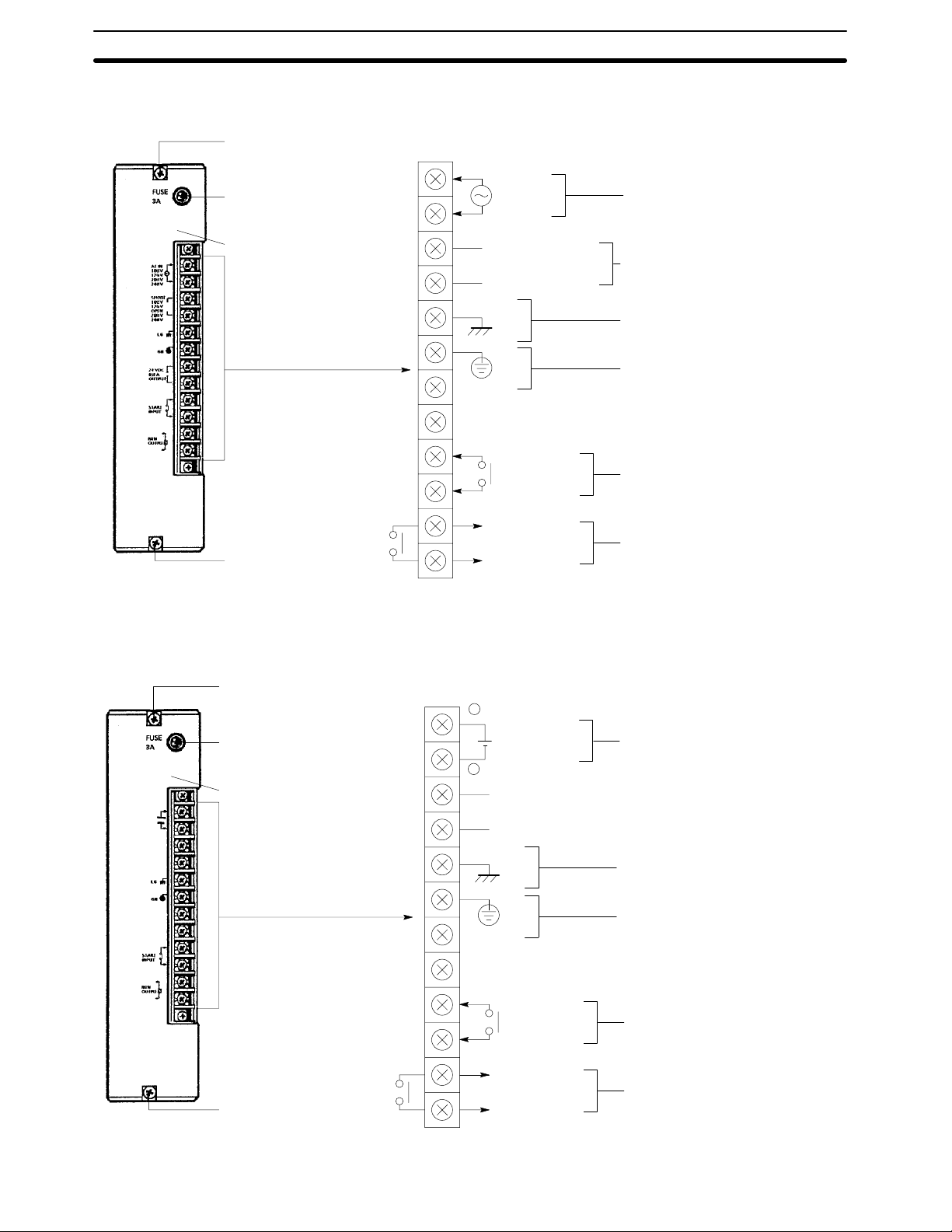

3G2A5-PS222-E

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

•

(3 A, 250 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

Mounting screw

Do not loosen this screw.

AC input

Voltage selector

Short: 100 to 120 V

Open: 200 to 240 V

LG

GR

+

0.8 A, 24 VDC output

-

Connect a 100 to 120 VAC or 200 to

240 VAC power source

Short these terminals to select 100 to

120 VAC. Open them to select 200 to

240 VAC.

Ground this terminal at a resistance

of less than 100 W to improve noise

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100 W to prevent electric

shock.

Use these terminals to supply power

to DC Input Units. Use a separate

Power Supply if the I/O Unit operate

on more than 0.8 A. If a current higher

than 0.8 A is output, the PC stops.

These terminals are used to supply

external DC Input Units. If the Unit

requires more than 0.8 A a separate

supply must be used. The PC shuts off

automatically if a current of more than

0.8 A is drawn from the supply.

3G2A5-PS212-E

•

Mounting screw

Do not loosen this screw.

Fuse holder

Contains a MF61NR fuse

(4 A, 125 V, 6.35-dia. x32)

POWER indicator

Lights when power is supplied.

Terminals for

external connections

+

-

24 VDC input

LG

GR

Connect a 24-VDC power source

(2.3 A min.)

Ground this terminal at a resistance

of less than 100 W to improve noise

immunity or prevent electric shock.

Ground this terminal at a resistance

of less than 100 W to prevent electric

shock.

Mounting screw

Do not loosen this screw.

17

Page 31

I/O Interface Unit Section 2-8

2-6 Duplex Unit (C2000H Duplex)

The Duplex Unit shown below must be mounted to the CPU Rack in order to

operate the Duplex System. The following indicators and switches are located

on the front panel.

DUPLEX RUN (Green)

Lit during normal duplex

operation

DUPLEX BUS ERROR (Red)

Lit if an error occurs in the Duplex

System. When a DUPLEX BUS

ERROR occurs the active CPU

switches the system from a Duplex

System to a Simplex System.

VERIFY ERROR (Red)

Lit if the programs in both CPUs are

not the same. When a VERIFY

ERROR occurs, the active CPU

switches the system from a Duplex

System to a Simplex System.

ACTIVE CPU (Green)

Indicates which CPU is active.

CPU RUN (Green)

Lit when the active CPU is

operating normally.

WAITING (Green)

This indicator is lit on three different

occasions:

(1) While the program in the Duplex

System is being verified (1 to 20

seconds)

(2) When the start input is not applied

to the CPU

(3) When there is a failure in starting

the Duplex System

CPU ON/OFF switches

Use these switches to supply power to

each of the CPUs. To operate the CPU,

move the corresponding switch to the

ON position. When replacing the CPU,

move the corresponding switch to the

OFF position, and remove the CPU

from the Rack. Note that power is not

supplied to the CPU whose corresponding switch is OFF.

INITIAL SET

2-7 I/O Control Unit

An I/O Control Unit must be mounted to the CPU Rack in order to connect the

CPU Rack to an Expansion I/O Rack. In C1000H and C2000H Simplex Systems, the I/O Control Unit is mounted to the CPU Rack. In the C2000H Duplex

System, the I/O Control Unit is mounted to the I/O Rack. An I/O Control Unit can

be mounted even if no Expansion I/O Rack is used.

PROGRAM (Green)

Lit when both CPUs are in the

PROGRAM mode

CPU ERROR (Red)

Lit when an error occurs in the

CPU. Operation stops and the

RUN indicator is not lit.

MEMORY ERROR

Lit if an error is found in the PC

program

ACTIVE SYSTEM

2-8 I/O Interface Unit

An I/O Interface Unit is needed on each Expansion I/O Rack, in order to expand

the PC. If there is not an I/O Interface Unit on each Expansion I/O Rack, data

communication cannot take place. The I/O Interface Unit is mounted to the leftmost I/O position on the Expansion I/O Backplane.

18

Page 32

I/O Remove Unit Section 2-11

2-9 File Memory Unit

When a File Memory Unit is connected to the PC, contents of the Program

Memory and data areas can be transferred to and from File Memory (FM). For

details on operating the File Memory Unit, refer to the C1000H/C2000H Opera-

tion Manual.

The Unit can be mounted to either of the six rightmost slots on the Rack.

2-10 Space Unit

The Space Unit is included with the I/O Backplane to fill the space between the

Power Supply and the rightmost Unit mounted on the Backplane. This Unit only

applies to the I/O Backplane used in C2000H Duplex Systems. When mounting

this Unit be sure to remove the bracket on the Backplane first.

2-11 I/O Remove Unit

The I/O Remove Unit is unique to C2000H Systems. When mounted to a Rack of

a C2000H System, the I/O Remove Unit allows standard I/O Units to be removed

or mounted while the CPU is operating. The I/O Remove Units on each Rack are

connected by an I/O Remove Unit Connecting Cable.

In order to mount an I/O Unit to or remove an I/O Unit from any of the Racks in the

PC system, a Programming Console must be used to release the I/O Unit from

the control of the CPU. For details, refer to the PC Operation Manual.

Depending on the combination of I/O Units, a failed standard I/O Unit can be

replaced without affecting the other Units in the system.

When mounting or removing the I/O Units, the terminal block does not need to be

rewired. Simply mount the I/O Unit to the Backplane and then the terminal block

to the I/O Unit. When removing the I/O Unit, remove the terminal block first and

then remove the I/O Unit from the Backplane.

When an I/O Unit is mounted or removed while the CPU is operating on a Backplane which has an Interrupt Input Unit mounted to it, the Interrupt Input

(mounted only to C1000H and C2000H Simplex PCs) will be ignored.

Note 1. Remember that only a standard I/O Unit can be mounted or removed during

operation.

2. An I/O Remove Unit must be mounted on every Rack that will require I/O

units to be mounted or removed during operation. Even if none of the I/O

Units on the CPU Rack will be removed or mounted during operation, an I/O

Remove Unit is needed if I/O substitution is to take place on an Expansion

I/O Rack connected to the CPU Rack.

19

Page 33

I/O Units Section 2-12

Special I/O Units, such as the A/D Conversion Input Unit or the High-speed

Counter Unit, cannot be removed or mounted during operation. In addition, if

Special I/O Units and standard I/O Units are mounted on the same Rack, none of

the Units on that Rack can be removed or mounted without affecting the other

Units. However, there are combinations with other I/O Units that allow substitution during PC operation. The following table explains the instances in which

standard I/O Units, when used in combination with other I/O Units, can be

removed or mounted during PC operation. The groups defined in the table are

used only in this section and do not apply to groups of similar nature in other

manuals.

Group I/O Unit Mounted to 3G2C5-BI082 and 3G2C5-BI083 Backplane

Group A 16-/32-/64-point I/O When only Units from Group A are mounted to a Backplane the I/O Units can

be removed or mounted during PC operation.

Group B PC Link Unit

Host Link Unit

Group C A/D Conversion Unit

D/A Conversion Unit

Remote I/O Master

Remote I/O Slave

Others

When Units from Group B are mounted on the same Backplane as Units from

Group A, only the Units from Group A can be removed or mounted during PC

operation. However, this does not apply when using 3G2C5-BI083.

When Units from Group C are mounted on the same Backplane as Units from

Group A, neither Group a Units nor Group C Units can be removed or

mounted during PC operation.

Caution When removing or mounting an I/O Unit while the CPU is operating, be sure to

!

2-12 I/O Units

A-shape

remove the terminal block from the I/O Unit first and then remove the I/O Unit

from the Backplane. If the entire I/O Unit is removed from the Backplane, output

signals are not cleanly disconnected, but may be sent to external devices, causing a sudden pulse to go the external device. This may in turn cause the device to

shudder. Also, when remounting the I/O Unit to the Backplane, fir st mount the

I/O unit and then the terminal Block to the I/O Unit.

I/O Units come in 5 shapes; A-shape, B-shape, C-shape, D-shape, and

E-shape. Refer to Appendix B Specifications for the dimensions of each Unit.

Mounting screw

Provided at top and bottom

Nameplate

Fuse blowout alarm indicator

Provided on OD411/OD217/OA121/OA222

I/O indicators

Indicate ON/OFF status points

Terminal block mounting screw

Provided at top and bottom

20

20-terminal terminal block

Removable

Page 34

I/O Units Section 2-12

B-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of I/O signal

Terminal block mounting screw

Provided at top and bottom

38-terminal terminal block

Removable

C-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Terminal block mounting screw

Provided at top and bottom

38-terminal terminal block

Removable

21

Page 35

I/O Units Section 2-12

D-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Two 40-terminal terminal

block connectors

Removable

E-shape

Mounting screw

Provided at top and bottom

Nameplate

I/O indicators

Indicate ON/OFF status of points

Two 24-terminal terminal block connectors

4-terminal terminal block

22

Page 36

Memory Packs Section 2-13

2-13 Memory Packs

The Memory Pack fits into the slot located on the right side of the CPU. Because

the Memory Pack is not provided with the PC upon delivery, a Memory Pack

must be selected and installed in the CPU. There are two Memory Packs available, either RAM or ROM, that can be used for both the C1000H and C2000H

Systems.

Note Mount a Memory Pack to the CPU on the left and another Memory Pack to the

CPU on the right. These Memory Packs must have the same specifications.

When using the RAM Pack, there must not be any difference in write-protect

switch settings for the left and right CPUs, otherwise a collation error will result

and the PC will not operate.

RAM Pack Data can be randomly written to and read from the RAM Pack, making it possible

to enter your own program into the CPU. However, because this is not a fixed

program, the memory of the RAM Pack is erased when power is not supplied to

the CPU or when the RAM Pack is removed from the CPU without first being connected to a backup battery.

Caution

!

1. When removing the RAM Pack from the CPU, be sure to connect the RAM

Pack to a backup battery before removing it from the CPU or the data will be

lost. Do not use the backup battery located in the compartment above the

Memory Unit Compartment. It is used to backup memory in the CPU.

2. Do not remove the battery in the CPU when the RAM Pack has been

removed from the CPU.

There is a write-protect switch and a write-protect indicator on the RAM Pack, as

shown in the following diagram. Setting the write-protect switch to OFF allows

data to be written to the RAM Pack. Use a peripheral device, such as a Programming Console, to write to the RAM Pack.

Battery connector

RAM Pack

To write data to the RAM Pack, move the write-protect switch to the OFF position. After data is written to the RAM Pack, be sure to move the write-protect

switch to the ON position to protect the data from further alterations. If you try to

write data to the Memory Pack while the write-protect switch is in the ON position, the message DISABLED ROM will appear on the Programming Console.

Four models of RAM Packs are available, which vary in memory capacity: 8K,

16K, 24K, and 32K words. Refer to Appendix C Standard Models for model numbers.

Write-protect LED indicator

Write-protect switch

OFF

ON

23

Page 37

Memory Packs Section 2-13

ROM Pack Data contained in the ROM Pack is stored on EPROM chips and cannot be

altered or erased during the CPU’s operation. The ROM Pack can accept four

EPROM chips, which can be programmed for your particular application with the

PROM Writer. The EPROM chip is mounted to the Memory Pack and the entire

pack is installed in the CPU. Once the data is written to the chip the data will not

be lost when the power to the PC is OFF.

IC Sockets

SW1 No.

Selector

RAM Pack

24

Page 38

SECTION 3

Assembly

When we speak of a PC, we usually think of it as a single object. But actually even the simplest PCs are usually composed of

several different devices. In fact a single PC can be physically spread throughout a building, but we still call it one PC.

In this section, we will start with a Backplane and use all the Units discussed in Section 2 to build a PC.

3-1 Mounting the Units 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 C2000H Duplex System 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 C2000H Simplex System 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Memory Packs 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 System Configurations 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

Page 39

Mounting the Units Section 3-1

3-1 Mounting the Units

There is no single Unit that can be said to constitute a Rack PC. To build a Rack

PC, we start with a Backplane. The Backplane for the C1000H/C2000H is shown

below.

C1000H/C2000H Backplane

The Backplane is a simple device having two functions. The first is to provide

physical support for the Units to be mounted to it. The second is to provide the

connectors and electrical pathways necessary for connecting the Units

mounted to it.

The first device we will add to the Backplane is a Power Supply. The Power Supply fits into the rightmost position on the Backplane and provides electricity at the

voltages required by the other Units of the PC. It can also be used to power devices other than the PC if necessary.

Power Supply

The core of the PC is the CPU. The CPU contains the program consisting of the

series of steps necessary for the control task. The CPU fits into the position directly to the left of the Power Supply.

26

CPU

Page 40

Mounting the Units Section 3-1

Unlike the CPU of the Package-type PC, the CPU of the Rack PC has no I/O

points built in. So, in order to complete this kind of PC we need to mount one or

more I/O Units to the Backplane. Mount the I/O Units to the Backplane by pressing the I/O Unit firmly into position, making sure the connectors are properly

mated. Secure the Unit by tightening the mounting screws located on the top and

bottom of the Unit.

Mounting screws

Provided at the top and

bottom of the Unit

Connector

Make sure the connectors

are properly mated.

The figure below shows one I/O Unit mounted directly to the left slot of the CPU

Rack.

I/O Unit

I/O Units are where the control connections are made from the PC to all the various input devices and output devices. As you can see from the figure, there is

still some space available on the right side of the I/O Unit. This space is for any

additional I/O Units that may be required.

27

Page 41

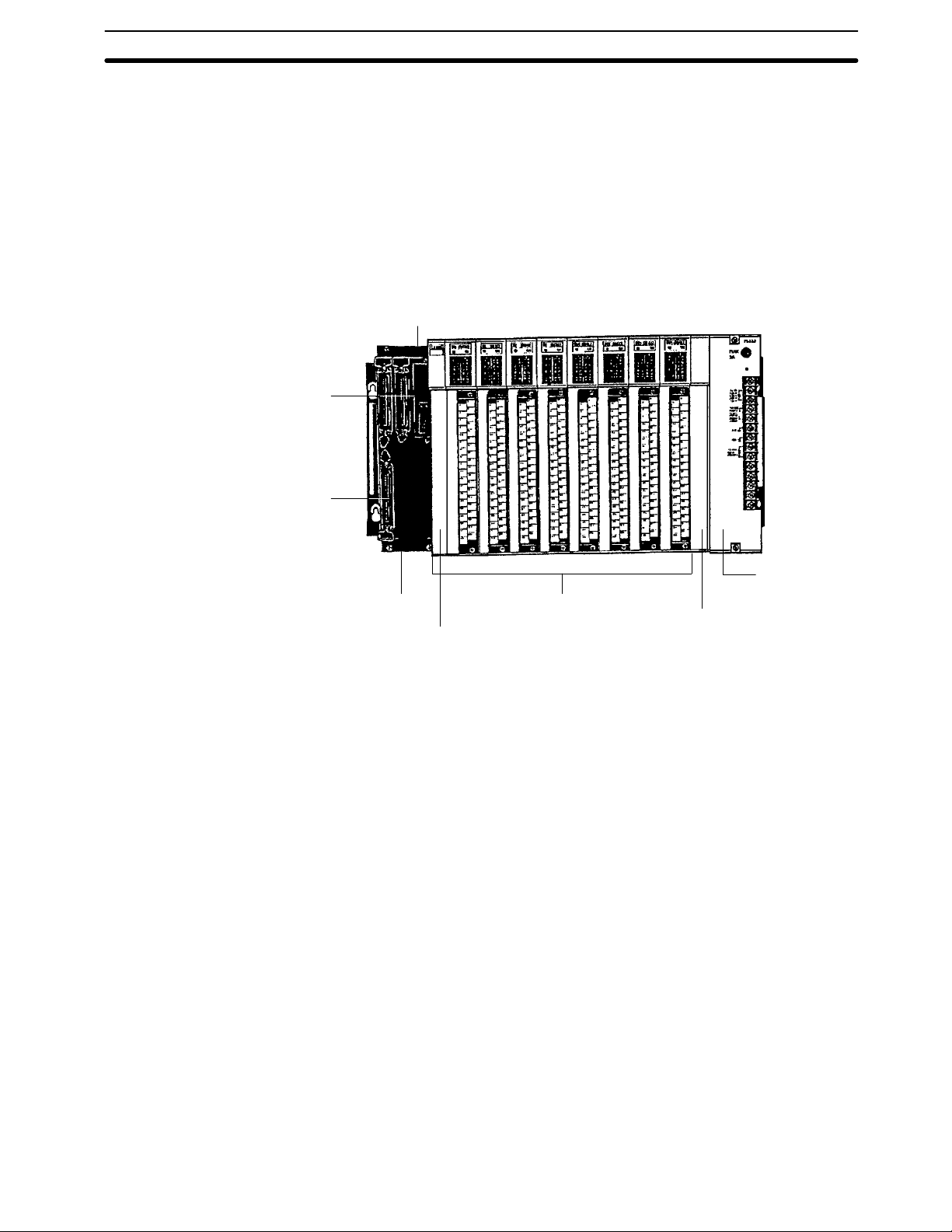

Mounting the Units Section 3-1

The figure above shows a total of six I/O Units mounted to the Backplane. Backplanes are available in different lengths, and can hold a different number of I/O

Units accordingly. Of course, not all I/O Units look exactly alike, but the ones in

the figure show their typical appearance. This configuration of Backplane,

Power Supply, CPU, and I/O Units is called a CPU Rack. This term refers to the

Backplane and all the Units mounted to it. However, if we want to include more

than six I/O Units in our configuration we can add an additional Backplane. First,

though, we have to mount an I/O Control Unit to the leftmost slot of the CPU

Rack.

I/O Control Unit

Now we can use a cable to connect the CPU Rack to another Backplane. This

Backplane has a Power Supply and I/O Units mounted to it, but it has no CPU of

its own. The additional Backplane must also have an I/O Interface Unit mounted

to its leftmost position. This configuration of additional Backplane, Power Supply, I/O Units, and I/O Interface Unit is called an Expansion I/O Rack.

CPU Rack

Expansion I/O Rack

28

I/O Interface Unit