Page 1

Electromagnetic Coupling Type RF-ID System

V670 Series

User’s Manual

ID Controller, Antenna, and ID Tag

ID Controller

Model V670-CD1D

Antenna

Model V670-H11

ID Tag

Model V670-D13F03

Catalog No. SCLB-702

Page 2

Introduction

Thank you very much for choosing the electromagnetic coupling type RF-ID system V670 Series. The V670 Series has been developed

by OMRON, based on the advanced technology and extensive experience. This user’s manual describes the functions, performance and

usage of V670 Series.

When you use the V670 Ser ies, follow the instructions below:

• Read this user’s manual with care, underst and the V670 Series fully and use it appr opriately.

• Keep this user’s manual handy.

Notes on use

When you use the V670 Series in the following environments, we would like you to operate it within the rating and functions, take

safety measures such as fail-safe system and consult our person in charge.

(1) Use in an unsuitable condition or environment which is not described in the user’s manual

(2) Use for nuclear energy control, railroad, aeronautica l system, car, combustion equipmen t, medical equipment, amusement

facility, safety device, etc.

(3) Use for application which may have a great influence on people’s lives and property and must be executed safely in particu-

lar.

Page 3

Notes on safety

For the safety, be sure to follow the instructions below:

1. Do not operate this device in any flammable, explosive or corrosive gas environment.

2. Do not disassemble, repair nor remodel this device.

3. Tighten the base lock screws and terminal block screws completely.

4. Be sure to use wiring crimp terminal of a specified size.

5. If any cable has a locking mechani s m, be sure to check that it has been loc ked before using it.

6. The DC power supply must meet the following items:

(1) Such DC power supply must be used for the V670 Series onl y and must not be connected to any other devices nor apparatuses.

(2) Voltage of such DC power supply must be within the specified rating (24 VDC+10%-10%).

7. Be sure to follow any other warnings, cautions and notices mentioned in this manual.

Notes on usage

1. Do not install Model V670-CD1D in the following areas:

• Place exposed to the direct sunlight.

• Humid place where moisture condensat ion may occur.

• Place affected by vibration or impact.

2. Preliminary check of installation site.

This device use s the freq uen cy ba nd 13 .56 MH z to co mmu nica te w ith a tag . This f requ enc y ban d 13.5 6 MHz is used also as the ISM

band (one of frequencies assigned to med ical or indu stria l heater; an appl icati on must be file d for instal lati on). So, such heat er may

affect the communication with a tag or may damage the tag, if the heater is located near this device. If you must this device near such

heater, we would like you to check the influence in advance. To minimize general influence of noise, follow the instructions below:

• Ground any metallic material located around this device according to Class D (Class III).

• Wire this device keeping away f rom high voltage and h eavy current.

3. Be sure to ground any ground terminal according to Class D (conventional Class III). Otherwise, performance may deteriorate.

4. Cleaning of Model V670-D13F03, Model V670-H11 and Model V670- CD1D.

• Do not use any thinner. Resin material and case paint are dissolved by thinner.

Page 4

Manual Revision History

A manual revision history code is added to the end of catalog number shown at the left lower part of front cover

and back cover

Catalog No. SCLB-702!

Revision

Code

-- October 2000 First Edition

Date of

Revision

Reason of Revision / Revised Page

!

!!

Revision code

Page 5

Contents

Chapter 1 Features and System Configuration

1-1 Features ..........................................................................................................................1-1

1-2 System Configuration.....................................................................................................1-2

Chapter 2 Specifications and Performance

2-1 Controller........................................................................................................................2-1

2-1-1 Component Names and Functions..................................................................................................... 2-1

2-1-2 General Specifications.......................................................................................................................2-3

2-1-3 Perfo rmance Sp ecifications............................................................................................................... 2-3

2-1-4 Communication Specifications..........................................................................................................2-4

2-1-5 I/O Specifications ..............................................................................................................................2-4

2-1-6 Example of Wiring.............................................................................................................................2-5

2-1-7 Outside Dimension ............................................................................................................................2-6

2-2 Antenna...........................................................................................................................2-7

2-2-1 Specifications.....................................................................................................................................2-7

2-2-2 Outside Dimension ............................................................................................................................2-7

2-3 Tag..................................................................................................................................2-8

2-3-1 Specifications.....................................................................................................................................2-8

2-3-2 Outside Dimension ............................................................................................................................2-8

2-3-3 Memory Map .....................................................................................................................................2-9

2-4 Cable.............................................................................................................................2-10

2-4-1 Specifications...................................................................................................................................2-10

2-4-2 Outside Dimension ..........................................................................................................................2-10

2-5 Communication Range Specifications .........................................................................2-11

2-5-1 Communication Area (Reference)................................................................................................... 2-11

2-5-2 Operation Time (Reference)............................................................................................................ 2-12

2-5-3 Traffic and Passing Speed (Reference)............................................................................................ 2-14

Chapter 3 Setting And Installation

3-1 Controller........................................................................................................................3-1

3-1-1 Switch Setting....................................................................................................................................3-1

3-1-1-1 How to Open Cover.................................................................................................................3-1

3-1-1-2 How to Set ...............................................................................................................................3-2

3-1-1-3 Setting List............................................................................................................................... 3-2

3-1-1-4 Setting Node Number Setup Switch........................................................................................3-3

3-1-1-5 Setting a Dip Switch ................................................................................................................ 3-4

3-1-2 Installation Site .................................................................................................................................. 3-6

3-1-3 How to Install .................................................................................................................................... 3-7

3-1-4 How to Connect Antenna...................................................................................................................3-8

3-1-5 How to Connect Extension Cable And How To Extend Antenna.....................................................3-9

3-1-6 How to Wire.......................................................................................................................................3-9

Page 6

Chapter 4 Functions

Contents

3-1-6-1 Wiring Power Supply And Grounding Cable ........................................................................3-10

3-1-6-2 Wiring Reset Signal ...............................................................................................................3-10

3-1-6-3 Wiring Output Signal.............................................................................................................3-11

3-1-7 Connecting RS-232C Interface........................................................................................................3-12

3-2 Antenna ........................................................................................................................3-16

3-2-1 Installation Site ............................ ...... ...... ............................................. ...........................................3-16

3-2-2 How To Install..................................................................................................................................3-16

3-3 Tag................................................................................................................................3-17

3-3-1 Installation Site ............................ ...... ...... ............................................. ...........................................3-17

3-3-2 How to Install...................................................................................................................................3-17

Chapter 4 Functions

4-1 Communication Designation Function...........................................................................4-1

4-1-1 Designation Of Command Trigger System Communication (ST).....................................................4-1

4-1-2 Designation of Automatic System Communication (SA/RA/PA) .....................................................4-2

4-1-3 Designation of External Trigger System Communication (SI/RI/PI)................................................4-3

4-2 Tag Designation Function...............................................................................................4-5

4-3 Operation Mode..............................................................................................................4-6

4-4 Operation Parameter Setting...........................................................................................4-8

4-4-1 Communication Res tri ction Time......................................................................................................4-8

4-4-2 Character Interval Monitoring Time..................................................................................................4-8

4-4-3 Response Ready Time........................................................................................................................4-9

4-5 Memory Check Function..............................................................................................4-10

4-6 Write Protect Function..................................................................................................4-11

Chapter 5 Control From Host Device

5-1 Controller Operation Status ...........................................................................................5-1

5-2 Command Response Format ..........................................................................................5-2

5-3 Command Response Flow..............................................................................................5-6

5-4 Command List................................................................................................................5-7

5-5 Communication Designation List...................................................................................5-8

5-6 Communication Command.............................................................................................5-9

Page 7

Contents

5-6-1 Read (RD)........................................................................................................................................5-10

5-6-2 Write (WT)....................................................................................................................................... 5-11

5-6-3 Computation Write (CW) ................................................................................................................ 5-12

5-6-4 Data Fill (DF) .................................................................................................................................. 5-13

5-6-5 Memory Check (MD) ...................................................................................................................... 5-14

5-6-6 Tag Function Designation (TF)........................................................................................................5-15

5-6-7 ID Read (ID)....................................................................................................................................5-16

5-7 Communication Subcommand .....................................................................................5-17

5-7-1 Command Processing Abort (AA)................................................................................................... 5-17

5-7-2 Polling Query (PC) .......................................................................................................................... 5-17

5-8 Controller Control Command.......................................................................................5-18

5-8-1 Operation Mode Change (MO)........................................................................................................ 5-18

5-8-2 Data Retransmission (RR)............................................................................................................... 5-18

5-8-3 Reset (XZ)........................................................................................................................................ 5-19

5-8-4 Controller Control (CC)...................................................................................................................5-19

5-8-5 Operation Condition Setting (SE).................................................................................................... 5-20

5-8-6 Parameter Setting (SP)..................................................................................................................... 5-22

5-9 Host Command.............................................................................................................5-23

5-9-1 Test (TS) ............................... ............................................. .............................................................. 5-23

5-9-2 Version Information (VS)...................... ..... ...... ............................................. ..................................5-23

5-10 Termination Code List..................................................................................................5-24

5-11 Example Of Communication Program.........................................................................5-25

Chapter 6 How To Use Self-Execution Mode

6-1 Available Conditions ......................................................................................................6-1

6-2 Setting Procedure ...........................................................................................................6-2

6-3 Example Of Setting ........................................................................................................6-3

Chapter 7 How to Use Programming Console

7-1 Component Name...........................................................................................................7-1

7-2 Outside Dimension.........................................................................................................7-2

7-3 Connection of Programming Console............................................................................7-3

7-3-1 Inserting Key Sheet............................................................................................................................7-3

7-3-2 Connecting Cable............................................................................................................................... 7-4

Page 8

Chapter 8 From Startup To Run

Contents

7-4 How to Use.....................................................................................................................7-5

7-5 Functions ........................................................................................................................7-6

7-5-1 Programming Console Function List.................................................................................................7-6

7-5-2 How to Operate..................................................................................................................................7-7

7-5-2-1 Password Input Screen.............................................................................................................7-7

7-5-2-2 Changing Operation Mode.......................................................................................................7-7

7-5-2-3 Accepting Key in Initial Screen of Monitor Mode..................................................................7-8

7-5-2-4 Accepting Key in Initial Screen of Run Mode......................................................................... 7-9

7-5-3 Displaying Details of Setting...........................................................................................................7-10

7-5-4 Address Setting................................................................................................................................7-12

7-5-4-1 For Reading............................................................................................................................7-12

7-5-4-2 For Writing.............................................................................................................................7-12

7-5-5 Data Setting......................................................................................................................................7-13

7-5-6 Reading/Writing Data ......................................................................................................................7-13

7-5-6-1 Reading ..................................................................................................................................7-13

7-5-6-2 Reading Again........................................................................................................................7-14

7-5-6-3 Writing ...................................................................................................................................7-15

7-5-6-4 Writing Again.........................................................................................................................7-15

7-5-7 Test ...................................................................................................................................................7-16

7-5-7-1 Setting Communication Mode...............................................................................................7-16

7-5-7-2 T est Reading................................... ............................................. ...........................................7-16

7-5-7-3 T est Writing.................................... ..... ...... ............................................. ................................7-16

7-5-8 Reading Latest Error Information....................................................................................................7-17

7-5-9 Statistic Error Information ...............................................................................................................7-18

7-5-10 Execution Monitor .................................................................................................................7-19

Chapter 8 From Startup To Run

8-1 Trial Operation ...............................................................................................................8-1

8-2 Diagnosis Function.........................................................................................................8-2

8-3 Errors and Countermeasures...........................................................................................8-3

8-4 Maintenance and Inspection...........................................................................................8-4

8-5 Troubleshooting..............................................................................................................8-5

Chapter 9 Characteristic Data Depending on Operating Condition

(Reference)

9-1 Influence of Back Metal of Antenna (Reference) ..........................................................9-1

9-2 Mutual Interference between Antennas (Reference)......................................................9-2

9-3 Mutual Interference between Tags (Reference) .............................................................9-3

Page 9

9-4 Influence of Back Metal of Tag (Reference)..................................................................9-4

9-5 Influence of Tag Angle (Reference)...............................................................................9-5

9-6 Chemical Resistance of Tag (Reference)........................................................................9-6

Appendix

Appendix 1 JIS8 Unit Code List (ASCII Code List) ................................................Appendix-1

Appendix 2 Order Format List..................................................................................Appendix-2

Appendix 3 Protective Structure ...............................................................................Appendix-3

Contents

Page 10

Structure of This Manual

Chapter 1 Features and System Configuration

Chapter 2 Specifications and Performance

Chapter 3 Setting and Installation

Chapter 4 Functions

Chapter 5 Control from Host Device

Chapter 6 How to Use Self-Execution Mode

Chapter 7 How to Use Programming Console

Chapter 8 From Startup to Run

Chapter 9 Characteristic Data (Reference) Depending on

Operating Cond ition

Appendix

Page 11

Chapter 1 Features and System Configuration

1-1 Features

The V670 Series is the electromagnetic coupling type RF-ID system which has achieved fast, long-life and high-performance communication. This ID syste m is the most suitable for process control of high-speed line and traffic control of moving object in a plant and an

application that information must be updated frequently in a process.

Model V670-CD1D

Model V670-D13F03

• Model V670-CD1D (ID controller, referred to as "Controller")

Model V670-CD1D connects to a pe rsonal computer (referred to as " PC") and/or programmable con troller (PLC) and controls the

RF-ID system.

Model V670-CD1D has a ge neral-purpose I /O terminal and a f unction to judg e and process inde pendently (Self-E xecution mode)

and, therefore, a very fast system can b e configured for simple process only without any host device.

• Model V670-H11 (Antenna)

Model V670-H11 is a waterpro of antenna (stand ard antenna) with di mensions of 4 x 5.3 cm. Mo del V670-H11 can achieve the

communication area of 20 mm in combination with model V670-D13F03.

Model V670-H11 has a very fast comm unication performance and can transfer 12 bytes of data in appr oximately 5 ms.

• Type V670-D13F03 (ID tag, referred to as "Tag")

Type V670-D13F03 is a waterproof tag which has 1 28 bytes of memory capaci ty with dimensions of 40 x 40 mm. Model V670D13F03 uses high-performance nonvolatile memory called Ferroelectric RAM (FeRAM) as internal memory. So, memory life is

semi-permanent. (The memory can be accessed one billion times.)

Model V670-H11

• Easy to use

By connecting the programming console model C200H-PRO27 (unbundled, referred to as "ProCon") to the Controller via the special

cable model V700-P10 (unbundled), the system operation status and error log information can be read. This is useful for system startup and maintenance at a working site.

Ferroelectric RAM (FeRAM)

Ferroelectric RAM is one of nonv ol ati le RAMs and d ata can be writte n into a nd read from it fa ster than con ve nt ion al mem ory (such

as EEPROM and flash ROM). Data can be written into the ferroelectric RAM semi-permanently.

While any conventional RAM cann ot hold data if no thi ng is written in to it fo r a sp ecified perio d (app rox im a tely 1 0 ye ars), th e ferroelectric RAM can hold data if anyt hing is writ ten into or read from it. So , the ch aracteristic of fe rroele ctric RAM is very ex cellent in

data-holding performance.

1-1

Page 12

1-2 System Configuration

• Example of Model V670-CD1D system configuration

Model V670-CD1D contains a serial interface based on RS-232C and can connect easily to a general-purpose PC and programmable

controller (PLC). Model V670-CD1D has a comman d execution mo de and self-ex ecution mode as an operation mo de and control s

the communication to a tag according to the in stru ctions from a host device (in the command execution mod e) or t he registered conditions (in the self-execution mode).

<Hose Devices>

Desktop PC

Notebook PC

Model V670-CD1D

Model V670-A4

(Only when extension cable is used)

Programmable Controller

Model V700-P10

Model C200H-PRO27

!

1-2

Model V670-H11

Tag

Page 13

Chapter 2 Specifications and Performance

2-1 Controller

2-1-1 Component Names and Functions

• Model V670-CD1D

(1)Node number setup switch

(2)Dip switch

(3)LED display

(4)Cover

(5)Connecting port for

programming console

(6)Connecting port for antenna

(7)RS-232C port

(8)Power supply terminals

(9)Reset terminal/Input terminal

(10)Output terminals

2-1

Page 14

2-1 Controller

No.

(1) Note number setup switch Sets a controller node

(2) Dip switch Sets every mode. Sets an input function, operation mode, protocol, com-

(3) LED display An operation status is shown on this LED displayed.

RUN Green Shows the RUN sta-

COMM Green Shows an operation

NORM/ERR Green Shows the end of

RST/IN Green

OUT1 Green

OUT2 Green

(4) Cover

(5) Connecting port for pro-

gramming console

(6) Connecting port for antenna Used to connect an

(7) RS-232C port Used to connect a

(8) Power supply terminal Terminal for power supply.

24 VDC+ Supplies t he power. Connects the "+" side of 24 VDC power supply.

24 VDC- Connects 0 V.

GR Ground Class D (Class III).

(9) Input terminal Terminal for input.

RST/IN Supplies a reset sig-

(10)

Output terminal Terminal for output.

OUT1 Output signal 1 When external output is used , it conne cts to thi s terminal

OUT2 Output signal 2

O.COM Output common

Name Function Description

Used to identify the controllers when a maximum of 31

number.

tus.

status.

communication.

Red Shows an error. Tu rns on once and tu rns off w hen the commu nication has

Shows an input status.

Shows an output status.

Shows an output status.

Cover common to (1), (2) and (5).

Used to connect a

programming console.

antenna.

host device.

nal or trigger signal.

controllers are connected to one host computer.

munication conditions, etc.

Turns on when an operati on is normal .

Turns on during the communication to a tag.

Turns on o nce and turns of f when th e communication has

ended correctly.

ended due to an error. Turns on when a system error

occurs.

Turns on when the RST/IN input signal turns ON.

Turns on when the OUT1 output signal turns ON.

Turns on when the OUT2 output signal turns ON.

Open as neces s ary.

Our programming console type C200H-PRO27 (unbundled)

can connect to this port through the connecting cable model

V700-P10 (unbundled). When you operate the programming

console, use a key sheet for the V700-P10.

One antenna can connect to this port. To extend the

cable, use model V670-A4!((((unbundled). (Available

antenna: Model V670-H11)

Based on the RS-232C, a general-purpose programma-

ble controller (PLC) and PC can connect to this port.

When external reset input and external trigger input are

used, they connects to this terminal together with 24

VDC- in pairs. Function can be selected with a dip

switch.

together with O.COM in pairs.

2-2

Page 15

2-1-2 General Specifications

Item Specifications

Model V670-CD1D

Power supply voltage

(Power consumption)

Ambient operating temperature

Ambient operating hum idity

Ambient stora ge temperature

Ambient storage humidity 35 to 85%RH (no condensation)

Insulation resistance 20 MΩ or more (at 1,000 VDC mega) (1) to (6).

(1) Between a group of the power supply terminals and the grounding terminal.

(2) Between a group of the power supply terminals and a group of the output terminals.

(3) Between a group of the power supply terminals and the case.

(4) Between a group of the output terminals and the grounding terminal.

(5) Between a group of the output terminals and the case.

(6) Between the grounding terminal and the case.

Withstand voltage Leakage current 5 mA or less at 1,000 VAC (for 1 minute).

Protective structure Contains a panel.

Vibration resistance

Performing sweep 10 times for 8 minutes in an upward, downward, leftward, rightward, forward and backward directions.

Impact

Ground According to Class D (convention al Cl ass I II)

Material PC/ASA resin

Weight Approximately 270 g

Installation DIN or M4 screws

Giving impact of 150 m/s

10 to 150 Hz, double amplitude 0.2 mm, acceleration 15 m/s

35 to 85%RH (no condensation)

Impressed to (1) to (6) above.

2

3 times each in upward, downward, leftward, rightward, forward

and backward directions, i.e., 18 times in total.

24 VDC±10%

(7 W or less)

0 to +55°C (no icing)

-20 to +75°C (no icing)

2-1 Controller

2

.

2-1-3 Performance Specifications

Item Specifications

Communication

function

Maintenance

function

Diagnosis function

I/O function Input contact: 1 (RST/IN)

CPU error, host communication error, satellite communication error.

Single/Repeat/Input mode access function.

Write protect function/Memory check function

Self-Execution Function

Error reading function

Output contact: 2 (OUT1 and OUT2)

2-3

Page 16

2-1 Controller

2-1-4 Communication Specifications

Item Specifications

Base specification RS-232C

Communication method

Transmission rate 9600 bps, 19200 bps, 38400 bps, 115200 bps *

Synchronization method

Start-stop synchronization (Stop bit 1 or 2) *

Transmission code

Maximum number of

connected controllers

Error control Vertical parity (even, odd, nil)*. Horizontal parity is used as FCS.

Line length A maximum of 15 m.

Suitable connector

Model XM2A-0901 (plug) and model XM2S-0911 (hood), which come with our controller.

Recommendable cable

CO-MA-VV-SB 5Px28AWG (Hitachi Cable)

EIA/TIA-232-E

ASCII7 unit or JIS8 unit *

31

D-SUB 9-pin, male

* This can be set by a dip switch of the control ler. For how to set, refer to Chapter 3 .

2-1-5 I/O Specifications

• Input Specifications (RST/IN)

Input voltage 24 VDC ±10% (including ripple)

Input impedance 2.2 kΩ

Input current 10 mA TYP (24 VDC)

ON voltage 19 to 24 V

OFF voltage 5 V or less

Input response time 4 0 µs or less

• Output Specifications (OUT1/OUT2)

The output is the open collector specification.

Item Specification

Maximum open/c los e

24 V ±10% 100 mA

ability

Leakage current 1 µA or less

Residual voltage 1.0 V or less

Input circuit Controller output section

Circuit Structure

24VDC

Circuit Structure

Controller input section

Internal circuit

2-4

Internal circuit

Relay

24VDC

InternalInternal

Page 17

2-1-6 Example of Wiring

2-1 Controller

Antenna Type

Model V670-H11

Connecting Cable

Model V700-P10

Programming Console

Model C200H-PRO27

24 VDC Power Supply

Controller

Model V670-CD1D

Host Programmable

Controller (PLC)

Antenna Cable

Model V700-A4!

(Only when extension

cable is used)

2-5

Page 18

2-1 Controller

2-1-7 Outside Dimension

(Unit: mm)

Case material PC/ASA resin

2-6

Page 19

2-2 Antenna

2-2-1 Specifications

Item Specifications

Model V670-H11

Oscillating frequency 13.56 MHz

Ambient operating temperature

Ambient operating humidity

Ambient storage temperature

Ambient storage humidity

Insulation resistance 20 MΩ or more (at 1,000 VDC mega).

Impressed between a group of terminals and a case.

Withstand voltage 1,000 VAC (for 1 minute).

Impressed between a group of terminals and a case. Leakage current 1 mA or less.

Protective structure IP67 (IEC60529 Standard)

Vibration resistance

Performing sweep 10 times for 8 minutes in an upward, downward, leftward, rightward, forward and backward directions.

Impact

Material ABS/epoxy filler

Cable length 2 m

Weight Approximately 160 g

Giving impact of 150 m/s

10 to 150 Hz, double amplitude 0.7 mm, acceleration 50 m/s

2

3 times each in upward, downward, leftward, rightward, forward

and backward directions, i.e., 18 times in total.

(Cable section material is PV C.)

-10 to +70°C

35 to 85%RH

-25 to +85°C

35 to 85%RH

2

.

2-2-2 Outside Dimension

• Model V670-H11

(Unit: mm)

Case material ABS resin

Filler resi n Epoxy resin

Cable PVC

2-7

Page 20

2-3 Tag

2-3-1 Specifications

Item Specifications

Model V670-D13F03

Memory capacity 128 bytes

Type of memory FeRAM (Ferroelectric RAM)

Memory life Number of accesses*: One billion

Data-holding period 10 yeas after accessing.

Ambient operating temperature

Ambient storage temperature

Ambient operating humidity

Protective structure IP67 (IEC60529 Standard)

Vibration

Performing sweep 10 times for 15 minutes in an upward, downward, leftward, rightward, forward and backward directions.

Impact

Material ABS/epoxy resin.

Weight Approximately 6 g

Giving impact of 500m/s

10 to 2,000 Hz, double amplitude 1.5 mm, acceleration 150 m/s

2

3 times each in upward, downward, leftward, rightward, forward and

backward directions, i.e., 18 times in total.

-10 to +70°C

-10 to +70°C

35 to 85%RH

2

.

* Number of accesses is the total number of read/write communication times.

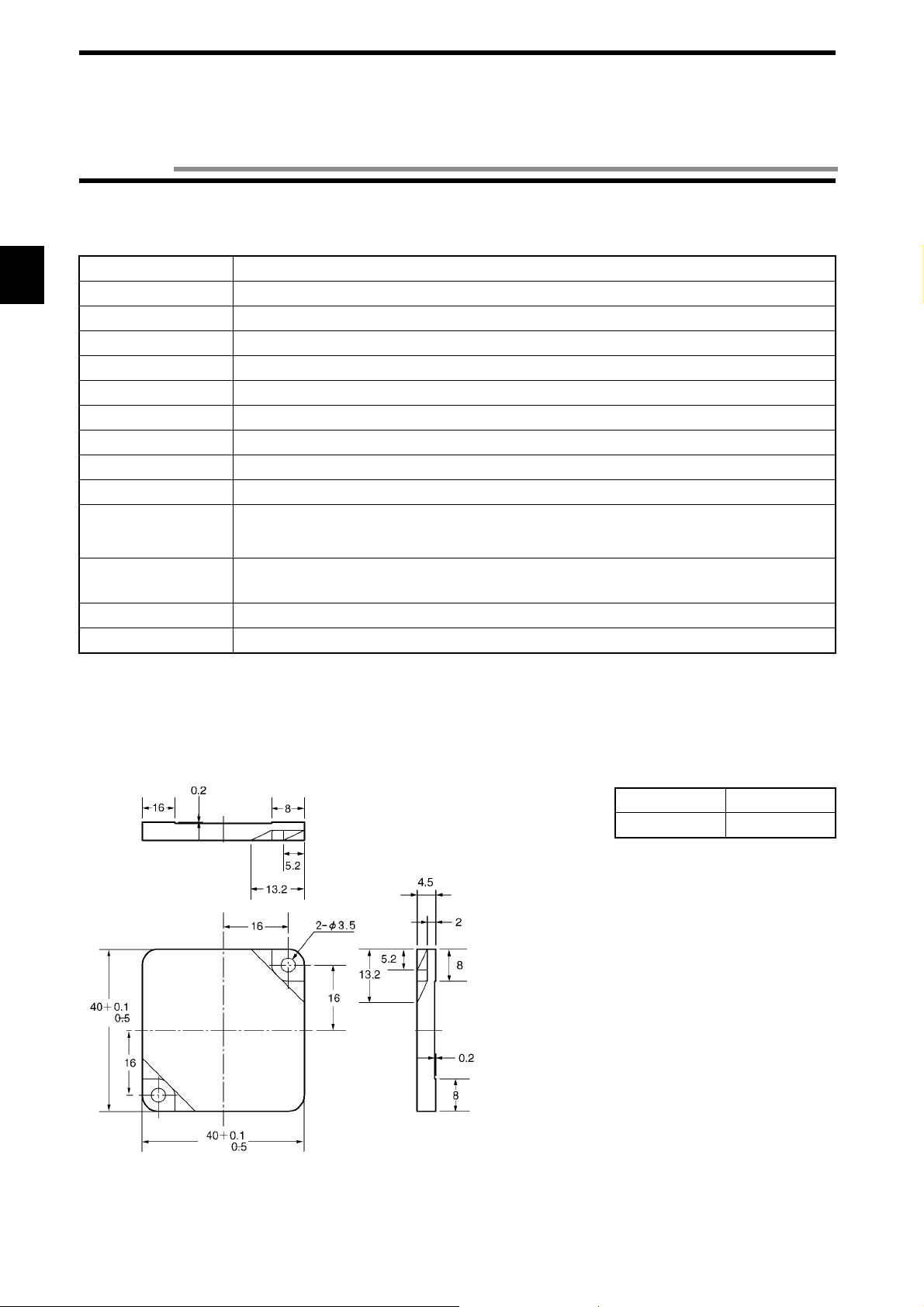

2-3-2 Outside Dimension

• Model V670-D13F03

Case material ABS resin

Filler resin Epoxy resin

(Unit: mm)

2-8

Page 21

2-3 Tag

2-3-3 Memory Map

There are a user area and ID code in memory in a tag. Memory capacity of user area is 128 bytes. You can write 1 byte of data into one

address. Memory area is divided into 4 bytes of pages and every page has its own address like 0000h to 0003h, 0004h to 0007, etc.

♦

Memory Map

Page User Address

$0000

1

.

.

.

.

* When a protect f unct ion is used, th e a dd resses 00 00h t o 00 03 h are u sed as pr ote ct ad dres s i nfo rmati on and cann ot be used as a user

area. For details, refer to "4-6 W rite Protec tio n Fun c tio n" .

♦

ID Code

This is a 4-byte area where tag identificatio n num ber (inherent tag number) is written. The ID code is writt en at shipment from a factory and it cannot be modified. The ID code can be read by an ID read command.

$0002

$0003

$0004

$007F

When a protect function is used When a protect function is not used

User Area

.

.

.

.

User Area

Specified address in a protect area$0001

User Area

2-9

Page 22

2-4 Cable

2-4-1 Specifications

Item

Insulation resistance

Model

50 MΩ or more between a terminal and

Model V700-P10 Model V670-A4!

20 MΩ or more between a terminal and

sheathing (at 250 VDC mega).

sheathing (at 1000 VDC mega).

!

!!

Withstand voltage 250 VAC, 1 minute. 1000 VAC, 1 minute.

Maximum operating

70°C70°C

temperature

Remarks Connector without waterproof specification. Connector without waterproof specification.

2-4-2 Outside Dimension

• Model V700-P10 (Programming console connecting cable)

Item Model V700-P10

Length Approximately 2 m

Weight Approximately 110 g

Connector (at a programming console side)

Connector (at a controller)

(Unit: mm)

• Model V670-A4!!!! (Antenna extension cable)

Item

Model

Length Approximately 3 m

Weight

Model V670-A40 Model V670-A41 Model V670-A42 Model V670-A43

Approximately 10 m Approximately 18 m Approximately 28 m

Approximately 140 g Approxi ma te ly 41 0 g Approxim ate ly 71 0 g

Approximatel y 1100 g

L1 3000 mm 10000 mm 18000 mm 28000 mm

Connector

Connection label

Coaxial cable 5 mm in diameter

Connector

(Unit: mm)

2-10

Page 23

2-5 Communication Range Specifications

Communication range varies depending on the installation conditions and environment conditions. Check the conditions mentioned in

this manual carefully.

♦ Maximum communication range (Actual value)

Antenna / Controller ID Tag Communication Range (Unit: mm)

Model V670-CD1D

+ Model V670-H11

Measurement conditions:

Model V670-D13F03 5 to 23 m

(Area width 20 mm or more if the range between a tag

and antenna is 5 to 20 mm.)

Antenna

Communication

range

Nonmetal

Tag

Nonmetal

2-5-1 Communication Area (Reference)

The communication area for model V67 0-H1 1 is shown be low . The communica tion area varies depe nding on the installation cond itions

and grounding environment.

The operation area formed on a plane, which is on an antenna center line and vertical to the antenna, is shown below.

Communication area characteristic

Nonmetal

Tag

Unit: mm

Antenna

Nonmetal

2-11

Page 24

2-5 Communication Rang e Specifications

2-5-2 Operation Time (Reference)

There are TAT (Turn Around Time) and communication time in the operat ion time.

Command

Communication time

Response

TAT means the total processing time required to operate V670 from the viewpoint of a host device. The communication time means a

time required for the communication between an antenna and tag, excluding host communication.

♦ Communication time

Time required for the communication between an antenna and ID tag. The time varies depending on data amount to be read and written.

The communication time can be calculated from the charts and formulas below.

• Read

Communication time (ms)

•

Write

Communication time (ms)

Number of processed bytes (Bytes)

• Write (with verificati on)

Communication time (ms)

Number of processed bytes (Bytes)

Number of processed bytes (Bytes)

Command Bytes Communication

time (ms)

Read 1 to 64 bytes

65 to 128 bytes

0.07 x N + 4.22

0.07 x N + 5.64

ID Read 4 bytes 1.59

Write 1 to 128 bytes 0.07 x N + 4.72

Write

(with verification)

1 to 64 bytes

65 to 128 bytes

0.14 x N + 6.45

0.14 x N + 7.79

N: Number of bytes to be processed

2-12

Page 25

2-5 Communication Range Specifications

In the communication with a tag, any data is read and written at every 4 bytes. Therefore, to minimize the communication time, specify

the address and the number of bytes suitably so that the address for writing can be a multiple of 4.

Example: If 4 bytes of data is written from the address 0001h, change the addr ess to 0000h.

If you cannot change as stated above due to the structure of change syst em, add the following time to the commu nication time.

When a protect function is used +2.9 ms

When a start address is not a multipl e of 4 +2.9 ms

When an end address (start address + the number of addresses) is not a multiple of 4 +2.9 ms

♦ TAT

Time from the start of command transmission by a host device to the end of receiving of response to the host device. It can be calculated

from the communication time and the number of characters of command/response. The formula is as follows:

TAT = command transfer time + communication time + response transmission time

Transmission time = x number of characters (second)

* The number of bits per character and baud rate vary depending on the communication conditions (baud rate, data length, parity and

stop bit).

Assuming that the number of cha r acters of command is A, the number of characters of response is B, the baud rate is 90 00 bps, data

length is 7 bits, parity is even and stop bit is 2 bits, the following formula can be obtained:

11 x (A + B)

TAT =

9600

Bits per character (bit)

Baud rate (bps)

+ communication time (second)

Correct Usage

The formula above calculates the time when processing (transmission of command) starts if the ID tag is within an area

of communication with an antenna. The time varies depending on a communication mode and ID tag status.

2-13

Page 26

2-5 Communication Rang e Specifications

2-5-3 Traffic and Passing Speed (Reference)

•

Read

Passing speed (m/min)

Number of processed bytes (Byte)

•

Write (without verification)

Passing speed (m/min)

Number of processed bytes (Byte)

Distance

Distance

Measurement Conditions:

Nonmetal

Tag

Passing speed (m/min)

Distance (mm)

Antenna

Nonmetal

• Write (with verificati on)

Passing speed (m/min)

Number of processed bytes (Byte)

• ID Read

Distance Passing speed

10 mm 750 m/min

15 mm 710 m/min

20 mm 600 m/min

Distance

2-14

Page 27

Chapter 3 Setting and Installation

3-1 Controller

3-1-1 Switch Setting

To set the switches, open a cover at the left upper part of the unit.

3-1-1-1 How to Open Cover

To open the cove r, insert a screwdriver , whic h comes with the controller, into a notch at the left end of the cover.

When the cover opens, you can see the two node number setup switches ( SW1 and SW2), two dip switches (SW3 and SW4) and connecting port for programming console.

Node number setup switch

Dip switch

Connecting port for programming

console

3-1

Page 28

3-1 Controller

3-1-1-2 How to Set

Set the switch using the screwdriver which comes with the controller as shown below.

• Setting a node number

Turn clockwise or counterclockwise.

• Setting a dip switch

Set to the right or left.

3-1-1-3 Setting List

Set the switches according to the list below. (The switches are set to a default value at shipment from a factory.)

Name Function Default Value

SW1 1: Node number setup switch used in N protocol. 00

SW2

(Left)

SW3-1

SW3-2 Switch to set an operation mode at startup.

SW3-3 Switch to enable or disable verification at writing. Disabling verification

SW3-4 Switch to set a protocol (1:1 / 1:N). 1:1 protocol

SW3-5 Set to OFF. OFF

SW3-6

SW3-7

SW3-8

SW4-1 Switch to set a communication speed of RS-232C. 9600 bps

SW4-2

SW4-3 Switch to set data length of RS-232C. 7 bits

SW4-4 Switch to set parity of RS-2 32C. Even parity

SW4-5

SW4-6 Switch to set stop bit of RS-232C. 2 bits

SW4-7 Set to OFF. OFF

SW4-8

Switch to change a function of input terminal (RST/IN).

Reset input

Command execution mode

3-2

(Right)

Page 29

3-1 Controller

3-1-1-4 Setting Node Number Setup Switch

♦

Node number

To connect several controllers to one host device using a link adapter etc., the host device needs to identify each of those controllers.

The number to identify them is referred to as node number. A unique node number must be assigned to every controller.

The command and response of 1:N protocol have the node number. So, unless the node number is assi gned appropriately, any communication cannot be made.

Setting node number

♦

Set the node number with the two node number setup switch. SW1 (left) is for an upper order and SW2 (right) for a lower order. Available number range is from 00 to 31 as shown below.

SW1 SW2

Upper

order

000

011

022

033

044

055

066

077

088

099

1010

1011

:::

2929

3030

3131

3 2 Disabled

3 3 Disabled

:::

9 9 Disabled

Lower

order

Node Number

Example of setting:

Node No. 0

Node No. 17

The factory default setting of the node number is 00.

Correct Usage

Never assign the numbers 32 to 99 to the node number setup switch.

3-3

Page 30

3-1 Controller

3-1-1-5 Setting a Dip Switch

♦

SW3

SW3-1: Input function change

SW3-1 Description

ON Functions as trigger input.

OFF Functions as reset input.

SW3-2: Operation mode

SW3-2 Description

ON Starts in the Self-Execution mode when the power supply turns ON.

OFF Starts in the Command E xecution mode when the power supply turns ON.

SW3-3: Verification at writing

SW3-3 Description

ON Enables verification at a write command.

OFF Disabl es verification at a write command.

SW3-4: Protocol designation

SW3-4 Description

ON Uses the 1:N protocol.

OFF Uses the 1:1 protocol.

Correct Usage

Set SW3-5, SW3-6, SW3-7 and SW3-8 to OFF always. Otherwise, any operation cannot be guaranteed.

3-4

Page 31

♦

SW4

SW4-1/4-2: Communication speed setting

SW4-2 SW4-1 Description

ON ON 115200 bps

OFF 38400 bps

OFF ON 19200 bps

OFF 9600 bps

SW4-3: Data length setting

SW4-3 Description

ON 8 bits

OFF 7 bits

3-1 Controller

SW4-4/4-5: Parity bit setting

SW4-5 SW4-4 Description

ON ON Even parity

OFF No parity

OFF ON Odd pari ty

OFF Even parity

SW4-6: Stop bit setting

SW4-6 Description

ON 1 bit

OFF 2 bits

Correct Usage

Set SW4-7 and SW4-8 to OFF always. Otherwise, any operation cannot be guaranteed.

3-5

Page 32

3-1 Controller

3-1-2 Instal lation Site

The controller model V670-CD1D has high r e liability as durab le control device under any environmental conditions. To increase the

system reliability and to fulfill the functions completely, install the controller according to the instructions below.

♦

Installation site

Do not install the controller at any place below:

• Place where the amb ient temperat ure is out of th e range between 0 and +55°C, where the temperature fluct uates considerably and

where moisture condensat io n occurs.

• Place where the relative humidity is out of t he range between 35 and 85%RH.

• Place where there is corrosive gas, fl ammable gas, dust, salt or iron powde r.

• Place affected by vibr ation or impact.

• Place exposed to the direct sunlight.

• Place splashed with water, oil or chemicals

Assembly in panel

♦

The ambient operating temperature of controller is between 0 and +55°C. The following conditions must be met.

• Provide sufficient space for ventilation.

• Do not install the controller near by any heating sources (heater, transformer and large-sized resistance).

• If the ambient temperature rises to 55°C or more, install a ventilating fan or air conditioner to keep the temperature at 55°C or less.

• If you wire a power line (for high current to drive a motor) near the controller, test it fully to reduce the influence of noise and wire it

according to the wiring conditio ns with care.

Note

When you install the controller, be sure to follow the instructions above and test it fully.

3-6

Page 33

3-1 Controller

3-1-3 How to Install

The controller can be installed in a panel with screws or on a DIN rail.

♦

Installation in a panel

If you install the controller in a panel, be sure to use spring washers, fla t washers and M4 screws. (Tightening torque: 1.2 N•m or less)

Do not use any organic solvent such as lock paint to fix screws. Otherwise, the case may crack.

♦

Installation on a DIN rail

DIN Rail

Recommendable DIN rail

Model PFP-100N2 (Rail

length 1 m)

(OMRON)

(Unit: mm)

• When you install the controller on the DIN rail, hook the

controller ov er the A an d push th e control ler in the direc tion B.

• When you remove the controller from the DIN rail, pull

the hook downward and remove the controller pushing

slightly upward.

End Plate

Support Rail

Model PFP-100N2

Hook

(Unit: mm)

End Plate

Model PFP-M

3-7

Page 34

3-1 Controller

3-1-4 How to Connect Antenna

You can connect one antenna to the controller. The antenna can be extended up to 30 m by using the extension cable model V670-A4!

(unbundled). Only one extension cable can be used.

♦

How to connect and disconnect a connector

• How to connect

Lock

• How to disconnect

Lock

(1) Hold the ca ble lock of connector and fit a lug of the co n-

troller in a groove in the conne ctor lock.

(2)Push the connector straight tightly.

(3)Turn the connector lock clockwise.

(1)Turn the connector lock counterclockwise.

(2)Hold the lock and pull out it straight.

Correct Usage

Do not pull the cable forcibly. Otherwise, the cable may be broken or damaged. When you connect or disconnect the

connector, be sure to turn off the power supply. Otherwise, a trouble may occur.

3-8

Page 35

3-1 Controller

3-1-5 How to Connect Extension Cable and How to Extend Antenna

The antenna can be extended by using the extension cable type V670-A4! (unbundled). The ext e nsion cables up to 28 m in le ngth are

available. When you use the extension cable, to prevent the devices being broken due to static electricity, follow the instructions below:

♦

Procedure to connect extension cable

Connect the antenna and exten sion cable with a connector accessory (accessory: WTN-B-384). Cover a metal part of connect or joint

with a sheath (Sumitomo Electri c Industries: SumiTube A 20 mm in diameter) as shown below.

Approximately

15 mm

Approximately

100 mm

Approximately

15 mm

Heat the sheath (120°C is recommendable) using a dr ie r etc . to s hrink it.

* The cable and connector may be deformed if the sheath is heated for a long time. Heat the sheath quickly.

Procedure to disconnect extension cable

♦

Remove the tube using a nipper etc. first and then remove the extension cable. If a new tube is required, use the heat shrinkable tube

(SumiTube A 20 mm in diameter) of Sumitomo Electric Industries which should be cut down to 10 cm.

3-1-6 How to Wire

Wire as shown in this figure.

3-9

Page 36

3-1 Controller

3-1-6-1 Wiring Power Supply and Grounding Cable

(Example of Wiring)

+24 VDC

Grounding of Class D

M3 self-up screws are used for the power supply and ground terminal. For a crimp terminal, use any of terminals below. Tightening

torque should be appr oximately 0.6 N•m.

♦

Applicable crimp terminal

Manufacturer Model Applicable Wire Type

Japan Solderless

Terminal

Japan Solderless

Terminal

♦

Recommendable DC power supply (small-sized) (OMRON)

Model Output Capacity Inpu t Voltage

S82K-03024 24 VDC 1.3 A 100/200 VAC

S82J-0224 24 VDC 1.1 A 100 VAC

* Rated power consumption of the controller is 24VDC and 0.2 A (7 W). Decide the capacity taking into consideration inrush current

(approximatel y 5 A).

1.25-N3A AWG24 to

AWG16

1.25-Y3A

Fork

(For M3)

3-1-6-2 Wiring Reset Signal

3-10

24 VDC

Reset Input

Page 37

3-1 Controller

• Crimp terminal for terminal

M3 self-up screws are used for the terminal.

For a crimp terminal, use the terminal below.

(For M3)

Tightening torque should be approximately 0.6 N•m.

Correct Usage

Take care that the input vol tag e does not exceed the a maximum impres s ed vo lta ge (26 .4 V). Othe rwis e, a trouble may

occur in devices.

3-1-6-3 Wiring Output Signal

DC Power

Supply

• Crimp terminal for terminal

M3 self-up screws are used for the terminal.

For a crimp terminal, use the terminal below.

(For M3)

Relay

External

I/O Unit

Tightening torque should be approximately 0.6 N•m.

3-11

Page 38

3-1 Controller

3-1-7 Connecting RS-232C Interface

Signal Name Code Signal Direction Pin No.

Input Output

Ground for maintenance GR — — Shield

Ground for maintenance or common return SG — — 5

Send data SD — 3

Receive data RD — 2

Request to send RS — 7

Clear to send CS — 8

Controller Pin Layout

(TOP VIEW)

Note 1. To prevent an operation error, ground the shielded wire either at the controller side or the computer side mentioned above. (The

figure above shows an example of groundi ng the shielded wire at the ID controller side.)

Note 2. Short-circuit pin No. 7 (RS) and pin No. 8 (CS) at the inside of the connector.

Connecting to a host device of IBM PC compatible machine, 9-pin

View of fitting face of cable connector

at the controller side

Controller

Controller Connecting Device

9-Pin, male

9-Pin, male

Shield

Shield

Connector with a cable

Connecting Device

Conector with a cable

View of fitting face of cable connector

at the host device side

IBM PC Compatible Machine

IBM P C Com patible Machine

9-Pin, female

9-Pin, f emale

3-12

(Shielded wire)

(Shielded wire)

Page 39

Connecting to a host device of NEC PC-9801 compatible machine, 25-pin

3-1 Controller

View of fitting face of cable connector

at the controller side

Controller

9-Pin, male

Shield

Connector with a cable

Connecting Device

(Shielded wire)

View of fitting face of cable connector

Connecting to the OMRON programmable controller (PLC) (C200H)

View of fitting face of cable connector

at the controller side

View of fitting face of cable connector

at the host device side

13

NEC PC-9801 Compatible Machine

25-Pin, male

at the host device side

Controller

9-Pin, male

Shield

Connecting Device

Connector with a cable

(Shielded wire)

Type C200H-ASC02

25-Pin, male

3-13

Page 40

3-1 Controller

♦

Assembling and connecting a connector for communication

Use our connector for communication , which comes with the controller. Prepare a connecting cable an d connector for a host computer

by yourself. Our connector which comes with the controller is based on the countermeasures against EMI.

(Instead of our connector which comes with the controller, you may use any other commercial connector. Refer to "Appendix 2 Order

Format List".)

To the ID controller

Plug

Model XM2A-0901

(which comes with the

controller)

(OMRON)

* 1. One set of connectors (based on the countermeasures against EMI) comes with the ID controller.

* 2. You may use any other cable if the cable specifications are the same as ours. (The outer diameter is 7 mm.)

♦

How to assemble a connector

Hood

Model XM2S-0911 *1

(which comes with the controller)

(OMRON)

Connecting cable

• Recommendable cable

CO-MA-VV-SB 5PX28AWG *2

(Hitachi Cable)

(1)Terminate the cable properly.

• Fit the cable bush in the cable in advance.

• Ravel the shield braid, turn back it and cover the

cable bush with the shield braid. The length of the

shield braid covering the cable bush should be 10

mm.

• Wind the shield tape on the shield braid.

Core

Shield braid

Shield tape

Cable bush

To the host computer

(2) Solder the core and plug pin.

Plug

Crossover

Cable bush

Aluminum tape

(Unit: mm)

Pin No. Code Name

Shield GR Ground

5 SG Ground for signal

3 SD Send data

2 RD Receive data

7 (Note) RS Request to send

8 (Note) CS Clear to send

Note. Short-circuit No. 7 (RS) and No. 8 (CS) pins with crossover.

3-14

Page 41

(3)Set the plug in the housing A2 of the h ood and fix the aluminum ta pe with a clamp.

Lock screw (2-M2.6)

Housing A2

3-1 Controller

Cable clamp

Housing B2

(4)Set the two connector lock screws and put the housing B2 there to complete the connector.

♦

How to connect and disconnect a connector

• When you connect the connector, be sure to hold the connector and insert it completely. When you have inserted the connector,

tighten the two lock screws with the Phillips screwdriver.

• When you disconnec t the conn ector, loosen the t wo lock scr ews and pull out the lug of conn ector hoo d strai ght. If it i s hard to pull

out the connector, hold the controller tightly and pull out it.

Phillips screwdriver

Lock screw

Correct Usage

Example of grounding a shielded wire at the controller side:

ID controller

Host computer

• To prevent an operation erro r, ground the shielded wire

either at the controller side or the host computer side.

(This figur e sh o w s an example of grou nding it at the controller side.)

• Short-circuit the RS pin and CS pin inside the connector.

3-15

Page 42

3-2 Antenna

3-2-1 Instal lation Site

♦

Installation site

Do not install the antenna at any place below:

• Place where the ambien t tempera tur e is ou t of the rang e be tween -1 0 an d +70°C, wh ere the t empera ture fluc tuat es cons iderab ly an d

where moisture condensat io n occurs.

• Place where the re lative humidity i s out of the range between 35 and 85%RH.

• Place where there is corrosive gas, fl ammable gas, dust, salt or iron powde r.

• Place affected by vibr ation or impact.

• Place splashed with water, oil or chemicals

Note

When you install the antenna, be sure to follow the instructions above and test it fully.

3-2-2 How to Install

• Installation on a surface

M4 screw

(Tightening torque: 1.2 N•m or less)

•

Installation on the back

Insert a nut which comes with the antenna into the section A.

M4 screw

(Tightening torque: 1.2 N•m or less)

(Unit: mm)

M4 nut

(Unit: mm)

3-16

Page 43

3-3 Tag

3-3-1 Installation Site

Do not install the tag at any place below:

• Place where there is corrosive gas, flammabl e gas or iron powder.

• Place where the ambi ent tempe rature i s o ut of th e rang e bet ween -10 a nd +70°C, where the tempe rature fl uct uates con sidera bly and

where moisture condensation occurs.

• In a microwave oven.

3-3-2 How to Install

Install the tag according to the following instructions:

• Neither shave, drill nor machine the tag.

• Do not apply any excessi ve force to the tag.

• Neither contact the tag and any metal with each oth er nor install the tag near an y metal.

* When the tag is used in both high temperature and low temperature, the tag may bend. However, the function is not affected.

Type V670-D13F03

♦

•

Tag installation direction

Antenna

Install this tag so that the tag surface ca n be in parallel with the antenna.

• Example of installation

Install the tag with the screws .

M3 screw (Tightening torque: 0.6 N•m or less)

(Unit: mm)

3-17

Page 44

Chapter 4 Functions

4-1 Communication Designation Function

Depending on an operation sequence, you can specify vario us communications through the communication command for communication with a tag. The following seven communicatio n de sig natio ns are avai labl e.

Code Name Description

ST Single command Trig ger When the command is received, the c om mu nic at ion w ith the ta g is e xe cut ed and

the response is returned.

SA Single Auto command After the command is received, the communication is executed when a tag has

been detected in a communication area and the response is returned.

SI Single Input trigger After the command is receive d, the comm unication w ith the tag is executed at the

leading edge timing of external input (TRG) and the response is returned.

RA Repeat Auto command "SA" designation is repeated. The communication with the same tag, which

exists continuously, is executed only one time.

RI Repeat Input trigger "SI" designation is repeated.

PA Poling Auto command "SA" designation is executed and the response is returned by the polling query

(PC) command.

PI Poling Input trigger "SI" designation is executed and the response is returned by the polling query

(PC) command.

Those seven communication designations are classified into three groups; a command trigger system which starts the communication by

sending a command, auto s yst em which detects a tag automatically and executes the communi cation, and input trigger syst em which

start the communication by external input.

According to this classification, the operation of every communication designation is described below.

4-1-1 Designation of Command Trigger System Communication (ST)

In the command trigger system communication designation, the communication with a tag is executed by sending a command and the

controller command processing is ended by terminating th e communication. If the tag is not in the communication area when the command is sent, an error (error code: 72) is returned to indicate that there is no tag in the communication area. Therefore, you must check

the tag in the communication area with a sensor etc. and return a command.

The communication with tag in the

communication area is executed when

a command from a host is received.

So, if the tag is not in the communication area, the response is returned to

indicate that there is no tag in the communication area.

* Responds whether there is a tag or not.

ST designation:

Antenna

Host → Controller

Tag

ST mode command

Host ← Controller

Controller ↔ Tag

(Tag action)

Communication

Tag

Response *

End of process

4-1

Page 45

4-1 Communication Designation Function

4-1-2 Designation of Automatic System Communication (SA/RA/PA)

In the auto system communication designation, a tag is detected automatically. So, unlike the command trigger system, you do not need to check the tag.

When the tag enters the communication area, the communication starts.

Tag

Antenna

SA designation:

For the single designation (SA), the controller command processing is ended by terminating the communication.

Host → Controller

Host ← Controller

Controller ↔ Tag

(Tag action)

SA mode command

Communication

Tag

Response

End of process

RA designation:

For the repeat designation (RA), the system waits until the next tag has come even after the communication is terminated. If the tag

once executes the communi cation, the tag does not execute the communication un til it has moved out of the communication area.

Repeat processing is ended by a command process abort command (AA).

Host → Controller

Host ← Controller

Controller ↔ Tag

(Tag action)

RA mode command

Waiting for a tag

Communication

A

Response

Waiting for a new tag

Tag A

Response

B

Waiting for a new tag

Communication

Communication

Tag B Tag B

Response

C

AA command

Response

End of

process

PA designation:

In the PA designation, similarly with RA, processing is repeated until the processing is terminated by a command process abort command (AA). However, no response is made after the communi catio n with one tag is ended. Response is returned by a pollin g qu ery

(PC) command instead. Use this designation when several controllers are connected to a host device through RS-485, etc. (Commercial

232C/485 converter is required.)

Host → Controller

Host ← Controller

Controller ↔ Tag

(Tag action)

4-2

PA designation command

Response

(Acceptance)

PC command

Waiting for a tag

Response

(No communication)

PC command

Commu nication

Tag

Response

(Result of communication)

End of process

Page 46

4-1 Communication Designation Function

4-1-3 Designation of External Trigger System Communication (SI/RI/PI)

In the external trigger system communication designation, the communication is started at a leading edge of an external input signal.

The communication is directly controlled by output of a sensor which detects a tag in the communication area. So, the communication

can be executed even in a fast line without fail.

To the external input of ID controller

The system waits for a leading edg e o f an

input signal when a command has been

issued by a host. (An sensor is one of

examples.) The communication is exe-

Tag

Antenna

cuted to the tag in the communication

area at the leading edge of the input signal. If the tag is not in the communication

area, an error occurs to indicate that there

is no tag in the communication area.

SI designation:

In the single designation (SI), the controller command processing is ended by terminating the communication.

Host → Controller

Host ← Controller

Controller ↔ Tag

External input

SI mode command

Waiting for input

* Responds whether there is a tag or not.

Response*

Communication

End of process

RI designation:

In the repeat designation (RI), the system waits for a leading edge of the next input signal even after the communication is ended. The

communication is executed to the tag whenever the leading edge of input signal is detected. Repeat processing is ended by a command

process abort command (AA).

Host → Controller

Host ← Controller

Controller ↔ Tag

External input

SI designation command

Waiting for

input

* Responds whether there is a tag or not.

Response*

Communication

Waiting for input

Communication

Response*

AA command

Response*

(Terminated)

End of

process

4-3

Page 47

4-1 Communication Designation Function

In the polling designation (PI), similarly with RI, processing is repeated until the processing is terminated by a command process abort

command (AA). However, no response is made after the communication with one tag is ended. Response is returned by a polling query

(PC) command inst ead . Use this desi gna tion w hen seve ral contro ller s ar e co nnec ted to a ho st de vi ce th rough RS- 485 etc. (Co mme rcial

232C/485 converter is required.)

PI designation:

Host → Controller

Host ← Controller

Controller ↔ Tag

External input

PI designation command

Response*

(Acceptance)

PC command

Waiting for input

Response*

(No communicatio n)

PC command

Communication

Response*

(Result of communication)

End of proces s

Correct Usage

To use the communication designation of SI, RI and PI, turn ON (trigger input) the dip switch 3-1.

4-4

Page 48

4-2 Tag Designation Function

When reading data or writing fixed data, you can use "Repeat Auto" designation or "Repeat Trigger" designation. However, if you write

different data per tag or if you use several commands (e.g., read → judge → write), you cannot us e this function.

To enable this process, you can use the Tag Designation function. By using this function, regard less of timing, you can only send the

commands consecutively to communication with an objective tag without fail. Moreover, a sensor for tag detection is not required. So,

the system configuration can be simplified.

Code Description

“sa” When a tag enters the communication area, the communication to the tag is executed. The communication is

made to any tag other than the tag to which the communication has been executed immediately before. If the

same tag exists continuously, the system waits until any other tag enters the communication area.

“st”

<Example of process sequence>

When you execute a command 1 and command 2 to the tags (A, B, ...) moving continuously, you can use the following sequence.

When a command has bee n re ce ive d, th e co mm u nic atio n is executed to the tag in the commu nic atio n ar e a. Th e com m u nication is made to any tag other than the tag to which the communication has been executed immediately before. Even if

any different tag is in the communication area, an error occurs to indicate that there is no tag in the communication area.

Host

↓

Controller

Command 1

(sa

designation)

Command 2

(st

designation)

Command 1

(sa

designation)

Command 2

(st

designation)

Host

↑

Controller

Controller

↓↑

Tag

Waiting

for a new

tag

Communication

1A

Response

Previous tag

only

Communication

2A

Response

Waiting

for a new

tag

Communication

1B

Response

Previous tag

only

Communication

2B

Tag

in communication

area

Tag A

Tag B

When you write differ ent data into the tags (A , B, ...) moving continuously, you can use the following sequ ence.

Host

↓

Controller

Host

↑

Controller

Controller

↓↑

Tag

Tag

in communication

area

Command 1

(sa

designation)

Waiting

for a ne w

tag

Communication

A

Response

Command 2

(st

designation)

Tag A

Waiting for a new tag

Communication

B

Response

Command 2

(sa

designation)

Tag B

Waiting for a new tag

Response

Command 1

(sa

designation)

4-5

Page 49

4-3 Operation Mode

There are two operation modes, i.e., Command Execution mode and Self-Execution mode. Through the dip switch 3-2, you can specify

one mode of them to be started at the power ON. Also, you can change the mode by a mode change command (MO) from a host device.

Power ON

Command Execution

mode

Mode change command (MO)

Self-Execution mode

(1)Command Execution mode

The communication is exe cuted by an in struction (command) from a host dev ice. In this mode, you can use all the command. All,

you can read/control the ext ernal I/O terminals (IN, OUT1 and OUT2) by a command from a host device.

(2)Self-Execution mode

The communication to a tag is executed automatically according to the o perating conditions registered in the controller, the communication result can be judged (jud g men t c on dit ions ), a nd th e self-co m ple tio n op eration, to which is output to the two exte rna l outputs

(OUT1 and OUT2) or to the RS-232C port (result output), can be performed. The ID system does not need to be controlled from a

host device. So, a simplified system can be built up very quickly. The following operating conditions can be registered.

Item Description

Execution process A communication command only can be used. An available communication mode is RA or RI

only.

Judgment conditions

One of the conditions below can be specified per output.

1) Judges the communication result and generates output.

2) Compares response data and set data with each other and generates output.

Result output When a preset judgment condition has been met, the three outputs below can be specified. The

judgment condition can be specified per output.

1) Outputs to OUT1. Output time can be specified.

2) Outputs to OUT2. Output time can be specified.

3) Responds to RS-232C.

The preset operating conditions are stored in nonvolatile memory in the controller. So, you do not need to set them at every power on.

4-6

Page 50

4-3 Operation Mode

<Example of usage >

When data is read out of the ta g into wh ic h de stin ation in form atio n ha s b een writt en , t he a pplic a bl e de stin at ion o nl y i s de tec ted and the

pulse is output, and reading could not be done due to any trouble, an error pulse is outp ut as shown below.

Error output

Fast movement

Setting and operation flow

•

Antenna

Tag

Coincidence

output

Trigger input

(Synchronization sensor)

Setting of operating conditions

Item Description

Execution process Communication command: RD

Communication mode: RI

OUT1 Outputs OUT1 in tms at data

matched.

OUT2 Outputs OUT2 at abnormal end.

RS-232C Nil

Error output

Coincidence

output

Trigger input

(Synchronization sensor)

Power ON

TRIG input

Data read (E)

Correct end

Trigger input (IN)

Coincidence output(OUT1)

Abnormal output (OUT2)

Communication process

Data matched

Data matched(D)

Coincidence

output pulse

Communication process

Data unmatched

Communication process

Data matched

Abnormal output

pulse

4-7

Page 51

4-4 Operation Parameter Setting