Page 1

(1/23)

Operation Manual

Product Name:

R/W Module Board Type (L) V700-HMC71

R/W Module Board Type (S) V700-HMC73

Issued: July 7, 2000

OMRON Corporation

Industrial Automation Company

Advanced Sensors Development Department

Sensing Devices & Components Division H.Q.

Revision history Revised date Revised item

− ′98/ 7/ 17

′00/ 7/ 07

New issue

“Applicable Standards” is added on the page 2

Page 2

(2/23)

Applicable Standards

FCC (USA) Part 15 subpart B and C

This device complies with part 15 of the FCC Rules. Operation is subjected to the following

two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

FCC ID : E4E6CYAID7000100

FCC NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment dose cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-Consult the dealer or an experienced radio / TV technician for help.

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Properly shielded an grounded cables and connectors must be used for connection to host

computer and / or peripherals in order to meet FCC emission limits.

AC adapter with ferrite core must be used for RF interference suppression.

Precautions of Use

This device uses a frequency of 125 kHz to communicate with a tag. Some transceivers,

motors, monitor units, and power supply (power IC) emit noise that adversely affects this

communication with the tag. If this product is to be used in an environment close to such

devices, please check the effects from these devices prior to use.

To minimise the effect of noise, please ground any metal object surrounding this device.

Page 3

(3/23)

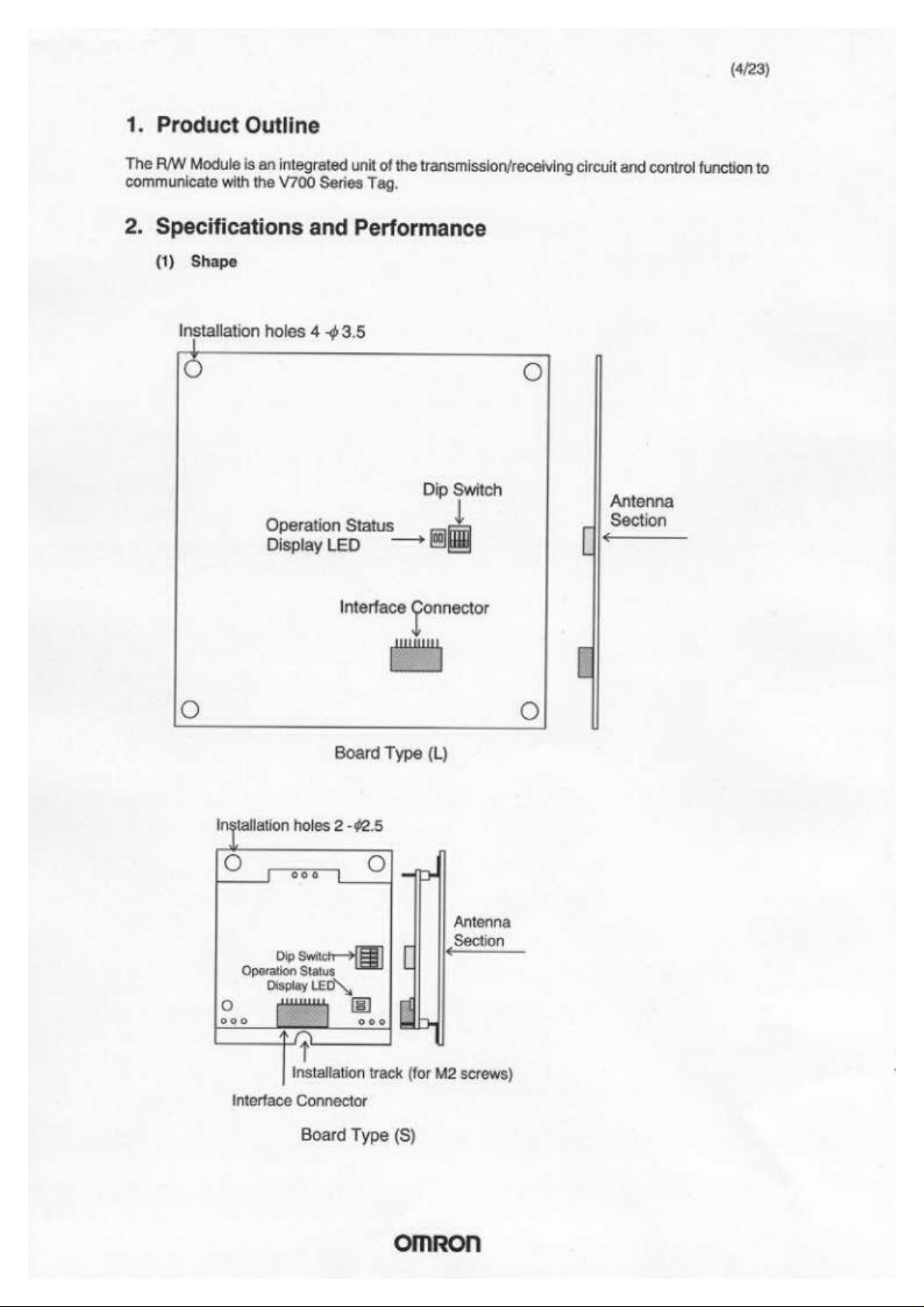

This manual specifies the specifications and transmission format of the R/W Module.

Table of Contents

1. Product Outline................................................................................... 4

2. Specifications and Performance..........................................................4

3. Operations of the R/W Module ............................................................9

3.1 Outline of operations....................................................................9

3.2 Oscillation Control........................................................................9

3.3 Input STOP................................................................................10

3.4 Memory Management on Tag....................................................10

3.5 Processing Tag Memory............................................................11

4. Controlling the Module from User board............................................14

4.1 Transmission Control Format.................................................... 14

4.2 Command/Response Format ....................................................15

4.3 Types of Commands and Responses ....................................... 16

5. Error Code List...................................................................................22

6. Processing Time (Indicative Data).....................................................23

Page 4

Page 5

(5/23)

• Dip Switch

Will not be used. Turn every dip switch OFF.

• Operating conditon displaying LED

LED Display Detail

Green lights on Lights on when communicating with the Tag

Red lights on Lights on when communication process does not complete

successfully.

• Interface Connector

This connector connects the R/W module to a User Board.

• Antenna Section

When communicating with the Tag, please bring the Tag close to the antenna

section.

(2) General Specifications

Item Board Type (L) Board Type (S)

External measurement

Installation 4 points Secured by

Electric current

Dissipation current 180 mA or less (during oscillation)

Vibration resistance Destruction: 20m/s2 10 to 150Hz, 0.15mm double

Shock resistance Destruction: 200m/s2, 3 times each in 6 directions

Ambient temperature

during use

Ambient temperature

during storage

Ambient humidity

during use

Radio frequency 125 kHz

Transmission distance

(Tag: V700 - D13P31)

Distance at center of

coil - Tag axis

80 × 80 × 5 mm 40 × 44 × 10 mm

Secured at 3 points,

M3 screws

5V ±10%

20 mA or less (no oscillation)

amplitude, with 4 sweeps of 8min each in 3 directions

-10 ~ +55°C

-25 ~ +65°C

25 ~ 85% RH or less (with no condensation)

5 ~ 65 mm 10 ~ 40 mm

M2 or M2.3 screws

Page 6

(6/23)

(3) Signal Interface Specifications

1

Item Specifications

Connector

specifications

S10B-ZR-SM3A-TF

(manufactured by J.S.T. MFG CO.,LTD.)

(applicable wires: AWG#32 ~ #26)

Transmission format 2 wire system semi-double serial (CMOS level)

Synchronization format Asynchronous mode; start-stop system

Transmission control

Cr control

format

Transmission speed 9600 bps (fixed)

Character format (fixed) Start bit Data bit Parity bit Stop bit Total

1 8 Even 1 11

Error detection format Even number parity

Bit transmission order Low order fist (from LSB)

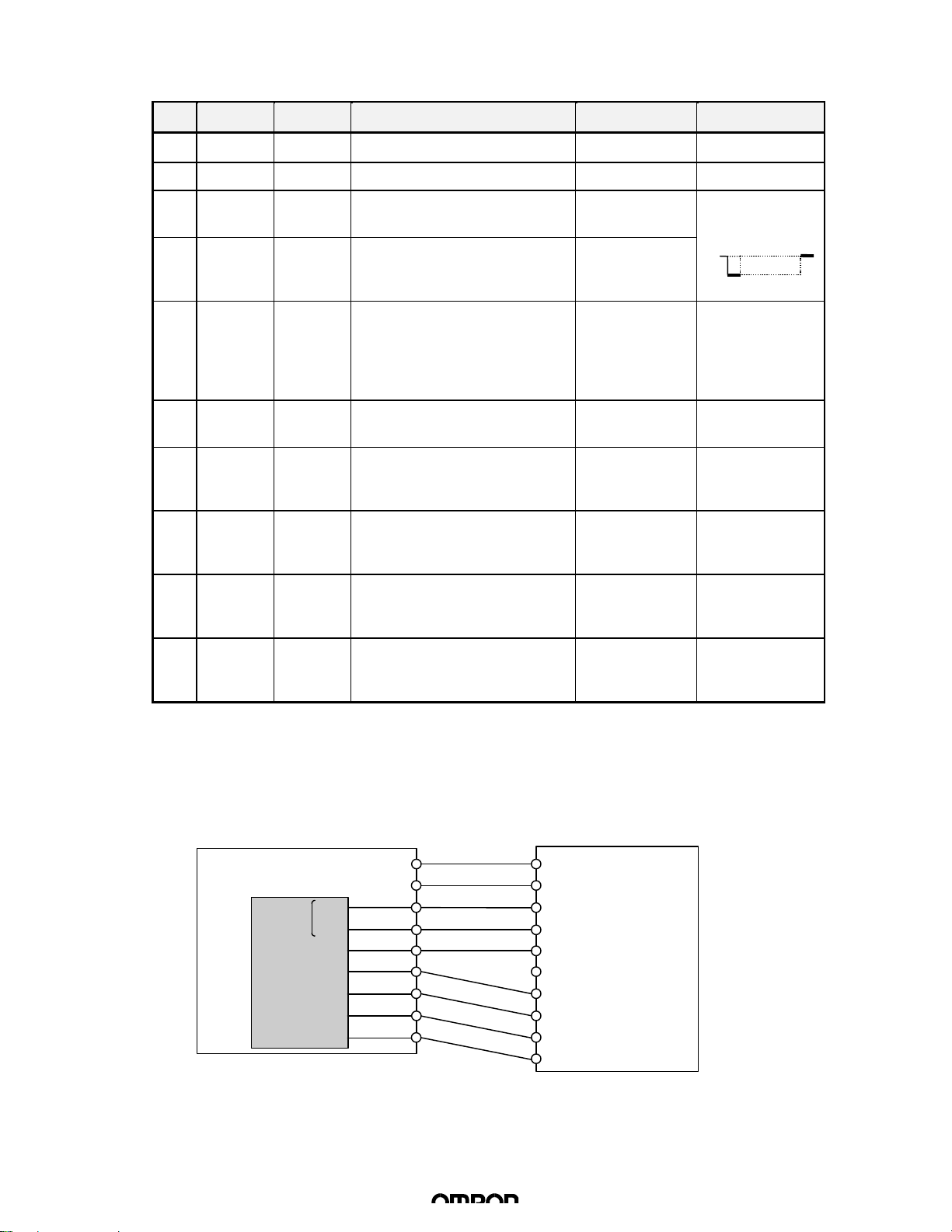

n Pin Layout and Connection with User board

For housing of cable connecting the R/W Module with the User board, please use the

following:

Manufactured by J.S.T. MFG CO.,LTD.

Socket housing: ZHR-10

Socket contact: SZH-002T-P0.5 or SZH-003T-P0.5

Housing: ZHR-10

Applicable wires:

AWG#32 ~ #26

R/W Module

Pin Header: S10B-ZR-SM3A-TF

2

:

:

:

:

10

Page 7

(7/23)

pin number

n

Names of Signals and Functions

No. Codes I/O Function Performance Signal Logic

1 5V - Power

5V ±10%

2 GND - Ground - 3 RXD Input Serial input CMOS CMOS input

47 kΩ pull up

4 TXD Output Serial output CMOS output

IOL=2mA,

0:0V, 1:5V

(positive logic)

5V

0V

IOH=2mA

5 STOP Input Receive process of command

being executed / command

CMOS input

47 kΩ pull up

↓ active

execution will be aborted and

after STOP is input, will be on

stand by for command

6 EXT_IN Input (unused) CMOS input

47 kΩ pull up

7 COMM Output Will be output while

communication is occurring

between tag

8 NORM Output Will be output after

transmission with tag is

successfully completed

9 ERR Output Will be output when

transmission with tag was

unsuccessful

CMOS output

IOL =10mA,

IOH =2mA

CMOS output

IOL =10mA,

IOH =2mA

CMOS output

IOL =10mA,

IOH =2mA

H active

H active

H active

-

dataSE

-

10 RUN Output Will be output when Module is

operating normally

CMOS output

IOL =10mA,

H active

IOH =2mA

n

Example of Connection with User board

Please refer to the below-indicated connection for connecting the Module to the User board. Any

signals that will be unused should not be connected.

User board

User CPU

TXD

SCI

RXD

OUT1

IN1

IN2

IN3

IN4

5V

GND

R/W Module

5V(1)

GND(2)

RXD(3)

TXD(4)

STOP(5)

EXT_IN(6)

COMM(7)

NORM(8)

ERR(9)

RUN(10)

Numbers in ( ) indicates

Page 8

Page 9

(9/23)

3. Operations of the R/W Module

3.1 Outline of operations

The R/W Module receives commands from the User board, executes read / write

processes on the Tag, and returns a response of the results of the process to the

User board. The status of the R/W Module operations will be reflected on the Output

/ LED.

User Board

R/W Module

Page 1

User CPU

n

Operations Timing Chart

Status

TXD

RXD

Tag

communications

Output /

LED

COMM

NORM

ERR

Initial

process

↓

↓

↓

Waiting for

command

Receiving

command

Command

Processing

command

Tag

Transmitting

response

Response

Page 2

:

Page n

Waiting

command

RUN

↓

3.2 Oscillation Control

The R/W Module supplies power to the Tag by oscillating the antenna, and thus

conducts communication with the Tag. The Module may be set on either the

“Oscillate Mode” “Stop Mode” depending on whether the Module should oscillate

while not in communication with the Tag. The “Stop Mode” conserves dissipation

power, and enables the R/W Module antenna to be installed close to the Tag to

conduct communications on a time sharing basis. The “Oscillate Mode” allows the

Module to constantly supply power to the Tag for FIFO processing.

Oscillation Status Operation Mode Switching Conditions

Stop Mode (conserves

dissipation power)

Oscillation Mode

(enables high-speed

processing)

The antenna stops

oscillating while not

processing commands

The antenna is

constantly oscillating

• Mode switching conditions at

start-up

• When oscillation OFF

command is active

• When oscillation ON command

is active

• When option is active in FIFO

Trigger / FIFO Auto Command

Page 10

(10/23)

3.3 Input STOP

When a STOP signal is input to the R/W Module, receiving and processing of

commands and command processing will stop and then, after the STOP signal is

deactivated, the Module will be on stand by for new commands. When the STOP

signal is input, oscillation will stop regardless of the setting of the oscillation control

mode.

If a STOP signal is input more than 50 msec prior to shut down, writing of unstable

data to the Tag may be prevented. However, if writing of the command in process

requires more than one page, not all pages may be completely rewritten.

3.4 Memory Management on Tag

The Tags used to conduct communication with the R/W Module may be one of the

following two types depending on memory capacity: 128 bytes (user area 112 bytes)

or 256 bytes (user area 240 bytes). The memory area recognizes every 8 bytes as

one page, distinguished by such addresses as 00h ~ 07h, 08h ~ 0Fh, and so on.

n

Memory Map (00h ~ EFh indicates to address)

Page 8 bytes / page

1 00h 01h 02h 03h 04h 05h 06h 07h

2 08h 09h 0Ah 0Bh 0Ch 0Dh 0Eh 0Fh

3 10h 11h 12h

4 18h 19h 1Ah

⋅⋅⋅ ⋅⋅⋅

⋅⋅⋅ ⋅⋅⋅

17h

1Fh

5 20h 27h

6 28h 2Fh

7 30h 37h

8

9

10 : :

11 : :

12

13

14 68h

15 70h

16 78h

⋅⋅⋅ ⋅⋅⋅

⋅⋅⋅ ⋅⋅⋅

⋅⋅⋅ ⋅⋅⋅

6Fh

77h

7Fh

: : :

: : :

112 bytes

240 bytes

29 E0h E1h

30 E8h E9h

⋅⋅⋅ ⋅⋅⋅

⋅⋅⋅ ⋅⋅⋅

E7h

EFh

Page 11

(11/23)

3.5 Processing Tag Memory

Tag 1

(1) Process Contents

The following three processes may be executed on the Tag Memory

1) Read

Reading data from Tag Memory. The area to execute the Read command

may be selected at random up to 16 pages.

2) Write

Writing data onto Tag Memory. The area to execute the Write command

may be selected at random up to 16 pages. When writing the same data

onto all pages (multiple write), there is no limitation on the number of pages.

Certain data within a page may be selected in units of bytes to be written

onto the Tag Memory (byte write).

3) Write Protection Set/OFF

Write protection may be set on the selected pages of Tag Memory. When

write protection is set, the data may be read, but not re-written. Write

protection may be set on any of the pages. Write protection may be set or

turned off by commands.

(2) Communication Operations

User →

Command Command

User ←

Tag

Communication

Tag Operation

The following 6 communications operation may be executed by changing the

process procedure and execution timing. Communication operations may be

specified by commands during command transmission.

1) Single Trigger

Communication with Tag will be executed immediately after receiving

command and a response will be transmitted. After response is transmitted,

the Module will be on stand by for new commands. During communication

with the Tag, there may only be one Tag within the communication area.

♦ Operation Sequence

Processing will be executed once only after receiving command. If there is

no Tag, a Tag absent error message will be transmitted.

Response 1

Command Process

Command Process

Response 2

(Tag Absence Error)

Page 12

(12/23)

Tag 1

Tag Operation

User ←

User →

Command Process

Command Process

(Oscillation)

(Oscillation)

Tag 1

Command

Command

Command Process

2) Single Auto

After receiving command, the Module waits for the Tag to approach,

communicates with the Tag, and then transmits a response. Once the

response is transmitted, Module will be on stand by for new commands.

During communication with the Tag, there must be one Tag within the

communication area.

♦ Operation Sequence

After receiving command, the Module waits for the Tag to approach, then

executes process once only after Tag is detected. When Module receives a

STOP command, the command will be completed.

User →

User ←

Tag

Communication

Tag Operation

STOP

Response

Tag

Detection

Tag Detection

(Truncation

Process)

3) FIFO Trigger

Module will communicate with Tag immediately after receiving command

and transmit response. After communication is completed, Module will

prohibit Tag from operating. Module will be on stand by for commands after

response is transmitted. During communication with Tag, there MUST BE

AN OPERATIONAL TAG (A TAG THAT IS NOT PROHIBITED FROM

OPERATION) within the communication area. When this command is

executed, Module automatically activates “Oscillation Mode”

♦ Operation Sequence

Upon receiving command, Module will execute process once only. If there

is no Tag, a Tag absence error will be transmitted. During processing of the

command, Tag will become inoperative, and thus will not respond to the

next command. Oscillation will continue after command is processed.

Response

Command Command

Response 2Response 1

(Tag Absence Error)

Tag

Communication

Page 13

(13/23)

(Oscillation)

Tag 1

Response

STOP

Command Process

(Oscillation)

Tag 2

Tag 1

Tag Operation

User ←

User →

Command Process

Command Process

(Oscillation)

4) FIFO Auto

Module will await Tag to approach after receiving command, then

communicate with Tag and transmit response. After communication is

completed, Module will prohibit Tag from operating. Module will be on stand

by after response transmission is completed. During communication with

the Tag, there MUST BE AN OPERATIONAL TAG (A TAG THAT IS NOT

PROHIBITED FROM OPERATION) within the communication area. When

this command is executed, Module automatically activates “Oscillation

Mode.”

♦ Operation Sequence

After receiving command, the Module waits for the Tag to approach, then

executes process once only after Tag is detected. During processing of the

command, Tag will become inoperative, and thus will not respond to the

next command. Oscillation will continue after command is processed.

When Module receives a STOP command, the command will be

completed.

User →

User ←

Tag

Communication

Tag Operation

Command

Response 1

Tag

Detection

Command

Tag Detection

(Truncation

Process)

5) FIFO Continue

After receiving command, the Module waits for the Tag to approach, then

communicates with the Tag and transmits a response. After communication

is completed, Tag will become inoperative. After transmitting a response,

Module will await Tag to approach again if it receives [ACK], and

CONTINUE UNTIL MODULE RECEIVES A STOP COMMAND. When

communicating with the Tag, THERE MUST ONLY BE ONE ACTIVE TAG

within the communication area.

♦ Operation Sequence

Upon receiving the command, Module awaits Tag to approach. When Tag

is detected, Module executes command and transmits a response.

Afterwards, when [ACK] is received, Module repeats the same operation.

Once process is executed on a Tag, the Tag becomes inoperative, and thus

a Tag will only be processed once. When Module receives a STOP

command, processing will stop.

Command STOPNACKACK

Tag

Communication

Tag

Detection

Response 1

Tag

Detection

Response 2

Response 2

Page 14

(14/23)

272 characters or less

Detection

Detection

Detection

Detection

Command

Respons

Process)

Command

Tag 3

Tag 2

Tag 1

Communication

Tag Operation

User ←

User →

6) FIFO Repeat

After receiving command, the Module waits for the Tag to approach, then

communicates with the Tag and transmits a response. After communication

is completed, Tag will become inoperative. MODULE WILL CONTINUE

PROCESS UNTIL IT RECEIVES A STOP COMMAND. When

communicating with the Tag, THERE MUST ONLY BE ONE ACTIVE TAG

(A TAG THAT IS NOT PROHIBITED FROM OPERATION) within the

communication area.

♦ Operation Sequence

Upon receiving the command, Module awaits Tag to approach. When Tag

is detected, Module executes command and transmits a response.

Afterwards, Module repeats the same operation. Once process is executed

on a Tag, the Tag becomes inoperative, and thus a Tag will only be

processed once. When Module receives a STOP command, processing will

stop.

STOP

Response 2

Tag

Tag

Tag

Response 1

Tag

4. Controlling the Module from User board

4.1 Transmission Control Format

The frame format consists of 16 types of text in even number units from through “0”~

“F” (Band the terminator [Cr] (ASCII code : 0Dh).

Text Terminator

Response 3

Tag

(Truncation

Cr

Data

Number of

characters

Details

Text 1 ~ 272 Parameters of each command (“0” ~ “F”)

Terminator 1 Code (0Dh) indicating the completion of transmission

frame

(Transmission Control Procedure)

Receipt commences when a character is received first, and when [Cr] is received,

the frame is recognized as finished. If the interval between data exceeds 2 seconds,

a transmission error will be recognized.

Page 15

(15/23)

4.2 Command/Response Format

n

Command

The frame consists of an operation option, parameters, and terminator.

Communication options can be attached to commands No. 01 through 08 only.

Command Option Parameter 1 ~ Parameter n Terminator

n

Response

The frame consists of a completion code, parameters, and terminator.

Cr

Completion

code

Parameter 1 ~ Parameter n Terminator

Cr

(1) Types of Commands

Specifies the process of the R/W Module

Command

Name

Number Details

Read 01 Reads Tag Memory data in units of pages

Write 02 Writes data onto Tag Memory in units of pages

Multiple Write 03 Writes the same data onto Tag Memory in units of

pages

Byte Write 04 Writes data onto Tag Memory in units of bytes

Write

Protection

08 Specifies setting or to undo write protection per

page

ACK 11 Is sent when User board successfully receives data

NACK 12 Is sent when User board does not receive data

successfully

STOP 13 Stops processing of command being executed

Oscillation ON 14 Activates Oscillation Mode on Module Antenna

Oscillation OFF 15 Stops Oscillation Mode on Module Antenna

Test 10 Transmits data received directly back to User board

Page 16

(16/23)

(2) Options

Specifies communication operations when command is one of 01 through 08.

Option Number Details

Single

Trigger

Single

00 Conducts communication with Tag on Single Trigger

Mode

01 Conducts communication with Tag on Single Auto Mode

Auto

FIFO

Trigger

08 Conducts communication with Tag on FIFO Trigger

Mode

FIFO Auto 09 Conducts communication with Tag on FIFO Auto Mode

FIFO

Continue

FIFO

Repeat

0A Conducts communication with Tag on FIFO Continue

Mode

0B Conducts communication with Tag on FIFO Repeat

Mode

(3) Completion Code

When command process is completed successfully, completion code becomes

“00”.

If process was not completed successfully, an error code will be transmitted.

4.3 Types of Commands and Responses

(1) Read

Read is used when data is to be read from the Tag. Data for any specified page

may be read. The maximum number of pages that may be read at one time is

16.

n

Command

The pages to be read will be transmitted as parameters. Page specifications shall be

made by specifying the bit indicating the page as 1 and the other bits as 0. Pages can

be specified at random.

Command Option Page specification (8 characters) Terminator

“0” “1” Cr

Bit 7 6 5 4 1 0 7 6 1 0 7 6 1 0 7 6 2 1 0

Page 30292827~ 24232221~ 16151413~ 8 7 6 5 ~ 1 * *

Value “00” ~ “FF” “00” ~ “FF” “00” ~ “FF” “00” ~ “FC”

*0,1 bits should be specified as 0. When 1 is specified, it will register as

an error (error code 14).

Page 17

(17/23)

(Data n)

⋅ ⋅ ⋅

(Data 1)

n

Response

The completion code (“00”when successful) and read data will be transmitted. The

read data will be transmitted continuously according to the order of page

specification.

Completion

code

“0” “0” Cr

(Data 1)

Read data* Terminator

⋅ ⋅ ⋅

(Data n)

*Data number n = specified page × 8

(2) Write

The Write command is used when data is to be written onto the Tag Memory in

units of pages. Data can be written on any specified page. The maximum

number of pages onto which data may be written at one time is 16.

n

Command

The pages to be written on and the data to be written onto each page will be

transmitted as parameters. Page specifications shall be made by specifying the bit

indicating the page as 1 and the other bits as 0. Data to be written should be specified

in the order of specification of the designated pages.

Command Option Page specification (8 characters) Data to be written*

“0” “2” Cr

Bit 7 6 5 4 1 0 7 6 1 0 7 6 1 0 7 6 2 1 0

Page 30292827~ 24232221~ 16151413~ 8 7 6 5 ~ 1 ** **

Value “00” ~ “FF” “00” ~ “FF” “00” ~ “FF” “00” ~ “FC”

* Data number n = specified page x 8

** 0,1 bits should be specified as 0. When 1 is specified, it will register as an error

(error code 14).

n

Response

The completion code (“00” when successful) will be transmitted.

Completion

code

“0” “0” Cr

Terminator

Page 18

(18/23)

⋅ ⋅ ⋅

(Data n)

⋅ ⋅ ⋅

(Data 1)

(3) Multiple Write

The Multiple Write command is used when the same data is written in units of

pages. Pages may be specified at random. There is no limit on the number of

pages that may be written at one time.

n

Command

The designated pages to be written and the data to be written onto each page is

transmitted as parameters. Page specifications shall be made by specifying the bit

indicating the page as 1 and the other bits as 0. Data to be written should be specified

in the order of specification of the designated pages.

Command Option Page specification Data to be written*

“0” “3” Cr

Bit 7 6 5 4 1 0 7 6 1 0 7 6 1 0 7 6 2 1 0

Page 30292827~ 24232221~ 16151413~ 8 7 6 5 ~ 1 ** **

Value “00” ~ “FF” “00” ~ “FF” “00” ~ “FF” “00” ~ “FC”

* Data number n = 8

** 0,1 bits should be specified as 0. When 1 is specified, it will register as an error

(error code 14).

n

Response

The completion code (“00” when successful) will be transmitted.

Completion

code

“0” “0” Cr

Terminator

(4) Byte Write

The Byte Write command is used when data is to be written onto the Tag

Memory in Units of Bytes. Data can only be written on the same specified page.

Data cannot be written on more than one page.

n

Command

The pages to be written on and the data to be written onto each page will be

transmitted as parameters. Address specifications are done by specifying the first

address where the data is to be written (specification range: 00h ~ EFh). Data will be

written in accordingly from the specified address. (The maximum volume of data is 8

bytes)

Command Option

“0” “4” Cr

Designated

Address

(Data 1)

Data to be written* Terminator

(Data n)

* Data number n = number of bytes to be written (maximum 8)

n

Response

The completion code (“00” when successful) will be transmitted.

Completion

code

“0” “0” Cr

Terminator

Page 19

(19/23)

(Data 4)

(Data 3)

(Data 2)

(Data 1)

(Data 4)

(Data 3)

(Data 2)

(Data 1)

(Data 4)

(Data 3)

(Data 2)

(Data 1)

(5) Write Protection

The Write Protection command is used to set or turn off write protection on Tag.

n

Command

The pages to set or turn off write protection on will be transmitted as parameters.

Page specifications shall be made by specifying the bit indicating the page as 1 and

the other bits as 0. If set and turn off were specified for the same page, the set

command will have priority.

Command Option Setting specification (8 characters) Turn off specification (8 characters)

“0” “8” Cr

Bit 7 6 5 4 1 0 7 6 1 0 7 6 1 0 7 6 2 1 0

Page 30292827~ 24232221~ 16151413~ 8 7 6 5 ~ 1 * *

Value “00” ~ “FF” “00” ~ “FF” “00” ~ “FF” “00” ~ “FC”

* 0,1 bits should be specified as 0. When 1 is specified, it will register as an error

(error code 14).

Command

code

“0” “0” Cr

Bit 7 6 5 4 1 0 7 6 1 0 7 6 1 0 7 6 2 1 0

Page 30292827~ 24232221~ 16151413~ 8 7 6 5 ~ 1 * *

Value “00” ~ “FF” “00” ~ “FF” “00” ~ “FF” “00” ~ “FC”

Setting specification (8 characters)

* 0, 1 bits are indicated as 0.

n

Response

The completion code (“00” when successful) and write protection status information

will be transmitted.

(6) ACK

ACK is transmitted after FIFO Continue is operated and the response is

received to allow reading of the following:

n

Command

Command

Terminator

“1” “1” Cr

n

Response

There is no response.

Page 20

(20/23)

(7) NACK

When the User board was not able to receive a response correctly, NACK is

transmitted to demand that the response to be transmitted again. When the R/w

Module receives this command, the most recent response will be transmitted

again.

n

Command

Command

“1” “2” Cr

n

Response

Terminator

The most recent response will be transmitted again.

(8) STOP

The STOP command is used to stop the R/W Module from executing a

command. When the R/W Module receives this command, it immediately stops

the execution of the current command and sets on stand by mode for a new

command.

n

Command

Command

“1” “3” Cr

n

Response

Completion Code

“0” “0” Cr

Terminator

Terminator

(9) Oscillation ON / OFF

The Oscillation ON / OFF command specifies the oscillation of the antenna.

n

Command

Oscillation ON Oscillation OFF

Command

“1” “4” Cr “1” “5” Cr

n

Response

Completion Code

“0” “0” Cr

Terminator

Terminator

Command

Terminator

Page 21

(21/23)

⋅ ⋅ ⋅

⋅ ⋅ ⋅

(10) Test

The Test command is to conduct transmission tests on the transmission to the

User board. When the R/W Module receives this command, it transmits the

same command to the User board.

n

Command

Command

“1” “0” Cr

n

Response

Completion

code

“0” “0” Cr

(Data 1)

Test Data (Same data as the command)

(Data 1)

Test Data

(Data n)

(Data n)

Terminator

Terminator

Page 22

(22/23)

5. Error Code List

(1) Transmission Between User board and R/W Module

Completion Code Name Details

10 Parity error

11 Framing error

12 Overrun error

14 Format error

18 Frame length error

(2) Transmission Between R/W Module and Tag

Completion Code Name Details

70 Transmission

error

• There is a parity error in one of the characters

among the command received.

• There is a framing error in one of the characters

among the command received.

• There is an overrun error in one of the characters

among the command received.

• The command format is not suitable for the

specification

Ex) Command section is not specified; page

specification is incorrect, etc.

• When the receiving frame exceeds 260

characters.

• When the intervals between the characters being

received exceeded 2 sec.

• Noise or other disruption occurred during

communication with Tag and command cannot be

executed properly.

71 Verification error

72 Tag absence error

7A Address

specification error

7B Outside of write

area error

7D Write protection

error

7F ID system error

(3) Hardware problem

Completion Code Name Details

7C Antenna hardware

error

• Tag is dated or incapable of being written correctly

for physical reasons.

• Tag is not present near antenna at time of

command execution.

• Page specification is incorrect.

• There is a Tag in the area where reading is

possible but writing is not.

• Write command was executed on a page specified

with write protection.

• The Tag used is not to specification of system.

• There is a hardware problem on the antenna.

Page 23

Loading...

Loading...