Conductive Level Controller

61F-GP-N8

Compact Plug-in Level Controllers for

Single or Two-point Level Cont rol o f

Conductive Materials (Liquids and

Solids)

Wide range of models: long-distance, high and

low-sensitivity, and two-wired types available.

24/100/110/120/200/220/230/240 VAC operation

possible.

Easy installation on DIN track.

Low-voltage (AC) electrodes.

Red LED operation indicator provided.

Conforms to EMC and LVD Directives.

UL/CSA approved.

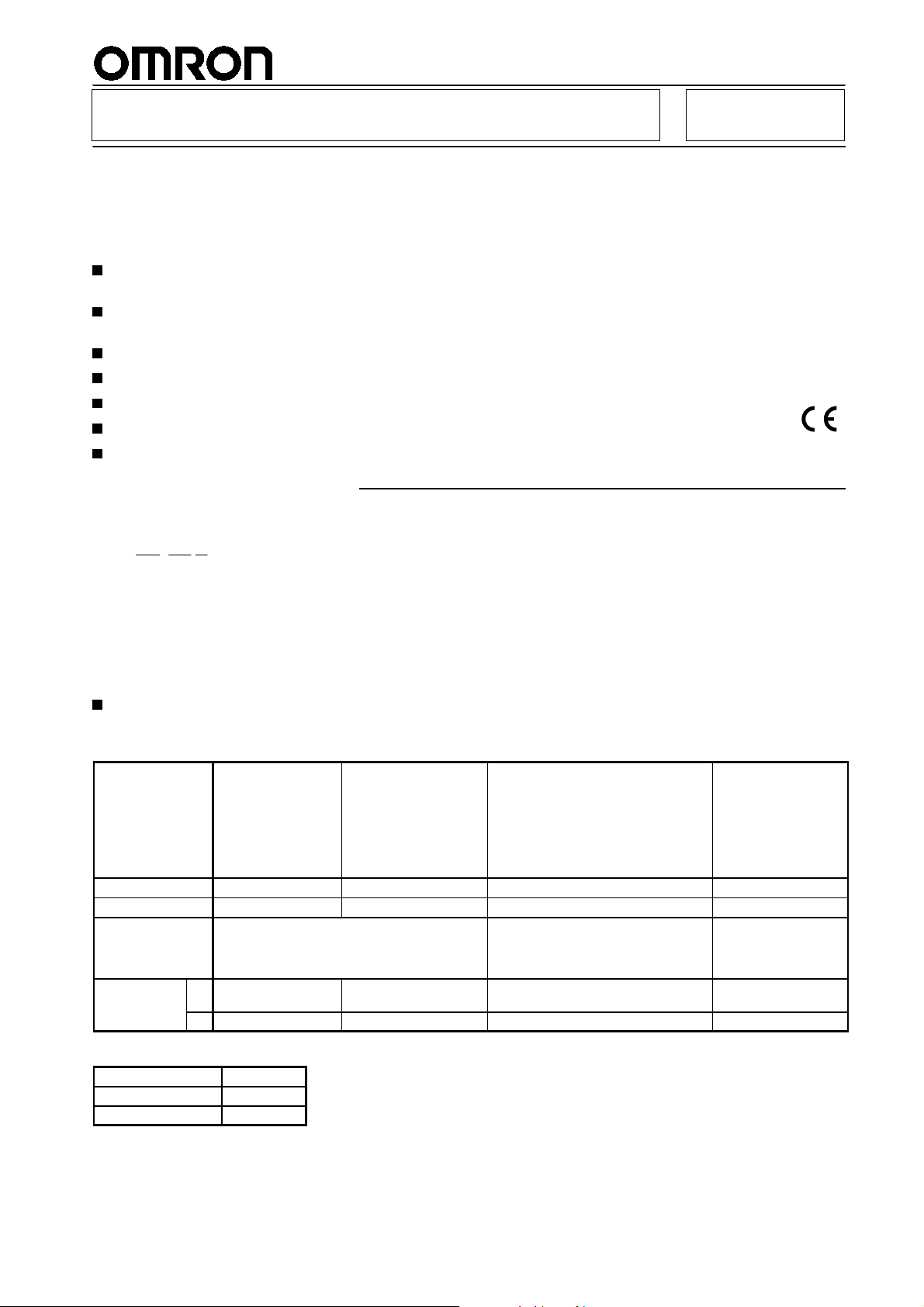

Ordering Information

Model Number Legend:

61F-GP-N8j

123

1. Plug-in Type

2. Compact 8-pin Type

Accessories (Order Separately)

Selection Guide for Electrode Holders and Separators

Electrode Holders

Applications

Mounting style Flange Screw Flange Screw

Insulator material Phenol resin Phenol resin Ceramics Tef l on

Max. temperature 70°C 150°C (without water drips or vapor on

No. of

electrodes

For city water and

other general-use

electrodes. Easy-toreplace separate

versions facilitate

maintenance of electrodes.

1 --- --- BF-1 BS-1

3 PS-3S PS-31 --- ---

When mounting space

is limited. Special 3-pole

holder of small size and

light weight. Ideal for

soft drink vendors, etc.,

where only limited

space is available.

3. Applications

None: General-purpose type

L: Long-distance type

H: High-sensitivity type (reverse acting)

HY: High-sensitivity type (standard acting)

D: Low-sensitivity type

R: Two-wired type

For low specific liquids. Used for sewage, sea water, etc., having a low specific resistance. In sewage use, electrode holders must be installed 10 to

20 cm apart from one another. For

acids, alkalis and sea water, electrode

holders may be as much as 1 meter

apart to operate properly.

the surface of the electrode holder)

When resistance to

high pressure is required. Ideal for use

in tanks where temperature or pressure

inside the tank is

high, e.g. 250°C

250°C (without water

drips or vapor on the

surface of the

electrode holder)

RC

Electrode Separators

No. of electrodes

1 F03-14 1P

3 F03-14 3P

Model

1

61F-GP-N8

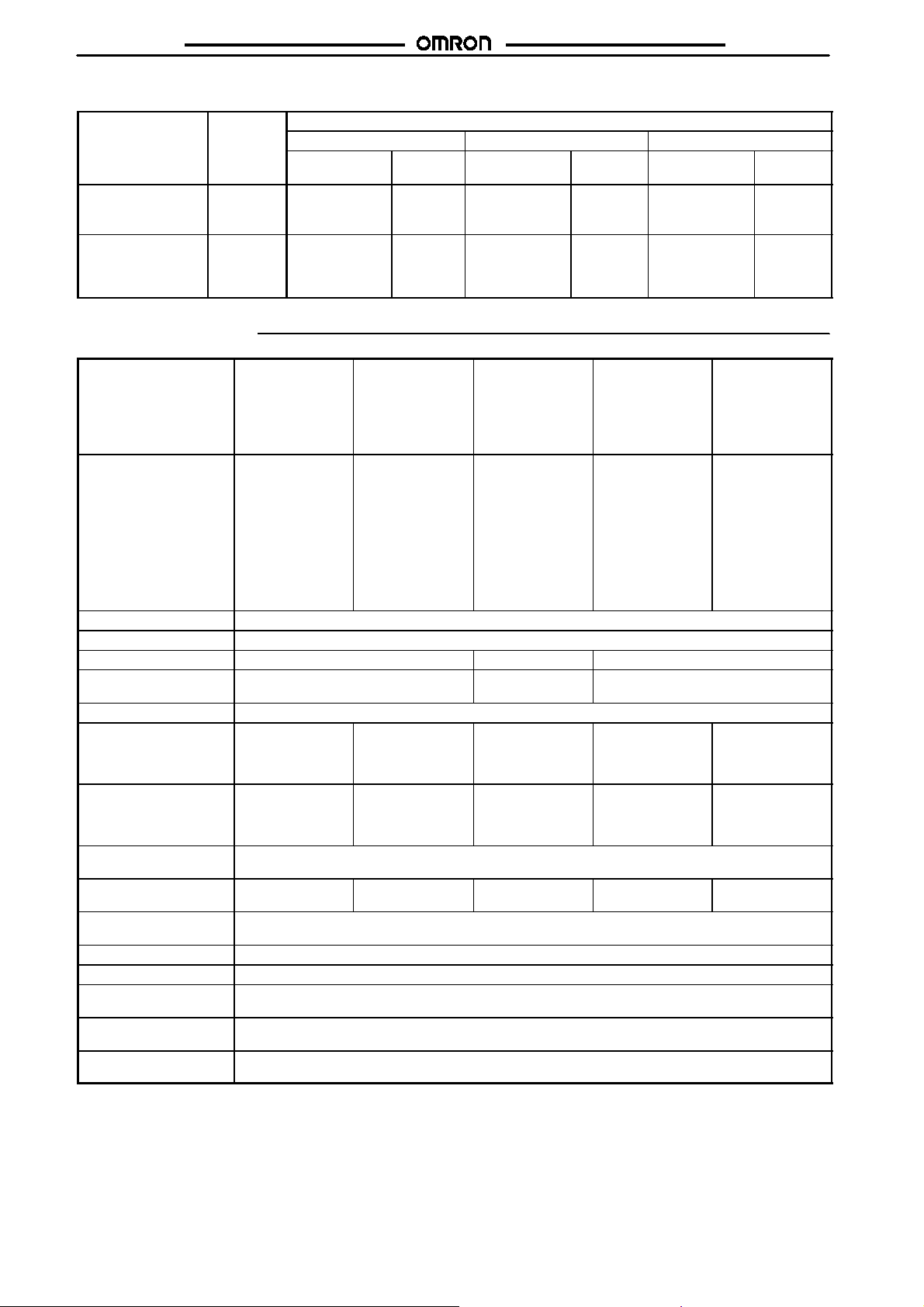

Selection Guide for Electrodes, Connecting, and Lock Nuts

Applicable liquids Material Models for individual electrode assembly components

Electrode (1m long) Connecting nut Lock nut

Purified city water,

industrial water,

sewage

Purified city water,

industrial water,

sewage, dilute alkaline solution

Equivalent

to SUS 304

(AISI-304)

SUS316

(AISI-316)

Model Indication

mark

F03-01 SUS201 1 line F03-02 SUS201 --- F03-03 SUS201 ---

F03-01 SUS316 2 lines F03-02 SUS316 6 F03-03 SUS316 6

Model Inscription Model Inscription

Specifications

61F-GP-N8

Model/Items General-purpose

Controlling materials

and operating

conditions

Supply voltage 24, 100, 110, 120, 200, 220, 230 or 240 VAC; 50/60 Hz

Operating voltage range 85% to 110% of rated voltage

Interelectrode voltage 8VAC 24 VAC 8VAC

Interelectrode current Approx. 1 mA AC max. Approx.

Power consumption Approx. 3.5 VA max.

Interelectrode operate

resistance

Interelectrode release

resistance

Response time Operate: 80 ms max.

Cable length

(see note 2)

Control output 1 A, 250 VAC (Inductive load: cosφ =0.4)

Ambient temperature Operating: --10°Cto55°C

Ambient humidity Operating: 45% to 85% RH

Insulation resistance

(see note 3)

Dielectric strength

(see note 4)

Life expectancy Electrical: 100,000 operations min.

Controller

61F-GP-N8

For control of ordinary purified water

or sewage water

Approx. 0 to 4 kΩ Approx. 0 to 1.3 kΩ

Approx. 15 k to

∞ Ω

Release: 160 ms max.

1kmmax. 2kmmax.

3 A, 250 VAC (Resistive load)

100 MΩ max. (at 500 VDC)

2000 VAC, 50/60 Hz for 1 min.

Mechanical: 5,000,000 operations min.

Long-distance

Controllers

61F-GP-N8L 2KM

(for 2 km)

61F-GP-N8L 4KM

(for 4 km)

For control of ordinary purified water

in cases where the

distance between

sewage pumps and

water tanks or between receiver

tanks and supply

tanks is long or

where remote control is required.

(for 2 km)

Approx. 0 to 0.5 kΩ

(for 4 km)

Approx. 4 k to ∞ Ω

(for 2 km)

Approx. 0.5 k to

∞ Ω (for 4 km)

4kmmax.

High-sensitivity

Controllers

61F-GP-N8H

61F-GP-N8HY

(see note 1)

For control of liquids with high specific resistance

such as distilled

water

0.4 mA AC max.

Approx. 15 kΩ to

70 kΩ

(see note 3)

Approx. 300 k to

∞ Ω

50 m max. 1kmmax. 800 m max.

Low-sensitivity

Controller

61F-GP-N8D

For control of liquids with low specific resistance

such as salt water,

sewage water, acid

chemicals, alkali

chemicals

Approx. 1 mA AC max.

Approx. 0 to 1.3 kΩ Approx. 0 to 2 kΩ

Approx. 4 k to ∞ Ω Approx. 15 k to

Two -wir ed

Controller

61F-GP-N8R

For control of ordinary purified water

or sewage water

used in combination with two-wiredtype electrode

holder (incorporating a resistor of

6.8 kΩ)

∞ Ω

Note: 1. The relay in the 61F-GP-N8H de-energizes when there is water present across the electrodes, whereas the relay in the 61F-GP-

N8HY energizes when there is water present across the electrodes.

2

61F-GP-N8

2. The length when using completely-insulated, 600-V, 3-conductor (0.75 mm2) cabtire cables. Usable cable lengths will become

shorter as the cable diameter or number of conductors becomes larger.

3. The insulation resistance and dielectric strength indicate values between power terminals and electrode terminals, between power

terminals and contact terminals, and between electrode terminals and contact terminals.

4. Possible to use with 10 kΩ or less, however, this may cause reset failure.

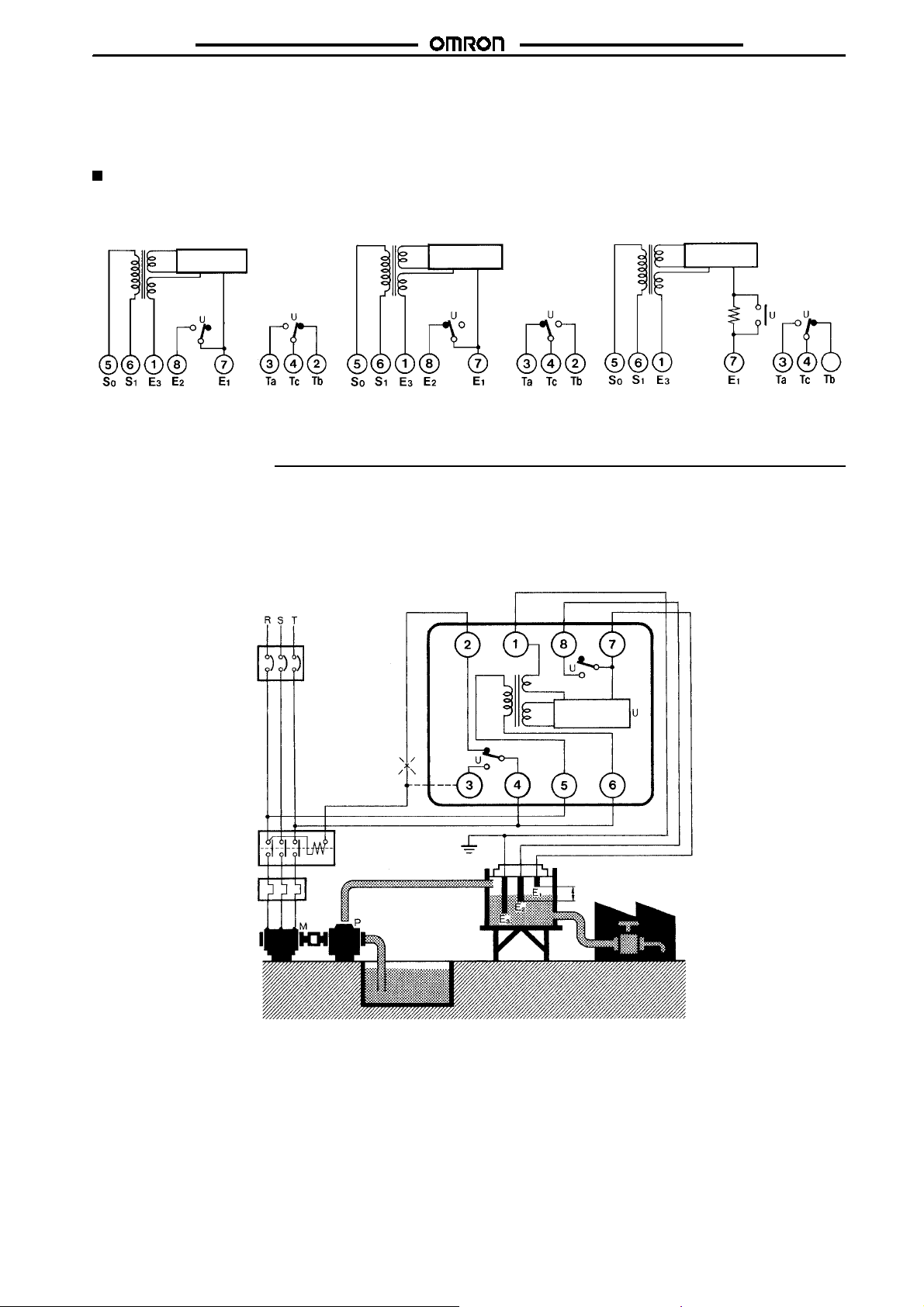

Internal Circuit Diagrams

61F-GP-N8/-N8L/-N8D/-N8HY 61F-GP-N8H

Power

supply

24 V

Control circuit

8 V (see note)

Power

supply

Note: 24 V for the 61F-GP-N8HY.

24 V

Control circuit

24 V

61F-GP-N8R

Power

supply

24 V

Control circuit

8V

Connections

61F-GP-N8

2

Automatic Water Supply and Drainage Control

1. Water Supply

Connect electromagnetic switch coil terminal A to terminal 2.

•

The pump stops when the water level reaches E1 and starts

•

when the water level drops below E2.

200-VAC power supply

MCCB

(See note 1

below.)

Contactor

THR

Reservoir

61F-GP-N8

(See note 2

below.)

2. Drainage

Connect the electromagnetic switch coil terminal A to terminal 3.

•

The pump starts when the water level reaches E1 and stops

•

when the water level drops below E2.

0V

200 V

Tank

8V

24 V

Control circuit

PS-3S

Stop

Start

Note: 1. The diagram shows the connections for water supply. When draining, change the connection from terminal 2 to terminal 3.

2. The earth terminal must be earthed.

3

Loading...

Loading...