Page 1

Cat. No. W485-E1-02

3G8F7-CRM21 (for PCI Bus)

3G8F8-CRM21 (for CompactPCI Bus)

TM

CompoNet Master Board

for PCI Bus / CompactPCI Bus

USER’S MANUAL

Page 2

Trademarks and Copyrights

Microsoft, Windows, Windows 2000, Windows XP, Windows Vista, Windows 7, Visual Basic, and

Visual C++ are registered trademarks of the Microsoft Corporation.

C++Builder is the registered trademark of the Embarcadero Technologies, Inc.

ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of the Open DeviceNet Vendor

Association, Inc.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

The copyright of the CompoNet Master Boards for PCI Bus and for CompactPCI Bus, and related

software belongs to OMRON Corporation.

Page 3

3G8F7-CRM21 (for PCI Bus)

3G8F8-CRM21 (for CompactPCI Bus)

CompoNet Master Board for PCI Bus / CompactPCI Bus

TM

User’s Manual

Revised September 2013

Page 4

iv

Page 5

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or

damage to property.

DANGER

WARNING

Caution

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury . Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury . Additionally, there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided , may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capita lized in this man ual. T he w ord "Unit" is also capitaliz ed when it r ef ers t o

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation "Ch," which appears in some parts of this manual and on some displays and on

OMRON products, has two meanings which must be distinguished in context. In one case, it means

"word" as an aggregation of da ta, an d is a b br eviated "Wd". In other case, it refers to a p hysical input or

output channel. In latter case, when a model has two input channels, they are referred to as Input 1

and Input 2.

The abbreviation "PC" refers to personal computers while "PLC" means Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Precautions for Safe Use

Supplementary c omments on what to do or avoid doing, to use the product

safely

Precautions for Correct Use

Supplementary comm ents on what to do or avoid doing, to prevent failure to

operate, or undesirable eff ect on product performance

Note Notes in the document refer to equivalent content to the Precautions for

Correct Use or to Precautions for Safe Use.

It also indicates information of particular interest for efficient and convenient

operation of the product.

1,2,3... 1. Indicates lists of one sort or another , such as procedures, checklists, etc.

v

Page 6

OMRON, 2009

r

f

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6 Conformance with the EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

SECTION 1

Outline of CompoNet and CompoNet Master Board . . . . . 1

1-1 Overview of the CompoNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Overview of the CompoNet Master Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Component Name and Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 LED Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Network Construction Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Board Preparation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2

Installation and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Mounting a Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Connecting the Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-4 Connecting the Communications Power Supply Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SECTION 3

Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-1 Settings at Communications Cycle Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-2 Access to I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-3 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-4 Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-5 Detailed Settings at Communications Cycle Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

SECTION 4

Operation by API Functions . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-1 Access to I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-2 Detailed Setting at Communications Cycle Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-3 Explicit Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-4 Setting the Time Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-5 Implementing the Reset Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

vii

Page 8

TABLE OF CONTENTS

4-6 Access to Detailed Status Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-7 PC Watchdog Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-8 Board Hardware Error Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SECTION 5

Operation by Accessing to Shared Memory. . . . . . . . . . . . . 55

5-1 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5-2 Communications Cycle Control Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5-3 Setting the Time Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

5-4 Implementing the Reset Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-5 PC Watchdog Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5-6 Board Hardware Error Notification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

SECTION 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6-1 LED Indications and Error Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6-2 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

APPENDIX A

API Function Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

A-1 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

A-2 Board Control API. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

A-3 Communications Control API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

A-4 Status Access API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A-5 I/O Data Access API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A-6 Explicit Messaging API. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

A-7 PC Watchdog Timer API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

A-8 Board Request Notification API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A-9 Errors Detectable by Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

APPENDIX B

Shared Memory Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

B-1 PCI Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

B-2 PC I Register Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

B-3 Shared Memory Area Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

B-4 Command Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

APPENDIX C

Communications Performance . . . . . . . . . . . . . . . . . . . . . . . 147

C-1 Remote I/O Communications Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

viii

Page 9

TABLE OF CONTENTS

APPENDIX D

Sample Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

D-1 Sample Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

APPENDIX E

Installation and Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

E-1 CompoNet Network Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

E-2 Wiring Formations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

E-3 Wiring for a CompoNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

E-4 Preparing and Mounting Flat Connectors on the Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

E-5 Wiring for Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

ix

Page 10

TABLE OF CONTENTS

x

Page 11

About This Manual

This manual describes the installation and operation of the 3G8F7-CRM21 CompoNet Master Board

for PCI Bus and the 3G8F8-CRM21 CompoNet Master Board for CompactPCI Bus. The CompoNet

Master Board functions as the CompoNet Master Unit. There are two types: One is compatible with

PCI bus (model # 3G8F7-CRM21), and the othe r is compa tib le with Co mpactPCI b u s (model # 3G8 F8CRM21) .

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate a CompoNe t Master Board. Be sure to read th e pre caution s pro v ided i n

the following section. Also be sure to read the CompoNet Slave Unit Operation Manual (see following

table) together with this manual.

The manual contains the following sections:

Precautions provide general precautions for using the CompoNet Master Board and related devices.

Section 1 outlines the CompoNet and the CompoNet Master Board. Read this section carefully before

you use the CompoNet Master Board for the first time.

Section 2 outlines the installation and setup. It includes procedures to mount a Board, to install a

driver, and to connect the communications cables.

Section 3 describes the functions of the CompoNet Master Boards. There are basic and special

functions.

Section 4 describes the operations by API functions to control the Board in the Windows operation

systems.

Section 5 describes the operations by shared memory access to control the Board in operation

systems, other than Windows.

Section 6 describes the troubleshooting. It is recommended to read them first to prevent any errors

from occurring.

Appendix A describes the API functions.

Appendix B describes the shared memory interfaces.

Appendix C explains the communications performance.

Appendix D describes the sample program provided in the product package.

Appendix E describes the construction of a CompoNet Network.

It includes the network specifications, the wiring procedures and the preparation of Flat Connectors.

xi

Page 12

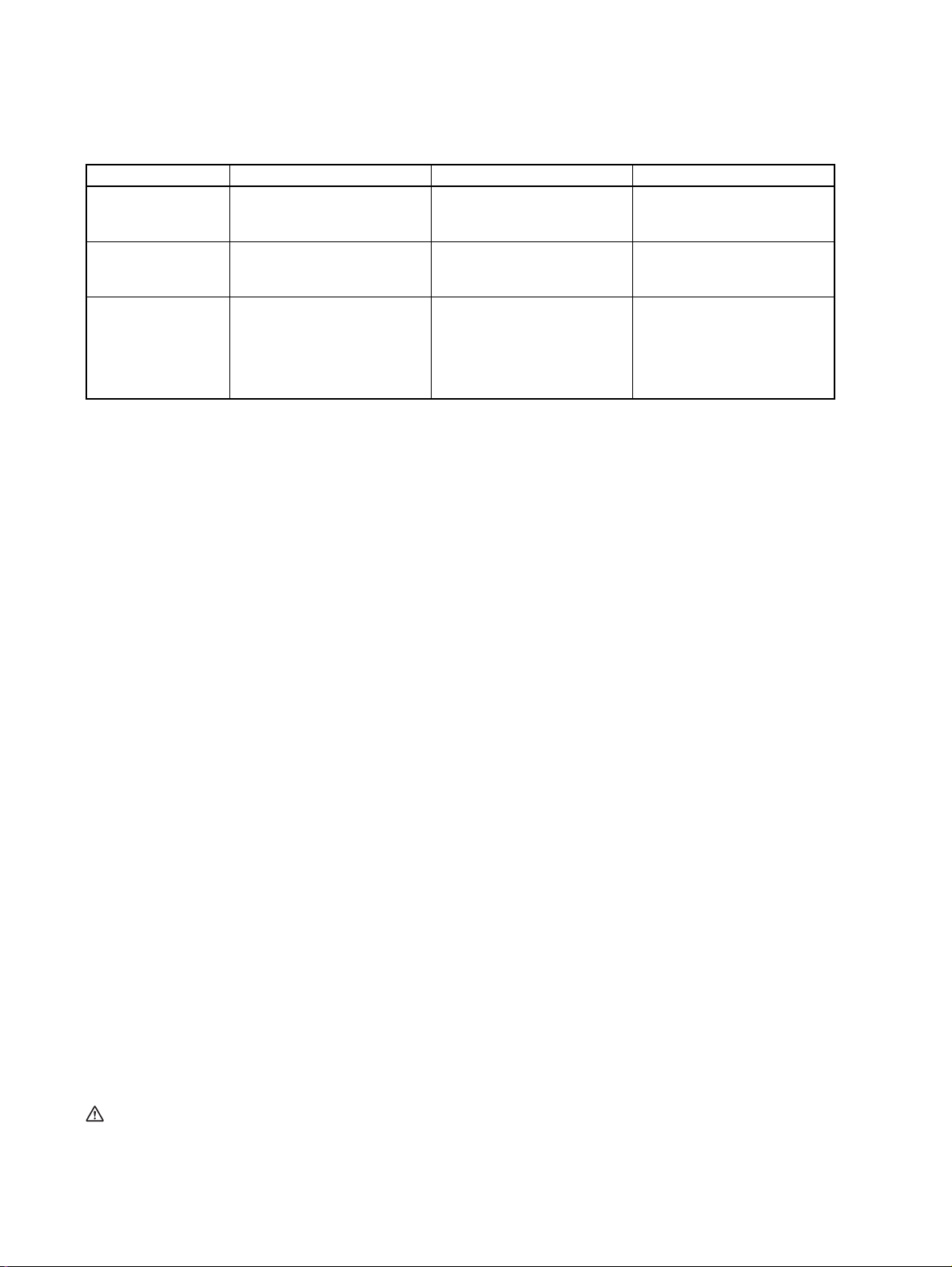

Related Manuals

Cat No. Model Name Description

W485

(this manual)

W457 CRT1

W456 CS1W-CRM21

3G8F7-CRM21

3G8F8-CRM21

CJ1WCRM21

CompoNet Master Board for

PCI Bus and for CompactPCI

Bus Operation Manual

CR1-series CompoNet

Slave Units and Repeater Unit

Operation Manual

CS/CJ-series CompoNet

Master Units Operation

Manual

TM

TM

Provides the specifications of

the CompoNet Master Board

Provides the specifications of

CompoNet Slave Units and

Repeater Units

TM

Provides an overview of

CompoNet Networks,

communications

specifications, wiring

methods, and CompoNet

Master Unit functions

WARNING

xii

The failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product or product failure. Please read each

section in its entirety, and be sure you understand the info rmation provided in th e section

and related sections before attempting any of the procedures or operations.

Page 13

Terms and Conditions Agreement

Read and understand this Manual

Please read and understand this catalog before purchasing the products. Please consult your

OMRON representative if you have any questions or comments.

Warranty, Limitations of Liability

Warranties

z Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

z Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A P AR TICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

z Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; pro vided th at in no even t sha ll

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding

the Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by Buyer must be approved in writing by Omron before shipment.

Omron Companies shall not be liable for the suitability or unsuitability or the results from the use

of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMP ANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

xiii

Page 14

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THA T THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirement s. Actual performance is subject to the Omron’s Wa rranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to change part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specification s of the

Product may be changed without any notice. When in doubt, special part numbers may be assigned

to fix or establish key specifications for your application. Please consult with your Omron’s representative at any time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

xiv

Page 15

PRECAUTIONS

This section provides general precautions for use of the CompoNet Master Boards.

The information contained in this section is important for the safe, reliable application of the CompoNet Master

Board. You must read this section and understand the information contained before attempting to set up or

operate a CompoNet Network using CompoNet Master Boards.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

4 Operating Environment Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

6 Conformance with the EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-2 Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6-3 Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

xv

Page 16

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel to read and use. The

personnel must have knowledge of electrical systems and would therefore be

electrical engineers or the equivalent:

• Perso nn e l in char ge of intr o ducin g FA systems

• Perso nn e l in char ge of de sig ning FA systems

• Personnel in charge of managing FA systems and facilities

2 General Precautions

The user must operate the product according to the performance

specifications described in the operation manuals. Before using the product

under conditions that are not described in the manual or when applying the

product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines or

safety equipment, or to other systems, machines and equipment that may

have a se rious influen ce on lives and property if used improperly, consul t your

OMRON representative.

Be certain the ratings and performance characteristics of the product are

sufficient for the systems, machines and equipment, and be sure to provide

the systems, machines and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit, and keep this

manual close at hand for reference during operation.

Be sure this manual is delivered to the persons actually using the CompoNet

Master Boards.

WARNING

It is extremely important that a PLC and all PLC Units be used for th e specified purpose

and under the specified conditions, especially in ap plications that can directly or indirect ly

affect human life. You must consult with your OMRON representative before applying a

PLC System to the above-mentioned applications.

xvi

Page 17

Safety Precautions 3

3 Safety Precautions

WARNING

WARNING

WARNING

WARNING

Caution

Caution

Do not attempt to take any Unit apart or touch the component inside while the power is

being supplied. Doing so may result in electric shock.

Do not touch any of the terminals or terminal blocks while the power is being supplied.

Doing so may result in electric shock.

Fail-safe measures must be taken by the user to ensure safe ty in the event of inco rrect,

missing or abnormal signals caused by broken signal lines, momentary power

interruptions or other causes. Serious accidents may result from abnormal operation if

proper measures are not provided.

Provide safety measures in external circuits (i.e., not in the personal computers) that

ensure safety of the system in any event of an abnormality due to malfunction of the PC

or another external factor affecting the PC operation. The failure to do so may result in

serious accidents. Emergency stop circuits, interlock circuits, limit circuits and similar

safety measures must be provided in external control circuits.

Confirm safety at the destination Sla ve Unit before changing it or transf erring par ameters

to another node. Changing or transferring any of these without confirming safety may

result in unexpected equipment operation.

A Slave Unit may change the output content if it faces a communications failure. When

you use outputting devices, confirm their operation specification on an event of

communications failure, and take the necessary safety measures.

4 Operating Environment Precautions

Caution

Do not operate the products in the following locations.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range

specified in the specifications

• Locations subject to condensation as the result of severe changes in

temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals (including

acids)

• Locations subject to shock or vibration

5 Application Precautions

Observe the following precautions when using a CompoNet Network.

• When more than one CompoNet system use Flat Cables, always

separate the Flat Cables from each ot her by at least 5 mm regard less of

whether Flat Cable I or II is us ed. Do not b un dle the F lat Cables. This is to

prevent unstable operation of the system due to interference.

xvii

Page 18

Application Precautions 5

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing or abnormal signals caused by broken signal

lines, momentary power interruption s or other causes.

• Configure the control circuits so that the power to the PC (near the

CompoNet Master Board) will be on after the power to the I/O Sla v e Units .

If the PC power supply is turned on first, normal operation will not be

ensured, even temporarily.

• Use the Boards within the communications distance and the number of

connectable Units as defined in the specifications.

• Do not attempt to disassemble, repair or modify any Units. Any attempt to

do so may result in a malfunction, fire or el ectric shock.

• When installing the Unit, ground to 100 Ω/min.

• Be certain all screws to fix the Board to the PC, as well as the screws on

connectors, cables and terminal blocks, are tightened to the torque

specified in the corresponding manual s. Incorrect tightening torque may

result in a malfunction.

• Be sure the Board on the PC is securely mounted.

• All installation and wiring must observe the instructions in this manual.

• Use correct wiring tools and components for wiring.

• Confirm the orientation and polarity before connecting the terminal blocks

or connectors.

• Do not supply electricity while a terminal block cover is open.

• Confirm voltage specifications before wiring the communications lines,

the power supplies or the I/O circuits. Incorrect specification may result in

a malfunction.

• Install exter nal breakers and take other safety measures against shortcircuiting in the external wiring. Insufficient safety measures against

short-circuiting may result in burning.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. The connection of bare stranded wires may result in

burning.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Be sure no waste metal enters the PC during the installation and wiring

work.

• Be certain the terminal blocks, connectors, expansion cables,

communications cables and other items with locking devices are properly

locked in place. Improper locking may result in a malfunction.

• Always use the power-supply voltages specified in the operation manual.

A malfunction or burning may occur as the result of incorrect voltage.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in a malfunction.

• Check the user program fo r proper execution before actually running it on

the Unit. The failure to check the program may result in unexpected

operation.

• Always tur n OFF the power supply to the personal computer, the Slave

Units and communications before attempting any of the following. The

failure to turn OFF the power supply ma y result in a malfunction or electric

shock.

xviii

Page 19

Application Precautions 5

• Mounting or removing a CompoNet Master Board

• Assembling devices

• Setting rotary switches

• Connecting cables or wiring the system

• Connecting or disconnecting the connectors

• Close the PC cover before wiring work. This is used to prevent wire waste

from entering the PC.

• Before touching a CompoNet Master Board, be sure to first touch a

grounded metallic object in order to discharge any static buildup. The

failure to do so may result in a malfunction or damage.

• When replacing parts, be sure to confirm that the rating of the new part is

correct. The failure to do so may result in a malfunction or burning.

• When transporting a CompoNet Master Board, use special packing boxes

and protect it from exposure to excessive vibration or impact during

transportation.

• Use the Board in the specified ambient operating temperature and

humidity.

• Store the Board in the specified ambient storage temper ature.

• Circuit boards have sharp edges such as leads of electric components.

Do not touch the parts where such components are mounted or the bac ks

of circuit boards by hand.

• Use only the specified communications cables.

• Do not extend connection distances beyond the ranges given in the

specifications.

• Observe the given precautions when wiring the communications cable.

• Separa te t he communications cables from the p ower lines or high-tension

lines.

• Do not bend th e comm unication s cab le s past their natur al b ending r ad ius .

• Do not pull on the communications cables.

• Do not place heavy objects atop the communications cables.

• Always lay communications cables inside ducts.

• Take appropriate and sufficient countermeasures when installing systems

in the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

• Do not use the computer’s standby or sleep function while you are using

the CompoNet Master Board. If the computer’s standby or sleep function

is activated during CompoNet Master Board usage, communications may

be broken or other unexpected errors may occur.

• The CompoNet Master Board does not support computer standby or

sleep functions. Do not use the computer’s standby or sleep function

while you are using the CompoNet Master Board.

xix

Page 20

Conformance with the EC Directives 6

6 Conformance with the EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

The OMRON products are electric components that usually are used after

being built in other machinery or manufacturing equipment. They are

designed to conform to the relevant EMC Directives. This will facilitate the

compliance of the final machinery or apparatus to such directives. However,

the installation and configuration of such machinery and apparatus in which

the OMRON products are mounted and used will differ according to their

characteristics. Thus it is virtually impossible for OMRON to ensure the

conformity of an entire system to the relevant EMC Directives. The users must

conduct the necessary tests and ensure the conformity of the system as a

whole.

The relevant EMC Directives are:

EN 61131-2 and EN 61000-6-2 for EMS, i.e., Electromagnetic susceptibility,

EN 61131-2 and EN 61000-6-4 for EMI, i.e., Electromagnetic Interference,

and EN61000-6-4 for Radiated emission, 10-m regulations, among EMC

(Electro-Magnetic Compatibility).

6-3 Conformity

1,2,3... 1. The OMRON product must be installed in a control panel.

The OMRON products in this manual comply with the relevant EMC

Directives. To ensure that the machinery or apparatus in which the OMRON

products are used complies with the EC Directiv es , the user m ust follow these

instructions:

2. DC power supply unit as well as DC power connected to I/O Units must

have reinforced insulation or double insulation.

3. Compliance to the EC Directives means conformity to the Emission

Standards (EN 61000-6-4). Radiated emission characteristics (10-m

regulations) may vary, however, depending on the configuration of the

control panel used, the compatibility with other devices connected to the

control panel, the effects of wiring and other conditions. The user must

confirm that the overall machine or equipment complies with the EC

Directives.

xx

Page 21

Outline of CompoNet and CompoNet Master Board

1-1 Overview of the CompoNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Overview of the CompoNet Master Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Component Name and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-1 3G8F7-CRM21 (for PCI Bus). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-2 3G8F8 -CRM21 (for CompactPCI Bus) . . . . . . . . . . . . . . . . . . . . . . 5

1-4 LED Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Network Construction Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-6 Board Preparation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-7 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-7-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-7-2 Development Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-7-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION 1

1

Page 22

Overview of the CompoNet Network Section 1-1

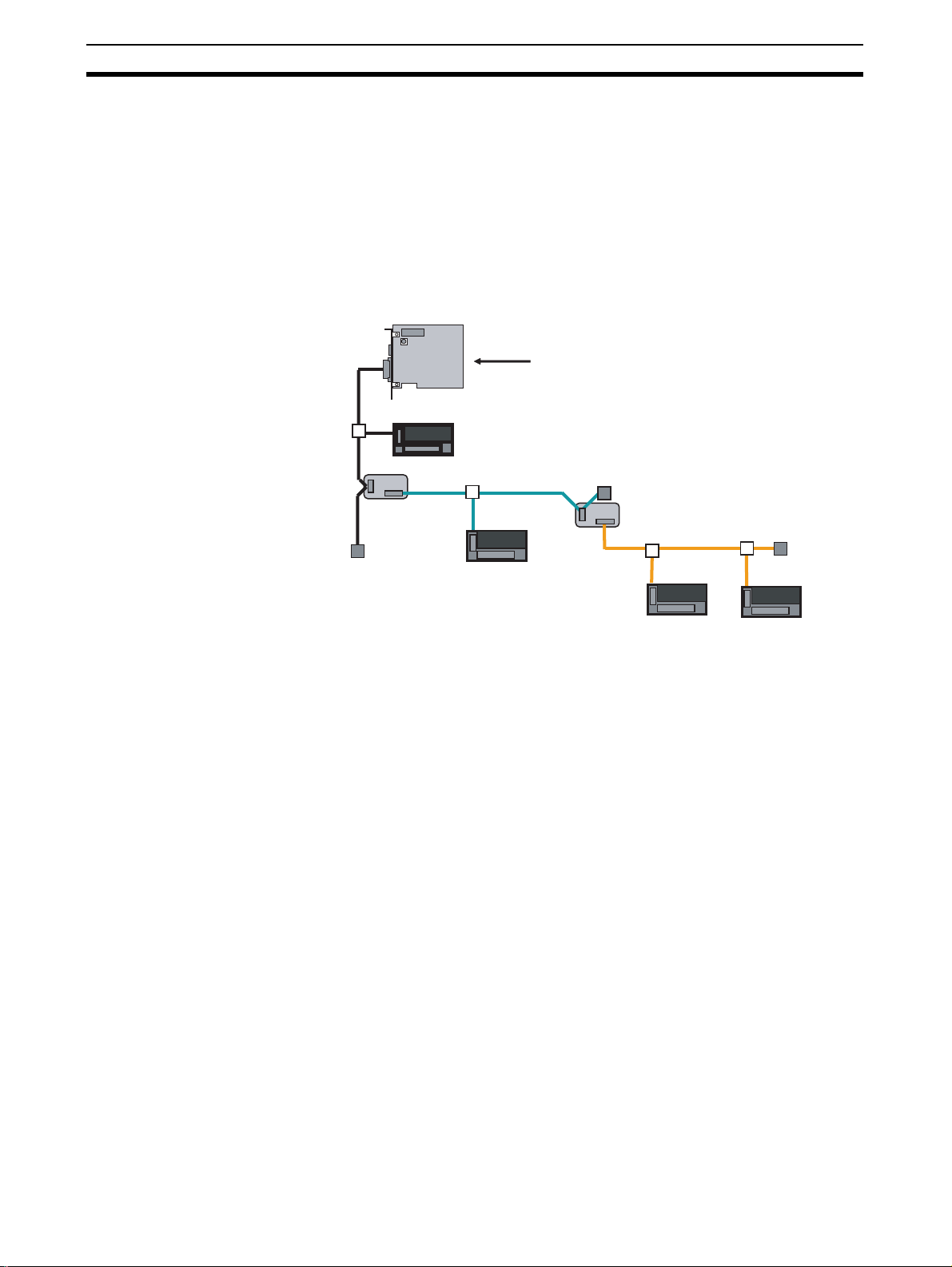

1-1 Overview of the CompoNet Network

CompoNet is a field network designed for communications between the input

and output components on the shop floor and a personal computer (or PC) or

a PLC. CompoNet requires less wiring labor but provides high maintainability.

The PC and the CompoNet Slave Unit exchange input and/or output data

cyclically through a CompoNet Master Board.

By using explicit messages, users can read data from the CompoNet Slave

Unit or write data into it.

High-Speed

Communications of

Multiple Nodes

Terminating

Resistor

Slave Unit

Repeater

Unit

Slave Unit

CompoNet Master Board

Terminating Resistor

Repeater Unit

Slave Unit

Terminating

Resistor

Slave Unit

Here are the main featur es of CompoNet:

CompoNet can provide remote I/O communications for multiple nodes as

many as maximum 2,560 points in a high speed such as 1000 points per

millisecond when the data rate is 4 Mbps*. This allows integration of

conventional system configuration with basic I/O Units into a CompoNet

network.

Greater Flexibility with

Repeater Units

2

* The data rate of 4 Mbps does not support T-branch connection. Thus any

Slave Unit with pre-attached cables is not usable.

Repeater Units can expand a network installation in the following ways:

• Extending the Communications cable,

• Increasing the number of connected nodes,

• Creating a branch connection from the trunk line, and

• Converting cable types.

Repeater Units can be used to expand the trunk line for up to two layers. The

lines downstream from the Repeater Units are called sub-trunk lines. The

maximum number of connectable Repeater Units is 64 per Master Board and

32 per trunk line.

Note The power to the sub-trunk lines must be supplied from the Repeater Units.

Page 23

Overview of the CompoNet Master Board Section 1-2

Bit-Level Distribution CompoNet is connectable with industry-standard e-CON connectors and

Slave Units of clamp terminal-block type. They allow bit-level controls of

conveyors or at warehouses where many sensors are placed over a wide

range.

Data Exchange by Explicit

Messages

Automatic Baud Rate

Detection

Explicit messages are used to access from the PC to the Slave Units and

Repeater Units connected to the CompoNet network. This feature facilitates

the maintenance of the entire networ k.

By setting the baud rate on the CompoNet Master Board, the Slave Units

automatically detect the baud rate of the CompoNet Master Board and follow

it. There is no need to set the rate individually on the Slave Units.

1-2 Overview of the CompoNet Master Board

CompoNet Master Board is a board that has a mastering function to control

inputs and outputs for the Slave Units connected to the CompoNet network.

The Board is either compatible with PCI bus (Model # 3G8F7-CRM21) or with

CompactPCI bus (Model # 3G8F8-CRM21).

Here are the main features of the CompoNet Master Board:

Control by API Functions In the Windows operation systems, all functions on the CompoNet Master

Board can be accessed by API functions.

Control by Shared

memory Accesses

In operation systems other than Windows, the CompoNet Master Board is

used via access to shared memory.

Flexible Allocation of the

Number of Connectable

Nodes

Registration Table

Function to Control

Participating Slave Units

Optimizing

Communications Cycle

Synchronous and

Asynchronous Access to

I/O Data

Other Functions • Communicat ions Stop Due to Communications Error function

The number of connectable nodes can be set differently for each Word Input

Slave Units, Word Output Slave Units, Bit Input Slave Units and Bit Output

Slave Units.

This function is used to pre-register the node addresses and models of Slave

Units that are to participate in the network, and to check whether a Slave Unit

that is actually participating is registered or not. If the Slave Unit is not

registered, it is not allowed to participate. The time can also be set to monitor

duration from power-on until a registered Slave Unit actually participates.

Remote I/O communications can be stopped until all registered Slave Units

participate in the network, but it can be started only with all Slave Units

participating. The latter function is called the All Registered Slave

Participation Standby Mode.

When the Registration Table function is used, the communications cycle is

optimized and fastened in accordance with the information in the table.

Both synchronous and asynchronous types of access are supported.

Synchronous access maintains synchronicity for each node, while

asynchronous access does not do that but instead provides faster access. In

the latter case, I/O data keeps synchronicity only within the same word.

• I/O Communications Manual Startup mode

• IN Data Zero Clear Due to Communications Error function

3

Page 24

Component Name and Function Section 1-3

1-3 Component Name and Function

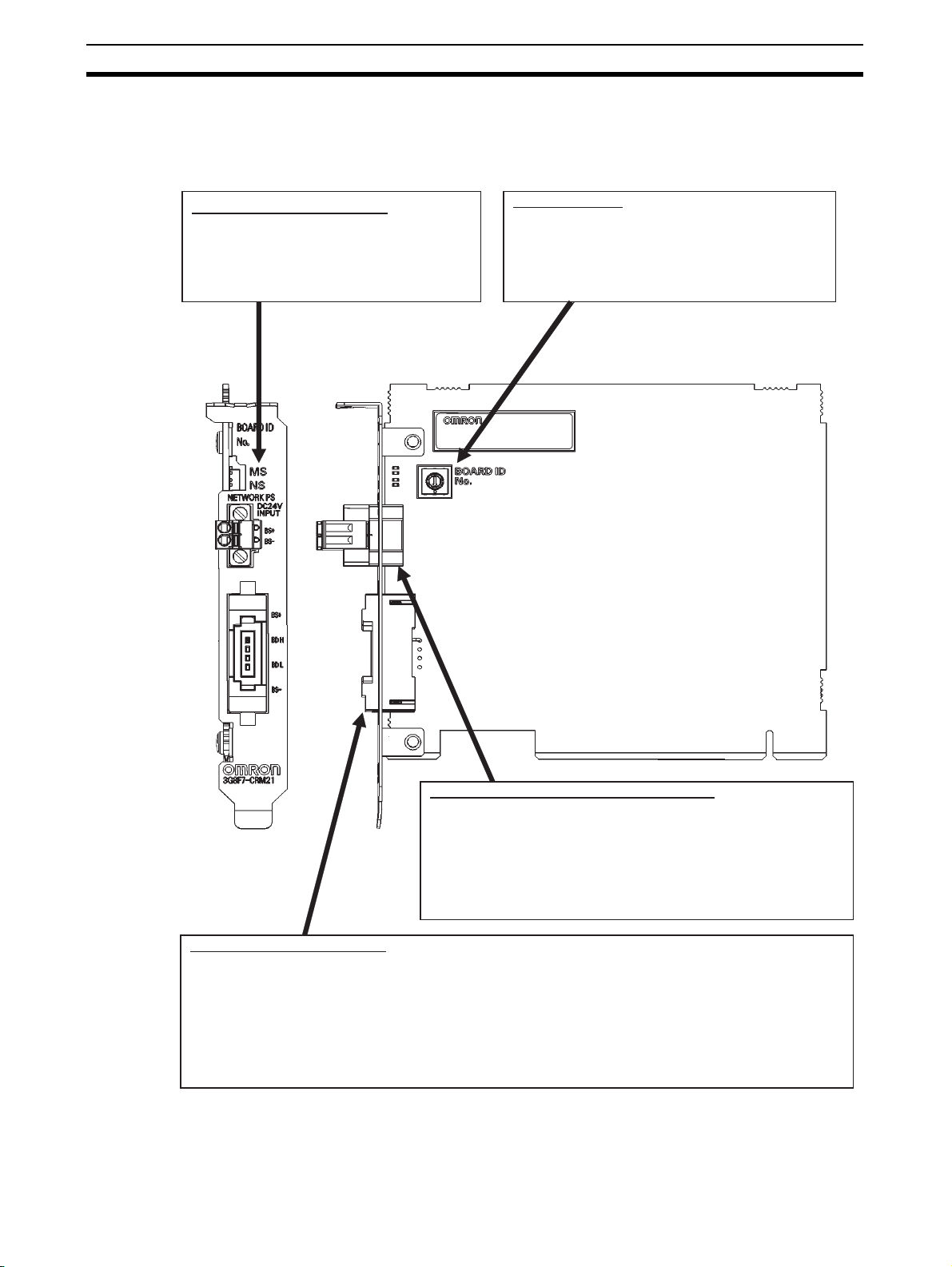

1-3-1 3G8F7-CRM21 (for PCI Bus)

LED Indicators (MS and NS)

They indicate the Module Status (MS)

and Network Status (NS) that are

defined in the CompoNet protocol.

Board ID Switch

This is used to set the board ID. It is set as a

decimal number. The number must not

overlap the IDs for other CompoNet Master

Boards mounted on the same personal

computer.

Communications power supply connector

This is used to connect a 24-VDC power supply when either

round cable II or Flat Cable I or II is used.

The communications power is supplied through this connector

and the round cable II, Flat Cable I or Flat Cable II to the Slave

Units and Repeater Units on the trunk line.

Note : Do not connect anything to this connector when a round

cable I is used.

Communications connector

This is used to connect to the communications cable.

The terminals BS+ and BS- are for communications power supply. The terminals BDH and BDL are for

communications data.

The BS+ and BS- can be used only for round cable II or Flat Cable I or II. They output the

communications power from the power supply connected to the communications power supply

connector.

Note : By attaching an Open Type Connector for Unit connection, the communications connector can be

converted to a terminal-block type.

4

Page 25

Component Name and Function Section 1-3

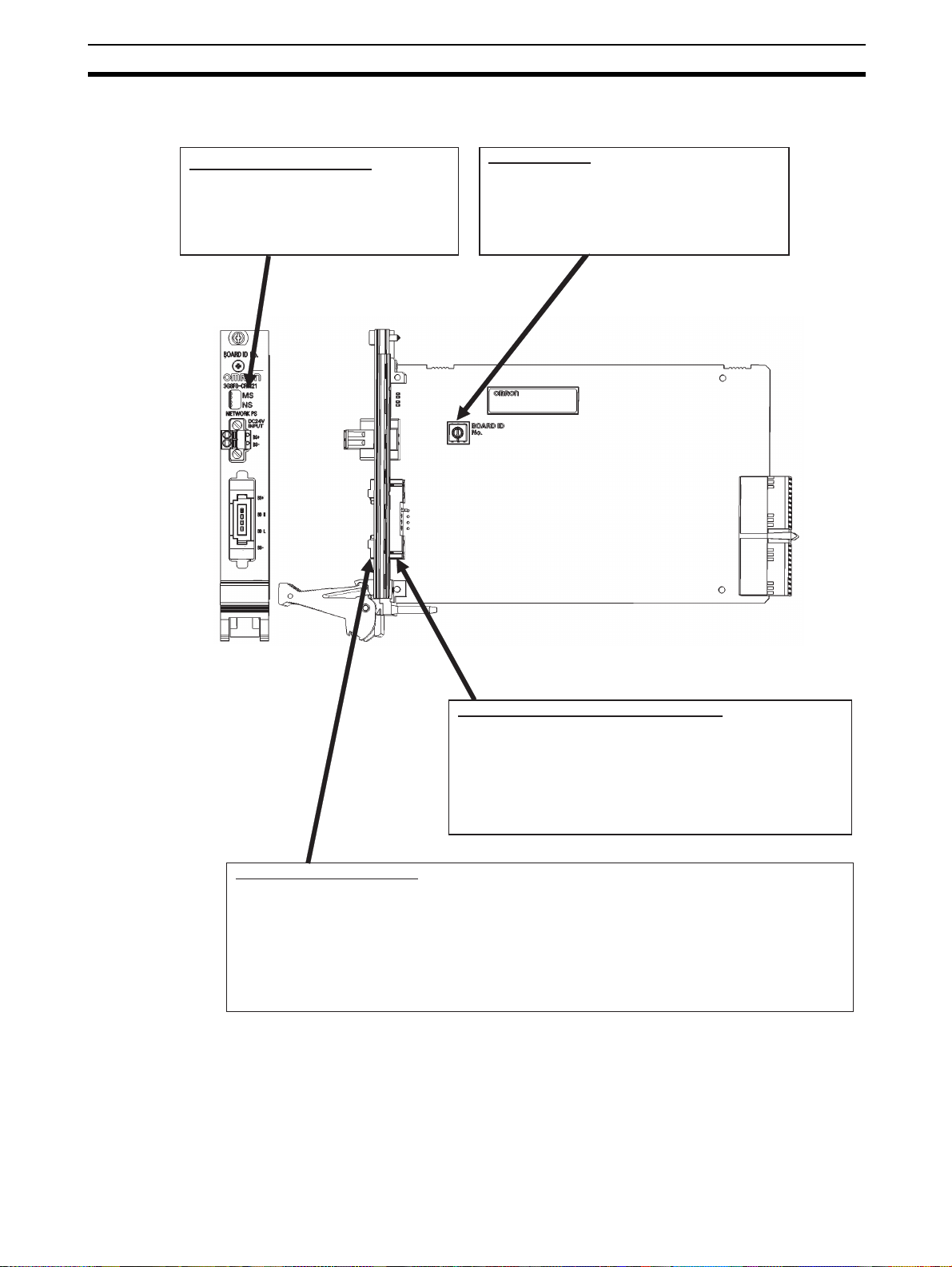

1-3-2 3G8F8-CRM21 (for CompactPCI Bus)

LED Indicators (MS and NS)

They indicate the Module Status (MS)

and Network Status (NS) that are

defined in the CompoNet protocol.

Board ID Switch

This is used to set the board ID. It is set as a

decimal number. The number must not

overlap the IDs for other CompoNet Master

Boards mounted on the same personal

computer.

Communications power supply connector

This is used to connect a 24-VDC power supply when either

round cable II or Flat Cable I or II is used.

The communications power is supplied through this connector

and the round cable II, Flat Cable I or Flat Cable II to the Slave

Units and Repeater Units on the trunk line.

Note : Do not connect anything to this connector when a round

cable I is used.

Communications connector

This is used to connect to the communications cable.

The terminals BS+ and BS- are for communications power supply. The terminals BDH and BDL are for

communications data.

The BS+ and BS- can be used only for round cable II or Flat Cable I or II. They output the

communications power from the power supply connected to the communications power supply

connector.

Note : By attaching an Open Type Connector for Unit connection, the communications connector can be

converted to a terminal-block type.

5

Page 26

LED Indication Section 1-4

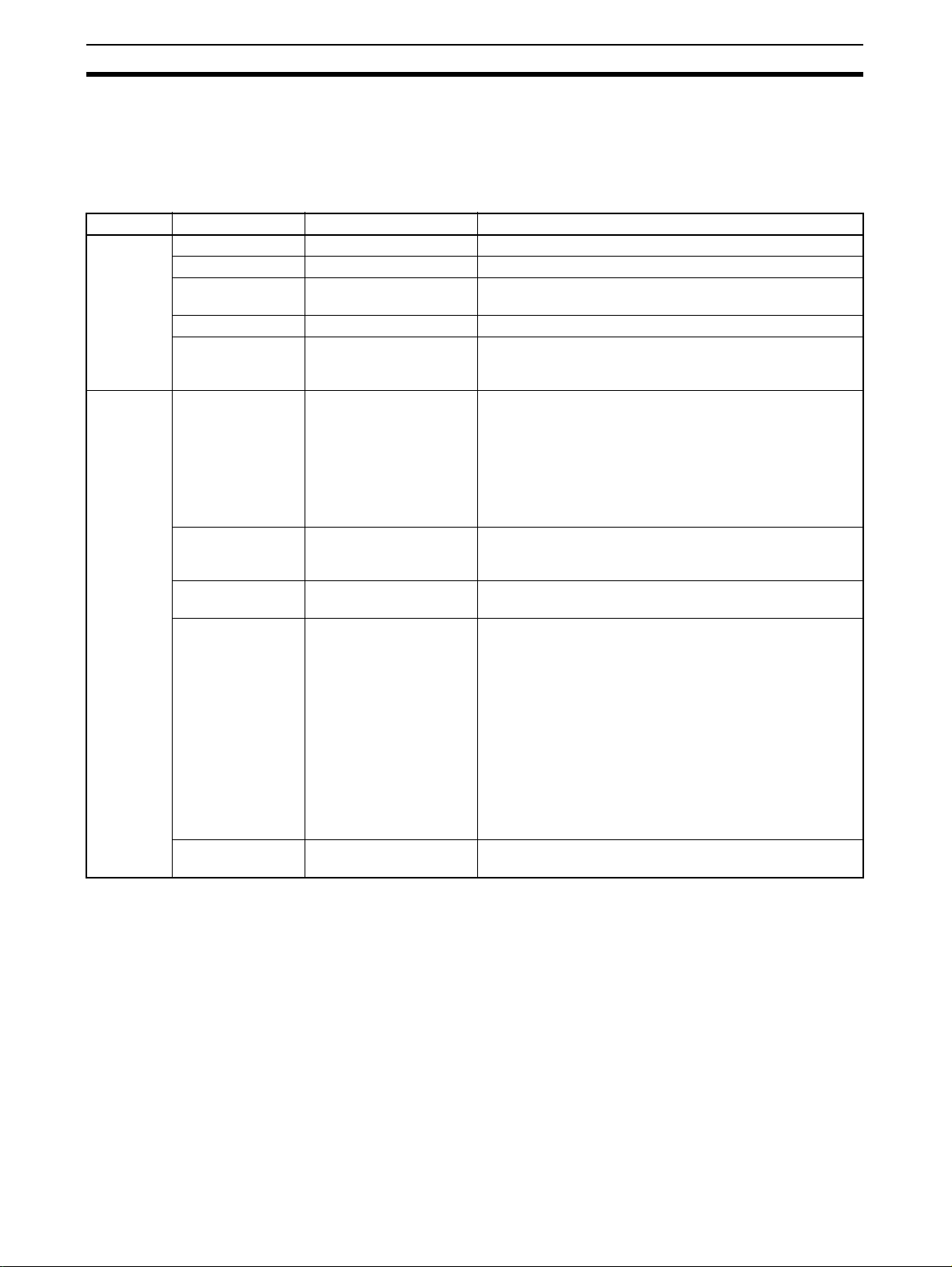

1-4 LED Indication

MS (Module Status) : To indicate the node status. (green and red)

NS (Network Status) : To indicate the communications status. (green an d red)

LED Name Indicating state Status Meaning

MS Green light Normal state The Master Board is in normal operation.

Green flash Stand-by It waits for a start-up by the application.

Red light Fatal error Master Board hardware error (including Watchdog Timer

(WDT) error)

Red flash Non-fatal error EEPROM read error or PC WDT error

Unlit Power-off or in

preparation

NS Green light Online and in remote I/O

communications

Green flash Online and in

preparation for remote

I/O communications

Red light Fatal communication

related error

Red flash Non-fatal communication

related error

Unlit Power-off or in

preparation

One of the following applies:

Power is off.

The system is resetting or initializing.

All of the followings apply:

⋅ Power is supplied. Remote I/O communications starts up.

⋅ None of the Slave and Repeater Units has

communications error.

⋅ No Registration Table error exists.

⋅ None of the Slave and Repeater Units has node address

duplication.

It is before the remote I/O communications starts or during

communication. (In any state other than the communication

stop due to a communications error.)

The communications circuit has an error.

One of the following applies:

⋅ One or more Slaves or Repeater Units has a

communications error.

⋅ One or more Slaves or Repeater Units has a Registration

Table error. That means a Slave Unit to participate is not

participating or a non-registered Slave Unit is

participating.

⋅ The communications stops due to a communications

error.

⋅ Illegal configuration error (an error of Repeater levels)

⋅ One or more Slaves or Repeater Units had node address

duplications.

One of the following applies: Power is off. The system is

resetting or initializing.

Note The indicators flash in 0.5 second interval, i.e., they light for 0.5 second and

become unlit for another 0.5 second.

6

Page 27

Network Construction Procedure Section 1-5

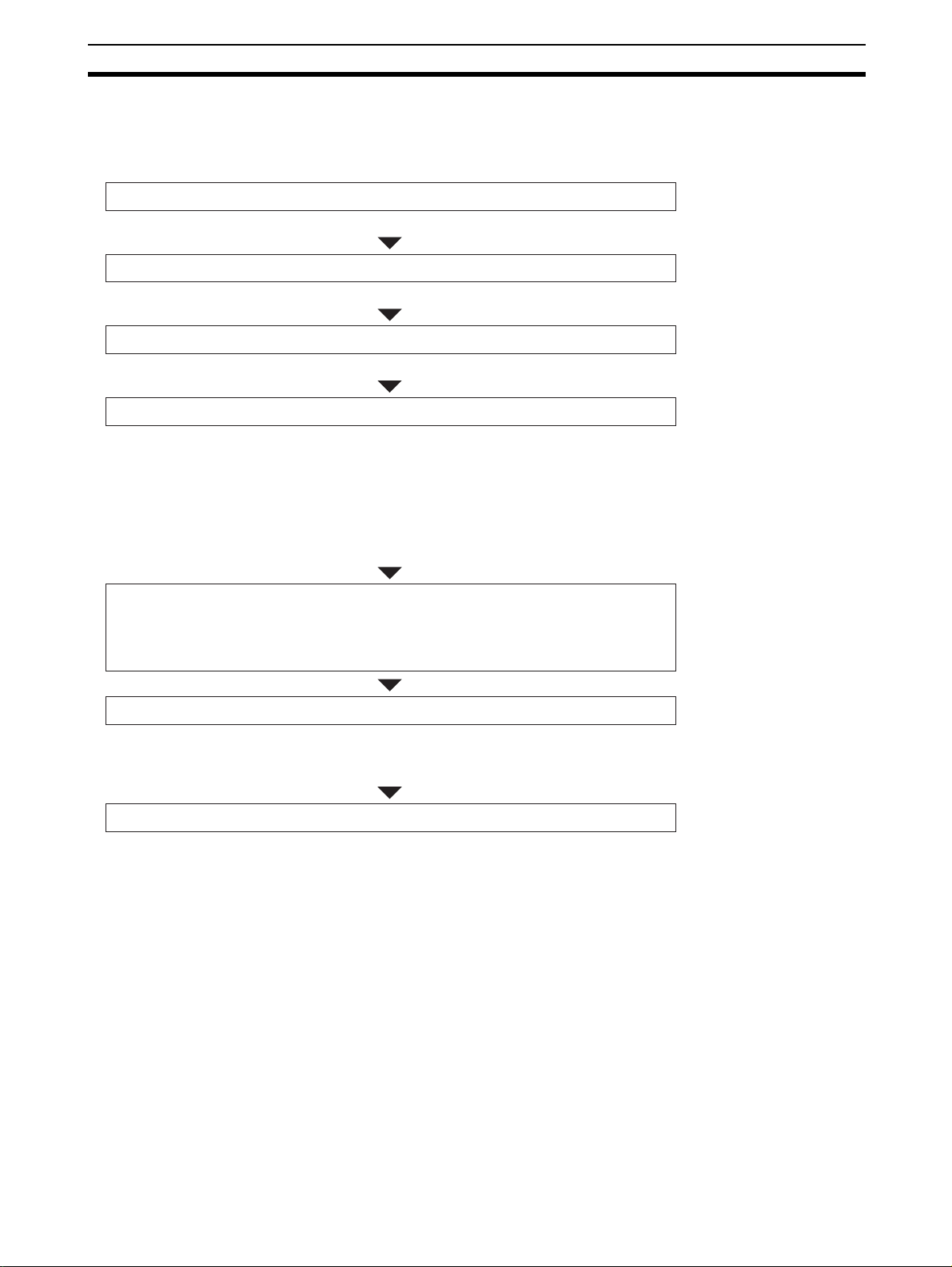

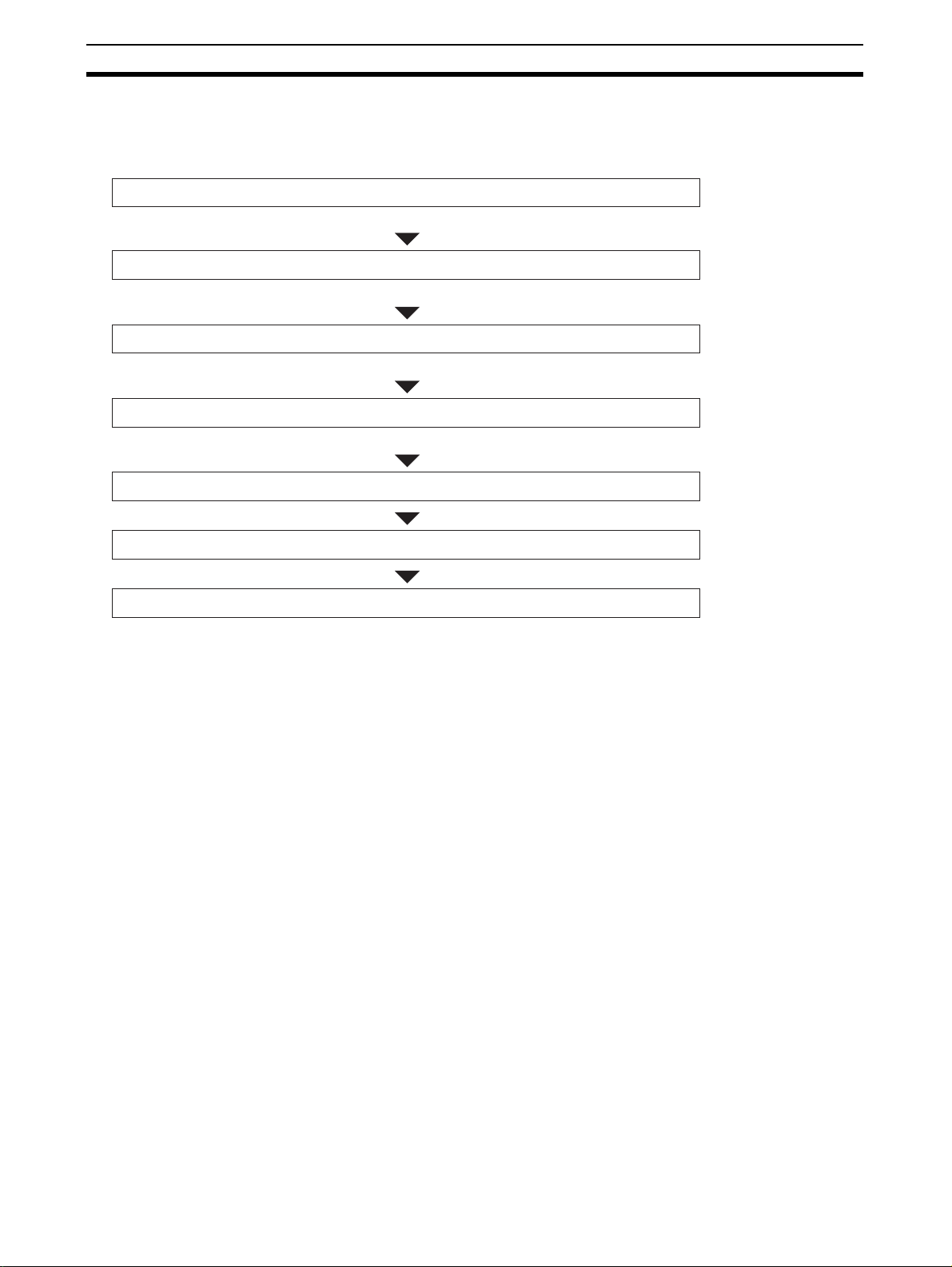

1-5 Network Construction Procedure

The following is the basic flow of a network configuration.

1) Decide the number of I/O points.

Examine the number of inputs and outputs on the entire system.

2) Correspond the I/O points to Slave Units.

Assign each of these inputs and outputs to a Slave Unit.

3) Decide the number of nodes.

Decide the number of connected nodes.

4) Decide the wiring formation and installation.

Decide following:

• Wiring formation: Trunk line - Branch line formation or Unrestricted wiring

formation,

• Wiring distance,

• Methods to supply the communications power and the I/O power to the

Slave Units in less wiring effort, and

• Cable type

5) Temporarily decide the number of connectable Slave Units

and the data rate.

Note The data rate of 4 Mbps does not support T-branch. Thus any Slave Unit

with pre-attached cables will not be usable.

See Appendix E:

Construction of a

CompoNet Network

See E.1.3 Maximum

Length and Maximum

Number of Connectable

Slave Units for Each

Type of Cables

6) Decide the communications cycle.

Decide the communications cycle in accordance with the number of

connectable Slave Units and the data rate. Examine if the required I/O

response time is obtained in the data rate.

7) Examine the distribution of CompoNet Master Boards.

If re-examination of the communication mode number, the data rate and the

use of Repeater Units does not ensure the synchronicity of communication

cycle and distance, provide the CompoNet Master Boards in distributed

locations.

See Appendix C:

Communications

Performance

7

Page 28

Board Preparation Procedure Section 1-6

1-6 Board Preparation Procedure

The following is the basic flow of a Board preparation.

1) Set the board ID for the CompoNet Master Board.

Select one from 0 to 9.

2) Mount the Board on the PC.

Mount the CompoNet Master Board on the PC.

3) Install the software.

When you use the Board in the Windows operation systems, install the driver.

4) Create a program.

Create a program to configure and control the CompoNet Master Board.

5) Turn on the PC.

6) Start up the created program.

7) The communication starts and the Slave Units participate.

See Section 2:

Installation and

Setup

See Section 4:

Operation by API

Functions,

Section 5:

Operation by

Shared Memory

Access, and

Appendix D:

Sample Program

8

Page 29

Specifications Section 1-7

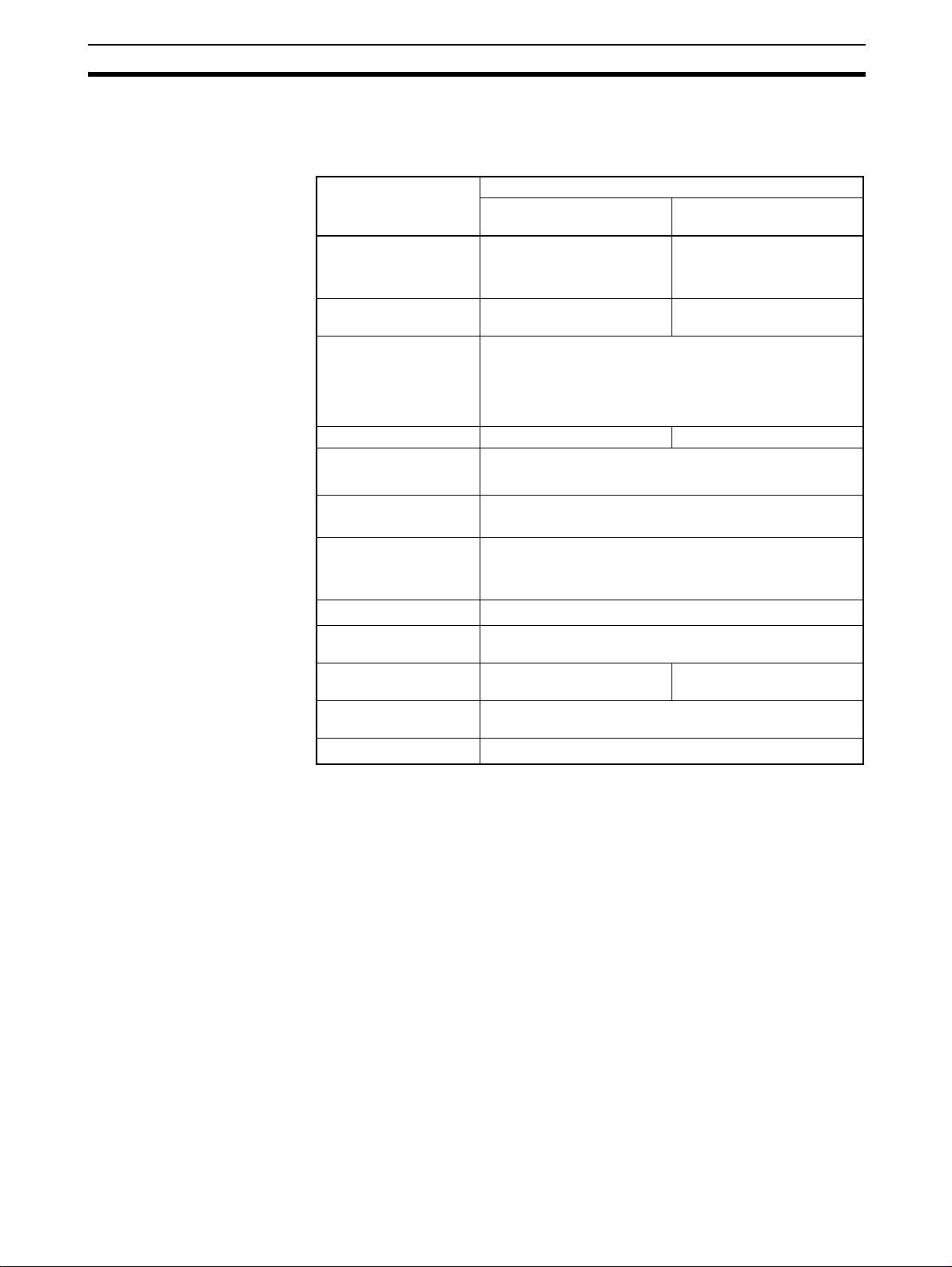

1-7 Specifications

1-7-1 General Specifications

Item Specifications

3G8F7-CRM21 (PCI) 3G8F8-CRM21

Bus specification PCI bus Rev2.2

5 V

Number of mountable

boards

Compatible OS Microsoft Windows 2000, Windows XP (32-bit edition),

Weight 90 g max. 150 g max.

Operation voltage

Consumption current Internal power supply: 5 VDC and 1.5 A max

Vibration resistance 10 to 57 Hz, Amplitude of 0.075 mm, 57 to 150 Hz

Shock resistance

Ambient operating

temperature

Ambient operating

humidity

Ambient operating

atmosphere

Storage temperature

4 pieces 7 pieces

Windows Vista (32-bit edition), or Windows 7 (32-bit

edition)

Other OS can be used, when the shared memory interface

is directly accessed.

Internal power supply: 5 VDC

3.3 VDC is not used.

Communications power supply: 24 VDC and 80 mA max

2

Acceleration 9.8 m/s

Z (8 min of each sweep time × 10 sweeps = total 80 min)

147 m/s2, 3 times each in X, Y and Z directions.

0 to 55°C

0% to 80% RH (with no

condensation)

No corrosive gas

-20 to +60

°C

, 80 min in each direction of X, Y and

(CompactPCI)

PICMG 2.0 R3.0

5 V

32-Bit 3U

±5%

0% to 90% RH (with no

condensation)

Precautions for Correct Use

The ambient operating temperature means the surrounding temperature

where the CompoNet Master Board for PCI Bus is actually used.

See the PC operation manual for the appropriate ambient operating

temperature for the PC.

1-7-2 Development Environment

• Microsoft Visual C++ (Ver 6.0 to Ver 2008)

• Microsoft Visual Basic (Ver 6.0)

• CODEGEAR C++ Builder (Ver 5 to V er 2009)

Precautions for Correct Use

When you use the Board in an OS other than Windows by directly accessing

the shared memory interface, provide the development environment

applicable for the OS.

9

Page 30

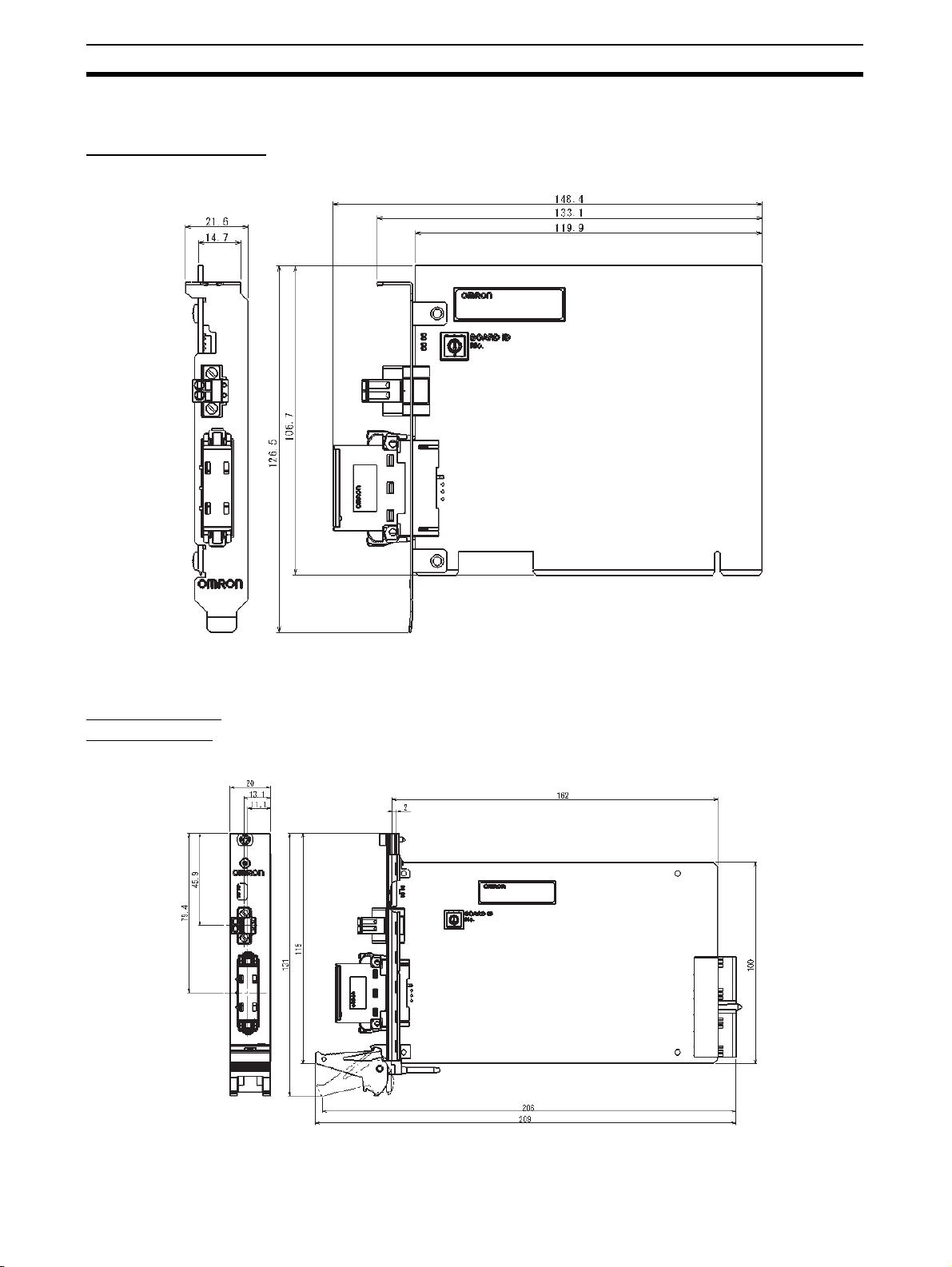

Specifications Section 1-7

1-7-3 Dimensions

3G8F7-CRM21 (PCI)

3G8F8-CRM21

(CompactPCI)

(unit: mm)

10

(unit: mm)

Page 31

Installation and Setup

2-1 Mounting a Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-1 Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-2 Setting the Board ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-1-3 Mounting the Board on the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-2 Installing the Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3 Connecting the Communications Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3-1 Connecting a Round Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3-2 Connecting a Flat Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-4 Connecting the Communications Power Supply Cables . . . . . . . . . . . . . . . . . 25

SECTION 2

11

Page 32

Mounting a Board Section 2-1

2-1 Mounting a Board

2-1-1 Confirmation

Before you mount a CompoNet Master Board on the PC, confirm the

following:

Note CompoNet Master Boards support Windows Plug & Play.

Item Description

Unused PCI bus slot Be sure that the PC you will use has an unused PCI bus slot.

Duplication of

interrupt requests

(IRQ)

CompoNet Master Boards use IRQs. IRQ are automatically

allocated for PCI bus. In a PC which mounts an ISA bus, an

IRQ for PCI bus may overlaps with that for ISA bus. This

prevents the PC from starting up. To avoid this, take one of the

following measures and be sure the IRQ for PCI bus does not

overlap with the IRQ that has been used by the ISA bus.

⋅ Call up the BIOS menu of the PC and set it not to use Plug &

Play.

⋅ Call up the BIOS menu of the PC, and on the setting step for

IRQ allocation for the PCI bus set the IRQ that has been

used by ISA bus to “Reserved” to prevent automatic

allocation.

Note

• As for the procedures to call the BIOS menu and to set the allocation, see

the operation manual of the PC you are using.

• You can confirm the IRQs that have been used by ISA bus in the following

procedure:

(1) Start up the PC that has no CompoNet Master Board mounted.

(2) On the Star t menu of the Windows, select Start

from the pop-up menu. Doub le-clic k the System. Select the Hardw are Tab.

Push the Device Manager button.

(3) D isplay the property of the ISA board whose IRQ is to be checked. Select

the Resource Tab and check the IRQ.

2-1-2 Setting the Board ID

A Board ID is the ID number given to a Board. By this number the PC

identifies a Board among the multiple CompoNet Master Boards mounted on

it.

0

1

9

2

8

3

7

4

6

5

→Setting→Control Panel

12

A small, flat-blade screwdriver is used to set IDs.

As long as no duplication occurs, any decimal number among 0 and 9 can be

set.

Precautions for Correct Use

When you set the Board ID, be sure not to duplicate an ID for multiple

CompoNet Master Boards mounted on a single PC.

Page 33

Mounting a Board Section 2-1

Note In the factory setting, the Board ID is set to 0.

2-1-3 Mounting the Board on the PC

After setting the ID, mount the CompoNet Master Board on the PCI slot of the

PC.

Precautions for Correct Use

•Be sure to turn off the PC and all peripheral devices, when you mount or

remove a CompoNet Master Board.

•Take necessary measures to prevent static electricity before you start the

procedures to mount a CompoNet Master Board. Otherwise, the electricity

may break the Board or the PC.

•Be sure not to damage any memories or other components in the PC, when

you work on mounting or removing a CompoNet Master Board.

•Do not touch any surface or components of the CompoNet Master Board by

hand.

Note The procedure to mount a Board for PCI bus differs by PCs. Refer to the

Operation Manual of the PC you use in order to follow the correct procedures.

Follow the mounting procedure given below:

1. Disconnect all cables from the CompoNet Master Board. Thi s includes the

communications cables and power supply cables.

2. Turn off the PC to which a Board is mounted. Disconnect the electrical

cord.

3. Remove the pac kage of the PC as instructed in the Oper ation Manual, and

prepare it to mount or remove a CompoNet Master Board.

4. Place the PCI bus connecter on the PC and the connector on the

CompoNet Master Board in the correct positions and orientations. Push

the CompoNet Master Board t o the end. Be sure the connector on the

CompoNet Master Board is pushed evenly onto the connector on the PC.

5. Do not apply an excessive load to the Board while mounting it.

6. Pull the CompoNet Master Board lightly to confirm that it won't come out.

7. Tighten the screws on the left side of the CompoN et Master Board panel

with 0.5 N⋅m torque, and secure the Board.

13

Page 34

Installing the Drivers Section 2-2

2-2 Installing the Drivers

If you are using Windows 2000, Windows XP, Windows Vista, or Windows 7,

use the Add New Hardware Wizard provided by the OS to install the

CompoNet Master Board driver.

Procedures are provided here for Windows 2000 and Windows 7. When you

use Windows XP or WindowsVista, displays and procedures differ only

slightly, but you can take the similar steps.

Windows 2000

Note To perform the following installation steps, you must log on as the

Administrator.

1,2,3... 1. Start up the PC after you mount a CompoNet Master Board on the PC.

The PC will recognizes the Board as a new hardware. The Found New

Hardware Wizard will starts up.

Click the Next button.

14

Page 35

Installing the Drivers Section 2-2

2. On the wizard page of Install Har d ware Device Driver s, select the bu tton

for Search for suitable driver for my device (recommended). Click the

Next button.

3. On the wizard page of Locate Driver Files, check the box for CD-ROM

drive. Click the Next button.

(Be sure to insert the attached CD-ROM before you select the drive.)

15

Page 36

Installing the Drivers Section 2-2

4. When the required driver file is found, click the Next button.

5. The installation is complete when the following page is shown and the

Finish button is clicked.

16

Page 37

Installing the Drivers Section 2-2

Windows 7

Note For Windows 7, you must log as the administrator to install the driver.

1,2,3... 1. After the Board is installed in the computer, start the Device Manager. Ne w

*1

hardware will be detected automatically. Open the Device Manager,

double-click Other devices.

*1.To open the Device Manager, click the Windows Start Button and select Control

Panel, Hardware and Sound, and Device Manager in that order.

and

2. The Network Contr oller will appear under Other devices.

Right-click Network Controller and then select Update Driver Software

from the menu.

17

Page 38

Installing the Drivers Section 2-2

3. How do you want to search for driver software? will be displayed.

Click Browse my computer for driver software.

4. Place the enclosed CD-ROM into the CD-ROM drive.

5. Browse for driver software on your computer will be displayed.

Click the Browse Button, sp ecify the CD-R OM drive (see follo wing figure),

and click the Next Button

*. The foll owing figure shows an example for which drive D is the CD-ROM drive.

18

Page 39

Installing the Drivers Section 2-2

6. The following dialog box will be displayed. Click Install this driver

software anywa y to start installation.

7. The installation will start.

19

Page 40

Installing the Drivers Section 2-2

8. A completion message (see the following figure) is displayed after the

installation process is completed.

Click the Close Button to complete driv er installation.

20

Page 41

Connecting the Communications Cables Section 2-3

2-3 Connecting the Communications Cables

This section outlines the connection procedures in a CompoNet network

system by using a round cable I or Flat Cable I.

2-3-1 Connecting a Round Cable

An Open Type Connector (DCN4-TB4) is used to connect a CompoNet

Master Board to the trunk line of either round cable I or II.

Align the terminal signals of the Connector. Press in the Connector until it

clicks into place.

Note To remove the inserted Connector, hold the latches on both sides and pull out

the Connector.

21

Page 42

Connecting the Communications Cables Section 2-3

CRT1

OD16

CRT1

OD16

Precautions for Correct Use

Please be aware that the wiring of the Open Type Connector (DCN4-TB4) will

protrude into the adjacent panel. Provide any measures to prevent it from

interfering with the connector and other component of the neighboring PCI

Board.

Example of round

cable I connection

DCN4-TB4 Open Type Connector

DCN4-TB4 Open Type Connector

MS

NS

WORD

NODE ADR

01234567 8

5

6

4

7

5

6

9

10 11

12

13

14

OUT

X1

15

MS

REMOTE

NS

WORD

NODE ADR

01234567 8

5

6

4

7

5

6

9

CRT1

TERMINAL

4

7

3

8

3

8

2

9

1

2

9

0

1

0

X10

[0

-

63]

-

OD16

-

1

10 11

12

13

14

OUT

X1

15

ANALOG

MS

CRT1

TERMINAL

NS

WORD

NODE ADR

5

6

4

12345678

7

5

6

4

7

3

8

3

8

2

9

1

2

0

9

1

0

X10

X1

[0

-

63]

-

AD04

A

/

D

SW

ON

1

INPUT

2

RANGE

CH0,1

3

4

INPUT

5

RANGE

CH2,3

6

7

RSV

8

LSET

REMOTE

CRT1

TERMINAL

4

7

3

8

3

8

2

9

1

2

9

0

1

0

X10

[0

-

63]

-

OD16

-

1

Word Slave Unit

DRS1-T Terminating Resistor

Note A commercially available relay terminal block can make a T-branching

connection.

22

Page 43

Connecting the Communications Cables Section 2-3

2-3-2 Connecting a Flat Cable

A Flat Connector Plug (DCN4-BR4 or DCN5-BR4) is used to connect a

CompoNet Master Board to the trunk line of either Flat Cable I or II. A Flat

Connector I Plug (DCN4-BR4) is used with Flat Cable I, while a Flat

Connector II Plug (DCN5-BR4) is used with Flat Cable II.

Flat Connector I Plug (DCN4-BR4) Flat Connector II Plug (DCN5-BR4)

Align the Plug face with the color seals (red, white, blue and black) matching

the signal names (red and BS+) on the connector. Press the plug until it clicks

into place.

Note To remove the inserted Plug, hold the latches on both sides and pull out the

Plug

.

23

Page 44

Connecting the Communications Cables Section 2-3

OD16

Precautions for Correct Use

•Please be aware that the Multidrop Connector (DCN4-MD4) will protrude into

the adjacent panel. Provide any measures to prevent it from interfering with

the connector and other component of the neighboring PCI Board.

•In a configuration where plural 3G8F7-CRM21 CompoNet Master Boards for

PCI Bus are used, only one side of adjacent two Boards shall use a DCN4 MD4 Multidrop Connector.

Example of T-branch

connection of Flat

Cable I

DCN4-BR4 Flat Connector Plug

DCN4-TR4 Flat Connector Socket

T-branch

DCN4-BR4 Flat Connector

Plug

DCN4-BR4 Flat Connector Plug

MS

NS

WORD

NODE ADR

01234567 8

5

6

7

4

5

6

7

4

3

8

3

8

2

9

1

OUT

2

9

0

1

0

X10

X1

[0

-

63]

CRT1

-

OD16

-

REMOTE

1

TERMINAL

Word Slave Unit

DCN4-TR4 Flat Connector Socket DCN4-TR4 Flat Connector Socket

T-branch

DCN4-BR4 Flat Connector

DCN4-TM4 Terminating Resistor

Plug

9

10 11

12

13

14

15

Bit Slave Unit

24

Page 45

Connecting the Communications Power Supply Cables Section 2-4

CR

T1

OD16

CR

T1

Example of multidrop

connection of Flat

Cable I

DCN4-BR4 Flat Connector Plug

DCN4-MD4 Multidrop Connector

DCN4-TM4 T erminating Resistor

MS

NS

WORD

NODE ADR

01234567

5

6

7

4

5

6

8

9

4

7

3

8

3

8

2

9

1

2

9

0

1

0

X10

X1

[0

-

63]

CR

T1

-

OD16

-

REMOTE

1

TERMINAL

10 11

12

13

14

OUT

15

MS

NS

WORD

NODE ADR

0 123 4567 8

5

6

4

7

5

6

9

4

7

3

8

3

8

2

9

1

2

9

0

1

0

X10

[0

-

63]

CR

T1

-

OD16

-

REMOTE

1

TERMINAL

10 11

12

13

14

OUT

X1

15

ANALOG

MS

CRT1

TERMINAL

NS

WORD

NODE ADR

5

6

4

12345678

7

5

6

4

7

3

8

3

8

2

9

1

2

0

9

1

0

X10

X1

[0

-

63]

-

AD04

A

/

D

SW

1

ON

INPUT

2

RANGE

CH0,1

3

4

INPUT

5

RANGE

CH2,3

6

7

RSV

8

LSET

Word Slave Unit

2-4 Connecting the Communications Power Supply Cables

When a round cable II, Flat Cable I or Flat Cable II is used, the Slave Units

can be supplied with the communications power through the CompoNet

Master Board. In this case, the communications power supply must be

connected to the CompoNet Master Board.

See Appendix E.5 Wiring for Power Supply, especially E.5.2 Wiring the

Communications Po wer Supply.

25

Page 46

Connecting the Communications Power Supply Cables Section 2-4

26

Page 47

3-1 Settings at Communications Cycle Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-1-1 Settings Required for Starting the Communicat ion s Cycl e . . . . . . . 28

3-2 Access to I/O Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-2-1 Allocation of I/O Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-2-2 Access to I/O Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3-1 Basic Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3-2 Detailed Status Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-4 Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-5 Detailed Settings at Communications Cycle Startup. . . . . . . . . . . . . . . . . . . . 37

3-5-1 Registration Table Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-5-2 Communications Stop Due to Communications Error Function . . . 39

3-5-3 I/O Commun icati ons Manual Startup Function . . . . . . . . . . . . . . . . 39

3-5-4 IN Data Zero Clear Due to Communications Error Function. . . . . . 40

SECTION 3

Functions

27

Page 48

Settings at Communications Cycle Startup Section 3-1

3-1 Settings at Communications Cycle Startup

The function CPNT_StartCycle is used to start the communications cycles for

the CompoNet Master Board from the user application. The function

CPNT_StartCycle uses the data rate and the number of occupied nodes as

arguments.

The command OPEN_SYSTEM is used to start the communications cycles

through the shared memory access.

To enable the superior function and start the communications cycle, execute

the function CPNT_StartCycleEx in Windows or the command

OPEN_SYSTEMEX for shared memory access. See Section 3-5.

3-1-1 Settings Required for Starting the Communications Cycle

Function Description

Data rate This is used to set the data rate for a network.

The Slave Units in the same network automatically follow the

data rate of the Master Board.

Data rate is selective among 4 Mbps, 3 Mbps, 1.5 Mbps and

93.75 kbps.

Number of occupied

nodes

The number of nodes can be set individually for Word IN Slave

Units, Word OUT Slave Units, Bit IN Slave Units and Bit OUT

Slave Units.

*1.Every 16 points of a Word IN Slave Unit or a Word OUT

Slave Unit occupies 1 node.

*2.Every 2 points of a Bit IN Slave Unit or a Bit OUT Slave Unit

occupies 1 node.

*3.Node addresses are allocated to Slave Units in ascending

order starting from #0. Unused addresses are also included

in this allocation order. They cannot be skipped.

*4.Only the Slave Units in this set range are to participate. Not

all of the occupied areas are necessarily allocated by a

Slave Unit.

Example: When a system consists of Slave Units as shown in

the table below , the number of nodes occupied by each type of

Slave Units are:

8 by Word IN Slave Units,

3 by Word OUT Slave Unit, (*3)

3 by Bit IN Slave Unit,

10 by Bit OUT Slave Units (*3)

Slave type

Word IN Slave Unit 16

Word IN Slave Unit 32

Word IN Slave Unit 16

Word IN Slave Unit 64

Word OUT Slave Unit 32

Bit IN Slave Unit 4

Bit IN Slave Unit 2

Bit OUT Slave Unit 2

Bit OUT Slave Unit 2

Node

address

0

1

3

4

1

0

2

0

9

# of points Remarks

(*1)

(*1)

(*1)

(*2)

28

Page 49

Settings at Communications Cycle Startup Section 3-1

Note • Ev ery 16 points of a W ord IN Slave Unit or a Word OUT Slave Un it occupi es

1 node. For example, when a Word Slav e Unit has 64 point s and is allocated

with the node address #10, it actually occupies the node address #10, #11

#12 and #13.

• Every 2 points of a Bit IN Slave Unit or a Bit OUT Slave Unit occupies 1

node. For example, when a Bit Slave Unit has 4 points and is allocated with

the node address #5, it actually occupies the node address #5 and #6.

Image of the number of nodes occupied by the above Slave Units

Allocation of Word IN Slave Units

Node address

0

Used by Word IN Slave Unit with node address 0.

1

Used by Word IN Slave Unit with node address 1.

2

3

Used by Word IN Slave Unit with node address 3.

4

Used by Word IN Slave Unit with node address 4.

5

6

7

The number

of occupied

nodes is 8.

Allocation of Word OUT Slave Units

Node address

0

Unused

1

Used by Word OUT Slave Unit node address 1.

2

Allocation of Bit IN Slave Units

Node address

Used by Bit IN Slave Unit node address 0.

0

1

Used by Bit IN Slave Unit node address 2.

2

Allocation of Bit OUT Slave Units

Node address

0

Used by Bit OUT Slave Unit node address 0.

1 to 8

Unused

9

Used by Bit OUT Slave Unit node address 9.

The number

of occupied

nodes is 3.

The number

of occupied

nodes is 3.

The number

of occupied

nodes is 10.

29

Page 50

Access to I/O Data Section 3-2

3-2 Access to I/O Data

3-2-1 Allocation of I/O Data

In the CompoNet network system, the I/O data is allocated separately for

Word IN Slave Units, Word OUT Slave Units, Bit IN Slave Units, and Bit OUT

Slave Units. It is allocated in the shared memory of the CompoNet Master

Board.

Allocation for W ord IN

Slave Units and Word

OUT Slave Units

• Every 16 points of a Word IN Slave Unit or a Word OUT Slave Unit

occupies 1 word in allocation area. For example, a 32-point IN Slave Unit

occupies 2 words in allocation area for Word IN Slave Units.

• The offset address that is allocated to the shared memo ry is deter mined

by the node address.

• Word MIX Slave Units occupy the allocation areas for both of Word IN

Slave Units and Word OUT Slave Units. For example, when a Word MIX

Slave Units has 16 inputs and 64 outputs, it occupies 1 word in the

allocation area for Word IN Slave Units and 4 words in the allocation area

for Word OUT Slave Units.

• An 8-point Slave Unit also occupies 1 node or 1 word. It is allocated to the

lower byte of the 1- word, while the upper byte remains open.

Allocation area for IN Data of a Word IN Slave Unit

Word address Bit 15 Bit 0

+0 [IN data of Word IN Slave Unit with node address 0]

+1 [IN data of Word IN Slave Unit with node address 1]

IN

area

+2 [IN data of Word IN Slave Unit with node address 2]

::

+62 [IN data of Word IN Slave Unit with node address 62]

+63 [IN data of Word IN Slave Unit with node address 63]

30

Allocation area for OUT Data of a Word OUT Slave Unit

Word address Bit 15 Bit 0

+0 [OUT data of Word OUT Slave Unit with node address 0]

+1 [OUT data of Word OUT Slave Unit with node address 1]

OUT

area

Note A single allocation area shall never be occupied by plural nodes. However, as

long as the same words are not allocated to more than one Unit, the Input

Area and Output Area with numerically the same node address can be

allocated to Slave Units with different node addresses. For example, OUT1

can be allocated to the 16 outputs for a Word OUT Slave Unit set for node

address 1, and IN1can be allocated to the 16 inputs for a Word IN Slave Unit

set for node address 1.

+2 [OUT data of Word OUT Slave Unit with node address 2]

: :

+62 [OUT data of Word OUT Slave Unit with node address 62]

+63 [OUT data of Word OUT Slave Unit with node address 63]

Page 51

Access to I/O Data Section 3-2

Precautions for Correct Use

When a Slave Unit occupies plural allocation areas, other Slave Units which

have the occup ied node addresses cannot participate.

Example: When a Slave Unit with node address 0 exists in a network and it

occupies 2 words in the IN area and 4 words in OUT area, Word IN

Slave Units whose node addr esses are 0 or 1, a nd Word OUT Slave

Units whose node addresses are 0, 1, 2 or 3 cannot participate.

Image of the above Precautions for Correct Use

Allocation area for IN Data of a Word IN Slave Unit