Page 1

Cat. No. W382-E1-04

WS02-CFDC1-E DeviceNet Configurator

3G8F5-DRM21-E ISA Board

3G8E2-DRM21-EV1 PCMCIA Card

DeviceNet Configurator

Ver. 2.@

OPERATION MANUAL

Page 2

WS02-CFDC1-E DeviceNet Configurator

3G8F5-DRM21-E ISA Board

3G8E2-DRM21-EV1 PCMCIA Card

DeviceNet Configurator Ver. 2.@

Operation Manual

Revised September 2005

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

Reference Indicates supplementary information on related topics that may be of interest

to the user.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Trademarks and Copyrights

DeviceNet is a registered trademark of the Open DeviceNet Vendor Association, Inc.

Windows, Windows 95, Windows 98, Windows Me, Windows NT, Windows 2000 and Windows XP are

registered trademarks of the Microsoft Corporation.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

The copyright of the DeviceNet Configurator software belongs to OMRON Corporation.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Confirming Product Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 ISA Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3 PCMCIA Card Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-4 Configurator Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 3

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-1 Starting the Configurator and the Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-2 Menu Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-3 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-4 Operation Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SECTION 4

Editing Device Parameters. . . . . . . . . . . . . . . . . . . . . . . . 59

4-1 Adding Devices to the Virtual Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4-2 Setting Slave Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-3 Adding Slaves to the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4-4 Setting Master Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4-5 Editing Master Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4-6 Parameter Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4-7 Master Parameter Editing Details (Tab Descriptions) . . . . . . . . . . . . . . . . . . . . . . 78

4-8 Manual I/O Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4-9 Advanced Settings

(Connection, Communication Cycle Time, Slave Function Settings, Etc.) . . . . . . 91

4-10 Creating and Editing I/O Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4-11 Displaying Device Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

vii

Page 7

TABLE OF CONTENTS

SECTION 5

Online Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5-1 Switching between Online and Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5-2 Downloading the Network Configuration/Device Parameters to Devices . . . . . . 108

5-3 Uploading and Verifying Device Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5-4 Monitoring Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

SECTION 6

Manipulating Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6-1 Saving and Reading Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

6-2 EDS File Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6-3 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

6-4 Using General-purpose Tools to Set Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

6-5 Exporting Data Created in Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

6-6 Importing Files Created in Version 1 of the Configurator. . . . . . . . . . . . . . . . . . . 138

6-7 Optional Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Appendices

A Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

B Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

C Error History Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

D Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

E Replacing the C200HW-DRM21-V1 on a CS-series CPU Rack

with the CS1W-DRM21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

F Replacing the C200HW-DRT21 with the CS1W-DRM21’s Slave Functions . . . 159

G Dimensions of PCMCIA Card and Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

viii

Page 8

About this Manual:

This manual describes the installation and operation of version 2 of the DeviceNet Configurator and

includes the sections described below.

Please read this manual and all manuals for related products carefully and be sure you understand the

information provided before attempting to install and operate the DeviceNet Configurator. Be sure to

read the precautions provided in the following section.

Section 1 Section 1 describes the features, specifications, operating conditions, and interfaces of the

DeviceNet Configurator.

Section 2 Section 2 explains how to install the ISA Board or PCMCIA Card hardware in the computer,

make the necessary hardware settings and computer settings, and install the DeviceNet Configurator

software in the computer.

Section 3 Section 3 explains the basic operation of the DeviceNet Configurator.

Section 4 Section 4 explains how to enable remote I/O communications by creating device parameters

for a virtual network constructed with the DeviceNet Configurator.

Section 5 Section 5 explains the online operation of the DeviceNet Configurator, such as data downloading to or uploading from devices and device monitoring.

Section 6 Section 6 provides information on manipulating files, including saving and reading procedures.

The Appendices provide information on error messages, troubleshooting, the error history, Unit

replacement, replacing the C200HW-DRM21-V1 on a CS1-series PLC with the CS1W-DRM21, replacing the C200HW-DRT21 with the CS1W-DRM21’s slave functions, and the dimensions of PCMCIA

Card and Unit.

The following manuals provide information on the DeviceNet and OMRON DeviceNet products.

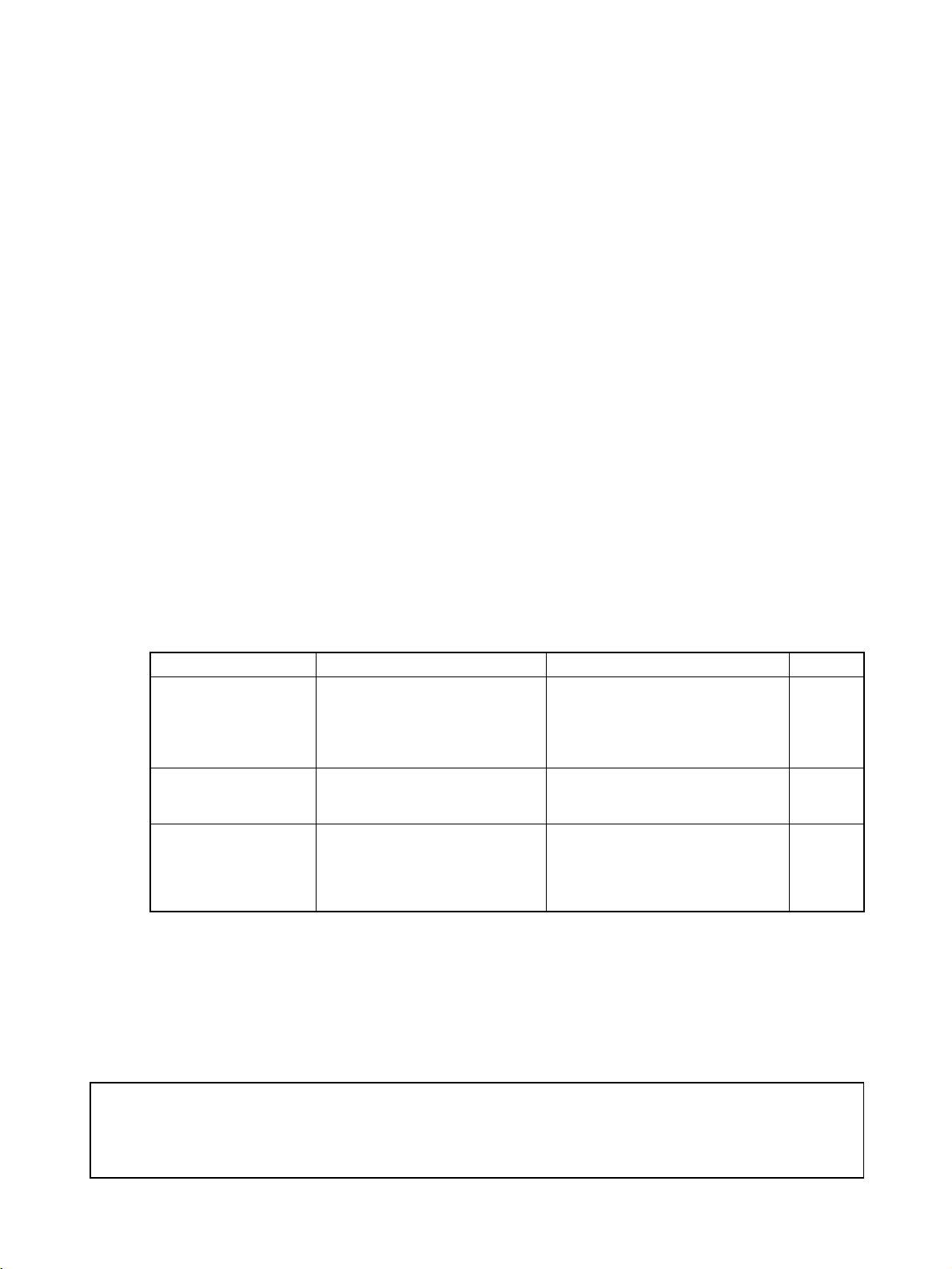

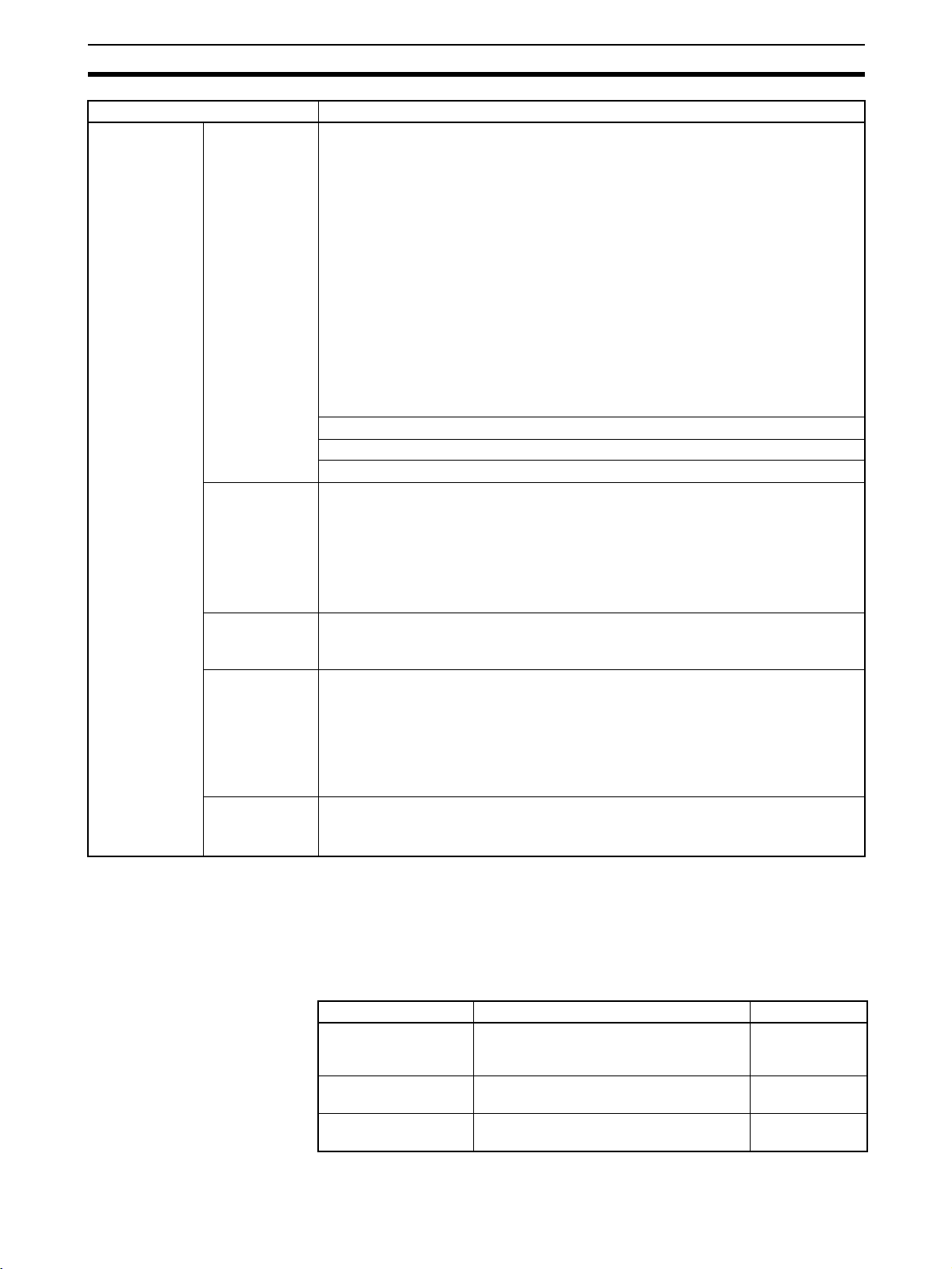

Manual Products Contents Cat. No.

DeviceNet Configurator

Ver. 2.@

Operation Manual

(This manual)

CS/CJ-series DeviceNet

Unit Operation Manual

DeviceNet

(CompoBus/D)

Operation Manual

WS02-CFDC1-E

DeviceNet Configurator

3G8F5-DRM21-E ISA Board

3G8E2-DRM21-EV1 PCMCIA

Card

CS1W-DRM21

CJ1W-DRM21

DeviceNet Unit

CVM1-DRM21-V1

DeviceNet Master Unit

C200HW-DRM21-V1

DeviceNet Master Unit

Information on using the

Configurator.

Information on CS/CJ-series

DeviceNet Units.

Information on C200H-series,

CVM1, and CV-series DeviceNet

Units, as well as general DeviceNet

communications specifications and

wiring methods.

W382

W380

W267

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for using the DeviceNet Configurator and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet

Configurator and personal computer. You must read this section and understand the information contained before

attempting to set up or operate a DeviceNet Configurator and personal computer.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating the DeviceNet

Configurator. Be sure to read this manual before operation and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Never attempt to disassemble a Board or Card or touch the inside of a Board

or Card while power is being supplied. Doing so may result in serious electrical shock or electrocution.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as “PLC”), in

order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a counter-

xvi

Page 16

Operating Environment Precautions 4

measure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!WARNING The CPU Unit refreshes I/O even when the program is stopped (i.e., even in

PROGRAM mode). Confirm safety thoroughly in advance before changing the

status of any part of memory allocated to I/O Units, Special I/O Units, or CPU

Bus Units. Any changes to the data allocated to any Unit may result in unexpected operation of the loads connected to the Unit. Any of the following operation may result in changes to memory status.

• Transferring I/O memory data to the CPU Unit from a Programming

Device.

• Changing present values in memory from a Programming Device.

• Force-setting/-resetting bits from a Programming Device.

• Transferring I/O memory files from a Memory Card or EM file memory to

the CPU Unit.

• Transferring I/O memory from a host computer or from another PLC on a

network.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

Do not install the Unit in any of the following locations.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidities outside the range specified in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salt.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Provide proper shielding when installing in the following locations:

• Locations subject to static electricity or other sources of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radiation.

• Locations near to power supply lines.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

xvii

Page 17

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the DeviceNet Configurator.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always connect to a class-3 ground (100

Units.

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Enable the scan list to before operating the system.

• When adding a new node to the network, make sure that the baud rate is

the same as other nodes.

• Use specified communications cables.

• Do not extend connection distances beyond the ranges given in the specifications.

• Always turn OFF the power supply to the personal computer, Slaves, and

Communications Units before attempting any of the following.

• Attaching or detaching the DeviceNet Board or Card.

• Assembling the Units.

• Setting rotary switches.

• Connecting or wiring the cables.

• Connecting or disconnecting connectors.

• Be sure that the communications cables and other items with locking

devices are properly locked into place.

• Be sure that all Board mounting screws, connector screws, and cable

screws are tightened to the torque specified in this manual.

• Always use the power supply voltage specified in this manual.

• Double-check all the wiring and connection of terminal blocks and connectors before mounting the Units.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cables from the power lines or high-tension lines.

• Do not bend the communications cables.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Be sure to wire communications cable inside ducts.

• Use appropriate communications cables.

• Before touching the PCI Board, be sure to first touch a grounded metallic

object in order to discharge any static build-up. Not doing so may result in

malfunction or damage.

Ω or less) when installing the

xviii

Page 18

Application Precautions 5

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Double-check all the wiring and switch settings before turning ON the

power supply.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• After replacing Units, resume operation only after transferring to the new

CPU Unit and/or Special I/O Units the contents of the DM Area, HR Area,

and other data required for resuming operation. Not doing so may result in

an unexpected operation.

• When transporting or storing the product, cover the PCBs with electrically

conductive materials to prevent LSIs and ICs from being damaged by

static electricity, and also keep the product within the specified storage

temperature range.

• Do not touch the mounted parts or the rear surface of PCBs because

PCBs have sharp edges such as electrical leads.

• Do not attempt to disassemble, repair, or modify any Units.

xix

Page 19

Page 20

SECTION 1

Overview

This section describes the features, specifications, operating conditions, and interfaces of the DeviceNet Configurator.

1-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Connecting to the DeviceNet Network. . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-3 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-4 Configurator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-5 Files Created with Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1-6 Importing Version 1 Configurator Files . . . . . . . . . . . . . . . . . . . . . . 6

1-1-7 Functions of the Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-1-8 Comparison with Previous Versions of the Configurator . . . . . . . . . 10

1-2 Confirming Product Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-3-1 Configurator Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-3-2 PCMCIA Card Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1

Page 21

Introduction Section 1-1

1-1 Introduction

The Configurator is a software package that allows the user to construct, set

up, and maintain a multivendor DeviceNet network through user-friendly

graphic displays.

The Configurator internally constructs a virtual network in the Network Configuration Window, making it possible to set up and monitor DeviceNet devices.

The Configurator is referred to as simple the Configurator in the rest of this

manual.

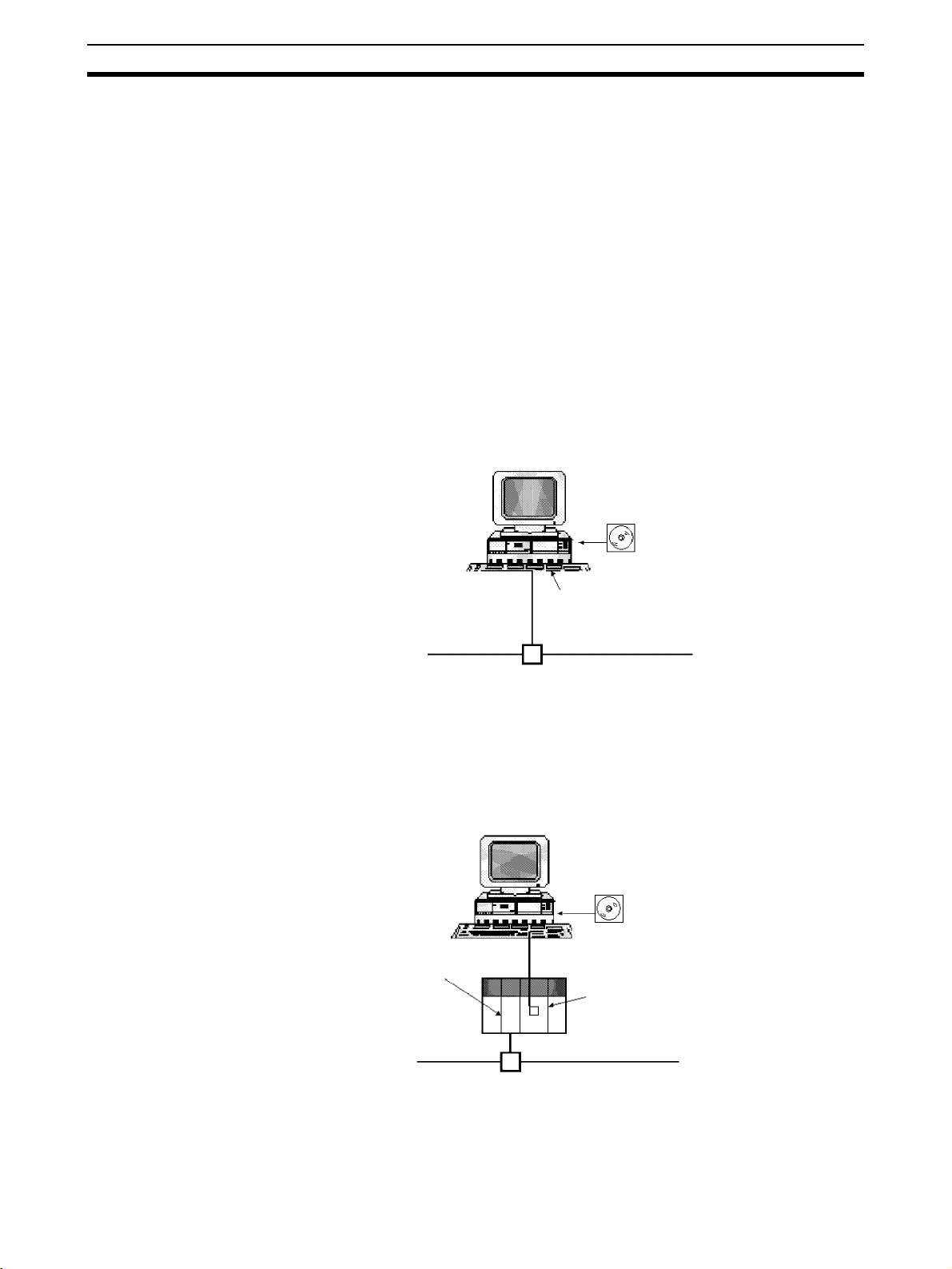

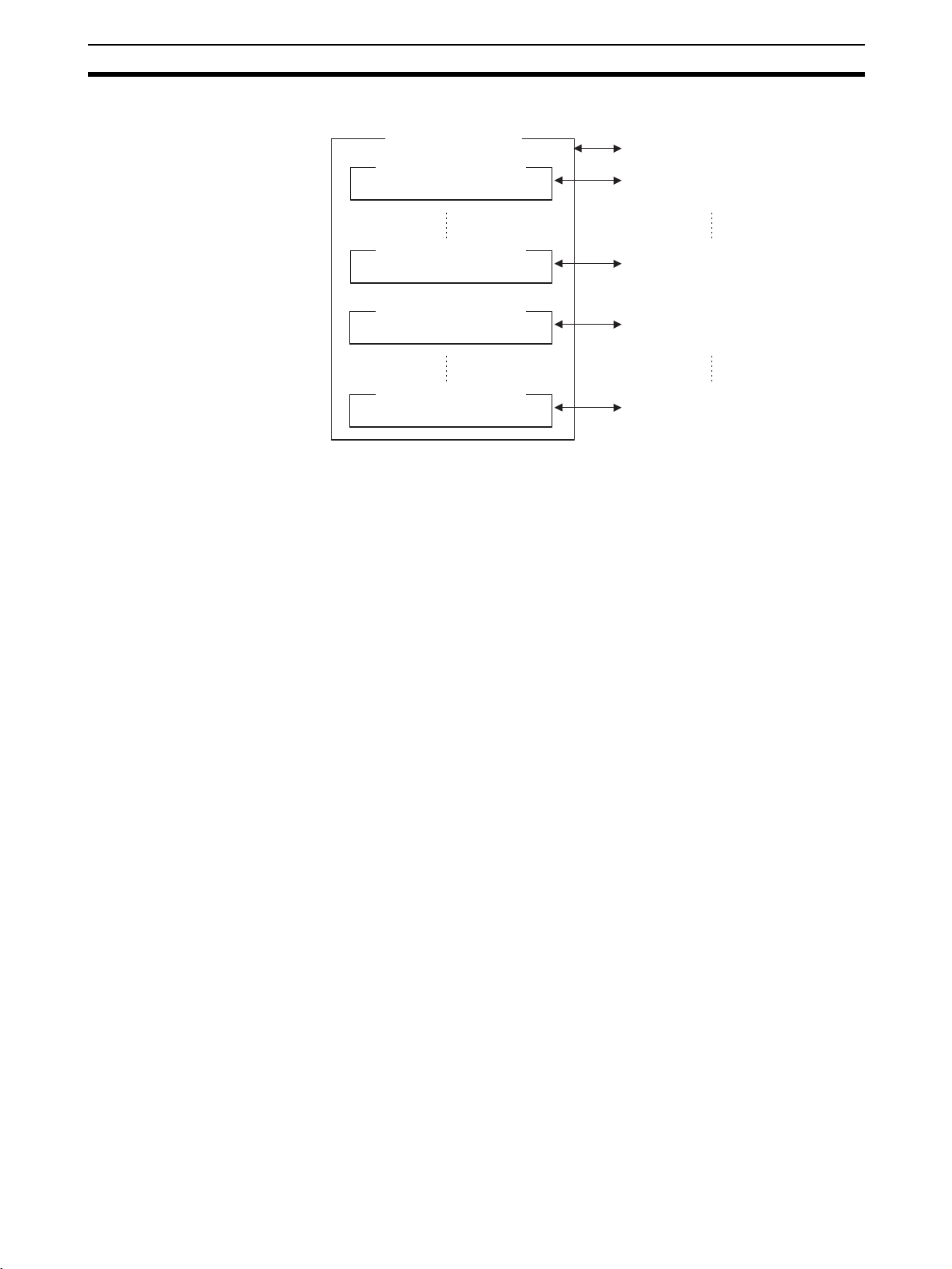

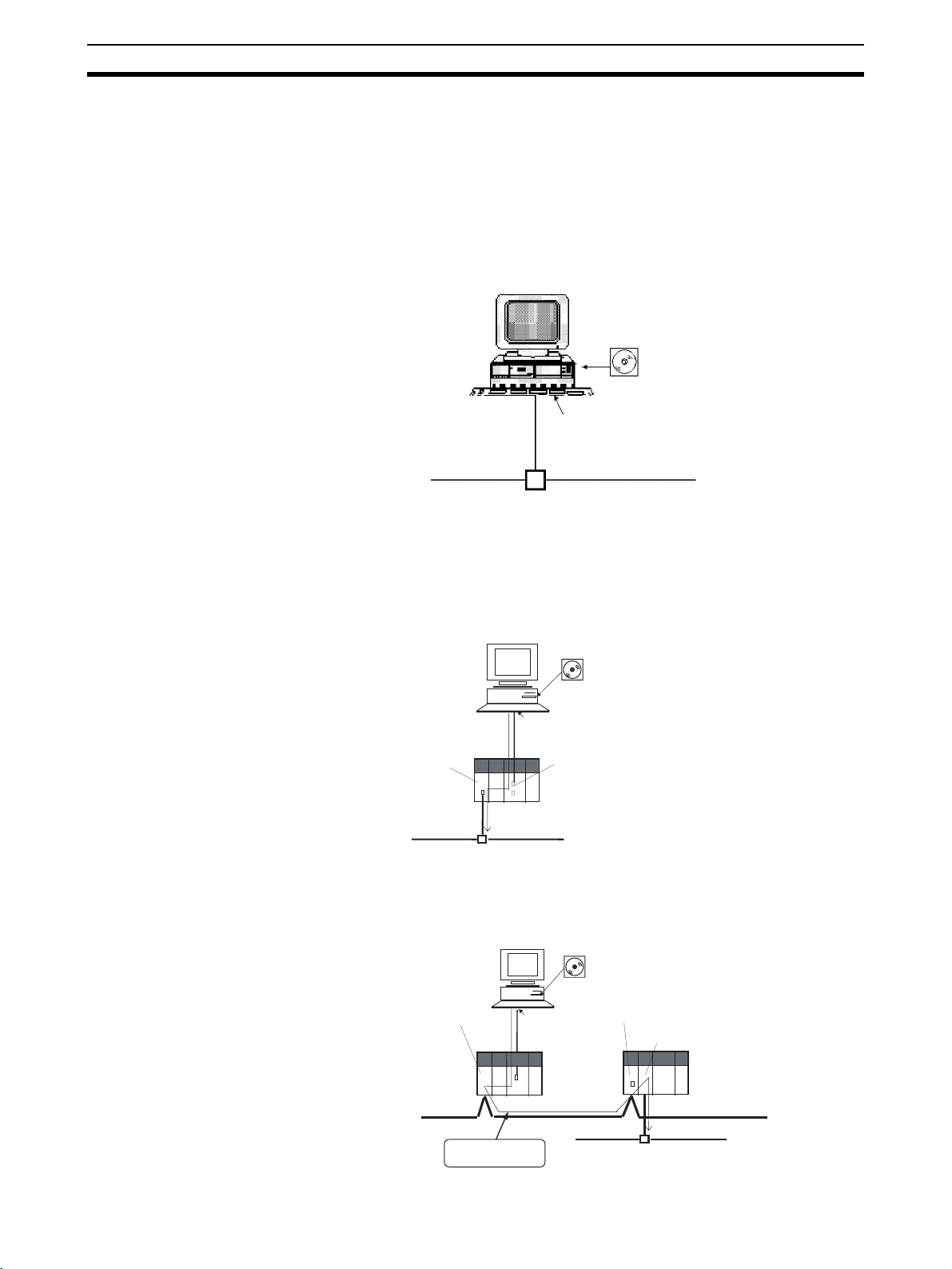

1-1-1 Connecting to the DeviceNet Network

The Configurator is connected to the DeviceNet network using one of the following three methods. The same online functions are supported by all three

methods.

Connection from

Dedicated Board/Card

Installed in Computer

Serial Connection from

COM port of Computer

The computer running the Configurator is connected to the DeviceNet network by installing an OMRON DeviceNet Board in the computer.

WS02-CFDC1-E

Configurator

Dedicated Board, or

Card

DeviceNet Network

The Configurator is treated as a single

DeviceNet node.

The computer running the Configurator is connected to the DeviceNet network by connecting from the COM port of the computer to the serial communications port (peripheral port) of a CS/CJ-series CPU rack containing a CS1WDRM21 or CJ1W-DRM21 DeviceNet Unit.

WS02-CFDC1-E

Configurator

CS/CJ-series

DeviceNet Unit

The Configurator is not treated as a

single DeviceNet node .

COM port

Peripheral bus or Host Link

Peripheral or RS-232C port of

CPU Unit or RS-232C port of

Communications Board/Unit

DeviceNet network

2

Page 22

Introduction Section 1-1

Ethernet Connection The computer running the Configurator is connected to the DeviceNet net-

work by connecting from the Ethernet port of the computer to a CS/CJ-series

Ethernet Unit.

WS02-CFDC1-E

Configurator

Ethernet port

CS/CJ-series

Ethernet Unit

CS/CJ-series

DeviceNet Unit

CPU Unit

Ethernet

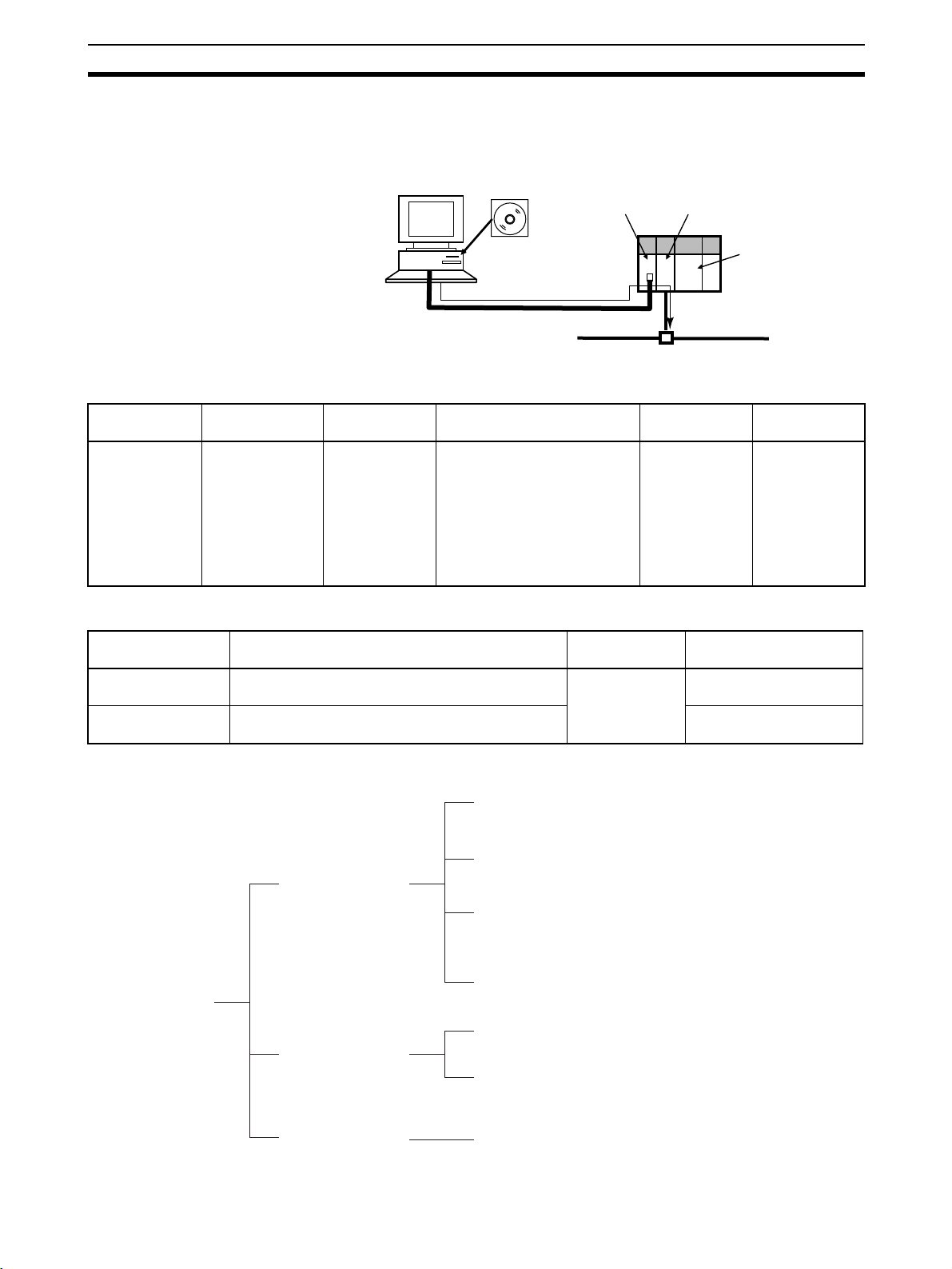

1-1-2 Models

Product Model Contents Method of connecting to

DeviceNet network

Configurator

(Ver. 2.@)

WS02-CFDC1-E Installation disk

(CD-ROM)

Either one of the following

methods

• Dedicated Board/Card (See

note.)

• Serial connection from COM

port of computer

• Ethernet connection from

Ethernet port of computer

Note Use the following dedicated Boards and Card.

Model Contents Personal

3G8E2-DRM21-EV1 Dedicated PCMCIA Card and Configurator

3G8F5-DRM21-E Dedicated ISA Board and Configurator (Ver. 2.@)

(Ver. 2.@) installation disk

installation disk

1-1-3 Overview

IBM PC/AT or

compatible

computer

IBM PC/AT or

compatible

DeviceNet network

Personal

Applicable OS

computer

Windows 95,

98, Me, 2000,

NT4.0 or XP

Applicable OS

Windows 95, 98, Me,

2000 or XP

Windows 95, 98 or NT4.0

Main functions of

Configurator

Setup functions

Monitoring functions

Storage functions

Remote I/O master user-set allocations (with creation of a scan

list) and remote I/O slave user-set allocations

Enabling or disabling master or slave function of CS/CJ-series

DeviceNet Unit.

Setting master device parameters except scan list parameters

(i.e., connection settings, device data checks, and

communications cycle time)

Setting other manufacturers' slave and master device

parameters

Displaying a device information list

Monitoring multistatus, Unit status, Master error logs, and

communications cycle data

Saving offline device information prepared with master device

parameters or online network device information (Data is saved

as network configuration files

.)

3

Page 23

Introduction Section 1-1

Note Master device parameters used in a scan list are created with either of the fol-

lowing methods.

a) Using the Parameter Wizard

b) Setting all parameters

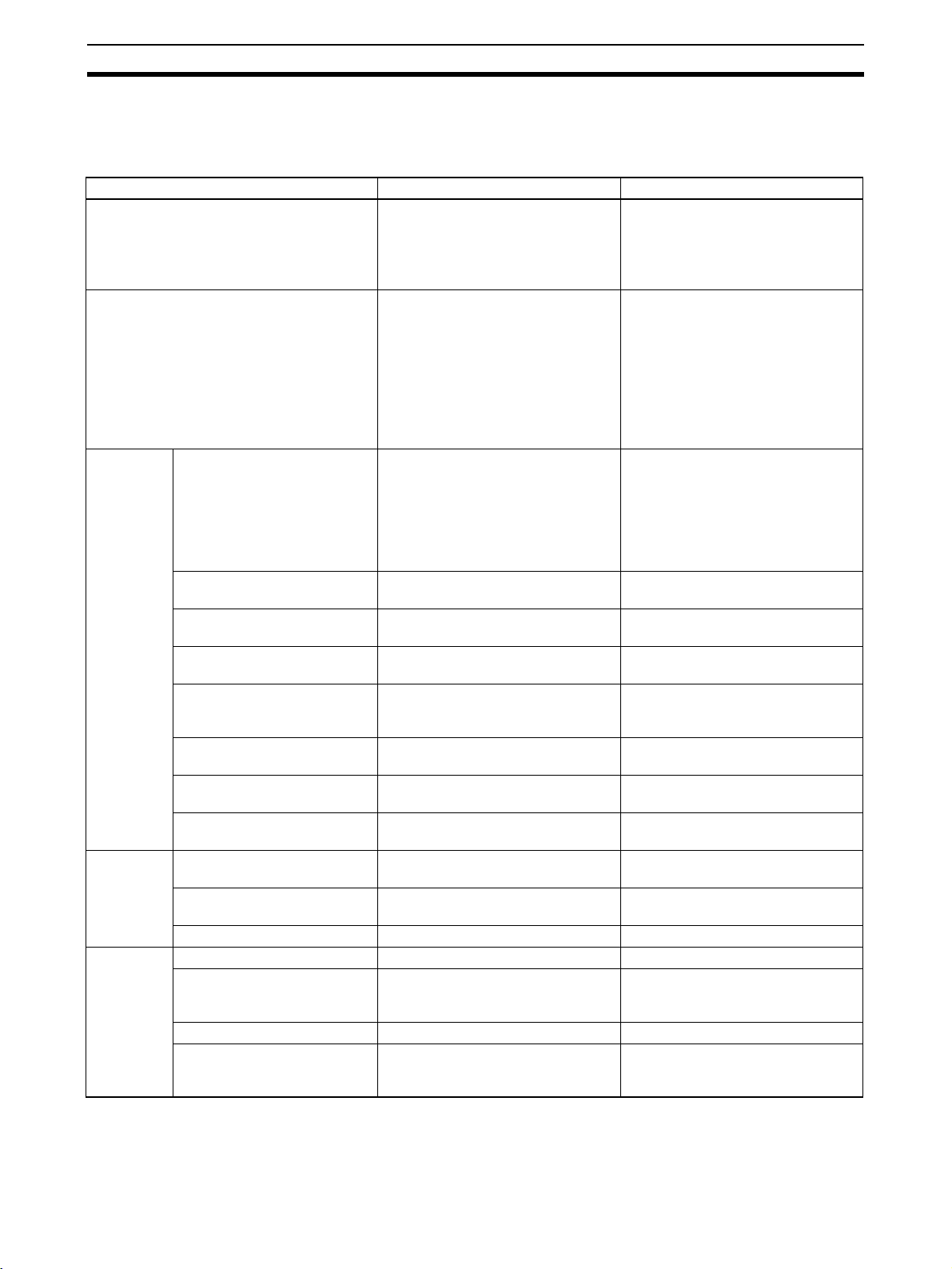

1-1-4 Configurator Specifications

Item Specification

Operating

environment

Network connection method Dedicated Board/Card 3G8F5-DRM21-E: Dedicated ISA Board

Node address

used

Connectable number of Boards/

Cards

DeviceNet masters OMRON CS1W-DRM21, CJ1W-DRM21, CVM1-DRM21-V1, or C200HW-DRM21-V1

Hardware Personal computer: IBM PC/AT or compatible

CPU: Pentium 166 MHz or higher

Memory: 32 Mbytes

Hard disk: A minimum of 15 Mbytes

OS Windows 95, 98, Me, NT4.0, 2000, or XP

Dedicated

Board/Card

Serial

connection

(Some limitations exist for the Dedicated Boards.)

3G8E2-DRM21-EV1: Dedicated PCMCIA Card

Serial connection Connect from the COM port of the computer to the

DeviceNet network, via the following serial communications port (Toolbus or Host Link) on a CS/CJ-series

PLC.

• Peripheral port of CPU Unit

• RS-232C port of CPU Unit

• RS-232C port of Serial Communications Board/Unit

Note The CS/CJ-series DeviceNet Unit (CS1W-

DRM21 or CJ1W-DRM21) is necessary to connect to the DeviceNet network using serial

communications.

Ethernet connection Connect from the Ethernet port of the computer to the

DeviceNet network, via an Ethernet Unit for a CS/CJseries PLC.

Note The CS/CJ-series Ethernet Unit (CS1W-

ETN@@ or CJ1W-ETN@@) and CS/CJ-series

DeviceNet Unit (CS1W-DRM21 or CJ1WDRM21) are necessary to connect to the

DeviceNet network using Ethernet.

A single node address is used.

No node address is used.

One/network

Note Device parameters of OMRON DeviceNet Units are output in the DRM_UNIT

file format for open network controllers or the NX-Server file format for the

DeviceNet.

4

Page 24

Introduction Section 1-1

Item Specification

Main functions Setup functions Master device parameter settings for OMRON’s Master

• Remote I/O master user-set allocations (with a scan list)

The node address order can be set as desired. Two output blocks and two input

blocks can be allocated. (See note.)

• Remote I/O slave user-set allocations

• Setting master remote I/O communications connections.

• Setting slave remote I/O communications connections.

• Enabling or disabling device data checks through remote I/O communications

(checks on slave vendor, device type, and product code data).

• Setting an explicit message monitor timer list.

• Setting a COS/cyclic heart beat timer value.

• Setting the communications cycle time.

Note 1. A device Parameter Wizard is supported for the Master.

2. Using remote I/O master user-set allocations eliminates restrictions on

node addresses. Furthermore, a number of masters can be mounted to

the PLC with no allocation area duplication.

Setting parameters for slaves (including other manufacturers’ slaves).

Setting node addresses and baud rates.

Setting I/O comments (for slave I/O data).

Monitoring

functions

Storage

functions

File export

functions

Other functions • Reading/preparing EDS files.

• Listing information on devices connected to the network (in node address order or

remote I/O configuration order, for example).

• Monitoring status of OMRON Master Unit.

• Monitoring error history of OMRON Master Unit (time, error code, and error condition).

• Monitoring communications cycle time.

• Monitoring slave status and parameters.

• Saving the parameters of devices connected to the network as network configuration

files.

• Saving the parameters of each device, in device units, as device parameter files.

• Exporting the network configuration list (contents displayed in the Detailed Display

Mode) in the CSV file format.

• Exporting I/O comments in CSV file format.

• Device parameters of OMRON’s Master Units are exported in the DRM_UNIT (virtual unit) file format for open network controllers.

• Device parameters of OMRON’s Master Units are exported in the NX-Server file format for the DeviceNet.

• Printing master/slave device parameters.

• Setting/reading parameters with explicit messages.

Note To use the Configurator to construct a DeviceNet network or make master or

slave settings, the EDS file is required. If other manufacturers’ slaves are

used, obtain the correct EDS files.

1-1-5 Files Created with Configurator

It is possible to create the following files with the Configurator.

Files Description Extension

Network configuration

files

Device parameter files Parameters for each device (master or

EDS files A common device definition file on the

The parameter file for all devices (master

and slave devices) on a single virtual

network (Network Configuration Window)

slave)

DeviceNet network

.npf

.dvf

.eds

5

Page 25

Introduction Section 1-1

Note In addition, files can be exported and saved in the following formats.

• The network configuration (contents displayed in the Detailed Display

Mode) can be saved in the CSV file format.

• I/O comments can be exported to a CSV file

• Device parameters of OMRON Master Units can be saved in the

DRM_UNIT (virtual unit) file format for open network controllers.

• Device parameters of OMRON Master Units can be saved in the NX-

Server file format for the DeviceNet.

1-1-6 Importing Version 1 Configurator Files

Version 2 of the Configurator can import files created with version 1 of the

Configurator.

Files Description Extension

Network configuration

files

Master parameter files Parameters for each master device .dsf

Slave parameter files Parameters for each slave device .dpf

The parameter file for all devices (master

and slave devices) on a single virtual

network (Network Configuration Window).

.ntf

1-1-7 Functions of the Configurator

The DeviceNet Configurator has 2 modes: Online and offline.

Online: The Configurator is connected to the DeviceNet network for net-

work communications.

Offline: The Configurator is not connected to the DeviceNet network.

The Configurator has the following functions that allow the user to design, set

up, and control the DeviceNet network.

Windows 95, 98, Me,

NT4.0, 2000, or XP

Compatibility

Graphic Displays The Configurator has Windows-style displays that are easy to understand and

Network Management The Configurator constructs a virtual network in the Network Configuration

The Configurator will operate under the Windows operating systems.

Other applications can be run simultaneously while monitoring the DeviceNet

network’s status.

Note The ISA Board is compatible with Windows 95, 98, and NT4.0 only.

The PCMCIA Card is compatible with Windows 95, 98, Me, 2000, and XP

only.

easy to use.

Required master and slave settings are made just by selecting the icons. It is

not necessary to input complicated commands. Even a beginner can make

settings and monitor operation with ease.

Window and adds necessary devices to the network. The construction of the

network is thus possible offline.

It is possible for the virtual network (i.e., the Network Configuration Window)

to read the network configuration from a file or actual network.

Furthermore, the network configuration can be downloaded from the virtual

network (i.e., the Network Configuration Window) and all settings can be registered with actual devices.

Online Connections to

DeviceNet Network

6

The online functions of the Configurator are executed by connecting the Configurator to the DeviceNet network through a dedicated Board or Card. (In that

case, the Configurator will be treated as a single node on the DeviceNet network.)

Page 26

Introduction Section 1-1

Connection can also be made from the COM port of the computer to the serial

communications port of a CS/CJ-series CPU Unit (or the Serial Communications Board/Unit) via Toolbus or Host Link. In this case, a CS/CJ-series

DeviceNet Unit (CS1W-DRM21 or CJ1W-DRM21) is necessary for connection

to the DeviceNet network.

Similarly, connection can be made from the Ethernet port of the computer via

a CS/CJ-series Ethernet Unit. In this case also, a CS/CJ-series DeviceNet

Unit (CS1W-DRM21 or CJ1W-DRM21) is necessary for connection to the

DeviceNet network.

Device Settings The following parameter settings are for other manufacturers’ slaves as well

as OMRON’s master and slave devices.

A comment can be added to the I/O data of each device.

Setting Description CS1W-DRM21 C200HW-DRM21-V1

Master functions enable/disable

I/O allocations Slaves are allocated to the master in the desired

Communication cycle time Sets the communication cycle time.

Connection setting During remote I/O communications, the user can

Device data check Determines whether slave device data items

Slave functions enable/disable

Slave functions I/O allocation I/O allocations can be made for slaves of the

Remote I/O

communications startup

Explicit message communications set/reset

Enables or disables the master functions for

remote I/O communications.

areas and order.

If the I/O allocations are simple, the Parameter

Wizard can be used to allocate I/O very easily.

I/O allocations are possible as well by just drag-

ging and dropping the slave to the allocation

area.

(The interval for I/O communications with

slaves.)

make connection settings for up to two connections per slave. Automatic connection settings

can be selected as well.

(i.e., the vendor, device type, and product code)

are checked during remote I/O communications.

Enables or disables the slave functions for

remote I/O communications.

CS1-series DeviceNet Unit. (I/O can be

allocated freely.)

Determines whether or not to start remote I/O

communications when the master is started.

Setting or resetting the function to enable explicit

message communications without remote I/O

communications.

and

CVM1-DRM21-V1

Ye s N o

Ye s Ye s

Ye s Ye s

Ye s N o

Ye s N o

Ye s N o

Ye s N o

(See note 1.) Yes

(See note 2.) Yes

Note 1. The same function can be achieved with the master functions enable/dis-

able setting.

2. When not registered in the scan list, explicit message communications are

possible without remote I/O communications.

Device Monitoring The status, error log, etc., of a device can be monitored, provided that the

device supports the monitor function. The monitor function is supported by

OMRON’s Master Units and some Special Slaves.

7

Page 27

Introduction Section 1-1

Master Status Monitor

The status of the specified OMRON master is displayed. The status of a slave

will be displayed as well if it is in remote I/O communications with the Master.

Slave Status Monitor

The status of the specified MULTIPLE I/O TERMINAL (i.e., DRT1-COM Communications Unit) will be displayed. The configuration of the I/O Unit connected to the Communications Unit will be displayed as well.

Master Error Log Display

The error log in the specified OMRON master can be read, displayed, or

cleared.

Communication Cycle Time Display

The present communication cycle time of the specified OMRON master will

be displayed. The maximum communications cycle time and minimum communications cycle time counted from the moment previous values are

refreshed will be displayed as well. The maximum communications cycle time

and minimum communications cycle time can be reset any time.

8

Page 28

Introduction Section 1-1

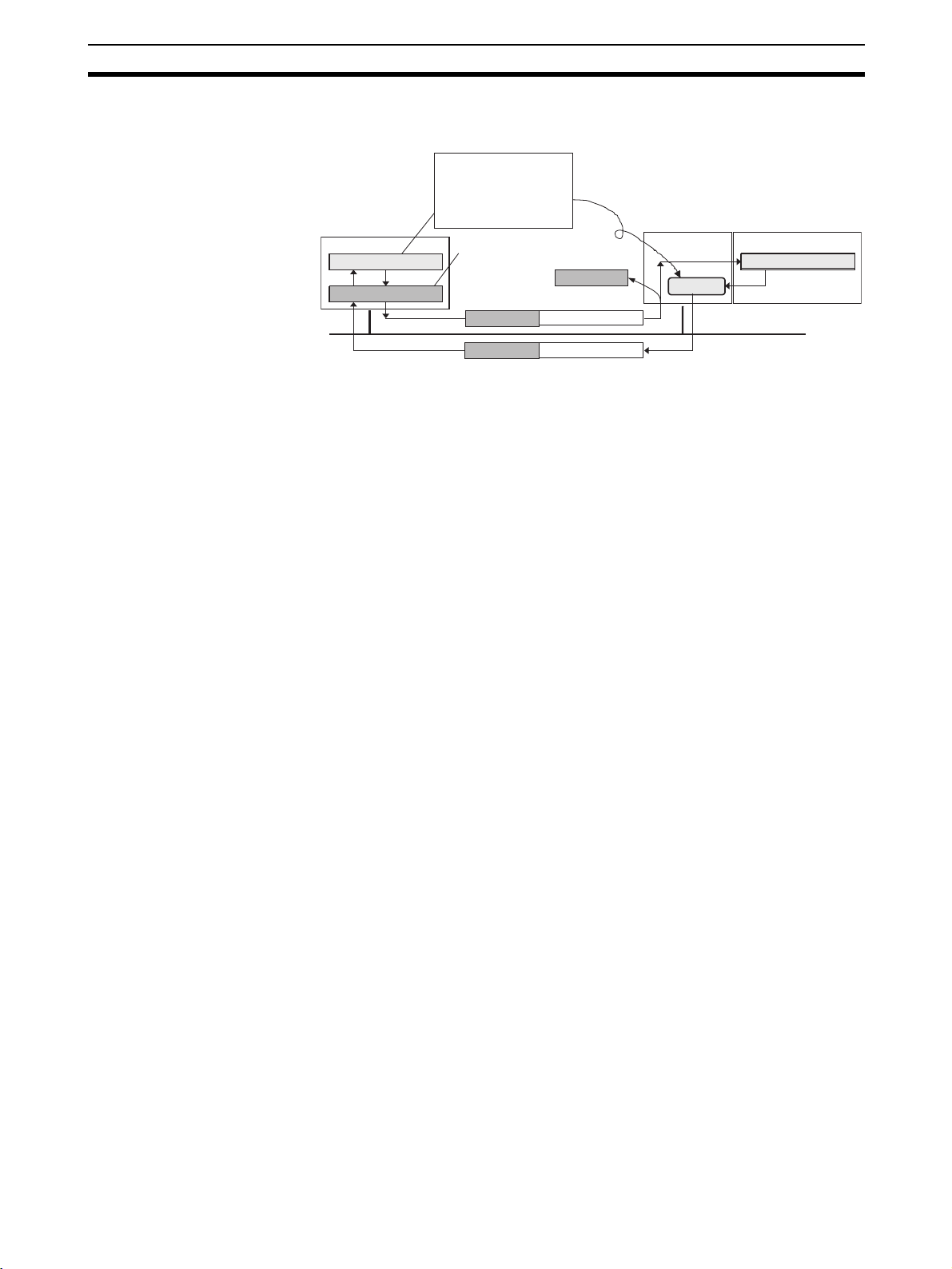

File Management The Configurator saves or loads the following data in files.

Network Configuration

(List of devices)

Master device parameter

Network configuration file

Parameter file of each master device

Device (EDS File)

Management

Master device parameter

Slave device parameter

Slave device parameter

Parameter file of each master device

Parameter file of each slave device

Parameter file of each slave device

• The network configuration file includes the parameters for all devices

(master and slave devices). The parameter file for each master and slave

device contains the individual device parameters. Parameter files can be

managed independently from network configuration files.

• Files from version 1 of the Configurator are not compatible with those of

version 2. Files from version 1 of the Configurator can be read, however,

by using the import function.

Note Device parameter files of the CS-series CS1W-DRM21 DeviceNet Unit are

compatible with Unit setup files that can be backed up in the Memory Card of

the CS1-series CPU Unit.

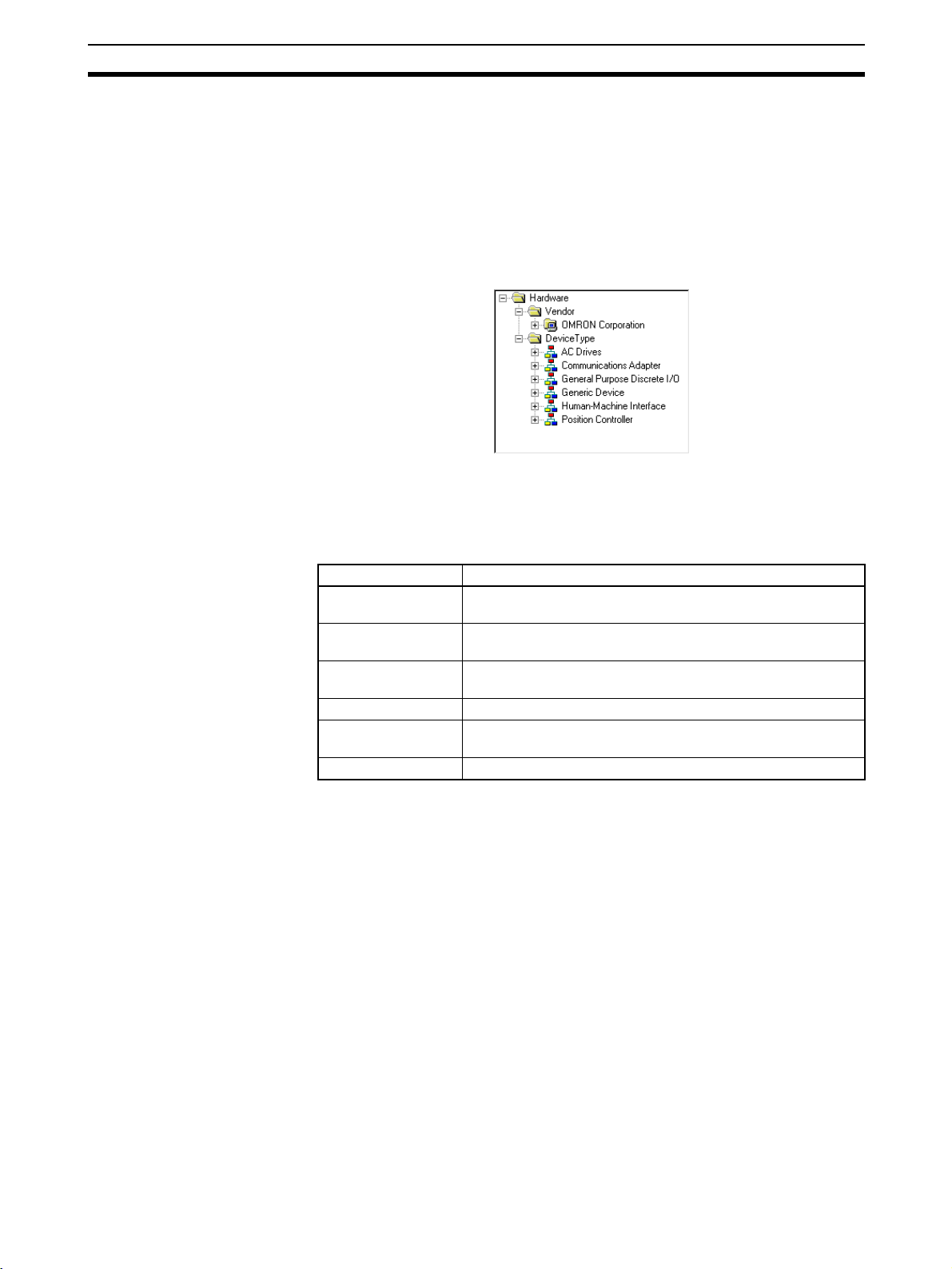

The construction of a network with the Configurator requires the appropriate

EDS files. Information on each device is obtained from the EDS file.

If no EDS file is provided, use the hardware (EDS file) management function

to install or create an EDS file.

Other Functions DeviceNet vendor definition files, device type definition files, and slave setup

files for the MULTIPLE I/O TERMINALs can be set for the Configurator, with

which additional DeviceNet vendors and device types can be used.

Furthermore, the Expansion Module can be installed so that edit and monitoring functions can be added for other manufacturers’ devices (masters and

slaves) or OMRON devices that will be released in the future.

Note When the dedicated Board is used to connect to the DeviceNet network, the

Configurator will be a single node on the DeviceNet network. Be sure that the

node address of the computer is not duplicated with that of any other node.

9

Page 29

Introduction Section 1-1

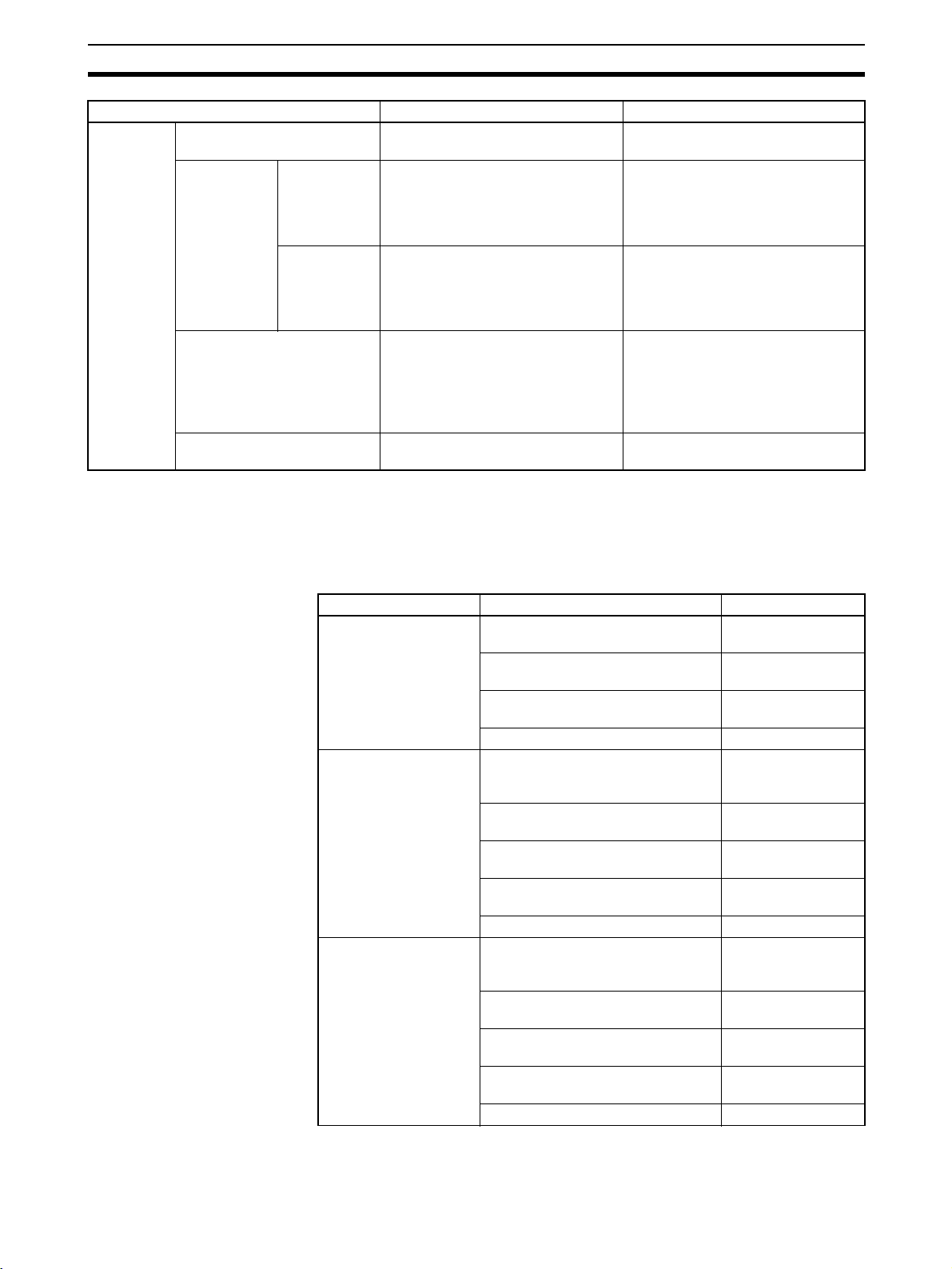

1-1-8 Comparison with Previous Versions of the Configurator

The following table lists the difference in function between version 1.20 and

version 2.@ of the Configurator.

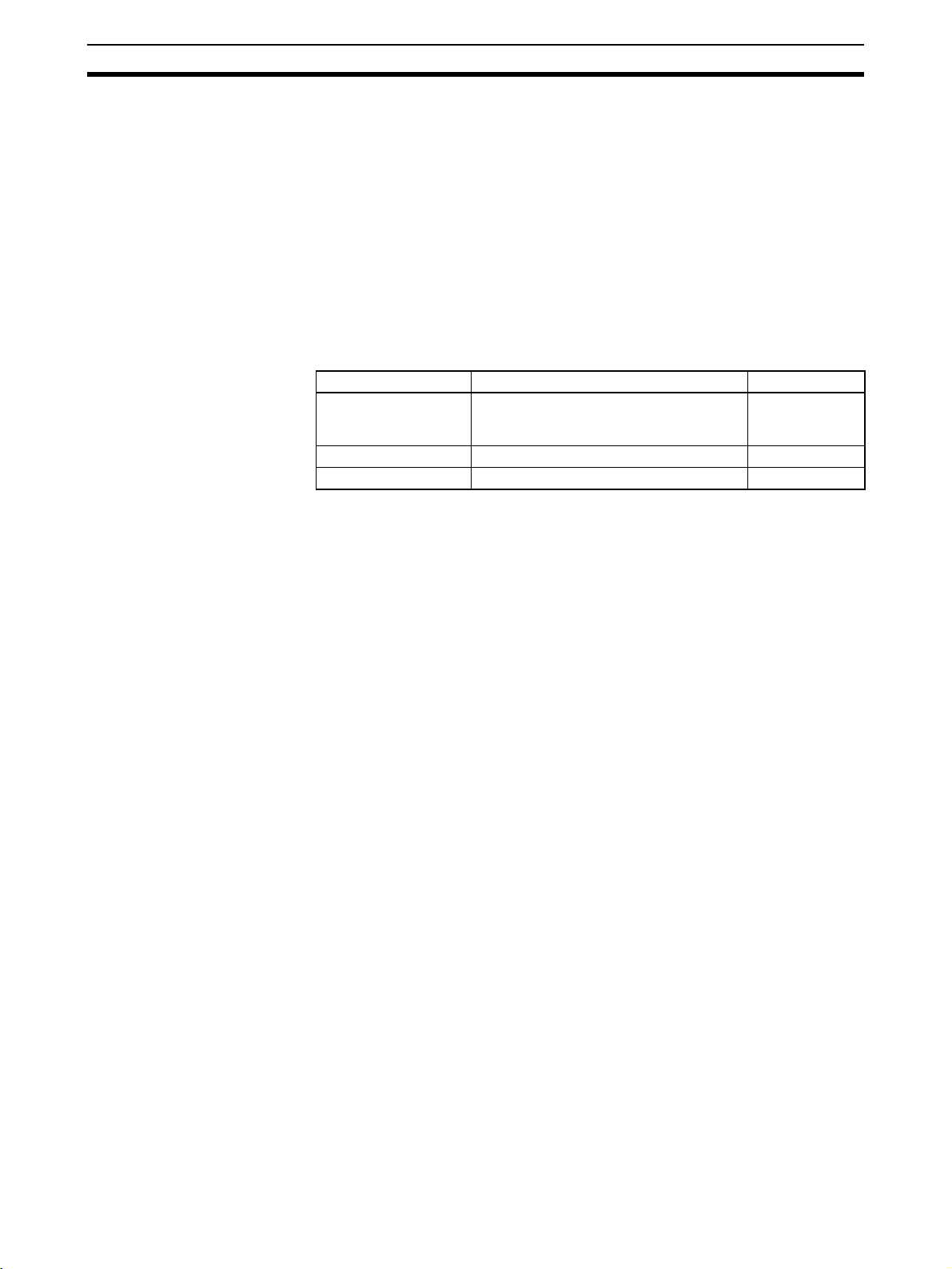

Item Version 2.@ Version 1.20

Basic configuration/operations Dragging and dropping offline make

Network connection • Dedicated ISA Board

Supported

DeviceNet

masters

Monitor

functions

Storage

functions

OMRON masters CS1W-DRM21, CJ1W-DRM21,

Slave remote I/O allocations Possible with CS/CJ-series PLCs

Master remote I/O

communications settings

Slave remote I/O

communications settings

Enabling or disabling device

data checks in remote I/O

communication

Explicit message monitoring

timer list settings

COS/Cyclic heart beat timer

settings

I/O comment settings (for

slave I/O data)

Display of list of data on network devices

Unit status monitoring Possible with CS/CJ-series PLCs

Slave function monitoring Possible Impossible

Network configuration files Possible (extension: .npf) Possible (extension: .ntf)

Device parameter files Possible (extension: .dvf) Possible

EDS files Possible (extension: .eds) Impossible

Compact flash memory Stored in compact flash memory and

it possible to create a virtual network

(for display) in the Configurator.

Each device (Master or slave) can

also be set online.

• Dedicated PCMCIA Card

• From the COM port of the computer

to the serial port of the PLC. (Possible with CS/CJ-series PLCs only.)

• From the Ethernet port of the computer to the Ethernet Unit of the

PLC. (Possible with CS/CJ-series

PLCs only.)

CVM1-DRM21-V1 or C200HWDRM21-V1

Note Output is possible in file for-

mats compatible with open

network controllers or NXServers for DeviceNet.

only.

Possible with CS/CJ-series PLCs

only.

Possible with CS/CJ-series PLCs

only.

Possible with CS/CJ-series PLCs

only.

Possible with CS/CJ-series PLCs

only.

Possible with CS/CJ-series PLCs

only.

Possible Impossible

Possible Possible

only.

downloaded to the master. (Possible

with CS/CJ-series PLCs only.)

Each device must be set online,

except the scan list of the master.

• Dedicated ISA Board

• Dedicated PCMCIA Card

CVM1-DRM21-V1 or C200HWDRM21-V1

Note The CS1W-DRM21, open

network controllers, or NXServers for DeviceNet cannot

be used.

Impossible

Impossible

Impossible

Impossible

Impossible

Impossible

Impossible

(master: Extension: .dsf

slave: Extension: .dpf)

Impossible

10

Page 30

Confirming Product Contents Section 1-2

Item Version 2.@ Version 1.20

File export

functions

I/O command output in CCV

file format

Device

parameter of

OMRON

masters

EDS file creation Possible

I/O allocation duplication

check between Masters

Output for

open network

controllers in

DRM_UNIT

file format

Output for NXServers for

DeviceNet in

NX-Server file

format

Possible Impossible

Possible Impossible

Possible Impossible

Device discrimination data and I/O

data files are created. Device parameter data files cannot be created.

Impossible Possible

Conditionally possible

Tentative EDS files (with device

discrimination data only) are

created. Device I/O data or

parameter data files cannot be

created.

1-2 Confirming Product Contents

Please check the contents of your product as soon as if arrives.

Product Contents Quantity

WS02-CFDC1-E

Configurator

3G8F5-DRM21-E

ISA Board

3G8E2-DRM21-EV1

PCMCIA Board

Configurator installation disk

(CD-ROM)

3G8F5/3G8E2 setup disk (driver

setup tool on CD-ROM)

User registration card and software

license

Information 1

Dedicated ISA board 1 (with

Configurator installation disk

(CD-ROM)

3G8F5/3G8E2 setup disk (driver

setup tool on CD-ROM)

User registration card and software

license

Information 1

Dedicated PCMCIA board 1 (with

Configurator installation disk

(CD-ROM)

3G8F5/3G8E2 setup disk (driver

setup tool on CD-ROM)

User registration card and software

license

Information 1

1

1

1

1communications

connector included)

1

1

1

1communications

connector included)

1

1

1

11

Page 31

Operating Environment Section 1-3

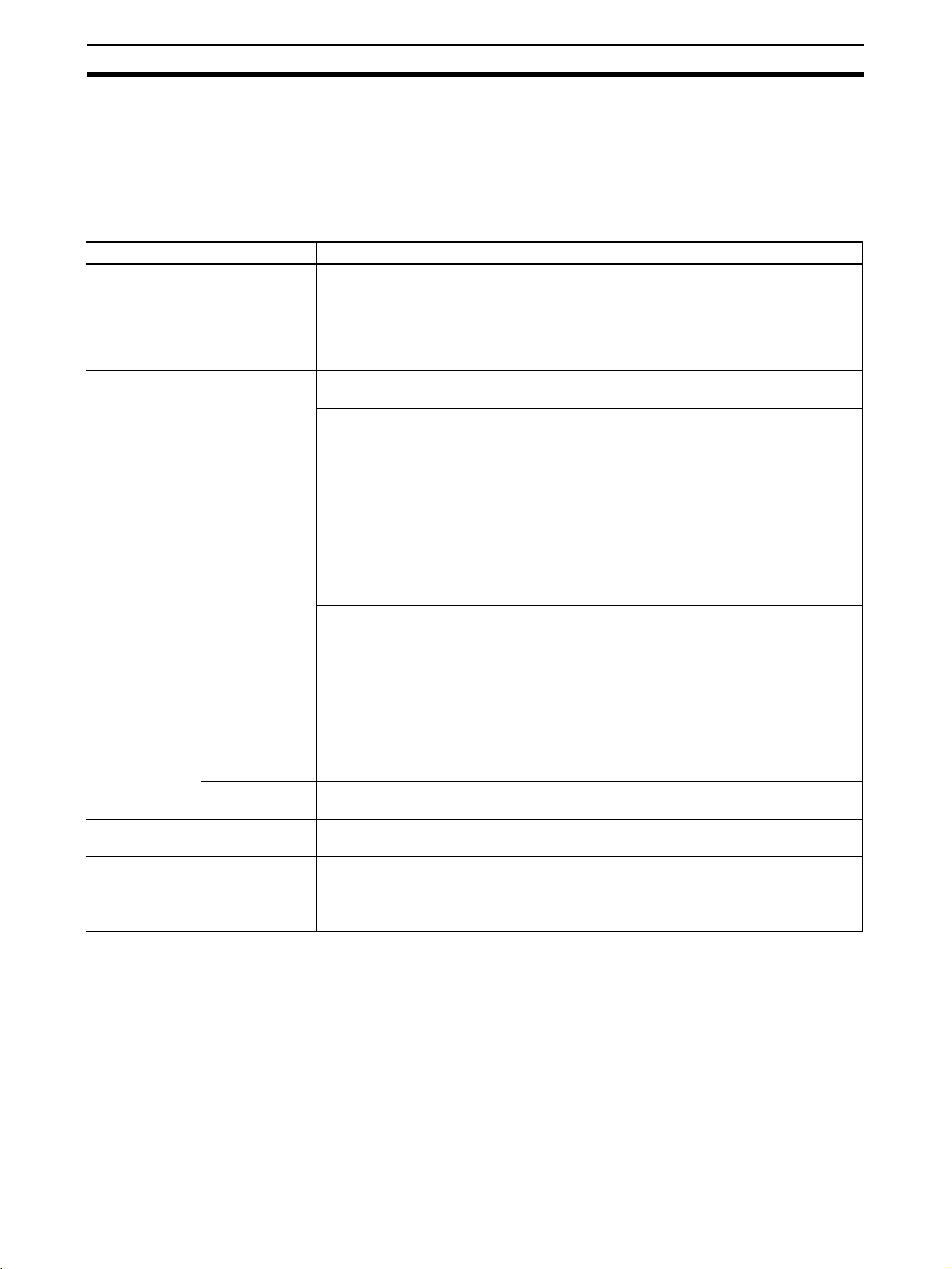

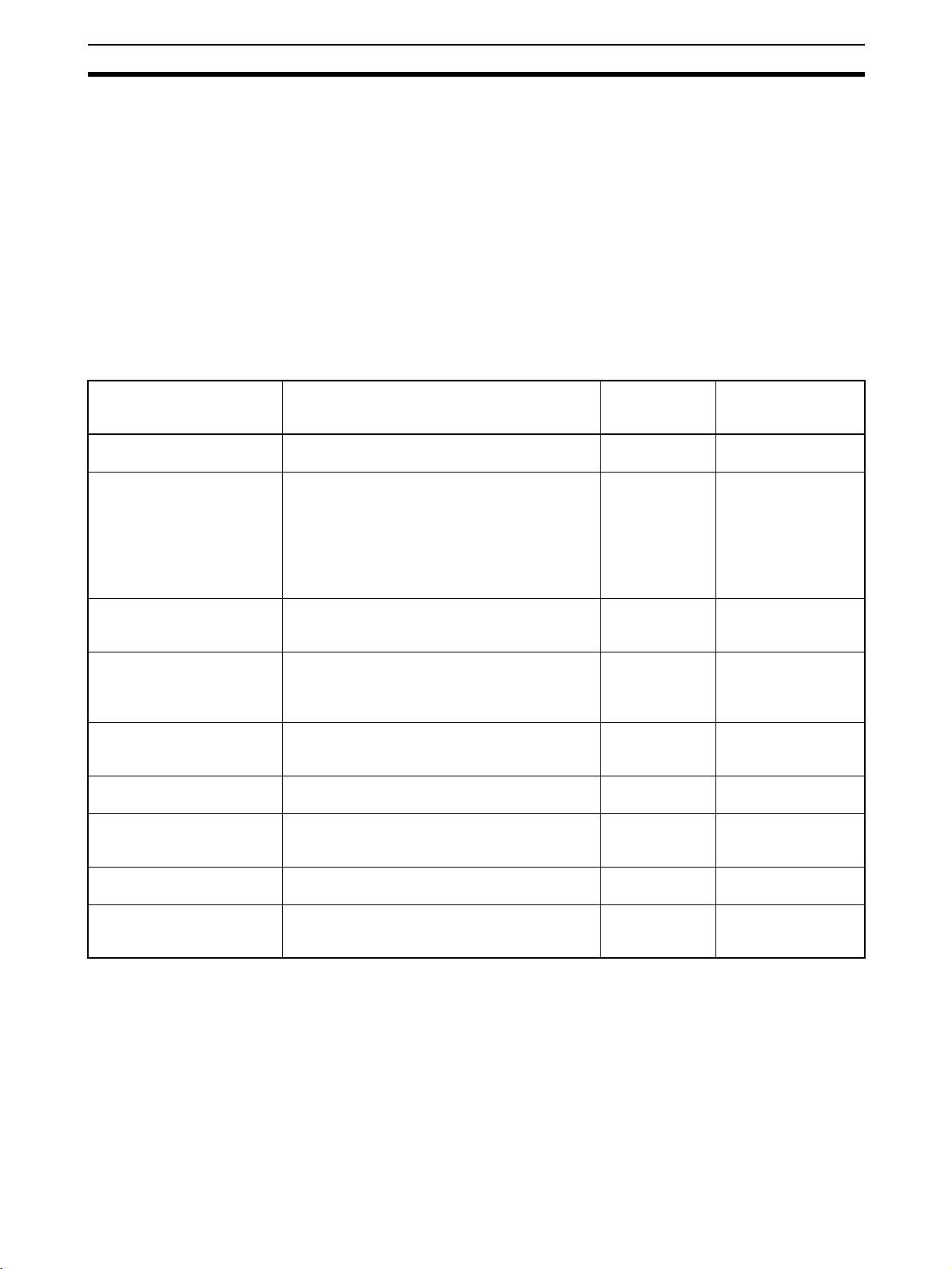

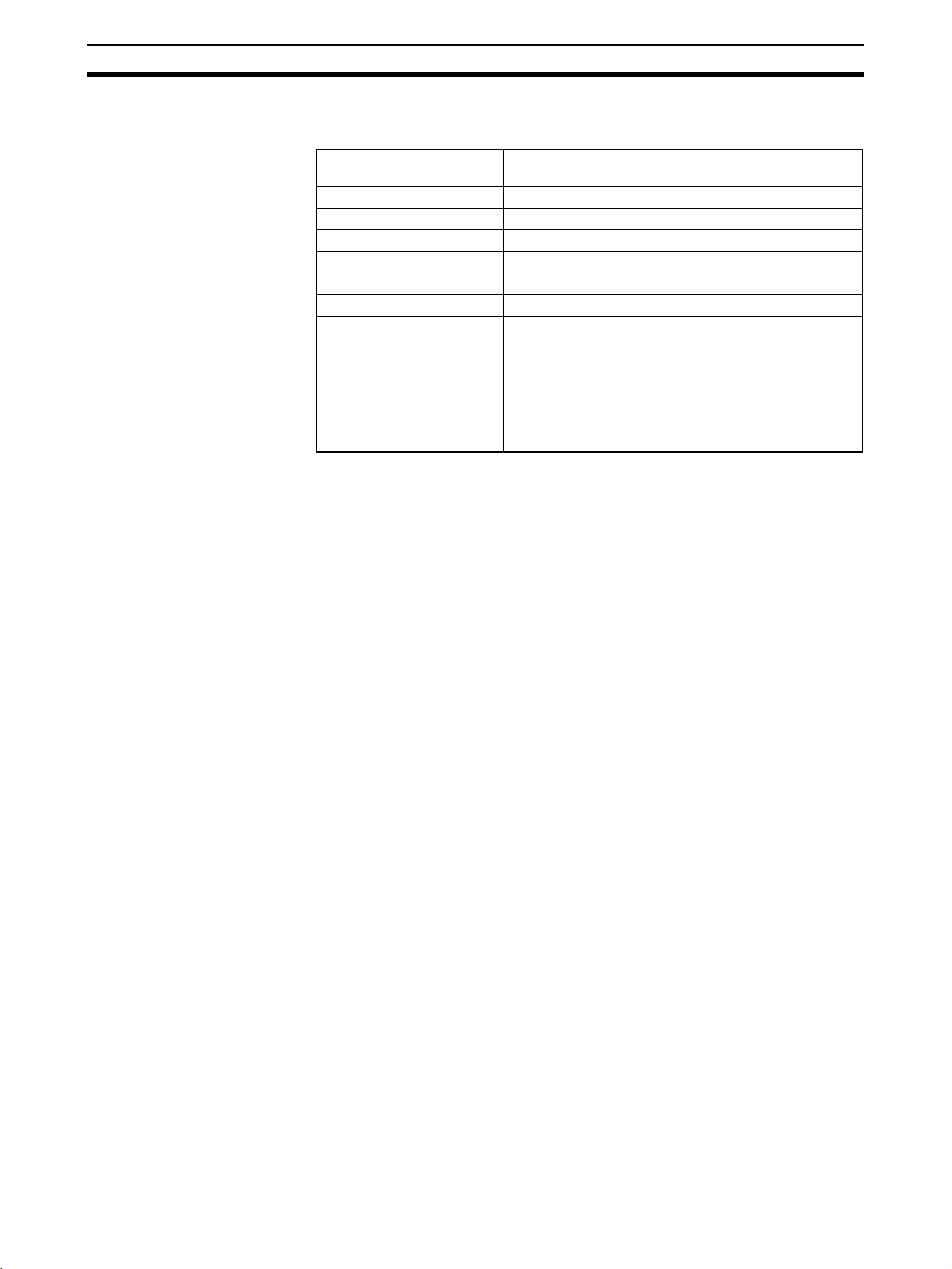

1-3 Operating Environment

The Configurator operates in the following environment.

Compatible personal

computer

OS Windows 95, 98, Me, NT4.0, 2000, or XP

CPU Pentium 166 MHz or better

Available hard disk space 15 Mbytes min.

Memory 32 Mbytes min.

CD-ROM drive 1 (used for software installation)

Display VGA or better

Hardware for network

connection

1-3-1 Configurator Precautions

Observe the following precautions when using the Configurator.

• The only DeviceNet masters that can be handled by the Configurator are

OMRON’s CS1W-DRM21, CJ1W-DRM21, CVM1-DRM21-V1, and

C200HW-DRM21-V1.

• When a dedicated Board or Card is used, the Configurator is connected

to the DeviceNet network as a single node. The Configurator cannot be

connected to the network unless a node address is available. No node

address is required if the Configurator is connected via Ethernet or a

serial communications port.

• Do not use the Configurator in a location with too much electromagnetic

noise. If noise is too extreme, the computer may run out-of-control,

although there will be no negative effects on the DeviceNet network even

if noise causes the computer to run out-of-control.

IBM PC/AT or compatible personal computer

One of the following is required for online connection to

the DeviceNet network.

OMRON DeviceNet Board/Card

Dedicated PCMCIA Card (3G8E2-DRM21-EV1)

Dedicated ISA Board (3G8F5-DRM21-E)

Ethernet port

COM port

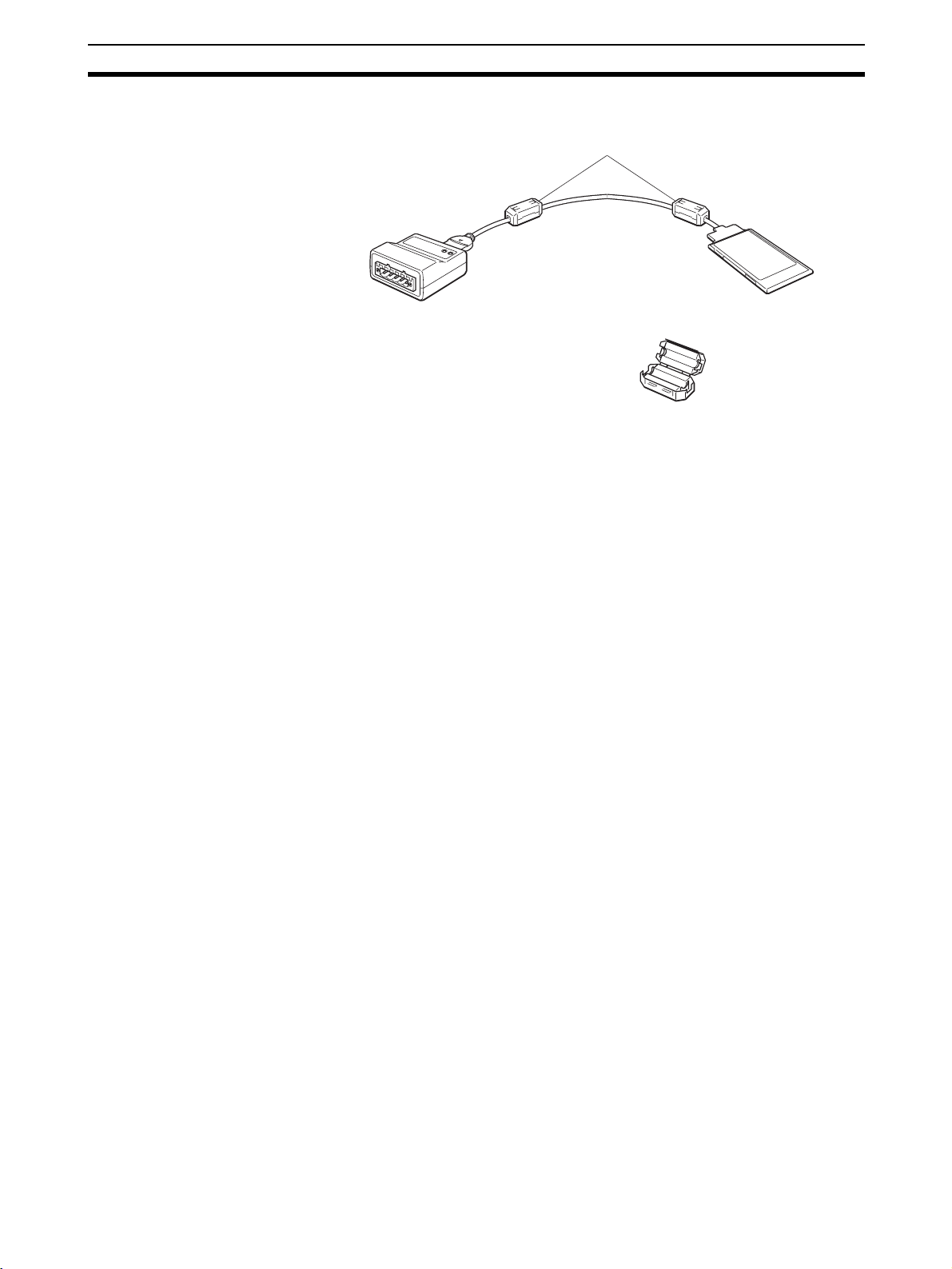

1-3-2 PCMCIA Card Precautions

• Use the PCMCIA Card Unit on a level surface, as shown in the following

diagram.

• Do not bend or pull the cable that connects the PCMCIA Card and the

PCMCIA Card Unit.

• The PCMCIA Card is a portable peripheral device. Do not leave it connected to the network.

• Attaching ferrite cores between the PCMCIA Card and the PCMCIA Card

Unit can reduce noise from the network.

12

Page 32

Operating Environment Section 1-3

Attach one ferrite core near the Unit and another near the card, as shown

in the following diagram.

Ferrite cores

Ferrite core

We recommend one of the following ferrite cores.

Company:Fair-Rite Products Corp.

Models: 0443-164251

045A-164257

Address: PO Box J, One Commercial Row, Wallkill, NY 12589 USA

Phone: (845) 895-2055

Fax: (845) 895-2629

13

Page 33

Operating Environment Section 1-3

14

Page 34

SECTION 2

Installation

This section explains how to install the ISA Board, PCI Board, or PCMCIA Card hardware in the computer, make the

necessary hardware settings and computer settings, and install the DeviceNet Configurator software in the computer.

2-1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 ISA Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-1 Preparation for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2-2 ISA Board Components and Functions . . . . . . . . . . . . . . . . . . . . . . 19

2-2-3 DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-2-4 Installation in the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2-5 3G8F5/3G8E2-DRM21 Driver Setup Software Installation. . . . . . . 20

2-3 PCMCIA Card Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-3-1 Preparation for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-3-2 PCMCIA Card Components and Functions . . . . . . . . . . . . . . . . . . . 25

2-3-3 PCMCIA Card Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-3-4 3G8F5/3G8E2-DRM21 Driver Setup Software Installation. . . . . . . 28

2-4 Configurator Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

15

Page 35

Installation Procedure Section 2-1

2-1 Installation Procedure

The following flowchart shows the steps involved in installing the Configurator.

When only designing

the network

(When creating a

settings file offline)

Connecting

with a

PCMCIA Card

Install the

PCMCIA Card

2-2 ISA Board Installation

This section explains how to set the dedicated ISA Board used by the Configurator and install the Board in the computer.

When connecting to the network

to make settings or monitor.

(When using online)

Connecting

with an ISA

Board

Install the

ISA Board

Install the driver

setup tool

Install the

Configurator

Connecting

via Ethernet

Connecting

by COM

port

2-2-1 Preparation for Installation

The dedicated ISA Board used by the Configurator is not a plug-and-play

board. Before installing the Board, check the items listed in the following table.

Item Description

Windows OS Verify that the OS is Windows 95, 98, or NT4.0.

Unused expansion slot Verify that there is an unused expansion slot (ISA slot) in

Available memory The ISA Board for the Configurator occupies 16 KB of

Unused I/O port address The ISA Board for the Configurator occupies 8 port

Note The dedicated ISA Board used by the Configurator cannot be used with Win-

dows Me, 2000, or XP.

Windows 95/98

Procedure

When Windows 95/98 is being used, follow this procedure to verify the available memory and I/O port addresses and reserve these addresses for the

Configurator’s ISA Board.

the computer.

memory between the memory range of C0000 and

DFFFF as a system resource.

Verify that the computer has 16 KB of available memory

between the memory range of C0000 and DFFFF and

select a leading address. The leading address is needed

during the driver installation.

addresses between the memory range of 200 and 2FF as

a system resource.

Verify that the computer has 8 addresses available and

select a leading I/O address. The leading I/O address is

needed when setting the ISA Board’s DIP switch.

16

Page 36

ISA Board Installation Section 2-2

1,2,3... 1. Click the Start Button and select Control Panel from the Settings Menu.

2. Double-click the System Icon in the Control Panel Window.

3. Select the Device Manager Tab from the System Properties Window.

4. Select Computer and click the Properties Button at the bottom of the win-

dow.

5. Select the View Resources Tab.

6. Select Input/output (I/O) from the View Resources Page and click the OK

Button. The current I/O port allocations will be displayed. Find an unused

I/O port address that can be used for the ISA Board.

17

Page 37

ISA Board Installation Section 2-2

7. Select the Reserve Resources Tab.

8. Selecting Input/output (I/O) from the Reserve Resources Page, click the

Add Button, and register the range of I/O port addresses for the ISA Board

as shown in the following diagram.

In this example, I/O port addresses 250 through 257 (hexadecimal) are reserved.

Windows NT 4.0

Procedure

18

9. Follow the same procedure in steps 5 to 8 to reserve 16-Kbytes of memory.

10. Click the OK Button at the bottom of the Computer Properties Window to

accept the changes and close the window. A pop-up window will appear;

restart the computer as required.

When Windows NT 4.0 is being used, the operating system does not monitor

the status of memory and I/O port addresses. Refer to the user’s manuals for

the computer and peripheral devices being used and locate an unused

address for the Configurator’s ISA Board.

Page 38

ISA Board Installation Section 2-2

2-2-2 ISA Board Components and Functions

The following diagram shows the main components of the Configurator’s ISA

Board and their functions.

ISA Bus Connector

Connect to the computer's

ISA slot.

DIP Switch

Sets the I/O port address

which the ISA Board will use.

DeviceNet Communications Connector

Connects to the DeviceNet

communications cable.

2-2-3 DIP Switch Settings

Before connecting the ISA Board to the computer, set the I/O port address

that the Board will use with the Board’s DIP switch.

!Caution Do not touch the ISA Boards connectors or components. Take precautions

against static electricity when handling the ISA Board.

Set the I/O port address with the DIP switch as shown in the following table.

Be sure to set addresses that aren’t being used by another device in order to

avoid a conflict. (A pin setting of 0 is OFF and 1 is ON.)

I/O port addresses

(Hexadecimal)

200 to 207 0 0 0 0 0 0 Used for the game port.

208 to 20F 1 0 0 0 0 0 ---

210 to 217 0 1 0 0 0 0 ---

218 to 21F 1 1 0 0 0 0 ---

220 to 227 0 0 1 0 0 0 ---

228 to 22F 1 0 1 0 0 0 ---

230 to 237 0 1 1 0 0 0 ---

238 to 23F 1 1 1 0 0 0 ---

240 to 247 0 0 0 1 0 0 ---

248 to 24F 1 0 0 1 0 0 ---

250 to 257 0 1 0 1 0 0 Factory default setting.

258 to 25F 1 1 0 1 0 0 ---

LED Indicators

Indicate the status of the ISA Board

and the DeviceNet network.

DIP switch pin settings Remarks

123456

19

Page 39

ISA Board Installation Section 2-2

I/O port addresses

(Hexadecimal)

260 to 267 0 0 1 1 0 0 ---

268 to 26F 1 0 1 1 0 0 ---

270 to 277 0 1 1 1 0 0 ---

278 to 27F 1 1 1 1 0 0 Used for LPT2.

280 to 287 0 0 0 0 1 0 ---

288 to 28F 1 0 0 0 1 0 ---

290 to 297 0 1 0 0 1 0 ---

298 to 29F 1 1 0 0 1 0 ---

2A0 to 2A7 0 0 1 0 1 0 ---

2A8 to 2AF 1 0 1 0 1 0 ---

2B0 to 2B7 0 1 1 0 1 0 ---

2B8 to 2BF 1 1 1 0 1 0 ---

2C0 to 2C7 0 0 0 1 1 0 ---

2C8 to 2CF 1 0 0 1 1 0 ---

2D0 to 2D7 0 1 0 1 1 0 ---

2D8 to 2DF 1 1 0 1 1 0 ---

2E0 to 2E7 0 0 1 1 1 0 ---

2E8 to 2EF 1 0 1 1 1 0 Used for COM port 4.

2F0 to 2F7 0 1 1 1 1 0 ---

2F8 to 2FF 1 1 1 1 1 0 Used for COM port 2.

DIP switch pin settings Remarks

123456

Note There are some boards marketed that cannot distinguish between I/O port

addresses 200 through 2FF and addresses 600 through 6FF. If one of these

boards is allocated address 2@@, it will occupy address 6@@ as well. To avoid

any possible conflicts when assigning an address between 600 and 6FF, be

sure to assign an address that corresponds to an unused address between

200 and 2FF. (For example if 6A0 to 6A7 are selected, make sure that 2A0 to

2A7 are unused.)

2-2-4 Installation in the Computer

The ISA Board must be installed into one of the computer’s expansion slots

(ISA slots). When installing the Board, turn OFF the computer’s power and

take precautions against static electricity. Refer to the computer’s user’s manual for detailed installation procedures.

If there are no problems with the I/O port settings, the computer should recognize the ISA Board when the computer is turned ON and the ISA Board should be usable. If the ISA Board has been installed successfully, proceed to 2-2-5 3G8F5/3G8E2-DRM21 Driver Setup Software Installation.

2-2-5 3G8F5/3G8E2-DRM21 Driver Setup Software Installation

The operations and displays shown in the following procedure may differ

slightly depending on the version of Windows software being used. The displays for Windows 98 are shown here.

1,2,3... 1. Exit all other Windows-based programs.

2. Insert 3G8F5/3G8E2-DRM21 setup disk into the CD-ROM drive.

3. Double-click Setup.exe.

The 3G8F5/3G8E2-DRM21’s setup program will start.

20

Page 40

ISA Board Installation Section 2-2

The following window will be displayed when the setup program has been

loaded. Click the Next Button after reading the precautions.

4. Specify the destination directory for the driver files. If the default directory

shown in the window is acceptable, click the Next Button. To specify a different directory, click the Browse Button, specify the desired directory, and

click the Next Button. If a new directory is specified, the software will create

it automatically.

21

Page 41

ISA Board Installation Section 2-2

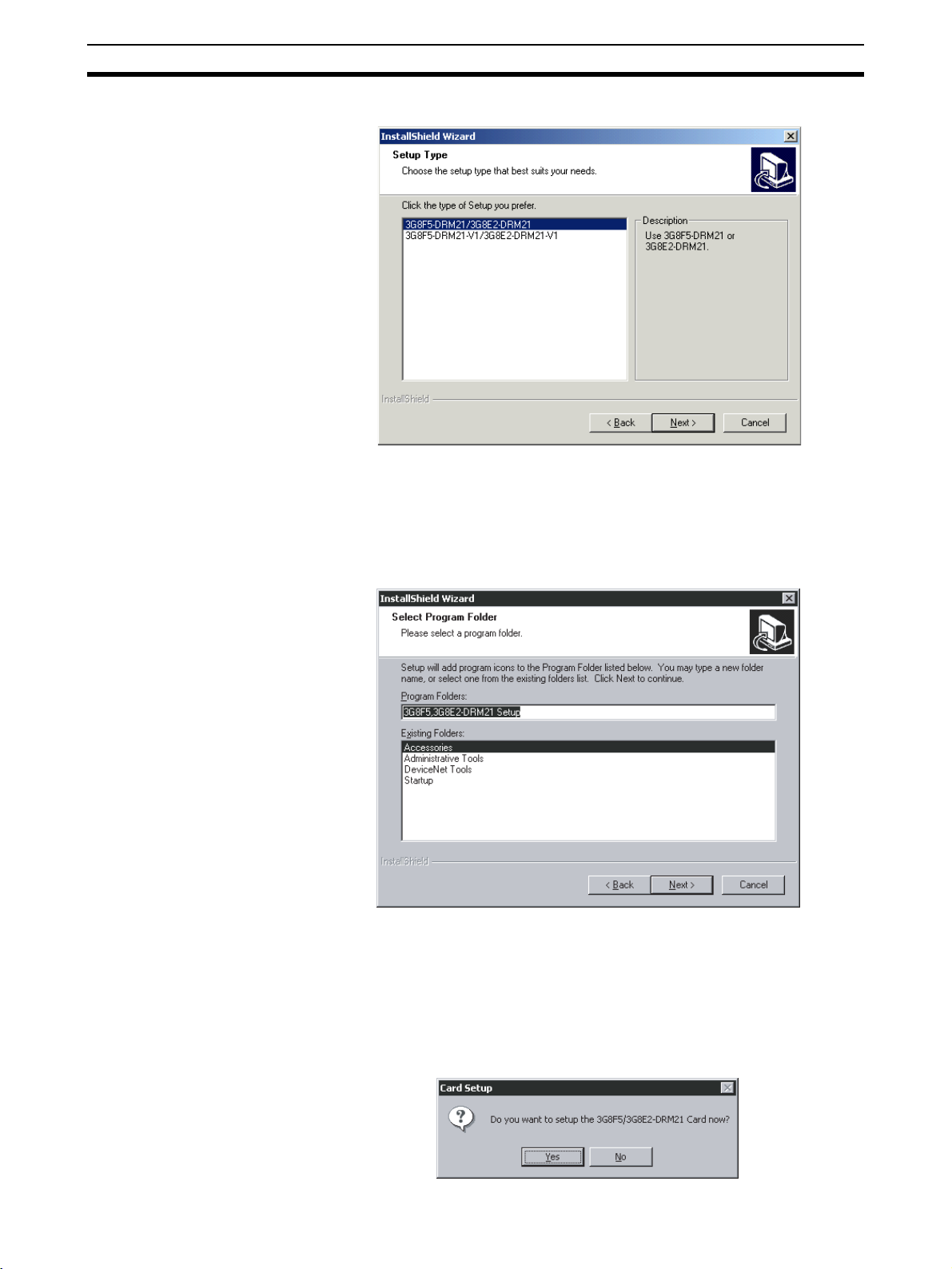

5. Select 3G8F5-DRM21/3G8E2-DRM21.

6. Specify the name of the 3G8F5/3G8E2-DRM21 program folder where the

Software icons will be registered. If the default program folder is acceptable, click the Next Button. To specify a different folder, select an existing

folder or enter a new folder name and then click the Next Button.

Note The program folder name specified here will be registered under De-

viceNet Tools in the Start Menu.

22

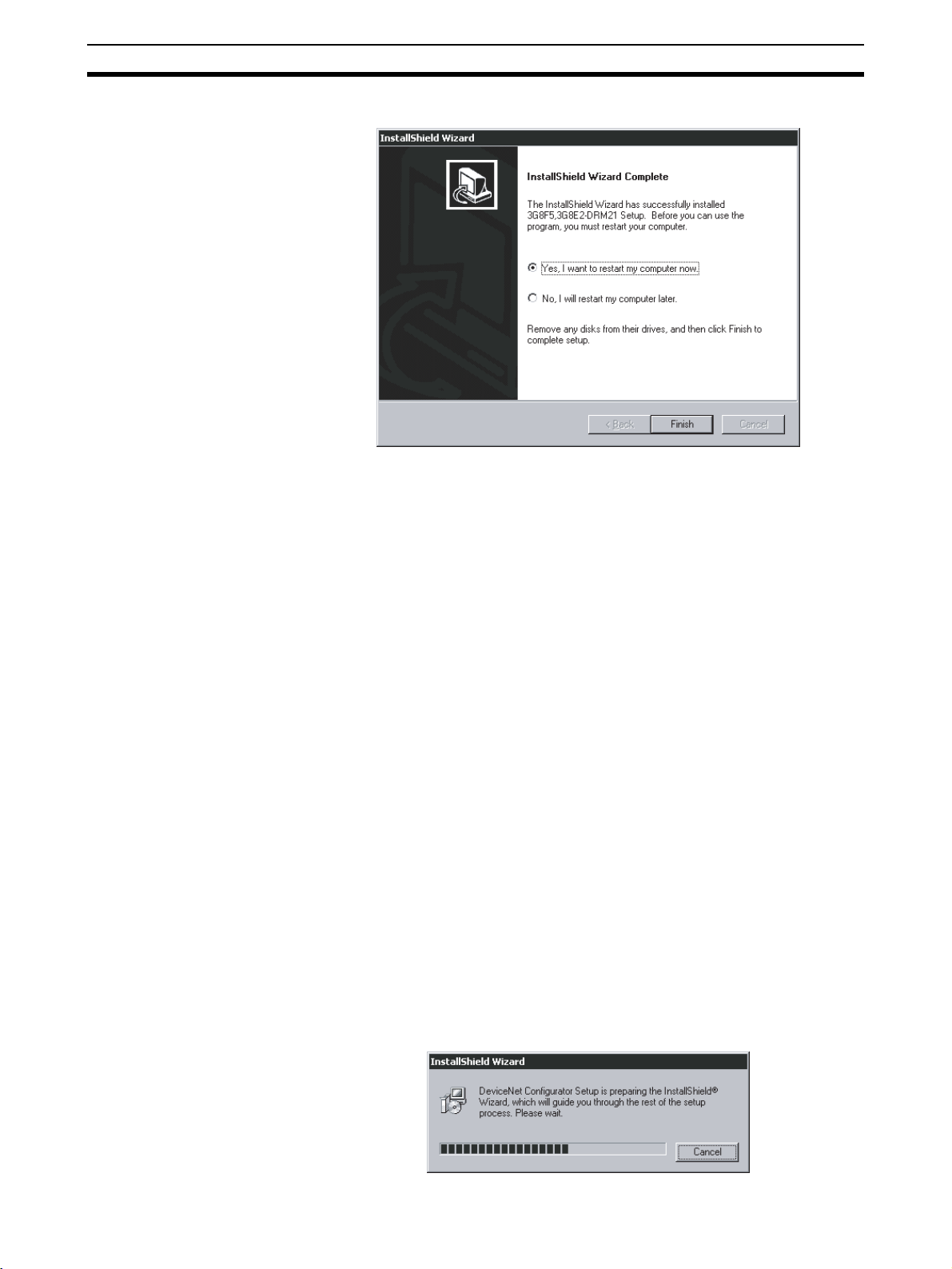

7. The installation program will be started and the 3G8F5/3G8E2-DRM21

files will be copied to the destination directory.

8. A program group folder will be created automatically when the 3G8F5/

3G8E2-DRM21 Driver Setup Software installation has been completed.

9. A pop-up window will be displayed asking whether you want to setup the

device driver. If you click the No Button, the installation program will end

without performing the setup for the ISA Board or PCMCIA Card.

Page 42

ISA Board Installation Section 2-2

Note The setup for the ISA Board or PCMCIA Card can be performed later

by clicking the Start Button, then selecting Program, DeviceNet

Tools, 3G8F5/3G8E2-DRM21 Setup, 3G8F5/3G8E2-DRM21-Setup.

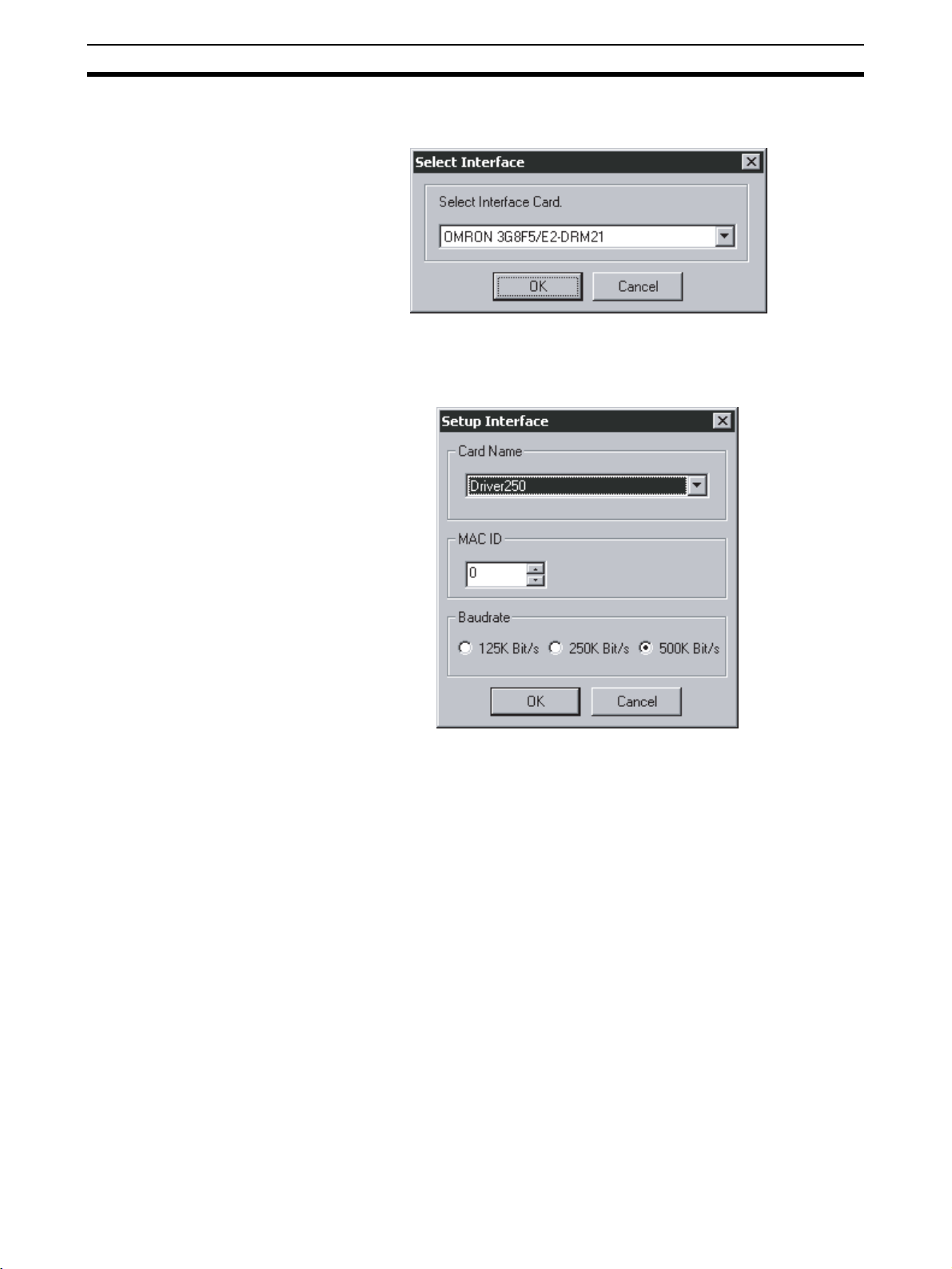

10. The setup program for the device driver will start. There is already a card

driver registered, so click the Edit Button. The New selection is used to add

a driver for the ISA Board or PCMCIA Card.

The Remove selection is used to delete the selected driver.

Note a) The card name that is displayed first depends on the operating en-

vironment.

b) The card name registered here will be used on the Configurator to

access the ISA Board or PCMCIA Card.

c) Register a name for each ISA Board and PCMCIA Card.

11. Set the I/O port address, memory address, and interrupt (IRQ) for the ISA

Board or PCMCIA Card being used with the Configurator. (Refer to the

screen in step 12. )

12. Input the I/O port address set on the board’s DIP switch and input a memory address that is available in the computer. Set the interrupt to None.

The Card Name and Driver Name can be changed if necessary.

Make sure that all of the settings are correct and click the OK Button. The

Configuration Window shown in step 10 will be displayed.

Note a) The Configurator does not use interrupts. Set the interrupt level to

None.

b) Do not select -V1 Type in the above Card Setup Dialog Box when

using an ISA Board.

23

Page 43

PCMCIA Card Installation Section 2-3

13. Click the OK Button to exit the setup program.

With Windows 95/98, the Configurator can be run immediately. Click the

OK Button to start the Configurator. With Windows NT, a pop-up window

will be displayed asking whether or not to restart Windows.

14. This completes installation of the 3G8F5-DRM21-E Driver Setup Software.

2-3 PCMCIA Card Installation

This section explains how to set the PCMCIA Card used by the Configurator

and install the card in the computer.

2-3-1 Preparation for Installation

Before installing the PCMCIA Card, check the items listed in the following

table.

Item Description

Windows OS Verify that the OS is Windows 95, 98, Me, 2000, or XP. The PCMCIA Card can only be used in this

environment.

Unused card slot Verify that there is an unused card slot (type II) in the computer.

Available memory The PCMCIA Card used by the Configurator

Unused I/O port

address

occupies 16 KB of memory as a system

resource. Verify that the computer has 16 KB of

available memory.

The PCMCIA card used by the Configurator

occupies 3 ports as a system resource. Verify

that the computer has 3 I/O port addresses

available.

Note The 3G8E2-DRM21-EV1 PCMCIA Card for the Configurator can’t be used

with the Windows NT4.0 operating system.

The PCMCIA Card memory and I/O port combinations used by the Configurator are set automatically by the Windows 95/97 Plug & Play

feature. Use one of the automatically set combinations.

24

Page 44

PCMCIA Card Installation Section 2-3

2-3-2 PCMCIA Card Components and Functions

The following diagram shows the main components of the Configurator’s

PCMCIA Card (Card and Unit sections) and their functions.

Unit section

This section controls DeviceNet

communications.

MS LED

NS LED

LED Indicators

Indicate the status of the PCMCIA

Card and the DeviceNet networ

Card section

This section is inserted into the

computer's card slot.

k.

2-3-3 PCMCIA Card Setup

The operations and displays shown in the following procedure may differ

slightly depending on the version of Windows software being used. Use the

following procedure for setup.

Before Starting the Setup Before starting the setup procedure, remove any PCMCIA Cards (including

those used by the Configurator) that are currently being used. Since the PCMCIA Card can’t be used temporarily during the setup, it may not be possible to

continue the setup operation midway through the operation.

PCMCIA Card Setup

1,2,3... 1. Insert the 3G8F5/3G8E2-DRM21 setup disk into the CD-ROM drive.

2. Install the PCMCIA Card when the Windows system is active. The PCMCIA Card will be recognized as new hardware and the Add New Hardware

Wizard Window will be displayed. Click the Next Button.

25

Page 45

PCMCIA Card Installation Section 2-3

3. Select Search for the best driver for your device as the driver search

method, then click the Next Button.

4. Select CD-ROM drive as the driver location to be searched, then click the

Next Button.

26

5. The driver file will be recognized as shown below. Click the Next Button to

install the driver.

Page 46

PCMCIA Card Installation Section 2-3

6. After the driver has been installed, click the Finish Button.

Verifying Driver Resources

1,2,3... 1. Check that the driver has been installed correctly, as follows:

Click the Start Button, select Control Panel from the Settings Menu, double-click the System Icon in the Control Panel, and select the Device Man-

ager Tab from the top of the System Properties Window (refer to page 24).

Check that SST Device has been added. Then click the + to the left of SST

Devices to check that the PCMCIA Card driver 3G8E2-DRM21-V1 or

5136-DNP-PCM(n) (where n is the PCMCIA slot number) is displayed and

that x or ! is not displayed next to it.

2. Verify the resources currently being used, as follows:

Double-click 3G8E2-DRM21-V1 or 5136-DNP-PCM(n) to display the

3G8E2-DRM21-V1 or 5136-DN-PCM(n) Properties Window and select the

27

Page 47

PCMCIA Card Installation Section 2-3

Resources Tab from the top of the window. The automatically set Input/

Output Range and Memory Range values will be displayed.

This completes installation of the PCMCIA Card driver. Write down the values of Input/Output Range and Memory Range because these will be

needed later when installing the Configurator.

2-3-4 3G8F5/3G8E2-DRM21 Driver Setup Software Installation

The operations and displays shown in the following procedure may differ

slightly depending on the version of Windows software being used. The displays for Windows 98 are shown here.

1,2,3... 1. Exit all other Windows-based programs.

2. Insert 3G8F5/3G8E2-DRM21 setup disk into the CD-ROM drive.

3. Double-click Setup.exe.

The 3G8F5/3G8E2-DRM21’s setup program will start.

The following window will be displayed when the setup program has been

loaded. Click the Next Button after reading the precautions.

28

Page 48

PCMCIA Card Installation Section 2-3

4. Specify the destination directory for the driver files. If the default directory

shown in the window is acceptable, click the Next Button. To specify a different directory, click the Browse Button, specify the desired directory, and

click the Next Button. If a new directory is specified, the software will create

it automatically.

5. Select 3G8F5-DRM21-V1/3G8E2-DRM21-V1.

6. Specify the name of the 3G8F5/3G8E2-DRM21 program folder where the

Software icons will be registered. If the default program folder is acceptable, click the Next Button. To specify a different folder, select an existing

folder or enter a new folder name and then click the Next Button.

29

Page 49

PCMCIA Card Installation Section 2-3

Note The program folder name specified here will be registered under De-

viceNet Tools in the Start Menu.

7. The installation program will be started and the 3G8F5/3G8E2-DRM21

files will be copied to the destination directory.

8. A program group folder will be created automatically when the 3G8F5/

3G8E2-DRM21 Driver Setup Software installation has been completed.

9. A pop-up window will be displayed asking whether you want to setup the

ISA Board or PCMCIA Card. Click the Yes Button. If you click the No But-

ton, the installation program will end without performing the setup for the

ISA Board or PCMCIA Card.

30

Note The setup for the ISA Board or PCMCIA Card can be performed later

by clicking the Start Button, then selecting Program, DeviceNet

Tools, 3G8F5/3G8E2-DRM21 Setup, 3G8F5/3G8E2-DRM21-Setup.

10. The setup program for the device driver will start. There is already a card

driver registered, so click the Edit Button. The New selection is used to add

a driver for the ISA Board or PCMCIA Card.

Page 50

PCMCIA Card Installation Section 2-3

The Remove selection is used to delete the selected driver.

Note a) The card name that is displayed first depends on the operating en-

vironment.

b) The card name registered here will be used on the Configurator to

access the ISA Board or PCMCIA Card.

c) Register a name for each ISA Board and PCMCIA Card.

11. Set the I/O port address, memory address, and interrupt (IRQ) for the ISA

Board or PCMCIA Card being used with the Configurator. (Refer to the

screen in step 12. )

12. Input the values that were confirmed in the PCMCIA Card setup for the I/

O Port, Memory Address, and Interrupt (IRQ).

Select -V1 Type in the Card Setup Dialog Box shown below when using the

3G8E2-DRM21-EV1.

The Card Name and Driver Name can be changed if necessary.

Make sure that all of the settings are correct and click the OK Button. The

Configuration Window shown in step 10 will be displayed.

Note The Configurator does not use interrupts. Set the interrupt level to

None.

31

Page 51

Configurator Installation Section 2-4

13. Click the OK Button to exit the setup program.

With Windows NT, a pop-up window will be displayed asking whether or

not to restart Windows.

14. This completes installation of the 3G8E2-DRM21-EV1 Driver Setup Software.

2-4 Configurator Installation

This section explains how to install the Configurator. The Configurator is

installed by executing the setup program of the Configurator.

Preparation for

Installation

Installation The operations and displays shown in the following procedure may differ

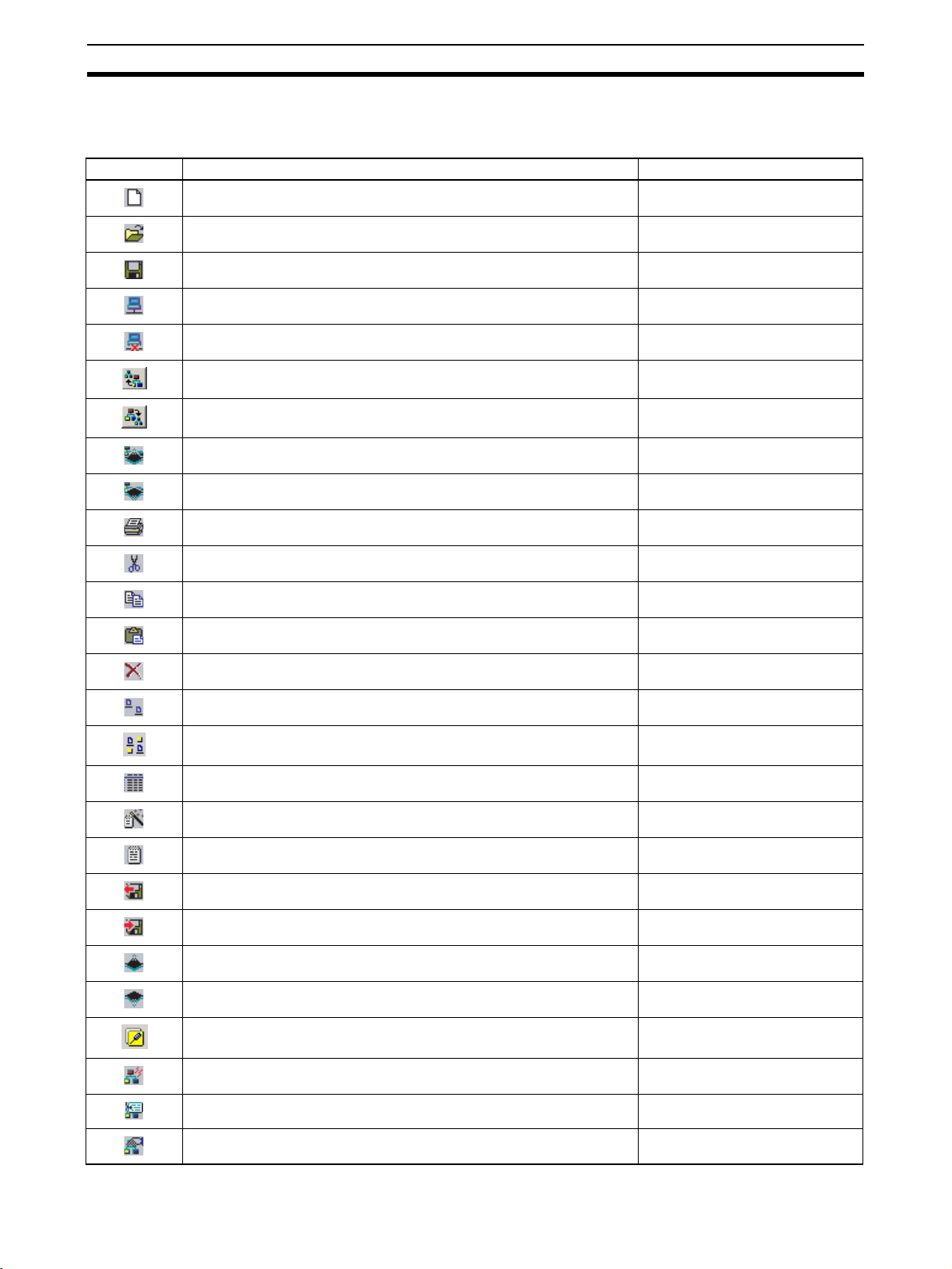

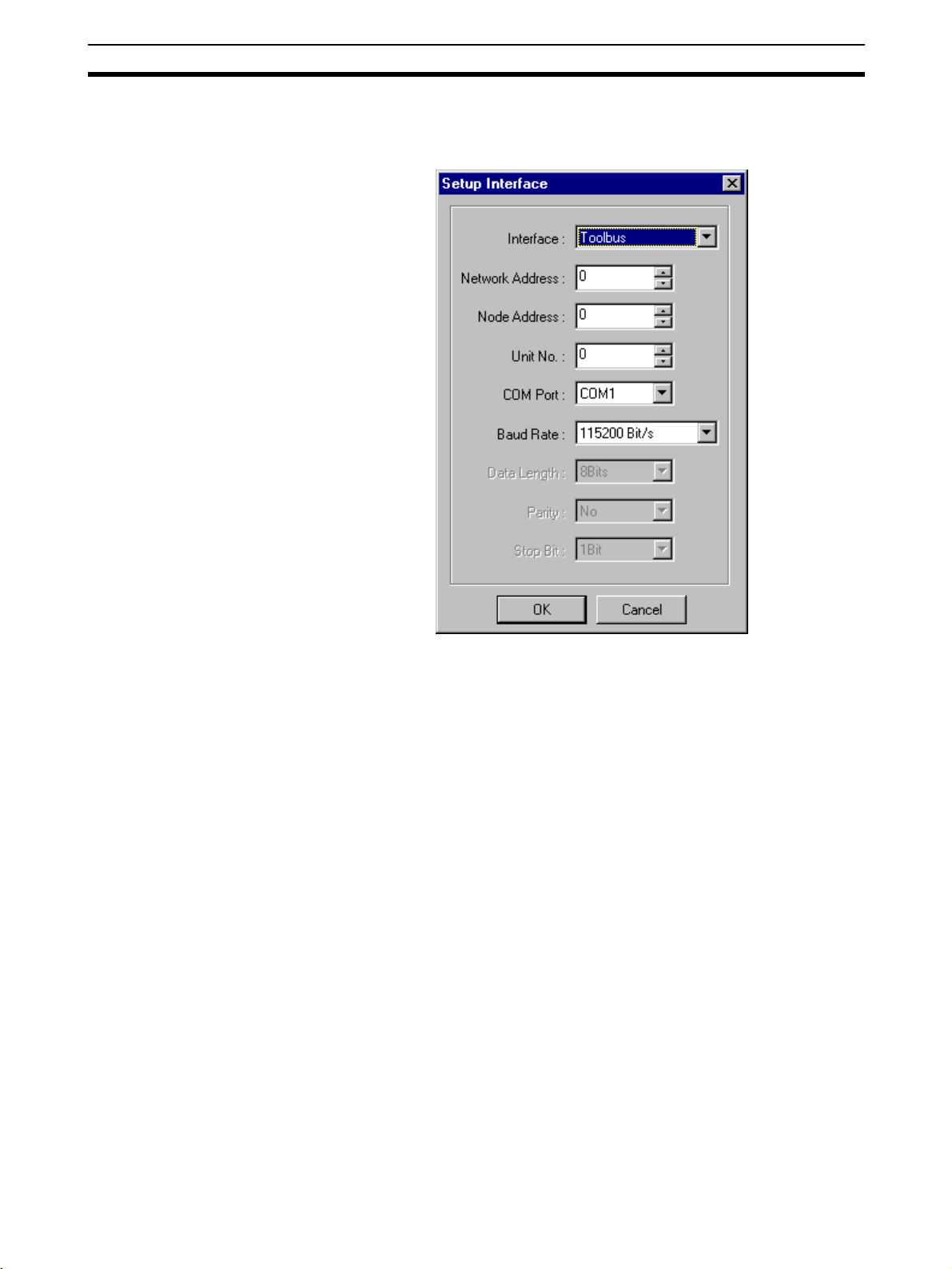

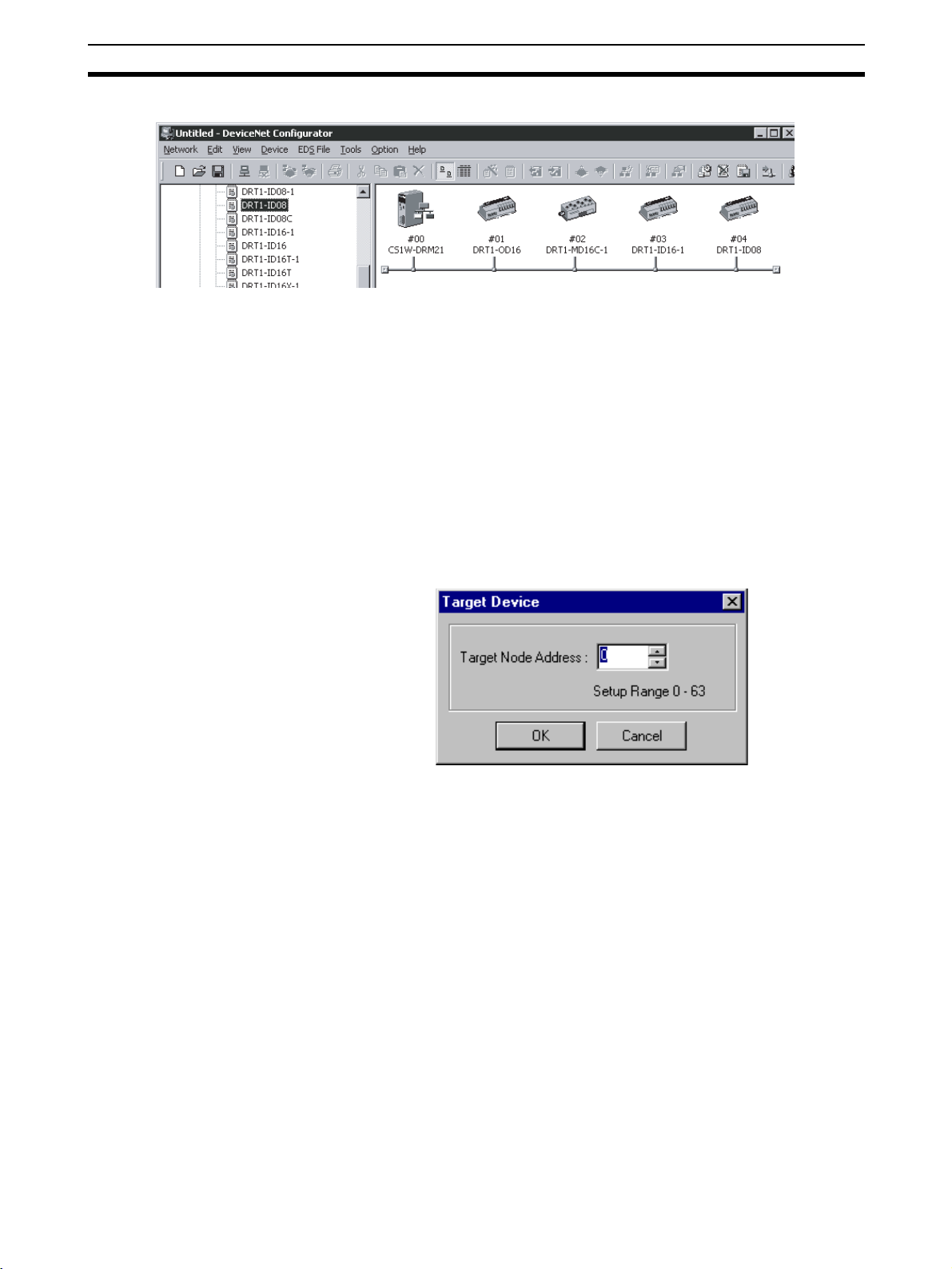

1,2,3... 1. Exit all other Windows-based programs.