Omron 3G3RX2-A2037, 3G3RX2-A2022, 3G3RX2-A2004, 3G3RX2-A4007, 3G3RX2-A4015 Instruction Manual

...Page 1

高機能型汎用インバータ

RX2シリーズ(形3G3RX2-□□□□□)

取扱説明書

このたびは、インバータ形3G3RX2シリーズをお買い求めいただきまして、誠にありがとうございます。

この製品を安全に正しくご使用いただくために、お使いになる前に、この取扱説明書と安全上のご注

意および下記のマニュアルを熟読し、機器の知識、安全上の情報、注意事項のすべてについて習熟し

てから使用してください。また、お読みになったあとも、お使いになるときにはいつでも見られるように、

本書とユーザーズマニュアルは、最終的にお使いになる方のお手元にも届けられるよう、お取り計らい

をお願いします。

ユーザーズマニュアル SBCE -4 37

OMRONCorporation2019AllRightsReserved.

PIM2824133-4A

NT3171

Page 2

ご承諾事項

ご承諾事項

「当社商品」について特別の合意がない場合には、お客様のご購入先にかかわらず、本ご承諾事項記

載の条件を適用いたします。

定義

本ご承諾事項中の用語の定義は次のとおりです。

• 「当社商品」:「当社」の FA システム機器、汎用制御機器、センシング機器、電子・機構部品

• 「カタログ等」:「当社商品」に関する、ベスト制御機器オムロン、電子・機構部品総合カタロ

グ、その他のカタログ、仕様書、取扱説明書、マニュアル等であって電磁的方法で提供される

ものも含みます。

• 「利用条件等」:「カタログ等」に記載の、「当社商品」の利用条件、定格、性能、動作環境、取

り扱い方法、利用上の注意、禁止事項その他

• 「お客様用途」:「当社商品」のお客様におけるご利用方法であって、お客様が製造する部品、電

子基板、機器、設備またはシステム等への「当社商品」の組み込み、または利用を含みます。

• 「適合性等」:「お客様用途」での「当社商品」の (a) 適合性、(b) 動作、(c) 第三者の知的財産

の非侵害、(d) 法令の遵守および (e) 各種規格の遵守

記載事項のご注意

「カタログ等」の記載内容については次の点をご理解ください。

• 定格値および性能値は、単独試験における各条件のもとで得られた値であり、各定格値および

性能値の複合条件のもとで得られる値を保証するものではありません。

• 参考データはご参考として提供するもので、その範囲で常に正常に動作することを保証するも

のではありません。

• 利用事例はご参考ですので、「当社」は「適合性等」について保証いたしかねます。

• 「当社」は、改善や当社都合等により、「当社商品」の生産を中止し、または「当社商品」の仕

様を変更することがあります。

ご利用にあたってのご注意

ご採用およびご利用に際しては次の点をご理解ください。

• 定格・性能ほか「利用条件等」を遵守しご利用ください。

• お客様ご自身にて「適合性等」をご確認いただき、「当社商品」のご利用の可否をご判断ください。

「当社」は「適合性等」を一切保証いたしかねます。

• 「当社商品」がお客様のシステム全体の中で意図した用途に対して、適切に配電・設置されてい

ることをお客様ご自身で、必ず事前に確認してください。

• 「当社商品」をご使用の際には、(i) 定格および性能に対し余裕のある「当社商品」のご利用、冗長

設計などの安全設計、(ii) 「当社商品」が故障しても、「お客様用途」の危険を最小にする安全設計、

(iii) 利用者に危険を知らせるための、安全対策のシステム全体としての構築、(iv) 「当社商品」お

よび「お客様用途」の定期的な保守、の各事項を実施してください。

• 「当社」は DDoS 攻撃(分散型 DoS 攻撃)、コンピュータウイルスその他の技術的な有害プログ

ラム、不正アクセスにより、「当社商品」、インストールされたソフトウェア、またはすべての

コンピュータ機器、コンピュータプログラム、ネットワーク、データベースが感染したとして

も、そのことにより直接または間接的に生じた損失、損害その他の費用について一切責任を負

わないものとします。

2

Page 3

ご承諾事項

お客様ご自身にて、①アンチウイルス保護、②データ入出力、③紛失データの復元、④「当社商

品」またはインストールされたソフトウェアに対するコンピュータウイルス感染防止、⑤「当社

商品」に対する不正アクセス防止についての十分な措置を講じてください。

• 「当社商品」は、一般工業製品向けの汎用品として設計製造されています。従いまして、次に掲

げる用途での使用は意図しておらず、お客様が「当社商品」をこれらの用途に使用される際には、

「当社」は「当社商品」に対して一切保証をいたしません。ただし、次に掲げる用途であっても

「当社」の意図した特別な商品用途の場合や特別の合意がある場合は除きます。

(a) 高い安全性が必要とされる用途(例:原子力制御設備、燃焼設備、航空・宇宙設備、鉄道設

備、昇降設備、娯楽設備、医用機器、安全装置、その他生命・身体に危険が及びうる用途)

(b) 高い信頼性が必要な用途(例:ガス・水道・電気等の供給システム、24 時間連続運転シス

テム、決済システムほか権利・財産を取扱う用途など)

(c) 厳しい条件または環境での用途(例:屋外に設置する設備、化学的汚染を被る設備、電磁

的妨害を被る設備、振動・衝撃を受ける設備など)

(d) 「カタログ等」に記載のない条件や環境での用途

• 上記の (a) から (d) に記載されている他、「本カタログ等記載の商品」は自動車(二輪車含む。

以下同じ)向けではありません。自動車に搭載する用途には利用しないで下さい。自動車搭載

用商品については当社営業担当者にご相談ください。

保証条件

「当社商品」の保証条件は次のとおりです。

• 保証期間 ご購入後 1 年間といたします。

(ただし「カタログ等」に別途記載がある場合を除きます。)

• 保証内容 故障した「当社商品」について、以下のいずれかを「当社」の任意の判断で実施し

ます。

(a) 当社保守サービス拠点における故障した「当社商品」の無償修理

(ただし、電子・機構部品については、修理対応は行いません。)

(b) 故障した「当社商品」と同数の代替品の無償提供

• 保証対象外 故障の原因が次のいずれかに該当する場合は、保証いたしません。

(a)「当社商品」本来の使い方以外のご利用

(b)「利用条件等」から外れたご利用

(c) 本ご承諾事項「ご利用にあたってのご注意」に反するご利用

(d)「当社」以外による改造、修理による場合

(e)「当社」以外の者によるソフトウェアプログラムによる場合

(f) 「当社」からの出荷時の科学・技術の水準では予見できなかった原因

(g) 上記のほか「当社」または「当社商品」以外の原因(天災等の不可抗力を含む)

責任の制限

本ご承諾事項に記載の保証が、「当社商品」に関する保証のすべてです。

「当社商品」に関連して生じた損害について、「当社」および「当社商品」の販売店は責任を負い

ません。

輸出管理

「当社商品」または技術資料を、輸出または非居住者に提供する場合は、安全保障貿易管理に関す

る日本および関係各国の法令・規制を遵守ください。お客様が法令・規則に違反する場合には、

「当社商品」または技術資料をご提供できない場合があります。

3

Page 4

安全上のご注意

危険

警告

注意

安全上のご注意

正しい取り扱いをしなければ、この危険のために、時 に死亡に至っ

たり、重傷を負う場合も起こり得ます。

また、同様に深刻な物的損害を受けるおそれがありま す。

正しい取り扱いをしなければ、この危険のために、軽 傷や中程度の

傷害を負ったり、万一の場合には重症や死亡に至るお それがありま

す。また、同様に重大な物的損害を受けるおそれがあ ります。

正しい取り扱いをしなければ、この危険のために、時 に軽傷や中程

度の傷害を負ったり、あるいは物的損害を受けるおそ れがあります。

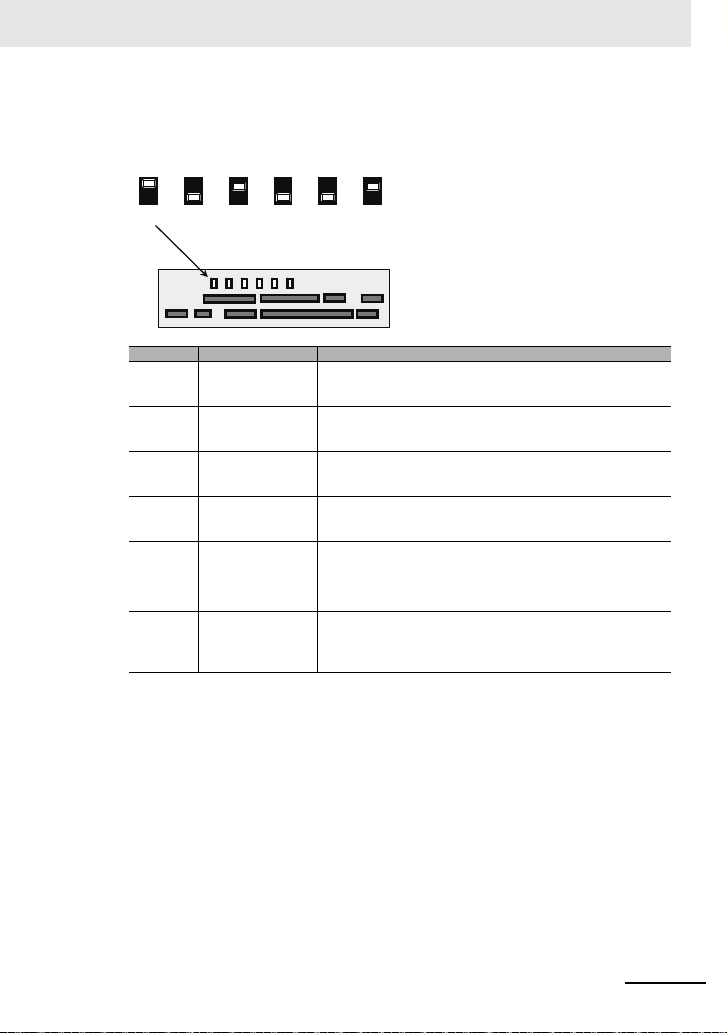

図記号の説明

本文中に図記号を用いた注記を記載しています。

本内容にも十分注意をはらい、必ず守ってください。

記号は禁止(してはいけないこと)を示します。

具体的な内容は、 の中や近くに絵や文章で示します。

左図の場合は、「分解禁止」を示します。

記号は危険、注意を示します。

具体的な内容は、 の中や近くに絵や文章で示します。

左図の場合は、「感電による危険」を示します。

記号は危険、注意を示します。

具体的な内容は、 の中や近くに絵や文章で示します。

左図の場合は、「特定しない一般的な危険」を示します。

記号は危険、注意(警告を含む)を意味しています。

具体的な内容は、 の中と文章で示します。

左図の場合は、「高温注意」を示します。

記号は強制(必ず守ること)を示します。

具体的な内容は、 の中や近くに絵や文章で示します。

左図の場合は、「一般的な強制事項」を示します。

記号は強制(必ず守ること)を示します。

具体的な内容は、 の中と文章で示します。

左図の場合は、「必ずアース接地すること」を示します。

4

Page 5

万一の場合、感電による重度の傷害が起こるおそれがあります。

警告

*1. 10 分 : 形 3G3RX2-A2004 〜 -A2220 および形 3G3RX2-A4007 〜 A4220

*2. 15 分 : 形 3G3RX2-A2300 〜 -A2550、形 3G3RX2-A4300 〜 -A4550、-B4750、

-B4900、-B411K、-B413K

入力電源 OFFを確認してから正しく配線してください。

万一の場合、感電による重度の傷害が起こるおそれがあります。

配線作業は、電気工事の専門家が行ってください。

万一の場合、感電による重度の傷害が起こるおそれがあります。

配線変更、スライドスイッチ(SW1 〜 SW6)の変更、オペレータ・オプ

ション類の脱着、冷却ファンの交換はインバータの入力電源を OFFにして

から行ってください。

万一の場合、感電・発火による重度の傷害が起こるおそれがあります。

接地端子は必ずアースしてください。

(200V 級 :D 種接地、400V 級 :C 種接地)

万一の場合、感電による重度の傷害が起こるおそれがあります。

通電中および電源遮断後 15 分以内 *1*2 は端子台カバーを外さないでくだ

さい。

万一の場合、感電による重度の傷害が起こるおそれがあります。

濡れた手でオペレータ、スイッチ類を操作しないでください。

万一の場合、感電による重度の傷害が起こるおそれがあります。

緊急遮断入力機能が働いた状態になっても、主電源が遮断されたわけでは

ありません。

製品の確認は、インバータの入力電源を OFFにしてから行ってください。

やけどのおそれがあります。

通電中や電源遮断後のしばらくの間は、インバータのフィン、制動抵抗器、

モータなどは高温になる場合がありますので触れないでください。

安全上のご注意

5

Page 6

安全上のご注意

注意

保守や点検、部品交換を行う際は、安全を確保したあとで行ってください。

軽度の発火、発熱、機器破損がまれに起こるおそれがあります。

端子(PD/+1,P/+,N/ −)に抵抗器を直接接続しないでください

軽度の傷害がまれに起こるおそれがあります。

安全を確保するための停止装置を設置してください。

※ 保 持用に選定されたブレーキは安全を確保するための停止装置ではあり

ません

制動抵抗器や回生制動ユニットの発熱により、中程度のやけどがまれに起

こるおそれがあります。

必ず指定された制動抵抗器や回生制動ユニットを使用し、制動抵抗器を使

用する場合には、抵抗器の温度を監視するサーマルリレーを設置してくだ

さい。

また、制動抵抗器や回生制動ユニットの異常過熱時にインバータの電源を

OFF するシーケンスを組んでください。

製品内部には高電圧部分があり、短絡させると製品の破損や物的損害がま

れに起こるおそれがあります。設置や配線時には切り粉やリード線くずな

どの金属物が製品内部に入らないようにカバーをつけるなどの処置を行っ

てください。

負荷の短絡により物的損害がまれに起こるおそれがあります。

インバータの電源側にはインバータ容量に応じた配線用遮断器(MCCB)

を設置するなどの安全対策を施してください

けがのおそれがあります。

分解や修理、改造は行わないでください。

立ち上げ時、調整時、メンテナンス時、交換時にパラメータを誤って設定

すると予期せぬ動作が起きるおそれがあります。

出力端子機能が出力中に、DriveProgramming が停止すると、出力状態を

保持したままになりますので、周辺機器を停止させるなど安全対策を施し

てください。

6

Page 7

安全上の要点

設置・保管

下記環境下での保管および使用は避けてください。

• 日光が直接当たる場所

• 周囲温度が仕様を超える場所

• 相対湿度が仕様を超える場所

• 温度の変化が急激で結露するような場所

• 腐食性ガス、可燃性ガスのある場所

• 可燃物またはその近くの場所

• ちり、ほこり、塩分、鉄粉が多い場所

• 水、油、薬品などの飛まつがかかる場所

• 本体に直接振動や衝撃が伝わる場所

輸送・設置・配線

• 部品の故障、製品故障の原因となります。強い衝撃を与えたり、落下させたりしないでください。

• 運搬時は、フロントカバー・端子台カバーを持たずにフィンを持ってください。

• インバータの入力電源定格電圧と、交流電源の電圧が一致していることを確認してください。

• 製品が破損しますので、制御入出力端子に交流電源を接続しないでください。

• 端子台のねじは確実に締め付けてください。また、配線は本体を据え付けてから行ってください。

• 本製品の出力 (U、V、W) に三相誘導モータ以外の負荷を接続しないでください。

• 次のような場所で使用する際は、遮断対策を十分に行ってください。機器破損の原因となります。

• 静電気などによるノイズが発生する場所

• 強い磁界が生じる場所

• 電源線が近くを通る場所

• DriveProgramming を使用する場合は、プログラムデータが正常にダウンロードできたことを確認

してから動作を開始してください。

運転・調整

• 本製品は低速から高速までの設定ができますので、使用するモータ設備の許容範囲を十分確認した

あとで運転を行ってください。

• 保持用にブレーキが必要な場合は、別に用意してください。

• DriveProgramming で時刻機能を使用して制御を行う場合、LCD オペレータの電池消耗で予期せ

ぬ動作が起きるおそれがあります。

電池消耗は、[E042]RTC エラーで検出し、インバータまたはプログラムを停止させるなどの対策

を行ってください。

LCD オペレータが取り外されたり、断線したりした場合、DriveProgramming は時刻機能で待機

状態になります。

• 運転信号を入れたままアラームリセットを行うと突然始動することがありますので、運転信号が切

れていることを確認してからアラームリセットを行ってください。

• 瞬停・不足電圧減速停止後や、リセット時に再始動となる設定 (bA-30,bb-20,bb-21) を行うと、

電源復帰後に突然再始動しますので注意してください。

• オペレータのストップボタンは機能設定したときだけ有効ですので、緊急停止スイッチは別に用意

してください。

• 通電中に信号チェックを行い、誤って制御入力端子に電圧が印加されるとモータが突然動き出すこ

とがあります。信号チェックを行う際は安全を確かめて行ってください。

• 運転時にモータの回転方向、異常音、振動を確認してください。

安全上の要点

7

Page 8

安全上の要点

保守・点検

• コンデンサの寿命は周囲温度に影響されます。ユーザーズマニュアルに記載されている製品寿命

カーブをご覧ください。コンデンサが寿命に達し、製品として機能を果たさなくなった場合には、

本体の交換が必要となります。

• LCD オペレータで不要になった電池の廃棄については、地方自治体により規制を受ける場合があ

ります。それぞれの自治体規制に従って廃棄してください。電池を廃棄する際は、電池をテープな

どで絶縁してから廃棄してください。

リチウム一次電池(過塩素酸塩含有率が 6ppb 以上)を組み込んだ製品が米国・カリフォルニア

州へ輸出・経由される場合、次の表示が義務化されています。

PerchlorateMaterial-specialhandlingmayapply.

Seewww.dtsc.ca.gov/hazardouswaste/perchlorate

リチウム一次電池が組み込まれた貴社製品を米国・カリフォルニア州へ輸出される場合は、貴社

製品の梱包箱または輸送箱などに上記表示を行っていただくようお願いします。

• 電池は液漏れ、破裂、発熱、発火などのおそれがありますので、+、−の短絡、充電、分解、加

熱、火への投入、強い衝撃を与えることなどは絶対に行わないでください。また、床に落下させる

などして強い衝撃をあたえてしまった電池は、液漏れするおそれがありますので絶対に使用しない

でください。

• 電池の交換は熟練した技術者によって行われることが UL 規格で定められています。交換作業は熟

練した技術者がご担当ください。また、本マニュアルに記載された方法で交換してください。

• LCD オペレータの表示が寿命で認識できなくなった場合は、LCD オペレータを交換してください。

8

Page 9

使用上の注意

WEEE 指令に従った廃棄をお願いするマークです。

取り付け

取付方向は縦長方向で壁取り付けとしてください。

また、取り付け壁の材質は金属板等の不燃材としてください。

設置・配線

ご使用のエンコーダ用電源か製品の定格電圧(DC + 12V または DC + 5V)と一致していることを

確認してください。

再始動選択機能

再始動選択機能(bb-24)トリップリトライ機能(bb-28)を使用すると、アラーム停止後に突然始

動しますので、近寄らないでください。

保守・部品の交換

• インバータは数多くの部品より構成されており、これらの部品がすべて正常に動作しなければ本来

の機能を発揮することはできません。

このため、定期的な点検により、部品や装置が不具合に至る前兆をできるだけ早い時期に発見し、

処置を行う必要があります。

また、これらの部品は無期限に継続して使用できるものではなく、正常な使用状態においても、そ

の種類により定まる或る年数、即ち耐用年数を経過すると特性の変化や動作不良を起こし易くなる

ものであり、一定期間を経過する毎に部品の交換を行わねばインバータの特性の変化や故障の発生

を防止することはできません。(JEMA 発行「汎用インバータ定期点検のおすすめ」から引用)

• 冷却ファンが寿命に達したときは、修理を依頼してください。

製品の廃棄

本製品を廃棄する際は、条例などの規則に従ってください。

使用上の注意

9

Page 10

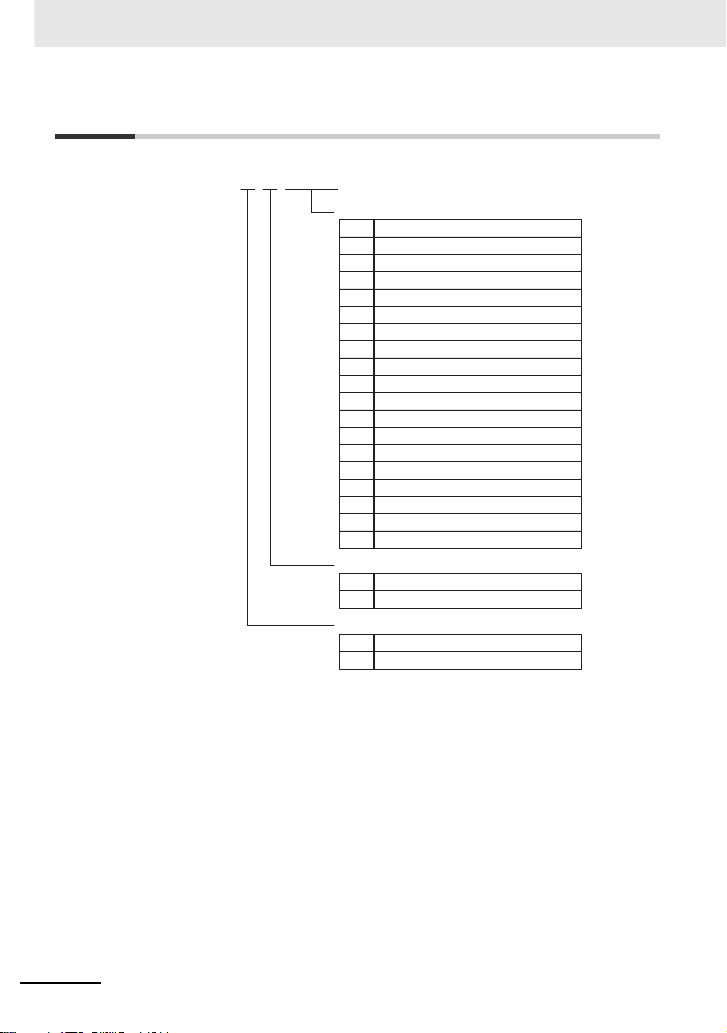

形式基準

最大適用モータ容量(ND)

電圧クラス

保護構造

形3G3RX2-A2055

004

007

015

022

037

055

075

110

150

185

220

300

370

450

550

750

900

11K

13K

0.4kW

0.75kW

1.5kW

2.2kW

3.7kW

5.5kW

7.5kW

11kW

15kW

18.5kW

22kW

30kW

37kW

45kW

55kW

75kW

90kW

110kW

132kW

24三相 AC200V(200V 級)

三相 AC400V(400V 級)

ABIP20*/ULopentype

IP00/ULopentype

* 社内試験による自己宣言です。

形式基準

10

Page 11

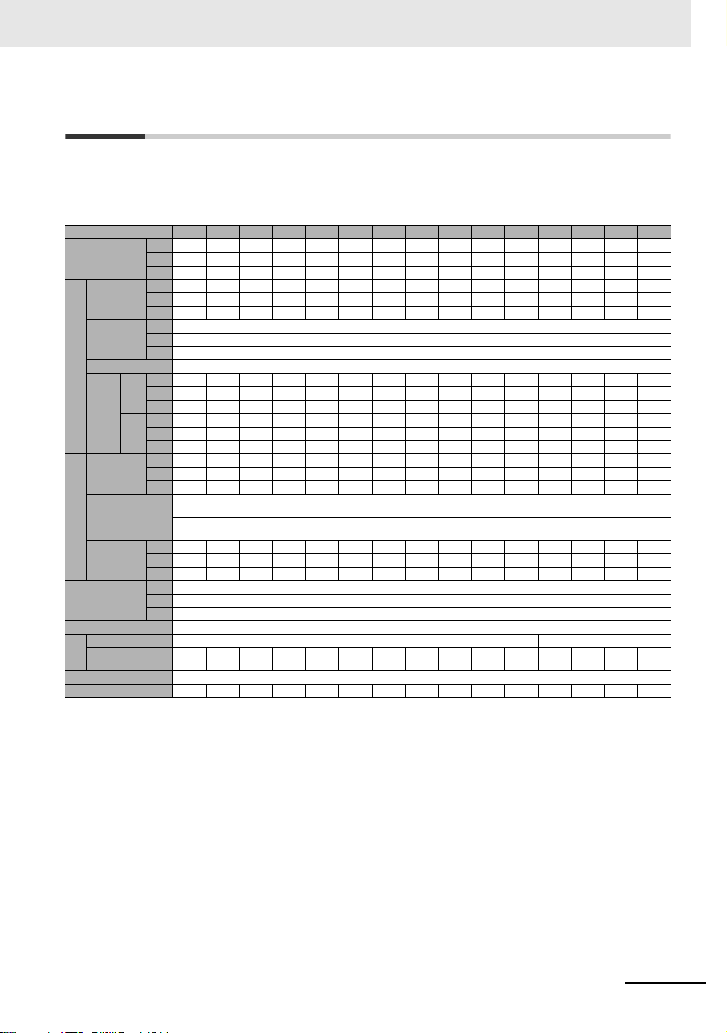

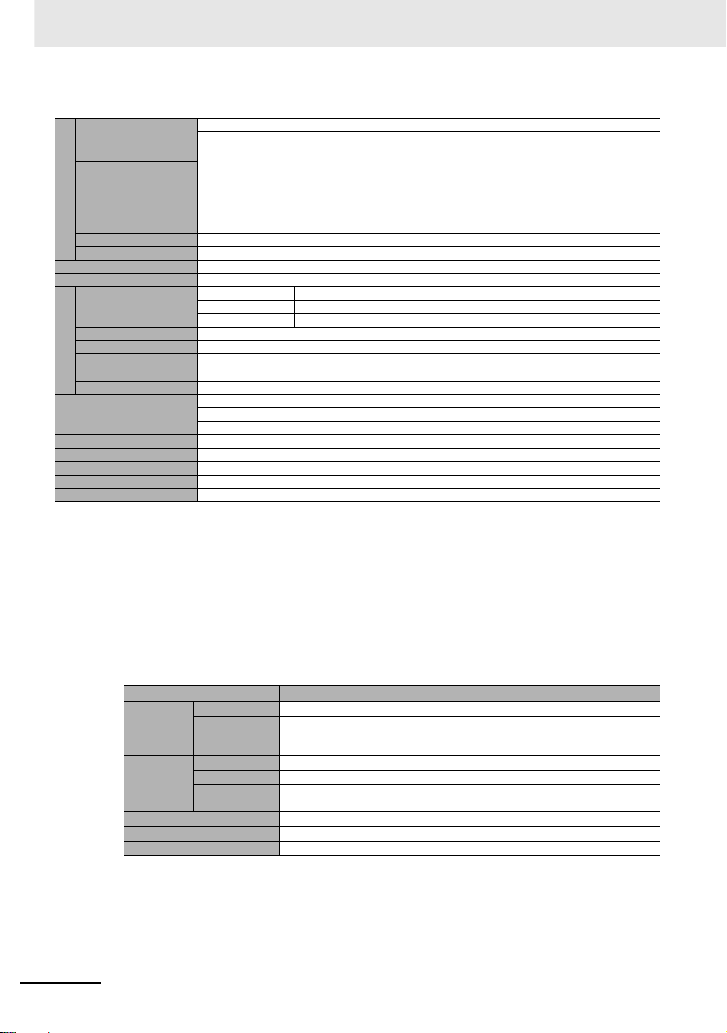

仕様

仕様

■仕様

200V 級

形 3G3RX2-A2 □□□□□

適用モータ

(4 極)

容量(kW)

定格出力

電流(A)

過負荷

電流定格

出

定格出力電圧 三相(3 線)200 〜240V(受 電電圧に依存します)

力

定格

容量

(kVA)

定格入力

電流(A)*1

入

定格入力

力

交流電圧

電源設備

容量(kVA)

*2

キャリア

周波数

変更範囲 *3

モータ始動トルク *4 200%/0.3Hz

回生制動 制動抵抗動作回路内蔵(放電抵抗別置) 回生制動ユニット別置

制

接続可能な

動

最小抵抗値(Ω)

保護構造 IP20*5/ULopentype

概略質量(kg) 3333366610101022333347

*1. 定格入力電流は、定格電流出力時の値です。電源側のインピーダンス(配線、ブレーカ、入 力リアクトルオプションなど)により値が変わります。定格

銘板の数値と異なりますが、この電流値を参考に余裕をもって周辺機器を選定してください。

*2. 電源設備容量は、220V 出力の定格電流出力時の値です。電源側のインピーダンス(配線、ブレーカ、入力リアクトルオプションなど)により値が変わ

ります。

*3. キャリア周波数[bb101]/[bb201]の設定は、表記に従って定格設定に、内部で制限がかかります。また、キャリア周波数[bb101]/[bb201]

の設定は、(駆動する最大出力周波数 ×10)Hz 以上になるように設定してください。誘導モータ(IM)制御の場合、V/f 制御以外の制御は、キャリア

周波数を 2kHz 以上に設定してください。同期モータ(SM)/ 永久磁石モータ(PMM)制御の場合、キャリア周波数を 8kHz 以上に設定してくださ

い。

*4. 標準モータで ND 定格におけるセンサレスベクトル制御適用時の値。トルク特性は、制御方式やご使用のモータにより異なる場合があります。

*5. 社内試験による自己宣言です。

A2004 A2007 A2015 A2022 A2037 A2055 A2075 A2110 A2150 A2185 A2220 A2300 A2370 A2450 A2550

VLD 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75

LD 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75

ND 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

VLD 4.4 8.0 10.4 15.6 22.8 33.0 46.0 60.0 80.0 93.0 124 153 185 229 295

LD 3.7 6.3 9.4 12.0 19.6 30.0 40.0 56.0 73.0 85.0 113 140 169 210 270

ND 3.2 5.0 8.0 11.0 17.5 25.0 32.0 46.0 64.0 76.0 95.0 122 146 182 220

VLD 110%60sec/120%3sec

LD 120%60sec/150%3sec

ND 150%60sec/200%3sec

VLD 1.5 2.8 3.6 5.4 7.9 11.4 15.9 20.8 27.7 32.2 43.0 53.0 64.1 79.3 102.2

200

LD 1.3 2.2 3.3 4.2 6.8 10.4 13.9 19.4 25.3 29.4 39.1 48.5 58.5 72.7 93.5

V

ND 1.1 1.7 2.8 3.8 6.1 8.7 11.1 15.9 22.2 26.3 32.9 42.3 50.6 63.0 76.2

VLD 1.8 3.3 4.3 6.5 9.5 13.7 19.1 24.9 33.3 38.7 51.5 63.6 76.9 95.2 122.6

240

LD 1.5 2.6 3.9 5.0 8.1 12.5 16.6 23.3 30.3 35.3 47.0 58.2 70.3 87.3 112.2

V

ND 1.3 2.1 3.3 4.6 7.3 10.4 13.3 19.1 26.6 31.6 39.5 50.7 60.7 75.7 91.5

VLD 5.2 9.5 12.4 18.6 27.1 39.3 54.8 71.4 95.2 110.7 147.6 182.1 220.2 272.6 351.2

LD 4.4 7.5 11.2 14.3 23.3 35.7 47.6 66.7 86.9 101.2 134.5 166.7 201.2 250.0 321.4

ND 3.8 6.0 9.5 13.1 20.8 29.8 38.1 54.8 76.2 90.5 113.1 145.2 173.8 216.7 261.9

VLD 2.0 3.6 4.7 7.1 10.3 15.0 20.9 27.2 36.3 42.2 56.3 69.4 83.9 103.9 133.8

LD 1.7 2.9 4.3 5.4 8.9 13.6 18.1 25.4 33.1 38.6 51.3 63.5 76.7 95.3 122.5

ND 1.5 2.3 3.6 5.0 7.9 11.3 14.5 20.9 29.0 34.5 43.1 55.3 66.2 82.6 99.8

VLD 0.5 〜 10.0kHz

LD 0.5 〜 12.0kHz

ND 0.5 〜 16.0kHz

50 50 35 35 35 16 10 10 7.5 7.5 5 - - - -

制御電源:電源単相200 〜 240V/ 許容変動幅 170 〜264V、

50Hz(許容変動幅 47.5 〜 52.5Hz)/60Hz(許容変動幅 57 〜 63Hz)

主回路電源:三相(3 線)200 〜 240V/ 許容変動幅 170 〜 264V、

50Hz(許容変動幅 47.5 〜 52.5Hz)/60Hz(許容変動幅 57 〜 63Hz)

11

Page 12

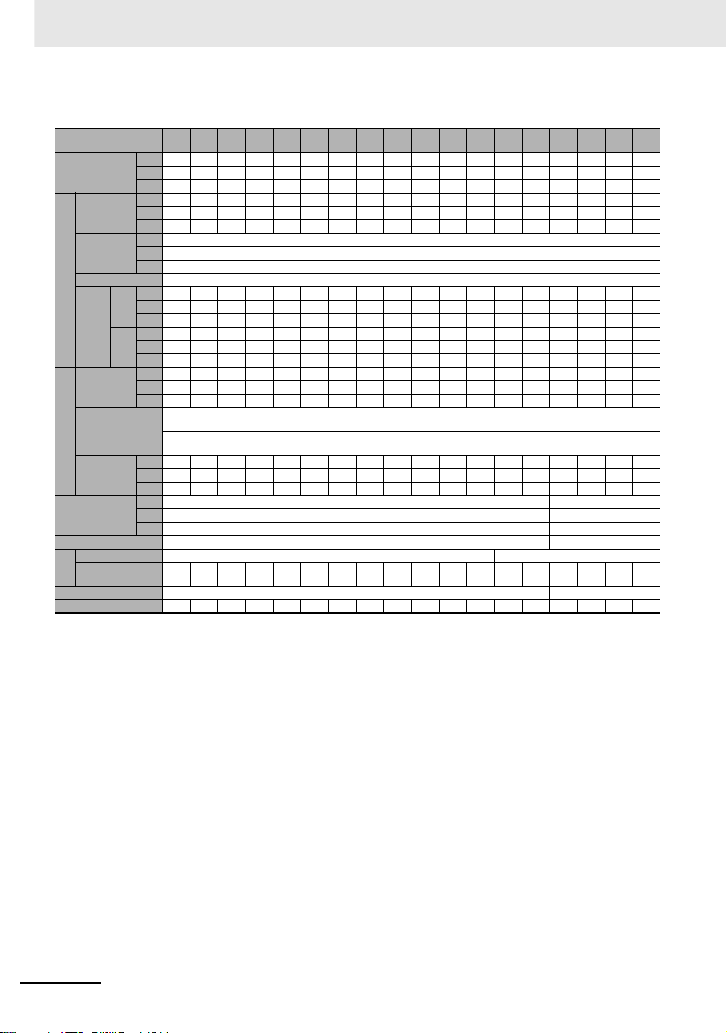

仕様

400V 級

機種略号(形式)

3G3RX2- □□□□□

適用モータ

(4 極)

容量(kW)

定格出力

電流(A)

過負荷

電流定格

出

定格出力電圧 三相(3 線)380 〜 500V(受電電圧に依存します)

力

定格

容量

(kVA)

定格入力

電流(A)*1

入

定格入力

力

交流電圧

電源設備

容量(kVA)

*2

キャリア

周波数範囲 *3

モータ始動トルク *4 200%/0.3Hz 180%/0.3Hz

回生制動 制動抵抗動作回路内蔵(放電抵抗別置) 回生制動ユニット別置

制

接続可能な

動

最小抵抗値(Ω)

護構造 IP20*5/ULopentype IP00/ULopentype

概略質量(kg) 3 3 3 3 6 6 6 8.5 8.5 8.5 22 31 31 31 41 41 53 53

*1. 定格入力電流は、定格電流出力時の値です。電源側のインピーダンス(配線、ブレー カ、入力リアクトルオプションなど)により値が変わります。定格

銘板の数値と異なりますが、この電流値を参考に余裕をもって周辺機器を選定してください。

*2. 電源設備容量は、440V 出力の定格電流出力時の値です。電源側のインピーダンス(配線、ブレーカ、入力リアクトルオプションなど)により値が変わ

ります。

*3. キャリア周波数[bb101]/[bb201]の設定は、表記に従って定格設定に、内部で制限がかかります。また、キャリア周波数[bb101]/[bb201]

の設定は、(駆動する最大出力周波数 ×10)Hz 以上になるように設定してください。誘導モータ(IM)制御の場合、V/f 制御以外の項目は、キャリア

周波数を 2kHz 以上に設定してください。同期モータ(SM)/ 永久磁石モータ(PMM)制御の場合、キャリア周波数を 8kHz 以上に設定してくださ

い。

*4. 標準モータで ND 定格におけるセンサレスベクトル制御適用時の値。トルク特性は、制御方式やご使用のモータにより異なる場合があります。

*5. 社内試験による自己宣言です。

A4007 A4015 A4022 A4037 A4 055 A4075 A4110 A4150 A4185 A4220 A4300 A4370 A4450 A455 0 B4750 B4900

VLD 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110 132 160

LD 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110 132 160

ND 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90 110 132

VLD 4.1 5.4 8.3 12.6 17.5 25.0 31.0 40.0 47.0 62.0 77.0 93.0 116 147 176 213 252 316

LD 3.1 4.8 6.7 11.1 16.0 22.0 29.0 37.0 43.0 57.0 70.0 85.0 105 135 160 195 230 290

ND 2.5 4.0 5.5 9.2 14.8 19.0 25.0 32.0 39.0 48.0 61.0 75.0 91.0 112 150 180 217 260

VLD 110%60sec/120%3sec

LD 120%60sec/150%3sec

ND 150%60sec/200%3sec

VLD 2.8 3.7 5.8 8.7 12.1 17.3 21.5 27.7 32.6 43.0 53.3 64.4 80.4

400V

LD 2.1 3.3 4.6 7.7 11.1 15.2 20.1 25.6 29.8 39.5 48.5 58.9 72.7 93.5

ND 1.7 2.8 3.8 6.4 10.3 13.2 17.3 22.2 27.0 33.3 42.3 52.0 63.0 77.6

VLD 3.6 4.7 7.2 10.9 15.2 21.7 26.8 34.6 40.7 53.7 66.7 80.5

500V

LD 2.7 4.2 5.8 9.6 13.9 19.1 25.1 32.0 37.2 49.4 60.6 73.6 90.9

ND 2.2 3.5 4.8 8.0 12.8 16.5 21.7 27.7 33.8 41.6 52.8 65.0 78.8 97.0

VLD 4.9 6.4 9.9 15.0 20.8 29.8 36.9 47.6 56.0 73.8 91.7

LD 3.7 5.7 8.0 13.2 19.0 26.2 34.5 44.0 51.2 67.9 83.3

ND 3.0 4.8 6.5 11.0 17.6 22.6 29.8 38.1 46.4 57.1 72.6 89.3

VLD 3.7 4.9 7.5 11.4 15.9 22.7 28.1 36.3 42.6 56.3 69.9 84.4

LD 2.8 4.4 6.1 10.1 14.5 20.0 26.3 33.6 39.0 51.7 63.5 77.1 95.3

ND 2.3 3.6 5.0 8.3 13.4 17.2 22.7 29.0 35.4 43.5 55.3 68.0 82.6

VLD 0.5 〜 10.0kHz 0.5 〜 8.0kHz

LD 0.5 〜 12.0kHz 0.5 〜 8.0kHz

ND 0.5 〜 16.0kHz 0.5 〜 10.0kHz

100 100 100 70 70 35 35 24 24 20 15 15 - - - - - -

制御電源:電源単相380 〜 500V(許容変動幅 323 〜 550V)、

50Hz(許容変動幅 47.5 〜52.5Hz)/60Hz(許容変動幅 57 〜 63Hz)

主回路電源:三相(3 線)380 〜 500V(許容変動幅 323 〜 550V)、

50Hz(許容変動幅 47.5 〜52.5Hz)/60Hz(許容変動幅 57 〜 63Hz)

101.8 121.9 147.6 174.6 218.9

110.9 135.1 159.3 200.9

103.9 124.7 150.3 180.1

100.5 127.3 152.4 184.5 218.2 273.7

116.9 138.6 168.9 199.2 251.1

110.7 138.1 175.0 209.5 253.6 300.0 376.2

101.2 125.0 160.7 190.5 232.1 273.8 345.2

129.9 155.9 187.9 225.2

108.3 133.3 178.6 214.3 258.3 309.5

105.2 133.4 159.7 193.2 228.6 286.7

122.5 145.2 176.9 208.7 263.1

101.6 136.1 163.3 196.9 235.9

B411K B413K

12

Page 13

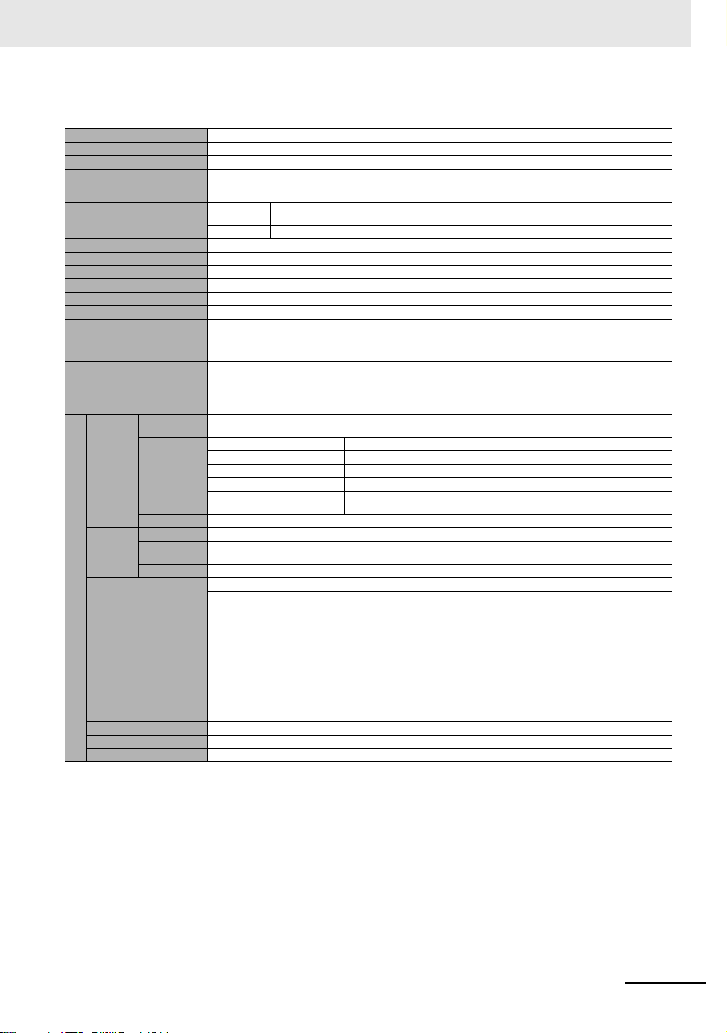

仕様

共通仕様

制御方式(モータへの出力) 正弦波 PWM 制御電圧出力(線間正弦波変調)

出力周波数範囲*1 0.00 〜 590.00Hz

周波数精度 最高周波数に対して、デジタル指令 ±0.01%、アナログ指令 ±0.2%(25 ℃ ±10 ℃)

周波数分解能

制御方式(周波数・電圧演算)*2

速度変動*3 ±0.5%(センサレスベクトル制御時)

加速・減速時間 0.00 〜 3600.00sec(直線、S 字、U 字、逆 U 字、EL-S 字)

ディスプレイモニタ 出力周波数、出力電流、出力トルク、トリップ来歴、入出力端子状態、入出力電力*4、PN 間電圧など

始動機能 直流制動後始動、周波数拾い込み始動、周波数引込始動、減電圧始動、リトライ再始動

停止機能 フリーランストップ停止、減速停止後直流制動または端子直流制動動作(ブレーキ力、時間、動作速度調整)

ストール防止機能 過負荷制限機能、過電流 抑制機能、過電圧抑制機能

保護機能*5

その他の機能

周波数

外部信号*6

設定

外部ポート RS485 シリアル通信による設定(プロトコル:Modbus-RTU)

標準操作パネル

正転・逆転

運転/停止

入

力

*1. 出力周波数範囲は、制御方式や使用するモータに依存します。60Hz を超えて運転する場合は許容最高周波数をモータメーカにご確認ください。

*2. 制御モードを変更する場合、モータ定数の設定が適切でないと、所望の始動トルクが得られ ない、あるいはトリップする可能性があります。

*3. モータ速度の可変領域について、可変領域は、お客様のシステム、モータの使用環境によっ て異なります。詳しくはお問い合わせください。

*4. 入力電力・出力電力とも参考値表示であり、効率値の計算等には適しません。厳密な値を求 めるには外部の機器をご使用ください。

*5. 保護機能で IGBT エラー[E030]が発生した場合、短絡保護だけでなく、IGBT が破損している場合にも発生します。イ ンバータの動作状況によって

は、IGBT エラーの代わりに過電流エラー[E001]が発生する場合もあります。

*6. 工場出荷設定では、Ai1/Ai2 端子を電圧および電流をスイッチで切り替えた際に、入力される電圧入力が 9.8V、電流入力が 19.8mAを入 力することで、

最高周波数が指令されます。特性を変更したい場合は、アナログスタートエンド機能で調整します。

外部ポート RS485 シリアル通信による設定(プロトコル:Modbus-RTU(最大:115.2kbps))

入力端子機能

バックアップ電源端子 P+/P-:DC24V 入力(入力許容電圧:24V±10%)

STO 入力端子 2 端子(同時入力)

サーミスタ入力端子 1 端子(正温度係数/負温度係数抵抗素子切替え可)

デジタル設定:0.01Hz

アナログ設定:最高周波数 /4000

(Ai1 端子 /Ai2 端子:12bit/0 〜 +10V または 0 〜 +20mA、Ai3 端子 12bit/-10 〜 +10V)

過電流エラー、モータ過負荷エラー、制動抵抗器過負荷エラー、過電圧エラー、メモリエラー、不足電圧エラー、

電流検出器エラー、CPU エラー、外部トリップエラー、USP エラー、地絡エラー、受電過電圧エラー、瞬時停電エ

ラー、温度検出器エラー、冷却ファン回転数低下、温度エラー、入力欠相エラー、IGBT エラー、出力欠相エラー、

サーミスタエラー、ブレーキエラー、低速域過負荷エラー、インバータ過負荷エラー、RS485 通信エラー、など、

V/f 自由設定(7 点)、 上限・下限周波数リミッタ、周波数ジャンプ、曲線加減速、手動トルクブースト、省エネ運転、

アナログ出力調整機能、最低周波数、キャリア周波数調整、モータ電子サーマル機能(自由設定も可)、

インバータ電子サーマル機能、外部スタート・エンド(量・割合)、周波数入力選 択、トリップリトライ、瞬停再始動、

各種信号出力、初期化設定、PID 制御、電源遮断時自動減速、ブレーキ制 御機能、商用切り替え機能

オートチューニング(オン・オフライン)など

標準操作

上下左右キーによるパラメータ設定

パネル

Ai1/Ai2 端子(電圧切替時) 0 〜 10Vdc 電圧入力による設定(入力インピーダ ンス :10kΩ)

Ai1/Ai2 端子(電流切替時) 0 〜 20mA 電流入力による設定(入力イ ンピーダンス :100Ω)

Ai3 端子 -10 〜 +10Vdc電圧入力による設定(入力インピーダンス :10kΩ)

多段速端子(入力端子機能使用) 15 段 速

パルス列入力

(A/B 端子、入力端子機能使用)

RUN(運転)/STOP(停止)キーによる実行(正転 / 逆転はパラメータ設定で切り替え)

正転運転(FW)/ 逆転運転(RV)(入力端子機能割り付け時)

外部信号

3 ワイヤ入力可(入力端子機能割り付け時)

11 端子(A 端子及び B 端子はパルス列入力可)

FW(正転)/RV(逆転)、CF1 〜 4(多段速 1 〜 4)、SF1 〜 7(多段速ビット 1 〜 7)、ADD(周波数加算)、

SCHG(周波数指令切替)、STA(3 ワイヤ起動)/STP(3 ワイヤ停止)/FR(3 ワイヤ正逆)、

AHD(アナログ指令保持)、FUP(遠隔操作増速 /FDN(遠隔操作減速)、UDC(遠隔操作データクリア)、

F-OP(強制指令切替)、SET(第 2 制御)、RS(リセット)、JG(ジョギング)、DB(外部直流制動)、

2CH(2 段加減速)、FRS(フリーランストップ)、EXT(外部異常)、USP(復電再始動防止)、CS(商用切替)、

SFT(ソフトロック)、BOK(ブレーキ確認)、OLR(過負荷制限切替)、KHC(積算入力電力 クリア)、

OKHC(積算出力電力クリア)、PID(PID1 無効)、PIDC(PID1 積分リセット)、PID2(PID2 無効)、

PIDC2(PID2 積分リセット)、SVC1 〜 4(PID1 多段目標値 1 〜 4)、PRO(PID ゲイン切替)、

PIO(PID 出力切替)、SLEP(SLEEP 条件成立)/WAKE(WAKE 条件成立)、TL(トルク制限有効)、

TRQ1、2(トルクリミット切替 1、2)、PPI(P/PI 制御切替)、CAS(制御ゲイン切替)、FOC(予備励磁)、

ATR(トルク制御有効)、TBS(トルクバイアス有効)、LAC(加減速キャンセル)、Mi1 〜 11(汎用入力 1 〜 11)、

PCC(パルスカウンタクリア)、ECOM(EzCOM 起動)、PRG(プログラム RUN)、HLD(加減速停止)、

REN(運転許可信号)、PLA(パルス列入力 A)、PLB(パルス列入力 B)

V/f 制御(定トルク / 低減トルク / 自由)、自動ブースト制御、カスケード型センサレスベクトル制御、

IM

0Hz 域センサレスベクトル制御、センサ付きベクトル制御

SM/PMM 同期起動型スマートセンサレスベクトル制御、IVMS 起動型スマートセンサレスベクトル制御

最大 32kHz×2

13

Page 14

仕様

共通仕様 続き

出力端子機能

出

リレーおよびアラームリレー

力

(16、AL)

EDM 出力端子 STO診断用出力

モニタ出力端子*8 パラメータのモニタデータから選択して出力可能

EMC フィルタ切替*9 EMC ノイズフィル タを有効化可能(機種により切替方法は異なります)

PC 外部アクセス USBMicro-B

周囲温度*14

使

保存温度*10 -20 〜 65 ℃

用

環

境

*7. 信号出力のしきい値は組合せモータ、パラメータ調整等により異なります。

*8. アナログ電圧モニタ、アナログ電流モニタはアナログメータ接続用の目安出力です。 接続されるメータ、アナログ出力回路のバラつきにより最大出力値

*9. EMC フィルタを 有効にする場合には、中性点接地の電源に接続してください。漏れ電流増大の原因になります。

*10.保存温度は輸送中の温度です。

*11.JISC60068-2-6:2010(IEC60068-2-6:2007)の試験方法に準拠

*12.高度 1000m 以上でご使用の場 合、100m 高度が上がる毎に気圧がおよそ 1% 減少します。高度が 100m 上がる毎に、定格電流に対し 1% の電流ディ

*13.絶縁距離は UL、CE 規 格に準拠

*14.400V 級インバータは 500Vac 以下の入力電圧でご使用ください。電源変動により入力電圧が 500Vac を超えてしまう場合は、40 ℃以下の周囲温度

*15.時刻機能を使用する場合は、別売りの電池(CR2032、3V)が必要です。ご購入時、LCD オペレータには電池は入っていません。

湿度 20 〜 90%RH(結露のない所)

振動*11

使用場所*12 標高 1000m 以下、(腐食ガス、オイルミスト、塵埃のない所)

寿命部品

適合規格*13 UL、cUL、CE 規格準拠、RCM、機能安全 SIL3/PLe(取得予定)

塗装色 ブラック(Black)

操作、表示 LCD オペレータ*15

オプションスロット数 3ポート

その他のオプション 制動抵抗器、交流リアクトル、直流リアクトル、ノイズフィルタなど

が 10V ま たは 20mA より若干ずれる場合があります。特性を変更したい場合は、Ao1 調整、Ao2 調整機能で調整します。一部出力できない モニタデー

タがあります。

レーティングを行い、評価を実施してください。2500m 以上の環境でご使用の場 合はお問い合わせください。

でご使用ください。

適合規格

CE

UL

KC KN61800-3

EAC RCM EN61800-3:2004+A1:2012

トランジスタ出力 5 端子、1a 接点リレー 1 点、1c 接点リレー 1 点

RUN(運転中)、FA1 〜 5(到達信号)、IRDY(運転準備完了)、FWR(正転運転中)、RVR(逆転運転中)、

FREF(周波数指令操作パネル)、REF(運転指令操作パネル)、SETM(第 2 制御選択中)、AL(アラーム信号)、

MJA(重故障信号)、OTQ(オーバートルク)*7)、IP(瞬時停電中)、UV(不足電圧中)、TRQ(トルク制限中)、

IPS(停電減速中)、RNT(RUN 時間オーバー)、ONT(電源 ON 時間オーバー)、THM(電子サーマル警告)、

THC(電子サーマル警告)、WAC(コンデンサ寿命予告)、WAF(ファン寿命予告)、FR(運転指令信号)、

OHF(冷却フィン加熱予告)、LOC/LOC2(低電流信号)、OL/OL2(過負荷予告)、BRK(ブレーキ解放)、

BER(ブレーキ異常)、ZS(零速検出信号)、OD/OD2(PID 偏差過大)、FBV/FBV2(PID フィードバック比較)、

NDc(通信断線)、Ai1Dc/Ai2Dc/Ai3Dc(アナログ断線 Ai1/Ai2/Ai3)、

WCAi1/WCAi2/WCAi3(ウィンドウコンパレータ Ai1/Ai2/Ai3)、LOG1 〜 7(論理演算結果 1 〜 7)、

MO1〜7(汎用出力1〜7)、OVS(受電過電圧)など

ND(標準負荷) -10 〜 50 ℃

LD(軽負荷) -10 〜 45℃

VLD(超軽負荷) -10 〜 40 ℃

2

(0.6G)10 〜 55Hz:3G3RX2-A2004 〜 A2220/3G3RX2-A4007〜 A4220

5.9m/s

2

2.94m/s

(0.3G)10 〜 55Hz:3G3RX2-A2300 〜 A2550/3G3RX2-A4300 〜 A413K

主回路平滑コンデンサ設計寿命 10 年

冷却ファン設計寿命 10 年(冷却ファン搭載機種)ただし塵埃なきこと

制御回路基板上の記憶素子

EMC EN61800-3:2004+A1:2012

Machinery

US UL61800-5-1

CA CSAC22.2No.274

FS

IEC61800-5-2:2016STOSIL3

ISO13849-1:2015Cat.4PLe

IEC61800-5-1/A1:2016

IEC61800-5-2:2016 STOSIL3

ISO13849-1:2015Cat.4PLe

適合規格

14

Page 15

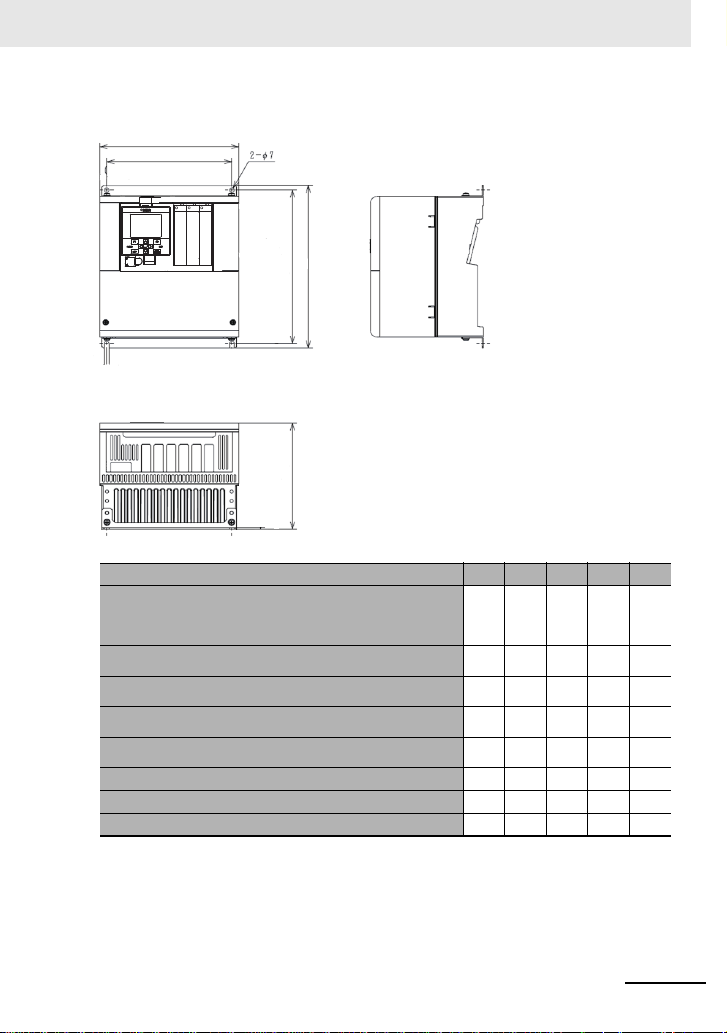

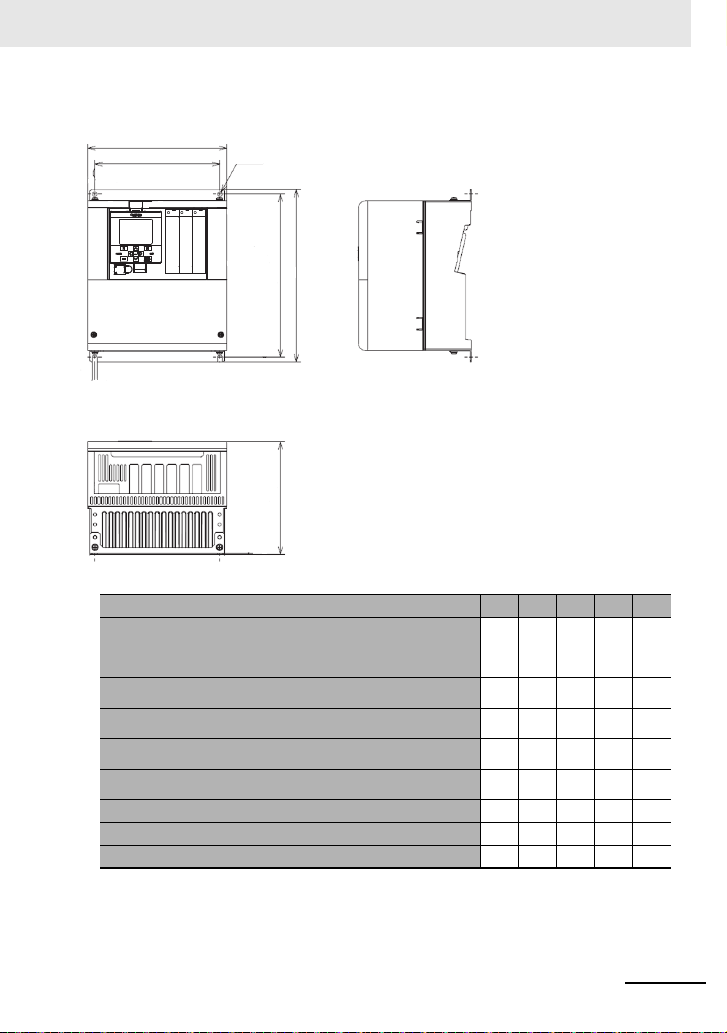

■外形寸法 (mm)

W

H1DH

W1

200V 級 :

3G3RX2-A2004,3G3RX2-A2007,3G3RX2-A2015,

3G3RX2-A2022,3G3RX2-A2037

400V 級 :

3G3RX2-A4007,3G3RX2-A4015,3G3RX2-A4022,

3G3RX2-A4037

200V 級 :

3G3RX2-A2055,3G3RX2-A2075,3G3RX2-A211

400V 級 :

3G3RX2-A4055,3G3RX2-A4075,3G3RX2-A4110

200V 級 :

3G3RX2-A2150,3G3RX2-A2185,3G3RX2-A2220

400V 級 :

3G3RX2-A4150,3G3RX2-A4185,3G3RX2-A4220

200V 級 :

3G3RX2-A2300

400V 級 :

3G3RX2-A4300

200V 級 :

3G3RX2-A2370,3G3RX2-A2450

400V 級 :

200V 級 : 3G3RX2-A2550 480 380 700 670 250

400V 級 : 3G3RX2-B4750,3G3RX2-B4900 390 300 700 670 270

400V 級 : 3G3RX2-B411K,3G3RX2-B413K 480 380 740 710 270

3G3RX2-A4370,3G3RX2-A4450,3G3RX2-A4550

形 3G3RX2- W W1 H H1 D

150 130 255 241 140

210 189 260 246 170

245 229 390 376 190

300 265 540 510 195

390 300 550 520 250

仕様

15

Page 16

仕様

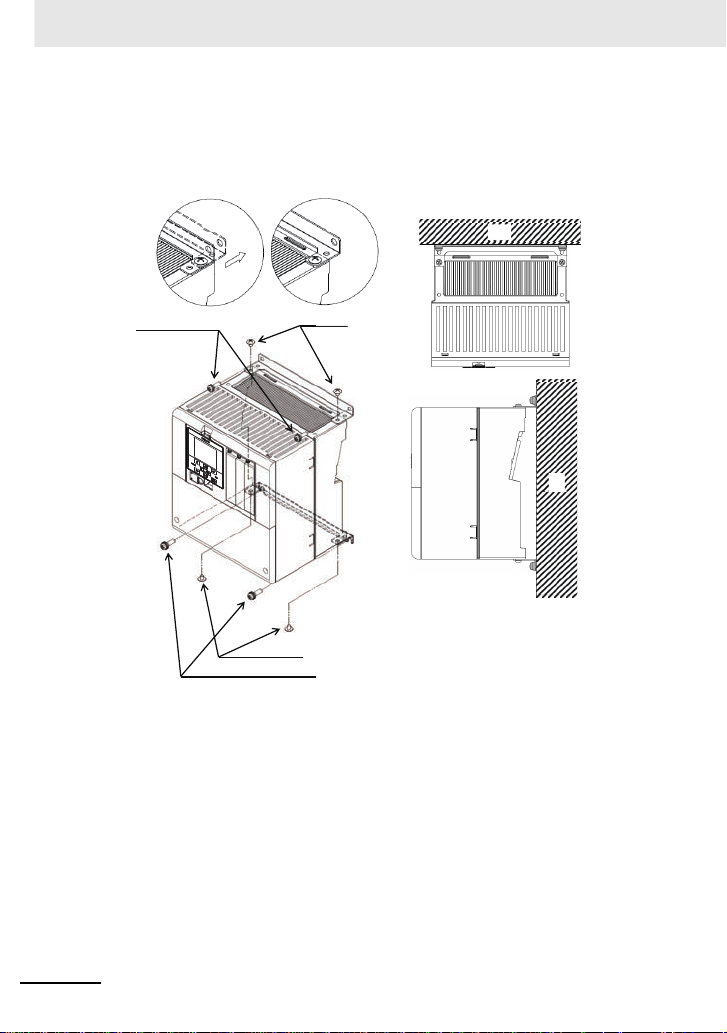

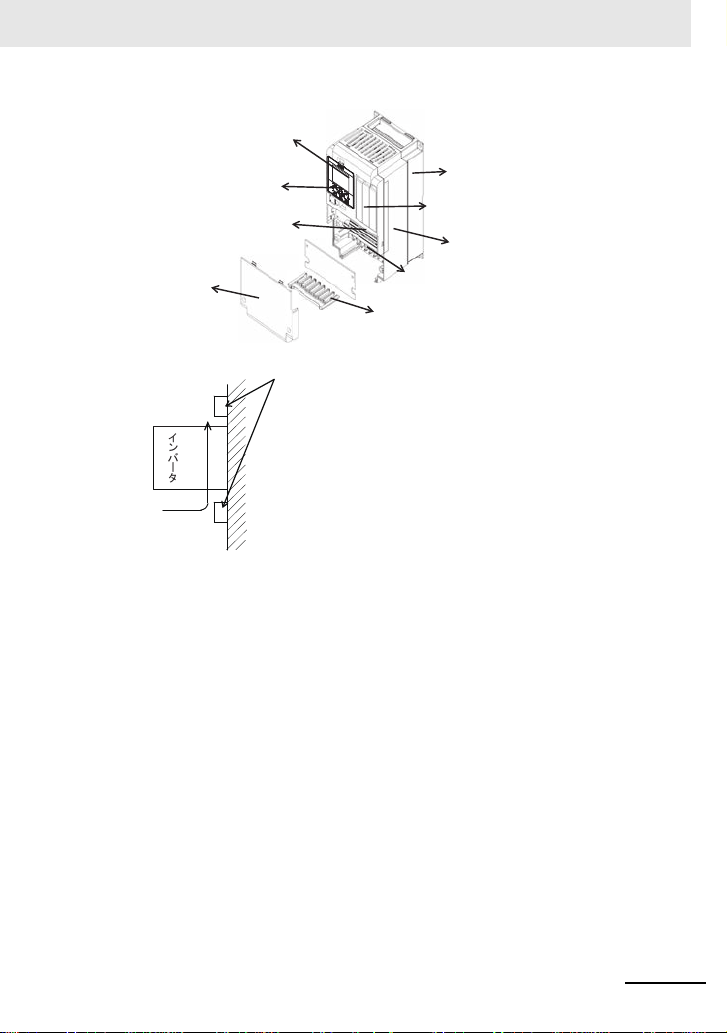

■取付上の注意

3G3RX2-A2110 において軽負荷定格 (LD)/ 超軽負荷定格 (VLD) にてご使用される場合、ならびに、

3G3RX2-A2220 において超軽負荷定格電流 (VLD) にてご使用される場合、以下の図の据付け方法に注

意して取り付ける必要があります。以下の手順で、お客様にて対応をお願いします。

手順①

お客様にて準備いただくネジ

手順④

お客様にて準備いただくネジ

図 据付け方法

ネジ

手順③

手順④

手順②

ネジ

手順③

壁

壁

図 平面・右側面図

※ 軽負荷定格 (LD)/ 超軽負荷定格 (VLD) への設定は [Ub-03]=00(VLD)、[Ub-03]=01(LD) と設定す

ることで変更します。

16

Page 17

図 据付け方法

M3×8 ネジ 手順① 手順①

手順①

手順②

手順②

スペーサ

スペーサ

お客様にて

準備いただくネジ

お客様にて

準備いただくネジ

M3×8 ネジ

壁

壁

図 平面・右側面図

形 3G3RX2-A2220 の場合

※ 超軽負荷定格 (VLD) への設定は [Ub-03]=00 と設定することで変更します。

仕様

17

Page 18

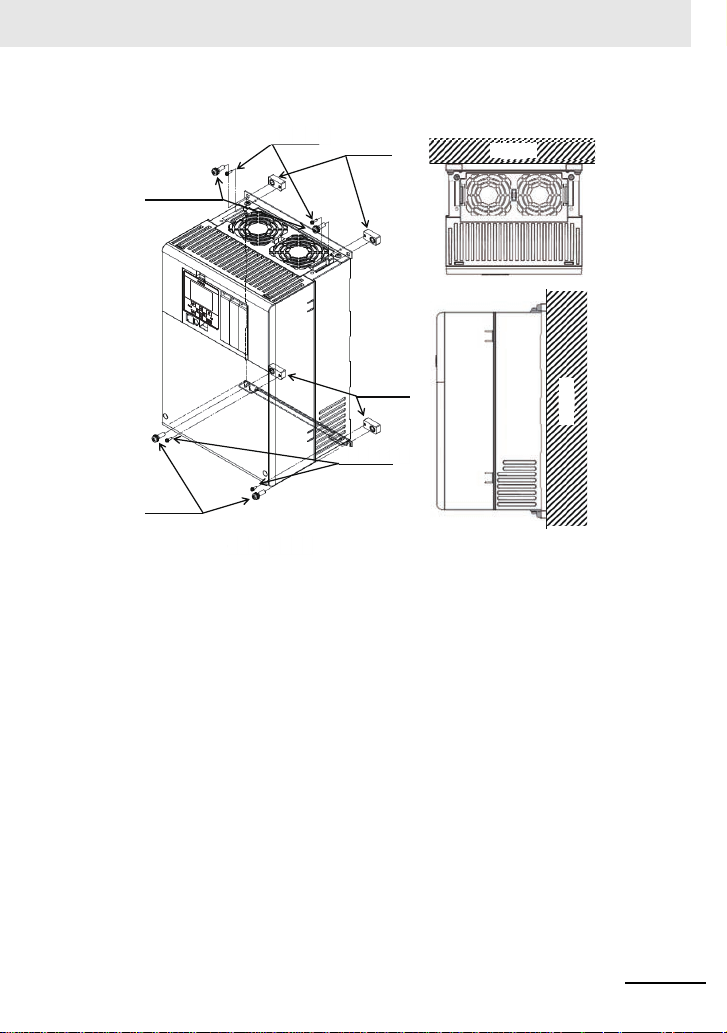

設置条件

ねじ留め

ねじ留め

ねじ留め

ねじ留め

5cm以上5cm以上

30cm以上

30cm以上

5cm以上5cm以上

10cm以上

10cm以上 *1

*1 メンテナンス修理用スペースとして下部を 22cm 以上開けて据え付けてください。

・ 3G3RX2-A2150〜3G3RX2-A2220

・ 3G3RX2-A4150〜3G3RX2-A4220

下記の寿命部品交換には、インバータ本体を取り外す必要があります。

・ 3G3RX2-A2055〜3G3RX2-A2110

・ 3G3RX2-A4055〜3G3RX2-A4110

3G3RX2-A2004 〜 3G3RX2-A2550

3G3RX2-A4007 〜 3G3RX2-A4550

の場合

3G3RX2-B4750 〜 3G3RX2-B413K

の場合

設置条件

■機器周辺寸法条件

設置方法、設置方向にはご注意ください!

• インバータは、振動を受けない重量に耐えられる取り付け面に、ねじ、またはボルトで、がた

つきの無いようにしっかりと垂直に取り付けてください。

• 正しく取り付けない場合、冷却能力が低下し、トリップまたは破損の恐れがあります。

不燃性(金属など)の取り付け面に据付けてください!

• インバータは高温(最高 150 ℃程度)になります。火災の恐れがありますので、不燃性の垂直

な壁面(金属など)に据付けてください。また、本体重量を十分に支えられる構造になっている

ことを確認してください。

• 発熱体(制動抵抗器、リアクトル等)がある場合は、インバータと十分に離してください。

18

Page 19

ᨺ⇕䝣䜱䞁

ᵝ㖭ᯈ

䜸䝥䝅䝵䞁䜹䝉䝑䝖᥋⥆㒊

㼁㻿㻮䠄 㻹㼕㼏㼞㼛㻙㻮

㻕

➃Ꮚྎ䜹䝞䞊

ไᚚᅇ㊰➃Ꮚྎ

㟁⥺ᘬฟᯈ

ᅇ㊰➃Ꮚྎ

㻸㻯㻰䜸䝨䝺䞊䝍

ቨ

䞉ୖୗ䛾㓄⥺䝎䜽䝖䛺䛹䛜䚸㻌෭༷

䛾㏻㢼䜢ጉ䛢䛺䛔ᵝ䛻༑ศ䛺

䝇䝨䞊䝇䜢☜ಖ䛧䛶䛟䛰䛥䛔䚹㻌

叻呉吧 呎吖

✵Ẽ䛾ὶ䜜

■使用環境条件

• 設置場所の湿度は、標準仕様に記載されている

湿度(20 〜 90%RH)で使用してください。特に、結露がない場所で使用してください。

• 結露が起き、インバータ内部に水滴が付着すると、電気回路が短絡し故障の原因になります。

また、直射日光の当たる場所への設置は避けてください。

設置条件

19

Page 20

主回路

㻱㻸㻮㻌㻖㻝

₃㟁㐽᩿ჾ 㟁☢᥋ゐჾ

㻹㻯

㻟┦

ὶ

㟁※

㻾㻛㻸㻝

㻿㻛㻸㻞

㼀㻛㻸㻟

㻾㻜

㼀㻜

㼁㻛㼀㻝

㼂㻛㼀㻞

㼃㻛㼀㻟

ไᚚᅇ㊰㟁※

㻰✀᥋ᆅ㻔㻞㻜㻜㼂 ⣭㻕

㻯✀᥋ᆅ㻔㻠㻜㻜㼂 ⣭㻕

㻶㻡㻝 䝁䝛䜽䝍

㻟 ┦ὶ䝰䞊䝍㻌㻖㻞

㻹

ᅇ㊰➃Ꮚ㒊

㻟䡚

▷⤡∦䜎䛯䛿➃Ꮚ

↓ຠ

᭷ຠ

㻼

㻼㻰

㻾㻮

㻺

▷⤡∦

ෆⶶ 㻱㻹㻯 䝣䜱䝹䝍㻌㻖㻟

㻞㻜㻜㼂⣭䠖

㻞㻜㻜䡚㻞㻠㻜㼂㼍㼏

㻠㻜㻜㼂⣭䠖

㻟㻤㻜䡚㻡㻜㻜㼂㼍㼏

主回路

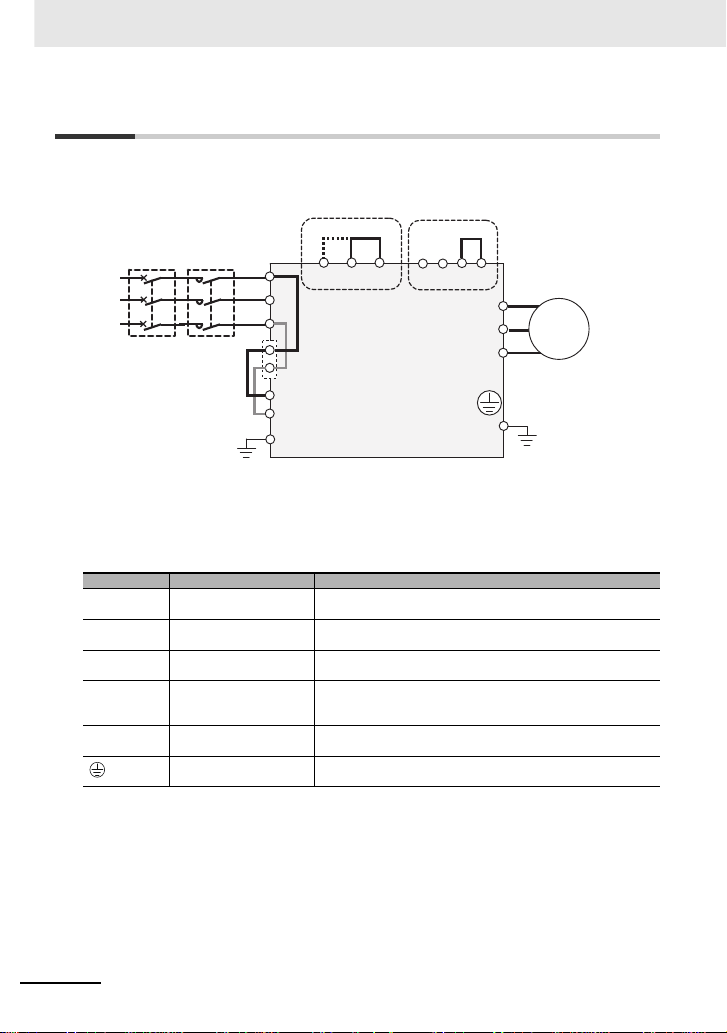

■主回路配線図

■主回路端子

R、S、T

(L1、L2、L3)

U、V、W

(T1、T2、T3)

PD、P

(+1、+)

P、RB

(+、RB)

P、N

(+、-)

20

*1. ELB の代わりにヒューズをいれてもよい。

*2. 規格に適合させる場合は後述の条件に合った機器・配線材を使用してください。

*3. 出荷時、EMC フィルタは有効に設定されています。規格適合が不要で ELB がトリップする場合には無効

に変更してください。

端子記号 端子名称 内容説明

主電源入力端子 交流電源に接続します。

インバータ出力端子 三相モータ を接続します。

直流リアクトル接続端子 端子 PD-P 間の短絡片を外し、オプションの力率改善用リアクトル

外部制動抵抗器接続端子 制動抵抗動作回路内蔵機種は、オプションの外 部制動抵抗器を接続

回生制動ユニット接続端子 オプションの回生制動ユニット BRD を接続します。

インバータ用接地端子 インバータケースの接地端子です。大地に接地してください。

DCL を接続します。

します。制動抵抗動作回路を搭載していない機種には、RB 端子は

ありません。

200V 級は D 種接地、400V 級は C 種接地に接続してください。

Page 21

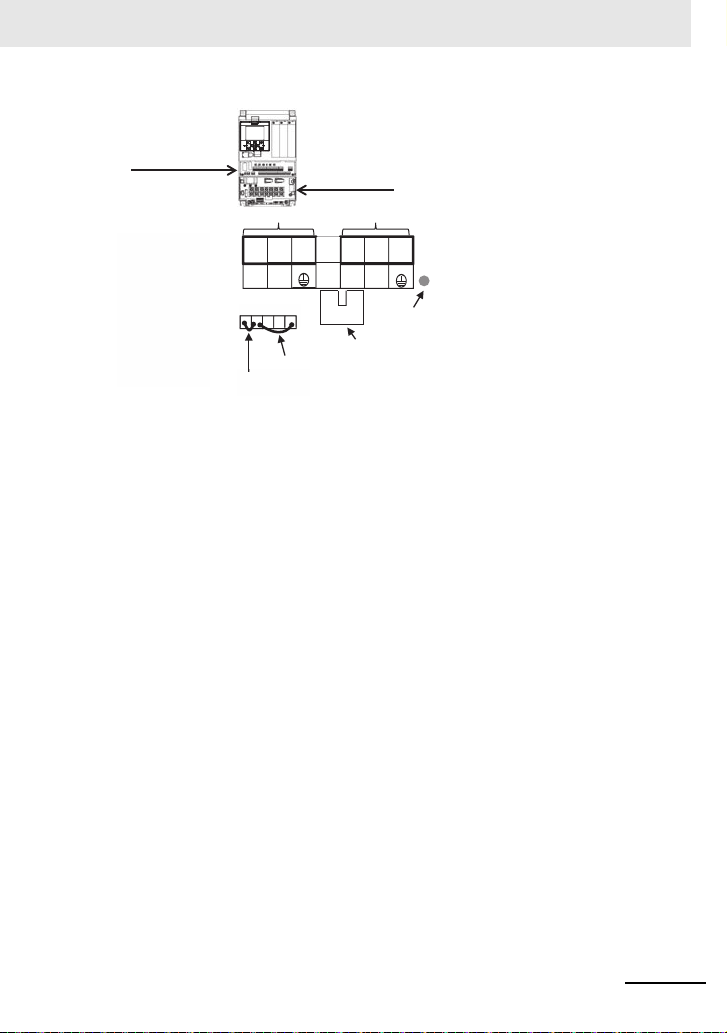

主回路

㟁※ධຊ⥺

䝰䞊䝍 ฟຊ⥺

㻼㻰㻙㻼▷⤡∦

㻱㻹㻯

䝣 䜱 䝹䝍 ᭷ຠ

㻱㻹㻯

䝣 䜱 䝹䝍 ↓ຠ

ไᚚᅇ㊰➃Ꮚྎ

ᅇ㊰➃Ꮚྎ

㟁

㼀㻜 㻳

㻱㻹㻯

㻾㻮

㻔㻾㻮㻕

㻼㻰

㻔㻗 㻝㻕

㻼

㻔㻗 㻕㻺㻔㻙㻕

㻳

䝏䝱䞊䝆䝷䞁 䝥

㻔㏻㟁Ⅼⅉ㻕

㻾

㻔㻸㻝㻕㻿㻔㻸㻞㻕㼀㻔㻸㻟㻕㼁㻔㼀㻝㻕㼂㻔㼀㻞㻕㼃㻔㼀㻟㻕

㻾㻜

㻻㻲㻲㻌㻳㻌㻌㻌㻌㻌㻌㻻㻺

㻱㻹㻯

* EMC フィルタは短絡コネクタを入れ替えて有効 / 無効を切り替えます。

* 端子配列例です。

21

Page 22

主回路

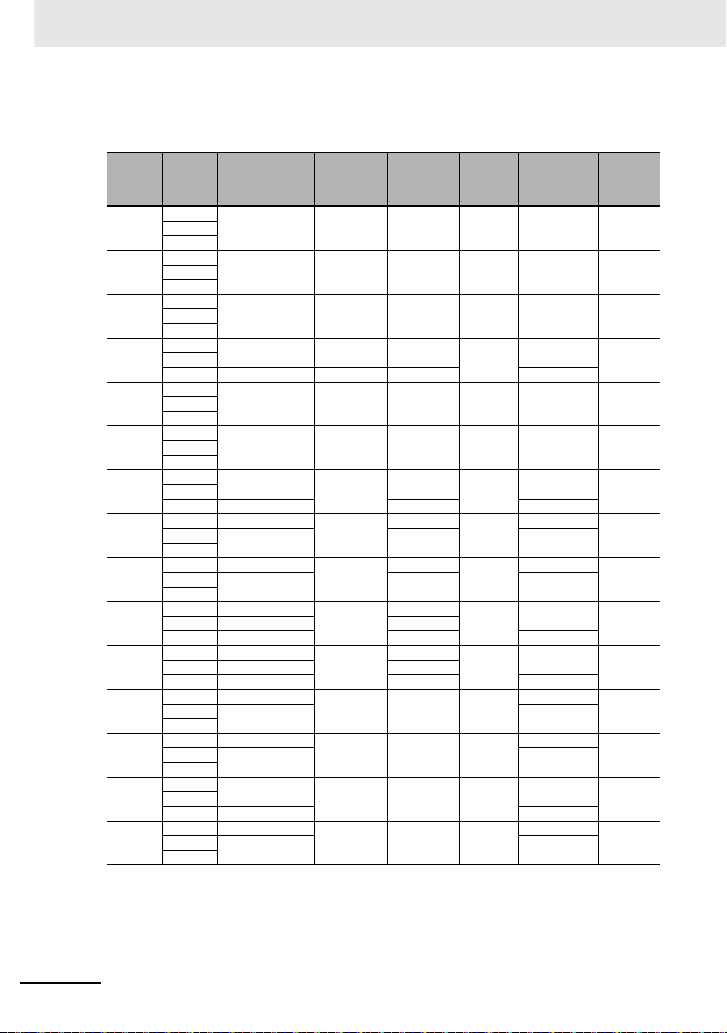

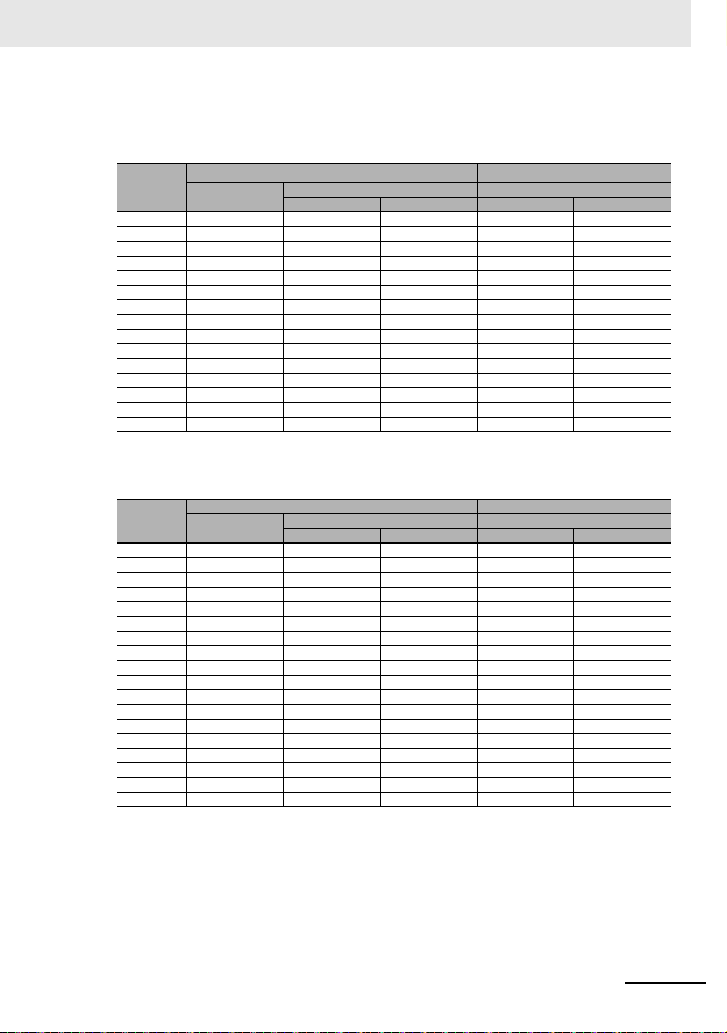

■主回路配線の端子配線径

200V 級

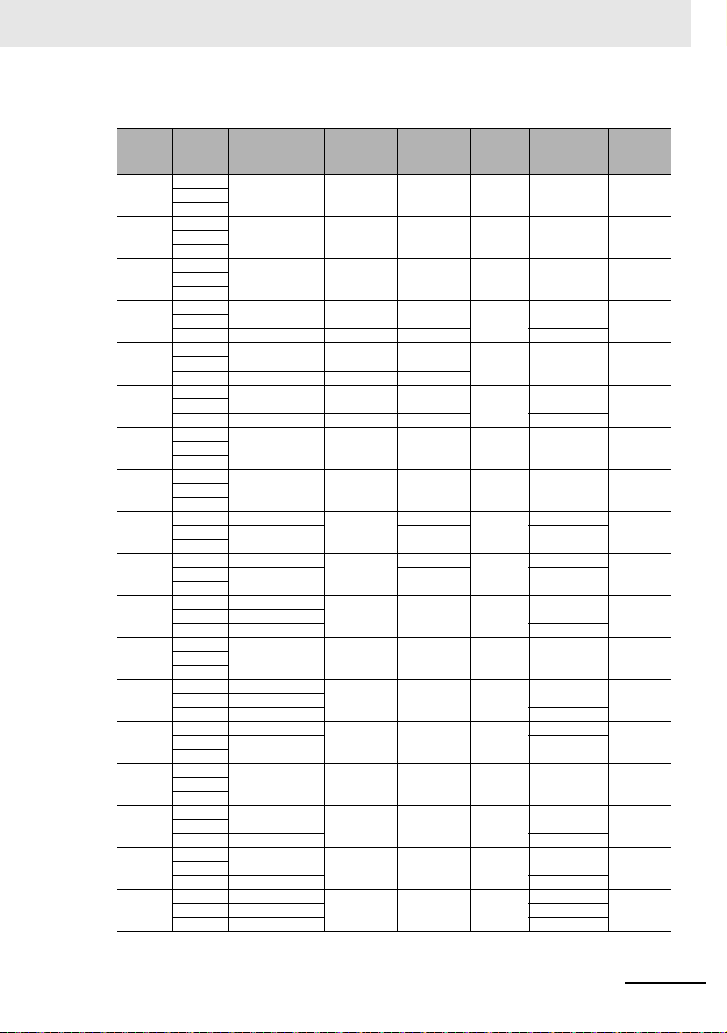

形式

定格設定

3G3RX2

A2004

A2007

A2015

A2022

A2037

A2055

A2075

A2110

A2150

A2185

A2220

A2300

A2370

A2450

A2550

(注)1. 上記表に記載の電線径は、HIV 線(耐熱 75 ℃)基準の設計値を示します。

ND

VLD

ND

VLD

ND

VLD

ND

VLD 10(5.3) 10(5.3) 10(5.3) 5.5-4/5.5-4

ND

VLD

ND

VLD

ND

VLD 6(13.3) 6(13.3) 14-5/8-5

ND 6(13.3)

VLD

ND 4(21.2)

VLD

ND 3(26.7)

VLD 1(42.4) 1(42.4) 60-6/14-6

ND 1(42.4)

VLD 2/0(67.4) 2/0(67.4) 70-8/14-6

ND 2/0(67.4)

VLD

ND 4/0(107.2)

VLD

ND

VLD 2/0×2(67.4×2) 70- 8/22-8

ND 350kc(177)

VLD

2. 主回路端子台に電線を接続する場合は、使用電線に合った丸型 圧着端子(UL 規格対応品)を使用 してください。圧

着端子は圧着端子メーカの推奨する圧着工具を使用し圧着してください。

動力線

2

接地線

)

AWG(mm

R、S、T、U、V、

W、P、PD、N

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1)

10(5.3) 10(5.3) 10(5.3) M4 5.5-4/5.5-4 1.4LD

8(8.4) 8(8.4) 8(8.4) M5 8-5/8-5 3.0LD

8(8.4)

4(21.2) 4(21.2) 22-6/14-6

3(26.7) 3(26.7) 38-6/14-6

1/0×2(53.5×2) 60-8/22-8

1/0×2(53.5×2) 60-8/22-8

1/0×2(53.5×2)

3/0×2(85.0×2) 80-10/38-8

AWG(mm

6(13.3)

6(13.3)

6(13.3)

6(13.3)

6(13.3)

4(21.2) - M8

4(21.2) - M8

4(

21.2) - M

3(26.7) - M10

2

)

制動抵抗器

P-RB 間

AWG(mm

8(8.4)

6(13.3)

4(21.2)

3(26.7)

1(42.4)

動力線

端子ネジ

2

サイズ

)

M4

M5

M6

M6

M6

M8

8

圧着端子

動力線 / 接地線

2-4/2-4

8-5/8-5

14-6/14-6

22-6/14-6

38-6/14-6

60-8/14-6

70-8/22-8

100-8/22-8

60-8/22-8

180-10/38-8

締付トルク

N・m

1.4LD

3.0LD

4.0LD

2.5 〜 3.0LD

2.5 〜 3.0LD 2(33.6) 2(33.6)

5.5 〜 6.6LD 1/0(53.5) 1/0(53.5)

6.0LD

15.0LD

6.0 〜 10.0LD

19.6LD

22

Page 23

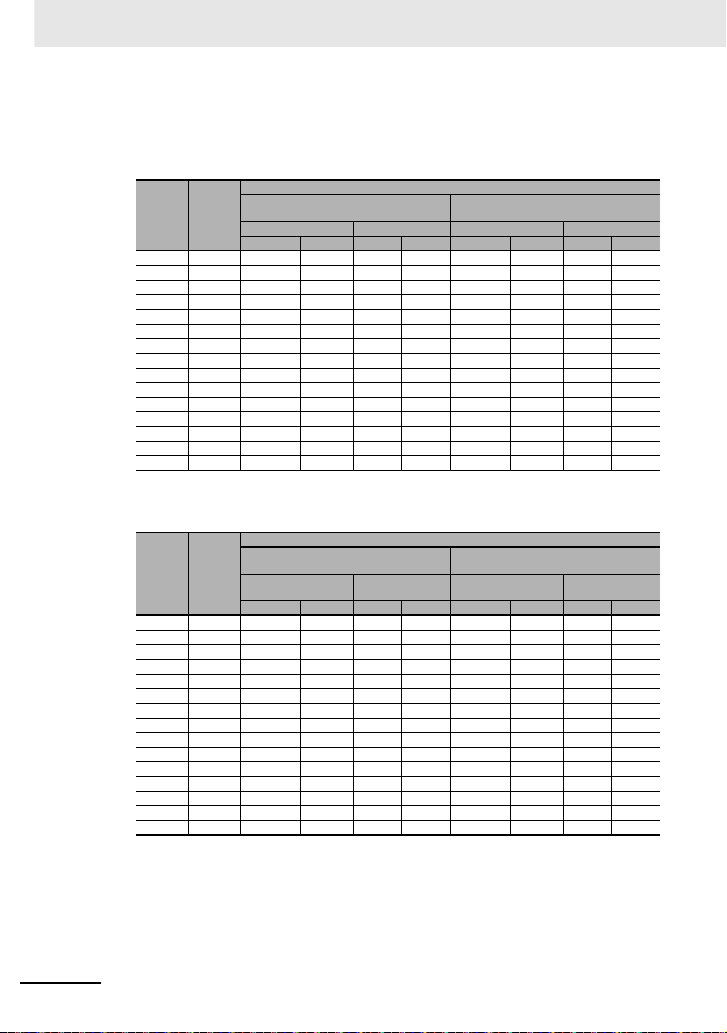

400V 級

形式

3G3RX2定格設定

A4007

A4015

A4022

A4037

A4055

A4075

A4110

A4150

A4185

A4220

A4300

A4370

A4450

A4550

B4750

B

B411K

B413K

(注)1. 上記表に記載の電線径は、HIV 線(耐熱 75°C)基準の設計値を示します 。

ND

VLD

ND

VLD

ND

VLD

ND

VLD 12(3.3) 12(3.3 ) 12(3.3) 5.5-4/5.5-4

ND

VLD 10(5.3) 10(5.3 ) 10(5.3)

ND

VLD 8(8.4) 8(8.4) 8(8.4) 8-5/8-5

ND

VLD

ND

VLD

ND 8(8.4)

VLD

ND 6(13.3)

VLD

ND 3(26.7)

VLD 1(42.4) 60-8/14-8

ND

VLD

ND 1(42.4)

VLD 2/0(67.4) 70-8/14-8

ND 2/0(67.4)

VLD

ND

VLD

ND

4900

VLD 2/0×2(67.4×2) 70-10/38-8

ND

VLD 3/0×2(85.0×2) 80-10/38-8

ND 3/0×2(85.0×2)

VLD

2. 主回路端子台に電線を接続する場合は、使用電線に合った 丸型圧着端子(UL 規格対応品 )を使用してください。

圧着端子は圧着端子メーカの推奨する圧着工具を使用し圧着してください。

動力線

2

接地線

)

AWG(mm

R、S、T、U、V、

W、P、PD、N

AWG(mm

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4LD

14(2.1) 14(2.1) 14(2.1)

12(3.3) 12(3.3) 12(3.3)

10(5.3) 10(5.3) 10(5.3)

8(8.4) 8(8.4) 8(8.4) M6 8-6/8-6 4.0LD

8(8.4) 8(8.4) 8(8.4) M6 8-6/8-6 4.0LD

6(13.3) 6(13.3) 14-6/8-6

4(21.2) 4(21.2) 22-6/8-6

8(8.4)

8(8.4)

6(13.3) - M8

1(42.4) 6(13.3) - M8 60-8/14-8 15.0LD

6(13.3) - M8

1/0×2(53.5×2) 60-8/22-8

4(21.2) - M8

1/0×2(53.5×2) 4 (21.2) - M10 60-10/22-8 6.0 〜 10.0LD

(53.5×2)

1/0×2

2/0×2(67.4×2)

250kc×2(127×2)

3(26.7) - M10

2(33.6) - M10

2(33.6) - M10

2

)

制動抵抗器

P-RB 間

AWG(mm

8(8.4)

6(13.3)

主回路

動力線

端子ネジ

2

サイズ

)

M4

圧着端子

動力線 / 接地線

2-4/2-4

M5 5.5-5/5.5-5 3.0LD

5.5-5/5.5-5

M5

8-6/8-6

M6

14-6/8-6

M6

38-8/14-8

60-8/14-8

70-8/22-8

60-10/38-8

70-10/38-8

80-10/38-8

150-10/38-8

6.0 〜 10.0LD 1/0(53.5)

6.0 〜 10.0LD

6.0 〜 10.0LD

締付

トルク

N・m

1.4LD

3.0LD

4.0LD

4.0LD

6.0LD 2(33.6)

19.6LD

19.6LD 4/0×2(1 07×2) 100-10/38-8

23

Page 24

主回路

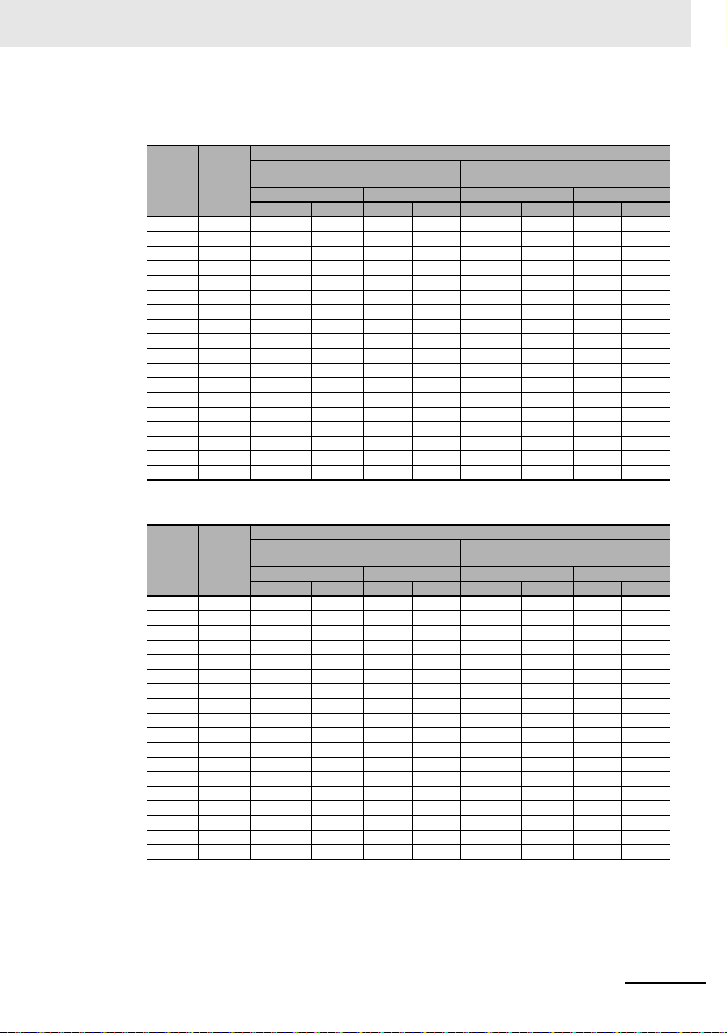

■適用ブレーカ

200V 級

• インバータ ND 定格設定時

適用

形式

モータ

3G3RX2

(kW)

A2004 0.4 EB-30E 5 HS8 HS8 EB-30E 5 HS8 HS8

A2007 0.75 EB-30E 10 HS8 HS8 EB-30E 5 HS8 HS8

A2015 1.5 EB-30E 15 HS8 HS8 EB-30E 10 HS8 HS8

A2022 2.2 EB-30E 20 HS8 HS8 EB-30E 15 HS8 HS8

A2037 3.7 EB-30E 30 HS8 HS20 EB-30E 20 HS8 HS20

A2055 5.5 EB-50E 40 HS20 HS25 EB-30E 30 HS8 HS20

A2075 7.5 EB-50E 50 HS35 HS35 EB-50E 40 HS20 HS25

A2110 11 EB-100E 75 HS50 H65C EB-100E 60 HS35 HS50

A2150 15 RXK125-S 125 H65C H80C EB-100E 100 HS50 H65C

A2185 18.5 RXK125-S 125 H80C H100C EB-100E 100 HS50 H65C

A2220 22 EXK225 150 H80C H125C RXK125-S 125 H65C H80C

A2300 30 EXK225 200 H125C H150C EXK225 150 H80C H125C

A2370 37 RXK250-S 250 H150C H200C EXK225 200 H100C H125C

A2450 45 EX400 300 H200C H250C EXK225 225 H125C H150C

A2550 55 EX400 400 H200C H300C EX400 300 H150C H250C

力率改善リアクトルなし

漏電遮断器(ELB) 電磁接触器(MC) 漏電遮断器(ELB) 電磁接触器(MC)

形式例 定格電流 AC-1 AC-3 形式例 定格電流 AC-1 AC-3

適用器具(入力電圧 200 〜 220V )

力率改善リアクトル

(形 3G3AX-AL または形 3G3AX-DL)あり

• インバータ LD/VLD 定格設定時

適用器具(入力電圧 200 〜 220V )

適用

形式

モータ

3G3RX2

(kW)

A2004 0.75 EB-30E 10 HS8 HS8 EB-30E 5 HS8 HS8

A2007 1.5 EB-30E 15 HS8 HS8 EB-30E 10 HS8 HS8

A2015 2.2 EB-30E 20 HS8 HS8 EB-30E 15 HS8 HS8

A2022 3.7 EB-30E 30 HS8 HS20 EB-30E 20 HS8 HS20

A2037 5.5 EB-50E 40 HS20 HS25 EB-30E 30 HS8 HS20

A2055 7.5 EB-50E 50 HS35 HS35 EB-50E 40 HS20 HS25

A2075 11 EB-100E 75 HS50 H65C EB-100E 60 HS35 HS50

A2110 15 RXK125-S 125 H65C H80C EB-100E 100 HS50 H65C

A2150 18.5 RXK125-S 125 H80C H100C EB-100E 100 HS50 H65C

A2185 22 EXK225 150 H80C H125C RXK125-S 125 H65C H80C

A2220 30 EXK225 200 H125C H150C EXK225 150 H80C H125C

A2300 37 RXK250-S 250 H150C H200C EXK225 200 H100C H125C

A2370 45 EX400 300 H200C H250C EXK225 225 H125C H150C

A2450 55 EX400 400 H200C H300C EX400 300 H150C H250C

A2550 75 EX600B 500 H300C H400C EX400 400 H200C H300C

(注)1.表に記載した形式は選定例です。ご使用の際は、表の定格 電流を元に、電源回路の短絡電流や関連法規などを考

慮の上、適切な遮断容量、感度電流を持つ機種を選定ください。

2. 適用モータ容量は、標準モータ 4 極の 60Hz200Vac(200V 級)を使用する場合の選 定例です。

3. 電磁接触器を AC-1 級でご使用の場合の電気的耐久性は、50 万回ですが、モータ駆動中の緊急停止は 25 回と

なります。

4. モータ駆動中の緊急停止あるいは商用運転がある場合のモータ側の 電磁接触器は、モータの定格電流に対して

AC-3 級で選定してくださ い。

5. インバータの定格容量がモータ容量よりも大きい場合は、インバー タ形式を元に選定してください。

力率改善リアクトルなし

漏電遮断器(ELB) 電磁接触器(MC) 漏電遮断器(ELB)

形式例 定格電流 AC-1 AC-3 形式例 定格電流 AC-1 AC-3

力率改善リアクトル

(形 3G3AX-AL または形 3G3AX-DL)あり

電磁接触器

(MC)

24

Page 25

400V 級

• インバータ ND 定格設定時

適用

形式

モータ

3G3RX2

(kW)

A4007 0.75 EX50C 5 HS8 HS8 EX50C 5 HS8 HS8

A4015 1.5 EX50C 10 HS8 HS8 EX50C 5 HS8 HS8

A4022 2.2 EX50C 10 HS8 HS8 EX50C 10 HS8 HS8

A4037 3.7 EXK50-C 15 HS8 HS10 EX50C 10 HS8 HS8

A4055 5.5 EXK50-C 20 HS8 HS20 EXK50-C 15 HS8 HS20

A4075 7.5 EXK50-C 30 HS8 HS25 EXK50-C 20 HS8 HS20

A4110 11 EXK50-C 40 HS20 HS35 EXK50-C 30 HS8 HS25

A4150 15 EXK50-C 50 HS25 HS50 EXK50-C 40 HS20 HS35

A4185 18.5 EXK100-C 75 HS35 HS50 EXK 50-C 50 HS20 HS35

A4220 22 EXK100-C 75 HS50 H65C EXK60-C 60 HS35 HS50

A4300 30 EXK100-C 100 HS50 H80C EXK100-C 75 HS50 H65C

A4370 37 RXK125-S 125 H80C H 100C EXK100-C 100 HS50 H65C

A4450 45 EX K225 150 H80C H125C RXK125-S 125 H65C H80C

A4550 55 EX K225 200 H100C H125C EXK225 150 H80C H100C

B4750 75 RXK250-S 250 H150C H200C EXK225 200 H100C H125C

B4900 90 EX400 300 H200C H250C EXK225 225 H125C H150C

B411K 110 EX400 400 H200C H300C EX400 300 H15 0C H250C

B413K 132 EX600B 500 H250C H300C EX400 350 H200C H250C

力率改善リアクトルなし

漏電遮断器(ELB) 電磁接触器(MC) 漏電遮断器(ELB) 電磁接触器(MC)

形式例 定格電流 AC-1 AC-3 形式例 定格電流 AC-1 AC-3

適用器具(入力電圧 400 〜 44 0V)

力率改善リアクトル

(形 3G3AX-A L または形 3G3AX-DL)

主回路

あり

• インバータ LD/VLD 定格設定時

適用

形式

モータ

3G3RX2

(kW)

A4007 1.5 EX50C 10 HS8 HS8 EX50C 5 HS8 HS8

A4015 2.2 EX50C 10 HS8 HS8 EX50C 10 HS8 HS8

A4022 3.7 EXK50-C 15 HS8 HS10 EX50C 10 HS8 HS8

A4037 5.5 EXK50-C 20 HS8 HS20 EXK50-C 15 HS8 HS20

A4055 7.5 EXK50-C 30 HS8 HS25 EXK50-C 20 HS8 HS20

A4075 11 EXK50-C 40 HS20 HS35 EXK50-C 30 HS8 HS25

A4110 15 EXK50-C 50 HS25 HS50 EXK50-C 40 HS20 HS35

A4150 18.5 EXK100-C 75 HS35 HS50 EXK 50-C 50 HS20 HS35

A4185 22 EXK100-C 75 HS50 H65C EXK60-C 60 HS35 HS50

A4220 30 EXK100-C 100 HS50 H80C EXK100-C 75 HS50 H65C

A4300 37 RXK125-S 125 H80C H 100C EXK100-C 100 HS50 H65C

A4370 45 EX K225 150 H80C H125C RXK125-S 125 H65C H80C

A4450 55 EX K225 200 H100C H125C EXK225 150 H80C H100C

A4550 75 EX400 250 H150C H200C EXK225 200 H100C H125C

B4750 90 EX400 300 H200C H250C EXK225 225 H125C H150C

B4900 110 EX400 400 H200C H300C EX400 300 H 150C H250C

B411K 132 EX600B 500 H250C H300C EX400 350 H200C H250C

B413K 160 EX600B 600 H400C H400C EX400 400 H250C H300C

(注)1.表に記載した形式は選定例です。ご使用の際は、表の定格電流を元 に、電源回路の短絡電流や関連法規などを考

慮の上、適切な遮断容量、感度電流を持つ機種を選定ください。

2. 適用モータ容量は、標準モータ 4 極の 60Hz400Vac(400V 級)を使用する 場合の選定例です。

3. 電磁接触器を AC-1 級でご使用の場合の電気的耐久性は、50 万回ですが、モータ駆動中の緊急停止は 25 回と

なります。

4. モータ駆動中の緊急停止あるいは商用運転がある場合の モータ側の電磁接触器は、モータの定格電流に対して

AC-3 級で選定してく ださい。

5. インバータの定格容量がモータ容量よりも大きい場合は 、インバータ形式を元に選定してください。

力率改善リアクトルなし

漏電遮断器(ELB) 電磁接触器(MC) 漏電遮断器(ELB) 電磁接触器(MC)

形式例 定格電流 AC-1 AC-3 形式例 定格電流 AC-1 AC-3

適用器具(入力電圧 400 〜 44 0V)

力率改善リアクトル

(形 3G3AX-AL または形 3G3AX-D L)あり

25

Page 26

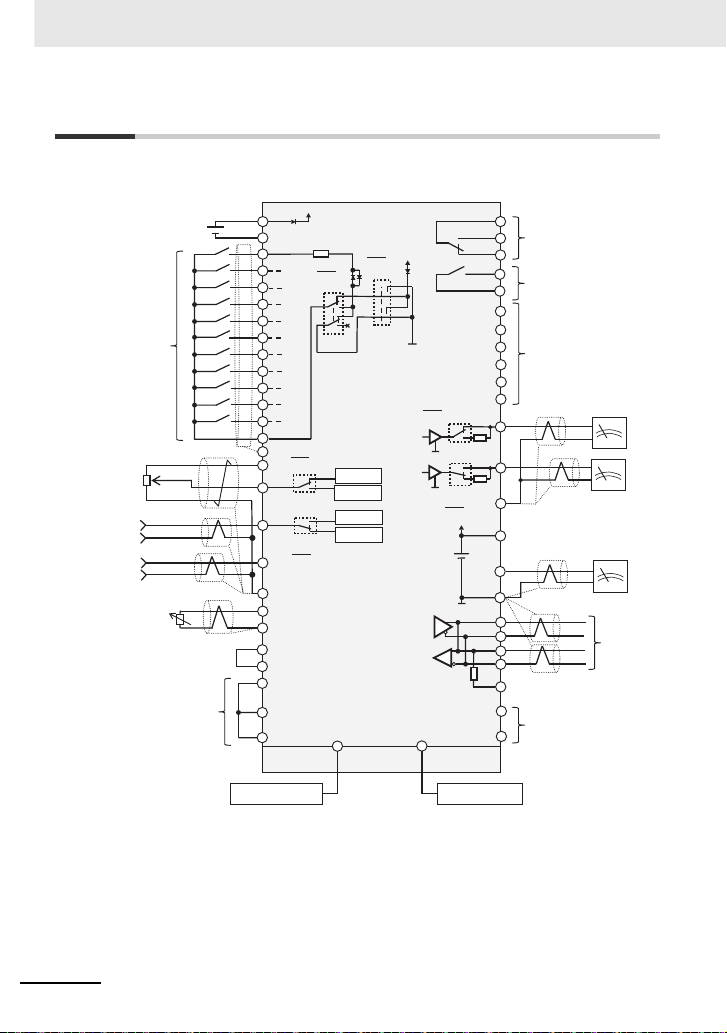

制御回路

ไᚚᅇ㊰➃Ꮚ㒊

䝞䝑䜽䜰䝑䝥⏝

㻞㻠㼂⤥㟁⏝➃Ꮚ

㻼㻗

㻼㻙

㻝㻛㻾㻿

㻞㻛㻿㻯㻴㻳

㻟㻛㻶㻳

㻠㻛㻲㻾㻿

㻡㻛㻞㻯㻴

㻢㻛㻯㻲㻝

㻣㻛㻯㻲㻞

㻤㻛㻾㼂

㻥㻛㻲㼃

㻭㻛㻱㼄㼀

㻮㻛㼁㻿㻼

㻯㻻㻹

㻯㻹㻝

䜲䞁䝍䞊䝣䜵䞊䝇

㻞㻠㼂㟁※➃Ꮚ

㻼㻞㻠

㻴

㻭㼕㻝

㻭㼕㻞

㻭㼕㻟

㻸

䜰䝘䝻䜾

ධຊ 㻝

㻔㻗㻕

㻔㻙㻕

㻔㼼 㻝㻜㼂㻕

㻔㻜 㼂㻕

㼀㻴㻗

㻭㻸㻞

㻭㻸㻝

㻭㻸㻜

㻝㻢㻭

㻝㻢㻯

㻝㻝㻛㻾㼁㻺

㻝㻞㻛㻲㻭㻝

㻝㻟㻛㻲㻭㻞

㻝㻠㻛㻵㻾㻰㼅

㻝㻡㻛㻻㻸

㻯㻹㻞

㻲㻹

㻯㻹㻝

㻭㼛㻝

㻭㼛㻞

㻸

㻿㻼

㻿㻺

㻿㻼

㻿㻺

㻾㻼

㻼㻞㻠㻿

㻿㼀㻯

㻯㻹㻿

㻿㼀㻝

㻿㼀㻞

㻱㻰㻗

㻱㻰㻙

㼀㻴㻙

䜰䝷䞊䝮䝸䝺䞊

㻝㻯᥋Ⅼ

䝸䝺䞊

㻝㻭᥋Ⅼ

ฟຊ➃Ꮚ

䈜䝅䞁䜽 㻛䝋䞊䝇ᑐᛂ

㻸

㻸

㻝㻜㼂

㻝㻜㼂

㻞㻜㼙㻭

㻝㻜㼂

㻝㻜㼂

㻞㻜㼙㻭

㻞㻜㼙㻭

ධຊ➃Ꮚ

䝃䞊䝭䝇䝍

㻾㻿㻠㻤㻡➃Ꮚ

㻹㼛㼐㼎㼡㼟㏻ಙ

㻿㼀㻻ධຊ

㻿㼀㻻☜ㄆฟຊ

䜰䝘䝻䜾

ධຊ 㻞

䜰䝘䝻䜾

ධຊ 㻟

ධຊ➃Ꮚ䛾䝅䞁䜽䞉

䝋䞊䝇ㄽ⌮䛾ษ᭰䛿䚸

㻿㼃㻢䛷ษ䜚᭰䛘䜎䛩䚹

㻼㻞㻠

㻯㻹㻝

㻰㻯㻞㻠㼂

㻼㻞㻠

㻯㻹㻝

㻼㻞㻠

㻵㻺

㻱㼄

䝋䞊䝇

䝅䞁䜽

㻔㻿㼃㻡㻕

㻔㻿㼃㻢㻕

㻔㻿㼃㻝㻕

㻔㻿㼃

㻞㻕

㻔㻿㼃㻟㻕

㻔㻿㼃㻠㻕

㻝㻢㻛㼆㻿

᧯స㒊

㼁㻿㻮

㻾㻶㻠㻡

㻼㻯㻔㻼㼞㼛㻰㼞㼕㼢㼑㻺㼑㼤㼠㻕

㻸㻯㻰䜸䝨䝺䞊䝍

䈜㻾㻿㻠㻤㻡➃Ꮚ䛾䝅䜾䝘䝹

䜾䝷䜴䞁䝗䛿㻯㻹㻝䛷䛩䚹

㻞㻜㼙㻭

㟁ᅽධຊ

㟁ὶධຊ

㟁ᅽධຊ

㟁ὶධຊ

制御回路

26

■制御回路への配線

Page 27

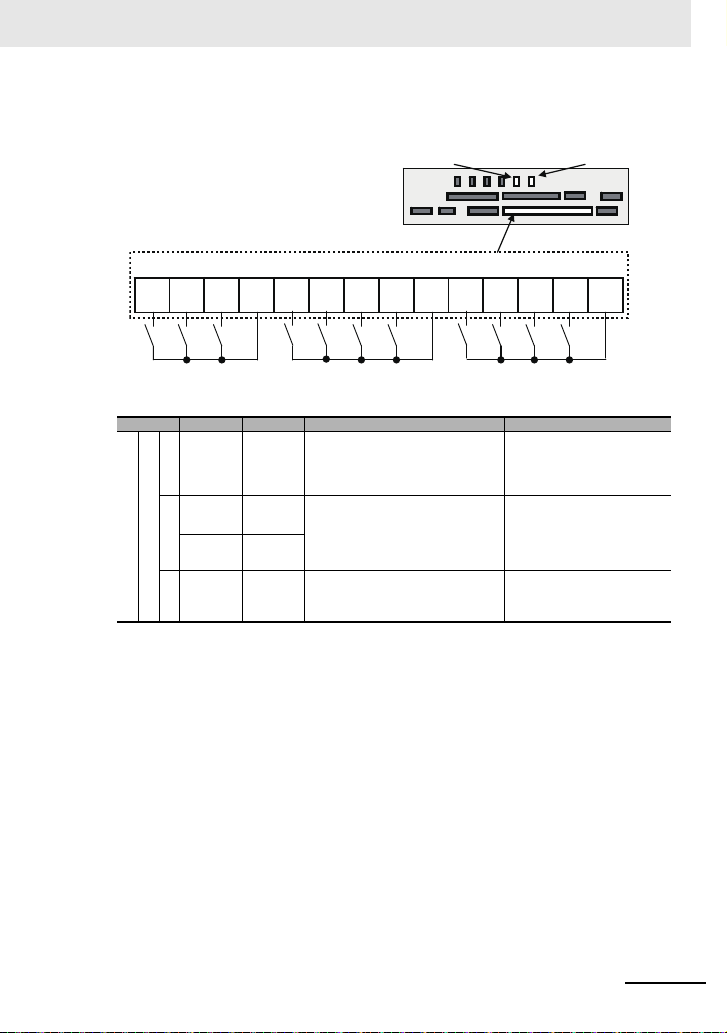

■入力端子

ධຊ➃Ꮚ㻌

㻝

㻌

㼇㻾㻿㼉 㻌

㻞

㻌

㼇㻿㻯㻴㻳㼉

㻌

㻟

㻌

㼇㻶㻳㼉㻌

㻠

㻌

㼇㻲㻾㻿㼉 㻌

㻡

㻌

㼇㻞㻯㻴㼉 㻌

㻢

㻌

㼇㻯㻲㻝㼉 㻌

㻣

㻌

㼇㻯㻲㻞㼉 㻌

㻤

㻌

㼇㻾㼂㼉 㻌

㻥

㻌

㼇㻲㼃㼉 㻌

㻭

㻌

㼇㻱㼄㼀㼉 㻌

㻮

㻌

㼇㼁㻿㻼 㼉㻌

㻯㻻㻹 㻌㻯㻻㻹 㻌㻯㻻㻹 㻌

ไᚚᅇ㊰➃Ꮚ㒊㻌

㻿㼃㻢 㻌

㻿㼃㻡 㻌

• COM はすべて同じ電位です。

• 1 〜 9、A、B と COM の間に電源を接

続する場合は、SW5 を外部電源 (EX) に

切り替えます。

• 入力端子のシンク / ソースは SW6 で切

り替えます。

( 配線例)

• 端子機能名は工場出荷初期設定で記載しています。

イ

ン

テ

リ

ジ

ェ

ン

ト

入

力

端

子

端子記号 端子名称 内容説明 電気的特性

9、8、7、

6、5、4、

接

3、2、1

点

デ

A パルス

ジ

パ

タ

ル

ル

B パルス

ス

入

力

COM 入力端子用

コ

モ

ン

入力端子 各端子 に対応したパラメータ設定によって

入力 -A

入力 -B

コモン

端子機能が選択できます。

シンク論理、ソース論理の切り替えは、

SW6 の SRC/SINK を切り替えること で可

能です。

パルス入力用の端子です。A、B 端子は、

入力端子としても使用できます。

各端子に対応したパラメータ設定によって

端子機能が選択できます。

最大入力パルスは 32kpp s です。

デジタル入力端子

(1、2、3、4、5、6、7、8、9、A、B)の

コモン端子です。COM 端子は 3 つありま

す。

制御回路

各入力 /COM 間電圧

• ON 電圧Min.DC18V

• OFF 電圧Max.DC3V

• 最大許容電圧 DC27V

• 負荷電流 5.6mA(DC27V 時)

各入力 /COM 間電圧

• ON 電圧Min.DC18V

• OFF 電圧Max.DC3V

• 最大許容電圧 DC27V

• 負荷電流 5.6mA(DC27V 時)

• 最大 32kpps パルス入力

27

Page 28

制御回路

正転 FW 逆転 RV 内容

OFF OFF 指令はありません。

ON OFF 正転指令動作

OFF ON 逆転指令動作

ON ON 指令はありません(論理不整合)

* CF3,4 を使用すると最大 15 速まで設定できます。

多段速 1

CF1

多段速 2

CF2

内容

OFF OFF 設定している周波数指令が有効

ON OFF [Ab-11]の周波数指令が 有効

OFF ON [Ab-12]の周波数指令が有効

ON ON [Ab-13]の周波数指令が有効

■入力端子機能([端子記号 : 設定番号])

ここでは出荷初期値の機能について説明します。詳細機能はユーザーズマニュアル (SBCE-437) で確認

してください。

[RS:028]リセット

• トリップした際にリセットします。

[SCHG:015]指令先切替

• 主速指令[AA101](OFF)と補助速指令

[AA102](ON)を切り替えます。

[JG:029]ジョギング

• [JG]ON で運転指令が入ると、[AG-20]の周

波数で動作します。

[FRS:032]フリーランストップ

• [FRS]ON でモータがフリーランします。

[2CH:031]二段加減速

• [2CH]ON で加減速時間 2[AC124]

[AC126]が有効になります。

[EXT:033]外部トリップ

• [EXT]ON でトリップ[E012]を発行します。

[FW:001]正転と[RV:002]逆転

[CF1:003]多段速 1 と[CF2:004]多段速 2 指令

[USP:034]復電再始動防止

• [USP]ON の状態で、電源投入時、運転指令が

入っているとトリップ[E013]を発行します。

28

Page 29

■出力端子

㻝㻢㻭 㻝㻢㻯

䝸䝺䞊

ฟຊ➃Ꮚ

㼄

㻭㻸㻞 㻭㻸㻝 㻭㻸㻜

䜰䝷䞊䝮䝸䝺䞊

ฟຊ➃Ꮚ

㼄

ไᚚᅇ㊰➃Ꮚ㒊

㻝㻝㻝㻞

㼇㻲㻭㻝㼉

㻝㻟

㼇㻲㻭㻞㼉

㻝㻠㻝㻡

㼇㻻㻸 㼉

㻯㻹㻞

ฟຊ➃Ꮚ

㻾㼅 㻾㼅 㻾㼅

㻾㼅 㻾㼅

㻔 㓄⥺㻕

㼇㻭㻸㼉 㼇㼆㻿㼉

㼄

㻦 䝷䞁䝥䚸䝸䝺䞊䚸㻼㻸㻯䛺䛹䛾⨨

㻦䝸䝺䞊

㼇㻵㻾㻰㼅㼉 㼇㻾㼁㻺㼉

㻾㼅

オープンコレクタ

リレー

• 端子機能名は工場出荷初期設定で記載しています。

イ

ン

テ

リ

ジ

ェ

ン

ト

出

力

端

子

端子記号 端子名称 内容説明 電気的特性

15

14

13

12

11

CM2 出力端子用

16A

16C

デ

ジ

タ

ル

AL0

出

AL1

力

AL2

出力端子 各端子 に対応したパラメータ設定によって

コモン

1a リレー端子A 接点出力のリレーで す。 接点最大容量

1c リレー端子C 接点出力のリレーで す。 接点最大容量

端子機能が選択できます。

シンク論理、ソース論理のいずれでも使用

可能です。

11 〜 15 の出力端子用のコモン端子

です。

制御回路

オープンコレクタ出力

• 各端子 /CM2 間

• ON 時電圧降下 4V 以下

• 最大許容電圧 27V

• 最大許容電流 50mA

• AC250V、2A(抵抗)

• AC250V、1A(誘導)

接点最小容量

• DC1V、1mA

AL1/AL0:

• AC250V、2A(抵抗)

• AC250V、0.2A(誘導)

AL2/AL0:

• AC250V、1A(抵抗)

• AC250V、0.2A(誘導)

接点最小容量(共通)

• AC100V、10mA

• DC5V、100mA

29

Page 30

制御回路

電源 状態 AL0 -AL1 AL0-AL2

ON 正常 開 閉

ON トリップ 閉 開

OFF−開閉

電源 状態 AL0 -AL1 AL0-AL2

ON 正常 閉 開

ON トリップ 開 閉

OFF−開閉

■出力端子機能

ここでは出荷初期値の機能について説明します。詳細機能はユーザーズマニュアル (SBCE-437) で確認

してください。

[RUN:001]運転中信号

• 運転(PWM 出力)中、ON します。

[FA1:002]周波数到達信号

• 出力周波数が指令周波数に到達すると ON しま

す。

[FA2:003]周波数到達信号 2

• 出力周波数が設定した周波数[CE-10]〜

[CE-13]に到達すると ON します。

[IRDY:007]運転準備完了

• 運転可能状態となった時に ON します。

[OL:035]過負荷予告

• 電流が過負荷予告レベルを超えると ON します。

[ZS:040]零速検出信号

• 出力周波数が 0Hz 検出レベル[CE-33]を下回

ると ON します。

[AL:017]動作について

• [CC-17]=00 の場合

• [CC-17]=01 の場合

30

Page 31

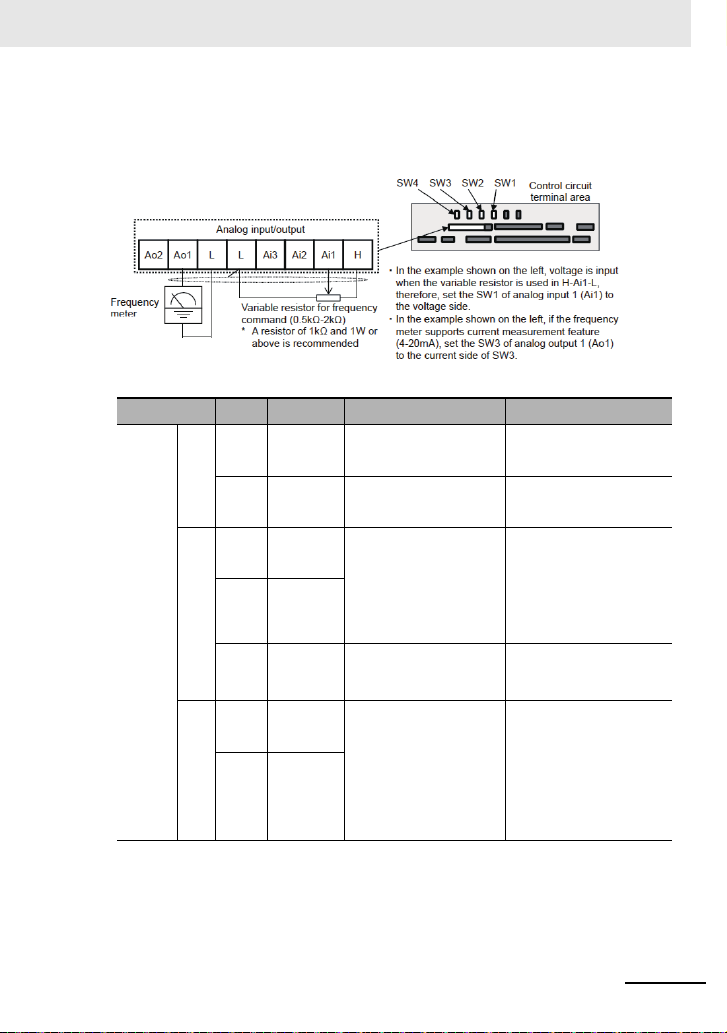

■アナログ入出力端子

㻭㼛㻞 㻭㼛㻝

䜰䝘䝻䜾ධฟຊ

㻴㻭㼕㻝㻭㼕㻞㻭㼕㻟㻸㻸

࿘Ἴᩘᣦ௧⏝ྍኚᢠჾ

㻔㻜㻚㻡㼗䃈䡚㻞㼗䃈㻕

䈜㻝㼗䃈䚸㻝㼃௨ୖ᥎ዡ

ไᚚᅇ㊰➃Ꮚ㒊

㻿㼃㻟㻿㼃㻠 㻿㼃㻞 㻿㼃㻝

࿘Ἴᩘィ

• 左の例は、可変抵抗器を H-Ai1-L 間に配

線する場合で電圧入力になりますので、

アナログ入力 1(Ai1)の SW1 を電圧側

に設定します。

• 左の例は、周波数計が電流対応型(4 〜

20mA)の場合、アナログ出力 1(Ao1)

の SW3 を電流側に設定します。

( 配線例 )

制御回路

端子記号 端 子名称 内容説明 電気的特性

電

源

電

圧

電

流

切

り

Ai1

替

ア

え

ナ

可

ロ

能

Ai2

グ

ア

入

ナ

力

ロ

グ

Ai3

入

出

力

ア

Ao1

端

ナ

子

ロ

グ

出

Ao2

力

アナログ

電源コモン

L

速度設定用電源DC10V 電源です。アナログ入力端子

H

アナログ

入力端子 1

(電圧 / 電流

切替 SW1)

アナログ

入力端子 2

(電圧 / 電流

切替 SW2)

アナログ

入力端子 3

アナログ

出力端子 1

(電圧 / 電流

切替 SW3)

アナログ

出力端子 2

(電圧 / 電流

切替 SW4)

アナログ入力端子(Ai1、Ai2、Ai3)及び、

アナログ出力端子(Ao1、Ao2)のコモン

端子です。

L 端子は 2 つあります。

(Ai1、Ai2、Ai3)を電圧入力で使用し、可

変抵抗器を使用して電圧入力する場合に使

用します。

Ai1 と Ai2 は、DC0 〜 10V 電圧入力と 0

〜 20mA 電流入力を切替スイッチで切り替

え、いずれかが使用できます。

速度指令入力、フィードバック入力として

使用できます。

-10 〜 10V 電圧入力が使用でき ます。

速度指令、フィードバック入力として使用

できます。

Ao1 と Ao2 は、インバータの監視 データ

の出力として、DC0 〜 10V 電圧 出力と 0

〜 20mA 電流出力を切替スイッチで切り替

え、いずれかが使用できます。

最大許容入力電流 20 mA

電圧入力の場合:

• 入力インピーダンス約 10kΩ

• 許容入力電圧DC-0.3V 〜 12V

電流入力の場合:

• 入力インピーダンス約 100Ω

• 最大許容入力電流24mA

電圧入力だけ:

• 入力インピーダンス約 10kΩ

• 許容電圧入力 -12V 〜 12V

電圧出力の場合:

• 最大許容出力電流 2mA

• 出力電圧精度 ±10%

(周囲温度:25 ℃ ±10 ℃)

電流入力の場合:

• 許容負荷インピーダンス 250Ω 以下

• 出力電流精度:±20%

(周囲温度:25 ℃ ±10 ℃)

31

Page 32

制御回路

• TH 端子への接続は、TH+-TH- への配線

だけでツイストし、他の線とは分離して

ください。

• サーミスタは微弱電流のため、主回路線

(動力線)との分離を行ってください。

• サーミスタへの配線は、20m 以内として

ください。

サーミスタ端子

■外部サーミスタ端子

( 配線例 )

እ㒊䝃䞊䝭䝇䝍➃Ꮚ 㻌

㼀㻴 㻙㻌㼀㻴㻗 㻌

ไᚚᅇ㊰➃Ꮚ㒊㻌

㻌

䝃䞊䝭䝇䝍㻌

端子記号 端子名称 内容説明 電気的特性

外部サーミスタ入力外部サーミスタを接続し、温度異常となっ

TH+

ア

ナ

ロ

グ

入

力

TH-

外部サーミスタ

用コモン

た場合、インバータをトリップさせます。

TH+、TH- にサーミ スタをつなぎます。抵

抗異常の検出レベルは、0 〜 10000Ω の間

で調整可能です。

[推奨サーミスタ特性]推奨:(株)芝浦電

子製作所 PB-41E

許容定格電力:100mW 以上

温度異常時のインピーダンス:3kΩ

DC0 〜 5V

[入力回路]

䝃䞊䝭䝇䝍 㻌

㼀㻴 㻗

㼀㻴 㻙㻌

㻰㻯㻡㼂㻌 㻌

㻝㼗 䃈㻌

㻞㼗䃈㻌

㻌

32

Page 33

ไᚚᅇ㊰➃Ꮚ㒊

㻿㼃㻠

㻿㼃㻟

㻿㼃㻞

㻿㼃 㻝

㻿㼃㻡

㻿㼃㻢

㻝㻜㼂

㻞㻜㼙㻭

㻝㻜㼂

㻞㻜㼙㻭

㻝㻜㼂

㻞㻜㼙㻭

㻝㻜㼂

㻞㻜㼙㻭㻵㻺㻱㼄

㻿㻵㻺㻷

㻿㻾㻯

㻭㼛㻞 㻭㼛㻝 㻭㼕㻞

㻭㼕㻝 㻼㻚㻿㻱㻸

㻔㻿㼃㻠㻕㻌 㻌 㻌㻌 㻔㻿㼃㻟㻕㻌 㻌㻌㻌㻌㻌㻌㻌 㻔㻿㼃㻞㻕㻌 㻌㻌㻌㻌㻌㻌㻌 㻔㻿㼃㻝㻕㻌 㻌㻌㻌㻌㻌 㻌 㻔㻿㼃㻡㻕㻌 㻌㻌㻌㻌㻌㻌㻌 㻔㻿㼃㻢㻕

* スイッチは、電源を投入する前に切り替えを

行ってください。故障の原因になります。

(工場出荷時設定)

制御回路

スイッチの構成

表記 SW 名称 内容説明

Ai1

(SW1)

Ai2

(SW2)

Ao1

(SW3)

Ao2

(SW4)

P.SEL

(SW5)

SRC/SINK

(SW6)

入力 1 切替

入力 2 切替

出力 1 切替

出力 2 切替

入力端子の

電源供給方法切替

シンク / ソース切替

アナログ

アナログ

アナログ

アナログ

入力端子

アナログ入力 1(A i1 端子)の入力仕様を切 り替えます。

10V:電圧入力が可能です。

20mA:電流入力が可能です。

アナログ入力 2(A i2 端子)の入力仕様を切 り替えます。

10V:電圧入力が可能です。

20mA:電流入力が可能です。

アナログ出力 1(A o1 端子)の出力仕様を 切り替えます。

10V:出力が電圧出力になります。

20mA:出力が電流出力になります。

アナログ出力 2(A o2 端子)の出力仕様を 切り替えます。

10V:出力が電圧出力になります。

20mA:出力が電流出力になります。

入力端子への給電方法を切り替えます。

IN:内部電源で入力端子を駆動します。

EX:外部電源を入力端子に入力し駆動します。

(EX の場合、入力端子 -COM 間 に電源が必要です。)

入力端子のシンク / ソース論理を切り替えます。

SW5 が IN の場合に有効です。

SINK:シンク論理にします。

SRC:ソース論理にします。

33

Page 34

制御回路

㻔㻗㻕㻌 㻌 㻌 㻔㻙㻕

ไᚚᅇ㊰➃Ꮚ㒊㻌

㻹㼛㼐㼎㼡㼟㻌㏻ಙ㻌

㻾㻼㻿㻺㻿㻼㻿㻺㻿㻼㻯㻹㻝

⤊➃ᢠ䜢᭷ຠ䛻䛩䜛ሙྜ䚸㻌㻾㻼㻙㻿㻺

䜢▷⤡䛧䛶䛟䛰䛥䛔㻌䚹㻌

㻯㻹㻝䛿እ㒊ᶵჾ䛾

㻿㻳䠄 䝅䜾䝘䝹䜾䝷䞁䝗 䠅

䛻᥋⥆䛧䛶䛟䛰䛥䛔䚹㻌

■ RS485 通信端子

RS485通信端子台の配列と端子の内容を下記に示します。

(配線例 )

同じ名称の SP、SNはそれぞれ内部でつながっていますので、複数配線する時に利用できます。

RS458通信シリアル

通信

端子

記号

SP

SN

RP

(CM1)

端子名称 内容説明 電気的特性

SP 端子:RS-485 差動 (+) 信号

SN 端子:RS-485 差動 (-)信号

RP 端子:終端抵抗を 介し SP に接続

Modbus通信用

RS-485端子

CM1 端子:外部通信 機器のシグナルグラ

ウンドと接続します。(FM 端子兼用 )

SP 端子、SN 端子はそれぞれ 2 つあり、

内部でつながっています。

最大ボーレートは 1 15.2kbps です。

終端抵抗 (120Ω)内蔵

有効:RP-SN短絡

無効:RP-SN開放

34

Page 35

■ STO 端子、EDM 端子

制御回路端子部

出荷時の配線状態

STO端子

ST2 STC ST1

P24S STC CMS

STO 機能で使用する STO 端子、EDM 端子です。STO 機能の詳細はユーザーズマニュアル

(SBCE-437) を参照してください。

制御回路端子部

制御回路

EDM端子

端子記号 端 子名称 内容説明 電気的特性

ST1/ST2 STO 入力端子

ED+ ED-

負荷

P24S

CMS

STC 入力論理切替端子

ED+ EDM 信号出力端子 (+)

ED- EDM 信号出力端子 (-)

24V 出力端子

(STO 入力専用 )

24V 出力端子コモ ン

(STO 入力専用 )

配線例

ST1/ST2 端子専用の接 点信号用の DC24V

電源です。コモンは C MS です。

ST1/ST2 端子専用の接 点信号用の DC24V

電源のコモン端子です。

STO 入力のロジック切替 端子です。

短絡線の接続位置を変更することで入力ロ

ジックを変更することができます。

また、外部電源を使用する場合は、短絡線を

外し、ST1/ST2 の入力 コモンとして使用し

ます。

STO の入力端子です。 ST1-STC/ST1-STC 間電圧

EDM 信号 (STO 状態モニタ ) のプラス側の

端子です。

EDM 信号 (STO 状態モニタ ) のマイナス側

の端子です。

最大出力電流 100mA

< シンク論理時 >

短絡線:P24S-STC 間に接続

< ソース論理時 >

短絡線:CMS-STC 間 に接続

• ON 電圧Min.DC15V

• OFF 電圧Max.DC5V

• 最大許容電圧 DC27V

• 負荷電流 5.8mA(DC27V 時 )

内部抵抗:4.7kΩ

オープンコレクタ出力

• ED+/ED- 間

• ON 時電圧降下 4V 以下

• 最大許容電圧 27V

• 最大許容電流 50mA

35

Page 36

制御回路

㻌

䝬䜲䝘䝇䝗䝷䜲䝞䛷

⅊Ⰽ䛾㒊ศ䜢

ᢲ䛧㎸䜐

㟁⥺䜢ᕪ䛧㎸䜐

䝬䜲䝘䝇䝗䝷䜲䝞䜢

ᘬ䛝ᢤ䛟䛸㟁⥺䛿

ᅛᐃ䛥䜜䜛

㻞㻚㻡㼙㼙

■配線時の推奨端子

• 配線のしやすさや接続の信頼性向上のため、信号線には下記仕様の棒端子を推奨します。

• 制御回路端子台はスプリングクランプ式です。

スリーブ有りの棒端子

電線サイズ

2

mm

(AWG)

0.25(24) AI0,25-8YE 8 12.5 0.8 2.0

0.34(22) AI0,34-8TQ 8 12.5 0.8 2.0

0.5(20) AI0,5-8WH 8 14 1.1 2.5

0.75(18) AI0,75-8GY 8 14 1.3 2.8

*メーカ:フェニックスコンタクト㈱

かしめ工具CRIMPFOXUD6-4 または CRIMPFOXZA3

棒端子型式*

L1

[mm]L2[mm]φd[mm]φD[mm]

■配線方法

1 制御回路端子台の灰色の部分をマイナスドライバ(幅 2.5mm 以下)で押し込みます。

(電線挿入部が開口します)

2 マイナスドライバを押し込んだまま、電線挿入部(丸穴)に電線または棒端子を差し込みま

す。

3 マイナスドライバを抜くと電線が固定されます。

電線を引き抜く時も,灰色部分をマイナスドライバで押し込んだ(電線挿入部開口)状態で引

き抜いてください。

36

Page 37

EU 指令の適合条件

警告

EU 指令の適合条件

■規格

EMC EN61800-3:2004/AI:2012

機能安全 IEC61800-5-2:2016

• 本製品は工業環境向けに設計されたものです。

住居環境でご利用されると、電波妨害の原因となる可能性があります。その場合には、電波妨害に

関する適切な対策が必要となります。

• 本製品は家庭用施設に供給する電力系統に接続することは意図されていません。

■製造者および EU 代理人

製造者(Manufacturer): オムロン株式会社

EU 代理人 (RepresentativeandImporterinEU):

* Cau tionforEMC は英文記載の内容が優先されます。

和文は参考表記です。

概要:

形 3G3RX2 シリーズ(以下 RX2 とする)は、3 相入力、3 相出力の opentype の交流インバー

タです。RX2 は筐体内で使用されることを意図しています。RX2 は、交流モータに対し、調整可能

な電圧と周波数の両方を供給します。RX2 は、モータの速度制御を行うために要求される電圧と周波

数を自動的に制御します。RX2 は、多重定格を持つ装置であって、操作者は LCD オペレータを用い

て負荷定格の選択をすることができます。

ENISO13849-1:2014

EN61800-5-1:2007

〒 600-8530 京都市下京区塩小路通堀川東入

OMRONEuropeB.V.

Wegalaan67-69,2132JDHoofddorp,TheNetherlands

■ EMC(電磁両立性)についての注意点

形 3G3RX2 シリーズは、電磁両立性 EMC 指令(2014/30/EU)に準拠しています。欧州においてイン

バータを使用する場合、欧州における EMC 指令およびその他の基準を満たすために、以下の仕様と要件

を満たす必要があります。

1.供給電源:

(a) 電圧変動-15% 〜 10% 以内

(b) 電圧不平衡±3% 以内

(c) 周波数変動±4% 以内

(d) 電圧歪み±10% 以内

本機器は、電気作業、インバータ操作、起こり得る危険な状況、これらの知識を十分に持

つ専門の技術者によって、設置、調整、修理を行ってください。本紙記載の予防措置を怠

ると、身体の怪我に至る場合があります。

37

Page 38

EU 指令の適合条件

2.据付:

(a) 形 3G3RX2 シリーズには EMC フィルタが内蔵されています。内蔵 EMC フィルタを有効である

ことが必要です。

(b) EN61800-3 において、C3 フィルタだけ内蔵したインバータは、C1 フィルタが要求される住宅

地域の低電圧公共電源に接続できないことに注意してください。

(c) C2 対応のための外部フィルタを使用する場合、EN61800-3 において、次の注記が必要です。

「この製品は、住宅地に対し、高周波障害の可能性があるため、EMC 対応のための追加処置が必

要な場合があります」

(d) EN61800-3-12 において、主電源系統の高調波を抑制するために追加で AC リアクトルまたは

DC リアクトルを設置する必要があります。

3.配線 :

(a) モータ配線には、シールド線(遮蔽ケーブル)を使用してください。配線の長さは、Table1 に

記載の長さ以下で使用してください。

(b) EMC 要求を満たすためには、Table1 に記載のキャリア周波数の設定で使用してください。

(c) 電源入力とモータ配線、信号線はそれぞれ分離してください。

4.使用環境

(フィルタをご使用の際)

(a) 形 3G3RX2 シリーズの内蔵 EMC フィルタを有効にしたうえで、下表の仕様範囲で使用してく

ださい。

Table1

形式

3G3RX2

A2004 C3 10m 2kHz -- -- -- -A2007 C3 10m 2kHz A4007 C3 10m 2kHz

A2015 C3 10m 2kHz A4015 C3 10m 2kHz

A2022 C3 10m 2kHz A4022 C3 10m 2kHz

A2037 C3 10m 2kHz A4037 C3 10m 2kHz

A2055 C3 5m 2kHz A4055 C3 5m 2kHz

A2075 C3 5m 2kHz A4075 C3 5m 2kHz

A2110 C3 5m 2kHz A4110 C3 5m 2kHz

A2150 C3 10m 1kHz A4150 C3 10m 2kHz

A2185 C3 10m 1kHz A4185 C3 10m 2kHz

A2220 C3 10m 1kHz A4220 C3 10m 2kHz

A2300 C3 5m 2kHz A4300 C3 5m 2kHz

A2370 C3 5m 2kHz A4370 C3 5m 2kHz

A2450 C3 5m 2kHz A4450 C3 5m 2kHz

A2550 C3 5m 2kHz A4550 C3 5m 2kHz

-- -- -- -- B4750 C3 3m 2kHz

-- -- -- -- B4900 C3 3m 2kHz

-- -- -- -- B411K C3 3m 2kHz

-- -- -- -- B413K C3 3m 2kHz

Cat.

ケーブル長

キャリア

周波数設定形式3G3RX2

Cat. ケーブル長

キャリア

周波数設定

■電気安全(定電圧指令(LVD))についての注意点

次項 UL 規格の適合条件と同一ですので、温度条件、設置条件等の記載事項に従うことが必要です。

38

Page 39

UL/CSA 規格の適合条件

UL/CSA 規格の適合条件

■規格

US UL61800-5-1

CA CSA22.2No.274

FS IEC61800-5-2:2016STOSIL3

概要:

形 3G3RX2 シリーズ(以下 RX2 とする)は、3 相入力、3 相出力の "opentype" の交流インバータ

です。RX2 は筐体内で使用されることを意図しています。RX2 は、交流モータに対し、調整可能な

電圧と周波数の両方を供給します。RX2 は、モータの速度制御機能として、自動的に要求された電圧

- 周波数の割合を維持します。RX2 は、多重定格を持つ装置であって、操作者は LCD オペレータを

用いて負荷定格の選択をすることができます。

* ULcaution は英文記載の内容が優先されます。

和文は参考表記です。

表示:

UL 認証における最大周囲温度:

ND(標準負荷): 50 ℃

LD(軽負荷): 50 ℃ *

VLD(超軽負荷): 45 ℃ *

保管環境温度: 65 ℃(輸送時)

据付けの指定 汚染度2、過電圧カテゴリ III

配線: 本書の主回路配線、制御回路配線をご確認ください。

* 実使用は共通仕様の温度範囲で使用してください。

短絡耐量と装置(インバータ)の過電流保護定格

• 200V 級機種(形 3G3RX2-A2 □)

• 400V 級機種(形 3G3RX2-A4 □、-B4 □)

内蔵保護 :

インバータの短絡保護は、分岐回路の保護をするわけではありません。分岐回路については、

NationalElectricalCode や、各地域で要求される規格に基づいた保護回路を実施してください。

ISO13849-1:2015Cat.4PLe

電源出力((a)Arms の正弦波電流以下)、最大電圧が (b)V に制限された系統に接続してくださ

い。

電源出力((a)Arms の正弦波電流以下)、最大電圧が (b)V に制限された系統に接続してくださ

い。

200V A2004 〜 A2220 5,000Arms 240V

400V A4007 〜 A4220 5,000Arms 500V

3G3RX2- □□□□□ (a) (b)

A2300 〜 A2550 10,000Arms 240V

A4300 〜 A4550、

B4750、B4900

B411K、B413K 18,000Arms 500V

10,000Arms 500V

内蔵のソリッドステート短絡保護に分岐回路保護は含まれていません。

分岐回路保護は、CanadianElectricalCode,Part 1もしくはそれと同等の規約を遵守してくだ

さい。

39

Page 40

UL/CSA 規格の適合条件

フィールド配線端子サイズと端子締め付けトルク :

形式名

3G3RX2

(注)1. フィールド配線の温度定格は、75 ℃だけです。

負荷仕様選択締付トルク

A2004

A2007

A2015

A2022

A2037

A2055

A2075

A2110

A2150

A2185

A2220

A2300

A2370

A2450

A2550

VLD

ND

VLD

ND ND

VLD

ND ND

VLD

ND ND

VLD

LD LD

ND ND

VLD

LD LD

ND ND

VLD

LD

ND ND

VLD

ND 6 ND

VLD

2.5 〜 3.0

ND 4 ND

VLD

2.5 〜 3.0

LD 2 LD

ND 3 ND 8

VLD

5.5 〜 6.6

LD 1/0 LD

ND 1 ND 6

VLD

LD LD 2

ND 2/

VLD

ND 15 4/0 ND

VLD

LD Parallelof1/0 LD

ND Parallelof1/0 ND 1

VLD

10 〜 12

LD Parallelof3/0 LD

ND 350kcmil ND 1/0

2. 銅線だけ使用してください。

(N.m)

1.4 14LD

1.4 14 A4007

1.4 14 A4015

1.4 10 A4022

1.4 10 A4037

38A4055

3

4

6

6〜10

6〜10

電線径

(AWG)

6

8

4

3

1

2/0

Parallelof1/0

0 ND 3

Parallelof1/0

Parallelof2/0

Parallelof3/0

形式名

3G3RX2

A4075

A4110

A4150

A4185

A4220

A4300

A4370

A4450

A4550

B4750

B4900

B411K

B413K

負荷仕様選択締付トルク

VLD

VLD

VLD

VLD

VLD

VLD

LD

VLD

VLD

VLD

VLD

VL

VLD

VLD

VLD 6 〜 10 Parallelof1/0

VLD

ND

VLD

LD

ND

VLD

LD

ND

VLD

LD Parallelof4/0

ND Parallelof3/0

(N.m)

1.4 14LD LD

1.4 14LD LD

1.4 14LD LD

1.4

3

3

48LD LD

48LD LD

4

4

D

6

15 1LD Parallelof1/0 LD

15

15

10 〜 12 Parallelof1/0LD

10 〜 12

10 〜 12

10 〜 12

電線径

(AWG)

12

14

10

12

8

10

6

4

1

1/0

2/0

Parallelof2/0

Parallelof1/0

Parallelof3/0

Parallelof2/0

P.of250kxmil

40

Page 41

ヒューズと回路ブレーカによる保護要求

200V 級モデル

形式名

3G3RX2

A2004 ClassJorT 600 15 - A2007 ClassJorT 600 30 - A2015 ClassJorT 600 40 - A2022 ClassJorT 600 40 - A2037 ClassJorT 600 50 - A2055 ClassJorT 600 100 - A2075 ClassJorT 600 150 - A2110 ClassJorT 600 150 - A2150 ClassJorT 600 150 - A2185 ClassJorT 600 200 - A2220 ClassJorT 600 200 - A2300 ClassJorT 600 300 - A2370 ClassJorT 600 300 - A2450 ClassJorT 600 400 - A2550 ClassJorT 600 500 - -

型式

400V 級モデル

形式名

A4007 ClassJorT 600 15 - A4015 ClassJorT 600 20 - A4022 ClassJorT 600 30 - A4037 ClassJorT 600 30 - A4055 ClassJorT 600 75 - A4075 ClassJorT 600 75 - A4110 ClassJorT 600 75 - A4150 ClassJorT 600 100 - A4185 ClassJorT 600 100 - A4220 ClassJorT 600 100 - A4300 ClassJorT 600 200 - A4370 ClassJorT 600 200 - A4450 ClassJorT 600 200 - A4550 ClassJorT 600 250 - B4750 ClassJorT 600 300 - B4900 ClassJorT 600 400 - B411K ClassJorT 600 500 - B413K ClassJorT 600 500 - -

型式

ヒューズ ブレーカ

電圧(V) 電流(A) 電圧(V) 電流(A)

ヒューズ ブレーカ

電圧(V) 電流(A) 電圧(V) 電流(A)

UL/CSA 規格の適合条件

最大定格 最大定格

最大定格 最大定格

41

Page 42

韓国電波法(KC)

یࡈ߇ΰח

ࢇЕ߶הࡈˁ߾۰یࡈଟּࢶࡳԻࢶଢ۽ૡɼձ؇ࡵԻ۰

ɼࢽࡈˁ߾۰یࡈଜЕˁࡉࢷળɾۺࢂࡉԮɼݡТЬ

韓国電波法(KC)

使用者への案内

この機器は業務用環境で使用する目的で適合性評価を受けた機器です。

家庭用環境で使用する場合、電波干渉の恐れがあります。

42

Page 43

Page 44

インダストリア ル オートメーションビジネスカンパ ニー

●製品に関するお問い合わせ先

お客様相談室

0120-919-066

携帯電話・PHS・IP電話などではご利用いただけませんので、下記の電話番号へおかけください 。

電話

055-982-5015

■営業時間:8:00〜21:00 ■営業日:365日

●FAXやWebページでもお問い合わせいただけます。

クイック オムロン

(通話料がかかります)

FAX055-982-5051/www.fa.omron.co.jp

●その他のお問い合わせ

納期・価格・サンプル・仕様書は貴社のお取引先、または貴社

担当オムロン販売員にご相談ください。

オムロン制御機器販売店やオムロン販売拠点は、Webページで

ご案内しています。

お断りなく仕様などを変更することがありますのでご了承ください。

Page 45

High-function General-purpose Inverter

RX2 series (3G3RX2-@@@@@)

Instruction Manual

Thank you for purchasing this OMRON Product. Please read this Instruction

Manual and User's Manual, and thoroughly familiarize yourself with the

functions and characteristics of the product before use. Be sure you are using

the most recent version of the User's Manual. Please retain this Instruclion

Manual and the User's Manual for future reference, and be sure they are delivered to the final user of the Inverter Drive.

User’s Manual I620-E1

OMRON Corporation

OMRON Corporation 2019 All Rights Reserved

PIM 2824133-4A

NT3171X

Page 46

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTE NDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder sha ll be, at Omron ’s election, to (i) replace (in the form orig in al ly

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

2

Page 47

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT (S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVE R AL L EQ U IP MENT OR SYSTEM.

Programmable Products

Omron Companies shall not be respo nsi bl e f or t he use r’s pro gra mmi ng of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the use r must co rrela te it t o ac tual applica tio n req uirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographi cal or proofreading errors or omissions.

3

Page 48

Safety Precautions

Safety Precautions

Explanation of Symbols

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally, there may be significant property damage.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or in property damage.

This symbol indicates a prohibited item (an item you must not do).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “disassembly prohibited.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “beware of electric shock.”

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “non-specific general danger.”

This symbol indicates caution (including warning).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “risk of hot surface.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “general compulsory items.”

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “grounding required.”

4

Page 49

Safety Precautions

WARNING

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric sho ck.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric sho ck.

Do not change wiring and slide switches (SW1 to SW6), put on or take off

Operator and optional devices, replace cooling fans while the i nput power is

being supplied. Doing so may result in a serious injury due to an electric

shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to

an electric shock or fire.

(200-V class: type-D grounding, 400-V class: type-C grounding)

Do not remove the terminal cover during the power supply and 15

minutes*1*2 after the power shut off. Doing so may result in a serio us injury

due to an electric shock.

Do not operate the Operator or switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Inspection of the inverter must be conducted after the power supply was

turned off. Not doing so may result in a serious injury due to an electric

shock.

The main power supply is not necessarily shut off even if the emergency shut

off function is activated.

Do not touch the inverter fins, braking resistors and the motor, which become

too hot during the power supply and for some time after the power shut off.

Doing so may result in a burn.

*1. 10 minutes: For models 3G3RX2-A2004 to A2220 and 3G3RX2-A4007 to A4220

*2. 15 minutes: For models 3G3RX2-A2300 to A2550 and 3G3RX2-A4300 to B413K

5

Page 50

Safety Precautions

Be sure to confirm safety before conducting mainte nance, inspection or parts

replacement.

Do not connect resistors to the terminals (PD/+1, P/+, N/-) directly. Doing so

might result in a small-scale fire, heat generation, or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a

minor injury.

(A holding brake is not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit.

In case of a braking resistor, install a thermal relay that monitors the

temperature of the resistor. Not doing s o might r esult i n a mode rate bur n due

to the heat generated in the braking resistor/regenerati ve braking unit.

Configure a sequence that enables the inverter power to turn off when

unusual over eating is detected in the braking resistor/regenerative braking

unit.

The inverter has high voltage parts inside which, if short-circuited, might

cause damage to itself or other property. Place covers on the openings or

take other precautions to make sure that no metal objects such as cutting

bits or lead wire scraps go inside when installing and wiring.

Take safety precautions such as setting up a molded-case circuit breaker

(MCCB) that matches the inverter capacity on the power supply side.

Not doing so might result in damage to property du e to th e short ci rcuit of the

load.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

If a parameter is set incorrectly when starting up, adjusting, maintaining, or

replacing, an unexpected operation may occur.

CAUTION

If the DriveProgramming stops during multi-funct ion output, the output status

is held. Take safety precautions such as stopping peripheral devices.

6

Page 51

Precautions for Safe Use

Precautions for Safe Use

Installation and Storage

Do not store or use the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to ambient temperature exceeding the specifications.

• Locations subject to relative humidity exceeding the specifications.

• Locations subject to condensation due to severe temperature fluctuations.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Transportation, Installation, and Wiring

• Do not drop or apply strong impact on the product. Doing so may result in damaged parts or

malfunction.

• Do not hold by the front cover and terminal cover, but hold by the fins during transportation.

• Confirm that the rated input voltage of the inverter is the same as AC power supply voltage.

• Do not connect an AC power supply voltage to the control input/output terminals. Doing so may result

in damage to the product.

• Be sure to tighten the screws on the terminal block securely. Wiring work must be done after

installing the unit body.

• Do not connect any load other than a three-phase inductive motor to the U, V, and W output

terminals.

• Take sufficient shielding measures when using the product in the following locations. Not doing so

may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

• When using DriveProgramming, confirm that the program data is downloaded normally before

starting operation.

7

Page 52

Precautions for Safe Use

Operation and Adjustment

• Be sure to confirm the permissible range of motors and machines before operation because the

inverter speed can be changed easily from low to high.

• Provide a separate holding brake if necessary.

• If the clock command is u sed in DriveP rogramming , an un expecte d operat ion may occur du e to we ak

battery. Take measures such as detecting a weak battery by [E042] RTC Error and stopping the

inverter or programs. When the LCD Operator is removed or disconnected, DriveProgramming is in a

waiting status by the clock command.

• Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine may

abruptly start.

• Do not come close to the machine when you enable "restart" setting that results in automatic start

after a deceleration stop, (bA-30, bb-20, bb-21) the machine may abruptly start aft er the power is

turned on.

• Provide a separate emergency stop switch because the STOP Key on the Operator is valid only when

function settings are performed .

• When checking a signal during the power supply and the voltage is erroneously applied to the control

input terminals, the motor may start abruptly. Be sure to confirm safety before checking a signal.

• Check whether the motor rotation direction is correct and unusual sound or vibration occurs during

operation.

Maintenance and Inspection

• The capacitor service life is influenced by the ambient temperature. Refer to “Smoothing Capacitor

Life Curve” described in the manual. When a capacitor reaches the end of its service life and does

not work as the product, you need to replace the capacitor.

• When disposing of LCD operators and wasted batteries, follow the applicable ordinances of your

local government. When disposing of the battery, insulate it using tape.

The following display must be indi cated when products usin g lithium primary batteri es (with

more than 6 ppb of perchlorate) are transport to or through the State of California, USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardou s waste / p erc hl ora te

Label or mark the above display on the ex terior of all outer shi pping packages of your products when exporting your p roducts w hich the li thium prim ary batter ies (with m ore than 6 ppb

of perchlorate) are installed to the State of California, USA.

• Do not short + and –, charge, disassemble, heat, put into the fire, or apply strong impact on the

battery. The battery may leak, explode, produce heat or fire. Never use the battery which was applied

strong impact due to such as fall on the floor, it may leak.

• UL standards establish that the battery shall be replaced by an expert engineer. The expert engineer

must be in charge of the replacement an d also replace the battery acc ording to th e method descri bed

in this manual.

• When the display of LCD Operator can not be recognized due to the service life, replace the LCD

Operator.

8

Page 53

Precautions for Correct Use

Dispose of in accordance with WEEE Directive

Precautions for Correct Use

Installation

Mount the product vertically on a wall with the product’s longer sides upright.

The material of the wall must be noninflammable such as a metal plate.

Installation and Wiring

• Confirm that the power voltage for the encoder is the same as the rated voltage (+12V DC or +5V

DC) of the product.

Restart Selection Function

• Do not come close to the machine when using Instantaneous power failure/ under-voltage trip

(bb-24) or over-current (bb-28) because the machine may abruptly start after the alarm cleared.

Maintenance and Parts Replacement

• Generally speaking, inverters contain components and wi ll operate properly only when each compo-

nent operates normally. Some of the electrical components require maintenance depending on application conditions. Periodic inspection and replacement are necessary to ensure proper long-term

operation of Inverters.

• When a cooling fan reaches the end of its service life, replace it.

Product Disposal

Comply with the local ordinance and regulations when disposing of the product.

9

Page 54

Nomenclature

3 G 3 R X2 - A 2 0 5 5

(ND)

IP20*/UL open typeA

B IP00/UL open type

* Based on self declaration.

Nomenclature

10

Page 55

Inverter Specifications

Inverter Specifications

■Inverter Specifications

200V Class Specifications

3G3RX2-A2 A2004 A2007 A2015 A2022 A2037 A2055 A2075 A2110 A2150 A2185 A2220 A2300 A2370 A2450 A2550

Applicable motor