Page 1

Cat. No. I558-E1-02

USER’S MANUAL

SYSDRIVE JX

SERIES

Compact Simplified Inverters

Page 2

Page 3

Introduction

Thank you for choosing the general-purpose Inverter 3G3JX. This User's Manual (hereinafter called

"this manual") describes the parameter setting methods required for installation/wiring and

operation of the 3G3JX model, as well as troubleshooting and inspection methods.

z This manual should be delivered to the actual end user of the product.

z After reading this manual, keep it handy for future reference.

z This manual describes the specifications and functions of the product as well as the relations

between them. You should assume that anything not described in this manual is not possible with

the product.

z Intended readers

This manual is intended for:

Those with knowledge of electrical systems (qualified electrical engineers or the equivalent), and

also in charge of:

• Introducing the control equipment

• Designing the control system

• Installing and/or connecting the control equipment

• Field management

Introduction

1

Page 4

Read and Understand This Manual

Read and Understand This Manual

Please read and understand this manual before using the product. Please consult your OMRON representative

if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

Page 5

Read and Understand This Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

3

Page 6

Read and Understand This Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

4

Page 7

Safety Precautions

Safety Precautions

Indications and Meanings of Safety Information

In this user's manual, the following precautions and signal words are used to provide information to ensure the

safe use of the 3G3JX Inverter.

The information provided here is vital to safety. Strictly observe the precautions provided.

Meanings of Signal Words

Indicates an imminently hazardous situation which, if not avoided,

WARNING

CAUTION

Alert Symbols in This Document

is likely to result in serious injury or may result in death. Additionally

there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

WARNING

Turn off the power supply and implement wiring correctly. Not doing so may result in a serious injury

due to an electric shock.

Wiring work must be carried out only by qualified personnel. Not doing so may result in a serious

injury due to an electric shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to an electric shock or

fire.

(200-V class: type-D grounding, 400-V class: type-C grounding)

Do not remove the front cover during the power supply and 5 minutes after the power shutoff. Doing

so may result in a serious injury due to an electric shock.

Do not operate the Digital Operator or switches with wet hands. Doing so may result in a serious

injury due to an electric shock.

Inspection of the Inverter must be conducted after the power supply has been turned off. Not doing

so may result in a serious injury due to an electric shock.

The main power supply is not necessarily shut off even if the emergency shutoff function is

activated.

Do not change wiring, mode change switches (S7, S8), optional devices or replace cooli ng fans

while the input power is being supplied.

Doing so may result in a serious injury due to an electric shock.

5

Page 8

Safety Precautions

Do not connect resistors to the terminals (+1, P/+2, N/-) directly.

Doing so might result in a small-scale fire, heat generation or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury. (A holding

brake is not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking

resistor, install a thermal relay that monitors the temperature of the resistor. Not doing so might

result in a moderate burn due to the heat generated in the braking resistor/regenerative braking

unit. Configure a sequence that enables the Inverter power to turn off when unusual overheating is

detected in the braking resistor/regenerative braking unit.

The Inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or

other property. Place covers on the openings or take other precautions to make sure that no metal

objects such as cutting bits or lead wire scraps go inside when installing and wiring.

Do not touch the Inverter fins, braking resistors and the motor, which become too hot during the

power supply and for some time after the power shutoff. Doing so may result in a burn.

CAUTION

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches

the Inverter capacity on the power supply side. Not doing so might result in damage to property due

to the short circuit of the load.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

6

Page 9

Precautions for Safe Use

Precautions for Safe Use

Installation and Storage

Do not store or use the product in the following places.

•Locations subject to direct sunlight.

•Locations subject to ambient temperature exceeding the specifications.

•Locations subject to relative humidity exceeding the specifications.

•Locations subject to condensation due to severe temperature fluctuations.

•Locations subject to corrosive or flammable gases.

•Locations subject to exposure to combustibles.

•Locations subject to dust (especially iron dust) or salt.

•Locations subject to exposure to water, oil, or chemicals.

•Locations subject to shock or vibration.

Transporting, Installation, and Wiring

•Do not drop or apply a strong impact on the product. Doing so may result in damaged parts or malfunction.

•Do not hold by the front cover, but hold by the fins during transportation.

•Do not connect an AC power supply voltage to the control input/output terminals. Doing so may result in

damage to the product.

•Be sure to tighten the screws on the terminal block securely.

Wiring work must be done after installing the unit body.

•Do not connect any load other than a three-phase inductive motor to the U, V, and W output terminals.

•Take sufficient shielding measures when using the product in the following locations. Not doing so may

result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

Operation and Adjustment

•Be sure to confirm the permissible range of motors and machines before operation because the Inverter

speed can be changed easily from low to high.

•Provide a separate holding brake if necessary.

Maintenance and Inspection

•Be sure to confirm safety before conducting maintenance, inspection or parts replacement.

7

Page 10

Precautions for Correct Use

Precautions for Correct Use

Installation

•Mount the product vertically on a wall or on a DIN track (optional) with the product's longer sides upright.

The material of the wall has to be nonflammable such as a metal plate.

Main Circuit Power Supply

•Confirm that the rated input voltage of the Inverter is the same as AC power supply voltage.

Error Retry Function

•Do not come close to the machine when using the error retry function because the machine may abruptly

start when stopped by an alarm.

•Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine may

abruptly start.

Non-Stop Function at Momentary Power Interruption

•Do not come close to the machine when selecting restart in the non-stop function at momentary power

interruption selection (b050) because the machine may abruptly start after the power is turned on.

Operation Stop Command

•Provide a separate emergency stop switch because the STOP key on the Digital Operator is valid only when

function settings are performed.

•When checking a signal during the power supply and the voltage is erroneously applied to the control input

terminals, the motor may start abruptly. Be sure to confirm safety before checking a signal.

Product Disposal

•Comply with the local ordinance and regulations when disposing of the product.

8

Page 11

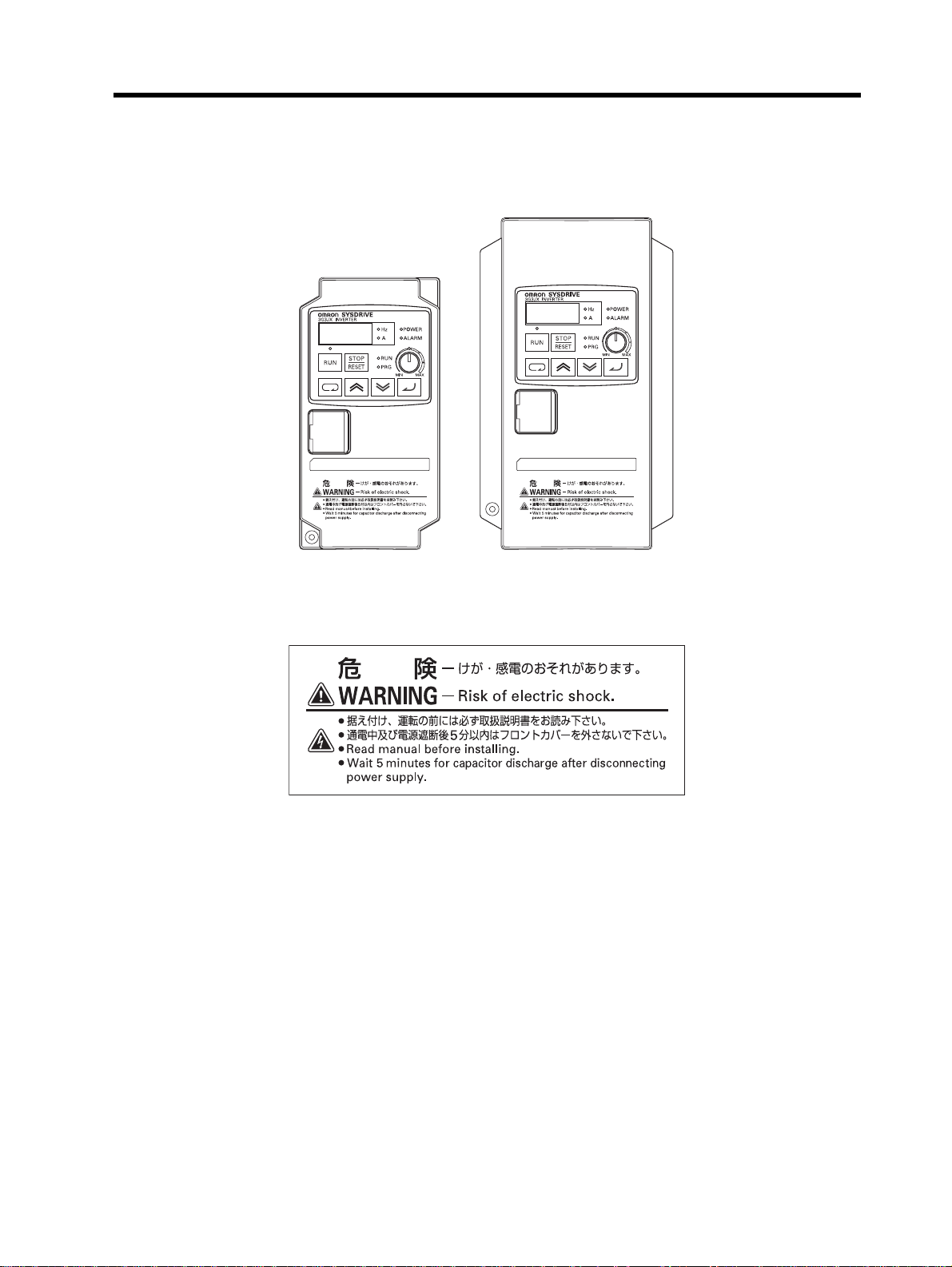

Warning Labels

Warning labels are located on the Inverter as shown in the following illustration.

Be sure to follow the instructions.

Precautions for Correct Use

Warning Description

9

Page 12

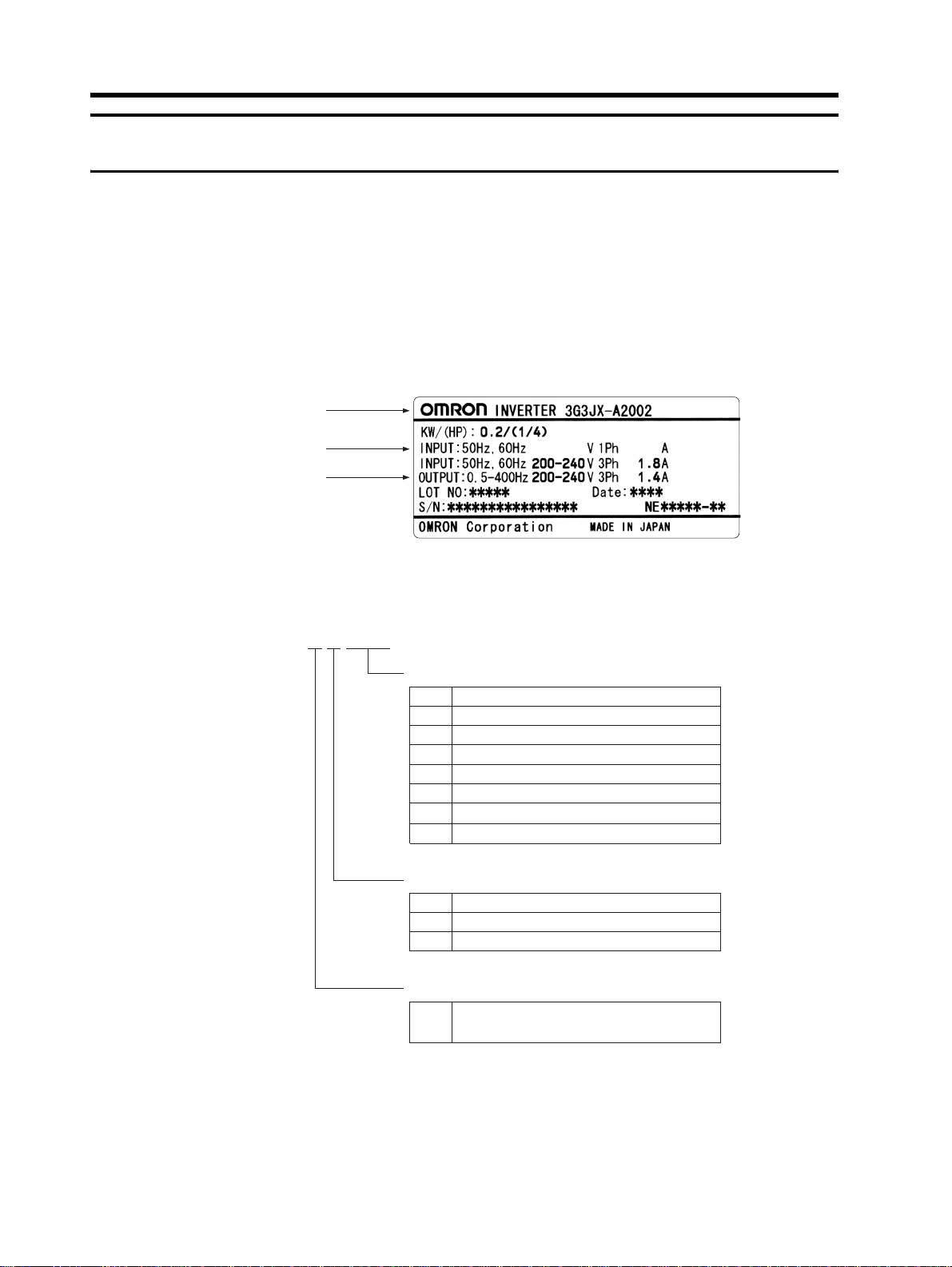

Checking Before Unpacking

Checking Before Unpacking

Checking the Product

On delivery, be sure to check that the delivered product is the Inverter 3G3JX model that you

ordered.

Should you find any problems with the product, immediately contact your nearest local sales

representative or OMRON sales office.

zChecking the Nameplate

Inverter model

Input specifications

Output specifications

zChecking the Model

3G3JX-A2002

Maximum applicable motor capacity

0.2 kW

002

0.4 kW

004

0.75 kW

007

1.5 kW

015

2.2 kW

022

3.7 kW

037

5.5 kW

055

7.5 kW

075

Voltage class

3-phase 200 V AC (200-V class)

2

1/3-phase 200 V AC (200-V class)

E

3-phase 400 V AC (400-V class)

4

Enclosure rating

Panel-mounting (IP10 min.) or closed

A

wall-mounting models

Checking the Accessories

Note that this manual is the only accessory included with the 3G3JX model.

Mounting screws and other necessary parts must be provided by the user.

10

Page 13

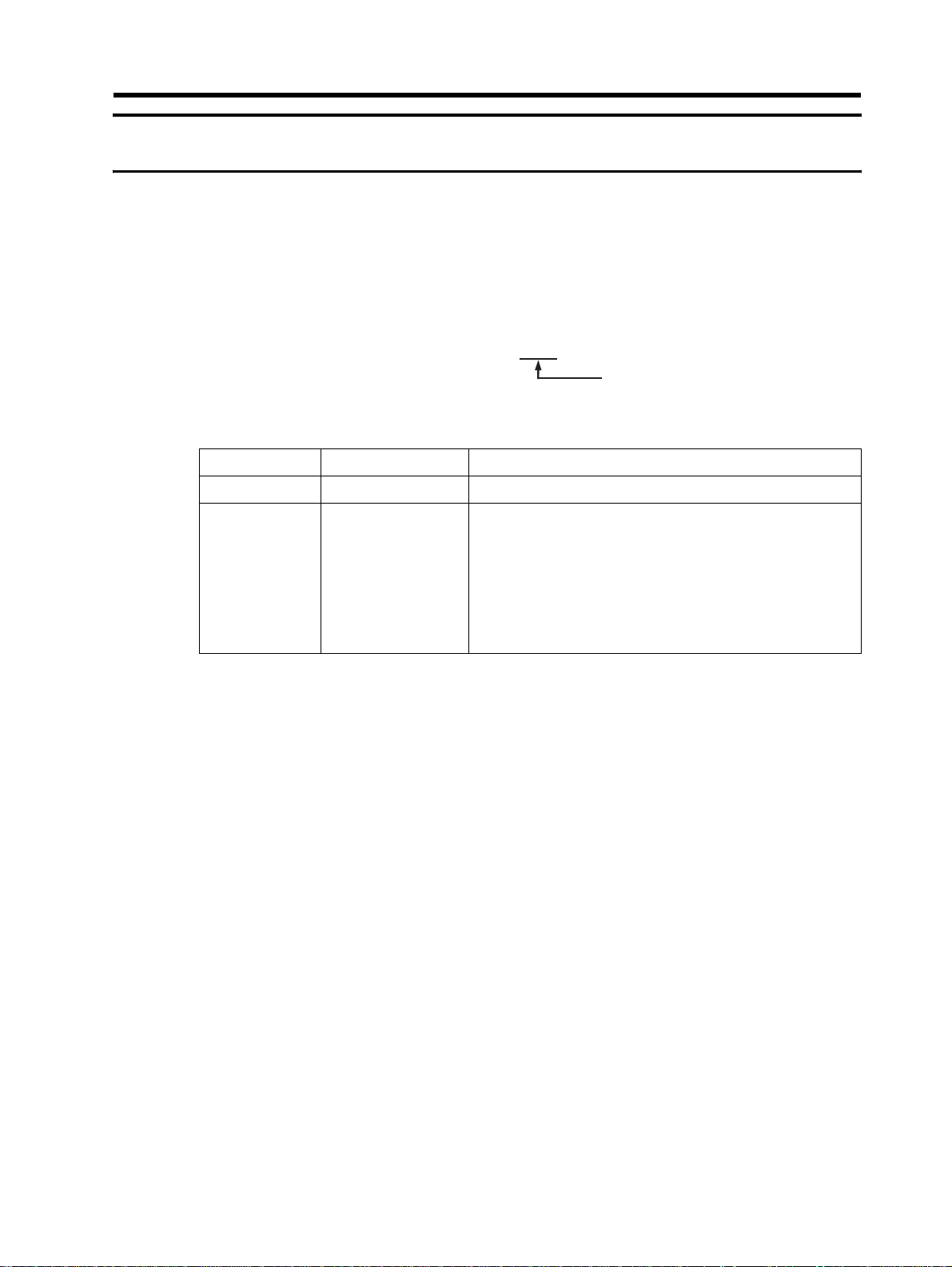

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number located at the

lower left of the front and back covers.

Cat. No.

Revision code Revision date Changes and revision pages

01 December 2007 First printing

02 April 2008

I558-E1-02

Revision code

New Inverters with different capacities added (3G3JX-

A2055/-A2075/-A4055/-A4075)

New functions added for with 5.5-/7.5-kW Inverters

Manual descriptions improved and/or corrected

Page10, Page 1-1, Page 1-2, Page 2-2, Page 2-8, Page 213, Page 2-14, Page 2-15, Page 2-16, Pages 4-77 to 4104, Page 7-1, Page 7-2, Page 7-6, Page 7-18, Page 7-20,

Page 7-26, Page 7-27, Page 7-30

11

Page 14

About This Manual

About This Manual

This User's Manual is compiled chapter by chapter for user's convenience as follows.

Understanding the following configuration ensures more effective use of the product.

Chapter 1 Overview Describes features and names of parts.

Provides external dimensions, installation dimensions, peripheral device

Chapter 2 Design

Chapter 3 Operation

Chapter 4 Functions Describes the functions of the Inverter.

Chapter 5

Chapter 6

Maintenance

Operations

Inspection and

Maintenance

design/selection instructions, and other information necessary for

design.

Describes names of parts, the Inverter's operations, including how to use

the keys on the Digital Operator, and the monitor function.

Describes the causes and their countermeasures if the Inverter fails,

including the solutions to possible troubles (troubleshooting).

Describes items for periodic inspection and/or maintenance for the

Inverter.

Overview

Chapter 7 Specifications

Appendix

Provides Inverter specifications, as well as the specifications and

dimensions of peripheral devices.

Describes the summarized parameter settings as a reference for users

who have used this Inverter and understood the functions.

12

Page 15

Contents

Introduction..............................................................................................1

Read and Understand This Manual.........................................................2

Safety Precautions ..................................................................................5

Precautions for Safe Use.........................................................................7

Precautions for Correct Use....................................................................8

Checking Before Unpacking....................................................................10

Revision History.......................................................................................11

About This Manual...................................................................................12

Chapter 1 Overview

1-1 Functions.................................................................................................1-1

1-2 Appearance and Names of Parts.............................................................1-3

Chapter 2 Design

2-1 Installation................................................................................................2-1

2-2 Wiring.......................................................................................................2-6

Chapter 3 Operation

3-1 Test Run Procedure.................................................................................3-3

3-2 Test Run Operation .................................................................................3-4

3-3 Part Names and Descriptions of the Digital Operator..............................3-9

3-4 Operation Procedure (Example: Factory Default)....................................3-11

3-5 Keys.........................................................................................................3-17

3-6 Parameter Transition................................................. .... ..... .... .... .... .... .....3-18

3-7 Parameter List ..... .... .... .... .... ..... .... .... .... .... ...............................................3-20

Chapter 4 Functions

4-1 Monitor Mode...........................................................................................4-1

4-2 Function Mode.........................................................................................4-5

Chapter 5 Maintenance Operations

5-1 Special Display List................... .... .... .... .... ..... .... .... .... .... ..... .... .... .... .... .....5-1

5-2 Troubleshooting.......................................................................................5-5

Chapter 6 Inspection and Maintenance

6-1 Inspection and Maintenance....................................................................6-1

6-2 Storage....................................................................................................6-7

Chapter 7 Specifications

7-1 Standard Specification List............................................ ..... .... .................7-1

7-2 Measurement Method of Output Voltage.................................................7-5

13

Page 16

Contents

7-3 Connection Example............................................................................... 7-6

7-4 Dimensional Drawing .............................................................................. 7-8

7-5 Options.................................................................................................... 7-14

Appendix

Appendix-1 Parameter List ................................................................................ App-1

Appendix-2 Product Life Curve.......................................................................... App-17

Index

14

Page 17

Chapter 1

Overview

1-1 Functions.......................................................... 1-1

1-2 Appearance and Names of Parts.................... 1-3

Page 18

1-1 Functions

1Overview

1

1-1 Functions

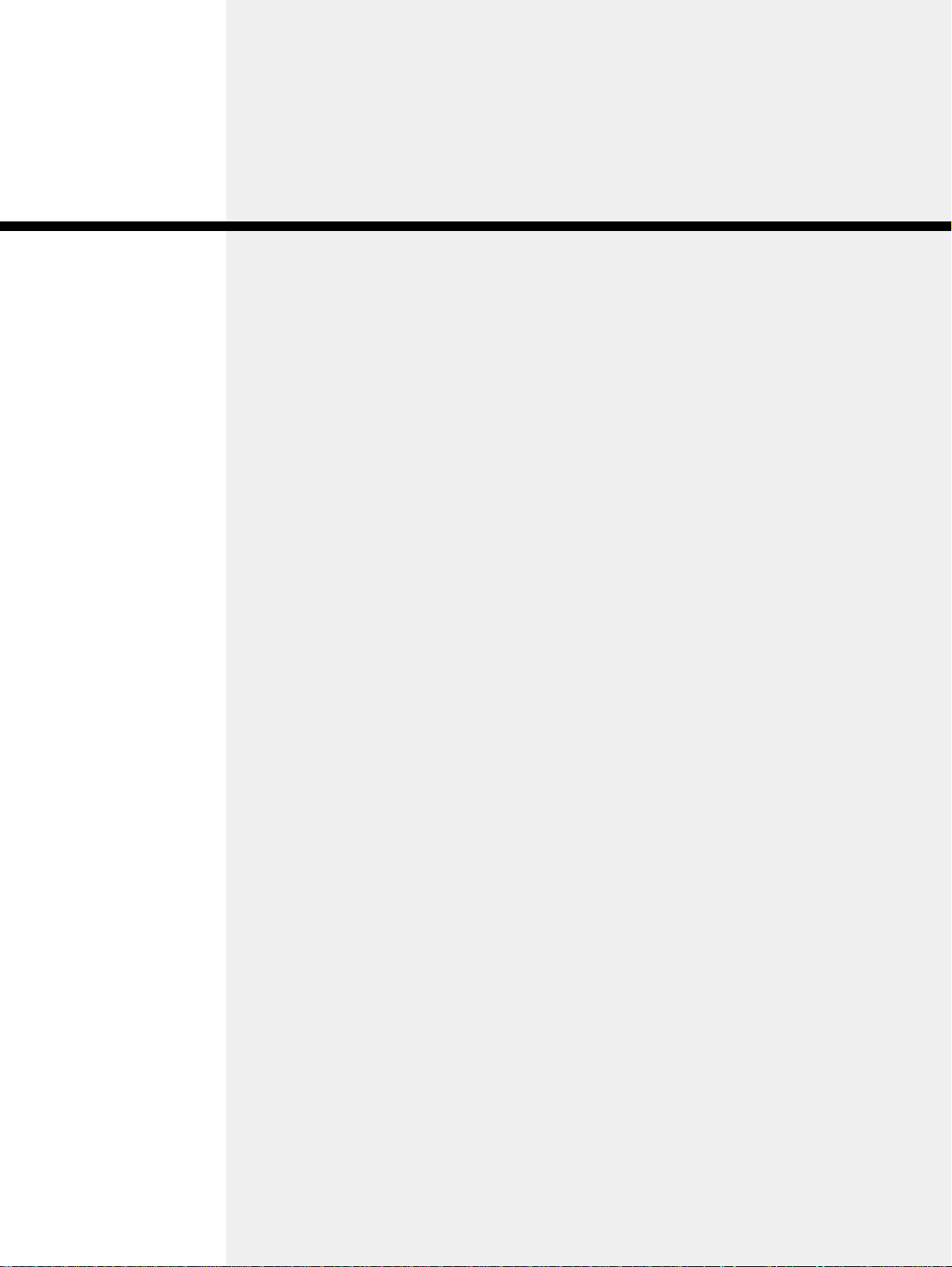

3G3JX Inverter Models

Overview

Rated voltage Enclosure rating Max. applicable motor capacity Model

0.2 kW 3G3JX-A2002

0.4 kW 3G3JX-A2004

0.75 kW 3G3JX-A2007

3-phase 200 V AC

IP20

(Complies with

JEM1030)

3-phase 400 V AC

1.5 kW 3G3JX-A2015

2.2 kW 3G3JX-A2022

3.7 kW 3G3JX-A2037

5.5 kW 3G3JX-A2055

7.5 kW 3G3JX-A2075

0.4 kW 3G3JX-A4004

0.75 kW 3G3JX-A4007

1.5 kW 3G3JX-A4015

2.2 kW 3G3JX-A4022

3.7 kW 3G3JX-A4037

5.5 kW 3G3JX-A4055

7.5 kW 3G3JX-A4075

0.2 kW 3G3JX-AE002

0.4 kW 3G3JX-AE004

1/3-phase 200 V AC

0.75 kW 3G3JX-AE007

1.5 kW 3G3JX-AE015

2.2 kW 3G3JX-AE022

International Standards Models (EC Directives and UL/cUL Standards)

The 3G3JX Inverter meets the EC Directives and UL/cUL standard requirements for worldwide use.

Classification Applicable standard

EC Directives

UL/cUL Standards UL508C

EMC Directive EN61800-3: 2004

Low-voltage Directive EN61800-5-1: 2003

1-1

Page 19

1-1 Functions

Compact Simplified Inverter for Customer's Environment and Application Demands

Simple Wiring and Easy Installation

The main circuit adopts upper/lower wiring as with a conductor. In addition, the side-by-side

mounting of the Inverters and the built-in zero-phase reactor contribute to space saving in control

panel.

Wide Ranging Capacity and Power Supply

In spite of its compact size, the 3G3JX Inverter provides a wide ranging capacity from 0.2 to 7.5 kW.

Moreover, the three-phase 200 V, three-phase 400 V, and single/three-phase 200 V common types

are made to meet the power supply specifications for use outside Japan.

PID Function

The PID function is featured for the easier control of the fan and pump. It helps to control airflow and

pressure.

Emergency Shutoff Function

Switching the dedicated switch (S8) changes from the multi-function input (input 3) to the

emergency shutoff input. You can directly turn off a motor control power module without operating

the software.

Compliance With All Standards

The 3G3JX Series has achieved compliance with CE and UL/cUL.

1

Overview

The RoHS Directive

The standard model meets the requirements of the RoHS Directive.

Noise and Harmonics Suppression Option

The three-phase models incorporate a zero-phase reactor (radio noise filter) as a standard

specification.

For the single/three-phase common type, optional suppression is available.

When the optional DC reactor is added, the 3G3JX Series will also meet the requirements specified

by the Ministry of Land, Infrastructure, Transport and Tourism of Japan.

Handles a Variety of I/O Signals

The 3G3JX Series can handle a variety of I/O signals for wide-ranging applications.

•Analog voltage input: 0 to 10 V

•Analog current input: 4 to 20 mA

1-2

Page 20

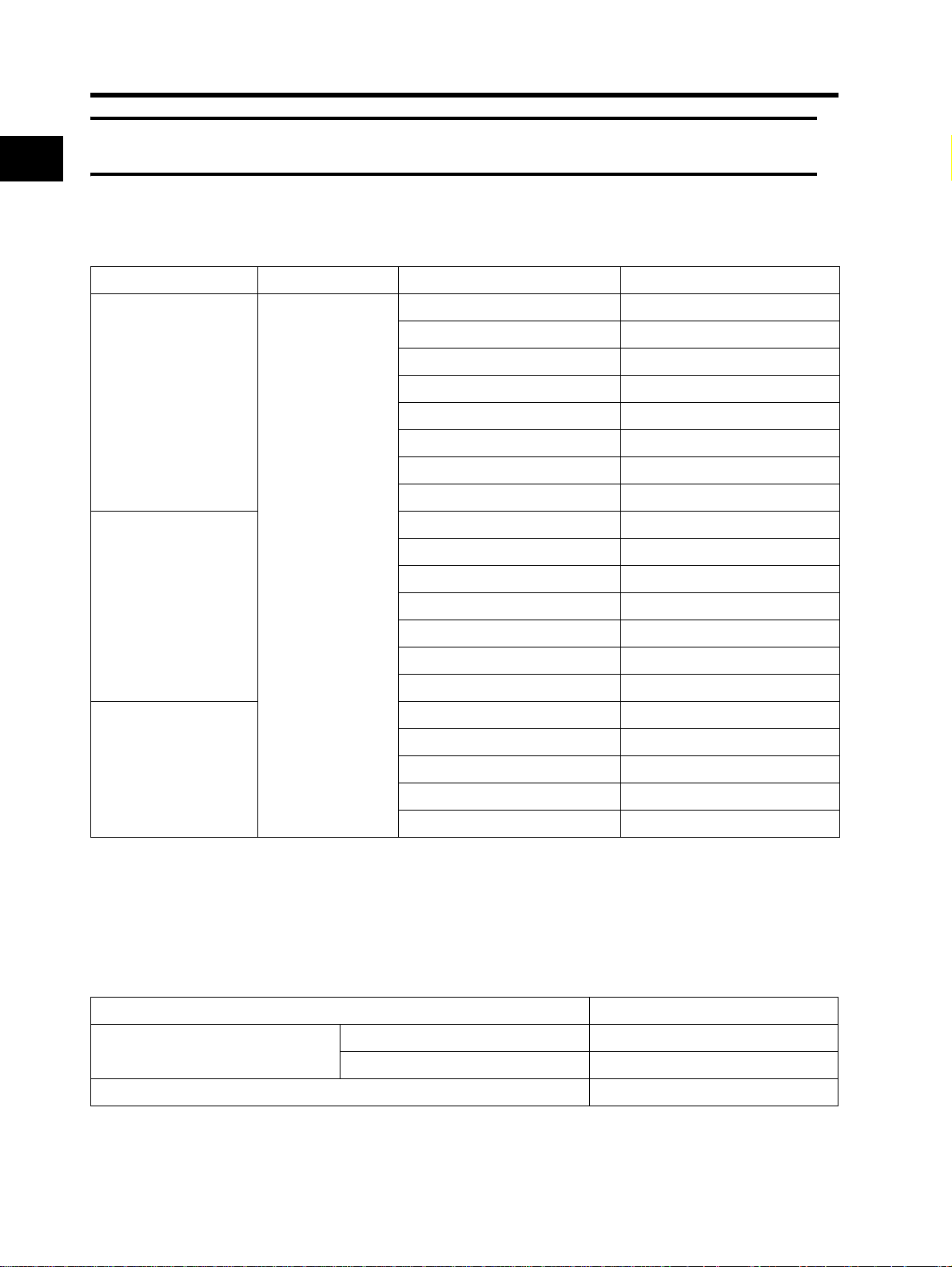

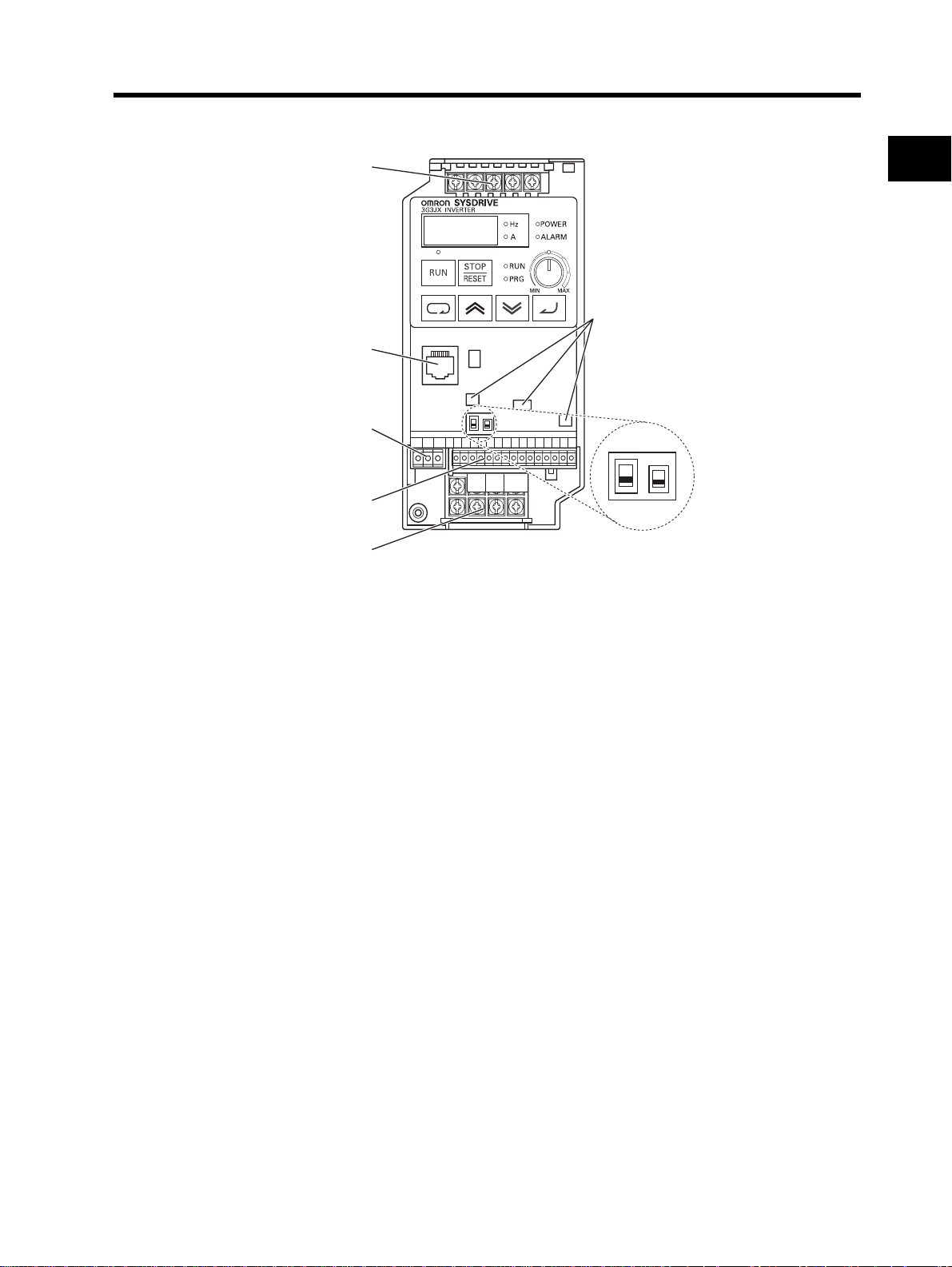

1-2 Appearance and Names of Parts

r

1

1-2 Appearance and Names of Parts

Overview

Top cover

Fin

Digital Operator

Front cover

Bottom cover

•The size of the fin varies with the motor capacity.

•There are two sizes depending on the motor capacity, but the fundamental structure is the same.

•Remove the front cover when connecting the power supply, the motor, and the control signal.

FREQ (FREQUENCY) adjuste

Main housing

Connection to RJ45 Jack

Connect the communications cable after opening the cover of the communications connector.

Remove the front cover to switch communications. Refer to "Removing the Front Cover" (page 2-

6) for instructions on how to remove the front cover.

Communications connector

8k8k8k8

(with cover)

1-3

*The cover of the communications connector is removable. Remove the front cover to attach it.

Page 21

Names of Parts Inside the Front Cover

1-2 Appearance and Names of Parts

Main circuit terminal block

(input side)

8k8k8k8

Communications connector

Relay output terminal block

Control circuit terminal block

Main circuit terminal block

(output side)

S7: OPE/485 communications selector (Default = OPE side)

S8: Emergency shutoff function selector (Default = OFF)

OPE

Do not touch these!

(ELECTRICAL HAZARD:

For factory maintenance only)

S7 S8

485

ON

OFF

1

Overview

(Caution)

Do not switch the emergency shutoff function selector (S8) without reason as the allocation of the

multi-function input terminals may change.

For details, refer to "Emergency Shutoff Input Function" (page 4-45).

1-4

Page 22

1-2 Appearance and Names of Parts

1

Overview

1-5

Page 23

Chapter 2

Design

2-1 Installation........................................................2-1

2-2 Wiring................................................................ 2-6

Page 24

2

Design

2-1 Installation

2Design

2-1 Installation

WARNING

Turn off the power supply and implement wiring correctly. Not doing so may result in a serious injury

due to an electric shock.

Wiring work must be carried out only by qualified personnel. Not doing so may result in a serious

injury due to an electric shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to an electric shock or fire.

(200-V class: type-D grounding, 400-V class: type-C grounding)

CAUTION

Do not connect resistors to the terminals (+1, P/+2, N/-) directly.

Doing so might result in a small-scale fire, heat generation or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury. (A holding

brake is not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking

resistor, install a thermal relay that monitors the temperature of the resistor. Not doing so might result

in a moderate burn due to the heat generated in the braking resistor/regenerative braking unit.

Configure a sequence that enables the Inverter p ower to turn off when unusual overheating is

detected in the braking resistor/regenerative braking unit.

The Inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or

other property. Place covers on the openings or take other precautions to make sure that no metal

objects such as cutting bits or lead wire scraps go inside when installing and wiring.

Safety Information

Installation and Storage

Do not store or use the product in the following places.

•Locations subject to direct sunlight.

•Locations subject to ambient temperature exceeding the specifications.

•Locations subject to relative humidity exceeding the specifications.

•Locations subject to condensation due to severe temperature fluctuations.

•Locations subject to corrosive or flammable gases.

•Locations subject to exposure to combustibles.

•Locations subject to dust (especially iron dust) or salts.

•Locations subject to exposure to water, oil, or chemicals.

•Locations subject to shock or vibration.

2-1

Page 25

2-1 Installation

w

w

Transporting, Installation, and Wiring

•Do not drop or apply strong impact on the product. Doing so may result in damaged parts or malfunction.

•Do not hold by the front cover, but hold by the fins during transportation.

•Do not connect an AC power supply voltage to the control input/output terminals. Doing so may result in

damage to the product.

•Be sure to tighten the screws on the terminal block securely.

Wiring work must be done after installing the unit body.

•Do not connect any load other than a three-phase inductive motor to the U, V, and W output terminals.

•Take sufficient shielding measures when using the product in the following locations. Not doing so may

result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

Precautions for Use

Installation

•Install the Inverter vertically on the wall or DIN tracks (optional).

Install the Inverter on a nonflammable wall surface material, like metal.

2

Design

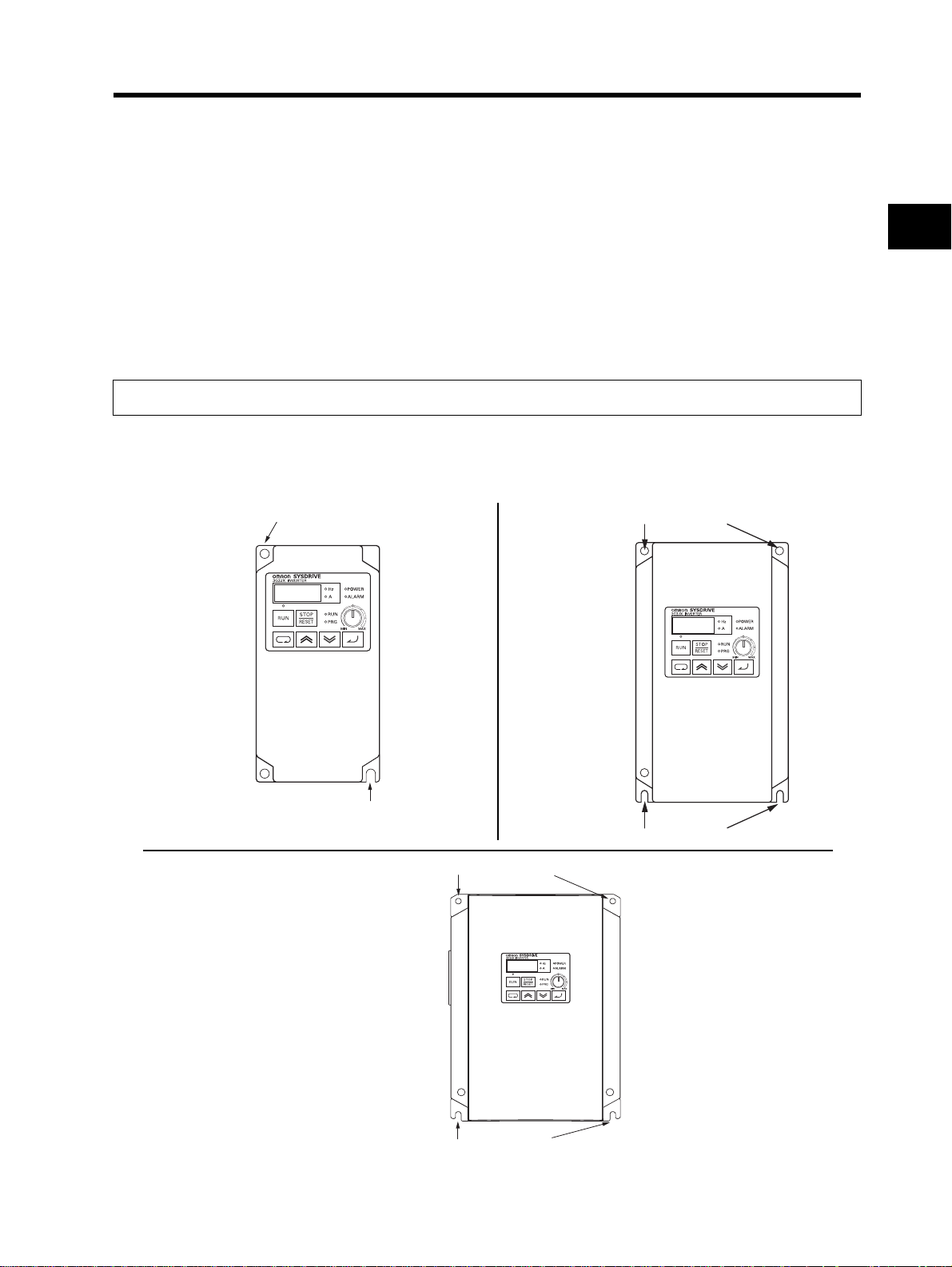

Model

3G3JX-A2002

A2004

A2007

AE002

AE004

Screw size for

installation: M5

Position for installing a screw

Position for installing a scre

Model

3G3JX-A2055

-A2075

-A4055

-A4075

Model

3G3JX-A2015

A2022

A2037

A4004

A4007

A4015

A4022

A4037

AE007

AE015

AE022

Screw size for

installation: M5

Position for installing a scre

Positions for installing screws

Positions for installing screws

Screw size for

installation: M6

Position for installing a screw

2-2

Page 26

2-1 Installation

Main Circuit Power Supply

•Confirm that the rated input voltage of the Inverter matches the AC power supply voltage.

Installation Environment

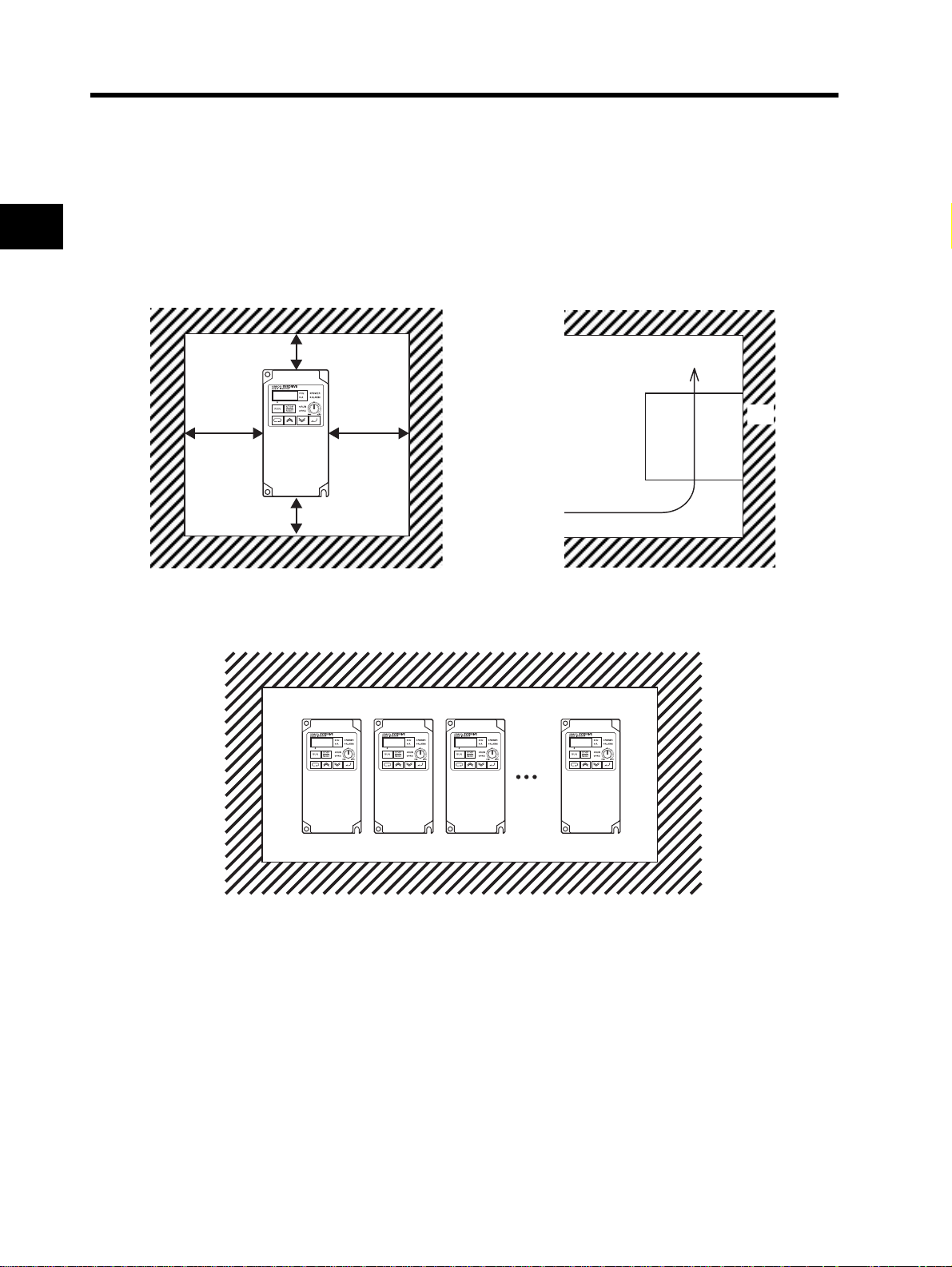

2

•Increased ambient temperatures will shorten the life of the Inverter.

•Keep the Inverter away from heating elements (such as a braking resistor, DC reactor, etc.).

If the Inverter is installed in a control panel, keep the ambient temperature within the range of the

specifications, taking dimensions and ventilation into consideration.

Design

10 cm min.

5 cm min. 5 cm min.

10 cm min.

•You can install multiple 3G3JX Inverters side by side in the control panel (side-by-side installation). Again,

keep the ambient temperature within the specified range (40°C or below).

Airflow

Wall

•If the ambient temperature is from 40°C through to 50°C, the carrier frequency should be reduced and the

Inverter capacity should be increased.

2-3

Page 27

2-1 Installation

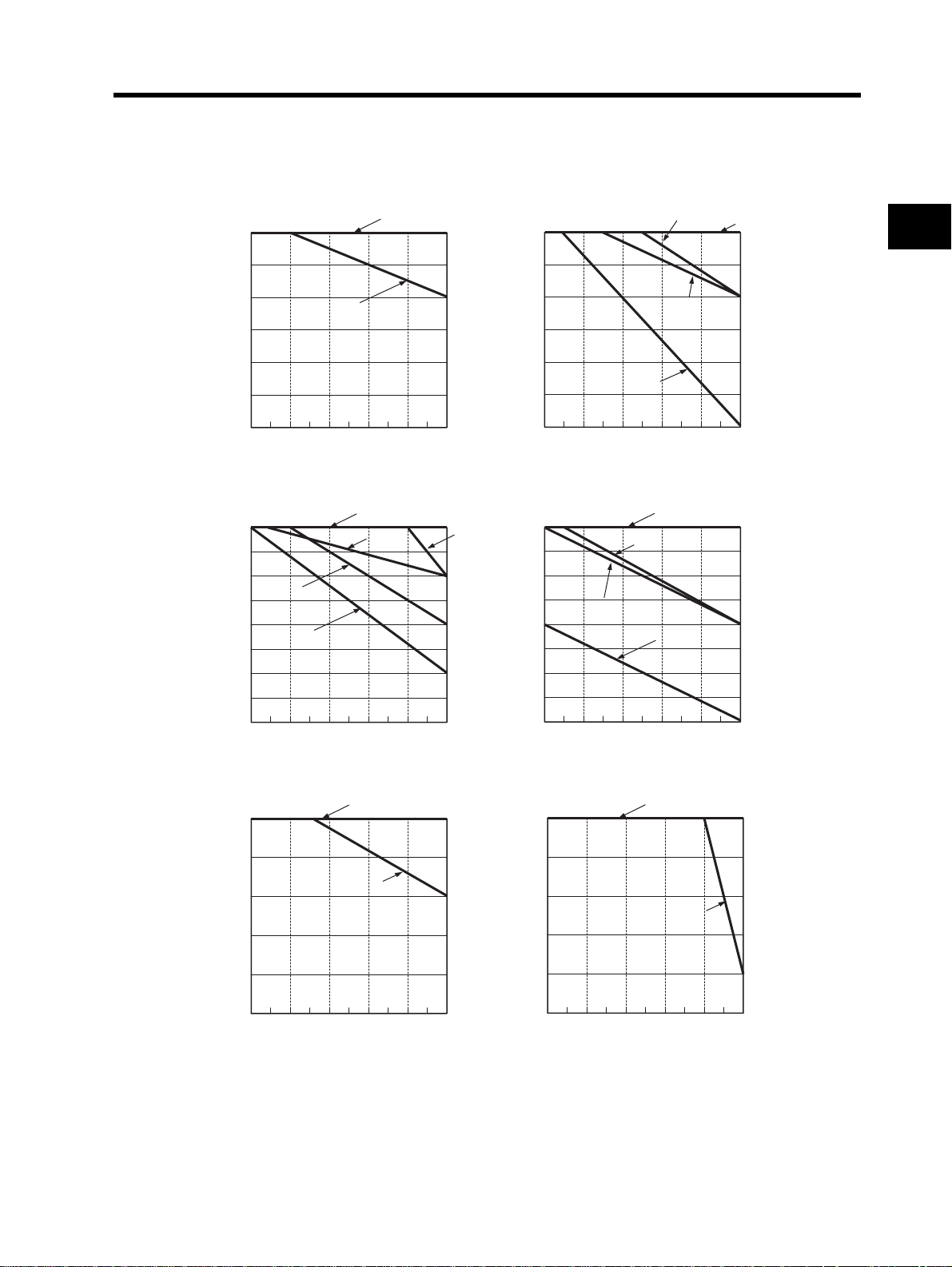

•To raise the carrier frequency, reduce the output current (or derate the rated current) as shown in the graph

below.

(1) Side-By-Side installation (ambient temperature:40°C)

0.4 to 2.2kW

5.5/kW

100%

200-V Class

0.2 to 2.2 · 5.5/7.5kW

400-V Class

100%

2

95%

90%

85%

80%

75%

Output current (Rated current %)

70%

2

3.7 kW

4 6 8 10 12

Carrier frequency [kHz]

(2) Ambient temperature 50°C

200-V Class

100%

95%

90%

0.75kW

85%

80%

75%

70%

65%

Output current (Rated current %)

60%

3.7kW

2

4 6 8 10 12

Carrier frequency [kHz] Carrier frequency [kHz]

0.2/0.4/2.2/5.5kW

7.5kW

1.5kW

95%

90%

85%

80%

75%

Output current (Rated current %)

70%

100%

95%

90%

85%

80%

75%

70%

65%

Output current (Rated current %)

60%

4 6 8 10 12

2

400-V Class

4 6 8 10 12

2

3.7kW

Carrier frequency [kHz]

5.5kW

0.4 to 1.5/7.5kW

2.2kW

3.7kW

7.5kW

Design

(3) Ambient temperature 40°C

200-V Class

100%

95%

90%

85%

80%

Output current (Rated current %)

75%

2

4 6 8 10 12

Carrier frequency [kHz] Carrier frequency [kHz]

0.2 to 2.2 · 5.5/7.5kW

3.7kW

400-V Class

100%

95%

90%

85%

80%

Output current (Rated current %)

75%

2

4 6 8 10 12

0.4 to 2.2 · 5.5/7.5kW

3.7kW

2-4

Page 28

2

Design

2-1 Installation

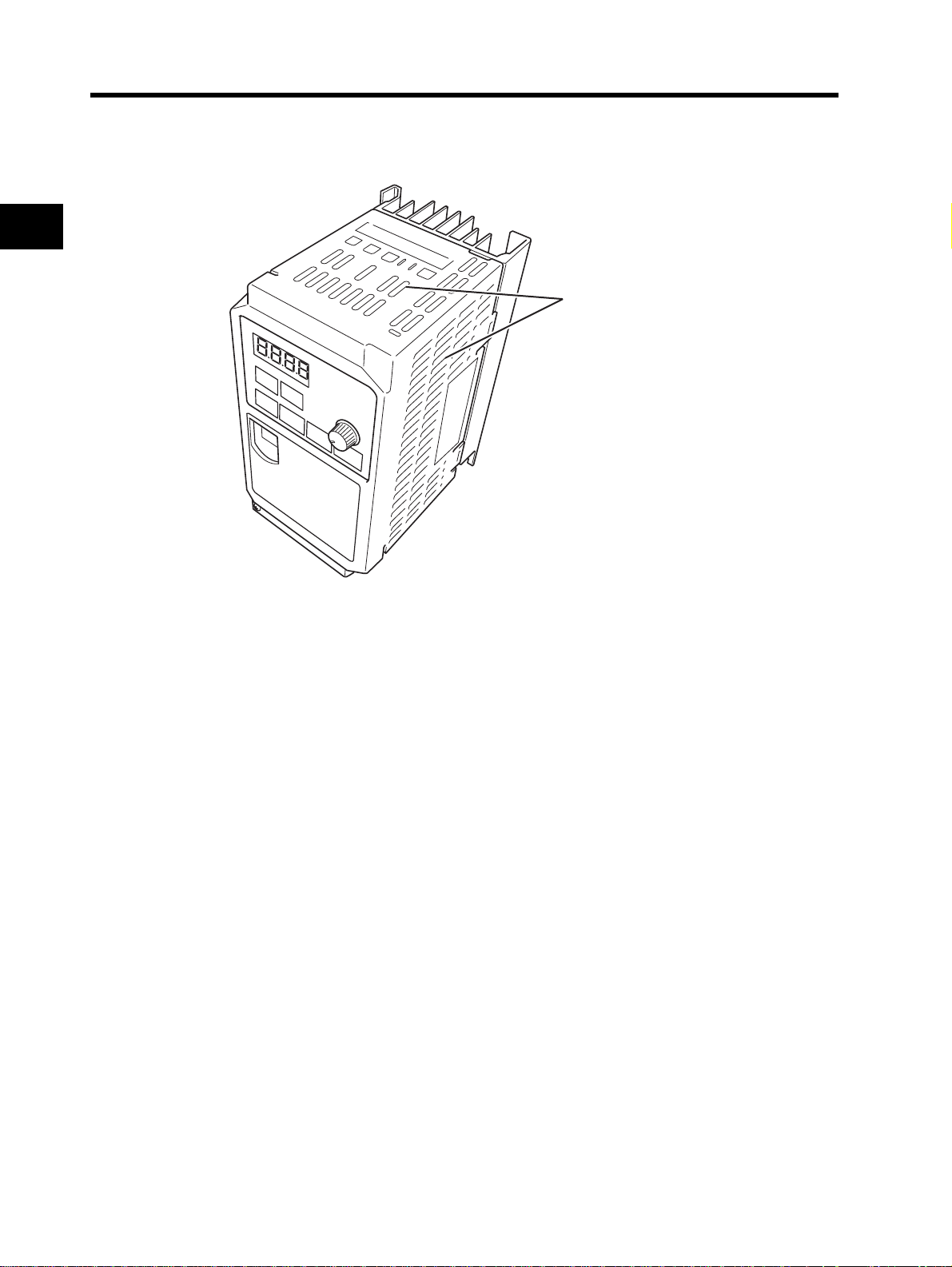

•Before installing the Inverter, place a cover over all the ventilation openings to shield them from foreign

objects.

After completing the installation process, be sure to remove the covers from the Inverter before operation.

Ventilation openings

(Both sides and top)

2-5

Page 29

2-2 Wiring

2-2 Wiring

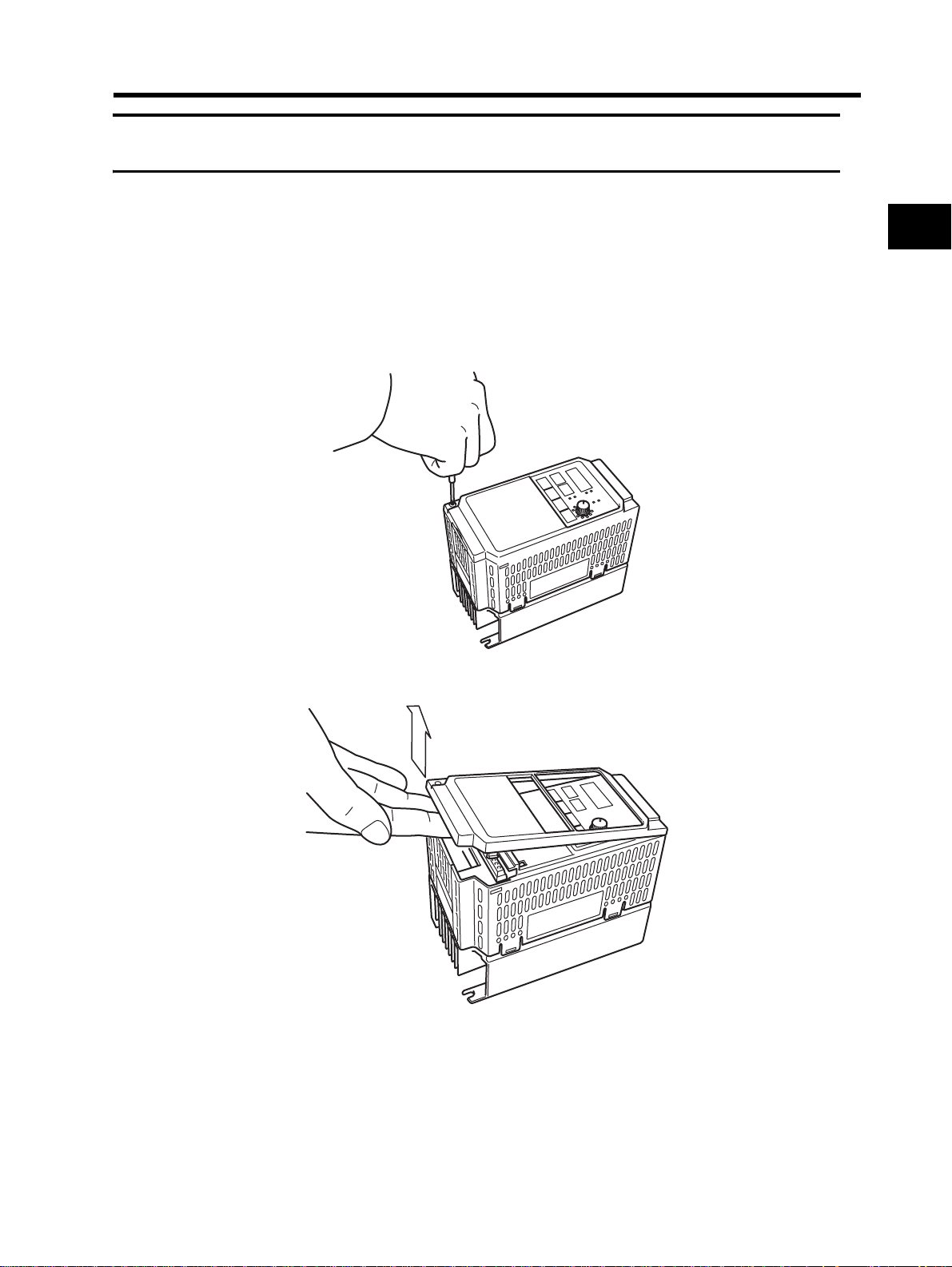

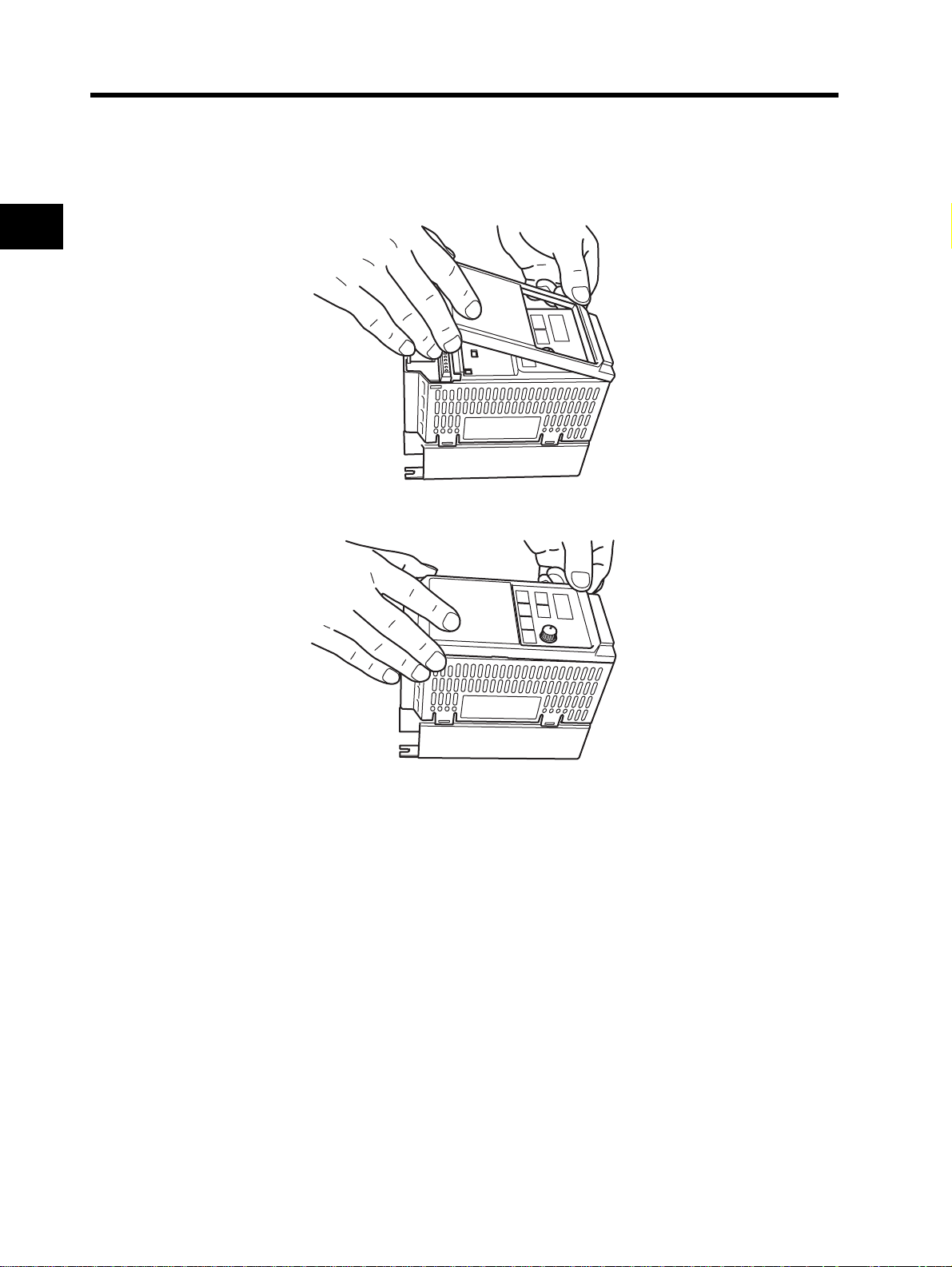

Removing and Mounting the Front Cover

Removing the Front Cover

Loosen the mounting screw at the lower left of the front cover. Lift the bottom of the front cover to

remove while holding the body.

1. Loosen the front cover mounting screw.

2. Lift the bottom of the front cover to remove.

2

Design

2-6

Page 30

2

Design

2-2 Wiring

Mounting the Front Cover

Hang the upper side of the front cover on the hooks, and push down both sides of the cover

simultaneously until it clicks into place.

1. Hang the upper side on the hooks. (Two hooks)

2. Push down the cover until it clicks into place. (Both sides)

2-7

Page 31

Standard Connection Diagram

2-2 Wiring

3-phase 200 V AC

1/3-phase 200 V AC *2

3-phase 400 V AC

Multi-function input 1

Multi-function input 2

Multi-function input 3

Multi-function input 4

Multi-function input 5

Sequence input common

Frequency reference power supply

Frequency

reference

(1 to 2 kΩ)

DC reactor

(optional)

R/L1 (L1) *1

S/L2 (L2)

T/L3 (N/L3)

P24

PSC

S1

S2

S3

S4

S5

SC

FS

Frequency reference input (voltage)

Frequency reference common

Frequency reference input (current)

FV

FC

FI

+1 P/+2 N/-

Regenerative

braking unit

U/T1

V/T2

W/T3

MB

Relay output *3

MA

MC

Common

P1PCMulti-function output

Multi-function output common

AM Analog monitor output

2

M

Design

*1. The items in parentheses indicate terminal symbols for 3G3JX-AE.

*2. Connect a single-phase 200-V AC input to terminals L1 and N/L3.

*3. By factory default, MA is set to NC contact, and MB to NO contact in the

relay output (MA, MB) contact selection (C036).

2-8

Page 32

2-2 Wiring

Wiring to the Power Supply and Motor

2

Design

(Example) 3G3JX-A2004

Main circuit terminal block (input side)

Main circuit terminal block (output side)

Power supply

Ground

(Example) 3G3JX-A2037

Main circuit terminal block (input side)

Main circuit terminal block (output side)

Power supply

Ground

R/L1S/L2 T/L3

N/- P/+2 +1

U/T1 V/T2 W/T3

Motor

earth

Motor

•Do not connect the power supply other than to R/L1, S/L2, or T/L3.

•Do not remove the short-circuit bar between P/+2 and +1, except when a DC reactor is connected.

Note 1: Install an earth leakage breaker on the power supply input side.

(Select an earth leakage breaker having a larger high-frequency sensed current and avoid

unnecessary operation.)

If the wiring between the Inverter and the motor is too long (longer than 10 m), the thermal

relay may malfunction due to harmonics. Install an AC reactor on the Inverter output side,

or use a current sensor instead of the thermal relay.

Motor

earth

R/L1S/L2T/L3

U/T1V/T2

W/T3

Motor

N/- P/+2 +1

2-9

Page 33

2-2 Wiring

Note 2: Connect securely to the ground as specified (type-D grounding for 200-V class, and

type-C grounding for 400-V class). Do not share the grounding electrode with other strong

electrical devices.

Example of incorrect grounding Example of correct grounding

Inverter

Inverter

Inverter

Inverter

Ground bolt

Inverter

Inverter

Wiring the Control Circuit Terminals and Relay Terminals

Relay

output

MB MA MC

Analog

monitor

output

Frequency

reference

input

Multi-function input

Multi-function

output

2

Design

AM

FS FV FI FC S5 S4 S3 S2 S1 SC

PSC P24

PC

P1

Short-circuit bar

2-10

Page 34

2

Design

2-2 Wiring

Wiring Example of the Control Circuit Terminal Block (Sink Logic)

At sink logic (NPN) : External power supply input

At source logic (PNP) : Power supply output

Note: By factory default, the input logic of the multi-function input terminal circuit is

set to the sink logic.

Reverse rotation RUN command

Forward rotation RUN command

AM

Frequency meter

FS FV FI FC S5 S4 S3 S2 S1 SC

Variable resistor

frequency reference

(1 to 2 k)

Input common

Reset input

Multi-step speed reference 2

Multi-step speed reference 1

External power supply

terminal for input signal

PSC P24

Short-circuit bar

(at sink logic

[when internal

power supply is

used])

Frequency arrival signal

(27 V DC 50 mA max.)

PC P1

RY

Note 1: When connecting a relay to the multi-function output terminal, install a surge-absorbing

diode in parallel with the relay. The output circuit can break down due to surge voltage when

the relay is switched on/off.

Note 2: Remove the short-circuit bar when the external power supply is used.

Note 3: For the signal line, use a twisted shield wire and apply the shield coating as illustrated

below. Keep the length to 20 m or less.

Perform insulating treatment.

Ground connection is not required.

Connect to the ground terminal of the Inverter.

Note 4: Keep the wiring away from the power cable of the main circuit and from the wiring on the

relay control circuit. (More than 10 cm apart)

2-11

Page 35

Selecting the Sequence Input Method (Sink/Source Logic)

C

Logic Selection Method for the Multi-function Input Terminals

When the internal power supply is used, you can switch the logic by rearranging the short-circuit bar

on the control circuit terminal block. The default setting is sink logic.

2-2 Wiring

2

Sink logicSource logic

<Sink Logic>

S1 SC PSC P24 PC

Short-circuit bar

<Source Logic>

S1 SC PSC P24

Short-circuit bar

PC

Note 1: Remove the short-circuit bar when the external power supply is used.

Inside the Inverter

When interface power supply is used

+V

Short-circuit

bar

COM

Output unit etc.

P24

PSC

SC

S1

S5

Inverter

24 V DC

When external power supply is used

+V

COM

Output unit etc.

DC24V

P24

PSC

SC

S1

S5

Inverter

Design

24 V D

COM

0V

Output unit etc.

Short-circuit

bar

P24

PSC

SC

S1

S5

Inverter

24 V DC

\

COM

24 V DC

0V

Output unit etc.

P24

PSC

SC

S1

S5

Inverter

24 V DC

2-12

Page 36

2-2 Wiring

Wiring the Main Circuit Terminals

Connecting the Main Circuit Terminals

2

Design

Motor output

(kW)

Applicable Inverter model

0.2 3G3JX-A2002 1.25 mm

3G3JX-A2004

0.4

3G3JX-A4004 3 A

3G3JX-A2007 2.0 mm

0.75

3G3JX-A4007 1.25 mm

3G3JX-A2015 2.0 mm

1.5

3G3JX-A4015 2.0 mm

3G3JX-A2022 2.0 mm

2.2

3G3JX-A4022 2.0 mm

3G3JX-A2037 3.5 mm

3.7

3G3JX-A4037 2.0 mm

3G3JX-A2055 5.5 mm

5.5

3G3JX-A4055 3.5 mm

3G3JX-A2075 8.0 mm

7.5

3G3JX-A4075 3.5 mm

0.2 3G3JX-AE002 2.0 mm

0.4 3G3JX-AE004 2.0 mm

0.75 3G3JX-AE007 2.0 mm

1.5 3G3JX-AE015 5.5 mm

2.2 3G3JX-AE022 5.5 mm

Wiring Applicable device

Power cable

2

1.25 mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Earth leakage breaker

(ELB)

5 A 10 A

5 A

10 A 15 A

5 A 6 A

15 A 15 A

10 A 10 A

20 A 20 A

10 A 10 A

30 A 30 A

15 A 15 A

50 A 40 A

30 A 20 A

60 A 50 A

30 A 25 A

5A 14 A

5 A ⎯

10 A ⎯

15 A ⎯

20A ⎯

Fuse size

(class J)

Rated 600 V

10 A

•For the main circuit terminals, always use insulated electrical wires with a rated voltage of 600 V and a rated

temperature of 80°C or higher.

•Use the crimp-type terminal with an insulating sleeve to connect to the terminals.

•Up to two wires can be connected to one terminal.

•To prevent possible voltage drops, increase the wire size in accordance with the cable length.

2

•To connect the 100-V or 200-V model to the relay output terminal block, use a wire of 0.75 mm

•To connect seven wires or more to the control circuit terminal block, use a shield line of 0.5 mm

.

2

or less.

•Strip the signal line by 5 to 6 mm, and connect the exposed wire. (In the case of stranded wires, make sure that

the wires are not unraveled.)

•Make sure that the maximum outside coating diameter of the signal line is 2.0 mm or less (except for the alarm

signal line). (For the mark tube mounted cable and multi-core cable, keep both the mark tube and the sheathstripped length 40 mm or more from the connecting end. A thick line may prevent proper closing of the cover of

the terminal block.)

•To meet UL standards, always insert a UL-standard fuse (J type) on the power supply side.

•Use a ground wire with a larger diameter than that of the power cable shown above.

2-13

Page 37

2-2 Wiring

k

Choose the sensitivity current of the earth leakage breaker (ELB), depending on the total distance (L) between

the Inverter and the power supply, and the Inverter and the motor.

L

100 m max. 30

300 m max. 100

800 m max. 200

Sensitivity

current (mA)

Guide of leakage current: If a CV wire is used and routed through a metal pipe,

Due to the higher specific inductive capacity of the H-IV wire, the leakage current

increases about eight times. Use a wire with a sensitivity current one-level higher.

The leakage current mentioned here is the effective value of the fundamental

wave, and high-frequency currents are excluded.

Terminal Arrangement

Main circuit terminal block Model (3G3JX-) Screw size W (mm)

Upper side of the body

R/L1 S/L2 T/L3

Lower side of the body

N/- P/+2 +1

U/T1 V/T2

W/T3

the leakage current is 30 mA/km.

A2002 to A2007

AE002 to AE004

(*1)

M3.5 7.1

2

Design

7.1

Main Circuit

Terminal Bloc

Upper side of the body

A2015 to A2037

R/L1 S/L2 T/L3

Lower side of the body

U/T1 V/T2 W/T3 N/- P/+2 +1

*1. For 3G3JX-AE, R/L1 corresponds to L1, S/L2 to L2, and T/L3 to N/L3.

Connect a single-phase 200-V AC input to terminals L1 and N/L3.

Relay Output

Terminal Block

MB MA MC

AM FS FV FI FC S5

A4004 to A4037

AE007 to AE022

(*1)

A2055 to A2075

A4055 to A4075

Control Circuit Terminal Block

S4 S3 S2 S1 SC PSC P24 PC P1

M4 9.2

M5 13

9.2 or 13

Main Circuit

Terminal Block

2-14

Page 38

2-2 Wiring

2

Design

Model

(3G3JX-)

Main circuit M3.5 7.1 M4 9.2 M5 13

Control circuit M2 ⎯ M2 ⎯ M2 ⎯

Relay M2.5 ⎯ M2.5 ⎯ M2.5 ⎯

Ground M4 ⎯ M4 ⎯ M5 13

A2002 to A2007

AE002 to AE004

Screw size W (mm) Screw size W (mm) Screw size W (mm)

A2015 to A2037

A4004 to A4037

AE007 to AE022

A2055 to A2075

A4055 to A4075

Screw Tightening Torque

Screw Tightening torque

M2 0.2 N•m (max. 0.25 N•m)

M2.5 0.5 N•m (max. 0.6N•m)

M3.5 0.8 N•m (max. 0.9 N•m)

M4 1.2 N•m (max. 1.3 N•m)

M5 3.0 N•m (max. 3.3 N•m)

Explanation of the Main Circuit Terminal Connection

Terminal

symbol

R/L1, S/L2,

T/L3 *

U/T1,

V/T2, W/T3

+1,

P/+2

P/+2, N/-

* For 3G3JX-AE's terminal symbols, R/L1 corresponds to L1, S/L2 to L2, and T/L3 to N/L3.

Connect a single-phase 200-V AC input to terminals L1 and N/L3.

Terminal name Function Connection example

Main power supply

input terminal

Inverter output

terminal

External DC reactor

terminal

Regenerative

braking unit

connection terminal

Ground terminal

Connect the input power supply.

Connect to the motor.

Normally connected by the short-circuit

bar. Remove the short-circuit bar

between +1 and P/+2 when a DC reactor

is connected.

Connect optional regenerative braking

units.

(If a braking torque is required)

Ground (Connect to ground to prevent

electric shock and reduce noise.)

ELB

Power supply

Do not remove the short-circuit bar

between +1 and P/+2 when a DC

reactor is not connected.

Motor

2-15

Page 39

Main Circuit Connection Diagram

)

2-2 Wiring

Regenerative braking unit

R/L1

S/L2

T/L3 *

Inverter

3G3JX

Power supply

Molded case

circuit-breaker

(MCCB)

MC

AC reactor

noise filter

Fuse

* For 3G3JX-AE's terminal symbols, R/L1 corresponds to L1, S/L2 to L2, and T/L3 to N/L3.

Wiring the Main Circuit Terminals (Input Side)

Installing a Molded-case Circuit Breaker (MCCB)

•Always connect the Inverter and power supply via a molded-case circuit breaker (MCCB) to protect

the Inverter from damage that may result from short-circuiting.

•Always connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via an MCCB,

according to the Inverter capacity.

•Install one MCCB per Inverter.

•Choose an appropriate MCCB capacity according to the fuse size on page 2-13.

•When choosing MCCB's time characteristics, be sure to consider the Inverter's overload protection

(1 minute at 150% of the rated output current).

•By programming the sequence as illustrated below, you can turn off the power via the relay outputs

(MA, MB, and MC) for the 3G3JX Series.

P/+2 N/-

U/T1

V/T2

W/T3

M

2

Design

Molded-case

Power supply

circuit breaker

(MCCB)

MC

OFF

ON

X1

X1

X1

X2

X2

DC (24 V) relay

R/L1

S/L2

T/L3 *

MA

MC

Inverter

3G3JX

(30 V DC, 50 mA max.

* For 3G3JX-AE's terminal symbols, R/L1 corresponds to L1, S/L2 to L2, and T/L3 to N/L3.

Installing a Ground Fault Interrupter

•The Inverter's output uses high-speed switching, and so generates high-frequency current

leakage. (Generally, if the power cable is 1 m, the leakage current is approx. 100 mA per Inverter,

and approx. 5 mA is added per additional meter of the power cable.)

•At the power supply input part, install a special-purpose ground fault interrupter for Inverters that

excludes high-frequency leakage current and detects only the leakage current within a frequency

range that is hazardous to humans. (Choose a ground fault interrupter with a sensitivity current of

at least 10 mA per Inverter.)

•Alternatively, use a general ground fault interrupter with a sensitivity current of 200 mA or more per

Inverter, and with an operating time of 0.1 s or more.

2-16

Page 40

2-2 Wiring

Installing a Magnetic Contactor (MC)

•If the power supply of the main circuit is shut off due to sequencing, a magnetic contactor (MC) can

be used. (When forcibly stopping the load with an MC on the primary side of the main circuit,

however, the regenerative braking does not work and the load coasts to a stop (free run).)

•Frequently opening and closing the magnetic contactor (MC) to start and stop a load may cause

2

Connection Sequence to the Terminal Block

the Inverter to break down. To extend the life of the Inverter's internal electrolytic capacitor, limit

the frequency to no more than once every 30 minutes.

•Input power supply can be connected to any terminal because the phase sequence of the input

power supply is irrelevant to that of the terminal block (R/L1, S/L2, and T/L3).

Design

Installing an AC Reactor

•If the Inverter is connected to a large-capacity power transformer (660 kVA or more) or the phase

advance capacitor is in use, a large peak current may flow through the input power circuit, causing

the converter unit to break down.

•Install an optional AC reactor on the input side of the Inverter. An AC reactor will also improve the

power factor of the power input side.

Installing a Surge Absorber

•Always use a surge absorber or diode when magnetic contactors (MC), electromagnetic relays,

solenoid valves, solenoid, and magnetic brakes are used.

Connecting a Regenerative Braking Unit

When running a load with a large inertia or a vertical axis, regenerative energy will return to the

Inverter.

If overvoltage in the main circuit is generated during deceleration, this indicates that the

regenerative energy exceeds the capacity of the Inverter. In this case, use a regenerative braking

unit.

Select a regenerative braking unit referring to the allowable operation cycle of the regenerative

braking unit specifications regardless of the Inverter capacity.

When using a braking resistor with the resistor of a regenerative braking unit removed, refer to the

connectable resistance of the regenerative braking unit and the allowable braking frequency of the

braking resistor in making a selection.

Refer to “ 7-5 Options” (page 7-14 to 16) for further information when making a selection.

2-17

Page 41

2-2 Wiring

r

•When using a regenerative braking unit, be sure to include a sequence whereby the power supply

for the Inverter will be turned off in the event of abnormal overheating. Not doing so may result in

fire.

For a regenerative braking unit: Use the error contact output (MA, MB).

Molded-case

Power supply

XB

circuit breaker

(MCCB)

OFF ON

MC

Magnetic contactor

MC

(MC)

R/L1 (L1) *

S/L2 (L2)

T/L3 (N/L3)

N/- P/+2 +1

Inverter

3G3JX

2

Design

MC

SA

MC

SA

NP

AL1

AL2

PRB R1R2

Regenerative braking unit

DCL

DC reacto

* The items in parentheses indicate terminal symbols for 3G3JX-AE.

<Braking Resistors and Braking Resistor Units for the Inverter>

Name Model Specifications

3G3AX-RBU21

For general use (with built-in resistor)

3/1-phase

Regenerative

braking unit

3G3AX-RBU22

3G3AX-RBU41

200 V

3-phase

400 V

For heavy instantaneous regenerative power

(with built-in resistor)

For general use (with built-in resistor)

Installing a Noise Filter on the Input Side

•The Inverter's output uses high-speed switching, so noise may be transmitted from the Inverter to

the power line, affecting peripheral devices.

•It is recommended that a noise filter be installed on the input side to minimize noise transmission.

(Installing a noise filter on the input side can also reduce the noise from the power line to the

Inverter.)

<Recommended Input Noise Filters for the Inverter>

General EMC-conforming

3G3AX-NFI 3G3AX-EFI

2-18

Page 42

2-2 Wiring

Molded-case

circuit breaker

Power supply

2

(MCCB)

Molded-case

circuit breaker

(MCCB)

Input noise

filter for

Inverter *

Inverter

3G3JX

Other device

M

Design

Wiring the Main Circuit Terminals (Output Side)

* Use a noise filter designed for Inverters. A general-purpose noise filter will be less effective and

may not reduce noise.

Connect the Terminal Block to the Load

•Connect motor output terminals U/T1, V/T2, and W/T3 to motor lead wires U, V, and W.

•Check that the motor rotates forward with the forward command. Switch over any two of the output

terminals (U/T1, V/T2, W/T3) and reconnect if the motor rotates in reverse to the forward

command.

Never Connect a Power Supply to the Output Terminals

•If voltage is applied to the output terminals, the internal circuit of the Inverter will be damaged.

Never connect a power supply to output terminals U/T1, V/T2, or W/T3.

2-19

Page 43

Never Short-circuit or Ground the Output Terminals

•Never touch the output terminals by hand.

•If the output wires come into contact with metal materials, an electric shock or ground fault will

occur. This is extremely hazardous. Be careful not to short-circuit the output wires.

2-2 Wiring

Do Not Use a Phase Advance Capacitor or Noise Filter

•Doing so may result in damage to the Inverter or cause the parts to burn. Never connect a phase

advance capacitor or LC/RC noise filter to the output circuit.

Do Not Use an Electromagnetic Switch

•If a load is connected to the Inverter during running, an inrush current will actuate the overcurrent

protective circuit in the Inverter. Do not connect an electromagnetic switch or magnetic contactor

(MC) to the output circuit.

Install a Noise Filter on the Output Side

Connect a noise filter to the output side of the Inverter to reduce induction and radio noise.

Power

supply

Molded-case circuit breaker

(MCCB)

Inverter

3G3JX

Signal line

Noise filter

3G3AX-NFO

Induction noise

M

Radio noise

AM radioController

2

Design

Induction noise: Electromagnetic induction can generate noise on the signal line, causing the

controller to malfunction.

Radio noise: Electromagnetic waves from the Inverter and I/O cables can cause the radio receiver

to generate noise.

Countermeasures Against Induction Noise

To reduce induction noise from the output side, the following method is also effective.

•Run the cables collectively through the mounted metal pipe. Keeping the metal pipe at least 30 cm

away from the signal line reduces induction noise.

Power

supply

Molded-case circuit breaker

(MCCB)

Inverter

3G3JX

M

30 cm min.

Signal line

Controller

2-20

Page 44

2

Design

2-2 Wiring

Cable Length Between Inverter and Motor

Use a cable of 50 m or less between the Inverter and the motor. If the cable length is increased, the

stray capacitance between the Inverter outputs and the ground is increased proportionally. An

increase in stray capacitance causes high-frequency leakage current to increase, affecting the

current detector in the Inverter's output unit and peripheral devices. If your system configuration

requires a cable length of 50 m or more, perform the following:

•Wire in metallic ducts.

•Use separate cables for each phase.

•Set the Inverter to a lower carrier frequency (b083).

Do Not Use Single-phase Motors

•A single-phase motor uses the capacitor start method or split-phase start method to determine its

rotation direction at startup, and thus is not suitable for the variable speed control via the Inverter.

Do not use single-phase motors.

* If a capacitor start motor is used, the capacitor may be damaged by a sudden electric charge and

discharge caused by Inverter output. If a split-phase start motor is used, the startup coil may burn

because the centrifugal switch does not operate.

2-21

Page 45

Specifications of the Control Circuit Terminals

2-2 Wiring

Input signal

Monitor

signal

Frequency

reference

input

Terminal

symbol

PSC

S1

S2 Reverse/Stop

S3 Fault reset

S4

S5

SC Input signal common ⎯

AM

FS Frequency reference power supply ⎯

FV Voltage frequency reference signal ⎯

FI Current frequency reference signal ⎯

Terminal name and function Default setting Specifications

External power supply terminal for input

signal (input).......................At sink logic

Internal power supply output terminal for

input signal (output)......At source logic

Multi-function input terminals S1 to S5

Select 5 functions among the 31

functions and allocate them to from

terminals S1 to S5.

The terminal allocation is changed

automatically when the emergency

shutoff function is used. Refer to

"Emergency Shutoff Input Function"

(page 4-45).

Analog frequency monitor/

Analog output current monitor

Forward/Stop

Emergency stop

fault

Multi-step speed

reference 1

Analog

frequency

monitor

⎯

24 V DC ±10%

30 mA max.

24 V DC ±10%

100 mA max.

Contact input

Close: ON (Start)

Open: OFF (Stop)

Minimum ON time:

12 ms min.

10 V DC

10 mA max.

0 to 10 V DC

Input impedance 10 kΩ

When installing variable

resistors at FS, FV, and FC

(1 to 2 kΩ)

4 to 20 mA DC

Input impedance 250 Ω

2

Design

Output signal

Relay output

signal

FC Frequency reference common ⎯

Multi-function output terminal

P1

PC Output signal common ⎯

MA

MB

MC

Select the status of the Inverter and

allocate it to terminal P1.

MB MA MC

Under normal operation : MA-MC Closed

Under abnormal operation or power

shutdown : MA-M

(Default)

C Open

Frequency

arrival signal at

a constant

speed

Contact ratings

250 V AC 2.0 A (resistance load) 100 V AC min.

30 V DC 3.0 A (resistance load) 5 V DC

27 V DC

50 mA max.

0.2 A (inductive load) 10 mA

0.6 A (inductive load) 100 mA

2-22

Page 46

2-2 Wiring

Ω

(

)

Functions and Connections of the Control Circuit Terminals

2

Design

Terminal

function

Contact

input

(for

switching

function)

Power

supply

External

analog

frequency

reference

Monitor

output

Terminal

symbol

Terminal name Function and connecting method Wire size

Select functions and allocate them to terminals S1 to S5.

S1

S2

S3

S4

Multi-function

input

(The figure below illustrates the wiring of the sink logic.)

S5

P24 Internal 24 V DC 24 V DC output

SC Input common Input signal common

If the multi-function input is set as the sink logic, the PSC

terminal acts as an external power supply input terminal.

If the multi-function input terminal is set as the source logic,

the PSC terminal acts as an internal power supply output

PSC

Input power

supply

terminal.

Frequency

FS

reference power

• External voltage directive is 0 to 9.8 V.

(Nominal input: 10 V)

supply output

FS FV FI FC

Variable resistor

(1/2 W min.)

1 to 2 kΩ

FS

FV

FI

Frequency

reference Input

(Voltage

directive)

Frequency

reference Input

(Current

directive)

Frequency

FC

reference

common

4 to 19.6 mA DC

Nominal input: 20 mA

• Choose from frequency or output current.

Output terminal specifications

AM

Multi-function

analog output

0 to 10 V DC full-scale

1 mA max.

SC S5 S4 S3 S2 S1

*1

FC

FI

FV

-

+

FS

FV

FC

FI

+

-

0 to 9.8 V DC

(Nominal input: 10 V)

Input impedance 10

AM

SC

Shield wire

of 0.14 to

0.75 mm

2

Recomme

nded wire

size:

0.75 mm

2

Output terminal specifications

Open collector output

27 V DC max.

50 mA max.

Open

Collector

Output

Relay

output

P1

PC

MA

MB

MC

Multi-function

*2

output

Multi-function

output common

Relay output

Relay output

common

P1

PC

RY

Select the status of the Inverter and allocate it to terminal P1.

Selection of functions is the same as the multi-function

*3 *4

output.

*1. Simultaneous input of current and voltage is not possible. Do not connect the signal lines simultaneously.

*2.

By factory default, multi-function output P1 is set to NO contact. To switch to NC contact, change the C031

setting.

2-23

Page 47

*3. Below are the contact specifications of the relay output.

2-2 Wiring

Output

terminal

MA-MC

MB-MC

By factory default, the relay output (MA, MB) contact selection (C036) is set at NC contact between MA-MC, and

*4.

NO contact between MB-MC.

Contact

capacity

Max.

Min.

Max.

Min.

Resistance load Inductive load

250 V AC 2.5 A

30V DC 3 A

100 V AC 10 mA

5 V DC 100 mA

250 V AC 1 A

30 V DC 1 A

100 V AC 10 mA

5 V DC 100 mA

250 V AC 0.2 A

30 V DC 0.7 A

250 V AC 0.2 A

30 V DC 0.2 A

Mode Selector

RS-485 Communication/Operator Selector (S7)

Select the mode according to the option connected to the communications connector.

When using the 3G3AX-OP01 supplied with the Inverter, it is available regardless of the switch

condition.

Symbol Name Status Description

S7

RS-485 communication/

operator selector

485 RS485 ModBus communication

OPE [Default] Digital Operator (Option: 3G3AX-OP1)

2

Design

Emergency shutoff selector (S8)

Use this selector to enable the emergency shutoff input function.

Symbol Name Status Description

ON Emergency shutoff input enabled

OFF

[Default]

Normal

S8

Emergency

shutoff

selector

*1 The multi-function input terminal 3 is switched to a terminal for emergency shutoff input, and the allocation of

other multi-function input terminals is also changed automatically. Do not set to ON immoderately. For details,

refer to "Emergency Shutoff Input Function" (page 4-45).

*1

2-24

Page 48

2

Design

2-2 Wiring

Conforming to EC Directives

Conforming Standards

•EMC directive EN 61800-3

•Low-voltage directive EN 61800-5-1

Concept of Conformity

EMC Directive

OMRON products are the electrical devices incorporated and used in various machines or

manufacturing equipment. For this reason, we make efforts to conform our products to their related

EMC standards so that the machines or equipment which have incorporated our products should

easily conform to the EMC standards. The 3G3JX models have conformed to the EMC directive EN

61800-3 by following the installation and wiring method as shown below. Your machines or

equipment, however, vary in type, and in addition, EMC performance depends on the configuration,

wiring, or location of the devices or control panels which incorporate the EC directive conforming

products. This in turn does not allow us to confirm the condition and the conformity in which our

products are used. Therefore, we appreciate confirmation of the final EMC conformity for the whole

machine or equipment on your own.

Wiring the Power Supply

•Be sure to connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via an EMC

conforming dedicated noise filter 3G3AX-EFI.

•Keep the ground cable as short as possible.

•Keep the cable between the Inverter and the noise filter as short as possible.

Connecting a Motor to the Inverter

•When connecting a motor to the Inverter, be sure to use shielded braided cables.

•Keep the cables as short as possible.

Low-voltage Directive

The 3G3JX models have conformed to the EMC directive EN61800-5-1 by performing the machine

installation and wiring as shown below.

•The 3G3JX models are an open type device. Be sure to install it inside the control panel.

•The power supply and voltage (SELV) with reinforced or double insulation should be used for

wiring to the control circuit terminals.

•To satisfy requirements of the LVD (low-voltage) directive, the Inverter must be protected with a

molded case circuit breaker (MCCB) in case a short-circuiting accident occurs. Be sure to install a

molded case circuit breaker (MCCB) on the power supply side of the Inverter.

•Use one molded case circuit breaker (MCCB) per Inverter.

•Use the crimp-type terminal with an insulation sleeve to connect to the main circuit terminals.

•When not using the braking resistor or braking resistor unit, connect the crimp-type terminal with

an insulation sleeve to the braking resistor connection terminals (P/+2, N/-).

2-25

Page 49

Chapter 3

Operation

3-1 Test Run Procedure......................................... 3-3

3-2 Test Run Operation.......................................... 3-4

3-3 Part Names and Descriptions of the Digital

Operator............................................................ 3-9

3-4 Operation Procedure (Example: Factory Default)

...........................................................................3-11

3-5 Keys................................................................... 3-17

3-6 Parameter Transition ....................................... 3-18

3-7 Parameter List..................................................3-20

Page 50

3Operation

WARNING

Do not remove the front cover during the power supply and 5 minutes after the power shutoff.

Doing so may result in a serious injury due to an electric shock.

3

Operation

Do not operate the Digital Operator or switches with wet hands. Doing so may result in a serious

injury due to an electric shock.

Inspection of the Inverter must be conducted after the power supply has been turned off. Not doing

so may result in a serious injury due to an electric shock.

The main power supply is not necessarily shut off even if the emergency shutoff function is activated.

Do not change wiring, mode change switches (S7, S8), optional devices or replace cooling fans while

the input power is being supplied.

Doing so may result in a serious injury due to an electric shock.

CAUTION

Do not touch the Inverter fins, braking resistors and the motor, which become too hot during the

power supply and for some time after the power sh utoff. Doing so may result in a burn.

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches the

Inverter capacity on the power supply side. Not doing so might result in damage to property due to

the short circuit of the load.

Safety Information

Operation and Adjustment

•Be sure to confirm the permissible range of motors and machines before operation because the Inverter

speed can be changed easily from low to high.

•Provide a separate holding brake if necessary.

Precautions for Use

Error Retry Function

•Do not come close to the machine when using the error retry function because the machine may abruptly

start when stopped by an alarm.

•Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine may

abruptly start.

Non-Stop Function at Momentary Power Interruption

•Do not come close to the machine when selecting restart in the non-stop function at momentary power

interruption selection (b050) because the machine may abruptly start after the power is turned on.

3-1

Page 51

Operation Stop Command

•Provide a separate emergency stop switch because the STOP key on the Digital Operator is valid only when

function settings are performed.

•When checking a signal during the power supply and the voltage is erroneously applied to the control input

terminals, the motor may start abruptly. Be sure to confirm safety before checking a signal.

3

Operation

3-2

Page 52

3-1 Test Run Procedure

3-1 Test Run Procedure

Item Description Reference page

Installation and Mounting

3

Wiring and Connection Connect to the power supply and peripheral devices. 2-6

Operation

Display Status Check Make sure that th ere are no faults in the Inverter.

Install the Inverter according to the installation conditions. 2-1

•Make sure that the installation conditions are met.

•Select peripheral devices that meet the specifications, and wire correctly.

Power On Check the following before turning on the power.

•Make sure that an appropriate power supply voltage is supplied and that the power input

terminals (R/L1, S/L2, and T/L3) are wired correctly.

3G3JX-A2: 3-phase 200 to 240 V AC

3G3JX-AE: 1/3-phase 200 to 240 V AC

(Connect to L1 and N/L3 for 1 phase)

3G3JX-A4: 3-phase 380 to 480 V AC

•Make sure that the motor output terminals (U/T1, V/T2, and W/T3) are connected to the

motor correctly.

•Make sure that the control circuit terminals and the control device are wired correctly

and that all control terminals are turned off.

•Set the motor to no-load status (i.e., not connected to the mechanical system).

•After checking the above, turn on the power.

•When the power is turned on normally, the display shows:

RUN LED indicator : ON ALARM LED indicator : OFF

POWER LED indicator : ON RUN command LED indicator : ON

Volume LED indicator : ON Data LED indicator (frequency) : ON

Data display : Displays the set value in d001.

•If an error occurs, the error code is displayed on the data display. In this case, refer to

"Chapter 5 Maintenance Operations" and make the necessary changes to remedy.

Parameter Initialization Initialize the parameters.

•Set parameter No. b084 to "02", and press the key while holding down the and

keys simultaneously.

Parameter Settings Set the parameters requi red for a test run.

•Set the motor capacity selection (H003) and the motor pole number selection (H004).

No-load Operation Start the no-load motor via the Digital Operator.

•Use the FREQ adjuster on the Digital Operator to rotate the motor.

Actual Load Operation Connect the mechanical system and operate via the Digital Operator.

•If there is no problem with the no-load operation, connect the mechanical system to the

motor and operate via the Digital Operator.

Operation Refer to "Chapter 4 Functions", and set the necessary parameters.

3-3

Page 53

3-2 Test Run Operation

Power On

Checkpoints Before Turning On the Power

•Make sure that an appropriate power supply voltage is supplied and that the power input terminals

(R/L1, S/L2, and T/L3) are wired correctly.

3G3JX-A2: 3-phase 200 to 240 V AC

3G3JX-AE: 1/3-phase 200 to 240 V AC (Connect to L1 and N/L3 for 1 phase)

3G3JX-A4: 3-phase 380 to 480 V AC

•Make sure that the motor output terminals (U/T1, V/T2, and W/T3) are connected to the motor

correctly.

•Make sure that the control circuit terminals and the control device are wired correctly and that all

control terminals are turned off.

•Set the motor to no-load status (i.e., not connected to the mechanical system).

3-2 Test Run Operation

3

Operation

Power On

•After checking the above, turn on the power.

Display Status Check

•When the power is turned on normally, the display shows:

[Normal] RUN LED indicator (during RUN) : ON ALARM LED indicator : OFF

POWER LED indicator : ON RUN command LED indicator : ON

Volume LED indicator : ON Data LED indicator (frequency) : ON

Data display : Displays the set value in d001

•If an error occurs, refer to "Chapter 5 Maintenance Operations" and make the necessary changes

to remedy.

[Fault] RUN LED indicator (during RUN) : ON ALARM LED indicator : ON

POWER LED indicator : ON RUN command LED indicator : ON

Volume LED indicator : ON Data LED indicator (frequency) : ON

Data display : An error code, such as "E-01", is displayed.

(The display varies depending on the type of error.)

3-4

Page 54

3-2 Test Run Operation

Parameter Initialization

3

Operation

•Initialize the parameters using the following procedure.

•To initialize the parameters, set parameter b084 to "02".

Key sequence Display example Description

Power On

k0.0

Press the Mode key once, and then press the Decrement key three

bk-k-k-

bk0k0k1

times to display "b---".

Press the Mode key.

"b001" is displayed.

Use the Increment or Decrement key to display "b084".

bk0k8k4

Press the Mode key. The set value in "b084" is displayed.

0k0

Use the Increment or Decrement key to display "02".

0k2

Press the Enter key. The set value is entered and "b084" is displayed.

bk0k8k4

Press the STOP/RESET key while holding down the Mode and

Decrement keys simultaneously.

When the display blinks, release the STOP/RESET key first, and then

the Mode and Decrement keys.

Displays initialization.

=k.k0k0

(In 1 s) The parameter number is displayed again in approximately 1 s.

dk0k0k1

3-5

Page 55

3-2 Test Run Operation

Setting the Motor Capacity Selection (H003) and Motor Pole Number Selection

(H004)

Parameter

No.

H003 1165h

H004 1166h

Key sequence Display example Description

Register

No.

Name Description Setting range

200-V class

0.2/0.4/0.75/

Motor

capacity

selection

Motor pole

number

selection

Sets the capacity of the

motor connected to the

Inverter.

Sets the pole number of

the motor connected to

the Inverter.

Press the Mode key twice to display the mode selection.

1.5/2.2/3.7/

5.5/7.5

400-V class

0.4/0.75/1.5/

2.2/3.7/5.5/7.5

2/4/6/8 Pole 4 No

bk-k-k-

Use the Increment or Decrement key to display "H---".

hk-k-k-

Unit of

setting

kW

Default

setting

Varies

with the

capacity.

Interrupt

during

RUN

No

3

Operation

Press the Mode key. "H003" is displayed.

hk0k0k3

Press the Mode key. The set value in "H003" is displayed.

0.2k0

Use the Increment or Decrement key to set the rated motor capacity.

0.4k0

Press the Enter key. The set value is entered.

0.4k0

(In approx. 1 s) The parameter number is displayed again.

hk0k0k3

3-6

Page 56

3-2 Test Run Operation

No-load Operation

Forward/Reverse Rotation via the Digital Operator

3