Omron 3G3JV-AB007, 3G3JV-AB001, 3G3JV-AB015, 3G3JV-A4004, 3G3JV-A4002 Quick Start Manual

...Page 1

3G3JV

quick start guide

020 8450 8087

020 8450 0173

www.omron.co.uk

oeeuk_sales@eu.omron.com

1 Apsley Way, Staples Corner, London, NW2 7HF

Fax number

020 8233 1468

Factory automation technical support

24hr technical helpsheet/datasheet faxback service

020 8450 4646

General telephone enquiries and technical support

UK website

Direct e-mail address for sales enquiries

Page 2

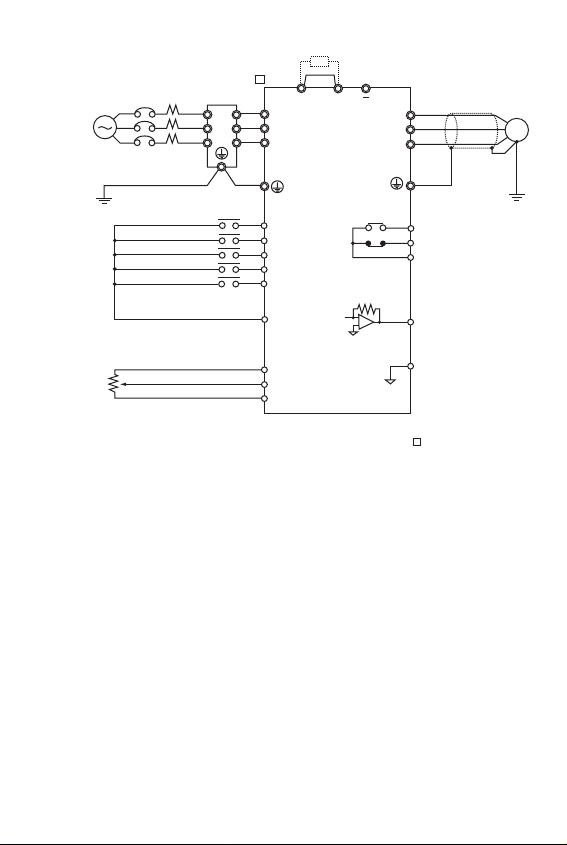

Standard Connections

Note 1: Connect single-phase 200 V AC to terminals R/L1 and S/L2 of the 3G3JV-AB .

Note 2: The braking resistor cannot be connected because no braking transistor is incorporated.

3G3JV PFI

Noise Filter

L1

L2

L3

3-phase 200 V AC

single-phase 200 V AC

(see note 1)

+1 +2

L1í

R/L1

L2í

S/L2

L3í

T/L3

M

Forward/Stop

Multi-function input 1 (S2)

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

Sequence input common

Frequency reference power

External frequency

adjuster

(2 kΩ 1/4 W min.)

supply 20mA at +12V

Frequency reference input

Frequency reference common

S1

S2

S3

S4

S5

SC

FS

FR

FC

Multi-function contact output

MA

NO

MB

NC

MC

Common

AM

Analogue monitor output

AC

Analogue monitor output

common

Page 3

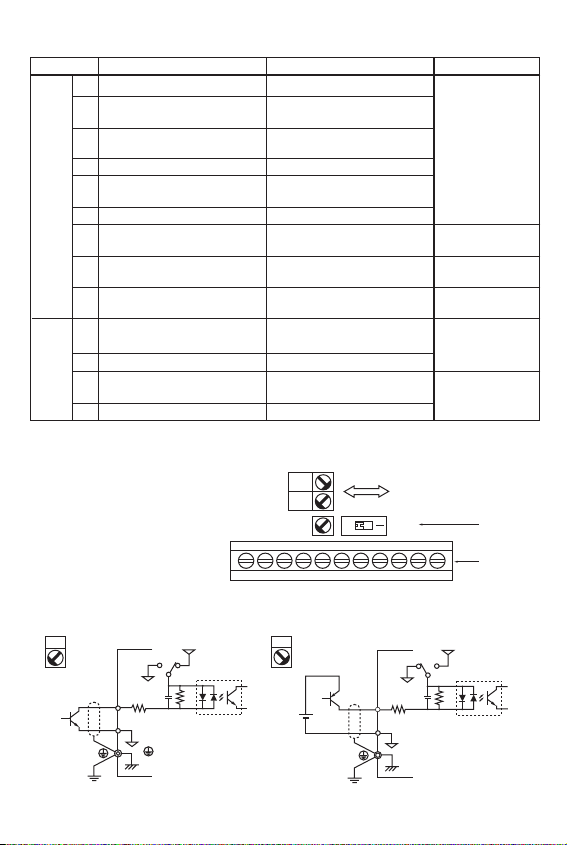

NPN

PNP

SW7

SW7

OFF

SW8

SW8

VI

Control circuit

terminal block

Control circuit

terminal block

Forward/Stop

Multi-function Input 1

Multi-function input 2

Multi-function input 3

Multi-function input 4

Sequence Input Common

Frequency reference Power Supply

Frequency Reference Input

Frequency Reference Common

Multi-function output: NO

Multi-function output: NC

Multi-function output Common

Analogue Monitor output

Analogue Monitor output Common

Forward at ON/Stops at OFF

Set by parameter n36

(Reverse/Stop)

Set by parameter n37

(External Fault: NO)

Set by parameter n38 (Fault Reset)

Set by parameter n39

(Multi-step reference 1)

Common for S1 through S5

DC power supply for frequency

reference use

Input terminal for frequency

reference use

Common for frequency

reference use

Set by parameter n40

(during running)

Common for MA amd MB use

Set by parameter n44

(Output frequency)

Common for AM use

Photocoupler

8 mA at 24VDC

Note: NPN is the

default setting for

these terminals.

No external power

supply is required.

Refer to connections

shown below.

20mA at 12VDC

0 to 10VDC

(20Kohms)

4 to 20mA

0 to 20mA

Relay output

1A max. at 30VDC

and 250 VAC

12mA max. at 0 to

10VDC

S1

S2

S3

S4

S5

SC

FS

FR

FC

MA

MB

MC

AM

AC

Input

Output

Control Circuit Terminals

Selecting Input Method

Symbol Name Function Signal Level

Note: Functions in parentheses are default settings.

Switches SW7 and SW8, both of which are

located above the control circuit terminals,

are used for input method selection.

Remove the front cover and optional cover

to use these switches.

Selecting Sequence Input Method

By using SW7, NPN or PNP input can be selected as shown below.

(Default setting)

NPN

GND

S1 to 5

3.3k

SC

GND

24V

SW7

0.1

µ

360

PNP

24 V DC

(±10%)

S1 to 5

24V

SW7

GND

0.1

µ

360

3.3k

SC

GND

Page 4

L

169

169

169

169

169

169

169

169

169

169

174

174

W

71

71

71

111

111

111

111

111

111

111

144

144

H

45

45

45

50

50

50

50

50

50

50

50

50

X

156

156

156

156

156

156

156

156

156

156

161

161

Y

51

51

51

91

91

91

91

91

91

91

120

120

d

5

5

5

5

5

M5

M5

M5

M5

M5

M5

M5

Model

3G3JV

AB001

AB002

AB004

AB007

AB015

A4002

A4004

A4007

A4015

A4022

A4030

A4040

Filter

3G3JV

PFI1010E

PFI1010E

PFI1010E

PFI1020E

PFI1020E

PFI3005E

PFI3005E

PFI3010E

PFI3010E

PFI3010E

PFI3020E

PFI3020E

Installation

Dimensions

Rated

Voltage

Model

3G3JV-

Supply Recommendations

Noise Filter Specifications

Y

W

X

d

H

L

H

128

128

128

128

128

128

128

128

128

128

128

128

H1

118

118

118

118

118

118

118

118

118

118

118

118

W

68

68

68

108

108

108

108

108

108

108

140

140

W1

56

56

56

96

96

96

96

96

96

96

128

128

D

70

70

112

129

154

81

99

129

154

154

161

161

AB001

AB002

AB004

AB007

AB015

A4002

A4004

A4007

A4015

A4022

A4030

A4040

Single Phase

200 VAC

MCCB (A)

5

5

10

20

20

5

5

5

10

10

20

20

Wire (mm2)

2

2

2

3.5

5.5

2

2

2

3.5

3.5

5.5

5.5

Two, 5 dia. holes

H1

H

5

6

W1

W

8.5

D

5

Page 5

Displays relevant data items, such as frequency reference,

output frequency and parameter set values.

Sets the frequency reference within a range between 0Hz

and the maximum frequency.

The frequency reference can be monitored or set while this

indicator is lit.

The output frequency of the Inverter can be monitored or

set while this indicator is lit.

The output current of the inverter can be monitored while

this indicator is lit.

The values set in U01 through U10 are monitored while

this indicator is lit.

The direction of rotation can be selected while this indicator

is lit when operating the Inverter with the RUN Key.

The operation of the Inverter through the Digital Operator

or according to the set parameteres is selectable while this

indicator is lit.

Note: The status of this indicator can be only monitored

while the Inverter is in operation. Any RUN

command input is ignored while this indicator is lit.

The parameter in n01 through to n79 can be set or monitored while this indicator is lit.

Note: While the Inverter is in operation, the parameters

can be only monitored and only some parameters

can be changed. Any RUN command input is

ignored while this indicator is lit.

Switches the setting and monitor item indicators in

sequence.

Parameter being set will be cancelled if this key is pressed

before entering the setting.

Increases multi-function monitor numbers, parameter numbers and parameter set values.

Decreases multi-function monitor numbers, parameter

numbers and parameter set values.

Enters multi-function monitor numbers, parameter numbers

and internal data values after they are set or changed.

Starts the Inverter running when the 3G3JV is in operation

with the Digital Operator.

Stops the Inverter unless parameter n06 is not set to

disable the STOP Key.

Data display

FREQ adjuster

FREF indicator

FOUT indicator

IOUT indicator

MNTR indicator

F/R indicator

LO/RE indicator

PRGM indicator

Mode Key

Increment Key

Decrement Key

Enter Key

RUN Key

STOP/RESET Key

Appearance Name Function

Keys

Data display

FREQ adjuster

Indicators

(Setting/Monitor

item indicators)

Page 6

Parameter Access:

0 - Limited Parameter access

1 - Full Parameter access

8 - Factory Parameter Initialise

Operation Mode Selection:

0 - Stop/Reset key or Keypad enabled

1 - Multi-function terminal input is enabled

Freq. Ref. Selection:

0 - Digital Operator

1 - Speeds from Digital Inputs (n21 - n28)

2 - Analogue Freq. Ref. (0-10V)

3 - Analogue Freq. Ref. (4-20mA)

4 - Analogue Freq. Ref. (0-20mA)

Maximum Frequency (FMAX)

Maximum Voltage (VMAX)

Maximum Voltage Frequency (FA)

Acceleration time 1

Deceleration time 1

Frequency Reference 1

Frequency Reference 2

"

Frequency Reference 8

Rated Motor Current

Multi-function input 1 (S2)

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

Multi-function output (MA/MB and MC)

Analogue Monitor Output:

0 - Output Frequency

1 - Output Current

Carrier Frequency Selection

DC Injection Braking Current

DC Injection Braking at Stop Time

DC Injection Braking at Start Time

Stall pevention during deceleration:

0 = Stall Prevention Enabled

1 = Braking Resistor Enabled

n01

n02

n03

n09

n10

n11

n16

n17

n21

n22

"

n28

n32

n36

n37

n38

n39

n40

n44

n46

n52

n53

n54

n55

0 to 9

0,1

0 to 4

20 to 400

1 to 255V

0.2 to 400

0.0 to 999

0.0 to 999

0.0 to FMAX

"

2 to 8, 10 to 22

0.2 to 8, 10 to 22

2 to 8, 10 to 22

2 to 8, 10 to 22,34

0 to 7, 10 to 17

0,1

1 to 4, 7 to 9

0 to 100%

0.0 to 25.5

0.0 to 25.5

0,1

1

0

0

60

200

60

10

10

6

0

"

0

0 to 150% of

rated inverter

output current

2

5

3

6

1

0

Varies with

the capacity

50

0.5

0

0

5-2

5-7

5-8

5-4

5-4

5-4

5-15

5-15

5-11

5-11

"

5-11

5-3

5-19

5-19

5-19

5-19

5-22

5-24

6-2

6-5

6-5

6-5

6-7

Parameter No. Description Range Default Manual Ref. Page

Quick Start Parameter List (Refer to manual for complete list)

Page 7

Power ON

Press the Mode Key repeatedly until the PRGM

indicator is lit.

Use the Increment or Decrement Key to set the

parameter number.

Press the Enter Key.

The data of the selected parameter number will be

displayed.

Use the Increment or Decrement Key to set the

data. At that time the display will flash.

Press the Enter Key so that the set value will be

entered and the data display will be lit. (see note 1)

The parameter number will be displayed.

In approx. 1s

Key sequence Indicator Display example

Explanation

Example of Parameter Settings

Multi-function Inputs

Value Function

2 Reverse/Stop

3 External fault (NO)

4 External fault (NC)

5 Fault reset

6 Multi-step speed reference 1

7 Multi-step speed reference 2

8 Multi-step speed reference 3

10 Inching command

12 External base block (NO)

13 External base block (NC)

17 Local/Remote selection

Multi-function Outputs

Value Function

0 Fault output

1 During RUN

2 Frequency agree

6 Overtorque being monitored (NO)

12 RUN mode

13 Inverter ready

15 Undervoltage in progress

Analogue Output Functions

Value Function

0 Output frequency

1 Output current

Note: Refer to Section 5-20 to 24 for full set value listings

Note 1: To cancel the set value, press the Mode Key instead. The parameter number will be displayed.

Note 2: There are parameters that cannot be changed while the Inverter is in operation. Refer to the list of

parameters. When attempting to change such parameters, the data display will not change by pressing

the Increment or Decrement Key.

Cancels

set data

In approximately 1s

Page 8

Check output for short circuit or ground fault.

The Load is too large, reduce it or use larger Inverter.

Check motor FLA rating compared to Inverter and V/F setting.

Load inertia is too large and the motor is regenerating.

Increase deceleration time (n020 or n022).

Connect an external braking resistor and set n092 to 1.

Check braking resistor and wiring.

Check mains power supply voltage and connections.

Check correct supply for Inverter being used.

Monitor for mains dips or interruptions.

Refer to manual for installation guidelines and recommendations.

Check cooling fan (if fitted).

Check V/F characteristic or reduce Carrier frequency.

Check and reduce the load.

Check V/F characteristic (Vmax and Fmax).

Increase the running speed of the motor.

Increase acceleration/deceleration times.

Check your control terminal wiring.

A multi-functional digital input has been set to 3 or 4.

Run signal must be removed before this can be reset.

Inverter must be stopped when Local/Remote switching

attempted.

Inverter must be stopped when Comms/Remote switching

attempted.

Check your control terminal wiring.

A multi-function digital input has been set to 12 or 13.

Forward and reverse run signal have been applied

simultaneously.

Overcurrent

Output current is higher than

250% of Inverter rated current.

Overvoltage

DC bus voltage has exceeded

detection level.

Main circuit undervoltage

DC bus voltage is below

detection level.

Unit overheated

Temperature inside the inverter

has exceeded 110°C.

Motor overload

The Inverter is protecting the motor

from overload based on an internal

I≈T calculation using n036 setting.

External fault

An external fault has been input.

Sequence error

Sequence input when Inverter

running.

External baseblock

An external baseblock command

has been input.

Sequence error has occurred

OC

OV

uV1

OH

OL1

EF*

SER

(flashing)

bb

(flashing)

EF

(flashing)

Fault Display Fault name and meaning Possible cause and remedy

Protective and Diagnostic Functions

Note: Refer to Section 7-2 for full fault code listings.

Improper procedures can result in personal injury or

equipment damage. Use the Quick Start Guide only if you

are familiar with standard safety precautions common to

variable speed drives. See Operation Manual I528 for

further details.

Loading...

Loading...