Page 1

Cat. No. I528-E1-1

USER’S MANUAL

FIRST DRAFT!

SYSDRIVE 3G3JV

Compact Simplified Inverter

Page 2

Thank you for choosing this SYSDRIVE 3G3JV

-series product. Proper use

and handling of the product will ensure proper product performance, will

lengthen product life, and may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product

with care.

NOTICE

1. This

2. Although care has been given in documenting the product, please contact

3. The product contains potentially dangerous parts under the cover. Do not

4. We recommend that you add the following precautions to any instruction

5. Specifications

manual describes the functions of the product and relations with other

products. You should assume that anything not described in this manual is

not possible.

OMRON representative if you have

your

manual.

attempt

injury

assemble the product.

manuals

S Precautions on the dangers of high-voltage equipment.

S Precautions

been

prove product performance.

to open the cover under any circumstances. Doing so

or death and may damage the product. Never attempt to repair or dis

you prepare for the system into which the product is being installed.

on touching the terminals of the

turned of

f. (These

and functions may be changed without notice in order to im

terminals are live even with the power turned of

any suggestions on improving this

may result in

product even after power has

f.)

-

-

Items to Check Before Unpacking

Check

the following items before removing the product from the package:

S Has

the correct product been delivered (i.e., the correct model number and

specifications)?

S Has the product been damaged in shipping?

S Are any screws or bolts loose?

Page 3

Overview

1-1 Function

1-2 Nomenclature

1

Chapter 1

Page 4

3 p ase 00 C

C osed,

S g e p ase 00 C

C osed,

C ect es

Overview Chapter 1

1-1 Function

The compact simple SYSDRIVE 3G3JV-Series Inverter ensures greater

ease of use than any conventional model.

The 3G3JV Inverter meets EC Directives and UL/cUL standard requirements for worldwide use.

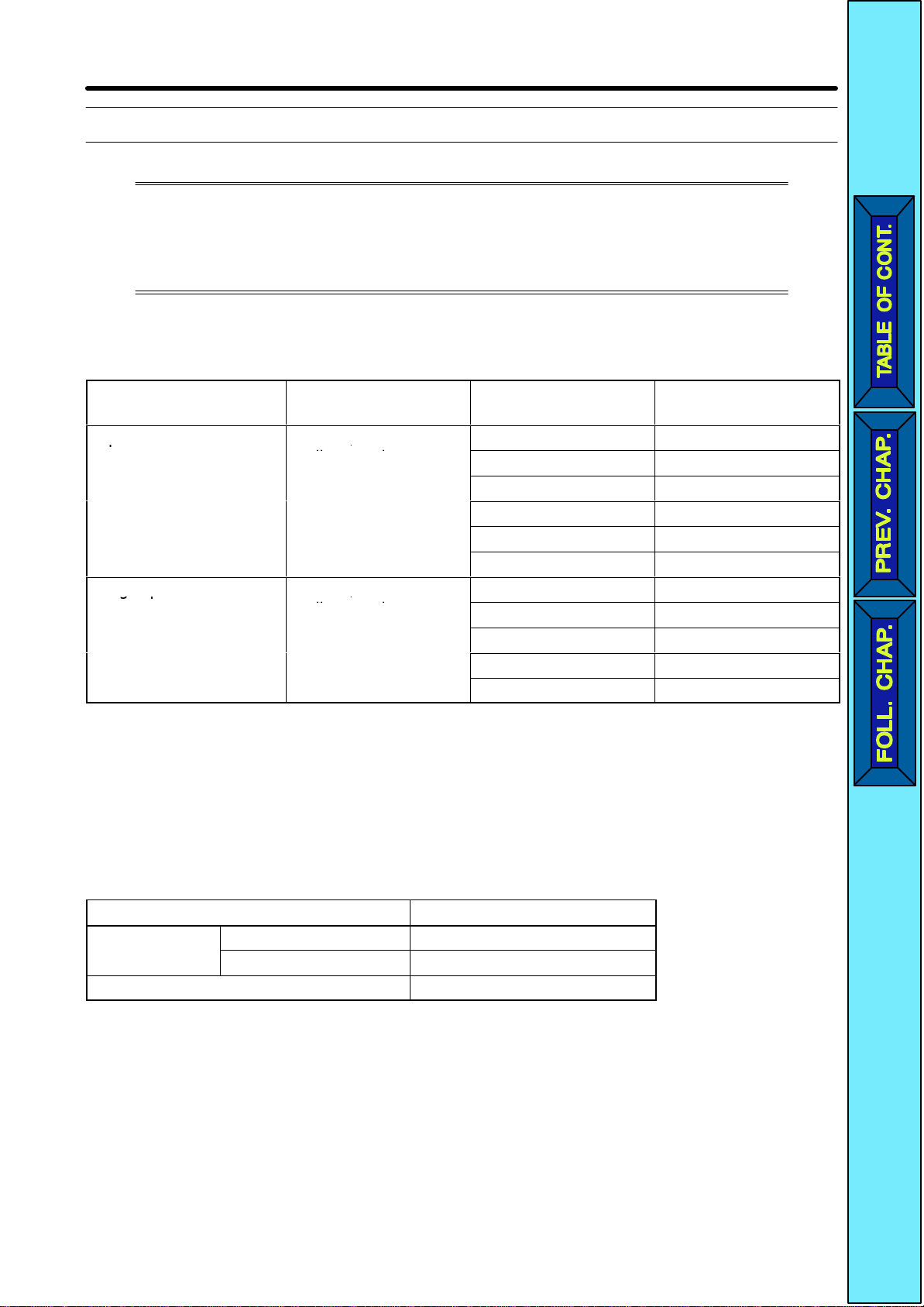

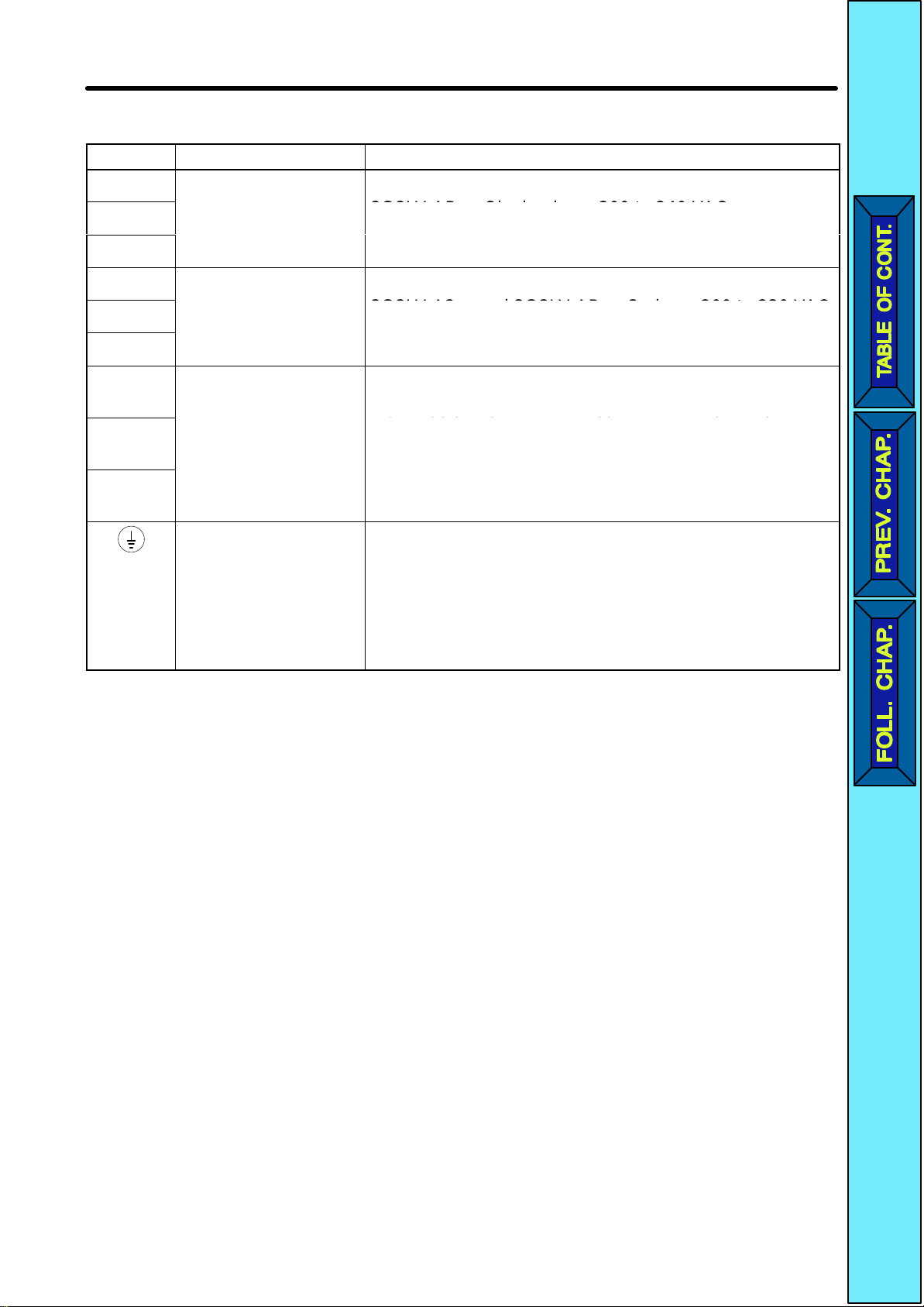

H SYSDRIVE 3G3JV Inverter Models

•The following 3- and single-phase 200-VAC-class 3G3JV models are available.

Rated voltage Protective

structure

3-phase 200 VAC Closed,

wall-mounting type

(conforming to IP20)

Single-phase 200 VAC Closed,

wall-mounting type

(conforming to IP20)

Maximum applied

motor capacity

0.1 (0.1) kW 3G3JV-A2001

0.2 (0.25) kW 3G3JV-A2002

0.4 (0.55) kW 3G3JV-A2004

0.75 (1.1) kW 3G3JV-A2007

1.5 (1.5) kW 3G3JV-A2015

2.2 (2.2) kW 3G3JV-A2022

0.1 (0.1) kW 3G3JV-AB001

0.2 (0.25) kW 3G3JV-AB002

0.4 (0.55) kW 3G3JV-AB004

0.75 (1.1) kW 3G3JV-AB007

1.5 (1.5) kW 3G3JV-AB015

Model

Note The figures in parentheses indicate capacities for motors used outside Japan.

H International Standards (EC Directives and UL/cUL

Standards)

The 3G3JV Inverter meets the EC Directives and UL/cUL standard requirements for

worldwide use.

EC Directives

UL/cUL UL508C

1-2

Classification Applicable standard

EMC directive EN50081-2 and EN5008-2

Low-voltage directive prEN50178

Page 5

Overview Chapter 1

H Versatile Easy-to-use Functions

•Incorporates

•Easy to initialize and operate with the FREQ adjuster on the Digital Operator.

•Ease

can

•Optional

face cards.

of maintenance. The cooling fan is easily replaceable. The life of the cooling fan

be prolonged by turning on the cooling fan only when the Inverter is in operation.

the

functions and operability ensured by the conventional 3G3EV Series.

RS232 (3G3JV

-PSI232J)

and RS422/485 MODBUS (3G3JV

-PSI485J) inter

H Suppression of Harmonics

Connects to DC reactors, thus suppressing harmonics more effectively than conventional AC reactors.

Further

of the DC and AC reactors.

improvement in the suppression of harmonics is possible with the combined use

-

1-3

Page 6

Overview Chapter 1

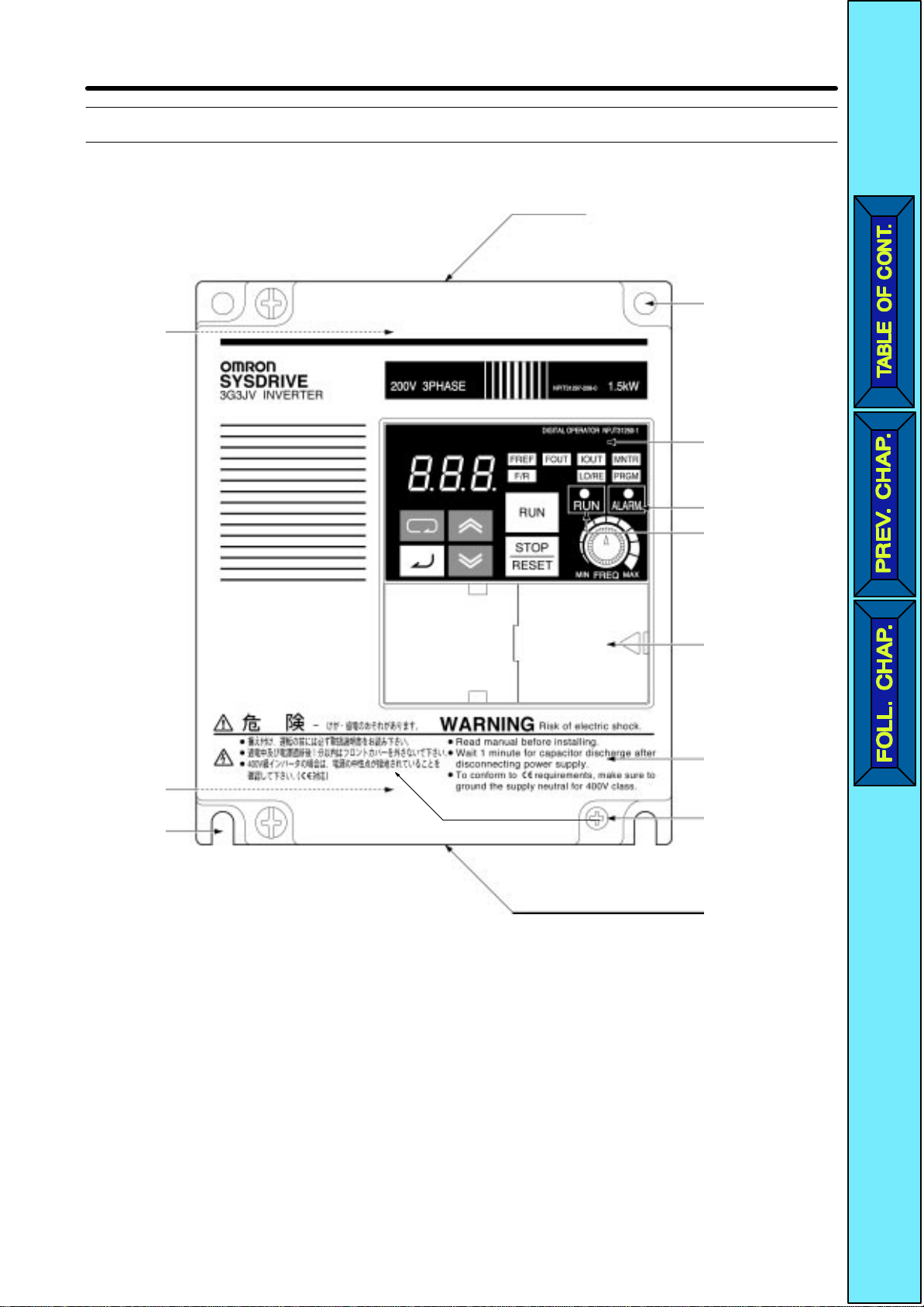

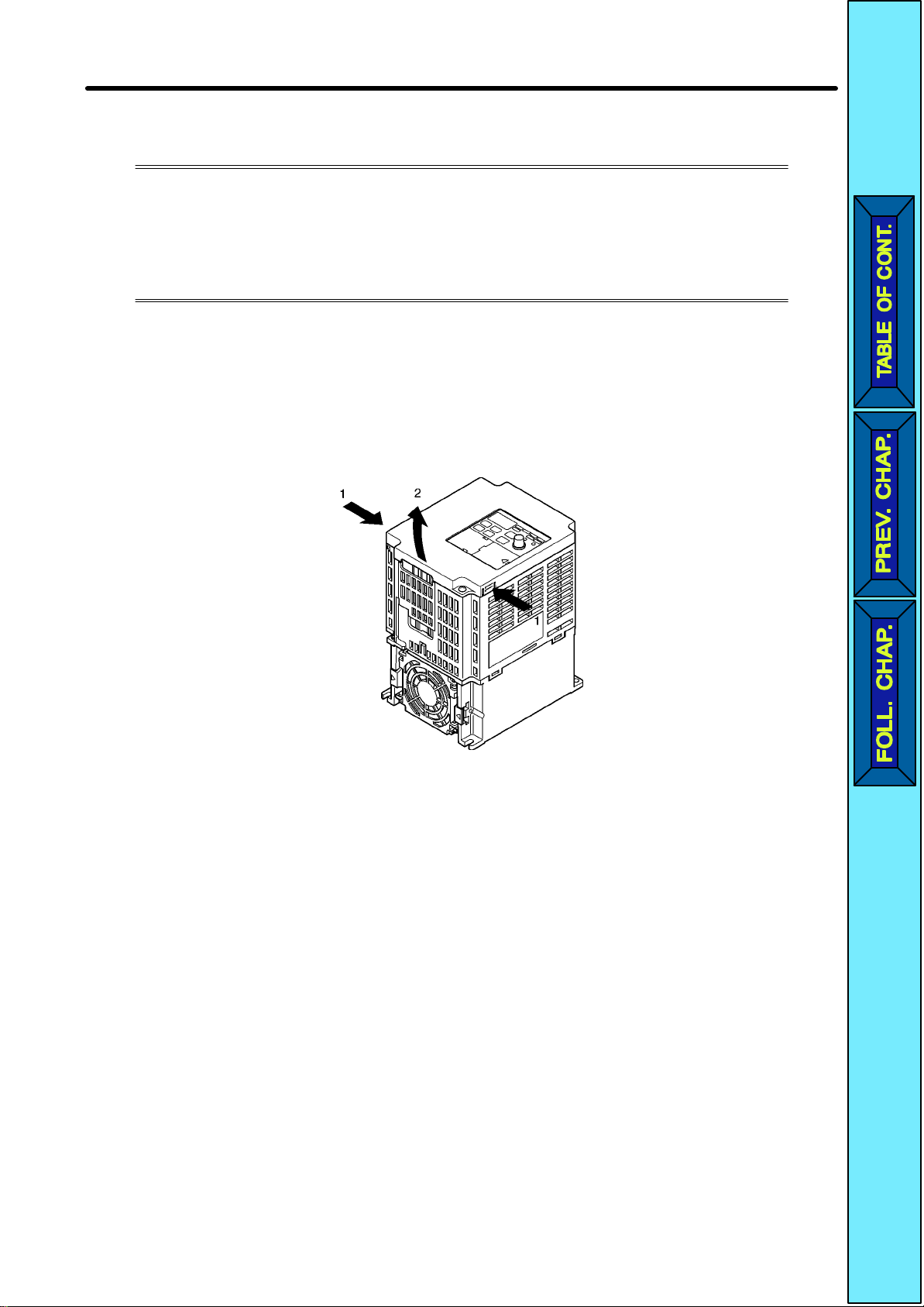

1-2 Nomenclature

H Panel

Top protection cover

Mounting holes

Terminal

block

(Two)

Digital Operator

ALARM display

RUN indicator

Terminal

block

U-shaped

cutouts

(Two)

Note 1. The

front cover functions as a terminal cover

be removed.

Note 2. Instead

outs located diagonally.

3G3JV-A2001 (0.1 kW), 3G3JV-A2002 (0.25 kW), 3G3JV-A2004 (0.55 kW),

and 3G3JV-A2007 (1.1 kW)

3G3JV-AB001 (0.1 kW), 3G3JV-AB002 (0.25 kW), and 3G3JV-AB004

(0.55 kW)

of mounting holes, each of

Optional cover

Front cover

Front cover

mounting screw

Bottom

protection cover

. The Digital Operator Unit cannot

the following models has two U-shaped cut

-

1-4

Page 7

Overview Chapter 1

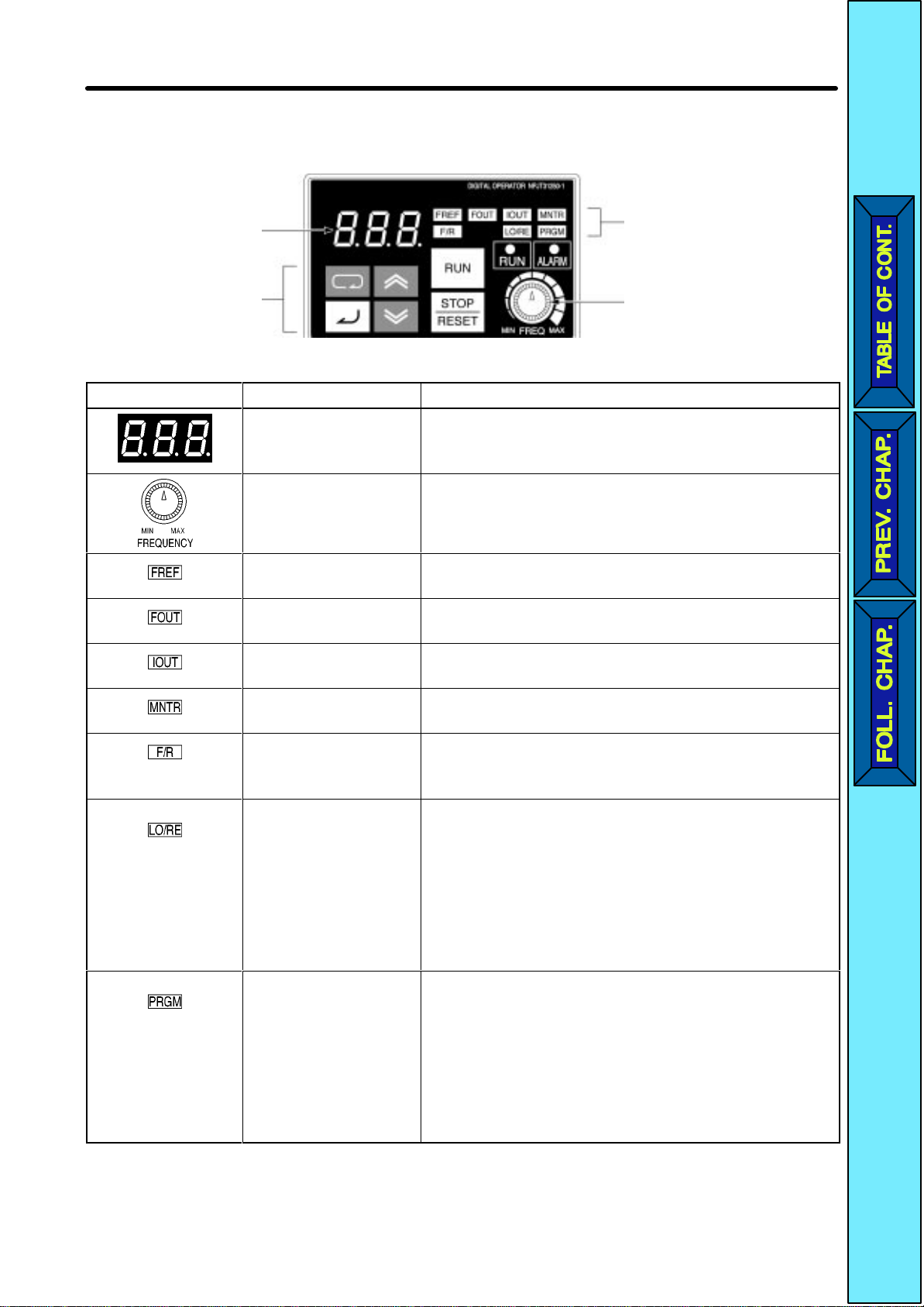

H Digital Operator

Indicators

Data display

(Setting/Monitor

item indicators)

Keys

Appearance Name Function

Data display Displays relevant data items, such as frequency

reference, output frequency, and parameter set

values.

FREQ adjuster Sets the frequency reference within a range

between 0 Hz and the maximum frequency.

FREF indicator The frequency reference can be monitored or set

while this indicator is lit.

FOUT indicator The output frequency of the Inverter can be

monitored while this indicator is lit.

IOUT indicator The output current of the Inverter can be

monitored while this indicator is lit.

MNTR indicator The values set in U01 through U10 are

monitored while this indicator is lit.

F/R indicator The direction of rotation can be selected while

this indicator is lit when operating the Inverter

with the RUN Key.

LO/RE indicator The operation of the Inverter through the Digital

Operator or according to the set parameters is

selectable while this indicator is lit.

FREQ adjuster

Note This status of this indicator can be only

monitored

Any RUN command input is ignored while

this indicator is lit.

PRGM indicator The parameters in n01 through n79 can be set or

monitored while this indicator is lit.

Note While the Inverter is in operation, the pa-

rameters can be only monitored and only

some parameters can be changed. Any

RUN command input is ignored while this

indicator is lit.

while the Inverter

is in operation.

1-5

Page 8

Overview Chapter 1

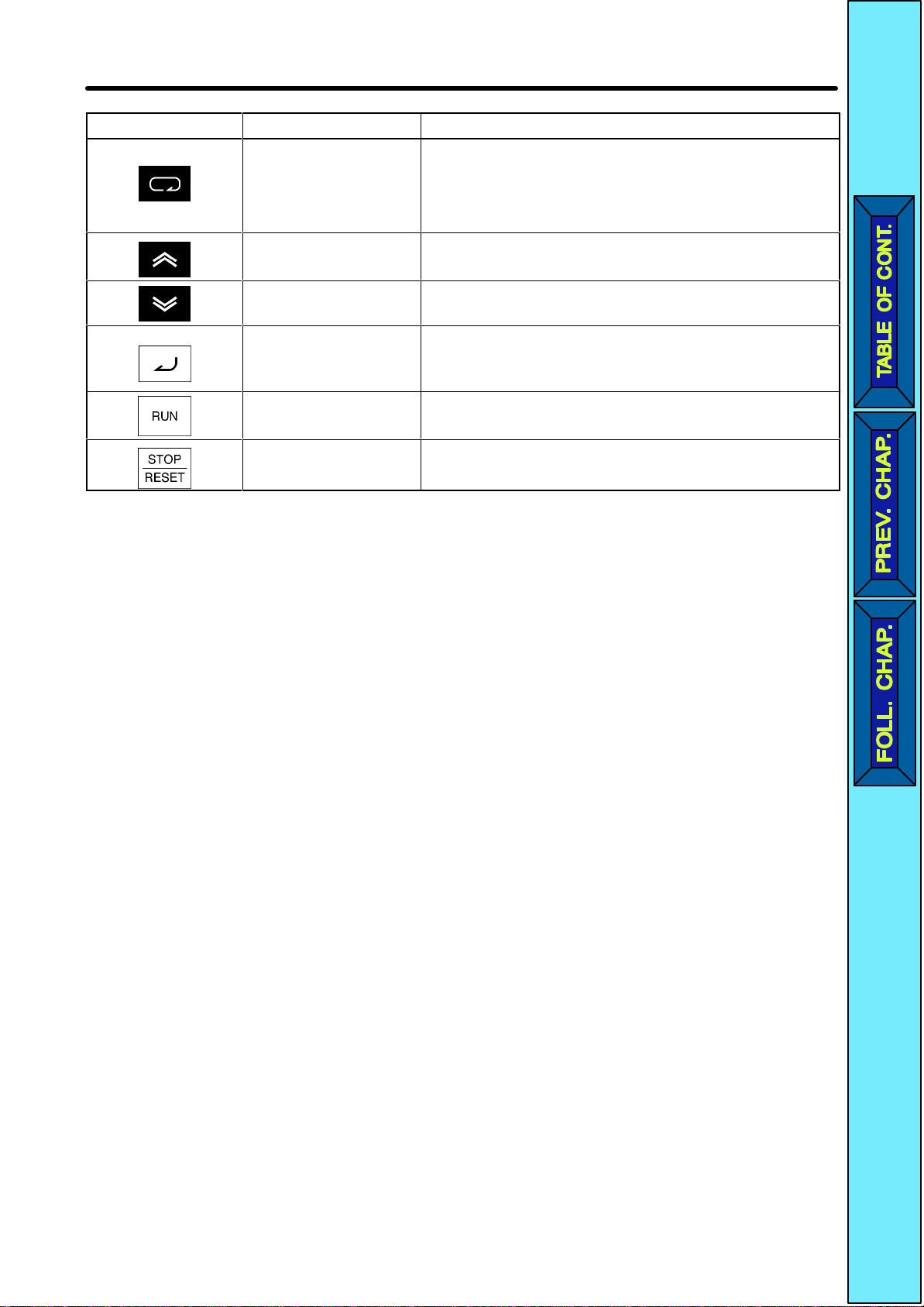

Appearance FunctionName

Mode Key Switches the setting and monitor item indicators

in sequence.

Parameter being set will be canceled if this key is

pressed before entering the setting.

Increment Key Increases multi-function monitor numbers,

parameter numbers, and parameter set values.

Decrement Key Decreases multi-function monitor numbers,

parameter numbers, and parameter set values.

Enter Key Enters multi-function monitor numbers,

parameter numbers, and internal data values

after they are set or changed.

RUN Key Starts the Inverter running when the 3G3FV is in

operation with the Digital Operator.

STOP/RESET Key Stops the Inverter unless parameter n06 is not

set to disable the STOP Key.

1-6

Page 9

Design

2-1 Installation

2-2 Wiring

2

Chapter 2

Page 10

ated o tage

ode 3G3J

eg t( g)

3 p ase 00 C

S g e p ase 00 C

Design Chapter 2

2-1 Installation

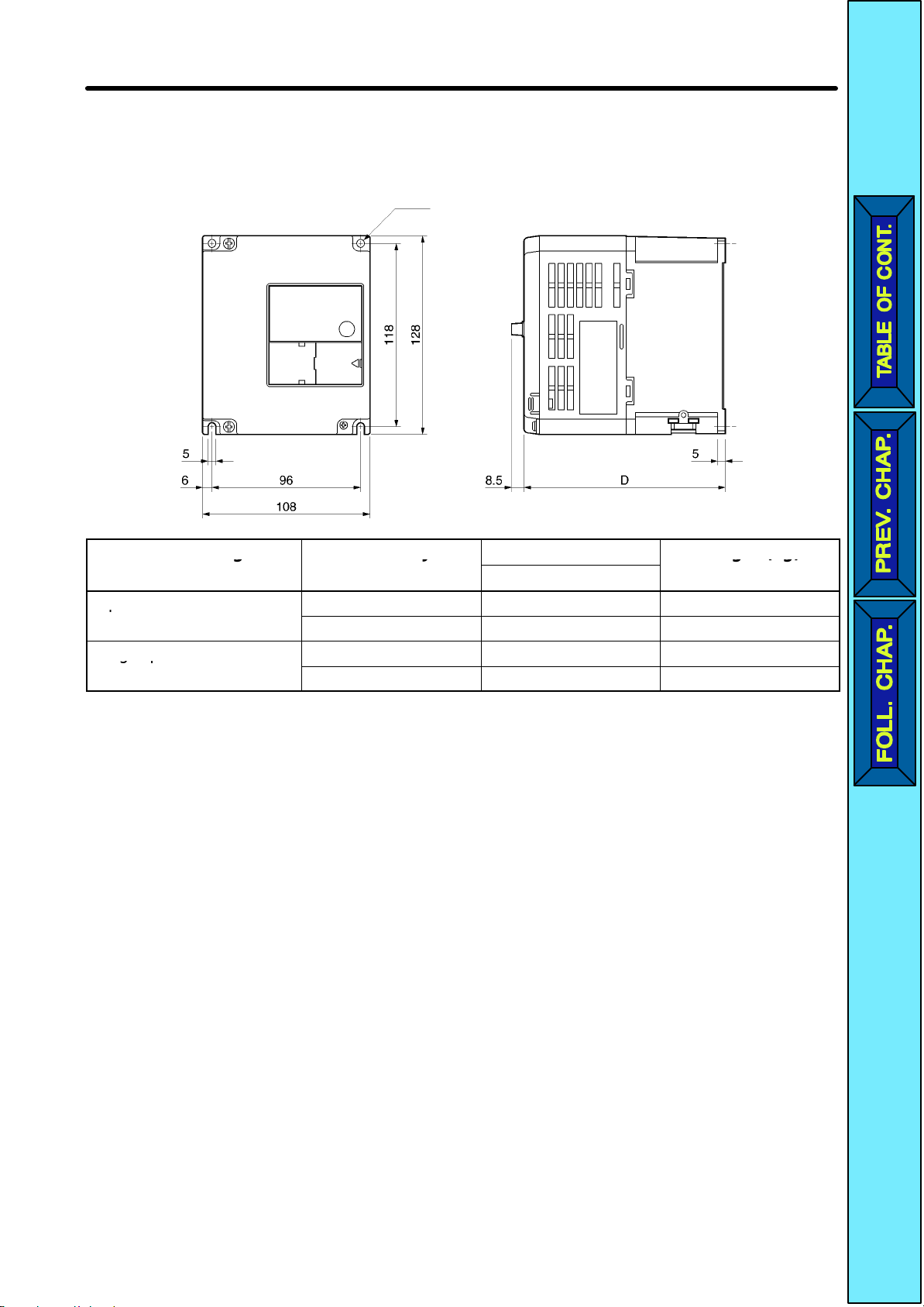

2-1-1 Dimensions

D 3G3JV-A2001 to 3G3JV-A2007 (0.1 to 0.75 kW) 3-phase 200-VAC Input

3G3JV-AB001 to 3G3JV-AB004 (0.1 to 0.4 kW) Single-phase 200-VAC

Input

Rated voltage Model 3G3JV-

3-phase 200 VAC

Single-phase 200 VAC

A2001 70 Approx. 0.5

A2002 70 Approx. 0.5

A2004 102 Approx. 0.8

A2007 122 Approx. 0.9

AB001 70 Approx. 0.5

AB002 70 Approx. 0.5

AB004 112 Approx. 0.9

Dimensions (mm)

D

Weight (kg)

2-2

Page 11

ated o tage

ode 3G3J

eg t( g)

3 p ase 00 C

S g e p ase 00 C

Design Chapter 2

D 3G3JV-A2015 to 3G3JV-A2022 (1.5 to 2.2 kW) 3-phase 200-VAC Input

3G3JV-AB007 to 3G3JV-AB015 (0.75 to 1.5 kW) Single-phase 200-VAC

Input

Two, 5-dia. holes

Rated voltage Model 3G3JV-

3-phase 200 VAC

Single-phase 200 VAC

A2015 129 Approx. 1.3

A2022 154 Approx. 1.5

AB007 129 Approx. 1.5

AB015 154 Approx. 1.5

Dimensions (mm)

D

Weight (kg)

2-3

Page 12

Design Chapter 2

2-1-2 Installation Conditions

Caution Be

!

sure to install the product in the correct direction and provide spe

cified

clearances between the Inverter and control panel

or with oth

er devices. Not doing so may result in fire or malfunction.

Caution Do not allow foreign objects to enter inside the product. Doing so

!

may result in fire or malfunction.

Caution Do

!

not apply any strong impact. Doing so

may result in damage to

the product or malfunction.

Caution Provide an appropriate stopping device on the machine side to

!

secure

safety

. (A holding brake is not a stopping

device for securing

safety.) Not doing so may result in injury.

Caution Provide an external emergency stopping device that allows an

!

instantaneous stop of operation and power interruption. Not doing

so may result in injury.

-

-

2-4

Page 13

Design Chapter 2

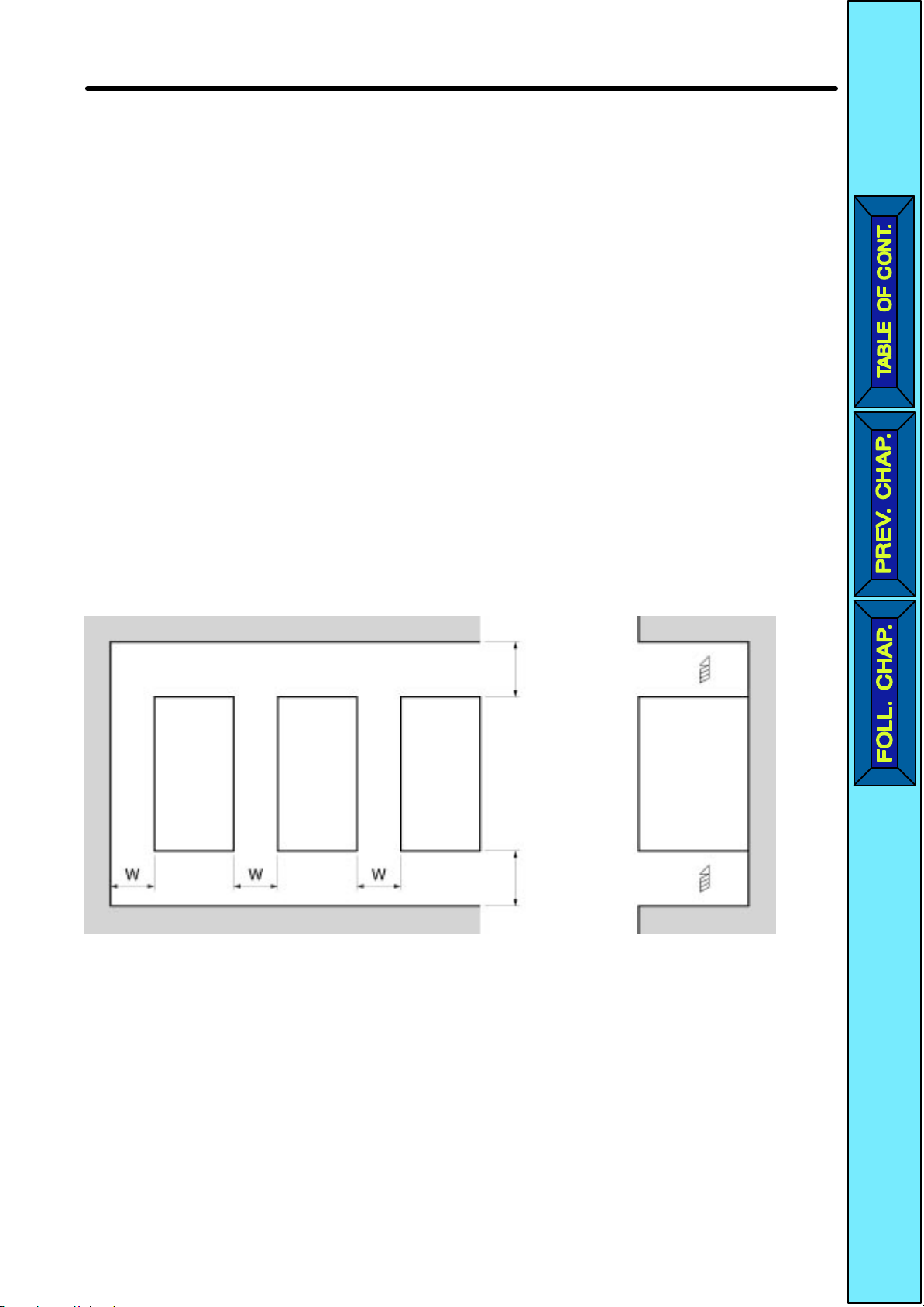

H Installation Direction and Dimensions

•Install the Inverter under the following conditions.

Ambient temperature for operation (panel-mounting): –10°C to 50°C

Humidity: 90% or less (no condensation)

•Install

in a totally enclosed panel that is completely protected from floating dust.

•When

der, oil, water, or other foreign matter does not get into the Inverter.

•Do not install the Inverter on inflammable material such as wood.

the Inverter in a clean location free from oil mist and dust. Alternatively

installing or operating the Inverter

, always take special care so that metal pow

, install it

H Direction

•Install the Inverter on a vertical surface so that the characters on the nameplate are

oriented

upward.

H Dimensions

•When

heat dissipation from the Inverter.

installing the Inverter

W = 30 mm min.

, always provide the following clearances to allow normal

100 mm min. Air

-

Inverter

SideInverter Inverter

100 mm min. Air

2-5

Page 14

Design Chapter 2

H Ambient Temperature Control

•To

enhance operation reliability

from extreme temperature changes.

the Inverter is installed in an enclosed environment such as a box, use a cooling fan

•If

or air conditioner to maintain the internal air temperature below 50°C.

life of the built-in electrolytic capacitors of the Inverter is prolonged by maintaining

The

the internal air temperature as low as possible.

surface temperature of the Inverter may rise approximately 30°C higher than the

•The

ambient

far as possible if the equipment and wires are easily influenced by heat.

temperature. Be sure to keep away equipment and wires from the Inverter as

H Protecting Inverter from Foreign Matter during Installation

•Place a cover over the Inverter during installation to shield it from metal power pro-

duced by drilling.

Upon

ventilation will be affected, causing the Inverter to overheat.

completion of installation, always remove the cover from the Inverter

, the Inverter should be installed in an environment

. Otherwise,

free

2-6

Page 15

Design Chapter 2

2-2 Wiring

WARNING Wiring must be performed only after confirming that the power

!

supply has been turned OFF. Not doing so may result in electrical

shock.

WARNING Wiring must be performed by authorized personnel. Not doing so

!

may result in electrical shock or fire.

WARNING Be sure to confirm operation only after wiring the emergency stop

!

circuit. Not doing so may result in injury.

WARNING Always

!

connect the ground terminals

to a ground of 100 Ω or less for

the 200-VAC class, or 10 Ω or less for the 400-VAC class. Not

connecting to a proper ground may result in electrical shock.

Caution Install external breakers and take other safety measures against

!

short-circuiting in external wiring. Not doing so may result in fire.

Caution Confirm

!

that the rated input voltage of the Inverter is the same as the

AC power supply voltage. An incorrect power supply may result in

fire, injury, or malfunction.

Caution Connect

!

the Braking Resistor and Braking Resistor Unit as specified

in the manual. Not doing so may result in fire.

Caution Be

!

sure to

wire correctly and securely

. Not doing so may result in in

jury or damage to the product.

-

Caution Be

!

Caution Do

!

sure to firmly tighten the screws on the terminal block. Not

so may result in fire, injury, or damage to the product.

not connect an AC power to the U, V

, or W output. Doing so may

result in damage to the product or malfunction.

doing

2-7

Page 16

Design Chapter 2

2-2-1 Removing and Mounting the Covers

It

is necessary to remove the front cover

er, and the bottom protection cover from the Inverter to wire the terminal

block.

Follow the instructions below to remove the covers from the Inverter.

To mount the covers, take the opposite steps.

H Removing the Front Cover

•Loosen the front cover mounting screws with a screwdriver.

, optional cover

, top protection cov

-

•Press

tom

lowing illustration.

the left and right sides of the front cover in the arrow 1 directions and lift the bot

of the cover in the arrow 2 direction to

remove the front cover as shown in the fol

-

-

2-8

Page 17

Design Chapter 2

H Removing the Top and Bottom Protection Covers and

Optional Cover

D Removing the Top and Bottom Protection Covers

•After

D Removing the Optional Cover

•After

removing the front cover

directions.

removing the front cover

position A as a fulcrum.

, pull the top and bottom protection covers in the arrow

, lift the optional cover

Position A

in the arrow 2 direction based on

1

Note The

moved.

front cover functions as a terminal cover

. The Digital Operator cannot be re

2-9

-

Page 18

Design Chapter 2

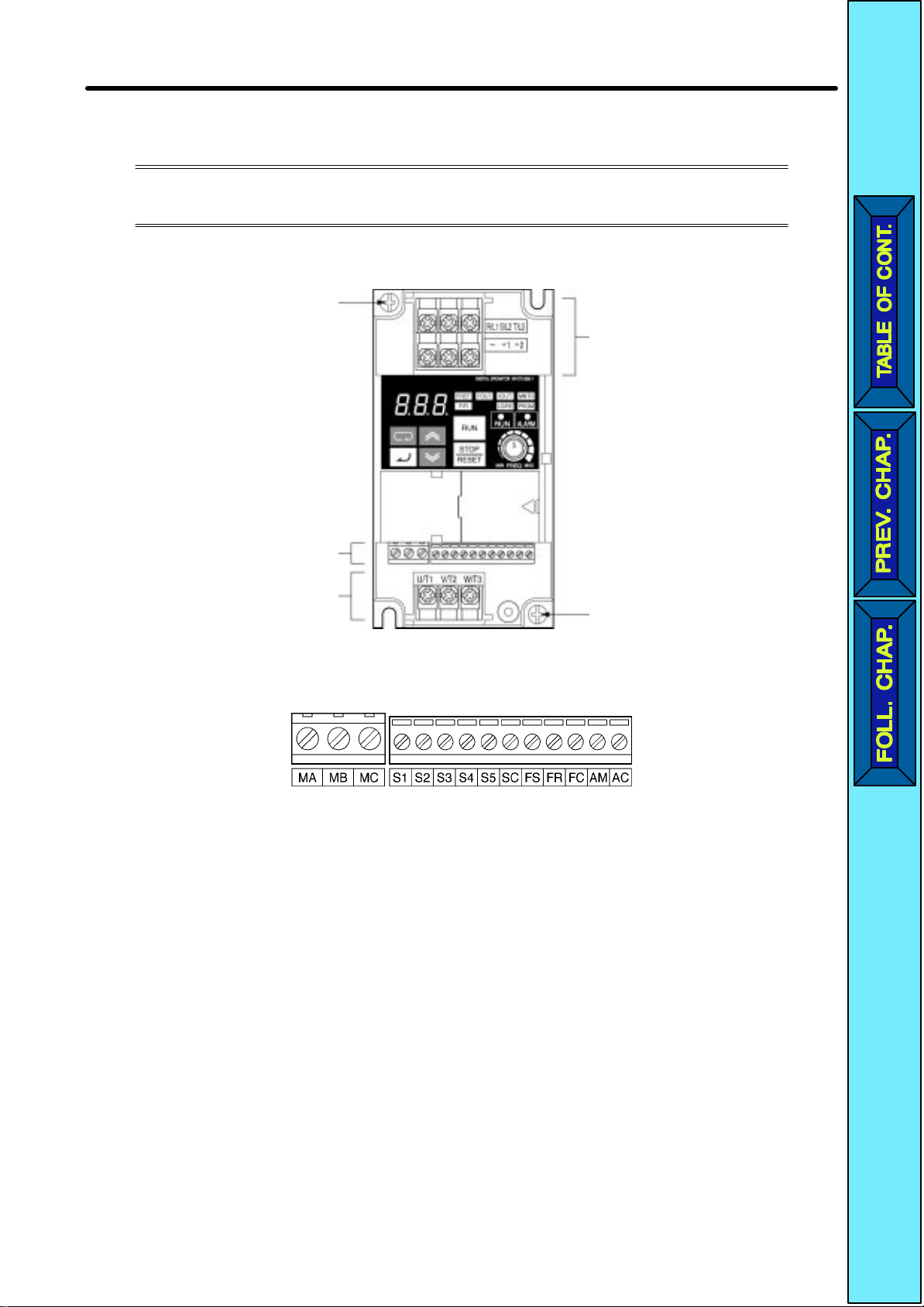

2-2-2 Terminal Block

Before wiring the terminal block, be sure to remove the front cover, top

protection cover, and the bottom protection cover.

H Position

Control circuit terminals

Main circuit output terminals

of T

erminal Block

Ground terminal

H Arrangement of Control Circuit Terminals

Main circuit input terminals

Ground terminal

2-10

Page 19

Design Chapter 2

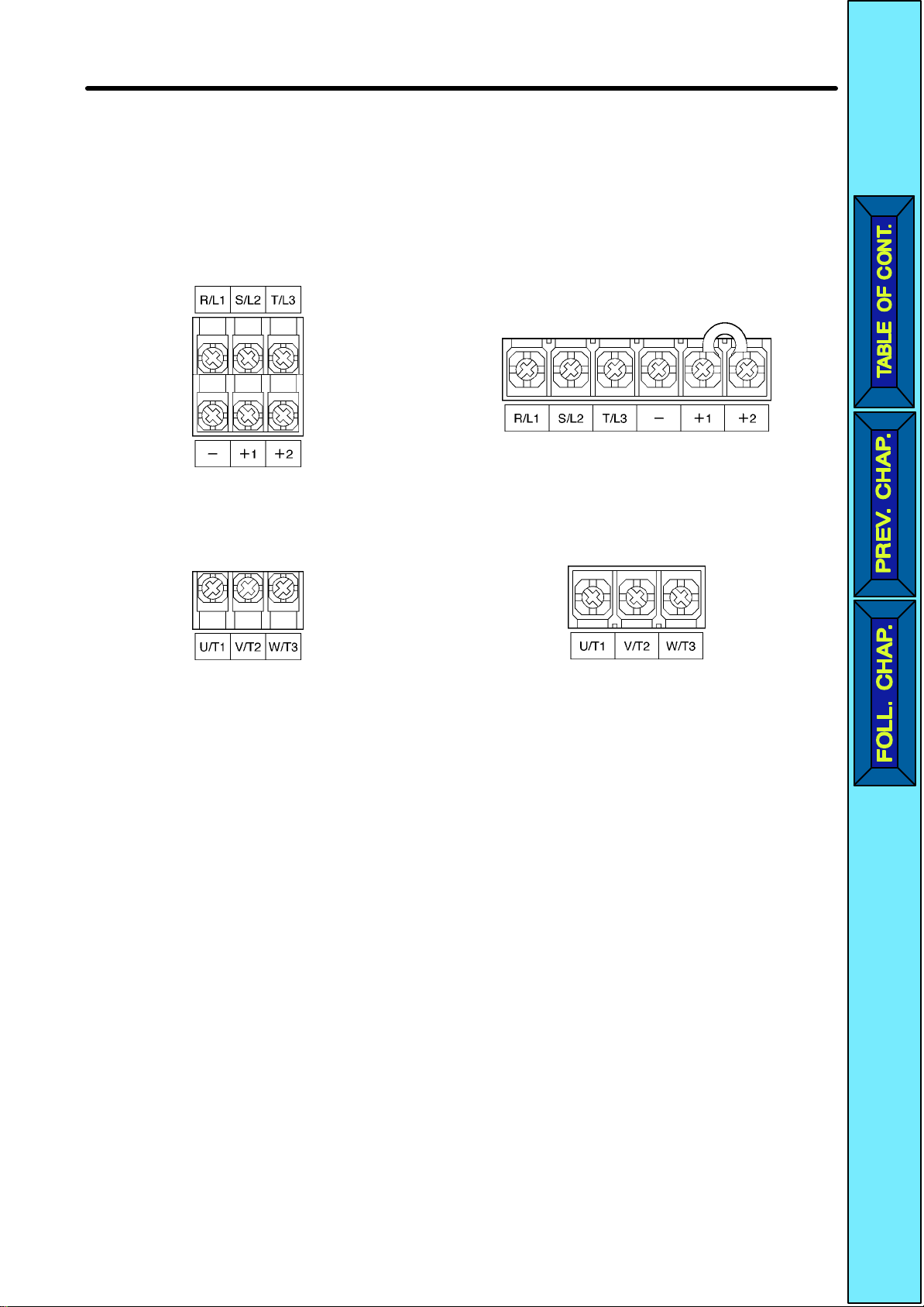

H Arrangement of Main Circuit Terminals

D 3G3JV-A2001 to 3G3JV-A2007

3G3JV-AB001 to 3G3JV-AB004

Main Circuit Input Terminals

(Upper Side)

Main Circuit Output Terminals

(Lower Side)

D 3G3JV-A2015 to 3G3JV-A2022

3G3JV-AB007 to 3G3JV-AB015

Main Circuit Input Terminals

(Upper Side)

Main Circuit Output Terminals

(Lower Side)

2-11

Page 20

(T

iti

)

Design Chapter 2

H Main Circuit Terminals

Symbol Name Description

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

+1

+2

–

Power supply input

terminals

Motor output

terminals

Connection terminals

+1 and +2:

DC reactor

connection terminals

+1 and –:

DC power supply

input terminals

Ground terminal Be sure to ground the terminal under the following

–

3G3JV-A2j: 3-phase 200 to 230 VAC

3G3JV-ABj: Single-phase 200 to 240 VAC

Note Connect single-phase input to terminals R/L1

and S/L2.

3-phase power supply output for driving motors.

3G3JV-A2j and 3G3JV-ABj: 3-phase 200 to 230 VAC

Note The maximum output voltage corresponds to the

power supply input voltage of the Inverter.

Connect the DC reactor for suppressing harmonics to

terminals +1 and +2.

When driving the Inverter with DC power, input the DC

power to terminals +1 and –.

erminal +1 is a pos

conditions.

ve terminal.

3G3JV-A2j: Ground at a resistance of 100 Ω or less.

3G3JV-ABj: Ground at a resistance of 100 Ω or less.

Note Be sure to connect the ground terminal directly

to the motor frame ground.

2-12

Page 21

8 mA at 24 VDC

(during running)

1 A max. at 30 VDC

10 VDC

Design Chapter 2

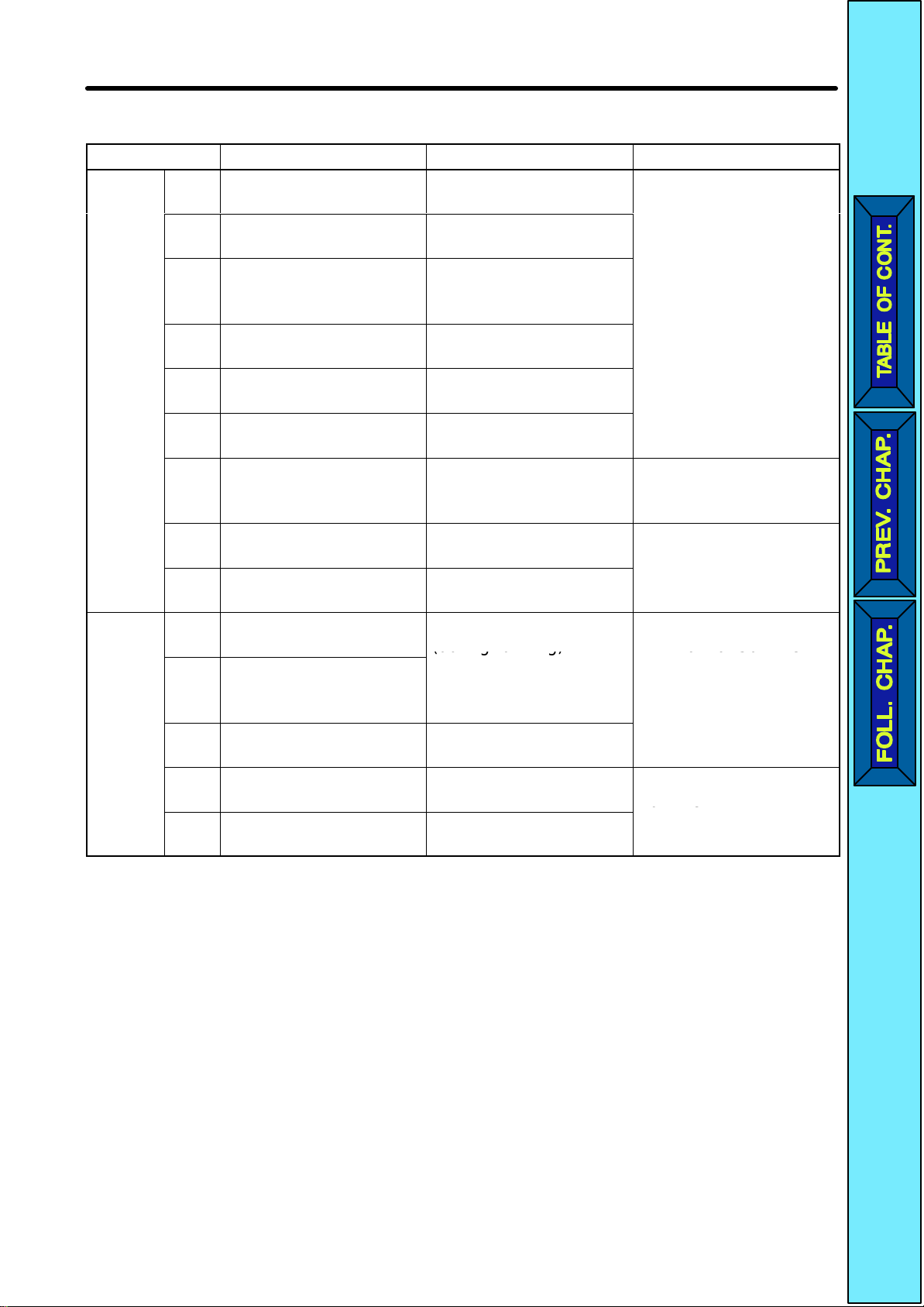

H Control Circuit Terminals

Symbol Name Function Signal level

Input

Output

S1 Forward/Stop Forward at ON. Stops

at OFF.

S2 Multi-function input 1

(S2)

S3 Multi-function input 2

(S3)

S4 Multi-function input 3

(S4)

S5 Multi-function input 4

(S5)

SC Sequence input com-

mon

FS Frequency reference

power supply

FR Frequency reference

input

FC Frequency reference

common

MA Multi-function contact

output (Normally open)

MB Multi-function contact

output (Normally

closed)

MC Multi-function contact

output common

AM Analog monitor output Set by parameter n44

AC Analog monitor output

common

Set by parameter n36

(Reverse/Stop)

Set by parameter n37

(External fault: Normally open)

Set by parameter n38

(Fault reset)

Set by parameter n39

(Multi-step reference 1)

Common for S1

through S5

DC power supply for

frequency reference

use

Input terminal for frequency reference use

Common for frequency

reference use

Set by parameter n40

(during running)

Common for MA and

MB use

(Output frequency)

Common for AM use

Photocoupler

8 mA at 24 VDC

20 mA at 12 VDC

0 to 10 VDC (20 kΩ)

Relay output

1 A max. at 30 VDC

1 A max. at 250 VAC

2 mA max. at 0 to

10 VDC

Note Functions in parentheses are default settings.

2-13

Page 22

Design Chapter 2

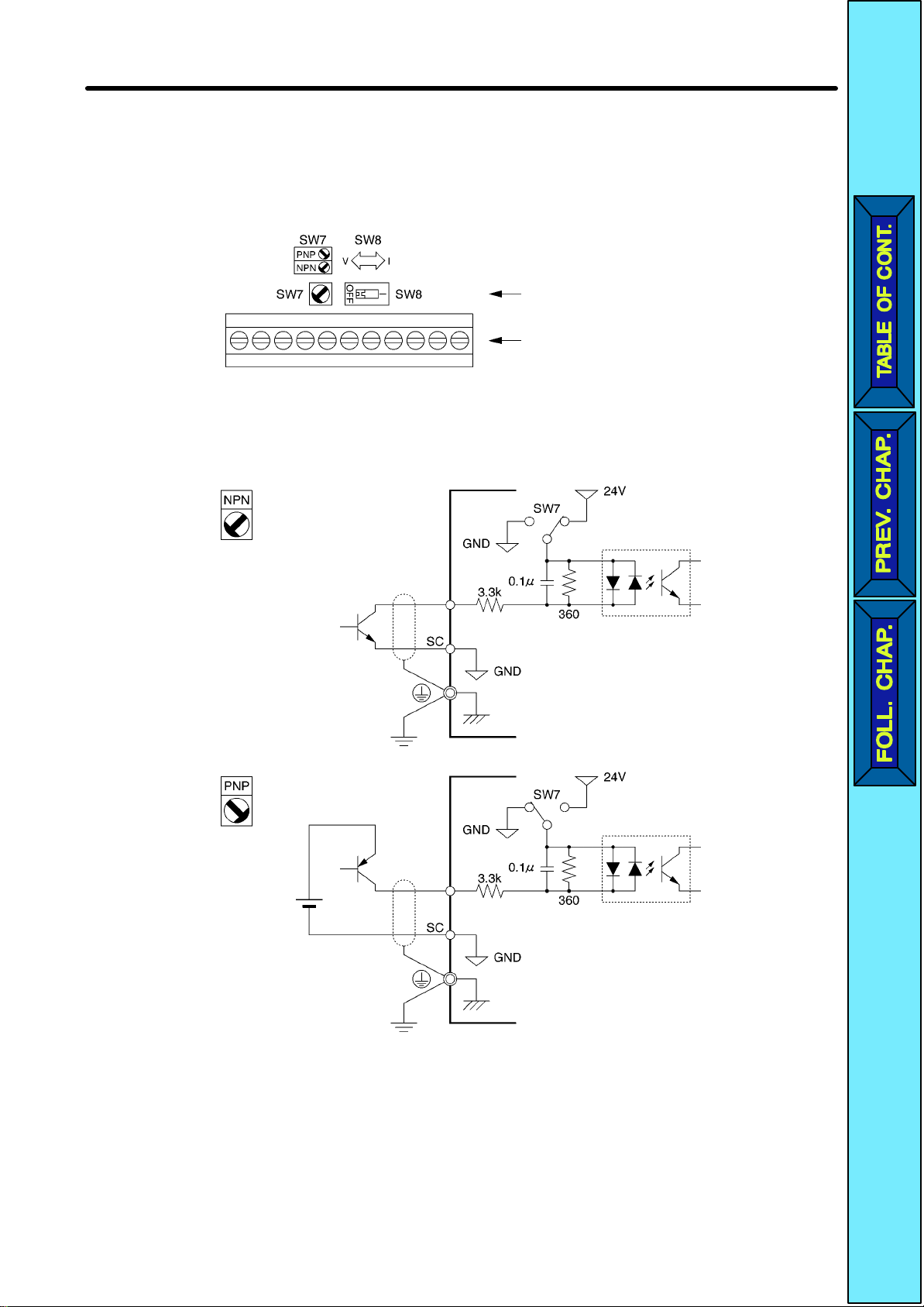

H Selecting Input Method

•Switches

SW7 and SW8, both of which are located above the control circuit terminals,

are used for input method selection.

Remove the front cover and optional cover to use these switches.

Selector

Control circuit

terminal block

D Selecting Sequence Input Method

•By using SW7, NPN or PNP input can be selected as shown below.

S1 to 5

2-14

S1 to 5

24 VDC

Page 23

Design Chapter 2

D Selecting Frequency Reference Input Method

•By using SW8, frequency reference voltage or current input can be selected.

Parameter

input method.

settings are required together with the selection of the frequency reference

Frequency reference input

method

SW8 setting Frequency reference

selection (parameter n03)

Voltage input V (OFF) Set value 2

Current input I (ON) Set value 3 or 4

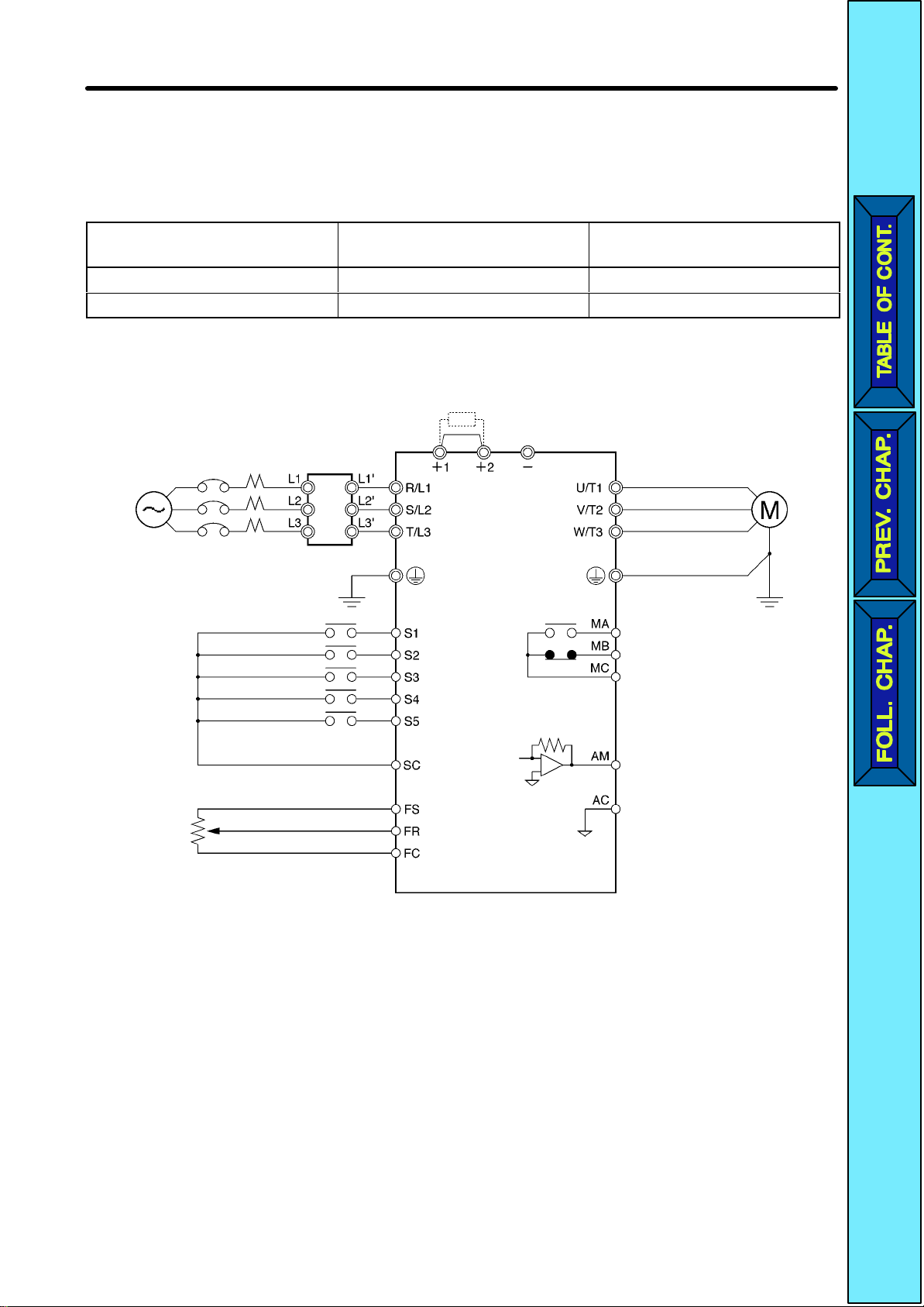

2-2-3 Standard Connections

DC reactor

(optional)

Noise Filter

3-phase 200 VAC

Single-phase 200 VAC

(see note 1)

Forward/Stop

Multi-function

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

input 1 (S2)

Multi-function contact output

NO

NC

Common

Sequence input common

Frequency reference power

supply 20 mA at +12 V

FREQ

adjuster

Frequency reference input

Frequency reference common

Note 1. Connect

Note 2. The

braking resistor cannot be connected because no braking transistor is

corporated.

single-phase 200 V

AC to

Analog monitor output

Analog monitor output common

terminals R/L1 and S/L2 of the 3G3JV

-ABj.

in

2-15

-

Page 24

Design Chapter 2

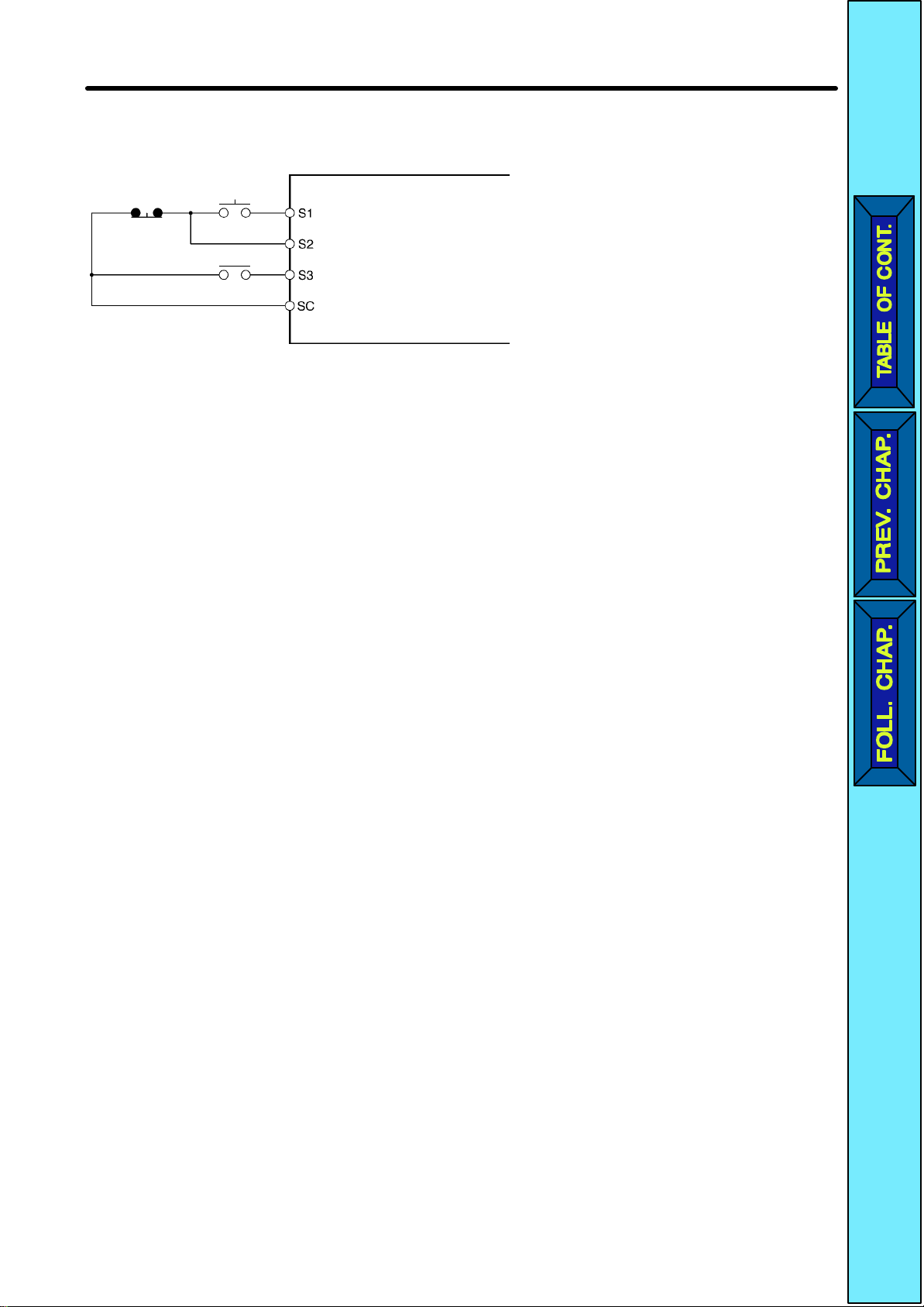

D Example of 3-wire Sequence Connections

Stop

switch

(NC)

RUN

switch

(NO)

Direction switch

RUN input (Operates with the stop switch and RUN switch closed.)

Stop input (Stops with the stop switch opened.)

Forward/Stop reference (Forward with the direction switch opened

and reverse with the direction switch closed.)

Sequence input common

Note Set parameter n37 for 3-wire sequence input.

2-16

Page 25

Design Chapter 2

2-2-4 Wiring around the Main Circuit

H Wire

Size, T

erminal Screw, Screw T

ightening T

orque, and

Molded-case Circuit Breaker Capacities

•For the main circuit and ground, always use 600-V polyvinyl chloride

(PVC) cables.

any cable is long and may cause voltage drops, increase the wire size according to

•If

the cable length.

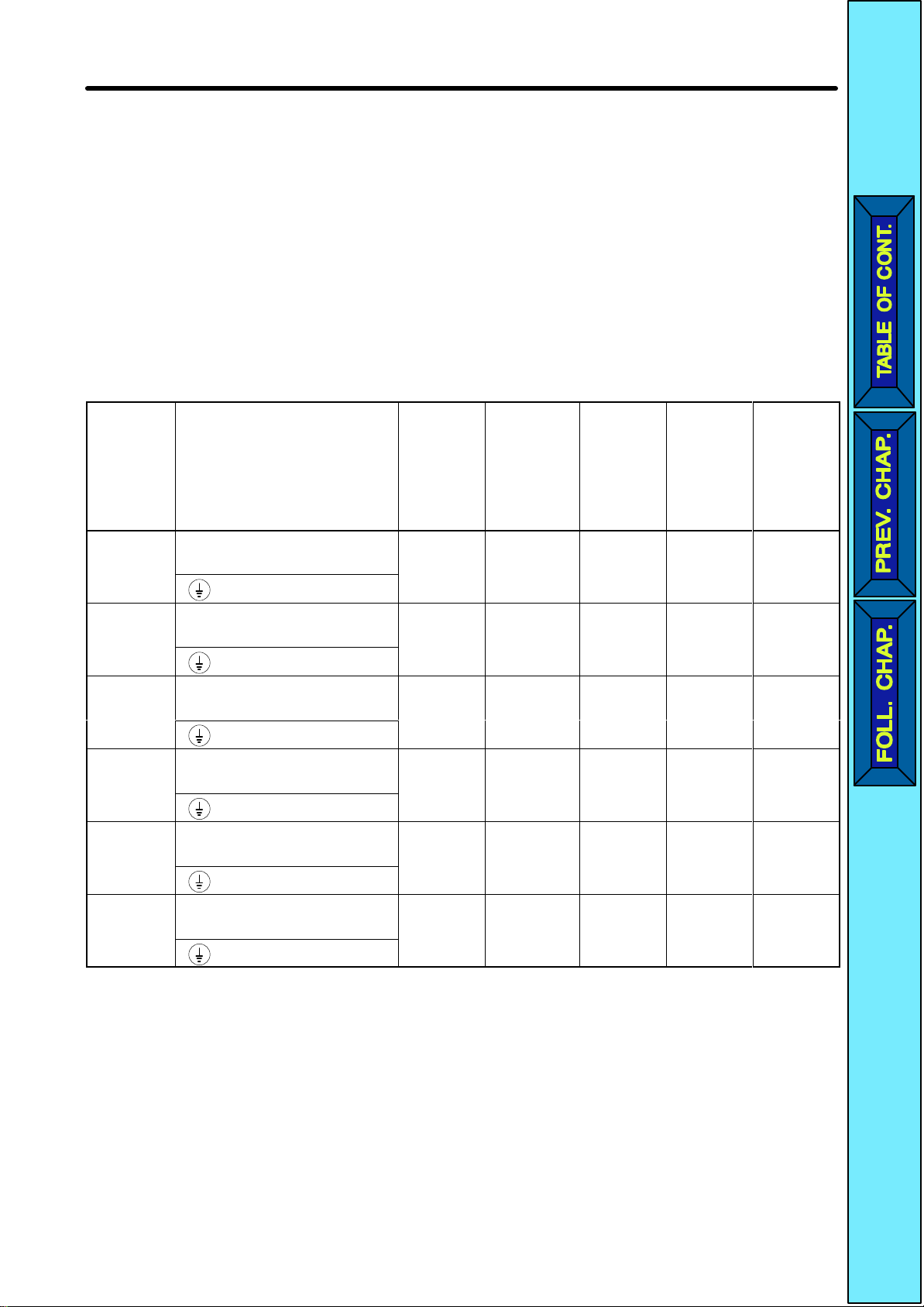

D 3-phase 200-VAC Model

Model

3G3JV-

A2001

A2002

Terminal symbol Termi-

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

Screw

nal

screw

M3.5 0.8 to 1.0 0.75 to 2 2 5

M3.5 0.8 to 1.0 0.75 to 2 2 5

tighten-

ing

torque

(NSm)

Wire

size

(mm

2

)

Recom-

mended

wire

size

2

(mm

)

Molded-

case

circuit

breaker

capac-

ity (A)

A2004

A2007

A2015

A2022

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

M3.5 0.8 to 1.0 0.75 to 2 2 5

M3.5 0.8 to 1.0 0.75 to 2 2 10

M3.5 0.8 to 1.0 2 to 5.5 2 20

M3.5 0.8 to 1.0 2 to 5.5 3.5 20

2-17

Page 26

Design Chapter 2

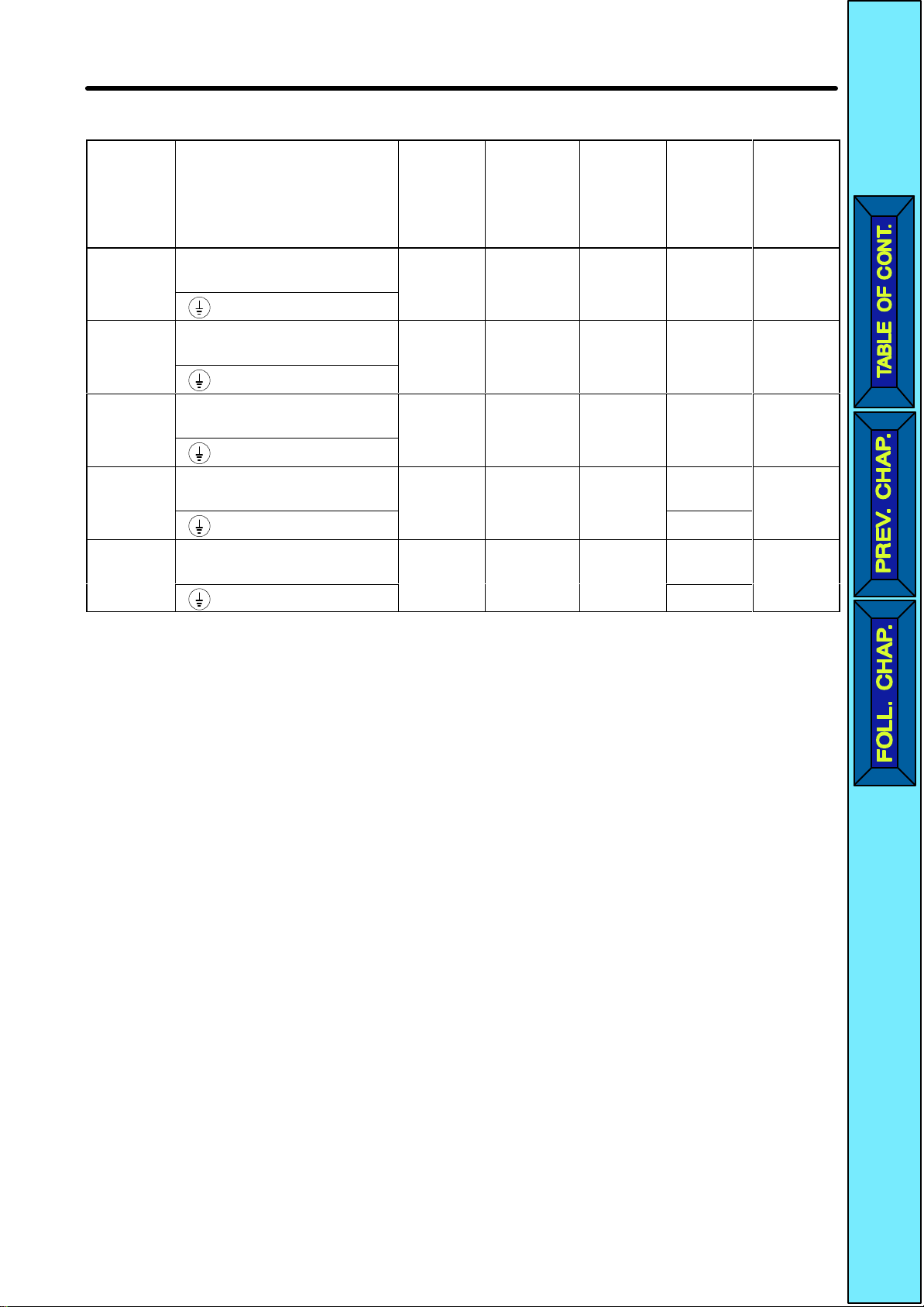

D Single-phase 200-VAC Model

Model

3G3JV-

AB001

AB002

AB004

AB007

AB015

Terminal symbol Termi-

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, –, +1,

+2, U/T1, V/T2, W/T3

Terminal

nal

screw

M3.5 0.8 to 1.0 0.75 to 2 2 5

M3.5 0.8 to 1.0 0.75 to 2 2 5

M3.5 0.8 to 1.0 0.75 to 2 2 10

M3.5 0.8 to 1.0 2 to 5.5

M3.5 0.8 to 1.0 2 to 5.5

torque

(NSm)

Wire

size

(mm

2

)

Recom-

mended

wire

size

2

(mm

3.5

2

5.5

2

breaker

)

20

20

Circuit

capac-

ity (A)

2-18

Page 27

Design Chapter 2

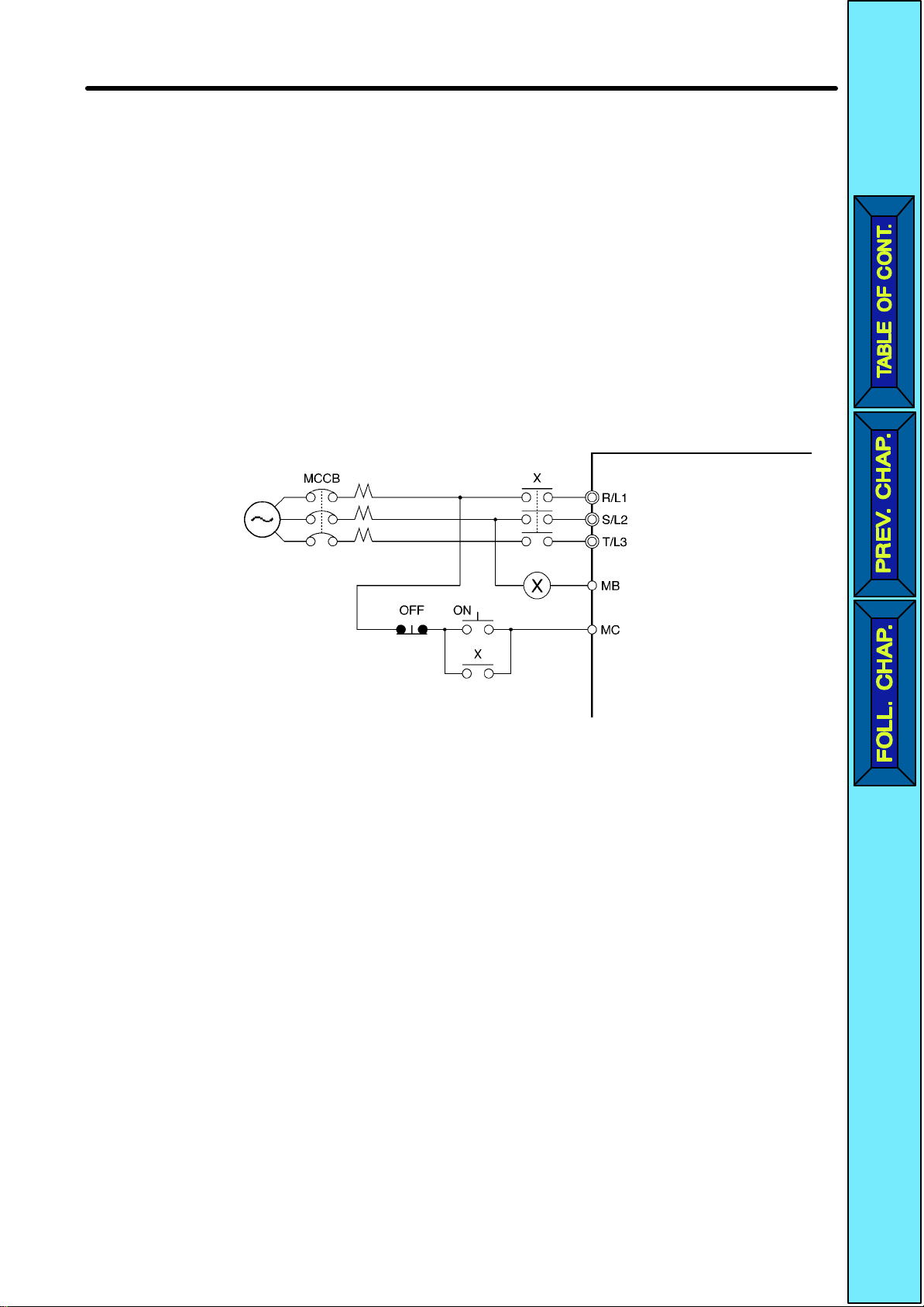

H Wiring on the Input Side of the Main Circuit

D Installing a Molded-case Circuit Breaker

Always

molded case circuit breaker (MCCB) suitable to the Inverter.

•Choose an MCCB with a capacity of 1.5 to 2 times the Inverter’s rated current.

•For the MCCB’s time characteristics, be sure to consider the Inverter’s overload

protection (one minute at 150% of the rated output current).

•If

a

the following diagram.

connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via a

the MCCB is to be used in common among multiple Inverters, or other devices, set up

sequence such that the power supply will be turned of

Power

supply

3-phase/Singlephase 200 VAC

f by a fault output, as shown in

Inverter

Fault output

(NC)

D Installing a Ground Fault Interrupter

Inverter

ated.

general, a leakage current of approximately 100 mA will occur for each Inverter (when

In

the power cable is 1 m) and approximately 5 mA for each additional meter of power

cable.

Therefore,

which

mans and excludes high-frequency leakage current.

outputs use high-speed switching, so high-frequency leakage

current is gener

at the power supply input area, use a special-purpose breaker for Inverters,

detects only the

leakage current in the frequency range that is hazardous to hu

-

-

2-19

Page 28

Design Chapter 2

•For

the special-purpose breaker for Inverters, choose a ground fault interrupter with a

sensitivity amperage of at least 10 mA per Inverter.

•When

tivity

more.

using a

amperage of 200 mA or more per Inverter and with an operating time of 0.1 s or

general leakage breaker

, choose a ground fault interrupter with a sensi

D Installing a Magnetic Contactor

If

the power supply of the main circuit is to be shut of

netic contactor can be used instead of a molded-case circuit breaker.

When

load

stop.

•A

•When

a magnetic contactor is installed on the primary side of the main circuit to stop a

forcibly, however

load can be started and stopped by opening and

the primary side. Frequently opening and closing the magnetic contactor, however,

may cause the Inverter to break down.

the Inverter is operated with

performed after recovery from a power interruption.

, the regenerative braking does not work and the load coasts to a

the Digital Operator

f because of the sequence, a mag

closing the magnetic contactor on

, automatic operation cannot be

D Connecting Input Power Supply to the Terminal Block

Input

power supply can be connected

phase

and R/L3).

sequence of input power supply is irrelevant to the phase sequence (R/L1, S/L2,

to any terminal on the terminal block because the

-

-

D Installing an AC Reactor

If

the

Inverter is connected to a large-capacity power transformer (660 kW or more) or

the

phase advance capacitor is switched, an excessive peak current may flow

the input power circuit, causing the converter unit to break down.

To prevent this, install an optional AC reactor on the input side of the Inverter.

This also improves the power factor on the power supply side.

D Installing a Surge Absorber

Always

inductive

solenoid, and magnetic brakes.

2-20

use a surge absorber or diode for the inductive loads near the Inverter

loads

include magnetic contactors, electromagnetic relays, solenoid valves,

through

. These

Page 29

Design Chapter 2

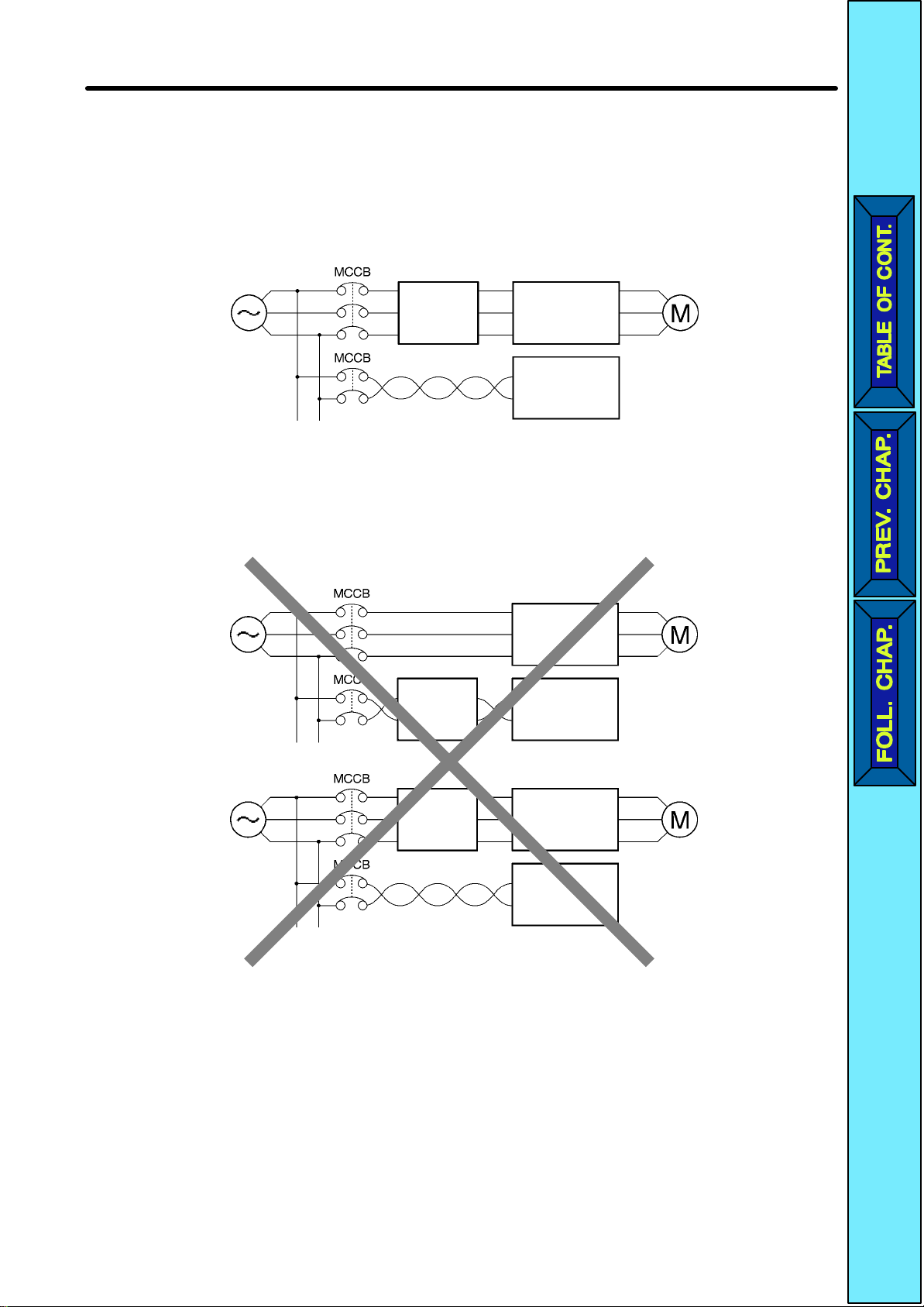

D Installing a Noise Filter on the Power Supply Side

Install

verter.

Wiring Example 1

a Noise Filter to eliminate noise transmitted between the power line and the In

-

Power

supply

3G3IV-PHF

Noise

Filter

3G3JV

SYSDRIVE

Programmable

Controller

Other controllers

Note Use a special-purpose Noise Filter for the SYSDRIVE 3G3JV.

Wiring Example 2

Power

supply

Generalpurpose

noise

filter

3G3JV

SYSDRIVE

Programmable

Controller

Note

Power

supply

Generalpurpose

noise

filter

Do not use any general-purpose noise filter

Other controllers

3G3JV

SYSDRIVE

Programmable

Controller

Other controllers

. No general-purpose

effectively suppress noise generated from the Inverter.

noise filter can

2-21

Page 30

Design Chapter 2

H Wiring on the Output Side of the Main Circuit

D Connecting the Terminal Block to the Load

Connect output terminals U/T1, V/T2, and W/T3 to motor lead wires U, V, and W.

Check

the

forward command.

that the motor rotates forward with the forward command. Switch over any two

output terminals to each

other and reconnect if the motor rotates in reverse with the

of

D Never Connect a Power Supply to Output Terminals

Never connect a power supply to output terminals U/T1, V/T2, or W/T3.

If

voltage is applied to the output terminals, the internal circuit of the Inverter will be

aged.

dam

-

D Never Short or Ground Output Terminals

If

the output terminals are touched with bare hands or the output wires come into contact

with

the Inverter casing, an electric shock or

ardous.

Also, be careful not to short the output wires.

grounding will occur

. This is extremely haz

-

D Do not Use a Phase Advancing Capacitor or Noise Filter

Never connect a phase advance capacitor or LC/RC Noise Filter to the output circuit.

Doing so will result in damage to the Inverter or cause other parts to burn.

D Do not Use an Electromagnetic Switch of Magnetic Contactor

Do not connect an electromagnetic switch of magnetic contactor to the output circuit.

If

a load is connected to the Inverter during running, an inrush current will actuate

overcurrent protective circuit in the Inverter.

the

D Installing a Thermal Relay

The Inverter has an electronic thermal protection function to protect the motor from

overheating.

polar

motor

motor and set n33 to 2 (no thermal protection).

this case, program the sequence so that the magnetic contactor on the input side of

In

the main circuit is turned off by the contact of the thermal relay.

If, however

is used, always install a thermal relay (THR) between the Inverter and the

, more than one motor is operated with one inverter

or a multi-

2-22

Page 31

Design Chapter 2

D Installing a Noise Filter on the Output Side

Connect

tion noise.

a Noise Filter to the output side of the Inverter to reduce radio noise and

induc

-

Power

supply

Signal line

Induction Noise: Electromagnetic

3G3JV

SYSDRIVE

induction generates noise

3G3IV-PLF

Noise

Filter

Induction noise Radio noise

Controller

AM radio

on the signal line, caus

ing the controller to malfunction.

Radio Noise: Electromagnetic waves from the Inverter and cables cause the

broadcasting radio receiver to make noise.

D Countermeasures against Induction Noise

As

described previously

ing generated on the output side. Alternatively, cables can be routed through a

grounded

metal pipe to prevent induction noise. Keeping the metal

away from the signal line considerably reduces induction noise.

, a Noise Filter can be used to prevent induction noise from be

pipe at least 30 cm

-

-

Power supply

3G3JV

SYSDRIVE

Signal line

Metal pipe

30 cm min.

Controller

2-23

Page 32

Design Chapter 2

D Countermeasures against Radio Interference

Radio

duce

Inverter in a totally enclosed steel box.

The cable between the Inverter and the motor should be as short as possible.

noise is generated from the Inverter as well as the input and output lines. T

o re

radio noise, install Noise Filters on both input and output sides, and also install the

Steel box

-

Power supply

Noise

Filter

3G3JV

SYSDRIVE

Noise

Filter

Metal pipe

D Cable Length between Inverter and Motor

If

the cable between

rent

will increase, causing the Inverter output current to increase as well. This may af

peripheral devices.

prevent

To

this, adjust the carrier frequency (set in n46) as shown in the table below

details, refer to the parameter settings.

Cable length 50 m max. 100 m max. More than 100 m

Carrier frequency 15 kHz max. 10 kHz max. 5 kHz max.

the Inverter and the motor is long, the high-frequency leakage cur

-

fect

. For

2-24

Page 33

Design Chapter 2

H Ground Wiring

•Always

or less.

•Do

tools.

Always use a

•

ment and minimize the length of the ground wire.

Leakage current flows through the Inverter. Therefore, if the distance between the

ground

nal of the Inverter will become unstable.

•When using more than one Inverter, be careful not to loop the ground wire.

use the

not share the ground wire

electrode and the ground terminal

ground terminal of the 200-V Inverter with a ground resistance of 100

with other devices such as welding machines or power

ground

wire that complies with technical standards on electrical equip

is too long, the potential on the ground termi

Ω

-

-

2-25

Page 34

Design Chapter 2

H Countermeasures against Harmonics

With

the continuing development of electronics, the

ics from industrial machines has been causing problems recently.

The

Ministry of International T

in

September 1994 for the suppression of harmonics from electrical house

hold

appliances and electrical equipment in

rade and Industry provided some guidelines

Japan. Since then, the prob

lem has been drawing considerable attention.

Refer

to the following information for the definition of

monic currents with voltages) and countermeasures against the generation of harmonics from the Inverter.

D Harmonics

Definition

Harmonics consist of electric power produced from AC power and alternating at frequencies that are integral multiples of the frequency of the AC power.

generation of harmon

harmonics (i.e., har

-

-

-

-

The

following frequencies are harmonics of a 60- or 50-Hz commercial power supply

Second harmonic:

Third harmonic:

120 (100) Hz

180 (150) Hz

Second harmonic (120 Hz)

Basic frequency (60 Hz)

Third harmonic (180 Hz)

Problems Caused by Harmonics Generation

The

waveform of the commercial power supply will be distorted if the commercial power

supply

will malfunction or generate excessive heat.

contains excessive harmonics. Machines with such a commercial power supply

Basic frequency (60 Hz) Third harmonic (180 Hz)

.

2-26

Distorted current wave

form

Page 35

Design Chapter 2

D Causes of Harmonics Generation

•Usually, electric

supply into DC power.

Such

AC power

tween DC and AC.

Obtaining DC from AC Using Rectifiers and Capacitors

DC

voltage is obtained by converting AC voltage into a pulsating one-side voltage with

rectifiers

and smoothing the pulsating one-side voltage with capacitors. Such AC cur

rent, however, contains harmonics.

Inverter

The Inverter as well as normal electric machines has an input current containing harmonics

comparatively

er is higher than that of any other electric machine.

because the Inverter

machines have built-in circuitry that converts commercial AC power

, however

, contains

harmonics due to the dif

ference in current flow be

converts AC into DC. The output current of the Inverter is

high. Therefore, the ratio of harmonics in the output current of the Invert

-

-

-

A current flows into the

capacitors. The current

is different from the

voltage in waveform.

Voltage

Time

Rectified

Voltage

Time

Smoothed

Voltage

Time

Current

Time

2-27

Page 36

Design Chapter 2

D Countermeasures with Reactors against Harmonics Generation

DC/AC Reactors

The

DC reactor and

and greatly.

AC reactor suppress harmonics and currents that change suddenly

DC reactor suppresses harmonics better than the AC reactor

The

. The DC reactor used

with the AC reactor suppresses harmonics more effectively.

input power factor of the Inverter is improved by

The

suppressing the harmonics of the

input current of the Inverter.

Connection

Connect

the

power supply to the Inverter and making sure that the charge indicator of the Inverter

turns off.

Do not touch the internal circuitry of the Inverter in operation, otherwise an electric

shock or burn injury may occur.

the DC reactor to the internal DC power supply of the Inverter after shutting of

Wiring Method

[With

DC Reactor]

DC reactor

(optional)

f

Power supply

3-phase 200 VAC

or single-phase

200 VAC

[With DC and AC Reactors]

Power supply

3-phase 200 VAC

or single-phase

200 VAC

DC reactor

(optional)

AC reactor

(optional)

SYSDRIVE

3G3JV

SYSDRIVE

3G3JV

2-28

Page 37

aocs

o yet y e e s e ded cab e

Design Chapter 2

Reactor Effects

Harmonics

as shown in the following table.

are ef

fectively suppressed when the DC reactor is used with the AC reactor

Harmonics

suppression

method

No reactor 65 41 8.5 7.7 4.3 3.1 2.6 1.8

AC reactor 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

DC reactor 30 13 8.4 5 4.7 3.2 3.0 2.2

DC and AC

reactors

5th

har-

monic

28 9.1 7.2 4.1 3.2 2.4 1.6 1.4

7th

har-

monic

Harmonic generation rate (%)

11th

har-

monic

13th

har-

monic

17th

har-

monic

monic

19th

har-

23rd

har-

monic

2-2-5 Wiring Control Circuit Terminals

A control signal line must be 50 m maximum and separated from power

lines.

The

frequency reference must be input into the

twisted-pair wires.

H Wiring Sequence I/O Terminals

Inverter through shielded,

25th

har-

monic

Wire

the sequence input terminals (S1 to S5 and SC) and multi-function contact output

terminals (MA, MB, and MC) as described below.

D Wires Used

Wire type Wire size Wire to be used

Single wire 0.5 to 1.25 mm

Stranded wire 0.5 to 0.75 mm

2

2

Polyethylene-shielded cable

2-29

Page 38

Design Chapter 2

D Solderless Terminals for Control Circuit Terminals

The use of solderless terminals for the control circuit terminals is recommended because solderless terminals are easy to connect securely.

Note When using the following solderless terminal, make sure that the wire size is

0.5 mm

2

.

1.0 dia.

Model: Phoenix Contact’s A1 0.5-8 WH

2.6 dia.

(Size: mm)

D Wiring Method

1. Loosen the terminal screws with a thin-slotted screwdriver.

2. Insert the wires from underneath the terminal block

3. Tighten the terminal screws firmly to a torque of 0.5 NSm.

Note 1. Always

power cables.

Note 2. Do

not solder the wires to the control

tact well with the control circuit terminals if the wires are soldered.

Note 3. The

end of each wire connected to the control circuit terminals must be stripped

for approximately 5.5 mm.

separate the control

Thin-slotted screwdriver

signal line from the main circuit cables and other

circuit terminals. The wires may not con

Control circuit

terminal block

-

Strip the end for 5.5 mm

if no solderless terminal

is used.

Wires

2-30

Solderless

terminal or wire

without soldering

Note Applying a torque of greater

than 0.5 NSm may damage the

terminal block. If the tightening

torque is insufficient, however,

wires may be disconnected.

Page 39

o yet y e e s e ded cab e

Design Chapter 2

H Wiring Frequency Reference Input Terminals

Wire

the frequency reference input terminals FR and FC as described below for execut

frequency references with

ing

ternal power supply.

D Wires Used

Use

shielded, twisted-pair wires for wiring in order to prevent the Inverter from malfunc

tioning due to noise.

Wire type Wire size Wire to be used

Single wire 0.5 to 1.25 mm

Stranded wire 0.5 to 0.75 mm

D Solderless Terminals for Frequency Reference Input Terminals

The use of solderless terminals for the frequency reference input terminals is recommended because solderless terminals are easy to connect securely.

the D/A Unit for digital-to-analog data conversion or ex

2

2

Polyethylene-shielded cable

for measurement use

-

-

-

Note Make

sure

that the wire size is 0.5 mm2 when using the following solderless termi

nal.

1.0 dia.

Model: Phoenix Contact’s A1 0.5-8 WH

2.6 dia. (Size: mm)

D Wiring Method

•The

wiring method of the frequency reference input terminals is the

control circuit terminals.

•Always

cables.

separate the control signal line from the main

circuit cables and other power

-

same as that of the

•Connect

the shield to the ground terminal of the

the load.

•Cover

the shield with tape so that the shield will

wires or machines.

Inverter

. Do not connect the shield to

not come into contact with other signal

2-31

Page 40

Design Chapter 2

2-2-6 Conforming to EC Directive

The following description provides the wiring method of the Inverter to

meet

DC Directive requirements. If the following requirements

tisfied, the whole equipment incorporating the Inverter will need further

confirmation.

H Standard Connection

D Main Circuit Terminals

are not sa

-

Line breakers

Noise Filter

3-phase 200 VAC or

single-phase 200 VAC

D Control Circuit Terminals

Forward/Stop

Multi-function input 1 (S2)

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

Sequence

input common

Clamp core

Multi-function

NO

NC

Common

Analog-monitor output

contact output

Frequency reference power

supply at +12 V

FREQ

adjuster

Frequency reference input

Frequency reference common

Note I/O signals can be connected to a single shielded cable.

2-32

Analog monitor output common

Page 41

Design Chapter 2

D Wiring the Power Supply

Make sure that the Inverter and Noise Filter are grounded together.

•Always

connect the power input terminals (R/L1, S/L2, and T/L3) and power supply via

a dedicated Noise Filter.

•Reduce the length of the ground wire as much as possible.

•Locate

the Noise Filter as close as possible to the Inverter

. Make sure that the cable

length between the Noise Filter and the Inverter does not exceed 40 cm.

•The following Noise Filters are available (all footprint type).

3-phase 200-VAC Noise Filter

Inverter 3-phase 200-VAC Noise Filter

Model 3G3JV- Model 3G3JV- Rated current (A)

A2001/A2002/A2004/A2007 PFI2010-E 10

A2015/A2022 PFI2020-E 20

Single-phase 200-VAC Noise Filter

Inverter Single-phase 200-V Noise Filter

Model 3G3JV- Model 3G3JV- Rated current (A)

AB001/AB002/AB004 PFI1010-E 10

AB007/AB015 PFI1020-E 20

D Connecting a Motor to the Inverter

•When

•Reduce

er

and the motor does not exceed 20 cm.

ter) close to the output terminals of the Inverter.

Clamp Filter 2CAT3035-1330 TDK

connecting a motor to the Inverter

the length of

the cable as short as possible and ground the shield on the Invert

, be sure to use a cable with a braided shield.

side as well as the motor side. Make sure that the cable length between the Inverter

Furthermore, connect a clamp core (Clamp Fil

Product Model Manufacturer

D Wiring a Control Cable

•Be sure to connect a cable with a braided shield to the control circuit terminals.

•Ground the shield on the Inverter side only.

-

-

2-33

Page 42

30

30

Design Chapter 2

D Grounding the Shield

In

order to

connected to the ground plate as shown below.

ground the shield securely

, it is recommended that a cable clamp be directly

Ground plate

Shield

Cable clamp

Cable

H LVD Conformance

•Always connect the Inverter and power supply via a molded case circuit breaker

(MCCB)

from short-circuiting.

•Use one MCCB per Inverter.

•Select a suitable MCCB from the following table.

suitable to the Inverter for protecting the Inverter from damage that may result

200-V Models

Inverter MCCB (Mitsubishi Electric)

Model 3G3JV- Type Rated current (A)

A2001

A2002

A2004 5

A2007 10

A2015 20

A2022 20

AB001

AB002

AB004 10

AB007 20

AB015 20

The frequency reference power supply (FS) of the Inverter is of basic insulation

construction.

When connecting the Inverter to peripheral devices, be sure to increase

the degree of insulation.

NF30

NF30

5

5

5

5

2-34

Page 43

Preparing for

Operation and

Monitoring

3-1 Nomenclature

3-2 Outline of Operation

3

Chapter 3

Page 44

Preparing for Operation and Monitoring Chapter 3

3-1 Nomenclature

Data display

Keys

Appearance Name Function

Data display Displays relevant data items, such as frequency

reference, output frequency, and parameter set

values.

FREQ adjuster Sets the frequency reference within a range

between 0 Hz and the maximum frequency.

FREF indicator The frequency reference can be monitored or set

while this indicator is lit.

FOUT indicator The output frequency of the Inverter can be

monitored while this indicator is lit.

IOUT indicator The output current of the Inverter can be

monitored while this indicator is lit.

MNTR indicator The values set in U01 through U10 are

monitored while this indicator is lit.

F/R indicator The direction of rotation can be selected while

this indicator is lit, when operating the Inverter

with the RUN Key.

LO/RE indicator The operation of the Inverter through the Digital

Operator or according to the parameters set is

selectable while this indicator is lit.

Indicators

Setting/Monitor item indicators

FREQ adjuster

3-2

Note This status of this indicator can be only

monitored

Any RUN command input is ignored while

this indicator is lit.

PRGM indicator The parameters in n01 through n79 can be set or

monitored while this indicator is lit.

Note While

rameters

some

while the Inverter

is in operation.

the Inverter is in operation, the pa

can be only

monitored and only

parameters can be changed. The

RUN command input is ignored while

this indicator is lit.

-

Page 45

Preparing for Operation and Monitoring Chapter 3

Appearance FunctionName

Mode Key Switches the setting and monitor item indicators

in sequence.

Parameter setting being made is canceled if this

key is pressed before entering the setting.

Increment Key Increases multi-function monitor numbers,

parameter numbers, and parameter set values.

Decrement Key Decreases multi-function monitor numbers,

parameter numbers, and parameter set values.

Enter Key Enters multi-function monitor numbers,

parameter numbers, and internal data values

after they are set or changed.

RUN Key Starts the Inverter running when the 3G3FV is in

operation with the Digital Operator.

STOP/RESET

Key

Stops the Inverter unless n06 is not set to

disable the STOP Key.

3-3

Page 46

Preparing for Operation and Monitoring Chapter 3

3-2 Outline of Operation

H Selecting Indicators

Whenever

the Mode Key is pressed, an indicator is lit in sequence begin

ning with the FREF indicator. The data display indicates the item corresponding to the indicator selected.

The

FOUT or

Inverter

cator

is turned of

will be lit by turning the Inverter on again if the Inverter is turned of

IOUT indicator will be lit by turning the Inverter on again if the

f while the FOUT or IOUT indicator is lit. The FREF indi

while an indicator other than the FOUR or IOUT indicator is lit.

Power On

FREF (Frequency Reference)

Monitors and sets the frequency reference.

FOUT (Output Frequency)

Monitors the output frequency.

Note This

IOUT (Output Current)

Monitors the output current.

Note This

indicator will be lit by turning the Inverter on

if the Inverter is turned off while this indicator is lit.

indicator will be lit by turning the Inverter on again

if the Inverter is turned off while this indicator is lit.

again

-

f

3-4

MNTR (Multi-function Monitor)

Monitors the values set in U01 through U10.

F/R (Forward/Reverse Rotation)

Selects the direction of rotation.

LO/RE (Local/Remote)

Selects the operation of the Inverter through the Digital

Operator or according to the parameters.

PRGM (Parameter Setting)

Monitors or sets the values in n01 through n79.

The FREF indicator is lit again.

Page 47

Preparing for Operation and Monitoring Chapter 3

H Example of Frequency Reference Settings

Key

sequence

Note 1.

The Enter Key need not be pressed when performing the setting for

frequency

Indicator Display

example

Power On

Note If the FREF indicator has not been lit,

press

FREF indicator is lit.

Use the Increment or Decrement Key to set

the frequency reference.

The data display will flash while the

frequency reference is set. (see note 1)

Press the Enter Key so that the set value will

be entered and the data display will be lit.

(see note 1)

Explanation

the Mode Key repeatedly until the

reference will change when the set value is changed with the Incre

ment or Decrement Key while the data display is continuously lit.

Note 2. The frequency reference can be set in either of the following cases.

n03

S Parameter

for frequency reference selection is set to 1 (i.e., frequency refer

ence 1 is enabled) and the Inverter is in remote mode.

n08.

The

-

-

S Parameter

n07 for frequency selection in local mode is set to 1 (i.e., the Digital

Operator is enabled) and the Inverter is in local mode.

S Frequency references 2 through 8 are input for multi-step speed operation.

Note 3. The frequency reference can be changed, even during operation.

3-5

Page 48

Preparing for Operation and Monitoring Chapter 3

H Example of Multi-function Display

Key

sequence

Indicator Display Explanation

Power On

Press the Mode Key repeatedly until the

MNTR indicator is lit.

U01 will be displayed.

Use the Increment or Decrement Key to

select the monitor item to be displayed.

Press the Enter Key so that the data of the

selected monitor item will be displayed.

The monitor number display will appear again

by pressing the Mode Key.

3-6

Page 49

U06

put te a

U0

Output te a

U09

o og ( ost

Preparing for Operation and Monitoring Chapter 3

D Status Monitor

Item Display Display

Function

unit

U01 Frequency

Hz Monitors the frequency reference. (Same as FREF)

reference

U02 Output

Hz Monitors the output frequency. (Same as FOUT)

frequency

U03 Output current A Monitors the output current. (Same as IOUT)

U04 Output voltage V Monitors the internal output voltage reference value

of the Inverter.

U05 DC bus voltage V Monitors the DC voltage of the internal main circuit of

the Inverter.

U06 Input terminal

---

Shows the ON/OFF status of inputs.

status

: Input ON : No input

Terminal S1: Forward/Stop

Terminal S2: Multi-function input 1 (S2)

Terminal S3: Multi-function input 2 (S3)

Terminal S4: Multi-function input 3 (S4)

Terminal S5: Multi-function input 4 (S5)

U07 Output terminal ---

Not

used

Shows the ON/OFF status of outputs.

status

Not

used

U09 Error log (most

---

Displays the latest error.

recent one)

Error

U10 Software No. --- OMRON use only.

: Closed : Open

Terminal MA: Multi-function

contact output

3-7

Page 50

Preparing for Operation and Monitoring Chapter 3

H Example of Forward/Reverse Selection Settings

Key

sequence

Indicator Display

example

Explanation

Press the Mode Key repeatedly until the F/R

indicator is lit.

The present setting will be displayed.

For: Forward; rEv: Reverse

Use the Increment or Decrement Key to

change the direction of motor rotation. The

direction of motor rotation selected will be

enabled when the display changes after the

key is pressed.

Note The direction of motor rotation can be changed, even during operation.

H Example of Local/Remote Selection Settings

Key

sequence

Note 1. Local

Indicator Display

example

Press the Mode Key repeatedly until the

LO/RE indicator is lit.

The present setting will be displayed.

rE: Remote; Lo: Local

Use the Increment or Decrement Key to set

the Inverter to local or remote mode. The

selection will be enabled when the display

changes after the key is pressed.

Explanation

or remote selection is possible only when the Inverter is not in operation.

The present setting can be monitored when the Inverter is in operation.

Note 2. Local or remote settings in multi-function input terminals can be changed

through the multi-function input terminals only.

Note 3. Any RUN command input will be ignored while the LO/RE indicator is lit.

3-8

Page 51

Preparing for Operation and Monitoring Chapter 3

H Example of Parameter Settings

Cancels set data.

In approximately 1 s.

Key

sequence

In

approximately

1 s.

Indicator Display

example

Note 1. To cancel the set value, press

will be displayed.

Explanation

Power On

Press the Mode Key repeatedly until the

PRGM indicator is lit.

Use the Increment or Decrement Key to set

the parameter number.

Press the Enter Key.

The data of the selected parameter number

will be displayed.

Use the Increment or Decrement Key to set

the data. At that time the display will flash.

Press the Enter Key so that the set value will

be entered and the data display will be lit.

(see note 1)

The parameter number will be displayed.

the Mode Key instead. The parameter number

Note 2. There

Refer

the

data display will not change

are parameters that cannot be changed while

the Inverter is in operation.

to the list of parameters. When attempting to change such parameters,

by pressing the Increment or Decrement Key

3-9

.

Page 52

Preparing for Operation and Monitoring Chapter 3

3-10

Page 53

Chapter 4

Test Run

4-1 Procedure for Test Run

4-2 Operation Example

4

Page 54

Test Run Chapter

4

WARNING Turn

!

ON the input power supply only after mounting the front

cover

terminal covers, bottom cover, Operator, and optional items. Not

doing so may result in electrical shock.

WARNING Do not remove the front cover, terminal covers, bottom cover,

!

Operator, or optional items while the power is being supplied. Not

doing so may result in electrical shock.

WARNING Do

!

not operate the Operator or switches with wet hands. Doing so

may result in electrical shock.

WARNING Do not touch the inside of the Inverter. Doing so may result in

!

electrical shock.

WARNING Do

!

not come close to the machine when using the error retry function

because

the machine may

abruptly start when stopped by an alarm.

Doing so may result in injury.

,

WARNING Do not come close to the machine immediately after resetting

!

momentary power interruption to avoid an unexpected restart (if

operation

after

momentary

is set to be continued in the

power interruption is reset). Doing so may result in

processing selection function

injury.

WARNING Provide

!

on

the Operator is valid only when function settings are performed.

a separate emergency stop switch because the STOP Key

Not doing so may result in injury.

WARNING Be

!

sure

confirm that the RUN signal is turned OFF before turning ON

the power supply, resetting the alarm, or switching the

LOCAL/REMOTE

selector

. Doing

so while the RUN signal is turned

ON may result in injury.

Caution Be

!

sure to confirm permissible ranges of motors and machines be

fore operation because the Inverter speed can be easily changed

low to high. Not doing so may result in damage to the product.

from

-

Caution Provide a separate holding brake when necessary. Not doing so

!

may result in injury.

4-2

Page 55

Test Run Chapter

4

Caution Do

!

Caution Do

!

not perform a signal check during operation. Doing so may result

in injury or damage to the product.

not carelessly change settings. Doing so may result in injury or

damage to the product.

4-3

Page 56

Test Run Chapter

4-1 Procedure for Test Run

1. Installation and Mounting

4

Install

that the installation conditions are met.

2. Wiring and Connection

Connect to the power supply and peripheral devices. Refer to page 2-7. Select

peripheral devices which meet the specifications and wire correctly.

3. Power Connection

Carry

Always

Make

Ensure

Set the motor to no-load status (i.e., not connected to the mechanical system).

the Inverter according to the installation conditions. Refer to page

out the following pre-connection checks before turning on the power supply

ensure that a power supply to the correct voltage is used and that the power

input terminals (R/L1, S/L2, and T/L3) are wired correctly.

3G3JV-A2: 3-phase 200 to 230 VAC

3G3JV-AB: Single-phase 200 to 240 VAC (Wire R/L1 and S/L2)

sure that the motor output terminals (U/T1, V/T2, and W/T3) are connected to

the motor correctly.

that the control circuit terminals and the control device are wired correctly

Make sure that all control terminals are turned off.

2-2. Ensure

.

.

Having conducted the above checks, connect the power supply.

4. Check the Display Status

Check to be sure that there are no faults in the Inverter.

If the display at the time the power is connected is normal, it will read as follows:

RUN indicator: Flashes

ALARM indicator: Off

Setting/Monitor indicators: FREF, FOUT, or IOUT is lit.

Data display: Displays the corresponding data of the indicator that is lit.

When a fault has occurred, the details of the fault will be displayed. In that case,

refer to

5. Initializing Parameters

Initialize the parameters.

Set n01 to 8 for initialization in 2-wire sequence.

6. Setting Parameters

Set the parameters required for a test run.

Set

loading.

Chapter

the rated motor current in order to prevent the motor from burning due to over

7 Maintenance Operations

and take necessary remedies.

-

4-4

Page 57

Test Run Chapter

7. No-load Operation

Start the no-load motor using the Digital Operator.

Set the frequency reference using the Digital Operator and start the motor using

key sequences.

8. Actual Load Operation

Connect the mechanical system and operate using the Digital Operator.

4

When

system to the motor and operate using the Digital Operator.

9. Operation

Basic Operation:

Operation

page 5-1.

Advanced Operation:

Operation that uses PID control or other functions. Refer to page 6-1.

For operation within standard parameters, refer to

Refer

ous

torque detection, torque compensation, and slip compensation.

there are no dif

based on the basic settings required to start and stop the Inverter

to

Chapter

advanced functions, such as stall prevention, carrier frequency setting,

ficulties using the

5 Basic

Operation

no-load operation, connect the mechanical

Chapter

and

Chapter

6 Advanced Operation

. Refer to

5 Basic Operation

for the vari

over

.

-

-

4-5

Page 58

Test Run Chapter

4-2 Operation Example

1 Power Connection

Checkpoints before Connecting the Power Supply

4

•Check

nals (R/L1, S/L2, and T/L3) are connected to the motor correctly.

•Make

motor correctly.

•Ensure that the control circuit terminals and the control device are wired correctly.

Make sure that all control terminals are turned off.

•Set the motor to no-load status (i.e., not connected to the mechanical system).

that the power supply is of the correct voltage and that the motor output termi

3G3JV-A2: Three-phase 200 to 230 VAC

3G3JV-AB: Single-phase 200 to 240 VAC (Wire R/L1 and S/L2)

sure that the motor output terminals (U/T1, V/T2, and W/T3) are connected to the

Connecting the Power Supply

•After conducting the above checks, connect the power supply.

2 Check the Display Status

•If the display is normal when the power is connected, it will read as follows:

-

Normal

RUN indicator: Flashes

ALARM indicator: Off

Setting/Monitor indicators: FREF, FOUT, or IOUT is lit.

Data display: Displays the corresponding data for the indicator that is lit.

•When

Chapter 7

4-6

a fault has occurred, the details of the fault will be displayed. In that

Maintenance

Fault

RUN indicator: Flashes

ALARM indicator: Lit (fault detection) or flashes (alarm detection)

Setting/Monitor indicators: FREF, FOUT, or IOUT is lit.

Data display: The fault code, such as UV1, is displayed. The display will differ de-

pending on the type of fault.

Operations

and take necessary action.

case, refer to

Page 59

Test Run Chapter

3 Initializing Parameters

•Initialize the parameters using the following procedure.

•To initialize the parameters, set n01 to 8.

4

Key sequence Indicator Display

example

In approximately

1 s.

Power On

Press the Mode Key repeatedly until the

PRGM indicator is lit.

Press the Enter Key. The data of n01 will be

displayed.

Use the Increment or Decrement Key to set

n01 to 8. The display will flash.

Press the Enter Key so that the set value will

be entered and the data display will be lit.

The parameter number will be displayed.

Explanation

4 Setting the Motor Current Parameter

•Set

the motor current parameter in n32 in order to prevent the motor from burning

to overloading.

due

Setting the Rated Motor Current

•Check

•This

(OL1).

burning.

Setting

range

Note 1. The standard rated current of the maximum applicable motor is the default

Note 2. Motor overload detection (OL1) is disabled by setting the parameter to 0.0.

the rated current on the motor nameplate and set the motor current parameter

parameter is used

for the electronic thermal function for motor overload detection

By setting the correct parameter, the overloaded motor will be protected from

n32 Rated Motor Current Changes during

operation

0.0% to 120% (A) of rated

output current of the Inverter

Unit of

setting

0.1 A Default setting (see

rated motor current.

No

note 1)

.

4-7

Page 60

Test Run Chapter

4

Key sequence Indicator Display

example

In approximately

1 s.

5 No-load Operation

•Start

the no-load motor (i.e., not connected to the mechanical system) using the Digital

Operator.

Explanation

Displays the parameter number.

Use the Increment or Decrement Key until n32

is displayed.

Press the Enter Key. The data of n32 will be

displayed.

Use the Increment or Decrement Key to set

the rated motor current. The display will flash.

Press the Enter Key so that the set value will

be entered and the data display will be lit.

The parameter number will be displayed.

Note

Before operating the Digital Operator

, check that the FREQ adjuster is set to MIN.

Forward/Reverse Rotation with the Digital Operator

Key

sequence

Indicator Display

example

Explanation

Monitors the frequency reference.

Press the RUN Key. The RUN Indicator will be lit.

Turn the FREQ adjuster clockwise slowly.

The monitored frequency reference will be

displayed.

The motor will start rotating in the forward direction

according to the frequency reference.

Press the MODE Key to turn on the F/R indicator.

“For” will be displayed.

Use the Increment or Decrement Key to change the

direction of motor rotation. The direction of motor

rotation selected will be enabled when the display is

changed after the Key is pressed.

4-8

Page 61

Test Run Chapter

4

•After

•Check that no faults have occurred in the Inverter during operation.

changing the frequency reference or the rotation direction, check that there is no

vibration or abnormal sound from the motor.

Stopping the Motor

•On completion of operating the motor in the no-load state in the forward or reverse

direction, press the STOP/RESET Key. The motor will stop.

6 Actual Load Operation

•After

Note Before

checking the operation with the motor in

system and operate with an actual load.

operating the Digital Operator

no-load status, connect the mechanical

, check that the FREQ adjuster is set to MIN.

Connecting the System

•After

confirming that the motor has stopped completely

tem.

, connect the mechanical sys

-

sure to tighten all the screws when fixing the motor axis in

•Be

the mechanical system.

Operation Using the Digital Operator

•In

case a fault occurs during operation, make sure the Stop Key on the Digital Operator

is easily accessible.

•Use the Digital Operator in the same way as no-load operation.

•First set the frequency reference to a low speed of one tenth the normal operating

speed.

Checking the Operating Status

•Having

ing smoothly at slow speed, increase the frequency reference.

•After

vibration

function monitor U03) to ensure that the output current is not becoming excessive.

checked that the operating direction is correct and that the machine is operat

changing the frequency reference or the rotation direction, check that there is no

or abnormal sound from the motor

. Check the monitor display (IOUT or multi-

-

4-9

Page 62

Test Run Chapter

4

4-10

Page 63

5

Chapter 5

Basic Operation

5-1 Initial Settings

5-2 V/f Control

5-3 Setting the Local/Remote Mode

5-4 Selecting the Operation Command

5-5 Setting the Frequency Reference

5-6 Setting the Acceleration/Deceleration

Time

5-7 Selecting the Reverse Rotation-prohibit

5-8 Selecting the Interruption Mode

5-9 Multi-function I/O

5-10 Analog Monitor Output

Page 64

Basic Operation Chapter

This section explains the basic settings required to operate and stop the

Inverter.

The

settings of parameters described here will be suf

verter operations.

First,

make these basic settings, then skip to the explanations

functions, even when your application requires

cial

as

stall

prevention, carrier frequency setting, overtorque detection, torque

compensation, slip compensation. Refer to

.

tion

Chapter 6 Advanced Opera-

ficient for simple In

of those spe

special functions, such

-

-

5-1 Initial Settings

•The following initial settings are required.

Parameter Write-prohibit Selection/Parameter Initialization (n01): Set n01 to 1 so

that n01 through n79 can be set or displayed.

5

Rated

the parameter.

Motor Current (n32): Check the rated current on the motor nameplate and set

H Setting the Parameter Write-prohibit Selection/Parameter

Initialization (n01)

•Set n01 to 1 so that n01 through n79 can be set or displayed.

n01 Parameter Write-prohibit Selection/Parameter

Initialization

Setting

range

Note This parameter makes it possible to write-prohibit parameters, change the pa-

0, 1, 6, 8, 9 Unit of

setting

rameter set or displayed range, or initialize all parameters to default values.

1 Default setting 1

Set Values

Value Description

0 Only n01 can be displayed and set. The n02 through n79 parameters can be

displayed only.

1 The n01 through n79 parameters can be displayed and set.

6 Only the error log memory is cleared.

8 Enables the initialization of all parameters in 2-wire sequence so that the

parameters will return to default values.

9 Enables the initialization of all parameters in 3-wire sequence.

Changes during

operation

No

5-2

Page 65

Basic Operation Chapter

5

H Setting the Rated Motor Current (n32)

Set

the rated motor

loading.

Check the rated current on the motor nameplate and set the parameter.

parameter is used for the electronic thermal function for motor overload detection

This

(OL1). By setting the correct parameter, the overloaded motor will be protected from

burning.

current (n32) in order to prevent the motor from burning due to over

-

n32 Rated Motor Current Changes during

operation

Setting

range

Note 1. The standard rated current of the maximum applicable motor is the default

Note 2. Motor overload detection (OL1) is disabled by setting the parameter to 0.0.

0.0% to 120% (A) of rated

output current of Inverter

rated motor current.

Unit of

setting

0.1 A Default setting (see

No

note 1)

5-3

Page 66

Basic Operation Chapter

5

5-2 V/f Control

H Setting the V/f Patterns (n09 to n15)

•Set the V/f pattern so that the motor output torque is adjusted to the required load

torque.

3G3JV incorporates an automatic torque boost function. Therefore, a maximum of

• The

150%

system

teristic changes are required.

torque can be output at 3 Hz without changing

in trial

operation and leave the default settings as they are if no torque charac

the default settings. Check the

-

n09 Maximum Frequency (FMAX) Changes during

operation

Setting

range

n10 Maximum Voltage (VMAX) Changes during

Setting

range

n11 Maximum Voltage Frequency (FA) Changes during

Setting

range

n12 Middle Output Frequency (FB) Changes during

Setting

range

n13 Middle Output Frequency Voltage (VC) Changes during

Setting

range

50.0 to 400 (Hz) Unit of

setting

1 to 255 (V) Unit of

setting

0.2 to 400 (Hz) Unit of

setting

0.1 to 399 (Hz) Unit of

setting

1 to 255 (V) Unit of

setting

0.1 Hz

(see note)

1 V Default settings 200

0.1 Hz

(see note)

0.1 Hz

(see note)

1 V Default setting 12

Default setting 60.0

operation

operation

Default setting 60.0

operation

Default setting 1.5

operation

No

No

No

No

No

n14 Minimum Output Frequency (FMIN) Changes during

operation

Setting

range

n15 Minimum Output Frequency Voltage (VMIN) Changes during

Setting

range

5-4

0.1 to 10.0 (Hz) Unit of

setting

1 to 50 (V) Unit of

setting

0.1 Hz Default setting 1.5

operation

1 V Default setting 12

No

No

Page 67

Basic Operation Chapter

5

Note Values

will be

set in 0.1-Hz increments if the frequency is less than 100 Hz and

1-Hz increments if the frequency is 100 Hz or greater.

Output

voltage (V)

•

The vertical-axis load or the load with high viscous friction may require high torque at

Note 1. Set the parameters so that

the

satisfied.

n14 x n12 < n11 x n09

Note 2. The

nored if parameters n14 and

n12 are the same in value.

Frequency (Hz)

following

value set in n13 will be ig

condition will be

-

low speed. If the torque is insufficient at low speed, increase the voltage in the lowspeed

range by 1 V

, provided that no overload (OL1

or OL2) is detected. If an overload

is detected, decrease the set values or consider the use of an Inverter model with a

higher capacity.

required torque of fan or pump control increases in proportion to the square of the

•The

speed. By setting a quadratic V/f pattern to increase the voltage in the low-speed

range, the power consumption of the system will increase.

5-5

Page 68

Basic Operation Chapter

5-3 Setting the Local/Remote Mode

The 3G3JV operates in local or remote mode. The following description

provides information on these modes and how to select them.

H Basic Concept

Operation mode Basic concept Description

Local The Inverter in a system

operates independently in

this mode so that the

Inverter can be checked

independently.

Remote The Inverter in a system