Page 1

Simple, Compact Inverters

3G3JV

Series

Note: Do not use this document to operate the Unit.

OMRON Corporation

FA Systems Division H.Q.

66 Matsumoto

Mishima-city, Shizuoka 411-8511

Japan

Tel:(81)55-977-9181

Fax:(81)55-977-9045

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel:(31)2356-81-300/Fax:(31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173 U.S.A.

Tel:(1)847-843-7900/Fax:(1)847-843-8568

OMRON IDM Controls

9510 North Houston, Tx. 77088 U.S.A.

Tel: (1)800-395-4106/Fax: (1)713-849-4666

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue, #11-01, UE Square,

Singapore 239920

Tel:(65)6835-3011/Fax:(65)6835-2711

Authorized Distributor:

Note: Specifications subject to change without notice.

Cat.No.I905-E1-05

Printed in Japan

0204-1M

Page 2

Contents

There has been a great demand for inverters that provide easier motor

speed control. OMRON's simple, compact 3G3JV Series meets the demand.

The 3G3JV Inverters provide versatile functions and ensure powerful performance.

The front panel of the 3G3JV Inverter has a frequency adjuster that makes it

possible to start the motor and easily control the motor speed.

The 3G3JV Inverters are easy to mount and operate and support a wide range

of applications for efficient motor control.

The frequency

adjuster on the front

panel makes it

possible to easily

adjust the speed of

the motor.

The Inverter can be

operated immediately

after the power is

turned ON.

The 3G3JV Inverter performs versatile speed control, such as

multi-step speed control up to a maximum of nine steps,

acceleration and deceleration (UP/DOWN) control, and jog

operations. Furthermore, the 3G3JV Inverter provides a variety

of useful functions, including slip compensation, overtorque

detection, and speed search functions.

Features

Applications

Nomenclature

Using Digital Operator

List of Parameters

Function of Each Parameter

Specifications

Dimensions

Standard Connections

Protective and Diagnostic Functions

Options

Inverter Models

This catalog provides information for the

selection of models, but does not provide

operational precautions. For information on

the operation of the 3G3JV Inverters and

operational precautions, be sure to read the

operation manual.

11

14

22

27

28

29

34

47

2

4

6

8

The cooling fan can

be easily mounted or

dismounted. The

cooling fan can also

be turned on only

when the 3G3JV

Inverter is in operation,

prolonging the life of

the fan.

The 3G3JV Inverters

are compact and

space-saving to

mount easily into a

panel.

The 3G3JV Inverter incorporates main circuit terminals

arranged in two rows on the top and bottom of the housing,

making it possible to

mount the 3G3JV

Inverter like a

contactor. The

optional DIN Track

Mounting Bracket

makes it possible to

easily mount a

3G3JV Inverter to a

DIN track.

The 3G3JV Inverter supports a variety of I/O, such as analog

inputs between 0 and 10V, 4 to 20 mA, or 0 to 20 mA, multifunction I/O, and analog monitor outputs. Multi-function inputs

can set to either PNP or NPN, providing flexibility in input

signals.

Actual

Standard models meet CE and UL/cUL standards.

Size

Three-phase 100 W at 200 V

68 x 128 x 78.5 mm (W x H x D)

2

C

3

Page 3

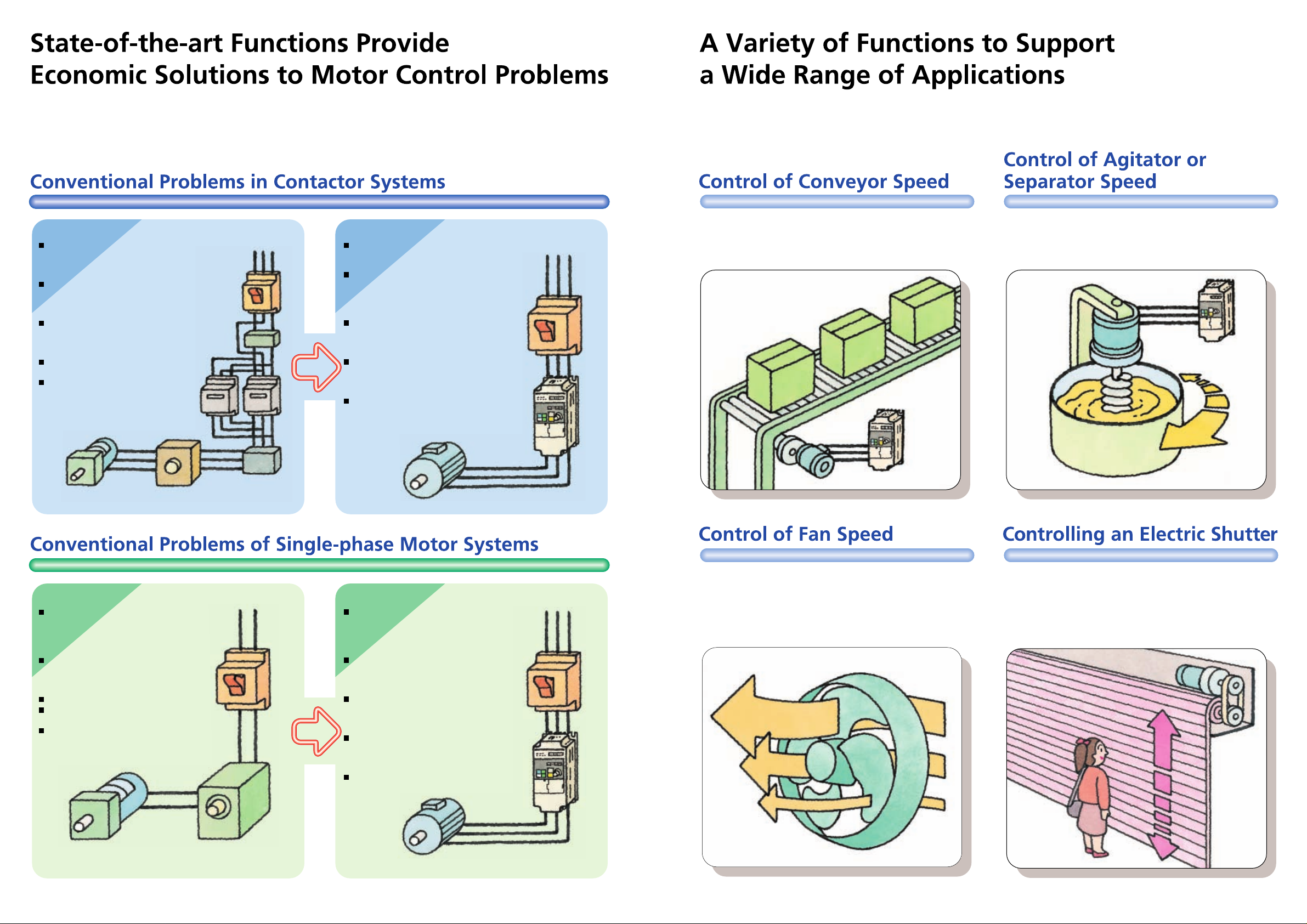

Conventional Systems

Conventional Systems

Relay contact welding occurs, which

may put the system and operators in

danger. Furthermore, the life of the

system is comparatively short.

The system employs a gearbox for

speed control, the designing and

adjustment of which require time and

labor.

To ensure the safety of the system, the

system needs peripheral safety

devices, the wiring of which requires

time and labor.

The motor always rotates at top speed,

consuming a high amount of power.

A strong shock is produced when the

motor is driven, which may cause

loads to shift, deteriorate the quality of

products, or put the system and

operators in danger.

Three-phase

inductive

motor

Gear box

Starter

Contactor

Breaker

Open-phase

detection

Current leakage

detection

3G3JV Inverter Solutions

3G3JV Inverter Solutions

A 3G3JV Inverter has no mechanical

relay contacts and thus allows a safe,

long-life system operation.

A 3G3JV Inverter performs versatile

speed control, such as multi-step speed

control for up to nine steps, acceleration

and deceleration (UP/DOWN) control,

and jog operations.

A 3G3JV Inverter provides a variety of

protective functions, such as a highspeed current limit, ground fault

protection, and undervoltage protection.

A 3G3JV Inverter drives the motor at

flexible speeds within the rated speed

range of the motor, thus reducing motor

power consumption.

A 3G3JV Inverter provides soft-start and

soft-stop functions, preventing loads

from shifting and deterioration of product

quality, while ensuring the safety of the

system.

Three-phase

inductive motor

Breaker

3G3JV

Inverter

A 3G3JV Inverter provides soft-start and soft-stop functions to

prevent loads from shifting. Furthermore, a 3G3JV Inverter

performs flexible speed control of the conveyor up to nine

steps.

A 3G3JV Inverter performs flexible speed control of a compact

agitator or separator.

Conventional Systems

Conventional Systems

A strong shock results at the moment

the motor is driven, which may cause

load shifting, deteriorates the quality of

products, or puts the system and

operators in danger.

The capacity of the motor is small.

Therefore, the rotation speed of the

motor will drop if a speed reducer is

used for the maintenance of the torque.

The rotation of the motor fluctuates.

Failures in the motor are not detected

by the host controller.

The types of available motors are

limited.

Gear box

4

Breaker

Speed controller

3G3JV Inverter Solutions

3G3JV Inverter Solutions

A 3G3JV Inverter provides soft-start and

soft-stop functions, preventing loads

from shifting and deterioration of

product quality while ensuring the safety

of the system.

The 3G3JV Inverters are available up to

a maximum motor capacity of 3.7 kW

and ensure smooth rotation speed and

torque in the motor.

A three-phase motor has less speed

fluctuation compared with a singlephase motor, ensuring the safe

operation of the system.

A 3G3JV Inverter can report errors in

contact outputs or data to a host

controller, such as a Programmable

Controller.

A wide range of motors is available.

Three-phase

inductive motor

Breaker

3G3JV

Inverter

A 3G3JV Inverter provides optimum control of fan speed

according to the room temperature. The 3G3JV Inverter has

no mechanical relay contacts, ensuring the safety and

reliability of the system compared with the ON/OFF control of

contactors. Optimum control of fan speed also saves energy.

A 3G3JV Inverter provides multi-step speed control to open

and close an electric shutter safely and efficiently. The shutter

opens quickly at a high speed, but closes at a medium-range

speed while the system checks the safety of the operation and

decelerates to low speed before it is fully closed to prevent

people from being caught by the shutter.

5

Page 4

Nomenclature

Panel

Top protection cover:

Remove this cover when wiring the upper terminal block.

Upper terminal block:

A terminal block on the input side of the main circuit.

Digital Operator:

Used to set parameters, perform various

monitoring, and start and stop the Inverter.

ALARM indicator:

RUN indicator:

Displays the operating status of the Inverter.

Alarm (Red): Lights when an error occurs. Flashes when a warning

occurs.

RUN (Green): Flashes when no RUN command is input during normal

status. Lights when a RUN command is input during normal status.

Optional cover:

Remove this cover when setting the input method selector.

Front cover:

Remove this cover when wiring the upper or lower terminal block.

Front cover mounting screw:

A screw for fixing the front cover.

Lower terminal blocks:

A terminal block on the output side of the main

circuit and a terminal block for the control circuit.

Bottom protection cover:

Remove this cover when wiring the lower terminal blocks.

6

Page 5

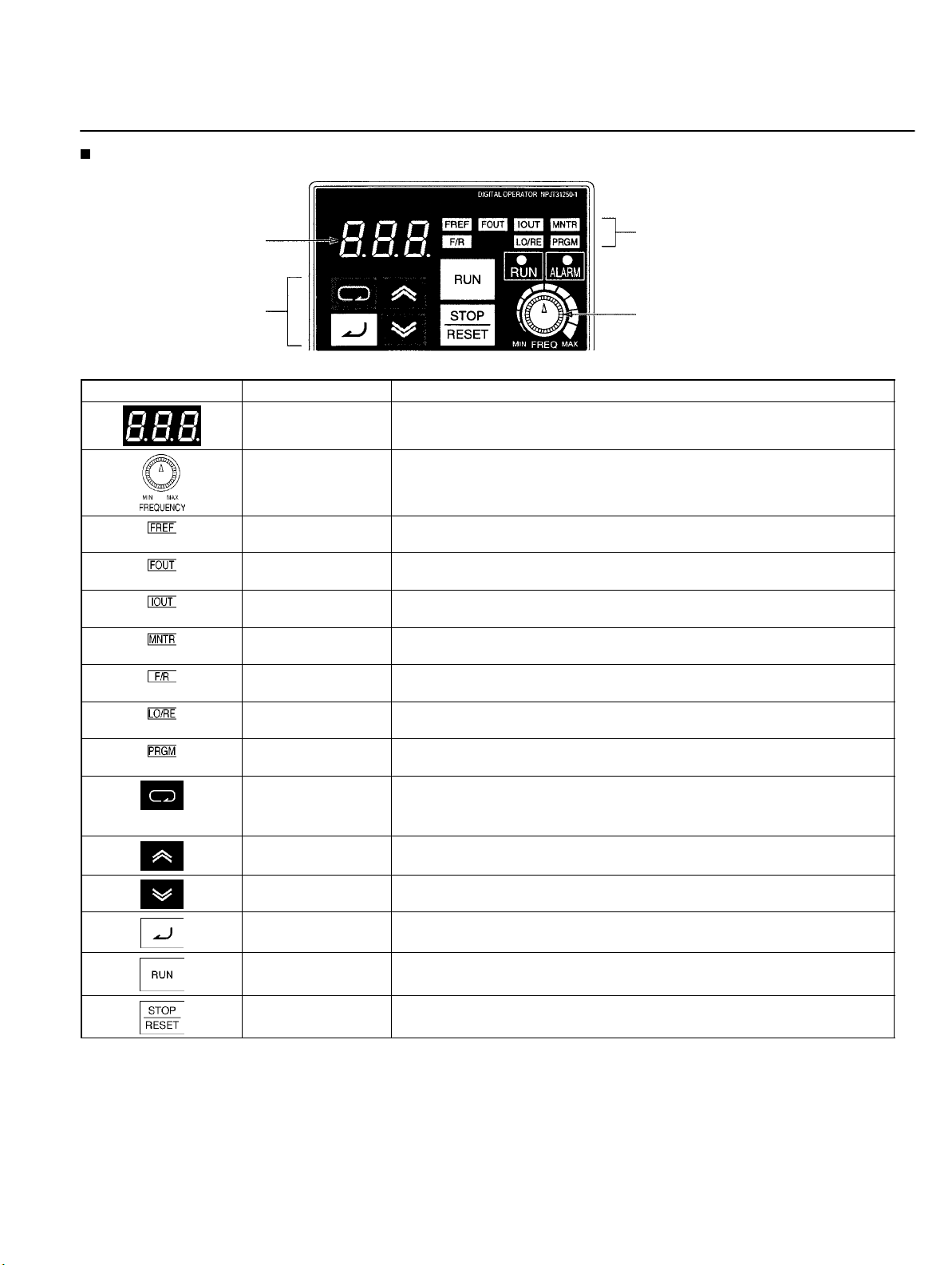

Digital Operator

Nomenclature

Data display

Keys

Appearance Name Function

Data display Displays relevant data items, such as frequency reference, output frequency,

and parameter set values.

Frequency adjuster Sets the frequency reference within a range between 0 Hz and the maximum

frequency.

Frequency reference

indicator

Output frequency

indicator

Output current

indicator

Multi-function

monitor indicator

Forward/Reverse

selection indicator

Local/Remote

selection indicator

Parameter setting

indicator

Mode Key Switches the setting and monitor item indicators in sequence.

Increment Key Increases multi-function monitor numbers, parameter numbers, and

Decrement Key Decreases multi-function monitor numbers, parameter numbers, and

Enter Key Enters multi-function monitor numbers, parameter numbers, and internal

RUN Key Starts the Inverter running when the 3G3JV is in operation with the Digital

The frequency reference can be monitored or set while this indicator is lit.

The output frequency of the Inverter can be monitored while this indicator is

lit.

The output current of the Inverter can be monitored while this indicator is lit.

The values set in U01 through U10 are monitored while this indicator is lit.

The direction of rotation can be selected while this indicator is lit when

operating the Inverter with the RUN Key.

The operation of the Inverter through the Digital Operator or according to the

set parameters is selectable while this indicator is lit. (See note 1.)

The parameters in n01 through n79 can be set or monitored while this

indicator is lit. (See note 2.)

Parameter being set will be canceled if this key is pressed before entering

the setting.

parameter set values.

parameter set values.

data values after they are set or changed.

Operator.

Indicators

(Setting/Monitor item

indicators)

FREQ adjuster

STOP/RESET Key Stops the Inverter unless parameter n06 is set to disable the STOP Key.

Used to reset the Inverter when an error occurs. (See note 3.)

Note: 1. The status of the local/remote selection indicator can be only monitored while the Inverter is in operation. Any RUN com-

mand input is ignored while this indicator is lit.

2. While the Inverter is in operation, the parameters can be only monitored and only some parameters can be changed. Any

RUN command input is ignored while the parameter setting indicator is lit.

3. For safety reasons, the reset function cannot be used while an operation instruction (forward/reverse) is being input. Turn

the operation instruction OFF before using this function.

7

Page 6

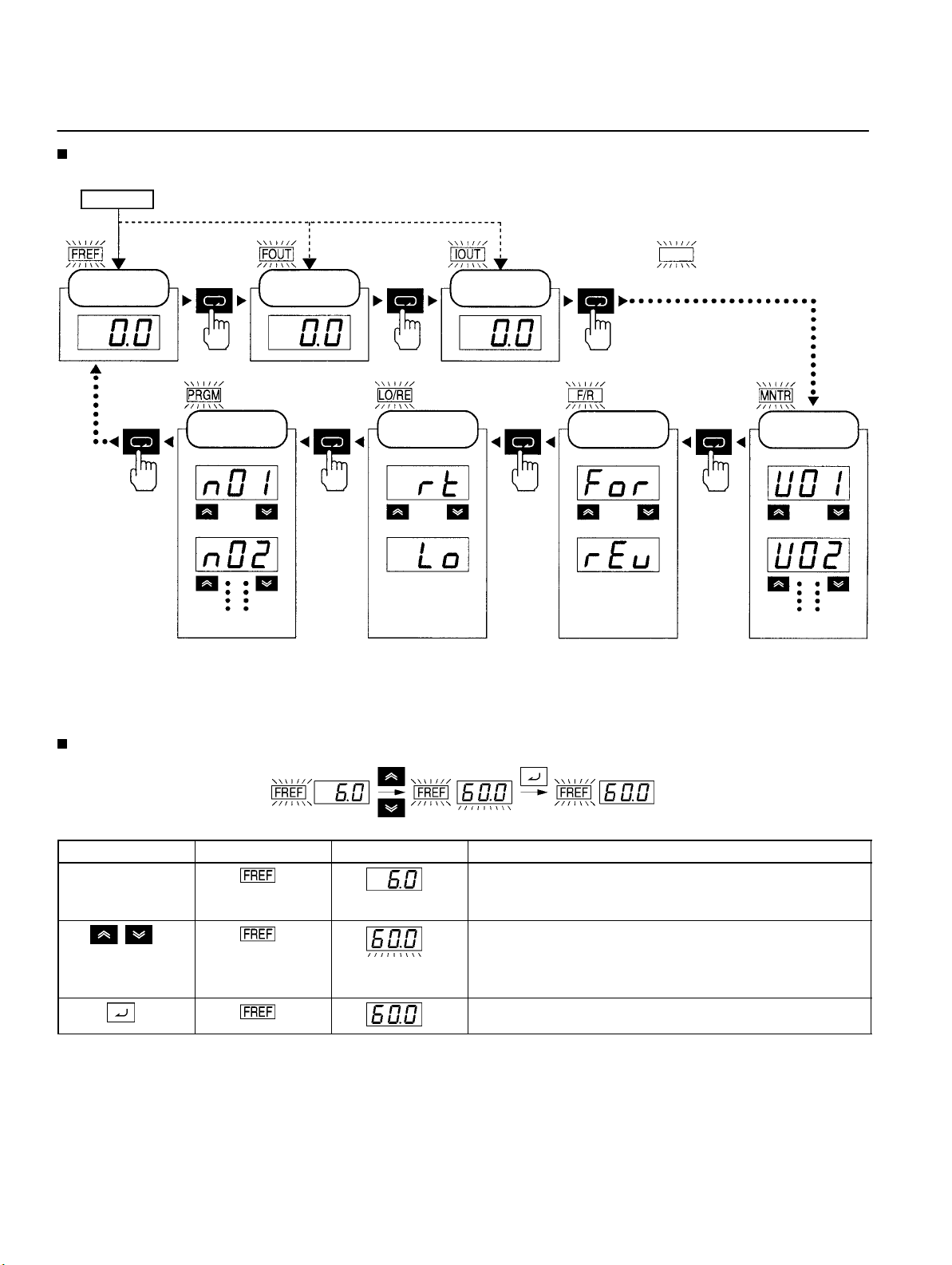

Using Digital Operator

Selecting Indicators

Power ON

Frequency

reference

Output

frequency

Output current

represents a lit indicator.

Parameter

settings

Parameter n01

Parameter n02

Other parameters

Note: If the power is turned OFF with the FOUT or IOUT indicator lit, the same indicator will light when the power is turned ON again.

In other cases, the FREF indicator will light when the power is turned ON.

Local/Remote

selection

Remote mode

Local mode

Direction of

rotation

Forward

Reverse

Multi-function

monitor

Frequency reference

Output frequency

Other monitor items

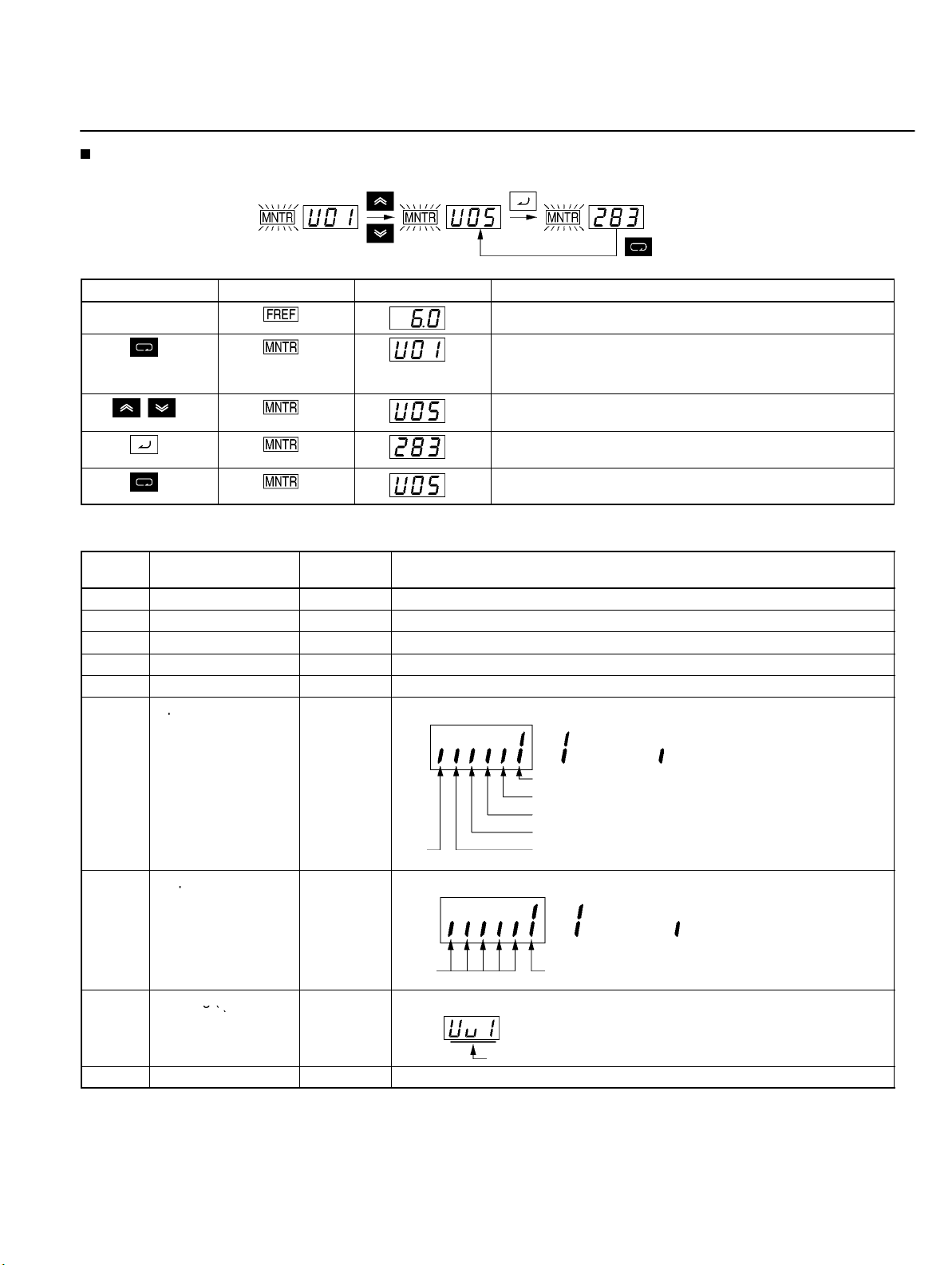

Example of Frequency Reference Settings

Flashing

Key sequence Indicator Display example Explanation

Power ON

Note If the FREF indicator has not been lit, press the Mode

Key repeatedly until the FREF indicator is lit.

Use the Increment or Decrement Key to set the frequency

reference.

The data display will flash while the frequency reference is

set. (see note 1)

Press the Enter Key so that the set value will be entered and

the data display will be lit. (see note 1)

Note: The Enter Key need not be pressed when performing the setting for n08. The frequency reference will change when the set

value is changed with the Increment or Decrement Key while the data display is continuously lit.

8

Page 7

Using Digital Operator

p

p

g(

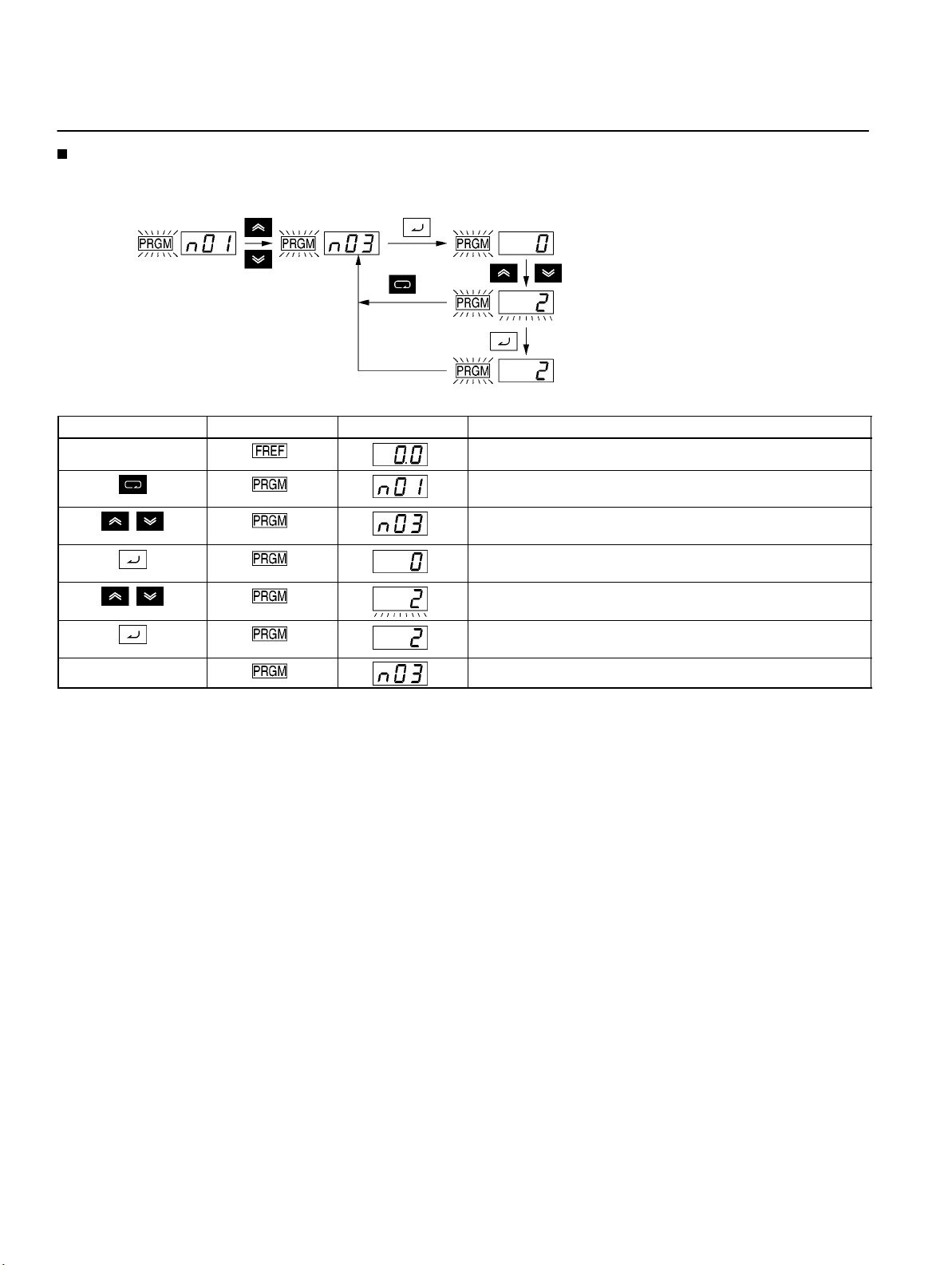

Example of Multi-function Display

Frequency

reference

Key sequence Indicator Display Explanation

DC bus

voltage

Monitor

data

Complete

Power ON

Press the Mode Key repeatedly until the MNTR indicator is

lit.

U01 will be displayed.

Use the Increment or Decrement Key to select the monitor

item to be displayed.

Press the Enter Key so that the data of the selected monitor

item will be displayed.

The monitor number display will appear again by pressing

the Mode Key.

Status Monitor

Item Display Display

unit

U01 Frequency reference Hz Monitors the frequency reference. (Same as FREF)

U02 Output frequency Hz Monitors the output frequency. (Same as FOUT)

U03 Output current A Monitors the output current. (Same as IOUT)

U04 Output voltage V Monitors the internal output voltage reference value of the Inverter.

U05 DC bus voltage V Monitors the DC voltage of the internal main circuit of the Inverter.

U06 Input terminal status ---

U07 Output terminal ---

status

U09 Error log (most

recent one)

---

Shows the ON/OFF status of inputs.

Terminal S1: Forward/Stop

Terminal S2: Multi-function input 1 (S2)

Terminal S3: Multi-function input 2 (S3)

Not

used

Shows the ON/OFF status of outputs.

Not

used

Displays the latest error.

Terminal S4: Multi-function input 3 (S4)

Terminal S5: Multi-function input 4 (S5)

Terminal MA: Multi-function contact

output

Function

: Input ON : No input

: Closed : Open

Error

U10 Software No. --- OMRON use only.

9

Page 8

Using Digital Operator

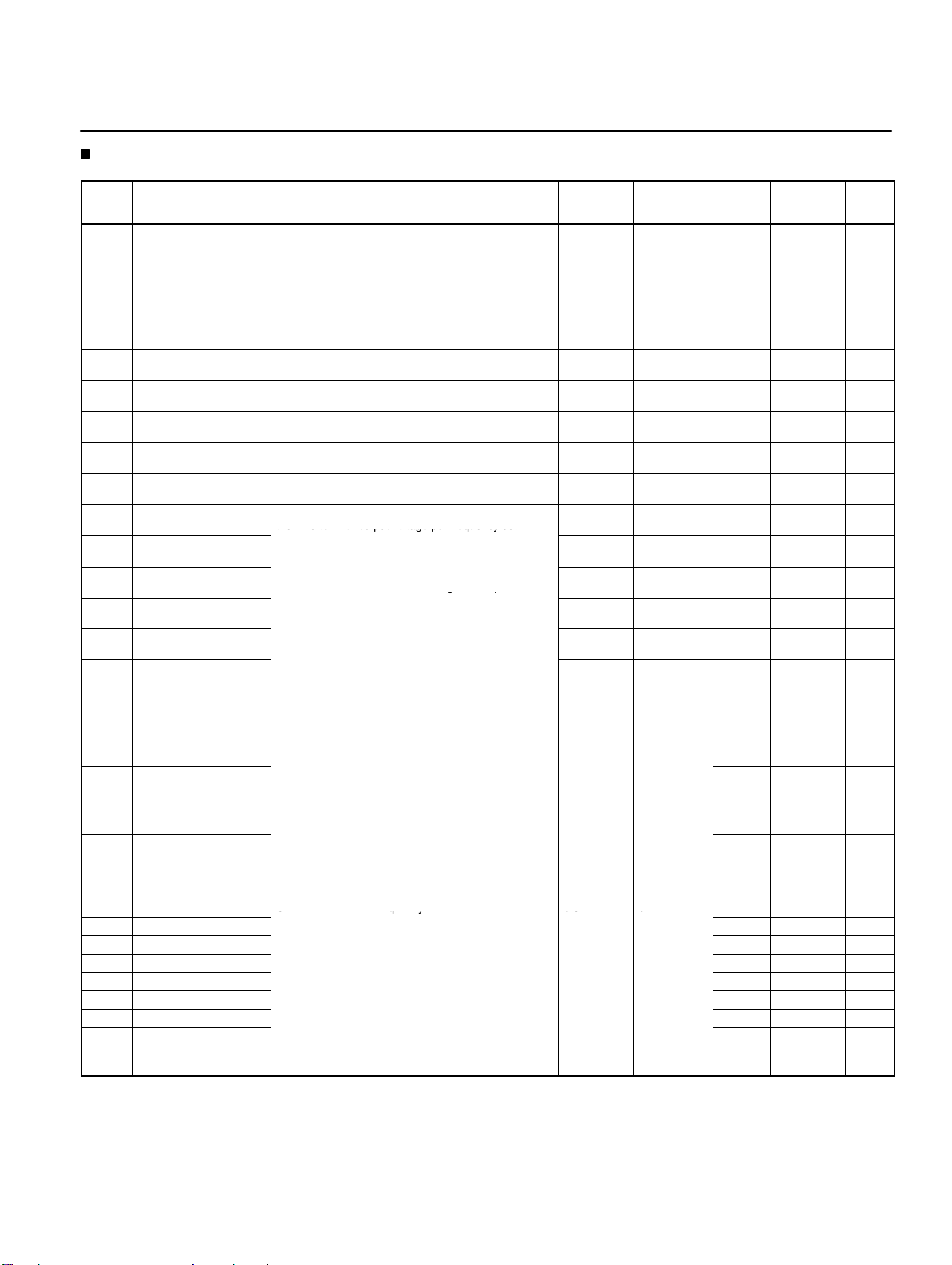

Example of Parameter Settings

The following example shows how to set 2 to enable the frequency reference control terminal for 0- to 10-V input in parameter n03

(Frequency Reference Selection).

Cancels set

data.

In approximately 1 s.

Key sequence Indicator Display example Explanation

Power ON

Press the Mode Key repeatedly until the PRGM indicator is

lit.

Use the Increment or Decrement Key to set the parameter

number.

Press the Enter Key.

The data of the selected parameter number will be displayed.

Use the Increment or Decrement Key to set the data. At that

time the display will flash.

Press the Enter Key so that the set value will be entered and

the data display will be lit. (see note 1)

In approximately 1 s. The parameter number will be displayed.

Note: 1. To cancel the set value, press the Mode Key instead. The parameter number will be displayed.

2. There are parameters that cannot be changed while the Inverter is in operation. Refer to the list of parameters. When attempting to change such parameters, the data display will not change by pressing the Increment or Decrement Key.

Enable the frequency reference

control terminal for 0- to 10-V input.

Complete

10

Page 9

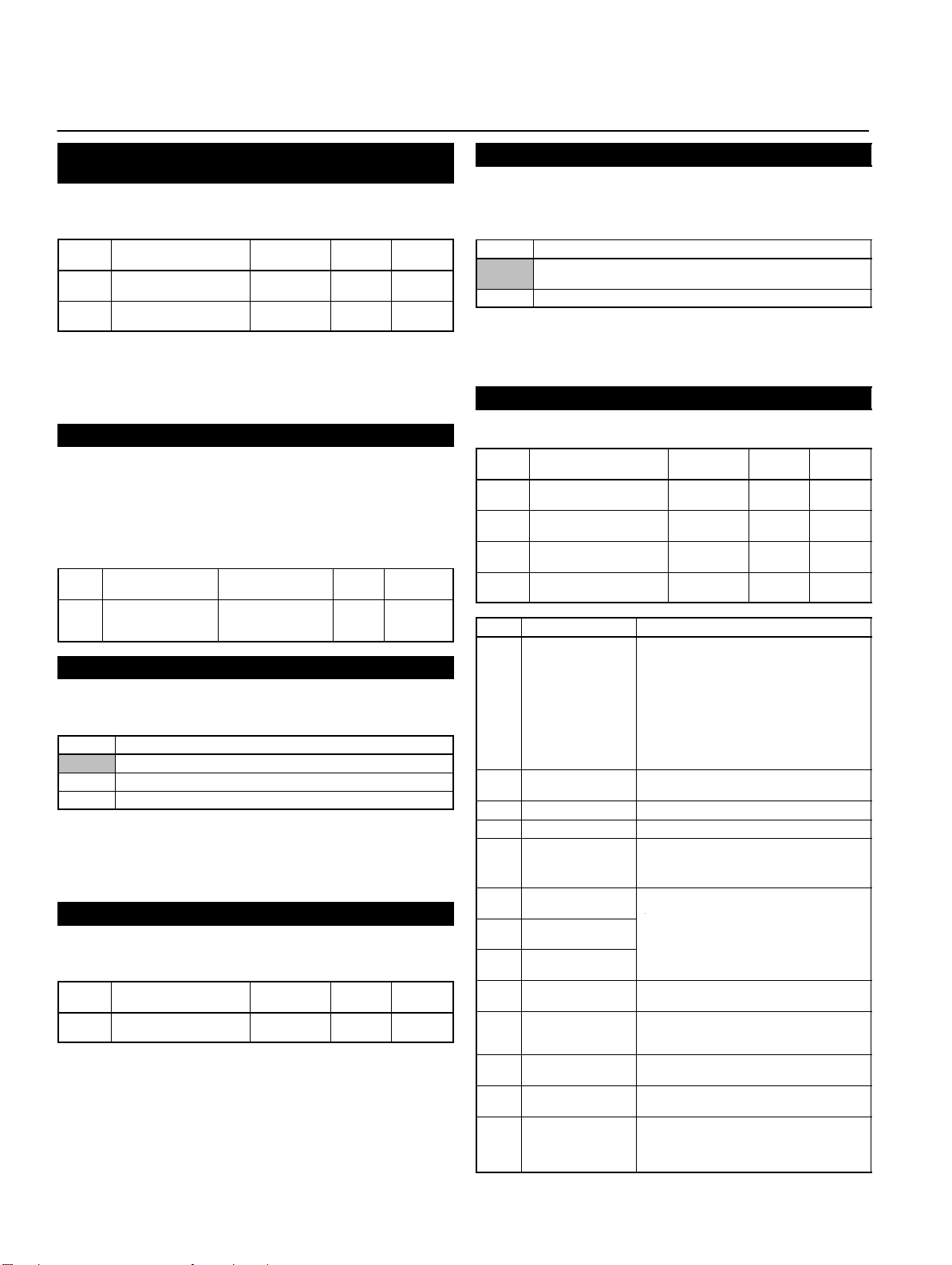

List of Parameters

the Inverter with output voltage per frequency set.

gp

(

Acceleration/Deceleration time

(Acceleration/De

Uqy

00

0

ti-step speed references (multi-function input). See

the reference pages for the relationship between

List of Parameters

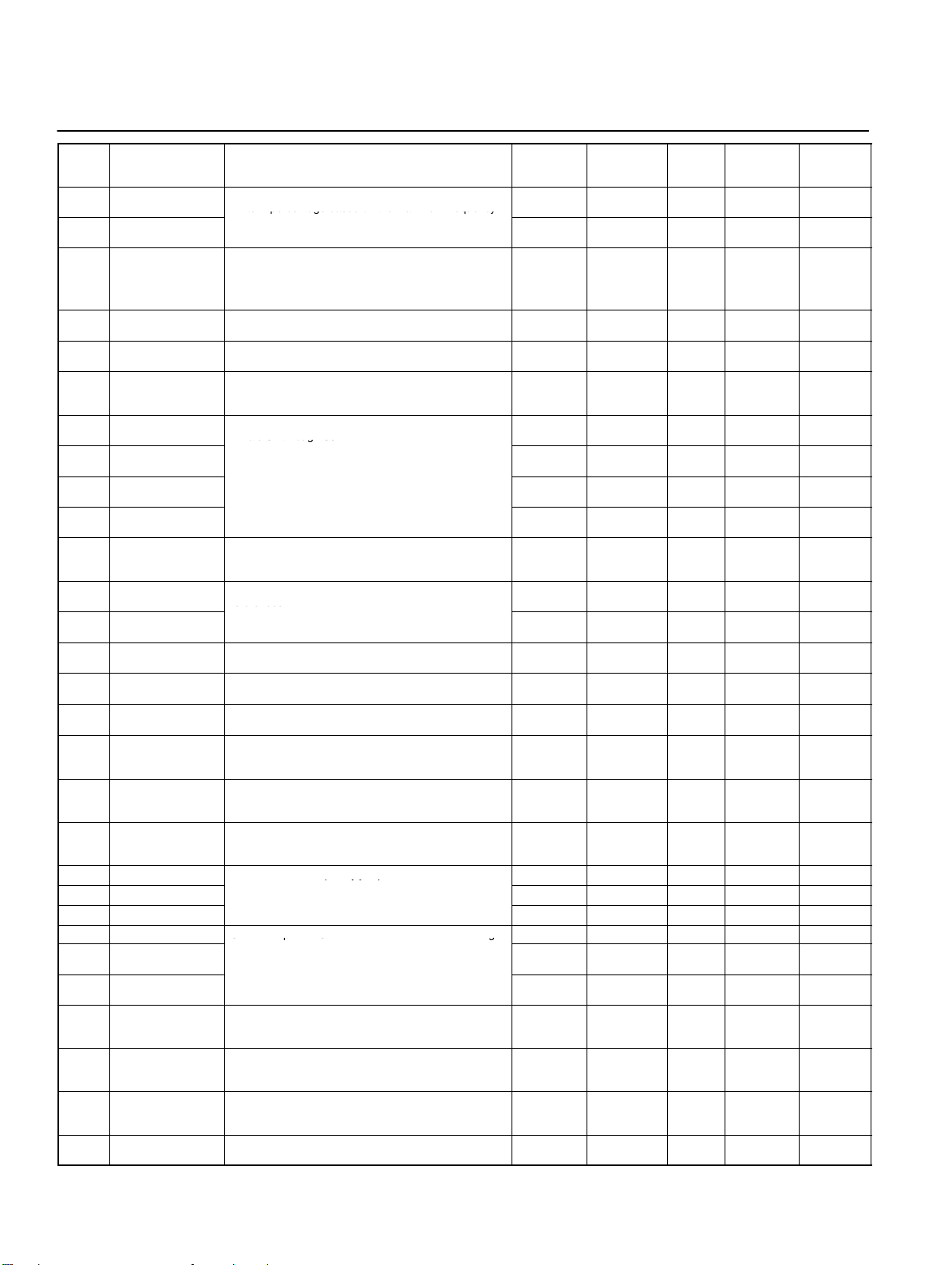

Param-

eter

No.

n01 Parameter

n02 Operation mode selec-

n03 Frequency reference

n04 Interruption mode selec-

n05 Reverse rotation-prohibit

n06 STOP/RESET Key func-

n07 Frequency selection in

n08 Key sequential

n09 Maximum frequency

n10 Maximum voltage

n11 Maximum voltage fre-

n12 Middle output

n13 Middle output

n14 Minimum output

n15 Minimum output

n16 Acceleration time 1

n17 Deceleration time 1

n18 Acceleration time 2

n19 Deceleration time 2

n20 S-shape acceleration/de-

n21 Frequency reference 1

n22 Frequency reference 2

n23 Frequency reference 3

n24 Frequency reference 4

n25 Frequency reference 5

n26 Frequency reference 6

n27 Frequency reference 7

n28 Frequency reference 8 0.0 No 15

n29 Inching frequency com-

Name Description Setting

write-prohibit selection/

parameter initialization

tion

selection

tion

selection

tion selection

local mode

frequency setting

(FMAX)

(VMAX)

quency (FA)

frequency (FB)

frequency voltage (VC)

frequency (FMIN)

frequency voltage

(VMIN)

celeration characteristic

mand

Used to prohibit parameters to be written, sets

parameters, or change the monitor range of

parameters.

Used to initialize parameters to default values.

Used to select the input method for the RUN and STOP

commands in remote mode.

Used to set the input method for the frequency reference in remote mode.

Used to set the stopping method for use when the

STOP command is input.

Used to select the operation with the reverse command

input.

Used to select the stop method in remote mode with

n02 for operation mode selection set to 1.

Used to set the input method for the frequency reference in local mode.

Used to enable the Enter Key for setting the frequency

reference with the Increment and Decrement Keys.

Used to set the V/f pattern as the basic characteristic of

the Inverter with output voltage per frequency set.

Note Set the parameters so that the following condition

will be satisfied.

n14 x n12 < n11 x n09

Note The value set in n13 will be ignored if parameters

n14 and n12 are the same in value.

Acceleration time: The time required to go from 0% to

100% of the maximum frequency.

Deceleration time: The time required to go from 100%

to 0% of the maximum frequency.

Note The actual acceleration or deceleration time is ob-

tained from the following formula.

Acceleration/Deceleration time =

celeration time set value) × (Frequency reference

value) ÷ (Max. frequency)

Used to set S-shape acceleration/deceleration characteristics.

Used to set internal frequency references. 0.0 to max.

Note Frequency reference 1 is enabled in remote mode

with n03 for frequency reference selection set to 1.

Note These frequency references are selected with mul-

the reference pages for the relationship between

multi-step speed references and frequency references.

Used to set the inching frequency command. 6.0 No 15

Acceleration/De-

=

-

range

0, 1, 6, 8, 9 1 1 No 14

0, 1 1 0 No 14

0 to 4 1 0 No 14

0, 1 1 0 No 14

0, 1 1 0 No 14

0, 1 1 0 No 14

0, 1 1 0 No 14

0, 1 1 0 No 14

50.0 to 400 0.1 Hz 60.0 No 14

1 to 255

(see note 1)

0.2 to 400 0.1 Hz 60.0 No 14

0.1 to 399 0.1 Hz 1.5 No 14

1 to 255

(see note 1)

0.1 to 10.0 0.1 Hz 1.5 No 14

1 to 50

(see note 1)

0.0 to 999 0.1 s

-

0 to 3 1 0 No 15

frequency

Unit of

setting

(see note 2)

1 V 200 (see

1 V 12 (see

1 V 12 (see

0.1 Hz

Default

setting

note 1)

note 1)

note 1)

10.0 Yes 15

10.0 Yes 15

10.0 Yes 15

10.0 Yes 15

6.0 No 15

0.0 No 15

0.0 No 15

0.0 No 15

0.0 No 15

0.0 No 15

0.0 No 15

Changes

during op-

eration

No 14

No 14

No 14

Refer-

ence

page

Note: 1. With 400-class Inverters, the default settings and maximum values setting ranges for n10, n13, and n15 are double those

given in the table.

2. Values longer than 3 digits are rounded up to the next unit multiple.

11

Page 10

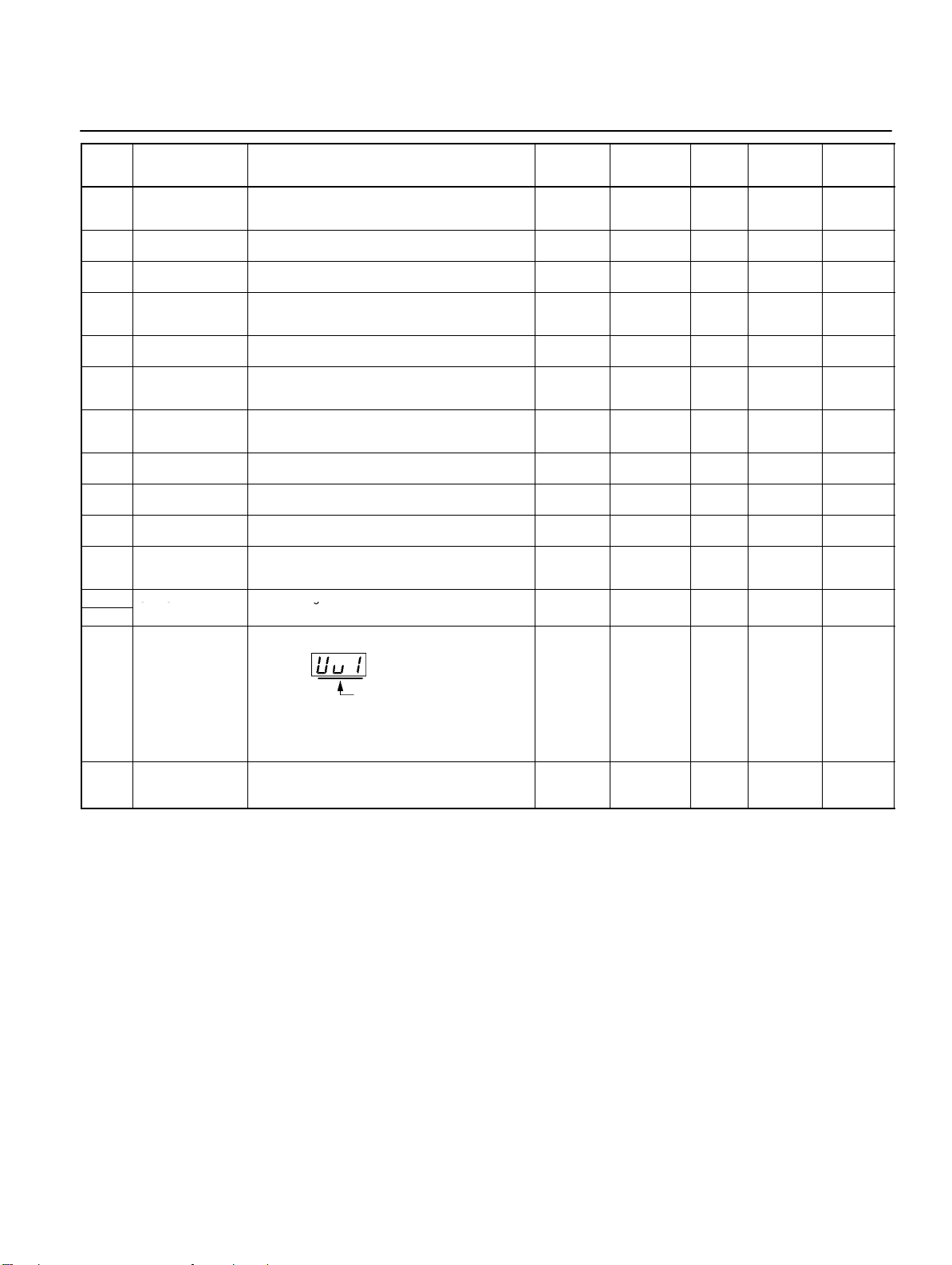

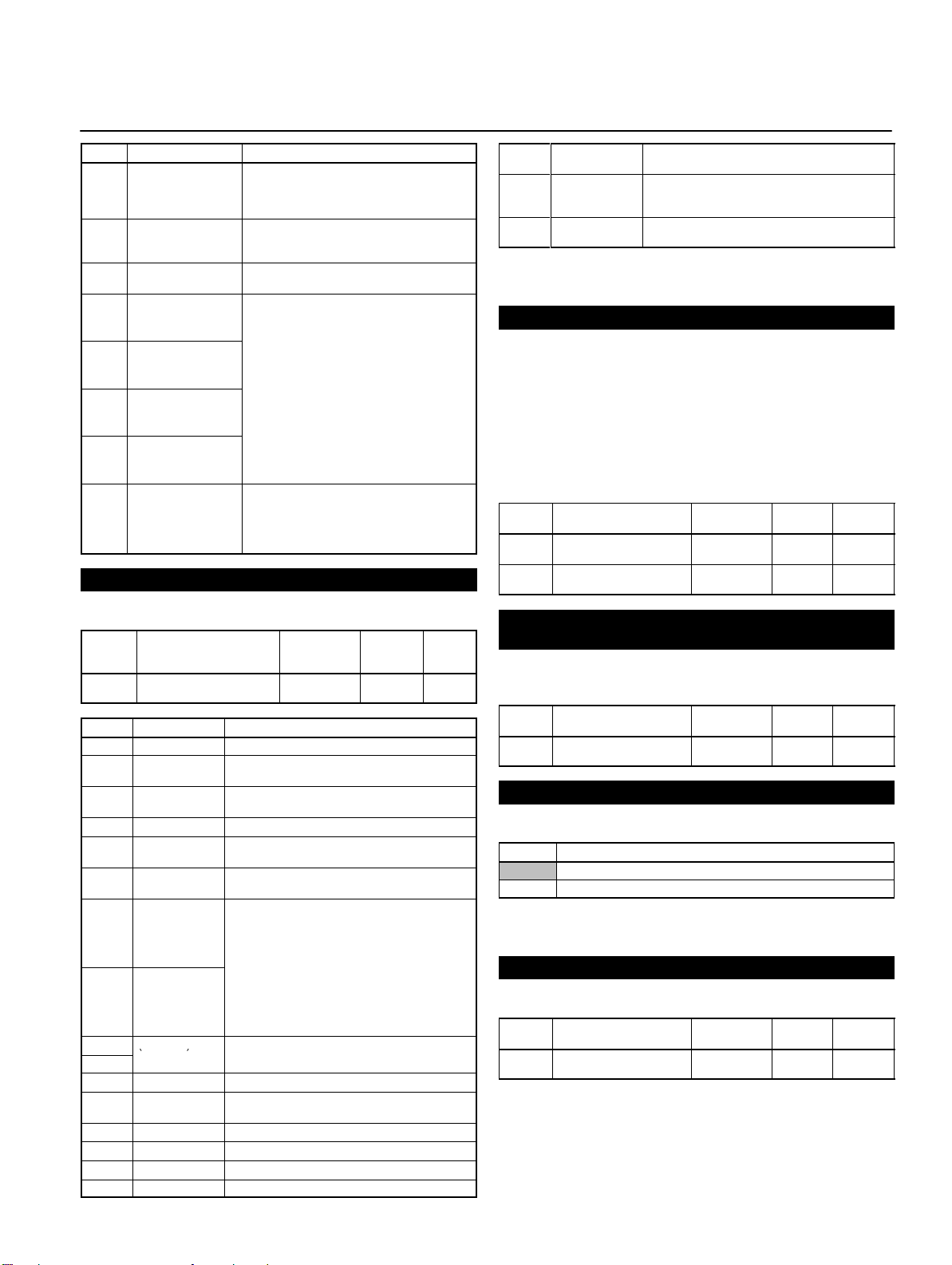

List of Parameters

limits in percentage based on the maximum frequency

minals S2 through S5.

n39

Multi-function input 4

2 to 34

16No

16

references.

qyjp

Note These values must satisfy the following condi

UpC g

Param-

eter

No.

n30 Frequency reference

n31 Frequency reference

n32 Rated motor current Used to set the rated motor current for motor overload

n33 Motor protection

n34 Motor protective

n35 Cooling fan opera-

n36 Multi-function input 1

n37 Multi-function input 2

n38 Multi-function input 3

n39 Multi-function input 4 2 to 34 1 6 No 16

n40 Multi-function output

n41 Frequency reference

n42 Frequency reference

n43 Analog frequency

n44 Analog monitor

n45 Analog monitor

n46 Carrier frequency

n47 Momentary power

n48 Fault retry Used to set the number of times the Inverter is reset

n49 Jump frequency 1

n50 Jump frequency 2

n51 Jump width

n52 DC control current

n53 Interruption DC

n54 Startup DC control

n55 Stall prevention

n56 Stall prevention level

n57 Stall prevention level

n58 Frequency detection

Name Description Setting

Used to set the upper and lower frequency reference

upper limit

lower limit

characteristics

time setting

tion function

(Input terminal S2)

(Input terminal S3)

(Input terminal S4)

(Input terminal S5)

(MA/MB and MC

output terminals)

gain

bias

reference filter time

output

output gain

selection

interruption compensation

control time

time

during deceleration

during acceleration

during operation

level

limits in percentage based on the maximum frequency

as 100%.

detection (OL1) based on the rated motor current.

Note Motor overload detection (OL1) is disabled by set-

ting the parameter to 0.0.

Used to set the motor overload detection (OL1) for the

electronic thermal characteristics of the motor.

Used to set the electric thermal characteristics of the

motor to be connected in 1-minute increments.

Used to operate the Cooling Fan of the Inverter while

the Inverter is turned on or only while the Inverter is in

operation.

Used to select the functions of multi-function input terminals S2 through S5.

Used to select the functions of multi-function output

terminals.

Used to the input characteristics of analog frequency

references.

Used to set the digital filter with a first-order lag for analog frequency references to be input.

Used to set the output frequency or current as a monitored item.

Used to set the output characteristics of analog monitor

output.

Used to set the carrier frequency. 1 to 4, 7 to91 Varies

Used to specify the processing that is performed when

a momentary power interruption occurs.

and restarted automatically in the case the Inverter has

an overvoltage fault, overcurrent fault, or ground fault.

Used to set the frequency jump function.

tion: n49 y n50

Used to impose DC on the induction motor for braking

control.

Used to select a function to change the deceleration

time of the motor automatically so that there will be no

overvoltage imposed on the motor during deceleration.

Used to select a function to stop the acceleration of the

motor automatically for stall prevention during

acceleration.

Used to select a function to reduce the output

frequency of the Inverter automatically for stall

prevention during operation.

Used to set the frequency to be detected. 0.0 to 400 0.1 Hz 0.0 No 19

range

0 to 110 1% 100 No 16

0 to 110 1% 0 No 16

0.0 to 120%

of rated output current

0 to 2 1 0 No 16

1 to 60 1 min 8 No 16

0, 1 1 0 No 16

2 to 22 1 2 No 16

0 to 22 1 5 No 16

2 to 22 1 3 No 16

0 to 7, 10 to171 1 No 17

0 to 255 1% 100 Ye s 17

–99 to 99 1% 0 Ye s 17

0.00 to 2.00 0.01 s 0.10 No 17

0, 1 1 0 No 17

0.00 to 2.00 0.01 1.00 Ye s 17

0 to 2 1 0 No 18

0 to 10 1 0 No 18

0.0 to 400 0.1 Hz 0.0 No 18

0.0 to 400 0.1 Hz 0.0 No 18

-

-

0.0 to 400 0.1 Hz 0.0 No 18

0 to 100 1% 50 No 18

0.0 to 25.5 0.1 s 0.5 No 18

0.0 to 25.5 0.1 s 0.0 No 18

0, 1 1 0 No 18

30 to 200 1% 170 No 19

30 to 200 1% 160 No 19

Unit of

setting

(see note)

0.1 A Varies

Default

setting

with the

capacity.

with the

capacity.

Changes

during op-

eration

No 16

No 18

Reference

page

Note: Values longer than 3 digits are rounded up to the next unit multiple.

12

Page 11

List of Parameters

OO

g

Param-

eter

No.

n59 Overtorque

n60 Overtorque

n61 Overtorque

n62 UP/DOWN

n63 Torque

n64 Motor rated slip Used to set the rated slip value of the motor in use. 0.0 to 20.0 0.1 Hz Varies

n65 Motor no-load

n66 Slip compensation

n67 Slip compensation

n68 to

n74

n75 Low-speed carrier

n76

n77

n78 Error log Used to display the latest error recorded.

Name Description Setting

Used to enable or disable overtorque detection and

detection function

selection

detection level

detection time

command frequency

memory

compensation gain

current

gain

time constant

OMRON’s control

reference use

frequency reduction

selection

OMRON’s control

reference use

select the processing method after overtorque

detection.

Used to set overtorque detection level. 30 to 200 1% 160 No 19

Used to set the detection time of overtorque. 0.1 to 10.0 0.1 s 0.1 No 19

Used to store the adjusted frequency reference with the

UP/DOWN function.

Used to set the gain of the torque compensation

function.

Used to set the no-load current of the motor in use

based on the rated motor current as 100%.

Used to set the gain of the slip compensation function. 0.0 to 2.5 0.1 0.0 Ye s 21

Used for the response speed of the slip compensation

function.

Do not change the set value. --- --- --- --- ---

Used to select a function to reduce the carrier

frequency when Inverter is at low speed.

Do not change the set value. --- --- --- --- ---

range

0 to 4 1 0 No 19

0, 1 1 0 No 20

0.0 to 2.5 0.1 1.0 Ye s 21

0 to 99 1% Varies

0.0 to 25.5 0.1 s 2.0 No 21

0.1 1 0 No ---

--- --- --- --- ---

Unit of

setting

(see note)

Default

setting

with the

capacity.

with the

capacity.

Changes

during op-

eration

Yes 21

No 21

Reference

page

Display

Note “– – –” will be displayed if no error has been re-

corded.

Note This parameter is monitored only.

n79 Software number Used to display the software number of the Inverter for

OMRON’s control reference use.

Note This parameter is monitored only.

Note: Values longer than 3 digits are rounded up to the next unit multiple.

--- --- --- --- ---

13

Page 12

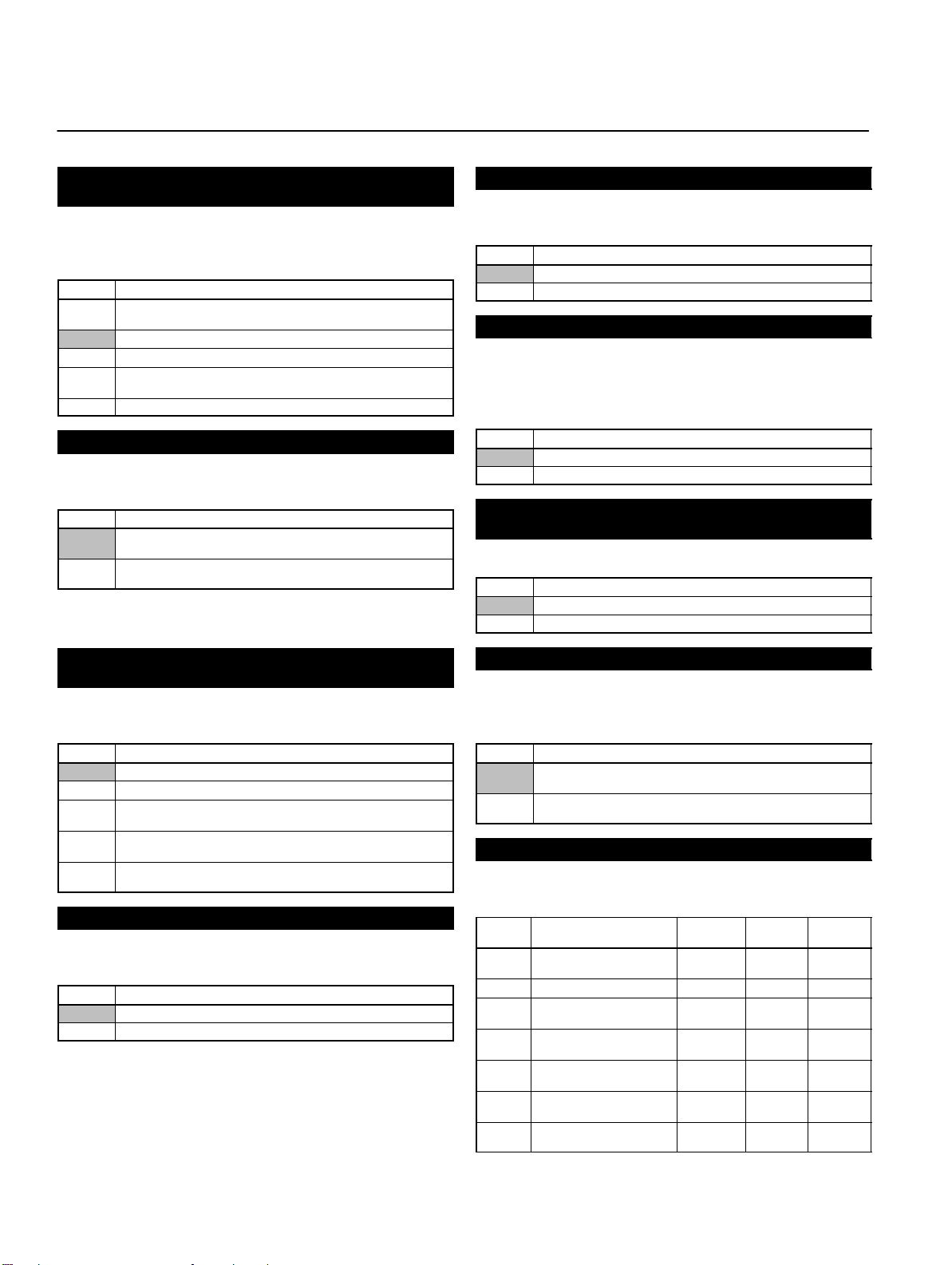

Function of Each Parameter

Note: The shaded values indicate default settings.

Parameter Write-prohibit Selection/Parameter

Initialization (n01)

This parameter makes it possible to write-prohibit parameters,

change the parameter set or displayed range, or initialize all parameters to default values.

Value Description

0 Only n01 can be displayed and set. The n02 through n79

1 The n01 through n79 parameters can be displayed and set.

6 Only the error log memory is cleared.

8 Enables the initialization of all parameters in 2-wire sequence so

9 Enables the initialization of all parameters in 3-wire sequence.

parameters can be displayed only.

that the parameters will return to default values.

Operation Mode Selection (n02)

Select the method of operation mode input to start or stop the Inverter in remote mode.

Value Description

0 The RUN and STOP/RESET Keys of the Digital Operator are

1 Multi-function input in 2- or 3-wire sequence through the control

Note: In local mode, RUN commands can be entered using the

enabled.

circuit terminals is enabled.

Digital Operator only.

Reverse Rotation-prohibit Selection (n05)

Select the operation to be performed when the reverse rotation

command is input.

Value Description

0 Reverse rotation possible (command accepted)

1 Reverse rotation prohibited (command not accepted)

STOP/RESET Key Function Selection (n06)

When parameter n02 is set to 1, set whether or not to use the

STOP/RESET Key of the Digital Operator to stop the Inverter in

remote mode. The STOP/RESET Key is always enabled in local

mode regardless of the setting in n02.

Value Description

0 The STOP/RESET Key of the Digital Operator is enabled.

1 The STOP/RESET Key of the Digital Operator is disabled.

Frequency Reference Selection (n07)

(Local Mode)

Select the input method of frequency references in local mode.

Value Description

0 The FREQ adjuster of the Digital Operator is enabled.

1 Key sequences on the Digital Operator are enabled.

Frequency Reference Selection (n03)

(Remote Mode)

Select the method for inputting the frequency reference to the Inverter in remote mode.

Value Description

0 The FREQ adjuster of the Digital Operator is enabled.

1 Frequency reference 1 (n21) is enabled.

2 The frequency reference control terminal (for 0- to 10-V input) is

3 The frequency reference control terminal (for 4- to 20-mA current

4 The frequency reference control terminal (for 0- to 20-mA current

enabled.

input) is enabled.

input) is enabled.

Interruption Mode Selection (n04)

Select the stopping method to be used when the STOP command is input.

Value Description

0 Frequency deceleration stop (Decelerates to stop in preset time.)

1 Free running (Output shut OFF by STOP command.)

Key Sequential Frequency Setting (n08)

Select whether to enable the Enter Key when setting the frequency reference with the Increment and Decrement Keys on

the Digital Operator.

Value Description

0 The Enter Key is enabled. (The setting is made valid by pressing

1 The Enter Key is disabled. (The setting is directly treated as a

the Enter Key.)

frequency reference without the Enter Key being pressed.)

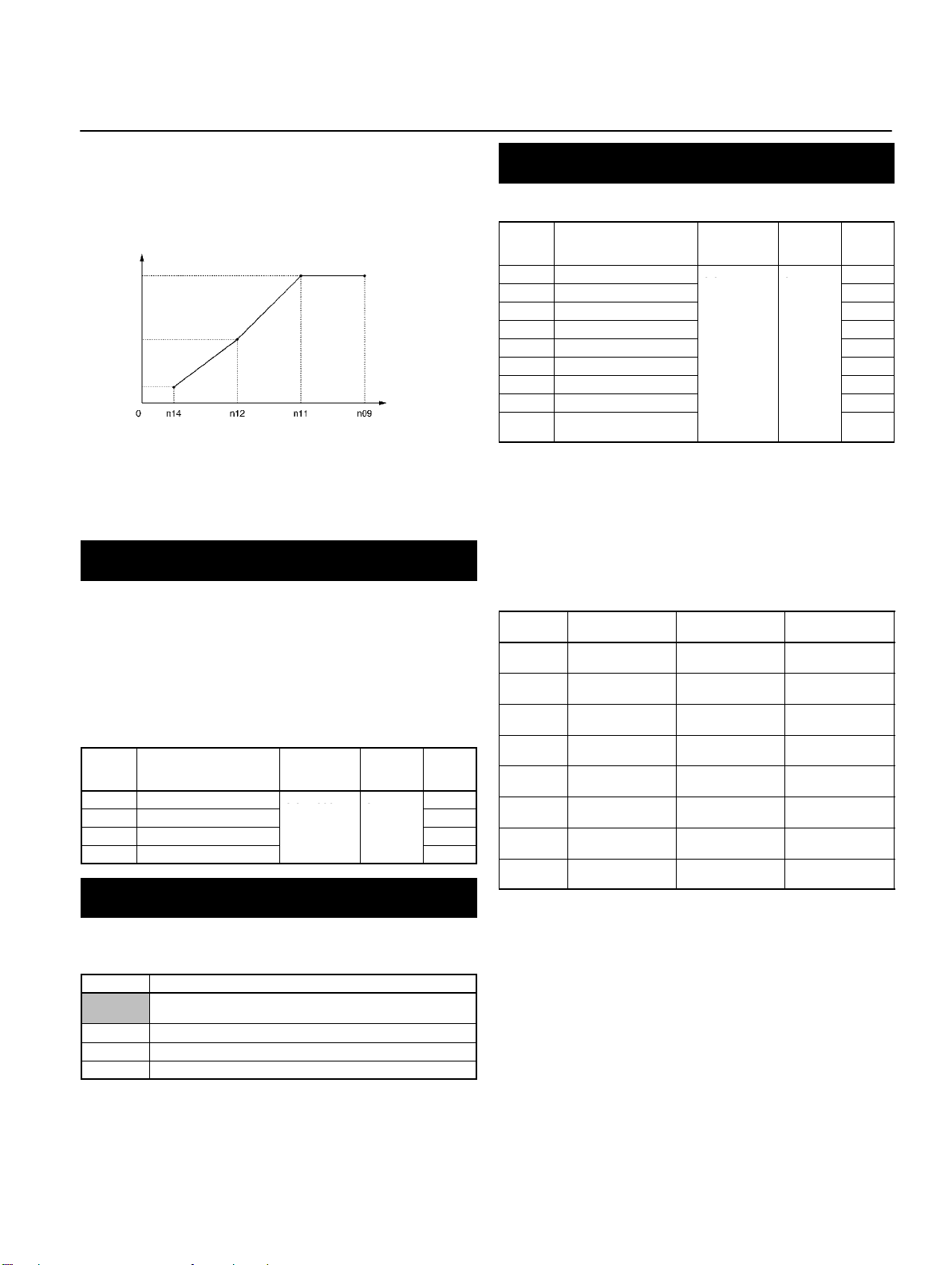

V/f Pattern Settings (n09 to n15)

Set the V/f pattern as the basic characteristic of the Inverter with

output voltage per frequency set.

Value Name Setting

n09 Maximum Frequency

n10 Maximum Voltage (VMAX) 1 to 255 1 V 200

n11 Maximum Voltage

n12 Middle Output Frequency

n13 Middle Output Frequency

n14 Minimum Output

n15 Minimum Output

(FMAX)

Frequency (FA)

(FB)

Voltage (VC)

Frequency (FMIN)

Frequency Voltage (VMIN)

range

50.0 to 400 0.1 Hz 60.0

0.2 to 400 0.1 Hz 60.0

0.1 to 399 0.1 Hz 1.5

1 to 255 1 V 12

0.1 to 10.0 0.1 Hz 1.5

1 to 50 1 V 12

Unit of

setting

Default

settings

14

Page 13

Function of Each Parameter

0 0 999

0

00

1)

Note: For n09, n11, and n12, the unit of setting is as follows:

Values will be set in 0.1-Hz increments if the frequency is

less than 100 Hz and 1-Hz increments if the frequency is

100 Hz or greater.

Output

voltage (V)

n10

n13

n15

Frequency

(Hz)

Note: 1. Set the parameters so that the following condition will

be satisfied.

n14 x n12 < n11 x n09

2. The value set in n13 will be ignored if parameters n14

and n12 are the same in value.

Acceleration/Deceleration Time Settings

(n16 to n19)

The acceleration time is the time required to go from 0% to 100%

of the maximum frequency and the deceleration time is the time

required to go from 100% to 0% of the maximum frequency. The

actual acceleration or deceleration time is obtained from the following formula.

Acceleration/Deceleration time =

(Acceleration/Deceleration time set value) × (Frequency reference value) ÷ (Max. frequency)

Value Name Setting

n16 Acceleration time 1

n17 Deceleration Time 1

n18 Acceleration time 2 10.0

n19 Deceleration Time 2 10.0

range

0.0 to 999 0.1 s

Unit of

setting

Default

set-

tings

10.0

10.0

S-shape Acceleration/Deceleration Characteristic

(n20)

Any one of three S-shape acceleration/deceleration times (0.2,

0.5, and 1.0 s) is selectable.

Value Description

0 No S-shape acceleration/deceleration characteristic

1 S-shape acceleration/deceleration characteristic time is 0.2 s

2 S-shape acceleration/deceleration characteristic time is 0.5 s

3 S-shape acceleration/deceleration characteristic time is 1.0 s

(Trapezoidal acceleration/deceleration)

Setting the Frequency References 1 to 8 and the

Inching Frequency Command (n21 to n28 and n29)

Set internal frequency references.

Value Name Setting

n21 Frequency reference 1

n22 Frequency reference 2

n23 Frequency reference 3

n24 Frequency reference 4 0.0

n25 Frequency reference 5 0.0

n26 Frequency reference 6 0.0

n27 Frequency reference 7 0.0

n28 Frequency reference 8 0.0

n29 Inching frequency com-

mand

range

0.0 to max.

frequency0(see note

Note: 1. Values will be set in 0.1-Hz increments if the frequency is less

than 100 Hz and 1-Hz increments if the frequency is 100 Hz

or over.

2. Frequency reference 1 is enabled with n03 for frequency reference selection set to 1. (Remote mode)

3. Frequency references 1 to 8 are enabled by setting multistep speed references 1, 2, and 3 in n36 to n39 for multi-function input. Refer to the following table for the relationship between multi-step speed references 1 to 3 and frequency references 1 to 8.

Frequency

reference

Frequency

reference 1

Frequency

reference 2

Frequency

reference 3

Frequency

reference 4

Frequency

reference 5

Frequency

reference 6

Frequency

reference 7

Frequency

reference 8

Multi-step speed

reference 1

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

OFF ON ON

ON ON ON

Multi-step speed

reference 2

Note: 1. “ON” and “OFF” represent “input ON” and “input OFF,” re-

spectively.

2. Inching frequency commands take precedence over multistep speed references.

Unit of

setting

0.1 Hz

Multi-step speed

6.0

0.0

0.0

6.0

reference 3

Default

set-

tings

Note: When the S-shape acceleration/deceleration character-

istic time is set, the acceleration and deceleration times

will be lengthened according to the S-shape at the beginning and end of acceleration/deceleration.

15

Page 14

Function of Each Parameter

8.

Frequency Reference Upper and Lower Limit

Settings (n30 and n31)

Set the upper and lower frequency reference limits in percentage based on the maximum frequency as 100%.

Value Name Setting

n30 Frequency Reference

n31 Frequency Reference

Upper Limit

Lower Limit

range

0 to 110 1% 100

0 to 110 1% 0

Unit of

setting

Default

settings

Note: If n31 is set to a value less than the minimum output fre-

quency (FMIN) (n14), the Inverter will have no output

when a frequency reference less than the minimum output frequency input is ON.

Rated Motor Current Setting (n32)

Set the rated motor current as the reference value for motor

overload detection (OL1).

Note: 1. Setting 0.0 disables the motor overload detection (OL1) func-

Value Name Setting range Unit of

n32 Rated Motor Current 0.0% to 120% (A) of

tion.

2. The rated motor current value is factory-set for each Inverter

according to the maximum applicable motor capacity.

Default

settings

the capacity.

rated output current

of Inverter

setting

0.1 A Varies with

Motor Protection Characteristic Selection (n33)

Set the motor overload detection (OL1) for the electronic thermal

characteristics of the motor.

Value Description

0 Protection characteristics for general-purpose induction motors

1 Protection characteristics for Inverter-dedicated motors

2 No protection

Note: When connecting multiple motors to one Inverter, set 2

(equivalent to n32 = 0.0). In addition, take overload prevention measures by mounting a thermal relay in each

motor, for example.

Motor Protective Time Setting (n34)

Set the electronic thermal characteristics of the motor to be connected in 1-minute increments.

Value Name Setting

n34 Motor Protective Time

Setting

range

1 to 60 1 min 8

Note: 1. The default setting does not need any changes in normal op-

eration.

2. To set the parameter according to the characteristics of the

motor, confirm the thermal time constant with the motor

manufacturer and set the parameter with some margin. In

other words, set the value a little shorter than the thermal time

constant.

3. To detect motor overloading more quickly, reduce the set value, provided that it does not cause any application problems.

Unit of

setting

Default

settings

Cooling Fan Operation Function Selection (n35)

This parameter is used to operate the cooling fan of the Inverter

while the Inverter is turned on or only while the Inverter is in operation.

Value Description

0 The fan rotates only while the RUN command is input and for 1

1 The fan rotates while the Inverter is turned ON.

Note: 1. This parameter is available only if the Inverter incorporates a

minute after the Inverter stops operating.

cooling fan.

2. If the operation frequency of the Inverter is low, the life of the

fan can be prolonged by setting the parameter to 0.

Multi-function Input Selection (n36 to n39)

Select the functions of multi-function input terminals S2 to S5.

Value Name Setting

n36 Multi-function Input 1

n37 Multi-function Input 2

n38 Multi-function Input 3

n39 Multi-function Input 4

Value Function Description

0 Forward/Reverse

2 Reverse/Stop Reverse rotation command (2-wire

3 External fault (NO) ON: External fault

4 External fault (NC) OFF: External fault

5 Fault reset ON: Fault reset

6 Multi-step speed

7 Multi-step speed

8 Multi-step speed

10 Inching frequency

11 Acceleration/Decel-

12 External base block

13 External base block

14 Search command

(S2)

(S3)

(S4)

(S5)

rotation command

reference 1

reference 2

reference 3

command

eration time selection

command (NO)

command (NC)

(Searching starts

from maximum frequency)

3-wire sequence (to be set in n37 only)

This setting overrides the n36 setting.

sequence) (ON: Reverse)

Note Disabled while RUN command is

Signals to select frequency references 1 to

8.

ON: Inching frequency command

ON: Acceleration/deceleration time 2

ON: Output shut OFF (while motor coasting

to a stop and “bb” flashing)

OFF: Output shut OFF (with motor free

running and “bb” flashing)

ON: Speed search (Searching starts from

n09)

range

2 to 8, 10 to221 2

0, 2 to 8, 10

to 22

2 to 8, 10 to221 3

2 to 8, 10 to

22, 34

S1: RUN input (RUN when ON)

S2: STOP input

(STOP when OFF)

S3: Forward/Reverse rotation

command

(ON: Reverse)

input

Unit of

setting

1 5

1 6

Default

settings

16

Page 15

Function of Each Parameter

tact opened

(

ON (no reset required)

• Overtorque detection level (n60)

()

Value Function Description

15 Search command

(Searching starts

from preset frequency)

16 Acceleration/Decel-

eration-prohibit command

17 Local or remote

selection

19 Emergency stop

fault (NO)

20 Emergency stop

alarm (NO)

21 Emergency stop

fault (NC)

22 Emergency stop

alarm (NC)

34 Up or down com-

mand

Multi-function Output Selection (n40)

Select the functions of multi-function output terminals.

Value Name Setting

n40 Multi-function Output (MA/

Value Function Description

0 Fault output ON: Fault output

1 Operation in

2 Frequency

3 Idling ON: Idling

4 Frequency

5 Frequency

6 Overtorque

7 Overtorque

8

9

10 Alarm output ON: Alarm being detected (Nonfatal error)

11 Base block in

12 RUN mode ON: Local mode

13 Inverter ready ON: Inverter ready to operate

14 Fault retry ON: Fault retry

Value Function Description

MB and MC)

progress

detection

detection 1

detection 2

being monitored

(NO-contact

output)

being monitored

(NC-contact

output)

(Not used) ---

progress

ON: Speed search (Searching starts from

the frequency specified by n03.)

ON: Acceleration/Deceleration is on hold

ON: Local mode (operated with the Digital

Operator)

The Inverter stops according to the setting in

n04 for interruption mode selection when the

emergency stop input turns ON.

Note NO: Emergency stop with the con-

Note Fault: Fault output is ON and reset

Note “STP” is displayed (lit with fault in-

Up or down command (set in n39 only)

This setting overrides the n38 setting.

ON: Operation in progress

ON: Frequency detection

ON: Output frequency y frequency detection

level (n58)

ON: Output frequency x frequency detection

level (n58)

Output if any of the following parameter

conditions is satisfied.

• Overtorque detection function selection (n59)

• Overtorque detection level (n60)

• Overtorque detection time (n61)

Note NO contact: ON with overtorque be-

ON: Base block in progress

tact closed.

NC: Emergency stop with the con-

with RESET input. Alarm output is

ON

put ON and flashes with alarm input ON)

S4: Up command

S5: Down command

range

0 to 7, 10 to171 1

ing detected; NC contact: OFF with

overtorque being detected

.

no reset required).

Unit of

setting

.

Default

set-

tings

15 UV in progress ON: Undervoltage being monitored (main circuit

16 Rotating in

17 Speed search

reverse

direction

in progress

undervoltage UV or UV1 detected)

ON: Rotating in reverse direction

ON: Speed search in progress

Note: Use “operation in progress” or “frequency detection 1/2”

for the timing of the external brake.

Gain and Bias Settings (n41 and n42)

Set the input characteristics of analog frequency references in

n41 (for the frequency reference gain) and n42 (for the frequency reference bias).

Set the frequency of maximum analog input (10 V or 20 mA) in

n41 as percentage based on the maximum frequency as 100%.

Set the frequency of minimum analog input (0 V, 0 mA, or 4 mA)

in n42 as percentage based on the maximum frequency as

100%.

Value Name Setting

n41 Frequency Reference

n42 Frequency Reference

Gain

Bias

range

0 to 255 1% 100

–99 to 99 1% 0

Unit of

setting

Default

settings

Analog Frequency Reference Filter Time Setting

(n43)

The digital filter with a first-order lag can be set for analog frequency references to be input.

Value Name Setting

n43 Analog Frequency Refer-

ence Filter Time

range

0.00 to 2.00 0.01 s 0.10

Unit of

setting

Default

settings

Analog Monitor Output Setting (n44)

Set a monitored item for analog monitor output.

Value Description

0 Output frequency (Reference: 10 V at max. frequency)

1 Output current (Reference: 10 V with rated output current)

Note: The values in parentheses are applicable when n45 is

set to 1.00.

Analog Monitor Output Gain Setting (n45)

Set the output characteristics of analog monitor output.

Value Name Setting

n45 Analog Monitor Output

Gain

range

0.00 to 2.00 0.01 1.00

Unit of

setting

Default

settings

17

Page 16

Function of Each Parameter

Carrier Frequency Selection (n46)

Set the carrier frequency.

Value Description

1 2.5 kHz

2 5.0 kHz

3 7.5 kHz

4 10.0 kHz

7 2.5 kHz (12×): 12 times as high as output frequency (between 1.0

8 2.5 kHz (24×): 24 times as high as output frequency (between 1.0

9 2.5 kHz (36×): 36 times as high as output frequency (between 1.0

and 2.5 kHz)

and 2.5 kHz)

and 2.5 kHz)

Note: Normally, the factory setting need not be changed.

Momentary Power Interruption Compensation

(n47)

The parameter specifies the processing that will be performed

when a momentary power interruption occurs.

Value Description

0 Disabled.

1 The Inverter will continue operating if power is restored within 0.5

2 The Inverter will restart when power is restored.

s.

Fault Retry (n48)

Output

frequency

n51

Reference

n50 n49

frequency

DC Control Functions (n52 to n54)

Used to impose DC on the induction motor for braking control.

Value Name Setting

n52 DC Control Current 0 to 100 1% 50

n53 Interruption DC Control

n54 Startup DC Control Time 0.0 to 25.5 0.1 s 0.0

Time

range

0.0 to 25.5 0.1 s 0.5

DC Control Current:

Set this value in percentage based on the rated output current of

the Inverter as 100%.

Output

frequency

Unit of

setting

Default

set-

tings

Set the number of times the Inverter is to be automatically reset

and restarted when the Inverter has an overvoltage fault, overcurrent fault, or ground fault.

Value Name Setting

n48 Fault Retry 0 to 10 1 0

range

Unit of

setting

Default

set-

tings

Frequency Jump Function (n49 to n51)

Set the frequency jump function.

Value Name Setting

n49 Jump Frequency 1 0.0 to 400 0.1 Hz

n50 Jump Frequency 2 0.0 to 400 0.1 Hz

n51 Jump Width 0.0 to 25.5 0.1 Hz 0.0

Note: 1. Values will be set in 0.1-Hz increments if the frequency is less

than 100 Hz and 1 Hz-increments if the frequency is 100 Hz

or greater.

2. Make settings so that n49 y n50.

range

Unit of

setting

(see note

1)

(see note

1)

Default

settings

0.0

0.0

FMIN

(n14)

Time

n54 n53

Stall Prevention during Deceleration (n55)

Select a function to change the deceleration time of the motor

automatically so that there will be no overvoltage imposed on the

motor during deceleration.

Value Description

0 Stall prevention during deceleration

1 No stall prevention during deceleration

Output

frequency

Deceleration time is

controlled to prevent

overvoltage.

Time

Deceleration time (Set value)

18

Page 17

Function of Each Parameter

Stall Prevention Level during Acceleration (n56)

Set the operation level of a function to stop the acceleration of

the motor automatically for stall prevention during acceleration.

Set this value in percentage based on the rated output current of

the Inverter as 100%.

Value Name Setting

n56 Stall Prevention Level

during Acceleration

range

30 to 200 1% 170

Stall Prevention during Acceleration

Output

current

Output

frequency

The output frequency is

controlled so that the

Inverter will not stall.

n56

Unit of

setting

Default

settings

Time

Time

Stall Prevention Level during Operation (n57)

Select the operation level of a function to reduce the output frequency of the Inverter automatically for stall prevention during

operation. Set this value in percentage based on the rated output

current of the Inverter as 100%.

Value Name Setting

n57 Stall Prevention Level

during Operation

range

30 to 200 1% 160

Unit of

setting

Default

settings

Overtorque Detection Function Selection

(n59 to n61)

Set n59 to enable or disable overtorque detection and select the

processing to be performed after overtorque detection.

Value Description

0 Inverter does not monitor overtorque.

1 Inverter monitors overtorque only when speed is matched.

2 Inverter monitors overtorque only when speed is matched.

3 Inverter always monitors overtorque during operation.

4 Inverter always monitors overtorque during operation.

Set the overtorque detection level in n60 and the overtorque

detection time in n61.

Value Name Setting

n60 Overtorque Detection

n61 Overtorque Detection

Note: 1. In n60, set the overtorque detection level in percentage

Overtorque Detection

It continues operation (issues warning) even after overtorque is

detected.

It discontinues operation (through protective function) when

overtorque is detected.

It continues operation (issues warning) even after overtorque is

detected.

It discontinues operation (through protective function) when

overtorque is detected.

Unit of

setting

Level

Time

range

30 to 200 1% 160

0.1 to 10.0 0.1 s 0.1

based on the rated output current of the Inverter as 100%.

2. In n61, set the overtorque detection time in 0.1-s increments.

See note.

Output

n60

current

Default

set-

tings

Stall Prevention during Operation

Output

n57

current

Time

Output

frequency

The output frequency is

controlled so that the

Inverter will not stall.

Time

Frequency Detection Level (n58)

Set the frequency to be detected.

Note: When frequency detection 1 and 2 are to be output, n40

(multi-function output) must be set.

Value Name Setting

n58 Frequency Detection

Level

range

0.0 to 400 0.1 Hz 0.0

Unit of

setting

Default

settings

Overtorque

detection

(NO)

Time

n61

Time

Note: Overtorque detection will be canceled if the out-

put current decreases from the detection level by

approximately 5% of the Inverter rated current.

19

Page 18

Function of Each Parameter

UP/DOWN Command Frequency Memory

Selection (n62)

Select whether to store the frequency reference adjusted with

the UP/DOWN function.

Value Description

0 The frequency on hold is not retained.

1 The frequency on hold for 5 s or more is retained.

The UP/DOWN function uses UP and DOWN commands to

change frequency references.

When using the UP/DOWN function, set multi-function input 4

(n39) to 34 (UP or DOWN command). The terminals for multifunction input 3 (S4) and multi-function input 4 (S5) will be set to

function in the following way:

Multiple-function input 3 (S4): UP command

Multiple-function input 4 (S5): DOWN command

Operation of UP/DOWN Function

RUN command

(Forward rotation)

UP command (S4)

DOWN command

(S5)

Output frequency

Upper limit

Use n62 (UP/DOWN command frequency memory) to set

whether the frequency reference on hold is stored or not when

an UP or DOWN command is sent to the multi-function input terminals.

If n62 is set to 1, the output frequency held by the UP/DOWN

function for 5 s or more will be stored in the memory. This value

will be stored in memory even if power is interrupted. When a

RESET command is input, operation will start with this value as

the frequency.

If n62 is set to 0, the frequency will be cleared. If parameter initialization is performed (i.e.: n01 is set to 8 or 9), the stored frequency will be initialized.

Note: If the UP/DOWN function is used in remote mode, fre-

quency references can only be given with UP/DOWN

commands and inching commands. Multi-step speed

references will be invalid.

Time

Time

Time

20

Lower limit

Status

Frequency

detection

Time

Time

Status U: UP (acceleration)

D: DOWN (deceleration)

H: Hold

U1: Frequency acceleration restricted by upper limit.

D1: Frequency deceleration restricted by lower limit.

Page 19

Function of Each Parameter

Torque Compensation Gain (n63)

Set the gain of the torque compensation function.

Note: Normally, the factory setting need not be changed.

Value Name Setting

n63 Torque Compensation

Gain

range

0.0 to 2.5 0.1 1.0

Unit of

setting

Default

settings

Slip Compensation Functions (n64 to n67)

In n64, set the rated slip value of the motor in use.

In n65, set the no-load current of the motor in use based on the

rated motor current as 100%.

In n66, set the gain of the slip compensation function.

In n67, set the response speed of the slip compensation function.

Value Name Setting

n64 Motor Rated Slip 0.0 to 20.0 0.1 Hz

n65 Motor No-load Cur-

n66 Slip Compensation

n67 Slip Compensation

rent

Gain

Time Constant

range

0 to 99 1%

0.0 to 2.5 0.1 0.0

0.0 to 25.5 0.1 s 2.0

Note: If 0.0 is set for n66, the slip compensation function will be

disabled.

Unit of set-

ting

Default

settings

Varies

with the

capacity.

21

Page 20

3p

Sg p

Op

C

Specifications

Specifications

3-phase

200-V AC

models

Single-phase

200-V AC

models

Model 3G3JV- A2001 A2002 A2004 A2007 A2015 A2022 A2037

Power

supply

Heat radiation (W) (see note 2) 13.0 18.0 28.1 45.1 72.8 94.8 149.1

Weight (kg) 0.5 0.5 0.8 0.9 1.3 1.5 2.1

Cooling method Natural cooling Cooling fan

Model 3G3JV- AB001 AB002 AB004 AB007 AB015 --- ---

Power

supply

Heat radiation (W) (see note 2) 14.1 20.0 31.9 51.4 82.8 --- ---

Weight (kg) 0.5 0.5 0.9 1.5 1.5 --- ---

Cooling method Natural cooling Cooling fan

Rated voltage and frequency 3-phase 200 to 230 V AC at 50/60 Hz

Allowable voltage fluctuation –15% to 10%

Allowable frequency

fluctuation

Input power supply capacity

(kVA) (see note 1)

Rated voltage and frequency Single-phase 200 to 240 V AC at 50/60 Hz

Allowable voltage fluctuation –15% to 10%

Allowable frequency

fluctuation

Input power supply capacity

(kVA) (see note 1)

±5%

0.4 0.9 1.6 2.7 4.3 5.9 9.3

±5%

0.5 0.9 1.6 2.7 4.3 --- ---

Note: 1. The power supply capacity, is the capacity when the Inverter is operating at its rated output. The value will vary with the

impedance at the input power supply side. (Because the power factor of the input power supply changes, the power factor

will improve if an AC reactor is inserted.) The ratio with the rated current of the motor used and the rated output current of

the Inverter will vary.

2. The “heat radiation” is the power consumed in the Inverter when it is operating at its rated output.

Max. applicable motor capacity (kW) 0.1 0.2 0.4 0.75 1.5 2.2 3.7

Output

specifications

Control

characteristics

Protective

functions

Rated output capacity (kW) 0.3 0.6 1.1 1.9 3.0 4.2 6.7

Rated output current (A) 0.8 1.6 3.0 5.0 8.0 11.0 17.5

Rated output voltage (V) 3-phase 200 to 230 V AC (according to the input voltage)

Max. output frequency 400 Hz parameter setting

Harmonic-current countermeasures DC reactor (option) connection possible

Control method Sine wave PWM (V/f control)

Carrier frequency 2.5 to 10.0 kHz (in vector control)

Frequency control range 0.1 to 400 Hz

Frequency precision (temperature

characteristics)

Frequency setting resolution Digital commands: 0.1 Hz (less than 100 Hz) and 1 Hz (100 Hz or over)

Output frequency resolution 0.01 Hz (calculated resolution)

Overload capacity 150% of rated output current for 1 min

External frequency set signal Selectable with FREQ adjuster: 0 to 10 V DC (20 kΩ), 4 to 20 mA (250 Ω), and 0 to 20 mA

Acceleration/deceleration time 0.0 to 999 s (Independent acceleration and deceleration time settings)

Braking torque Approx. 20%

Voltage/frequency characteristics Set a user V/f pattern

Motor protection Protection by electronic thermal

Instantaneous overcurrent protection Stops at approx. 250% of rated output current

Overload protection Stops in 1 min at approximately 150% of rated output current

Overvoltage protection Stops when main-circuit DC voltage is approximately 410 V

Undervoltage protection Stops when main-circuit DC voltage is approximately 200 V (160 V for single-phase 200-V AC

Momentary power interruption

compensation (selection)

Cooling fin overheating Detects at 110°C ± 10°C

Grounding protection Protection at rated output current level

Charge indicator (RUN indicator) Lit when the main circuit DC voltage is approximately 50 V or less.

Digital commands: ±0.01% (–10°C to 50°C)

Analog commands: ±0.5% (25°C ± 10°C)

Analog commands: 0.06 Hz/60 Hz (equivalent to 1/1000)

(250 Ω)

model)

Stops for 15 ms or more. By setting the Inverter to momentary power interruption mode,

operation can be continued if power is restored within approximately 0.5 s.

22

Page 21

Specifications

Environment

Degree of protection Panel-mounting models: Conforms to IP20

Location Indoors (with no corrosive gas, oil spray, or metallic dust)

Ambient temperature Operating: –10°C to 50°C

Ambient humidity Operating: 95% max. (with no condensation)

Ambient temperature –20°C to 60°C

Altitude 1,000 m max.

Insulation resistance 5 MΩ min. (Do not carry out any insulation resistance or withstand voltage tests)

Vibration resistance 9.8 m/s2 max. between 10 to 20 Hz

2

max. between 20 and 50 Hz

2.0 m/s

23

Page 22

Specifications

3p

Op

C

3-phase

400-V AC

models

Model 3G3JV- A4002 A4004 A4007 A4015 A4022 A4037

Power

supply

Heat radiation (W) (see note 2) 23.1 30.1 54.9 75.7 83.0 117.9

Weight (kg) 1.0 1.1 1.5 1.5 1.5 2.1

Cooling method Natural cooling Cooling fan

Rated voltage and frequency 3-phase 380 to 460 V AC at 50/60 Hz

Allowable voltage fluctuation –15% to 10%

Allowable frequency

fluctuation

Input power supply capacity

(kVA) (see note 1)

±5%

1.3 1.9 3.6 5.1 5.9 9.1

Note: 1. The power supply capacity, is the capacity when the Inverter is operating at its rated output. The value will vary with the

impedance at the input power supply side. (Because the power factor of the input power supply changes, the power factor

will improve if an AC reactor is inserted.) The ratio with the rated current of the motor used and the rated output current of

the Inverter will vary.

2. The “heat radiation” is the power consumed in the Inverter when it is operating at its rated output.

Max. applicable motor capacity (kW) 0.2 0.4 0.75 1.5 2.2 3.7

Output

specifications

Control

characteristics

Protective

functions

Environment

Degree of protection Panel-mounting models: Conforms to IP20

Rated output capacity (kW) 0.9 1.4 2.6 3.7 4.2 6.6

Rated output current (A) 1.2 1.8 3.4 4.8 5.5 8.6

Rated output voltage (V) 3-phase 380 to 460 V AC (according to the input voltage)

Max. output frequency 400 Hz parameter setting

Harmonic-current countermeasures DC reactor (option) connection possible

Control method Sine wave PWM (V/f control)

Carrier frequency 2.5 to 10.0 kHz (in vector control)

Frequency control range 0.1 to 400 Hz

Frequency precision (temperature

characteristics)

Frequency setting resolution Digital commands: 0.1 Hz (less than 100 Hz) and 1 Hz (100 Hz or over)

Output frequency resolution 0.01 Hz (calculated resolution)

Overload capacity 150% of rated output current for 1 min

External frequency set signal Selectable with FREQ adjuster: 0 to 10 V DC (20 kΩ), 4 to 20 mA (250 Ω), and 0 to 20 mA

Acceleration/deceleration time 0.0 to 999 s (Independent acceleration and deceleration time settings)

Braking torque Approx. 20%

Voltage/frequency characteristics Set a user V/f pattern

Motor protection Protection by electronic thermal

Instantaneous overcurrent protection Stops at approx. 250% of rated output current

Overload protection Stops in 1 min at approximately 150% of rated output current

Overvoltage protection Stops when main-circuit DC voltage is approximately 820 V

Undervoltage protection Stops when main-circuit DC voltage is approximately 400 V

Momentary power interruption

compensation (selection)

Cooling fin overheating Detects at 110°C ± 10°C

Grounding protection Protection at rated output current level

Charge indicator (RUN indicator) Lit when the main circuit DC voltage is approximately 50 V or less.

Location Indoors (with no corrosive gas, oil spray, or metallic dust)

Ambient temperature Operating: –10°C to 50°C

Ambient humidity Operating: 95% max. (with no condensation)

Ambient temperature –20°C to 60°C

Altitude 1,000 m max.

Insulation resistance 5 MΩ min. (Do not carry out any insulation resistance or withstand voltage tests)

Vibration resistance 9.8 m/s2 max. between 10 to 20 Hz

Digital commands: ±0.01% (–10°C to 50°C)

Analog commands: ±0.5% (25°C ± 10°C)

Analog commands: 0.06 Hz/60 Hz (equivalent to 1/1000)

(250 Ω)

Stops for 15 ms or more. By setting the Inverter to momentary power interruption mode,

operation can be continued if power is restored within approximately 0.5 s.

2

max. between 20 and 50 Hz

2.0 m/s

24

Page 23

Terminal Block

terminals

3G3JV-A4j: 3-phase 380 to 460 V AC

3G3JV A2j: 3 phase 200 to 230 V AC

3G3JV-A4j: 3-phase 380 to 460 V AC

When driving the Inverter with DC power, input the DC power to terminals +1

Position of Terminal Block

Ground terminal

Specifications

Main circuit input

terminals

Control circuit

terminals

Main circuit

output terminals

Note: This illustration shows the terminal block with the front cover removed.

Ground

terminal

Arrangement of Control Circuit Terminals

Main Circuit Terminals

Symbol Name Description

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

+1

+2

–

Power supply input

Motor output terminals 3-phase power supply output for driving motors.

Connection terminals +1

and +2:

DC reactor connection

terminals

+1 and –:

–

DC power supply input

terminals

Ground terminal Be sure to ground the terminal under the following conditions.

3G3JV-A2j: 3-phase 200 to 230 V AC

3G3JV-ABj: Single-phase 200 to 240 V AC

-

Note Connect single-phase input to terminals R/L1 and S/L2.

3G3JV-A2j: 3-phase 200 to 230 V AC

3G3JV-ABj: 3-phase 200 to 240 V AC

3G3JV-A4j: 3-phase 380 to 460 V AC

Note The maximum output voltage corresponds to the input power supply

Connect the DC reactor for suppressing harmonics to terminals +1 and +2.

When driving the Inverter with DC power, input the DC power to terminals +1

and –.

(Terminal +1 is a positive terminal.)

3G3JV-A2j: Ground at a resistance of 100 Ω or less.

3G3JV-ABj: Ground at a resistance of 100 Ω or less.

3G3JV-A4j: Ground at a resistance of 10 Ω or less. Connect to a neutral point

on the power supply to conform to EC Directives.

Note Be sure to connect the ground terminal directly to the motor frame

-

voltage for the Inverter.

ground.

25

Page 24

Specifications

p

p

( pu peda ce 0 )

ug)

aa30 C

Control Circuit Terminals

Symbol Name Function Signal level

Input

Output

S1 Forward/Stop Forward at ON. Stops at OFF.

S2 Multi-function input 1 (S2) Set by parameter n36 (Re-

verse/Stop)

S3 Multi-function input 2 (S3) Set by parameter n37 (Fault

reset)

S4 Multi-function input 3 (S4) Set by parameter n38 (Exter-

nal fault: Normally open)

S5 Multi-function input 4 (S5) Set by parameter n39 (Multi-

step reference 1)

SC Sequence input common Common for S1 through S5

FS Frequency reference power

supply

FR Frequency reference input Input terminal for frequency

FC Frequency reference common Common for frequency refer-

MA Multi-function contact output

(Normally open)

MB Multi-function contact output

(Normally closed)

MC Multi-function contact output

common

AM Analog monitor output Set by parameter n44 (Output

AC Analog monitor output com-

mon

DC power supply for frequen-

cy reference use

reference use

ence use

Set by parameter n40 (during

running)

Common for MA and MB use

frequency)

Common for AM use

Photocoupler

8 mA at 24 V DC (see note 2)

20 mA at 12 V DC

0 to 10 V DC

(Input impedance = 20 kΩ)

Relay output

1 A max. at 30 V DC

1 A max. at 250 V AC

2 mA max. at 0 to 10 V DC

Note: 1. Functions in parentheses are default settings.

2. The input method is set to NPN by default, so use the GND common for wiring. An external power supply is not required.

When a power supply is used and a common on the plus side is used for wiring, set SW7 to PNP and use a 24-V DC (±10%)

power supply.

26

Page 25

Dimensions

3G3JV

p

gp

3G3JV

p

gp

p

3G3JV

Dimensions

3G3JV-A2001 to 3G3JV-A2007 (0.1 to 0.75 kW)

3-phase 200-V AC Input

3G3JV-AB001 to 3G3JV-AB004 (0.1 to 0.4 kW)

Single-phase 200-V AC Input

Rated voltage Model

3-phase 200 V AC

Single-phase 200 V AC

3G3JV-

A2001 70 3 Approx. 0.5

A2002 70 3 Approx. 0.5

A2004 102 5 Approx. 0.8

A2007 122 5 Approx. 0.9

AB001 70 3 Approx. 0.5

AB002 70 3 Approx. 0.5

AB004 112 5 Approx. 0.9

Dimensions

(mm)

D t

Weight (kg)

3G3JV-A2037 (3.7 kW) 3-phase 200-V AC Input

3G3JV-A4037 (3.7 kW) 3-phase 400-V AC Input

3G3JV-A2015 to 3G3JV-A2022 (1.5 to 2.2 kW)

3-phase 200-V AC Input

3G3JV-AB007 to 3G3JV-AB015 (0.75 to 1.5 kW)

Single-phase 200-V AC Input

3G3JV-A4002 to 3G3JV-A4022 (0.2 to 2.2 kW)

3-phase 400-V AC Input

Two, 5-dia. holes

t

Rated voltage Model

3-phase 200 V AC

Single-phase 200 V AC

3-phase 400 V AC

3G3JV-

A2015 129 Approx. 1.3

A2022 154 Approx. 1.5

AB007 129 Approx. 1.5

AB015 154 Approx. 1.5

A4002 81 Approx. 1.0

A4004 99 Approx. 1.1

A4007 129 Approx. 1.5

A4015 154 Approx. 1.5

A4022 154 Approx. 1.5

Dimensions

(mm)

D

Weight (kg)

Rated voltage Model

3G3JV-

3-phase 200 V AC A2037 161 Approx. 2.1

3-phase 400 V AC A4037 161 Approx. 2.1

Dimensions

(mm)

D

Weight (kg)

27

Page 26

Standard Connections

Standard Connections

DC reactor

(optional)

Noise Filter

3-phase 200 V AC

Single-phase 200 V AC (see note 1)

3-phase 400 V AC

Multi-function contact output

NO

NC

Common

Analog monitor output

Analog monitor output common

FREQ adjuster

(2 kΩ, 1/4 W min.)

Forward/Stop

Multi-function input 1 (S2)

Multi-function input 2 (S3)

Multi-function input 3 (S4)

Multi-function input 4 (S5)

Sequence input common

Frequency reference power supply

20 mA at +12 V

Frequency reference input

Frequency reference common

Note: 1. Connect single-phase 200 V AC to terminals R/L1 and S/L2 of the 3G3JV-ABj.

2. The braking resistor cannot be connected because no braking transistor is incorporated.

Input Method Selection

Switches SW7 and SW8, both of which are located above the control circuit terminals, are used for input method selection.

Remove the front cover and optional cover to use these switches.

Selector

Control circuit terminal block

Sequence Input Method Selection

By using SW7, NPN or PNP input can be selected as shown below.

24 V

(Factory setting)

S1 to 5

24 V DC

(±10%)

S1 to 5

Frequency Reference Input Method Selection

By using SW8, frequency reference voltage or current input can be selected.

Parameter settings are required together with the selection of the frequency reference input method.

Frequency reference input method SW8 setting Frequency reference selection (parameter n03)

Voltage input V (OFF) Set value 2

Current input I (ON) Set value 3 or 4

28

Page 27

Protective and Diagnostic

Functions

Fault Detection (Fatal Error)

The Inverter will detect the following faults if the Inverter or motor burns or the internal circuitry of the Inverter malfunctions. When the

Inverter detects a fault, the fault code will be displayed on the Digital Operator, the fault contact output will operate, and the Inverter

output will be shut off causing the motor to coast to a stop. The stopping method can be selected for some faults, and the selected

stopping method will be used with these faults. If a fault has occurred, refer to the following table to identify and correct the cause of

the fault. Use one of the following methods to reset the fault after restarting the Inverter. If the operation command is being input,

however, the reset signal will be ignored. Therefore, be sure to reset the fault with the operation command turned off.

• Turn on the fault reset signal. A multi-function input (n36 to n39) must be set to 5 (Fault Reset).

• Press the STOP/RESET Key on the Digital Operator.

• Turn the main circuit power supply off and then on again.

Fault Displays and Processing

Fault display Fault name and meaning Probable cause and remedy

%c

%U

uU1

%h

Overcurrent (OC)

The Inverter output current is as high

as or higher than 200% of the rated

output current.

Overvoltage (OV)

The main circuit DC voltage has

reached the overvoltage detection level

(200-V models: 410 V DC min.; 400-V

models: 820 V DC min.).

Main circuit undervoltage (UV1)

The main circuit DC voltage has

reached the undervoltage detection

level (200 V DC for the 3G3JV-A2j,

160 V DC for the 3G3JV-ABj, and 400

V DC for the 3G3JV-A4j).

Radiation fin overheated (OH)

The temperature of the radiation fins of

the Inverter has reached 110_C ±

10_C.

• A short-circuit or ground fault has occurred and at the Inverter output.

→ Check and correct the motor power cable.

• The V/f setting is incorrect.

→ Reduce the V/f set voltage.

• The motor capacity is too large for the Inverter.

→ Reduce the motor capacity to the maximum permissible motor capacity.

• The magnetic contactor on the output side of the Inverter has been opened and closed.

→ Rearrange the sequence so that the magnetic contactor will not open or close while the Inverter

has current output.

• The output circuit of the Inverter is damaged.

→ Replace the Inverter.

• The deceleration time is too short.

→ Increase the deceleration time.

• The power supply voltage is too high.

→ Decrease the voltage so it will be within specifications.

• There is excessive regenerative energy due to overshooting at the time of acceleration.

→ Suppress the overshooting as much as possible.

• Power supply to the Inverter has phase loss, power input terminal screws are loose, or the power

cable is disconnected.

→ Check the above and take necessary countermeasures.

• Incorrect power supply voltage

→ Make sure that the power supply voltage is within specifications.

• Momentary power interruption has occurred.

→ Use the momentary power interruption compensation (Set n47 so that the Inverter restarts after

power is restored)

→ Improve the power supply.

• The internal circuitry of the Inverter is damaged.

→ Change the Inverter.

• The ambient temperature is too high.

→ Ventilate the Inverter or install a cooling unit.

• The load is excessive.

→ Reduce the load.

→ Decrease the Inverter capacity.

• The V/f setting is incorrect.

→ Reduce the V/f set voltage.

• The acceleration/deceleration time is too short.

→ Increase the acceleration/deceleration time.

• The ventilation is obstructed.

→ Change the location of the Inverter to meet the installation conditions.

• The cooling fan of the Inverter does not work.

→ Replace the cooling fan.

29

Page 28

Protective and Diagnostic Functions

Fault display Probable cause and remedyFault name and meaning

%l1

%l2

%l3

gf

efj External fault j (EFj)

f00

f01

f04

f05