Page 1

Cat. No. I516-E1-05

USER’S MANUAL

SYSDRIVE 3G3FV

High-function General-purpose Inverter

Page 2

Thank you for choosing this SYSDRIVE 3G3FV-series product. Proper use and

handling of the product will ensure proper product performance, will length

product life, and may prevent possible accidents.

Please read this manual thoroughly and handle and operate the product with care.

1. To ensure safe and proper use of the OMRON Inverters, please read this USER’S MANUAL (Cat.

No. I516-E1) to gain sufficient knowledge of the devices, safety information, and precautions before actual use.

2. The products are illustrated without covers and shieldings for closer look in this USER’S MANUAL. For actual use of the products, make sure to use the covers and shieldings as specified.

3. This USER’S MANUAL and other related user’s manuals are to be delivered to the actual end

users of the products.

4. Please keep this manual close at hand for future reference.

5. If the product has been left unused for a long time, please inquire at our sales representative.

NOTICE

1. This manual describes the functions of the product and relations with other products. You

should assume that anything not described in this manual is not possible.

2. Although care has been given in documenting the product, please contact your OMRON

representative if you have any suggestions on improving this manual.

3. The product contains potentially dangerous parts under the cover. Do not attempt to open

the cover under any circumstances. Doing so may result in injury or death and may damage

the product. Never attempt to repair or disassemble the product.

4. We recommend that you add the following precautions to any instruction manuals you prepare for the system into which the product is being installed.

Precautions on the dangers of high-voltage equipment.

Precautions on touching the terminals of the product even after power has been

turned off. (These terminals are live even with the power turned off.)

5. Specifications and functions may be changed without notice in order to improve product

performance.

Items to Check when Unpacking

Check the following items when removing the product from the package:

Has the correct product been delivered (i.e., the correct model number and speci-

fications)? Check the nameplate as shown below.

Inverter model

Input specification

Output specification

Has the product been damaged in shipping?

Are any screws or bolts loose?

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual.

Always heed the information provided with them. Failure to heed precautions can result in

injury to people or damage to property.

!

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death

!

or serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor

!

or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products,

often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 4

General Precautions

Observe the following precautions when using the SYSDRIVE Inverters and peripheral

devices.

This manual may include illustrations of the product with protective covers removed in order

to describe the components of the product in detail. Make sure that these protective covers

are on the product before use.

Consult your OMRON representative when using the product after a long period of storage.

WARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

!

WARNING Operation, maintenance, or inspection must be performed after turning OFF the

!

power supply, confirming that the CHARGE indicator (or status indicators) are OFF,

and after waiting for the time specified on the front cover. Not doing so may result in

electrical shock.

WARNING Do not damage, pull on, apply stress to, place heavy objects on, or pinch the cables.

!

Doing so may result in electrical shock.

WARNING Do not touch the rotating parts of the motor under operation. Doing so may result in

!

injury.

WARNING Do not modify the product. Doing so may result in injury or damage to the product.

!

Caution Do not store, install, or operate the product in the following places. Doing so may

!

result in electrical shock, fire or damage to the product.

Locations subject to direct sunlight.

Locations subject to temperatures or humidity outside the range specified in the

specifications.

Locations subject to condensation as the result of severe changes in temperature.

Locations subject to corrosive or flammable gases.

Locations subject to exposure to combustibles.

Locations subject to dust (especially iron dust) or salts.

Locations subject to exposure to water, oil, or chemicals.

Locations subject to shock or vibration.

Caution Do not touch the Inverter radiator, regenerative resistor, or Servomotor while the

!

power is being supplied or soon after the power is turned OFF . Doing so may result in

a skin burn due to the hot surface.

Caution Do not conduct a dielectric strength test on any part of the Inverter. Doing so may

!

result in damage to the product or malfunction.

Caution Take appropriate and sufficient countermeasures when installing systems in the fol-

!

lowing locations. Not doing so may result in equipment damage.

Locations subject to static electricity or other forms of noise.

Locations subject to strong electromagnetic fields and magnetic fields.

Locations subject to possible exposure to radioactivity.

Locations close to power supplies.

Page 5

Transportation Precautions

Caution Do not hold by front cover or panel , instead, hold by the radiation fin (heat sink) while

!

transporting the product. Doing so may result in injury.

Caution Do not pull on the cables. Doing so may result in damage to the product or malfunc-

!

tion.

Caution Use the eye-bolts only for transporting the Inverter. Using them for transporting th e

!

machinery may result in injury or malfunction.

Installation Precautions

WARNING Provide an appropriate stopping device on the machine side to secure safety. (A

!

holding brake is not a stopping device for securing safety.) Not doing so may result in

injury.

WARNING Provide an external emergency stopping device that allows an instantaneous stop of

!

operation and power interruption. Not doing so may result in injury.

Caution Be sure to install the product in the correct direction and provide specified clear-

!

ances between the Inverter and control panel or with other devices. Not doing so

may result in fire or malfunction.

Caution Do not allow foreign objects to enter inside the product. Doing so may result in fire or

!

malfunction.

Caution Do not apply any strong impact. Doing so may result in damage to the product or

!

malfunction.

Wiring Precautions

WARNING Wiring must be performed only after confirming that the power supply has been

!

turned OFF. Not doing so may result in electrical shock.

WARNING Wiring must be performed by authorized personnel. Not doing so may result in

!

electrical shock or fire.

WARNING Be sure to confirm operation only after wiring the emergency stop circuit. Not doing

!

so may result in injury.

WARNING Always connect the ground terminals to a ground of 100 Ω or less for the 200-V AC

!

class, or 1 0 Ω or less for the 400-V AC class. Not connecting to a proper ground may

result in electrical shock.

Page 6

Caution Install external breakers and take other safety measures against short-circuiting in

!

external wiring. Not doing so may result in fire.

Caution Confirm that the rated input voltage of the Inverter is the same as the AC power sup-

!

ply voltage. An incorrect power supply may result in fire, injury, or malfunction.

Caution Connect the Braking Resistor and Braking Resistor Unit as specified in the manual.

!

Not doing so may result in fire.

Caution Be sure to wire correctly and securely. Not doing so may result in injury or damage to

!

the product.

Caution Be sure to firmly tighten the screws on the terminal block. Not doing so may result in

!

fire, injury, or damage to the product.

Caution Do not connect an AC power to the U, V, or W output. Doing so may result in damage

!

to the product or malfunction.

Operation and Adjustment Precautions

WARNING Turn ON the input power supply only after mounting the front cover, terminal covers,

!

bottom cover, Operator, and optional items. Not doing so may result in electrical

shock.

WARNING Do not remove the front cover, terminal covers, bottom cover, Operator, or optional

!

items while the power is being supplied. Doing so may result in electrical shock or

damage to the product.

WARNING Do not operate the Operator or switches with wet hands. Doing so may result in

!

electrical shock.

WARNING Do not touch the inside of the Inverter. Doing so may result in electrical shock.

!

WARNING Do not come close to the machine when using the error retry function because the

!

machine may abruptly start when stopped by an alarm. Doing so may result in injury.

WARNING Do not come close to the machine immediately after resetting momentary power

!

interruption to avoid an unexpected restart (if operation is set to be continued in the

processing selection function after momentary power interruption is reset). Doing so

may result in injury.

WARNING Provide a separate emergency stop switch because the STOP Key on the Operator

!

is valid only when function settings are performed. Not doing so may result in injury.

Page 7

WARNING Be sure to confirm that the RUN signal is turned OFF before turning ON the power

!

supply, resetting the alarm, or switching the LOCAL/REMOTE selector. Doing so

while the RUN signal is turned ON may result in injury.

Caution Be sure to confirm permissible ranges of motors and machines before operation

!

because the Inverter speed can be easily changed from low to high. Not doing so

may result in damage to the product.

Caution Provide a separate holding brake when necessary. Not doing so may result in injury.

!

Caution Do not perform a signal check during operation. Doing so may result in injury or dam-

!

age to the product.

Caution Do not carelessly change settings. Doing so may result in injury or damage to the

!

product.

Maintenance and Inspection Precautions

WARNING Do not touch the Inverter terminals while the power is being supplied.

!

WARNING Maintenance or inspection must be performed only after turning OFF the power

!

supply, confirming that the CHARGE indicator (or status indicators) is turned OFF,

and after waiting for the time specified on the front cover. Not doing so may result in

electrical shock.

WARNING Maintenance, inspection, or parts replacement must be performed by authorized

!

personnel. Not doing so may result in electrical shock or injury.

WARNING Do not attempt to take the Unit apart or repair. Doing either of these may result in

!

electrical shock or injury.

Caution Carefully handle the Inverter because it uses semiconductor elements. Careless

!

handling may result in malfunction.

Caution Do not change wiring, disconnect connectors, the Operator, or optional items, or

!

replace fans while power is being supplied. Doing so may result in injury, damage to

the product, or malfunction.

Page 8

Warning Labels

Warning labels are pasted on the product as shown in the following illustration. Be sure to

follow the instructions given there.

Warning Labels

Contents of Warning

Page 9

Checking Before Unpacking

Checking the Product

On delivery, always check that the delivered product is the SYSDRIVE 3G3MV Inverter that you

ordered.

Should you find any problems with the product, immediately contact your nearest local sales

representative.

Checking the Nameplate

Inverter model

Input specifications

Output specifications

Checking the Model

3G3FV-A2037-CUE

Specifications

None Japanese model

-E English model

-CE Model conforming to EN standards

-CUE Model conforming to EN and UL/cUL

standards

3G3FV-A2001

Specifications

Maximum applicable motor capacity

Voltage class

Installation type

Series name: 3G3MV Series

Page 10

Maximum Applicable Motor Capacity

004 0.4 kW

007 0.75 kW

015 1.5 kW

022 2.2 kW

037 3.7 kW

055 5.5 kW

075 7.5 kW

110 11 kW

150 15 kW

185 18.5 kW

220 22 kW

300 30 kW

370 37 kW

450 45 kW

550 55 kW

750 75 kW

11K 110 kW

16K 160 kW

18K 185 kW

22K 220 kW

30K 300 kW

Voltage Class

2 Three-phase 200-V AC input (200-V class)

4 Three-phase 400-V AC input (400-V class)

Installation Type

A Panel-mounting (IP10 min.) or closed wall-mounting models

C Closed wall-mounting models (IP00 min.)

Checking for Damage

Check the overall appearance and check for damage or scratches resulting from transportation.

Checking the Accessories

Note that this manual is the only accessory provided with the 3G3MV. Set screws and other necessary

parts must be provided by the user.

Page 11

About this Manual

This manual is divided into the chapters described in the following table. Information is organized by

application area to enable you to use the manual more efficiently.

Chapter Contents

Chapter 1 Overview Describes features and nomenclature. Also describes new functions.

Chapter 2 Installation Provides information required for system design, such as product

dimensions, installation dimensions, peripheral device design

information, and peripheral device selection information.

Chapter 3 Preparing for Operation Describes nomenclature, Digital Operator procedures, such as key

operations, for operating and monitoring Inverters, and mode contents

and configuration.

Chapter 4 Trial Operation Describes the method for controlling operation through a Digital

Operator to perform trial operation of the system.

Chapter 5 Basic Operation Describes basic Inverter control functions for users not familiar with

Inverters. The functions that must be understood to drive a motor with

an Inverter are described. Each of the four control modes of the

3G3FV-series Inverters is described in order alone with the settings

required for all modes and individual modes. Refer to the information

for all control modes and then to items required for the control mode

you will be using.

Chapter 6 Advanced Operation Describes all of the functions provided by the Inverter. These functions

will enable more advanced applications, and includes functions that

will improve motor control through the Inverter, such as

responsiveness (torque characteristics), increasing speed accuracy,

PID control, torque limits, torque controls, overtorque detection,

protective functions, and other functions. Each of the four control

modes of the 3G3FV-series Inverters is described in order alone with

the characteristics of each mode and fountains common to all modes.

Refer to the information for all control modes and then to items

required for the control mode you will be using.

Chapter 7 List of Parameters Lists basic information on Inverter parameters as a reference for users

already familiar with Inverter operation. Parameters are listed in order

with the page numbers of further information for easy reference.

Chapter 8 Maintenance Operations Provides maintenance, inspection, fault analysis, and troubleshooting

information required to deal with problems that may occur during

operation.

Chapter 9 Specifications Provides Inverter specifications, as well as the specifications and

dimensions of peripheral devices.

Page 12

Read and Understand this Manual

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

БББББББББББББББББББББББББББББББ

a period of one year (or other period if specified) from date of sale by OMRON.

БББББББББББББББББББББББББББББББ

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

БББББББББББББББББББББББББББББББ

NON–INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR P ARTICULAR PURPOSE OF THE

БББББББББББББББББББББББББББББББ

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

БББББББББББББББББББББББББББББББ

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

БББББББББББББББББББББББББББББББ

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

БББББББББББББББББББББББББББББББ

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

БББББББББББББББББББББББББББББББ

STRICT LIABILITY.

БББББББББББББББББББББББББББББББ

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

БББББББББББББББББББББББББББББББ

which liability is asserted.

БББББББББББББББББББББББББББББББ

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

БББББББББББББББББББББББББББББББ

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

БББББББББББББББББББББББББББББББ

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

БББББББББББББББББББББББББББББББ

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 13

Application Considerations

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

БББББББББББББББББББББББББББББББ

the combination of products in the customer’s application or use of the products.

БББББББББББББББББББББББББББББББ

At the customer’s request, OMRON will provide applicable third party certification documents identifying

БББББББББББББББББББББББББББББББ

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

БББББББББББББББББББББББББББББББ

complete determination of the suitability of the products in combination with the end product, machine,

БББББББББББББББББББББББББББББББ

system, or other application or use.

БББББББББББББББББББББББББББББББ

The following are some examples of applications for which particular attention must be given. This is not

БББББББББББББББББББББББББББББББ

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

БББББББББББББББББББББББББББББББ

uses listed may be suitable for the products:

БББББББББББББББББББББББББББББББ

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

БББББББББББББББББББББББББББББББ

or uses not described in this manual.

БББББББББББББББББББББББББББББББ

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

БББББББББББББББББББББББББББББББ

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

БББББББББББББББББББББББББББББББ

industry or government regulations.

БББББББББББББББББББББББББББББББ

• Systems, machines, and equipment that could present a risk to life or property.

БББББББББББББББББББББББББББББББ

Please know and observe all prohibitions of use applicable to the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOL VING SERIOUS RISK TO LIFE OR

БББББББББББББББББББББББББББББББ

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERL Y RATED AND

БББББББББББББББББББББББББББББББ

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

БББББББББББББББББББББББББББББББ

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

БББББББББББББББББББББББББББББББ

consequence thereof.

Page 14

Disclaimers

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

CHANGE IN SPECIFICATIONS

БББББББББББББББББББББББББББББББ

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

БББББББББББББББББББББББББББББББ

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

БББББББББББББББББББББББББББББББ

key specifications for your application on your request. Please consult with your OMRON representative

БББББББББББББББББББББББББББББББ

at any time to confirm actual specifications of purchased products.

БББББББББББББББББББББББББББББББ

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

БББББББББББББББББББББББББББББББ

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

БББББББББББББББББББББББББББББББ

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

БББББББББББББББББББББББББББББББ

must correlate it to actual application requirements. Actual performance is subject to the OMRON

БББББББББББББББББББББББББББББББ

Warranty and Limitations of Liability.

БББББББББББББББББББББББББББББББ

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

БББББББББББББББББББББББББББББББ

ERRORS AND OMISSIONS

Page 15

How to Change the Digital Operator Display from

Japanese to English

If the Digital Operator displays messages in Japanese, change to the English mode using

the following steps.

(This manual provides descriptions for the English mode.)

Power ON

<Ć3J=3 <Z2

U1Ć01= 0.00 HZ

FV* S0D^>]@8 *

D^W2L^ S0D^

FV* S0D^>]@8 *

6]7.3>/C2

9^]:^>]@8

FN]:^

A1Ć00= 1 **

FN]:^

A1Ć00= 0

English

Entry Accepted

** Main Menu **

Operation

Select Language

English

Page 16

Table of Contents

Chapter 1. Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Functions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Nomenclature 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 New Functions 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Software Ver. VSG101040 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Software Ver. VSG101043 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-3 Software Ver. VSG101113 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-4 Software Ver. VSG101114 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Installation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Mounting 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Dimensions 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Installation Conditions 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 Removing and Mounting the Front Cover 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Terminals 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Standard Connection Diagram 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Wiring Around the Main Circuit 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 Wiring Control Circuit Terminals 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-6 Installing and Wiring PG Speed Control Cards 2-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3. Preparing for Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Using the Digital Operator 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Modes 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Operation Mode 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Initialize Mode 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Program Mode 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Auto-tuning Mode 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Modified Constants Mode 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Operation Mode Selection Key and Local/Remote Selection Input 3-31. . . . . . . . . . . . . . . . . . . . .

Chapter 4. Trial Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Procedure 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Operation Example 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 Power Connection 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-2 Checking the Display Status 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-3 Initializing Parameters 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-4 Setting Input Voltage 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-5 Auto-tuning 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-6 No-load Operation 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-7 Actual Load Operation 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5. Basic Operation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Common Settings 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 Setting the Access Level and Control Mode 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Frequency Reference Settings from Control Circuit Terminals 5-4. . . . . . . . . . . . . . . . . .

5-1-3 Frequency Reference Settings from Digital Operator 5-8. . . . . . . . . . . . . . . . . . . . . . . . .

5-1-4 Run Source and Responsiveness Settings 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 17

Table of Contents

5-1-5 Acceleration/Deceleration Time Settings 5-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-6 Disabling Reverse Operation (b1-04) 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-7 Selecting the Stopping Method (b1-03) 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-8 Multi-function Input Settings (H1-01 through H1-06) 5-15. . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Open-loop Vector Control 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-1 Auto-tuning Procedure 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-2 Auto-tuning Faults 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 V/f Control 5-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-1 Setting the Motor Parameters 5-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3-2 V/f Pattern Selection (E1-03) 5-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Flux Vector Control 5-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-1 PG Speed Control Card Settings 5-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-2 Setting the Zero-speed Operation Parameters 5-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-3 Auto-tuning 5-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-4 Speed Loop (ASR) Structure 5-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4-5 Adjusting Speed Control Loop (ASR) Gain 5-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 V/f Control with PG 5-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5-1 Setting the Motor Parameters 5-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5-2 V/f Pattern Selection (E1-03) 5-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5-3 PG Speed Control Card Settings 5-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5-4 Speed Loop (ASR) Structure 5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5-5 Adjusting Speed Control Loop (ASR) Gain 5-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6. Advanced Operation 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Open-loop Vector Control 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-1 Summary of Open-loop Vector Control Functions 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-2 Torque Limit Function 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-3 Adjusting Speed Feedback 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-4 Setting Magnetic Flux Characteristics for Open-loop Vector Control 6-6. . . . . . . . . . . . .

6-1-5 Operation for Saturated Output Voltage 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-6 Startup Torque Compensation 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-7 Selecting Auto-tuning Carrier Frequency 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1-8 Setting/Adjusting Motor Parameters 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Normal V/f Control 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1 Summary of V/f Control Functions 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2 Energy-saving Control Function 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-3 Hunting-prevention Function 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-4 Setting Motor Parameters 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Flux Vector Control 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-1 Summary of Flux Vector Control Functions 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-2 Droop Control Function 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3 Zero-servo Function (Position-lock) 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-4 Torque Control 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-5 Speed/Torque Control Switching Function 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-6 Torque Limit Function 6-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-7 Setting/Adjusting Motor Parameters 6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-8 Operation for Saturated Output Voltage 6-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-9 Selecting Auto-tuning Carrier Frequency 6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 V/f Control With PG Feedback 6-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-1 Summary of V/f Control With PG Feedback Functions 6-36. . . . . . . . . . . . . . . . . . . . . . . .

6-4-2 Energy-saving Control Function 6-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4-3 Hunting-prevention Function 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 18

Table of Contents

6-4-4 Setting Motor Parameters 6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Common Functions 6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-1 Summary of Common Control Functions 6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-2 Application Parameters (b) 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-3 Tuning Parameters (C) 6-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-4 Reference Parameters (d) 6-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-5 Motor Parameters (E) 6-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-6 Option Parameters (F) 6-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-7 External Terminal Functions: H 6-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-8 Protective Functions: L 6-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5-9 Operator Parameters: o 6-110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7. Parameter Lists 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

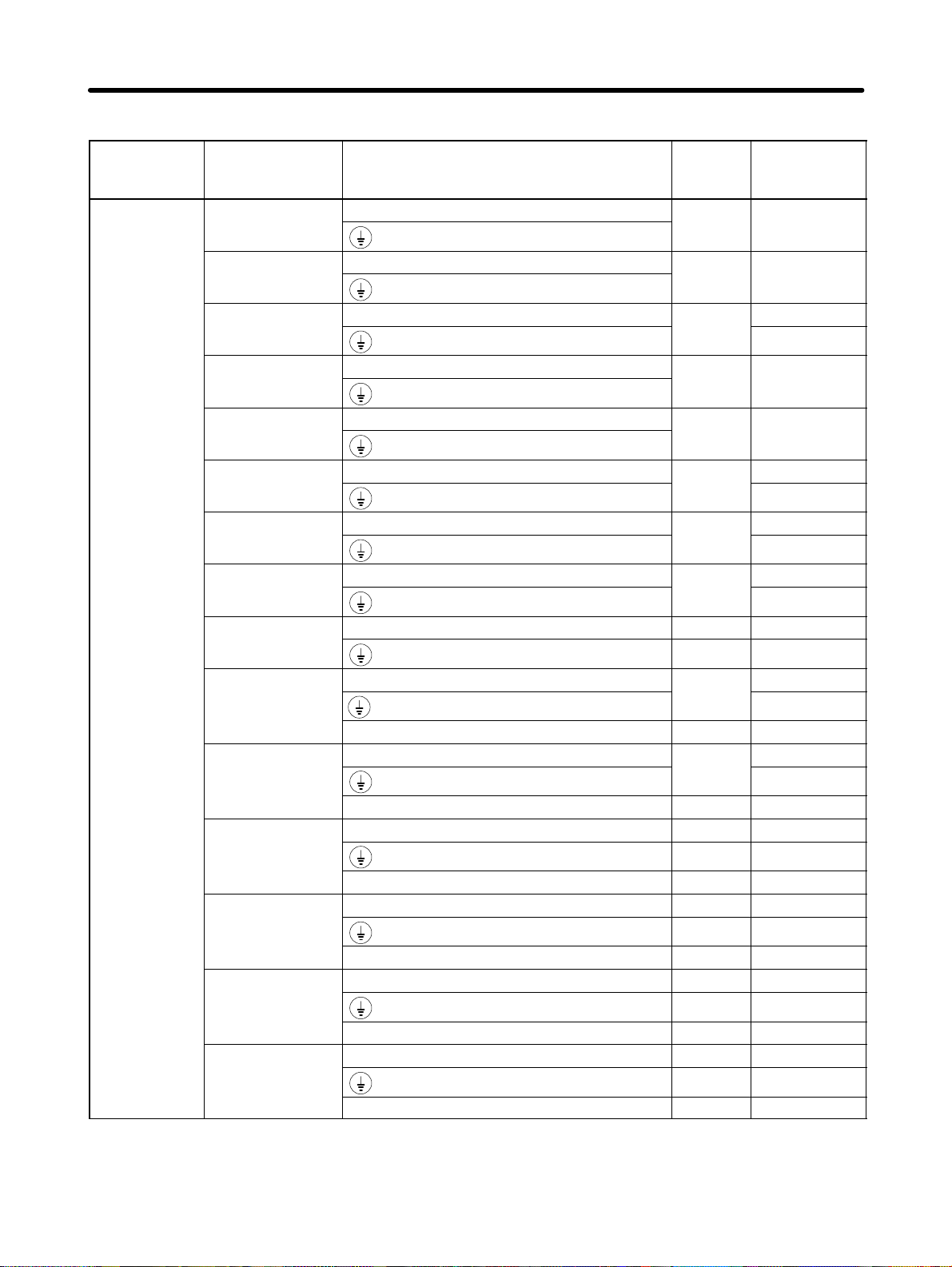

7-1 Initialize Mode Parameters 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Program Mode Parameter List 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-1 Application Group: b 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-2 Tuning Parameters 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-3 Reference Parameters List 7-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-4 Motor Constant Parameter Lists 7-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-5 Options Parameter Lists 7-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-6 Terminal Parameter Lists 7-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-7 Protection Parameter Lists 7-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2-8 Operator Parameter Lists 7-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8. Maintenance Operations 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Protective and Diagnostic Functions 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1-1 Fault Detection 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1-2 Minor Fault Detection 8-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1-3 Operation Errors 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Troubleshooting 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Maintenance and Inspection 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9. Specifications 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1 Inverter Specifications 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Option Specifications 9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10. Appendix 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1 Notes on Using the Inverter for a Motor 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History R-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 19

Introduction

1-1 Function

1-2 Nomenclature

1-3 New Functions

1

Chapter 1

Page 20

Introduction Chapter 1 1-1 Functions

The general-purpose SYSDRIVE 3G3FV Inverter provides full current vector control

based on adv a n c e d c o n trol logic. An auto-tuning function allows for easy vector control.

The Digital Operator’s display area features a 2-line by 16-character liquid crystal display. Parameters can be displayed in up to seven languages, including Japanese. The

parameter settings and monitor items can be understood at a glance, providing an interactive feel during operation.

1-2

Page 21

yp

pyp

yp

pyp

Introduction Chapter 1

SYSDRIVE 3G3FV Inverter Models

• The following 200- and 400-V class 3G3FV Inverter models are available.

• A total of 21 types of Inverters are available for maximum applicable motor capacities of 0.4 to 300 kW.

Voltage class Protective structure Maximum applied motor capacity Model

200-V class

(3-phase)

400-V class

(3-phase)

NEMA1 type

Open chassis type

NEMA1 type

Open chassis type

0.4 kW 3G3FV-A2004

0.75 kW 3G3FV-A2007

1.5 kW 3G3FV-A2015

2.2 kW 3G3FV-A2022

3.7 kW 3G3FV-A2037

5.5 kW 3G3FV-A2055

7.5 kW 3G3FV-A2075

11 kW 3G3FV-A2110

15 kW 3G3FV-A2150

18.5 kW 3G3FV-B2185

22 kW 3G3FV-B2220

30 kW 3G3FV-B2300

37 kW 3G3FV-B2370

45 kW 3G3FV-B2450

55 kW 3G3FV-B2550

75 kW 3G3FV-B2750-E

0.4 kW 3G3FV-A4004

0.75 kW 3G3FV-A4007

1.5 kW 3G3FV-A4015

2.2 kW 3G3FV-A4022

3.7 kW 3G3FV-A4037

5.5 kW 3G3FV-A4055

7.5 kW 3G3FV-A4075

11 kW 3G3FV-A4110

15 kW 3G3FV-A4150

18.5 kW 3G3FV-B4185

22 kW 3G3FV-B4220

30 kW 3G3FV-B4300

37 kW 3G3FV-B4370

45 kW 3G3FV-B4450

55 kW 3G3FV-B4550

75 kW 3G3FV-B4750-E

110 kW 3G3FV-B411K-E

160 kW 3G3FV-B416K-E

185 kW 3G3FV-B418K-E

220 kW 3G3FV-B422K-E

300 kW 3G3FV-B430K-E

1-3

Page 22

Introduction Chapter 1

Selection of Modes for Vector Control and V/f Control

• The 3G3FV has the following four control modes.

Open-loop vector control (without PG*) [Factory default]

Flux vector control (with PG)

V/f control (without PG)

V/f control (with PG)

*PG stands for “pulse generator” (encoder).

• Vector control is a method for removing interferences with magnetic flux and torque, and controlling

torque according to references. Current vector control independently controls magnetic flux current

and torque current by simultaneously controlling the motor’s primary current and its phases. This allows smooth rotation and high torque, along with accurate speed and torque control, at very low

speeds.

• Vector control can be replaced from the conventional V/f control system. If the motor parameter required for vector control is unknown, it can be set automatically with the auto-tuning function.

• The respective control modes are effective for the following applications:

Open-loop vector control (without PG): General variable speed drive

Flux vector control (with PG): Simple servo-drive, high-precision speed control, torque control

V/f control (without PG): Conventional Inverter control mode. Used for multiple drives.

V/f control (with PG): Simple speed feedback control

• The control characteristics for each mode are shown in the following table.

Vector control V/f control

Without PG With PG Without PG With PG

Speed control range 1:100 1:1,000 1:40 1:40

Speed control precision ±0.2% ±0.02% ±2 to 3% ±0.03%

Starting torque 150% at 1 Hz 150% at 0 Hz 150% at 3 Hz

Auto-tuning Function

• This function is valid with vector control.

• The motor parameters are set automatically just by entering the motor’s rating plate value. This fea-

ture allows flux vector control to operate accurately with virtually any normal AC induction motor

regardless of the supplier.

Torque Control

• This function is valid with flux vector control (with PG).

• Torque is controlled by taking multi-function analog input signals as torque references.

• Switching is possible between torque control and speed control.

V/f Pattern Settings

• This function is valid for V/f control.

• Select a V/f pattern according to the application from among the 15 preset V/f patterns.

1-4

Page 23

Introduction Chapter 1

• Custom V/f pattern can be set.

Frequency References

• The following five types of frequency references can be used to control the output frequency of the

Inverter.

Numeric input from the Digital Operator

Voltage input within a range from 0 to 10 V

Voltage input within a range from 0 to ±10 V (With minus voltage, rotation is in the opposite direc-

tion of the run command.)

Current input within a range from 4 to 20 mA

Input by Optional Card

The Inverter can be set to use any of the above types by designating it with parameters.

• A maximum of eight frequency references can be registered in the Inverter. Including inching, this

enables multi-step speed operation with up to nine speed steps via remote multi-step reference

inputs.

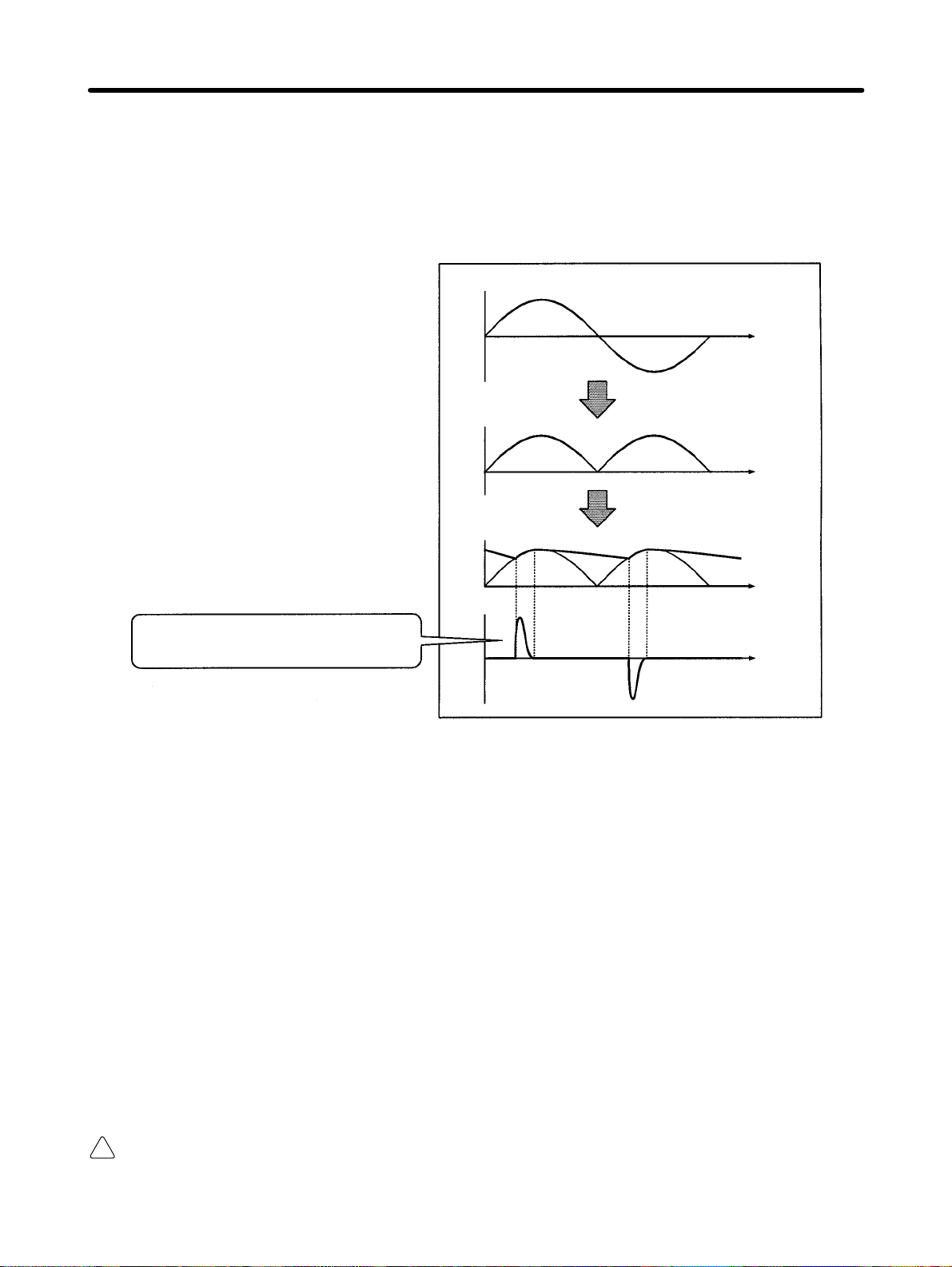

PID Control

• The Inverter has a PID control function, enabling easy follow-up control.

• Follow-up control is a control method in which the Inverter varies the output frequency to match the

feedback value from the sensor with the set target value.

• Follow-up control can be applied to a variety of control operations, depending on the contents

detected by the sensor.

• PID control is available for the following applications.

Speed control: With a speed sensor, such as a tacho-generator, the Inverter regulates the

rotation speed of the motor regardless of the load of the motor or synchronizes the rotation speed of the motor with that of another motor.

Pressure control: With a pressure sensor, the Inverter performs constant pressure control.

Flow-rate control: By sensing the flow rate of a fluid, the Inverter performs precise flow-rate

control.

Temperature control: With a temperature sensor, the Inverter performs temperature control by

fan speed.

Zero-servo Control

• This function is valid with vector control (with PG).

• Even at a motor speed of zero (0 Hz), a torque of 150% of the motor’s rated torque can be generated

and the average servomotor holding power (stopping power) can be obtained.

Speed Control By Feedback

• This function is valid with PG.

• An optional PG Speed Control Card be used to enable feedback control for speeds, thereby improving

speed control accuracy.

1-5

Page 24

Introduction Chapter 1

Dwell Function

• By holding the output frequency for a constant time during acceleration and deceleration, acceleration

and deceleration can be performed without stepping out even when driving a motor with a large startup load.

Low Noise (0.4- to 160-kW Models)

• The output transistor of the Inverter is an IGBT (insulated gate bipolar transistor). Using a sine-wave

PWM method with a high-frequency carrier, the motor does not generate metallic noise.

Monitor Function

• The following items can be monitored with the Digital Operator.

Frequency reference, output frequency, output current, motor speed, output voltage reference,

main-circuit DC voltage, output power, torque reference, status of input terminals, status of output

terminals, operating status, total operating time, software number, speed deviation value, PID feedback value, fault status, fault history, etc.

• All types of data can be monitored even with multi-function analog output.

Seven-language Digital Operator (from Software Ver. VSG101113)

• Application a s a global inverter is enabled by displays in Japanese, English, French, German, Italian,

Spanish, or Portuguese.

• The Digital Operator area utilizes a 16-character x 2-line liquid crystal display. Parameter setting items

and monitor display can be easily read in any of seven languages to operate the Inverter in a conversational style.

Harmonic Countermeasures (0.4- to 160-kW Models)

• DC reactors (optional) can be connected to 0.4- to 15-kW models.

• Models of 18.5 to 160 kW have a built-in DC reactor.

Parameter Hierarchy and Three Types of Access Levels

• The 3G3FV has a number of parameters for carrying out the various functions. These parameters are

classified into hierarchical levels to make them easier to use. The levels are as follows, from top to

bottom: Mode Group Function Parameter.

Level name Contents

Mode Classified according to operation

Operation mode: For operating the Inverter. (All kinds of monitoring

are possible.)

Initialize mode: For selecting the language displayed at the Digital

Operator , setting access levels, and initializing.

Program mode: For setting parameters for operation.

Auto-tuning mode: For automatic calculation or setting motor

parameters. (Only under the vector control mode.)

Modified constants mode: For setting or referencing parameters

changes after shipping.

Group Classified by application.

Function Classified by function.

Parameter Individual parameter settings.

1-6

Page 25

Introduction Chapter 1

• The 3G3FV allows the following three kinds of access levels to be set in order to further simplify parameter setting. (An access level is a range of parameters that can be set or referenced.)

Quick-start: Sets/reads parameters required for trial operation. [Factory setting]

Basic: Sets/reads parameters that are commonly used.

Advanced: Sets/reads all the parameters that can be used.

• In general, press the Enter Key to move from an upper to a lower level. This varies somewhat, however, according to the access level, as shown in the following diagram. For the Quick-start access level,

which has few parameters that can be set, pressing the Enter Key jumps directly to the Parameter

level; whereas for the Advanced access level, which has many, pressing the Enter Key first leads to

the Group level.

[Mode] [Group] [Function] [Parameter]

MENU

Operation mode

Initialize mode

Program mode

Auto-tuning

mode

Modified

constants mode

b Application

ADVANCED

BASIC

c Tuning

b1 Sequence b1-01 Reference source

b1-02 Run source

QUICK-START

b2 DC braking

b3 Speed search

C1 Accel/Decel

b1-03 Stopping method

b2-01 Zero speed level

b2-02 DC injection braking current

b3-01 Beginning speed search

b3-02 Speed search operation current

C1-01 Accel Time 1

C1-02 Decel Time 1

1-7

Page 26

Introduction Chapter 1 1-2 Nomenclature

Panel

Protection cover (top and bottom)

Mounting hole

Heat sink

Digital Operator

Front cover

Terminals

1-8

Page 27

Introduction Chapter 1

Terminals (with Front Cover Removed)

Example: 200-V Class Inverter with 0.4-kW Output

Control

circuit

terminals

Main circuit

terminals

Power input

Braking Resistor

Motor output

1-9

Page 28

Introduction Chapter 1

Digital Operator

Operation Mode Indicators

DRIVE: Lit when in operation mode.

FWD: Lit when there is a forward command input.

REV: Lit when there is a reverse command input.

SEQ: Lit when the forward/reverse command from

REF: Lit when the frequency reference from

Two-line LCD that displays data for monitoring,

parameter names, and set values with 16 characters per line.

Execute operations such as setting parameters,

monitoring, JOG, and auto-tuning.

the control circuit terminal is enabled.

control circuit terminals 13 and 14 is enabled.

Data Display

Keys

Key Name Function

Operation Mode

Selection Key

Switches between Operator and parameter setting (run command and

frequency reference). This key can be enabled or disabled with a

parameter setting (o2-02).

Menu Key Displays each mode.

Escape Key Returns to the status before the Enter Key is pressed.

Jog Key Enables JOG operation when the 3G3FV is in operation with the

Digital Operator.

Forward/Reverse

Rotation Selection Key

Reset/Digit Selection

Key

Selects the rotation direction of the motor when the 3G3FV is in

operation with the Digital Operator.

Selects digits for parameter settings. Also acts as the reset key when

an fault has occurred. (see note)

Increment Key Selects modes, groups, functions, parameter names, and set values.

This key increases numbers when pressed.

Decrement Key Selects modes, groups, functions, parameter names, and set values.

This key decreases numbers when pressed.

Enter Key Enters modes, functions, parameters, and set values after they are

set.

Run Key Starts the 3G3FV running when the 3G3FV is in operation with the

Digital Operator.

Stop Key Stops the 3G3FV running. This key can be enabled or disabled with a

parameter setting (o2-02) in operation with the control circuit terminal.

Note For safety reasons, the reset operation will not function when a forward or reverse run command

is being input. Use the reset after turning OFF the run command.

1-10

Page 29

Introduction Chapter 1 1-3 New Functions

The following software versions have been implemented for the 3G3FV Series to add

and upgrade functions.

August 1996: Software Ver. VSG101032 (S1032)

April 1997: Software Ver. VSG101040 (S1040)

Sept. 1998: Software Ver. VSG101043 (S1043)

Sept. 1999: Software Ver. VSG101113 (S1113)

Sept. 2000: Software Ver. VSG101114 (S1114)

The software version can be confirmed using the 5-digit number display for the FLASH

ID for U1-14.

This section describes the new functions and improvements for each software version.

Refer to Chapter 5 Basic Operation and Chapter 6 Advance Operation.

1-3-1 Software Ver. VSG101040

CompoBus/D (DeviceNet) Communications Card

The CompoBus/D Communications Card can be used to connect the Inverter to a DeviceNet network.

The following function additions and improvements were made to support this new functionality.

CompoBus/D Addition to the Frequency Reference Selection (Parameter b1-01)

A function was added to Frequency Reference Selection so that the Inverter frequency reference can

be input via DeviceNet communications.

CompoBus/D Addition to the Run Source Selection (Parameter b1-02)

A function was added to Run Source Selection so that the Inverter run command can be input via DeviceNet communications.

Communications External Fault Input (Parameters F9-01 to F9-03)

A function was added to support an external fault input from DeviceNet communications to stop the

Inverter when an error occurs. Sequence settings and operation designation for errors for the communications external fault input have been added.

Two-motor Switching Control

A function was added to enable switching control between two motors using one Inverter. The following

function additions were made to support this new functionality.

Control Mode Setting Second Motor (Parameter E3-01)

A control mode setting was added so that the second motor can be set to a different mode.

Note The control mode setting was limited to 0 (

was changed in system version VSG101043 to support all control modes 0 to 3.

V/f control without PG) or 2 (open-loop vector control), but

V/f Pattern Settings for Second Motor (Parameters E4-01 to E4-06)

V/f pattern settings were added so that the second motor can be set to a different pattern.

1-11

Page 30

Introduction Chapter 1

Parameter Settings for Second Motor (Parameters E5-01 to E5-06)

Parameter settings were added so that different parameters can be set for the second motor.

Inverter Output Noise Reduction

The noise output by 400-V class Inverters was reduced to reduce the affect on peripheral devices and

conform to EN standards. The following function improvements were added to support noise reduction.

Default Setting Change for Carrier Frequency (Parameters C6-10 to C6-03)

The default carrier frequency setting for 400-V class Inverters was changed for the reduction of output

noise.

Inverter Overload Function Change (OL2 Detection)

The Inverter overload detection function was changed because the Inverter’s rated output current

would be reduced if it was set higher than the carrier frequency.

Note If an Inverter overload is detected before a motor overload (0L1), lower the Inverter’s carrier fre-

quency setting.

Operation Selection after Switching to Remote Mode (Parameter b1-07)

Operation can be switched between Digital Operator and the frequency reference (b1-01) and between

Digital Operator and the run command (b1-01) by setting the local/remote selection using the Digital

Operator’s operation mode selection key or multi-function inputs (H1-01 to H1-06). The new function

can be used to enable or disable run commands when switching between the two forms of operation.

Note If the run command is enabled when switching operation, the Inverter can start operation immedi-

ately after switching operation. You must take appropriate safety measures when using this function.

PG Disconnection Detection (PGO) Detection Time Setting (Parameter

F1-14)

A setting for PG disconnection (PGO) was added so that the detection time can be adjusted.

New Functions for Multi-function Inputs 1 to 6 (H1-01 to H1-06)

The following functions were added to the multi-function inputs.

• Sample/hold function for the analog frequency reference (setting: 1E)

• PID control integral reset (setting: 30)

Constant Output Area Settings for Flux Vector Control (E1-11 to E1-13)

Settings were added to enable controlling V/f characteristics to compensate voltage increases caused

by motor impedance when special motors, such as constant power-output motors and machine tool

shaft motors, are used in the constant output area.

Vector Control Adjustment Settings (C3-05, C5-08, C8-09, C8-30)

Adjustment functions were added for vector control.

1-12

Page 31

Introduction Chapter 1 1-3-2 Software Ver. VSG101043

CompoBus/D Communications Improved

The following functions were added for DeviceNet communications using a CompoBus/D Communications Card.

Network Reference/Network Control Support (CompoBus/D Communications

Remote I/O)

A function was added to switch between inputting the Inverter frequency reference and a run command

using CompoBus/D communications from remote I/O. The Network Reference Bit can be turned ON

and OFF to switch between the method set for the frequency reference selection (b1-01) and a frequency reference from communications. In the same way, the Network Control Bit can be turned ON

and OFF to switch between the method set for the run source selection (b1-02) and a run command

from communications.

Selection of Operation for Communications Errors (Parameter F9-06)

A setting was added to select the operation of the Inverter when a communications error is detected.

The selection can be made according to the application, e.g., a deceleration stop, free-run stop, continuing operation, etc.

Torque Limit/Torque Reference Operation Selection via Communications

(Parameter F9-05)

A function was added to set the torque limit and torque reference (for torque control) from communications. This enables controlling torque operation from communications when the vector with PG control

mode is used.

Note The CompoBus/D Communications Card does not support the torque limit/torque reference func-

tion. Leave this function disabled.

V/f Control with PG and Flux Vector Control for Two-motor Switching

Control (Parameter E3-01)

Settings were added for V/f Control with PG and Flux V ector Control to the control modes for the second

motor, enabling feedback control of 2 motors with 1 Inverter.

Note 1. Wiring for the pulse generator or encoder must be switched between the two motors.

Note 2. Use a pulse generator with the same specifications for both motors. (There is only one group

of parameters for the pulse generator.)

Motor Parameter Autotuning (Parameter C8-30)

An autotuning function was added to autotune the motor parameters for special motors.

Ground Fault Protection Operation Selection (Parameter: L8-10)

A setting was added to enabled and disable ground fault protection so that it can be disable when

required by the application.

1-13

Page 32

Introduction Chapter 1

Improved English Messages

The English messages displayed on the Digital Operator when the language is set to English (A1-00 =

0) have been improved.

1-3-3 Software Ver. VSG101113

Messages in 7 Languages

Application as a global inverter is enabled by displays in Japanese, English, French, German, Italian,

Spanish, or Portuguese.

Low-speed Rotation Inconsistencies Greatly Reduced

Improvements in the current detector for vector control and in the responsiveness of current control

have greatly reduced torque ripple. This greatly reduces the low-speed inconsistencies for the 3G3FV

Series.

Better Motor Speed Control Accuracy (Parameter C3-06)

Previously the motor speed control accuracy for vector control was greatly reduced when the limit of

Inverter’s voltage output was approached (a voltage greater than that of the input power supply cannot

be output). If the new output voltage control method is used, the output voltage will be controlled so that

the limit will not be reached, thus maintaining speed accuracy. The linear characteristic of torque control

has also been improved.

Note The current may increase by about 10% when this function is used. Be sure to select an Inverter

with ample output current capacity.

Improved Motor Parameter Autotuning

A new method has been added for autotuning to produce greater accuracy.

Improved PID Control

Additions have been made to PID control to increase the range of possible applications.

PID Control Reverse Characteristics (Parameter b5-09)

Previously, only positive characteristic PID control, in which the feedback value increases when the

Inverter’s output frequency increases, was possible. In addition to this, reverse characteristic PID control is now possible, in which the feedback value decreases when the Inverter’s output frequency

increases.

Frequency Reference + PID Control (Parameters b5-01 and b5-10)

A control method using the frequency reference and PID control has been added between the previous

frequency reference or PID control. This is ideal for applications in which the target speed is set, but fine

adjustments need to be made with PID control (such as tension control).

Reverse Motor Control for PID Control (Parameter b5-11)

Motor rotation in only one direction was possible for previous PID control, but a reverse control setting

has been added to produce rotation in the reverse direction when the PID control result is negative.

1-14

Page 33

Introduction Chapter 1

Feedback Loss Detection for PID Control (Parameters b5-12 to b5-14)

A function has been added to detect the loss of the feedback signal (e.g., as a result of line disconnection) and specify the operation when an error is detected.

PID Control Target Value Added to Multi-function Inputs (Parameters H3-05 and

H3-09)

A function was added so that both the analog frequency reference and the PID control target value can

be input as analog signals for frequency reference + PID control.

PID Integral Hold Added to Multi-function Inputs (Parameters H1-01 to H1-06)

A function was added to hold the the calculated integral value for PID control.

Jump Frequencies Added to PID Control (Parameters d3-01 to d3-04)

The setting disabled frequencies (jump frequencies) have been enabled for PID control. This function

can be used to avoid frequency ranges that cause machine vibration during PID control.

Motor Startup Responsiveness Improved

Compensation functions have been added to ensure faster motor startup.

Startup Torque Compensation Function for Open-loop Vector Control (Parameters

C4-03 to C4-05)

A startup torque compensation function has been added to ensure faster startup for open-loop vector

control. If this function is used, high torque can be output immediately after startup to enable better control of lifting and lowering operations for large machines with high friction or cranes.

Note This function cannot be used during regenerative condition or when using a second motor.

Magnetic Flex Compensation (Parameter b2-08)

Large-capacity motors have large electrical constants, and time is required to develop magnetic flex in

the motor after power has been turned ON. To improve this situation, a magnetic flex compensation

function has been added to the startup DC braking function, enabling magnetic flex to be built up in the

motor during DC braking.

Braking Function with Stall Prevention during Deceleration (Parameter

L3-04)

Even if regenerative energy is handled using a Braking Resistor or Braking Resistor Unit, overvoltages

(OV) can be detected during rapid deceleration. A stall prevention function for deceleration has been

added to the braking function (regeneration processing) to limit voltages when main circuit overvoltages

are likely to be detected, thus enabling faster braking without overvoltage detection.

Inverter Overload (OL2) Protection Selection for Low-speed Operation

(Parameters L8-17 and L8-19)

An Inverter overload protection operation selection has been added to protect from overcurrent damage at low speeds. This function allows the best protection to be selected according to the application.

1-15

Page 34

Introduction Chapter 1

Protection Setting for Motors for Vector Control (Parameter E1-02)

A special protection setting has been provided for vector-control motors, which have high resistance to

overloads even at low speeds.

Bias Function for Analog Monitor Cards (Parameters F4-05 and F4-06)

A bias function has been added to the analog output from Analog Monitor Cards to enable adjusting the

offset voltage.

NC Contact Emergency Stop Function for Multi-function Inputs

(Parameters d3-01 to d3-04)

An NC contact emergency stop function has been added to the previous NO function.

Bias Function for Reverse Motor Control for Multi-function Inputs

(Parameters H3-05 and H3-09)

A function has been added for reverse motor operation by establishing a frequency bias 2 (setting: D)

for the multi-function inputs that causes reverse operation when the sum of the bias values is negative.

Run Command Selection Outside of Drive Mode (Parameter b1-08)

A function has been added to enable or disable run command inputs in mode other than Drive Mode,

e.g., Program Mode or Initialize Mode.

Note If this function is used, a run command can be input and Inverter operation stared even when

adjusting parameters in Program Mode. Proper safety measures must be taken to prevent dangerous situations.

Motor Core Loss Adjustment for Torque Compensation (Parameter

E2-10)

A motor core loss setting has been added to enable fine adjustment of torque compensation (totally

automatic torque boast) in V/f control without PG and V/f control with PG control modes.

Changes in Default Settings and Setting Ranges

The defaults and setting ranges for the following parameters have been changed for applications.

Cumulative Operation Time Display Change (Parameter o2-07)

Previously 0 was display when the default value was set for the cumulative operation time, but this has

been changed to display the current cumulative operation time as the default.

New Parameter Setting Ranges

Parameter

number

E2-06 Motor leakage inductance All Inverters 0% to 30% 0% to 40%

E5-06 Motor 2 leakage inductance All Inverters 0% to 30% 0% to 40%

L2-03 Minimum baseblock time All Inverters 0.0 to 5.0 s 0.1 to 5.0 s

L8-02 Inverter overheat detection pre-

alarm level

Parameter name Applicable

Inverters

All Inverters 50 to 110°C 50 to 130°C

Previous setting

range

New setting

range

1-16

Page 35

Introduction Chapter 1

New Parameter Default Setting

Parameter

number

L2-04 Voltage restart time Inverters of

Parameter name Applicable

Inverters

55 kW or larger

Previous setting

range

0.6 s 1.0 s

New setting

range

1-3-4 Software Ver. VSG101114

PG Speed Deviation Detection Function Upgrade (F1-04)

This function has been changed so that the conditions can be selected for speed deviation (DEV) detection. Either of the following two conditions can be selected by means of an F1-04 parameter setting.

Detect only when the frequency reference matches the output frequency (within the range set in

L4-02).

Detect only when the frequency reference matches the PG feedback speed (within the range set

in L4-02).

1-17

Page 36

Installation

2-1 Mounting

2-2 Wiring

2

Chapter 2

Page 37

g

Installation Chapter 2 2-1 Mounting

2-1-1 Dimensions

3G3FV-A2004/-A2007/-A2015/-A2022/-A2037

3G3FV-A4004/-A4007/-A4015/-A4022/-A4037

External Dimensions Mounting Dimensions

Two, 5.5 dia.

Four, M5

200-V

400-V

2-2

Voltage class Model 3G3FV-

A2004/A2007/A2015 160

A2022/A2037 180

A4004/A4007 160

A4015/A4022/A4037 180

Dimensions (mm)

D

Page 38

Installation Chapter 2

3G3FV-A2055/-A2075/-A4055/-A4075

External Dimensions Mounting Dimensions

Two, 7 dia.

Four, M6

3G3FV-A2110/-A2150/-A4110/-A4150

External Dimensions Mounting Dimensions

Two, 7 dia.

20 (see note)

Four, M6

Note *The dashed lines apply only to the A2150.

2-3

Page 39

g

Installation Chapter 2

3G3FV-B2185/-B2220/-B4185/-B4220/-B4300/-B4450

External Dimensions Mounting Dimensions

Four, M6

Voltage class Model 3G3FV-

H H1 D1

200-V B2185/B2220 450 435 174.5

400-V

B4185/B4220 450 435 174.5

B4300/B4370/B4450 625 610 175

Dimensions (mm)

2-4

Page 40

g

Installation Chapter 2

3G3FV-B2300/-B2370/-B2450/-B2550/-B4550/-B4750-E

External Dimensions Mounting Dimensions

Two, 12 dia.

Four, M10

Voltage class Model 3G3FV-

W H W1 H1

200-V

400-V B4550/B4750-E 455 820 350 795

B2300B2370 425 675 320 650

B2450/B2550 475 800 370 775

Dimensions (mm)

2-5

Page 41

g

Installation Chapter 2

3G3FV-B2750-E/-B411K-E/-B416K-E

External Dimensions Mounting Dimensions

Two, 14 dia.

Four, M12

Voltage class Model 3G3FV-

D D2 W2

200-V B2750-E 400 max. 158 695

400-V

B411K-E 375 max. 130 695

B416K-E 400 max. 158 695

Dimensions (mm)

2-6

Page 42

Installation Chapter 2

3G3FV-B418K-E/-B422K-E

External Dimensions Mounting Dimensions

Six, 14 dia.

Six, M12

3G3FV-B430K-E

External Dimensions Mounting Dimensions

Six, 14 dia.

Six, M12

2-7

Page 43

Installation Chapter 2

Two, 4 dia.

Panel cutout

(for cables)

39

125

88

427

16

2-1-2 Installation Conditions

Panel face

Front side of panel

18.8

Back side of panel

30 min.

Cautions and Warnings

WARNING Provide an appropriate stopping device on the machine side to secure safety. (A

!

holding brake is not a stopping device for securing safety.) Not doing so may result in

injury.

WARNING Provide an external emergency stopping device that allows an instantaneous stop of

!

operation and power interruption. Not doing so may result in injury.

Caution Be sure to install the product in the correct direction and provide specified clear-

!

ances between the Inverter and control panel or with other devices. Not doing so

may result in fire or malfunction.

Caution Do not allow foreign objects to enter inside the product. Doing so may result in fire or

!

malfunction.

Caution Do not apply any strong impact. Doing so may result in damage to the product or

!

malfunction.

2-8

Page 44

Installation Chapter 2

Direction and Dimensions

• Install the Inverter on a vertical surface so that the characters on the nameplate are oriented upward.

• When installing the Inverter, always provide the following installation space to allow normal heat dis-

sipation from the Inverter.

W = 30 mm min.

Inverter Inverter Inverter

WWW

Installation Site

• Install the Inverter under the following conditions.

NEMA1 Type

Ambient temperature for operation: –10 to 40°C

Humidity: 90% RH or less (no condensation)

120 mm min.

120 mm min.

Air

Side

Air

Open Chassis Type

Ambient temperature for operation: –10 to 45°C

Humidity: 90% RH or less (no condensation)