OMP 70” FUSION Instruction Manual

70” FUSION

Instruction Manual

E50-E60 motor with 1900-2100 Watts

OHIO MODEL PRODUCTS, 199 Stratford Lane, Xenia, Ohio 45385, (937) 372-0603

Wingspan: 70"

Wing Area: 1045 sq. in.

Length: 69.5"

Approx. Weight: 7.25-7.75 lbs.

Engine: 1.20 glow, 20 cc gas

www.ohiomodelplanes.com

Thank you for purchasing the OMP Fusion Profile. In our continuing effort to bring the best in

performance to our customers, we have redesigned the highly popular 67” Fusion into a 70” model for both

electric and gas/glow versions. The Fusion was the first profile designed to perform precise and crisp pattern

and IMAC maneuvers effortlessly yet still retain the capability to let out all the stops for ultimate 3d flying.

Now you can evolve your flying skills to a new level without having to spend a fortune on an expensive pattern

or IMAC airplane as the Fusion offers the best of both worlds to the sport flyer at every level. You can learn

precision and 3D aerobatics at a very reasonable cost using reasonably priced radio equipment and readily

available glow or gas size sport motors and E50 size electric motors. Our Fusion offers the perfect blend of

aerodynamic design parameters which allow you to perform anything you can imagine: F3A pattern, IMAC

sequences, elevators, positive and inverted harriers, waterfalls, knife edge spins, positive and inverted flat spins,

and of course rock solid hovers and torque rolls. I hope you will enjoy the Fusion X3D Profile as much as we

have – Mike Pilkenton and John Drake.

A QUICK WORD ABOUT SAFETY AND RADIO CONTROL FLYING MODELS

With radio control aircraft, like any hobby or sport, there are certain risks. The operator of these models

is responsible for these risks. If misused or abused, you may cause serious bodily injury and/or damage to

property. With this in mind, you will want to be certain that you build your model carefully and correctly. If

you are not an experienced flier, have your work checked and ask for help in learning to fly safely. This model

aircraft is not a toy and must be operated and flown in a safe manner at all times. Always perform a pre-flight

check of the model including all control surfaces, proper function of the radio gear, structure, radio range, and

any other area relating to the safe operation of this aircraft.

Models are not insurable but operators are. You can obtain coverage through membership in the

Academy of Model Aeronautics (AMA). For an AMA information package call 1-800-435-9262, ext. 292 or

visit the AMA website at "

www.modelaircraft.org".

OHIO MODEL PRODUCTS GUARANTEE AND CUSTOMER SERVICE

Ohio Model Products guarantees this ARF to be free from defects in both material and workmanship at the

date of purchase. This does not cover any parts damaged by use, misuse, modification, or long term storage. In

no case shall OMP's liability exceed the original cost of this kit. Because OMP has no control over the final

assembly or equipment/components used in the final assembly, no liability shall be assumed for any damage

resulting from the use of this model by the user. By the act of using the final assembled model, the user accepts

all resulting liability. If at the time of purchase, you should find any missing or damaged parts, or have any

questions about this product, please contact us at omp@ohiomodelplanes.com or call OMP at (937) 372-0603.

ENGINES, PROPELLERS AND MUFFLERS

The recommended engine range for the Fusion is a 1.20 glow, a 20 cc gas, or E50-E60 size electric

motors that will produce 1900-2100 watts. There are a tremendous variety of engines available and each type

has its own advantages and disadvantages. Selecting the proper size of propeller for your particular engine is a

very important part of the whole set up. The Fusion, as all high performance 3d aircraft, was designed to use

low pitch props. What you need is air flow and vertical performance, not straight-line speed. We recommend

using the lowest pitch, highest diameter propeller you can find for your particular engine. The use of high pitch

props can cause air "cavitation" around the prop blades during hovering or slow vertical maneuvers. Air

cavitation may sound neat but it's not what you want because the prop is no longer biting into "clean air" and

you may loose altitude very quickly; so be wise when selecting your prop. Also, please be aware that the power

available in today's engines, while tremendously advantageous for 3d flying, can quickly lead to over speeding

the plane. Manage your throttle wisely to prevent over speeding and stressing the airframe.

Note: As with all ARFs, it’s a good idea to read all the instructions and study the parts

before you begin construction. Make sure you have a flat and sturdy workbench and

follow all safety advice for the tools and adhesives you plan to use.

Also note that the assembly pictures are from both the Fusion ARF and various kit builds

however the assembly process is the same.

Building Supplies and Tools Required to Complete the Model:

• Thin and Medium CA

• CA Accelerator

• 5 minute Epoxy

• Hobby knife

• Screwdrivers

• Covering iron

• Engine and Prop

• Radio Gear

COVERING:

1. OMP recommends lightly going over all the covering with a covering iron set at medium temperatures.

With all ARFs, varying temperatures and transport delays can cause covering material to loosen over time.

Pay attention to all covering seams and make sure all are properly adhered to the model.

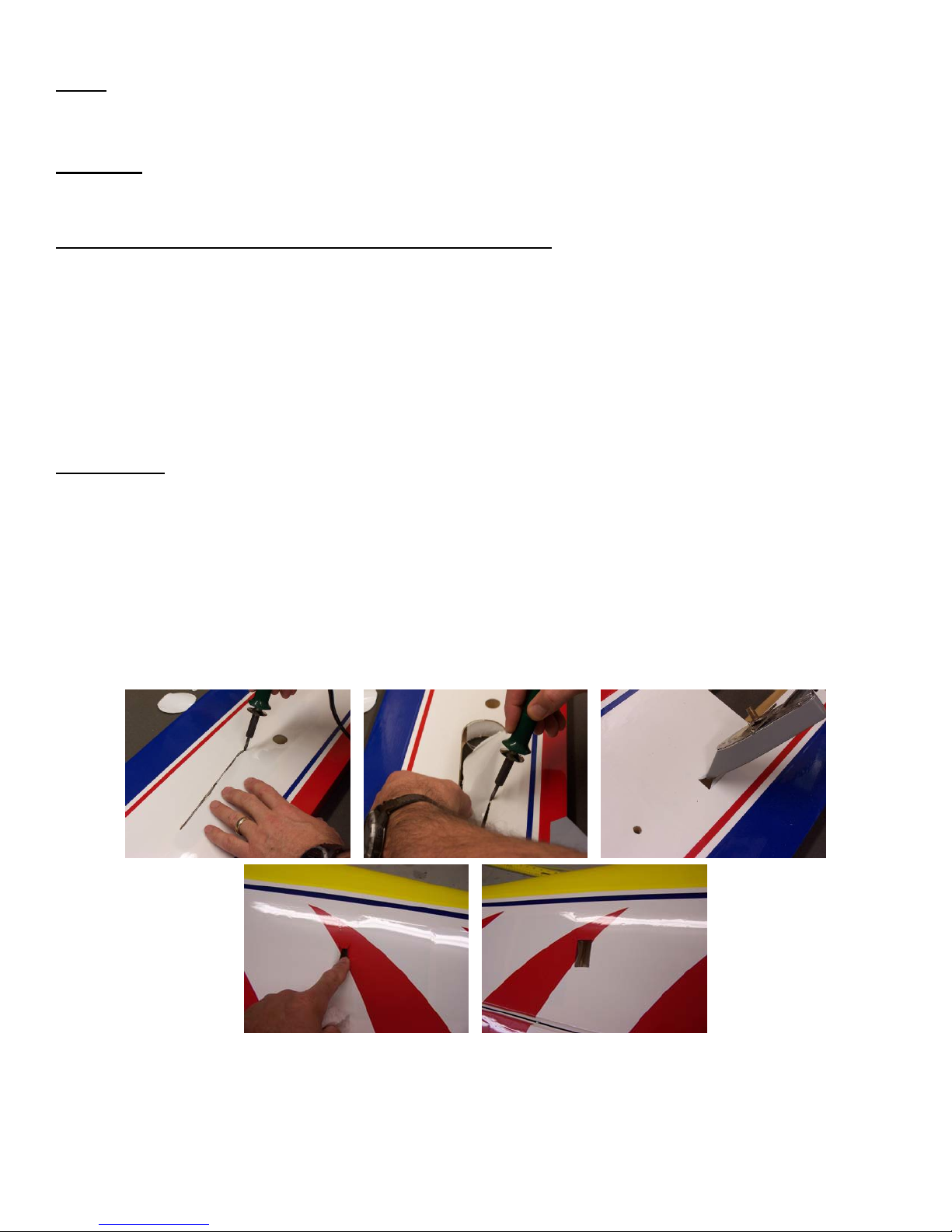

2. Carefully cut the covering away from the various openings on both sides of the fuselage. Servo openings in

the wings and fuselage should be cut from corner to corner and the covering ironed down on the inside.

Only cut the throttle servo opening on the right side of the fuselage. Other holes can be cut out using either

a sharp hobby knife or the tip of a hot soldering iron. The latter technique acts to seal the covering edges as

you cut away.

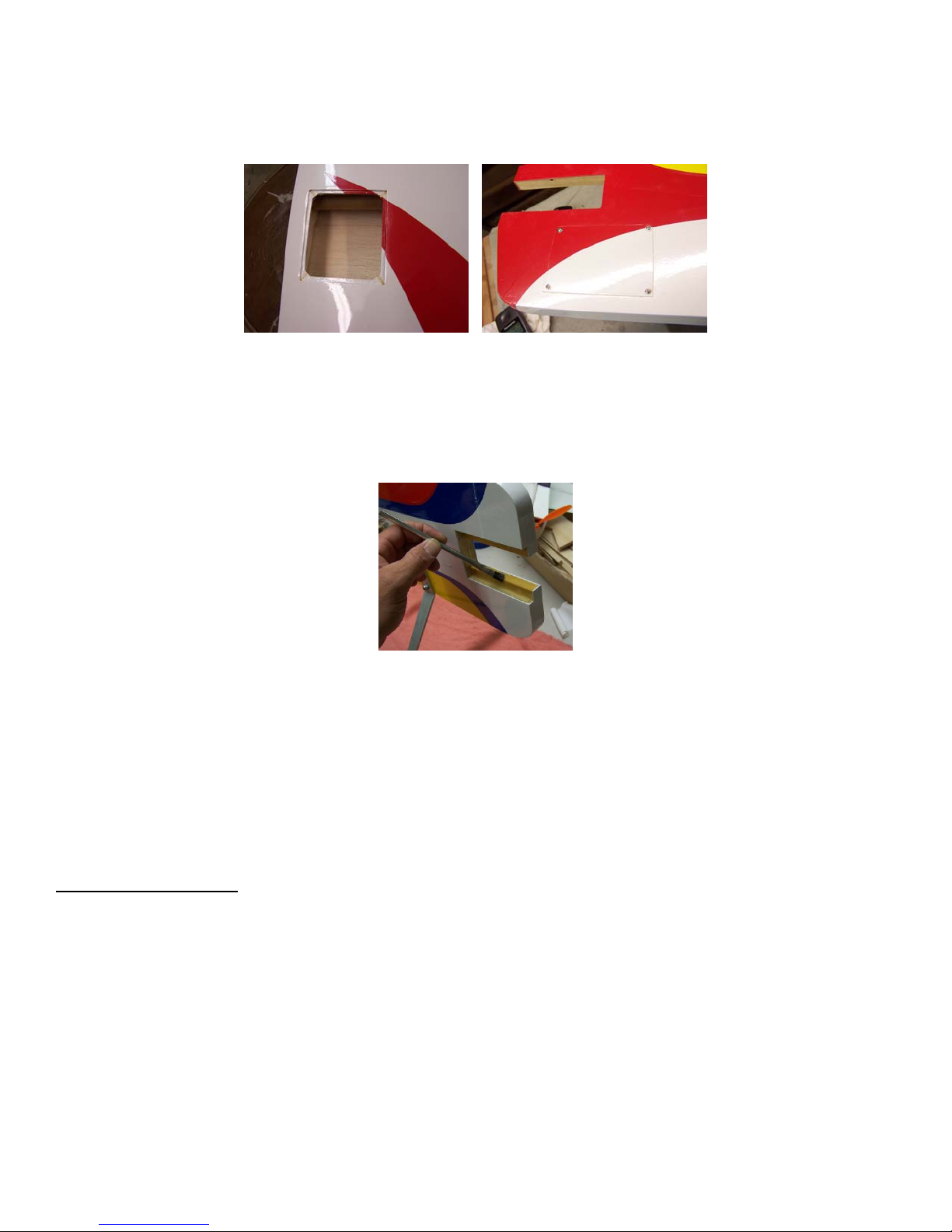

3. Cut the covering away from the hatch opening in the nose of the fuselage and iron down the covering

around the perimeter. A pre covered hatch is provided which can be secured with 4 screws. To properly

balance the model, the flight pack battery, ignition battery or other item may be placed in this hatch. For

example the author installed the gas engine ignition module into this hatch and used an IBEC system instead

of a separate ignition battery. With a sharp exacto knife, cut a small rectangular hole in the back side of the

throttle servo opening big enough for a servo wire connector to pass through. Make a small notch in the

upper right hand corner of the nose battery hatch. If required, run the battery wire from the hatch opening to

the hole you cut in the back of servo opening and down the tunnel to the receiver.

4. Be sure to seal any exposed wood with a thin coating of epoxy to prevent engine oil from soaking in. This

is especially important around the engine compartment and servo openings with exposed areas. The Fusion

ARF already has a factory applied coating of epoxy around the engine mounting area. If you need to widen

the engine mounting rails be sure to reseal the wood.

5. Some modelers prefer to seal the hinge gaps using strips of appropriate covering or clear trim tape. We

have found this to be helpful with models intended for higher speed flight or models with unusually large

hinge gaps. OMP profiles utilize a very tight double beveled hinge line and do not normally require this

step. Sealing the hinge gaps is therefore left as an option for the modeler. If desired this can be

accomplished using strips of clear covering applied along the hinge lines after the surfaces have been

installed.

RADIO SELECTION:

You will require at least a 6-channel radio system with 5 standard size servos and one mini size servo

for the throttle. The Fusion can use servos ranging from 70 in-oz of torque up to 130 in-oz high speed digitals.

The use of higher speed more powerful servos will allow the pilot to fly the Fusion much more aggressively for

advanced aerobatics and 3D performance. To take full advantage of the flight performance, a radio system with

mixing capabilities is best. This will greatly enhance the maneuverability of your model. A good example

would be coupling the elevators to the flaps. This can be done in both directions. For example you can mix up

flaps with down elevator (and vise versa) for really tight turns or loops. This is commonly referred to as

flaperons" and requires the aileron servos to be plugged into separate channels, usually 1 and 6. You can also

"

mix up flaps with up elevators for quick descent elevators; this is referred to as "

spoilerons".

AIRFRAME ASSEMBLY:

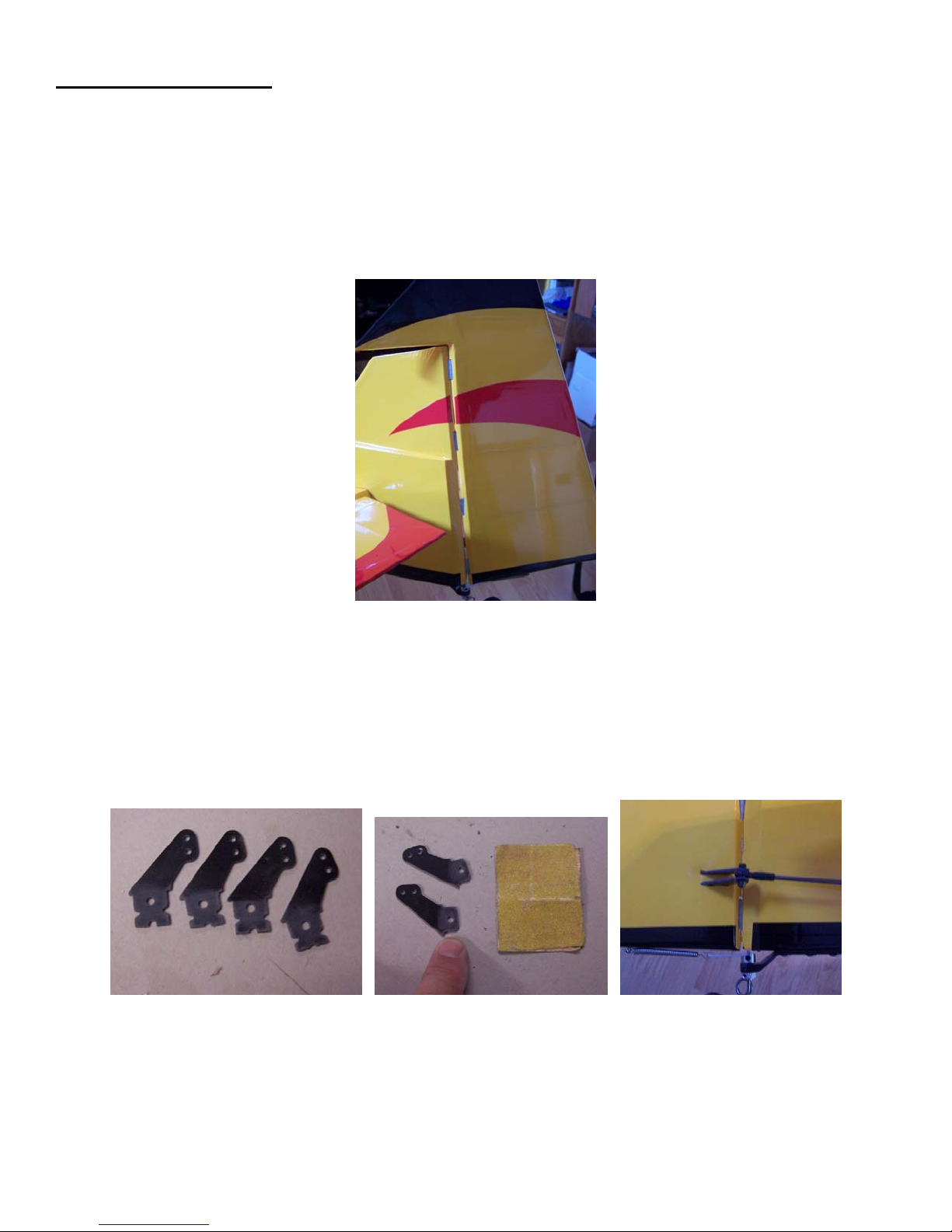

1. Flat nylon hinges are provided for this model and the slots have been pre-cut by the factory. Hint: clean the

hinges first with isopropyl alcohol to remove any plastic mold release agent prior to gluing in place. Also,

lightly sand them to take the shine off. Test fit the rudder and hinges (4 total) making sure it operates freely

with no binding. Make sure your hinges rotate freely at 90 degrees to the surface and are centered on the

hinge line. When satisfied, glue in place using epoxy making sure the hinge line is tight. Thoroughly clean

any excess epoxy away from the hinges using isopropyl alcohol and paper towels. Use masking tape to hold

the control surface in place with a tight hinge line while the glue cures.

2. Locate the Carbon fiber rudder horns (2) and choose which side to put the horns on. Either side is Ok,

however, remember the rudder servo has to be on the same side! Locate the two slots in the rudder for the

horns and carefully remove the covering only on the side that the horn will be on. Sand the tabs of the

control horns and test fit into the slots. It may be necessary to cut off some of the tab so that the horn fully

seats into the wood. It is very important that the horns align with each other and that the control rod pivot

point aligns over the hinge line. When satisfied, glue the horns in place using thin CA.

3. Locate the parts for the main landing gear. Two guide holes are provided in the fuselage for mounting the

main landing gear. Cut the covering away from these holes and mount the main landing gear using the

supplied bolts, washers, and lock nuts. Mount the wheels to the main gear by installing the supplied bolt

(bolt has a smooth shank on it) into the wheel, installing a nut on the bolt (tighten just enough to allow the

Loading...

Loading...