3.3 - 1

3.3

Three Terminal Adjustable Low Dropout

TO-257/TO-258 Positive Voltage Regulators

0 03 R3

Supersedes 4 11 R2

7.5A, 5A, 3A, 1.5A LOW DROPOUT POSITIVE

ADJUSTABLE REGULATORS

FEATURES

• Operates Down to 1V Dropout, 1.5V @ Max. Current

• .015% Line Regulation

• .01% Load Regulation

• 1% Reference Voltage

• Hermetic TO-257 and TO-258 Isolated Packages

• Electrically Equivalent to LT1083, 84, 85 and 86

DESCRIPTION

These three terminal positive adjustable voltage regulators are designed to provide

7.5A, 5A, 3A, and 1.5A with higher efficiency than conventional v oltage regulators. The

devices are designed to operate to 1 Volt input to output differential and the dropout

voltage is specified as a function of load current. All devices are pin compatible with

older three terminal regulators. Supplied in the easy-to-use hermetic metal TO-257

and TO-258 JEDEC packages also supplied in Omnirel’s new surface mount D2Pac..

These devices are ideally suited for Military applications where small size, hermeticity

and high reliability are required.

ABSOLUTE MAXIMUM RATINGS @ 25°C

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . ............................ 35 V

Operating Junction Temperature Range . ................... - 55°C to + 150°C

Storage Temperature . ............................. - 65°C to + 150°C

Output Current - OM183SC . ....................................... 7.5 A

OM184SC . ........................................ 5 A

OM185ST/SR. ....................................... 3 A

OM186ST/SR . ....................................... 1.5 A

Note: OM183SC and OM184SC products are packaged in the TO-258 Package (7.5A & 5A).

OM185ST and OM186ST products are packaged in the TO-257 Package (3A & 1.5A).

OM185ST

OM186ST

OM183SC

OM184SC

OM185SR

OM186SR

3.3 - 2

3.3

OM183SC - OM186ST - OM186SR

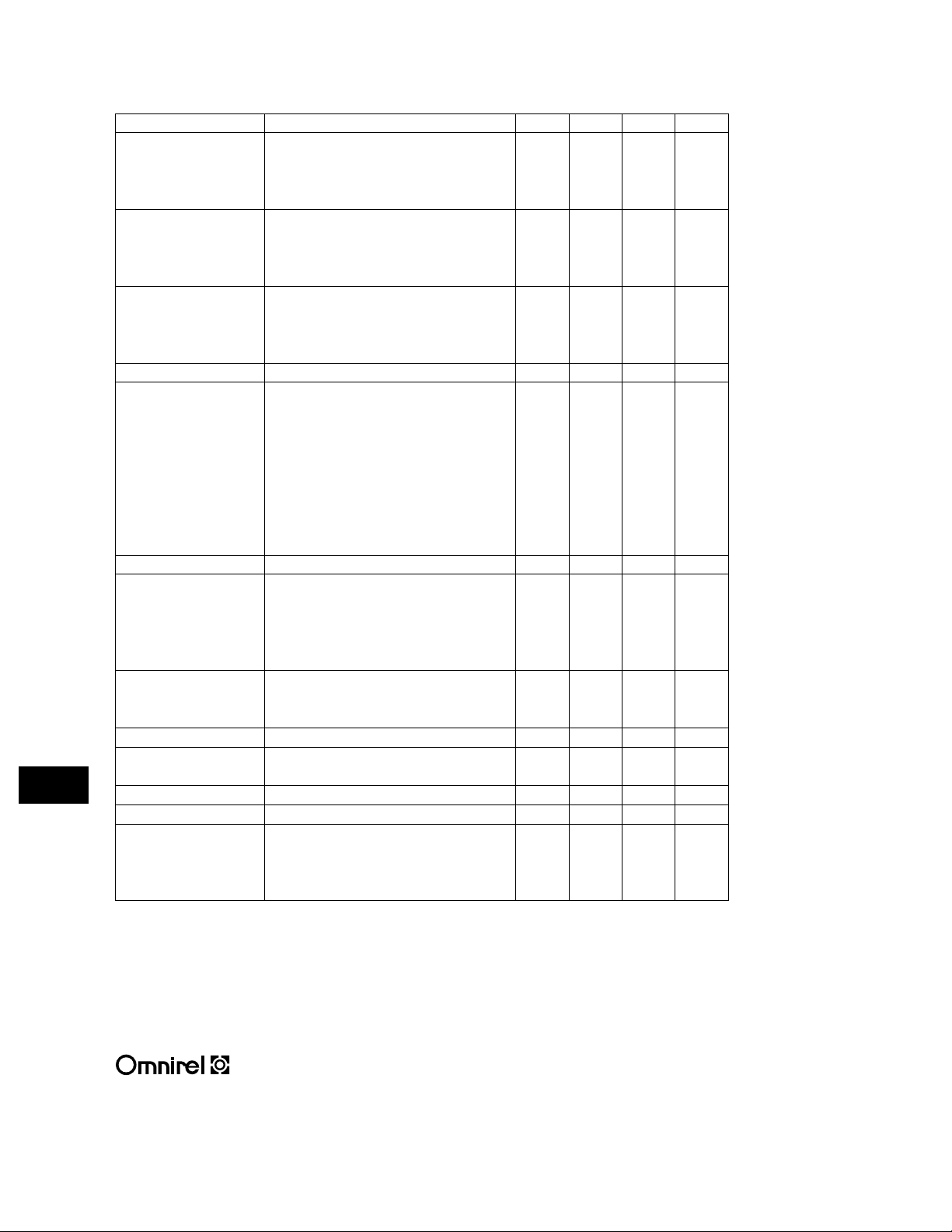

ELECTRICAL CHARACTERISTICS (T

C

= 25°C unless otherwise noted)

Parameter Conditions Min. Typ. Max. Units

Reference V oltage I

OUT

= 10 mA, Tj= 25°C

(V

IN

- V

OUT

) = 3 V 1.238 1.250 1.262 V

10mA ≤ I

OUT

≤ I

FULL LOAD

1.5 V ≤ (VIN- V

OUT

) ≤ 25 V (Note 3) 1.220 1.250 1.270 V

Line Regulation I

LOAD

= 10 mA, 1.5 V ≤ (VIN- V

OUT

) ≤ 15 V, 0.015 0.2 %

T

j

= 25°C 0.035 0.2 %

15 V ≤ (V

IN

- V

OUT

) ≤ 35 V (Notes 1 & 2) 0.05 0.5 %

Load Regulation (V

IN

- V

OUT

) = 3 V

10 mA ≤ I

OUT

≤ I

FULL LOAD

Tj= 25°C 0.5 0.8 %

(Notes 1, 2, 3) .8 1.0 %

Dropout Voltage ∆V

REF

=

1%, I

OUT

= I

FULL LOAD

1.3 1.5 V

Current Limit

OM183SC (V

IN

- V

OUT

) = 5 V 8.0 A

(V

IN

- V

OUT

) = 25 V 0.4 A

OM184SC (V

IN

- V

OUT

) = 5 V 5.5 A

(V

IN

- V

OUT

) = 25 V 0.3 A

OM185ST/SR (V

IN

- V

OUT

) = 5 V 3.2 A

(V

IN

- V

OUT

) = 25 V 0.2 A

OM186ST/SR (V

IN

- V

OUT

) = 5 V 1.5 A

(V

IN

- V

OUT

) = 25 V 0.75 A

Minimum Load Current (V

IN

- V

OUT

) = 25 V 5 10 mA

Thermal Regulation T

A

= 25°C, 30 ms pulse

OM183SC Guaranteed by design 0.002 0.01 %/W

OM184SC 0.003 0.15 %/W

OM185ST/SR 0.004 0.02 %/W

OM186ST/SR 0.010 0.05 %/W

Ripple Rejection f = 120 Hz

C

ADJ

= 25 µF Tantalum

I

OUT

- I

FULL LOAD (VIN

- V

OUT

) = 3 V 60 75 dB

Adjust Pin Current T

J

= 25°C 55 µA

Adjust Pin Current Change 10mA ≤ I

OUT

≤ I

FULL LOAD

1.5 V ≤ (VIN- V

OUT

) ≤ 25 V 0.2 5 µA

Temperature Stability -55°C ≤ T

J

≤ +150°C 0.5 %

Long T erm Stability T

A

= 125°C, 1000 Hrs. 0.3 1 %

Thermal Resistance Junction-to-Case

TO-257AA/D

2

Pac 4.2 °C/W

TO-258AA 2.75 °C/W

Note 1: Load and line regulation are measured at a constant junction temperature by low duty cycle pulse testing.

Note 2: Line and load regulation are guaranteed up to the maximum power dissipation (OM183/60W, OM184/45W, OM185/30W,

OM186/15W). Power dissipation is determined by the input/output differential and the output current. Guaranteed maximum

power dissipation will not be available over the full input/output voltage range.

Note 3: I

FULL LOAD

curve is defined as the minimum value of current limit as a function of input to output voltage. Note that power

dissipation is only achievable over a limited range of input to output voltage.

Note 4: Dropout voltage is specified over the full output current range of the device.

3.3 - 3

3.3

OM183SC - OM186ST - OM186SR

TYPICAL PERFORMANCE CHARACTERISTICS

Minimum Input/Output Differential (V)

2

1

0

012345678910

Output Current (A)

OM183SC Dropout Voltage

TJ = 25°C

Output Voltage Deviation (%)

0.10

0.05

0

-0.05

-0.10

-0.15

-0.20

-50 -25 0 25 50 75 100 125 150

Temperature (°C)

OM183SC Load Regulation

I = 7.5A

Output Voltage Deviation (%)

0.10

0.05

0

-0.05

-0.10

-0.15

-0.20

-50 -25 0 25 50 75 100 125 150

Temperature (°C)

OM184SC Load Regulation

I = 5A

Minimum Input/Output Differential (V)

2

1

0

012

Output Current (A)

OM186ST Dropout Voltage

TJ = 25°C

Output Voltage Deviation (%)

0.10

0.05

0

-0.05

-0.10

-0.15

-0.20

-50 -25 0 25 50 75 100 125 150

Temperature (°C)

OM185ST Load Regulation

I = 3A

Minimum Input/Output Differential (V)

2

1

0

0123456

Output Current (A)

OM184SC Dropout Voltage

TJ = 25°C

Minimum Input/Output Differential (V)

2

1

0

01234

Output Current (A)

OM185ST Dropout Voltage

TJ = 25°C

Short Circuit Current (A)

12

10

8

6

4

2

0

50 101520253035

Input/Output Differential (V)

OM183SC Short Circuit Current

TJ = 150°C

TJ = -55°C

I

FULL LOAD

TJ = 25°C

Short Circuit Current (A)

10

9

8

6

6

5

4

3

2

1

0

50 10 15 20 25 30 35

Input/Output Differential (V)

OM184SC Short Circuit Current

TJ = 25°C

TJ = -55°C

I

FULL LOAD

TJ = 150°C

Short Circuit Current (A)

6

5

4

3

2

1

0

50 10 15 20 25 30 35

Input/Output Differential (V)

OM185ST Short Circuit Current

TJ = 25°C

TJ = -55°C

I

FULL LOAD

TJ = 150°C

0.10

0.05

0

-0.05

-0.10

-0.15

-0.20

-50 -25 0 25 50 75 100 125 150

Temperature (°C)

OM186ST Load Regulation

I = 3A

Output Voltage Deviation (%)

Short Circuit Current (A)

3.0

2.5

2.0

1.5

1

.5

0

50 10 15 20 25 30 35

Input/Output Differential (V)

OM186ST Short Circuit Current

TJ = 25°C

TJ = -55°C

I

FULL LOAD

TJ = 150°C

3.3

205 Crawford Street, Leominster, MA 01453 USA (508) 534-5776 FAX (508) 537-4246

OM183SC - OM186ST - OM186SR

Pin 1 - Adjust

Pin 2 - V

OUT

Pin 3 - V

IN

123

Pin 1 - Adjust

Pin 2 - V

OUT

Pin 3 - V

IN

123

MECHANICAL SPECIFICATIONS

P/N OM183SC and OM184SC JEDEC TO-258AA

P/N OM185ST and OM186ST JEDEC TO-257AA

Stability

The OM183-186 Series requires the use of an output

capacitor as part of the device frequency compensation.

For all operating conditions, the addition of 150µF aluminum electrolytic or a 22µF solid tantalum on the output

will ensure stability. Normally, capacitors much smaller

than this can be used. Many different types of capacitors

with widely varying characteristics are available. These

capacitors differ in capacitor tolerance (sometimes ranging

up to ±100%), equivalent series resistance, and capacitance temperature coefficient.

The 150µF or 22µF values given will ensure stability.

When the adjustment terminal is bypassed to improve the

ripple rejection, the requirement for an output capacitor

increases. The values of 22µF tantalum or 150µF aluminum cover all cases of bypassing the adjustment terminal. Without bypassing the adjustment terminal, smaller

capacitors can be used with equally good results and the

table below shows approximately what size capacitors are

needed to ensure stability.

Recommended Capacitor Values

Normally, capacitor v alues on the order of 100µF are used

in the output of many regulators to ensure good transient

response with heavy load current changes. Output capacitance can be increased without limit and larger values of

output capacitor further improve stability and transient

response of the OM183SC regulators.

Output Voltage — Adjustable Regulators

The OM183-OM186 devices develop a 1.25V reference

voltage between the output and the adjust terminal (see

below). By placing a resistor, R1, between these two terminals, a constant current is caused to flow through R1

and down through R2 to set the overall output voltage.

Normally this current is the specified minimum load current

of 10mA. Because I

ADJ

is very small and constant when

compared with the current through R1, it represents a

small error and can usually be ignored.

Basic Adjustable Regulator

APPLICATION NOTES

Input Output Adjustment

10µF 10µF Tantalum, 50µF Aluminum None

10µF 22µF Tantalum, 150µF Aluminum 20µF

.165

.155

.707

.697

.750

.500

.200 TYP.

.695

.685

.835

.815

V

IN

.270

.240

.045

.035

.550

.530

.092 MAX.

.065

.055

.140 TYP.

.005

V

OUT

IN OUTOM183SC

I

50 µA

R2

= V

(1 + ) + I

REF

ADJ

R1

V

ADJ

ADJ

R2

OUT

V

R1

REF

R2

.150

.140

.200

.430

.410

.190

.045

.035

.038 MAX.

.005

.120 TYP.

.420

.410

.665

.645

.537

.527

.750

.500

.035

.025

.100 TYP.

OM183SC - OM186ST - OM186SR

OM 183 S R M

Omnirel Device Isolated Package Hi-Rel Screening

Type Package Style Level

PART NUMBER DESIGNATOR

Figure 1 shows a typical soldering profile for the D2and D3Packages when soldering a to a printed circuit board.The

profile will vary from system to system and solders to solders. Factors that can affect the profile include the type of soldering system used, density and type of components on the board or substrate material being used.This profile shows

temperature versus time.The two profiles described are based on a high density and a low density board.The type solder used was 62/36/2 Tin Lead Silver with a melting point between 177-189ºC.An convection/infrared soldering reflow

system was used.The circuit and solder joints heat up first due to their mass followed by the components which typically run 30 degrees cooler than the solder joints.

TYPICAL HEATING PROFILE

TYPICAL SOLDERING PROFILE

MECHANICAL OUTLINE SOLDERING FOOTPRINT

Pin 1: Adjust

Pin 2: Vout

Pin 3: Vin

Case N/C

205 Crawford Street, Leominster, MA 01453 USA (508) 534-5776 FAX (508) 537-4246

123

Loading...

Loading...